Tekleen LPF6P, LPF6XLP, LPF6LP, LPF6SP, LPF8P User Manual

...

USERS’

MANUAL

LPF

AUTOMATIC FILTERS, INC.

2672 S. LA CIENEGA BLVD.

LOS ANGELES, CA 90034

310 839 2828 800 336 1942

FAX 310 839 6878

www.Tekleen.com

info@Tekleen.com

Tekleen

Table of Contents

SECTION I INTRODUCTION

1.1 Description 1

1.2 Theory of Operation 1

1.3 Recommended Applications 1

1.4 Design Features 2

1.5 Filter Specifications Chart 3

1.6 Measurement Conversion Table 3

SECTION II INSTALLATION AND HOOK-UP

2.1 Mechanical Hook-Up and Orientation 4

2.2 Plumbing Hook-Up 4

2.3 GB6, DP Gauge, and Electric Ball Valve Connection 5

SECTION III OPERATION AND ADJUSTMENTS

3.1 Start-up 6

3.2 Backflush Requirements 7

SECTION IV MAINTENANCE

4.1 Filter Cleaning 8

4.2 Dirt Collector Replacement 8

4.3 Piston Removal/Replacement 8

4.4 Periodic Inspection 9

SECTION V TROUBLESHOOTING GUIDE

5.1 Excessive Pressure Drop Through Filter Without Flushing 9

5.2 Frequent Continuous Flushing While Filling Main Pipeline 10

5.3 Frequent Continuous Flushing During Normal Operation 10

5.4 Screen Will Not Clean Properly 11

SECTION VI SPARE PARTS

6.1 Recommended Spare Parts 12

6.2 Spare Parts List 12

APPENDICES

Appendix I Special Construction and Features 13

Appendix II System with Discharge to Atmosphere 14

Appendix III Piston 14

ILLUSTRATIONS

Particle Removal Process 15

Pressure Drop Chart 16

LPF Cutaway 17

LPF with GB6 Controller 18

2XLPF with GB7 Controller 19

LPF with Pressure Sustaining Valve 20

LPF with Bypass Relief Valve 21

WARRANTY 22

Automatic Filters, Inc.

LPF Filters Manual

SECTION I INTRODUCTION

1.1 Description

The LPF series models (Low Pressure Filter) are automatic, self cleaning

screen type water filters. The filtration system consists of a tank body with

a coarse screen, fine screen, electric motor, single flush valve and an

electronic controller.

1.2 Theory of Operation

Pressurized water enters the filter inlet and travels through the coarse screen

from the outside in. The water then travels through the fine screen from the

inside out where small contaminants (down to 25 microns) are filtered. The

clean water then exits through the outlet.

When the fine screen becomes contaminated, a pressure differential is

sensed causing the automatic controller to open the flushing valve and start

the electric motor. When the flushing valve opens, the pressure in the

hydraulic motor chamber is reduced causing the clean water to reverse flow

at the nozzles through the filter element pushing contaminants off the screen,

through the dirt collector and out the flushing valve.

The electric motor rotates the dirt collector as water passes through the nozzles.

Lateral movement allows the dirt collector to vacuum the entire screen.

When the screen is clean, the unit automatically closes the electric valve,

returning the filter to normal operation.

The entire cleaning cycle takes approximately 10-15 seconds. It should be

noted that even during the backflush cycle the filtration process continues

uninterrupted.

1.3 Recommended Applications

Tekleen filters are ideal for filtering out silt, scale, sand, rust, dirt and organic

material like algae, zebra mussels, and clams from virtually all types of water

sources.

Automatic Filters, Inc.

LPF Filters Manual

1

1.4 Design Features

Among the many features of the LPF models is the avoidance of the danger

of forcing contaminated water back into the system, which often happens

with sand filters. Tekleen filters will deliver clean water or no water at all.

The most predominant feature is its ability to remove organics such as algae

and other suspended particles.

All filter internal elements can be removed and disassembled from the filter

body without disruption of the plumbing.

The backwash cycle, Tekrinse, uses 90% less rinse water than other filters

on the market today.

For special constructions and applications, see Appendix I, page 13.

Automatic Filters, Inc.

LPF Filters Manual

2

1.4 Filter Specifications Chart

Model Flange Size

inches

LPF3SP

LPF4LP

LPF4P

LPF4LPE

LPF4LP

LPF6P

LPF6XLP

LPF6LP

LPF6SP

LPF8P

LPF8LP

LPF8SP

LPF10P

LPF10LP

LPF12P

LPF12LP

LPF14P

LPF14LP

LPF16LP

LPF16SP

LPF18SP

LPF20SP

3

3

4

4

4

6

6

6

6

8

8

8

10

10

12

12

14

14

16

16

18

20

Screen Area

sq. ft.

1.4

2.5

1.4’

2.5

5

2.5

8

5

7

5

8

7

7

11

11

12.5

12.5

16

16

24

24

24

Max Flow

gpm

200

300

300

400

500

600

800

800

1,750

1,320

1,500

1,750

1,750

2,630

2,630

4,000

4,000

6,000

6,000

7,000

8,000

10,000

Specifications: Carbon steel body with baked on powder epoxy coating or stainless

steel 316L body at the same price. Internal parts: stainless steel dirt collector,

stainless steel screen. Maximum 150 psi, 200° F. Standard screen mesh 50µ

to 1000µ. Optional high temperature, and high pressure.

1.5 Measurement Conversion Table

Mesh

Micron

Inch

20

850

.033

40

590

.016

60

250

.010

80

177

.007

Automatic Filters, Inc.

LPF Filters Manual

100

150

.006

140

105

.004

200

74

.003

325

44

.002

550

25

.001

3

SECTION II INSTALLATION AND HOOK-UP

2.1 Mechanical Hook-Up and Orientation

The positioning of the filter tank should be determined by the disposal of

waste water and to allow easy access and removal of filter element (Consult

manufacturer for required clearances).

The Tekleen filter can

rest on the inlet and

outlet flanges or can be

mounted on a stand if

desired.

The electronic controller

should be mounted in

close proximity to the

filter tank.

2.2 Plumbing Hook-Up

The waste discharge pipe should be at least one inch larger in diameter than

the size of the discharge valve (1” valve to 2” pipe & 2” valve to 3” pipe).

The waste pipe should be kept as short as possible with no more than one elbow.

Discharge lines should not be elevated. This will affect the pressure difference

required for the cleaning cycle. If it is necessary to run discharge lines uphill,

please consult with the manufacturer.

Note: A block valve should be installed immediately upstream of the filter.

During start-up, the block valve should only be barely cracked open to prevent

a surge of pressure across the filter when the pump is started. Once the

pump is on-line, slowly open the block valve. This would prevent any possible

damage to the filter due to a pressure surge.

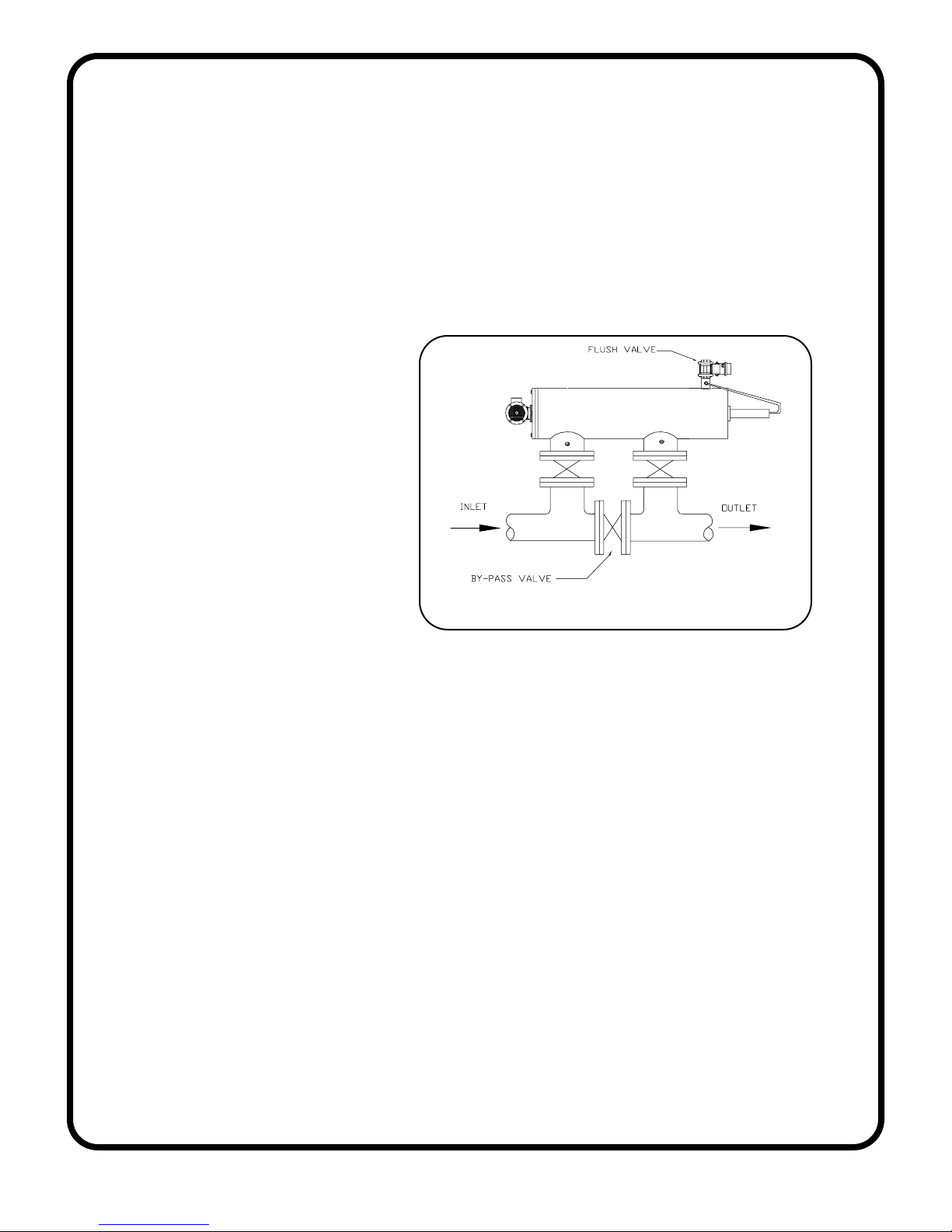

STANDARD HOOK-UP AND ORIENTATION

Automatic Filters, Inc.

LPF Filters Manual

4

2.3 GB6, DP Gauge, and Electric Ball Valve Connection

Before power is applied to the electronic controller, make all connections

between controller, DP Gauge, and electric ball valve (see page 18).

1. BALL VALVE: Plug controller into appropriate power source. Activate

manual start switch and visually inspect the open and close movement

of the ball valve.

2. FLUSHING TIME ADJUSTMENT: The flush time is normally set to 10

seconds. Flush time should be adjusted to allow piston indicator pin to

reach the end of the slot during one backwash cycle. NOTE: Excessive

flush time will not improve cleaning, and may lead to filter damage.

3. PRESSURE DIFFERNTIAL ADJUSTMENT: The differential switch is preset for 7 psi. It can be changed to different set points (see your electronic

controller manual).

USING 1/4 INCH DIAMETER TUBING

1. Attach tubing to the low pressure 1/4" fitting (on the outlet flange). Attach

the other end of the tubing to the fitting on the DP switch marked “low”

pressure.

2. Attach tubing to the high pressure 1/4" fitting (on the inlet flange). Attach

the other end of the tubing to the fitting on the DP switch marked “high”

pressure.

3. If the filter comes with a piston, attach tubing to the end of piston. Attach

the other end to the fitting on the flush outlet (before the flush valve).

Important Notes: Do not run tubing more than three feet in length (preferably

two feet or less). Due to the pressure drop across the tubing, the

electronic controller may not operate properly if tubing is too long.

Automatic Filters, Inc.

LPF Filters Manual

5

Electronic controller should be sealed completely to avoid moisture

from entering. This will prevent possible shorting of circuits.

For more operating details and set-up, please refer to your electronic rinse

controller manual.

SECTION III OPERATION AND ADJUSTMENTS

3.1 Start-Up

During start-up, the block valve at the filter inlet should be cracked open to

prevent a surge of pressure across the filter when the pump is started. Once

the pump is on-line, slowly open the block valve. This will prevent any possible

damage to the filter due to a pressure surge.

During the initial filling of the main pipeline, there may not be enough back pressure downstream from the filter to allow the cleaning cycle to function

properly. Therefore, it is necessary to install a valve on the outlet line to be

partially closed (i.e., gate valve, ball valve or butterfly valve).

If a downstream main line valve is partially closed, enough to provide 15 psi

on the filter inlet pressure gauge, the self cleaning cycle will operate properly .

Once the total system is fully charged, the downstream valve can be adjusted,

as long as 15 psi is maintained at the inlet flange during the backwash cycle.

If systems are to come on automatically , it is advisable to install a flow control

or a pressure sustaining valve downstream from filters to create backpressure

on filters in order to enable proper flushing while pipe lines are being filled.

Once the system is fully charged push the manual flush button on the

electronic controller, check the rotation of the electric motor on the end cover.

The motor should turn clockwise during the flush cycle.

Automatic Filters, Inc.

LPF Filters Manual

6

Loading...

Loading...