Introduction

Thank you for purchasing the Tekno RC NB48 1/8th 4WD Nitro Competition Buggy. The NB48

represents the state-of-the-art in 1/8th nitro buggy technology. We hope you have as much fun

driving your new vehicle as we did developing it. We are always working on new projects, so please

check our website (www.teknorc.com) regularly for the latest news, parts, and kits. Thanks again.

Additional equipment and parts needed:

2/3 channel surface radio transmitter and receiver

High torque steering and brake servo

RX battery, switch harness

.21 nitro engine, tuned pipe, manifold, and glow plug

Fuel bottle, fuel, 1/8th buggy starter box, and glow ignitor

1/8th scale buggy tires, wheels & CA glue

Paint for body

Tools needed:

Hex drivers (1.5mm, 2.0mm, 2.5mm)

Nut drivers (5.0mm, 5.5mm, 7.0mm)

Hobby knife

Needle-nose pliers, screwdrivers

4mm turnbuckle wrench

4mm arm reamer

Lexan body scissors & reamer

Disclaimer: Tekno RC is not responsible or liable for any property or personal damage, loss,

or injury incurred as a result of using this product. This kit is meant for use by persons 14

years of age or older and in the strict connes of a legally permitted RC track or facility.

Warnings:

Always double-check that your radio gear is working properly before operating vehicle.

Never operate the vehicle indoors (unless the RC track is an indoor facility). Use caution

while operating vehicle so as not to collide with people who may be turn mashalling or

who might otherwise not be aware that a fast moving RC vehicle is in the vicinity.

Warranty:

We warrant that the parts included in this kit are free from defects. If you nd a defective

part in your kit, please contact us at info@teknorc.com and we will help you to resolve the

issue. We do not warranty parts that may be broken during operation of the vehicle or

otherwise. Refer to the end of this instruction manual for a listing of spare/replacement

and option parts. All spare parts and other info are available on our website (www.teknorc.com)

and through our network of domestic and international dealers and distributors.

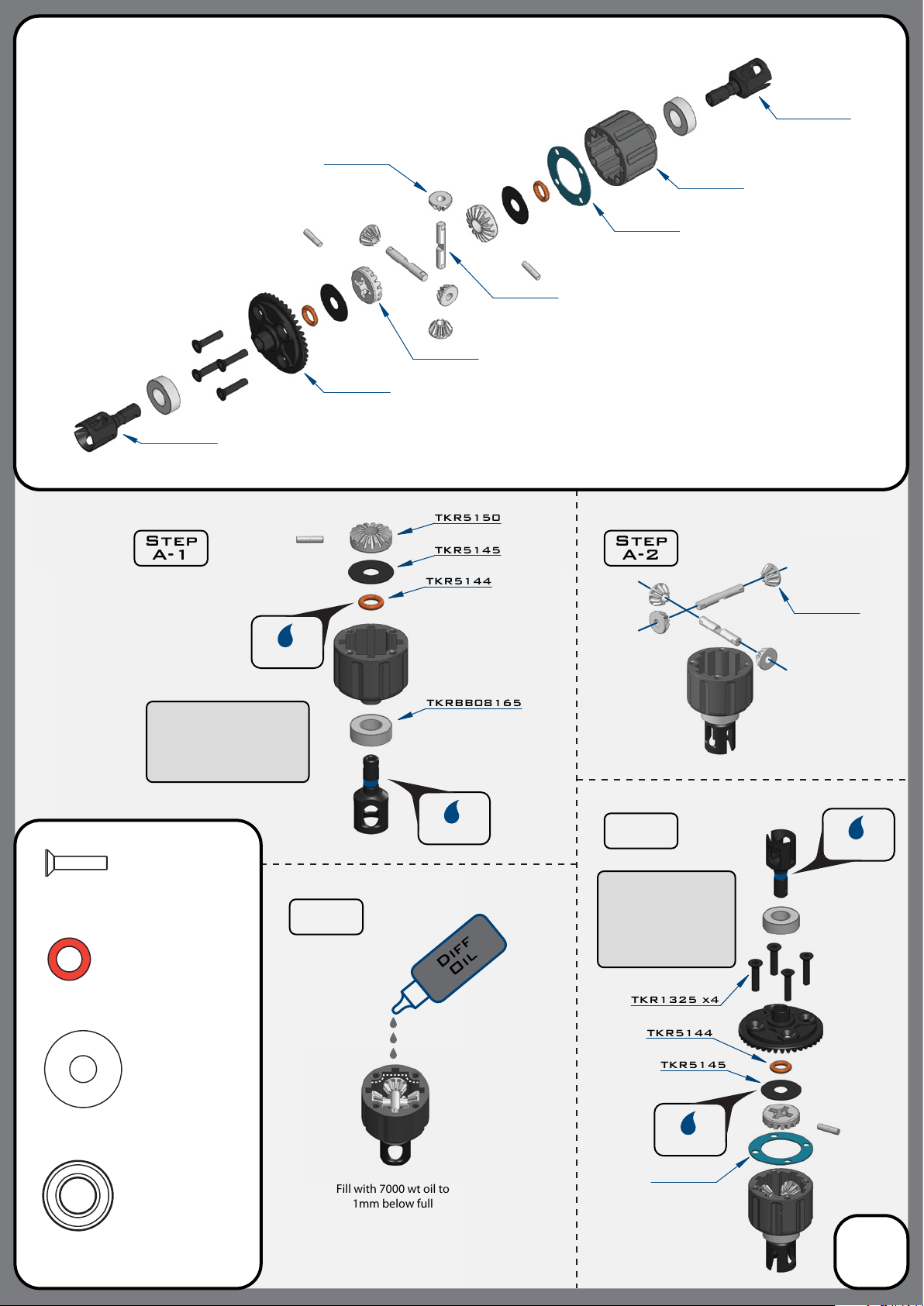

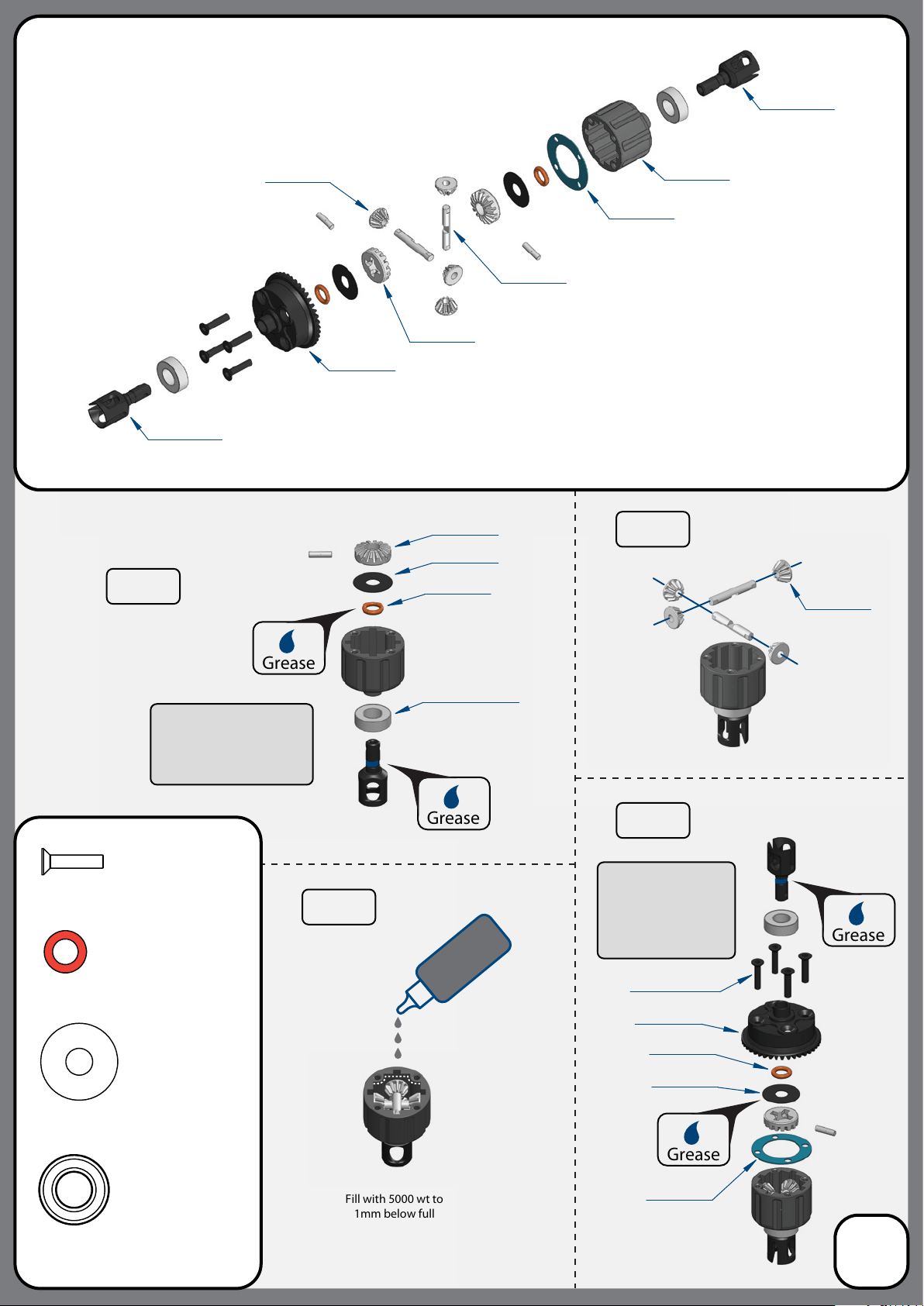

Bag A

Front Differential

(overview)

TKR5114X

TKR5114X

TKR5150

TKR5113

TKR5143

TKR5149

TKR5150

TKR5151

Step

A-1

Note: Apply a liberal amount

of grease to the outdrives,

o-rings, and the large

di shims. This will ensure

smooth operation.

x4

TKR1325

M3x14mm Flat Head Screw

x2

TKR5144

Differential 0-rings

Grease

Step

A-3

TKR5150

TKR5145

TKR5144

TKRBB08165

Grease

Diff

Oil

Step

A-2

Step

A-4

Note: Apply a liberal

amount of grease in the

areas between the shims

and o-rings, as well as

around the outdrive and

both sides of the seal

TKR1325 x4

TKR5144

TKR5150

Grease

x2

TKR5145

Differential Shims (6x17mm)

x2

TKRBB08165

Ball Bearing(8x16x5mm)

TKR5145

Grease

TKR5143

Fill with 7000 wt oil to

1mm below full

3

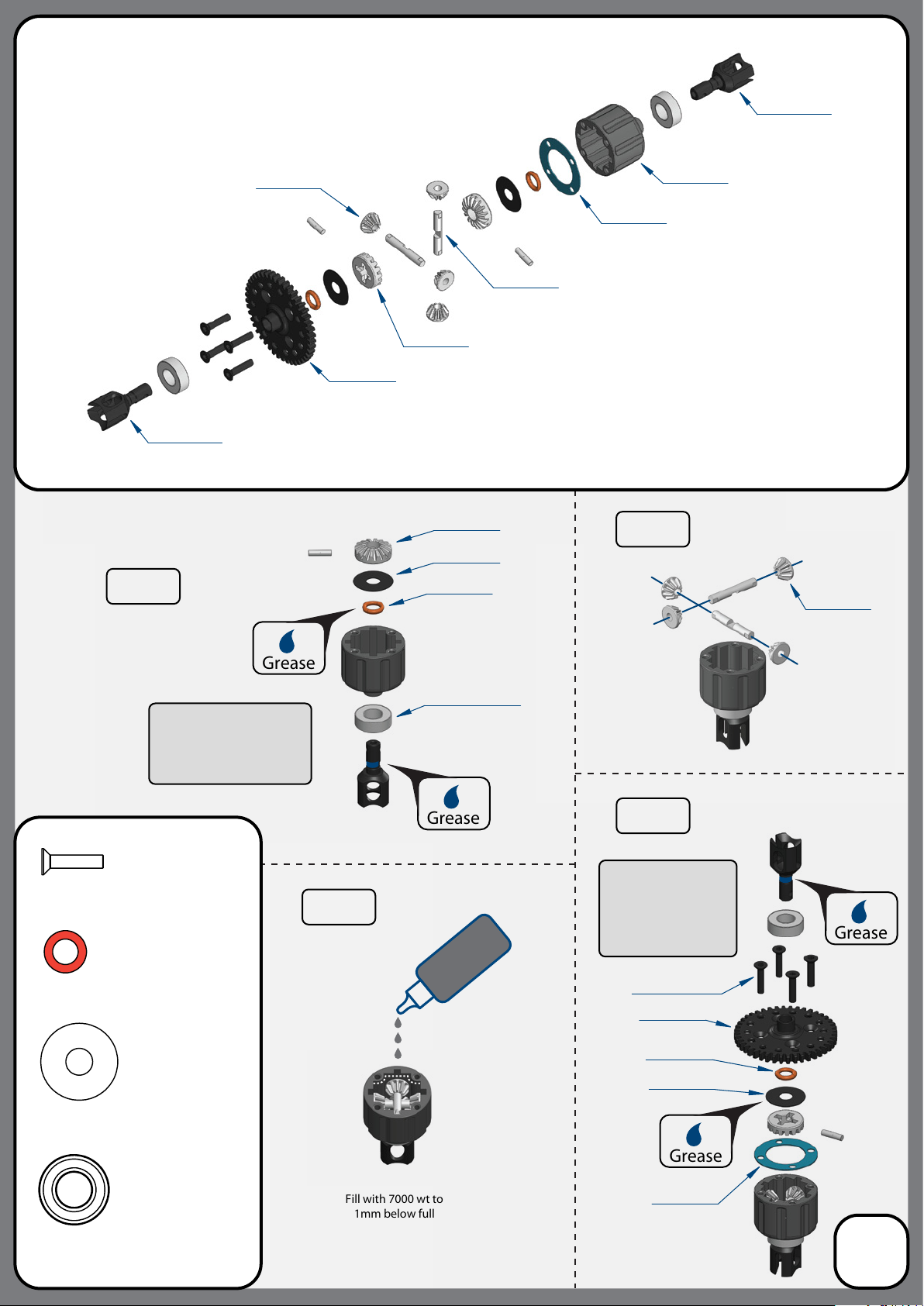

Bag B

Center Differential

(overview)

TKR5112X

TKR5112X

Step

B-1

TKR5150

TKR5115

TKR5150

TKR5150

TKR5145

TKR5144

TKR5113

TKR5143

TKR5149

Step

B-2

TKR5150

Note: Apply a liberal amount

of grease to the outdrives,

o-rings, and the large

di shims. This will ensure

smooth operation.

x4

TKR1325

M3x14mm Flat Head Screw

x2

TKR5144

Differential 0-rings

x2

Grease

Step

B-3

TKRBB08165

Grease

Diff

Oil

Step

B-4

Note: Apply a liberal

amount of grease in the

areas between the shims

and o-rings, as well as

around the outdrive and

both sides of the seal

TKR1325 x4

TKR5115

TKR5144

TKR5145

Grease

TKR5145

Differential Shims (6x17mm)

x2

TKRBB08165

Ball Bearing(8x16x5mm)

Fill with 7000 wt

1mm below full

Grease

to

TKR5143

4

Bag C

Rear Differential

(overview)

TKR5114X

TKR5114X

Step

C-1

TKR5150

TKR5302

TKR5150

TKR5150

TKR5145

TKR5144

TKR5113

TKR5143

TKR5149

Step

C-2

TKR5150

Note: Apply a liberal amount

of grease to the outdrives,

o-rings, and the large

di shims. This will ensure

smooth operation.

x4

TKR1325

M3x14mm Flat Head Screw

x2

TKR5144

Differential 0-rings

x2

Grease

Step

C-3

TKRBB08165

Grease

Diff

Oil

Step

C-4

Note: Apply a liberal

amount of grease in the

areas between the shims

and o-rings, as well as

around the outdrive and

both sides of the seal

TKR1325 x4

TKR5302

TKR5144

TKR5145

Grease

TKR5145

Differential Shims (6x17mm)

x2

TKRBB08165

Ball Bearing(8x16x5mm)

Fill with 5000 wt

1mm below full

Grease

to

TKR5143

5

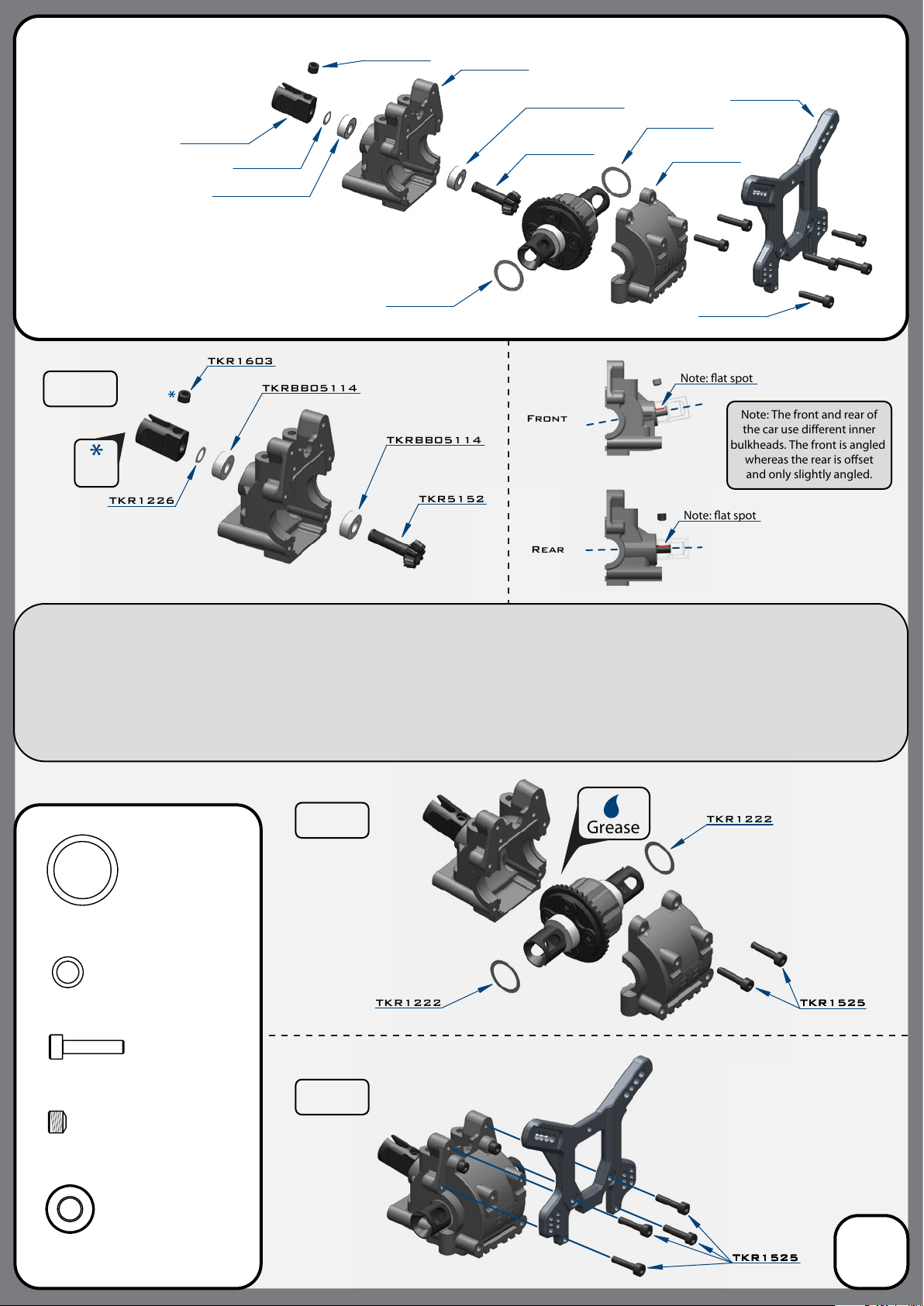

Bag D

Front Gearbox

(overview)

TKR5075

TKRBB05114

TKR1226

TKR1603

TKR5012

TKRBB05114

TKR5152

TKR5028

TKR1222

TKR5012

Step

D-1

Thread

Lock

TKR1226

TKR1222

TKR1603

TKRBB05114

Front

TKRBB05114

TKR5152

Rear

TKR1525

Note: at spot

bulkheads.

Note: at spot

Note: The front and rear of

the car use dierent inner

The front is angled

whereas the rear is oset

and only slightly angled.

Note: TKR1222 - The gear mesh should be as close as possible without any binding. Test the tment of the di

with both TKR1222 shims on the gear-side of the di. If the di turns freely without binding, continue to next

step. If the di binds and does not turn freely (it will make a grinding or crunching sound when spun), remove

one TKR1222 shim from the gear side and install it onto the other side of the di. Reassemble and test the mesh

again. If it is still binding, remove the second TKR1222 shim from the gear side and install it onto the other side

of the di. When you are satised that you have the best gear mesh possible continue to the next step.

x2

TKR1222

13x16x0.1mm Diff shim

x1

TKR1226

5x7x0.2mm shim

x6

TKR1525

M3x14mm Cap Head Screw

x1

TKR1603

M5x4mm Set Screw

x2

TKRBB05114

Ball Bearing (5x11x4)

Step

D-2

Step

D-3

TKR1222

Grease

TKR1222

TKR1525TKR1525TKR1525TKR1525

TKR1525TKR1525

6

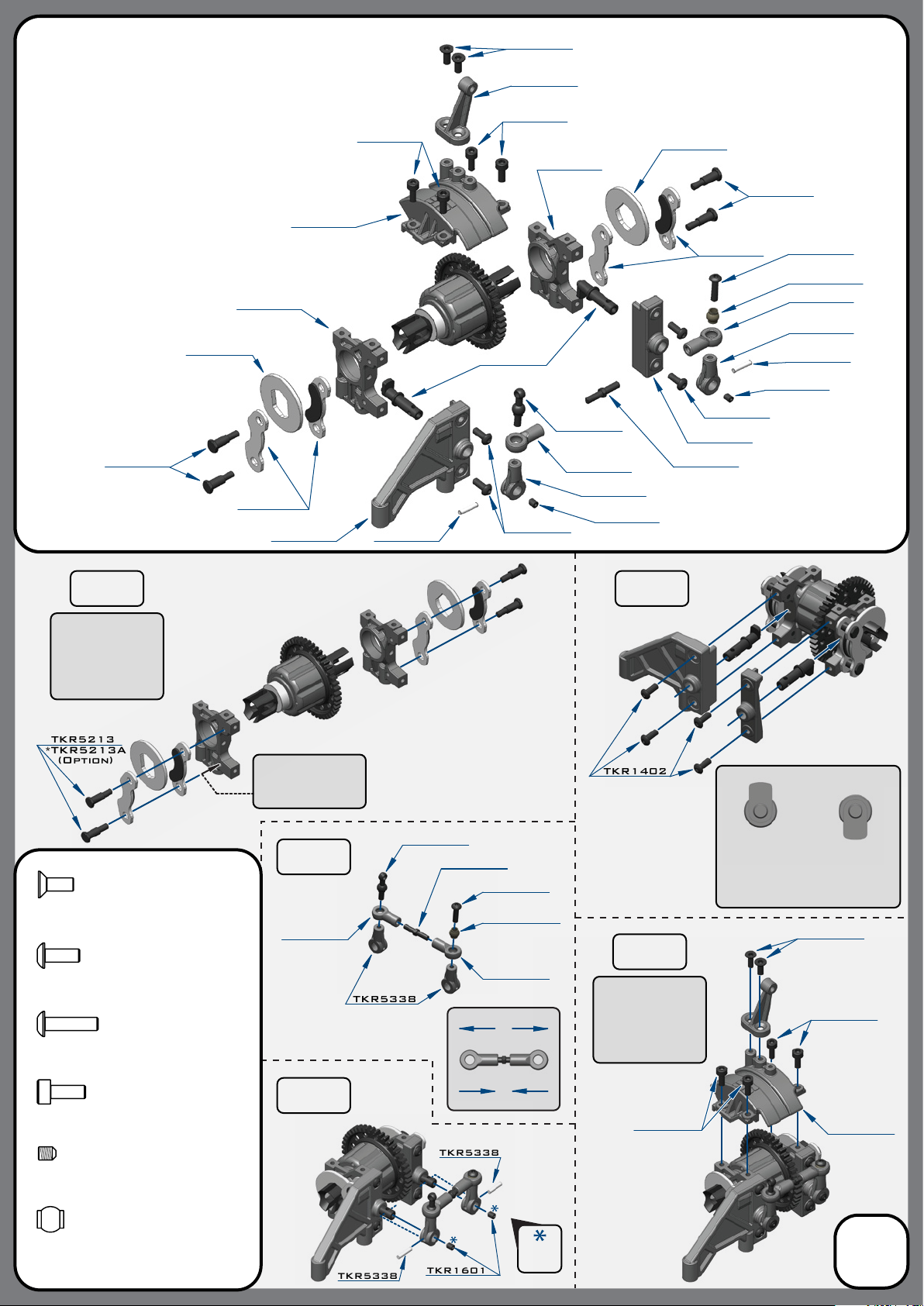

Bag E

Center Differential Assembly

*Front engine configuration

(overview)

TKR5310

TKR1522

TKR1322

TKR5346

TKR1522

TKR5345

TKR5310

TKR5213

TKR5213

Step

E-1

Note: For optional

rear engine

conguration,

please see step

E1-RE on page 32

TKR5310

TKR5345

TKR5314

TKR5362

TKR5338

TKR5215

TKR1402

TKR5219

TKR5056

TKR5338

TKR1601

Step

E-2

TKR5314

TKR1402

TKR5338

TKR5057

TKR1404

TKR5058A

TKR5056

TKR5338

TKR5338

TKR1601

TKR5213

*TKR5213A

(Option)

X2

TKR1322

M3x8mm Flat Head Screw

x4

TKR1402

M3x8mm Button Head Screw

x1

TKR1404

M3x12mm Button Head Screw

x4

TKR1522

M3x8mm Cap Head Screw

x2

TKR1601

M3x4mm Set Screw

Pre-thread all brake

post holes with a

separate M3 screw

Step

E-3

TKR5056

Step

E-4

TKR5219

TKR5338

TKR5057

TKR1404

TKR5058A

TKR5056

(longer link)

more rear bias

(shorter link)

more front bias

TKR5338

TKR1402

Step

E-5

Note: For optional

rear engine

conguration,

please see step

E5-RE on page 32

TKR1522

Rear Front

Note: Orientation of the brake

cams TKR5215. The rear cam

should be pointing up & the front

cam should be pointing down.

TKR1322

TKR1522

TKR5310

x1

TKR5058A

Pivot Ball M3x5.8mm

No Flange

TKR5338

TKR1601

Thread

Lock

7

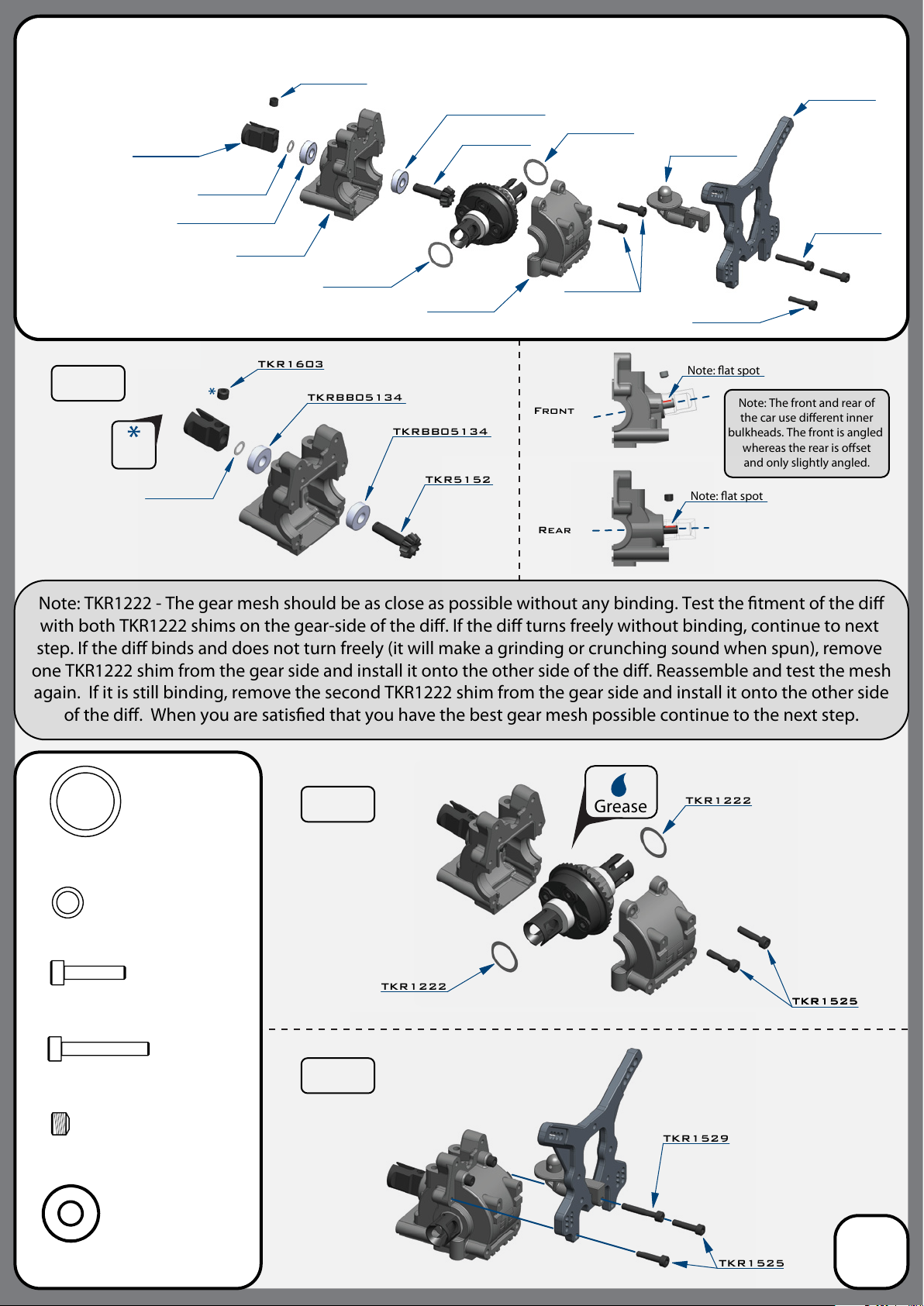

Bag F

Rear Gearbox

(overview)

TKR5075

TKR1226

TKR1603

TKRBB05134

TKR5152

TKR5029

TKR1222

TKR5026

Step

F-1

Thread

Lock

TKRBB05134

TKR1226

TKR5316

TKR1603

TKR1222

TKRBB05134

TKR5316

TKRBB05134

TKR5152

Front

Rear

TKR1525

TKR1525

Note: at spot

Note: The front and rear of

the car use dierent inner

bulkheads.

whereas the rear is oset

and only slightly angled.

Note: at spot

TKR1529

The front is angled

Note: TKR1222 - The gear mesh should be as close as possible without any binding. Test the tment of the di

with both TKR1222 shims on the gear-side of the di. If the di turns freely without binding, continue to next

step. If the di binds and does not turn freely (it will make a grinding or crunching sound when spun), remove

one TKR1222 shim from the gear side and install it onto the other side of the di. Reassemble and test the mesh

again. If it is still binding, remove the second TKR1222 shim from the gear side and install it onto the other side

of the di. When you are satised that you have the best gear mesh possible continue to the next step.

x2

TKR1222

13x16x0.1mm Diff Shim

x1

TKR1226

5x7x0.2mm shim

x4

TKR1525

M3x14mm Cap Head Screw

x1

TKR1529

M3x20mm Cap Head Screw

x1

TKR1603

M5x4mm Set Screw

x2

Step

F-2

Step

F-3

TKR1222

Grease

TKR1222

TKR1525TKR1525

TKR1529

TKRBB05134

Ball Bearing (5x13x4)

TKR1525

8

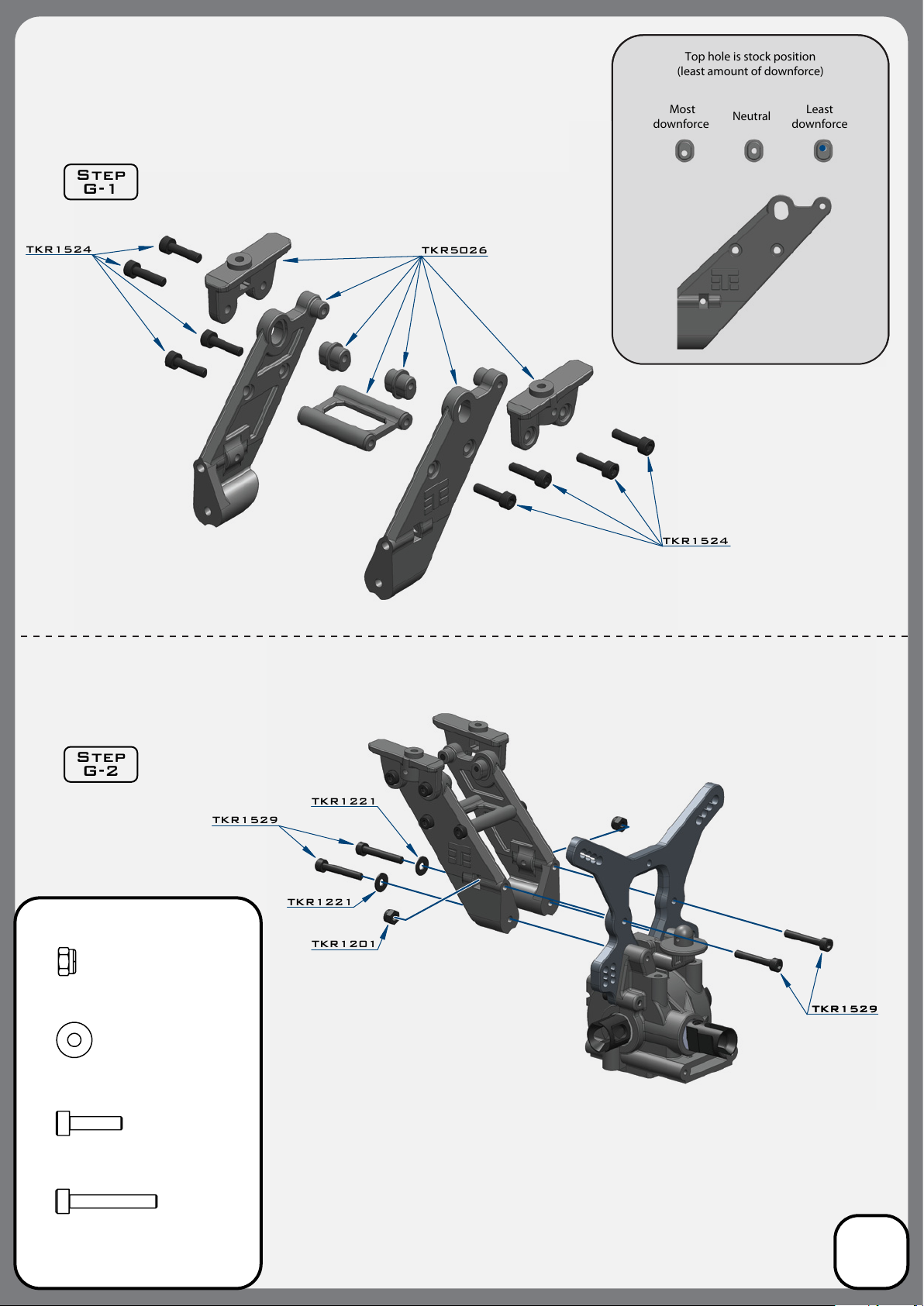

Bag G

Wing Mount

Top hole is stock position

(least amount of downforce)

Step

TKR1524

G-1

TKR5026

Most

downforce

TKR1524

Neutral

Least

downforce

Step

G-2

TKR1529

x2

TKR1201

M3 Lock Nut Black

x2

TKR1221

M3x8mm Washer

x8

TKR1524

M3x12mm Cap Head Screw

x4

TKR1529

M3x20mm Cap Head Screw

TKR1221

TKR1221

TKR1201

TKR1529TKR1529

9

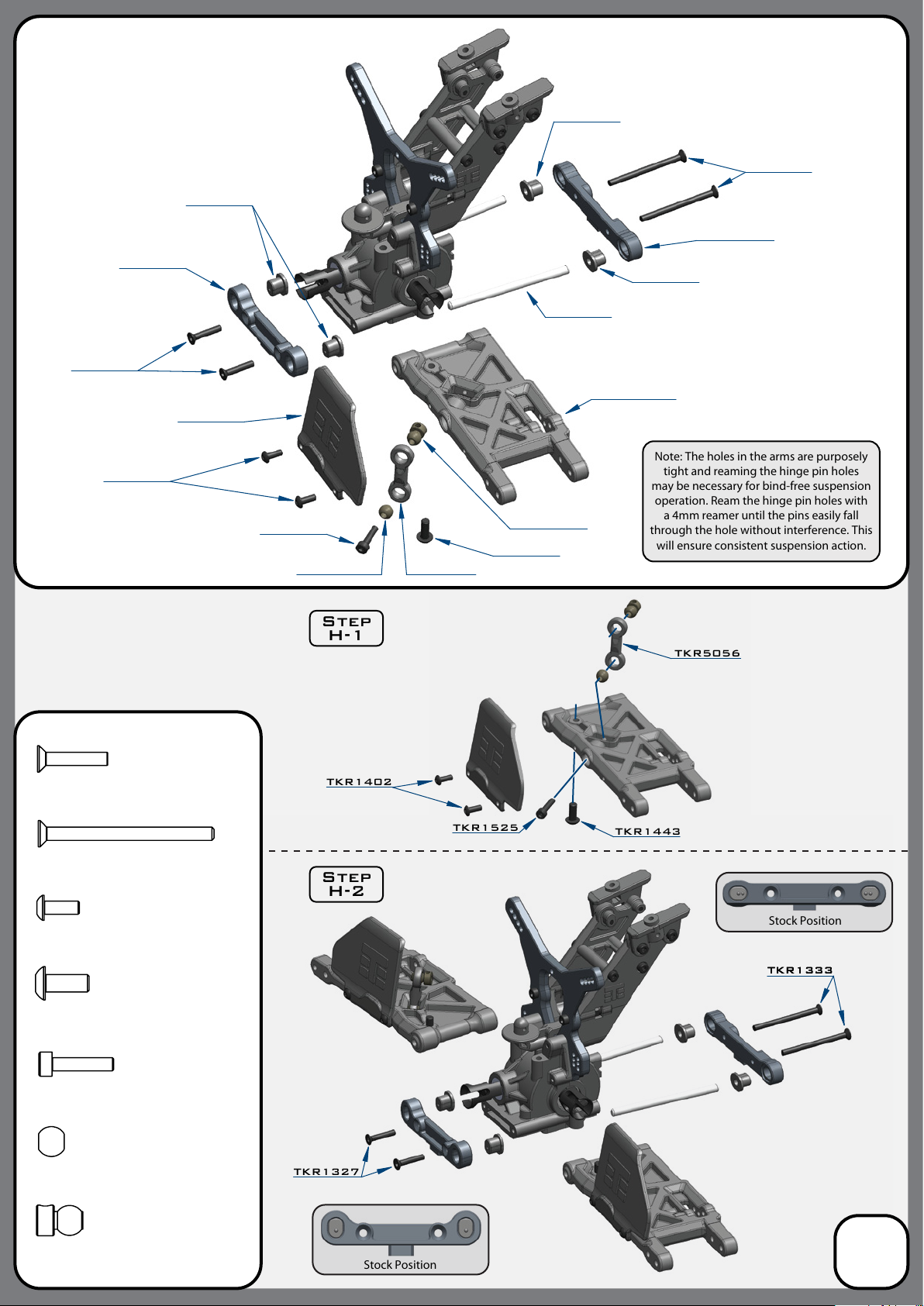

Bag H

Rear Suspension

(overview)

TKR5021

TKR5013

TKR1327

TKR5033

TKR1402

TKR1525

TKR5049A

TKR5056

TKR5020

TKR5079A

TKR1443

TKR5021

TKR5030XT

TKR1333

TKR5013B

*TKR5013

(Option)

TKR5021

Note: The holes in the arms are purposely

tight and reaming the hinge pin holes

may be necessary for bind-free suspension

operation. Ream the hinge pin holes with

a 4mm reamer until the pins easily fall

through the hole without interference. This

will ensure consistent suspension action.

x2

TKR1327

M3x16mm Flat Head Screw

x2

TKR1333

M3x40mm Flat Head Screw

x4

TKR1402

M3x8mm Button Head Screw

x2

TKR1443

M4x10mm Button Head Screw

x2

TKR1525

M3x14mm Cap Head Screw

Step

H-1

TKR1402

Step

H-2

TKR1525

TKR5056

TKR1443

Stock Position

TKR1333TKR1333

x2

TKR5049A

Pivot Ball Sway Bar

x2

TKR5079A

Stabilizer Ball

TKR1327

Stock Position

10

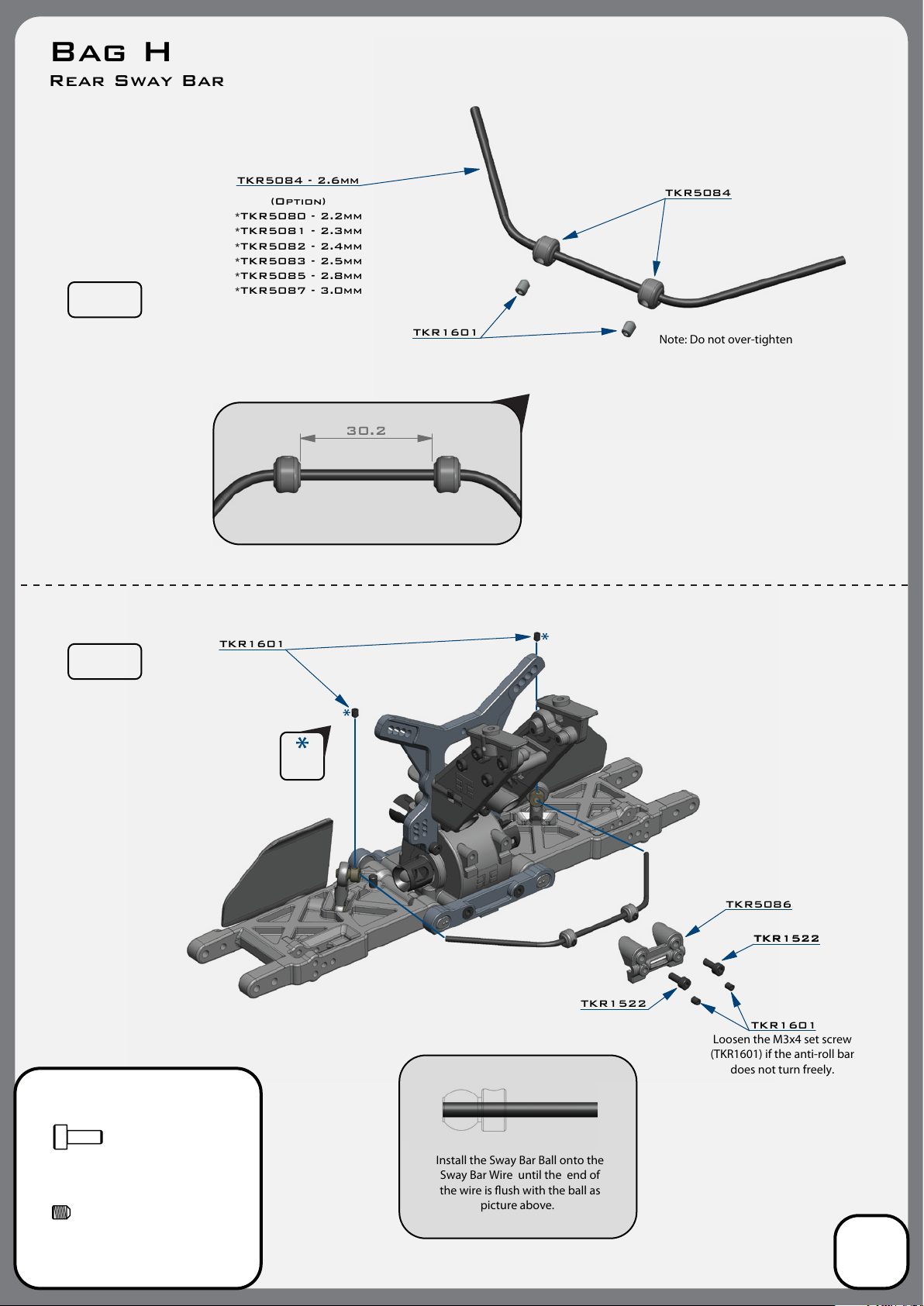

Bag H

Rear Sway Bar

Step

H-3

TKR5084 - 2.6mm

(Option)

*TKR5080 - 2.2mm

*TKR5081 - 2.3mm

*TKR5082 - 2.4mm

*TKR5083 - 2.5mm

*TKR5085 - 2.8mm

*TKR5087 - 3.0mm

30.2

TKR1601

TKR5084

Note: Do not over-tighten

Step

H-4

TKR1601

Thread

Lock

TKR1522

TKR5086

TKR1522TKR1522

TKR1601

Loosen the M3x4 set screw

(TKR1601) if

does not

the anti-roll bar

turn freely.

x2

TKR1522

M3x8mm Cap Head Screw

x6

TKR1601

M3x4mm Set Screw

Install the Sway Bar Ball onto the

Sway Bar Wire until the end of

the wire is ush with the ball as

picture above.

11

Bag I

Rear Hub/CVA Assembly

Step

TKR5073

I-1

Grease

Note: Rear hubs (TKR5040)

are left/right interchangeable.

Step

I-2

TKR5072

TKRBB13194

TKR5073

TKR5070

TKR5040

TKRBB08165

TKR5071B

*TKR5071

*TKR5071C

*TKR5071X

(Option)

TKR1603

Thread

Lock

Note: notch on pin

needs to line up

with set screw.

x4

TKR1201

M3 Locknut Black

x2

TKR1603

M5x4mm Set Screw

x2

TKR5071X

M3x16.8mm Pin

x2

TKR5073

CV Joint Pin

x2

Note: Do not overtighten rear

outer hinge pin (TKR5034).

Hinge pin should rotate freely.

TKR1201

TKR5034

TKR1201

TKR5021TKR5021TKR5021

A

B

A

B

TKRBB08165

Ball Bearing (8x16x5)

x2

TKRBB13194

Ball Bearing (13x19x4)

Hole "B" is the stock position

*Only use hole A in the arm with

hole A in the hub

*Only use hole B in the arm with

hole B in the hub

The outside hole oers greater stability and

recommended for bumpy open tracks.

is

Inside hole oers greater amount of steering

and is recommended for at technical tracks.

12

Bag I

Rear Camber Links

This side mounts on hub

Note: no ange

TKR5053A

Step

I-3

Step

I-4

TKR5051

Left

TKR5050

This side mounts on shock tower

Note: ange

TKR5052A

Note: Notch always goes on

left side of vehicle

TKR5051

TKR5052A

28.00

This side mounts on shock tower

Note: ange

TKR5050

TKR5051

Right

TKR5053A

TKR5051

This side mounts on hub

Note: no ange

TKR1201

x4

TKR1201

M3 Locknut Black

x4

TKR1529

M3x20mm Cap Head Screw

x2

TKR5052A

Pivot Ball M3x6.8mm

x2

3

2

1

6

4

5

TKR1529

A

B

C D

TKR5053A

Pivot Ball M3x6.8mm

No Flange

Stock position is 5/ C

13

Bag J

Front Suspension

(overview)

TKR5020

TKR5021

TKR1327

TKR5017

TKR1333

TKR5021

Step

J-1

TKR5017

TKR1443

TKR1443

TKR5079A

TKR5036XT

TKR1525

TKR5021

TKR5056

TKR5049A

TKR1525

Note: The holes in the arms are purposely

tight and reaming the hinge pin holes

may be necessary for bind-free suspension

operation. Ream the hinge pin holes with

a 4mm reamer until the pins easily fall

through the hole without interference. This

will ensure consistent suspension action.

x2

TKR1327

M3x16mm Flat Head Screw

x2

TKR1333

M3x40mm Flat Head Screw

x2

TKR1443

M4x10mm Button Head Screw

x2

TKR1525

M3x14mm Cap Head Screw

x2

TKR5049A

Pivot Ball Sway Bar

x2

TKR5079A

Stabilizer Ball

Step

J-2

TKR1333

Stock Position

Stock Position

TKR1327TKR1327

14

Bag J

Front Sway Bar

Step

J-3

TKR5083 - 2.5mm

(Option)

*TKR5080 - 2.2mm

*TKR5081 - 2.3mm

*TKR5082 - 2.4mm

*TKR5084 - 2.6mm

*TKR5085 - 2.8mm

*TKR5087 - 3.0mm

30.2

TKR1601

TKR5083

Note: Do not over-tighten

Step

J-4

Loosen the M3x4 set screw

(TKR1601) if

does not

TKR1522

TKR1601

the anti-roll bar

turn freely.

TKR5086

TKR1601

TKR1522TKR1522

Thread

Lock

TKR1601

x2

TKR1522

M3x8mm Cap Head Screw

x6

TKR1601

M3x4mm Set Screw

Install the Sway Bar Ball onto the

Sway Bar Wire until the end of

the wire is ush with the ball as

picture above.

15

Bag K

Front Steering

Step

K-1

TKR5072

TKR5073

x8

TKR1221

M3x8mm Washer

x2

TKR1401

M3x6mm Button Head Screw

x4

TKR1445

M4x14mm Button Head Screw

x2

TKR1447

M4x16mm Button Head Screw

x2

Grease

TKR5073

Note: Fully tighten screws

(TKR1445), then loosen until

spindles (TKR5041) move freely.

This will ensure smooth

operation and minimize play.

TKR5070

Step

K-2

TKR1221

TKR1401

TKR5042B

*TKR5042

(Option)

TKR5054A

TKR1445

TKR1445

TKR5054A

TKRBB13194

TKRBB08144

Note: The steering stops provide adjustable

travel limiters that you can adjust to your

driving style. For very tight tracks you may

want to experiment with less limiting washers

(more steering travel). However, with too

much steering travel the rear end can lose

traction more easily coming out of corners.

After months of testing on dierent track

surfaces, 4 washers is the most consistent setting.

TKR5041

TKR1603

Note: notch on pin

needs to line up

with set screw.

TKR5071C

*TKR5071

*TKR5071B

*TKR5071X

(Option)

Thread

Lock

TKR1448

M4x18mm Button Head Screw

x2

TKR1603

M5x4mm Set Screw

x4

TKR5054A

Spindle Pin Sleeve

x4

TKR5055A

Suspension Pin Sleeve Front

x2

TKR5071

M3x16.8mm Pin

x2

TKR5073

CV Joint Pin

x2

Step

K-3

Note: Fully tighten screws

(TKR1447, TKR1448), then loosen

until spindles carriers (TKR5042B)

move freely. This will ensure

smooth operation and minimize play.

TKR1447

TKRBB08144

TKRBB13194

TKR1448

x2

TKR5055A

16

Bag K

Front Camber Links

This side mounts on hub

Note: no ange

TKR5053A

Step

K-4

Step

K-5

TKR5051

Left

TKR5050

This side mounts on shock tower

Note: ange

TKR5051

TKR5052A

TKR5051

TKR1529

This side mounts on shock tower

Note: ange

Right

TKR5050

TKR5052A

TKR5051

This side mounts on hub

Note: no ange

TKR5053A

x4

TKR1201

M3 Lock Nut Black

x4

TKR1529

M3x20mm Cap Head Screw

x2

TKR5052A

Pivot Ball M3x6.8mm

TKR1201

TKR1201

TKR1529

3

6

2

1

4

5

18.00

Note: Notch always goes on

left side of vehicle

A

B

x2

TKR5053A

Pivot Ball M3x6.8mm

No Flange

Stock position is 2A

17

Bag L

Steering Assembly

(overview)

TKR5123

TKR1323

TKR5056

TKR1323

TKR5100

TKR5103

TKR5056

TKR5056

TKR5123

TKR5104

TKR5052A

Step

L-1

x2

TKR1201

M3 Lock Nut Black

x8

TKR5056

Note: Tighten nut all the way

down, then back it o 4 full turns

Note: Apply a small

drop of oil for easy

o-ring installation.

TKR5052A

TKR5122

TKR1529

TKRBB06103

Thread

Lock

TKR5231

TKR1323

Step

L-2

TKRBB050825

TKR5122

TKR5101X

Thread

Lock

TKRBB050825

TKR1221

M3x8mm Washer

x2

TKR1323

M3x10mm Flat Head Screw

x2

TKR1529

M3x20mm Cap Head Screw

x4

TKR5052A

Pivot Ball M3x6.8mm

x1

TKR5231

O-ring 16x12x2

x4

TKRBB050825

Ball Bearing (5x8x2.5)

Step

L-3

TKR5052A

Step

L-4

TKR1201

TKR1221

TKR5052A

Left

TKR5052A

Please note pivot ball orientation

TKRBB06103TKRBB06103

29.80

Note: Notch always

the left side of the

goes on

vehicle

TKR5052A

Right

Note: Stock bumpsteer setting is

between Ackermann plate and pivot ball.

4 x TKR1221

4 washers

x4

TKRBB06103

Ball Bearing (6x10x3)

TKR1529

TKRBB06103

Stock Position

(in center hole)

18

Bag M

Front End Assembly

TKR1443

Thread

Lock

Step

M-1

Step

M-3

Note: Inititial bumpsteer setting

above and 2 washers below the pivot ball.

x2

TKR1201

M3 Lock Nut Black

x8

TKR1221

M3x8mm Washer

x1

TKR1323

M3x10mm Flat Head Screw

TKR5121

TKR5107

TKR1323

Step

M-2

is 2 washers

TKR1201

TKR5102A

TKR1443

Note Step M-2:

Line up the bottom of the

steering posts (TKR5102A)

with the corresponding recess

cut in the

Note: on steps M-2, M-3 and M-4 Do not

tighten the

the assembly steps are complete. Position

the entire front assembly on the chassis

screws all the way down until

and tighten each screw evenly.

chassis.

TKR1201

x2

TKR1343

M4x10mm Flat Head Screw

x4

TKR1344

M4x12mm Flat Head Screw

x2

TKR1346

M4x15mm Flat Head Screw

x4

TKR1401

M3x6mm Button Head Screw

x5

TKR1443

M4x10mm Button Head Screw

x1

TKR1522

M3x8mm Cap Head Screw

Step

M-4

Note: For optional

rear engine

conguration,

please see step

M4-RE on page 32

TKR1522

TKR5018

TKR1443

Note: For optioanl rear engine motor

conguration, please see page 32

TKR1401

TKR5342

TKR5362

TKR1346

TKR1344

x2

TKR1529

M3x20mm Cap Head Screw

TKR1343

Thread

Lock

TKR1344TKR1344

19

Bag N

Center/Rear Assembly

Step

N-1

TKR5377

Step

N-2

Note: Two rear chassis braces are included in

the kit. The longer brace is the stock brace.

The short brace is optional. The longer brace

will provide less ex. Adding the short brace

will further stien the chassis. Running only

the short brace will provide the most ex.

TKR1443

TKR5362

TKR1344

TKR1343

TKR5362

TKR5376

x4

TKR1343

M4x10mm Flat Head Screw

x8

TKR1344

M4x12mm Flat Head Screw

x2

TKR1443

M4x10mm Button Head Screw

TKR1344

20

Shock Filling Instructions

For both front and rear shocks

The following steps and information will provide you with the proper way to ll and bleed

your Tekno RC NB48 shocks.

After thorough testing, we've found it's easiest to complete steps 1 through 3 on

each shock before moving onto step 4. By the time you've nished step 3

on the last shock the rst one should be ready for step 4.

Step 1. Extend the shock shaft all the way down. Fill the shock with oil until the body is

approximately 90% full.

Step 2. Slowly pump the shock shaft up and down about 3-5 times to release air bubbles from

underneath the piston.

Step 3. Let the shock rest vertically with the shock shaft fully extended for ve minutes or until all

of the air bubbles have released.

Step 4. Push the shaft in so that ~20mm of shaft is between the bottom of the cartridge and the

top of the rod end. Make sure that you match the rebound amount between the left and right

shocks. The vented cap design doesn’t provide much rebound. We've found that running the

least amount of (0%) rebound in both the front and rear shocks gives the most consistent

overall performance.

Step 5. Next you will top o the shock with oil. Fill to just a hair below full, level with the top of

the shock body, but not doming over the top. If you do overll the shock, it won’t hurt

performance, it will just spill out.

Step 6. In this step you will be placing the bladder inside the shock cap. Slowly screw the shock

cap onto the shock body while holding the shock vertically. Continue screwing slowly until oil

begins to bleed out of the bleeder hole. At this point, rotate the shock over about 50-60 degrees

with the bleeder hole pointing up. Continue to screw the cap on and bleed the shock until the

cap is tight. Wipe o excess oil. A good hand tightening is all that is needed, but feel free to

use tools to make them tighter if you wish.

Note: It’s very important to consider ambient temperature when selecting shock oil viscosity.

We recommend #500 cst for the front suspension and #400 cst for the rear suspension for 70-80°F

(21-26°C) outside temperature. You may need to go up or down 50-100cst in shock oil for each

10°F (5°C) of temperature change (lower temperature -> lower viscosity). The oils in the kits are

a great starting point. We suggest starting with the kit oils and moving up or down depending

on the track conditions and ambient temperature.You can build the shocks in any manner you

prefer, but we’ve found this way provides the best handling and more consistent shocks.

They will also last longer between rebuilds.

Use part #’s TKR6008 (shock bushings and cartridge guides) and TKR6009

(o-ring pack) to rebuild your shocks regularly.

We also oer a line of optional CNC shock pistons (TKR6050 -> TKR6054).

The included pistons are TKR6051 (8x1.3mm holes).

21

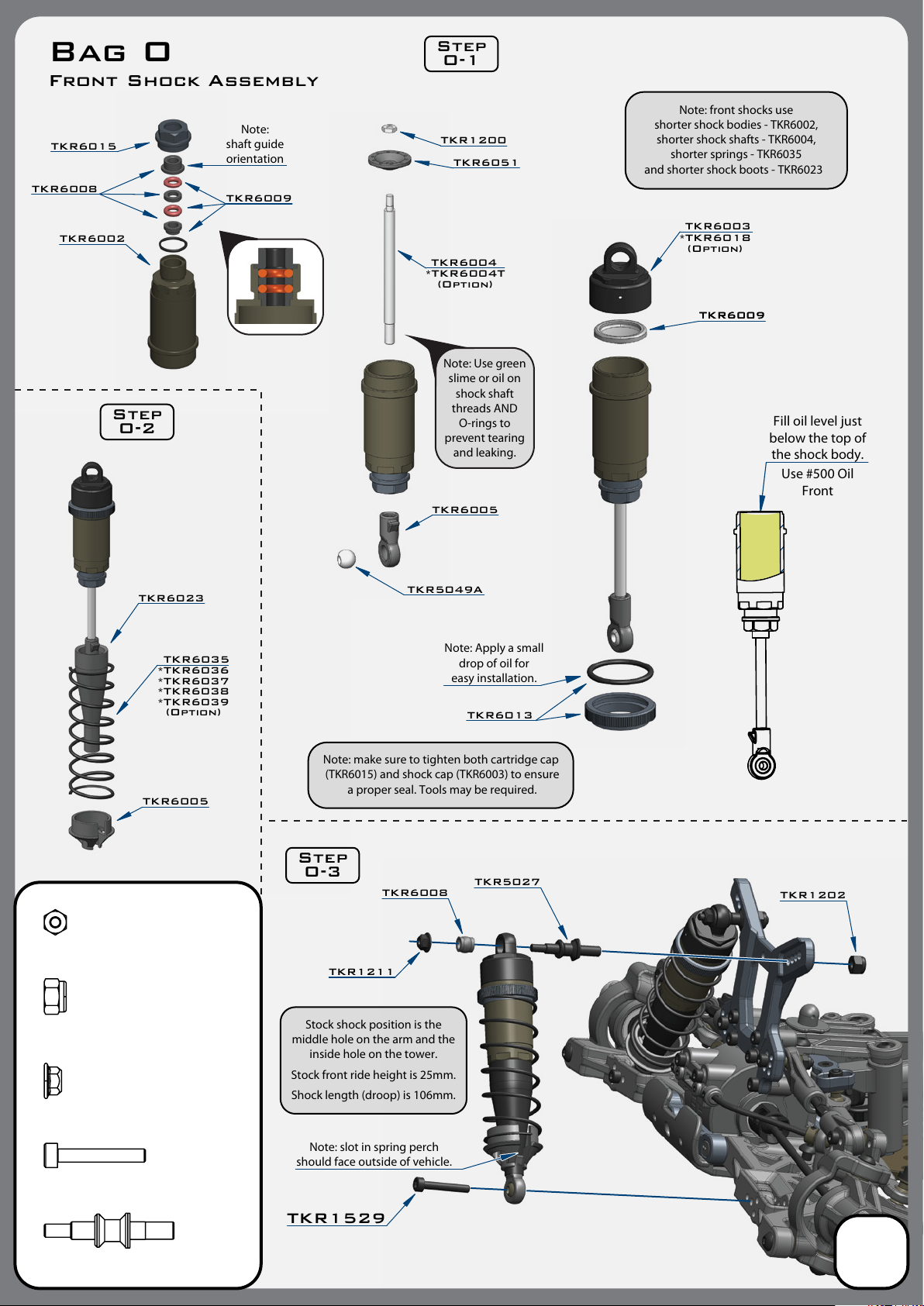

Bag O

Front Shock Assembly

Note:

TKR6015

TKR6008

TKR6002

Step

O-2

shaft guide

orientation

TKR6009

Step

O-1

TKR1200

TKR6051

*TKR6050

*TKR6052

*TKR6053

*TKR6054

(Option)

TKR6004

*TKR6004T

(Option)

Note: Use green

slime or oil on

shock shaft

threads AND

O-rings to

prevent tearing

and leaking.

TKR6005

Note:

shorter shock bodies -

shorter shock shafts -

and shorter shock boots -

front shocks use

shorter springs -

TKR6003

*TKR6018

(Option)

TKR6009TKR6009

TKR6035

TKR6002,

TKR6004,

TKR6023

Fill oil level just

below the

top of

the shock body.

Use #500 Oil

Front

TKR6023

TKR6035

*TKR6036

*TKR6037

*TKR6038

*TKR6039

(Option)

TKR6005

x2

TKR1200

Hex 4035 - M2.5

x2

TKR1202

M4 Lock Nut Black

x2

TKR1211

M3 Lock Nut Flange Black

x2

TKR1529

M3x20mm Cap Head Screw

TKR5049A

Note: Apply a small

drop of oil for

easy installation.

TKR6013

Note:

make sure to tighten both cartridge cap

(TKR6015) and shock cap (TKR6003) to ensure

a proper seal. Tools may be required.

Step

O-3

TKR6008

TKR1211

Stock shock position is the

middle hole on the arm and the

inside hole on the tower.

Stock front ride height is 25mm.

Shock length (droop) is 106mm.

Note: slot in spring perch

should face outside of vehicle.

TKR5027

TKR1202

TKR5027

Shock Stand Off

x2

TKR1529

22

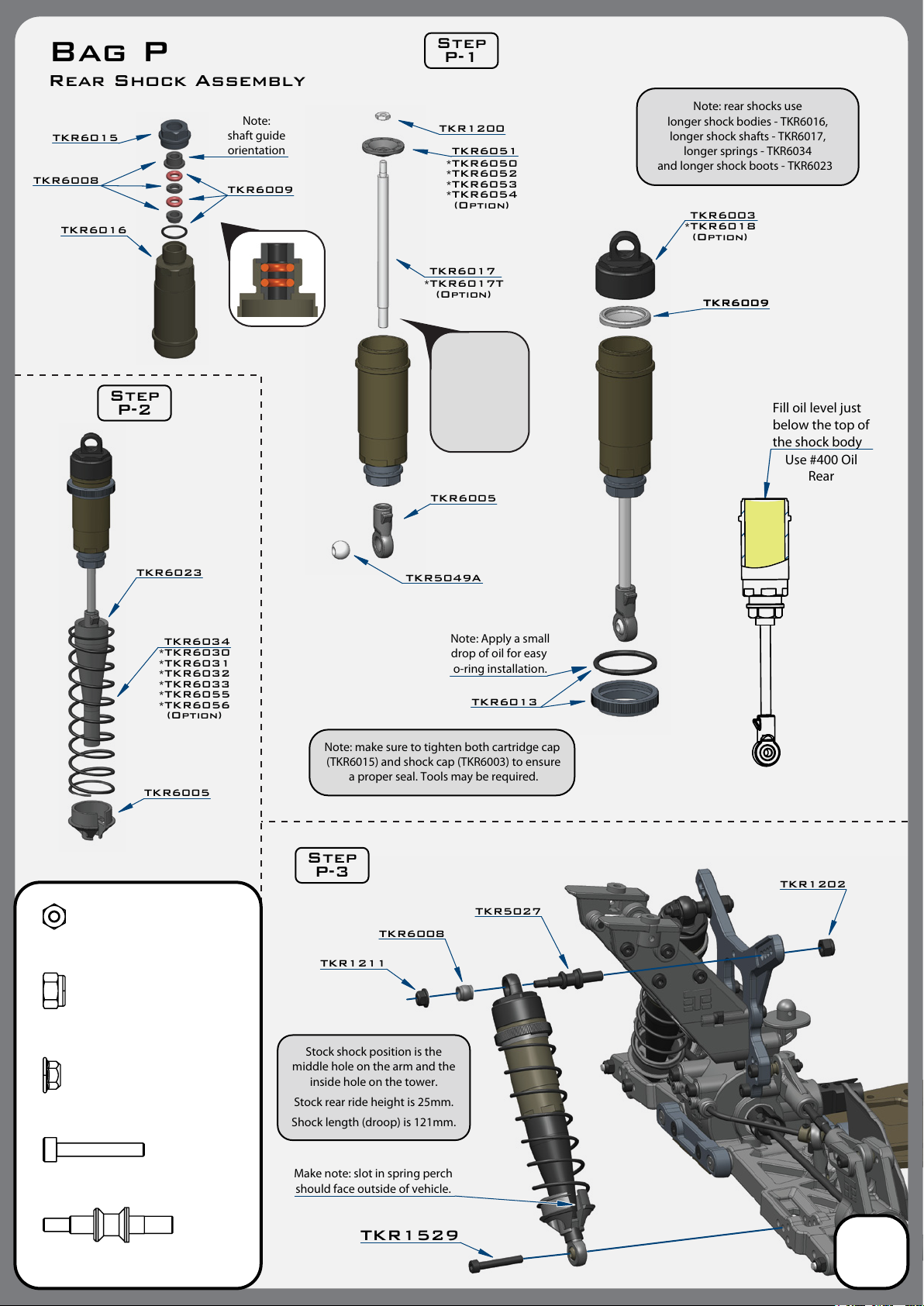

Bag P

Rear Shock Assembly

Note:

TKR6015

TKR6008

TKR6016

Step

P-2

shaft guide

orientation

TKR6009

Step

P-1

TKR1200

TKR6051

*TKR6050

*TKR6052

*TKR6053

*TKR6054

(Option)

TKR6017

*TKR6017T

(Option)

Note: Use green

slime or oil on

shock shaft

threads AND

O-rings to

prevent tearing

and leaking.

TKR6005

Note:

longer shock bodies -

longer shock shafts -

and longer shock boots -

rear shocks use

longer springs -

TKR6003

*TKR6018

(Option)

TKR6009TKR6009

TKR6034

Fill oil level just

below the

the shock body

TKR6016,

TKR6017,

TKR6023

Use #400 Oil

Rear

top of

TKR6023

TKR6005

x2

TKR1200

Hex 4035 - M2.5

x2

TKR6034

*TKR6030

*TKR6031

*TKR6032

*TKR6033

*TKR6055

*TKR6056

(Option)

TKR5049A

Note: Apply a small

drop of oil for easy

o-ring installation.

TKR6013

Note:

make sure to tighten both cartridge cap

(TKR6015) and shock cap (TKR6003) to ensure

a proper seal. Tools may be required.

Step

P-3

TKR5027

TKR6008

TKR1211

TKR1202

TKR1202

M4 Lock Nut Black

x2

TKR1211

M3 Lock Nut Flange Black

x2

TKR1529

M3x20mm Cap Head Screw

x2

TKR5027

Shock Stand Off

Stock shock position is the

middle hole on the arm and the

inside hole on the tower.

Stock rear ride height is 25mm.

Shock length (droop) is 121mm.

Make note: slot in spring perch

should face outside of vehicle.

TKR1529

23

Bag Q

RX Tray Mud Guard

Step

Q-1

Electronics (not included)

Screws (not included)

TKR5317

TKR1525

TKR1221

Step

Q-2

Note: We recommend using

a piece of thin foam or other

type of padding under the

battery to reduce shock.

Likewise, we suggest either

using a couple layers of 2-sided

tape under the receiver or

simply use another piece of

foam and let the receiver ‘oat’

in the box. The servo wires will

help keep the receiver in place

and provide shock protection.

TKR1401

TKR1525

TKR1221

TKR1525

Switch (not included)

TKR1221

Electronics (not included)

Wire Routing Diagram

Step

Q-3

x8

TKR1221

M3X8mm Washer

x13

TKR1401

M3x6mm Button Head Screw

x8

TKR1525

M3x14mm Cap Head Screw

x6

TKR1601

M3x4mm Set Screw

RED = Switch / YELLOW = Brake Servo / BLUE = Steering Servo

Antenna tube installation

TKR1401

TKR1401

TKR1401

Electronics (not included)

24

Bag Q

Mud Guard Installation

Step

Q-4

TKR1343

Step

Q-5

Note: Do not overtighten radio tray screws.

TKR1323

x3

TKR1323

M3x10mm Flat Head Screw

X6

TKR1343

M4x10mm Flat Head Screw

Note: Do not overtighten radio tray screws.

25

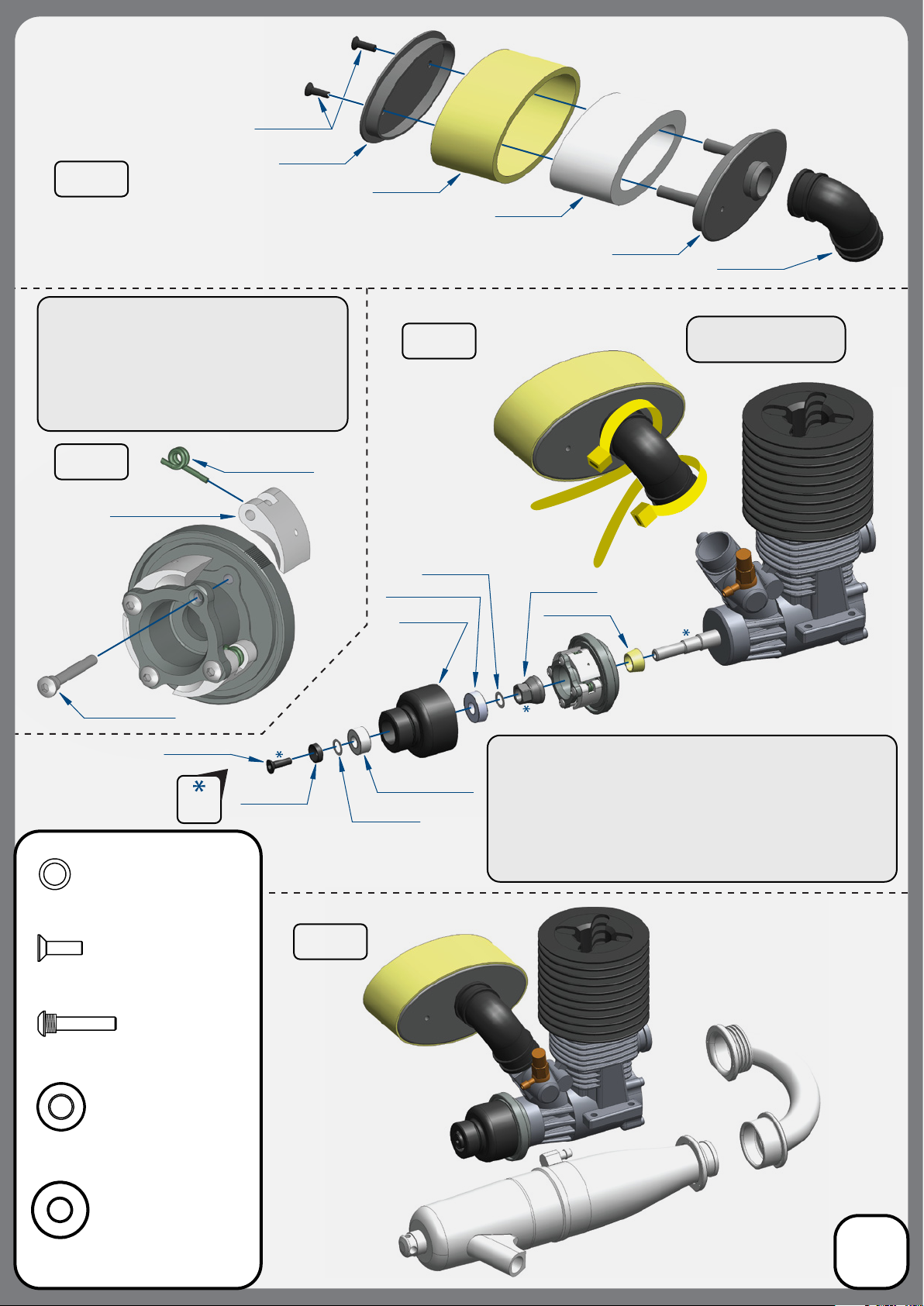

Bag R

Air Filter / Clutch

TKR1323

Step

TKR5324

R-1

Note: Your kit contains 3 sets of clutch springs. 0.9mm

(green), 1.0mm (gold), and 1.1mm (red) springs are

included. The stock setting is to use (2x) 0.9mm springs

on opposing shoes and then use (2x) 1.0mm springs on

the other shoes. If the track is very high bite you can use

(2x) 1.0mm springs and (2x) 1.1mm springs for more

‘pop’. However, we strongly recommend trying the

stock setting rst and adjusting from there.

Step

R-2

TKR5351 x4

TKR5353 x4

TKR5324

*TKR5363

(Option)

(foams only)

Step

R-3

TKR1226

TKRBB05134

TKR4215

TKR5324

*TKR5363

(Option)

(foams only)

TKR5353

TKR5353

TKR5324

TKR5324

Note: Secure air lter hose

with 2 zip ties (included).

TKR5353 X4

TKR1323

Thread

Lock

x4

TKR1226

5x7x0.2mm shim

x3

TKR1323

M3x10mm Flat Head Screw

x4

TKR5353

Clutch Pin

x1

TKR5353

Step

R-4

TKRBB05115

TKR1226

*Engine and Pipe Sold Separately

Note: Properly shimming the clutch bell is critical. The clutch bell must

not rub on the ywheel. Depending on your particular engine, you may

need to use a few of the 5x7x.2mm shims (TKR1226) to properly space the

clutch bell. The clutch bell must also move freely when the end washer and

screw are fastened. There is no ‘one size ts all’ for the number and order of

clutch bell shims that need to be used. In rare cases, the clutch bell may be

too long. Simply put the clutch bell at on a sheet of 200 grit sand paper

(teeth side up) and sand about .2mm o the bottom. This should only take a

minute and it will ensure that your clutch is working properly.

*Engine and Pipe Sold Separately

TKRBB05115

Ball Bearing (5x11x5)

x1

TKRBB05134

Ball Bearing (5x13x4)

*Manifold and pipe springs not

shown or included

26

Bag S

Engine / Pipe

Installation

Step

S-1

Note: For optional

rear engine

conguration,

please see step

S1-RE on page 32

VERY IMPORTANT - With the set screws that secure the

pipe hanger wire set loose, install pipe onto pipe hanger

wire. Adjust the wire such that the pipe and the manifold

connections from the engine are not bent or angled. The

pipe must t naturally. You may need to bend the pipe

hanger wire to accomplish this. Then tighten the set

screw that secures the wire to the wire hanger block. The

wire must then be cut ush to the wire hanger block so it

will not interfere with the fuel tank. If the wire is not ush

with the block, you may risk puncturing your fuel tank.

! ! !

Thread

Lock

TKR1603

TKR5321

TKR5321

TKR1228

TKR1343

TKR5323

TKR1228

TKR1343

Note: For optioanl rear engine motor cong-

uration, please see step S1-RE on page 32

*You may need to bend the pipe wire hanger forward

or backward depending on your particular pipe.

Step

S-2

Step

S-3

X5

TKR1525

TKR1525

Thread

Lock

TKR1343

M4x10mm Flat Head Screw

x1

TKR1524

M3x12mm Cap Head Screw

x4

TKR1525

M3x14mm Cap Head Screw

x1

TKR1603

M5x4mm Set Screw

Set Screw

(not included)

Thread

Lock

TKR1524

27

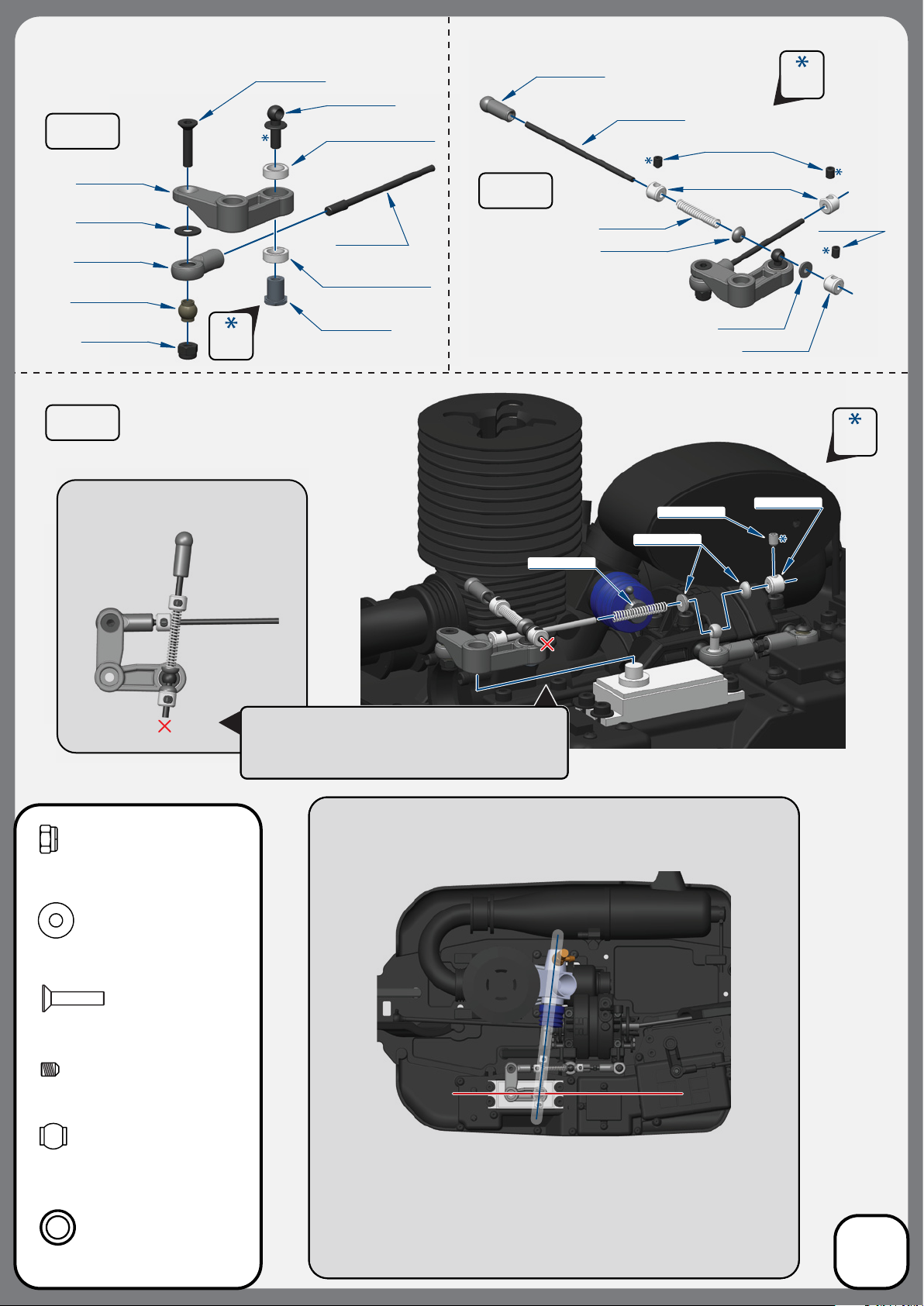

Bag T

Steering Linkage

TKR1201

TKR5058A

Step

T-1

Step

T-2

TKR1221

TKR5320

TKR1325

TKR5056

TKR5357

TKR5056

TKR1407

TKR1221

Step

T-3

x2

TKR1201

M3 Lock Nut Black

x2

TKR1221

M3x8mm Washer

x1

TKR1325

M3x14mm Flat Head Screw

TKR1201

x1

TKR1407

M3x16mm Button Head Screw

x2

TKR5058A

Pivot Ball M3x5.8mm

No Flange

PARALLEL

Note: Oset servo arm so it is parallel with the connecting arm at neutral or zero servo position.

28

Bag T

Brake Linkage

Step

T-4

TKR1325

TKR5331

TKRBB050825

TKR5336

TKR5336

TKR1601

Thread

Lock

TKR5320

TKR1221

TKR5056

TKR5058A

TKR1201

Step

T-6

Note: Your throttle linkage

should look something like this.

Thread

Lock

TKR5336

TKRBB050825

TKR5331

Step

T-5

TKR5336

TKR5336

TKR5336

TKR5336

TKR1601

TKR5336

TKR5336

TKR5336

TKR5336

TKR1601

Thread

Lock

x1

TKR1201

M3 Lock Nut Black

x1

TKR1221

M3x8mm Washer

x1

TKR1325

M3x14mm Flat Head Screw

x4

TKR1601

M3x4mm Set Screw

x1

TKR5058A

Pivot Ball M3x5.8mm

No Flange

x2

TKRBB050825

Ball Bearing (5x8x2.5)

Note: After your throttle linkage is adjusted correctly, you

may need to cut the excess wire from the throttle linkage

rod. Leave approx. 5mm of wire behind the linkage stopper.

If too much wire is left it will interfere with the body.

Note: You may need to rotate the carburetor and ball end to achieve proper throttle

linkage alignment. The ball end should be leaning back when the forward engine position

is used. The ball end should be leaning forward when the rear engine position is used.

This will eliminate any binding due to improper alignment.

Note: Throttle linkage rod and carburetor angle should be colinear (form a straight line).

Note: The throttle arm of the throttle/brake servo horn should be parallel with the

direction of the vehicle (point straight ahead as shown). The spring and linkage stopper

on the throttle linkage should be adjusted such that the carburetor is fully closed at this

position. The linkage stopper should be very tight. Full throttle end point should not ex

the radio tray or put undue stress on the carburetor. Go fully open, then back o a couple

ticks. Brake adjustment should be done in a similar matter. On the track, make a nal

adjustments to the brakes to suit your particular driving style.

29

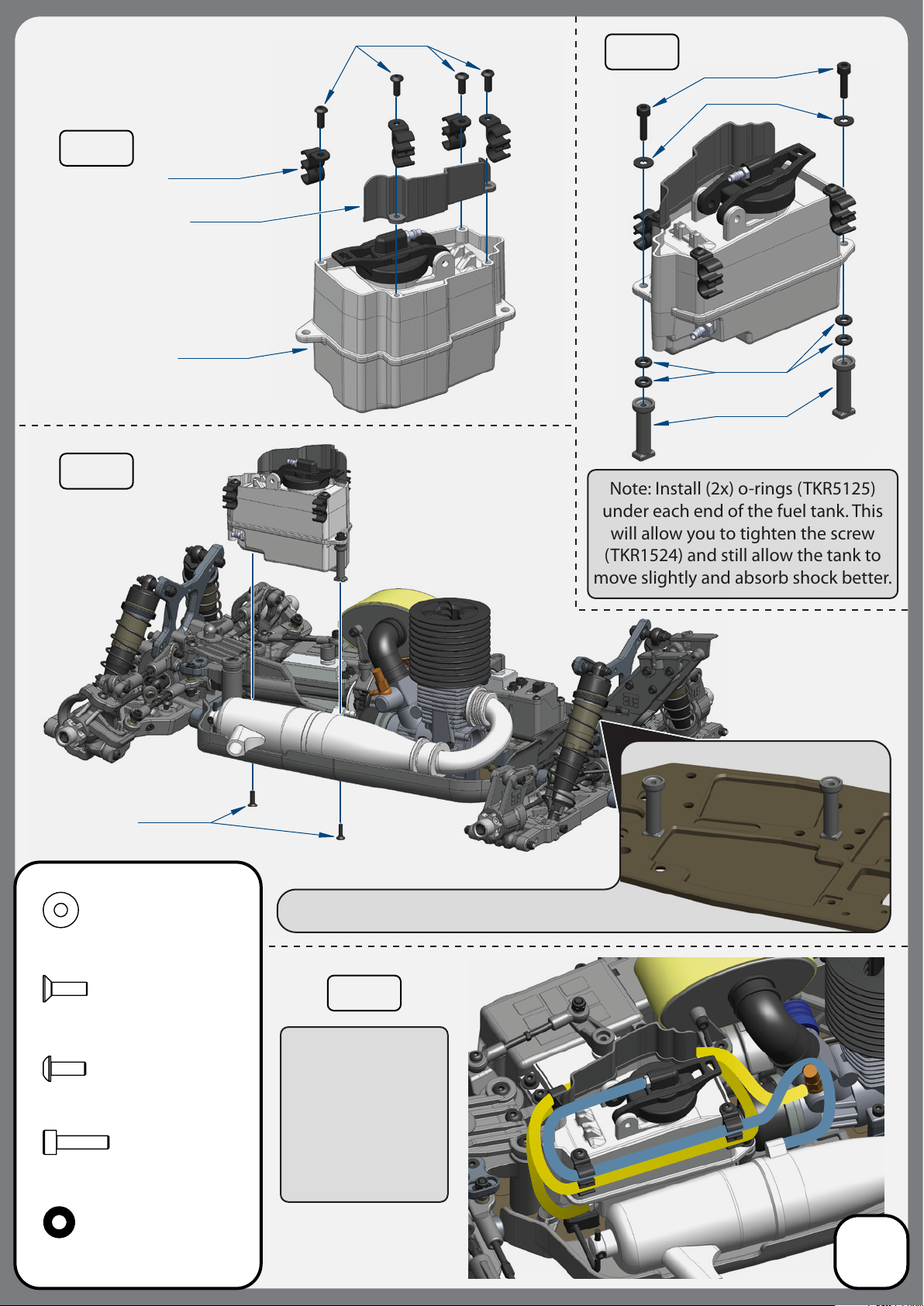

Bag U

Fuel Tank

Step

U-1

TKR5340

TKR5340

TKR1402

Step

U-2

TKR1524

TKR1221

Step

U-3

TKR5340

TKR5125

TKR5341

Note: Install (2x) o-rings (TKR5125)

under each end of the fuel tank. This

will allow you to tighten the screw

(TKR1524) and still allow the tank to

move slightly and absorb shock better.

TKR1323

x2

TKR1221

M3x8mm Washer

x2

TKR1323

M3x10mm Flat Head Screw

x4

TKR1402

M3x8mm Button Head Screw

x2

TKR1524

M3x12mm Cap Head Screw

x4

TKR5125

O-ring 3x7mm

*Align the fuel tank posts to the cutouts in the chassis

Step

U-4

Note: Fuel tubing

wraps around the

tank 1 1/2 times

from the pick up

nipple (yellow line).

Pressure line is

shown in blue.

30

Bag V

Wing and Body

Step

V-1

Step

V-2

TKR5037

*TKR5037B

*TKR5037Y

(Option)

TKR1220

TKR5026

TKR1325

TKR1220

TKR5026

TKR1201

x2

TKR1201

M3 Lock Nut Black

x2

TKR1325

M3x14mm Flat Head Screw

x2

TKR1235

Body Clip

x4

Step

V-3

TKR1235

TKR5116

*TKR5116B

*TKR5116C

(Option)

TKR5116

Wheel Nut

31

Rear Engine Optional Configuration

Step

E1-RE

Note: Center dierential orientation.

Gear is towards the rear of the

vehicle for rear engine conguration.

Pre-thread all brake

post holes with a

separate M3 screw

TKR5213

*TKR5213A

(Option)

Step

M4-RE

TKR5342

REAR

ywheel cover

TKR5213

*TKR5213A

(Option)

TKR1401

Step

E5-RE

TKR1322

*Note: The air lter

hanger orientation

has changed

Flywheel Covers

FRONT REAR

TKR1603

Step

TKR5321

S1-RE

Note: The orientation of the engine mounts (TKR5323) and the

exhaust pipe hanger (TKR5321) have changed to

accommodate the rear engine conguration.

TKR5321TKR5321

TKR1228

TKR1343

TKR5323

Thread

TKR1228

TKR1343

Note: Throttle linkage rod and carburetor

angle should be colinear (form a straight line).

Lock

32

TKR5300 Spare Parts List

TKR5300 - NB48 4WD Nitro 1/8th Scale Competition Buggy Kit

TKR5301 – Chassis (7075, 4mm, hard anodized, lightened, NB48)

TKR5302 - Dierential Ring Gear (40t, rear, CNC, NB48)

TKR5310 – Center Dierntial Mount (NB48, NT48)

TKR5314 - Brake Pad Set (4pcs, NB48, NT48)

TKR5316 – Rear GearBox (oset, rear, NB48, NT48)

TKR5317 – Radio Tray and Mud Guard Set (left/right side, NB48, NT48)

TKR5319 – Radio Tray Covers (NB48, NT48)

TKR5320 - Servo Horns (steering, throttle, NB48, NT48)

TKR5321 - Exhaust Wire Mount Set (CNC, NB48, NT48)

TKR5323 - Engine Mounts (CNC, NB48, NT48)

TKR5324 - Air Filter Set (hose, lter, housing, NB48, NT48)

TKR5331 - Throttle Pivot Ball Assembly (CNC, NB48, NT48)

TKR5336 – Throttle, Brake Linkage (NB48, NT48)

TKR5338 – Brake Levers, Brake Cam Stays (w/ pins)

TKR5340 - Fuel Tank (w/ clunk, NB48)

TKR5341 - Fuel Tank Post and Air Filter Hanger Set (NB48, NT48)

TKR5342 - Flywheel Cover Set (NB48, NT48)

TKR5345S - Brake Disc Set (steel, NB48, NT48, 2pcs)

TKR5350 - Flywheel (4-shoe)

TKR5351 - Clutch Shoes (7075, 4pcs, NB48, NT48)

TKR5353 - Clutch Springs and Hardware Set (NB48, NT48)

TKR5357 - Steering Servo Turnbuckle (NB48, NT48)

TKR5362 - Chassis Brace Set (NB48, NT48)

TKR5363 - Air Filter Foams (inner, outer, pre-oiled, 3pcs each, NB48, NT48)

TKR5376 - Driveshaft (center, rear, steel, NB48)

TKR5376A - Driveshaft (center, rear, aluminum, NB48)

TKR5377 - Driveshaft (center, front, steel, NB48, NT48)

TKR5377A - Driveshaft (center, front, alminum, NB48, NT48)

TKR5383 - Body (NB48, w/ window mask)

TKR5385 - Decal Sheet (NB48)

TKR4214 - Clutch Bell (14t, NB48)

TKR4215 - Clutch Bell (15t, NB48)

TKR5012 – Gearbox (front)

TKR5013 – Adjustable Hinge Pin Braces (rear, 7075 CNC, gun metal ano)

TKR5013B – Adjustable Hinge Pin Brace (+1.5 deg, rear, 7075 CNC, gun metal ano)

TKR5017 – Adjustable Hinge Pin Braces (front, 7075 CNC, gun metal ano)

TKR5018 – Front Bumper

TKR5020 – Hinge Pins (inner, front/rear)

TKR5021 – Hinge Pin Inserts, Wheelbase Shims (complete set)

TKR5026 – Wing Mount, Body Mount Set

TKR5027 – Shock Standos (2pcs)

TKR5028 – Shock Tower (front, 7075 NC, gun metal ano)

TKR5029 – Shock Tower (rear, 7075 NC, gun metal ano)

TKR5030XT – Suspension Arms (rear, 2pcs)

TKR5033 – Rear Arm Mud Guards

TKR5034 – Hinge Pins (outer, rear)

TKR5036XT – Suspension Arms (front, 2pcs)

TKR5037 – Wing (white)

TKR5037B - Wing (black)

TKR5037Y - Wing (yellow)

TKR5040 – Rear Hubs (2pcs)

TKR5041 – Spindles (left and right)

TKR5042 – Spindle Carriers (left and right)

TKR5049A – Pivot Balls (6.8mm, no ng, sway bar, shck ends, almnm, 4pcs)

TKR5050 – Turnbuckle (camber link, front/rear, 2pcs)

TKR5051 – Rod Ends (6.8mm, camber links, 8pcs)

TKR5052A – Pivot Balls (6.8mm, inside camber, strng links, aluminum, 4pcs)

TKR5053A – Pivot Balls (6.8mm, anged, outside camber, aluminum, 4pcs)

TKR5054A – Spindle Bushings (4pcs, aluminum, hard ano)

TKR5055A – Arm Bushings (4pcs, aluminum, hard ano)

TKR5056 – Rod Ends (5.8mm, brake/steering/sway bar linkage, 8pcs)

TKR5058A – Pivot Balls (5.8mm, no ange, brake/strng link, aluminum, 4pcs)

TKR5070 – Stub Axles (hardened steel, 2pcs)

TKR5071 – Wheel Hubs (17mm, aluminum, black ano, w/pins, 2pcs)

TKR5071X – Wheel Hubs (17mm, aluminum, lightened, gun metal ano, w/pins, 2pcs)

TKR5071B – Wheel Hubs (17mm, alum, ltnd, gun metal ano, 1mm o, w/pins, 2pcs)

TKR5071C – Wheel Hubs (17mm, alum, ltnd, gun metal ano, 2mm o, w/pins, 2pcs)

TKR5072 – Driveshafts (f/r, hardened steel, 2pcs)

TKR5073 – CV Rebuild kit (f/r, for 2 axles)

TKR5075 – Di Coupler (f/r, hardened steel)

TKR5079A – Stabilizer Balls (6.8mm, sway bars, aluminum, 4pcs)

TKR5080 – Sway Bar (f/r, 2.2mm)

TKR5081 – Sway Bar (f/r, 2.3mm)

TKR5082 – Sway Bar (f/r, 2.4mm)

TKR5083 – Sway Bar (f/r, 2.5mm)

TKR5084 – Sway Bar (f/r, 2.6mm)

TKR5085 – Sway Bar (f/r, 2.8mm)

TKR5086 – Sway Bar Mounts

TKR5087 – Sway Bar (f/r, 3.0mm)

TKR5100 – Ackerman Plate (aluminum, gun metal ano)

TKR101X - Servo Saver Spring (HD, EB48, SCT410, NB48)

TKR5102A – Steering Posts (aluminum, gun metal ano)

TKR5103 – Servo Saver Post (aluminum, gun metal ano)

TKR5104 – Steering Bell Cranks

TKR5107 – Steering Top Plate, Center Di Top Plate, Center Di Rear Support

TKR5116 – Wheel Nuts (17mm, serrated, gun metal ano, M12x1.0, 4pcs)

TKR5122 – Steering Rack Bushings (aluminum, gun metal ano, 2pcs)

TKR5123 – Turnbuckle (steering links, 2pcs)

TKR5125 – O-Ring (ESC tray, 3pcs)

TKR5126 – Antenna tube (universal, w/ caps, 5pcs)

TKR5231 – Servo Saver Nut and Spring

TKR5112X – Dierential Outdrives (center, lightened)

TKR5113 – Dierential Case (f/c/r)

TKR5114X – Dierential Outdrives (f/r, lightened)

TKR5115 – Spur Gear (44t, hardened steel, lightened)

TKR5149 – Dierential Cross Pins (6pcs)

TKR5150 – Dierential Gear Set (internal gears only)

TKR5151 – Dierential Ring Gear (40t, straight cut)

TKR5152 – Di Pinion (10T, CNC, straight cut)

TKR5143 – Dierential Seals (3pcs)

TKR5144 – Dierential O-Rings (6pcs)

TKR5145 – Dierential Shims (6x17mm, 6pcs)

TKR5148 – Complete Front Dierential

TKR5389 – Complete Rear Dierential

TKR5390 – Complete Center Dierential

TKR5213 – Brake Posts (4pcs)

TKR5213A – Brake Posts (aluminum, 4pcs)

TKR5215 – Brake Cams (steel, 2pcs)

TKR5219 – Brake Linkage Ball Lever (steel)

TKR5057 – Turnbuckle (brake bias adjustment)

TKR6002 – Shock Body (front, aluminum, hard ano, 2pcs)

TKR6003 – Shock Caps (aluminum, black ano, 2pcs)

TKR6003B – Shock Caps (non-vented top, 2pcs)

TKR6004 – Shock Shafts (front, steel, 2pcs)

TKR6004T – Shock Shafts w/ TiNi coating (front, steel, 2pcs)

TKR6005 – Shock Rod Ends and Spring Perches (6.8mm, shock ends, 4pcs)

TKR6008 – Shock Shaft Guide, Piston, and Bushing Set (for 2 shocks)

TKR6009 – Shock O-Ring and Bladder Set (for 2 shocks)

TKR6009B – Shock O-Ring Set (16pcs, for 2 shocks)

TKR6009C – Shock Bladder Set (rm, 4pcs)

TKR6013 – Shock Adjustment Nuts (aluminum, gun metal ano, 2pcs)

TKR6015 – Shock Cartridge Caps (aluminum, gun metal ano, 2pcs)

TKR6016 – Shock Body (rear, aluminum, hard ano, 2pcs)

TKR6017 – Shock Shafts (rear, steel, 2pcs)

TKR6017T – Shock Shafts w/ TiNi coating (rear, steel, 2pcs)

TKR6018 – Shock Cap and Spring Adjuster Set (composite, for 2 shocks)

TKR6021 – Shock Set (front, complete)

TKR6022 – Shock Set (rear, complete)

TKR6023 - Shock Boot Set (2 front, 2 rear)

TKR6030 – Shock Spring Set (rear, 1.4 x 11.0T, 85mm)

TKR6031 – Shock Spring Set (rear, 1.4 x 10.5T, 85mm)

TKR6032 – Shock Spring Set (rear, 1.4 x 10.0T, 85mm)

TKR6033 – Shock Spring Set (rear, 1.4 x 9.5T, 85mm)

TKR6034 – Shock Spring Set (rear, 1.4 x 9.0T, 85mm)

TKR6035 – Shock Spring Set (front, 1.5 x 9.0T, 70mm)

TKR6036 – Shock Spring Set (front, 1.5 x 8.5T, 70mm)

TKR6037 – Shock Spring Set (front, 1.5 x 8.0T, 70mm)

TKR6038 – Shock Spring Set (front, 1.5 x 7.5T, 70mm)

TKR6039 – Shock Spring Set (front, 1.5 x 7.0T, 70mm)

TKR6055 – Shock Spring Set (rear, 1.4 x 8.5t, 80mm)

TKR6056 – Shock Spring Set (rear, 1.4 x 8.0t, 80mm)

TKR6050 - Shock Pistons (CNC, conical, 10x1.1mm)

TKR6051 - Shock Pistons (CNC, conical, 8x1.3mm)

TKR6052 - Shock Pistons (CNC, conical, 10x1.2mm)

TKR6053 - Shock Pistons (CNC, conical, 8x1.4mm)

TKR6054 - Shock Pistons (CNC, conical, 10x1.3mm)

TKRBB050825 – Ball Bearing (5x8x2.5mm, 4pcs)

TKRBB05114 – Ball Bearing (5x11x4, 4pcs)

TKRBB05115 – Ball Bearing (5x11x5, 4pcs)

TKRBB05134 – Ball Bearing (5x13x4, 4pcs)

TKRBB06103 – Ball Bearing (6x10x3, 4pcs)

TKRBB08144 – Ball Bearing (8x14x4, 4pcs)

TKRBB08165 – Ball Bearing (8x16x5, 4pcs)

TKRBB13194 – Ball Bearing (13x19x4, 4pcs)

TKR1200 – M2.5 Locknuts (zinc nish, 10pcs)

TKR1201 – M3 Locknuts (black, 10pcs)

TKR1202 – M4 Locknuts (black, 10pcs)

TKR1211 – M3 Locknuts (anged, black, 10pcs)

TKR1221 – M3x8mm Washer (black, 10pcs)

TKR1222 – 13x16x.1mm Di Shims (10pcs)

TKR1235 – Body Clips (10pcs)

TKR1227 - M4x9mm Washer (zinc nish, 10pcs)

TKR1322 – M3x8mm Flat Head Screws (black, 10pcs)

TKR1323 – M3x10mm Flat Head Screws (black, 10pcs)

TKR1325 - M3x14mm Flat Head Screws (black, 10pcs)

TKR1327 - M3x16mm Flat Head Screws (black, 10pcs)

TKR1328 - M3x18mm Flat Head Screws (black, 10pcs)

TKR1333 - M3x40mm Flat Head Screws (black, 10pcs)

TKR1341 - M4x6mm Flat Head Screws (black, 10pcs)

TKR1343 - M4x10mm Flat Head Screws (black, 10pcs)

TKR1346 - M4x15mm Flat Head Screws (black, 10pcs)

TKR1401 - M3x6mm Button Head Screws (black, 10pcs)

TKR1402 - M3x8mm Button Head Screws (black, 10pcs)

TKR1407 - M3x16mm Button Head Screws (black, 10pcs)

TKR1443 - M4x10mm Button Head Screws (black, 10pcs)

TKR1445 - M4x14mm Button Head Screws (black, 10pcs)

TKR1447 - M4x16mm Button Head Srews (black, 10pcs)

TKR1448 - M4x18mm Button Head Screws (black, 10pcs)

TKR1522 - M3x8mm Cap Head Screws (black, 10pcs)

TKR1524 - M3x12mm Cap Head Screws (black, 10pcs)

TKR1525 - M3x14mm Cap Head Screws (black, 10pcs)

TKR1529 - M3x20mm Cap Head Screws (black, 10pcs)

TKR1601 - M3x4mm Set Screws (black, 10pcs)

TKR1603 - M5x4mm Set Screws (black, 10pcs)

33

Setup Sheet

Name: Kit Set-up

Track Conditions:

Outdoor Rough

Date: Event/Track:

Indoor Wet Dry High Bite Low Bite

Smooth Hard Packed Loose/Loamy Blue Groove

Bumpsteer/Ackerman/Servo Saver/Steering Stop:

# washers

over4

under

0

ballstud

# washers

over

2

under

2

ballstud

Front End:

# of turns

from fully

1

2

3

1

2

3

4

4

5

6

A B

RI DE H EI GH T:

TO E ( in /o ut ):

tightened

4

Suspension:

FR ONT

25mm

1 deg out

# washers

4

3 deg in

front

middle

rear

RE AR

25mm

ST D/ EM UL /V EN T:

PI STO N:

OI L:

BL ADDE R:

RE BOUN D:

SP RING :

NO TES :

Tires / Wheels:

BR AND:

TR EAD:

Shocks:

FR ONT

RE AR

Vented Vented

8x1.3 8x1.3

500

400

stock stock

% %

10 10

Pink Red

FR ONT

RE AR

Front Ou ter

(S wee p)

Rear End:

CAM BER :

CAS TER: Deg

SH OC K LE NG TH

(D RO OP ):

Front Inn er

(K ick Up)

0.0 0.5R 1.0R1.0F 0.5F

10.0˚

10.5˚

11.0˚

11.5˚

12.0˚

SWAY BAR :

NO TES :

BO DY:

WI NG:

1.5 deg151.5 deg

106 127

2.5mm

2.6mm

Body/Wing:

stock

stock

CO MPOU ND:

IN SERT :

WH EEL:

NO TES :

Dierential Oil:

7

NO TES :

CE NTERFR ONT

7 5

RE AR

Equipment:

EN GINE :

1

2

3

1

4

2

3

4

5

6

A B DC

(DOWNFORCE POSITION)

Wheelbase:

2

mm

/F RO NT

PI PE

PLUG:

FU EL:

RX BATT:

SE RVOS:

st eer ing

th rot tle /bra ke

Drivetrain:

3

mm

/R EA R

la rge 2mm

CLUTCH/S PUR :

CLUTCH S HOE S:

15

44

(t ee th )

stock 7075 alum

Rea r Ou ter

( Toe In)

sm all 1mm

Rea r In ner

(A nti -Squ at)

3.5˚ 4.0˚ 4.5˚2.5˚ 3.0˚

3.0˚

1.0˚

Notes:

2.5˚

2.0˚

1.5˚

CLUTCH S PRI NGS:

EN GINE PO SITI ON:

BR AKE BIAS :

2x 0.9mm, 2x 1.0mm

Front Rea r

fr ont re ar

% %

40 60

Chassis Braces:

Ce nte r Rea r Left Rea r Ri ght

Setup Sheet

Name:

Track Conditions:

Outdoor Rough

Date: Event/Track:

Indoor Wet Dry High Bite Low Bite

Smooth Hard Packed Loose/Loamy Blue Groove

Bumpsteer/Ackerman/Servo Saver/Steering Stop:

# washers

over

under

ballstud

# washers

over

under

ballstud

Front End:

# of turns

from fully

1

2

3

1

2

3

4

4

5

6

A B

RI DE H EI GH T:

TO E ( in /o ut ):

tightened

Suspension:

FR ONT

# washers

front

middle

rear

RE AR

ST D/ EM UL /V EN T:

PI STO N:

OI L:

BL ADDE R:

RE BOUN D:

SP RING :

NO TES :

Tires / Wheels:

BR AND:

TR EAD:

Shocks:

FR ONT

% %

FR ONT

RE AR

RE AR

Front Ou ter

(S wee p)

Rear End:

CAM BER :

CAS TER: Deg

SH OC K LE NG TH

(D RO OP ):

Front Inn er

(K ick Up)

0.0 0.5R 1.0R1.0F 0.5F

12.0˚

11.5˚

11.0˚

10.5˚

10.0˚

SWAY BAR :

NO TES :

Body/Wing:

BO DY:

WI NG:

CO MPOU ND:

IN SERT :

WH EEL:

NO TES :

Dierential Oil:

NO TES :

CE NTERFR ONT

RE AR

Equipment:

EN GINE :

1

2

3

1

4

2

3

4

5

6

A B DC

(DOWNFORCE POSITION)

Wheelbase:

mm

/F RO NT

PI PE

PLUG:

FU EL:

RX BATT:

SE RVOS:

st eer ing

th rot tle /bra ke

Drivetrain:

mm

/R EA R

la rge 2mm

CLUTCH/S PUR :

CLUTCH S HOE S:

(t ee th )

Rea r Ou ter

( Toe In)

sm all 1mm

Rea r In ner

(A nti -Squ at)

3.5˚ 4.0˚ 4.5˚2.5˚ 3.0˚

3.0˚

1.0˚

Notes:

2.5˚

2.0˚

1.5˚

CLUTCH S PRI NGS:

EN GINE PO SITI ON:

BR AKE BIAS :

Front Rea r

fr ont re ar

% %

Chassis Braces:

Ce nte r Rea r Left Rea r Ri ght

Tekno RC

10755 Scripps Poway Pkwy #598

San Diego CA 92131

USA

www.teknorc.com

Loading...

Loading...