www.teknikoffice.co.uk

Teknik

The original desktop.

Writing Desk

5418269

NOTE: THIS INSTRUCTION

BOOKLET CONTAINS IMPORTANT

SAFETY INFORMATION.

PLEASE READ AND KEEP FOR

FUTURE REFERENCE.

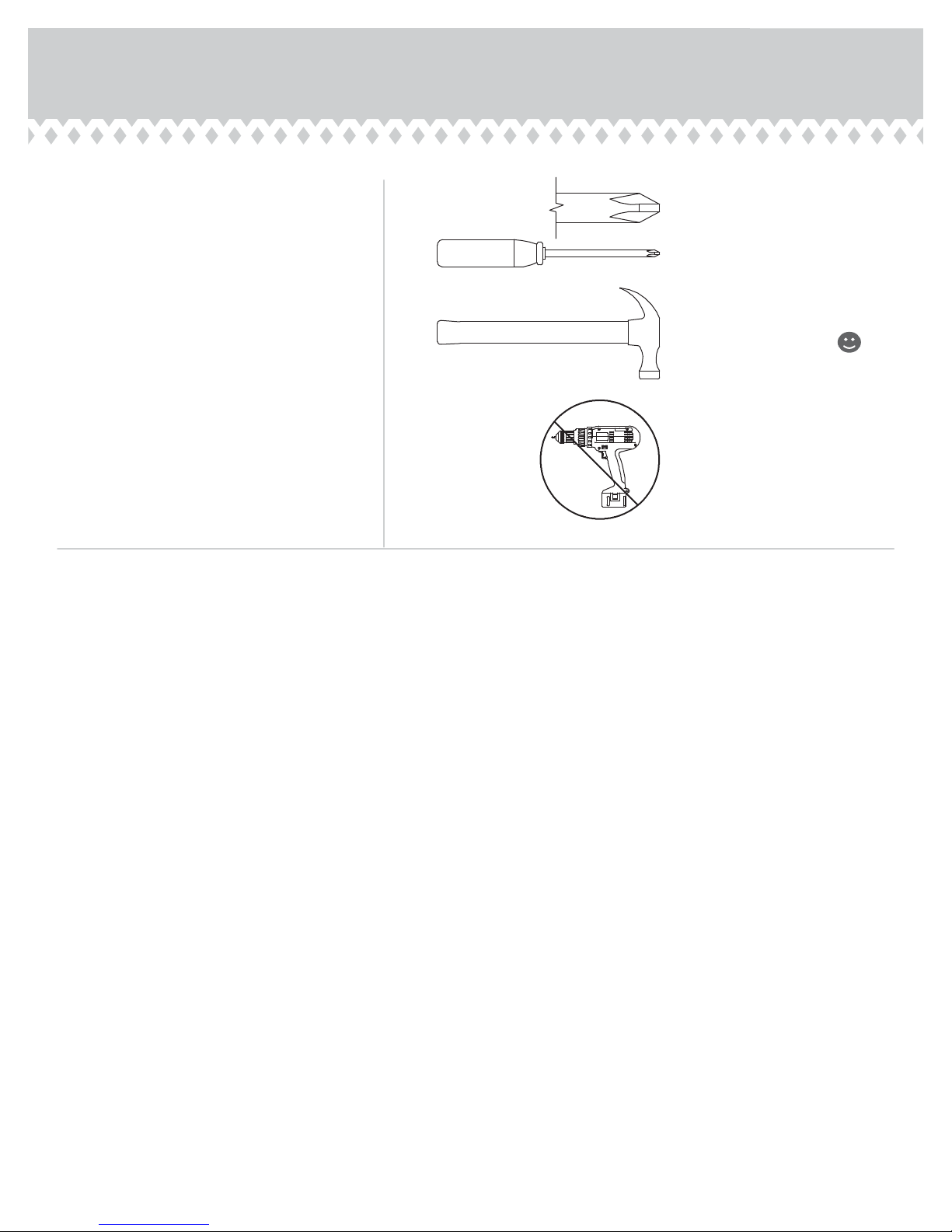

Table of Contents Assembly Tools Required

Part Identifi cation

Hardware Identifi cation

Assembly Steps

Français

Español

Safety

Warranty

5-18

19-21

22-24

25-26

27

3

No. 2 Phillips Screwdriver

4

Tip Shown Actual Size

Hammer

Not actual size

Skip the power trip.

This time.

Page 2

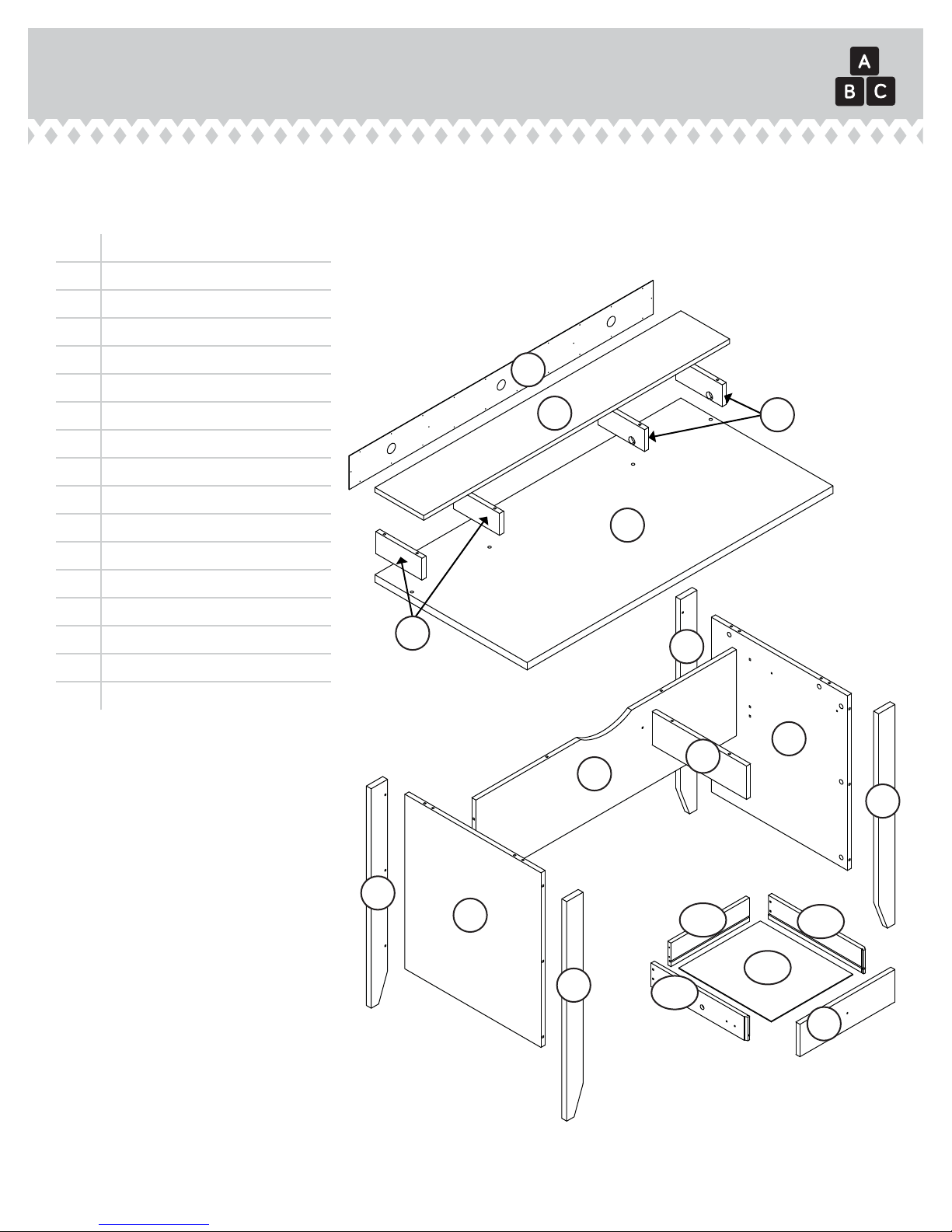

Part Identifi cation

å While not all parts are labeled, some of the parts will have a label or an inked letter on the edge

to help distinguish similar parts from each other. Use this part identifi cation to help identify similar parts.

A RIGHT END (1)

B LEFT END (1)

C HUTCH RIGHT END (2)

D UPRIGHT (1)

Now you know

our ABCs.

E TOP (1)

F HUTCH TOP (1)

G MODESTY PANEL (1)

H BACK (1)

I RIGHT FRONT LEG (1)

J LEFT FRONT LEG (1)

K REAR LEG (2)

L DRAWER FRONT (1)

M HUTCH LEFT END (2)

D20 DRAWER RIGHT SIDE (1)

D21 DRAWER LEFT SIDE (1)

D74 DRAWER BACK (1)

D716 DRAWER BOTTOM (1)

M

H

F

C

E

K

A

D

G

I

K

B

J

D21

D74

D20

D716

L

P

age 3

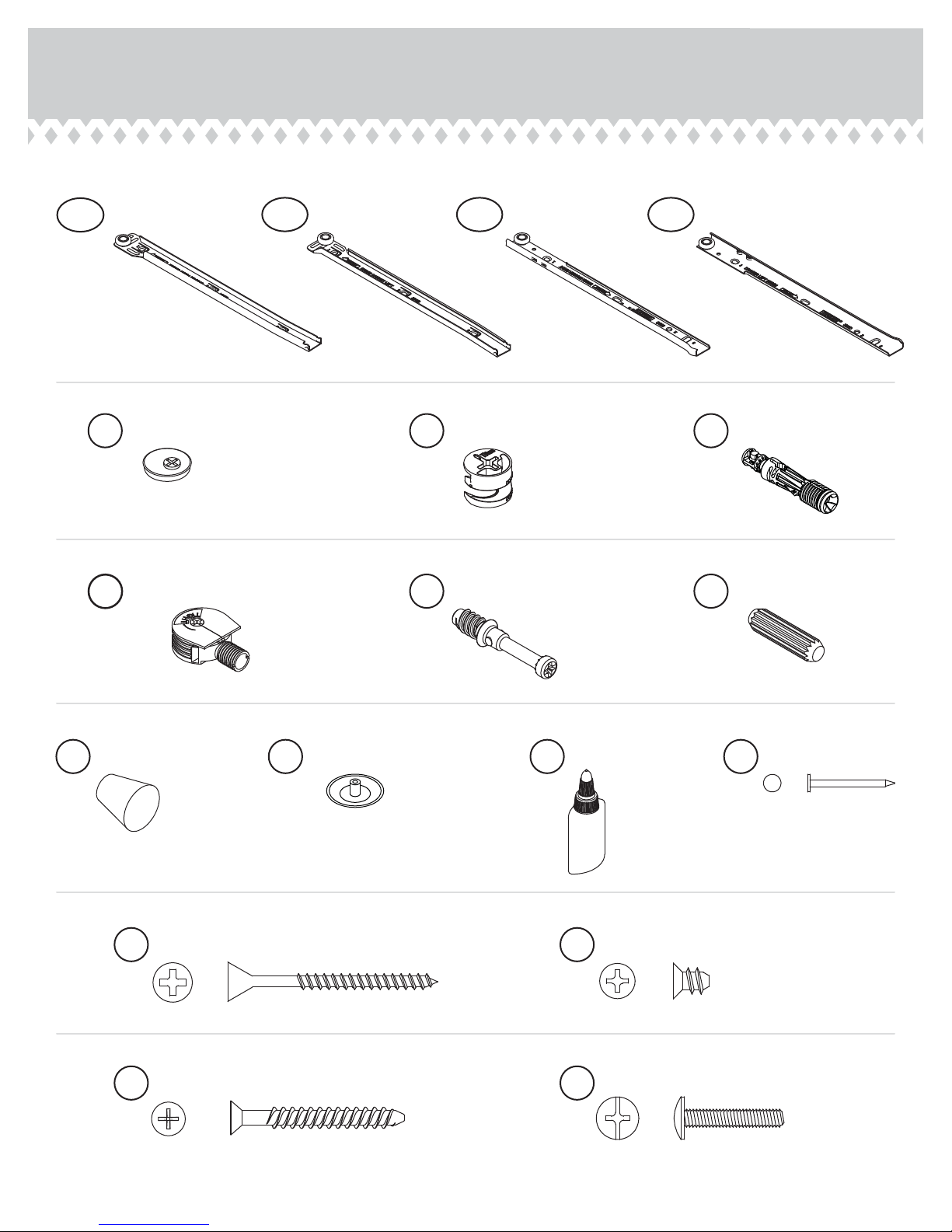

Hardware Identifi cation

å Screws are shown actual size. You may receive extra hardware with your unit.

35GA

CABINET RIGHT - 1

10A

SLIDE CAM - 2

7F

TWIST-LOCK® FASTENER - 4

35GB

CABINET LEFT - 1

35GC

1F

HIDDEN CAM - 20

8F

CAM SCREW - 6

DRAWER RIGHT - 1

35GD

DRAWER LEFT - 1

2F

CAM DOWEL - 14

15F

WOOD DOWEL - 12

25K

KNOB - 1

2S

BLACK 1-7/8" FLAT HEAD SCREW - 7

30S

BLACK 1-9/16" FLAT HEAD SCREW - 4

Page 4

12P

CAM COVER - 6

54M

GLUE - 1

3S

GOLD 5/16" FLAT HEAD SCREW - 8

37S

BLACK 7/8" MACHINE SCREW - 1

1N

NAIL - 24

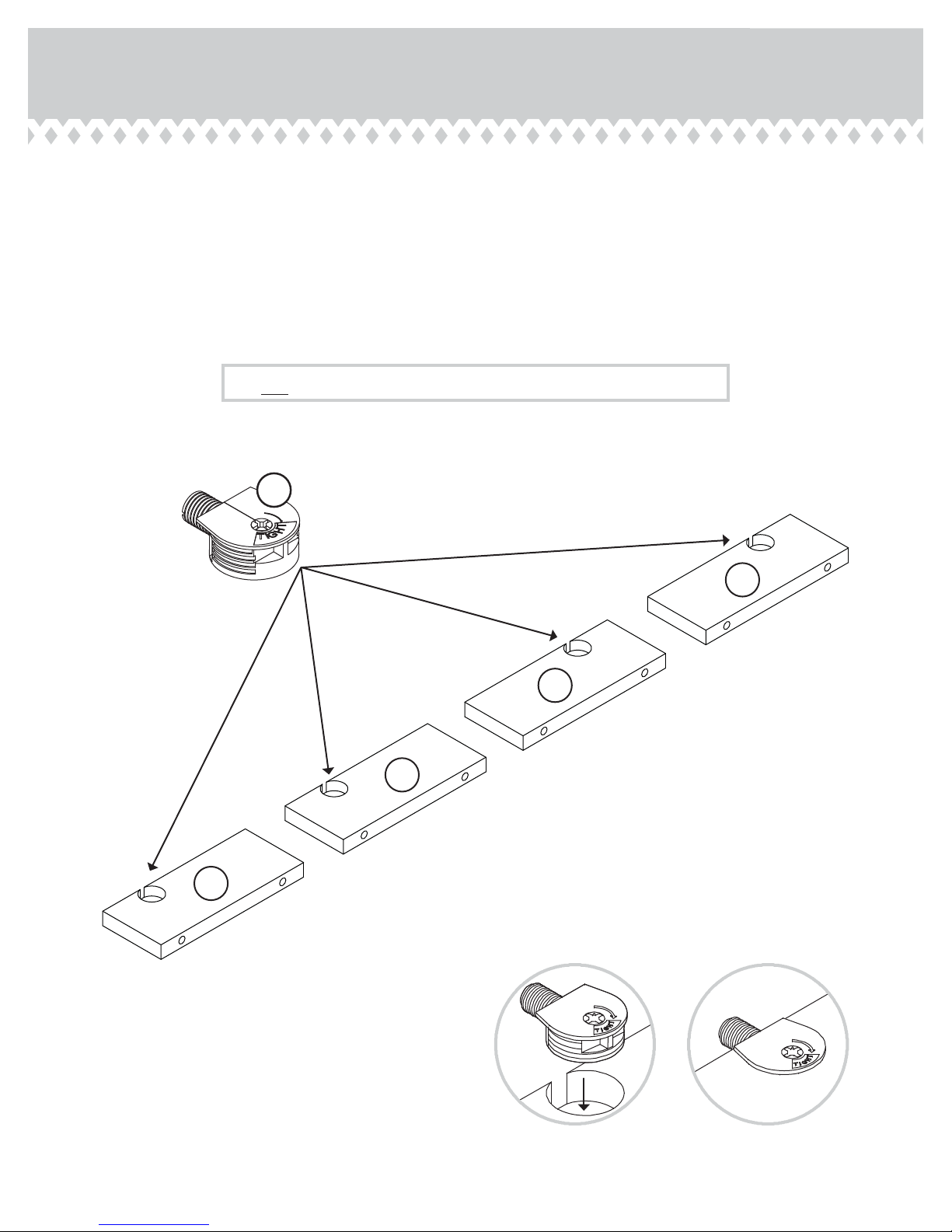

Step 1

Assemble your unit on a carpeted fl oor or on the empty

å

carton to avoid scratching your unit or the fl oor.

To begin assembly, push a SAUDER TWIST-LOCK®

å

FASTENER (7F) into the large holes in the

HUTCH ENDS (C and M).

Do not tighten the TWIST-LOCK® FASTENERS in this step.

7F

M

M

C

C

P

age 5

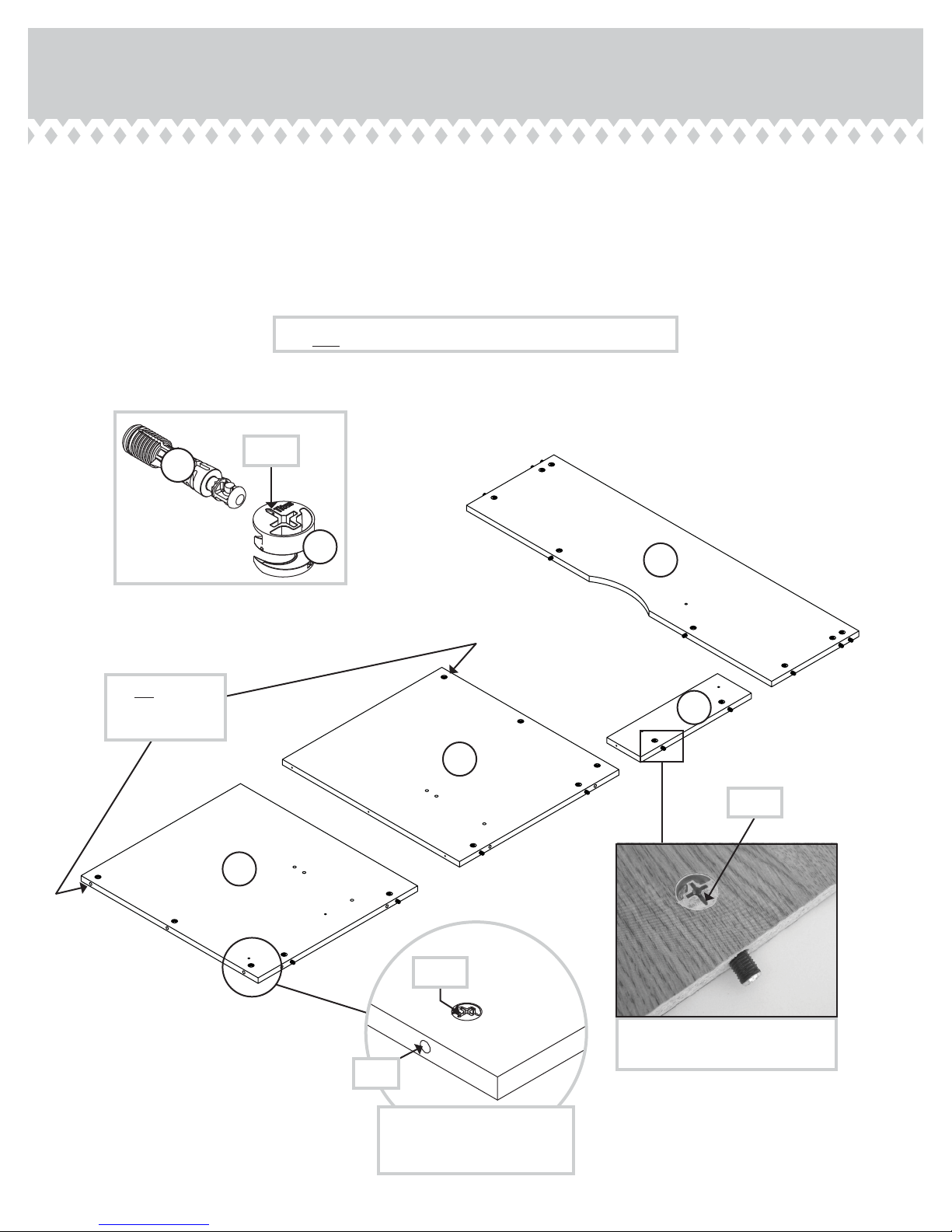

Step 2

Push twenty HIDDEN CAMS (1F) into the ENDS (A and B),

å

UPRIGHT (D), and MODESTY PANEL (G). Then, insert the metal

end of a CAM DOWEL (2F) into each HIDDEN CAM, except the

long edges of the ENDS (A and B).

Do not tighten the HIDDEN CAMS in this step.

2F

(14 used)

(20 used)

Do not insert

CAM DOWELS

into these edges.

Arrow

1F

G

D

B

Arrow

A

Page 6

Arrow

Insert the metal end of the CAM

DOWEL into the HIDDEN CAM.

Hole

The arrow in the HIDDEN

CAM must point toward the

hole in the edge of the board.

Step 3

Turn six CAM SCREWS (8F) into the FRONT LEGS (I and J).

å

Fasten the ENDS (A and B) to the FRONT LEGS (I and J).

å

Tighten six HIDDEN CAMS.

(6 used)

8F

I

These surfaces

should be even.

J

Angled edge

Surface with

HIDDEN CAMS

B

These surfaces

should be even.

J

Angled edge

I

Surface with

HIDDEN CAMS

A

Edge with HIDDEN CAMS

1

2

P

age 7

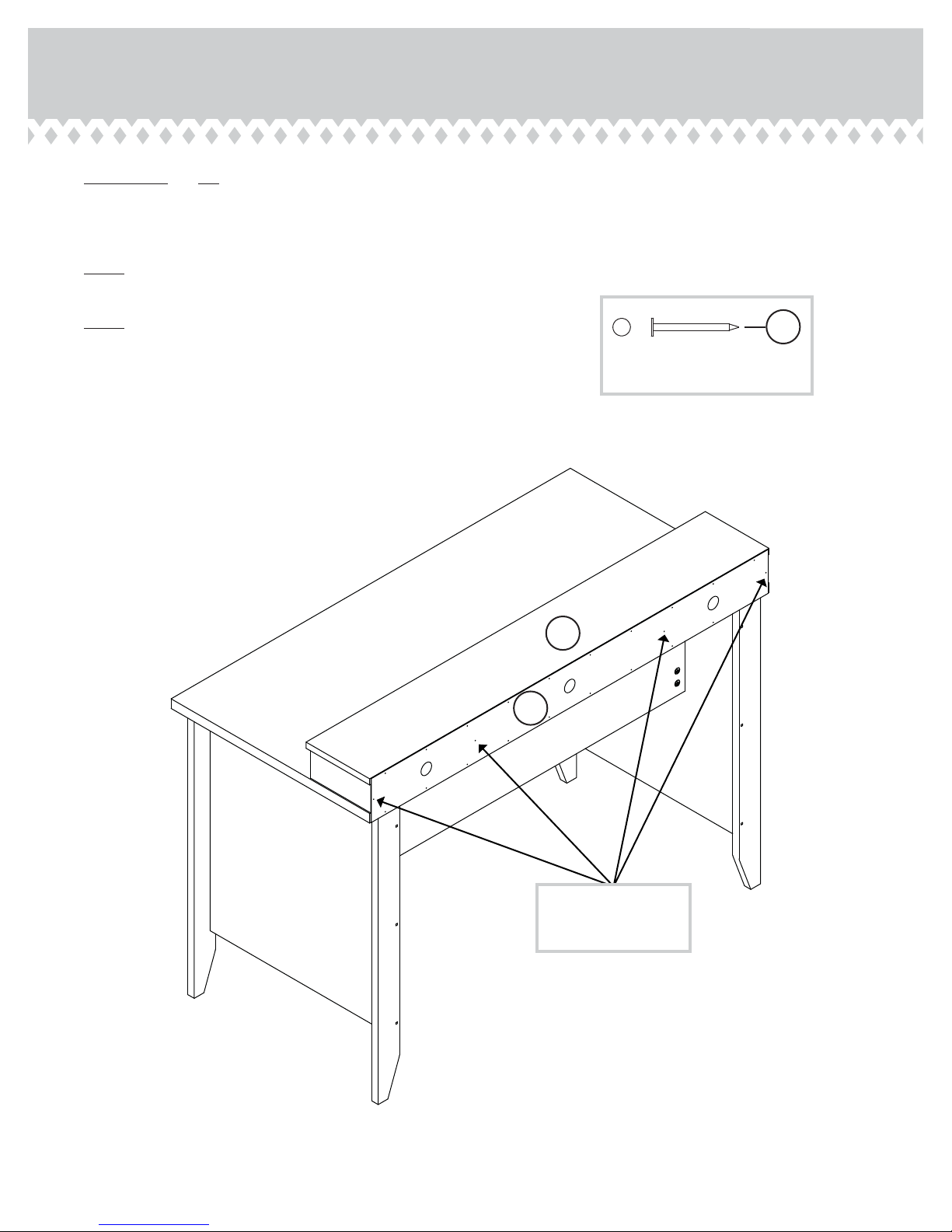

Step 4

Fasten the REAR LEGS (K) to the ENDS (A and B). Use six

å

BLACK 1-7/8" FLAT HEAD SCREWS (2S).

Angled edge

Some assembly

(and snacks) required.

Surface with

HIDDEN CAMS

Surface with

HIDDEN CAMS

K

K

A

BLACK 1-7/8" FLAT HEAD SCREW

B

2S

(6 used in this step)

Page 8

Step 5

Fasten the CABINET RIGHT (35GA) to the RIGHT END (A)

å

and the CABINET LEFT (35GB) to the UPRIGHT (D). Use

four GOLD 5/16" FLAT HEAD SCREWS (3S) through

holes #1 and #3.

3S

GOLD 5/16" FLAT HEAD SCREW

(4 used in this step)

Roller end

2

1

3

D

Roller end

1

2

3

I

A

Surface with

HIDDEN CAMS

Edge and surface

with HIDDEN CAMS

P

age 9

Step 6

Fasten the MODESTY PANEL (G) to the ENDS (A and B).

å

Tighten six HIDDEN CAMS.

Surface with

HIDDEN CAMS

A

Caution

Risk of damage or

injury. HIDDEN CAMS

must be completely

tightened. HIDDEN

CAMS that are not

completely tightened

may loosen, and parts

may separate. To

completely tighten:

Surface without

HIDDEN CAMS

B

Surface with

HIDDEN CAMS

G

Notch

Start Tighten

Arrow

Maximum

210 degrees

Minimum

190 degrees

Arrow

Page 10

Step 7

First, fi ll four holes in the TOP (E) 1/4 to 1/2 full with GLUE (54M).

å

Then, insert four WOOD DOWELS (15F) into the holes. Wipe away

the excess GLUE.

Next, place drops of GLUE (54M) onto the WOOD DOWELS (15F)

å

in the TOP (E).

Finally, fasten the TOP (E) to the ENDS (A and B) and MODESTY

å

PANEL (G). Tighten six HIDDEN CAMS.

NOTE: Be sure the WOOD DOWELS in the TOP insert into the

å

holes in the ENDS. Wipe away the excess GLUE.

Fill the holes 1/4 to 1/2 full with GLUE.

Caution

!

Inspect the parts thoroughly before

assembling. Disassembly of glued

parts is extremely di cult.

15F

54M

Place GLUE in the

exact holes shown.

A

with holes

Surface

G

B

E

15F

Finished edge

54M

P

age 11

Step 8

Fasten the UPRPIGHT (D) to the TOP (E). Tighten two

å

HIDDEN CAMS.

Fasten the UPRIGHT (D) to the MODESTY PANEL (G). Use

å

one BLACK 1-7/8" FLAT HEAD SCREW (2S).

Maximum

210 degrees

Minimum

190 degrees

2S

Arrow

Surface without

HIDDEN CAMS

D

E

BLACK 1-7/8" FLAT HEAD SCREW

(1 used in this step)

G

Page 12

Step 9

Carefully stand your unit upright.

å

Fasten the HUTCH UPRIGHTS (C and M) to the TOP (E).

å

Tighten four TWIST-LOCK® FASTENERS.

Fill the holes in the edges of the HUTCH UPRIGHTS (C

å

and M) 1/4 to 1/2 full with GLUE (54M). Then, insert eight

WOOD DOWELS (15F) into the holes. Wipe away the

excess GLUE.

Place drops of GLUE (54M) onto the WOOD

å

DOWELS (15F) in the HUTCH UPRIGHTS (C and M).

Press the HUTCH TOP (F) onto the WOOD DOWELS in

å

the HUTCH UPRIGHTS. Wipe away the excess GLUE.

(8 used)

F

Surface without holes

15F

M

How to use the SAUDER TWIST-LOCK® FASTENER

1. Insert the dowel end of the FASTENER into the hole of the

adjoining part.

NOTE: The dowel end of the FASTENER must remain fully

inserted in the hole of the adjoining part while locking

the FASTENER.

2. Tighten the FASTENER with a Phillips screwdriver as tight

as possible.

Dowel end

Unfi nished edge

Surface with

TWIST-LOCK®

FAST EN ER

M

C

E

C

Surface without

TWIST-LOCK®

FAST EN ER

Caution

!

Inspect the parts thoroughly before

assembling. Disassembly of glued

parts is extremely di cult.

54M

Fill the holes 1/4 to 1/2 full with GLUE.

P

age 13

Step 10

IMPORTANT: Do not pick up or move your unit by using

å

the TOP (F).

Fasten the BACK (H) to your unit using the NAILS (1N).

å

NOTE: Be sure to tap NAILS into the holes that line up

å

over the HUTCH UPRIGHTS (C and M).

NOTE: Perforations have been provided for access

å

through the BACK. Carefully cut out the holes needed.

1N

NAIL

(24 used in this step)

F

Unfi nished

surface

H

Page 14

These holes must line

up over the HUTCH

UPRIGHTS (C and M).

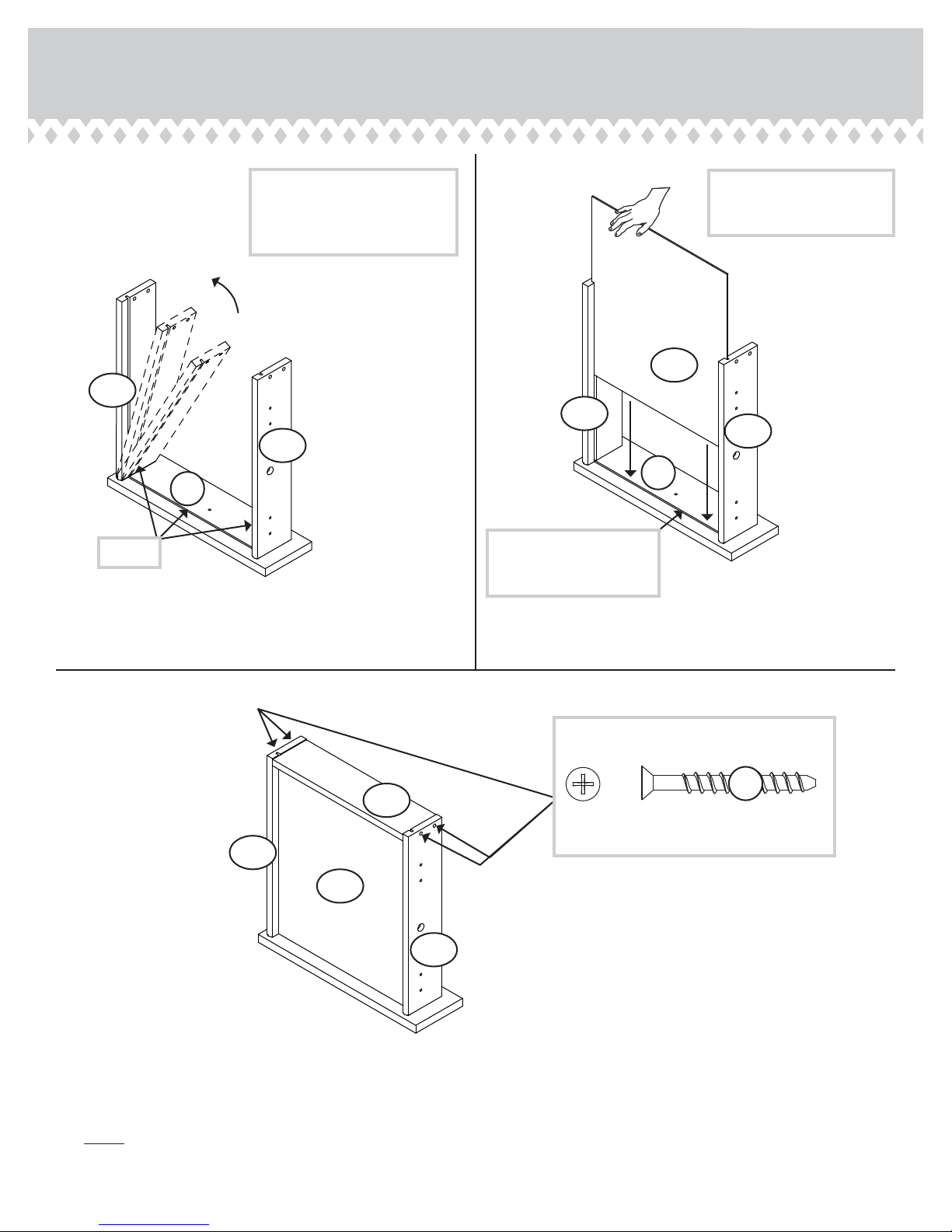

Step 11

12

D20

The tabs should insert freely

into the slots. Gently tilt the

DRAWER SIDES side to side

until the tabs slip into the slots.

D21

With the palm of your hand,

tap the DRAWER BOTTOM

down into the groove.

Unfi nished

surface

D716

D20

D21

L

L

Groove

Insert the DRAWER SIDES (D20 and D21) at an angle

å

into the slot at each end of the DRAWER FRONT (L).

Be sure the DRAWER

BOTTOM inserts into the

DRAWER FRONT groove.

Slide the DRAWER BOTTOM (D716) into the grooves in the

å

DRAWER SIDES (D20 and D21) and DRAWER FRONT (L).

3

D74

D20

D716

D21

Fasten the DRAWER BACK (D74) to the DRAWER SIDES (D20

å

and D21). Use four BLACK 1-9/16" FLAT HEAD SCREWS (30S).

NOTE: Be sure the DRAWER BOTTOM (D716) inserts into the

å

groove of the DRAWER BACK (D74).

Start each screw a few turns before

completely tightening any of them.

30S

BLACK 1-9/16" FLAT HEAD SCREW

(4 used in this step)

P

age 15

Step 12

Insert a SLIDE CAM (10A) into the DRAWER SIDES (D20 and D21).

å

Fasten the DRAWER RIGHT (35GC) to the DRAWER RIGHT SIDE (D20)

å

and the DRAWER LEFT (35GD) to the DRAWER LEFT SIDE (D21). Use

four GOLD 5/16" FLAT HEAD SCREWS (3S) through holes #1 and #3.

NOTE: The screw head in the CAM must be visible through the slotted

å

hole in the SLIDE.

Fasten the KNOB (25K) to the DRAWER FRONT (L). Use a BLACK 7/8"

å

MACHINE SCREW (37S).

Roller end

10A

1

2

3

D21

Screw head - turn CAM to line up holes in

the SLIDES with holes in DRAWER SIDES

10A

Roller end

D20

L

1

25K

37S

2

3

BLACK 7/8" MACHINE SCREW

(1 used for the KNOB)

Page 16

3S

GOLD 5/16" FLAT HEAD SCREW

(4 used in this step)

Step 13

To insert the drawer into your unit, tip the front of the

å

drawer down and drop the rollers on the drawer behind the

rollers on the unit. Lift the front of the drawer up and slide

it into the unit.

Push a CAM COVER (12P) onto each visible HIDDEN CAM.

å

20 lbs.

12P

50 lbs.

10 lbs.

Place the roller on the SLIDE

behind the roller on the RAIL.

(6 used)

To cover HIDDEN CAMS

P

age 17

Step 14

To make adjustments to the drawers, loosen SCREW #3 in the SLIDES a 1/4 turn, then turn the CAM

å

clockwise or counter-clockwise. Notice how the drawer raises or lowers as you turn the CAM. The

higher the screw in the oblong hole, the higher your drawer front will be. The lower the screw, the

lower the drawer front. By adjusting the drawers this way, it will help the DRAWER FRONTS line up

better when closed. Tighten the SCREW when fi nished with adjustments.

NOTE: Please read the back pages of the instruction booklet for important safety information.

å

This completes assembly. Clean with your favorite furniture polish or a damp cloth. Wipe dry.

å

Loosen screw #3 a 1/4 turn, turn the cam a 1/4 turn

maximum in both the clockwise and counter-clockwise

directions to make adjustments, and then tighten screw #3.

The higher the screw in the oblong hole, the

higher your drawer front will be. The lower the

screw, the lower the drawer front.

Cam

Page 18

WARNING

Please use your furniture correctly and safely. Improper use can cause safety hazards,

or damage to your furniture or household items. Carefully read the following chart.

Look out for: What can happen: How to avoid the problem:

• Overloaded shelves and drawers.

• Improper loading can cause the product

to be top-heavy.

• Risk of injury.

• Top-heavy furniture can tip over.

• Overloaded shelves and drawers can

break.

• Never exceed the weight limits shown in

the instructions.

• Work from bottom to top when loading

shelves and drawers. Place the heavier

items on the lower shelves or in lower

drawers.

• Improperly moving furniture that is not

designed and equipped with casters.

• Placing TVs on furniture items that are

not designed to support a television is

hazardous.

• Furniture can tip over or break if

improperly moved.

• Physical injury. Furniture can be very

heavy.

• Breakage of tops - particularly with

double pedestal furniture (drawers at both

ends).

• Risk of injury or death. TVs can be very

heavy. Plus the weight and location of the

picture tube tends to make TVs unbalanced

and prone to tipping forward.

• Unload shelves and drawers from top to

bottom before moving the unit.

• Do not push furniture, especially on a

carpeted fl oor. Have a friend help you lift

the item and set it in place.

• Provide support to the center section of

the top when lifting the furniture.

• This product is not designed to support a

television.

Loading...

Loading...