Introduction

Additional equipment and parts needed:

•

Monster truck body and paint (or equivalent size body)

•

1/8th scale ESC and motor system (or equivalent)

•

High torque steering servo (at least 350 oz/in)

•

4s (4 cell) LiPo battery (at least 5000mAh)

•

1/8th scale Monster truck tires, wheels & CA glue (or premounts)

•

MOD1 Pinion 15 tooth - 25 tooth (TKR4175 - TKR4185)

Tools needed:

•

Hex drivers 1.5mm (TKR1104), 2.0mm (TKR1105), 2.5mm (TKR1106)

•

Nut drivers 5.0mm (TKR1107, 5.5mm (TKR1108), 7.0mm (TKR1109)

•

Hobby knife

•

Needle-nose pliers

•

Shock tool (TKR1115) OR adjustable (Crescent) wrench (for shock assembly)

•

4mm turnbuckle wrench (TKR1103) - 5.5/7.0 two sided wrench (TKR1119)

•

4mm arm reamer (or #19 drill bit)

Disclaimer: Tekno RC is not responsible or liable for any property or personal damage, loss, or injury incurred as a

result of using this product. This kit is meant for use by persons 14 years of age or older and in the strict connes of

a legally permitted RC track or facility.

Warnings: Always double-check that your radio gear is working properly before operating vehicle. Never operate the

vehicle indoors (unless the RC track is an indoor facility). Use caution while operating vehicle so as not to collide with

people who may be turn marshalling or who might otherwise not be aware that a fast moving RC vehicle is in the vicinity.

Warranty: We warrant that the parts included in this kit are free from defects. If you nd a defective part in your kit,

please contact us @ info@teknorc.com and we will help you to resolve the issue. We do not warranty parts that may be

broken during operation of the vehicle or otherwise. Refer to the end of this instruction manual for a listing of

spare/replacement and option parts. All spare parts and other info are available on our website (www.teknorc.com)

and through our network of domestic and international dealers and distributors.

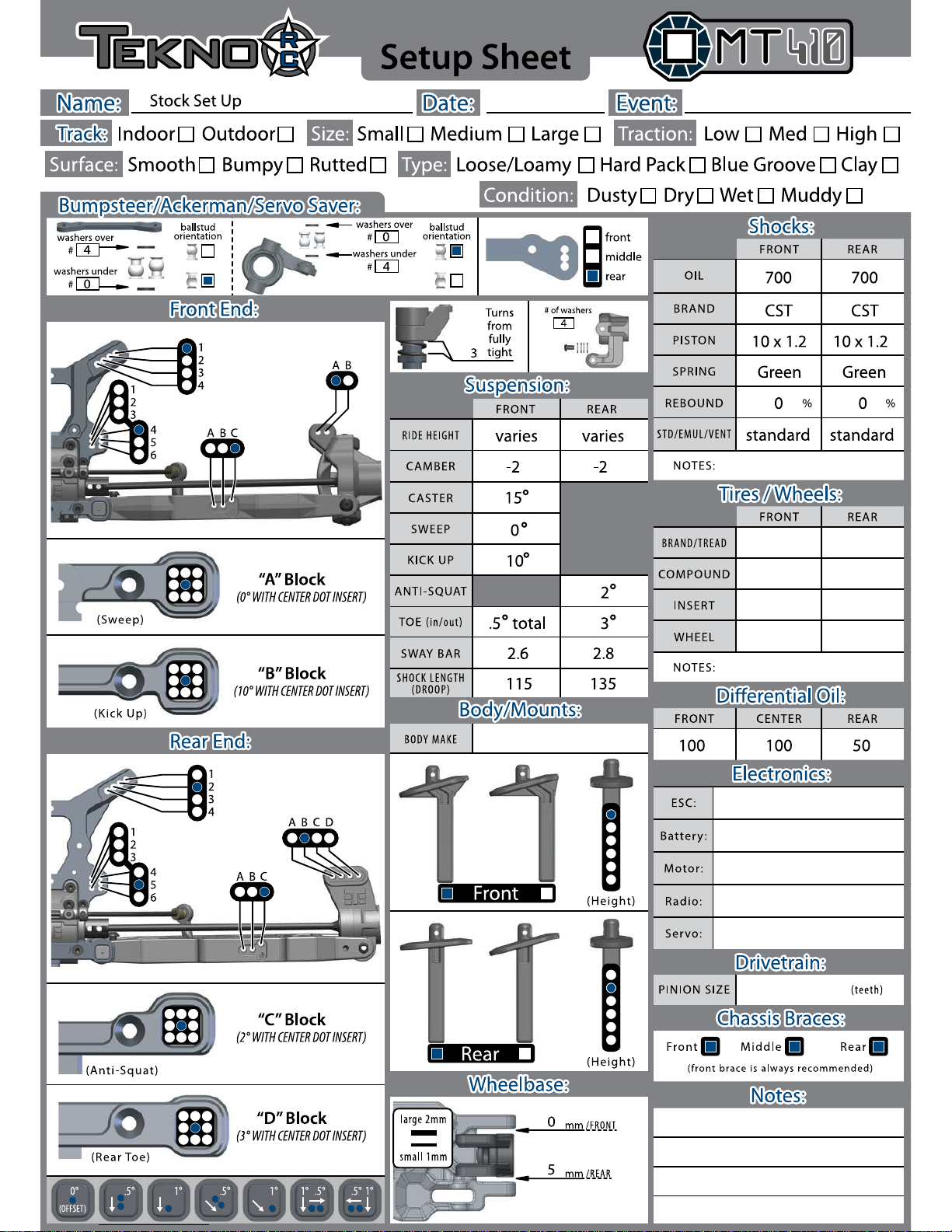

Thank you for purchasing the Tekno RC MT410 1/10th Scale Electric 4WD Competition Monster Truck.

We are always working on new projects, so please check our website

at www.teknorc.com or our Facebook page at www.facebook.com/teknorc

regularly for the latest news, parts, and kits.

Take your time! When you work your way through these building instructions, keep an eye out

for the following important indicators below:

•

RED TEXT - This indicates important areas of the build process that shold be observed.

•

YOUTUBE - We also have many useful build videos on Youtube, so be sure to check these out!

https://www.youtube.com/c/teknorc

Thread Lock icons

Thread lock is always used when a screw is inserted into any metal part. (Included with kit)

Thread

Lock

Grease icons

Grease is usually used on any areas with movement and for sealing. (Included with kit)

Grease

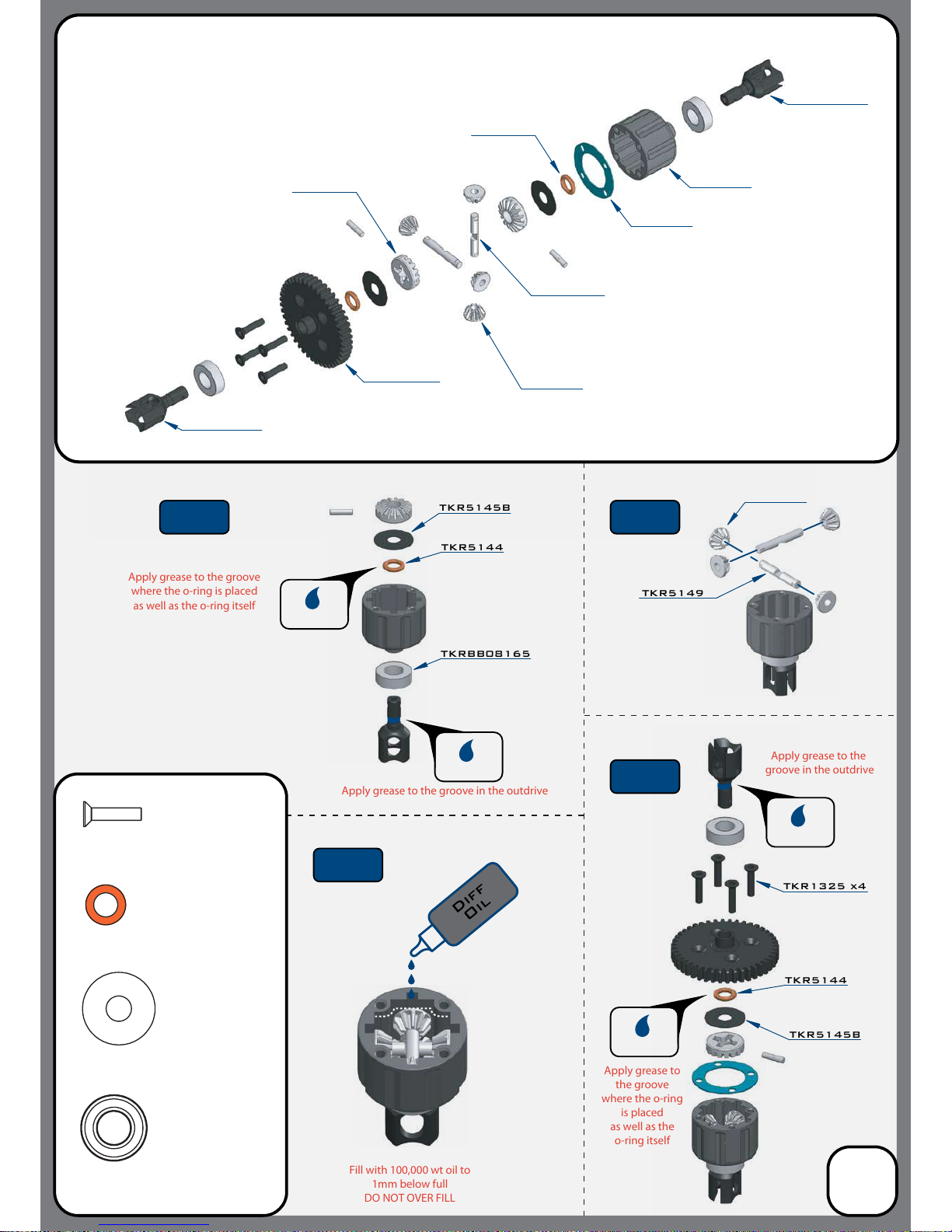

Apply grease to the groove

where the o-ring is placed

as well as the o-ring itself

Apply grease to

the groove

where the o-ring

is placed

as well as the

o-ring itself

Apply grease to the groove in the outdrive

Apply grease to the

groove in the outdrive

Fill with 100,000 wt oil to

1mm below full

DO NOT OVER FILL

TKR5145B

TKR5144

Bag A

Center Differential

(overview)

TKR5237K

TKR5149

TKR5150

TKR5150

TKR5143

TKR5113

*TKR5237

*TKR5115

(Option)

TKR1325

M3x14mm Flat Head Screw

x4

TKR5144

TKR5145B

TKRBB08165

Ball Bearing(8x16x5mm)

x2

TKR5144

Differential 0-rings

x2

TKR5145B

Differential Shims (6x17mm)

x2

TKR1325 x4

TKR5149

TKRBB08165

Diff

Oil

TKR5114XB

TKR5114XB

TKR5150

TKR5144

3

Grease

Grease

Grease

Grease

Step

A-2

Step

A-1

Step

A-4

Step

A-3

*TKR5149A

(Option)

*

TKR5149A

(Option)

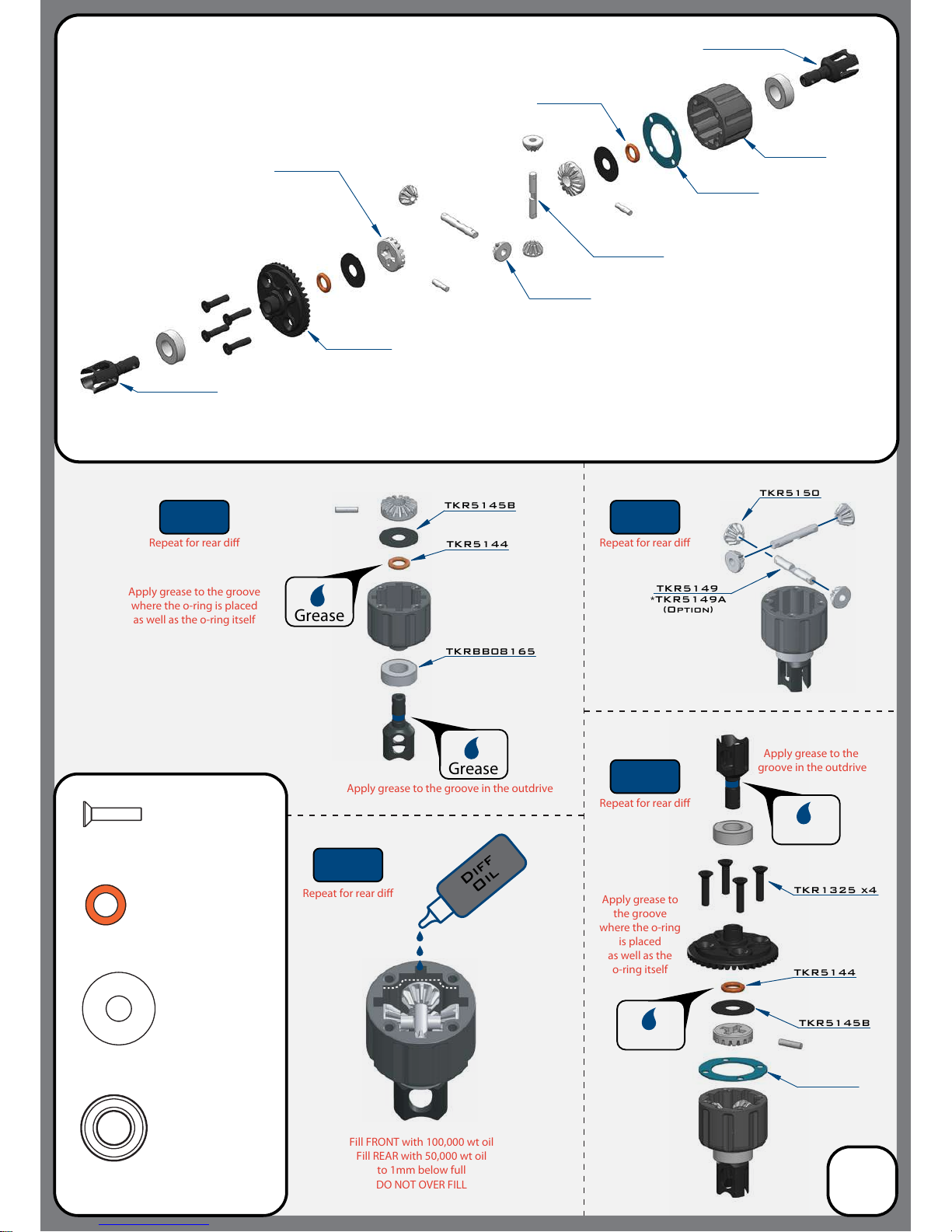

Apply grease to the groove

where the o-ring is placed

as well as the o-ring itself

Repeat for rear di

Fill FRONT with 100,000 wt oil

Fill REAR with 50,000 wt oil

to 1mm below full

DO NOT OVER FILL

Repeat for rear di

Repeat for rear di

Repeat for rear di

*TKR5149A

(Option)

Apply grease to the groove in the outdrive

TKR5145B

TKR5144

TKRBB08165

Grease

Grease

TKR5149

TKR5150

*

TKR5149A

(Option)

Diff

Oil

Apply grease to

the groove

where the o-ring

is placed

as well as the

o-ring itself

Apply grease to the

groove in the outdrive

Bag B

Front and Rear Differential

(overview)

TKR5403

TKR5149

TKR5150

TKR5150

TKR5143

TKR5113

TKR1325

M3x14mm Flat Head Screw

x8

TKR5144

TKR5145B

TKRBB08165

Ball Bearing(8x16x5mm)

x4

TKR5144

Differential 0-rings

x4

TKR5145B

Differential Shims (6x17mm)

x4

TKR1325 x4

TKR5114XB

TKR5114XB

TKR5143

TKR5144

4

Grease

Grease

Step

B-2

Step

B-1

Step

B-4

Step

B-3

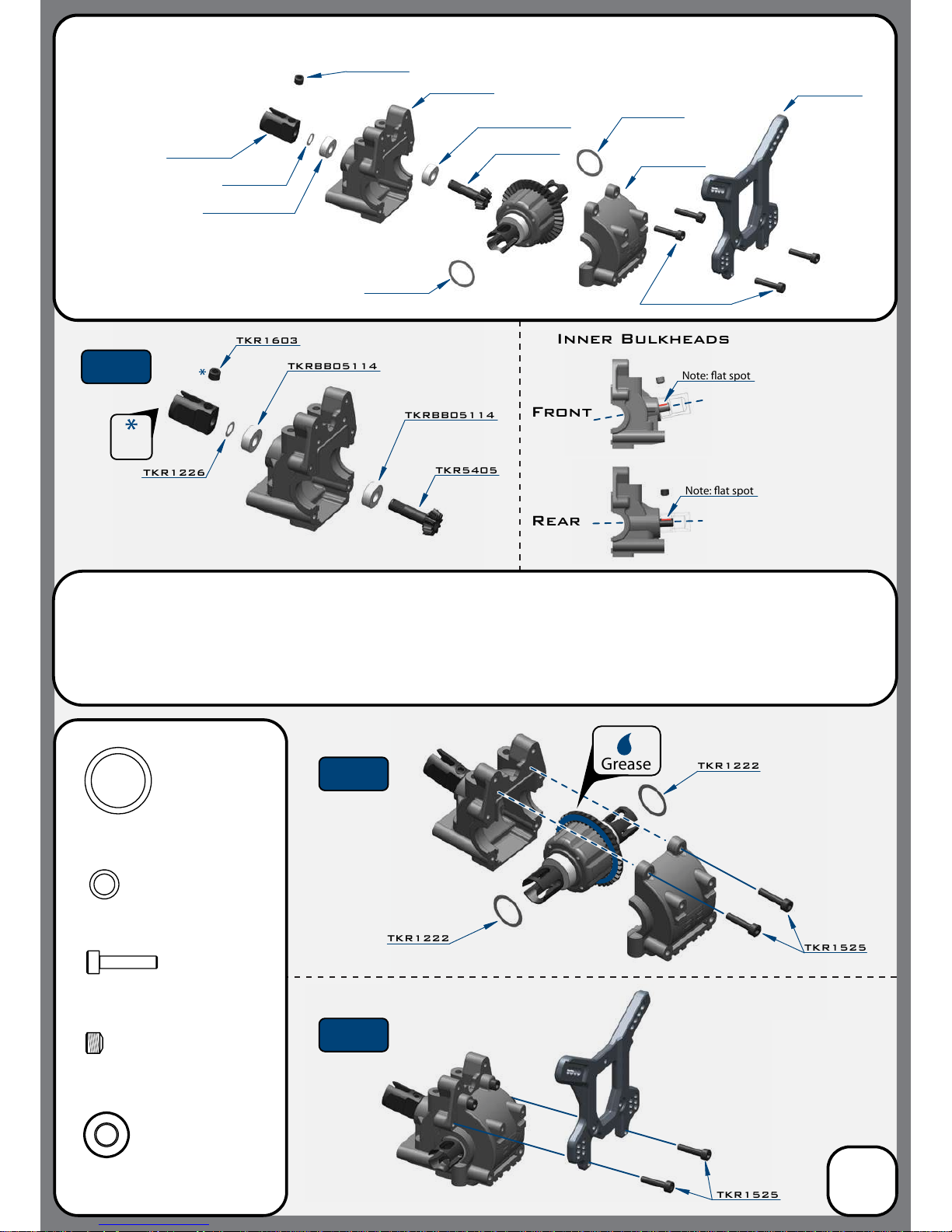

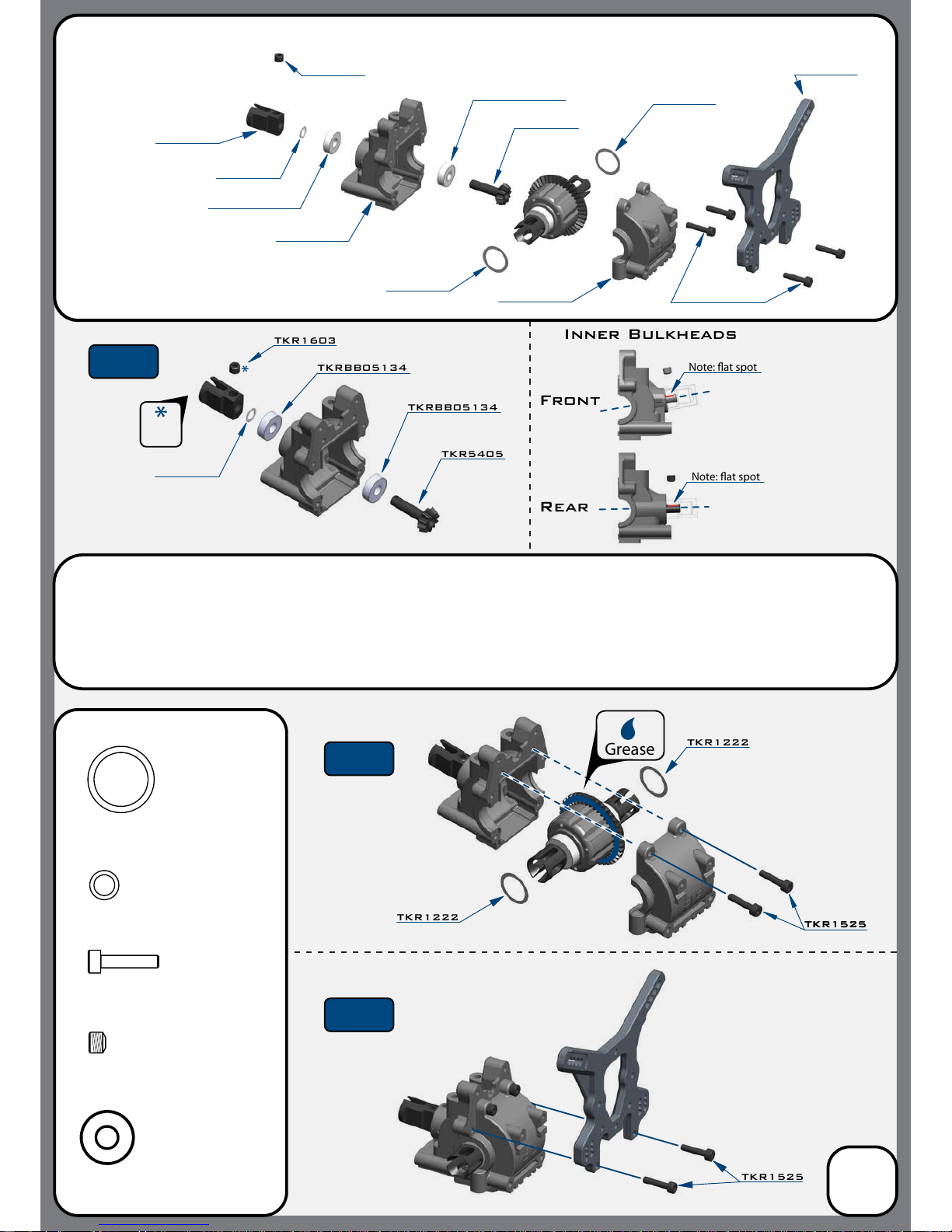

TKR5012

TKR5012

TKR5028

TKR5075

TKR5405

Front

Inner Bulkheads

Rear

TKR1603

TKRBB05114

TKRBB05114

TKR5405

TKR1222

TKR1222

TKR1525

TKR1222

TKRBB05114

TKR1222

TKR1525 x4

TKR1226

TKR1226

TKRBB05114

TKR1525

TKR1525

M3x14mm Cap Head Screw

x4

TKRBB05114

Ball Bearing (5x11x4)

x2

x2

TKR1222

13x16x0.1mm Diff shim

TKR1603

Note: at spot

Note: at spot

TKR1603

M5x4mm Set Screw

x1

Grease

Bag C

Front Gearbox

(overview)

Step

C-1

Step

C-2

Step

C-3

5

Thread

Lock

TKR1226

5x7x0.2mm shim

x1

Note: Step C-2 To properly shim the di, you will start by test tting the di with no shims and check for

side to side play. If no (or very little) play is present, then continue on to the next step. If you feel

excessive side to side play, then start by adding one shim on the gear side of the di assembly. This

will move the mesh tighter and remove any play. If the mesh is too tight at this point, move the shim

to the other side. In some rare cases, two shims may be necessary.

Note: The front and rear of

the car use dierent inner

bulkheads.

The front is angled

whereas the rear is

only slightly angled.

*These may not be needed

*These may not be needed

*These may not be needed

*These may not be needed

TKR5075

TKR5016B

TKR5029

TKR1222

TKR1222

TKR1525

TKR1222

TKR5016B

TKR1525

M3x14mm Cap Head Screw

x4

TKRBB05134

Ball Bearing (5x13x4)

x2

TKR1222

13x16x0.1mm Diff Shim

x2

TKRBB05134

TKRBB05134

TKR5405

TKRBB05134

TKR1603

TKR1603

TKR1525TKR1525

Front

Note: at spot

Rear

Note: at spot

TKR1525 x4

TKR1222

TKR1226

TKRBB05134

TKR1603

M5x4mm Set Screw

x1

TKR1226

5x7x0.2mm shim

x1

Grease

Inner Bulkheads

Bag D

Rear Gearbox

(overview)

6

Step

D-1

Step

D-2

Step

D-3

Thread

Lock

Note: The front and rear of

the car use dierent inner

bulkheads.

The front is angled

whereas the rear is

only slightly angled.

*These may not be needed

*These may not be needed

*These may not be needed

*These may not be needed

TKR5405

TKR1226

Note: Step D-2 To properly shim the di, you will start by test tting the di with no shims and check for

side to side play. If no (or very little) play is present, then continue on to the next step. If you feel

excessive side to side play, then start by adding one shim on the gear side of the di assembly. This

will move the mesh tighter and remove any play. If the mesh is too tight at this point, move the shim

to the other side. In some rare cases, two shims may be necessary.

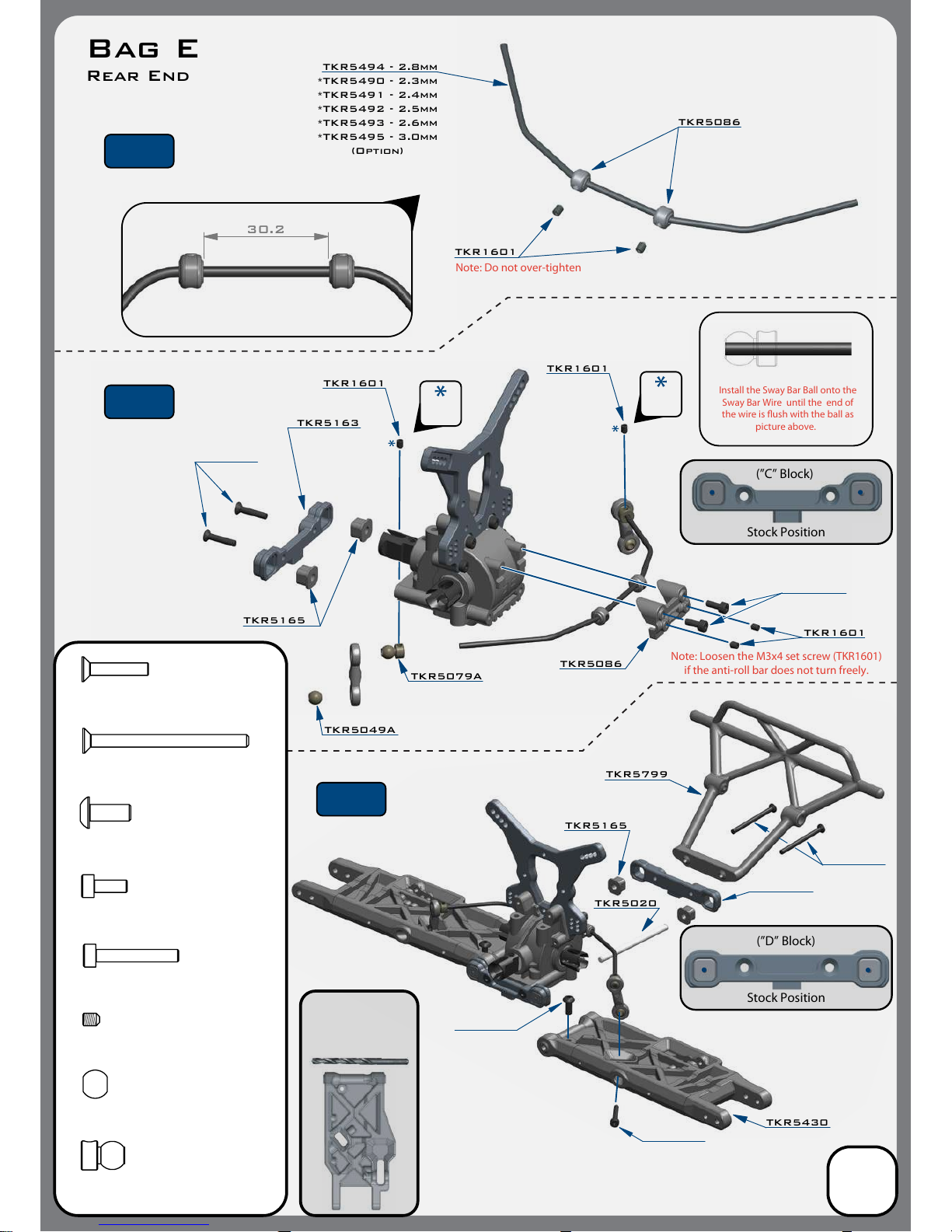

TKR1601

TKR5494 - 2.8mm

TKR5086

Note: Do not over-tighten

Stock Position

(”D” Block)

Stock Position

(”C” Block)

*TKR5490 - 2.3mm

*TKR5491 - 2.4mm

*TKR5492 - 2.5mm

*TKR5493 - 2.6mm

*TKR5495 - 3.0mm

(Option)

30.2

TKR1601

TKR1601

TKR5086

Install the Sway Bar Ball onto the

Sway Bar Wire until the end of

the wire is ush with the ball as

picture above.

Note: Loosen the M3x4 set screw (TKR1601)

if

the anti-roll bar does not

turn freely.

TKR5049A

TKR5020

TKR5163

TKR5165

TKR5799

TKR5430

TKR1601

TKR5079A

TKR5165

Bag E

Rear End

Thread

Lock

Thread

Lock

7

TKR1327

TKR1333

M3x40mm Flat Head Screw

x2

TKR1443

M4x10mm Button Head Screw

x2

TKR5049A

Pivot Ball Sway Bar

x2

TKR5079A

Stabilizer Ball

x2

TKR1522

M3x8mm Cap Head Screw

x2

TKR1529

M3x20mm Cap Head Screw

x2

TKR1327

M3x16mm Flat Head Screw

x2

TKR1333TKR1333

TKR1443

TKR1529

x6

TKR1601

M3x4mm Set Screw

Step

E-1

Step

E-2

Step

E-3

TKR5164

Use a #19 drill bit or

4mm reamer to ream

arms until hinge pin

falls through freely.

Note: With these stock

center dot settings,

Anti-Squat = 2° / Rear Toe = 3°

TKR1522

TKR5472

TKR5073

TKR5070

TKR5073

TKR5034

TKR1601

TKR1201

TKR1201

TKR5165

Grease

Step

F-1

Step

F-2

Changes to the wheelbase have a dramatic eect on handling,

since it shifts the disribution of weight over the rear wheels.

This adjusts traction. By shortening the wheelbase at the rear, you

are placing more weight over the rear wheels.

Changes to the wheelbase also change the amount of sweep the

rear driveshaft will have. More driveshaft sweep creates an eect

similar to anti-squat, where the rear end gets pushed upwards on

throttle. This helps reduce chassis slap when landing jumps on throttle.

(FRONT)

(REAR)

Bag F

Rear Hub/CVA Assembly

8

Thread

Lock

Note: Notch on pin

needs to line up

with set screw.

TKR5199

TKRBB13194

TKRBB08165

TKR5071C

*TKR5199A

*TKR5199B

(Option)

TKR1603

TKR5073

CV Joint Pin

x2

TKR1201

M3 Locknut Black

x4

TKR1603

M5x4mm Set Screw

x2

TKRBB13194

Ball Bearing (13x19x4)

x2

TKRBB08165

Ball Bearing (8x16x5)

x2

TKR5071C

M3x16.8mm Pin

x2

TKR1601

M3x4mm Set Screw

x4

Note: Below the TKR1601 set screws are meant to keep the outer hinge pins from moving. After installing the outer

hinge pins, install TKR1601 in the locations indicated. Very slowly tighten the set screws until you feel some

resistance from contacting the hinge pin. DO NOT OVERTIGHTEN. Also be sure to loosen

TKR1601 before removing the hinge pin or you may damage some parts.

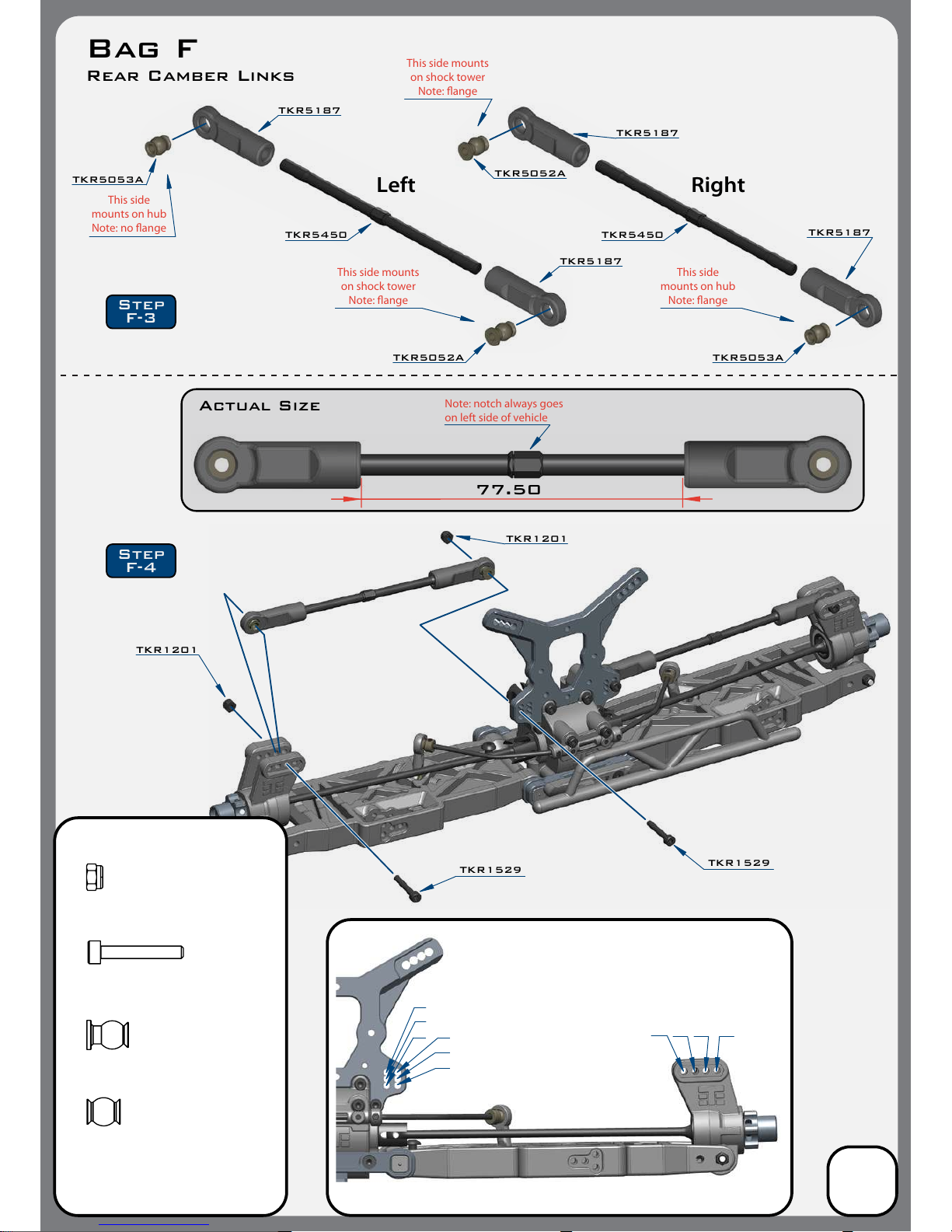

TKR5187

TKR5450

TKR5052A

This side

mounts on hub

Note: no ange

This side mounts

on shock tower

Note: ange

TKR5053A

Actual Size

77.50

Note: notch always goes

on

left side of vehicle

TKR1529

TKR1201

Right

Left

TKR1201

TKR1529

This side mounts

on shock tower

Note: ange

TKR5052A

TKR5053A

This side

mounts on hub

Note: ange

TKR5450

TKR5187

TKR5187

TKR5187

Step

F-3

Step

F-4

Bag F

Rear Camber Links

9

TKR1201

M3 Locknut Black

x4

TKR1529

M3x20mm Cap Head Screw

x4

TKR5053A

Pivot Ball M3x6.8mm

No Flange

x2

TKR5052A

Pivot Ball M3x6.8mm

x2

A

B

C

Stock position is 5/B

D

1

2

3

4

5

6

TKR1528

M3x18mm Cap Head Screw

x2

TKR1327

M3x16mm Flat Head Screw

x4

Note: “Top” side up

Step

F-5

Step

F-6

Bag F

Rear Bumper

10

TKR1327

TKR1327

TKR1327

TKR5799

TKR1327

TKR5799

TKR1528

Use a #19 drill bit or

4mm reamer to ream

arms until hinge pin

falls through freely.

Stock Position

(”B” Block)

Stock Position

(”A” Block)

30.2

TKR1601

TKR1601

TKR1601

TKR5086

TKR5483 - 2.6mm

TKR5086

Install the sway bar ball onto the

sway bar wire until the end of

the wire is ush with the ball as

picture above.

Loosen the M3x4 set screw

(TKR1601) if

the anti-roll bar

does not

turn freely.

Note: Do not over-tighten

TKR1601

TKR5165

TKR1522

TKR1522

M3x8mm Cap Head Screw

x2

Bag G

Front End

*TKR5480 - 2.3mm

*TKR5481 - 2.4mm

*TKR5482 - 2.5mm

*TKR5484 - 2.8mm

*TKR5485 - 3.0mm

(Option)

Thread

Lock

Thread

Lock

11

TKR1327

TKR1333

M3x40mm Flat Head Screw

x2

TKR1443

M4x10mm Button Head Screw

x2

TKR5049A

Pivot Ball Sway Bar

x2

TKR5079A

Stabilizer Ball

x2

TKR1529

M3x20mm Cap Head Screw

x2

TKR1327

M3x16mm Flat Head Screw

x2

TKR1333

TKR1443

TKR1529

TKR5020

TKR1601

M3x4mm Set Screw

x6

Step

G-1

Step

G-2

Step

G-3

TKR5162

TKR5161

TKR5436

TKR5056

TKR5049A

TKR5079A

TKR5165

TKR5165

Note: With these stock settings,

Kick Up = 10° / Arm Sweep = 0°

TKR1522

TKR5472

TKR5193

TKR5054A

TKR1445

TKRBB08165

TKR5194

TKR5070

TKR1447

TKR1447

TKR1601

TKR1601

TKR1601

TKRBB13194

TKR1221

TKR1401

TKR1445

TKR5054A

Spindle Pin Sleeve

x4

TKR5055A

Suspension Pin Sleeve

x4

Grease

TKR5073

TKR5073

Step

H-1

Step

H-3

Step

H-2

Thread

Lock

TKR5071C

TKR1603

TKR1445

M4x14mm Button Head Screw

x4

TKR1447

M4x16mm Button Head Screw

x4

TKR5073

CV Joint Pin

x2

TKR1603

M5x4mm Set Screw

x2

TKRBB13194

Ball Bearing (13x19x4)

x2

TKRBB08165

Ball Bearing (8x16x5)

x2

TKR5071C

M3x16.8mm Pin

x2

TKR1601

M3x4mm Set Screw

x8

TKR5055A

TKR1401

M3x6mm Button Head Screw

x2

Note: The TKR1601 set screws are meant to keep the TKR1445 screws from coming loose. After installing TKR1445

and ensuring the steering action is free, install TKR1601 in the locations indicated. Very slowly tighten the screws

until you feel some resistance from contacting the TKR1445 screws. DO NOT OVERTIGHTEN. Also be sure to loosen

TKR1601 before unscrewing TKR1445 or you will damage the screws and the parts.

Bag H

Front Spindle / CVA Assembly

12

Note: notch on pin

needs to line up

with set screw.

TKR1221

M3x8mm Washer

x8

Note: The TKR1601 set screws are meant to keep the TKR1447 screws from coming

loose. After installing TKR1447 and ensuring the steering action is free, install TKR1601

in the locations indicated. Very slowly tighten the screws until you feel some resistance

from contacting the TKR1447 screws. DO NOT OVERTIGHTEN. Also be sure to loosen

TKR1601 before unscrewing TKR1447 or you will damage the screws and the parts.

DO NOT SKIP THIS STEP!

Note: The steering stops provide adjustable

travel limiters to control overall steering throw.

We recommend at least 4 washers on each side.

With too much steering travel

the rear end will lose traction around

corners, the vehicle will be very hard to drive

and it will be more prone to breaking parts.

TKR1529

TKR1201

TKR1529

TKR1201

TKR1201

M3 Lock Nut Black

x4

TKR1529

M3x20mm Cap Head Screw

x4

TKR5052A

Pivot Ball M3x6.8mm

x2

TKR5053A

Pivot Ball M3x6.8mm

No Flange

x2

TKR5187

TKR5451

TKR5187

TKR5052A

TKR5053A

Right

TKR5187

This side

mounts on hub

Note: no ange

This side

mounts on hub

Note: no ange

This side mounts

on shock tower

Note: ange

This side mounts

on shock tower

Note: ange

TKR5187

Left

TKR5451

TKR5053A

TKR5052A

Step

H-5

Step

H-4

64.00

Note: Notch always goes

on

left side of vehicle

Actual Size

Bag H

Front Camber Links

13

Stock position is 4/A

1

2

3

4

5

6

A

B

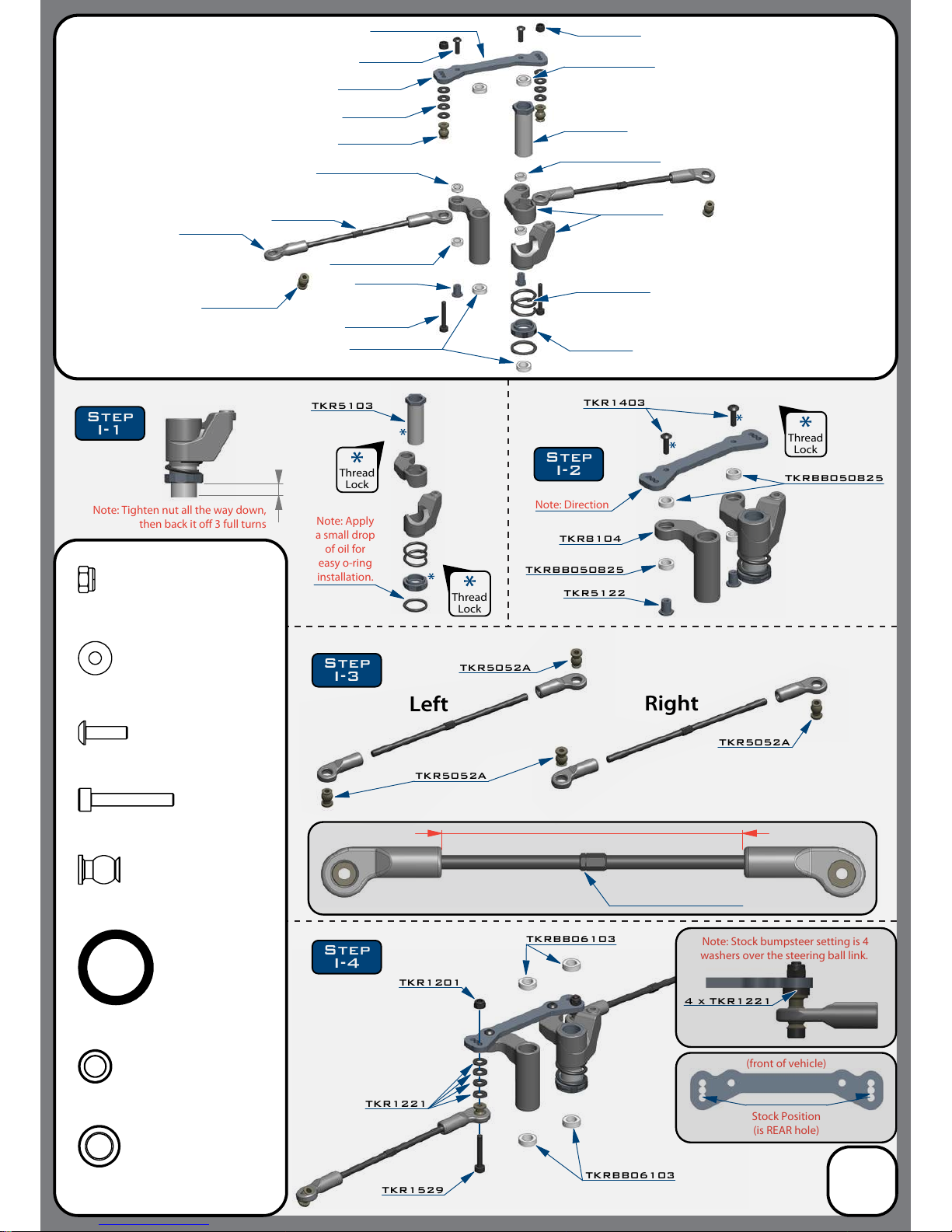

TKR1403

TKRBB050825

TKRBB050825

Note: Apply

a small drop

of oil for

easy o-ring

installation.

Note: Tighten nut all the way down,

then back it o 3 full turns

Stock Position

(is REAR hole)

(front of vehicle)

TKR8100

TKR5056

TKR5424

TKR5052A

TKR5101X

TKR5231

TKR1201

TKRBB06103

TKRBB06103

TKR1529

Note: Stock bumpsteer setting is

4

washers over the steering ball link.

4 x TKR1221

TKR1221

TKRBB06103

TKRBB050825

Note: Direction

TKR8104

TKR5122

TKR8104

TKR1529

TKR5122

TKR1221

TKR8100

TKR1403

TKR5103

TKR5103

TKR1201

TKRBB06103

TKRBB050825

TKRBB050825

TKR5052A

TKR1201

M3 Lock Nut Black

x2

O-ring 16x12x2

TKR5231

x1

TKRBB06103

Ball Bearing (6x10x3)

x4

TKRBB050825

Ball Bearing (5x8x2.5)

x4

TKR1529

M3x20mm Cap Head Screw

x2

TKR5052A

Pivot Ball M3x6.8mm

x4

TKR1221

M3x8mm Washer

x8

TKR5052A

TKR5052A

TKR5052A

Thread

Lock

Thread

Lock

Thread

Lock

Right

Left

Step

I-1

Step

I-2

Step

I-3

Step

I-4

TKR1403

M3x10mm Button Head Screw

x2

Bag I

Steering Assembly

(overview)

14

72.60

Note: Notch always

goes on

the left side of the

vehicle

Actual Size

TKR1201

TKR1443

TKR5102A

TKR1443

Note: on steps

J-1, J-2 and J-4

Do not tighten

the chassis

screws

all the way down

until the assembly

steps are complete.

Position the entire

front assembly on

the chassis and

tighten each

screw evenly.

TKR1528

TKR1443

TKR1344

TKR1343

TKR5062

Note: Initial bumpsteer setting

is 4 washers

below the steering ball link.

TKR1327

TKR1344

TKR1346

TKR8104

TKR1443

TKR5518C

TKR1529

TKR1528

M3x18mm Cap Head Screw

x2

TKR1522

M3x8mm Cap Head Screw

x1

TKR1343

M4x10mm Flat Head Screw

x2

TKR1344

M4x12mm Flat Head Screw

x4

TKR1201

M3 Lock Nut Black

x2

TKR1327

M3x16mm Flat Head Screw

x2

TKR1443

M4x10mm Button Head Screw

x5

TKR1529

M3x20mm Cap Head Screw

x2

TKR1221

M3x8mm Washer

x8

Note Step J-4:

Line up the bottom of the

steering posts (TKR5102A)

with the corresponding recess

cut in the

chassis.

Thread

Lock

Thread

Lock

Thread

Lock

Step

J-2

Step

J-4

Step

J-3

Step

J-1

TKR1522

TKR1346

M4x15mm Flat Head Screw

x2

Bag J

Front End Assembly

15

TKR8104

TKR5263

TKR1522

TKR5191

TKR1443

TKR5062

TKR1344

TKR1343 x5

TKR1445

TKR5062

TKR5076

TKR1344 x5

TKR1524

TKR1522

M3x8mm Cap Head Screw

x2

TKR1524

M3x12mm Cap Head Screw

x4

TKR1343

M4x10mm Flat Head Screw

x5

TKR1443

M4x10mm Button Head Screw

x1

TKR1445

M4x14mm Button Head Screw

x1

TKR1344

M4x12mm Flat Head Screw

x7

Thread

Lock

Thread

Lock

Step

K-1

Step

K-3

Step

K-2

Step

K-4

TKR5263

*TKR5262

(option)

*TKR5262

(option)

TKR5260

Bag K

Center/Rear

Assembly

16

TKR1211

TKR1529

TKR6007

TKR5527

TKR1212

Note: slot in spring

perch should face

outside of vehicle.

TKR1523

TKR5791

TKR6008

TKR6008

TKR6009

TKR6016

M2.5 Lock Nut Zinc

TKR1200

x2

TKR1529

M3x20mm Cap Head Screw

x2

TKR1212

M4 Lock Nut Flange

x2

TKR1211

M3 Lock Nut Flange Black

x2

TKR1200

TKR6008

TKR6017

TKR6140B

TKR5049A

*TKR6017T

(Option)

*TKR6051

(Option)

Note:

shaft guide

orientation

Note: Use green

slime or oil on

shock shaft

threads AND

O-rings to

prevent tearing

and leaking.

TKR6144

*TKR6015

(Option)

Step

L-1

Step

L-2

Step

L-4

Step

L-3

Step

L-5

Note: Shock boots

must be installed

before attaching

rod end.

Thread

Lock

(conical)

TKR6140B

TKR1605

TKR6091

*TKR6090

*TKR6092

*TKR6093

(Option)

(Option)(Option)

Bag L

Front Shock Assembly

17

Stock shock position is outside

hole on the arm and outside

hole on the tower.

Shock length (droop) is 115mm.

Ride height will vary depending

on wheels and tires used.

Start with driveshafts level.

TKR1523

M3x10mm Cap Head Screw

x1

TKR1605

M3x10mm Set Screw

x2

TKR6018

*TKR6003

*TKR6003B

(Option)

Use #700wt oil

FRONT

700

*TKR6013

(Option)

*TKR1213

(Option)

TKR6018

Note:

Make sure to tighten

both cartridge cap (TKR6008)

and shock cap (TKR6018)

to ensure a proper seal.

Tools may be required.

You MUST

drill 1-2mm

(1/16th)

hole here

for bleeder

Refer to lling

instructions on

page 19 during

this step.

TKR1211

TKR1529

TKR6007

TKR5527

TKR1212

Note: slot in spring

perch should face

outside of vehicle.

TKR1212

TKR1523

TKR5791

TKR1605

TKR6008

TKR6008

TKR6009

TKR6060

M2.5 Lock Nut Zinc

TKR1200

x2

TKR1529

M3x20mm Cap Head Screw

x2

TKR1212

M4 Lock Nut Flange

x2

TKR1211

M3 Lock Nut Flange Black

x2

TKR1200

TKR6061

*TKR6061T

(Option)

Note:

shaft guide

orientation

Note: Use green

slime or oil on

shock shaft

threads AND

O-rings to

prevent tearing

and leaking.

*TKR6015

(Option)

Step

M-5

Thread

Lock

Use #700wt oil

REAR

700

TKR6008

*TKR6051

(Option)

(conical)

TKR6140B

TKR5049A

TKR6145

Note: Shock boots

must be installed

before attaching

rod end.

*TKR6013

(Option)

*TKR1213

(Option)

TKR6018

You MUST

drill 1-2mm

(1/16th)

hole here

for bleeder

Step

M-1

Step

M-2

Step

M-4

Step

M-3

TKR6081

*TKR6080

*TKR6082

*TKR6083

(Option)

TKR6140B

Refer to lling

instructions on

page 19 during

this step.

Note:

Make sure to tighten

both cartridge cap (TKR6008)

and shock cap (TKR6018)

to ensure a proper seal.

Tools may be required.

Bag M

Rear Shock Assembly

18

Stock shock position is outside

hole on the arm and 2nd from

outside hole on the tower.

Shock length (droop) is 135mm.

Ride height will vary depending

on wheels and tires used.

Start with driveshafts level.

TKR1523

M3x10mm Cap Head Screw

x1

TKR1605

M3x10mm Set Screw

x2

19

Shock Filling Instructions

For both front and rear shocks

Step 1. Drill a small bleeder hole on the side of all 4 shock caps with a 1-2mm or 1/16” drill bit.

There’s a small dimple on the side of the shock caps over the logo to help guide the bit. Remove the

ashing leftover from drilling, insert bladder and set aside.

Step 2. Extend the shock shaft all the way down. Fill the shock with oil until the body is approximately

95% full.

Step 3. SLOWLY pump the shock shaft up and down 3-5 times to release air bubbles from

underneath the piston.

Step 4. Let the shock rest vertically with the shock shaft fully extended for approximately ve

minutes or until all of the air bubbles have released from the oil.

Step 5. Top o each shock with oil (about 1-2mm below the rim of the shock body). Add a few drops of oil

on top of each bladder inside of the caps. Put a paper towel down to catch excess oil and have another ready

to wipe the shock with. Place the cap on the shock and screw on about half way. Some oil will leak out.

Step 6. Push the shock shaft up to about 90% to set rebound. Some oil will leak out.

Step 7. While holding the shock shaft at 90%, fully tighten the shock cap.

Step

1

Step

2

Step

3

Step

4

Step

5

Step

6

Step

7

We've found it's easiest to complete steps 1 through 4 on each shock before moving onto step 5.

By the time you've nished step 4 on the last shock the rst one will be ready for step 5.

Up and down

3-5 Times

Fill with oil

Let rest about

5 minutes

Screw on cap

about half way

Push shaft up

Tighten cap

Drill with

1-2mm

(or 1/16th)

Drill Bit

AND

Insert bladder

TKR5060

TKR5065

Steering servo (not included)

TKR1525

Electronic Speed Control (not included)

double sided tape

TKR5065

TKR5125

Note: Install ESC tray on the

mudguard (do not overtighten)

.

Note: CA glue 3 black o-rings (TKR5125) to the bottom legs of the ESC tray.

TKR1322

TKR1525TKR1525

TKR5065

TKR5065

TKR5065

TKR1401

TKR1322

TKR1322

TKR1401

Receiver (not included)

TKR1401

M3x6mm Button Head Screw

x6

TKR1322

M3x8mm Flat Head Screw

x5

TKR1525

M3x14mm Cap Head Screw

x6

TKR5125

O-ring 3x7mm

x3

TKR1221

M3X8mm Washer

x4

TKR1221

TKR1221

Note: Feed the servo wire underneath the esc tray

in between the mounting screws on the mud guard,

then feed both ESC and servo wires into the RX

box as shown. I

nstall wire retainers (TKR5065)

to secure them properly.

CA

glue

Step

N-4

Step

N-3

Step

N-1

Step

N-2

Bag N

Final Assembly

20

*TKR5060C

(Option)

Hook side

Battery Strap Installation:

1. Fit straps loosely

2.

Position on chassis

3.

Proceed to step O-2

TKR1343TKR1343

TKR1341

TKR1343

TKR1322

TKR1322

M3x8mm Flat Head Screw

X6

TKR1341

M4x6mm Flat Head Screw

X6

TKR1343

M4x10mm Flat Head Screw

X5

TKR1346

M4x15mm Flat Head Screw

X2

TKR1228

M4 Countersunk Washer

X2

TKR1524

TKR5211X

Motor (not included)

Thread

Lock

Logo side

Thread

Lock

TKR1524

M3x12mm Cap Head Screw

x2

TKR1346

TKR1228

TKR1346

TKR1228

Thread

Lock

Thread

Lock

Note: Install MOD1

pinion 15t - 25t

(TKR4175-4185)

at this step.

Adjust gear mesh

and tighten screws

(TKR1346) well.

*Use thread lock.

Bag O

Final Assembly

21

Step

O-2

Step

O-3

Step

O-4

Step

O-5

Step

O-1

Bag O

Final Assembly

TKR5058A

Pivot Ball M3x5.8mm

No Flange

x2

TKR1201

M3 Lock Nut Black

x2

TKR5230

M3x18 Threaded Rod

x1

TKR5058A

TKR1325

TKR1201

TKR1221

TKR5220

TKR1221

TKR1201

TKR1407

TKR5230

TKR5056

TKR5058A

TKR5056

Note: Oset servo arm so it is parallel with the connecting arm at neutral or zero servo position.

PARALLEL

1mm

22

TKR1407

M3x16mm Button Head Screw

x1

TKR1221

M3x8mm Washer

x2

TKR1325

M3x14mm Flat Head Screw

x1

Step

O-6

Step

O-7

Step

O-8

*TKR5251B

*TKR5252B

*TKR5253B

(Option)

Insert post and

adjust height to

provide proper

body clearance

Choose the post with the oset that

matches your specic body holes

Choose the post with the angle

that matches your specic body

0mm oset 5 angled 0mm oset 15 angled

TKR1525

5mm oset 15 angled 10mm oset 15 angled

TKR1525

TKR1525

M3x14mm Cap Head Screw

x4

Bag P

Body Mounts

Front

Rear

23

Step

P-1

Step

P-2

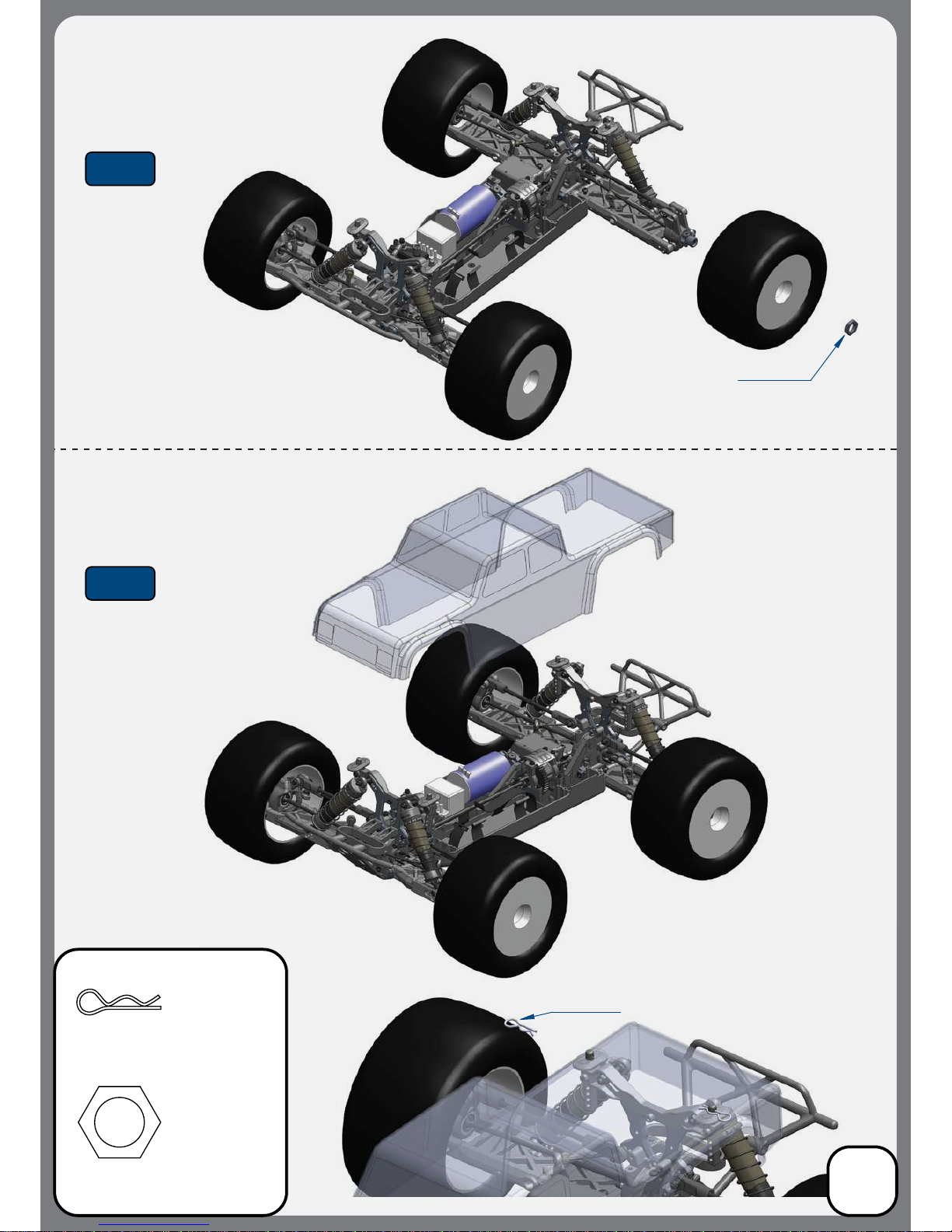

TKR5116

Wheel Nut

x4

Bag p

Wheels/Body

24

TKR1235

TKR1235

Body Clip

x4

Note: Wheels and Tires NOT INCLUDED

Note: Body NOT INCLUDED

Step

P-3

Step

P-4

TKR5116

*TKR5116B

*TKR5116C

(Option)

25

TKR5603 - MT410.3 – 1/10th Electric 4x4 Pro Monster Truck Kit

Parts List

TKR40007K - Battery Straps (2 short, 1 long)

TKR5010 - Battery Tray, Mud Guard (left side, EB48)

TKR5011 - Radio Tray, Mud Guard (right side, EB48)

TKR5012 - Gearbox (front, EB48)

TKR5016B - Gearbox (rear, angled, 5x13x4mm bearing)

TKR5020 - Hinge Pins (inner, front/rear, EB48)

TKR5028 - Shock Tower (front, 7075 NC, gun metal ano, EB48)

TKR5029 - Shock Tower (rear, 7075 NC, gun metal ano, EB48)

TKR5034 - Hinge Pins (outer, rear, EB48)

TKR5049A - Pivot Balls (6.8mm, no ng, sway bar, shck ends, almnm, 4pcs, EB48)

TKR5052A - Pivot Balls (6.8mm, inside camber, strng links, aluminum, 4pcs, EB48)

TKR5053A - Pivot Balls (6.8mm, anged, outside camber, aluminum, 4pcs, EB48)

TKR5054A - Spindle Bushings (4pcs, aluminum, hard ano, EB48)

TKR5055A - Arm Bushings (4pcs, aluminum, hard ano, EB48)

TKR5056 - Rod Ends (5.8mm, brake/steering/sway bar linkage, 8pcs, EB48)

TKR5058A - Pivot Balls (5.8mm, no ange, brake/strng link, aluminum, 4pcs, EB48)

TKR5060 - Steering Servo Brace (aluminum, gun metal ano, EB48)

TKR5062 - Chassis Brace Set (front/rear/center, EB48)

TKR5065 - ESC Tray and Radio/Battery Tray Accessories (EB48)

TKR5070 - Stub Axles (hardened steel, 2pcs, EB48)

TKR5071C - Wheel Hubs (aluminum, lightened, 2mm oset, w/pins, 2pcs, EB48)

TKR5073 - CV Rebuild kit (f/r, for 2 axles, EB48)

TKR5075 - Di Coupler (f/r, hardened steel, EB48)

TKR5076 - Driveshaft (center, rear, hardened steel, EB48)

TKR5079A - Stabilizer Balls (6.8mm, sway bars, aluminum, 4pcs, EB48)

TKR5086 - Sway Bar Mounts (EB48)

TKR5101X - Servo Saver Spring (HD, EB48, SCT410, NB48)

TKR5102A - Steering Posts (aluminum, gun metal ano, EB48)

TKR5103 - Servo Saver Post (aluminum, hard ano, EB48)

TKR5116 - Wheel Nuts (serrated, gun metal ano, 4pcs, EB48)

TKR5122 - Steering Rack Bushings (aluminum, gun metal ano, 2pcs)

TKR5125 - O-Ring (ESC tray, 3pcs)

TKR5126 - Antenna tube (universal, w/ caps, 5pcs)

TKR5161 - V2 Adjustable Hinge Pin Brace ("A" block, 7075 CNC aluminum, EB/NB/ET/NT/SCT)

TKR5162 - V2 Adjustable Hinge Pin Brace ("B" block, 7075 CNC aluminum, EB/NB/ET/NT/SCT)

TKR5163 - V2 Adjustable Hinge Pin Brace ("C" block, 7075 CNC aluminum, EB/NB/ET/NT/SCT)

TKR5164 - V2 Adjustable Hinge Pin Brace ("D" block, 7075 CNC aluminum, EB/NB/ET/NT/SCT)

TKR5165 - V2 Hinge Pin Inserts, Wheelbase Shims (EB/NB/ET/NT/SCT)

TKR5187 - Rod Ends (straight, 6.8mm, EB/NB/ET/NT48, 8pcs)

TKR5191 - Tapered Driveshaft (center, front, 7075 aluminum, black ano, EB48/ET48)

TKR5193 - Spindles (trailing, L/R, requires TKR5194, EB/NB/ET/NT48, EB/NB.3)

TKR5194 - Spindle Carriers (trailing, 15 degree, L/R, EB/NB/ET/NT48, EB/NB.3)

TKR5199 - Rear Hubs (L/R, CV or uni, EB/NB/ET/NT48, EB/NB.3)

TKR5211X - Motor Mount Insert (aluminum, gun metal anodized, lightened)

TKR5220 - Servo Horns (steering, brakes)

TKR5230 - Steering linkage (M3x18mm threaded rod, 10pcs)

TKR5231 - Servo Saver Nut and Spring

TKR5260 - CNC Split Cntr Di Mount (mtr mnt only, 7075, gun metal ano, EB/ET/SCT)

TKR5263 - Split Cntr Di Mount (composite, requires TKR5260, EB/ET/SCT/SL)

TKR5288 - Chassis (7075, black anodized, lightened)

TKR5424 - Turnbuckle (steering links, 2pcs, MT410)

TKR5430 - Suspension Arms (rear, 2pcs, ET48, NT48)

TKR5436 - Suspension Arms (front, 2pcs, ET48, NT48)

TKR5450 - Turnbuckle (camber link, rear, 2pcs, ET48, NT48)

TKR5451 - Turnbuckle (camber link, front, 2pcs, ET48, NT48)

TKR5472 - Driveshafts (f/r, hardened steel, 2pcs, ET48, NT48)

TKR5483 - Sway Bar (front, 2.6mm, ET48, NT48)

TKR5494 - Sway Bar (rear, 2.8mm, ET48, NT48)

TKR5518C - Front Bumper Set (SCT410, revised w/ skid)

TKR5527 - Shock Standos (SCT410, 2pcs)

TKR5791 - Body Mount Set (front, rear, SCT410)

TKR5799 - Rear Bumper Set (SCT410)

TKR8100 - Ackerman Plate (aluminum, gun metal ano, EB48)

TKR8104 - Steering Bell Cranks, Steering/Center Di Top Plate

Dierential List

TKR5113 - Dierential Case (f/c/r)

TKR5114XB - Dierential Outdrives (f/r, lightened, revised)

TKR5143 - Dierential Seals (3pcs)

TKR5144 - Dierential O-Rings (6pcs)

TKR5145B - Dierential Shims (6x17x.3mm, 6pcs, revised)

TKR5149 - Dierential Cross Pins (6pcs, requires TKR5150)

TKR5150 - Dierential Gear Set (internal gears only)

TKR5237K - Spur Gear (44t, black, composite, EB48)

TKR5403 - Dierential Ring Gear (40t, NT48 fr, ET48 fr/rr)

TKR5405 - Di Pinion (straight cut, 9t, CNC, ET48/NT48)

Shocks List

TKR6007 - Shock Cap Bushings (4pcs, EB/NB/ET/NT/SCT)

TKR6008 - Shock Shaft Guide, Piston, and Bushing Set (for 2 shocks)

TKR6009 - Shock O-Ring and Bladder Set (for 2 shocks)

TKR6016 - Shock Body (rear, aluminum, hard ano, 2pcs)

TKR6017 - Shock Shafts (rear, steel, 2pcs)

TKR6018 - Shock Cap and Spring Adjuster Set (composite, for 2 shocks)

TKR6060 - Shock Body (rear, x-long, aluminum, hard ano, 2pcs)

TKR6061 - Shock Shafts (rear, x-long, steel, 2pcs)

TKR6081 - Shock Spring Set (1.6 x 10.0T, 95mm, green, 4.20 lb/in)

TKR6091 - Shock Spring Set (1.6 x 8.5T, 80mm, green, 5.17 lb/in)

TKR6140B - Locking Shock Rod End and Spring Perch Set (revised, 16mm shocks)

TKR6144 - Shock Boots (long length, rear EB/NB/SCT, front ET/NT, 2pcs)

TKR6145 - Shock Boots (XL length, rear ET/NT, 2pcs)

Bearings List

TKRBB050825 - Ball Bearing (5x8x2.5mm, 4pcs)

TKRBB05114 - Ball Bearing (5x11x4, 4pcs)

TKRBB05134 - Ball Bearing (5x13x4, 4pcs)

TKRBB06103 - Ball Bearing (6x10x3, 4pcs)

TKRBB08165 - Ball Bearing (8x16x5, 4pcs)

TKRBB13194 - Ball Bearing (13x19x4, 4pcs)

Hardware List

TKR1200 - M2.5 Locknuts (zinc nish, 10pcs)

TKR1201 - M3 Locknuts (black, 10pcs)

TKR1211 - M3 Locknuts (anged, black, 10pcs)

TKR1212 - M4 Locknuts (anged, black, 10pcs)

TKR1220 - M3 Countersunk Washers (aluminum, natural, 10pcs)

TKR1221 - M3x8mm Washer (black, 10pcs)

TKR1222 - 13x16x.1mm Di Shims (10pcs)

TKR1226 - 5x7x.2mm shims (10pcs)

TKR1228 - M4 Countersunk Washers (black anodized, 10pcs)

TKR1235 - Body Clips (angled, 10pcs)

TKR1322 - M3x8mm Flat Head Screws (black, 10pcs)

TKR1325 - M3x14mm Flat Head Screws (black, 10pcs)

TKR1327 - M3x16mm Flat Head Screws (black, 10pcs)

TKR1333 - M3x40mm Flat Head Screws (black, 10pcs)

TKR1341 - M4x6mm Flat Head Screws (black, 10pcs)

TKR1343 - M4x10mm Flat Head Screws (black, 10pcs)

TKR1344 - M4x12mm Flat Head Screws (black, 10pcs)

TKR1346 - M4x15mm Flat Head Screws (black, 10pcs)

TKR1401 - M3x6mm Button Head Screws (black, 10pcs)

TKR1403 - M3x10mm Button Head Screws (black, 10pcs)

TKR1407 - M3x16mm Button Head Screws (black, 10pcs)

TKR1443 - M4x10mm Button Head Screws (black, 10pcs)

TKR1445 - M4x14mm Button Head Screws (black, 10pcs)

TKR1447 - M4x16mm Button Head Screws (black, 10pcs)

TKR1522 - M3x8mm Cap Head Screws (black, 10pcs)

TKR1523 - M3x10mm Cap Head Screws (black, 10pcs)

TKR1524 - M3x12mm Cap Head Screws (black, 10pcs)

TKR1525 - M3x14mm Cap Head Screws (black, 10pcs)

TKR1528 - M3x18mm Cap Head Screws (black, 10pcs)

TKR1529 - M3x20mm Cap Head Screws (black, 10pcs)

TKR1601 - M3x4mm Set Screws (black, 10pcs)

TKR1603 - M5x4mm Set Screws (black, 10pcs)

TKR1605 - Mx10mm Set Screws (black, 10pcs)

Option Parts

TKR1103 - Turnbuckle Wrench (4mm, 5mm, hardened steel)

TKR1104 - XT Hex Wrench (1.5mm, adjustable length, 4mm shank)

TKR1105 - XT Hex Wrench (2.0mm, adjustable length, 4mm shank)

TKR1106 - XT Hex Wrench (2.5mm, adjustable length, 4mm shank)

TKR1107 - XT Nut Driver (5.0mm, adjustable length, 4mm shank)

TKR1108 - XT Nut Driver (5.5mm, adjustable length, 4mm shank)

TKR1109 - XT Nut Driver (7.0mm, adjustable length, 4mm shank)

TKR1110 - XT Nut Driver (8.0mm, adjustable length, 4mm shank)

TKR1115 - Pivot Ball and Shock Multi-tool (aluminum)

TKR1119 - Wrench (5.5mm, 7.0mm, hardened steel)

TKR1125 - XT Hex Wrench (2.0mm ball end, adjustable length, 4mm shank)

TKR1126 - XT Hex Wrench (2.5mm ball end, adjustable length, 4mm shank)

TKR1213 - M4 Locknuts (aluminum, anged, gun metal ano, serrated, 4pcs)

TKR5060C - Steering Servo Brace (carbon ber, EB48)

TKR5070A - Stub Axles (7075 aluminum, hard ano, 2pcs)

TKR5115 - Spur Gear (44t, hardened steel, lightened, EB48)

TKR5116B - Wheel Nuts (T Logo, 17mm, serrated, gun metal ano, M12x1.0, 4pcs)

TKR5116C - Wheel Nuts (Star Logo, 17mm, serrated, gun metal ano, M12x1.0, 4pcs)

TKR5119 - Spur Gear (46t, hardened steel)

TKR5147 - Complete Center Dierential (w/ plastic spur)

TKR5149A - Dierential Cross Pins (aluminum, 6pcs, requires TKR5150)

TKR5199A - Aluminum Rear Hubs (gun metal ano, EB/NB/ET/NT, 2pcs)

TKR5237 - Spur Gear (44t, composite, EB48)

TKR5251B - Aluminum Servo Horn (23t spline, M3 clamp, double hole arm)

TKR5252B - Aluminum Servo Horn (24t spline, M3 clamp, double hole arm)

TKR5253B - Aluminum Servo Horn (25t spline, M3 clamp, double hole arm)

TKR5261 - CNC Split Cntr Di Mnt (complete, 7075, gun metal ano, EB/ET/SCT)

TKR5262 - CNC Split Cntr Di Mount (di mounts only, 7075, gun metal ano, EB/ET/SCT)

TKR5433 - Rear Arm Mud Guards (ET48, NT48)

TKR5446 - Complete F/R Dierential (ET48 fr/rr, NT48 front only)

TKR5480 - Sway Bar (front, 2.3mm, ET48, NT48)

TKR5481 - Sway Bar (front, 2.4mm, ET48, NT48)

TKR5482 - Sway Bar (front, 2.5mm, ET48, NT48)

TKR5484 - Sway Bar (front, 2.8mm, ET48, NT48)

TKR5485 - Sway Bar (front, 3.0mm, ET48, NT48)

TKR5490 - Sway Bar (rear, 2.3mm, ET48, NT48)

TKR5491 - Sway Bar (rear, 2.4mm, ET48, NT48)

TKR5492 - Sway Bar (rear, 2.5mm, ET48, NT48)

TKR5493 - Sway Bar (rear, 2.6mm, ET48, NT48)

TKR5495 - Sway Bar (rear, 3.0mm, ET48, NT48)

TKR5496 - Sway Bar (rear, 2.1mm, EB.3/NB.3/SL/SCT.3, ET48, NT48)

TKR5497 - Sway Bar (rear, 2.2mm, EB.3/NB.3/SL/SCT.3, ET48, NT48)

TKR5498 - Sway Bar (rear, 2.7mm, EB.3/NB.3/SL/SCT.3, ET48, NT48)

TKR5499 - Sway Bar (rear, 2.9mm, EB.3/NB.3/SL/SCT.3, ET48, NT48)

TKR6003B - Shock Caps (aluminum, non-vented top, 2pcs)

TKR6009B - Shock O-Ring Set (16pcs)

TKR6015 - Shock Cartridge Caps (aluminum, gun metal ano, 2pcs, EB48)

TKR6017T - Shock Shafts w/ TiNi coating (rear, steel, 2pcs, EB48)

TKR6051 - Shock Pistons (CNC, conical, 8×1.3)

TKR6061T - Shock Shafts w/ TiNi coating (rear, x-long, steel, 2pcs)

TKR6080 - Shock Spring Set (1.6 x 10.5T, 95mm, pink, 3.96 lb/in)

TKR6082 - Shock Spring Set (1.6 x 9.5T, 95mm, yellow, 4.48 lb/in)

TKR6083 - Shock Spring Set (1.6 x 9.0T, 95mm, orange, 4.80 lb/in)

TKR6090 - Shock Spring Set (1.6 x 9.0T, 80mm, pink, 4.80 lb/in)

TKR6092 - Shock Spring Set (1.6 x 8.0T, 80mm, yellow, 5.60 lb/in)

TKR6093 - Shock Spring Set (1.6 x 7.5T, 80mm, orange, 6.11 lb/in)

TKR6146 - Shock Cartridge Set (CNC, Delrin, EB/NB/ET/NT/SCT)

TKR6152 - Full Option Shock Kit (122mm, no springs, no pistons)

TKR6153 - Full Option Shock Kit (137mm, no springs, no pistons)

TKR6160 - Shock Piston Blanks (CNC, at/tapered, 16 dimples)

TKR6162 - Shock Pistons (CNC, at/tapered, 3×2.1, 10.4mm2, 4pcs)

Tekno RC

10755 Scripps Poway Pkwy #598

San Diego CA 92131

USA

Loading...

Loading...