Page 1

Tekelec 1100 Application Server

Hardware Manual

910-2969-001 Revision H

February 2007

Page 2

Copyright 2007 Tekelec.

All Rights Reserved

Printed in U.S.A.

Notice

Information in this documentation is subject to change without notice. Unauthorized use or copying of this

documentation can result in civil or criminal penalties.

Any export of Tekelec products is subject to the export controls of the United States and the other countries

where Tekelec has operations.

No part of this documentation may be reproduced or transmitted in any form or by any means, electronic

or mechanical, including photocopying or recording, for any purpose without the express written

permission of an authorized representative of Tekelec.

Other product names used herein are for identification purposes only, and may be trademarks of their

respective companies.

RoHS 5/6 - As of July 1, 2006, all products that comprise new installations shipped to European Union

member countries will comply with the EU Directive 2002/95/EC "RoHS" (Restriction of Hazardous

Substances). The exemption for lead-based solder described in the Annex will be exercised. RoHS 5/6

compliant components will have unique part numbers as reflected in the associated hardware and

installation manuals.

WEEE - All products shipped to European Union member countries comply with the EU Directive

2002/96/EC, Waste Electronic and Electrical Equipment. All components that are WEEE compliant will be

appropriately marked. For more information regarding Tekelec's WEEE program, contact your sales

representative.

Trademarks

The Tekelec logo, EAGLE, G-Flex, G-Port, IP

7

, IP7Edge, IP7 Secure Gateway, and TALI are registered

trademarks of Tekelec. TekServer is a trademark of Tekelec. All other trademarks are the property of their

respective owners.

Patents

This product is covered by one or more of the following U.S. and foreign patents:

U.S. Patent Numbers:

5,008,929, 5,953,404, 6,167,129, 6,324,183, 6,327,350, 6,456,845, 6,606,379, 6,639,981, 6,647,113, 6,662,017,

6,735,441, 6,745,041, 6,765,990, 6,795,546, 6,819,932, 6,836,477, 6,839,423, 6,885,872, 6,901,262, 6,914,973,

6,940,866, 6,944,184, 6,954,526, 6,954,794, 6,959,076, 6,965,592, 6,967,956, 6,968,048, 6,970,542

Ordering Information

For additional copies of this document, contact your sales representative.

Page 3

— DRAFT —

Table of Contents

Chapter 1. About This Manual

Introduction ............................................................................................... 1-2

Where to Find Information in This Manual .......................................... 1-2

Where to Find Other Information .......................................................... 1-3

Programs Needed to View Linked Documents ............................ 1-4

Documents That Show How to Perform a Procedure................... 1-5

Installation Documents...................................................................... 1-5

Applications Documents ................................................................... 1-6

Documentation Packaging and Updates............................................... 1-6

Documentation Admonishments ........................................................... 1-6

Customer Assistance ................................................................................ 1-7

Chapter 2. Safety and Pre-Installation Requirements

Introduction ............................................................................................... 2-2

Safety Information .................................................................................... 2-2

Regulatory Compliance and Certification............................................. 2-4

Pre-Installation Site Requirements ......................................................... 2-6

Generic Site Requirements ................................................................ 2-6

Grounding and Power Requirements ............................................. 2-9

Chapter 3. T1100 AS Hardware System Overview

Introduction ............................................................................................... 3-2

T1100 AS Hardware System.................................................................... 3-2

T1100 AS Hardware Features.................................................................. 3-4

T1100 AS Rear I/O Panel .................................................................. 3-6

T1100 AS Status Indicators................................................................ 3-7

T1100 AS Chassis Installation and Replacement ........................... 3-8

Cable Management Arms.................................................................. 3-9

Breaker Panel ........................................................................................... 3-10

Breaker Panel LEDs.......................................................................... 3-11

Breaker Panel Power ........................................................................ 3-12

Breaker Panel Settings ..................................................................... 3-13

Power Distribution Units....................................................................... 3-13

910-2969-001 Revision H, February 2007 i

Page 4

Table of Contents

Ethernet Switches or Hubs.................................................................... 3-14

Console Servers....................................................................................... 3-14

Chapter 4. How to Install a T1100 AS Frame

Introduction............................................................................................... 4-2

How to Unpack the T1100 AS Frame and Conduct Inventory.......... 4-2

How to Install a T1100 AS Frame........................................................... 4-3

How to Cable a T1100 AS Frame.......................................................... 4-20

Chapter 5. How to Install Hardware in an Existing Frame

Introduction............................................................................................... 5-2

How to Unpack and Conduct Inventory .............................................. 5-2

How to Install an Individual T1100 AS Unit ........................................ 5-4

— DRAFT —

Recommended Tools ......................................................................... 4-3

How to Prepare the Floor for Heavy Duty Frames....................... 4-4

How to Anchor the HD Frame to the Floor ................................... 4-6

How to Anchor to Overhead Rack of HD Frame........................ 4-18

How to Cable Components Added to Existing Frames.................... 5-14

How to Cable a T1100 AS Unit Added to an Existing Heavy

Duty Frame................................................................................... 5-14

How to Cable a T1100 AS Installed in Customer-Provided

Frame............................................................................................. 5-14

Chapter 6. Post Installation Procedures

Introduction............................................................................................... 6-2

How to Connect Frame Ground and Logic Ground ........................... 6-2

Recommended Tools ......................................................................... 6-3

How to Ground in a DC Environment ........................................... 6-3

How to Ground the Logic Connector in a AC Environment..... 6-11

Post-Installation Checklist..................................................................... 6-13

How to Power Up................................................................................... 6-15

How to Power Up a Heavy Duty Frame ...................................... 6-15

How to Power Up Added T1100 AS Unit in

DC Environment.......................................................................... 6-15

How to Power Up a T1100 AS Unit in an AC Environment...... 6-16

How to Change Passwords ................................................................... 6-16

Chapter 7. Field Replaceable Units

Introduction............................................................................................... 7-2

Safety Information ............................................................................. 7-2

T1100 AS Hardware System FRUs and Part Numbers ................ 7-4

ii 910-2969-001 Revision H, February 2007

Page 5

Table of Contents

— DRAFT —

T1100 AS FRUs.................................................................................... 7-5

Tools Required .......................................................................................... 7-6

How to Replace a Console Server, Ethernet Switch, or Hub ............. 7-7

How to Access T1100 AS FRUs............................................................... 7-9

How to Slide T1100 AS Chassis Out from Frame.......................... 7-9

How to Slide T1100 AS Chassis Back into Frame ........................ 7-11

How to Remove T1100 AS Chassis from a Frame ....................... 7-12

How to Return a T1100 AS Chassis to the Frame........................ 7-15

How to Replace T1100 AS FRUs........................................................... 7-19

How to Replace the Air Filters ....................................................... 7-19

How to Replace the Rectangular Fan Assembly.......................... 7-21

How to Replace the Square Fan Assembly................................... 7-23

How to Replace Hard Disk Drive Assemblies ............................. 7-26

How to Replace Removable Media Disk Drives (CD/DVD)..... 7-32

How to Replace a Power Supply Module..................................... 7-38

How to Replace PCI Cards.............................................................. 7-40

How to Replace a T1100 AS Chassis FRU..................................... 7-46

Appendix A. T1100 AS Hardware Feature Information

Introduction .............................................................................................. A-2

Hardware Components........................................................................... A-2

Interfaces ................................................................................................... A-3

Out of Band Management Card............................................................. A-4

Electrical Features .................................................................................... A-4

Mechanical Design................................................................................... A-4

Mechanical Maintenance Features.................................................. A-4

Component Access front fascia ....................................................... A-5

Fans, Fan Assemblies, and Air Filters ............................................ A-5

Tekelec 1100 AS Main Board ........................................................... A-6

T1100 AS Diagnostics .............................................................................. A-6

Appendix B. Hardware Repair and Return

Introduction .............................................................................................. B-2

How to Obtain a Return Material Authorization................................ B-2

How to Locate T1100 AS Part Numbers............................................... B-3

Air Filter Part Number Information ............................................... B-3

Fan Assembly Part Number Information ...................................... B-3

Removable Media Disk Drive Assembly

Part Number Information............................................................ B-6

910-2969-001 Revision H, February 2007 iii

Page 6

Table of Contents

How to Arrange Return Shipping........................................................ B-19

Appendix C. ELAP or EPAP Network Integration

Introduction.............................................................................................. C-2

Network Overview.................................................................................. C-2

Customer-Supplied Information........................................................... C-4

IP Address Assignment .......................................................................... C-4

Netmask and Broadcast.......................................................................... C-6

Network Interface Functions ................................................................. C-6

Network Assumptions............................................................................ C-8

Network Configuration .......................................................................... C-8

Firewall and Router Filtering Considerations..................................... C-8

— DRAFT —

Hard Disk Drive Assembly Part Number Information................ B-9

PCI Card Part Number Information ............................................. B-12

T1100 AS Chassis Part Number Information............................... B-14

Specifically Targeted PCBs ............................................................. B-19

General Instructions ........................................................................ B-20

Returning a Crate............................................................................. B-20

Serial Communication .......................................................................... C-10

Modems ........................................................................................... C-11

Printers.............................................................................................. C-12

Tip Utility (EAGLE Only ............................................................... C-12

VT100 Ports ...................................................................................... C-12

Platform Security............................................................................. C-12

Glossary

Index

iv 910-2969-001 Revision H, February 2007

Page 7

DRAFT

List of Figures

Figure 2-1. European Directives CE Mark ..................................................2-4

Figure 2-2. Combined UL Mark for the United States and Canada ........2-5

Figure 2-3. Hazardous Substances ...............................................................2-5

Figure 2-4. Door Grounding Strap Placement ..........................................2-10

Figure 3-1. T1100 AS Hardware System in DC Environment ..................3-4

Figure 3-2. Tekelec 1100 AS Chassis ............................................................3-5

Figure 3-3. Interior View of T1100 AS Chassis ...........................................3-6

Figure 3-4. Rear I/O Panel ............................................................................3-7

Figure 3-5. T1100 AS Status Indicators ........................................................3-8

Figure 3-6. T1100 AS with Side Cable Management Arms ...................3-10

Figure 3-7. Front of Breaker Panel ..............................................................3-10

Figure 3-8. Breaker Panel LEDs ..................................................................3-11

Figure 3-9. Front and rear of AC power distribution unit ......................3-14

Figure 4-1. Floor Marking Template for HD Frame ..................................4-4

Figure 4-2. Anchor Assembly for Slab Floors .............................................4-7

Figure 4-3. Anchor Installation of HD Frame into Slab Floor ..................4-9

Figure 4-4. Anchor Assembly for Raised Floor Over Concrete .............4-10

Figure 4-5. Anchoring on Raised Floor Over Concrete Slab ..................4-12

Figure 4-6. Anchor Assembly for Use with Support Channel ...............4-14

Figure 4-7. Anchoring Frame to Raised Floor with Support

Channel .....................................................................................................4-15

Figure 4-8. Anchor Assembly for Support Channel with

Spring Nut ................................................................................................4-17

Figure 4-9. Anchoring Frame Using Support Channel/Spring Nut .....4-18

Figure 4-10. HD Frame with Overhead Rack ...........................................4-19

Figure 5-1. Slide Assembly ............................................................................5-3

Figure 5-2. Slide Assembly Extended View ...............................................5-5

Figure 5-3. Slide Assembly Inner Member Roller Side View ..................5-6

Figure 5-4. Frame Adapter Bracket Expanded ...........................................5-7

Figure 5-5. Frame Adapter Brackets and Slide Assemblies ......................5-7

Figure 5-6. Slide Assembly Outer Member .................................................5-8

Figure 5-7. Slide Assembly Detail Left Side From Rear ............................5-9

910-2969-001 Revision H, February 2007 v

Page 8

List of Figures

Figure 5-8. Slide Assembly Inner Member Mounting ...........................5-10

Figure 5-9. Detail of a Side Cable Management Arm ............................. 5-11

Figure 5-10. Side Cable Management Arm Installation

Figure 5-11. T1100 AS Rear Detail .............................................................5-13

Figure 5-12. Frame Mounting Detail ......................................................... 5-13

Figure 6-1. Frame Ground Cable Routes in DC Environment ................6-5

Figure 6-2. Frame Ground Cable Attachment Locations in

Figure 6-3. Chassis Ground Cable Attachment Location in

Figure 6-4. Logic Ground Cable Routes in DC Environment .................. 6-9

Figure 6-5. Frame and Logic Ground Cable Attachment Locations ..... 6-10

Figure 6-6. Logic Ground Cable Route in AC Environment ..................6-12

Figure 7-1. T1100 AS Chassis Front View ................................................. 7-10

Figure 7-2. Chassis Retention Hardware .................................................. 7-14

DRAFT

(T1000 AS shown) ................................................................................... 5-12

DC Environment ......................................................................................6-6

DC Environment .......................................................................................6-7

Figure 7-3. Right Slide Assembly Mounting and Retention Bracket .... 7-17

Figure 7-4. T1100 AS Chassis Rear View .................................................. 7-18

Figure 7-5. Inside view of T1100 showing fan filters ..............................7-20

Figure 7-6. Front Top Cover Removal - Screw Locations ......................7-22

Figure 7-7. Inside view of T1100 showing square fan assembly ........... 7-25

Figure 7-8. Inside view of T1100 showing hard drive locations ...........7-28

Figure 7-9. Hard drive removal .................................................................7-29

Figure 7-10. T1100 AS Chassis Label Locations .......................................7-30

Figure 7-11. Hard Disk Drive Label on T1100 AS Chassis ..................... 7-30

Figure 7-12. Disk Drive label locations (fans removed) .........................7-30

Figure 7-13. Inside view of T1100 showing CD/DVD

drive location ........................................................................................... 7-34

Figure 7-14. Front Top Cover Removal - Screw Locations ....................7-34

Figure 7-15. Removable Media Disk Drive Cables (drives

removed) ..................................................................................................7-35

Figure 7-16. CD/DVD inside bracket screw location .............................7-36

Figure 7-17. CD/DVD chassis screws .......................................................7-37

Figure 7-18. Rotate lock ring down to disengage power

supply module. .......................................................................................7-39

Figure 7-19. PCI Card Part Label ............................................................... 7-40

Figure 7-20. PCI Slots Label ........................................................................7-41

Figure 7-21. Chassis Rear Top Cover Views. ...........................................7-43

vi 910-2969-001 Revision H, February 2007

Page 9

List of Figures

DRAFT

Figure 7-22. PCI Cards and Slot Assignments ..........................................7-44

Figure 7-23. Left Slide Member Mounting ................................................7-47

Figure B-1. T1100 AS Chassis Front View .................................................. B-4

Figure B-2. T1100 AS Front Top Cover screws .......................................... B-5

Figure B-3. Fan Part number labels .............................................................B-5

Figure B-4. Removable Media Disk Drive Assembly Part Label ............ B-6

Figure B-5. T1100 AS Chassis Front View .................................................. B-7

Figure B-6. T1100 AS Front Top Cover screws .......................................... B-8

Figure B-7. CD/DVD label location ............................................................B-8

Figure B-8. T1100 AS Chassis Label Locations .......................................... B-9

Figure B-9. Base Unit/Hard Disk Label on T1100 AS Chassis .............. B-10

Figure B-10. T1100 AS front fascia open with hard drive locations ..... B-11

Figure B-11. Hard disk label locations ...................................................... B-11

Figure B-12. T1100 AS Chassis Label Locations ...................................... B-12

Figure B-13. PCI Slots Label on T1100 AS Chassis ................................. B-12

Figure B-14. T1100 AS Chassis Front View .............................................. B-13

Figure B-15. Frame Identification Label ................................................... B-15

Figure B-16. T1100 AS Chassis Front View .............................................. B-16

Figure B-17. Base Unit/Hard Disk Label on T1100 AS Chassis ............ B-17

Figure B-18. Memory Label on T1100 AS Chassis .................................. B-18

Figure B-19. PCI Card Label on T1100 AS Chassis ................................. B-18

Figure C-1. MPS Network Connections, Netra .........................................C-3

Figure C-2. MPS Network Connections, T1000 AS, T1100 AS ................C-3

910-2969-001 Revision H, February 2007 vii

Page 10

— DRAFT —

List of Tables

Table 1-1. Manual Organization ..................................................................1-2

Table 2-1. Space Requirements .....................................................................2-7

Table 3-1. Tekelec 1100 AS Chassis Dimensions and Weight .................. 3-9

Table 3-2. Breaker Panel LED Settings ...................................................... 3-12

Table 6-1. Post-Installation Checklist ........................................................ 6-14

Table 7-1. T1100 AS Field Replaceable Units and Part Numbers ...........7-5

Table A-1. Basic Interfaces ...........................................................................A-3

Table A-2. Optional Interfaces (on PCI Cards) .........................................A-3

Table C-1. IP Address for the DSM Network ............................................ C-4

Table C-2. IP Address for the Sync Network ............................................ C-5

Table C-3. EAGLE 5 ISS IP Addresses ....................................................... C-5

Table C-4. Interface Functions Required for MPS .................................... C-7

Table C-5. Interface Functions Required for MPS .................................... C-9

Table C-6. Serial Port Assignments for MPS Servers A and B .............. C-10

viii 910-2969-001 Revision H, February 2007

Page 11

— DRAFT —

List of Procedures

Procedure 4-1. How to Unpack Frame and Conduct Inventory...............4-2

Procedure 4-2. Mark Floor Layout................................................................4-4

Procedure 4-3. Create Cable and Anchor Holes for Raised Floors ..........4-5

Procedure 4-4. Anchor a HD Frame into a Slab Floor................................4-7

Procedure 4-5. Anchor the Frame to the Slab Beneath the

Raised Floor ..............................................................................................4-11

Procedure 4-6. Anchor Frame to Raised Floor with

Support Channel ......................................................................................4-14

Procedure 4-7. Anchor Frame with Support Channel/Spring Nut .......4-16

Procedure 4-8. Attach Overhead Rack Support ........................................4-19

Procedure 5-1. Unpack a T1100 AS Chassis.................................................5-2

Procedure 5-2. Installing a T1100 AS Chassis..............................................5-4

Procedure 6-1. Prepare the Ground Cables .................................................6-4

Procedure 6-2. Connect Ground Cable: Frame to Ground Window........6-4

Procedure 6-3. Connect T1100 AS Chassis Ground:

T1100 AS Chassis to Frame.......................................................................6-7

Procedure 6-4. Connect Logic Ground from Logic Ground

Terminal Strip to Ground Window........................................................6-9

Procedure 6-5. Connect Logic Ground: T1100 AS Logic

Ground Port to Logic Ground Terminal Strip ....................................6-11

Procedure 6-6. Connect Logic Ground Between Logic Ground Ports...6-12

Procedure 6-7. Verify AC ground ...............................................................6-13

Procedure 6-8. Power Up T1100 AS Unit in an AC Environment..........6-16

Procedure 7-1. Replace an Ethernet Switch, Hub, or Console Server......7-7

Procedure 7-2. Slide T1100 AS Chassis Out from Frame.........................7-10

Procedure 7-3. Slide T1100 AS Chassis Back into Frame.........................7-11

Procedure 7-4. Remove a T1100 AS Chassis from Frame........................7-12

Procedure 7-5. Return a T1100 AS Chassis to the Frame.........................7-16

Procedure 7-6. Replace Rectangular and Square Air Filters ...................7-20

Procedure 7-7. Replace a Rectangular Fan Assembly ..............................7-21

Procedure 7-8. Replace a Square Fan Assembly .......................................7-23

Procedure 7-9. Replace a Hard Disk Drive Assembly..............................7-26

Procedure 7-10. Replace a Removable Media Disk Drive Assembly.....7-32

910-2969-001 Revision H, February 2007 ix

Page 12

List of Procedures

— DRAFT —

Procedure 7-11. Replace a power supply module....................................7-38

Procedure 7-12. Replace a PCI Card........................................................... 7-40

Procedure 7-13. Replace a T1100 AS Chassis FRU ................................... 7-46

Procedure B-1. Obtaining an RMA...............................................................B-2

Procedure B-2. How to Locate serial numbers for Fan Assembly ...........B-3

Procedure B-3. How to Locate serial numbers for Removable

Media Disk Drive Assembly....................................................................B-7

Procedure B-4. How to Locate serial numbers for Hard Disk

Drive Assembly........................................................................................B-10

Procedure B-5. How to Locate serial numbers for PCI Cards ................B-13

Procedure B-6. How to Locate serial numbers for a

T1100 AS Chassis.....................................................................................B-15

Procedure B-7. Preparing Crate and Dolly for Return to Tekelec..........B-20

Procedure C-1. Configure Modem with Script ....................................... C-12

x 910-2969-001 Revision H, February 2007

Page 13

Draft

About This Manual

Introduction.......................................................................................................1-2

Where to Find Information in This Manual..................................................1-2

Where to Find Other Information ..................................................................1-3

1

Programs Needed to View Linked Documents .....................................1-4

Documents That Show How to Perform a Procedure ..........................1-5

Installation Documents .............................................................................1-5

Applications Documents...........................................................................1-6

Documentation Packaging and Updates.......................................................1-6

Documentation Admonishments...................................................................1-6

Customer Assistance........................................................................................1-7

910-2969-001 Revision H, February 2007 1-1

Page 14

Introduction

This manual is a generic manual that describes common components of Tekelec

1100 Application Server (AS) hardware systems and describes how to install and

replace them. A T1100 AS hardware system consists of one or more T1100 AS

(with applications loaded) and any additional hardware (such as hubs, switches,

or power distribution equipment) needed to support the applications.

NOTE: This manual includes links to documents that are specific to a given

product, depending on which product CD this manual is viewed. Although the

manual is the same on CDs for various products, the linked documents are

different on different product CDs. For more information about linked

documents, see “Where to Find Other Information” on page 1-3.

T1100 AS hardware systems are delivered with applications already loaded.

For more information about T1100 AS hardware systems in AC and DC

environments, see Chapter 3, “T1100 AS Hardware System Overview.”

Each time this manual is published, the revision level is changed. For example,

the first time this manual is published, it uses Revision A; the second time it is

published, it uses Revision B.

Draft About This Manual

Pary

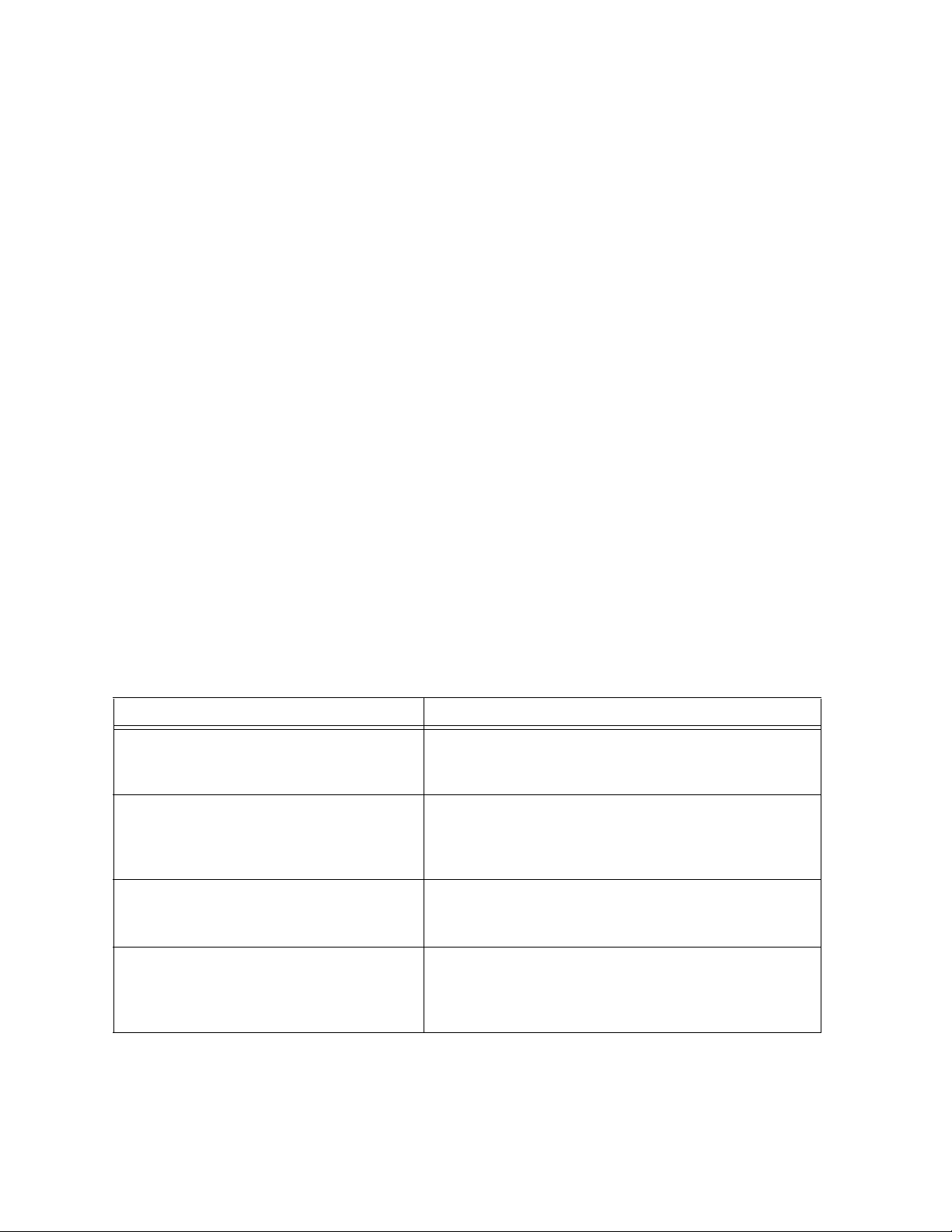

Where to Find Information in This Manual

Table 1-1 shows how this manual is organized.

Table 1-1. Manual Organization

Chapter Number and Title Description

Chapter 1, “About This Manual” Describes how to use the manual, where to find

other information, and how to contact Technical

Services.

Chapter 2, “Safety and Pre-Installation

Requirements”

Chapter 3, “T1100 AS Hardware

System Overview”

Chapter 4, “How to Install a T1100 AS

Frame”

Lists general safety instructions that readers should

be familiar with, and lists site requirements that

should be verified before installing T1100 AS

hardware systems.

Presents an overview of the various hardware

components that can be included in T1100 AS

hardware systems.

Describes how to install a heavy duty frame which

is delivered from manufacturing with T1100 AS

units mounted in a heavy-duty frame for use in a

DC environment.

1-2 910-2969-001 Revision H, February 2007

Page 15

About This Manual Draft

Preliminary

Table 1-1. Manual Organization (Continued)

Chapter Number and Title Description

Chapter 5, “How to Install Hardware in

an Existing Frame”

Chapter 6, “Post Installation

Procedures”

Chapter 7, “Field Replaceable Units” Describes the components of a T1100 AS hardware

Appendix A, “T1100 AS Hardware

Feature Information,”

Appendix B, “Hardware Repair and

Return,”

Describes how to install an individual T1100 AS

unit into a frame that has already been installed.

This chapter covers both:

• Adding a T1100 AS unit into a heavy duty frame

that already contains from 1 to 4 T1100 AS units

in a DC environment

• Installing a single T1100 AS unit into a

customer’s frame in an AC environment.

Presents a post-installation checklist and

instructions on how to verify voltage and to

power-up the system.

system that can be replaced in the field, and

includes procedures for replacing each type of

field-replaceable unit (FRU).

Describes in greater detail some of the hardware

features of the T1100 AS chassis.

Describes how to obtain a Return Material

Authorization, find part numbers on labels, and

ship returned equipment.

Where to Find Other Information

This manual is delivered on a compact disk (CD) that also contains the following

documentation (these documents can also be accessed from the introductory page

of the documentation CD):

• The CD contains linked documents shown in the following sections. To

display one of these documents from within this document, click anywhere in

the highlighted area. For information about software needed to open these

links, see “Programs Needed to View Linked Documents” on page 1-4.

• Optionally, the CD may also contain application documentation, which

describes the environment in which the T1100 AS hardware system runs as

well as provides information about the application.

NOTE: Documentation about T1100 AS hardware components (such as

breaker panels or Ethernet switches) that are supplied by other companies is

shipped with the T1100 AS hardware system. When unpacking a frame or

individual components, be sure to obtain this documentation and store it

where it can be accessed later.

910-2969-001 Revision H, February 2007 1-3

Page 16

Draft About This Manual

Pary

The following related publications are also included with the LSMS

documentation set

• The Tekelec EAGLE

Manual contains detailed information about the command-rejected error

messages generated by the commands used on the EAGLE 5 ISS as well as

error recovery procedures. This information can be helpful for the LSMS user

when viewing certain exception logs.

5 Integrated Signaling System Commands Error Recovery

• The Tekelec EAGLE 5 ISS ELAP Administration Manual provides a definition of

the user interface to the EAGLE

MPS/ELAP platform. The manual defines the methods for accessing the

interface, menus, screens available to the user and describes their impact. It

provides the syntax and semantics of user input and defines the output the

user receives, including information and error messages.

• The Tekelec EAGLE 5 ISS Maintenance Manual contains procedural

information required for maintaining the EAGLE 5 ISS and the card removal

and replacement procedures. The Tekelec EAGLE 5 ISS Maintenance Manual

provides preventive and corrective maintenance procedures used in

maintaining the different systems.

•The Tekelec EAGLE 5 ISS LNP Feature Activation Guide contains the procedures

necessary to activate the LNP feature using telephone number quantities from

24 million to 120 million telephone numbers.

•The Tekelec 1100 Application Server MPS Platform Software and Maintenance

Manual describes the platform software for the Multi-Purpose Server (MPS)

based on the Tekelec 1100 Application Server (T1100 AS) and describes how to

perform preventive and corrective maintenance for the T1100 AS-based MPS.

This manual should be used with the ELAP-based application (LNP).

Programs Needed to View Linked Documents

®

5 ISS LNP Application Processor on the

To view the linked documents, the workstation on which this manual is being

viewed needs to have the following programs:

• Most of the linked documents are in Portable Document Format (PDF), which

has a file type of

is clicked, the linked document is opened in the same window as this manual.

To return to this manual, click the Back button on the PDF display window.

• A document with a

linked document may open in a minimized window.

• A document with an

programs. Two commonly used programs are:

— Microsoft Windows® Media Player (this program is usually included with

Microsoft Internet Explorer)

— RealOne™ Player

1-4 910-2969-001 Revision H, February 2007

.pdf. PDF is also the format of this manual. When a PDF link

.doc file type can be viewed with Microsoft® Word. The

.mpg file type can be viewed with a variety of video

Page 17

About This Manual Draft

Preliminary

Documents That Show How to Perform a Procedure

The following documents illustrate how to perform procedures. The first

document uses a Word format; the others are videos with sound that can be

opened with most video programs.

• 822-0094-02.doc

SHIPPING CRATE, HEAVY DUTY, EAGLE

• fru-filter.mpg

“Replace Rectangular and Square Air Filters,” on page 7-20)

• fru-rect-fan.mpg

Procedure 7-7, “Replace a Rectangular Fan Assembly,” on page 7-21)

• fru-square-fan.mpg

Procedure 7-8, “Replace a Square Fan Assembly,” on page 7-23)

• fru-hdd.mpg

(also see Procedure 7-9, “Replace a Hard Disk Drive Assembly,” on page 7-26)

• fru-dvd.mpg

Procedure 7-10, “Replace a Removable Media Disk Drive Assembly,” on page

7-32)

• fru-pwr-sup.mpg

Procedure 7-11, “Replace a power supply module,” on page 7-38)

• replace_main_unit.mpg

chassis (also see Procedure 7-13, “Replace a T1100 AS Chassis FRU,” on page

7-46)

, WORK INSTRUCTIONS, UNPACKING, VERTICAL

, video that shows how to replace a filter (also see Procedure 7-6,

, video that shows how to replace a fan assembly (also see

, video that shows how to replace a fan assembly (also see

, video that shows how to replace a hard disk drive assembly

, video that shows how to replace a fan assembly (also see

, video that shows how to replace a fan assembly (also see

, video that shows how to replace a Tekelec 1000

Installation Documents

This section contains links to assembly drawings, interconnect diagrams, and

related installation documents.

NOTE: A given application or set of applications might support only a DC

environment or only an AC environment. For information about which

environment is supported, refer to the application documentation. If the

environment is not supported by the application, the link in this hardware

manual will open a document that states that the drawing is not available.

Linked Documents

The following documents provide information about T1100 AS hardware systems:

• AssemblyDrawingT1100.pdf

possible in a frame for AC and DC environments.

• InterconnectDiagramT1100.pdf

frame should be connected.

910-2969-001 Revision H, February 2007 1-5

, a drawing of the maximum configuration

, a diagram that shows how the elements in a

Page 18

Draft About This Manual

Pary

• BreakerSettingsT1100.pdf, information that shows mapping of breakers to

hardware components.

• PowerReqmtsT1100.pdf

required by each of the components in a T1100 frame.

Applications Documents

Tekelec 1100 Application Server units support a variety of applications. For more

information, refer to application documentation.

NOTE: Application documentation may also contain information about

additional hardware.

, information that shows the amount of power

Documentation Packaging and Updates

Customer documentation is provided with each system and is shipped to the sites

specified by the customer. The number of documentation sets provided are in

accordance with the contractual agreements.

Customer documentation is updated whenever significant changes are made that

affect system operation or configuration. Updates may be issued in the form of an

addendum or a reissue of the relevant documentation.

The document part number is shown on the title page along with the current

revision of the document and the date of publication. The bottom of each page

contains the document’s date of publication and the document’s part number.

When a document is reissued, the following information changes:

• The title page and revision number, the date of publication, and the new

software release number, if applicable.

• The date of publication and the document part number, if applicable, on the

bottom of each page.

Documentation Admonishments

Admonishments are icons and text that may appear in this and other Tekelec

manuals. Admonishments alert the reader to assure personal safety, to minimize

possible service interruptions, and to warn of the potential for equipment

damage.

The following admonishments, listed in descending order of priority, are used in

Tekelec manuals.

TOPPLE: This icon and text indicate the possibility of equipment damage

and personal injury from toppling.

topple

1-6 910-2969-001 Revision H, February 2007

Page 19

About This Manual Draft

Preliminary

DANGER: This icon and text indicate the possibility of personnel injury.

WARNING: This icon and text indicate the possibility of equipment damage.

CAUTION: This icon and text indicate the possibility of service interruption.

Customer Assistance

The Customer Care Center offers a point of contact through which customers can

receive support for problems that may be encountered during the use of Tekelec’s

products. The Customer Care Center is staffed with highly trained engineers to

provide solutions to your technical questions and issues seven days a week,

twenty-four hours a day. A variety of service programs are available through the

Customer Care Center to maximize the performance of Tekelec products that

meet and exceed customer’s needs.

To receive technical assistance, call the Customer Care Center at one of the

following locations:

• Tekelec, USA

Phone (US and Canada) +1 888-FOR-TKLC or 888-367-8552

Phone (international) +1 919-460-2150

Fax +1-919-460-0877

Email: support@tekelec.com

• Tekelec, Europe and UK

Phone +44 1784 467 804

Fax +44 1784 477 120

Email: ecsc@tekelec.com

910-2969-001 Revision H, February 2007 1-7

Page 20

Draft About This Manual

Pary

1-8 910-2969-001 Revision H, February 2007

Page 21

DRAFT

Safety and Pre-Installation

Requirements

Introduction.......................................................................................................2-2

Safety Information............................................................................................2-2

2

Regulatory Compliance and Certification ....................................................2-4

Pre-Installation Site Requirements.................................................................2-6

Generic Site Requirements........................................................................2-6

Grounding and Power Requirements.....................................................2-8

910-2969-001 Revision H, February 2007 2-1

Page 22

Introduction

This chapter presents:

• General safety considerations that should always be kept in mind when

Tekelec products are installed or replaced

• Listing of regulatory compliances and certifications that Tekelec products

support

• Site requirements that should exist before Tekelec products are installed

Safety Information

Safety icons and text are used throughout Tekelec manuals to warn the reader of

the potential of personal injury, service interruption, and equipment damage. For

information about what each of the icons mean, see “Documentation

Admonishments” on page 1-6.

Before beginning any procedure described in this manual, ensure that you are

familiar with each of the following safety admonishments. Additional safety

admonishments may be included, or repeated, for specific procedures.

Safety and Pre-Installation Requirements

Preliminary

TOPPLE: Always read and understand instructions completely before

working on, moving, raising or lowering the frame, any portion of the frame, or

attachments to the frame or equipment.

topple

TOPPLE: Never try to unpack any frame from the shipping container without

at least two people to steady any movement of the frame and related

components. At least two people are required to safely move and position any

topple

frame.

TOPPLE: Never pull out the shelf of any frame that is not anchored properly.

Some frames are required to be attached to overhead ladder racks before

shelves are extended.

topple

DANGER: No commercially AC powered equipment may be used or placed

within 7 ft. of –48V equipment. AC powered equipment within 7 ft. of –48V

equipment may create a shock or current loop that can be severely hazardous to

personnel and equipment.

2-2 910-2969-001 Revision H, February 2007

Page 23

Safety and Pre-Installation Requirements

DANGER: Do not wear metal, chains, rings, watches, or jewelry or carry

exposed metal, keys or tools in pockets when working on system equipment or

other related electrostatic-sensitive components. Always wear a wrist strap or

other electrostatic protection when handling printed circuit boards and other

electrostatic-sensitive devices.

WARNING: Do not leave or allow unused metal objects, such as screws or

washers, to remain anywhere within the equipment. Remove all unused

material from the equipment

WARNING: Do not allow any metal shavings to remain in the equipment

area. Metal Shavings may result from over tightened screws or bolts. These

small metal particles are hazardous to electronic equipment.

Be careful not to over tighten screws or bolts.

WARNING: Do not use tie wraps on or above the top traverse arms on a

frame. Always trim tie wrap flush and turn the trimmed tie wrap to the rear of

the cable.

Preliminary

CAUTION: All personnel associated with the installation of these systems

must adhere to all safety precautions and use required protection equipment, to

avoid the possibility of injury to personnel, service degradation, and/or service

interruption.

CAUTION: These systems have redundant power supplies to allow service

during normal maintenance. When repairs require a total power disconnect,

both input supply sources must be disconnected. This causes service

interruption and takes down the systems.

CAUTION: This equipment has a connection between the earthed conductor

of the DC supply circuit and the earthing conductor.

CAUTION: The Branch Circuit Overcurrent Protection shall be rated

minimum -48V, maximum 40A.

CAUTION: Equipment is to be installed in restricted access areas in

accordance with articles 110-16, 110-17, and 110-18 of the National Electric Code,

ANSI/NFPA 70.

910-2969-001 Revision H, February 2007 2-3

Page 24

Safety and Pre-Installation Requirements

Preliminary

CAUTION: A readily accessible disconnect device that is suitable, approved,

and rated shall be incorporated in the field wiring.

CAUTION: Connect to a reliably grounded SELV source which is reliably

earthed and electrically isolated from the AC source.

CAUTION: Use only listed closed loop connectors for connection to the

supply.

CAUTION: When some CPCI cards arrive from the manufacturer, they may

have a small plastic cover over the screws and/or the alignment ejector pins.

Remove and discard these plastic covers. If inserting the cards takes an

excessive amount of force, check for obstructions. Forcing the card into a slot

may damage the ejector handle or pin.

NOTE: Use a minimum of 26 AWG telecommunications line cord for

connection to the modem.

Regulatory Compliance and Certification

Tekelec products are tested to meet the following regulatory standards:

• Network Equipment Building System (NEBS) level 3 as listed in Telcordia

SR-3580.

• Applicable Telcordia Electromagnetic Compatibility and Electrical Safety

requirements in GR-1089-CORE.

• Applicable Physical Protection requirements in GR-63-CORE.

• Relevant directives and harmonized standards in support of the products

Compliance European (CE) mark required in Europe. Figure 2-1 shows the

mark used to indicate this compliance.

Figure 2-1. European Directives CE Mark

2-4 910-2969-001 Revision H, February 2007

Page 25

Safety and Pre-Installation Requirements

• Relevant standards in ElectroMagnetic Compatibility (EMC) directive

89/336/EEC.

• Relevant standards in Safety directive 73/23/EEC, supported by Certified

Body (CB) Test Certificates US/5923/UL or US/5451/UL issued by the

National Certification Body as tested to IEC 60950 with national differences

for European countries

• Underwriters Laboratories (UL) listed under UL File E200146 for USA and

c-UL for Canada. Figure 2-2 shows the mark used to indicate this compliance.

Figure 2-2. Combined UL Mark for the United States and Canada

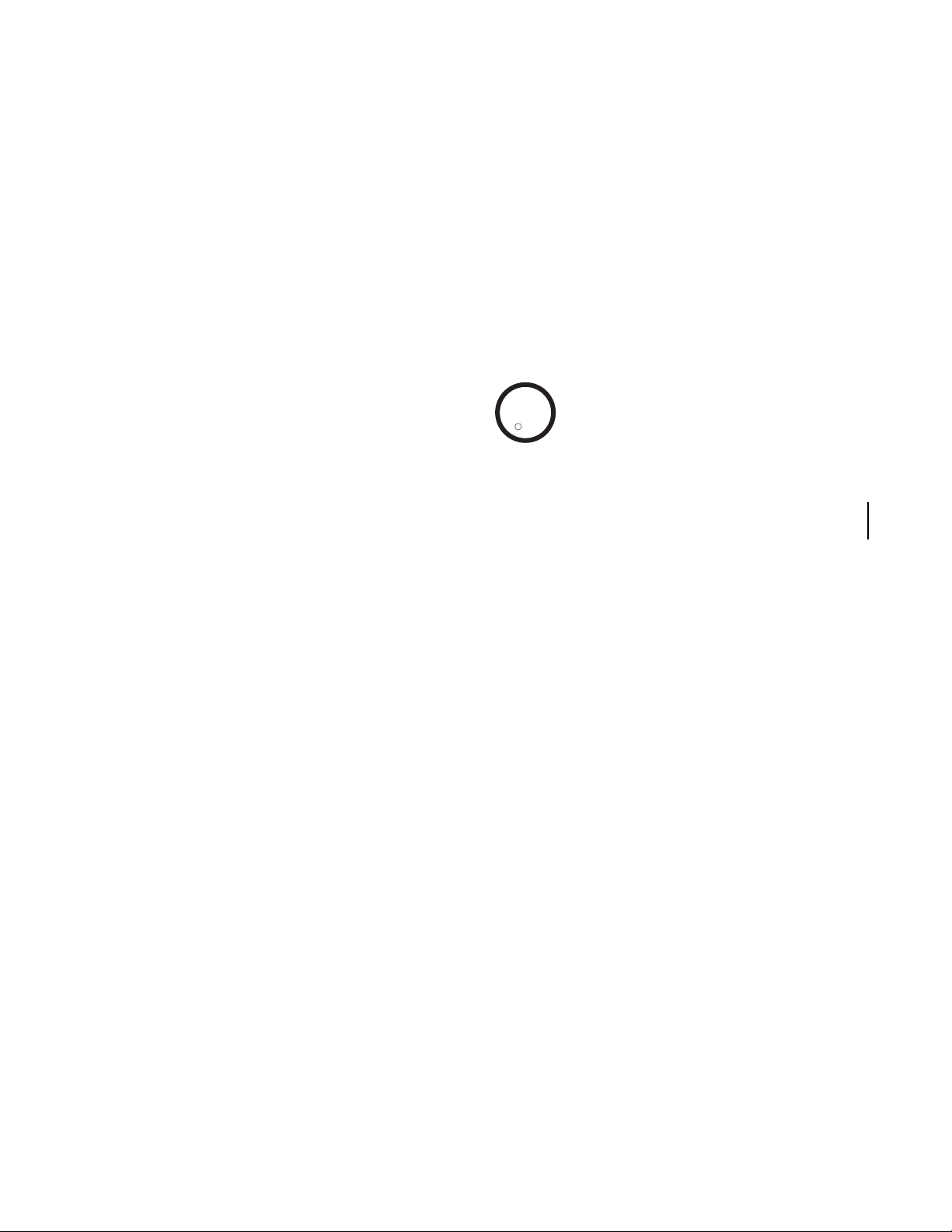

• Relevent standards in SJ/T 11363-2006 for limits of certain hazardous

substances.

Preliminary

U

C

R

L

LISTED

US

910-2969-001 Revision H, February 2007 2-5

Page 26

Preliminary

Figure 2-3. Hazardous Substances

Safety and Pre-Installation Requirements

䚼ӊৡ⿄

(Parts)

䞥ሲ䚼ӊ

(Metal Parts)

⬉䏃ഫ

(

Circuit Modules)

⬉㓚ঞ⬉㓚㒘ӊ

(

Cables & Cable Assemblies)

ล᭭㘮ড়⠽䚼ӊ

(Plastic and Polymeric parts)

᳝↦᳝ᆇ⠽䋼ܗ㋴(Hazardous Substance)

䪙 ∲ 䬝 ݁Ӌ䫀 ⒈㘨㣃 ⒈Ѡ㣃䝮

3E +J &G

ƻƻ ƻ ƻ ƻ ƻ

hƻ ƻ ƻ ƻ ƻ

hƻ ƻ ƻ ƻ ƻ

ƻƻ ƻ ƻ

㸼⼎䆹᳝↦᳝ᆇ⠽䋼䆹䚼ӊ᠔᳝ഛ䋼ᴤ᭭Ёⱘ䞣ഛ6-7[[[[[[[[

ƻ˖

ޚ㾘ᅮⱘ䰤䞣㽕∖ҹϟDŽ嘅

Indicates that the concentration of the hazardous substance in all homogeneous materials in the

parts is below the relevant threshold of the SJ/T 11363-2006 standard.

㸼⼎䆹᳝↦᳝ᆇ⠽䋼㟇ᇥ䆹䚼ӊⱘᶤϔഛ䋼ᴤ᭭Ёⱘ䞣䍙ߎ6-7[[[[[[[[

h˖

ޚ㾘ᅮⱘ䰤䞣㽕∖DŽ

Indicates that the concentration of the hazardous substance of at least one of all homogeneous

materials in the parts is above the relevant threshold of the SJ/T 11363-2006 standard.

&U

3%% 3%'(

ƻƻ

Pre-Installation Site Requirements

Before installing any T1100 AS hardware system, ensure that the requirements

described in both of the following sections have been met.

• “Generic Site Requirements” on page 2-6

• “Grounding and Power Requirements” on page 2-8

Generic Site Requirements

Ensure that the site where the product will be installed conforms to the

specifications listed in the following sections. These specifications are standard

telephony industry requirements for equipment installation.

Fire Protection

Local fire protection codes must be satisfied in the equipment room where the

system is to be located.

2-6 910-2969-001 Revision H, February 2007

Page 27

Safety and Pre-Installation Requirements

Environmental Requirements

Tekelec products are designed for environments that have temperature and

humidity controls.Temperature and humidity controls must be activated as

quickly as possible for equipment to operate at an optimum level.

When temperature and humidity controls fail, the equipment has been tested to

operate within the following ranges:

• Temperature

— 5° C to 40° C (41° F to 104° F) for normal operation

— -5° C to 50° C (23° F to 122° F) for no more than 96 hours in duration and at

elevations less than 1800 meters

— -5° C to 50° C (23° F to 122° F) for storing the product

• Humidity

— 5% to 85% non-condensing for normal operation

— 5% to 90% non-condensing (but not to exceed 0.024 kilograms of water per

kilogram of dry air) for no more than 96 hours in duration and at

elevations less than 1800 meters

Preliminary

Tekelec products are tested to operate at an elevations within the following range:

• Minimum: 60 meters below sea level at ambient temperature of 30° C (86° F)

• Maximum: 4000 meters above sea level at ambient temperature of 40° C

(104° F)

HVAC Requirements

Tekelec products are designed to bring cool air in from the bottom front and exit

heated air out the top rear of the installed equipment.

The required HVAC (Heating, Ventilation, and Air Conditioning) capacity

depends on the installed equipment. To calculate needed HVAC capacity,

determine the total wattage of the installed equipment and use the following

formula:

BTUs/hr. = watts x 3.413

The amount of power required by frame components is found at:

PowerReqmts.pdf

.

Lighting

Adequate lighting should be provided in the room where the equipment is to be

located. Lighting fixtures must be far enough from the equipment and cables to

prevent heat damage and to allow safe access to equipment and cables.

910-2969-001 Revision H, February 2007 2-7

Page 28

Safety and Pre-Installation Requirements

Preliminary

Earthquake Resistance

All Tekelec system configurations are designed to assure that the system remains

operational during and after an earthquake, even when the system is located on

the upper floors of a zone 4 central office.

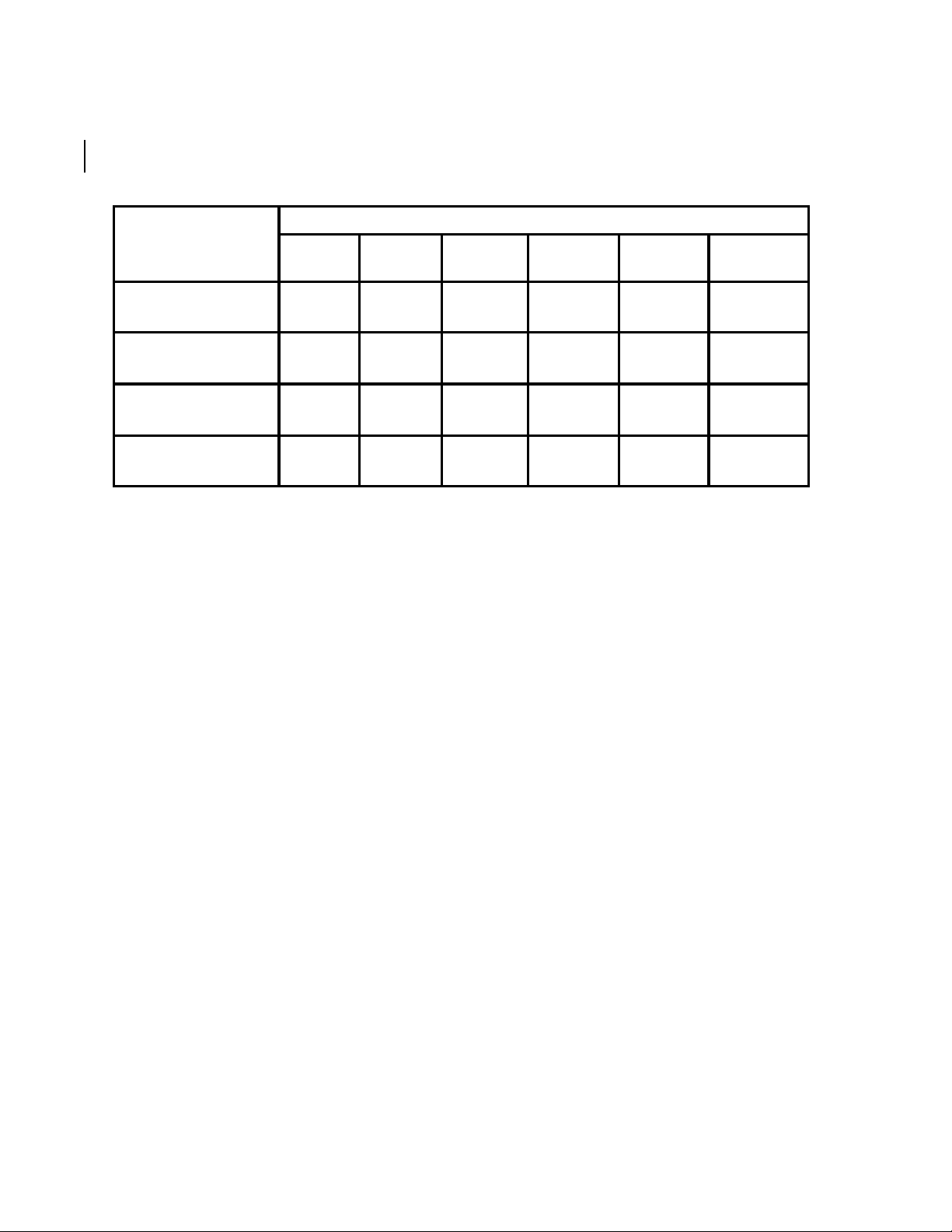

Space Requirements

Provide space as described in Table 2-1. These space requirements provide for

Tekelec equipment installed in a 23-inch heavy-duty frame, which measures 7 feet

high. Separator panels and end panels add to the width of multiple frame

systems.

Table 2-1. Space Requirements

Building Area Dimensions Notes

Halls 4.5 feet wide by 8

feet tall

(1.4 meters wide

by 2.4 meters tall)

Frame location 30 inches wide by

24 inches deep

(76.2 cm wide by

60.96 cm deep)

Side aisles 4 feet (1.2 meters) To allow maneuvering frames into

Front and rear

access

Side access 12 inches (31 cm) From walls or other frames

In addition, when planning the installation, be sure to take into account spare

hardware storage, modems, terminals, printers, cross connect panels, and all

other items that might require space in a system.

3 feet 6 inches

(107 cm)

To provide a clear, uncluttered route

for moving equipment between the

loading/receiving dock and the

planned system location

Floor area recommended for one

Tekelec frame (multiply by the

number of frames listed on the Initial

Sales Order)

Total area per frame = 720 square

inches (5.0 square feet)

(0.465 square meters)

place and provide ample work space

around the equipment

From walls or other frames

2-8 910-2969-001 Revision H, February 2007

Page 29

Safety and Pre-Installation Requirements

Floor Loading

Tekelec products installed in heavy-duty frames are designed for installation on

raised or solid floors, which are recommended to have a distributed load capacity

of no less than 100 pounds per square foot (504 kg/m2). Following are the

maximum weights of Tekelec frames:

• Maximum weight of EAGLE 5 ISS Control or Extension frames: 850 lbs (386

kg).

• Maximum weight of a two T1000/T1100 server frame (for example, the MPS

frame), including AC and DC LSMS frames: 600 lbs (273 kg).

• Maximum weight of the EOAP frame: 450 lbs (205 kg).

• Maximum weight of an application frame with up to six T1000/T1100 servers:

925 lbs (421 kg).

Use the following equation to calculate the floor loading:

Distributed floor capacity = Total equipment weight/floor area

Preliminary

Grounding and Power Requirements

Before installing a T1100 AS hardware system, refer to the application

documentation to determine whether it is to be installed in an Alternating

Current (AC) or Direct Current (DC) environment. Then, ensure that the

grounding and power requirements in the appropriate following sections have

been met.

• “Grounding Requirements” on page 2-9 (this section describes requirements

both for AC and DC environments)

• “Power Requirements in a DC Environment” on page 2-10

• “Power Requirements in an AC Environment” on page 2-11

Grounding Requirements

Tekelec systems operate as digital isolated ground plane systems in a central

office environment and require a single connection to the central office ground

window. The system’s ground cables must provide the sole grounding connection

between the entire system and the central office grounding.

WARNING: Always install an isolator pad between the frame and ground.

Tekelec frames are shipped with isolator pads to completely isolate the frames

from ground. If a non-Tekelec frame is used, an isolator pad must be provided.

910-2969-001 Revision H, February 2007 2-9

Page 30

Safety and Pre-Installation Requirements

Preliminary

The system can use three types of grounding paths:

• Battery return

The battery return grounding path is the return path for all –48VDC loads in

the system. This path is isolated from other system grounds and connects to

the rest of the central office through the –48VDC return connections located

on the breaker panels of each frame.

• Logic Ground

Some system types require connection to a logic ground. The logic ground

path provides a common voltage reference point between all circuit boards of

a system. Each connection terminates to the system ground. The logic ground

path is shown on your system’s interconnect drawing. The logic ground path

does not carry current.

NOTE: If the AC-powered T1100 AS unit uses serial RS232 connections,

the grounding in a standard serial cable will provide the logic ground

necessary for the data transmission.

NOTE: AC-powered T1100 AS units should not be used for RS485, DS0,

V.35, or other network connections unless specified by Tekelec.

• Frame/chassis ground

The frame/chassis ground path provides a low impedance connection for all

metal parts of the entire system, including the frame, doors, shelves, and end

panels. Each frame/chassis connection within the system lineup terminates to

the frame and connects to the main ground by way of Htaps, #6 American

Wire Gauge (AWG) to 1/0 cable.

NOTE: The frame/chassis ground path does not carry current.

For products installed in a frame, the doors installed are grounded to the

frame through a two-hole lug ground wire and through a screw-down latch.

Figure 2-4 shows a cutaway view example of an open frame door showing the

door ground strap.

2-10 910-2969-001 Revision H, February 2007

Page 31

Safety and Pre-Installation Requirements

Figure 2-4. Door Grounding Strap Placement

Preliminary

EMI shield

(where required)

Perforated door

(where required)

Door

ground strap

Frame number

(label)

Frame information

(label)

End panel

(where required)

04_frame_door-gnd_generic

Door

(rear view)

Frame

(front view)

Power Requirements in a DC Environment

A Direct Current environment must supply four feeds from the customer’s power

source. Each frame containing Tekelec products requires that power be provided

from one to four breakers at –48VDC.

Each frame is divided into A and B power buses. In the event of loss of power on

one of the buses, the other bus must be able to supply current for the entire frame.

Therefore, each bus requires wiring sized to handle up to the maximum amps at

–48VDC, with a maximum voltage drop of 0.6 volts. This requirement is met

automatically when power is supplied by breakers.

NOTE: If breakers are tripped by an overload, they must be switched

completely OFF and then ON to reset.

The following table contains detailed information on T1100 AS power

requirements in a DC environment: PowerReqmts.pdf

,

910-2969-001 Revision H, February 2007 2-11

Page 32

Safety and Pre-Installation Requirements

Preliminary

Power Requirements in an AC Environment

An Alternating Current environment must supply two feeds from separate

circuits.

The following table contains detailed information on T1100 AS power

requirements in a AC environment: PowerReqmts.pdf

,

2-12 910-2969-001 Revision H, February 2007

Page 33

DRAFT

T1100 AS Hardware System

Overview

Introduction.......................................................................................................3-2

T1100 AS Hardware System............................................................................3-2

3

T1100 AS Hardware Features..........................................................................3-4

T1100 AS Rear I/O Panel ..........................................................................3-6

T1100 AS Status Indicators .......................................................................3-7

T1100 AS Chassis Installation and Replacement...................................3-8

Cable Management Arms .........................................................................3-9

Breaker Panel...................................................................................................3-10

Breaker Panel LEDs .................................................................................3-11

Breaker Panel Power................................................................................3-12

Breaker Panel Settings.............................................................................3-13

Power Distribution Units ..............................................................................3-13

Ethernet Switches or Hubs............................................................................3-14

Console Servers...............................................................................................3-14

910-2969-001 Revision H, February 2007 3-1

Page 34

Introduction

Depending on the applications that run on them, T1100 AS hardware systems are

delivered in one of the following ways:

• Integrated applications

Most applications that run on T1100 AS systems are designed to be integrated

with features that run on a Signal Transfer Point (STP). T1100 AS systems for

these applications run in a Direct Current (DC) environment and are

delivered in one of the following ways:

— For most applications, the initial installation of the T1100 AS hardware

— Some applications allow a single T1100 AS unit to be added to a heavy

T1100 AS Hardware System Overview

Preliminary

system consists of one or more T1100 AS units, along with breaker panels

and Ethernet communication equipment, already installed by Tekelec

manufacturing in a heavy duty frame.

duty frame that has been previously installed and already contains one to

four T1100 AS units. To view the maximum configuration allowed, refer to

the Assembly drawings

.

For more information about these T1100 AS hardware systems, see “T1100 AS

Hardware System” on page 3-2.

• Non-integrated applications

Applications (such as provisioning applications or network management

applications) that do not need to integrate with STP features may not require a

DC environment.

To determine which environments are supported by the applications that run on

the T1100 AS systems, refer to the applications documentation.

This chapter provides an overview of T1100 AS hardware systems in each of the

possible environments and an overview of each of the components that can be

part of a T1100 AS hardware system.

T1100 AS Hardware System

A T1100 AS hardware system consists of the following hardware components,

which are assembled in a heavy-duty frame by Tekelec and delivered as one unit

when first ordered (some applications allow additional T1100 AS units, to a

maximum of six, to be added later):

• Depending on the applications loaded, from one to six T1100 AS units,

identified as A through E, starting with the topmost server identified as A.

Each server consists of T1100 AS hardware that is loaded at the factory with

platform software and application software. Some applications allow each

3-2 910-2969-001 Revision H, February 2007

Page 35

T1100 AS Hardware System Overview

server to be installed with different application software. (The minimum and

maximum number of servers in the frame depends on which applications are

loaded. For an overview of the T1100 AS units, see “T1100 AS Hardware

Features” on page 3-4.

NOTE: Some applications allow individual T1100 AS units (to a

maximum of six per frame) to be added later.

• Breaker Panels (BPs) for DC systems. For an overview, see “Breaker Panel” on

page 3-10; for more information, refer to the documentation delivered with

the product.

• Power Distribution Units for AC systems. For more information, refer to the

documentation delivered with the product

• Additional equipment, such as consoles, storage, and communications

switches and hubs. For more information on these components, refer to the

documentation delivered with the product.

Figure 3-1 shows an example T1100 AS hardware system.

NOTE: This figure shows a DC system. For more complete information about

the configuration used by your application, refer to the Assembly drawings

Preliminary

.

910-2969-001 Revision H, February 2007 3-3

Page 36

T1100 AS Hardware System Overview

Preliminary

Figure 3-1. T1100 AS Hardware System in DC Environment

2 4 5 763

BUSA

981 1210 11 1 2 43 6 75

BUSB

1098 11 12

T1100 AS Hardware Features

The Tekelec 1100 AS is a general-purpose application engine (AE) that offers high

transaction rates with low latency. It supports a variety of application solutions

for the wireless and wireline telecommunications infrastructure to provide the

building blocks for next-generation signaling systems.

3-4 910-2969-001 Revision H, February 2007

Page 37

T1100 AS Hardware System Overview

The Tekelec 1100 AS is a scalable computing platform constructed with

state-of-the-art components packaged in a compact-size, stand-alone enclosure.

The Tekelec 1100 AS chassis utilizes dual processors, and has eight PCI slots, four

internally mounted media devices, redundant hot-swappable power supplies,

and expandable memory.

Figure 3-2 shows a single Tekelec 1100 AS Services Platform. For clarity, it is

shown not mounted in a frame.

Figure 3-2. Tekelec 1100 AS Chassis

Preliminary

Figure 3-3 shows an exploded view of the T1100 AS chassis. This view shows

where the various hardware components, especially the Field Replaceable Units

(FRUs), are located.

910-2969-001 Revision H, February 2007 3-5

Page 38

Preliminary

Figure 3-3. Interior View of T1100 AS Chassis

T1100 AS Hardware System Overview

The following are the Field Replaceable Units:

1. Air filters (two)

2. Fan modules (three)

3. Hard disks (two)

4. Removable media disk drive assembly (CD/DVD)

5. Peripheral Component Interconnect (PCI) cards/PCI Express card

6. Power Supplies

7. Entire T1100 AS chassis

For more information about FRUs, see Chapter 7, “Field Replaceable Units.”

For more information about the hardware components, see Appendix A, “T1100

AS Hardware Feature Information.”

T1100 AS Rear I/O Panel

The rear input/output (I/O) panel is perforated to facilitate airflow and forms the

back wall of the Tekelec 1100 AS enclosure. It has openings for:

• Eight peripheral component interface (PCI) cards' I/O panels

•One PCI Express card

3-6 910-2969-001 Revision H, February 2007

Page 39

T1100 AS Hardware System Overview

• The I/O connectors on the rear edge of the main board (serial port, E1 or T1

clock inputs, and two USB ports)

• The power board I/O (logic ground connection)

• Five Serial ports

Power entry is at the rear of the Tekelec 1100 AS. There are two power supply

modules. The A and B power supply modules are hot-swappable.

Logic ground is carried on a connector on the power board. The connector is

bulkhead-mounted to the rear I/O panel. There are also two chassis ground

connector studs on the rear I/O panel. See Figure 3-4 for a detailed view of the

rear I/O panel.

NOTE: Figure 3-4 shows T1100 AS base configuration with empty PCI slots

Figure 3-4. Rear I/O Panel

Preliminary

T1100 AS Status Indicators

The T1100 AS platform provides the following light-emitting diode (LED) status

indicators on the front fascia of the Tekelec 1100 AS platform (see Figure 3-5):

• Critical, Major, and Minor visual alarm indicators indicate operational

condition of the Tekelec 1100 AS platform, including status of the major

subsystems: processors, volatile memory, non-volatile memory (disk drives,

etc.), and interfaces.

• Indicators for A and B power inputs.

910-2969-001 Revision H, February 2007 3-7

Page 40

T1100 AS Hardware System Overview

Preliminary

Figure 3-5. T1100 AS Status Indicators

For more information about the diagnostics that manage these alarm and status

indicators, see “T1100 AS Diagnostics” on page A-6.

T1100 AS Chassis Installation and Replacement

The T1100 AS chassis is installed in the frame using slides that have inner and

outer rails. The outer slide rail is attached to the frame and the inner slide rail is

attached to the T1100 AS chassis (see Figure 5-1 on page 5-3). The chassis is

installed by sliding the inner rails into the outer rails.

DANGER: Moving a T1100 AS chassis requires two people. Each T1100 AS

chassis weighs approximately 30 kg (65 lbs) and may cause personnel injury or

damage to the internal components due to shock and vibration if not handled

properly.

The Tekelec 1100 AS chassis is also field replaceable. Tekelec 1100 AS replacement,

including disconnecting cables, mounting a replacement system (of identical

configuration), and reconnecting cables requires no more than 30 minutes.

NOTE: All I/O connections are at the rear of the Tekelec 1100 AS chassis.

Table 3-1 lists the dimensions of the Tekelec 1100 AS chassis.

3-8 910-2969-001 Revision H, February 2007

Page 41

T1100 AS Hardware System Overview

Table 3-1. Tekelec 1100 AS Chassis Dimensions and Weight

Dimension Value Notes for Rack-Mounting

Preliminary

Depth 21.6 inches from

Height 6.9 inch high (4U)

Width 17.6 inches wide,

Weight 65 Pounds Moving the chassis requires two people.

1. Tekelec makes no warranties for servers that are installed without proper

clearances or that are removed from Tekelec-standard frames.

2. The Tekelec 1100 AS enclosures should be free to slide only during

installation, service, or repair; they should be locked down at all other

times.

Cable Management Arms

front surface to

rear bulkhead

form factor

with slides

Allows over 2.5 inches of depth for cable

management in a Tekelec Heavy Duty Frame.

Chassis slide lock brackets are used to anchor

the Tekelec 1100 AS chassis in position

during normal operation.

Allows for multiple Tekelec 1100 AS chassis

and associated Ethernet switches to be

mounted in a Tekelec Heavy Duty frame

Allows for a Tekelec 1100 AS chassis to be

installed in 19 inch racks. Adapter plates are

required to mount a Tekelec 1100 AS chassis

with slide rails in 23 inch frames.

The T1100 AS is installed on slides for easy access. When the chassis is slid in or

out, strain on the cables is relieved by side cable management arms. These cable

management arms are attached to the sides of the frame and fold inward towards

the back of the T1100 AS it is slid out from the frame (see Figure 3-6 on page 3-10).

A T1100 AS chassis that is shipped with these cable management arms also

includes tension bars that are mounted on the rear of the server to further reduce

strain on the cables.

910-2969-001 Revision H, February 2007 3-9

Page 42

T1100 AS Hardware System Overview

Preliminary

Figure 3-6. T1100 AS with Side Cable Management Arms

Breaker Panel

Breaker panels are used to provide redundant power paths to T1100 AS units and

other equipment in a heavy duty frame in a DC environment.

Figure 3-7 shows a breaker panel.

The breaker panel has two sides: side A and side B. Each side has twelve breakers,

although only certain breakers on each side are active (closed). The open position

of each breaker is marked by “O” and “|” marks the closed position.

Figure 3-7. Front of Breaker Panel

3-10 910-2969-001 Revision H, February 2007

Page 43

T1100 AS Hardware System Overview

Breaker Panel LEDs

Figure 3-8 shows a close-up of the Indicator Panel in the center of the front of each

breaker panel. Table 3-2 shows the possible LED settings and what each setting

indicates.

Figure 3-8. Breaker Panel LEDs

Preliminary

910-2969-001 Revision H, February 2007 3-11

Page 44

Preliminary

Table 3-2. Breaker Panel LED Settings

LED

Position

(from

top)

Label on

left side:

Label on

right side:

Color Indicates:

T1100 AS Hardware System Overview

Top 6

LEDs

Next 6

LEDs

13th

LED

14th

LED

15th

LED

1,3 through

10,12

PWR BUS AGreen Power is supplied from source A to breakers

indicated by numbers on left

Red No power is supplied from source A to

breakers indicated by numbers on left

Off Breakers indicated by numbers on left are not

used

1,3 through

10,12

PWR BUS BGreen Power is supplied from source B to breakers

indicated by numbers on left

Red No power is supplied from source B to

breakers indicated by numbers on left

Off Breakers indicated by numbers on left are not

used

BRK FAIL BUS A Green No breakers on side A have tripped

Red One or more breakers on side A have tripped

BRK FAIL BUS B Green No breakers on side B have tripped

Red One or more breakers on side B have tripped

CRITICAL No label Green No critical platform alarms are reported

Red One or more critical platform alarms are

reported

1

1

16th

LED

17th

LED

1

Both servers may send alarm information to the breaker panel for critical, major, or minor

MAJOR No label Green No major platform alarms are reported1

Red One or major platform alarms are reported

MINOR No label Green No minor platform alarms are reported1

Red One or minor platform alarms are reported

1

platform alarms. A CRITICAL, MAJOR, or MINOR LED is illuminated when one or more

alarm of that type is reported from either or both servers.

Breaker Panel Power

The breakers receive power from the input circuit on their respective side. Each

breaker controls the power to its corresponding power feed on the back of the

breaker panel. The power feeds connect to the individual hardware devices in the

frame.

3-12 910-2969-001 Revision H, February 2007

1

Page 45

T1100 AS Hardware System Overview