Tekno RC EB48.2 User Manual

Introduction

Additional equipment and parts needed:

2/3 channel radio transmitter and receiver

1/8th scale ESC and motor

High torque steering servo, optional brake servo

4-6s LiPo battery

1/8th scale buggy tires, wheels & CA glue

Paint for body

MOD1 Pinion (TKR4171->TKR4190)

Or Tekno RC Traktion Drive / Elektri-Clutch slipper system (TKR4301X)

Tools needed:

Hex drivers (1.5mm, 2.0mm, 2.5mm)

Nut drivers (5.0mm, 5.5mm, 7.0mm)

Hobby knife

Needle-nose pliers

Adjustable (Crescent) wrench (for shock assembly)

4mm turnbuckle wrench

Lexan Body Scissors

Disclaimer: Tekno RC is not responsible or liable for any property or personal damage, loss, or

injury incurred as a result of using this product. This kit is meant for use by persons 14 years of

age or older and in the strict connes of a legally permitted RC track or facility.

Warnings: Always double-check that your radio gear is working properly before operating vehicle.

Never operate the vehicle indoors (unless the RC track is an indoor facility). Use caution while

operating vehicle so as not to collide with people who may be turn mashalling or who might

otherwise not be aware that a fast moving RC vehicle is in the vicinity.

Warranty: We warrant that the parts included in this kit are free from defects. If you nd a

defective part in your kit, please contact us @ info@teknorc.com and we will help you to resolve

the issue. We do not warranty parts that may be broken during operation of the vehicle or

otherwise. Refer to the end of this instruction manual for a listing of spare/replacement and

option parts. All spare parts and other info are available on our website (www.teknorc.com)

and through our network of domestic and international dealers and distributors.

This project is dedicated to Herb Lewis.

Thank you for purchasing the Tekno RC EB48.2 1/8th Electric 4WD Competition Buggy. The EB48.2

represents the state-of-the-art in 1/8th Electric Buggy technology. We hope you have as much fun

driving your new vehicle as we did developing it. We are always working on new projects, so please

check our website (www.teknorc.com) regularly for the latest news, parts, and kits. Thanks again.

Rev-2

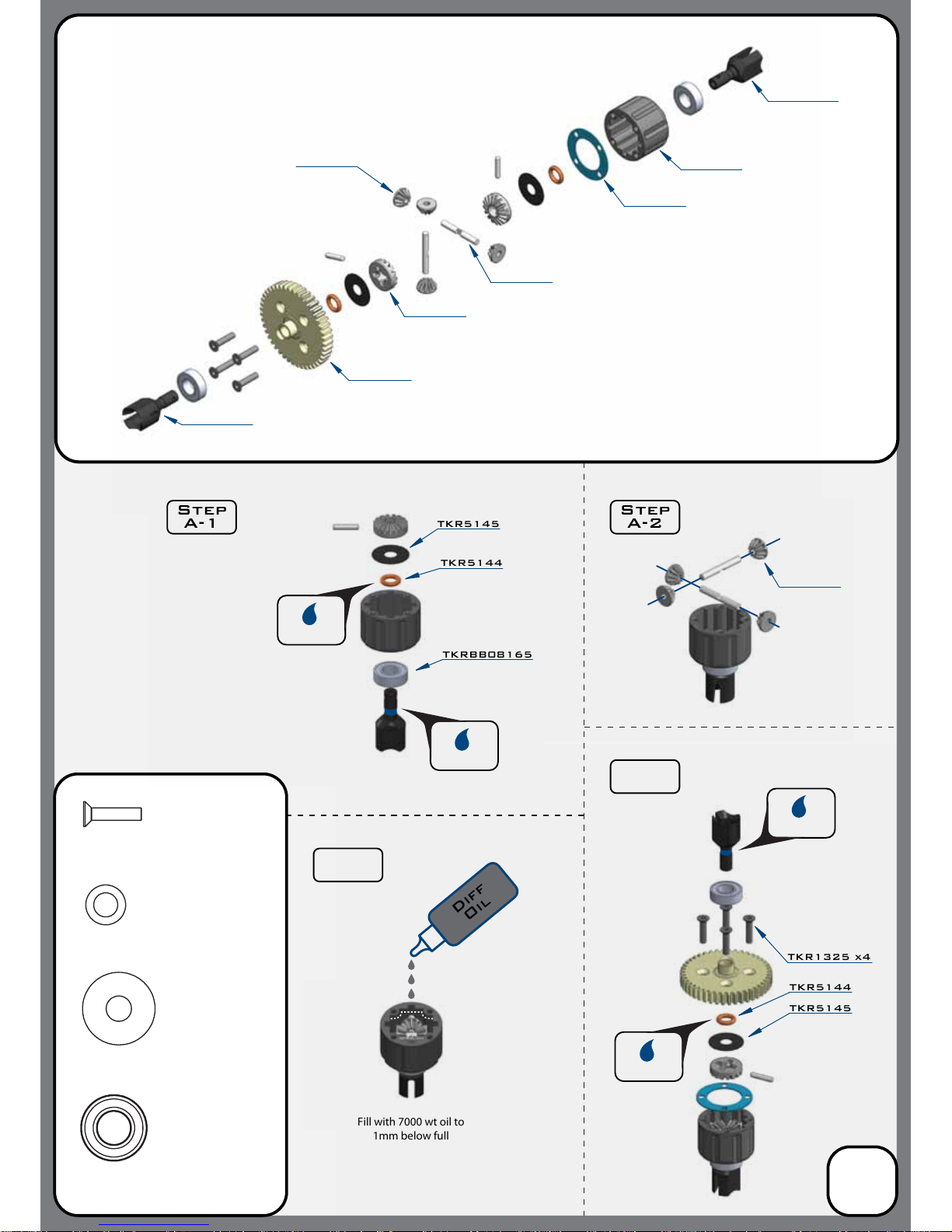

TKR5145

TKR5144

Bag A

Center Differential

(overview)

TKR5112X

TKR5112X

TKR5237

TKR5149

TKR5150

TKR5150

TKR5143

TKR5113

*TKR5115

*TKR5237K

(Option)

Step

A-2

TKR1325

M3x14mm Flat Head Screw

x4

TKR5144

TKR5145

Step

A-1

Fill with 7000 wt oil to

1mm below full

TKRBB08165

Ball Bearing(8x16x5mm)

x2

TKR5144

Differential 0-rings

x2

TKR5145

Differential Shims (6x17mm)

x2

TKR1325 x4

TKRBB08165

Diff

Oil

TKR5150

3

Step

A-4

Step

A-3

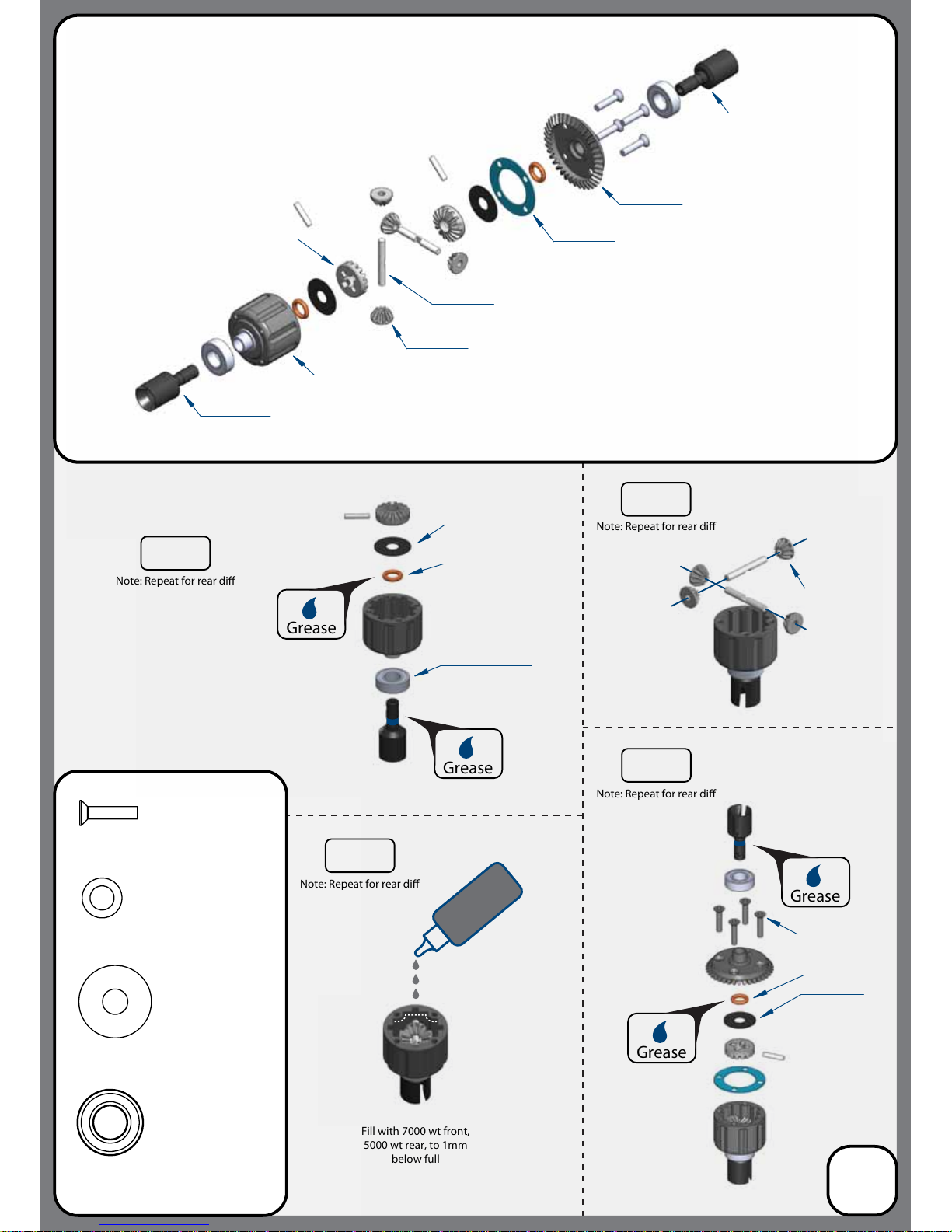

Grease

Grease

Grease

Grease

TKR1325

M3x14mm Flat Head Screw

x8

Fill with 7000 wt front,

5000 wt rear, to 1mm

below full

Note: Repeat for rear di

Note: Repeat for rear di

Note: Repeat for rear di

Note: Repeat for rear di

TKRBB08165

Ball Bearing(8x16x5mm)

x4

TKR5144

Differential 0-rings

x4

TKR5145

Differential Shims (6x17mm)

x4

TKR5114X

TKR5114X

TKR5113

TKR5151

TKR5143

TKR5149

TKR5150

TKR5150

Grease

Grease

Grease

Grease

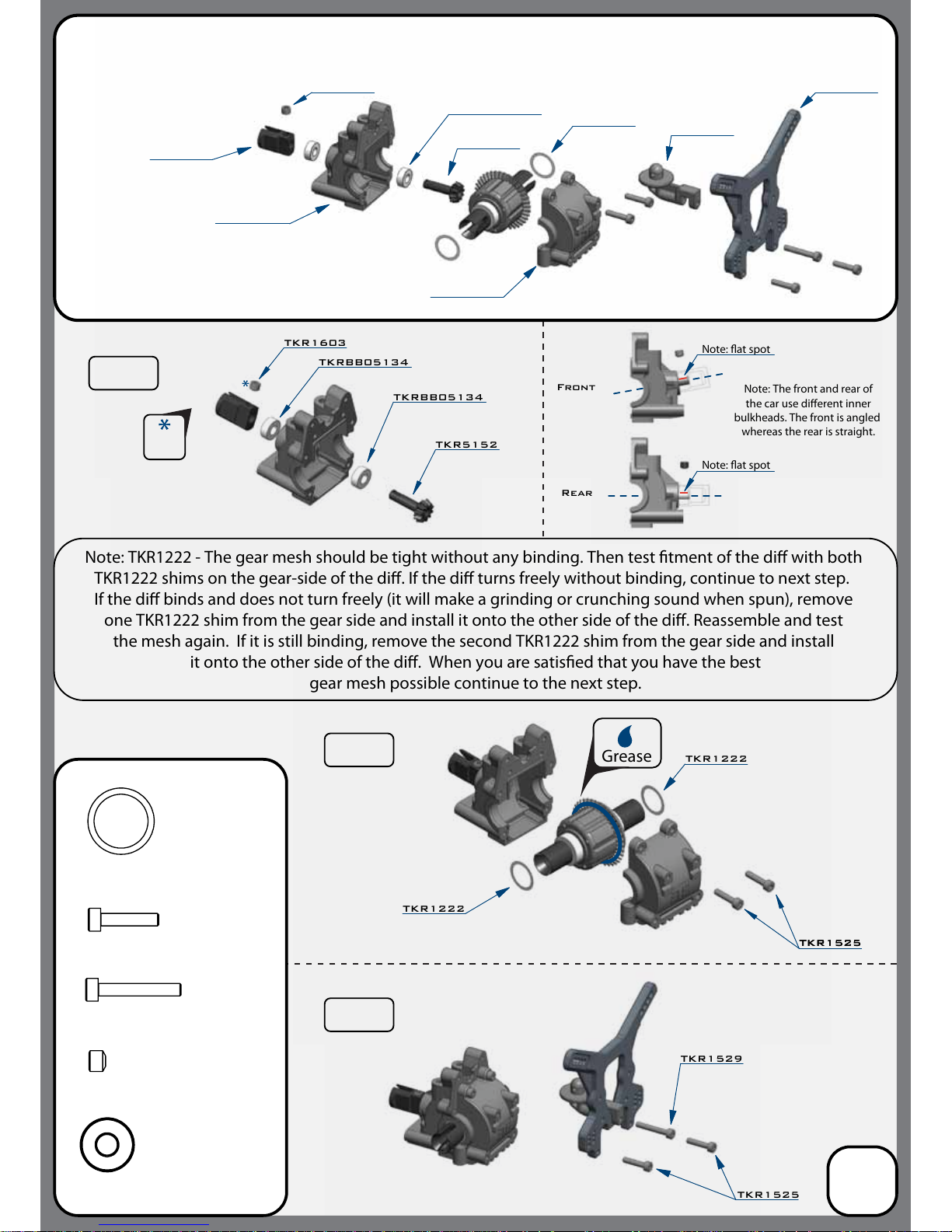

Bag B

Front/Rear Differential

(overview)

Step

B-1

Step

B-3

Step

B-4

Step

B-2

Diff

Oil

4

TKR5145

TKR5144

TKRBB08165

TKR5144

TKR5145

TKR1325 x4

TKR5150

TKR1525TKR1525TKR1525TKR1525

TKR5012

TKR5012

TKR5028

TKR5075

TKR5152

Front

Rear

Note: The front and rear of

the car use dierent inner

bulkheads.

The front is angled

whereas the rear is straight.

x2

TKR1222

TKR1603

TKRBB05114

TKRBB05114

TKR5152

TKR1222

TKR1222

TKR1525TKR1525

13x16x0.1mm Diff shim

Note: TKR1222 - The gear mesh should be tight without any binding. Then test tment of the di with both

TKR1222 shims on the gear-side of the di. If the di turns freely without binding, continue to next step.

If the di binds and does not turn freely (it will make a grinding or crunching sound when spun), remove

one TKR1222 shim from the gear side and install it onto the other side of the di. Reassemble and test

the mesh again. If it is still binding, remove the second TKR1222 shim from the gear side and install

it onto the other side of the di. When you are satised that you have the best

gear mesh possible continue to the next step.

TKR1222

TKRBB05114

TKR1525

M3x14mm Cap Head Screw

x6

TKR1603

M5x4mm Set Screw

TKRBB05114

Ball Bearing (5x11x4)

x2

x1

TKR1603

Grease

Note: at spot

Note: at spot

Bag C

Front Gearbox

(overview)

Step

C-1

Step

C-2

Step

C-3

5

Thread

Lock

TKR5075

TKR5016B

TKR5152

TKR5016B

TKR5026

TKR5029

TKR1222

TKR1222

TKR1525

TKR1529

TKR1222

13x16x0.1mm Diff Shim

x2

TKR1222

TKR1525

M3x14mm Cap Head Screw

x4

TKR1603

M5x4mm Set Screw

TKRBB05134

Ball Bearing (5x13x4)

x2

x1

TKR1529

M3x20mm Cap Head Screw

x1

TKR1603

TKRBB05134

TKRBB05134

TKR5152

TKRBB05134

TKR1603

TKR1525TKR1525

Grease

Front

Rear

Note: The front and rear of

the car use dierent inner

bulkheads.

The front is angled

whereas the rear is straight.

Note: at spot

Note: at spot

Note: TKR1222 - The gear mesh should be tight without any binding. Then test tment of the di with both

TKR1222 shims on the gear-side of the di. If the di turns freely without binding, continue to next step.

If the di binds and does not turn freely (it will make a grinding or crunching sound when spun), remove

one TKR1222 shim from the gear side and install it onto the other side of the di. Reassemble and test

the mesh again. If it is still binding, remove the second TKR1222 shim from the gear side and install

it onto the other side of the di. When you are satised that you have the best

gear mesh possible continue to the next step.

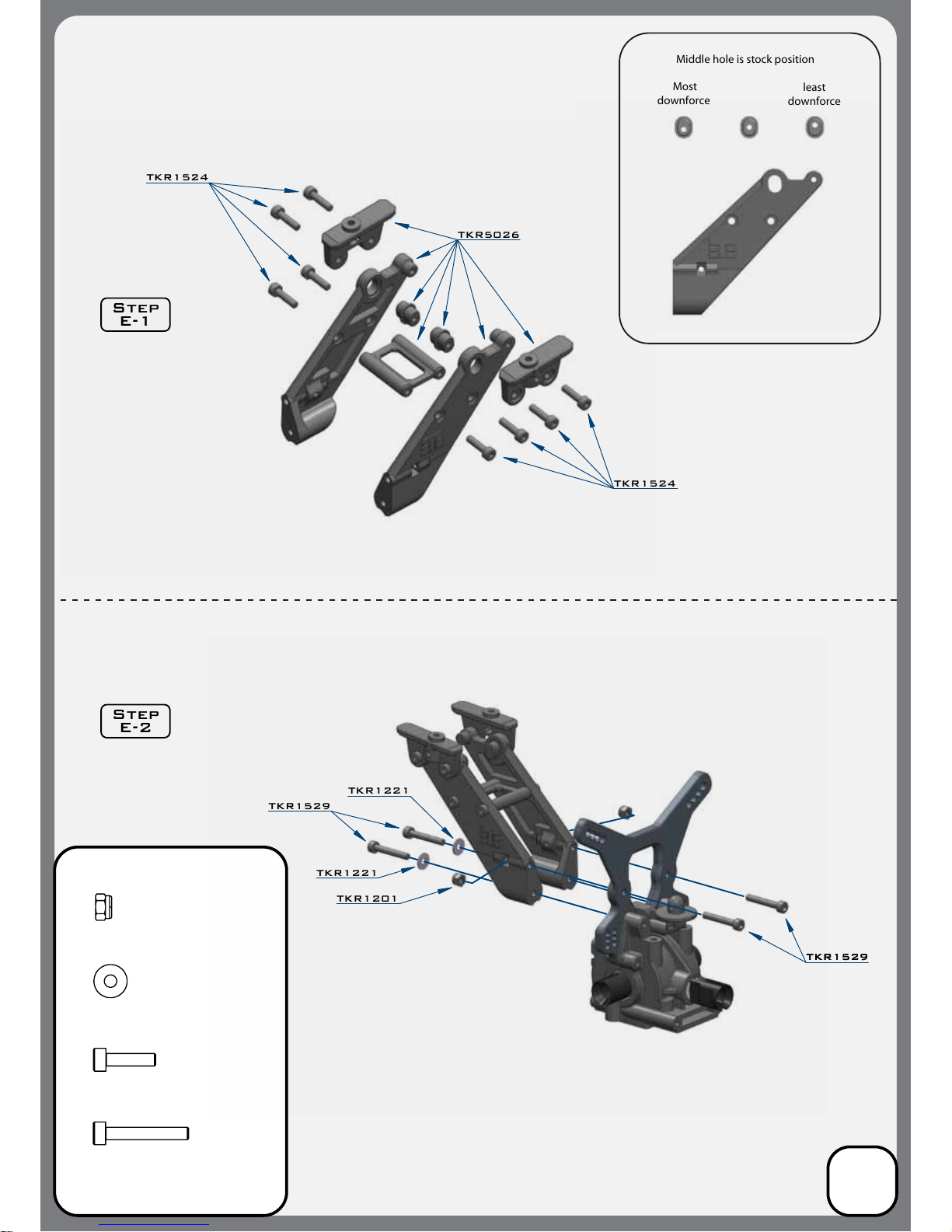

Bag D

Rear Gearbox

(overview)

6

Step

D-1

Step

D-2

Step

D-3

Thread

Lock

TKR1524

TKR1524

TKR1529TKR1529

TKR1529

TKR1201

TKR1221

TKR1221

Most

downforce

least

downforce

Middle hole is stock position

TKR5026

TKR1529

M3x20mm Cap Head Screw

x4

TKR1524

M3x12mm Cap Head Screw

x8

TKR1201

M3 Lock Nut Black

x2

TKR1221

M3x8mm Washer

x2

Step

E-1

Step

E-2

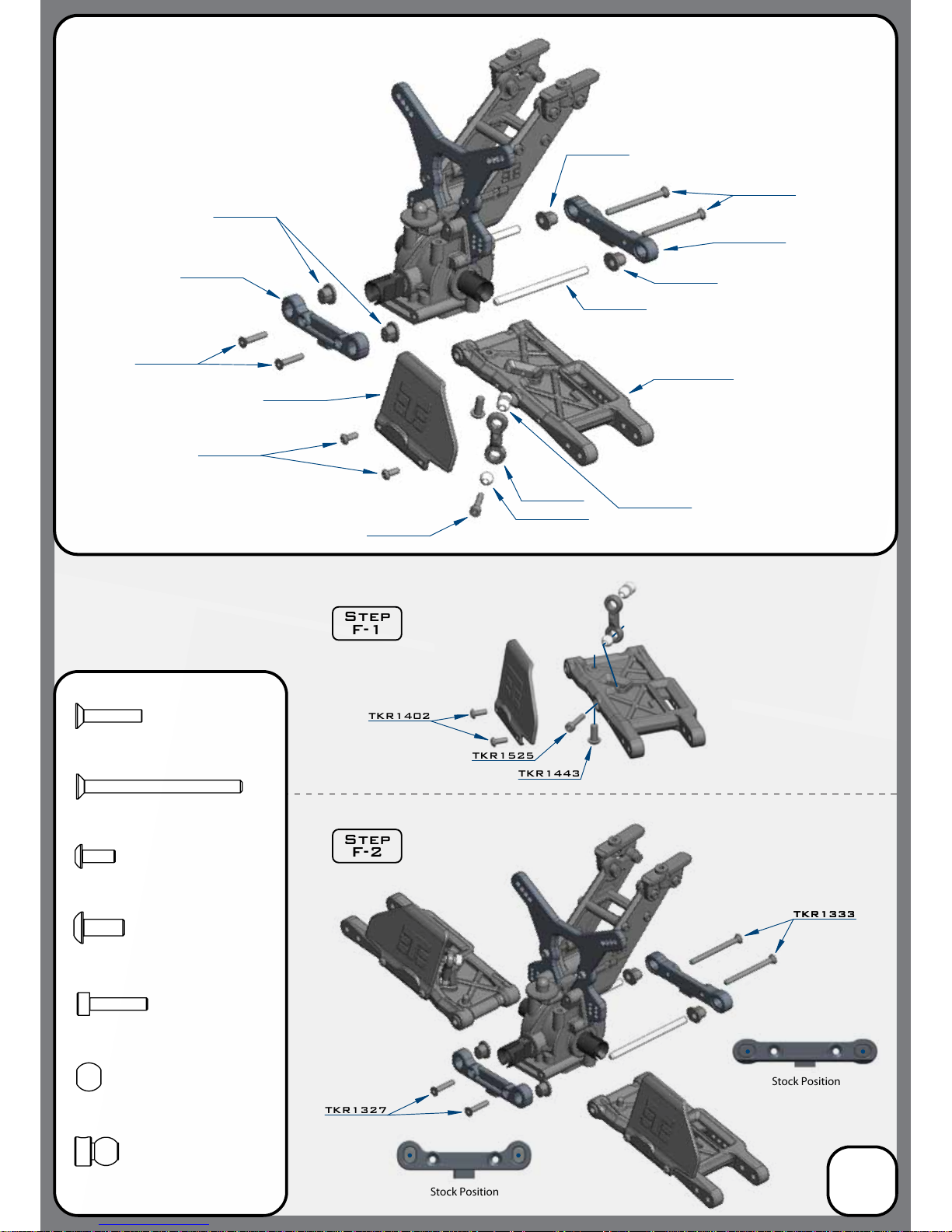

Bag E

Wing Mount

7

TKR1333TKR1333

TKR1327

TKR5030XT

TKR5013B

TKR5020

TKR5013

TKR5033

TKR5056

TKR5079A

TKR5021

TKR5021

TKR5021

TKR5049A

TKR1402

TKR1443

TKR1525

TKR1525

TKR1327

TKR1402

TKR1333

TKR1402

M3x8mm Button Head Screw

x4

TKR1333

M3x40mm Flat Head Screw

x2

TKR1443

M4x10mm Button Head Screw

x2

TKR5049A

Pivot Ball Sway Bar

x2

TKR5079A

Stabilizer Ball

x2

TKR1525

M3x14mm Cap Head Screw

x2

TKR1327

M3x16mm Flat Head Screw

x2

Stock Position

Stock Position

Step

F-1

Step

F-2

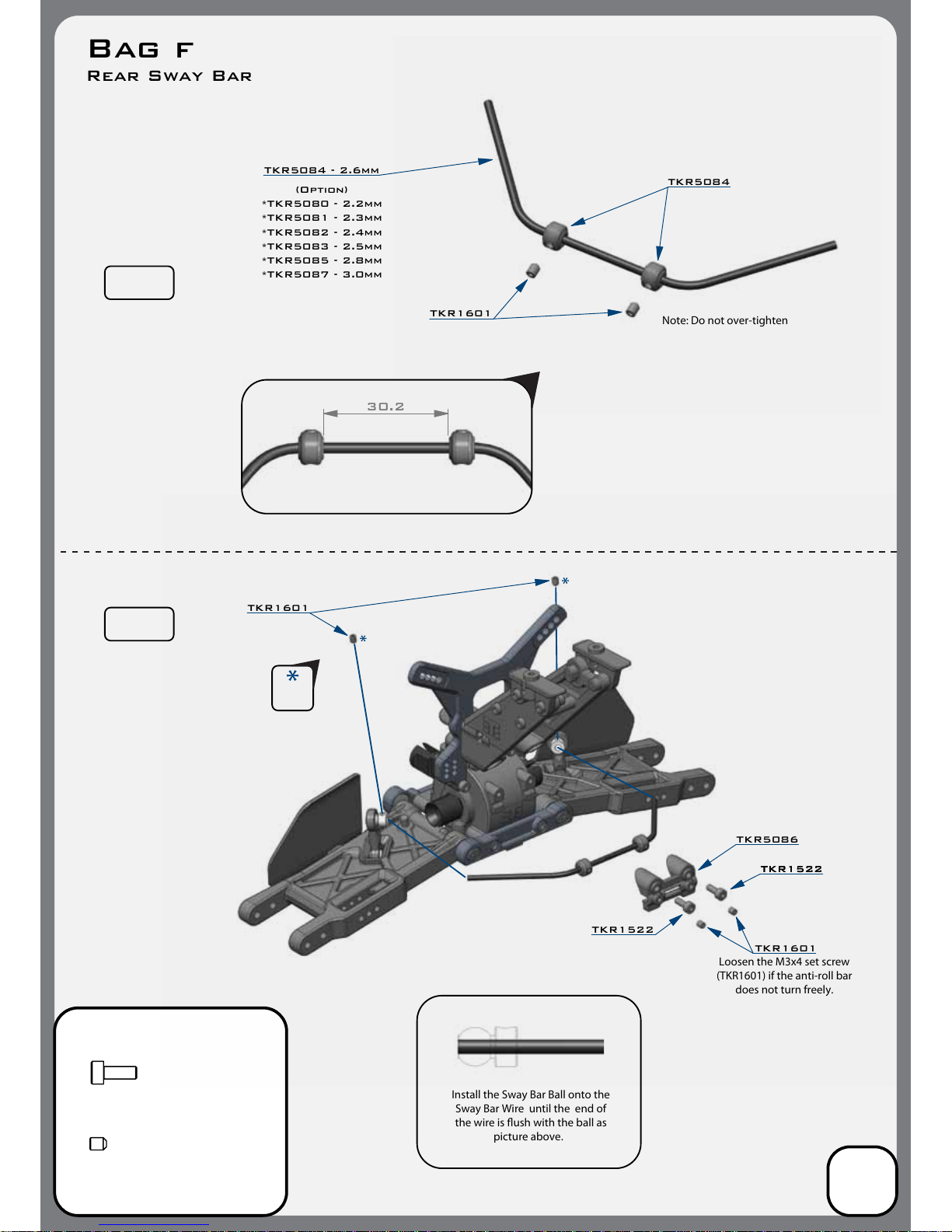

Bag f

Rear Suspension

(overview)

8

30.2

TKR1601

TKR1601

TKR1522TKR1522

TKR1601

TKR5086

TKR5084 - 2.6mm

TKR5084

TKR1522

M3x8mm Cap Head Screw

x2

TKR1601

M3x4mm Set Screw

x6

Install the Sway Bar Ball onto the

Sway Bar Wire until the end of

the wire is ush with the ball as

picture above.

Loosen the M3x4 set screw

(TKR1601) if

the anti-roll bar

does not

turn freely.

Note: Do not over-tighten

TKR1522

Bag f

Rear Sway Bar

(Option)

*TKR5080 - 2.2mm

*TKR5081 - 2.3mm

*TKR5082 - 2.4mm

*TKR5083 - 2.5mm

*TKR5085 - 2.8mm

*TKR5087 - 3.0mm

Step

F-3

Step

F-4

Thread

Lock

9

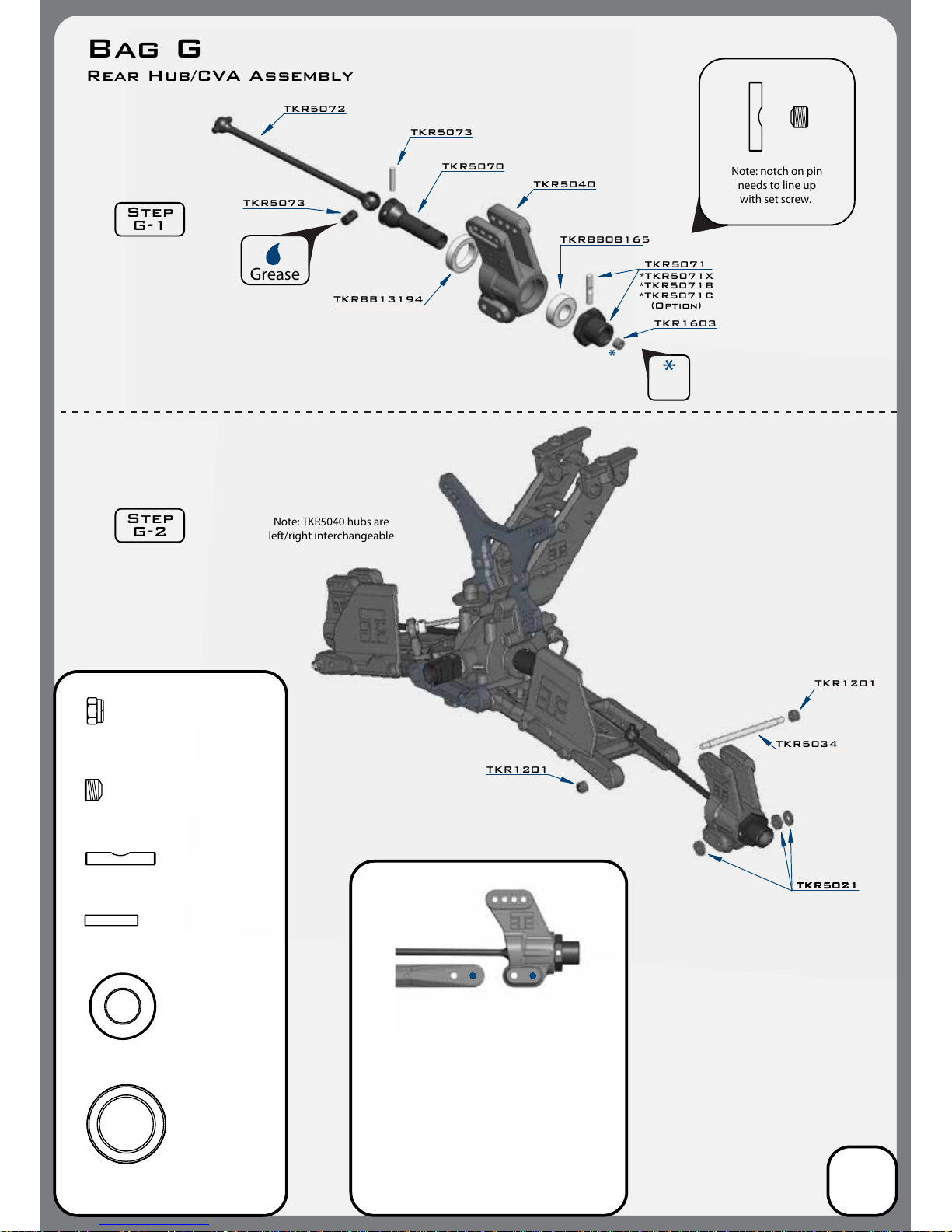

TKR5072

TKR5073

TKR5070

TKR5040

TKRBB13194

TKRBB08165

TKR5073

TKR5071

TKR1603

TKR5034

TKR5021TKR5021TKR5021

TKR1201

TKR1201

Hole "B" is the stock position

*Only use hole A in the arm with

hole A in the hub

*Only use hole B in the arm with

hole B in the hub

The outside hole oers greater stability and

is

recommended for bumpy open tracks.

Inside hole oers greater amount of steering

and is recommended for at technical tracks.

A

B

A

B

Note: notch on pin

needs to line up

with set screw.

Note: TKR5040 hubs are

left/right interchangeable

TKR5071

M3x16.8mm Pin

x2

TKR5073

CV Joint Pin

x2

TKR1603

M5x4mm Set Screw

x2

TKR1201

M3 Locknut Black

x4

TKRBB13194

Ball Bearing (13x19x4)

x2

TKRBB08165

Ball Bearing (8x16x5)

x2

*TKR5071X

*TKR5071B

*TKR5071C

(Option)

Step

G-1

Step

G-2

Grease

Bag G

Rear Hub/CVA Assembly

10

Thread

Lock

Loading...

Loading...