TeknoStamap LAM 610 B, LAM 510, LAM 610, LAM 507 B, LAM 510 B Use And Maintenance Manual

...

USE AND MAINTENANCE MANUAL

p. 1/47

MANUAL DOUGH SHEETER

LAM 500-600 - LAM 500-600 BENCH-TOP

22 04 001

ENGLISH

mod.04.01.10

MANUAL DOUGH SHEETER

LAM 500 – 600 WITH BASE

LAM 500 – 600 L / T

LAM 500 – 600 BENCH-TOP

This manual contains the CE declaration of conformity

29.12.2009

USE AND MAINTENANCE MANUAL

p. 2/47

MANUAL DOUGH SHEETER

LAM 500-600 - LAM 500-600 BENCH-TOP

22 04 001

ENGLISH

mod.04.01.10

1- GENERAL ............................................................................................................. 4

1.1 GUARANTEE....................................................................................................................... 5

1.2 GENERAL WARNINGS AND APPLICATION....................................................................... 6

1.3 RATING PLATE DATA......................................................................................................... 7

1.4 TRANSPORT INSTRUCTIONS............................................................................................ 8

1.5 INSTRUCTIONS FOR INDOOR HANDLING............... Errore. Il segnalibro non è definito.

1.6 DECOMMISSIONING......................................................................................................... 12

2- TECHNICAL SPECIFICATIONS......................................................................... 13

2.1 TECHNICAL DESCRIPTION.............................................................................................. 14

2.2 TECHNICAL SPECIFICATIONS ........................................................................................ 17

3- STARTING UP .................................................................................................... 20

3.1 INSTALLATION.................................................................................................................. 21

3.2 CONNECTION TO THE MAINS ......................................................................................... 22

4 - INSTRUCTIONS FOR USE................................................................................ 23

4.1 GENERAL INFORMATION ................................................................................................ 24

4.2 USE OF THE MACHINE .................................................................................................... 26

4.3 MACHINE CONTROLS...................................................................................................... 27

5- MAINTENANCE AND CLEANING...................................................................... 28

5.1 MAINTENANCE ................................................................................................................. 29

5.2 CLEANING......................................................................................................................... 29

6- OPERATING FAULTS ........................................................................................ 32

6.1 TROUBLESHOOTING ....................................................................................................... 33

7- SAFETY WARNINGS.......................................................................................... 34

7.1 SAFETY DEVICES............................................................................................................. 35

7.2 SAFETY AND IDENTIFICATION PLATES ......................................................................... 36

7.3 PROHIBITIONS AND OBLIGATIONS FOR PREVENTION OF ACCIDENTS .................... 37

8 - SPARE PARTS .................................................................................................. 38

8.1 INSTRUCTIONS FOR ORDERING.................................................................................... 39

8.2 PLATE N° 1 - STRUCTURE AND COMPONENTS .......................................................... 40

STRUCTURE AND COMPONENTS - REFERENCES ............................................................. 40

8.3 PLATE N° 2 - PULLEY AND MOTOR UNIT LAM 500 - 600 .............................................. 41

PULLEY AND MOTOR UNIT – REFERENCES ....................................................................... 42

8.4 PLATE N° 3 - CLUTCH UNIT LAM 500 - 600.................................................................... 43

CLUTCH UNIT – REFERENCES LAM 500/600 ....................................................................... 43

CLUTCH UNIT – REFERENCES LAM 500/600 ....................................................................... 44

8.5 PLATE N° 4 - HANDLE UNIT ............................................................................................ 45

HANDLE UNIT – REFERENCES ............................................................................................. 45

8.6 PLATE N° 5 - CONVEYOR BELT UNIT ............................................................................ 46

CONVEYOR BELT UNIT - REFERENCES .............................................................................. 46

8.7 TAV. N°7 - GRUPPO RASCHIATORI ................................................................................ 47

GRUPPO RASCHIATORI - RIFERIMENTI........................

8.8 TAV. N° 7 – GRUPPO BASAMENTO................................................................................. 49

GRUPPO BASAMENTO-RIFERIMENTI............................ Errore. Il segnalibro non è definito.

8.9 RICAMBI CONSIGLIATI..................................................................................................... 50

Errore. Il segnalibro non è definito.

USE AND MAINTENANCE MANUAL

p. 3/47

MANUAL DOUGH SHEETER

LAM 500-600 - LAM 500-600 BENCH-TOP

22 04 001

ENGLISH

mod.04.01.10

9- ACCESSORIES ON REQUEST.......................................................................... 51

9.1 Cutting device .................................................................................................................... 52

9.2............................................................................................................................................ 52

10- ELECTRICAL EQUIPMENT ............................................................................. 53

10.1 DESCRIPTION................................................................................................................. 54

10.2 DOCUMENTATION.......................................................................................................... 55

USE AND MAINTENANCE MANUAL

p. 4/47

MANUAL DOUGH SHEETER

LAM 500-600 - LAM 500-600 BENCH-TOP

22 04 001

ENGLISH

mod.04.01

1- GENERAL

Reproduction, even partial, forbidden without authorisation

Property of TEKNO STAMAP S.r.l.

USE AND MAINTENANCE MANUAL

p. 5/47

MANUAL DOUGH SHEETER

LAM 500-600 - LAM 500-600 BENCH-TOP

22 04 001

ENGLISH

mod.04.01

1.1 GUARANTEE

TEKNO STAMAP SRL guarantees the good working and the quality of this Tekno Stamap

machine for a period of 12 months from the machine shipping date ONLY IF the guarantee

coupon below is filled in and sent within 15 days of receiving the machine.

The guarantee is valid only if the machine is correctly used and maintained according to the

enclosed instructions. The guarantee is no longer applicable if the machine has been tampered

with in any way, modified or repaired without our authorisation, or if non authentic spare parts have

been used. The guarantee does not cover damage resulting from normal wear, from faults of the

user, or incorrect use of the machine. The conveyor belts are excluded from the guarantee.

The guarantee is limited to the replacement of the faulty part covered by guarantee. All other

claims, such as indemnities for interruptions in production or similar, are rejected.

If considered necessary, TEKNO STAMAP SRL may ask for the machine to be returned to the

factory for repair under guarantee.

Place of jurisdiction: 36100 Grisignano Vi

TEKNO STAMAP SRL – Via Vittorio Veneto 131 – 36040 Grisignano di Zocco (VI) – Italy

-----------------------------------------------------------------------------------------------------------------------------

To be returned to the manufacturer.

This coupon must be mailed before staring to work with the machine.

GUARANTEE COUPON

The manufacturer guarantees:

Model: ……………………………………………………………………………….

Serial number: ..…………...……………………………………………………………….

Date of installation or start-up: …………………..………………………………..

Name and complete address …………………………………………………………

……………………………………………………………………………………………..

……………………………………………………………………………………………..

Reproduction, even partial, forbidden without authorisation

Property of TEKNO STAMAP S.r.l.

USE AND MAINTENANCE MANUAL

p. 6/47

MANUAL DOUGH SHEETER

LAM 500-600 - LAM 500-600 BENCH-TOP

22 04 001

ENGLISH

mod.04.01

1.2 GENERAL WARNINGS AND APPLICATION

The aim of this manual is:

To facilitate understanding and operation of the machine and enable the system to be used to

−

its full technical potential.

To provide instructions for the most effective and rational maintenance and help the operator to

−

understand any faults and how to remedy them.

To warn against risks inherent in use of the machine due to failure to observe the safety

−

regulations.

To indicate working limits for maintaining hygiene and environmental conditions and to ensure

−

health at work.

These pages must be read carefully before starting the machine.

This manual forms an integral part of the product; it must be kept near the machine for prompt

easy consultation and must also be kept for future reference until the machine is scrapped.

The manufacturer does not guarantee the technical-legal suitability of the installation premises and

machine supporting services but provides all instructions for correct installation in the relevant

section of this manual.

For the above, the user is advised to contact an expert professional technician, also for

compliance with any local laws or regulations.

The machine is designed for the food industry.

•

It is a machine designed for sheeting of dough obtained with different types of ingredients like

flour, water, sugar, fat, butter, salt, yeast, etc. and of medium consistency

general.

The machine must be used only for the purpose for which it has been designed. All other uses

•

are considered inappropriate and therefore unreasonable.

The manufacturer cannot be held liable for incorrect use, inappropriate and/or

unreasonable acts.

The manufacturer cannot be held liable for any damage caused by inappropriate, incorrect or

unreasonable use, for example:

inappropriate use by non-trained personnel;

−

non-authorised modifications or work on the machine;

−

use of non-original spare parts or parts not specific for the model;

−

failure to follow the instructions, even partially.

−

for cake-making in

Reproduction, even partial, forbidden without authorisation

Property of TEKNO STAMAP S.r.l.

USE AND MAINTENANCE MANUAL

p. 7/47

MANUAL DOUGH SHEETER

LAM 500-600 - LAM 500-600 BENCH-TOP

22 04 001

ENGLISH

mod.04.01

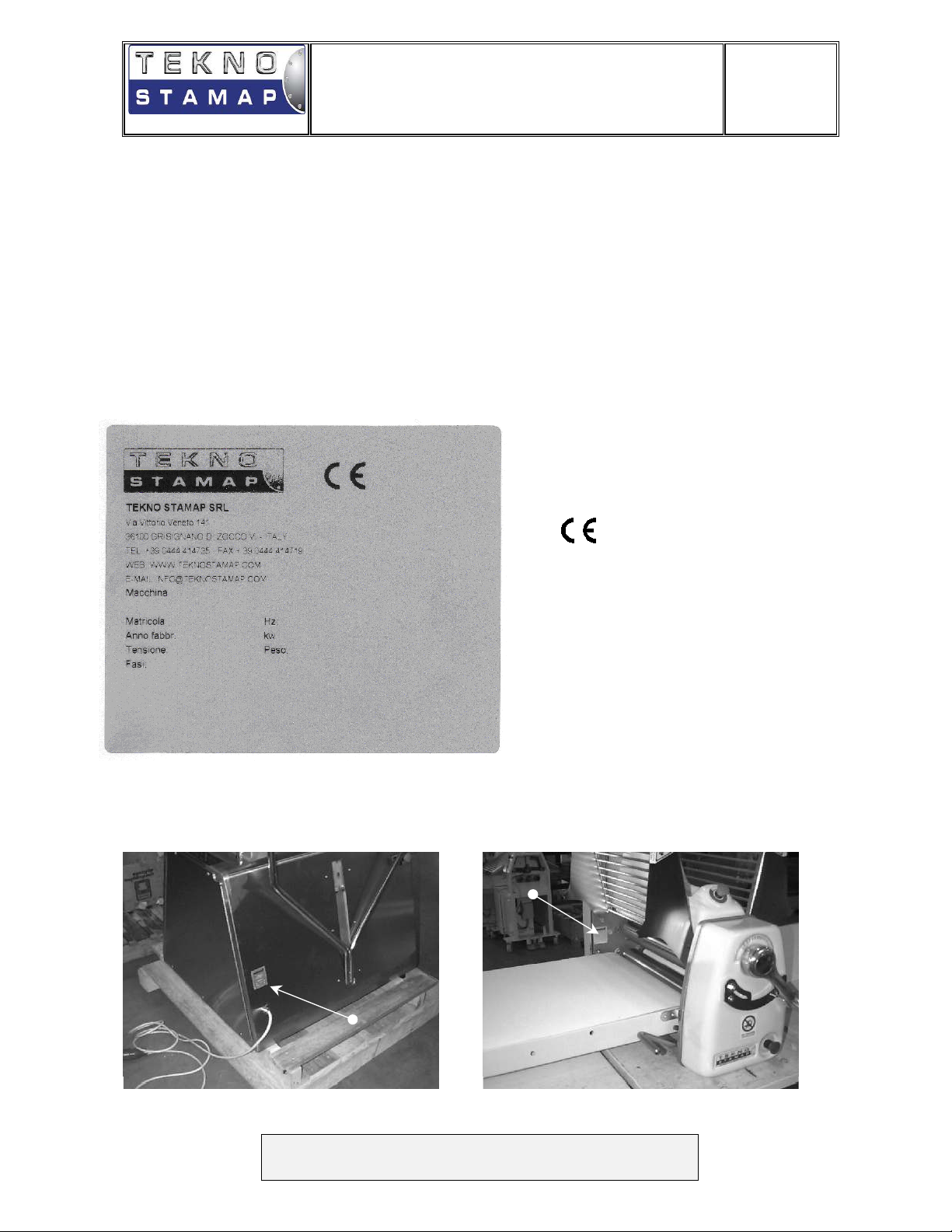

1.3 RATING PLATE DATA

Figure 1 shows the identification plate applied on the machine. In figure 2 an arrow clearly

indicates the position of the plate on the machine. The plate is made of screen printed aluminium

and the data are written in indelible ink to last as long as possible.

In place of the aluminium plate there may be an adhesive label complete with all the machine

identification data; any attempt to remove this label will destroy it.

It is forbidden to remove or replace the “CE MARKING” plate. If the plate is damaged or

removed, please inform TEKNO STAMAP s.r.l. immediately.

Figura 1

Figura 2 Figura 3

Basement version table-top version

Reproduction, even partial, forbidden without authorisation

Property of TEKNO STAMAP S.r.l.

USE AND MAINTENANCE MANUAL

p. 8/47

MANUAL DOUGH SHEETER

LAM 500-600 - LAM 500-600 BENCH-TOP

22 04 001

ENGLISH

mod.04.01

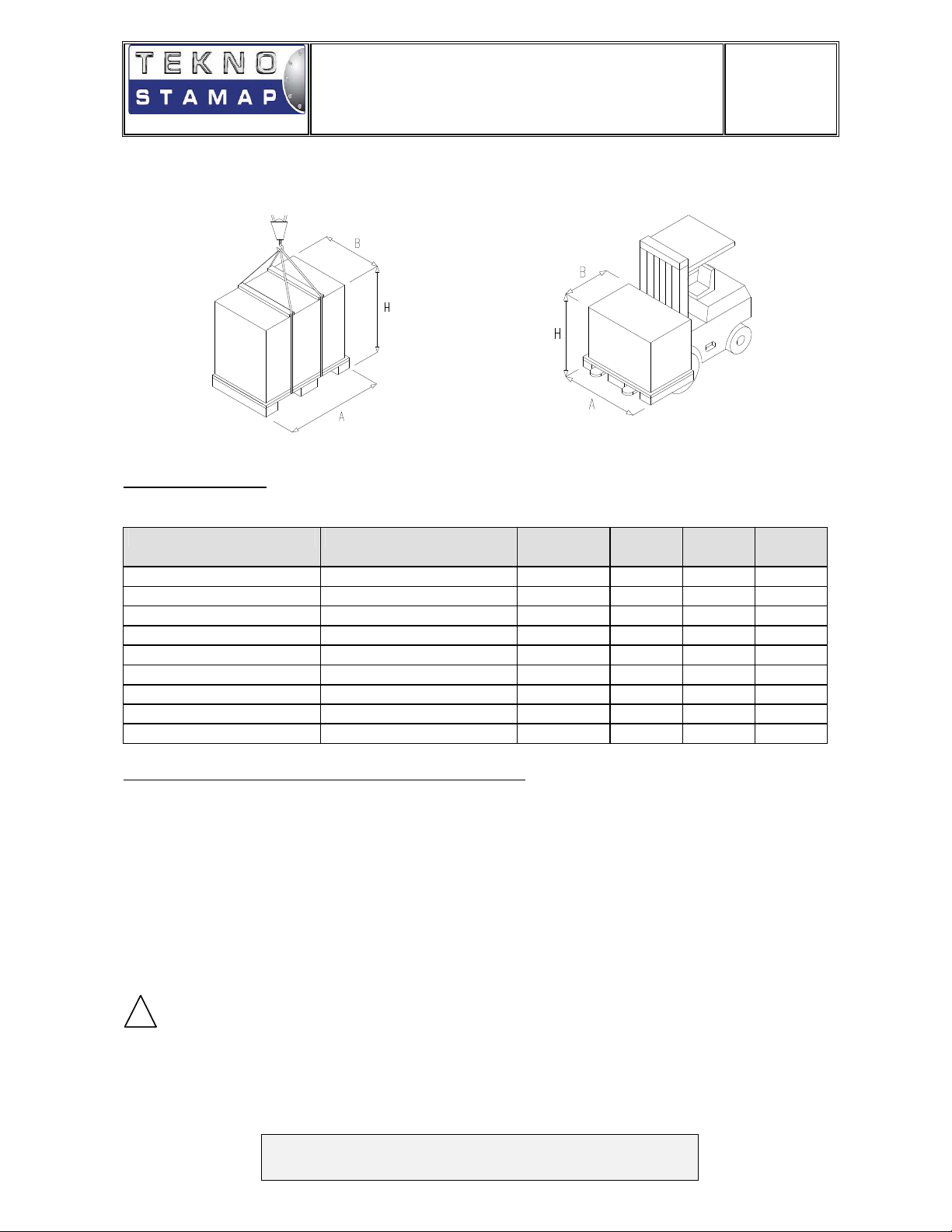

1.4 TRANSPORT INSTRUCTIONS

A B

PACKAGING DATA

The machine is supplied on a pallet, in a strapped triple-layer corrugated cardboard box.

−

MACHINE MOD. TYPE OF PACKAGING WEIGHT

LAM 507 BENCH-TOP Pallet and cardboard box 800 1200 1100

LAM 510 BENCH-TOP Pallet and cardboard box 800 1200 1250

LAM 610 BENCH-TOP Pallet and cardboard box 800 1200 1250

LAM 507 Pallet and cardboard box 1120 1170 1740

LAM 510 Pallet and cardboard box 1120 1170 1740

LAM 610 Pallet and cardboard box 1120 1170 1740

LAM 614 Pallet and cardboard box 1120 1170 1740

LAM 616 Pallet and cardboard box 1120 1170 1740

INSTRUCTIONS FOR TRANSPORT AND UNLOADING

Loading and unloading from the vehicle can be performed:

−

by means of crane, see figure “A”

−

by means of forklift truck, see figure “B”.

−

The machine must be transported adopting all precautions to prevent damage to the machine.

−

In particular the machine must not be placed on top of other materials and vice versa either

−

during transport or storage.

During transport the machine must be positioned so that it cannot be knocked by other

−

materials loaded on the same vehicle.

Before unloading from the vehicle, check that the packaging is intact and that there is no risk of

−

tipping over.

During unloading, place the machine carefully on the ground to prevent it being knocked.

−

A mm B mm H mm

KG.

!

CAUTION When handling, pay attention to all the indications on the packaging. The

capacity of the belts must be adequate for the weight of the packages. Do

not use metal belts.

Reproduction, even partial, forbidden without authorisation

Property of TEKNO STAMAP S.r.l.

USE AND MAINTENANCE MANUAL

p. 9/47

MANUAL DOUGH SHEETER

LAM 500-600 - LAM 500-600 BENCH-TOP

1.5 MACHINE ASSEMBLING

The machine is delivered on a pallet and wrapped with nylon film, and in order to guarantee

a safe transportation the working tables are dismantled and basement is fixed through 4

screws.

behind the working table a long screw will be used as supporting point for the working tables.

It is necessary to release this screw on both side of the table. Be careful not to loose the

white washers assembled with the screw

22 04 001

ENGLISH

mod.04.01

Reproduction, even partial, forbidden without authorisation

Property of TEKNO STAMAP S.r.l.

USE AND MAINTENANCE MANUAL

p. 10/47

MANUAL DOUGH SHEETER

LAM 500-600 - LAM 500-600 BENCH-TOP

This long screw will be inserted on the table as shown on the picture. Each washer will be

assembled at the end of the screw.

Now it is possible to hoist the table till the screw is located on it previous place, then fix it

through the small plate. The small plate will be fixed by the screw as indicated on the above

picture

Inside the packaging, you will find 2 supporting legs at Y. Once the working table is

assembled, it must be hoisted to place the legs which have to be hanged inside the slit as

shown in the picture

22 04 001

ENGLISH

mod.04.01

Reproduction, even partial, forbidden without authorisation

Property of TEKNO STAMAP S.r.l.

USE AND MAINTENANCE MANUAL

p. 11/47

MANUAL DOUGH SHEETER

LAM 500-600 - LAM 500-600 BENCH-TOP

Revolve lightly the leg and hoist it until it reaches the screws on the table and fix it on the

tables through the screws previously unscrewed as shown on the above picture

The ends of the table are fitted with 2 belt tie-rods which can be used as support for the

table as indicated on picture above

It is necessary to unscrew the 2 indicated screws and turn the complete tie-rod group till the

ideal position is reached, then screw the screws as previous position: so all the belt is in

tension. Now the working tables are assembled. To install completely the machine it is

necessary to open the side panels and unscrew the 4 screws which fix the machine on the

pallet.

22 04 001

ENGLISH

mod.04.01

Reproduction, even partial, forbidden without authorisation

Property of TEKNO STAMAP S.r.l.

USE AND MAINTENANCE MANUAL

p. 12/47

MANUAL DOUGH SHEETER

LAM 500-600 - LAM 500-600 BENCH-TOP

22 04 001

ENGLISH

mod.04.01

1.6 DECOMMISSIONING

1.6.1 SETTING ASIDE

If the machine has to be stored, it must be protected against dust and stored in a covered

−

place.

If the machine is not going to be used for a long time, it must be protected against dust and

−

atmospheric agents by means of appropriate covering.

No special precautions are required for the motor and electrical system; simply follow the above

−

instructions.

1.6.2 SCRAPPING

To scrap the machine, proceed as follows:

−

1. Eliminate the electricity supply cable.

2. Remove all moving parts that could be a hazard.

3. Dispose of the majority of parts as scrap metal and take to authorised scrapyards.

4. The other parts, plastic for example, must be disposed of according to current

regulations, via specialist firms if necessary.

Reproduction, even partial, forbidden without authorisation

Property of TEKNO STAMAP S.r.l.

USE AND MAINTENANCE MANUAL

p. 13/47

MANUAL DOUGH SHEETER

LAM 500-600 - LAM 500-600 BENCH-TOP

22 04 001

ENGLISH

mod.04.01.10

2- TECHNICAL SPECIFICATIONS

Reproduction, even partial, forbidden without authorisation

Property of TEKNO STAMAP S.r.l.

USE AND MAINTENANCE MANUAL

p. 14/47

MANUAL DOUGH SHEETER

LAM 500-600 - LAM 500-600 BENCH-TOP

22 04 001

ENGLISH

mod.04.01.10

2.1 TECHNICAL DESCRIPTION

APPLICATION

The machine is designed for the food industry.

•

It is a machine designed for sheeting of dough obtained with different types of ingredients like

flour, water, sugar, fat, butter, salt, yeast, etc. and of medium consistency for cake-making in

general.

The machine must be used only for the purpose for which it has been designed. All other uses

•

are considered inappropriate and therefore unreasonable.

Reproduction, even partial, forbidden without authorisation

Property of TEKNO STAMAP S.r.l.

USE AND MAINTENANCE MANUAL

p. 15/47

MANUAL DOUGH SHEETER

LAM 500-600 - LAM 500-600 BENCH-TOP

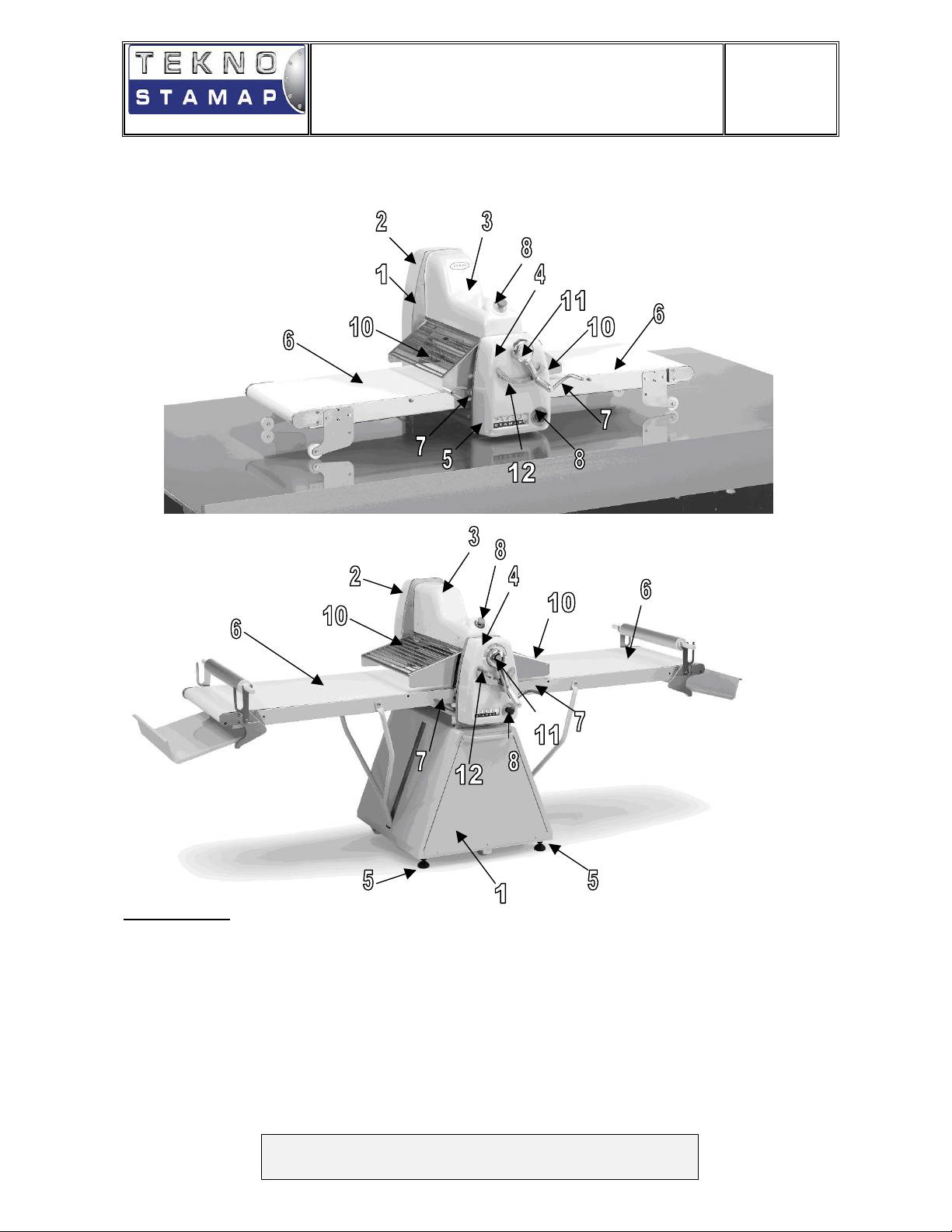

COMPOSITION OF THE MACHINE

Model Lam 500 - 600 bench-top

The dough sheeter consists mainly of a supporting structure (1) and three plastic covering

−

panels (2) - (3) - (4).

The supporting structure (1) consists of two sides (in aluminium) screwed together by means of

−

metal spacers.

Cover (2) houses the belt drive unit. Cover (3) houses the electric motor and cover (4) the drive

−

unit, called clutch unit, for reversing the movement of the machine.

The base is provided with levelling system (5) to ensure machine stability.

−

Model Lam 500 - 600 (with base)

The dough sheeter consists mainly of a supporting structure (1) and three plastic covering

−

panels (2) - (3) - (4).

The supporting structure (1) consists of a shaped welded metal sheet made of painted steel

−

with two sides (in aluminium) fitted above it and screwed together by means of metal spacers.

Cover (2) houses the belt drive unit. Cover (3) houses the electric motor and cover (4) the drive

−

unit, called clutch unit, for reversing the movement of the machine.

The base is provided with levelling system (5) to ensure machine stability.

−

OPERATION

Model Lam 500 - 600 bench-top and Lam 500 – 600 (with base)

The conveyor belts (6) are operated by the control lever (7), with movement according to the

−

position of the lever. It has two side operating positions and one central position (idle). By

turning the lever to the left, the conveyor belt (6) will move from right to left and vice versa; if

the lever is set to the central intermediate position (idle) the conveyor belts will be at a standstill.

If devices other than the control lever (7) are activated during operation, for example one of the

−

two safety grilles (10) is raised, the machine will immediately stop. Press the start button (9) to

re-start the machine.

Via the handle (11) the product thickness can be varied from zero (0) millimetres to thirty-five

−

(35) millimetres. The rolling thickness expressed in millimetres can be read on the self-adhesive

label coinciding with one of the handle references. Rolling must be performed gradually,

starting from the thickest size (35 mm) and gradually reaching the thickness required.

22 04 001

ENGLISH

mod.04.01.10

Reproduction, even partial, forbidden without authorisation

Property of TEKNO STAMAP S.r.l.

USE AND MAINTENANCE MANUAL

p. 16/47

MANUAL DOUGH SHEETER

LAM 500-600 - LAM 500-600 BENCH-TOP

MACHINE MOVEMENT

The single-speed motor

−

their turn, the calibrating cylinders operate the clutch centre drive. The electric motor rotation

can be reversed by means of the control lever (7) in conjunction with internal switches. This

control lever pivots the coupling gears which, according to the motor rotation direction, engage

the drive cylinder of one of the conveyor belts.

PROTECTIONS

The central area consisting of the two calibrating cylinders, considered the most dangerous

−

area for the operator, is completely covered and protected by two side protection grilles (10).

They are made entirely of stainless steel. If one of the two grilles is raised, even by a few

millimetres, a microswitch will cut in, immediately stopping the machine.

The conveyor surfaces, on which the conveyor belts rotate, are designed so that the operator

−

cannot insert his fingers between the surface and the belt.

ELECTRICAL SYSTEM

All the electrical components subject to rated voltage and the electric motors are enclosed in a

casing with IP 54 protection rating. The control elements, push-buttons and selectors operate at

low voltage (24V) and are enclosed in casing with IP 54 protection rating.

The machine is designed for earth connection to protect against indirect contact risks (Chap. 10).

The electrical power and control circuit is provided with its own protection devices against short

circuits and overloads.

On the front of the machine, opposite the operator’s normal working position, is the

stop/emergency button (see chap. 4.2). This button disables the start buttons, thus preventing the

machine from being started. Reset, which is obtained by pulling the button cap, does not

automatically restart the machine.

operates the calibration cylinders via pulley, belt and driven pulley. In

22 04 001

ENGLISH

mod.04.01.10

Reproduction, even partial, forbidden without authorisation

Property of TEKNO STAMAP S.r.l.

USE AND MAINTENANCE MANUAL

p. 17/47

MANUAL DOUGH SHEETER

LAM 500-600 - LAM 500-600 BENCH-TOP

2.2 TECHNICAL SPECIFICATIONS

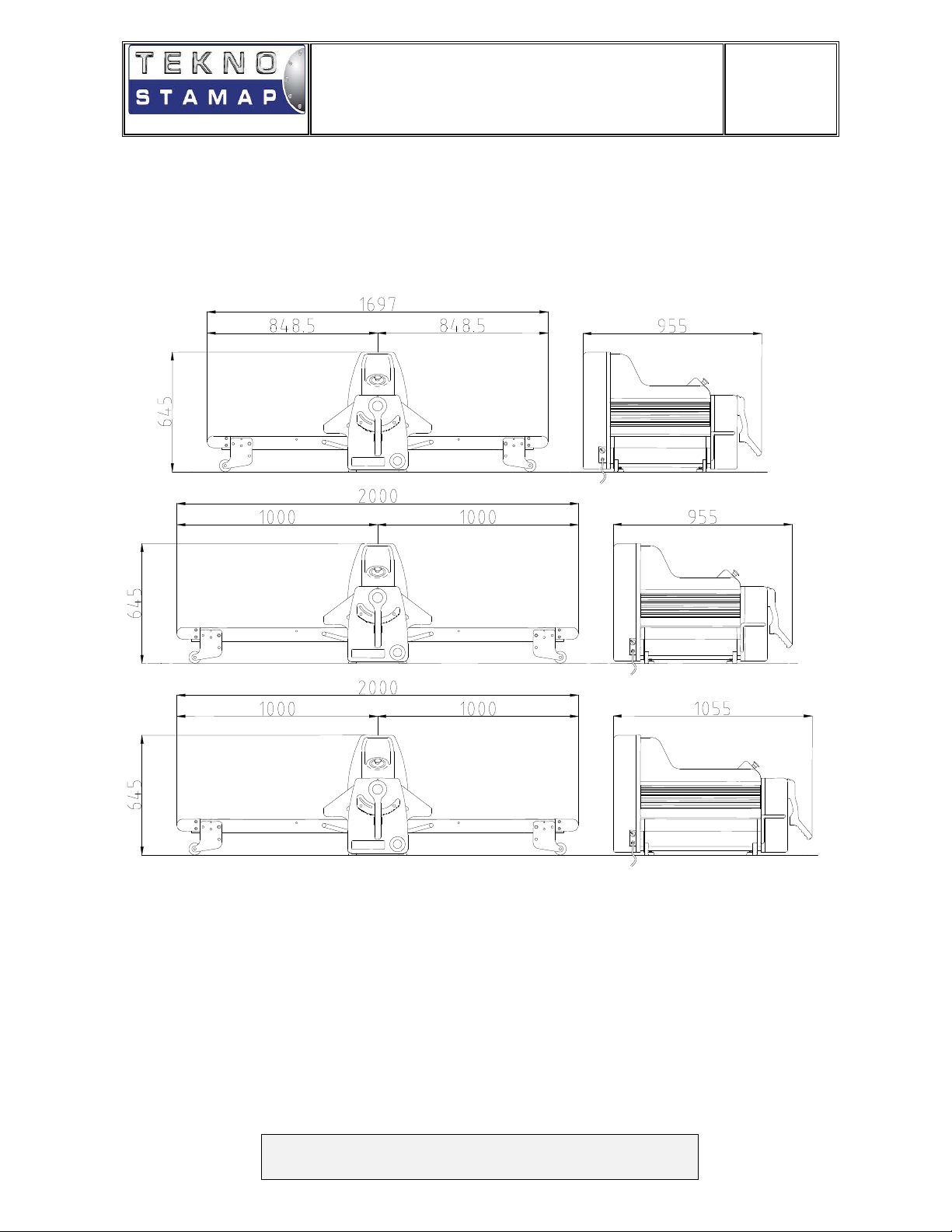

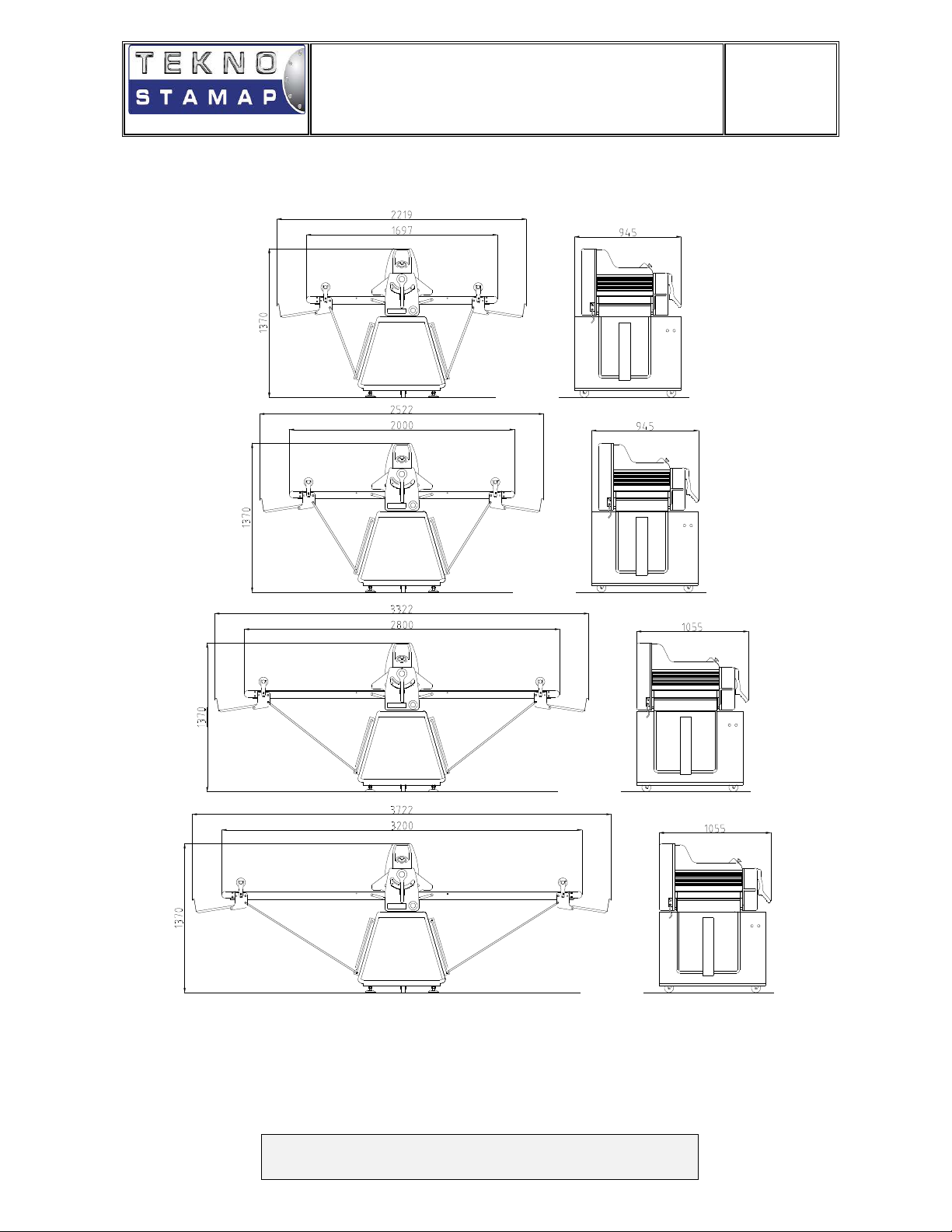

lam 507

Bench-top

22 04 001

ENGLISH

mod.04.01.10

lam 510

Bench-top

lam 610

Bench-top

Reproduction, even partial, forbidden without authorisation

Property of TEKNO STAMAP S.r.l.

USE AND MAINTENANCE MANUAL

p. 18/47

MANUAL DOUGH SHEETER

LAM 500-600 - LAM 500-600 BENCH-TOP

22 04 001

ENGLISH

mod.04.01.10

lam 507

lam 510

lam 614

lam 616

Reproduction, even partial, forbidden without authorisation

Property of TEKNO STAMAP S.r.l.

USE AND MAINTENANCE MANUAL

p. 19/47

MANUAL DOUGH SHEETER

LAM 500-600 - LAM 500-600 BENCH-TOP

MODEL Cylinder

diam.

LAM 507 B 84 mm 0.2-35 mm 50 cm/sec 500 750 0.55 89

LAM 510 B 84 mm 0.2-35 mm 50 cm/sec 500 1000 0.55 93

LAM 610 B 84 mm 0.2-35 mm 50 cm/sec 600 1000 0.55 99

LAM 507 84 mm 0.2-35 mm 50 cm/sec 500 750 0.55 140

Cylinder

opening

Outlet belt

speed

Belt

width

Belt

length

Motor power

Kw

22 04 001

ENGLISH

mod.04.01.10

Weight

Kg

LAM 510 84 mm 0.2-35 mm 50 cm/sec 500 1000 0.55 150

LAM 610 84 mm 0.2-35 mm 50 cm/sec 600 1000 0.75 150

LAM 614 84 mm 0.2-35 mm 50 cm/sec 600 1400 0.75 160

LAM 616 84 mm 0.2-35 mm 50 cm/sec 600 1600 0.75 170

LAM 614 L/T 84 mm 0.2-35 mm cm/sec 600 1400

LAM 616 L/T 84 mm 0.2-35 mm cm/sec 600 1600

NOISE: below 70 dB.

Reproduction, even partial, forbidden without authorisation

Property of TEKNO STAMAP S.r.l.

Loading...

Loading...