Page 1

OWNER’S MANUAL

BC 112A & 112C

Power Flex

™

Chargers

with Ni-Cd and Ni-MH capability

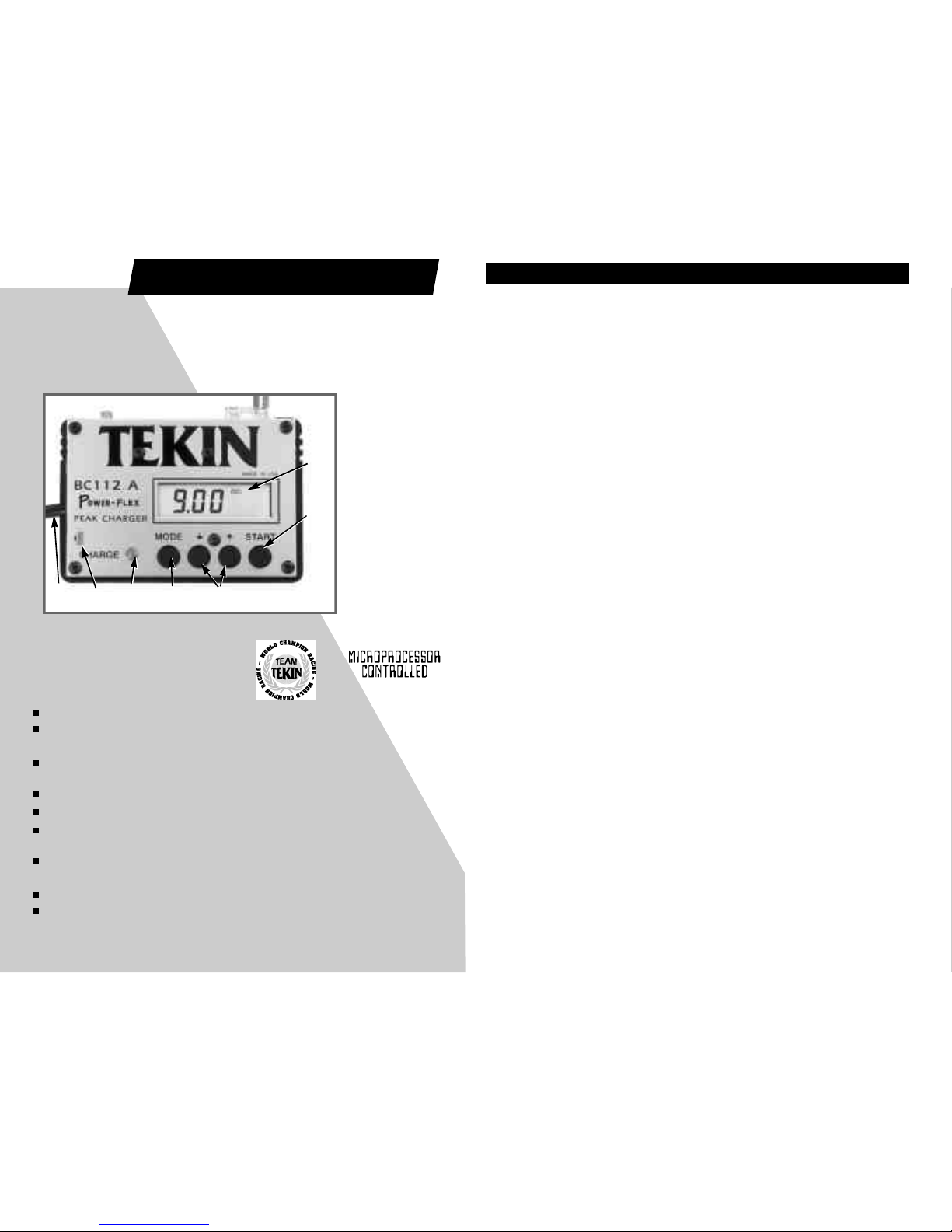

A) Digital Display

with

Annunciators

B) Charge Start

Button

C) Set Buttons

D) Mode Select

Button

E) Indicator LED

F) Output LED

G) Output Cable

Accepts 10-24 volts DC (both models) or household AC input (112C only).

Uses TEKIN’s exclusive high-performance Power-Flextm Negative Pulse

battery conditioner circuit.

Microprocessor controlled optimized charge profiles, and custom

multi-function LCD display with annunciators.

0 to 10 amp linear charge output with adjustable trickle charge.

Dual 12 bit high-precision analog to digital converters.

33 kHz high-frequency switch mode power supply for cool, efficient

operation under all conditions.

Proprietary Adaptive Sensing peak detection monitors the charge profile

and detects the correct optimum shut-off point for maximum accuracy.

Compact, dependable, lightweight construction.

Expandable to a complete charge/discharge-matching and test system.

MADE IN THE USA

T E K I N

ELECTRONICS, INC.

G F E D C

A

B

TA BL E OF CO NT EN TS

Power Source Selection .......................................... 1

AC Power Source ...................................................... 1,2

Fuse ........................................................................... 2

Power-Flex Circuit ....................................................... 2

Connecting the Battery Pack .................................... 2

Charger Settings and Display Modes ..................... 3

Display Profiles ............................................ 3,4

Set Modes ....................................................... 4

Start Button and Charge Profiles .............................. 5

Charge Profiles ............................................. 5

Timed Charge ................................................. 6

Selecting the Charge Amperage

Fast Charging ................................................ 6

Trickle Charging ............................................. 6

Miscellaneous Tips and Tricks ................................ 7

Charging ........................................................ 7

Discharging ................................................... 7

Optional Add/On Discharger ...................... 7

Troubleshooting ....................................................... 8

Error Codes ................................................. 8

About Tekin .............................................................. 9

Limited Warranty ..................................................... 9

TEKIN, BC112, Power-Flex, Slope Detector, Slope Detection, and Pro-Flex are trademarks of Tekin

Electronics, Inc.

- Copyright 1999 Tekin Electronics, Inc., All Rights Reserved-

Page 2

The BC 112 series charger’s can use virtually any power source that puts out

between 10 and 24 volts DC, with a current rating recommended of 4 amps or higher.

You can use a regulated supply or lead-acid battery. The power supply voltage should

be equal to or greater than the peak voltage to which you wish to charge your batteries. 12 volt supply is a sufficient to fast charge 7 cells. Up to 12 cells in series can be

fast charged with an input of 24 volts. If the power source output current is not rated

for at least 50% of the charge current set on the BC 112, the charge will terminate early.

Caution: If you use a lead-acid (automotive) battery as the power source, make sure

you have good ventilation. Lead-acid batteries generate explosive hydrogen gas when

they are being charged. Do not charge a lead-acid battery anytime a TEKIN charger

is also connected to it.

The BC 112 has an internal high-frequency, ripple-free buck switch mode power

supply converter which steps down the supply voltage down to whatever is needed by

the battery pack. This allows you to use a strong power supply input without causing

the charger to get excessively warm. When the voltage is stepped down, the amperage is stepped up. For this reason, an amp meter on your power supply may read

lower than the actual charge amperage. Use the meter on the charger for an accurate

reading of the charge current.

Connection: Once you have selected a suitable power source, connect the large RED

positive(+) clip of black input cable to the POS (+) terminal of the power source, and

the large BLACK negative (-) clip to the NEG (-) terminal of the power source The

heavy black input power cable of the charger plugs into the connector on the back of

the charger.

Warning: Improper or unsafe use of this or any other AC powered device can be hazardous. Do not operate or plug in the unit near water or moisture. Not for use outdoors,

except under dry, controlled conditions. Always unplug the charger when not in use. If

the AC power cord becomes frayed, worn, burned, or damaged in any way, you should

immediately shut off the power at the breaker box then unplug the unit from the AC outlet. Adamaged charger should not be used until it is properly repaired. Do not attempt

to open or repair the charger yourself. Never insert objects into the cooling vents on

the charger.

The BC 112C has a built-in 120 VAC power supply which will charge 1 to 12 cells

to a full peak at up to 10 amps. When using AC, first unplug the DC power cord from

the back of the charger. This will keep the clips from accidentally shorting and blowing

the fuse. Plug the AC power cord from the charger into any suitable wall outlet. Be sure

to keep soldering irons and sharp objects away from the power cord.

The BC 112C is available for use with different AC voltages. The standard voltage

is 120 volts for the USA. If your charger is intended for use with voltage other than 120,

it will have a tag attached to its power cord indicating so. In this case, use only the voltage specified on the tag. The BC 112C is designed, however, to work properly

on 220-240 volts when marked 240.

-1-

PO WE R S OU RC E SELE CTION

AC PO WE R SO URCE (M od el BC 1 12 C on ly )

The BC112C’s 24V output insures plenty of power is available to fully charge your

batteries, even with low AC line conditions.

You may use a second Tekin charger plugged in to the extra power plug on the

back of the BC112C. Use only a charger rated for 24 volts input, such as a BC112A or

BC110L. This will allow you to use 2 chargers from the same power supply. When doing

this, it is recommended that you set both chargers to a total current of 10 amps or less

(5 amps on each charger, for example.) If you operate the charger at over 120 watts

total output, the power supply may become excessively warm and shut down for a few

minutes until it cools. This is usually not a problem when charging 7 cells or less. If

shutdown does occur, a small fan may be used to help keep the internal power supply

cool, or you may reduce the charge amp rate. The power supply will come back on in

a few minutes.

If an overload occurs or improper connection is made, the fuse will blow. In this

case, disconnect the power and remove the fuse by pulling it straight out. Then

replace it with a 20 amp automotive style plug-in fuse (model 112Auses two fuses). Do

not use a fuse rated higher than 20 amps, or the charger could become damaged.

Normally a cell will noticeably begin to lose its edge and crispness to throttle a

response after just a few hard runs. This is caused by a gradual buildup of impurity and

crystal formation inside the cell, which is unavoidable, and increases the cell resistance. With each run the impurities increase, resulting in increasing internal resistance,

and therefore reduced voltage and power output. Discharging the battery fully after

each run will help reduce this to a certain extent, but the only way to totally minimize

this deterioration, and even actually reverse any previous deterioration, is to use the

TEKIN Power-Flex process. Power-Flex technology, which Tekin introduced, makes

your batteries perform like no other charge process can, and increases horsepower

beyond what even a new fresh cell can deliver.

The Power-Flex works by periodically turning off the charge current, and applying a

short-duration, high-amperage discharge pulse of negative current to the battery. This

“burping” effect acts to relieve the pressure buildup which occurs inside a cell during

charging, and to restore its chemical balance. It also improves the plate surface structure, for better power transfer. The net result is that the cell stays cooler during the

charging process, and delivers more voltage and capacity under a load, with lower

resistance. There are three user-adjustable levels of conditioning. Additionally, the

computer makes adjustments as required.

The BC112 has a factory installed Tamiya-style JST connector. If this is the type of

connector used on your batteries then just unplug the clip leads from the charger and

plug the battery pack right in. For other plug types, you may wish to install a mating

connector on the charger. If you use the alligator clips, you should solder some stub

wire leads onto the battery pack and clip onto them. The alligator clips should be

clipped onto soft, multi-strand wire to insure that a good connection(s) is made. A poor

connection can cause the charger to “false peak” and turn off before the charge is completed.

Please note: Kyosho-style packs use the same JST connectors as Tamiya, but may be

wired in reverse from that of the charger. Please be sure the positive (+,red) and the

negative (-,black) wires are matched with the red and black wires on the charger.

-2-

F U S E

PO WE R- FL EX CI RC UI T

CO NN EC TI NG THE BA TT ER Y P AC K

Page 3

a) The heatsink and /or panel may become warm in operation; use caution.

b) Output adapter cables should be no more than 7 inches longer than the original

cables.

c) The heatsink and panel are electrically live, and should not touch any wires,

batteries, or grounded automobile parts. This will cause a short to occur and could

blow the fuse.

d) Do not use a fuse rated higher than 20 amps, or the charger can become

damaged.

e) Keep at least 3 feet (1 meter) away from any operating transmitters to avoid

erratic operation while charging.

f) Never connect an electric motor to the battery charger.

New Battery Warning: Brand new battery packs may exhibit unusual voltage charac -

teristics the first time they are fast charged. There may be erratic voltage, and no peak

at all. causing the charger to overcharge the batteries. For this reason, you should

manually monitor the battery for the first charge. If the battery becomes excessively

warm, take it off the charger.

The BC112 charger settings and display modes are selected by pressing the MODE

button. Each time this button is pressed, the LCD display will increment to the next

mode and / or setting. A “Display Mode” is a mode used to monitor a particular parameter while charging. A “Set Mode” is one where a user value input setting is required,

and is shown by the SET annunciator on the LCD being lit. To change a setting, press

MODE until the display shows both desired parameter and set annunciators, then use

the set buttons (arrows) to change the value of the setting.

VOLTS:

Displays voltage from 0 to 19.99 volts. When a Ni-Cad or Ni-MH battery is connected to the charger the display shows the battery pack voltage. If no Ni-Cad is connected, the display shows the input voltage from the power supply. As a battery is

charging, the voltage will slowly rise. When the battery voltage reaches its highest

value (peak) the fast charge will shut off. The exact peak sensitivity where the cut-off

occurs will vary as the charger determines the optimum point.

AMPS:

Displays the current (0 to 10.00 amps) that is flowing into the battery. The reading

will be 0.00 unless there is a battery connected and charging.

TIME:

Displays the elapsed time of the most recently started fast charge cycle in hours and

minutes. When charging is complete, the time reading is stored until the next charge

cycle is started.

-3-

DI SP LAY M OD ES

CH AR GE R SET TI NG S an d D IS PL AY MODES

P R E C A U T I O N S

A/HR:

Displays the charge capacity in amp-hours (0 - 19.99 AH). This is the energy put into

the battery over the duration of the charge, and equals the charging current multiplied

by the charging time, or “coulombs”. How much energy is put into a battery while charging is a good indication of how much discharge capacity it will deliver. A battery with a

discharge capacity rating of 2000mAh needs a least 2.0 A/Hr of energy to fully charge

it from a dead state. When charging is complete, the capacity reading is stored until

the next charge cycle is started.

VOLTS PEAK:

Displays the voltage at which the battery peaks during the charge. The peak is the

highest voltage the battery reaches before the voltage begins to drop and ends the

charge cycle. The peak voltage is stored until the next charge is started.

Note: Set modes are not available while charging.

AMPS SET:

This set mode allows you to adjust the desired charge current from 0 to 10.00 amps.

The setting is saved in the charger’s memory and is recalled the next time you use the

charger, even if all power is removed. See section entitled “Selecting the Charge

Amperage” for help on choosing the proper current setting.

AMPS SET TRKL:

This allows you set the trickle (slow charge) current at amperage values from 0 to .5

amp (0 - 500mA). Unless the setting is at 0.0, current will flow into the battery anytime

the battery is connected to the charger. The SETTRKLvalue is kept in memory for the

next time you use the charger. See “Selecting the Charge Amperage” for help on

choosing the proper settings.

TIME SET:

This mode is for setting the duration of a Timed Charge, and can be set for up to 1hr

59 minutes. During a timed charge, there is no peak detection; the charge cycle lasts

for the time you set, regardless of the battery voltage. You must reset the charge time

duration each time you wish to do a timed charge. See the section entitled “Start Button

and Charge Profiles” for how to start a Timed Charge.

PF1-3 and OFF:

This is the Power-Flex Mode. In this mode there are 4 available settings; PF1, PF2,

PF3, and PF OFF. OFF and PF1 are for minimum or no conditioning, mostly used for

SCR or Ni-MH cells. PF2 is the normal setting, used for SCRC, SCE, P-170, 2000

mAh or for general Ni-Cad charging. PF3 may also be used regularly, but is especially

recommended for maximum conditioning of cells, or when recharging cells that have

not had a chance to rest overnight since their last run. Selection of the wrong level of

Power-Flex conditioning will not damage to the cells, but they may not attain optimum

performance. The Power-Flex setting will remain in memory for the next time you use

the charger. The charge light will blink while charging when Power-Flex is active. Cells

that have never been Power-Flex charged will need 2-3 charge cycles to obtain the

maximum results. Ni-Cd cells will deliver more power and lower resistance by using

Power-Flex, as well as last longer.

-4-

S E T M O D E S

Page 4

The BC112 is equipped with several charge profiles. Pressing the START button

sequences through these settings. Each time the START button is pressed, the next

charge profile in the sequence is displayed. Each time you press the button, the charger waits for 2 seconds to see if you will press the start button again to get to the next

setting. If START is not pressed again within 2 seconds, the charger will begin charging with the selected charge profile. Multiple presses of the START button will access

the charge profiles in order as explained below.

Use the charge profiles to select the cutoff sensitivity adjustment and type of battery you wish to charge. Each successive charge profile provides less sensitivity and

will cause the batteries to get warmer than the preceding one.

First Press: “OFF”

Fast charge current is shut off. Trickle Charge current will still flow if a non-zero value

is entered in the SET-TRKLmode.

Second Press: “P0”

Charge Profile”P”: This method is for minimal Peak charge. In this mode, the charger

acts as a Slope Detector, (tm) and will provide the best performance for Ni-MH cells.

It may also, however, be used with Ni-Cd cells, particularly if they are well matched.

The cutoff voltage is usually .03 volts, or less.

Third Press: “P1”

Charge Profile”P1”: This method is for a normal Peak charge. This setting provides

.03-.04 volts typical cut off level, and is best used for Ni-Cd cells, but may also be used

for Ni-MH cells.

Fourth Press: “P2”

Change Profile “P2”: This is the Re-Peak profile. Power-Flex settings are overiden to

PF OFF, and the peak detection is delayed to optimize the battery voltage just before

a run. Typical cutoff is .06-.08 volts. The cells will become quite warm with this setting.

Use only if desired on Ni-Cd cells, never Ni-MH cells, or excessive charging can occur.

Fifth press: “CS”

This is the Cold Start profile. Use this method for Ni-MH or Ni-Cads that have been

fully discharged. The microprocessor will automatically read the amperage, PowerFlex and voltage curve throughout the charge cycle to attain the best results. DO NOT

EVER use the CS profile on a battery that is not a least 50% discharged, or the battery

could be over-charged and damaged.

Sixth Press: Time Charge

Charges for a set amount of time. There is no peak detection, even if the batteries

become overcharged. The display shows a countdown of minutes remaining on the

charge. The time will count down until it reaches zero, at which point the charger will

shut off. Before starting a time charge, you need to enter the desired time in the TIMESET mode.

Seventh Press: “OFF”

The charger shuts off and returns to the top of the sequence.

-5-

ST AR T BUT TO N an d C HA RG E PROFILES

To start a Timed Charge, press the MODE button until TIME SET is displayed,

then use the SET (arrow) buttons to enter a time. Next, press the START button (5

times) until the time clock is displayed. The charger will run until the timer counts

down to zero.

INDICATOR LED: The Indicator LED will glow brightly while fast charging, and will

blink slowly to indicate when trickle current is flowing. If Power-Flex is turned on, the

LED will pulse occasionally during the charge cycle.

Note: When using the “P0” , “P1”, or “P2” charge profiles, you may set the AMPS SET

value up to 12 amps (rather than 10). The charger will operate at this higher setting for

3 minutes then automatically adjust back down to 10 amps. This feature is most useful for re-peaking to the highest voltage.

SE LE CT IN G T HE CHA RGE A MP ER AG E

TI ME D CHARGE

Fast Charging

Most Ni-Cad and Ni-MH batteries can be fast charged at 2 to 3 times their rated

hourly capacity without adverse effects. If you have the Power-Flex turned ON, you can

safely go to 4 times the rated capacity. Ni-Cad batteries are usually rated for capacity

in milliamp hours (Mah). A milliamp is 1/1000th of an AMP.A 2000 Mah battery should

be charged at 4000 (2000*2) TO 6000(2000*3) milliamps, which is equal to 4.0 to 6.0

amps. A 1200 mAh cell would be charged at 2.4 - 3.6 amps. A 3000 mAh Ni-MH cell

may be charged at 4-6 amps. Unless you are in a rush, it is usually better to charge at

the lower end of the range.

There are many different cell types on the market. Some cells, such as P-170 (purple), SCRC (black), and 2000mAh (brown) deliver maximum run time but are more sensitive in their charge procedure requirements. Always let these cells cool before fast

charging. These cells should be discharged fully at least once every 2-3 runs. Never

charge them at more than 3 times the rated capacity, except possibly just for a few minutes before running, to get an initial surge of power. Other cell types, such as SCR (red)

can withstand charging at higher amperages and peaks. You can charge these safely

at up to 4 times the rated capacity by using Power-Flex. Ni-MH cells should be charged

at 2-3 times the rated capacity maximum.Your dealer can help you determine the best

way to charge the cells you have.

When charging 12 cells, you may need to set the current below 4 amps. Otherwise

the peak voltage may exceed 19.99 volts, which will cause the charger to shut off

before it reaches a full peak.

Trickle Charging

Trickle or slow charging is usually done at 1/10th of the rated capacity. On a 2000 MAH

battery this would be 200mA or .20 amps. Trickle is used to “top off” the capacity and

equalize a battery that has been fast charged. Trickle can also be used without a previous fast charge. It would take about 12 to 16 hours to completely charge a dead battery with trickle alone.

When trickle charging at very low currents (less than .05A) the indicator LED may

not flash. You may still check the trickle current by using the AMPS display mode.

-6-

Page 5

When using the Power-Flex with cells that have not received regular Power-Flex

conditioning, it is common for the charger to false peak and trip off several times before

the charge is complete. This is due to erratic cell voltages that occur until Power-Flex

conditions cells for reduced resistance. Either turn the Power-Flex off, or leave it on

and restart the charge a few times. After Power-Flex conditioning has been used on

the cells for a few charges, they will produce a proper charge curve and increased

power.

When using a DC power supply, try to use one as powerful as possible for best

results. A13 to 14 volt power supply will allow a better, higher peak of 7 cells than a 12

volt supply or lead-acid battery will. A power supply with good filtering and regulation

will provide more reliable peaks, especially when using several chargers on one power

supply, or when using Power-Flex.

You may disable the key buzzer by pressing both middle buttons simultaneously.

The buzzer is reset on by momentarily removing all power from the charger.

Charging:

Always make sure your cells are cool before beginning a fast charge. If you have

just run the car, let the cells cool for about an hour before recharging. This is critical for

performance and cell life, as Ni-Cad cells do not accept a full charge at temperatures

over about 80 degrees Fahrenheit. After charging the cells let them cool fully.This usually takes at least 20 minutes. You may then re-peak them until they are slightly warm

to the touch. They will then be ready to run.

Discharging:

If you wish to get the best possible performance out of you batteries, you will need

to first discharge the pack before charging. Fully discharging cells is one of the most

effective ways to prevent memory, power loss and capacity loss. With P-170, SCRC

and 2000 mAh cells, this should always be done. The pack should first run down in the

car by normal use, then do one of the following.

1) Place an approximately 30 ohm, 10 watt resistor across the battery pack. The

resistor will cool off when the cells discharge in about 30 minutes. It can then be

removed and the pack allowed to rest for preferably at least 24 hours before charging.

2) Place a single 1 ohm 5 watt resistor across each individual cell. This method is

slightly better, as each cell then gets discharged independently of the other, thereby

assuring a fully matched discharge. These resistors are available as accessories at

better hobby shops.

Ni-MH cells do not generally require deep discharging for proper maintainence.

Optional Add-On Discharger/Cycler:

A precision electronic discharger is available from Tekin as an add-on module for

the BC112 series. This unit, model number DIS-350, will test, cycle, and match you batteries for absolutely maximum performance. It discharges at up to 30 amps, (45 amps

momentary) and will train your cells to run stronger, longer. The DIS-350 can be used

by itself, or connected to the input-output connectors and expansion wire on the side

of the charger for automatic cycling.

-7-

MI SC EL LA NE OU S T IP S & T RI CK S

Almost all problems are caused poor or loose connections that trip the peak detector when the wires are bumped or moved. Make certain the charger wires are tightly

connected to the battery pack, Any connectors should be clean (use motor spray) and

tight. Alligator clips are best clipped to piece of multi-strand flexible wire so the teeth

can sink in.

A) When using a 12 volt automotive charger or external AC power supply, line surges

or dropouts will occasionally cause problems.

B) If the unit slow charges, but will not fast charge when you press the start button,

the output wires may be shorted or hooked up in reverse.

C) Be careful not to hook up the charger backwards as the fuse may blow. You can

replace the fuse yourself with a 20 amp unit.

D) If the power supply, battery, fuse, and all connections all check out okay and the

charger either stays on or off all the time, of blow fuses, then the MOSFET transistor

inside the charger may have been damaged. This can happen if the units is shorted,

overheated of connected to an improper power supply.

E) If it should ever be necessary to return unit to factory for repair, be sure to enclose

a note stating the nature of the problem, the return address, shipping instructions and

any special instructions. Most repairs are shipped back out within 3 days, C.O.D.

Please allow up to 2 weeks for shipping.

If something unusual occurs while charging, the display may show one of the following error codes:

ECO:

An internal reset has occurred. This is usually caused by static. The charge must be

restarted.

EC2:

Indicates a problem with the power supply.The charge current has dropped below the

selected amperage value. The power supply may not be strong enough to maintain the

selected charge current. Try charging at a lower amperage setting by changing the

value in AMPS SET mode, or using a higher amperage rated power supply. If this does

not work, the problem may be from power supply disturbances or line transients.

EC5:

Indicated excessive current flow. Check to see if the battery is connected backwards or

shorted.

EC6:

This error code is caused by the Ni-Cad being connected to the charger backwards

(reverse polarity). Reconnect the battery correctly, and restart.

ECF: A high amp surge over 25 amps occurred due to a line voltage surge, and the

charger shut down to avoid blowing a fuse. Try charging again.

-8-

ER RO R COD ES

T R O U B L E S H O O T I N G

Page 6

TEKIN’s products are designed with racers in mind, and are suitable for use by

anyone. Our standard off-the-shelf items have won World Championships without any

additional enhancements. Many of our products use exclusive, or patented circuits to

deliver the highest performance. With TEKIN, you always get the right features and

specs to do the job.

Ultra-precise, high-density, computer controlled,

automated assembly machines ensure that you

get consistent high quality.

TEKIN staff of highly knowledgeable and skilled technicians

help insure quality performance. Most repairs are completed

in 2 to 3 working days. All TEKIN products carry a limited warranty which guarantees new units to be free of factory defects

for 120 days from the date of original purchase.

TEKIN ELECTRONICS, INC. guarantees this battery charger to be free from factory defects in materials and workmanship for a period of 120 days from date of purchase, verified by sales receipt. This warranty does not cover; suitability for specific

application, components worn by use, application of reverse or improper voltage (fuse

provides protection in most cases), tampering, misuse, or shipping. Our warranty liability shall be limited to repairing units to our original specifications. In no case shall our

liability exceed the original cost of the product. By the act of using this battery charger,

the user accepts all resulting liability. Batteries and other equipment damaged in connection with the use of this device are NOT covered by this warranty.

-9-

AB OU T TEK IN

LI MI TE D W ARRANT Y

TEKIN Electronics, Inc. • 940 Calle Negocio • San Clemente, CA92673

Phone: (949) 498-9518 • Fax: (949) 498-6339

Copyright 1999-2000 Tekin Electronics

Race all of TEKIN’s expert gear...

-10-

TSC G-12, G-12c,

G12cIII series speed

controls. World

Champion.

FM Chrome Micro Receiver

G-10, G-11 speed control

DIS-350 Discharger

Loading...

Loading...