Page 1

NOTE: Before Radio Calibrating, ensure speed control is

hooke d up to the recei ver, a charge d battery i s properly co nnected, and the transmitter is turned on. On your radio, set all

trim adjustments to the middle, throttle/brake EPAs set to max

and ensure that your throttle directio n is set to “normal” .

Calibrat ion is real ly very si mple, you j ust press and hold the

MODE butto n for 3 sec onds to e nter radio calibrate , let the

speed co ntrol “find” yo ur neutral , then let i t “find” your ful l

thrott le and full br ake. If yo u are unsure how to pe rform this

procedure, follow the detailed steps outlined below.

Congratul ations on your purchase of the B1/B1-R, Tekin’s

High Perf ormance Mini Brushed Motor Electronic Speed Control. The QuickTune

feat ure allows t he user to quickly and

accurately adjust all critical operating parameters. Just connect

the spee d control as described be low, perfor m a quick radio

calibr ate, and you are ready to race!

B1

Forward / Brake

PROFESSIONAL MINI B RUSHED SPEED CONTROL

• Adjustable Drag Brake/Reverse Type

• Voltage Cutoff for LiPo Cells

• Push ( Anti-Drag Braking )

• QuickTune Digital Setup

• Temperature Monitor

OWNER’S MANUAL

INTRODU CTION

The fo llowing stat ements nee d to be under stood befo re using

the B1/B1-R:

1. Turn on the transmitter first to avoid uncontrollable noise

to speed control.

2. Dis connect batt ery from s peed control when not in use .

3. Do no t hook-up the battery backw ards! No re verse voltage prot ection.

4. Do no t operate s peed contro l in or around wat er.

5. Insul ate expose d wires wit h heat shr ink tubing to prevent

short circuits.

6. The B1/B1R is intended f or Mini vehic les only.

SOLDERING

IMPORT ANT: Use extreme care and observe proper safety

precaut ions when so ldering. Al ways wear e ye protect ion. Be

sure t hat both wires are disconnec ted from the battery befo re

soldering on the posts.

Never keep a hot soldering iron on the speed control solder

posts fo r more than 3 seconds—the sol der post may beco me

de-sol dered from the spee d control and beco me damaged.

HINT: It should only take a few seconds to solder the wire to

the post. If you do not complete the solder joint in approximately 3 seconds, remove the iron, clean and tin the tip, then

repeat the procedure below. Applying a small amo unt of sol der

paste f lux can oft en help so lder flow on a st ubborn sur face.

SOLDERING CONT...

ATTACHING WIRES TO THE SPEED CONTROL:

1) Red Wire s are usual ly used to connect the speed co ntrol

to the positive battery terminal and the positive motor

terminal . Black wire is typic ally used for t he batter y

negative t erminal , and blue is used for the negat ive motor

connection. Inspect the sticker on the speed control or

refer to the diagrams to determine which color wire to

attach to each post.

2) Strip back the insulation of the wire by about 3/32” to

1/8” and “pr e-tin” t he wire by heat ing the end and a pplying sol der until it i s thoroughly c overed. You may s hake

of any excess solder while it is still hot. Be very careful

not to splash yourself with hot solder.

3) If there is no solder on the post, place the tip of the iron in

the notc h on top of t he post and apply a small amount of

solder to the post. When the solder has flowed, remove

the sol dering iro n, wipe the t ip clean and apply a smal l

amount o f fresh sol der to it.

4) Hold t he wire so the tinned e nd is in co ntact with the

notch of the post . Now touch the iron ti p to the wir e and

the post. Wait about 2 seconds for the solder to flow, and

then remove the iron while still holding the wire. You

may let go of the wire after a s econd or two when the

solder sets.

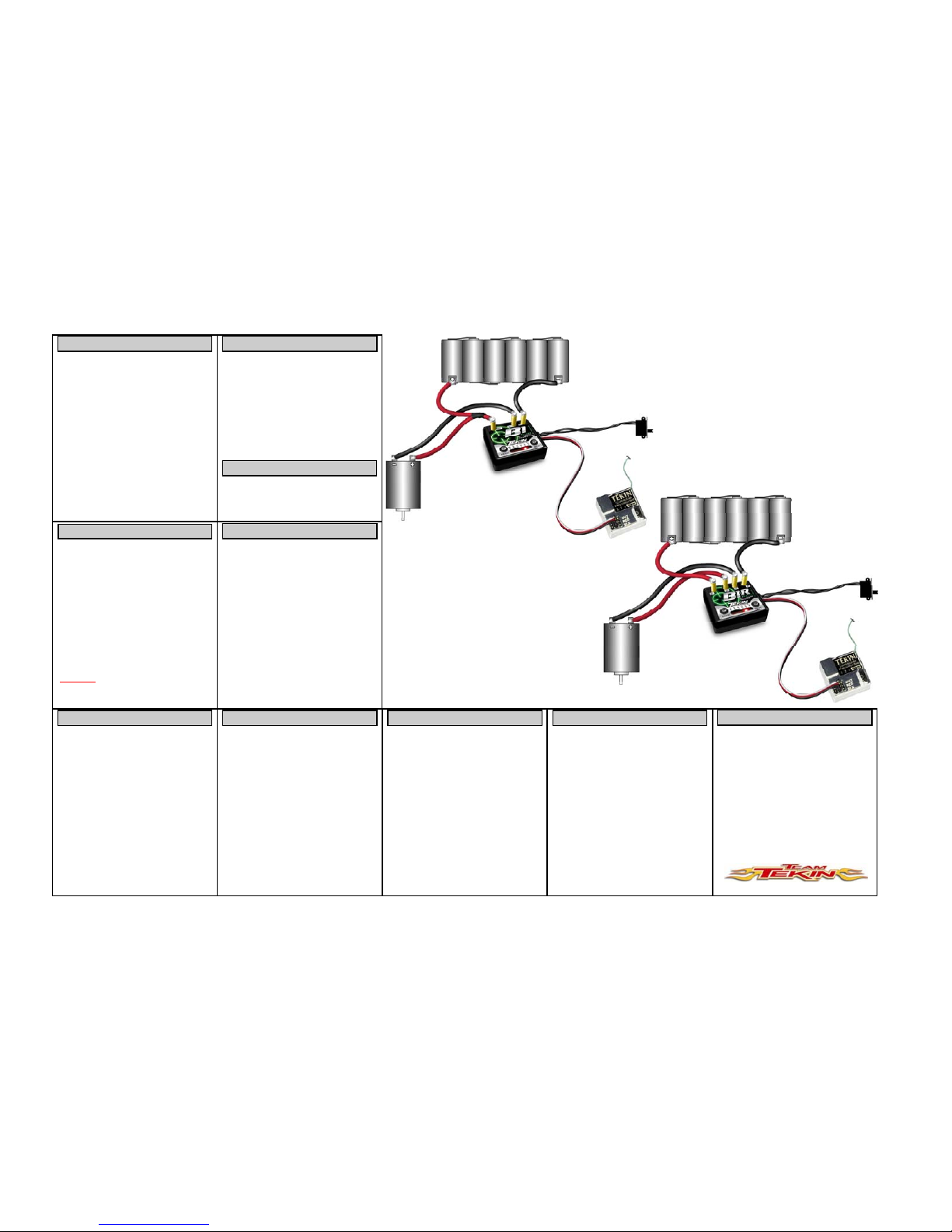

Fo r B1 C onne ctio n Diag ram, Ref er to Fig ure 2 ,

For B1R Connection Diagram, Use Figure 3.

1) Placement : Choose a l ocation for the spee d control that is

protect ed from de bris. HINT: To pre vent radio i nterference place the speed control as far away from the radio

receiver as possible and keep the power wires as short as

possibl e. If poss ible plan o n routing power and moto r

wires away from the radio receiver and radio wires.

2) Mounti ng: For best results cle an the bot tom of the s peed

control and chassis . Using the doubled-sided t ape,

(incl uded) mount the speed contr ol to chassis .

3) Using a sm all piece of double-side d tape, mount the ON/

OFF switch in a convenient place.

4) Determ ine how you would pr efer to co nnect the motor

and batte ry pack to the spee d control. U sing connec tor

pairs i s prefer able for mos t applic ations as i t allows yo u

to e asily switch bat tery pac ks and change motors.

Whether using co nnectors or di rect sol dering, co nsider

where yo ur batter y pack sits and how much wir e will be

needed to attach to the speed control.

HOOKUP INSTRUCTIONS

HOOKUP INSTRUCTIONS CONT...

NOTE: Make sure all wires are secure and a safe distance

from all moving parts—use the zip-ties in the accessory pack.

RADIO CALIBRATION

QuickTune MODES

MODE RANGE DEFAULT

DRAG B RAKE

(DRG B)

1-11 1 (OFF)

NEUTRAL WIDTH

(NW)

1-11 5

CUR REN T LIM ITE R

(LIM)

1-11 11 (OFF)

PUSH CONTROL (ANTI DR AG)

(PC)

1-11 1 (OFF)

REVERSE TYPE—-B1R

(RT)

THROTTLE PROFILES-B1

(TP)

1-3

1-6

3

3

VOL TAGE CUTO FF

(VC)

1-4 1 (NONE)

PRECAUTIONS

DO NOT CONNECT BATTER Y INCORRECTLY TO

SPEED CONTROL, VERIFY THAT THE BATTERY

POSITIVE WIRE WILL CONNECT TO THE SPEED

CONTROL POSITIVE WIRE B EFORE CONNECTING!

1) CONNECT SPEED CONTROL TO RECEIVER

Plug the speed control into the throttle channel of the receiver.

• Channel 1: Servo

• Channel 2: Speed Co ntrol

“REMEMBER: 1 to Turn, 2 to Burn”

3) CONNECT SPEED CONTROL TO MOTOR

Visually verify that the connector on the motor and the speed

control match the chart below, then connect.

Startup Se quence

When the po wer switc h is turned ON t he speed contr ol begins

looking f or the neut ral signal. If a neutral si gnal is found t he

Arming Seque nce (fl ashes LEDs /chime) will occur fol lowed by

LED3 on s teady

. NOTE: If Arming Sequence does not occ ur

see Troubl e Shooti ng section of this manual be fore pr oceeding.

One Touch Radi o Calibratio n

1) Turn on transmitter.

2) Turn on speed control.

3) Press and ho ld the M ODE button o n the spee d control for

3 seconds. All LEDs will blink red 3 times with 3 chimes.

The spee d control will make a pulsi ng chime as i t looks

for a neut ral signal— you do not need to do anything ye t.

4) When NEUTR AL positio n is found and r ecor ded, LED3

will fl ash and a confi rmation chi me will so und .

5) The puls ing chime wil l begin agai n and LED6 will flas h;

pull tr ansmitter t rigger to the full t hrottle posi tion and

hold unti l the confi rmation chi me sounds.

6) The puls ing chime wil l begin agai n and LED1 will flas h;

push trans mitter tr igger to the f ull brake pos ition and hold

until t he confirmat ion chime sounds .

7) Release trigger to return to neutral position. LEDs will

flash and t he arming se quence chi me will sound.

8) LED3 is now on steady. C alibrati on is co mplete and you

are ready t o drive!

NOTE: If any pro blems occu r, repeat r adio calibrat ion.

HINT: Once calibrated, the LEDs on the speed control will

advance as the t hrottle or brake is appl ied.

Hairpin Trigger Response: If you wish to have a very sho rt

trigger range, the n only sque eze the thro ttle/br ake trigger

partial ly during the radio calibr ation proce dure. Throttl e/Brake

response will not be quite as smooth, but yo u can pull full

throttle very quickly.

QuickTune :

1) Press the MODE button to access the desired setup mode.

The LED starts blinking to indicate that mode selection is

under way. Each time t he MODE butto n is pressed and

released, the LED advances. For example, to get to the

Voltage Cutoff adjus tment, si mply press and releas e the

MODE button 6 times. NOTE: Do not wait longer than

5 seconds to adjust the selected MODE or the speed control wil l return to normal ope ration.

2) Press and release the INCR button to adjust the value.

The first time INCR button is pressed, the LED(s) will

display the existing setting. Each time the INCR button is

pressed the value will advance, then after maximum, start

over again at the low end of the scale. If two LEDs are

on at once, it indicates a value mid-way between the

LEDs.

QuickTune Exam ple: Let ’s say you want t o use a 2 cell LiPo

battery. To change the Voltage Cutoff from the default setting

(1 = None) to setting 2 (2 = 6.0 Volt Cutoff), first follow step 1

above by pr essing and r eleasi ng the MODE but ton 6 tim es.

Now press and release the INC button, the LED should show

the curr ent setti ng of 1. Press and release the INC button agai n

and the LED will move to position 2, indicating that Voltage

Cutoff is now set to 6.0 Volts. Wait 5 seconds and the ESC

returns to normal operation.

HINT: If you wis h to set a nother Pro gram Feat ure, press the

MODE butto n again. After 5 seco nds pause, the values yo u

selected will be saved in memory and the speed control will

resume normal oper ation.

PIT TU NING : If you are in the pit area and cannot use your

transmi tter you may us e pit t uning mode t o adjust set tings by

following t his proce dure: Unplug t he steeri ng servo from the

receiver to avoid servo damage. Hold down either MODE or

INCR button while turning the power switch on. An LED sequence will occur indicating yo u are in pi t tune mode . The

user set tings will be active, but the moto r will no t run and the

speed control will not respond to receiver signals. Turn the

speed control powe r off and bac k on to r esume normal operation.

LED1: DRAG BRAKE contro l provides i mmediate br aking

action i n the neut ral zone. This gently slows the c ar down

when you l et off t he trigger . Drag Brake can provide a better

cornering approach . Higher values increase the degree of drag

braking.

QuickTune

Tekin’s Quic kTune electronic setup feature allows users to

change every critical operating parameter in a quick, easy, and

accur ate fashion. The basic oper ation is des cribed as :

• Use MOD E button to sc roll to a P rogram Feat ure.

• Use INCR ( increment ) button to view/adjust the Feature .

The B1 series has a built-in se lf-test mode that chec ks all major

systems on the spee d control. Bef ore using the self-test mo de,

be sure the rear whee ls are free to spin (off the ground) . To

activate the self-test, turn the speed control on, then press and

hold bot h MODE and INCR but tons simul taneously fo r 5

seconds . After 5 seconds, t he LEDs will ramp up in se ts of

two. Circuits inside the speed control are tested to see if any

proble ms have occ urred. If t he unit pass es self- test, the n LED3

wil l st ay on s tea dy.

If probl ems occur turn the po wer off to the unit and verify all

other co nnections are clean/ tight/cor rect (moto r, receiver, battery, plugs, etc) . After veri fication, po wer the unit back on.

NOTE: Activating the self-test mode also resets all the userprogram mable setti ngs and paramet ers to their defaul t values.

The use r’s radio cal ibration set tings are also reset to de faults.

SELF TEST

B1-R

Forward / Brake /

Reverse

ESC MOTOR

(M -) Blue Wire (-) Negative

(M +) Red Wire (+) Positive

2) CONNECT SPEED CONTROL TO BATTERY

Visually verify that the connector on the battery pack and the

speed control match the chart below., then connect.

DANGER: If the batter y wires to uch during the plug inst alla-

tion. It will cause an electrical short circuit resulting in damage

to the pack and poss ibly a fire hazar d. Tekin re commends t he

use of hi gh quality bat tery c onnectors, such as De an’s Plugs , to

impro ve power tr ansfer and minim ize the risk of shor t-circuit s.

ESC BATTERY

(B-) Black Wire (-) Negative

(B +) Red Wire (+) Positive

Pit Tune Mode

SPEED CONTROL SPECIFICATIONS

Controls , B1 Fwd/Brk

Input Power (Cells)

4-8 NiCd/NiMh

2-3S LiPo

Motor Limit Size 370 Si ze or smaller

Motor Limit Turns None

ON Resistance

B1

B1-R

0.0013 Ohms

0.0052 Ohms

Max Current

B1

B1-R

60 Amps

30 Amps

BEC 5 Volts, 1.5 Amps

Power Wires 16 GA Silicone

Dimensions 1.0 x 0.9 x 0.25 In.

(25.4 x 23 x 6.3 m m)

Weight (with wires) 0.28 Oz ( 8g)

Controls , B1-R Fwd/ Brk/Rev

The fo llowing ite ms are need ed to conne ct your s peed control:

• Soldering Iron

• 60/40 Electric Grade Solder (or silver solder)

• 4 pieces 16 Ga. Wire ( Included)

• Motor/B attery conne ctors (2 pair)

MOUNTING

SOLDERING, TOOLS NEEDED

SOLDERING CON T...

ATTACHING WIRES TO THE BATTERY:

The same techniques describe d in the prece ding sectio n may be

used to solder the wires to the battery connectors.

IMPORT ANT:

Take pr ecautio ns if removing f actor y battery

connec tors. Conne cting the bat tery backwar ds will c ause damage, and will void warranty. When s older ing connect ors to a

battery pack, cut only one wire of the battery pack at a time to

ensure that the expos ed wires canno t short to gether.

HINT: If you are using Dean’s connecto rs for both t he battery

and the mo tor, make sure that you have a mal e and a fe male

attache d to the spee d control wi res. That way, yo u cannot ac cidentall y connect the batter y to the mot or wires or vice ver sa.

1) If using a c onnector between batte ry and spee d control

make sure that the ends will be mat ed together correctly,

male t o female, and t hat the wir e colors match—red t o

red and blac k to black.

2) Solder the wires from the speed control to each of the

connectors, then solder wires from the battery to each

connector’s mate.

ATTACHING WIRES TO THE MOTOR:

The same t echniques described i n section 5 may be used to

solder the wires to the motor.

1) If using a c onnecto r between mo tor and spe ed control

make sure that the ends will be mate d together correctly,

male to female, and that the wire colors match—red to

red and blue to blue.

2) Solder the wires from the speed control to each of the

connectors, then solder wires from the motor to each

connector’s mate.

REMOVING WIRES:

1) Have a ho t iro n and the spe ed contro l secured. Cl ean the

tip of the iron and ap ply a small amount o f solde r. While

the tip is still smoking from the flux in the solder, touch

the tip of the iron to the top of the post.

2) As the so lder on the po st melts, pul l on the wire you wish

to remove.

HINT: If there is excess solder remaining on the post, you

may remo ve it by heat ing the po st until the solder j ust start s to

melt, then quickly tappi ng the spee d control agai nst the

workbench to knock off the exces s solder .

SOLDERING CON T...

Page 2

Listed be low are a number o f tips to ensure t hat you will get

years of trouble- free perfor mance from yo ur Tekin spe ed

control.

LED2: NEUTRAL WIDTH adjusts your deadband a round

the neu tral point . A low neutr al width value pro vides more

sensit ive trigger response ar ound neutr al.

LED3: CURRENT LIMITER adjusts the throttle response

during acceleration to control annoying wheelspin. Low values

allow low amounts of current to pass to the motor, higher values allo w higher amount s of cur rent. The top value (11) turns

OFF current limit.

LED4: PUSH CONTROL or ANTI-DRAG BRAKING

overcomes the natural drag of the motor when you return to

neutral. Racers refer to this as “creep” , this setting eliminates

the need to trim the throttle forward to create a coasting

(pushing) effect . Low values give you a shor t duration pus h,

higher value s a longe r duratio n push

LED5: BRAKE/REVERSE TYPE ** B1R ONLY**

1) Proportional Brake with Reverse Lockout (LED1 ON).

Propor tional brake will be applied dur ing rever se throt tle.

2) Forward to Brake to Reverse (LED1-2 ON). The car will

operate freely in forward and reverse. (Brakes to a stop

before switching into reverse)..

3) Proportional Brake with Reverse Delay (LED1-3 ON).

The car will only go in reverse if the trigger has been in

neutral for 1 second, otherwise it operates like

proportional brake with no revers e.

NO LIGHTS COME ON

Check f or dead batte ries. Chec k the connec tions bet ween the

batteries and the speed controller and that the switch is in the

“ON” position. Verify that there are no bad connections at the

spee d controller . Check fo r reverse battery co nnection.

ALL L EDs F LASH ING

No radio signal can be found. Chec k recei ver connect ion and

verify t hat ESC is plugged int o corre ct channel . Verify t ransmitter and recei ver are functi oning pro perly.

BOTTOM OR TOP 3 LEDs FL ASHING

Radio s ignal fo und, but neutr al point from trans mitter is out of

expec ted range. Spee d control not calibr ated properl y or radio

setti ngs have been c hanged. Rec alibrate speed cont rol as describe d in the R adio Cali bration sect ion.

ADJUSTMENT MODES CONT...

Before se nding your B1 /B1-R in fo r service , please revie w the

Instruc tions and Tro ubleshoo ting sectio ns. After reviewing

these i nstructions , if your s peed control still requi res service ,

please contact our customer service department for additional

assistance. To obtain the most current product service options

and pricing, consult the following:

WEBSITE: (www.teamtekin.com) Follow the instructions

from the Service Re quest sectio n of our webs ite.

PHONE/FAX: Contact our customer service department.

WARRANTY SERVICE: For warranty work, you MUST

CLAIM WARRANTY on A COMP LETELY FILLED OUT

PRODUCT SERVICE FORM and include a VALID CASH

REGISTER RECE IPT with pur chase dat e, deale r name &

phone# on it, or an i nvoice fro m previous ser vice. If warr anty

provisions have been voided, there will be service charges.

NOTE: Hobby de alers or distri butors are not authorize d to

replace TEKIN produc ts thought t o be defec tive.

Tekin, Inc.

McCall, Idaho

(208) 634-5559 / (208) 634-5 569 (FAX)

www.teamt ekin.co m

WARRANTY

TEKIN, INC. guarantees speed controllers to be free from factory def ects in mat erials and wor kmanship fo r a perio d of 120

days fro m date of pur chase, when verifie d by sales receipt. This warranty do es not co ver: suitabi lity for specific

applicat ion, co mponents wo rn by use o r improper voltage,

tamper ing, misuse, or shipping. O ur warranty l iabilit y shall be

limite d to repairi ng unit to our original specific ations. Bec ause

we have no control over the installation or use of this product,

in no cas e shall we be liable fo r damages.

Additionally, these items void the warranty:

1) Using the same polarity connectors on the battery and

motor wires from the speed controller.

2) Allowing water or moisture into the speed controller.

3) Incorrect wiring.

4) Use inconsistent with the instructions.

OPERATING TIPS

LED5: THROTTLE PROFILES ** B1 ONLY**

1) Mildest profile, concave (LED1 ON)

2) Mild pr ofile, co ncave (LED1- LED2 ON)

3) Line ar profi le (LED1- LED3 ON)

4) Aggressive profile convex (LED1-LED4 ON)

5) More aggressive profile, convex (LED1-LED5 ON)

6) Custom— User Adjustable Using Tekin HotWire PC

Connectio n (LED1-LED6 ON).

LED6: VOLTAGE CUTOFF

1) NONE (LED1 ON)

NiCd/NiMh Cells.

2) 6 Volts (LED1-LED2 ON)

2 Cells LiPo (2S)

3) 9 Volts (LED1-LED3 ON)

3 Cells LiPo (3S)

4) Custom (LED1-LED4 ON)

User Adjus table Cuto ff, requi res Tekin Ho tWire PC

Connection.

IMPORT ANT:

If us ing Lithium Polymer (LiPo) bat teries, DO

NOT operate your vehicle with the factory default Cutoff Voltage sett ing (None) .

PROPER ON/OFF PROCEDURE

Always turn your transmitter on first and then turn on your

speed co ntrol. At the conclus ion of your r un, simply re verse

the above procedure.

BATTERY POLARITY

It is e xtremely im portant to e nsure the bat tery pack i s

connec ted to the s peed contro l properly. Connecting t hem

backwards could ca use severe damage to the battery pack and/

or speed control.

DO NOT JAM THROTTLE

This will cause tre mendous reduc tion in run t ime and exce ssive

heat buil d-up.

RADIO INTERFERENCE

Try to kee p the rece iver at l east 1-2 inc hes away fro m any motor or battery wires.

RECEIVER BATTERY

The built -in BEC (Bat tery Eli minator Ci rcuit) is str ong enough

for 1 st andard ser vo. If you are us ing a high po wer ser vo you

may need a s eparate r eceiver bat tery (see Receiver Bat tery

section).

NO REVERSE

QuickTune mode, Brake /Reverse Type is set to option 1.

QuickTune mode, Brake /Reverse Type is set to option 3

(trans mitter tr igger must be in neutr al posit ion for 1 s econd

before reverse is enabled). Speed control is a B1, not a B1R

(not a reversing type).

MOTOR WILL NOT SHUT OFF OR RUNS SLOWLY

Incor rect radio calibratio n or thro ttle trim se tting on t ransmitter. Check tr ansmitter settings and recal ibrate s peed contro l.

Moisture in speed control: Unhook batteries and let the speed

control dry.

MOTOR CUT OUT/RADIO INTERFERENCE /POOR

RANGE

Transmit ter batte ries are low or damaged. M ismatc hed crystals. The three-wire cable from speed control to receiver may

also be too long; 6 inc hes is t he maximum. Thi s speed co ntrol

radiate s very lo w noise and you sho uld have no t rouble with

interf erence. If you do have inte rferenc e, mount the speed

control in the pan, and mount the receiver and antenna at the

top of the shock tower. Try to keep the receiver away from the

batteries, power wires, metal or graphite.

TROUBLESHOOTING

NOTE: Optio nal. Connec t a separate battery pac k to the

receiver using the “B” or “BAT” socket on your receiver. A

small switch should be used on the receiver pack to operate the

radio., and the receiver pack should have no more than 5 cells.

IMPORTANT: You must remove the red wire from the speed

control servo plug an d cover it with heat shr ink tubing.

The On-Bo ard Temperat ure Monito r works to provide you with

important feedback o n speed co ntrol tem perature, he lping you

to adjus t gearing and avoid long t erm heat damage. To us e;

1) The spe ed control must be c alibrated to your radio and

the radi o must be in the ne utral posit ion.

2) The middl e LED will be on st eady, and sho uld blink ou t

every 2 seconds.

3) At the moment that the center LED blinks out, one or

more of the other LED s will ligh t up.

4) LEDs 1-3 lit is typi cal of li ght loads or a s tock motor .

LEDs 1-5 lit indi cates he avy loads and i s typic al when

running mo d motors. LEDs 1-6 li t indicates hi gh inter nal

temper atures appro aching the rmal shutdo wn. Disco ntinue us e until the speed cont rol return s to normal o perating temperature.

SERVO WORKS, THROTTLE DE AD

Speed co ntrol not adjusted corr ectly. May be i n Pit Tune

mode. If LEDs are fl ickering, may i ndicate that Volt age Cutoff

is set above battery pack voltage. Check that cutoff is correctl y set and that battery i s fully char ged. Motor or connections to motor are bad. Receiver plug or connections are bad.

Speed c ontrol no t plugged in to thrott le channel o n receiver .

STUTTERING UNDER HE AVY ACCELERATION

Recei ver is getti ng magneti c field interfere nce. Try mount ing

receiver on its side and/or spacing it 3/16 inch up from the

chassis . If this doe s not work, t ry mounti ng it on its other side.

Move power wires away from receiver. Check for low current

limiter setting. Check for incorrect Voltage Cutoff setting.

BRAKES DO NOT WORK AT ALL

Speed control or radio transmitter improperly adjusted. Adjust

EPAs on transmitter all the way out and recalibrate speed control to radio.

AUTO COU NT NO T WO RKI NG

Mount t ransponder at front of car away fro m batterie s and

wir es .

SERVO AND THROTTLE DEAD

Check f or dead batt eries, bad c onnec tions to s peed cont rol,

dad rece iver plug c onnectio n. Switch may nee d replaci ng.

Broke n wires, bad crys tal, bad radi o equipme nt.

THROTTLE WORKS, SERVO DE AD

Broke n servo. Wiri ng of plug is bad or incor rectly wir ed.

TEMPERATUREE MONITOR

TROUBLESHOOTING CONT... SERVICE AND REPAIR

Figure 2.

B1 Connection Diagram

TROUBLESHOOTING CONT...

ADJUSTMENT MODES CONT...

Figure 3.

B1R Connection Diagram

RECEIVER BATTERY

Loading...

Loading...