Page 1

V1.8

TBS09S Modbus Master to SDI 12 Slave Converter

TBS09S_ModbusMaster

Modbus Master to SDI 12 Slave Converter

The TBS09S is a converter to connect SDI-12 sensors to a Modbus master. It can control multiple

SDI12 sensors in parallel by individually addressing the connected SDI-12 sensors.

Features

Modbus Master to SDI 12 Slave Converter

Multiple SDI-12 sensors can be connected

SDI-12 Standard V1.3

Modbus RTU, 19200 baud

Switched sensor supply voltage output

5 - 16V supply voltage

6mA current consumption when active

© 2020 Tekbox Digital Solutions

Factory 4, F5, Lot I-3B-1, Saigon HiTech Park, Q.9 | Ho Chi Minh City | Tel +84 287 1099865| office@tekbox.com| www.tekbox.com

20µA in idle, 4mA in active mode

Operating Temperature Range:

- 40°C … + 80°C

Target Applications

SDI-12 sensor networks with Modbus

controller

Page 2

V1.8

2

TBS09S

Modbus Master to SDI-12 Slave Converter

Contents

1 INTRODUCTION 3

2 PRODUCT SPECIFICATION 3

3 CALIBRATION AND SETTINGS 4

4 CONNECTIONS 5

5 SENDING SDI-12 COMMANDS THROUGH TBS09S 6

5.1 SUPPORTED SDI-12 COMMANDS 6

5.2 MODBUS DEFAULT CONFIGURATION AND FRAMES FORMAT 7

5.2.1 Default configuration 7

5.2.2 Modbus master to TBS09S: Modbus request format 7

5.2.3 TBS09S to Modbus master: Modbus response format 7

5.3 TBS09S MODBUS REGISTERS MAPPING 8

5.4 TBS09S MODBUS REQUESTS DETAILED DESCRIPTION 10

5.4.1 Modbus slave address change 10

5.4.2 Query sensor’s SDI-12 address (SDI-12 command: ?!) 11

5.4.3 Change sensor’s SDI-12 address (SDI-12 command: aAb!) 12

5.4.4 SDI-12 Measurement (SDI-12 commands: aM!/aMC!/aMx!/aMCx!/aC!/aCC!/aCCx!)12

5.5 TBS09S / SDI-12 SENSOR COMMUNICATION FLOW EXAMPLE 15

6 SDI-12 16

7 HISTORY 16

Page 3

V1.8

3

TBS09S

Modbus Master to SDI-12 Slave Converter

1 Introduction

The TBS09S is a converter to connect one or multiple SDI-12 sensors to a Modbus device such as a data logger

or telemetry unit. The converter is inserted in between the data logger or RTU with Modbus interface and the

sensor(s) with SDI-12 interface. The designation Modbus Master to SDI-12 Slave is ambiguous. Looking purely

at the converter, the device got a Modbus slave interface on one side and a SDI-12 master output at the other

side. However looking at its application, the device is a converter between a Modbus master (data logger, RTU,

etc.) and a SDI-12 slave (sensor with SDI-12 interface).

The following diagrams describe a typical use of TBS09S module that bridges a Modbus telemetry unit with a

SDI-12 sensor and highlight how the internal TBS09S Modbus/SDI-12 layers interact with them.

TBS09S application

2 Product specification

Application: converter used to interface Modbus master devices (eg RTU) with SDI-12 slave devices (eg

sensors)

o The converter embeds a Modbus slave and a SDI-12 master modules

SDI-12 compatibility:

o Version: v1.3

o SDI-12 commands not supported: aI!, a!, aV!, aRx!, aRCx!

o Data command supports up to 10 measurements maximum

Modbus compatibility:

Page 4

V1.8

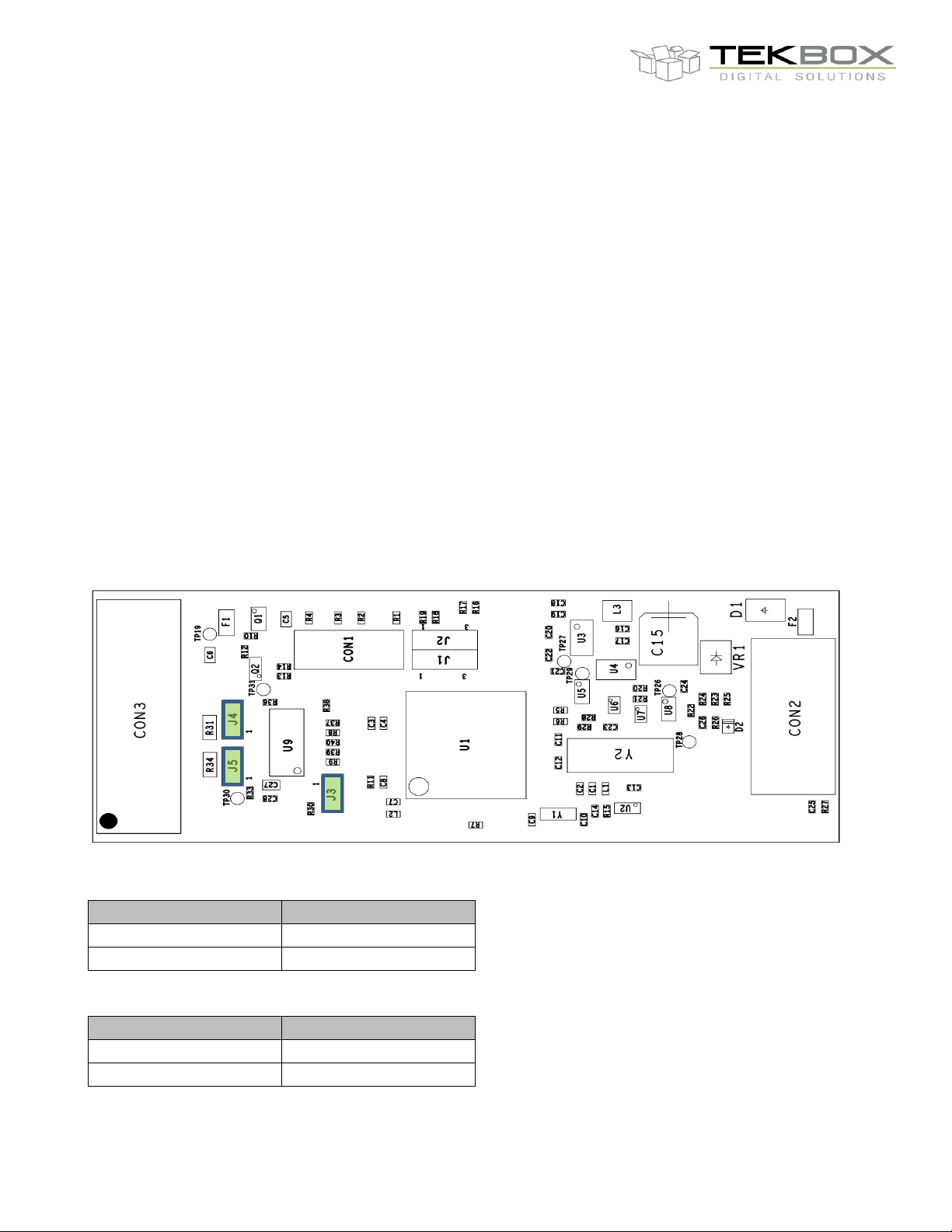

4

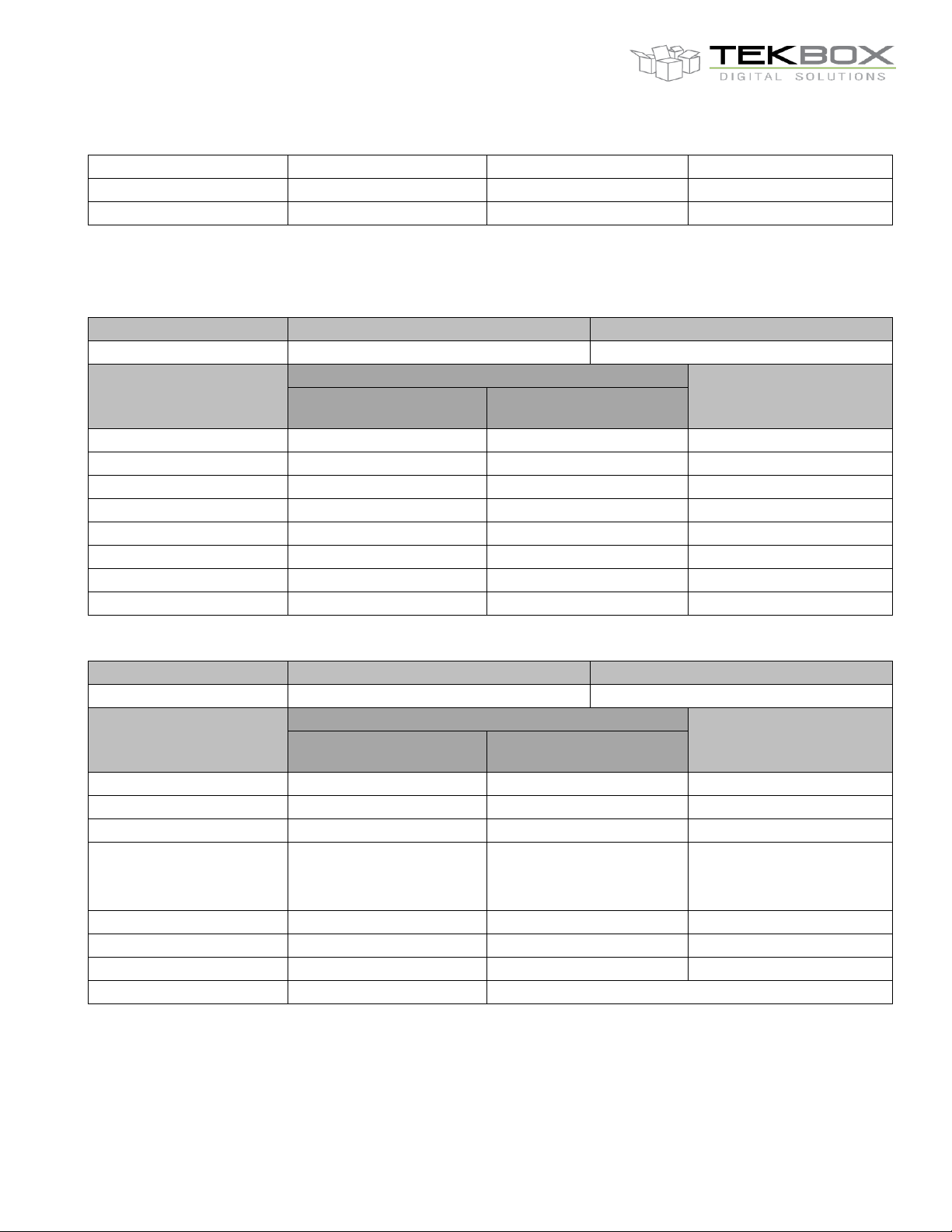

Configuration

J3

Half Duplex

Full Duplex

Configuration

J4 – J5

120 Ω termination

No termination

TBS09S

Modbus Master to SDI-12 Slave Converter

o Modbus RTU

o Baud rate: 19200

o Half or full duplex (configurable)

o 120 Ω termination (configurable)

Supply voltage: 5 – 16 V

Power consumption

o Active mode: 4 mA

o Idle mode: 20µA

Form factor: DINRAIL

3 Calibration and settings

TBS09S doesn’t require any calibration.

It comes factory-configured to operate by default in half duplex with no termination.

This configuration can be changed by the user by setting related jumpers J3/J4/J5 after lifting the housing:

Communication mode:

Modbus termination:

Page 5

V1.8

5

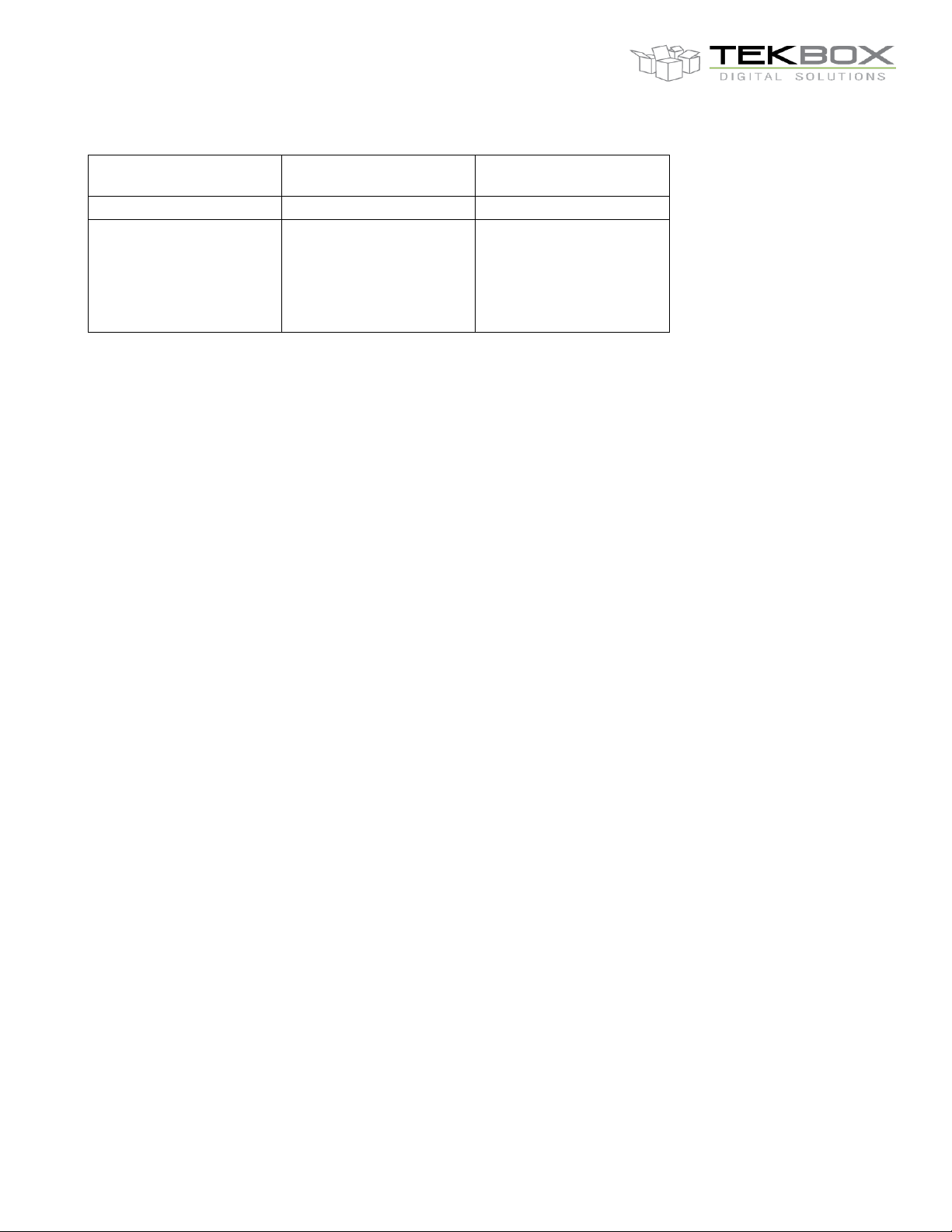

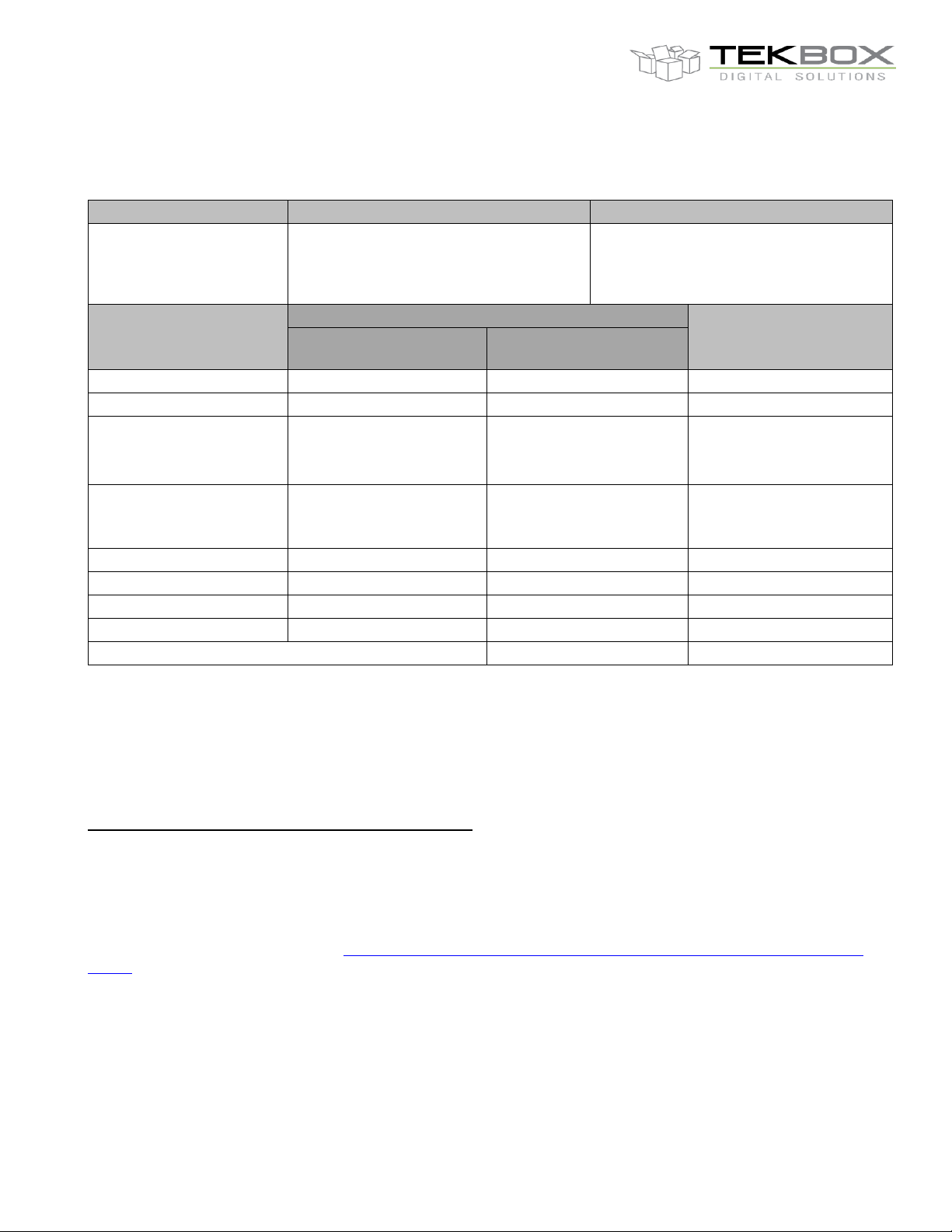

Slot name

Description

Comment

Shield

Cable shield

Connect to sensor’s

cable shield

Ground

Ground

Connect to ground

Data

SDI-12 data line

Connect to SDI-12

sensor data line

Power*

TBS09S supply voltage

input

Connect to +12V external

power supply

Slot name

Description

Comment

T+

TXD+ output

Connect to Modbus

master RXD+

T-

TXD- output

Connect to Modbus

master RXD-

R+

RXD+ input

Connect to Modbus

master TXD+ (full

duplex operation only –

must be left

unconnected in half

duplex)

R-

RXD- input

Connect to Modbus

master TXD- (full duplex

operation only – must

TBS09S

Modbus Master to SDI-12 Slave Converter

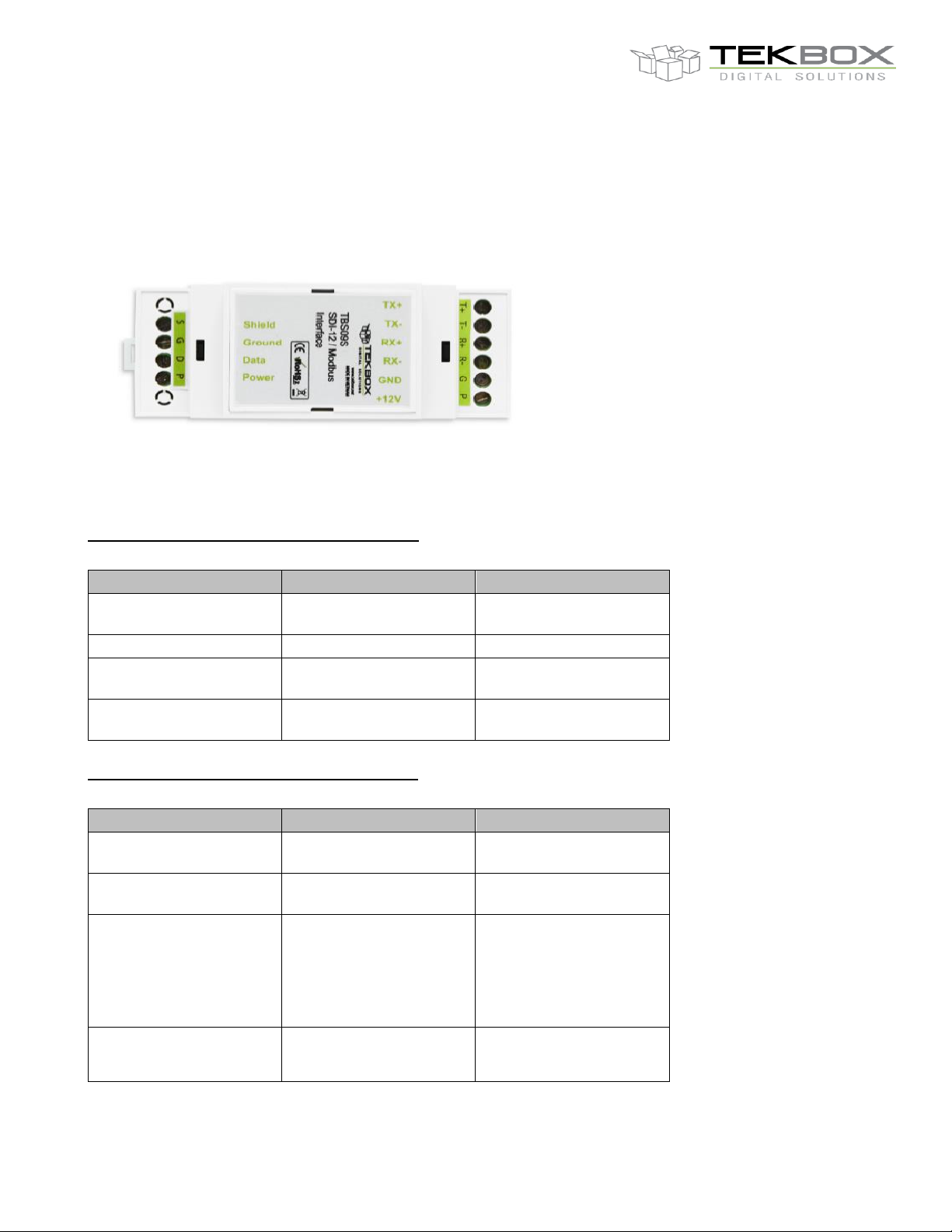

4 Connections

TBS09S provides one 4 slots connector (SDI-12) and one 6 slots connector (RS485):

SDI-12 terminal assignment, from top to bottom:

RS485 terminal assignment, from top to bottom:

Page 6

V1.8

6

be left unconnected in

half duplex)

G

Ground

Connect to ground

P*

SDI-12 sensor supply

voltage output (+12V,

connected to the

converter supply line

through a high side FET

switch)

Connect to SDI-12

sensor power line.

TBS09S

Modbus Master to SDI-12 Slave Converter

*The crossed connectivity is caused by the same converter hardware being used for both the Modbus master to

SDI-12 slave converter and the SDI-12 master to Modbus slave converter. This is subject to being changed in a

future hardware revision.

5 Sending SDI-12 commands through TBS09S

SDI-12 commands are encapsulated by Modbus which acts as a communication layer.

Executing a SDI-12 command over Modbus requires sending 2 Modbus requests:

One request with function code 6 to send the SDI-12 command

One request with function code 4 to get the result of the executed SDI-12 command.

5.1 Supported SDI-12 commands

TBS09S supports only a subset of SDI-12 commands vs SDI-12 v1.3 specification and has a limitation with respect

to Send Data command.

The following commands are supported:

Address Query ?!

Change Address aAb!

Start Measurement aM!

Start Measurement and Request CRC aMC!

Additional Measurements aM1! … aM9!

Additional Measurements and Request CRC aMC1! ... aMC9!

Start Concurrent Measurement aC!

Start Concurrent Measurement and Request CRC aCC!

Additional Concurrent Measurements aC1! … aC9!

Additional Concurrent Measurements and Request CRC aCC1! ... aCC9!

Send Data (*) aD0! … aD9!

Supported SDI-12 address range is aligned with SDI-12 v1.3 specification:

0 – 9

Page 7

V1.8

7

Modbus Master request

Slave Address

Function

Starting Address Hi

Starting Address Lo

Data Hi

Data Lo

Error Check Lo (CRC)

Error Check Hi (CRC)

TBS09S

Modbus Master to SDI-12 Slave Converter

a – z

A – Z

(*): Send Data aD0!...aD9! supports only up to 10 measurements irrespective of the maximum number of

characters that can be returned (75 for a concurrent measurement command, 35 otherwise).

5.2 Modbus default configuration and frames format

5.2.1 Default configuration

TBS09S uses following Modbus configuration:

Protocol: Modbus RTU

Baud rate: 19200, Parity: none

Modbus slave address: 1 (default). It is configurable via Modbus Address Change request within 0x01-

0xFF range

5.2.2 Modbus master to TBS09S: Modbus request format

All Modbus requests sent by the Modbus master (Modbus data logger, Modbus RTU) to TBS09S must be

formatted as described in following table as per Modbus specification.

Each field represents one byte in hexadecimal:

TBS09S uses only Modbus requests with function codes 4 or 6 depending on the command’s purpose.

The CRC must be calculated as per Modbus RTU standard (please note the less significant CRC byte is stored

first and followed by the most significant CRC byte).

Online calculators can be used for this, like https://www.lammertbies.nl/comm/info/crc-calculation and selecting

hexadecimal input type.

5.2.3 TBS09S to Modbus master: Modbus response format

Each field in below tables represents one byte.

Generic response to a Modbus request with function code 4

Page 8

V1.8

8

Modbus Slave response

(TBS09S)

Slave Address

(TBS09S Modbus address)

04

Byte Count

(2*N, N is the number of Input

Registers)

Input Register 1 Hi

Input Register 1 Lo

…

Input Register N Hi

Input Register N Lo

Error Check Lo (CRC)

Error Check Hi (CRC)

Modbus Slave response

(TBS09S)

Slave Address

(TBS09S Modbus address)

06

Register Address Hi

Register Address Lo

Register Value Hi

Register Value Lo

Error Check Lo (CRC)

Error Check Hi (CRC)

Register Address

Command

Description

Modbus configuration commands

0xB000

Modbus slave address change

Change TBS09S Modbus address

SDI-12 commands

0xA000

?!

Address Query command

0xA100

aAb!

Change Address command

0x0010

aM!

Start Measurement

0x0011

aM1!

Additional Measurements

0x0012

aM2!

Additional Measurements

TBS09S

Modbus Master to SDI-12 Slave Converter

Generic response to a Modbus request with function code 6

Note: in this case, the response is the mirror of the corresponding request.

5.3 TBS09S Modbus registers mapping

All available SDI-12 commands that can be sent over Modbus are mapped over a set of registers.

The following table lists all TBS09S Modbus registers with their associated commands (‘a’ refers to SDI-12 address

as per SDI-12 standard and is subsequently used as is in this document):

Page 9

V1.8

9

0x0013

aM3!

Additional Measurements

0x0014

aM4!

Additional Measurements

0x0015

aM5!

Additional Measurements

0x0016

aM6!

Additional Measurements

0x0017

aM7!

Additional Measurements

0x0018

aM8!

Additional Measurements

0x0019

aM9!

Additional Measurements

0x0020

aMC!

Additional Measurements and

Request CRC

0x0021

aMC1!

Additional Measurements and

Request CRC

0x0022

aMC2!

Additional Measurements and

Request CRC

0x0023

aMC3!

Additional Measurements and

Request CRC

0x0024

aMC4!

Additional Measurements and

Request CRC

0x0025

aMC5!

Additional Measurements and

Request CRC

0x0026

aMC6!

Additional Measurements and

Request CRC

0x0027

aMC7!

Additional Measurements and

Request CRC

0x0028

aMC8!

Additional Measurements and

Request CRC

0x0029

aMC9!

Additional Measurements and

Request CRC

0x0030

aC!

Start Concurrent Measurements

0x0031

aC1!

Additional Concurrent

Measurements

0x0032

aC2!

Additional Concurrent

Measurements

0x0033

aC3!

Additional Concurrent

Measurements

0x0034

aC4!

Additional Concurrent

Measurements

0x0035

aC5!

Additional Concurrent

Measurements

0x0036

aC6!

Additional Concurrent

Measurements

0x0037

aC7!

Additional Concurrent

Measurements

0x0038

aC8!

Additional Concurrent

Measurements

TBS09S

Modbus Master to SDI-12 Slave Converter

Page 10

V1.8

10

0x0039

aC9!

Additional Concurrent

Measurements

0x0040

aCC!

Additional Concurrent

Measurements and Request CRC

0x0041

aCC1!

Additional Concurrent

Measurements and Request CRC

0x0042

aCC2!

Additional Concurrent

Measurements and Request CRC

0x0043

aCC3!

Additional Concurrent

Measurements and Request CRC

0x0044

aCC4!

Additional Concurrent

Measurements and Request CRC

0x0045

aCC5!

Additional Concurrent

Measurements and Request CRC

0x0046

aCC6!

Additional Concurrent

Measurements and Request CRC

0x0047

aCC7!

Additional Concurrent

Measurements and Request CRC

0x0048

aCC8!

Additional Concurrent

Measurements and Request CRC

0x0049

aCC9!

Additional Concurrent

Measurements and Request CRC

Register address

Command

Description

0xB000

Modbus slave address change

Change TBS09S Modbus address

Modbus Master request

format

Example: change TBS09S Modbus address from 1 to 2

Modbus Slave response

format

Modbus Master request

Modbus Slave (TBS09S)

response

TBS09S Modbus Address

01

01

TBS09S Modbus Address

06

06

06

06

B0

B0

B0

B0

00

00

00

00

00

00

00

00

New TBS09S Modbus

Address

02

02

New TBS09S Modbus

Address

TBS09S

Modbus Master to SDI-12 Slave Converter

5.4 TBS09S Modbus requests detailed description

Following tables show each defined Modbus requests and the corresponding response format along with an

example.

All fields represent a byte coded in hexadecimal.

5.4.1 Modbus slave address change

Page 11

V1.8

11

Range: 0x01 – 0xFF

Error Check Lo (CRC)

2E

2E

Error Check Lo (CRC)

Error Check Hi (CRC)

CB

CB

Error Check Hi (CRC)

Register address

Command

Description

0xA000

Query sensor’s SDI-12 address

Sends ?! SDI-12 command

Modbus Master request

format

Example: returned sensor’s SDI-12 address is 2

Modbus Slave response

format

Modbus Master request

Modbus Slave (TBS09S)

response

TBS09S Modbus Address

01

01

TBS09S Modbus Address

06

06

06

06

A0

A0

A0

A0

00

00

00

00

00

00

00

00

00

00

00

00

Error Check Lo (CRC)

AB

AB

Error Check Lo (CRC)

Error Check Hi (CRC)

CA

CA

Error Check Hi (CRC)

Register address

Command

Description

0xA000

Read ?! response

Read sensor’s SDI-12 address

Modbus Master request

format

Example: returned sensor’s SDI-12 address is 2

Modbus Slave response

format

Modbus Master request

Modbus Slave (TBS09S)

response

TBS09S Modbus Address

01

01

TBS09S Modbus Address

04

04

04

04

A0

A0

02

02

00

00

32

(ASCII code: 0x32 =>

SDI-12 address=2)

SDI-12 Address

(represented by its ASCII

code)

00

00

00

00

00

01

AC

Error Check Lo (CRC)

Error Check Lo (CRC)

13

50

Error Check Hi (CRC)

Error Check Hi (CRC)

CA

TBS09S

Modbus Master to SDI-12 Slave Converter

5.4.2 Query sensor’s SDI-12 address (SDI-12 command: ?!)

Send SDI-12 ?! command

Read returned SDI-12 address

Page 12

V1.8

12

Register address

Command

Description

0xA100

Change sensor’s SDI-12 address

Sends aAb! SDI-12 command

Modbus Master request

format

Example: change SDI-12 address from 3 to 4

Modbus Slave response

format

Modbus Master request

Modbus Slave (TBS09S)

response

TBS09S Modbus Address

01

01

TBS09S Modbus Address

06

06

06

06

A1

A1

A1

A1

00

00

00

00

Current SDI-12 Address

(represented by its ASCII

code)

33

(ASCII code: 0x33 =>

SDI-12 address=3)

33

Current SDI-12 Address

(represented by its ASCII

code)

New SDI-12 Address

(represented by its ASCII

code)

34

(ASCII code: 0x34 =>

SDI-12 address=4)

34

New SDI-12 Address

(represented by its ASCII

code)

Error Check Lo (CRC)

BF

BF

Error Check Lo (CRC)

Error Check Hi (CRC)

11

11

Error Check Hi (CRC)

TBS09S

Modbus Master to SDI-12 Slave Converter

5.4.3 Change sensor’s SDI-12 address (SDI-12 command: aAb!)

Send SDI-12 aAb! command

5.4.4 SDI-12 Measurement (SDI-12 commands: aM!/aMC!/aMx!/aMCx!/aC!/aCC!/aCCx!)

The procedure is similar to a regular SDI-12 communication to get sensor’s measurements, except that the SDI12 commands are sent over Modbus.

This implies:

Send a SDI-12 measurement command (aM!/aMC!/aMx!/aMCx!/aC!/aCC!/aCCx!)

Get the specified time (ttt) and the number of measurement values (n / nn)

Send the SDI-12 data command (aD0! … aD9!)

Retrieve the measurements

Step 1 - Send a Measurement Command to the SDI-12 sensor:

TBS09S can transmit any of the following measurement commands to a SDI-12 sensor: aM!...aM9,

aMC!…aMC9!, aC!..aC9!, aCC!..aCC9!

Note: refer to TBS09S Modbus registers mapping for a complete list of supported SDI-12 commands and the

corresponding register address.

Page 13

V1.8

13

Register address

Command

Description

SDI-12 register address

SDI-12 Measurement Command

aM!/aMC!/aMx!/aMCx!/aC!/aCC!/aCCx!

Modbus Master request

format

Example: send SDI-12 command bM!

Modbus Slave response

format

Modbus Master request

Modbus Slave (TBS09S)

response

TBS09S Modbus Address

01

01

TBS09S Modbus Address

06

06

06

06

SDI-12 command register

address Hi

00

(M! register address Hi)

00

SDI-12 command register

address Hi

SDI-12 command register

address Lo

10

(M! register address Lo)

10

SDI-12 command register

address Lo

00

00

00

00

SDI-12 address

(represented by its ASCII

code)

62

(ASCII code: 0x62 =>

SDI-12 address=b)

62

SDI-12 address

(represented by its ASCII

code)

Error Check Lo (CRC)

09

09

Error Check Lo (CRC)

Error Check Hi (CRC)

E6

E6

Error Check Hi (CRC)

Register address

Command

Description

0xmm10

(mm: SDI-12 address

ASCII code)

Read SDI-12 measurement command

response

Read Specified time (ttt) and Number of

Measurements (n/nn)

Modbus Master request

format

Example: time=1s and 2 measurement values

Modbus Slave response

format

Modbus Master request

Modbus Slave (TBS09S)

response

TBS09S Modbus Address

01

01

TBS09S Modbus Address

04

04

04

04

SDI-12 address

(represented by its ASCII

code)

62

(ASCII code 0x62 =>

04

04

TBS09S

Modbus Master to SDI-12 Slave Converter

Send SDI-12 measurement command(aM!/aMC!/aMx!/aMCx!/aC!/aCC!/aCCx!)

Step 2 – Get the specified time and the number of measurements

As per SDI-12 standard, the measurements commands will return the specified time and the number of

measurement values:

M!/MC!/M1!...M9!/MC1!...MC9!

o Specified time: ttt

o Number of measurement values: n

C!/CC!/C1!...C9!/CC1!...CC9!

o Specified time: ttt

o Number of measurement values: nn

Page 14

V1.8

14

SDI-12 address=b)

10

10

00

00

00

00

01

Specified time ttt

02

02

00

00

Error Check Lo (CRC)

6F

02

Number of measurements

n/nn

Error Check Hi (CRC)

B6

2B

Error Check Lo (CRC)

85

Error Check Hi (CRC)

Register address

Command

Description

0x00Dm (m: 0 to 9)

Send SDI-12 Data command

Send aDm! (m: 0 to 9)

Modbus Master request

format

Example: send SDI-12 data command bD0!

Modbus Slave response

format

Modbus Master request

Modbus Slave (TBS09S)

response

TBS09S Modbus Address

01

01

TBS09S Modbus Address

06

06

06

06

00

00

00

00

SDI-12 Data Command

(D0! To D9! coded as

0xD0 to 0xD9)

D0

(0xD0 => D0! Data

command)

D0

SDI-12 Data Command

(D0! To D9! coded as

0xD0 to 0xD9)

00

00

00

00

SDI-12 address

(represented by its ASCII

code)

62

(ASCII code: 0x62 =>

SDI-12 address=b)

62

SDI-12 address

(represented by its ASCII

code)

Error Check Lo (CRC)

09

09

Error Check Lo (CRC)

Error Check Hi (CRC)

DA

DA

Error Check Hi (CRC)

Value

Value0

Value1

Value2

Value3

Value4

Value5

Value6

Value7

Value8

Value9

Index

0x00

0x01

0x02

0x03

0x04

0x05

0x06

0x07

0x08

0x09

TBS09S

Modbus Master to SDI-12 Slave Converter

Step 3 - Send SDI-12 Data Command to the SDI-12 sensor

Send the data command (any of aD0!...aD9!):

Step 4 – Retrieve the measurements

The Send Data command is implemented in TBS09S so it can handle up to 10 values (this is a limitation vs SDI12 v1.3 standard).

aDx! will then return a maximum of 10 measurements as follows:

a<Value0><Value1><Value2><Value3><Value4><Value5><Value6><Value7><Value8><Value9>

Each value is identified by its index:

and is stored in hexadecimal floating point over 4 bytes (0xByte3Byte2Byte1Byte0) and must be then individually

fetched with a specific modbus request.

Page 15

V1.8

15

Register address

Command

Description

0xmmii

mm: SDI-12 address

ASCII code, ii: value index

(0x00-0x09)

Retrieve aDx! value

Return aDx! value at index

Modbus Master request

format

Example: retrieve the 6th value returned by bD0!

Modbus Slave response

format

Modbus Master request

Modbus Slave (TBS09S)

response

TBS09S Modbus Address

01

01

TBS09S Modbus Address

04

04

04

04

SDI-12 address

(represented by its ASCII

code)

62

(ASCII code 0x62 =>

SDI-12 address=b)

04

04

Value Index

(00x00 to 0x09)

05

(0x05 => index of the 6th

value returned by bD0!)

41

Value – Byte3

00

00

CF

Value – Byte 2

02

02

1E

Value – Byte 1

Error Check Lo (CRC)

7E

B8

Value – Byte 0

Error Check Hi (CRC)

72

D6

Error Check Lo (CRC)

55

Error Check Hi (CRC)

TBS09S

Retrieve a measurement

Modbus Master to SDI-12 Slave Converter

The above example shows how to read the 6th measurement from a temperature sensor with SDI-12 interface.

The hexadecimal floating point value is 0x41CF1EB8; once converted to decimal representation this results in

+25.89 C.

Online hexadecimal floating point to decimal converters can be used to make the measurement readable like

https://www.h-schmidt.net/FloatConverter/IEEE754.html

5.5 TBS09S / SDI-12 sensor communication flow example

The below example shows how to measure and read the soil moisture and soil temperature over Modbus by using

SDI-12 TBSMP03 Tekbox sensor (https://www.tekbox.com/product/tbsmp03-sdi-12-soil-moisture-temperature-

probe/) connected to TBS09S.

With this test setup:

TBS09S Modbus slave address is 1

TBSMP03 SDI-12 address is 0

TBSMP03 returns 2 parameters, soil temperature first and then the soil moisture

Page 16

V1.8

16

Version

Date

Author

Changes

V1.0

9.8.2018

Thinh

Creation of the document

V1.1

9.19.2019

Thinh

Update new command

V1.5

24.6.2020

Hoa Hoang

Updated naming to Modbus Master to SDI 12 Slave

Converter

V1.6

15.7.2020

Mayerhofer

Complete rework of the document

V1.7

17.7.2020

Philippe

Updated link in 5.5

V1.8

2.4.2021

Mayerhofer

Updated drawing in chapter 1

TBS09S

Modbus Master to SDI-12 Slave Converter

[Modbus Master] 01 06 00 11 00 30 D9 DB Modbus Master sends 0M1! to the sensor

[TBS09S] 01 06 00 11 00 30 D9 DB TBS09S responds with ACK

[Modbus Master] 01 04 30 10 00 02 7F 0E Modbus Master reads ttt and n

[TBS09S] 01 04 04 00 01 00 02 2B 85 TBS09S returns ttt=1s and n=2 values

Modbus Master waits 1s

[Modbus Master] 01 06 00 D0 00 30 88 27 Modbus Master sends 0D0! to the sensor

[TBS09S] 01 06 00 D0 00 30 88 27 TBS09S responds with ACK

[Modbus Master] 01 04 30 00 00 02 7E CB Modbus Master reads 1

[TBS09S] 01 04 04 41 2D 99 99 8B FF TBS09S response data = 41,2D,99,99 =10.85

[Modbus Master] 01 04 30 01 00 02 2F 0B Modbus Master reads 2ndparameter (temperature)

[TBS09S] 01 04 04 41 DB 70 A4 F8 FF TBS09S response data = 41,DB,70,A4 = 27.43

6 SDI-12

SDI-12 is a standard for interfacing data recorders with microprocessor-based sensors. SDI-12 stands for

serial/digital interface at 1200 baud. It can connect multiple sensors with a single data recorder on one cable. It

supports up to 60 meter cable between a sensor and a data logger.

The SDI-12 standard is prepared by

SDI-12 Support Group

(Technical Committee)

165 East 500 South

River Heights, Utah

435-752-4200

435-752-1691 (FAX)

http://www.sdi-12.org

The latest standard is version V1.4 which dates from Jan 10th, 2019. The standard is available on the website of

the SDI-12 Support Group.

st

parameter (moisture)

7 History

Loading...

Loading...