Teknoware TKT67C Series, TKT6748C, TKT6756C, TKT6716C, TKT6732C Installation And Maintenance Instructions Manual

...

VOT2

TKT67C TAPSA CONTROL CENTRAL BATTERY UNIT

FOR EMERGENCY LIGHTING

Installation and maintenance instructions

Made In Finland

2

Table of contents

Table of contents ................................................................................................................ 2

1. Safety instructions ......................................................................................................... 4

2. Package contents and storing ....................................................................................... 4

2.1 Contents of package ............................................................................................................. 4

2.2 Storing ................................................................................................................................... 4

3. Product description ........................................................................................................ 5

3.1 Manufacturer ......................................................................................................................... 5

3.2 Terminology .......................................................................................................................... 5

3.3 Type ....................................................................................................................................... 5

3.4 Explanation of letters (in previous models) ........................................................................ 5

3.5 List of optional features........................................................................................................ 6

3.6 General description .............................................................................................................. 6

3.7 Technical specifications ....................................................................................................... 7

3.8 Directives and standards...................................................................................................... 9

4. Description of operations ............................................................................................ 10

4.1 Purpose of the central battery unit .................................................................................... 10

4.2 Circuit outputs .................................................................................................................... 10

4.3 Circuit board settings ......................................................................................................... 10

4.4 Parallel connection of output circuits ............................................................................... 10

4.5 Control unit.......................................................................................................................... 11

4.5.1 Individual luminaire monitoring test with basic settings ................................................................... 11

4.5.2 Circuit monitoring luminaire test with basic settings ........................................................................ 11

4.6 Operation of the central battery unit .................................................................................. 12

4.7 Normal Status ...................................................................................................................... 12

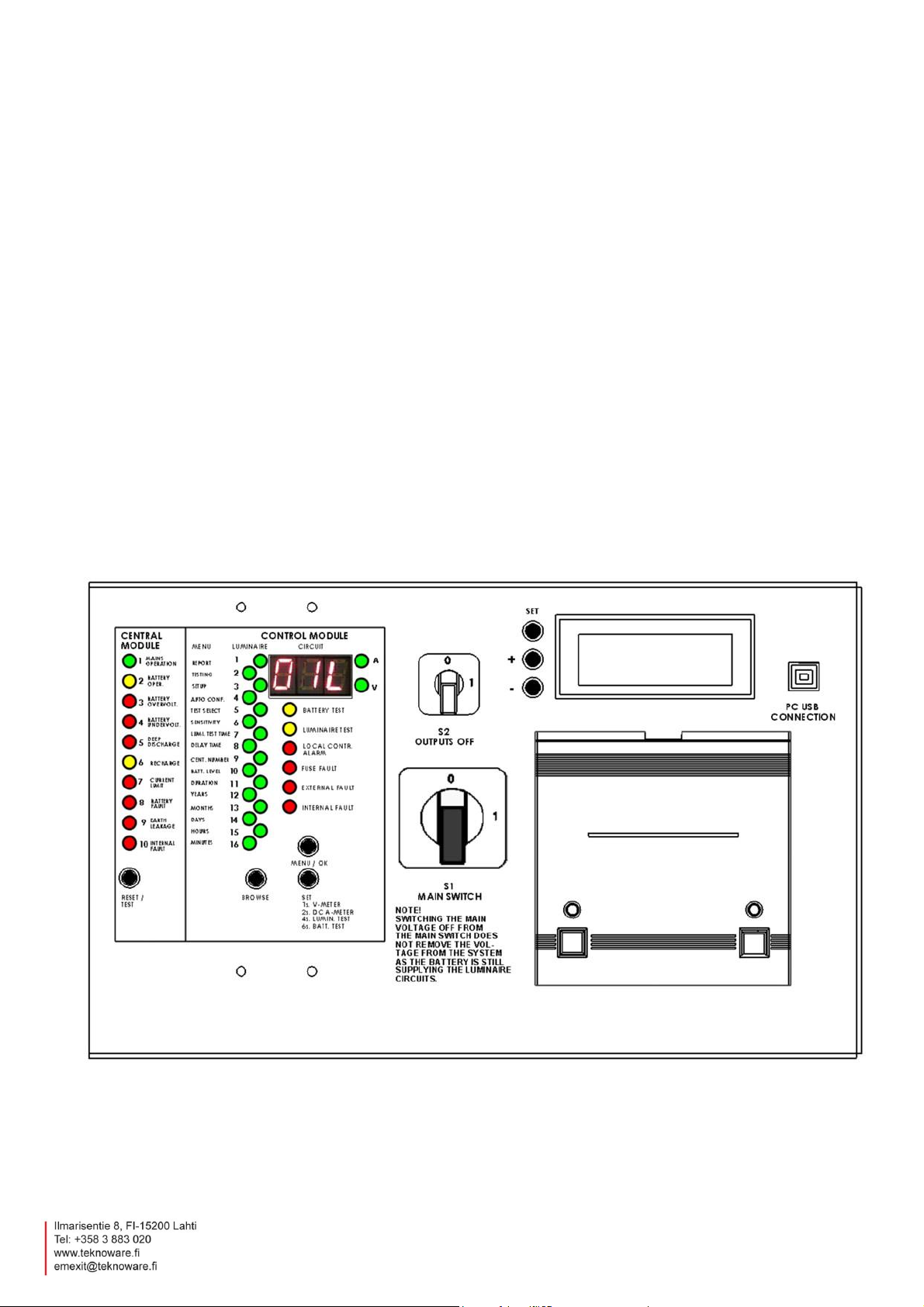

4.8 Central module panel .......................................................................................................... 13

4.9 Control Module panel luminaire monitoring LED’s and menu settings .......................... 15

4.10 Control Module panel test functions and alarms ............................................................ 21

4.11 Buttons .............................................................................................................................. 23

5. System planning and installation ................................................................................ 24

5.1 System planning ................................................................................................................. 24

5.1.1 Luminaire-specific addressable monitoring ..................................................................................... 24

5.1.2 Circuit monitoring ............................................................................................................................. 24

5.2 System installation ............................................................................................................. 24

5.2.1 Parts layout ...................................................................................................................................... 26

5.2.2 Circuit wiring in parallel connection ................................................................................................. 27

5.2.3 DIP switch settings in circuit boards ................................................................................................ 28

5.3 Commissioning ................................................................................................................... 29

5.3.1 Setting of battery type and capacity ................................................................................................. 29

5.3.2 Forced charging of the batteries ...................................................................................................... 30

5.3.3 Checking the luminaire circuits one at a time .................................................................................. 30

5.3.4 Configuration .................................................................................................................................... 30

VOT 2; Rev 1.2; EN; 09.07.2013

TKT67C – Installation and maintenance

3

6. Maintenance .................................................................................................................. 31

6.1 Replacing the batteries ....................................................................................................... 31

7. Disposal ......................................................................................................................... 32

8. Optional Features ......................................................................................................... 32

8.1 LCD display functions ........................................................................................................ 32

8.1.1 Button functions ............................................................................................................................... 32

8.1.2 LCD content ..................................................................................................................................... 33

8.1.3 LCD menu tree ................................................................................................................................. 33

8.1.4 Test history ...................................................................................................................................... 33

8.1.5 Battery test history ........................................................................................................................... 34

8.1.6 Error log ........................................................................................................................................... 35

8.1.7 Setup ................................................................................................................................................ 35

8.1.8 External USB connection ................................................................................................................. 36

8.2 Printer .................................................................................................................................. 37

8.2.1 Language selection of the printer (TKT67..CD) or optional feature TST6731 ................................. 37

8.2.2 Printing out test reports .................................................................................................................... 37

APPENDIX 1: Report Layout ............................................................................................ 38

APPENDIX 2: Mechanical dimensions ............................................................................ 39

APPENDIX 3: Connection alternatives for batteries ...................................................... 40

APPENDIX 4: Circuit diagram with 3-phase input ......................................................... 41

APPENDIX 5: Menu selections ........................................................................................ 54

© Copyright 2013 Teknoware Oy – We reserve the right to make modifications without notice

VOT 2; Rev 1.2; EN; 09.07.2013

TKT67C – Installation and maintenance

4

WARNING

There is always dangerous voltage level in the output circuits and inside the central battery unit if

the central battery unit is switched ON. Chancing the main switch to 0 –position will NOT make

the central battery unit de-energized. The central battery unit and the battery housing can be

opened only by electrically skilled person.

Device must be made de-energized before any maintenance or repair work. Remove the battery

fuses and set the main switch to OFF position.

1. Safety instructions

Read before installing the product.

This manual contains important information that must be followed during the installation and maintenance of

the central battery unit and the batteries. Installation of this device is allowed only to a person who has the

required permissions and qualifications.

National regulations for electric installations and building codes must be observed in the placing of the central

battery unit.

In the installation of batteries, constituted regulations must be observed.

2. Package contents and storing

2.1 Contents of package

The package contains a central battery unit of TKT67XXC series.

Store the package sheltered from the rain.

Do not place anything on top of the package.

NOTE: The package may contain sealed lead acid batteries that contain large quantities of energy and

may short circuit, if stored inappropriately. This must be considered when storing the package.

2.2 Storing

If you do not install the unit and batteries immediately, note the following:

Store the unit in a dry place, protected from humidity.

Store the unit and the batteries in the recommended storing temperature of +10 …+30C.

If the batteries are stored for a longer period of time, they must be recharged every 6 months

for at least 12 hours at a time.

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

5

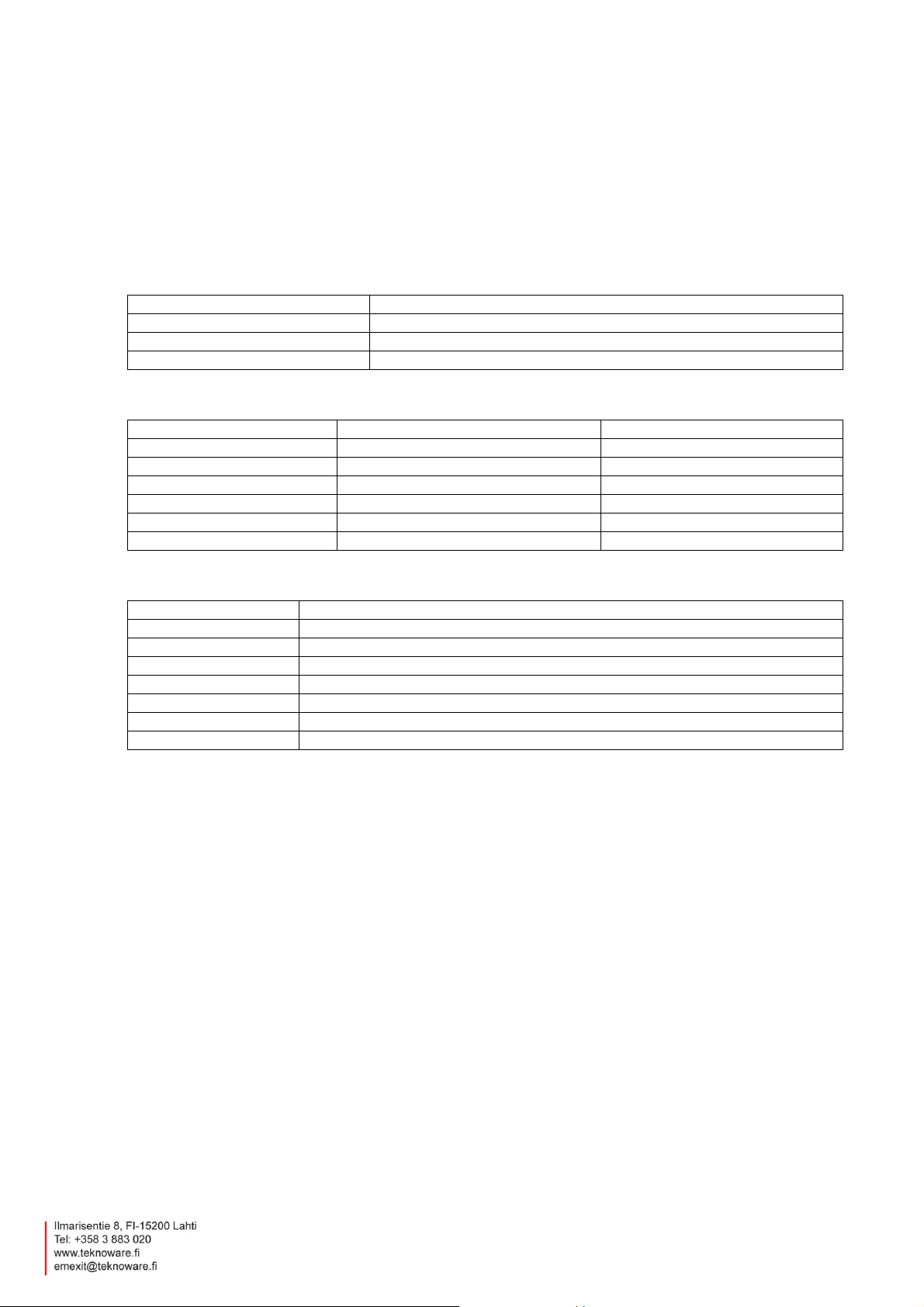

Term

Explanation

Control

Automatic testing

Maintained

Continuously active

Non-maintained

Active only during voltage interruptions

Model

Maximum number of circuits

Input Voltage

TKT6716C(N)

16

220-240 V AC 50/60Hz 3~

TKT6724C(N)

24

220-240 V AC 50/60Hz 3~

TKT6732C(N)

32

220-240 V AC 50/60Hz 3~

TKT6740C(N)

40

220-240 V AC 50/60Hz 3~

TKT6748C(N)

48

220-240 V AC 50/60Hz 3~

TKT6756C(N)

56

220-240 V AC 50/60Hz 3~

Letter

Explanation

C only

Control function

CD

Control and printer

CL

Control and LCD display

CO

Control and LON interface

CDL

Control, printer, and LCD display

CLO

Control, LCD display and LON interface

N

Charging for NiCd batteries

3. Product description

3.1 Manufacturer

Teknoware Oy

Ilmarisentie 8

FI-15200 Lahti

FINLAND

http://www.teknoware.fi/

3.2 Terminology

3.3 Type

3.4 Explanation of letters (in previous models)

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

6

TST6731

Integrated Printer TKT67xxC

TST6732

LCD Display Module TKT67xxC

TST6741

Extra Charger Module (adds power taken from mains 3,000 VA)

(1-2 pcs each 3,000 VA, Max each 180 Ah) TKT67xxC

XWT6772

Switched-Maintained Package for 16 circuits each 350 W TKT6716C

XWT6773

Switched-Maintained Package for 24 circuits each 350 W TKT6724C

XWT6774

Switched-Maintained Package for 32 circuits each 350 W TKT6732C

XWT6775

Switched-Maintained Package for 40 circuits each 350 W TKT6740C

XWT6776

Switched-Maintained Package for 48 circuits each 350 W TKT6748C

XWT6777

Switched-Maintained Package for 56 circuits each 350 W TKT6756C

TST6751

IC Interface for 8 circuits each 350 W TKT6708C

TST6752

IC Interface for 16 circuits each 350 W TKT6716C

TST6753

IC Interface for 24 circuits each 350 W TKT6724C

TST6754

IC Interface for 32 circuits each 350 W TKT6732C

TST6755

IC Interface for 40 circuits each 350 W TKT6740C

TST6756

IC Interface for 48 circuits each 350 W TKT6748C

TST6757

IC Interface for 56 circuits each 350 W TKT6756C

TST6722

LON Interface TKT67xxC

TST6701

BACnet Interface TKT67xxC

TST6721

ACM Interface TKT67xxC

TST6724

WebCM/ WebACM Interface TKT67xxC

TST1811E

BCM Interface TKT67xxC

3.5 List of optional features

For more information on optional features, see Chapter 8. Optional Features

Central monitoring options:

3.6 General description

TKT67xxC(N) central battery unit is designed and manufactured according to the standards EN 50171

and EN 60439-1.

In normal situation, the central battery unit operates using a 230 V AC mains voltage, maintaining the

battery charge level and supplying a voltage of 230 VAC to the maintained output circuits. If the mains

voltage is interrupted or it drops below 180 V, the central battery unit switches to battery use. This

connects a voltage of 220 VDC to the non-maintained circuits and the voltage supply to the maintained

circuit switches from 230 VAC to 220 VDC. The battery supply is used as long as the mains voltage

remains unavailable or the battery voltage has dropped to the deep discharge limit (173 V).

In addition to the above mentioned standard functions, the control unit of the central battery unit also

includes the following monitoring, testing and reporting functions:

testing the luminaires either through addressable monitoring or by measuring the circuit

current and by monitoring the condition of the batteries

testing the capacity of the battery

VOT 2; Rev 1.2; EN; 09.07.2013

TKT67C – Installation and maintenance

7

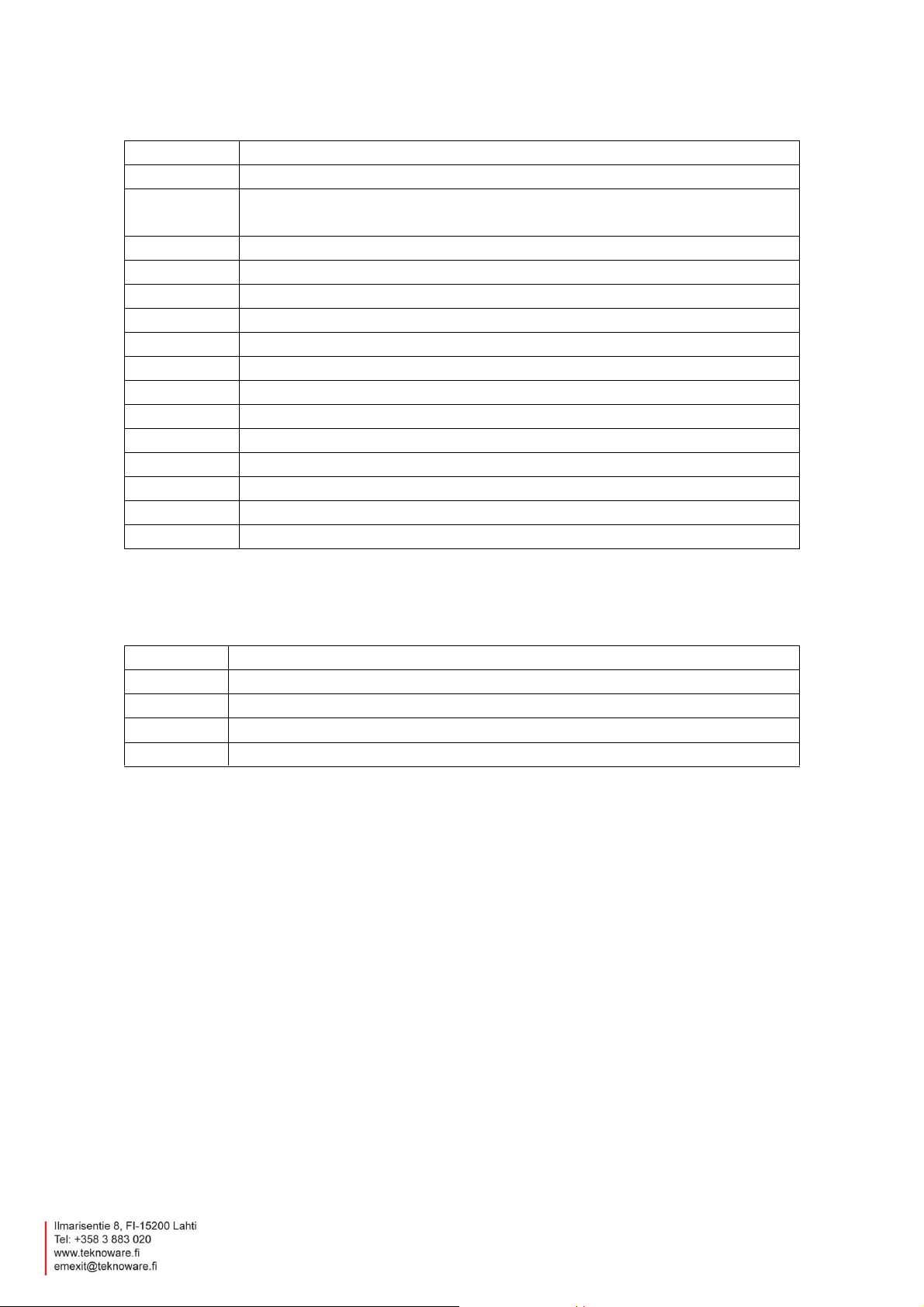

Mains connection:

N/PE 220-240 V AC 50/60 Hz 3~

Casing:

IP21

Output voltage:

mains connection: 220-240 VAC, battery operation: 216VDC

Battery voltage:

216 VDC

Battery charging time:

12 h 80 %

Max. batteries:

18 x 65 Ah

Max Input power

TKT6716C(N):

8,600 VA

Max Input power

TKT6724C(N):

11,400 VA

Max Input power

TKT6732C(N):

14,200 VA

Max Input power

TKT6740C(N):

17,200 VA

Max Input power

TKT6748C(N):

20,000VA

Max Input power

TKT6756C(N):

22,800 VA

Ambient temperature range:

+10 …+50C

Input fuse:

3-phase 16 A C-curve

indicating the address of the faulty luminaire with the LED and the number of the circuit,

in the addressable monitoring of the luminaires (7 segment display and LED bar)

indicating the faulty luminaire circuit with the LEDs and the number of the circuit in the

circuit monitoring (7 segment display)

a short operation test time can be set to take place after each 1…7 days

battery test every 6 months 4.1 and 4.7 at 0.00 o’ clock.

tests can also be started manually

reporting of the test results on a printer, in the TKT67xxCD(L) models or optional

integrated printer TST6731 (= log book)

LCD display (optional)

in the report, the test date, possible faulty luminaires, duration of the test and the

condition of the battery can be seen

interface options for central monitoring

The central battery unit does not require any other regular user action after its installation and

commissioning than checking the status of the signal LEDs (the left-hand side bar) at specified

intervals.

No separate data transfer cables are needed for the luminaires as the data is transferred via the power

supply cables.

A self-learning system; luminaires can be added or removed afterwards.

The central battery unit can be set for either addressable monitoring of the luminaires or for circuit

monitoring. In the addressable monitoring of the luminaires, the luminaires must be equipped with an

address module from Teknoware. All the Teknoware luminaires the type code of which ends in letter K

are fitted with this feature.

The batteries Pb (18 pcs) or NiCd (180 pcs) for the central battery unit always require a separate

battery container and battery cables.

All the functions related to the use of the central battery unit can be performed using its control panel

that also includes display LEDs to indicate the status of the unit. The panel functions are described in

Chapter 4.6 Operation of the central battery unit.

3.7 Technical specifications

VOT 2; Rev 1.2; EN; 09.07.2013

TKT67C – Installation and maintenance

8

Output circuit fuses:

5x20 mm sand-filled glass tube fuse 2,5 A

Output connector:

max. wire 4 mm2

Required short-circuit

current with 2.5 A fuse 0,4 s.

tripping time:

10 A

Battery Fuse:

TKT6716Cxx - TKT6756Cxx:

2x35 A plug fuse S 35 A/250 V Neozed

Charging circuit fuses:

5x20 mm glass tube fuse 6,3 A

Central battery unit

type

Output circuits

Total load capacity in battery use with

1-hour and 3-hour operating time

TKT6716C(N)

2x

(8x350W/ 4x700W/2x1,400W)

or 2,5A circuit, Max. 5,600VA

1 h 5,600 W 18x38 Ah

3 h 5,600 W 18x65 Ah

TKT6724C(N)

3x

(8x350W/ 4x700W/2x1,400W)

or 2,5A circuit, Max. 8,400VA

1 h 8,400 W 18x38 Ah

3 h 8,400 W 18x65 Ah

TKT6732C(N)

4x

(8x350W/4x700W/2x1,400W)

or 2,5A circuit, Max. 11,200VA

1 h 11,200 W 18x65 Ah

3 h 11,200 W 18x65 Ah

TKT6740C(N)

5x

(8x350W/4x700W/2x1,400W)

or 2,5A circuit, Max. 14,000VA

1 h 14,000 W 18x65 Ah

3 h 14,000 W 18x65 Ah

TKT6748C(N)

6x

(8x350W/4x700W/2x1,400W)

or 2,5A circuit, Max. 16,800VA

1 h 16,800 W 18x65 Ah

3 h 16,800 W 18x65 Ah

TKT6756C(N)

7x

(8x350W/ 4x700W/2x1,400W)

or 2,5A circuit, Max. 19,600VA

1 h 19,600 W 18x65 Ah

3 h 19,600 W 18x65 Ah

The central battery unit is equipped with a distribution fuse in the connecting terminal and with battery

circuit fuses. The output circuits’ fuses are on the top end of casing at connectors 1-2.

For more information, see chapter 5.2.1 Parts layout

The charging system of the central battery unit is equipped with a temperature compensation of the

battery charging voltage, which is approximately 0.06 V/°C (5 mV/°C/cell).

NOTE: The luminaires used with the central battery unit must be suitable for both AC and DC supply,

and according to EN 60598-2-22.

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

9

3.8 Directives and standards

The following directives and standards were applied in designing and manufacturing the central battery unit:

Quality: ISO 9001: 2008; (certified quality system)

Environment: ISO 14001: 2004; (certified environment system)

Electrical safety: 2006/95/EY LVD directive

Device standard: EN 50171: 2001; Central power supply systems

EN 50272-2: 2001; Safety requirements for secondary

battery installations Part 2:

Stationary batteries

EN 60439-1 + A1: 2005; Distribution units. Part 1:

Requirements for type tested and

partly type tested units.

IEC 62034: 2006; Automatic test systems for battery

powered emergency escape lighting

Electromagnetic compatibility: 2004/108/EC EMC directive

EN 61000-6-3: 2001; Electromagnetic compatibility

(EMC)-Part 6-3: Generic standard Emission standard for residential,

commercial and light industrial

environments.

EN 61000-6-2: 2005; Electromagnetic compatibility (EMC)

- Part 6-2: Generic standards Immunity for industrial environments

VOT 2; Rev 1.2; EN; 09.07.2013

TKT67C – Installation and maintenance

10

4. Description of operations

4.1 Purpose of the central battery unit

In a normal situation the purpose of the central battery unit is to

monitor the mains voltage

maintain the battery charge level

supply power for the maintained emergency luminaires

During a mains failure the central battery unit will supply voltage to the maintained and the nonmaintained emergency lighting circuits from the batteries.

The central battery unit also includes functions for testing and monitoring the condition of the luminaires

and the batteries.

4.2 Circuit outputs

Circuit output connections can be selected as maintained or non-maintained mode from circuit board.

For more information, see chapter 5.2 System installation.

4.3 Circuit board settings

In the central battery unit there are 1-7 circuit boards. Every board has eight output circuits. On circuit

boards there is a DIP-switch selector that defines the characteristic of the board. The functions of the

DIP-switches are:

DIPs 1-3 give the board its internal address

DIP 4 defines whether the board uses addressable central monitoring or circuit monitoring. Set

to OFF position defines board to use addressable central monitoring.

DIPs 5 and 6 are used when the parallel connection of the output circuits is used.

For information on the circuit boards’ DIP settings details, see chapter 5.2.3 DIP switch settings in

circuit boards.

4.4 Parallel connection of output circuits

Output circuits can be connected parallel to get a bigger circuit output power.

Factory settings give 8x 350 W output power

Two circuits connected parallel gives 4x 700 W output power

Four circuits connected parallel gives 2x 1,400 W output power

For more information on making a parallel connection between output circuits, see chapter 5.2.2 Circuit

wiring in parallel connection.

NOTE: When parallel connections are used, the output circuits’ connectors running the circuit numbers

may change. The circuit numbers must be changed to correspond with the amount of the connected

circuits.

VOT 2; Rev 1.2; EN; 09.07.2013

TKT67C – Installation and maintenance

11

4.5 Control unit

The monitoring function of the central battery unit can operate using three different operating principles:

addressable monitoring, circuit monitoring or a combination of both. This is selected with the DIP switch

4 (see more information in Chapter 5.2.3 DIP switch settings in circuit boards). Addressable monitoring

and circuit monitoring can be set for different circuit boards within the same unit: 8 circuits on

addressable monitoring, 8 circuits on circuit monitoring, etc.

In addressable monitoring of the luminaires, each luminaire has its own unique address. There can be

1...32 luminaires in one circuit. The luminaires have LOW 1-16 (luminaires 1-16) and HIGH 1-16

(luminaires 17-32) addresses. For example, the luminaire HIGH 2 indicates luminaire number 18. On

the display of the central battery unit this is presented with the letters L (LOW) or H (HIGH). The central

battery unit checks the operation and indicates the result for each luminaire separately.

The circuit monitoring measures the current of a circuit in battery mode. The changes in the current are

used to determine possible faults in the circuit. The number of luminaires in a circuit is not limited, but

the input power of a circuit cannot exceed 350 VA or 1,6 A. Note that circuit monitoring doesn’t give

luminaire-specific information. The limit value of the error alarm can be changed in the settings, (1-31) =

+/- 10.. 310 mA. The factory settings are 16 = +/- 160 mA.

NOTE: In parallel connection, the current values are multiplied by the number of the parallel connected

circuits. 700 W = 2x or 1,400 W = 4x.

NOTE: If circuit monitoring current limits are changed in a configured centre, the unit goes into a nonconfigured state and must be re-configured.

The descriptions of the signal LEDs and the buttons are presented in chapters 4.9 Control Module

panel luminaire monitoring LED’s and menu settings and 4.11 Buttons.

4.5.1 Individual luminaire monitoring test with basic settings

As a basic setting, the luminaire test is done automatically once a day at a predetermined time. The

central battery unit carries out the test as follows:

The central battery unit switches to battery mode and the Battery Oper. and the Luminaire Test LEDs

are lit for the duration of the test. L or H and the circuit number is displayed on the display of the control

unit. Whenever a functioning luminaire is detected, an indicator light is lit. After all circuits are tested,

the system returns to normal mode.

If a malfunctioning luminaire is found from any circuit, an indicator light will blink on the display. Also,

the External fault LED is lit and the external error alarm relay will operate. In correctly functioning

luminaires the LEDs are lit evenly.

For more information about testing the luminaires, see Chapter 4.10 Control Module panel test

functions and alarms.

4.5.2 Circuit monitoring luminaire test with basic settings

As a basic setting, the luminaire test is done automatically once a day at a predetermined time. The

central battery unit carries out the test as follows:

The central battery unit switches to battery mode and the Luminaire test LED is lit for the duration of the

test. The current of each circuit is measured and the circuit number increases as the test progresses.

The LEDs representing the measured relative current of each circuit will be lit. After all circuits have

been tested, the software returns to normal mode.

A fault indication will be given if in any of the circuits the measured current differs more than +/- 80 mA

when compared to the value which was stored during the last configuring. Each one LED in the column

represents a +/- 100 mA of current in a circuit. The deviation against the configured value is shown by

flashing the LEDs, corresponding the difference. The more LEDs there are flashing, the bigger is the

difference and more luminaires are likely to be failed. With the settings the current range can be

changed between 10 and 310 mA. The displays of the LEDs also operate in within this range. Also, in

VOT 2; Rev 1.2; EN; 09.07.2013

TKT67C – Installation and maintenance

12

this case the External fault LED will be lit and the external error alarm relay will operate. In working

luminaire circuits, the LEDs are lit evenly.

For more information about testing the luminaires, see Chapter 4.10 Control Module panel test

functions and alarms.

NOTE: In parallel connection the current values are multiplied by the number of the parallel connected

circuits. 700 W = 2x or 1,400 W = 4x.

4.6 Operation of the central battery unit

The functions are accessed by the menu structure. The green LEDs on the LED column show the basic

menu option and the number display shows the sub-options or values of it.

The menu functions of LEDs 1 and 2 are so-called basic functions. All other functions are related to the

settings of the central battery unit. The latter do not need to be changed in normal use. When the menu

functions are used, the central battery unit returns to normal mode if no functions are used for two

minutes. All functions can also be done via Bus interface using centralised management software.

4.7 Normal Status

In normal status the number display rotates the information of all circuits connected to the central

battery unit. In addressable monitoring the display will show the number of the circuit and the LED

corresponding to a luminaire will be lit. In circuit monitoring, the LEDs numbered from 16 to 1 will be lit;

the bigger the circuit input power, the greater the number of lit LEDs.

The information of each circuit will be shown for about four seconds at a time.

VOT 2; Rev 1.2; EN; 09.07.2013

TKT67C – Installation and maintenance

13

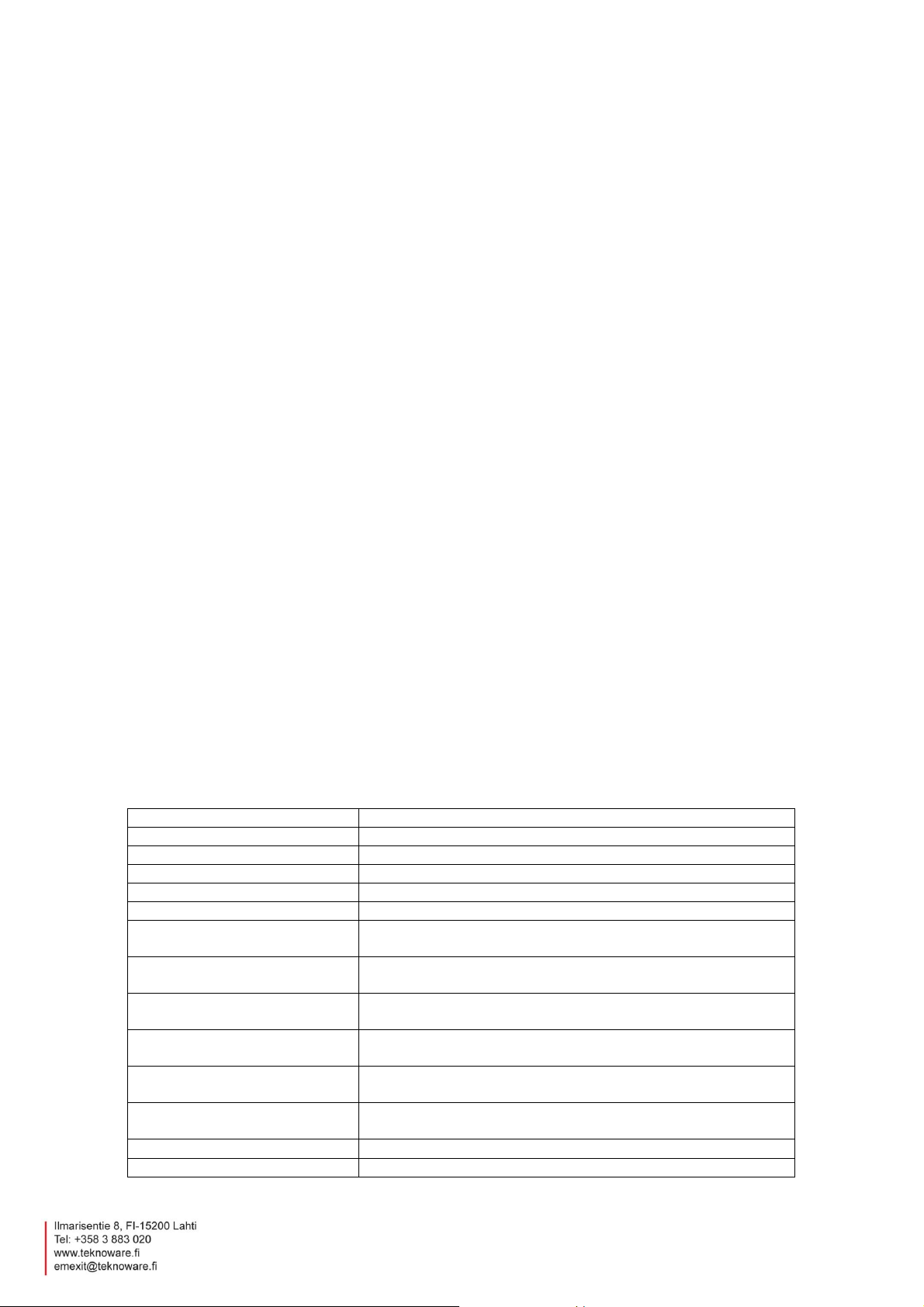

LED

Description

Reason for problem and solution

1 MAINS

OPERATION

The central battery unit is using

mains current.

The central battery unit can be

switched into emergency mode also

remotely, if the remote control

feature has been activated. In this

case:

Mains operation is flashing

Battery operation is lit

If Mains operation led is not lit, main fuse can be

blown or mains voltage is not present.

2 BATTERY

OPER.

The central battery unit is using

battery power. This means that the

mains voltage is interrupted or it has

dropped below 180 V.

The central battery unit can be in

battery operation because external

control has switched it to emergency

mode.

The central battery unit is in

luminaire or battery test.

Indicates if power is coming from battery.

Once the mains voltage recovers or increases

above 195 V, the central battery unit switches back

to mains voltage use and begins to charge the

batteries.

The battery is automatically recharged after the

mains voltage recovers.

3 BATTERY

OVERVOLT.

The battery voltage has increased

above 255 V (N = 278 V) in a normal

situation.

Battery fault and Internal fault LEDs

are also lit.

Battery charger is charging batteries with too high

voltage. Charger is faulty and it must be changed.

and/or

Batteries are at the end of their lifetime and must

be changed.

4 BATTERY

UNDERVOLT.

The battery voltage has dropped

below 228 V (N = 244 V) in a normal

situation.

Battery fault and Internal fault LEDs

are also lit.

The central battery unit has been for a long time in

battery operation.

Battery charger or batteries can be faulty and must

be changed.

Check battery condition. Every cell must have

about the same voltage level. Otherwise some

battery cell is in short circuit.

Check that temperature sensor is connected

properly and it is working. Resistance should be

about 2 kOhm. Voltage over sensor should be

about 5 Vdc.

5 DEEP

DISCHARGE

When this LED flashes, the battery

voltage has dropped below 195 V (N

= 210 V) (an early warning for a

deep discharge).

Internal fault LEDs are also lit.

When this LED is lit, the battery

voltage has dropped to the deep

discharge limit (173 V).

Battery operation and Internal fault

LEDs are also lit.

Check that remote control link is closed (CON5

pins 62 and 63).

Check that mains voltage is coming to Central

Battery Unit.

The Deep discharge LED stays lit until it is reset

with the Reset / Test button.

The mains voltage must have returned before the

deep discharge alarm can be reset.

4.8 Central module panel

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

14

If battery voltage is below deep discharge limit,

push forced charge button from charger, see

instructions in chapter 5.3.2.

Check that temperature sensor is connected

properly and it is working. Resistance should be

about 2 kOhm. Voltage over sensor should be

about 5 Vdc.

6 RECHARGE

When this LED is flashing, the

battery is recharging but the voltage

has not yet reached the

maintenance voltage.

When this LED is lit, the battery

voltage has reached the

maintenance voltage.

After a power failure the batteries are first boost

charged using a constant current. The boost

charging and the cyclic charging normally take 12

hours, after which the device switches to trickle

charging, i.e. the normal mode. In a normal mode,

the battery voltage is kept in about 243 V (N = 261

V). The charging current can be selected from the

charging board by using a DIP switch.

7 CURRENT

LIMIT

Not in use

8 BATTERY

FAULT

Possible fault in the battery or its

cabling.

This LED can be lit with other LEDs

that indicate the fault more

specifically.

If the battery is disconnected, the

charger doesn’t charge, the battery

fuse is blown or the battery doesn’t

accept charging current, the

following alarms are displayed on

the panel:

Mains operation LED

Battery undervoltage or

overvoltage LED

Battery fault LED

Internal fault LEDs

Battery fuses might be blown.

Refer to the instructions given for the LED that

specifies the battery fault (Battery overvoltage,

Battery undervoltage and Deep discharge).

To reset the possible battery fault alarm, press the

Reset / Test button.

9 EARTH

LEAKAGE

Possible earth leakage inside the

central battery unit.

Earth leakage detection will check if positive pole

of the battery has leakage to the body of the

central battery unit.

If there is not earth leakage, the earth leakage

sensor might be broken.

10 INTERNAL

FAULT

This LED alarms when some

internal fault of the central battery

unit is detected, a fault in the battery

or the charging circuit.

This LED can be lit with other LEDs

that indicate the fault more

specifically.

This LED is also lit when the

batteries are being changed.

Refer to the instructions given for the LED that

specifies the battery fault.

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

15

LED

Description

Instruction

Number display

Shows the number of the circuit whose

luminaires are shown with LEDs 1-16.

If “CC” is flashing on the display, the system

has not been configured.

For configuring the system, see

chapter 5.3.4 Configuration.

LEDs 1-16

There are two meanings of these leds:

1. To show information of the luminaires.

How many luminaires installed and

address of the luminaires.

Status of the luminaires.

2. To indicate selection in menu

Instructions how to check and change

settings from menu are below.

Addressable monitoring:

The LEDs display the status of

luminaires in the aforementioned

circuit.

If the LED is continuously lit, the

luminaire is functional.

If the LED is flashing, the

luminaire is faulty.

!f the LED is not lit, no luminaire

has been assigned for that

address.

Circuit monitoring:

The LED bars display the total input

power of the circuit.

If the LED or LEDs are flashing during

circuit monitoring, an error has been

detected in the circuit.

See the instructions given for

corresponding LEDs.

1 REPORT

Use this option to print out report of the

configuration of the central battery unit and the

status of the luminaires.

Value 1 = Print a report of all circuits.

Value 2 = Print a report of faulty circuits.

Value 9 = Displays circuit board + circuit

number on the display instead of a running

number

NOTE: This action requires a printer, which is

an optional feature TST6731 or the central

battery units of the type Tapsa Control

TKT67xxC(N)D(L).

To print a report,

1. Go to the menu with the

MENU / OK button.

The REPORT LED is lit.

2. Press the SET button once.

Number 1 will appear in the display.

3. Acknowledge by pressing the

MENU / OK button again.

Printing of the report will start.

NOTE: Printing of the reports is

blocked during the tests.

4.9 Control Module panel luminaire monitoring LED’s and menu settings

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

16

2 TESTING

Use this option to select a test to be started or

interrupted.

1 = Start of the luminaire test.

2 = Interruption of the luminaire test.

3 = Start of battery test for 2/3 of the time (the

same time as in the automatic test).

4 = Start of the battery test for the set operating

time (1 or 3 hours).

5 = Start of the battery test until the end of its

duration – the battery will be discharged.

6 = Interruption of the battery test /

acknowledging of a battery fault.

7 = Stop the local controller function or the

BLINK mode.

8 = Start the local controller function.

9 = Start the BLINK mode.

10 = Reconfiguration.

To start or interrupt a test,

1. Go to the menu with the

MENU / OK button.

2. Press the BROWSE button until

the TESTING led is lit.

3. Press the SET button until the

value you wish to select shows in

the display.

For example 6 = Interrupt the

battery test.

4. Acknowledge by pressing the

MENU / OK button again.

The required action begins.

3 SETUP

Use this option to enable / disable the settings

locking to change the operational settings of the

central battery unit.

To enable / disable the settings

locking,

1. Go to the menu with the MENU /

OK button.

2. Press the BROWSE button until

the SETUP led is lit.

3. Press the SET button to select the

correct value (0=locking enabled,

1=locking disabled).

4. Press the BROWSE button to

acknowledge the selection, and

return to the operational settings.

When the settings locking is disabled,

you can change the operational

settings.

4 AUTO CONF.

Use this option to change the status of the

automatic configuration.

Value 0 = Automatic configuration disabled.

Value 1 = Automatic configuration enabled.

Values 2 and 3 = Not in use.

To change the automatic configuration

status,

1. Go to the menu with the

MENU / OK button.

2. Press the BROWSE button until

the AUTO CONF. led is lit.

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

17

The default setting is 0 (zero).

NOTE: This function only works in addressable

monitoring. If circuit monitoring is chosen, the

central battery unit needs to be reconfigured

after changing the circuit load.

3. Press the SET button until the

value you wish to select is shown

in the display.

The automatic configuration settings

are changed.

5 TEST SELECT

Use this setting to choose between automatic

and manual tests.

7-segmentsdisplay

The first section in the 7-segment-display

determines every how often the luminaire

test is made, from 1 to 7, meaning the

number of days. If the number is 1, the test

is made every day, or if it is 7, the test is

done once a week.

The number of the second segment

determines the settings of the luminaire

tests.

0 = Luminaire and battery test, both manually.

1 = Luminaire and battery test, both

automatically (presumption).

2 = Luminaire test automatically, battery test

manually.

3 = Luminaire test manually, battery test

automatically.

The automatic luminaire test is made once per

day on the chosen time of the day.

The automatic battery test is made twice a year

(4th of January and 4th of July).

1 2

To choose between automatic and

manual tests,

1. Go to the menu with the

MENU / OK button.

2. Press the BROWSE button until

the TEST SELECT led is lit.

3. Press the SET button until the

value you wish to select shows in

the display.

The testing settings have been

changed.

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

18

6 SENSITIVITY

Use this option to set the limit for the current

variation, if the central battery unit is set to work

in circuit monitoring mode. The setting is +/-

80 mA as a standard.

To define how much the current can

change before an alarm is issued,

1. Go to the menu with the

MENU / OK button.

2. Press the BROWSE button until

the SENSITIVITY led is lit.

3. Choose the current value with the

SET button.

As a standard the value is

16 = 160 mA divided by two, which

gives +/- 80 mA.

4. Browse with the SET button the

value of the current can be

changed all the way up to

+/- 150 mA.

In the display this shows as the value

30. When the value 30 is exceeded,

the following value is the minimum

current the change of which the

central battery unit notices. The

minimum value is +/- 40 mA. In the

display this will be shown as the

number 8.

NOTE: In parallel connection the

current values are multiplied by the

number of the parallel connected

circuits. 700 W = 2x or 1,400 W = 4x.

7 LUMI. TEST

TIME

Use this option to choose a time for the

automatic luminaire test, in full hours.

To change the luminaire test time,

1. Go to the menu with the

MENU / OK button.

2. Press the BROWSE button until

the LUMI. TEST TIME led is lit.

3. Press the SET button until the

value you wish to select shows in

the display.

For example 15 = 15:00 = 3 pm

The luminaire test time has changed.

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

19

8 DELAY TIME

Use this option to select a 0 to 15 minute delay

when switching from battery use to mains

voltage use.

This function works only when the mains supply

has failed and then returned. The delay is

needed if mercury vapour lamps or similar

luminaires whose ignition requires a longer time

are used as general luminaires.

As a default setting there is no delay. The

number display shows the delay in minutes.

To change the delay time,

1. Go to the menu with the

MENU / OK button.

2. Press the BROWSE button until

the DELAY TIME led is lit.

3. Press the SET button until the

value you wish to select shows in

the display.

The delay time has changed.

9 CENT.

NUMBER

Use this selection to choose an individual

number for the central battery unit.

The number is printed on the report and so the

information on the reports can always be linked

to a specific central battery unit, if there are

more than one central battery units in the

building.

To set an individual number for the

unit,

1. Go to the menu with the MENU /

OK button.

2. Press the BROWSE button until

the CENT. NUMBER led is lit.

3. Press the SET button until the

value you wish to select shows in

the display.

The individual number has been

assigned.

10 BATT.

LEVEL

Normally, this value doesn’t need to be

changed.

Use this option to change the level of the

battery voltage at which the battery test is

stopped.

As a default the voltage level is 210 V. Number

10 is programmed to be added in the number

200 programmed, so the voltage will be 210 V.

As a default there is number 10 in the display,

which means this battery voltage of 210 V. The

limit that is reached first ends the test. The time

and the end voltage are recorded.

To change the voltage limit for a

battery test,

1. Go to the menu with the MENU /

OK button.

2. Press the BROWSE button until

the BATT. LEVEL led is lit.

3. Press the SET button until the

value you wish to select shows in

the display.

The voltage limit has been changed.

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

20

11 DURATION

Use this option to select a 1 h or 3 h battery

mode operating time.

To change the battery mode operating

time duration,

1. Go to the menu with the MENU /

OK button.

2. Press the BROWSE button until

the DURATION led is lit.

3. Press the SET button until the

value you wish to select shows in

the display.

The operating time has been

changed.

12 YEARS

Use this option to set the year.

The year is set by selecting the last two digits of

the year, 00...50 (e.g. 09 = 2009).

To set the system time and date,

1. Go to the menu with the MENU /

OK button.

2. Press the BROWSE button until

the right led is lit.

3. Press the SET button until the

value you wish to select shows in

the display.

4. Acknowledge by pressing the

MENU / OK button again.

The system time and date have been

set.

13 MONTHS

Use this option to set the month.

The number of the month is set, 1...12.

14 DAYS

Use this option to set the day.

The number of the day is set, 1...31.

15 HOURS

Use this option to set the hour.

The hours are set, 0...23 (0 = midnight, 12 =

midday).

16 MINUTES

Use this option to set the minutes.

The minutes are set, 00...59.

Note! If both battery and mains are disconnected, the factory defaults are restored and the control unit

needs to be reconfigured.

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

21

LED

Description

Instruction

BATTERY TEST

As a basic setting, the battery test is done

automatically twice a year: on the 4th of July

and on the 4th of January, at 12 pm (midnight).

If the LED is continuously lit, the battery

test is in progress.

If the LED is flashing, an error has been

detected in the battery test. In this case

the External fault LED will also be lit.

During the battery duration test, the central

battery unit is switched to battery mode and

all output circuits are switched on.

If the LEDs Internal fault is lit and Battery

test is flashing, the battery duration test

has failed.

A change of battery always requires a new

configuration, so that the software knows a

battery has been replaced.

The battery test can be started by pressing

one button on the control unit interface, or

manually using the control unit menu.

No action needed, unless the test

fails. If the test fails check condition

of batteries

To run the battery test yourself,

either

1. Press the BROWSE button for

8 seconds.

or

1. Press the MENU / OK button.

2. Use the BROWSE button to

select 2, TESTING.

3. Use the SET button to select 3,

battery test during 2/3 of the

operation time.

4. Accept the selection with the

MENU / OK button.

The battery test starts.

LUMINAIRE TEST

If the LED is continuously lit, the luminaire test

is in progress.

If the LED is flashing with External fault LED,

configuration is in progress.

Luminaire test must be carried out once in 1-7

days. Factory setting is once a day at

midnight (00.00 o’clock).

No action needed, unless the test

fails. If the test fails check condition

of luminaires.

To run the luminaire test yourself,

either

1. Press the BROWSE button for

3 seconds.

or

1. Press the MENU / OK button.

2. Use the BROWSE button to

select 2, TESTING.

3. Use the SET button to select 1 =

Starting the luminaire test.

4. Accept the selection with the

MENU / OK button.

The luminaire test starts. If a faulty

luminaire was found in any of the

circuits, its corresponding LED will

flash when its circuit number is

4.10 Control Module panel test functions and alarms

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

22

shown on the display.

If luminaire test will not start, check

battery voltage level. It must be

more than 200 VDC.

LOCAL CONTR.

ALARM

The central battery unit can be remote

controlled to send a local controller pulse to all

circuits, in which case all the non-maintained

addressable luminaires (Teknoware types

ending in K, or external luminaires fitted with

Teknoware address module) that are

connected to the central battery unit are

switched on. This feature can be activated by

opening loop 68-69.

If the LED is lit, the loop 68-69 is open.

If the LED is blinking slowly, K model

luminaires are turned on from the menu

with AC voltage.

.

Check the loop between connectors

68-69.

FUSE FAULT

If the LED is lit, there is a faulty fuse in the

control module.

If the LED is blinking slowly, there is a

faulty fuse in the circuit shown on the

display.

If the LED is blinking quickly, there is

some other fault in the circuit shown on

the display.

Check all circuit output fuses.

EXTERNAL FAULT

Alarms when an external fault is detected in

the luminaire or the luminaire test has

detected an error.

If the LED is flashing with Luminaire test LED,

configuration is in progress.

Check that all luminaires are

working.

INTERNAL FAULT

If the LED is lit continuously, there is a fault in

the battery or charging circuit. i.e. the alarm is

coming from the Central Module, or the

battery test has detected an error.

If the LED is flashing, there is a fault in a

circuit output fuse or output circuit

Check if battery or charger is faulty.

Measure voltage level of batteries.

In normal situation it should be

243-255 VDC.

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

23

MENU / OK

Used for selecting a menu or accepting a selection.

Used for starting tests and/or printing.

BROWSE

Used for browsing menus and making selections within the menu.

SET

Used for changing a desired setting in the menu.

Press for 3 seconds to start luminaire test.

Press for 8 seconds to start battery test.

V-METER, 1 second

(until the indicator LED

is lit)

Press and hold SET for 1 second: the voltage of the battery is displayed in the

LCD display

DC A-METER, 2 second

(until the indicator LED

is lit)

Press and hold SET for 2 seconds: DC discharge current from the battery

LUMIN. TEST, 4 second

(until the indicator LED

is lit)

Press and hold SET for 4 seconds: start of the luminaire test

BATT. TEST, 6 second

(until the indicator LED

is lit)

Press and hold SET for 6 seconds: start of the battery test

4.11 Buttons

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

24

5. System planning and installation

5.1 System planning

Tapsa Control central battery unit uses the circuit cabling to transfer data between the central battery

unit and the luminaires. This way there is no need for separate data cabling, and the circuit cabling can

be done in the same way as the regular cabling for emergency lighting system.

5.1.1 Luminaire-specific addressable monitoring

The following points should be taken into consideration when planning addressable monitoring:

The luminaires used in the system must be manufactured by Teknoware, and their type code

must end in letter 'K' (For example TWT6081K) or external luminaires fitted with Teknoware

address module. These types of luminaires include the technology that allows communication

between the luminaire and the central battery unit.

The luminaires must be coded with addresses from 1 to 32. The addresses can be selected

freely as long as two or more luminaires in the same circuit do not have the same address. The

coding (circuit no. / luminaire no.) can be marked in accordance with the electrical plan to the

address label delivered with the luminaire.

5.1.2 Circuit monitoring

Circuit-specific condition monitoring allows the usage of any emergency luminaires operating on AC/DC

voltage. However, in case of the fluorescent lamp luminaires, they shall be designed so that they switch

off when the lamp fails. This is because the system measures only the current of the circuit and detects

the failures from the changes in it.

5.2 System installation

The system must be installed according to the electrical plan or work description.

If you use addressable monitoring, make sure that all luminaires belonging to the same circuit have a

different address number (between 1 and 32). Set the address by changing the DIP switch settings.

The DIP switch is located in the data transfer unit or electronic ballast inside the luminaire. The

instructions for setting the addresses are included in the luminaires' installation instructions.

To install the system,

1. Make sure that the main switch is in the '0' position and the battery fuses are removed.

The batteries are always placed in a separate battery case, and connected in series (18 x 12 V) to

the + (red) and - (black) cables reserved for them. The batteries' temperature sensor is placed

between the batteries.

2. Check the polarity of the batteries.

3. Connect the supply cable to connectors 3~ L1, L2, L3, PE and N

4. The output circuits are connected to connectors X1-X7.

The circuit fuses F1-F56 are located at connectors X1-X7. The central battery unit outputs can be

connected as maintained or non-maintained, using the "Mode" wire links in the following way:

VOT 2; Rev 1.2; EN; 09.07.2013

TKT67C – Installation and maintenance

25 “Mode” link closed

Maintained emergency luminaire circuit (exit luminaire)

“Mode” link closed

Maintained emergency luminaire circuit (when using Local Controllers)

Or, while connecting Local Controllers and/or K-model maintained or

non-maintained emergency luminaires to a same circuit.

Or, while connecting maintained luminaires without Control function

and K model luminaires to a same circuit

“Mode” link open

Non-maintained emergency luminaire circuit

As factory setting, all circuits are connected as maintained (exit luminaire or Local Controller). If you

wish to change into non-maintained emergency luminaire circuits, the "Mode" link needs to be removed

from those circuits. Layout for “Mode” links is in next chapter.

NOTE! If you have control type luminaires (model type ends in letter K) or address modules with

maintained/non-maintained selection, all mode links can be closed. Luminaire will be selected

maintained or non-maintained with DIP switch. See further information from luminaire’s operation

manual.

5. Connect the alarms and the remote control switch into the connectors shown in APPENDIX 4:

Circuit diagram with 3-phase input.

6. Set the system date on time so that the automatic tests can take place when scheduled (factory

setting at 00.00 o’clock)

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

26

5.2.1 Parts layout

VOT 2; Rev 1.2; EN; 09.07.2013

TKT67C – Installation and maintenance

27

700 W (2 circuits combined) parallel connection

wiring for circuit board 1:

1,400 W (4 circuits combined) parallel connection

wiring for circuit board 1:

Note! If you are using parallel connections please note that all output circuits in same change over

board has 700 W or 1,400 W outputs. The next chapter has an explanation how to set the changeover

board to a parallel connection mode.

DIP Switches

Mode links

Circuit board layout:

5.2.2 Circuit wiring in parallel connection

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

28

Addressable monitoring

active (Factory settings)

Circuit monitoring

active

5.2.3 DIP switch settings in circuit boards

The DIP switch number 4 must be used to select a desired operating mode for each board. When the

DIP switch number 4 is in the 'OFF' position, the circuit board operates according to the addressable

luminaire monitoring principle.

When the DIP switch number 4 is in the 'ON' position, the circuit board operates according to the circuit

monitoring principle.

The factory setting for the circuit boards is addressable monitoring.

For more information, see Chapters 4.3 Circuit board settings and 4.4 Parallel connection of output

circuits.

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

29

5.3 Commissioning

All operations related to the system installation and commissioning must be performed by a

skilled electrician.

The two empty columns of the type label inside the central battery unit shall be marked with the

total load connected to the central battery unit and the nominal battery mode duration.

5.3.1 Setting of battery type and capacity

The charging current has been set to minimum at the factory. The battery type and capacity must be set

/ checked as follows:

1. Set the battery type and capacity with the recharge control unit DIP switch according to the

guidelines in the illustration below.

NOTE: The charging current and battery type must ALWAYS be set / checked based on the number of

ampere-hours (Ah) in the batteries used. Incorrect settings may damage the batteries. Battery sizes are

as shown in the sticker.

NOTE: THE CHARGING CURRENT SHALL ALWAYS BE SET WITH MAINS SUPPLY OFF. ONLY

ONE DIP SWITCH IS ALLOWED TO BE SWITCHED ON AT THE SAME TIME.

VOT 2; Rev 1.2; EN; 09.07.2013

TKT67C – Installation and maintenance

30

LED

Explanation

Luminaire test is flashing

External fault is flashing

Checking luminaire circuits on at a time is running.

WARNING

Using forced charging button is live working and it must be done in accordance with live

working declarations.

5.3.2 Forced charging of the batteries

Before using the Forced charging of batteries, test each battery separately with a battery tester.

There is a button for forced charging in the charger board. If the battery voltage is under 110 V, push

this button for 1-2 min and measure the battery voltage at the same time. Charging starts automatically

when battery voltage rises up over 110 VDC. If the batteries, the main input voltage and all fuses are

OK and the charger doesn’t charge, it is broken. It has to be replaced with a new one.

5.3.3 Checking the luminaire circuits one at a time

The circuit-specific checking can be done using either addressable or circuit monitoring. The central

battery unit can either be configured or not.

To checking the functionality of a single circuit,

1. Press the BROWSE button until the display shows the number of the circuit whose luminaires'

functionality you want to check.

2. Press the MENU / OK button.

3. Use the BROWSE button to select 2, Testing.

4. Use the SET button to select 1 = Starting the luminaire test

5. Accept the selection with the MENU / OK button.

As the checking process progresses, the LEDs will show the luminaires found in the circuit or the total

input power of the circuit. Once the test is complete, you can use the BROWSE button to have the

central battery unit display the tested luminaire circuits and the luminaires detected in them or the total

input power of the circuit.

5.3.4 Configuration

It is advisable to check before the configuration that all the luminaires are actually working, because the

configuration will teach the functionality of the existing luminaires to the testing system. The learned

configuration will then be used as a reference for all future tests.

NOTE: When CIRCUIT MONITORING is used, the central battery unit and the maintained luminaires

must be allowed to warm up for at least one (1) hour before the final configuration. This is essential,

because the warm-up time allows the luminaire currents to normalise.

The warm-up is carried out by running a luminaire test, as instructed under LUMINAIRE TEST in

chapter 4.9 Control Module panel. The warm-up phase is not necessary when using addressable

monitoring.

In addressable monitoring, the central battery unit sends inquiries to the circuits in order to determine

the luminaires in the circuits.

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

31

In circuit monitoring, the central battery unit will wait for a few minutes and let the luminaires warm up

before measuring the current in each circuit. The first luminaire test is automatically a configuration. The

configuration cannot be interrupted. The results of later tests are compared with the configuration data.

Once the Luminaire test and External fault LEDs go off, the central battery unit is configured and has

returned to normal mode. In normal mode, the display will show the information of each circuit one at a

time. The information of each circuit will be shown for four seconds.

You can browse the circuit information with the BROWSE button.

After the central battery unit has configured itself, it will return to the normal mode.

6. Maintenance

The condition of the emergency lighting system must be ensured by regular maintenance according to

the laws and regulations of local authorities.

In addition to the checks and inspections there is no regular maintenance required for the central

battery unit, other than changing the batteries when the specified emergency mode duration is no

longer achieved.

The luminaires need to have their light sources replaced once they have reached the end of their

lifetime.

Only a qualified electrician may perform such maintenance operations which require opening of

the casing of the central battery unit or the battery container.

6.1 Replacing the batteries

To replace the batteries,

1. Open the CBU door.

2. Switch off the battery fuse (see picture from chapter 5.2.1 Parts layout).

Mains operation and Internal fault LEDs will be lit.

3. Turn the S1 main switch and distribution fuse to '0' position (see picture from chapter 5.2.1 Parts

layout).

The display LEDs go off = the central battery unit is de-energized.

4. Remove the cover from the battery case(s).

5. Disconnect the cables coming from the central battery unit from the batteries.

Remove the minus cable first.

6. Remove the battery interconnection cables.

7. Pull the temperature sensor aside.

8. Lift off the batteries and replace them with new ones.

9. Place the batteries' temperature sensor between the batteries.

10. Connect the battery cables (pay attention to polarity and insulation distances).

11. Close the battery case cover(s).

VOT 2; Rev 1.2; EN; 09.07.2013

TKT67C – Installation and maintenance

32

12. Turn on the battery fuse.

13. Turn the mains fuse to '1' position.

14. Turn the mains switch to '1' position.

15. Carry out the system configuration according to the instructions in chapter 5.3.4 Configuration.

If the configuration is interrupted, check the charge level of the batteries.

16. Make sure that the central battery remains in normal mode.

17. Close the CBU door.

7. Disposal

Note the following issues regarding the disposal of the central battery unit system and its

components:

Batteries and fluorescent lamps are hazardous waste. Metal parts can be put into aluminium or

steel waste. Wires, connectors and printed circuit boards are electronics waste. The plastic

parts shall be separated based on the material markings.

Follow the local laws and regulations in disposing the central battery unit system and its

components.

8. Optional Features

Optional features are options that can be added to a central battery unit, depending on the model.

You can either

select a central battery unit that already includes the option, or

select the option as an added feature, depending on the model.

The options are presented in Chapter 3.5 List of optional features.

A sticker on the side of the central battery unit describes what optional features are included in your

central battery unit.

8.1 LCD display functions

The LCD display, under the name of TST6732, is an option for central battery systems. The LCD

displays the status of the central battery system, as well as stores test results in its memory. The

following information is available on the LCD: battery set charge, battery voltage, date, time, results of

battery tests and results of luminaire tests. The built-in memory of the LCD stores a two-year test

history.

8.1.1 Button functions

The LCD has three buttons, the uppermost of which has two separate functions: it the button is pressed

only briefly, it selects the current option; it is pressed and kept pressed for 1.5 s, the previous menu is

displayed. The middle and lowermost buttons are used for browsing for options and changing the value

of the selected parameter.

VOT 2; Rev 1.2; EN; 09.07.2013

TKT67C – Installation and maintenance

33

??.??.???? ??:??

System status

Voltage level xV

Charge current xA

Luminaire test log

23.03.11 23:59 OK

22.03.11 23:59 ERROR

23.03.2011 10:30

System status OK

Voltage level 243V

Discharge current 1.0A

Browse luminaire tests

Browse battery tests

Browse error log

Setup

8.1.2 LCD content

If the LCD has not been configured, it will display the status screen shown below. In a few minutes, it

will receive configuration data from the central battery system, with the exception of luminaire circuits.

Figure 1. LCD not yet configured

The first row shows the date and time in format: dd.mm.yy.hh.min. The date and time are provided by

the central battery system; alternatively, they can be manually set on the LCD.

The second row shows the status of the central battery system.

NOTE: For error code explanations, please refer to the error log. See chapter 8.1.6 Error log.

The third row shows the voltage level of the battery set. The fourth row shows the battery set charge

and discharge currents.

Figure 2. LCD after having received configuration data from the central battery system

8.1.3 LCD menu tree

When you press the SETUP button, the LCD menu tree is displayed. You can browse the menu by

pressing the +/- buttons. You can select four separate submenus from the menu. The submenus are

shown in Figure 3.

The luminaire test log contains a two-year test memory, or, alternatively, the test memory of the latest

730 tests.

The battery test log contains a two-year test memory, or, alternatively, the log of the latest 256 tests.

The error log contains entries for the latest 42 errors.

You can use the SETUP button to change the date and the time of the day, as well as start a

luminaire/battery test.

Figure 3. Main menu

8.1.4 Test history

When you select Browse luminaire tests, the display below is shown.

Figure 4. Luminaire test log

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

34

Test 23.03.2011 10:30

Change over board 1-#OO…..

Change over board 2-OO…..

CHANGE OVER BOARD 1, OUTPUT CIRCUIT>1

HI: OOOOOOOOOOOOOOOO

LO: O#OO…………

Browse luminaire tests

Browse battery tests

Browse error log

Setup

Date Time Log

23.03.11 10:30 Error

24.03.11 10:30 OK

End of log

The example shows a test date and time, as well as the test result, OK or ERROR. You can browse

the log by pressing the +/- buttons. If you want to view the test results for a particular date, use the +/-

buttons to select the desired date, and then accept your selection by briefly pressing the SETUP button.

To move back to the higher-level menu from the test log, press the SETUP button.

A central battery system may house 1 to 7 changeover boards, each with 8 outputs. Each output circuit

may have 32 luminaires, shown in displays 16 LO and 16 HI. If only 16 luminaires are available, HI and

LO are not shown in the display. If the central battery system makes use of more than one changeover

board, you can select the data for a desired board by first pressing the +/- buttons and then confirming

your selection by pressing the SETUP button. The symbols used in the display indicate the following.

O = OK

# = Error

? = Luminaire not recognised (a luminaire has been added; automatic configuration is not in operation)

- = Luminaire is not connected

Figure 5. Luminaire tests with changeover boards

The "1- #OO" symbol for changeover board 1 indicates an error in output circuit 1.

The "2- OO" symbols for changeover board 2 indicate that output circuit 2 has no errors.

If you want to view the data for a particular changeover board, first select the board using the +/-

buttons, then confirm your selection by pressing the SETUP button. To move back to the higher-level

menu from the test log, press the SETUP button for 1.5 s.

You can use the data display for changeover boards to view data for any output circuit. You can browse

the output circuits by pressing the +/- buttons. To view the data for luminaires, press the SETUP button.

If the luminaires have been given names using a PC programme, the names are shown on the last line.

To move back to the higher-level menu from the test log, press the SETUP button for 1.5 s.

Figure 6. Luminaire tests, output circuit data

The dots indicate a vacant address, O = OK and # = ERROR. Twenty luminaires have been

interconnected to provide service in a output circuit, with luminaire 2 malfunctioning (LO 2).

8.1.5 Battery test history

You can browse the battery test log for detailed information on battery tests. You can view battery test

results, if the central battery systems has performed an automatic battery test, or if a manual test has

been carried out. The battery test log contains test dates, test times and test results. If you want to view

the data for a particular battery test, first select the desired date using the +/- buttons, then confirm your

selection by pressing the SETUP button. To move back to the higher-level menu from the test log,

press the SETUP button for 1.5 s.

Figure 7. Main menu Browse battery tests

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

35

Battery test duration 01:25

Battery set voltage 221V

Browse luminaire tests

Browse battery tests

Browse error log

Setup

Date Time Error

>23.03.11 10:30 2

23.03.11 10:32 5

22.03.11 00:15 2

The log shows the date, time and duration of the test, as well as the voltage of the battery set at the end

of the test. To move back to the higher-level menu from the test log, press the SETUP button for 1.5 s.

Figure 8. Luminaire test log

8.1.6 Error log

In addition to the log of the luminaires and battery tests, the display shows an error log of all errors

detected in the central battery system. The log shows the date and time of each error, as well as a

corresponding error code. If you want to view the data for a particular log, first select the desired log

using the +/- buttons, then confirm your selection by pressing the SETUP button. To move back to the

higher-level menu from the test log, press the SETUP button for 1.5 s.

Figure 9. Error log

Error code: Error description:

1 Internal error

2 External error

3 Central battery system has not been configured

4 Internal and external error

5 Fuse fault or other malfunction in output circuit

6 Deep discharge

7 Error with changeover board

8 Overload

To move back to the higher-level menu from the test log, press the SETUP button.

8.1.7 Setup

You can change the settings and start tests by first selecting the desired function using the +/- buttons

and then confirming your selection by pressing the SETUP button. Using the Setup display, you can

start a battery or luminaire test, as well as set the date and time. Once you have started a battery test,

you can cancel it by pressing the SETUP button and then selecting Stop battery test.

You can start a luminaire test by selecting Start luminaire test. The first luminaire test will configure the

central battery system.

You can set the date and time by selecting Set date and time. In the clock settings, a blinking cursor

identifies a value that you can change with the +/- button. You can change the parameter whose value

you want to change by using the SETUP button. Once you have set the date and time, you can leave

the menu by pressing the SETUP button, after which the new settings will be stored in the central

battery system in a matter of few seconds.

To move back to the higher-level menu from the test log, press the SETUP button for 1.5 s.

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

36

Browse luminaire tests

Browse battery tests

Browse error log

Setup

Start battery test

Start luminaire test

Set date and time

Stop battery test

Start luminaire test

Set date and time

PC connected

Data transfer speed 1200

PC connected

Data transfer speed 1200

Connection opened

NOTE: A battery test cannot be started unless the battery set is sufficiently charged.

Figure 10. Settings and starting a test

8.1.8 External USB connection

A USB port on the LCD allows data entered in a separate PC programme to be transferred to the LCD.

Using the PC programme, luminaires can be given names, along with descriptive information. Connect

the LCD to the PC using a USB cable. Once you have connected the cable to the LCD, the following

display is shown:

Figure 11. USB cable connected

The LCD software will scan the USB ports, opening a connection. A new row will appear on the display,

informing you that a connection has been opened. The connection is now open.

Figure 12. Connection opened

The buttons on the LCD cannot be used if there is an active USB connection between the LCD and the

PC. For more information, please refer to the PC programme user's guide.

TKT67C – Installation and maintenance

VOT 2; Rev 1.2; EN; 09.07.2013

37

8.2 Printer

The central battery units of the type Tapsa Control TKT67..CD or optional feature TST6731 are

equipped with a printer. The results of the last test can be printed using the menu options as follows:

Press the MENU / OK button.

Use the BROWSE button to select 1, Report.

Use the SET button to select 1, Print a report of all circuits.

Accept the selection with the MENU / OK button.

The report can be attached to the central battery unit's logbook as a proof of a completed test.

8.2.1 Language selection of the printer (TKT67..CD) or optional feature TST6731