Page 1

Astra-421 Ver. RF

Wireless Optoelectronic Smoke Detector

Operation Manual

This operation manual is intended for studying principle of

operation, correct use, operating conditions and maintenance of

the wireless optoelectronic smoke detector «Astra-421» ver.RF

(hereinafter «detector») (figure 1).

The manufacturer reserves the right to make alteration regarding refinement of the product without prior notification. All

changes will be imported into new edition of the operation manual.

1 Function

1.1 The detector is intended for

detecting fire followed by smoke

spreading, forming and transmitting «Fire» notification to the receiver «Astra-RVA» (hereinafter

«receiver») of wireless intrusion/fire

detection and alarming system Ob-

server-1.

1.2 The detector supports 3 operat-

ing frequencies.

1.3 Electric power is supplied by a

lithium-thionyl-chloride battery cell

standard size AA, voltage 3,6 V

(included in delivery set).

2 Principle of Operation

The principle of operation of the detector is based on registering infrared radiation (hereinafter IR) that is reflected from

smoke particles in the smoke chamber by a photodetector. Further the electric signal formed by the photodetector is amplified

and sent to microcontroller in order to analyze the smoke density value. The detector generates «Fire» or «Warning» notification in accordance with a specified operating algorithm.

3 Specifications

Detector`s sensitivity, dB/m ................................ from 0,05 to 0,2

Response time, sec., max ......................................................... 5

Detection area, m2, max ........................................................ 110

Installation height, m, max ....................................................... 10

Technical Parameters of Radio Channel

Operating frequency, MHz ................................................ 433,42

Emission power, mWt, max ..................................................... 10

Wireless coverage range*, m, min ......................................... 300

General Technical Parameters

Current consumption:

- with transmitter turned OFF, mA, max............................... .0,05

- with transmitter turned ON, mA, max ................................... .25

Supply voltage, V ................................................. from 2,7 to 3,6

Technical readiness time, s, max…………………………….….60

Standby mode recovery time, s, max ...................................... 60

* Along the line-of-sight. Wireless coverage range is largely dependent

on the design features of construction, the installation location, the interference situation.

Overall dimensions, mm, max

- diameter .............................................................................. 100

- height ..................................................................................... 47

Weight, kg, max .................................................................... 0,12

Battery cell average life time, years, min ................................... 3

Operating Conditions

Temperature range, °С ..................................... from - 10 to + 55

Relative air humidity, % ................................ up to 93 at + 40 °С

without moisture condensation

4 Delivery Set

Wireless optoelectronic smoke detector

«Astra-421» ver. RF ........................................................... 1 pcs

Screw 3,9х32 ...................................................................... 2 pcs

Dowel 6х30 ......................................................................... 2 pcs

Battery cell .......................................................................... 1 pcs

Operation manual ............................................................. 1 copy

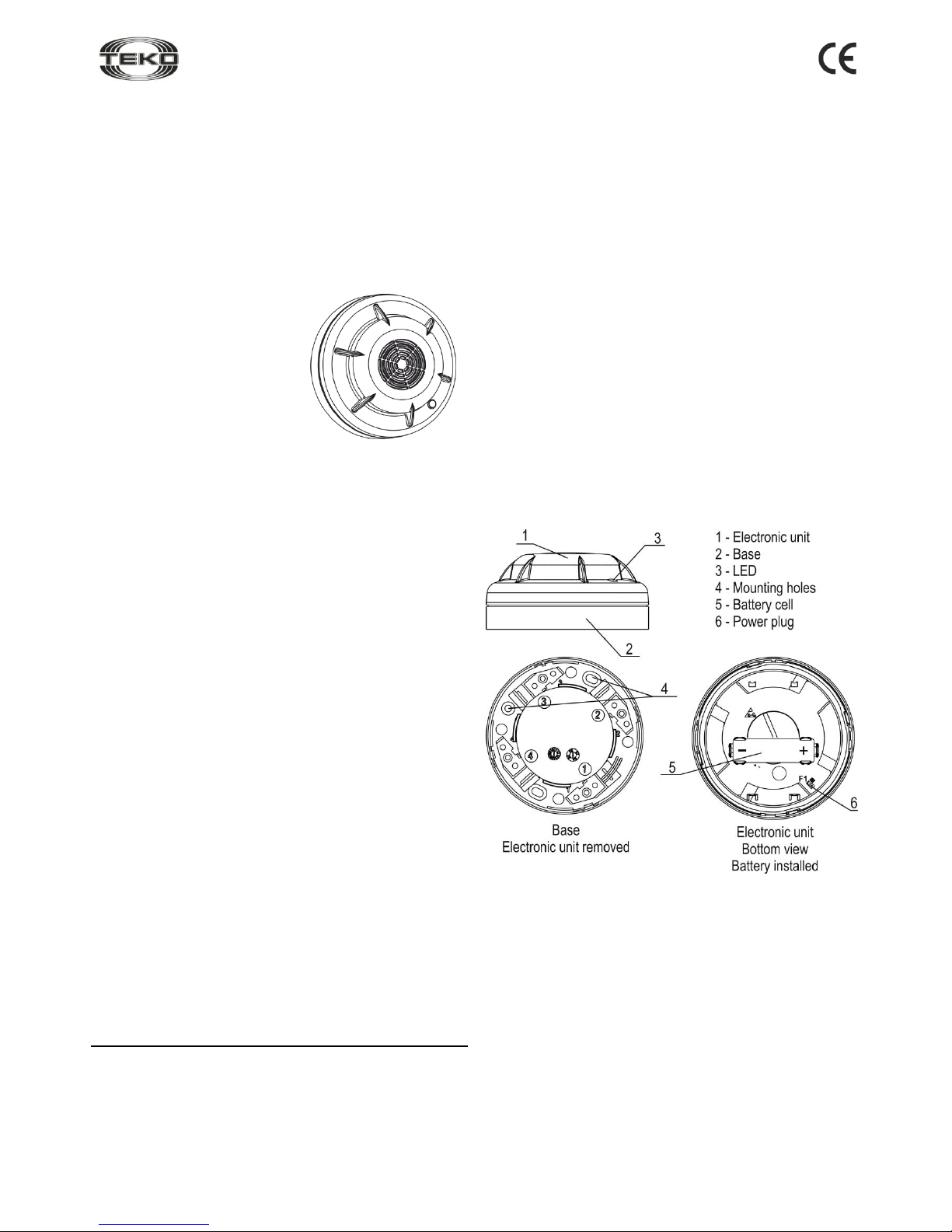

5 Structure

Constructively the detector consists of a removable electronic

unit and a base (figure 2).

Figure 2

Inside the electronic unit is a smoke chamber and printed circuit

board (PCB) with radio elements and photodetector.

Mounted on PCB is a LED for checking the detector`s operability.

The design of the detector provides for its installation on the

ceiling.

Note - It is not recommended to disassemble the electronic unit

of the detector, as it may damage the detector’s tuning.

Figure 1

Page 2

421-rkv16_1_en

2

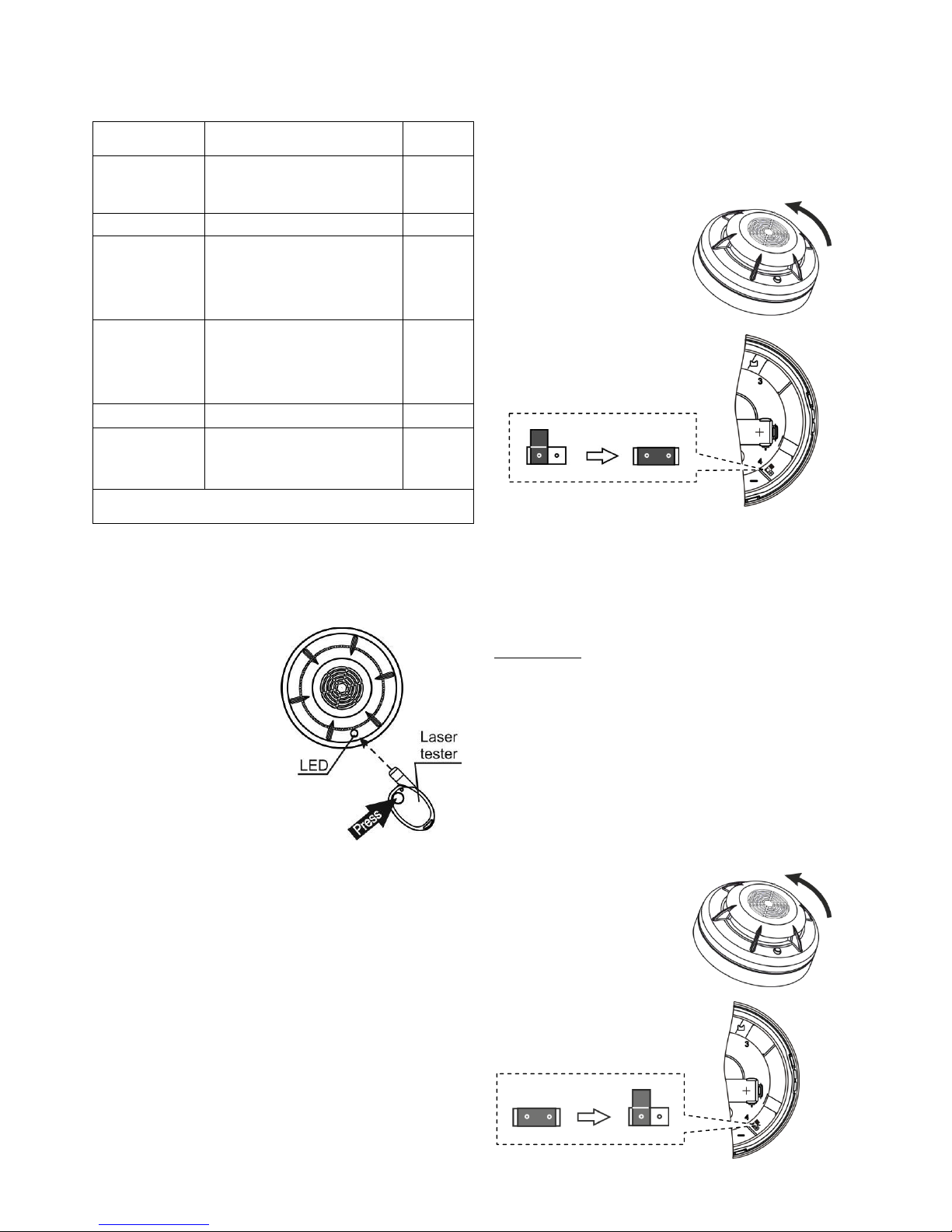

6 Information Capacity

Table 1- Notification types

Notification

types

LED

Receiver

Standby mode

Lights up for the time of 1-20

sec, then flashes once per 1

sec. Duration is up to 60 sec.

−

Norm

Not lit

+

Fire

Flashes once per 1,5

as the smoke density in the

secure area reaches the operation threshold. Flashes as

long as the smoke is there.

+

Warning

Flashes 2 times per 1 sec

during 5 sec as the smoke

density in the secure area

reaches 75% of the activation

threshold

+

Failure

Flashes 1 time per 3 sec

+

Low supply

voltage

Flashes 2 times successively

once per 10-15 sec, at supply

voltage less than 2,9 V.

+

«+» – notification is generated,

«–» – notification is not generated

Note - In case «Low supply voltage» notification is generated, it

is necessary to replace battery cell within one week.

7 Operation Modes

The detector provides for

«Test» and «Autotest»

operating modes, intended

for testing electronic circuits

of the detector.

7.1 The «Test» mode is

activated when reading a

coded message by LED sent

from laser tester «Astra-

941» (figure 3).

In 5 sec after reading the

message, the detector must

output the «Fire» notification

- if the detector operation is

normal, or «Failure» - in

case of a failure.

Figure 3

Note - Laser tester «Astra-941» is optional and delivered sepa-

rately.

7.2 The «Autotest» mode is activated by the detector auto-

matically every 24 hours. At that the operation threshold is adjusted depending on the environment and the «Test» mode is

activated. Upon successful completion of the test notification is

not generated. In case of failure, «Failure» notification is

generated.

8 Pre-starting Procedure

8.1 After transportation in conditions differing from those of

operation, keep the detector unpacked for 4 hours in the expected operating conditions.

ATTENTION! Check correspondence of frequency carrier

of the detector and the receiver.

8.2 Running Detector

Attention! Lithium-thionyl-chloride batteries have an effect of

«passivation» to provide the possibility of long-term storage. To

provide battery normal operation after long-term storage, hold

an «activation» procedure.

Step-1

Place the detector on-thespot.

Turn the electronic module

counterclockwise.

Remove the electronic unit

from the detector`s base.

Step-2

Install the battery cell.

Switch the detector ON by installing jumper on power plug.

Step-3

To replace battery:

- switch the detector OFF;

- remove the old one;

- after no less than 20 sec install the new battery.

When installing into detector the battery is automatically

«activated» and checked. The LED lights red (less than 20

sec.)

After checking:

In case the LED flashes 2 times successively with fre-

quency once per 10-15 sec («Low supply voltage»), remove

jumper, close the positive and negative poles of the battery

for 2-3 sec with a piece of wire and repeat switching by installing jumper back after at least 20 sec.

In case the LED flashes with frequency once per 1 sec

(«Standby mode») and notification «Power failure» is not

appears, the battery is considered as useful.

8.3 Registration Procedure

The detector registering in the receiver memory occurs at the

moment of powering up.

Step-1

Place the detector on-thespot.

Turn the electronic module

counterclockwise.

Remove the electronic unit

from the detector`s base.

Step-2

Switch the detector OFF by

removing jumper from

power plug

Page 3

421-rkv16_1_en

3

Step-3

Set the registration mode on a receiver according to procedure described in the «Astra-RVA» operation manual or the

Observer-1(2) system operation manual (available for free

downloading from www.controlex.eu) or Quick Start Guide.

Step-4

Switch the detector ON by installing jumper on two pins of

power plug

Step-5

Make sure the registration procedure is completed according

to procedure described in the «Astra-RVA» operation manual

or the Observer-1 system operation manual (available for

free downloading from www.controlex.eu) or Quick Start

Guide.

Once the registration procedure completed successfully

reassemble the detector.

- superpose the electronic unit and the base.

- rotate the electronic unit until matching the projections of

the electronic unit with the base` grooves.

- press the electronic unit to the base and rotate clockwise

until it stops.

Once the registration procedure failed remove jumper

from the power plug and after at least 20 sec repeat

steps 3-5.

Step-6

After successful registration of the detector, for long term

storage before its installation, it is allowed to switch the detector OFF by removing jumper from power plug.

When installing the detector on-site there is no need to reregister it in the memory of the same receiver, if the memory

of the receiver has not been cleared.

9 Installation

9.1 Selection of Installation Place

9.1.1 The detector is installed on a ceiling.

9.1.2 An area covered by a single detector, maximum distance

between detectors, and between a detector and a wall can be

calculated according to table 2.

Table 2

Secure room

height, m

Average area covered by 1 detector,

m2

Maximum distance, m

between

detectors

from detector to

wall

up to 3,5

up to 85

9,0

4,5

over 3,5 to 6,0

up to 70

8,5

4,0

over 6,0 to

10,0

up to 65

8,0

4,0

9.1.3 If the detector is installed on an inclined ceiling, it must

be mounted at the highest position.

9.1.4 For smoke particles to be able for freely penetrating the

smoke chamber through the grid, it is forbidden to mask the

detector.

9.2 Installation Procedure

Step-1

Place the detector on-the-spot.

Turn the electronic module

counterclockwise.

Remove the electronic unit from

the detector`s base.

Step-2

Switch the detector OFF by removing jumper from power plug

Step-3

Make markings on the

ceiling by using the applied

base.

Fasten the base to the

ceiling.

Step-4

Switch the detector ON by installing

jumper on two pins of power plug.

The LED lights up for 1 to 20 sec,

then flashes once per 1 sec during 60

sec (Standby mode).

Step-5

Mount the electronic unit onto the fastened base:

- superpose the electronic unit and the base.

- rotate the electronic unit until matching the projections of

the electronic unit with the base grooves.

- press the electronic unit body to the base and rotate clockwise until it stops.

Page 4

421-rkv16_1_en

4

Step-6

Activate the «Test» mode:

- press the red button on the

laser tester;

- direct a laser ray at the LED;

- irradiate the LED during 1 sec.

In 5 sec. make sure the «Fire»

report on the detector`s LED

(double blink per 1 sec. for 1317 sec.) and on the red LED of

the receiver (double blink per 1

sec) is appeared.

10 Maintenance

To ensure the alarm system reliable operation, testing and

maintenance of the detector is recommended.

Testing should be carried out as follows:

Check absence/output of the «Failure» notification on the

LED at least once a week;

Check the detector operability by using a laser tester at

least once in 3 months (by the method 9,6 step 6);

Clean the detector’s smoke chamber at least once in 3

months as follows:

1) Remove the electronic unit from the detector`s base

2) Switch off the detector by removing jumper from power plug

3) Clean by compressed air.

4) Switch on the detector by installing jumper on two pins of

power plug.

5) Wait for 60 sec (standby recovery time).

6) Activate the «Test» mode according to p.9.2 step 6.

7) Mount the electronic unit onto the fastened base.

11 Labeling

On a label attached to the case are indicated:

- trademark of the manufacturer;

- abbreviated marking of the detector;

- firmware version;

- frequency carrier;

- month and year (last two digits) of manufacture;

- conformity mark (if certificate is available);

- barcode, duplicating text information.

12 EC Conformity Declarations

This product is in conformity with the provisions of:

R&TTE Directive 1999/5/EC, Article 10.5;

EN 60950: 2001 Safety of information technology equipment;

EN 50371 Generic standard to demonstrate the compliance of lowpower electronic and electrical apparatuses with the basic restrictions

related to human exposure to electromagnetic fields (10 MHz - 300

GHz) – General public;

EN 301489-17 V1.1.1 (09-2000) Electromagnetic Compatibility and

radio spectrum Matters (ERM); Electromagnetic Compatibility (EMC)

standard for radio equipment and services; Part 17: Specific conditions

for wideband data Hiperlan equipment;

EN 300220-1 V1.3.1 (2000-09) Electromagnetic compatibility and Radio

spectrum Matters (ERM); Short range devices; Technical characteristics and test methods for radio equipment to be used in the 25 MHz to 1

000 MHz frequency range with power levels ranging up to 500 mWt;

Part 1: Parameters intended for regulatory purposes.

Construction of the detector provides for protection class IP41.

13 Recycling

13.1 Detector is not a danger to life, human health and the environment. On expiry of its lifetime recycling is done without taking special

measures to protect the environment.

13.2 Recycling of battery cells should be done by delivering the used

cells to a trading organization, service centre, manufacturer, or to an

organization accepting used batteries.

14 Warranty Terms

14.1 The manufacturer guarantees the compliance of the detector to

specifications if the user observes required conditions of transportation,

storage, installation and operation.

14.2 The storage warranty period is 5 years and 6 months from the date

of manufacture.

14.3 The operation warranty period is 5 years from the date of putting

into operation but no longer than 5 years 6 months from the date of

manufacturing.

14.4 The manufacturer guarantees replacement or repair of the product

during the warranty period.

14.5 The warranty doesn’t come into effect in the following cases:

- not adherence to instructions of the operation manual;

- mechanical damage of the detector;

- repair of the detector by any third-party service apart from the manufacturer.

14.6 Warranty applies to the detector only. All equipments from thirdparty manufacturers used in conjunction with the device, including batteries, are subject to their own warranty terms and conditions.

The manufacturer bears no responsibility for death, injury, property damage or other incidental or premeditated loss based on the

user's statement that the detector has failed to implement its functions.

Sales:

Controlex GmbH

Warranty service and

technical support:

ТЕКО-TD

Philosophenweg 31-33

47051 Duisburg, Germany

Phone: +49 (0) 203 / 393 91 188

Fax: +49 (0) 203 / 393 91 189

GSM: +49 (0) 178 / 218 48 22

E-mail: info@controlex.eu

Web: www.controlex.eu

Prospect Pobedy str. 19

420138 Kazan, Russia

Phone: +7 (843) 261-55-75

Fax: +7 (843) 261-58-08

E-mail: info@teko.biz

support@teko.biz

Web: www.teko.biz

Made in Russia

Loading...

Loading...