Introduction

Additional equipment and parts needed:

•

2 Channel radio and receiver

•

1/10th scale ESC

•

Motors: 540 size 6.5-8.5 turn OR 540 size 4-pole 4000-4600kv (550 size motors not recommended)

•

Standard size high torque steering servo (at least 200 oz/in)

* Running less than the recommended rating will increase the chance of premature servo failure.

•

2S (2 cell, 7.4v) shorty LiPo battery, 5000 mAh or higher recommended

•

Paint for body and CA Glue for wheels/tires

•

1/10th scale Associated oset stadium truck OR Traxxas Slash SC oset wheels & tires

(Losi oset is NOT COMPATIBLE)

•

32 pitch pinion 10 tooth - 25 tooth (see gearing recommendations on page 20 or 26 for more guidance)

Tools needed:

•

Hex drivers 1.5mm (TKR1104), 2.0mm (TKR1105), 2.5mm (TKR1106)

•

Nut drivers 5.5mm (TKR1108), 7.0mm (TKR1109)

•

Hobby knife

•

Needle-nose pliers

•

Shock tool (TKR1115) OR adjustable (Crescent) wrench (for shock assembly)

•

4mm turnbuckle wrench (TKR1103) AND 5.5/7.0 two sided wrench (TKR1119)

•

1/16th (or 1.6mm) drill bit for shock cap emulsion hole

•

Body reamer

Disclaimer: Tekno RC is not responsible or liable for any property or personal damage, loss, or injury incurred as a

result of using this product. This kit is meant for use by persons 14 years of age or older and in the strict connes of

a legally permitted RC track or facility.

Warnings: Always double-check that your radio gear is working properly before operating vehicle. Never operate the

vehicle indoors (unless the RC track is an indoor facility). Use caution while operating vehicle so as not to collide with

people who may be turn marshalling or who might otherwise not be aware that a fast moving RC vehicle is in the vicinity.

Warranty: We warrant that the parts included in this kit are free from defects. If you nd a defective part in your kit,

please contact us @ info@teknorc.com and we will help you to resolve the issue. We do not warranty parts that may be

broken during operation of the vehicle or otherwise. Refer to the end of this instruction manual for a listing of

spare/replacement and option parts. All spare parts and other info are available on our website (www.teknorc.com)

and through our network of domestic and international dealers and distributors.

Thank you for purchasing the Tekno RC ET410 1/10th Scale 4WD Competition Electric Truggy kit.

We are always working on new projects, so please check our website regularly at www.teknorc.com

or visit us on Facebook at www.facebook.com/teknorc for all the latest news, parts, and kits.

Take your time! When you work your way through these building instructions, keep an eye out

for the following important indicators below:

•

RED TEXT - This indicates important areas of the build process that should be observed.

•

YOUTUBE - We also have many useful build videos on Youtube, so be sure to check these out!

https://www.youtube.com/c/teknorc

Thread Lock icons

Thread lock is always used when a screw is inserted into any metal part. (Included with kit)

Thread

Lock

Grease icons

Grease is usually used on areas with movement and for sealing. (Included with kit)

Grease

TKR6517

TKR5144

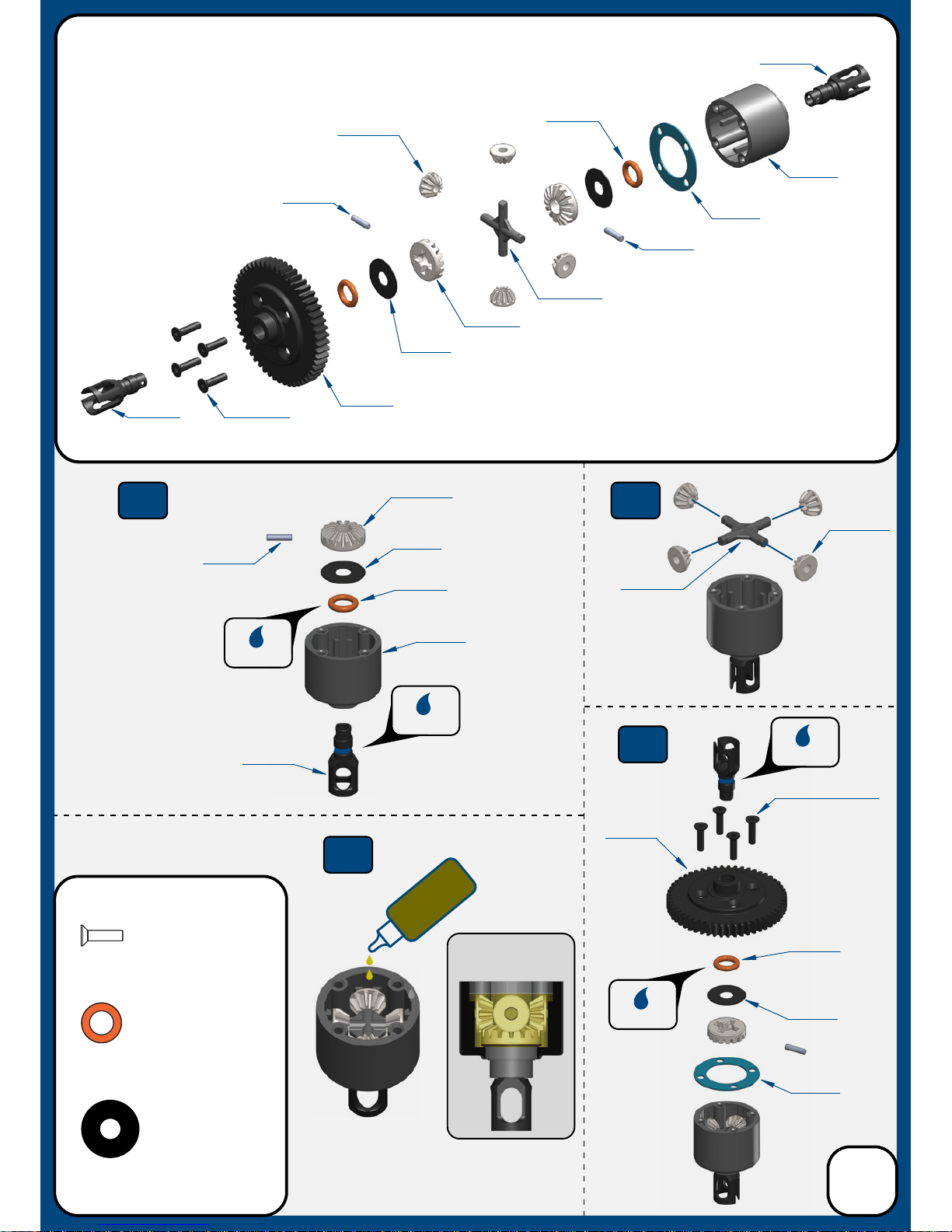

Bag A

Center Dierential

(overview)

TKR7253

TKR6513X

TKR6550

TKR6550

TKR6515

TKR6511

TKR5144

TKR6517

TKR6515

Step

A-2

Step

A-4

Fill Level

Step

A-3

Step

A-1

TKR5144

Dierential 0-rings

x2

TKR6517

Dierential Shims (5x14mm)

x2

TKR1303

M2.5x10mm Flat Head Screw

x4

TKR1303 x4

TKR5113

TKR6550

TKR6513X

Di

Oil

TKR7253

TKR6514

TKR6514

TKR6514

TKR6514

TKR6517

TKR6550

TKR5144

TKR1303 x4

3

Grease

Grease

Grease

Grease

Fill with #30,000 CST oil to

1mm below full

DO NOT OVER FILL

Note: Apply grease to the

groove in the outdrive.

Note: These screws

only need to be snug.

Do not over-tighten

or the internal gears

may bind up.

Note: Apply grease to the

recess inside TKR5113,

where the o-ring is placed

as well as the o-ring itself.

TKR6514

TKR6514

Bag B

Front and Rear Dierential

(overview)

TKR7221

TKR6513X

TKR6550

TKR6515

TKR6511

TKR5144

TKR6517

TKR1303 x4

TKR6514

TKR6514

TKR6515

TKR5144

TKR1303 x4

4

Grease

Step

B-1

Step

B-2

Repeat for rear di

Fill Level

Di

Oil

Step

B-3

Step

B-4

Repeat for rear di

TKR5144

Dierential 0-rings

x4

TKR6517

Dierential Shims (5x14mm)

x4

TKR1303

M2.5x10mm Flat Head Screw

x8

Grease

TKR6513X

Repeat for rear di

Fill FRONT with #30,000 CST oil

Fill REAR with #10,000 CST oil

to 1mm below full

DO NOT OVER FILL

Repeat for rear di

TKR6517

TKR5144

Grease

Grease

TKR6550

TKR6514

TKR6514

TKR7221

TKR6514

TKR6514

Note: Apply grease to the

groove in the outdrive.

TKR6550

TKR6517

TKR6550

TKR5113

Note: Apply grease to the

recess inside TKR5113,

where the o-ring is placed

as well as the o-ring itself.

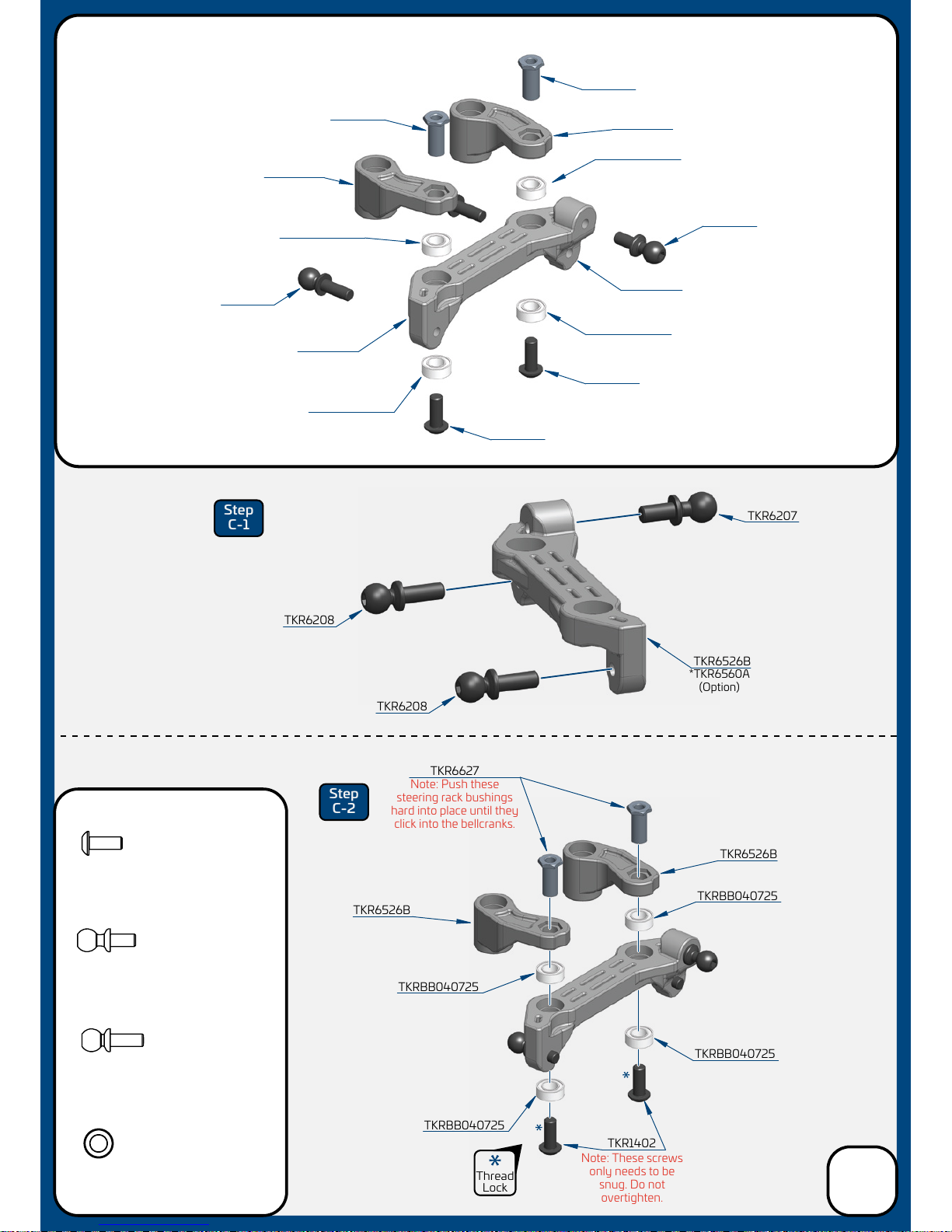

TKR6627

TKR6627

TKR6627

TKR1402

TKR1402

TKR1402

TKR6526B

TKR6526B

TKR6207

TKR6207

TKRBB040725

TKRBB040725

TKR6526B

TKR6526B

TKR6208

TKR6208

TKR6208

TKRBB040725

TKRBB040725

TKRBB040725

TKRBB040725

TKRBB040725

TKRBB040725

TKR6526B

TKR6526B

TKR6526B

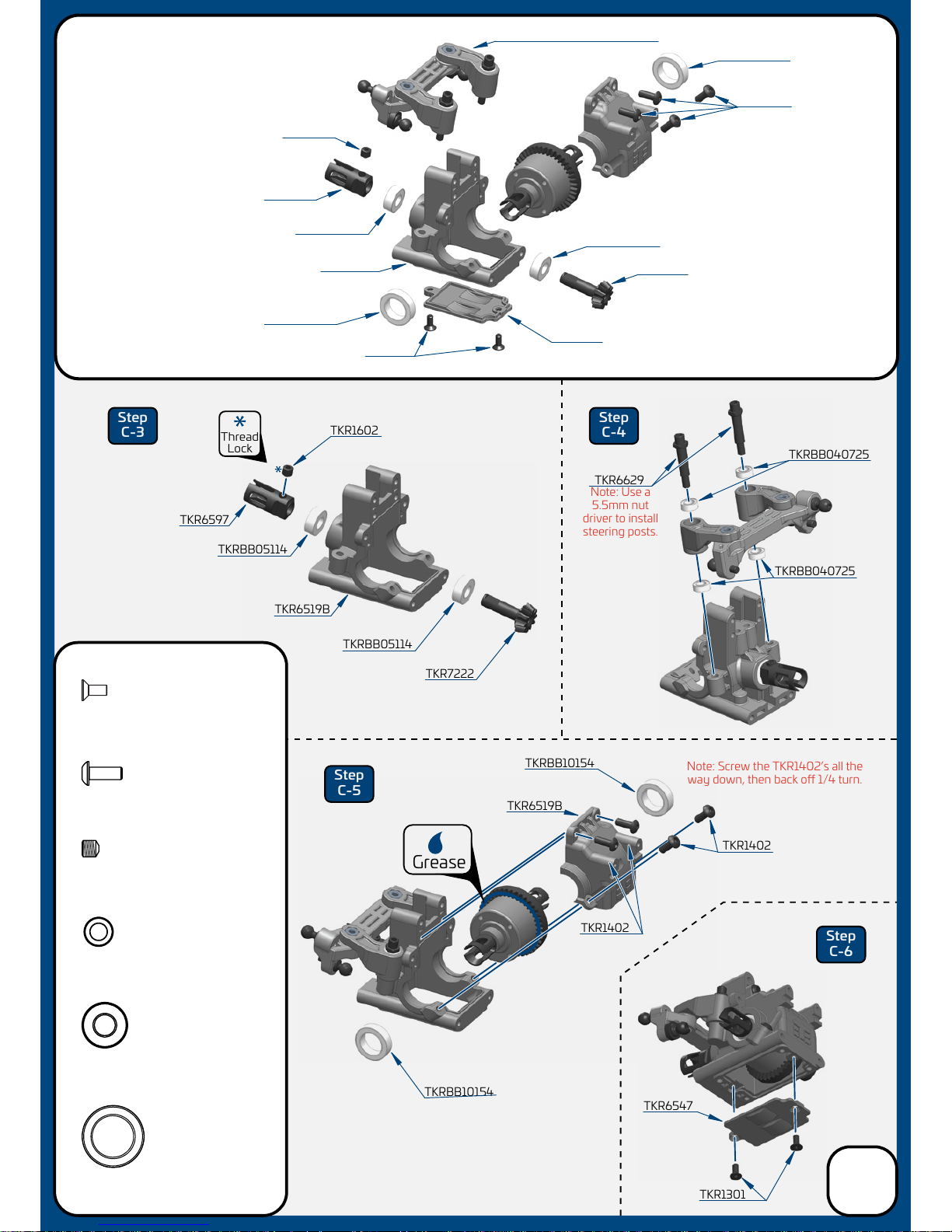

Step

C-1

Step

C-2

TKRBB040725

Ball Bearing (4x7x2.5)

x4

Thread

Lock

TKR6207

M3x6mm Ball Stud

x1

TKR6208

M3x8mm Ball Stud

x2

TKR1402

M3x8mm Button Head Screw

x2

Note: These screws

only needs to be

snug. Do not

overtighten.

Note: Push these

steering rack bushings

hard into place until they

click into the bellcranks.

*TKR6560A

(Option)

*TKR6560A

(Option)

Bag C

Steering Assembly

(overview)

5

TKR1301

TKRBB10154

TKRBB10154

TKR1602

TKRBB10154

TKRBB10154

TKR6519B

TKR1301

TKRBB05114

TKR6629

TKR7222

TKRBB05114

TKRBB05114

TKRBB05114

TKR7222

TKR6547

TKR6519B

TKR6597

TKR6547

TKRBB05114

Ball Bearing (5x11x4)

x2

TKR1602

TKR6597

(assembly from previous page)

Step

C-3

Step

C-4

Step

C-5

Step

C-6

TKR1301

M2.5x6mm Flat Head Screw

x2

TKR1402

M3x8mm Button Head Screw

x4

TKR1602

M4x4mm Set Screw

x1

TKRBB10154

Ball Bearing (10x15x4)

x2

TKRBB040725

Ball Bearing (4x7x2.5)

x4

TKRBB040725

TKRBB040725

TKR1402

Thread

Lock

Grease

TKR6519B

TKR1402

TKR1402

Note: Use a

5.5mm nut

driver to install

steering posts.

Note: Screw the TKR1402’s all the

way down, then back o 1/4 turn.

Bag C

Front Bulkhead Assembly

(overview)

6

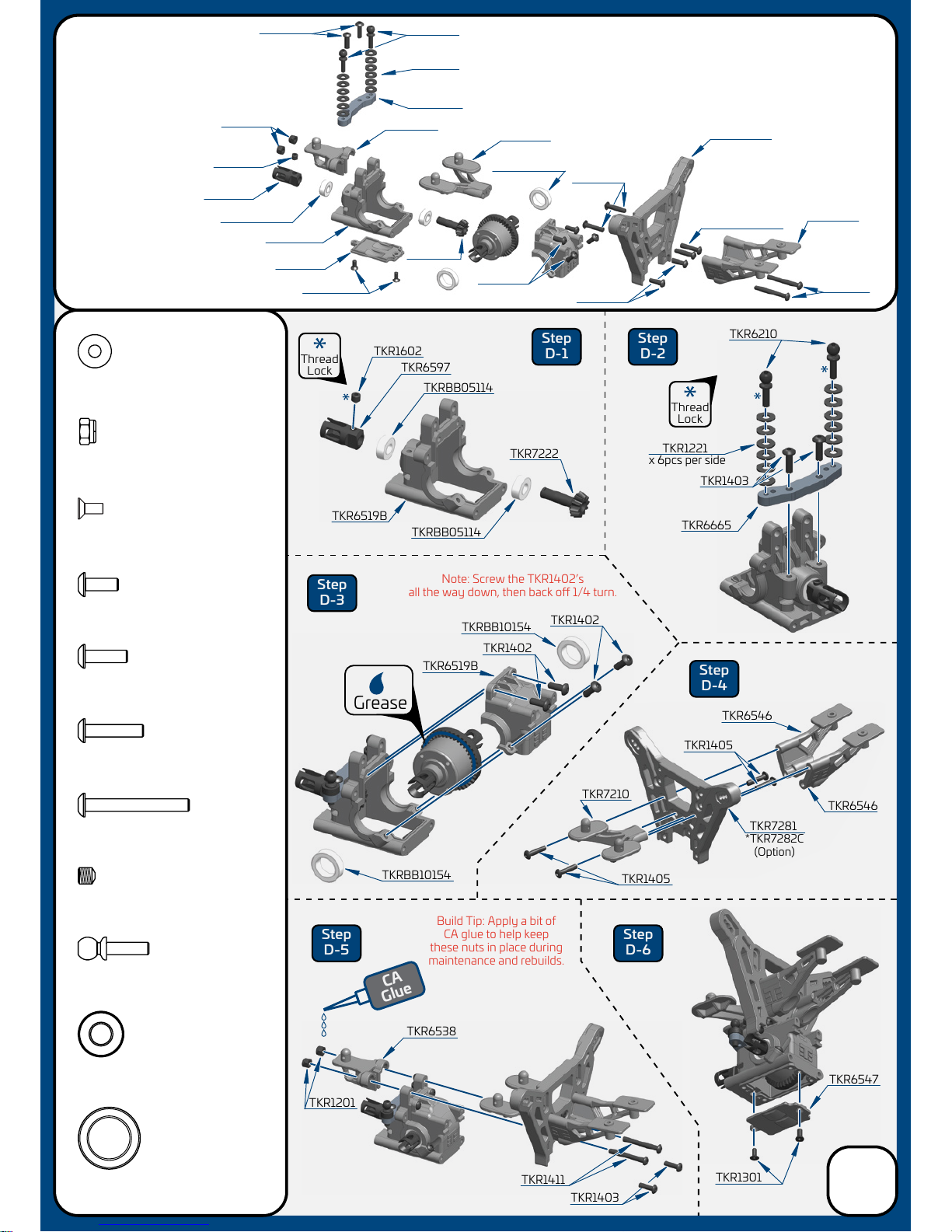

Step

D-1

Step

D-2

Step

D-3

Step

D-4

Step

D-5

Step

D-6

TKRBB05114

Ball Bearing (5x11x4)

x2

TKR1201

M3 Locknut Black

x2

TKR1301

M2.5x6mm Flat Head Screw

x2

TKR1402

M3x8mm Button Head Screw

x4

TKR1403

M3x10mm Button Head Screw

x4

TKR1405

M3x14mm Button Head Screw

x4

TKR1411

M3x25mm Button Head Screw

x2

TKR1602

M4x4mm Set Screw

x1

TKRBB10154

Ball Bearing (10x15x4)

x2

TKR6210

M3x10mm Ball Stud

x2

CA

Glue

TKR1221

M3x8mm Washer

x12

Bag D

Rear Bulkhead/

Wing Mount

Assembly

(overview)

Thread

Lock

Thread

Lock

TKR6210

TKR6538

TKR7210

TKR7281

TKR6546

TKR1405x2pcs

TKR1201

TKR1602

TKR6597

TKR1403

TKR1411

TKR1221

TKR6547

TKR6519B

TKRBB05114

TKR7222

TKRBB05114

TKR6597

TKR1602

TKRBB05114

TKR7222

TKR6665

TKR1221

TKR6665

TKR1405

TKR6210

TKR1403

TKR1403

TKR6519B

TKR6519B

TKRBB10154

TKRBB10154

TKR1402

TKR1402

TKR7281

TKR7210

TKR6547

TKR6546

TKR6538

TKR6546

TKR1405

TKR1403

TKR1405

TKRBB10154

TKR1301

TKR1301

TKR1411

TKR1402

4pcs

x 6pcs per side

Grease

*TKR7282C

(Option)

*TKR7282C

(Option)

TKR1201

Build Tip: Apply a bit of

CA glue to help keep

these nuts in place during

maintenance and rebuilds.

Note: Screw the TKR1402’s

all the way down, then back o 1/4 turn.

7

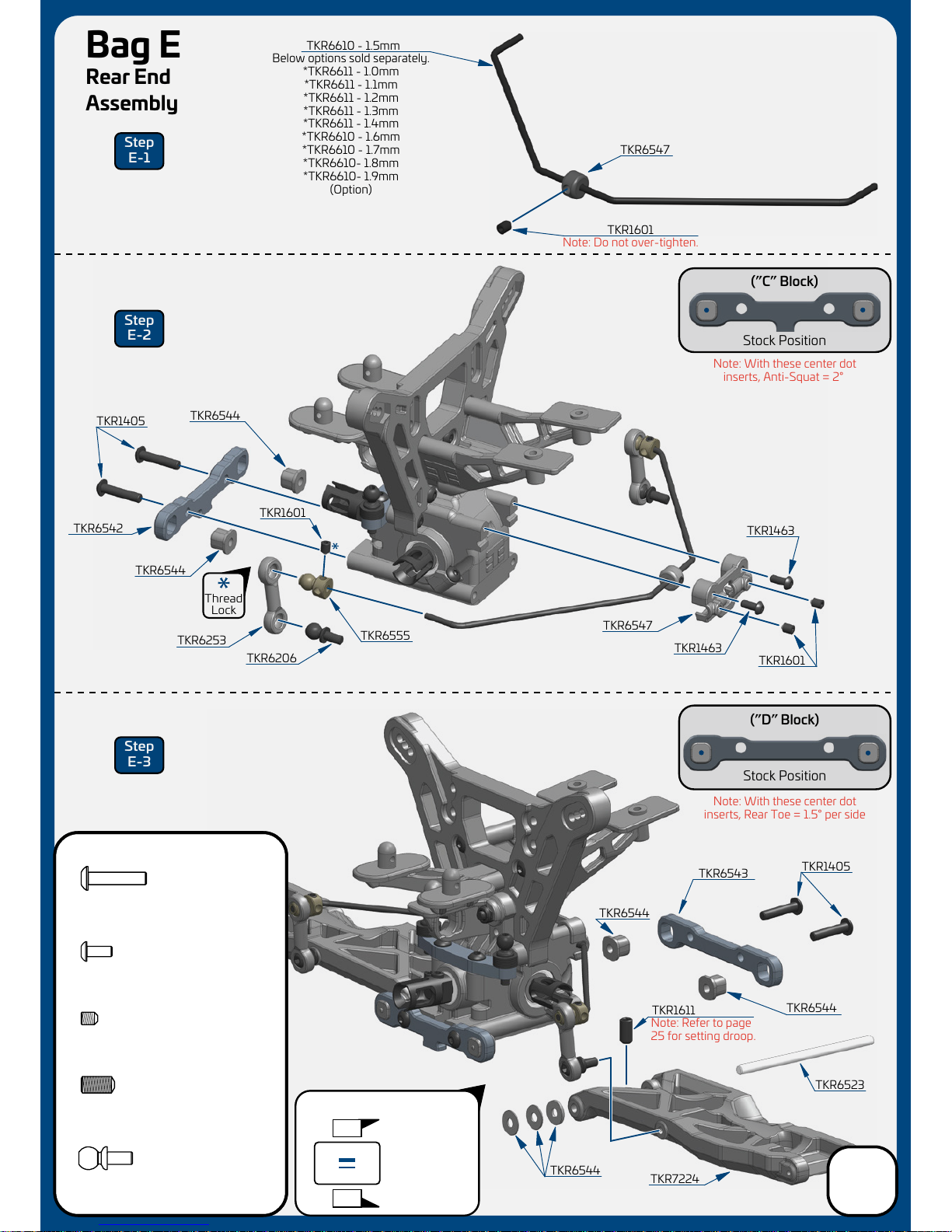

Stock Position

(”D” Block)

Stock Position

(”C” Block)

TKR1601

TKR7224

TKR6610 - 1.5mm

TKR6547

Note: With these center dot

inserts, Rear Toe = 1.5° per side

Note: Refer to page

25 for setting droop.

Note: With these center dot

inserts, Anti-Squat = 2°

Note: Do not over-tighten.

TKR6544

TKR6544

TKR6547

TKR6542

TKR1601

TKR6544

TKR1463

TKR6544

TKR6544

Bag E

Rear End

Assembly

Below options sold separately.

*TKR6611 - 1.0mm

*TKR6611 - 1.1mm

*TKR6611 - 1.2mm

*TKR6611 - 1.3mm

*TKR6611 - 1.4mm

*TKR6610 - 1.6mm

*TKR6610 - 1.7mm

*TKR6610- 1.8mm

*TKR6610- 1.9mm

(Option)

Thread

Lock

TKR1405

TKR1405

TKR6523

TKR6543

TKR1601

TKR6555

TKR6206

TKR6253

TKR1611

x5

TKR1601

M3x4mm Set Screw

Step

E-1

Step

E-2

Step

E-3

TKR1405

M3x14mm Button Head Screw

x4

TKR1463

M2.5x6mm Button Head Screw

x2

TKR1611

M4x8mm Set Screw

x2

TKR6206

M3x6mm Ball Stud

x2

TKR1463

8

all shims

go toward

the front

Wheelbase Shims

2mm

0mm

large 1mm

front

rear

small .5mm

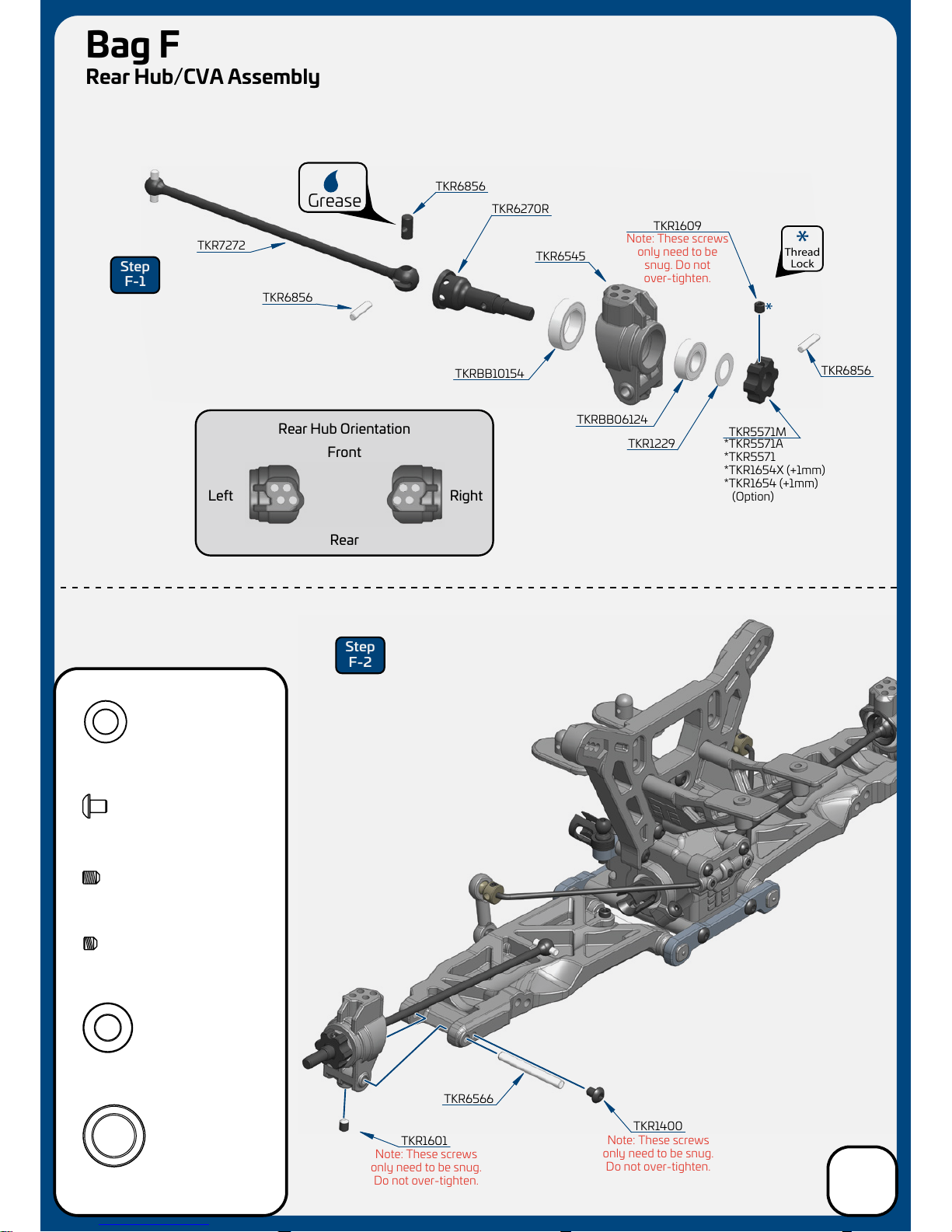

TKR6856

TKR6856

TKR6270R

TKR6545

TKRBB10154

TKRBB06124

TKR5571M

TKR1609

TKR1229

TKR7272

TKR6856

TKRBB10154

Ball Bearing (10x15x4)

x2

*TKR5571A

*TKR5571

*TKR1654X (+1mm)

*TKR1654 (+1mm)

(Option)

Note: These screws

only need to be

snug. Do not

over-tighten.

TKR1229

6x10x0.2mm Shim

x2

x2

TKR1601

M3x4mm Set Screw

TKR1609

M3x3mm Set Screw

x2

Step

F-1

Step

F-2

TKRBB06124

Ball Bearing (6x12x4)

x2

Grease

TKR1400

M3x4mm Button Head Screw

x2

Thread

Lock

TKR1601

TKR1400

TKR6566

Note: These screws

only need to be snug.

Do not over-tighten.

Note: These screws

only need to be snug.

Do not over-tighten.

Rear Hub Orientation

RightLeft

Rear

Front

Bag F

Rear Hub/CVA Assembly

9

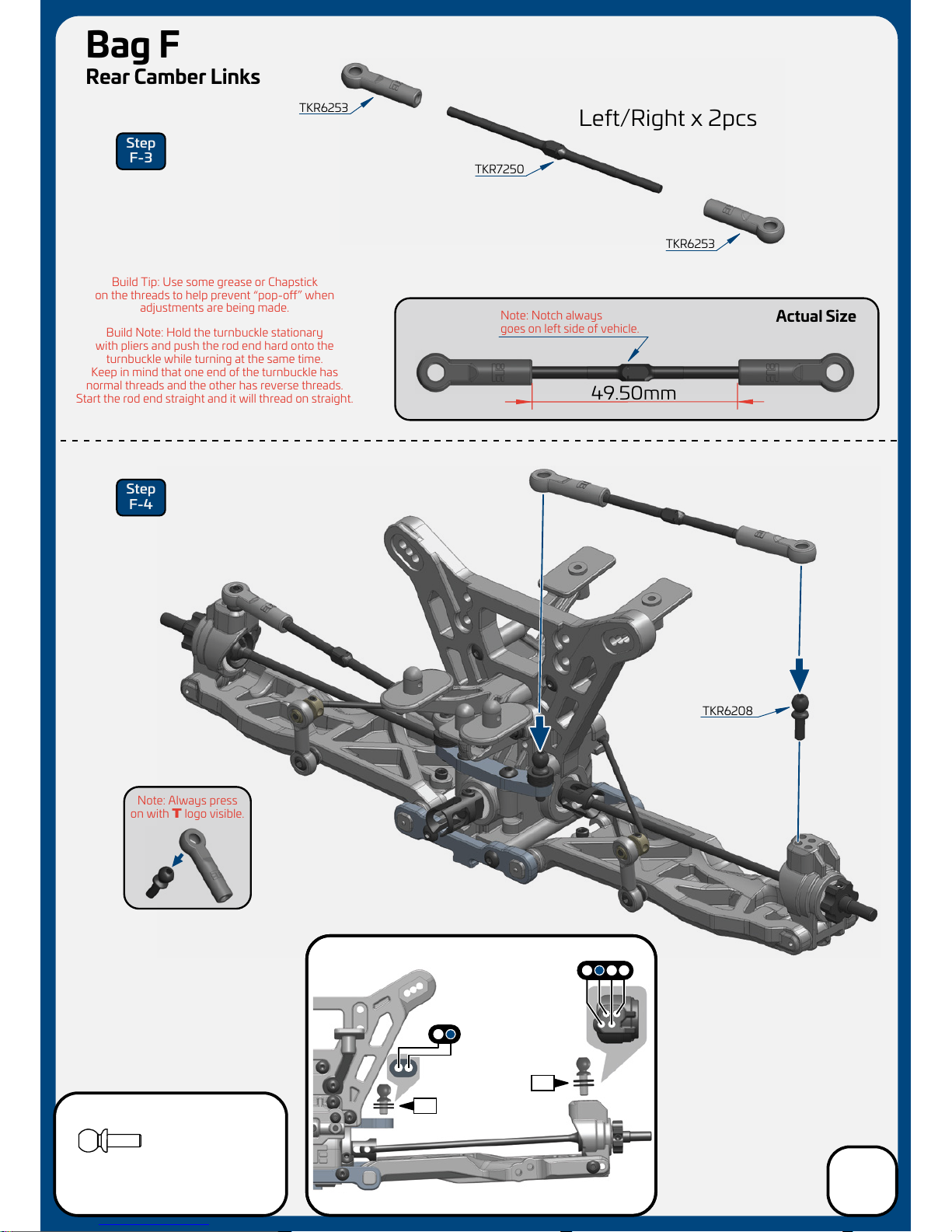

TKR7250

TKR6253

49.50mm

Note: Notch always

goes on

left side of vehicle.

Note: Always press

on with T logo visible.

Stock position is 2/B

6

0

Actual Size

Left/Right x 2pcs

TKR6253

TKR6208

Step

F-3

Step

F-4

DCBA

1 2

WASHERS

WASHERS

TKR6208

M3x8mm Ball Stud

x2

Build Note: Hold the turnbuckle stationary

with pliers and push the rod end hard onto the

turnbuckle while turning at the same time.

Keep in mind that one end of the turnbuckle has

normal threads and the other has reverse threads.

Start the rod end straight and it will thread on straight.

Build Tip: Use some grease or Chapstick

on the threads to help prevent “pop-o” when

adjustments are being made.

Bag F

Rear Camber Links

10

TKR1601

TKR6624 - 1.6mm

TKR6547

Note: Do not over-tighten.

Below options sold separately.

*TKR6623 - 1.0mm

*TKR6623 - 1.1mm

*TKR6623 - 1.2mm

*TKR6623 - 1.3mm

*TKR6623 - 1.4mm

*TKR6624 - 1.5mm

*TKR6624 - 1.7mm

*TKR6624- 1.8mm

*TKR6624- 1.9mm

(Option)

Stock Position

(”B” Block)

Stock Position

(”A” Block)

TKR1409

Bag G

Front End

Assembly

TKR1405

Note: With these center/upper dot

inserts, Arm Sweep = 0°

Note: With these center/lower dot

inserts, Kick Up is: 11°

For reference: With center dot

inserts, Kick Up = 10°

Step

G-2

Step

G-1

Step

G-3

TKR1409

M3x20mm Button Head Screw

x4

TKR1611

M4x8mm Set Screw

x2

TKR6523

TKR7225

TKR6540B

TKR6541B

TKR6544

TKR1611

TKR1409

TKR6544

Note: Refer to page 25 for setting droop.

TKR6544

TKR6544

TKR6547

TKR1601

TKR1463

Thread

Lock

TKR1601

TKR6555

TKR6548

TKR6253

TKR1405

M3x14mm Button Head Screw

x2

TKR1463

M2.5x6mm Button Head Screw

x2

x5

TKR1601

M3x4mm Set Screw

TKR1463

11

all shims

go toward

the front

Wheelbase Shims

2mm

0mm

large 1mm

front

rear

small .5mm

TKR1601

TKR6565

Bag H

Front CVA / Spindle &

Carrier Assembly

TKR1400

Step

H-1

Step

H-2

Step

H-3

Step

H-4

Step

H-5

TKR6856

TKR6856

TKR6270R

TKR6553

TKRBB10154

TKRBB06124

TKR5571M

TKR1609

TKR1229

TKR6596

TKR6596

TKR7272

TKR6856

TKR6552

TKR1601

Grease

Note: This screw

only needs to be

snug. Do not

over-tighten.

Repeat for

both sides

Note: These screws

only need to be

snug. Do not

over-tighten.

Note:

These screws

only need to be

snug. Do not

over-tighten.

Note:

These screws only

need to be snug.

Do not over-tighten.

TKRBB10154

Ball Bearing (10x15x4)

x2

x6

TKR1601

M3x4mm Set Screw

TKR1609

M3x3mm Set Screw

x2

TKRBB06124

Ball Bearing (6x12x4)

x2

TKR1400

M3x4mm Button Head Screw

x4

DO NOT SKIP

THIS STEP!

Note: These are steering

stop screws. They provide

a mechanical limit to the

steering throw and make

the car easier to drive

by greatly improving the

consistency of the steering.

TKR1221

TKR1400

Thread

Lock

TKR1229

6x10x0.2mm Shim

x2

TKR1221

M3x8mm Washer

x12

*TKR5571A

*TKR5571

*TKR1654X (+1mm)

*TKR1654 (+1mm)

(Option)

TKR6210

TKR1221

X 4pcs

TKR1201

TKR1201

TKR6208

TKR1221 x 4pcs

TKR6210

TKR6208

TKR1601

Note: This screw

is included to

keep the hole

from deforming.

Install before

TKR6208.

TKR1601

Note: This screw is

included to keep the

hole from deforming.

Install before TKR6208.

TKR6208

M3x8mm Ball Stud

x2

TKR1201

M3 Lock Nut Black

x2

TKR6210

M3x10mm Ball Stud

x2

12

TKR1201

M3 Lock Nut Black

x2

TKR6250

TKR6253

Right

Left

Right

Front Camber Links Steering Links

Left

TKR6253

TKR6253

TKR6253

TKR6250

TKR6250

TKR6250

TKR6253

TKR6253

TKR6253

TKR6253

Right

Left

TKR6208

TKR6664

TKR6208

TKR1201

TKR1201

Bag I

Front Camber Links

& Steering Links

Step

I-1

Step

I-2

Step

I-3

TKR6208

M3x8mm Ball Stud

x2

31.50mm

Note: Notch always

goes on

left side of vehicle.

Actual Size

Note: Always press

on with T logo visible.

Note: Always press

on with T logo visible.

Build Note: Hold the turnbuckle stationary

with pliers and push the rod end hard onto the

turnbuckle while turning at the same time.

Keep in mind that one end of the turnbuckle has

normal threads and the other has reverse threads.

Start the rod end straight and it will thread on straight.

Build Tip: Use some grease or Chapstick

on the threads to help prevent “pop-o” when

adjustments are being made.

30.00mm

Note: Notch always

goes on

left side of vehicle.

Actual Size

13

A

B

WASHERS

Stock position is 1/A

Bag I

Front Tower Assembly

Step

I-4

Step

I-5

TKR1403

TKR1409

TKR7210

TKR7210

TKR1405

TKR1405

TKR1403

M3x10mm Button Head Screw

x2

TKR1409

M3x20mm Button Head Screw

x2x2

0

TKR7281

Note: These screws

only need to be

snug. Do not

over-tighten.

*TKR7281C

(Option)

Note: Always press

on with T logo visible.

1

2

TKR1405

M3x14mm Button Head Screw

x4

14

A Block Inset

Note: It is nessesary to slightly loosen both screws holding

the A block in place before attaching the front clip to the

chassis. This is due to the fact that the A block is now

keyed into the front of the chassis. This feature helps

secure the front clip and improves durability.

CHASSIS

CHASSIS

A

BLOCK

A

BLOCK

TKR1323

TKR6501B

TKR6586

TKR1323

TKR1322

TKR1401

TKR6546

TKR1323

TKR6530

TKR6634

TKR6538

Step

J-1

Step

J-2

Step

J-3

TKR1322

M3x8mm Flat Head Screw

x2

TKR1401

M3x6mm Button Head Screw

x2

TKR1323

M3x10mm Flat Head Screw

x10

Thread

Lock

Thread

Lock

Bag J

Front/Center

Assembly

15

Install with hole

on top, like this.

Thread

Lock

Step

J-4

Step

J-5

Step

J-6

Step

J-7

TKR1402

TKR6634

TKR6634

TKR6600

TKR1211

TKR1409

TKR1323 x 8pcs

TKR6634

TKRBB10154

TKRBB10154

TKRBB101504

Ball Bearing(10x15x4mm)

x2

TKR1211

M3 Lock Nut Flange Black

x1

TKR1409

M3x20mm Button Head Screw

x1

TKR1323

M3x10mm Flat Head Screw

x8

TKR1402

M3x8mm Button Head Screw

x4

TKR6599

TKR6538

Note: Use both rear braces

for the least chassis flex.

Use just the long rear for

meduim flex and short rear for

the most flex. More flex is

best suited for bumpy tracks.

*TKR6635C

(Option)

Bag J

Center/Rear

Assembly

16

#550 cst

shock oil

TKR1240

TKR1211

Note: Slot in spring

perch should face

outside of car.

Note: Black screw

is RH threaded.

It goes on the left

side of the car.

Silver screw is

LH threaded.

It goes on the right

side of the car.

TKR1211

TKR6712

TKR6527

Thread

Lock

TKR6712

TKR6711

TKR6712

TKR6709

TKR6709

TKR6708

TKR6708

TKR1245

TKR6705

TKR6704

TKR6701

TKR6548

*TKR6704T

(Option)

*TKR6731

*TKR6732

*TKR6735

(Option)

Note: Use green

slime or oil on

shock shaft

threads AND

O-rings to

prevent tearing

and leaking.

Note: Screw rod end on

until distance measures

28mm at full extension.

TKR1604

TKR6701

TKR7235

*TKR7233

*TKR7234

*TKR7236

*TKR7237

(Option)

TKR6712

*TKR6712A

(Option)

#550

Refer to filling

instructions on

page 19 during

this step.

Step

K-1

Step

K-2

Step

K-3

Step

K-4

Step

K-5

TKR1240

M3x18mm Shock Mnt Screw

x2

TKR1248

M2x4mm Emulsion Screw

x2

TKR1245

M2x5mm Piston Screw

x2

TKR1211

M3 Lock Nut Flange Black

x4

TKR1604

M3x8mm Set Screw

x2

28.00mm

TKR6719A

Note: 1.7mm

piston with

writing up.

Note: Do not

over-tighten

Bag K

Front Shock

Assembly

17

Stock shock position is outside

hole on the arm and middle

hole on the tower (2/B)

Shock length (droop) is 88mm

Stock front ride height is 27mm with ST tires/31mm with SC tires

TKR1240

TKR1211

Note: Slot in spring

perch should face

outside of car.

TKR1211

TKR6712

TKR6527

TKR6712

TKR6709

TKR6756

TKR6709

TKR6708

TKR6708

TKR1245

TKR6701

TKR6548

TKR1604

TKR6701

TKR7245

*TKR7243

*TKR7244

*TKR7246

*TKR7247

(Option)

TKR6712

*TKR6712A

(Option)

TKR6719A

Step

L-1

Step

L-2

Step

L-3

Step

L-4

Step

L-5

TKR1240

M3x18mm Shock Mnt Screw

x2

TKR1248

M2x4mm Emulsion Screw

x2

TKR1245

M2x5mm Piston Screw

x2

TKR1211

M3 Lock Nut Flange Black

x4

TKR1604

M3x8mm Set Screw

x2

#350 cst

shock oil

Note: Screw rod end on

until distance measures

38mm at full extension.

#350

38.00mm

TKR6712

Note: Black screw

is RH threaded.

It goes on the right

side of the car.

Silver screw is

LH threaded.

It goes on the left

side of the car.

TKR6757

*TKR6757T

(Option)

Thread

Lock

Note: Use green

slime or oil on

shock shaft

threads AND

O-rings to

prevent tearing

and leaking.

Note: 1.8mm

piston with

writing up.

Refer to filling

instructions on

page 19 during

this step.

Note: Do not

over-tighten

TKR6705

*TKR6731

*TKR6732

*TKR6735

(Option)

Bag L

Rear Shock

Assembly

18

Stock shock position is inside

hole on the arm and middle

hole on the tower (2/A)

Shock length (droop) is 108mm

Stock rear ride height is 27mm with ST tires/31mm with SC tires

Shock Filling Instructions

For both front and rear shocks

Step 1. Start by drilling out the emulsion hole. Use a 1/16th (or 1.6mm) drill bit to drill all the way through and

clear any flashing created by this. Insert the four larger o-rings into the emulsion caps and set aside.

Install the small o-rings onto the small emulsion screws by placing the o-rings on a pit mat or towel and

pressing the screws into the o-rings (add 1 small drop of oil onto the seal to help make the screw slide in easier).

Step 2. Fill shock with oil all the way to the top and pump the shock shaft up and down 3-5 times.

Step 3. Screw on the cap all the way tight (shock tool TKR1115 is helpful for holding the shock body).

Be careful to not cross-thread the caps. Start by turning in the oposite direction before tightening.

Step 4. With the shock at about a 45° angle, push and hold the shock shaft to the top of the stroke and

insert the prepared emulsion screw/seal. Oil should leak out during this process. If it does not, add more oil.

Tighten the screw until snug (do not over-tighten). Wipe o excess oil before moving on to step 5.

Step 5. Pump the shock shaft up and down about 20 times vigorously. This emulsifies the oil.

Step 6. With the shock shaft fully extended, remove the emulsion screw from the cap to do the final bleed.

Step 7. With the shock at about a 45° angle, push and hold the shock shaft to the top and insert the

prepared emulsion screw/seal again. Oil will leak out during this process. Finish by tightening the screw

until snug (do not over-tighten).

We've found it's easiest to complete steps 1 & 2 on each shock before moving on to step 3.

By the time you've finished step 2 on the last shock, the first one will be ready for step 3.

Fill with oil,

Pump up and down

3-5 times,

Then screw on cap

Fill with oil,

Pump up and down

3-5 times,

Then screw on cap

Pump up

and down

30 times

Pump up

and down

20 times

Prepare caps by

drilling emulsion hole

AND

inserting seals

AND

Push smaller

screws into small

o-rings

Push shaft up

to bleed air out

THEN

Insert screw snug

(do not over-tighten)

TKR6714

TKR6712

TKR1248

TKR6714

Pull shaft down,

remove screw

THEN

Push shaft up to bleed air,

insert screw snug

(do not over-tighten)

Step

1

Step

2-3

Step

4

Step

5

Step

6-7

19

1/16th Drill Bit

Note: Do not

over-tighten

Note: Do not

over-tighten

TKR1323

M3x10mm Flat Head Screw

x6

TKR1221

M3X8mm Washer

x4

TKR1522

M3x8mm Cap Head Screw

x2

TKR1403

M3x10mm Button Head Screw

x2

TKR1409

M3x20mm Button Head Screw

x2

TKR1409

Steering servo (not included)

TKR1323

TKR1323

TKR1409

TKR1221

TKR6586

TKR6685

TKR1221

TKR6586

TKR6539

TKR1522

TKR1403

Motor (not included)

Step

M-1

Step

M-2

Step

M-3

TKR1221

Thread

Lock

Note: We recommend using a full

size servo with at least 200 oz/in

torque and metal gears. Running less than

our recommended rating will increase

the chance of premature servo failure.

IMPORTANT RADIO SETUP TIPS, MUST READ:

The Tekno RC ET410 is highly tunable, but can be very

aggressive depending on track conditions and tires used.

To help with this, we recommend that you are well informed

about setting up your Steering EPA, Servo Speed, Dual Rate,

and Exponential Curves.

PLEASE READ PAGE 27 FOR MORE DETAILS.

Vehicle

(2 cell)

(50-80 ft Straight)

Small Track

(pinion)

Large Track

(pinion)

(80-150 ft Straight)

ET410

Motor

540 2-Pole or

540 4-Pole

Gearing Recommendations

6.5T

7.5T

8.5T

16 tooth

17 tooth

18 tooth

17 tooth

18 tooth

19 tooth

4000kv

17 tooth 18 tooth

4600kv

16 tooth

17 tooth

Bag M

Final Assembly

20

Step

M-4

Step

M-6

TKR1323

TKR1323

TKR6685

TKR6586

TKR1323

M3x10mm Flat Head Screw

x3

TKR1523

TKR1523

TKR1221

TKR1221

Note: Refer to page 20 or 26

for a recommended pinion

chart to best suit your motor.

Note: MESH SHOULD BE AS TIGHT

AS POSSIBLE WITHOUT BINDING.

Pinion/Set screw

(not included)

Thread

Lock

Thread

Lock

TKR1321

M3x6mm Flat Head Screw

x2

TKR1221

M3X8mm Washer

x2

TKR1523

M3x10mm Cap Head Screw

x2

TKR1321

TKR6586

Fan (not included)

25mm and 30mm

fans compatible.

Screws

(not included)

Mount ESC, receiver & transponder

during this step. (not included)

Step

M-5

Thread

Lock

Bag M

Final Assembly

21

3.00mm

Note: Servo horn should be

positioned after trim and sub-trim

have been zero’d out. It should

be positioned about 4 degrees

o parallel from the steering

bellcranks.

Steering bellcranks should be

perfectly parallel from front to

rear of the chassis.

Step

M-7

Step

M-8

Step

M-9

Step

M-10

TKR5230

M3x18 Threaded Rod

x1

TKR6253

TKR1601

TKR5126

TKR6253

TKR6207

TKR6526B

TKR5230

TKR6207

M3x6mm Ball Stud

x1

TKR1601

M3x4mm Set Screw

x1

Cap Head Screw

(not included)

SERVO HORN ALIGNMENT

Actual Size

Note: Always press

on with T logo visible.

*TKR6563A

(Option)

Note: Rod end orientation.

Note: Servo horn orientation.

Bag M

Final Assembly

22

Note: Stock downforce is 6°

Note: Stock hole position is in the

rear of the wing. Wing forward creates

LESS rear downforce. Wing

rearward creates MORE rear downforce.

Note: Screw in TKR5230

until 8mm of threads are

still visible.

Note: More downforce will give more rear traction

everywhere, will jump more nose up, have less

steering into a turn, and have slightly less top speed.

Less downforce will have less rear traction everywhere,

will jump more level or nose down, have more steering

into a turn, and have a slightly higher top speed.

DOWNFORCE OPTIONS

3°

Shim/Direction

Total Wing Angle

1.5°

0°

1.5°

3°

TKR6634

TKR1403

TKR1403

TKR1402

TKR5230

TKR1323 TKR1323

TKR6605

TKR6546

TKR6634

Step

N-1

Step

O-1

Thread

Lock

8mm

*TKR6635C

(Option)

*TKR6598C

(Option)

*TKR6605X

(Option)

Bag N

Final Assembly

Bag O

Wing

23

TKR1323

M3x10mm Flat Head Screw

x2

TKR5230

M3x18 Threaded Rod

x1

TKR1403

M3x10mm Button Head Screw

x6

TKR1402

M3x8mm Button Head Screw

x2

Note: For hook and loop tape

placement. Look for indentations

on the side walls of the body.

BATTERY INSTALLATION

TKR6280

TKR5125

TKR6686

Thumb Screw Assembly

Wheels/Tires

(not included)

Note: Use either

Associated oset

staduim truck OR

Traxxas Slash SC

oset wheels/tires.

TKR6686

TKR6686

TKR6686

TKR1235

TKR1235

TKR6586

TKR1235

TKR1235

TKR1213

TKR1213

TKR7201

Step

O-2

Step

O-3

Step

O-4

TKR1235

Body Clip

x4

*TKR6503C

(Option)

TKR1213

M4 Alum Lock Nut Flange Black

x4

HOOK AND LOOP NOTE:

Please note that there is a slight handling dierence

between using body clips and using the hook and loop

tape to secure the body. Using only body clips to fasten the

body will allow more flex and be easier to drive in rougher

conditions. Using the hook and loop tape, with or without

the body clips, will result in a stier chassis that is better

suited for smoother tracks.

Bag O

Body/Tires

24

The purpose of making adjustments is to make the car go faster around the track, or to make it more controllable, or both if possible. A car

that's easier to drive should produce lower, more consistent lap times. It will also inspire more confidence in the driver, which is always

good when nerves start getting the best of you.

Before you start thinking about changing your car's setup, consider these two things: First, is the car in perfect working order? Be sure

that all of the suspension components operate freely without excessive play, and that the car isn't tweaked. Binding and worn out parts

will result in poor performance and inconsistent handling. Second, always consider tires before making other adjustments. Time spent

trying to get the vehicle to work with the wrong tires mounted will be wasted time. Without the right tires, even a great setup won’t be a

winning setup.

Bumpsteer

M

O

R

E

b

u

m

p

o

u

t

b

u

m

p

o

u

t

L

E

S

S

Ackermann

Eect

LESS MORE

D

R

O

O

P

M

E

A

S

U

R

E

M

E

N

T

A

D

J

U

S

T

H

E

R

E

Droop

Ride height is the distance from the bottom of the chassis to the running surface. Ride height

should only be checked and adjusted with your vehicle ready to run (i.e. with battery

installed/body on). Ride height is the first adjustment to be made and should be set with a ride

height measurement tool. Measurements should be taken from the flat parts of the chassis,

front and rear. Be sure to measure the front ride height at a point before the kick up in the

chassis starts. To measure ride height, first make sure the suspension is completely free, then

simultaneously compress the front and rear all the way down and let the vehicle settle. Take

your measurement from that position. Use the shock spring adjustment collars to raise or

lower the ride height to your desired setting. 27mm front and rear is a good starting point.

Think of bump steer as active toe when the suspension compresses or rebounds. To adjust bump steer

you have to change the angle of the steering link.

This is accomplished by adding or removing washers

under the ball stud on the steering spindles. Anytime

you change camber link locations, front arm pills,

front arm spacers, or Ackermann you will need to

check and possibly adjust your bumpsteer. It's best

to start with zero bumpsteer or slight bump out.

Think of Ackermann as active toe

when the steering moves from left

to right. More ackermann eect

makes more toe out at full turn and

produces more steering o-power.

Less ackermann eect makes less

toe out at full turn and produces

more steering on-power. A good

starting point is 0 washers behind

the ball stud.

Ride Height

MEASUREMENT

Camber

C

A

M

B

E

R

Static camber aects the car’s side to side traction. More negative camber front and rear quickens rotation in corners. Less negative camber will make the vehicle easier to drive but you may

give up some responsiveness (i.e. steering). To set your static camber have your vehicle at ride

height (see above) and adjust the camber links until desired angle is achieved. Please note that a

large adjustment of front camber will aect front toe and you may have to readjust the toe and

then re-check front camber again. A good starting measurement for camber is 1-2 degrees in

the front and 1.5-2.5 degrees in the rear.

Droop is the measured amount of down travel in the suspension. It is measured from the shock mounting

points while the vehicle is up on a stand allowing the arms to hang freely and is adjusted by turning the

droop screw located in the suspension arms front/rear. This screw limits the suspension travel by

providing a stopping point against the chassis. Left and right sides should always be equal, however the

front and rear of the vehicle can have dierent values. Droop aects all aspects of chassis

performance, including braking, acceleration, jumping, traction, and bump handling. A good

starting droop measurement is 88mm front, and 108mm rear.

Front toe is used to describe the angle in which the front wheels point when looking down at

them from the top of a vehicle. You will always use some amount of toe out. Toe-out will

aect how your vehicle enters and exits corners. More toe out will result in more o-power

steering and less on-power steering and less toe out will have the opposite results. To set your

front toe, have your vehicle at ride height (see above) and adjust the steering links until desired

angle is achieved. Please note that a large adjustment of front toe will aect front camber and

you may have to readjust the camber and then re-check front toe again. A good starting point

is approximately 0.5-1 degree of toe out per side.

Front Toe

O

U

T

_

_

_

_

I

N

I

N

_

_

_

_

O

U

T

25

Setup Information

TKRBB040725 – Ball Bearings (4x7x2.5mm,

sold in pack of 4pcs) Bearings for the

bellcrank/ackerman plate. 8pcs required in kit.

TKRBB05114 – Ball Bearings (5x11x4, 4pcs)

Di pinion support bearings for the front/rear

transmission housings. 4pcs required in kit.

TKRBB10154 – Ball Bearings (10x15x4mm,

sold in pack of 4pcs) Bearings for all three dis.

Also inner front steering blocks/rear hub carriers.

10pcs required in kit.

TKRBB06124 – Ball Bearings (6x12x4mm, 4pcs)

Bearings for outside of steering blocks and outer

rear hub carriers. 4pcs required in kit.

Changes to wheelbase can aect the overall handling of your vehicle, since it adjusts the distribution

of weight on the wheels as well as the angle of the driveshafts. Shortening the wheelbase at the

rear will give you more steering into a turn and o power, less steering out of a turn and on power.

Lengthening the wheelbase at the rear will yield the opposite results.

Shortening the wheelbase in the front will land jumps a little better and lengthening it will be better

through small bumps. In general a longer wheelbase is better on open and/or bumpy tracks and a

shorter wheelbase is better on tighter technical tracks.

This chart shows the recommended starting ratios for the

common motor types. Please consult the motor/esc

manufacturers recommended settings to ensure you

start with the best final drive ratio (FDR) for your equipment. When setting your mesh you want have it set as

tight as possible, without any binding. Tekno RC is not

responsible for damage done to your electronic equipment or gears due to improper gearing or mesh.

* For bearing maintenance, please refer to page 28.

Softer springs will increase

traction through the turns by

allowing more roll, slow down the

responsiveness of the vehicle,

and can be better in the bumps.

Stier springs will increase corner

speed if traction is available and

will also tend to jump and land

better. Once you find a set of

springs you like you will typically

only change them for tracks with

dramatically dierent conditions.

Sway bars are used to adjust a

vehicle's lateral grip by resisting

chassis roll. A thicker bar decreases

roll more than a thinner bar will. More

roll means more grip and less roll

means less grip. The front sway bar

aects mainly o-power steering at

corner entry. The rear sway bar

aects mainly on-power steering and

stability in mid-corner and at corner

exit.

Pistons with

smaller holes

work well for

smoother tracks

with large jumps

and pistons with

larger holes work well for rougher tracks with

less jumps. Smaller hole pistons will typically

use thinner oil than larger hole pistons. Shock

oil is also aected by the ambient temperature

so a change in viscosity might be necessary

with a change of 5°C or ~10°F.

Front Arm

Rear Arm

Wheelbase Adjustments

FORWARD

BACKWARD

FORWARD

BACKWARD

Front: Changing front di oil aects overall steering response. Thinner can increase o-power steering but

the vehicle may be twitchy and harder to drive. Thicker can increase on power steering and stability. We

recommend 30k in the front di.

Center: Changing center di oil aects the front-to-rear drive balance. Thicker will reduce o-power

steering and on-power rear traction but increases on-power steering and acceleration if traction is available.

Thinner will increase o-power steering and on-power rear traction but reduce on-power steering and

acceleration. We recommend 30k in the center di.

Rear: Thinner rear di oil increases o-power steering and reduces traction into a corner. It also reduces

on-power steering and increases traction out of a corner. Going too thin will make your vehicle inconsistent,

however. Thicker rear oil will have opposite eects, and once again, going too thick will make the vehicle

inconsistent. We recommend 5k to 10k in the rear di.

Dierentials

Springs

Pistons

Sway Bars Bearing Chart

Gearing Recommendations

PAR T#/COLOR F / R

Rear

Rear

Rear

Front

Front

Front

Front

Rear

Rear

1.3

1.3

9.37

8.87

63mm

63mm

3.01

3.22

Front

TKR7246

TKR7247

TKR7243

TKR7244

TKR7245

TKR7234

TKR7235

TKR7236

TKR7237

TKR7233

WIRE DIA.

1.3

1.3

1.3

1.4

1.4

1.4

1.4

1.4

COILS

11.25

10.50

9.87

9.75

9.37

9.00

8.75

10.12

LENGTH

63mm

63mm

63mm

50mm

50mm

50mm

50mm

50mm

LENGTH

COILS

WIRE DIA.

2.40

2.61

2.82

3.81

4.00

4.21

4.37

3.61

RAT E

TKR6610 Rear 1.5mm

TKR6610 Rear 1.6mm

TKR6610 Rear 1.7mm

TKR6610 Rear 1.8mm

TKR6610 Rear 1.9mm

TKR6624 Front 1.5mm

TKR6624 Front 1.6mm

TKR6624 Front 1.7mm

TKR6624 Front 1.8mm

TKR6624 Front 1.9mm

TKR6611 Rear 1.0mm

TKR6611 Rear 1.1mm

TKR6611 Rear 1.2mm

TKR6611 Rear 1.3mm

TKR6611 Rear 1.4mm

Part# F / R Size

TKR6623 Front 1.0mm

TKR6623 Front 1.1mm

TKR6623 Front 1.2mm

TKR6623 Front 1.3mm

TKR6623 Front 1.4mm

Vehicle

(2 cell)

(50-80 ft Straight)

Small Track

(pinion)

Large Track

(pinion)

(80-150 ft Straight)

ET410

Motor

540 2-Pole or

540 4-Pole

6.5T

7.5T

8.5T

16 tooth

17 tooth

18 tooth

17 tooth

18 tooth

19 tooth

4000kv

17 tooth 18 tooth

4600kv

16 tooth

17 tooth

26

Setup Information

(continued)

27

The Tekno RC ET410 is highly tunable, but can be very aggressive depending on track conditions and tires used. To help with this, we

recommend that you are well informed about setting up your Steering End Points (EPA), Dual Rate (D/R), Exponential Curves, and Servo

Speed.

Start by setting your EPA such that the vehicle can reach ‘full lock’ while on the ground. Be careful not to go too far with this setting as it

may damage your servo. Drive the vehicle around the track. If you are turning into pipes or losing traction out of a corner, you probably

have too much overall steering throw. The simplest way to reduce this is with Dual Rate. Reducing Dual Rate will turn down both the left

and right side EPA proportionately without having to adjust the EPA settings independently. D/R is usually pre-assigned to one of the

trim buttons on most mid-to-high level radios.

The next setting is ‘Expo’ or ‘Curve’. Expo does not change your EPA or D/R, it simply turns the wheels less around center and ramps up

to the end points as you reach full lock on the steering wheel. We would suggest starting at -15%. If you’re vehicle still feels “twitchy”

around center, dial in more negative expo to continue smoothing everything out. If it starts to feel too numb around center, dial some

back out.

Another valuable and often overlooked radio adjustment is “Servo Speed”. Servo Speed allows you to slow the steering servo down from

the transmitter resulting in reduced twitchiness. We like to set this at around -40 to start. If you find that it’s too lazy, increase the servo

speed slightly and run a few more laps. Repeat as necessary until the steering response feels natural without delay.

After setting the servo speed you might find that you need to go back and adjust the expo setting. This is normal, it might take a few

adjustments of each to achieve the proper steering “feel” to suit your driving style and track conditions.

With these four settings, you should be able to make your vehicle consistent and easy to drive lap after lap assuming the rest of the setup

is close for your particular track. Of course there are many other factors and setup options to tune for more or less steering, but sometimes all your vehicle needs is a small radio adjustment to keep you headed in the right direction.

Radio Information

Please read thoroughly

Notes:

Bearing Maintenance:

Performing regular maintenance will greatly improve your on track consistency and also extend the life of your vehicle.

Going through critical areas of the vehicle regularly will also allow you to find possible issues before they become a

problem that may cost you a race. Follow the guidelines below for maximum performance.

Bearings should always be smooth and free in order to preform their function. We recommend inspecting and cleaning

each bearing on a regular basis. It will be necessary to break down parts of the vehicle in order to inspect them properly.

The procedures below should be done every couple of weeks or prior to an important race.

1. Inspect the outer seals for any visible damage and check the rolling resistance of each bearing.

2. If any bearing does not spin freely, then take the following steps to clean them.

3. Spray the bearing with motor spray and spin it again to remove any debris trapped inside. Repeat if necessary. If

the bearing does not start to spin freely after cleaning, then they may need to be replaced.

4. Allow the clean bearing to dry or blow into the bearing with compressed air to speed up the drying process.

5. Oil each bearing with a proper bearing lubricant. One or two drops is enough.

Shock Maintenance:

When comparing the left and right shocks of the front end, they should feel identical. Same goes for the rears.

The procedures below should be done every race day to make sure they are leak free and operating correctly.

1. After removing the shocks from the vehicle, remove the springs and inspect each shock for visible leaks (build up of

debris at the bottom of the shock shaft or visible oil).

2. If the shock binds when pushing the shaft through its stroke, then the shaft may be bent and will need to be replaced.

3. If the shocks from left to right do not feel consistent when compared to each other, or have built up too much air

inside (feel empty when pushing the shaft through its stroke), then you will need to rebuild them following the steps

outlined on page 19 of this manual.

Properly maintained dierentials are essential for a smooth operating vehicle. Check all three dis regularly to make

sure they are filled and operating as designed.

1. Remove each di and verify the dierential action is happening and is smooth. If there is any notchy feel to them,

follow the steps below to rebuild them.

2. Open the di and pour out the oil. Remove the gears and pins to release the outdrives, then remove the

seals. Inspect everything to make sure there are no damaged parts. If the seals are old or show any signs

of degradation, replace them immediately. Re-lubricate the seals and outdrives, then rebuild the di

following the steps on page 3 and 4.

Hinge Point & Drive Line Maintenance:

Dierential Maintenance:

Checking the hinge points while the shocks are removed from the vehicle is the best time to inspect these parts. The

other items to inspect are the camber links, steering links and drive shafts. Follow the steps below every couple of

weeks in order to keep the vehicle preforming at the maximum level.

1. With the shocks o the vehicle, check the movement of the arms, hubs, and spindle carriers. They should move

freely. If there is a bind, then the inner or outer hinge pin may be bent and would need to be replaced. The arms

should not have any play when twisted or moved in any direction against the hinge points. If there is excessive

slop present, then the arms or hubs may be worn and will need to be replaced.

2. Remove the camber links, steering links and servo link from the vehicle. Check the movement of the spindles to see

if they turn freely. If they don’t, then check the kingpin shoulder screws to see if they are tightened down too far.

Also, check for slop. If there is excessive slop present, then the spindle carriers may need to be replaced.

3. Check the steering rack to make sure it moves freely. If it binds, then the screws holding the Ackermann or the

steering posts could be too tight. If they still bind, then check the bearings and follow the steps above to clean them.

4. After re-installing the camber links, steering links and servo link, check the movement of the rod ends on the ball

studs. If they have excessive slop or are binding, then they may need to be replaced.

5. Check the drive shafts by rotating them. Look for any wobbles. If they are bent, replace them immediately.

6. With the drive shafts removed, check for slop in the CV area. If it is present, then reposition the CV pin to another

fresh hole, re-lubricate and install back into the vehicle.

Maintenance:

28

29

TKR7200 - ET410 1/10th 4WD Competiton Electric Truggy Kit

Parts List

TKR5125 - O-Ring (ESC tray, 3pcs)

TKR5126 - Antenna tube (universal, w/ caps, 5pcs)

TKR5230 - Steering linkage (M3x18mm threaded rod, 10pcs)

TKR5571M - Wheel Hexes (12mm, steel, lightened, 4pcs)

TKR6206 - Ball Stud (5.5mm, short neck, 6mm thread, 4pcs)

TKR6207 - Ball Stud (5.5mm, long neck, 6mm thread, 4pcs)

TKR6208 - Ball Stud (5.5mm, short neck, 8mm thread, 4pcs)

TKR6210 - Ball Stud (5.5mm, short neck, 10mm thread, 4pcs)

TKR6250 - Turnbuckle (M3 thread, 55mm length, 4mm adjustment, 2pcs)

TKR6253 - Rod End Set (turnbuckles, sway bar, steering, EB410)

TKR6270R - Stub Axles (EB410 rear, ET410 F/R, hardened steel, 2pcs)

TKR6280 - Battery Strap Thumb Screw (EB410)

TKR6501B - Chassis (EB410/ET410, requires TKR6540B/TKR6541B)

TKR6519B - Bulkhead Set (revised, f/r, EB410)

TKR6523 - Hinge Pins (inner, front/rear, super hard, EB410, 2pcs)

TKR6526B - Bell Cranks, Ackerman Plate, Servo Horns (EB410)

TKR6527 - Shock Standos (EB410, 2pcs)

TKR6530 - Motor Mount Base (CNC, 7075, EB410)

TKR6538 - Chassis Brace, Body Mount Set (EB410)

TKR6539 - Motor Mount Insert (CNC, 7075, EB410)

TKR6540B - Hinge Pin Brace (CNC, 7075, EB410, A Block)

TKR6541B - Hinge Pin Brace (CNC, 7075, EB410, B Block)

TKR6542 - Hinge Pin Brace (CNC, 7075, EB410, C Block)

TKR6543 - Hinge Pin Brace (CNC, 7075, EB410, D Block)

TKR6544 - Hinge Pin Inserts, Wheelbase Shims (EB410)

TKR6545 - Rear Hubs (l/r, EB410)

TKR6546 - Wing Mount and Bumper (EB410)

TKR6547 - Sway Bar and Bulkhead Acc. (EB410)

TKR6548 - Pivot Balls (5.5mm, flanged, 4pcs)

TKR6552 - Spindle Carriers (l/r, EB410)

TKR6553 - Spindles (15°, l/r, EB410)

TKR6555 - Stabilizer Balls (5.5mm, sway bars, aluminum, 4pcs)

TKR6565 - Hinge Pins (outer, front, EB410, 2pcs)

TKR6566 - Hinge Pins (outer, rear, EB410, 2pcs)

TKR6586 - Side Guard, Servo Mount, Battery Acc. (EB410)

TKR6596 - Kingpin Shoulder Screws (EB410, 4pcs)

TKR6597 - Di Coupler (f/r, lightened, hardened steel, EB410)

TKR6599 - Tapered Driveshaft (center, rear, 7075, black ano, EB410)

TKR6600 - Tapered Driveshaft (center, front, 7075, black ano, EB410)

TKR6605 - Wing (lexan, pre-cut, EB410)

TKR6610 - Sway Bar Set (rear, 1.5, 1.6, 1.7, 1.8, 1.9mm, EB410)

TKR6624 - Sway Bar Set (front, 1.5, 1.6, 1.7, 1.8, 1.9mm, EB410/ET410)

TKR6627 - Steering Rack Bushings (aluminum, EB410, 2pcs)

TKR6629 - Steering Posts (steel, EB410, 2pcs)

TKR6634 - Center Di Support, Top Braces (EB410)

TKR6664 - Front Camber Link Plate (aluminum, EB410)

TKR6665 - Rear Camber Link Plate (aluminum, EB410)

TKR6685 - Rear Body Mount Panels (EB410, 2pcs)

TKR6686 - Body Mount Hook and Loop Tape Set (EB410, 4pcs)

TKR6856 - CV Rebuild kit (f/r, for 2 axles)

TKR7201 - Body (ET410)

TKR7210 - Body Mount Set (ET410)

TKR7213 - Decal Sheet (ET410)

TKR7224 - Suspension Arms (rear, ET410)

TKR7225 - Suspension Arms (front, ET410)

TKR7250 - Turnbuckle (M3 thread, 78mm length, 4mm adjustment, 2pcs)

TKR7272 - Driveshaft (f/r, hardened steel, ET410, 2pcs)

TKR7281 - Shock Tower Set (f/r, ET410)

Dierential List

TKR5144 - Dierential O-Rings (6pcs)

TKR6511 - Dierential Case (f/c/r, 3pcs, EB410)

TKR6513X - Dierential Cross Pins (composite, 3pcs, EB410)

TKR6514 - Dierential Outdrives (f/r/c, lightened, EB410)

TKR6515 - Dierential Seals (3pcs, EB410)

TKR6517 - Dierential Shims (5x14mm, hardened, 6pcs, EB410)

TKR6550 - Dierential Gear Set (internal gears only, EB410)

TKR7221 - Dierential Ring Gear (40t, ET410, use with TKR7222)

TKR7222 - Di Pinion (10t, ET410, use with TKR7221)

TKR7253 - Spur Gear (53t, 32 pitch, composite, black, EB/ET410)

Bearings List

TKRBB040725 - Ball Bearing (4x7x2.5mm, 4pcs)

TKRBB05114 - Ball Bearing (5x11x4, 4pcs)

TKRBB06124 - Ball Bearing (6x12x4, 4pcs)

TKRBB10154 - Ball Bearing (10x15x4, 4pcs)

Shocks List

TKR6701 - Locking Shock Rod End and Spring Perch Set (13mm shocks)

TKR6704 - Shock Shafts (EB410 front/ET410 rear, steel, 2pcs)

TKR6705 - Shock Piston Set (2x1.7, 2x1.8, flat/flat, 13mm, 4pcs)

TKR6708 - Shock Cartridge Guide Set (CNC, Delrin, 8pcs, EB410/ET410)

TKR6709 - Shock X-rings (8pcs, EB410)

TKR6711 - Shock Body (EB410 front/ET410 rear, aluminum, hard ano, 2pcs)

TKR6712 - Shock/Cartridge Cap & Bushing Set (4pcs each, EB410)

TKR6714 - Emulsion O-ring Set (4x cap seals, 8x emulsion o-rings, for 13mm shocks)

TKR6719A - Shock Adjustment Collars (aluminum, EB410, 2pcs)

TKR6756 - Shock Body (rear, aluminum, hard ano, ET410, 2pcs)

TKR6757 - Shock Shafts (rear, steel, ET410, 2pcs)

TKR7235 - Shock Spring Set (front, 1.4x9.375, 4.00lb/in, 50mm, yellow)

TKR7245 - Shock Spring Set (rear, 1.3x9.875, 2.82lb/in, 63mm, yellow)

Hardware List

TKR1201 - M3 Locknuts (black, 10pcs)

TKR1211 - M3 Locknuts (flanged, black, 10pcs)

TKR1213 - M4 Locknuts (aluminum, flanged, GM ano, serrated, 4pcs)

TKR1221 - M3x8mm Washer (black, 10pcs)

TKR1229 - 6x10x.2 Shims (10pcs)

TKR1235 - Body Clips (angled, 10pcs)

TKR1240 - Lower Shock Mount Screws (2 CW thread, 2 CCW thread)

TKR1245 - Shock Piston Retainer Screw (4pcs)

TKR1248 - M2x4mm Cap Head Screws (black, 10pcs)

TKR1301 - M2.5x6mm Flat Head Screws (black, 10pcs)

TKR1303 - M2.5x10mm Flat Head Screws (black, 10pcs)

TKR1321 - M3x6mm Flat Head Screws (black, 10pcs)

TKR1322 - M3x8mm Flat Head Screws (black, 10pcs)

TKR1323 - M3x10mm Flat Head Screws (black, 10pcs)

TKR1329 - M3x20mm Flat Head Screws (black, 10pcs)

TKR1400 - M3x4mm Button Head Screws (black, 10pcs)

TKR1401 - M3x6mm Button Head Screws (black, 10pcs)

TKR1402 - M3x8mm Button Head Screws (black, 10pcs)

TKR1403 - M3x10mm Button Head Screws (black, 10pcs)

TKR1405 - M3x14mm Button Head Screws (black, 10pcs)

TKR1409 - M3x20mm Button Head Screws (black, 10pcs)

TKR1411 - M3x25mm Button Head Screws (black, 10pcs)

TKR1463 - M2.5x6mm Button Head Screws (black, 10pcs)

TKR1522 - M3x8mm Cap Head Screws (black, 10pcs)

TKR1523 - M3x10mm Cap Head Screws (black, 10pcs)

TKR1601 - M3x4mm Set Screws (black, 10pcs)

TKR1602 - M4x4mm Set Screws (black, 10pcs)

TKR1604 - M3x8mm Set Screws (black, 10pcs)

TKR1609 - M3x3mm Set Screws (black, 10pcs)

TKR1611 - M4x8mm Set Screws (black, 10pcs)

Option Parts

TKR1103 - Turnbuckle Wrench (4mm, 5mm, hardened steel)

TKR1115 - Pivot Ball and Shock Multi-tool (aluminum)

TKR1119 - 5.5mm / 7.0mm Wrench (hardened steel)

TKR1654 - Composite 12mm Hex Adapters (+1mm, 4pcs)

TKR1654X - 12mm Aluminum Hex Adapters (+1mm, aluminum, 4pcs)

TKR5571 - Composite Wheel Hexes (12mm, 4pcs)

TKR5571A - Wheel Hexes (SCT410, 12mm, aluminum, 4pcs)

TKR6503C - Battery Strap (carbon fiber, EB410)

TKR6560A - Aluminum Ackerman Plate (CNC 7075 black ano, EB410/ET410)

TKR6563A - Aluminum Servo Horn (25T, standard, low profile, M3 clamp, EB410)

TKR6598C - Steering Top Plate (carbon fiber, EB410)

TKR6605X - Wing (lightweight, lexan, pre-cut, EB410)

TKR6611 - Sway Bar Set (rear, bars only, 1.0, 1.1, 1.2, 1.3, 1.4mm, EB410/ET410)

TKR6623 - Sway Bar Kit (complete front, 1.0, 1.1, 1.2, 1.3, 1.4mm, EB410)

TKR6635C - Center Di Top Plate and Fan Mount (carbon fiber, EB410)

TKR6704T - Shock Shafts (EB410 rear/ET410 front, steel, TiNi coated, 2pcs)

TKR6712A - Shock Caps (7075, emulsion, black ano, 2pcs

TKR6731 - Shock Pistons (CNC, 2x1.7, 2pcs)

TKR6732 - Shock Pistons (CNC, 2x1.8, 2pcs)

TKR6735 - Shock Piston Blanks (CNC, flat/flat, 13mm, 4pcs)

TKR6757T - Shock Shafts (rear, steel, TiNi coated, ET410, 2pcs)

TKR7233 - Shock Spring Set (front, 1.4x10.125, 3.61lb/in, 50mm, pink)

TKR7234 - Shock Spring Set (front, 1.4x9.75, 3.81lb/in, 50mm, green)

TKR7236 - Shock Spring Set (front, 1.4x9.0, 4.21lb/in, 50mm, orange)

TKR7237 - Shock Spring Set (front, 1.4x8.75, 4.37lb/in, 50mm, red)

TKR7243 - Shock Spring Set (rear, 1.3x11.25, 2.4lb/in, 63mm, pink)

TKR7244 - Shock Spring Set (rear, 1.3x10.5, 2.61lb/in, 63mm, green)

TKR7246 - Shock Spring Set (rear, 1.3x9.375, 3.01lb/in, 63mm, orange)

TKR7247 - Shock Spring Set (rear, 1.3x8.875, 3.22lb/in, 63mm, red)

TKR7281C - Shock Tower (front, carbon fiber, ET410)

TKR7282C - Shock Tower (rear, carbon fiber, ET410)

Box Setup (starting point)

27mm

4

0

2

0

0

0

0

6

27mm

-2°

15°

0°

11°

0.5° out

(per side) (per side)

1.6

88

2mm

0mm

2mm

0mm

1.5° in

2°

1.5mm

108

STOCKSTOCK

30K 30K

550 350

Stock Stock

1.7 1.8

Yellow Yellow

5 5

Emul Emul

10K

53

-2°

Tekno RC

10755 Scripps Poway Pkwy #598

San Diego CA 92131

USA

Loading...

Loading...