Tekno Point iCFV-xxC/H Installation Manual

iCFV-xxC/H

INSTALLATION

MANUAL IDRA INVERTER

Water cooled

air conditioners

IDRA INVERTER

CONTENTS

GENERAL INFORMATION

SYMBOLS

3

PERMITTED USE

3

RECOMMEDATIONS

4

UNIT DESCRIPTION

CONSTRUCTIVE DESCRIPTION

6

BEFORE PROCEEDING WITH INSTALLATION

6

INSTALLA TION iCFV 11

MINIMUM DISTANCES

15

THICKNESS OF THE COPPER PIPES

19

CONNECTIONS OF THE EXTERNAL UNIT

20

ELECTRICAL CONNECTIONS 22

FINAL STAGES 23

E LECTRICAL WI RI NGS 25

MAINTENANCE 33

2

1 - GENERAL INFORMATION

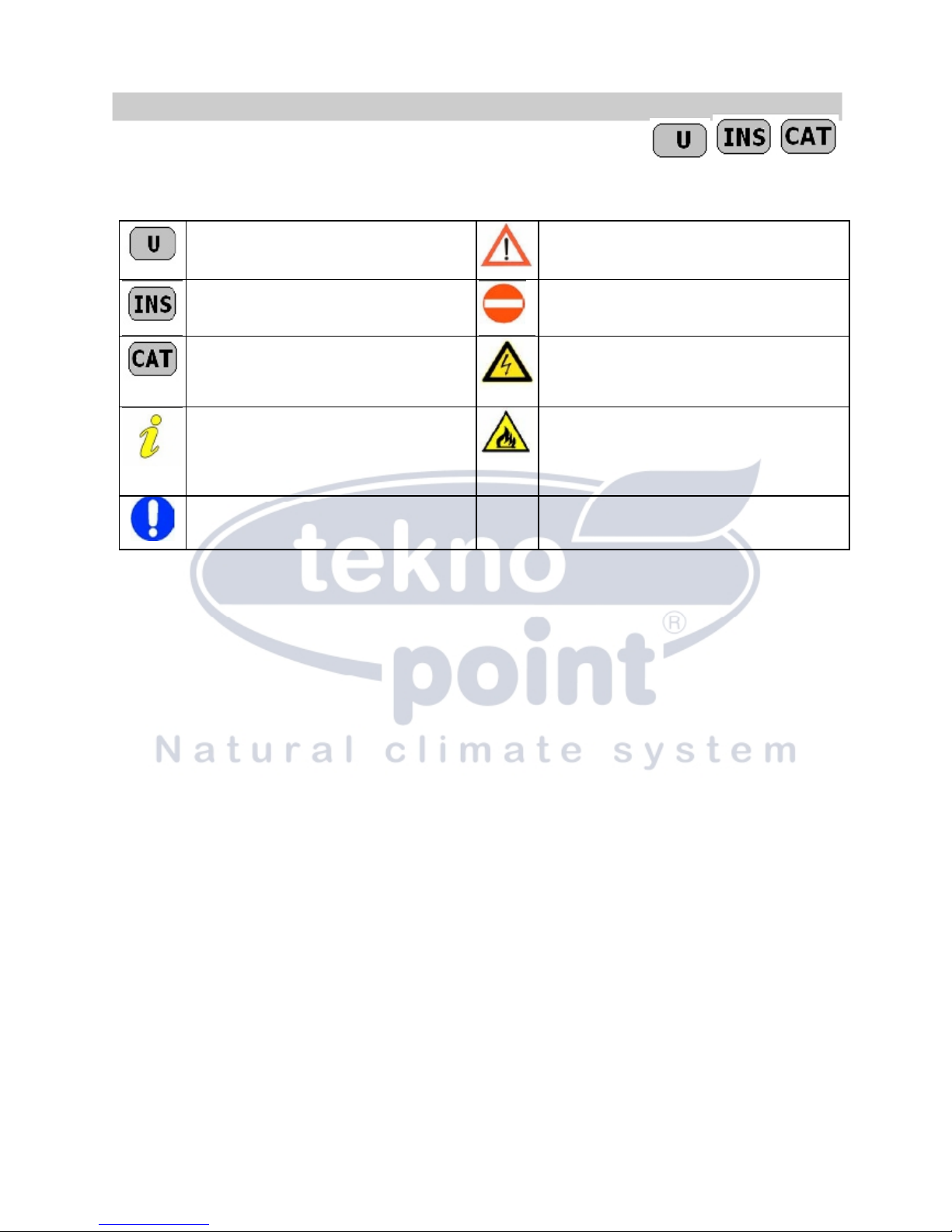

1.1 SYMBOLS

In this publication and/or on this unit the following symbols have been used:

1.2 PERMITTED USE

These machines have been created to heat or cool the air. Use of the units for applications other than those

specifically authorised by the manufacturer is considered inappropriate and, therefore, not allowed. The company

declines all contractual and extra-contractual responsibility for damage caused to people, animals and objects

resulting from errors in installation, calibration and maintenance, improper use, or from the partial or superficial

reading of the information contained in this manual. In addition, keeping in mind the continued product

improvement, T.P.I . reserves the right to change the information found in this manual at any moment without

notice, and declines all responsibility for any inaccuracies in this manual, if due to errors in printing

or copying.

Carefully read this booklet; all operations must be carried out by expert and qualified personnel who are

familiar with the related laws in force in the different countries concerned.

The guarantee will be void in the event the above-mentioned instructions are not followed.

The documentation provided with the unit

must be given to the final client (user) so that it can be kept for

any future maintenance or assistance required.

Upon receipt of merchandise

from the carrier make sure that both the packaging and the unit are intact.

If

damage

or

missing

components

are

noted,

specify

this

on

the

delivery

note

upon

receipt

of

the

unit:

Check all the parts to make sure they have not been damaged during transport. Any damage noted must be

communicated to the carrier writing "accepted with reserve" on the accompanying note, specifying the type of

damage; in addition the company must be informed via fax or certified letter of the formal claim within 8 days

of the receipt of merchandise.

3

USER:

Information, paragraph, chapter of the

manual that concerns the user.

DANGER:

Calls attention to actions that, if

incorrectly carried out, may cause serious injury.

INSTALLER:

Information, paragraph or

chapter of manual that concerns the

installer.

PROHIBITED:

Calls attention to prohibited

TECHNICAL ASSISTANCE CENTRE:

Information, paragraph, chapter of the manual

that concerns the technical assistance centre.

VOLTAGE DANGER:

Calls attention to actions that,

if incorrectly carried out, may cause serious injury or

death to those directly exposed.

IMPORTANT:

Calls attention to technical

information or practical advice which makes

using the unit efficient and economical.

DANGER OF HIGH TEMPERATURE:

Calls

attention to actions that, if incorrectly carried out

may cause serious injury to people caused by the

high temperature of the components.

COMPULSORY: Calls attention to mandatory

actions in order to obtain correct machine

operation.

1 - GENERAL INFORMATION

1.3 RECOMMENDATIONS

Conserve the manual in a dry place, to avoid deterioration, for at least 10 years for future reference.

Completely

and carefully read all the information contained in this manual. Pay particular attention to the any rules

accompanied by the words

«

DANGER

», «

PROHIBITED

»

«

MANDATORY

» in that, if not followed, may cause

damage to the machine and/or people and objects. For potential problems not considered in this manual, promptly

consult T.P.I.'S service assistance centre. The manufacturer declines all responsibility for damage due to

improper machine use or the partial or superficial reading of the information contained in this manual.

The machine must be installed in such a way that makes maintenance and/or repair operations possible.

In any case, the guarantee does not cover, costs due to ladders, scaffolding or other systems of elevation which

may be necessary for carrying out repairs under guarantee.

The manufacturer does not issue drawings or specifications relative to connection systems.

Any deviation from the requirements contained in the following manual must be validated in writing by the

manufacturer's technical assistance department

1.4 FUNDAMENTAL SAFETY RULES

The use of products which utilise energy, electricity and water require following a few fundamental safety rules

including:

Use of the equipment

by children and unassisted disabled persons is prohibited.

Touching the unit while

not wearing shoes or if any part of the body wet or humid is prohibited.

All cleaning operations without having first disconnected the power supply are prohibited; to disconnect the

power, move the switch to the «off» position.

Modification of the safety devices

or adjustment without the authorisation and indications of the manufacturer

is prohibited.

Pulling, removing, or twisting the unit's electrical cables,

even if disconnected from the power supply is

prohibited.

Opening the access doors

to the unit's internal components if prohibited if the unit has not been turned

off via the main switch.

Climbing on, sitting on, and/or resting

any type of object on the unit is prohibited.

Spraying

or dumping water on the equipment is prohibited.

Dispersing or leaving the packaging materials

(cardboard, staples, plastic bags etc.) within the reach

of children is prohibited as they represent a source of potential danger.

Respect the distances of safety

between the machine and other equipment or structures in

order to ensure sufficient space when accessing the unit for carrying out maintenance and/or

technical assistance procedures as described in this manual (see 'technical spaces' chapter).

Powering the unit

: should be via electrical cables that have a section suitable to the power of the

unit and the voltage values must correspond to those indicated for the respective units; all of the

units must be earthed according to the laws in force in the various countries.

Hydraulic

connection must

be carried out as in the instructions in order to guarantee correct

operation of the unit. If, during the winter months, the unit is not running, the hydraulic circuit must

be emptied.

Handle the unit

with the utmost care; do not turn it upside down or place any items that

may cause damage on top of it.

Tampering with, removing, or damaging the unit's identification plates make installation, maintenance

and ordering spare parts difficult.

4

1 - GENERAL INFORMATION

1.5

RECEIPT OF PRODUCT AND HANDLING

The unit is supplied on a wooden pallet and protected by cardboard packaging.

The following are also provided with the unit:

- Instruction booklet

- Guarantee certificate

- EC declaration

- Anti-vibration feet, water filter, gas fitting for internal unit (in models where necessary)

- Ventilation unit documentation (in its own packaging)

- connection card (inside electrical panel)

The Use and Maintenance booklet is an integral part of the unit; carefully read and

preserve it.

Remove the packaging only when the unit is in the installation position.

Once the packaging is removed, handling and movement of the unit must only be done by qualified

personnel with tools suited to the weight of the structure.

The condensing unit can only be handled when the unit is in a vertical position.

Do not disperse packaging materials in the environment or leave them within the reach of children as

they represent a potential source of danger.

Dispose of packaging according to the laws in force in the country concerned.

Check upon receipt of the unit that there is no damage caused by transport and/or handling

and that the packaging contains all accessories requested.

5

2 - UNIT DESCRIPTION

2.1 BEFORE PROCEEDING WITH INSTALLATION

Before installing the unit, carefully read and store the user manual and manufacturer's general conditions listed

below.

1. Make sure that the unit corresponds with the needs of the system.

2. Make sure that the cooling water flow is sufficient for the proper functioning of the system.

3. Make sure that refrigeration (MCW) and hydraulic piping is correct according to the manufacturer's

requirements.

4. Assemble the water filter provided to protect the plate exchanger (water inlet).

5. If impurities are present in the water, perform periodic filter maintenance.

6. Make sure the electrical connection terminals are powered by the correct voltage (see unit's identification

plate). An incorrect voltage will irreparably jeopardise the main components of the unit.

7. If alarms are activated, consult the user manual or contact the manufacturer’s service assistance centre.

8. Do not force, for any reason, the operation of the unit, or tamper or alter the safety devices inside it.

9. Start up cannot be carried out with incomplete, provisional systems or carried out in a precarious manner.

10. The connections to the unit (hydraulic and electric) must be carried out by skilled, competent personnel

and must meet all safety standards and health regulations currently in force in the country in which

the unit is used.

11. The technical documentation (diagrams and manuals) must be kept in good condition in an easily accessible

place for quick reference when needed.

12. The unit should not be used for purposes that do not correspond with the uses for

which it was built.

13. Respect the technical spaces indicated in this manual to ensure good access to the unit during maintenance.

14.

If

damage occurs to the unit caused by the failure to comply with the above-mentioned points or the

information contained in this manual, the manufacturer reserves the right to partially or completely void the

guarantee.

15. Contact the manufacturer's Technical Assistance Centre for further explanation or clarification regarding the

above information.

6

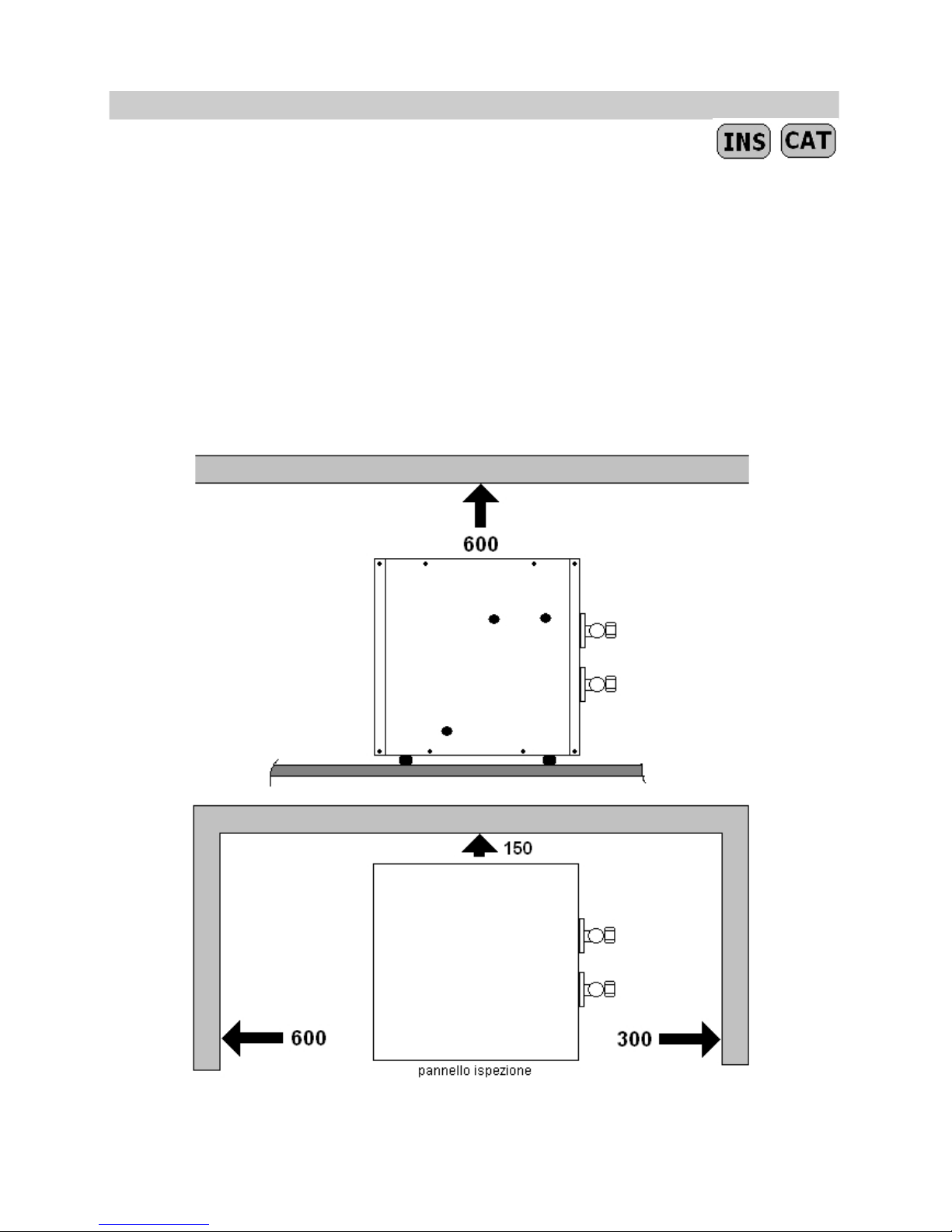

3 - INSTALLATION

3.1 PLACE OF INSTALLATION

The place of installation must be agreed upon with the custo mer, paying attention to the following:

· The unit must be placed in a suitably sized space whose dimensions conform to existing regulations in the

country where it will be installed.

· The condensing unit should not be installed outdoors.

· The surface on which it will be placed must be able to support its weight.

· In case of multiple installations (2 or more IDRA), DO NOT STACK the condensing units.

· Proper installation should allow authorised personnel to intervene in case of maintenance, in an easy manner,

observing the safety distances between units and other equipment indicated below:

7

3 - INSTALLATION

3.2 HYDRAULIC AND REFRIGERATION CIRCUITS

The installer is responsible for the correct selection and application of components according to current national

standards and as recommended below.

3.3 HYDRAULIC COMPONENTS

The hydraulic connections are made on the fittings located on the right side of machine.

The hydraulic connections are distinguished by labels that indicate the flow: WATER INLET AND OUTLET

Provide and interception tap on the water inlet, use piping with an internal diameter that corresponds to the

diameter of the condensing unit's fittings because otherwise operation problems may result (the guarantee is

voided if improper piping is used).

WARNING: ALWAYS MOUNT THE INSPECTION FILTER ON THE WATER INLET

AND ENSURE THE CORRECT POSITIONING OF THE FILTERING UNIT

RESPECT MINIMUM DIAMETERS REQUIRED ON THE UNIT, CHECK THE WATER SUPPLY FLOW.

3.4 REFRIGERATION CONNECTIONS

The refrigeration connections are made on the fittings located on the right side of the unit. The connections on

the refrigeration lines are "flare” connections.

3.5 CONNECTIONS BETWEEN THE EVAPORATOR AND CONDENSING UNITS

The indoor unit must be connected to the condensing unit via Flare connections with a refrigerator quality

copper pipe at the ends of flare nuts and insulated along the entire length. It is absolutely necessary to respect

the

diameters

provided

on

IDRA INVERTER units

otherwise

the

guarantee

will

be

voided.

If

evaporator

units

with

refrigeration fittings different than those on the IDRA INVERTER units are used, use dedicated reduction connections

(attention: mount these fittings on the evaporator unit).

3.6 PIPE PREPARATION

Use only refrigeration quality copper pipes with a suitable diameter for each model. The gas and liquid

pipes must absolutely be insulated with insulation that has a minimum thickness of 6mm.

Insert the flare nuts on the pipe ends before preparing them with a countersink tool. The pipes, separately

insulated with the relative fittings can later be bound to the condensing unit's evacuation pipe and the

electrical cables using clamps.

3.7 PIPE ROUTE

The radius of curvature of the pipes must be equal or greater than three and a half times the diameter of the

pipe axis. Do not bend the pipes more than 3 times consecutively and not make more than 10 curves on the total

length of the connection. If there is more than a 5m difference between the evaporator unit and condensing

unit, a siphon must be placed at every 3 m. The siphon must have a radius of curvature that is as narrow as

possible.

3.8 AIR EXTRACTION IN REFRIGERATION AND

EVAPORTATOR PIPES

The R410a load is only contained in the condensing unit. The inner unit contains a small quantity of neutral gas.

Therefore, after having made the connections, it is necessary to extract the air contained in

these connections and in the inner units.

WARNING: IT IS NECESSARY TO USE A COUNTER KEY TO TIGHTEN THE VALVES.

8

3 - INSTALLATION

3.9 ASSEMBLY PROCEDURE

The IDRA INVERTER condensing unit MUST BE INSTALLED in an accessible place that allows for safe technical interventions;

if this is not the case, the Technical Assistance Centre may refuse intervention.

THE IDRA INVERTER CONDENSING UNIT MUST NOT BE INSTALLED OUTDOORS BECAUSE DURING

WINTER MONTHS ITS HYDRAULIC CIRCUIT MAY BE DAMAGED

ALWAYS PUT AN INSPECTABLE FILTER ON THE WATER INLET (500 micron mesh).

Connect the connection pipes to the condensing unit and the internal unit.

Connect the vacuum pump to the fitting (suction), start it up, and make sure that the indicator pointer goes

down to 0.1 Mpa (-760 mm Hg). Before disconnecting the vacuum pump ensure the vacuum indicator is stable

for >15 minutes.

Close the service valve and disconnect the vacuum pump.

Remove the caps from the "GAS" and "LIQUID" valves and open them with a hexagonal key to release the

R410a contained in the IDRA INVERTER, then put the caps back on.

Check that the connections are sealed properly .To do this use an electronic leak detector or a spray solution

for leak detection.

3.10 ADJUSTING THE REFRIGERANT LOAD

Depending on the connection length of each route, it may be necessary to top up the R410a load (the condensing

units are pre-filled with a line of 5 metres). This operation must be carried out by a qualified person who is an

expert in refrigeration. The complete load is introduced via the service valve or via the condensing unit's Flare

(large fitting). If the refrigerant line is less than 5 m “discharge" the quantity of excess refrigerant. All operations

involving refrigeration circuits require observing recommendation regarding the disposal of R410a

(according to local laws in force).

*See the technical data sheet.

3.11 ELECTRICAL CONNECTIONS

A proper and effective earthing connection is mandatory

;

the manufacturer is not responsible for damages caused by inappropriate or insufficient connections.

Electrical connections must be made respecting the following:

•

Use cables which are compliant with the laws in force in the different countries.

•

Follow the order of connection for the phase, neutral and earthed conductors.

•

Install a suitable protection and electric energy sectioning device with a delayed curve, a contact opening of

•

at least three millimetres and an adequate interruption and differential protection power.

9

3 - INSTALLATION

If the unit powering is three-phase, make sure to follow the exact sequence of the phases.

The supply voltage of the condensing unit must have a value between ± 10% of the value

indicated on the manufacturing data plate. If this is not followed, contact the local supplier of electric power.

In the case of three-phase power, the imbalance between the three phases should not exceed 3%.

Putting electrical connection cables inside the condensing unit in any part not approved by the

manufacturer is prohibited.

The power cable must be passed through one the holes with a rubber fairlead located on the left side of the

machine. The electrical connections are made on the terminal board located inside the components and

electrical compartment on the rear of the inspection panel.

Connect the cable to the terminals inside the electrical panel.

Absolutely avoid direct contact with metal parts.

Make sure, after the condensing unit has been operating for about 10 minutes that the screws on the power

terminal are closed.

Warning: Verify compatibility when using evaporator units NOT PROVIDED BY T.P.I.

The

connection between the

ventilation and

condensing

unit

requires

a

pentapolar

cable

(5 X

1.5

mm

q).

Power the IDRA unit with a cable suitable to the power consumption and install a properly sized general isolator

switch (in compliance with laws in force).

10

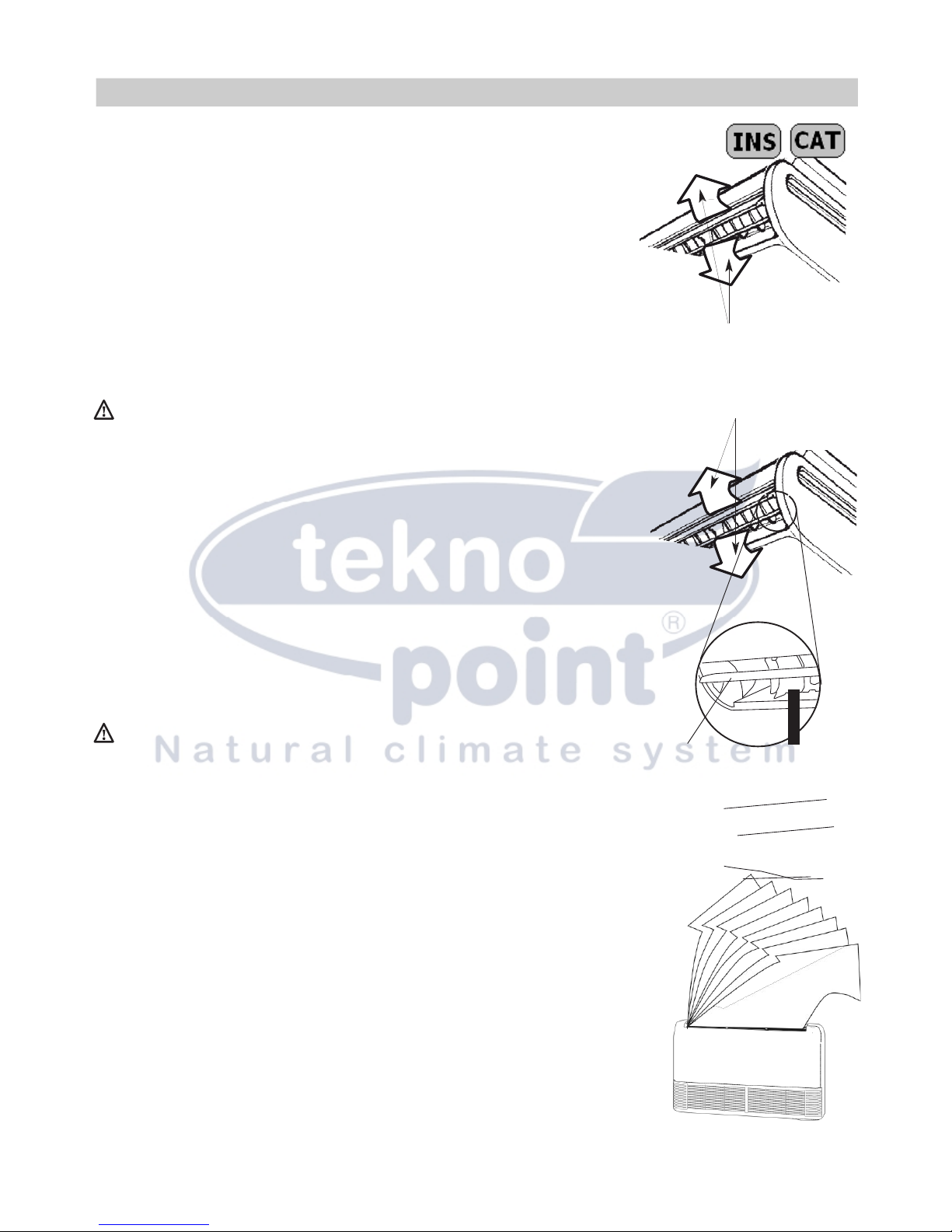

3 – INSTALLATION iCFV-xxC/H

ADjUSTING

THE DIRECTION OFTHE

AIR FLOW

When you press the SWING vertic al bu t ton , the o sc ill ating v er ti ca l mov e ment o f the

directional flaps is enabled, when you press the SWING horizontal button ,the

oscillating

horizontal movement of the directional flaps is enabled To ensure the uniform

diffusion of

air throughout the room.

Press the AIR DIRECTION button again and the oscillating movement of the flaps stops in the

desired position and the air flow is directed in one direction only:

-we recommend you direct them upwards in cooling mode(to avoid having the direct flow of cool air).

-we recommend you direct them downwards in heating mode(as hot air tends to rise).

ATTENTION

-Unplug the appliance or switch off the dedicated switch before performing any operations

(risk of personal injury from electrocution).

-Do not direct the air flow directly towards people, artworks or animals (risk of causing

damage to things and personal injury to people’s skin)

-Do not insert or attempt to insert your fingers or various objects in the internal and external unit

air outlets and in the inlet grilles (risk of personal injury from cuts).

-Do not touch the air conditioning unit with wet hands (risk of electrocution).

ADVICE ON ENERGYSAVINGS

-Do not programme too high a temperature (in heating mode) or too low a temperature

(in cooling mode).

-Avoid installing the internal/external units in places directly exposed to sunlight(this

could prevent the appliance from operating at its best).

-Avoid opening and closing doors and windows too frequently, as the ongoing heat exchange

with the outside hinders the operation of the air conditioning unit.

-Use the “Timer” for the timed starting of the appliance to prevent the appliance from

opera- ting unnecessarily while you are out.· Use the “SLEEP” function at night.

ATTENTION

-Do not attempt to perform maintenance operations requiring the opening of the appliance

yourself: the presence of live elements and the gas contained n the cooling circuit

make these operations particularly dangerous (risk of personal injury from electrocution

and cold burns).

-When moving home, contact an authorised specialist.

Note:

-In cooling mode, you may detect a slight mist coming out of the Internal Unit for a few

seconds: this is completely normal and due to the difference in temperature between

the air exiting the appliance and the air inside the room.

-During operation, you may hear a noise similar to the flowing of water: this is completely

normal, owing to the liquid refrigerant flow ing throug h t he pipin g.

-When the air conditioning unit starts or stops, especially in heating mode, you may hear

a little creaking: this is due to the thermal expansion of the parts making up the appliance.

11

Loading...

Loading...