Tekno NB-48.3 Building Instructions

Introduction

Disclaimer: Tekno RC is not responsible or liable for any property or personal damage, loss, or

injury incurred as a result of using this product. This kit is meant for use by persons 14 years of

age or older and in the strict connes of a legally permitted RC track or facility.

Warnings: Always double-check that your radio gear is working properly before operating vehicle.

Never operate the vehicle indoors (unless the RC track is an indoor facility). Use caution while

operating vehicle so as not to collide with people who may be turn marshalling or who might

otherwise not be aware that a fast moving RC vehicle is in the vicinity.

Warranty: We warrant that the parts included in this kit are free from defects. If you nd a

defective part in your kit, please contact us @ info@teknorc.com and we will help you to resolve

the issue. We do not warranty parts that may be broken during operation of the vehicle or

otherwise. Refer to the end of this instruction manual for a listing of spare/replacement and

option parts. All spare parts and other info are available on our website (www.teknorc.com)

and through our network of domestic and international dealers and distributors.

Additional equipment and parts needed:

2/3 channel surface radio transmitter and receiver

High torque steering and brake servo (at least 300 oz/in)

RX battery, switch harness

.21 nitro engine, tuned pipe, manifold, and glow plug

Fuel bottle, fuel, 1/8th buggy starter box, and glow ignitor

1/8th scale buggy tires, wheels & CA glue

Paint for body

Tools needed:

Hex drivers 1.5mm (TKR1104), 2.0mm (TKR1105), 2.5mm (TKR1106)

Nut drivers 5.0mm (TKR1107, 5.5mm (TKR1108), 7.0mm (TKR1109)

17mm Wheel Wrench (TKR1116)

Hobby knife

Needle-nose pliers

Pivot Ball and Shock Multi-tool (TKR1115, for shock assembly)

4mm turnbuckle wrench (TKR1103)

4mm arm reamer

Lexan Body Scissors

Thank you for purchasing the Tekno RC NB48.3 1/8th 4WD Nitro Competition Buggy. The NB48.3

represents the state-of-the-art in 1/8th nitro buggy technology. We hope you have as much fun

driving your new vehicle as we did developing it. We are always working on new projects, so please

check our website (www.teknorc.com) regularly for the latest news, parts, and kits. Thanks again.

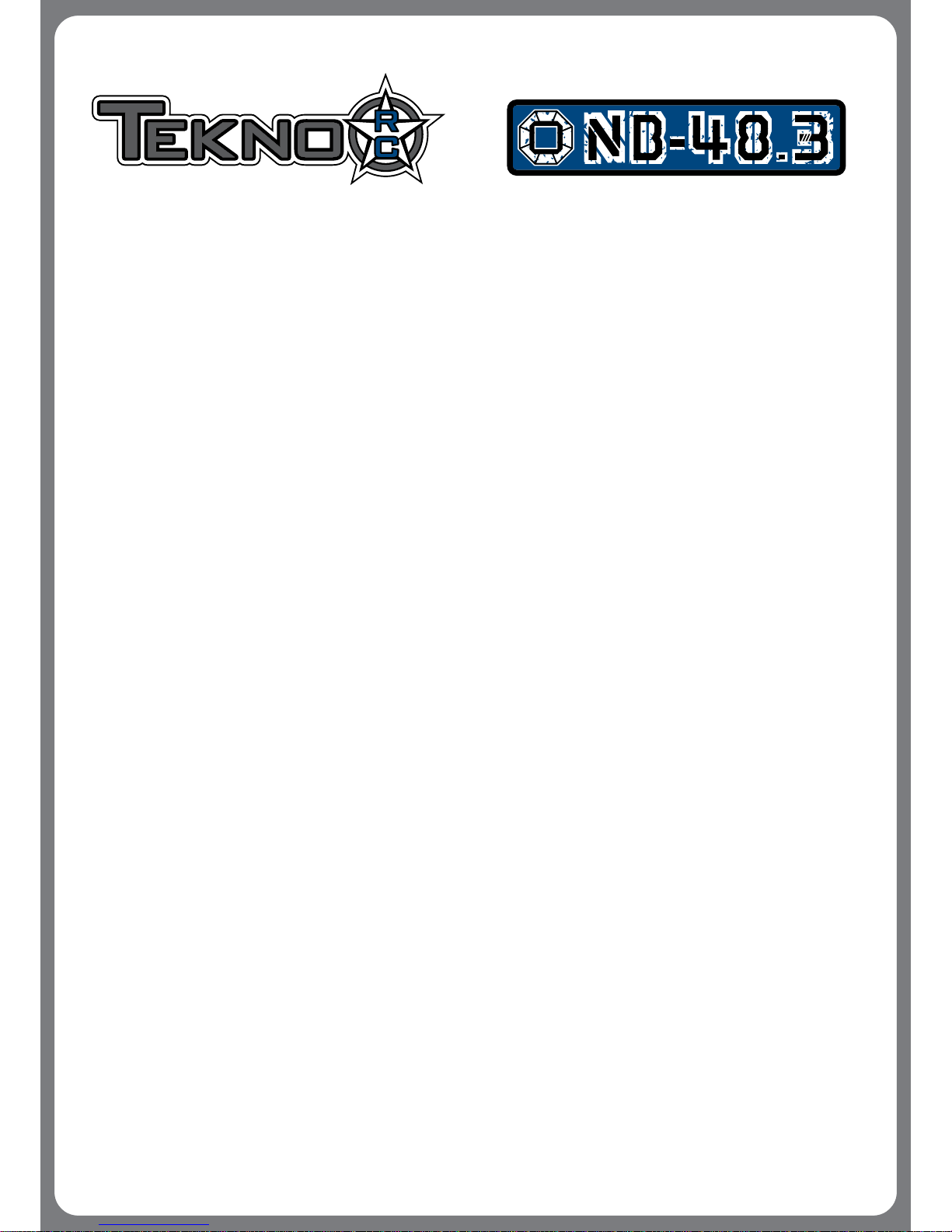

Apply grease to the groove

where the o-ring is placed

as well as the o-ring itself

Apply grease to the groove in the outdrive

Fill with 5000 wt oil to

1mm below full

DO NOT OVER FILL

TKR5145B

TKR5144

Bag A

Front Differential

(overview)

TKR5151

TKR5149

TKR5150

TKR5150

TKR5143

TKR5113

TKR1325

M3x14mm Flat Head Screw

x4

TKR5144

TKR5145B

TKRBB08165

Ball Bearing(8x16x5mm)

x2

TKR5144

Differential 0-rings

x2

TKR5145B

Differential Shims (6x17mm)

x2

TKR1325 x4

TKR5149

TKRBB08165

Diff

Oil

TKR5114X

TKR5114X

TKR5150

TKR5144

3

Grease

Grease

Grease

Grease

Step

A-2

Step

A-1

Step

A-4

Step

A-3

*TKR5149A

(Option)

*TKR5149A

(Option)

Apply a liberal

amount of grease in the

areas between the shims

and o-rings, as well as

around the outdrive and

both sides of the seal

TKR1325

M3x14mm Flat Head Screw

x4

TKRBB08165

Ball Bearing(8x16x5mm)

x2

TKR5144

Differential 0-rings

x2

TKR5145B

Differential Shims (6x17mm)

x2

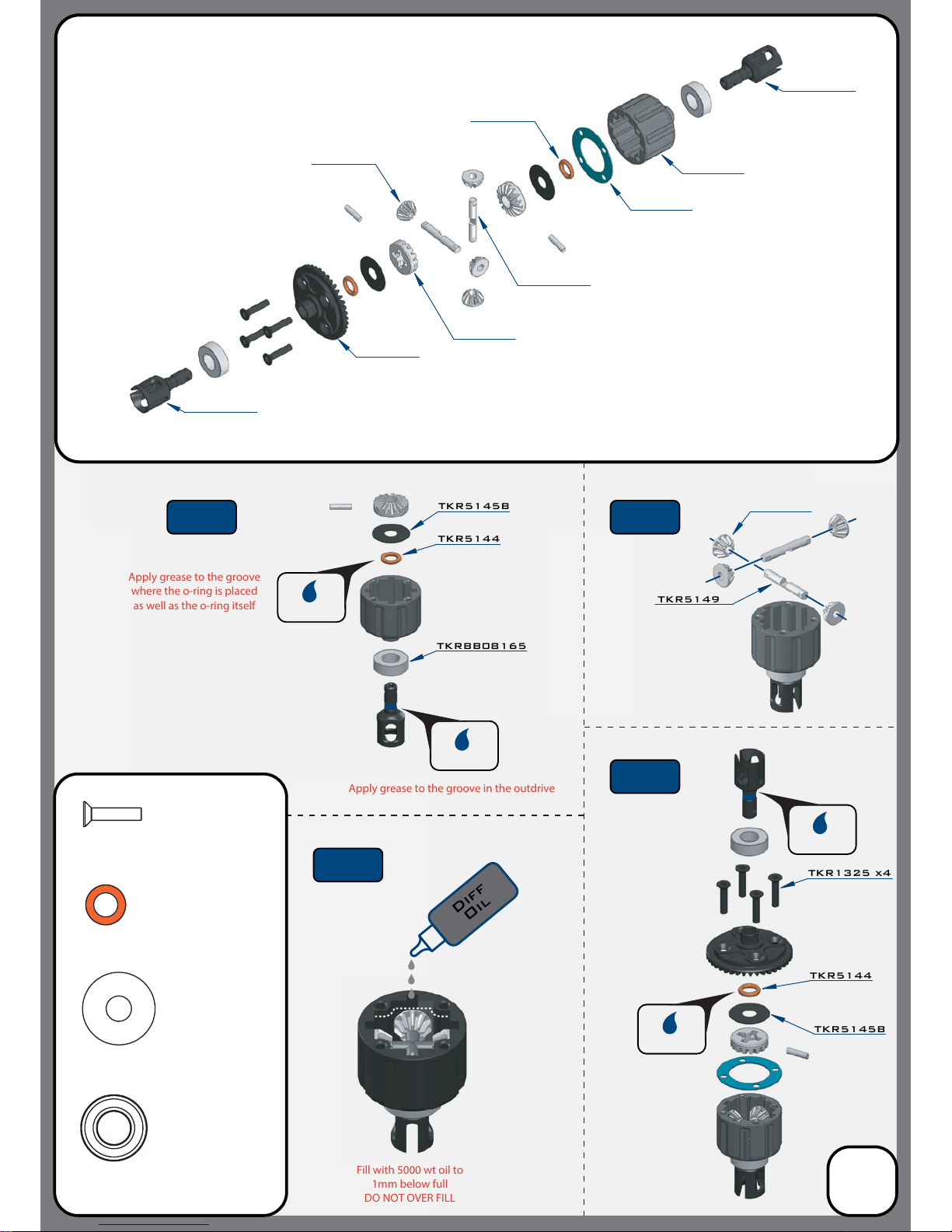

TKR5112X

TKR5112X

TKR5113

TKR5119

TKR5143

TKR5149

TKR5150

TKR5150

Grease

Grease

Grease

Grease

Bag B

Center Differential

(overview)

Step

B-1

Step

B-3

Step

B-4

Step

B-2

Diff

Oil

4

TKRBB08165

TKR5119

TKR5145B

TKR1325 x4

TKR5144

TKR5143

TKR5150

TKR5144

TKR5145B

TKR5150

Apply a liberal

amount of grease in the

areas between the shims

and o-rings, as well as

around the outdrive and

both sides of the seal

Apply grease to the groove

where the o-ring is placed

as well as the o-ring itself

Apply grease to the groove in the outdrive

Fill with 5000 wt oil to

1mm below full

DO NOT OVER FILL

TKR5149

*TKR5149A

(Option)

*TKR5115

(Option)

*TKR5115

(Option)

*TKR5149A

(Option)

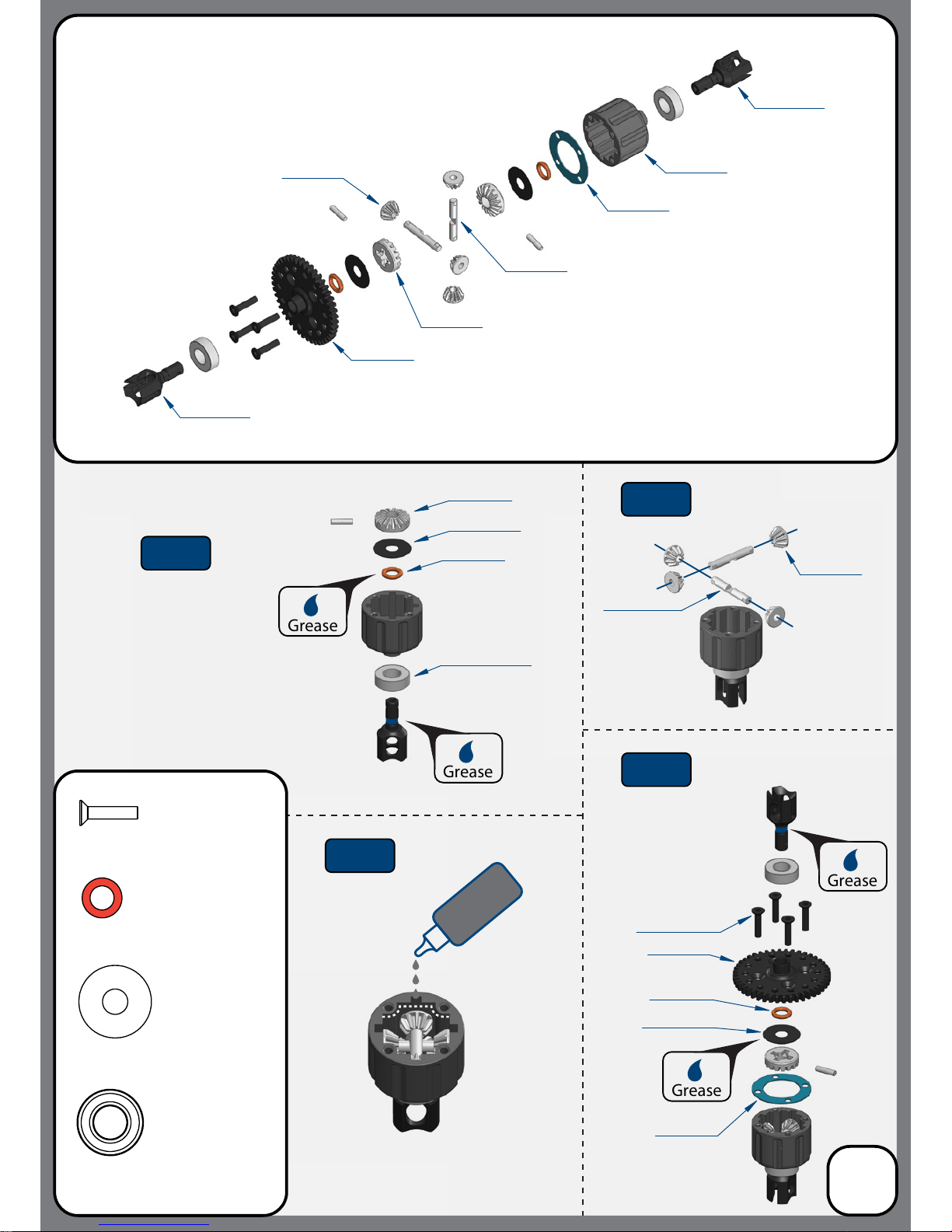

TKR1325

M3x14mm Flat Head Screw

x4

TKRBB08165

Ball Bearing(8x16x5mm)

x2

TKR5144

Differential 0-rings

x2

TKR5145B

Differential Shims (6x17mm)

x2

TKR5114X

TKR5114X

TKR5113

TKR5302

TKR5143

TKR5149

TKR5150

TKR5150

Grease

Grease

Grease

Grease

Apply grease to the groove

where the o-ring is placed

as well as the o-ring itself

Apply grease to the groove in the outdrive

Fill with 5000 wt oil to

1mm below full

DO NOT OVER FILL

*TKR5149A

(Option)

TKR5149

*TKR5149A

(Option)

Bag C

Rear Differential

(overview)

Step

C-1

Step

C-3

Step

C-4

Step

C-2

Diff

Oil

5

TKRBB08165

TKR5302

TKR5145B

TKR1325 x4

TKR5144

TKR5143

TKR5150

TKR5144

TKR5145B

TKR5150

Apply a liberal

amount of grease in the

areas between the shims

and o-rings, as well as

around the outdrive and

both sides of the seal

TKR5075

TKR5012

TKR5152

TKR5012

TKR5268

TKR1222

TKR1222

TKR1525

TKR1525

TKR1222

TKR1525

TKR1222

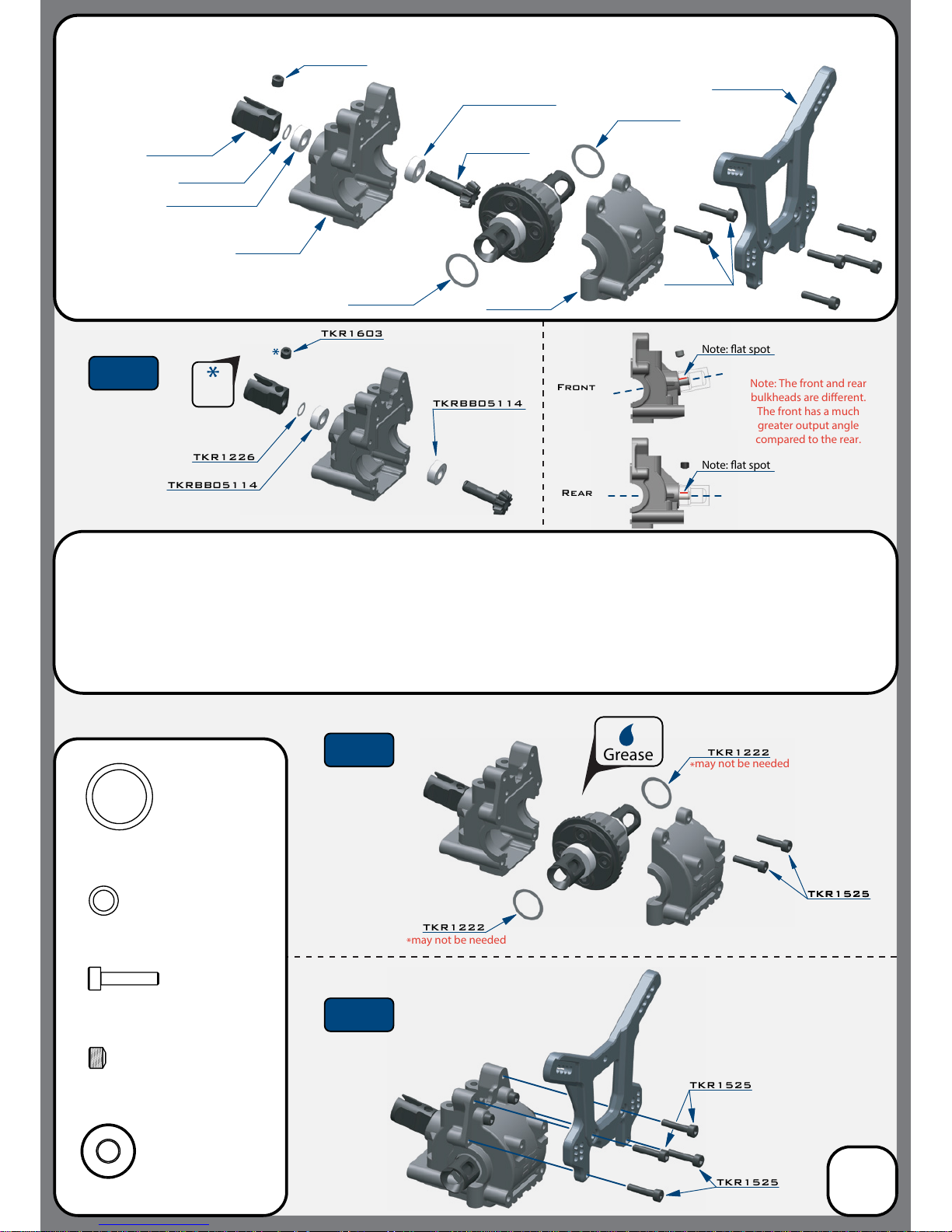

TKR1226

TKRBB05114

TKR1525

M3x14mm Cap Head Screw

x6

TKR1603

M5x4mm Set Screw

x1

TKR1222

13x16x0.1mm Diff Shim

x2

TKR1226

5x7x0.2mm Shim

x1

TKR1603

TKRBB05114

TKRBB05114

TKR1226

TKRBB05114

TKR1603

TKR1525TKR1525

Grease

Front

Rear

Note: at spot

Note: at spot

Note: The front and rear

bulkheads are dierent.

The front has a much

greater output angle

compared to the rear.

*

may not be needed

*

may not be needed

Bag D

Front Gearbox

(overview)

6

Thread

Lock

Step

D-1

Step

D-2

Step

D-3

Note: TKR1222 and TKR1226 Shims - The gear mesh should be tight without any binding. TKR1226 should

always be installed. Then test tment of the di with both TKR1222 shims on the gear-side of the di. If the di

turns freely without binding, continue to next step. If the di binds and does not turn freely (it will make a

grinding or crunching sound when spun), remove one TKR1222 shim from the gear side and install it onto the

other side of the di. Reassemble and test the mesh again. If it is still binding, remove the second TKR1222 shim

from the gear side and install it onto the other side of the di. When you are satised that you have the best

gear mesh possible continue to the next step. You may end up using only one shim on the gear side.

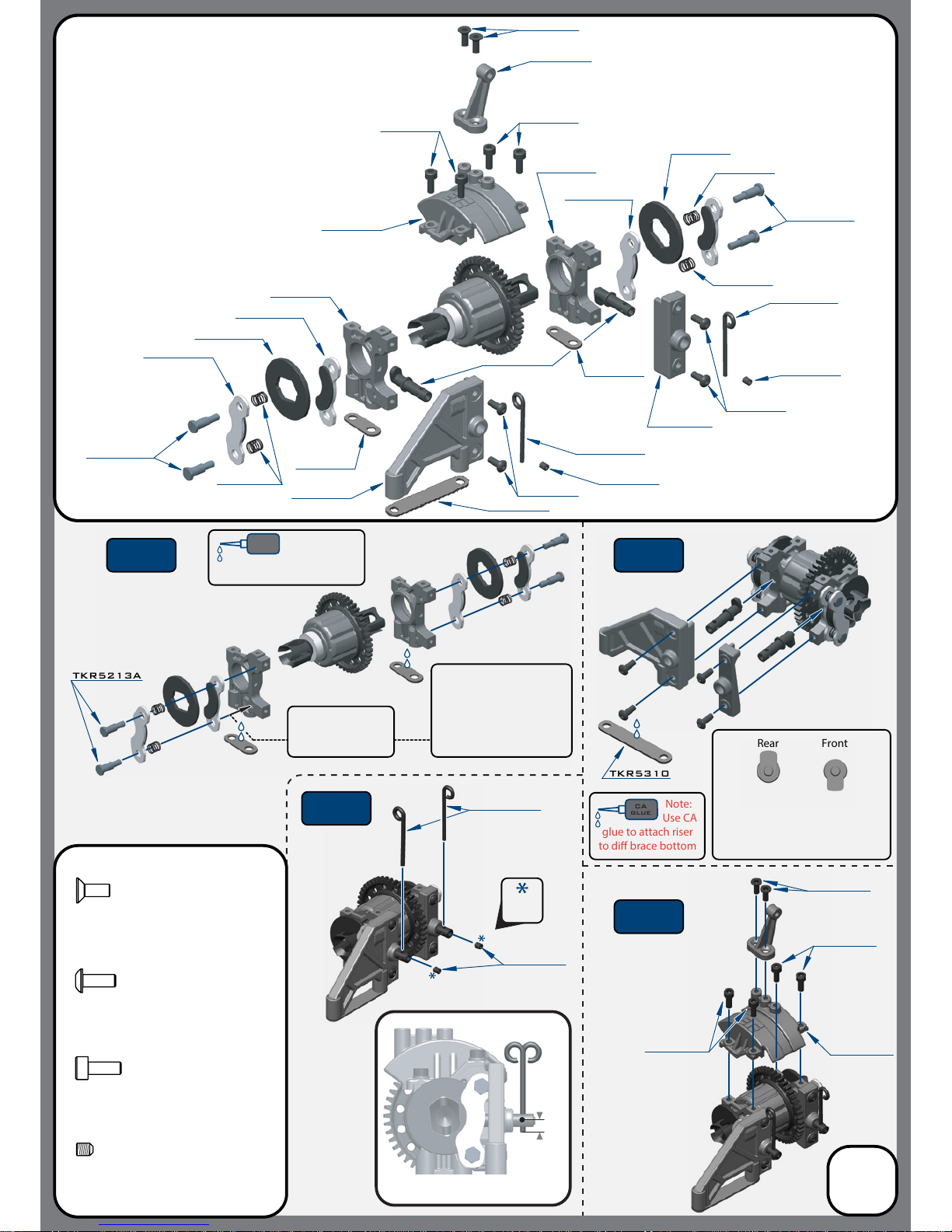

TKRBB05114

Ball Bearing (5x11x4)

x2

TKR5213A

TKR5213A

TKR1522

TKR5310

TKR5368

TKR5345B

TKR1522

TKR5213A

TKR5314B

TKR1601

TKR1601

TKR5310

TKR5336B

TKR5362

TKR5310

TKR5368

TKR5336B

TKR5345B

TKR5310

TKR1402

TKR5338

TKR1402

TKR5368

TKR5314B

TKR5314B

TKR5310

TKR5310

CA

glue

Note:

Use CA

glue to attach riser

to di brace bottom

TKR5310

Rear Front

Bag E

Center Differential Assembly

(overview)

Step

E-1

Step

E-3

Step

E-4

Step

E-2

7

TKR1522

TKR5310

TKR1322

TKR1522

TKR5215B

TKR5336B

TKR1601

TKR5346

TKR1322

Pre-thread all brake

post holes with a

separate M3 screw

Note: Tighten brake posts

(TKR5213A) all the way

down and then back o

1 FULL TURN. This will

ensure your brake discs

are free while on throttle.

Note: Orientation of the brake

cams TKR5215B. The rear cam

should be pointing up & the front

cam should be pointing down.

TKR1322

M3x8mm Flat Head Screw

X2

TKR1402

M3x8mm Button Head Screw

x4

TKR1522

M3x8mm Cap Head Screw

x4

TKR1601

M3x4mm Set Screw

x2

Thread

Lock

Note: Brake lever alignment

4mm

CA

glue

Note: Use CA

glue to attach

risers to di support bottoms

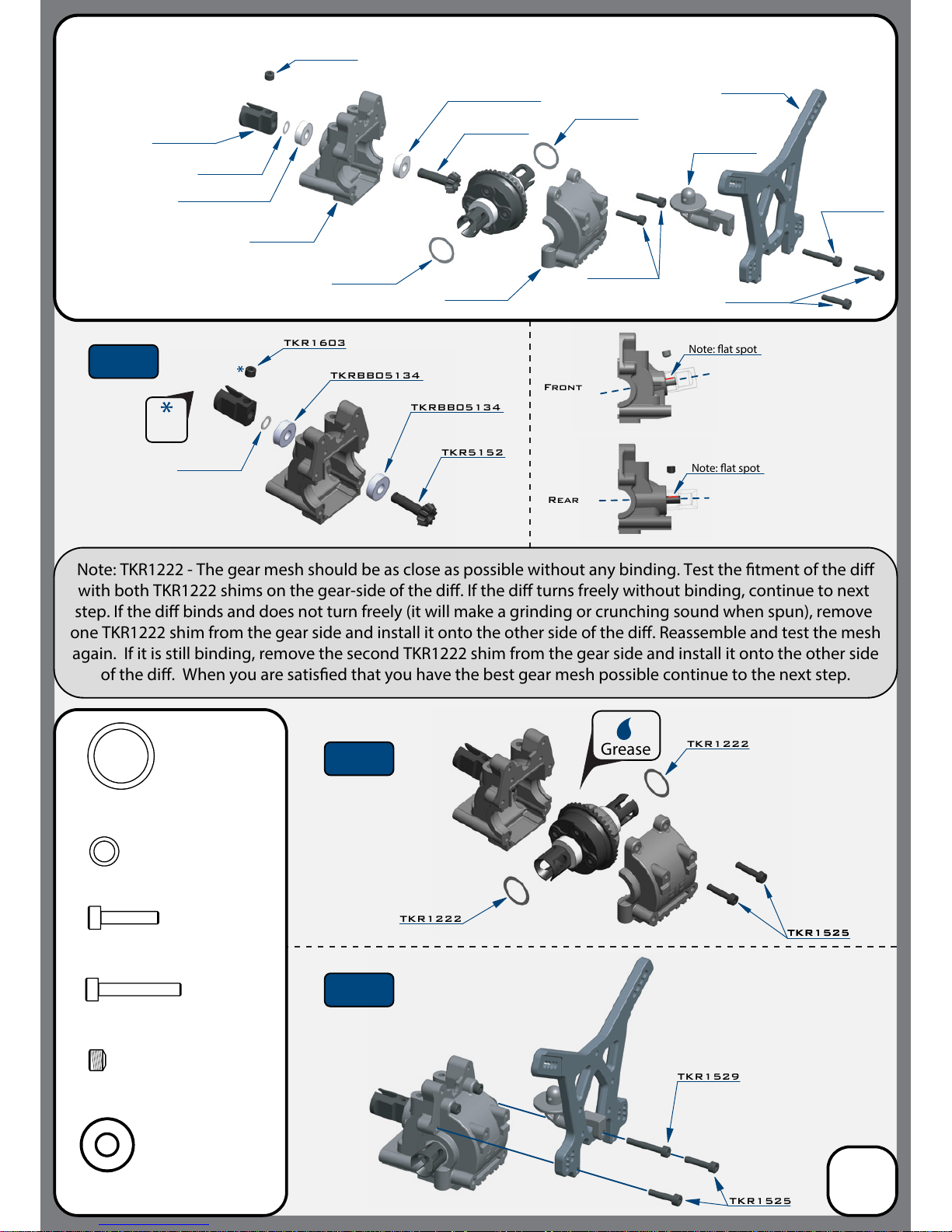

TKR5075

TKR5316

TKR5316

TKR5181

TKR5269

TKR1222

TKR1222

TKR1525

TKR1529

TKR1222

TKR1529

TKR1525

M3x14mm Cap Head Screw

x4

TKRBB05134

Ball Bearing (5x13x4)

x2

TKR1529

M3x20mm Cap Head Screw

x1

TKR1222

13x16x0.1mm Diff Shim

x2

TKRBB05134

TKRBB05134

TKR5152

TKRBB05134

TKR1603

TKR1603

TKR1525TKR1525

Grease

Front

Note: at spot

Note: TKR1222 - The gear mesh should be as close as possible without any binding. Test the tment of the di

with both TKR1222 shims on the gear-side of the di. If the di turns freely without binding, continue to next

step. If the di binds and does not turn freely (it will make a grinding or crunching sound when spun), remove

one TKR1222 shim from the gear side and install it onto the other side of the di. Reassemble and test the mesh

again. If it is still binding, remove the second TKR1222 shim from the gear side and install it onto the other side

of the di. When you are satised that you have the best gear mesh possible continue to the next step.

Rear

Note: at spot

TKR1525

TKR1525

TKR1222

TKR1226

TKRBB05134

TKR1603

M5x4mm Set Screw

x1

TKR1226

5x7x0.2mm shim

x1

Bag F

Rear Gearbox

(overview)

8

Step

F-1

Step

F-2

Step

F-3

Thread

Lock

Note: The front and rear of

the car use dierent inner

bulkheads.

The front is angled

whereas the rear is oset

and only slightly angled.

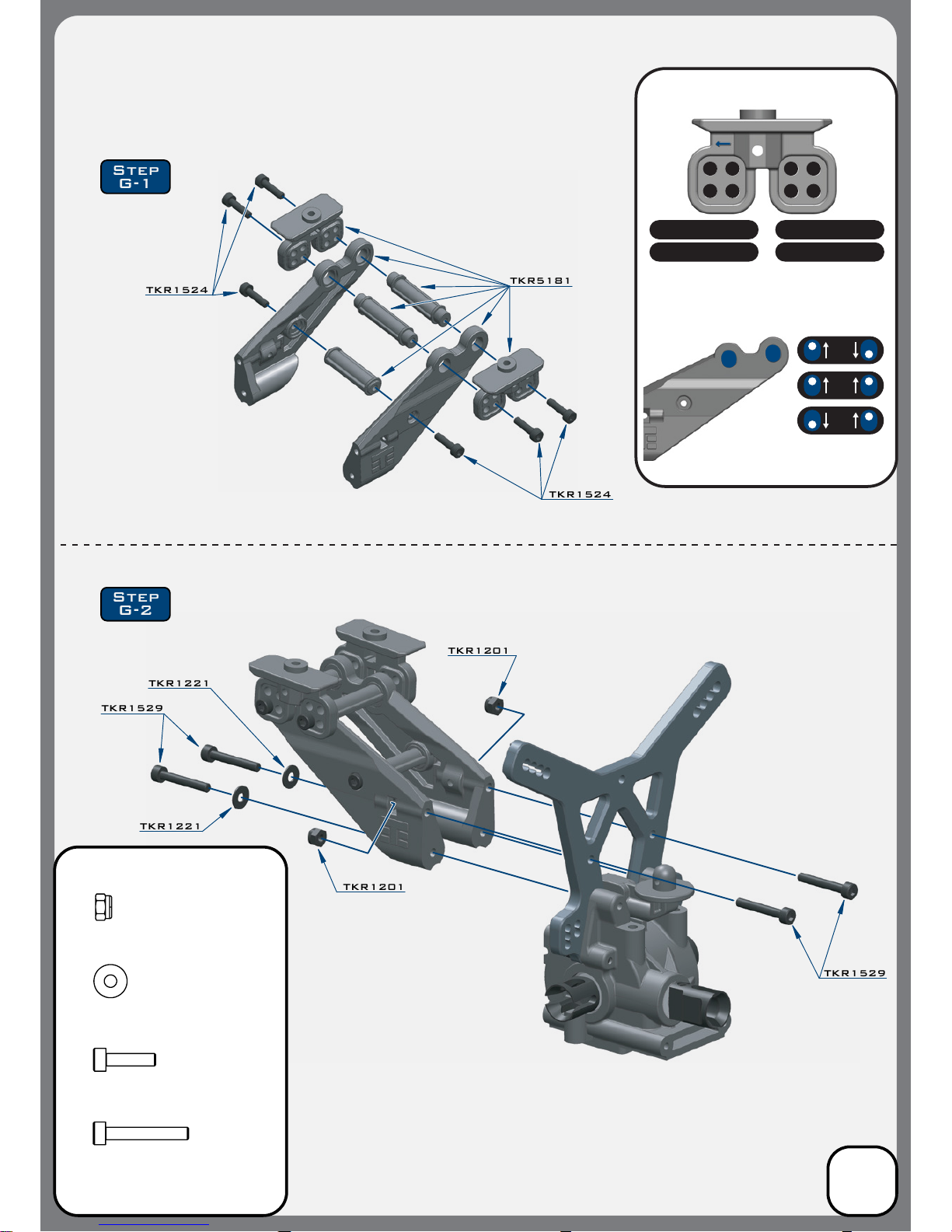

TKR5152

TKR1226

TKR1529

TKR1201

TKR1221

TKR1221

TKR1201

TKR1529

TKR1529

M3x20mm Cap Head Screw

x4

TKR1524

M3x12mm Cap Head Screw

x6

TKR1201

M3 Lock Nut Black

x2

TKR1221

M3x8mm Washer

x2

Step

G-1

Step

G-2

TKR1524

TKR1524

TKR5181

Bag G

Low Profile Wing Mount

9

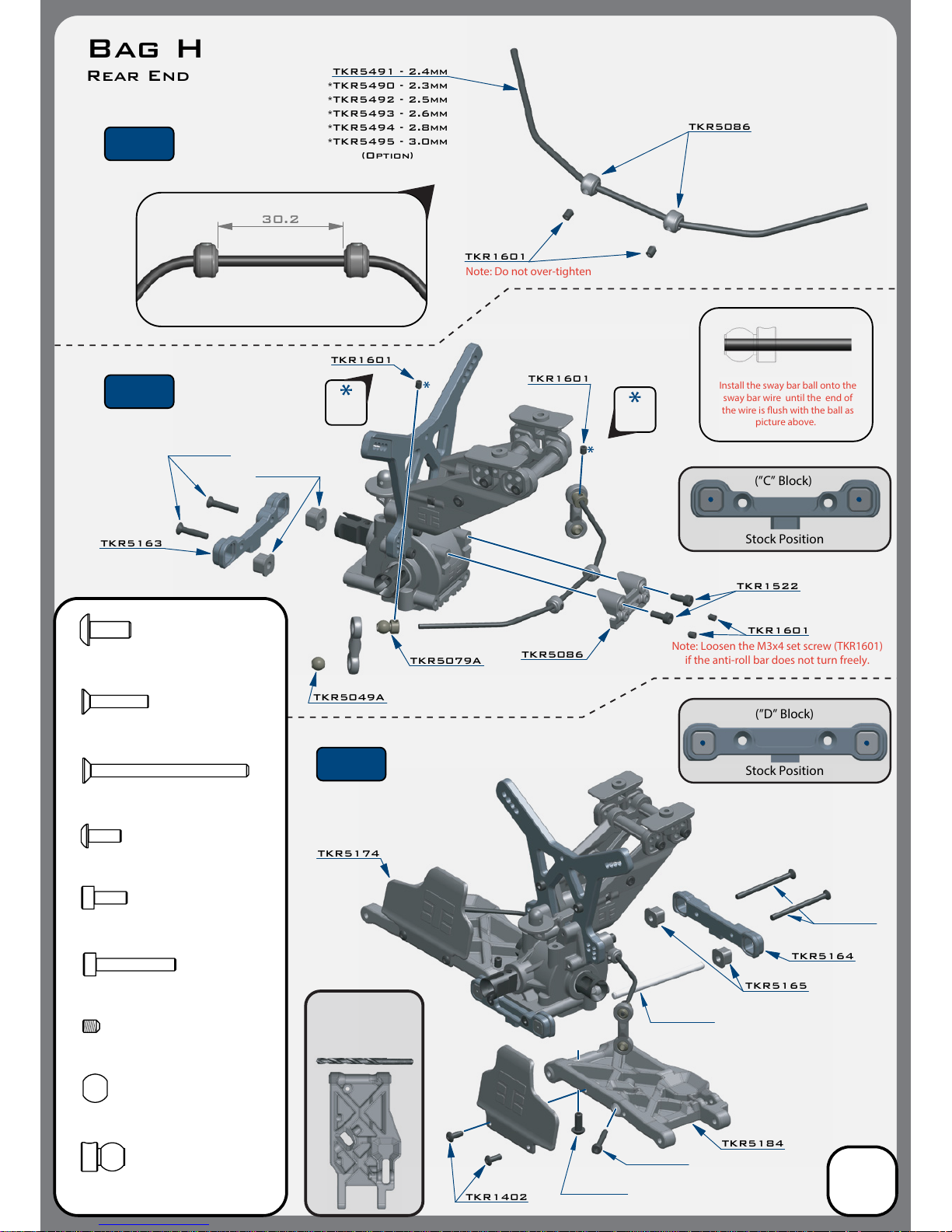

SETTINGS

1 2

3 4

1 2

3 4

POSITION SETTINGS

1 - REARWARD LOW 2 - FORWARD LOW

3 - REARWARD HIGH 4 - FORWARD HIGH

DOWNFORCE SETTINGS

(downforce angles)

Note: Stock position setting is

# 4, Forward High

Note: Stock downforce setting is 4

°

4

°

7

°

10

°

Stock Position

(”D” Block)

Stock Position

(”C” Block)

30.2

TKR1601

TKR1601

TKR1601

TKR5086

TKR5491 - 2.4mm

TKR5086

Install the sway bar ball onto the

sway bar wire until the end of

the wire is ush with the ball as

picture above.

Note: Loosen the M3x4 set screw (TKR1601)

if

the anti-roll bar does not

turn freely.

Note: Do not over-tighten

TKR5049A

TKR5163

TKR5164

TKR5165

TKR5184

TKR5174

TKR1402

TKR1601

TKR5079A

TKR1522

TKR1522

M3x8mm Cap Head Screw

x2

Bag H

Rear End

*TKR5490 - 2.3mm

*TKR5492 - 2.5mm

*TKR5493 - 2.6mm

*TKR5494 - 2.8mm

*TKR5495 - 3.0mm

(Option)

Thread

Lock

Thread

Lock

10

TKR1327

TKR1333

M3x40mm Flat Head Screw

x2

TKR1238

M4x10mm Droop Screw

x2

TKR5049A

Pivot Ball Sway Bar

x2

TKR5079A

Stabilizer Ball

x2

TKR1529

M3x20mm Cap Head Screw

x2

TKR1327

M3x16mm Flat Head Screw

x2

TKR1333TKR1333

TKR1238

TKR1529

TKR1601

M3x4mm Set Screw

x6

Step

H-1

Step

H-2

Step

H-3

TKR5020

TKR1402

M3x8mm Button Head Screw

x4

TKR5165

Note: With these stock

center dot settings,

Anti-Squat = 2° / Rear Toe = 3°

Use a #19 drill bit or

4mm reamer to ream

arms until hinge pin

falls through freely.

Loading...

Loading...