Page 1

R1L-BIR1

MICROOHM/BOND METER

MODEL R1L-BIR1

Instruction Manual

PN# R1L-BIR1-900

Publication Date: May 2019

REPRODUCTION AND DISTRIBUTION OF THIS TECHNICAL MANUAL IS AUTHORIZED FOR US

NOTE: This User’s Manual was as current as possible when this product was manufactured. However,

products are constantly being updated and improved. To ensure you have the latest documentation, refer

to www.tegam.com

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

GOVERNMENT PURPOSES. TEGAM PROPRIETARY INFORMATION.

REV. B

• sales@tegam.com

Page 2

TABLE OF CONTENTS

TABLE OF CONTENTS

1. INSTRUMENT DESCRIPTION

Purpose ............................................................... 1-1

Performance Characteristics Table 1, Figure 1 ........... 1-1

Description of Equipment ....................................... 1-2

Figure 2: Front Panel Controls ............................. 1-3

List of Items Furnished .......................................... 1-5

Storage and Shipping Requirements ........................ 1-5

Safety Information and Precautions ......................... 1-5

2. PREPARATION FOR USE AND INSTALLATION

Unpacking and Inspection ...................................... 2-1

Preparation for Use................................................ 2-1

3. OPERATING INSTRUCTIONS

Pushbutton Functions ............................................ 3-1

General Theory of Operation ................................... 3-2

4. PRINCIPLES OF OPERATION

Principles of Operation ........................................... 4-1

5. MAINTENANCE

Inspection ............................................................ 5-1

Cleaning .............................................................. 5-1

Calibration ........................................................... 5-2

Troubleshooting .................................................... 5-6

Table 2: Fault Symptoms and Repair Actions ........ 5-6

Preparation for Shipment ....................................... 5-7

Overhaul Instructions ............................................ 5-8

Figure 3: Parts Layout ........................................ 5-9

Figure 4, 5: Digital, Analog Section .................... 5-10

Table 3: Parts List – Main Board Assembly .......... 5-12

Table 4: Parts List – Final Assembly ................... 5-14

Table 5: Parts List – Front Panel Assembly .......... 5-15

Table 6: Parts List – Battery Board Assembly ...... 5-17

Table 7: Vendor Cage Code Directory ................. 5-18

6. SERVICE INFORMATION

Preparation for Repair or Calibration Service ............. 6-1

Expedite Repair and Calibration Form ...................... 6-2

Warranty .............................................................. 6-3

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

Page 3

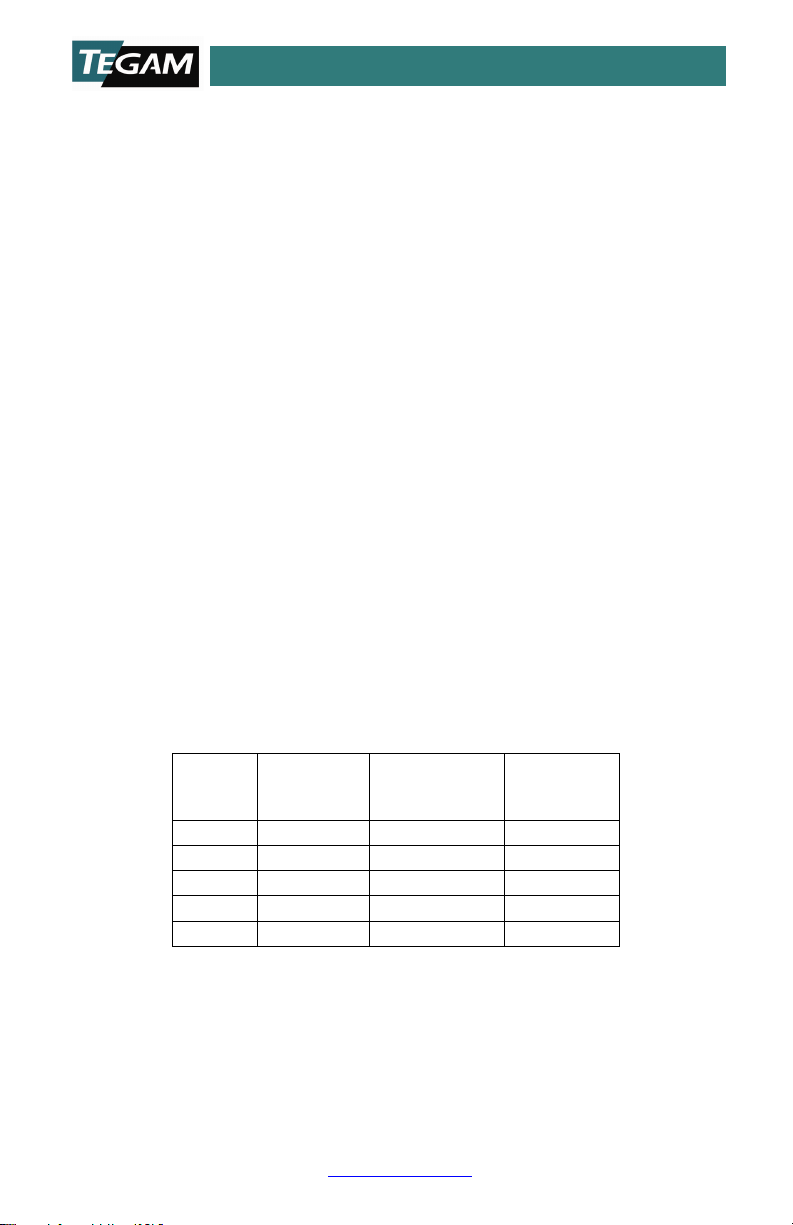

INSTRUMENT DESCRIPTION

Full

(Ω)

Test

Peak (A)

1

1.999 m

1 µ

1.4

2

19.99 m

10 µ

140 m

3

199.9 m

100 µ

14 m

4

1.999

1 m

1.4 m

5

19.99

10 m

140 µ

SECTION 1

INSTRUMENT DESCRIPTION

1.1 Introduction

The TEGAM Model R1L-BIR1 bond meter is a purpose built,

rechargeable battery powered portable instrument for ground

bond measurements. The R1L-BIR1 comes with push-pin

probes and Kelvin alligator clips, all housed within a

ruggedized case. It can accurately make measurements with

a resolution of 1 µΩ. It has full scale ranges from 2 mΩ to 20

Ω. The resistance reading is displayed on a 3½ digit liquid

crystal display on the front panel. An over-range condition is

indicated as a "1" followed by three blank digits (the decimal

point is also displayed in its normal position for the range

selected).

1.2 Performance Characteristics

This is a range-selection instrument, with a rotary 5 range

selector switch.

Range

Scale

Resolution

(Ω)

Current

Reactive loads not to exceed 2mH or 100µF with a minimum of

5µΩ per µH of series resistance. See figure 1 below.

Table 1: Specifications

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

1-1

Page 4

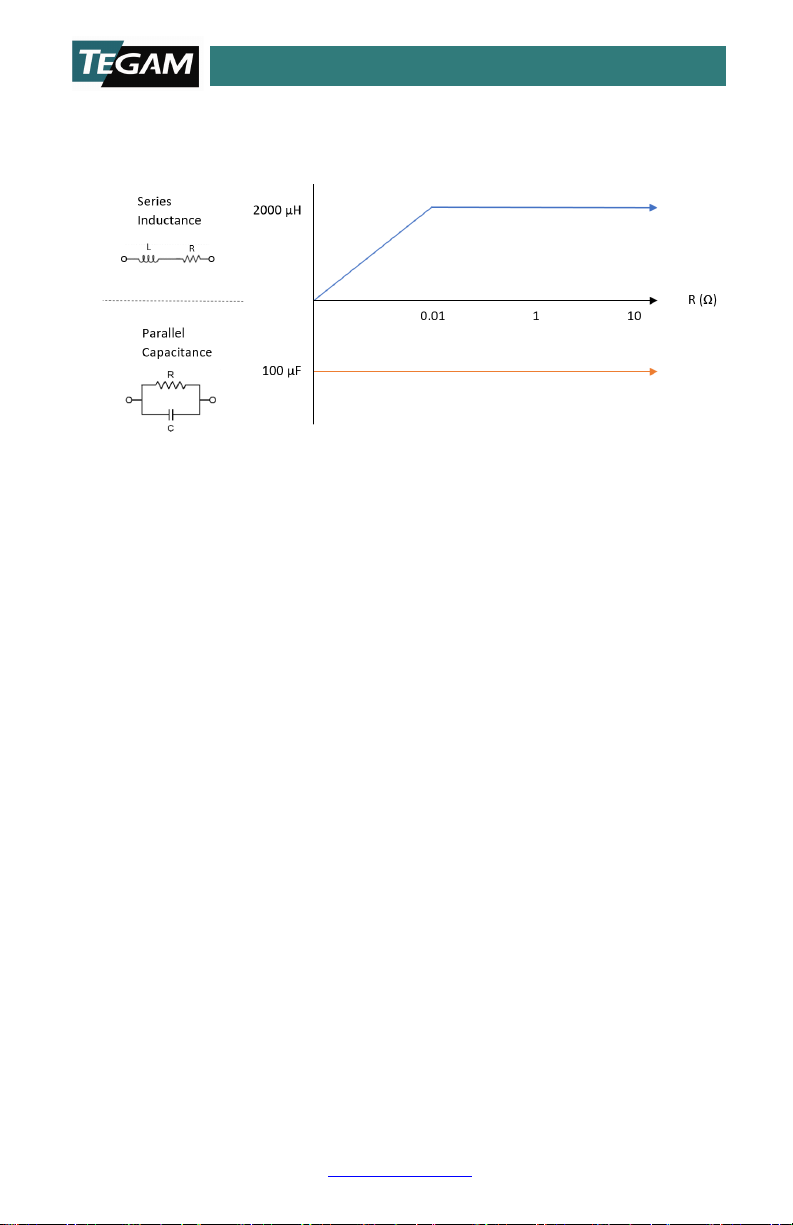

INSTRUMENT DESCRIPTION

Figure 1

Accuracy:

Accuracy on all ranges: ± (0.25% of reading + 1 count), when

powered from the batteries only.

1.3 Description of Equipment

Physical: The circuitry is enclosed in a rugged case.

Dimensions: 14.1 in (358 mm) W x 10.6 in (269 mm) D x 6.1

in (155 mm) H. Weight with accessories is 4.45 kg (9.8 lb).

Controls and connectors are of a size and spacing such that

the instrument may be operated while wearing safety gloves.

Electrical: The R1L-BIR1 is powered by an internal battery

consisting of three rechargeable NiCad ‘C’ cells (2800 mAh 3500 mAh) with a built-in charger. Input power for the charger

is 90 VAC to 250 VAC at 50 Hz or 60 Hz. Charging power is

supplied via a removable line cord; one end of which plugs into

a line filter on the front of the R1L-BIR1, and the other end being

a standard three-pin grounded line plug.

Fuse: ¼ A 3AG Slow blow, TEGAM PN#FU-202

Input Protection: The R1L-BIR1 will not be damaged by a

signal of 1 Vp-p applied across any pair of input terminals.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

1-2

Page 5

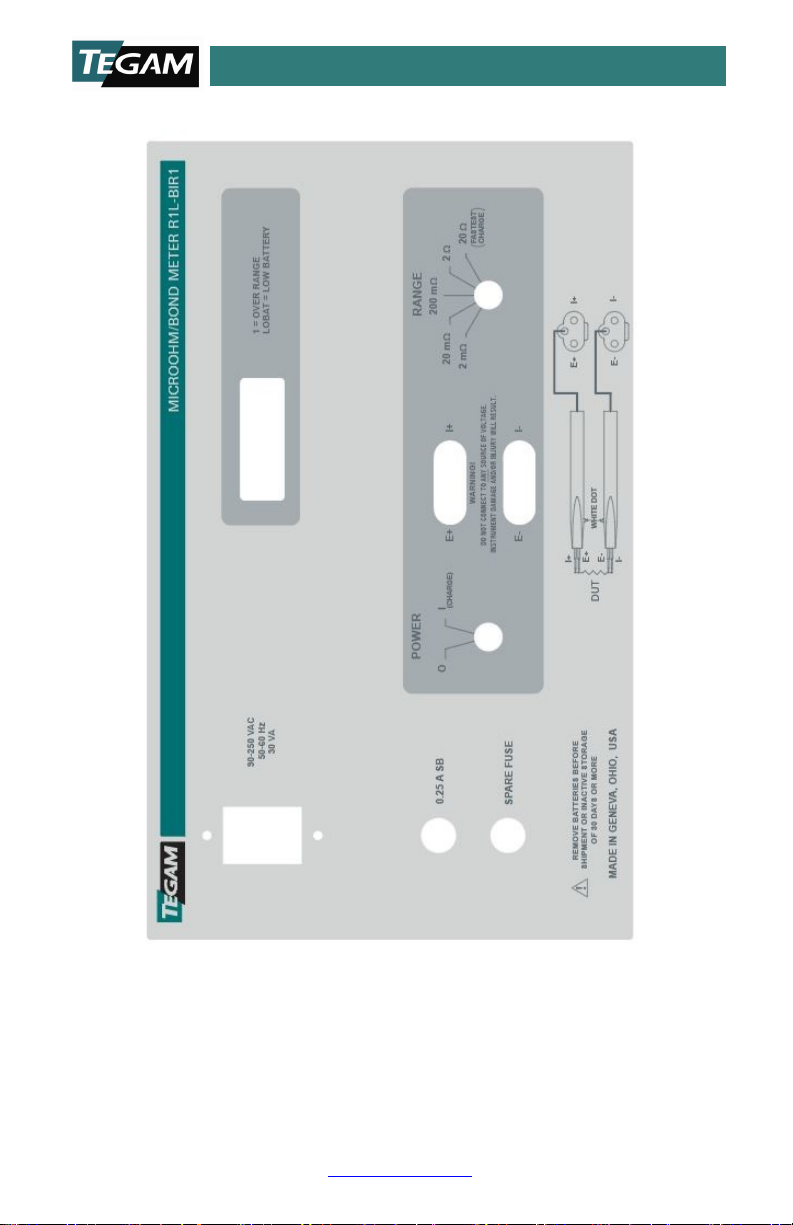

INSTRUMENT DESCRIPTION

Environmental: This unit will operate over a temperature

range from 0 °C to 50 °C, 75% RH non-condensing, up to

3050 m altitude.

Front Panel Controls and Displays (See figure 1)

RANGE Switch. The rotary 5 range selector switch may be used

to step through all five ranges.

POWER Switch. Used to turn the power on or off to the

instrument.

DISPLAY is a 3 ½ digit, displaying readings from 1.999 to

199.9.

Four binding posts for connection of test leads are marked +I,

+E, -E, and -I. Proper connections to the resistor under test

are described in Section 3.2 below.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

1-3

Page 6

INSTRUMENT DESCRIPTION

Figure 2: Front Panel Controls

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

1-4

Page 7

INSTRUMENT DESCRIPTION

!

1.4 List of Items Furnished

1 each Model R1L-BIR1 with power cord

3 each rechargeable NiCad battery cells (P/N: BA-110)

1 each R1L-BIR1 Instruction Manual (P/N: R1L-BIR1-900)

2 each Kelvin Clip Cables, one end with a dual banana

plug and the other end with a gold plated Kelvin clip

(P/N: KTL-100)

2 each Kelvin Probes, one end with a dual banana plug

and the other end with a Kelvin Probe with replaceable

tips (8 each) (P/N: BCP-10)

1.5 Storage and Shipping Requirements

Standard precautions which apply to electronic test

instruments should be followed. A hard mechanical shock,

such as from dropping the R1L-BIR1, could damage the

liquid crystal display. Care should be taken to prevent

damage to associated cables.

Remove the battery cells for inactive storage of 30 days or

more.

Temperature: -40 °C to +71 °C.

Relative humidity: 0 to 100%, non-condensing.

Altitude: 4570 m

See Section 5.6 below for shipping requirements.

1.6 Safety Information and Precautions

Grounding the Equipment

This product is grounded through the grounding

conductor of the power cord. To avoid electrical shock or

other potential safety hazards, plug the power cord into a

properly wired receptacle before using this instrument.

The proper grounding of this instrument is essential for

safety and optimizing instrument operation.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

1-5

Page 8

INSTRUMENT DESCRIPTION

Danger Arising from Loss of Ground

If the connection to ground is lost or compromised while

charging the batteries, a floating potential could develop

in the instrument. Under these conditions all accessible

parts, including insulating parts such as knobs and

terminals could develop a hazardous voltage and put the

user at risk.

Use the Proper Fuse

To avoid fire hazard, use only the correct fuse type as

specified for the AC power supply in the “Description of

Equipment” or “Maintenance” sections of this manual.

Do Not Use in Explosive Environments

The R1L-BIR1 microohmmeter is not designed for operation in explosive environments.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

1-6

Page 9

PREPARATION FOR USE AND INSTALLATION

WARNING

DO NOT CONNECT THE AC LINE CORD PRIOR TO

WILL PRESENT A POSSIBLE SHOCK HAZARD.

CAUTION

BE SURE TO OBSERVE THE PROPER POLARITY WHEN

INSERTING THE BATTERY CELLS OR DAMAGE MAY RESULT.

SECTION 2

PREPARATION FOR USE AND INSTALLATION

2.1 Unpacking and Inspection

Upon receipt, the R1L-BIR1 and accessories should be carefully unpacked and removed from the shipping container. Separate the units from the packing material and inspect both the instrument and the accessories for any external damage.

• If any dents, broken, or loose parts are seen, do not use the

equipment, and notify TEGAM immediately.

• Check that all items are present. If any items are missing,

notify TEGAM immediately.

• Note that the instrument is shipped with its battery

removed. Unwrap the 3 cells which comprise the battery.

2.2 Preparation for Use

Battery Installation

Be sure the power line cord is disconnected. Check that the

Power Switch is in the OFF position. Remove the ten screws

around the R1L-BIR1’s top (control/display) panel. Carefully

lift the unit out of its cabinet. Place the unit upside down on

a surface which will not mar or damage the control/display

panel.

REMOVING THE UNIT FROM ITS CASE OR WHILE THE

UNIT IS OUT OF ITS CASE, OR ELSE THE MAINS VOLTAGE

Insert the battery cells, one at a time, in accordance with the

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

2-1

Page 10

PREPARATION FOR USE AND INSTALLATION

WARNING

VIA THE GROUND PIN OF THE POWER CABLE, IF THIS

POWER CABLE IS SHORTED TO THE PANEL, THE PANEL

; SO DO

NOT TOUCH THE PANEL WHEN AC POWER IS CONNECTED.

polarity indications marked on both the battery cell and the

battery holder. Insert the positive end of the battery cells

first.

After installing the cells, reinstall the instrument in its case and

secure the ten screws.

Power Up

Plug the power cord into the R1L-BIR1 front panel receptacle,

and plug the other end into a standard AC outlet. For battery

operation (with charged battery cells), this step is omitted.

Turn on the POWER rotary switch. Note that this switch turns

on both line and battery power.

Charging the Battery Cells

Prior to battery operation, it is recommended the R1L-BIR1

Microohm/Bond Meter be plugged into AC power for at least

14 hours to charge the battery cells. To charge the battery

cells, the Power Switch must be turned ON, and the Range

Switch should be set to 20 Ω. With the Range Switch set to

lower ranges, the charge rate decreases and the batteries will

be discharged, especially on the 2 mΩ range, even with no

resistance connected to the instrument. (However, the

discharge rate in this range will permit operation for at least

14 hours with no resistance connected.)

ALTHOUGH THE FRONT PANEL IS NORMALLY GROUNDED

CONNECTION IS FAULTY AND IF THE HIGH SIDE OF THE

COULD POSSIBLY HAVE MAINS VOLTAGE ON IT

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

2-2

Page 11

OPERATING INSTRUCTIONS

WARNING

MAY BE PRESENT AT THESE POSTS.

SECTION 3

OPERATING INSTRUCTIONS

The R1L-BIR1 is designed for field or bench-top operation. Use appropriate cables connecting their terminations to the four binding posts marked +I, +E, -E, and -I.

DO NOT TOUCH THE BINDING POSTS WHEN THEY ARE

CONNECTED TO EXTERNAL CIRCUITS. LETHAL VOLTAGES

3.1 Rotary Switch Functions

Operation of the Model R1L-BIR1 is simple. There are only two

switches.

The RANGE rotary switch manually scrolls through the five

ranges.

Full scale on any range may be described as 2,000 counts

(actually 1,999), since this is a 3½ digit meter. If the readings

are exceeding 1,999 counts, step to the next higher range. If

the readings are less than 2,000 counts, step down a range,

so that it will read 1,999 counts, or less. The decimal point is

located automatically for the correct reading.

If the selected range is too low for the value of the resistor

under test, the display will show over-range.

The POWER rotary switch turns on the power to operate the

unit or turns off the power to the unit. The appearance of the

display will show that power is on; absence of the display

indicates that either power is off, batteries are discharged, or

there is some malfunction. Note that when power is turned

off, it may take several seconds to discharge circuit capacity

to completely blank the display. The black markings seen have

no effect and disappear when power is turned back on.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

3-1

Page 12

OPERATING INSTRUCTIONS

WARNING

FROM OTHER COMPONENTS AND APPARATUS.

3.2 General Theory Of Operation

Measurement Principle

A 4-terminal measurement method is used to determine the

resistance of the item under test. This method allows the

accurate measurement of low values of resistance in spite of

the other resistances present in the connection leads. A known

current is supplied to the item under test via two wire leads

connected to the +I and -I binding posts on the R1L-BIR1

Microohm/Bond Meter front panel. Two other wire leads

connected to the +E and -E binding posts on the R1L-BIR1

front panel sense the voltage developed across the resistance

under test due to the supplied known current. The R1L-BIR1

then calculates the resistance of the item under test utilizing

Ohm's law, and displays it on a 3 ½ digit display.

Kelvin Clip Cable Description

A Kelvin clip consists of two opposing jaws of an alligator style

clip which are insulated from each other, so one jaw may be

used to connect a source of current to the resistance under

test, and the other jaw used to measure the voltage at the test

point. The two jaws are spring loaded to clamp onto a cylinder

of ½ inch diameter or less.

OPERATING THE R1L-BIR1 MICROOHM/BOND METER AND

TAKING RESISTANCE MEASUREMENTS ON A POWERED OR

ENERGIZED COMPONENT COULD CAUSE SERIOUS HARM

TO THE OPERATOR AND/OR DAMAGE THE R1L-BIR1. BE

SURE THE ITEM TO BE MEASURED IS DISCONNECTED

If the battery cells have not been installed, refer to section

2.2. Battery only operation will result in the most stable and

accurate readings. The R1L-BIR1 may be operated while

charging the batteries, however it will not conform to

specifications in this configuration.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

3-2

Page 13

OPERATING INSTRUCTIONS

NOTE: The amount of current available for charging the

battery decreases as lower resistance ranges are selected. In

the 2 mΩ range, the current supplied to the resistance under

test exceeds the charging current, and the battery will be

drained.

To obtain the best accuracy, allow the R1L-BIR1 to warm up

for 15 minutes on the 20 Ω range before making

measurements. Even if in battery operation, this will not cause

appreciable battery discharge.

Using the Kelvin Clip cables

Plug one Kelvin Clip cable dual banana plug across the +E and

+I binding posts, and plug the other Kelvin Clip cable dual

banana plug across the -E and -I binding posts. Note that in

both cases, the small "I" marked on the dual banana plug

should go into the respective I binding post.

If Kelvin Clip cables are not used, a pair of shielded cables

may be utilized. As occurs in the Kelvin Clip cables in the

above paragraph, one cable should have its shield connected

to the “+I” binding post and its center conductor connected to

the +E binding post. Similarly, the other cable should have its

shield connected to the -I binding post and its center

conductor to the -E binding post. It is also recommended that

the resistance of the cables should not exceed 350

mΩ/conductor.

NOTE: Particularly in the 2 mΩ range, where a test current of

approximately 1.4 A is used, excessive lead resistance will

prevent an accurate measurement.

Set the Range Switch to the desired measurement range and

read the resistance on the liquid crystal display. If the

resistance is higher than the selected range, the display will

show a "1" and three blank digits, indicating over-range. The

decimal point will also appear in the proper location for the

selected range.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

3-3

Page 14

OPERATING INSTRUCTIONS

After prolonged operation on battery power, when the battery

voltage approaches the end of its useful range, the "LO BAT"

indicator will be seen on the display. Although the battery cells

are not fully discharged and they will not be damaged by

additional use, this is a warning to the operator that the

battery cells need to be charged.

Use of HTP-100 probes with R1L-BIR1

1. Connect the BLUE spade lug from the LEFT HTP-100 Probe

to the RED E+ terminal of the R1L-BIR1.

2. Connect the RED spade lug from the LEFT HTP-100 Probe

to the RED I+ terminal of the R1L-BIR1.

3. Connect the WHITE spade lug from the RIGHT HTP-100

Probe to the BLACK E- terminal of the R1L-BIR1.

4. Connect the BLACK spade lug from the RIGHT HTP-100

Probe to the Black I- terminal of the R1L-BIR1.

5. Hold the RED HTP-100 Probe in your left hand and the

WHITE HTP-100 Probe in your right hand, and push the

probe points against the surface to be measured with

sufficient force to cause the points to retract slightly.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

3-4

Page 15

PRINCIPLES OF OPERATION

SECTION 4

PRINCIPLES OF OPERATION

Power Supply

The internal switching power supply U8 accepts nominal line

voltages between 90 and 250 VAC 50/60 Hz, allowing

operation worldwide. C1, C2, U1, R1, R2 and R101 form a

constant current regulator set to approximately 758 mA for

charging the battery. D5 is used to isolate the AC power for

the battery. D7 serves to clamp the voltage to less than 5 V

when the battery is disconnected. The negative 3.6 volt power

supply for U2 and U10 is developed by U5.

Test Current Path

The test current used to perform the resistance measurement

originates from the battery + terminal connected to the +3.6

V power symbol at the emitter of Q1. It flows through Q1 into

the COM1 terminal of SW1 and out of the terminal selected by

the switch for the measurement range chosen. Each pole of

the COM1 section of SW1 is connected to a different tap on

the current sensing resistor string made up of R13, R48, R50,

R52 and R54. The test current flows into the sense resistor

string at the tap selected, out of R54 into D3 and out of D3 to

the I+ test jack. The external test leads conduct the current

through the resistance being measured and back to the I- test

jack, where it returns to ground and then to the battery terminal.

Test Current Regulator

The test current is controlled to a constant value for each

range with a feedback loop. The main loop amplifier is U9A.

The output of U9A controls the conduction of Q1 using Q2,

such that if the output voltage of U9A increases, the test

current increases. The inputs of U9A compare the voltage

across the current sensing resistor string with a 3 volt

reference voltage produced by U4, the voltmeter IC. The

voltage across the sensing resistor string is maintained at 1.5

V, half the value of the reference voltage because R9 and R11

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

4-1

Page 16

PRINCIPLES OF OPERATION

are twice the value of R8 and R9. The reference voltage of 3

V is present between the VREF signal at one end of R9 and the

+3.6 V power supply present at one end of R11. The voltage

at one end of the sensing resistor string is present at U11A

pin 1 which feeds R8. The voltage at the other end of the

sensing resistor string is present at U11B pin 7 which feeds

R10. U11A and U11B are very high input impedance buffer

amplifiers which sense the voltage across the current carrying

portion of the sensing resistor string without causing errors in

the test current. R127, R129 and CR1 provide overvoltage

input protection for pin 3 of U11A, and similarly R46, R128

and CR2 for U11B. U2B will shut off the current source if the

voltage on the I+ binding post becomes less than about -3 V.

Test Current Adjustment

The test current on the 2 milliohm range is 1.4 amps. It is

very stable, but not adjustable. The 1.4 A current stability is

determined by the stability of R54, the 3 V reference

developed by U4 and to a minor extent other circuit

components. The test currents on the four other ranges are

adjusted to approximately 1/10, 1/100, 1/1000 and 1/10000

of the actual value of the 2 milliohm range test current during

the calibration/ adjustment process. Trimpots R53, R51, R49

and R114 are used for this adjustment, and are adjusted

sequentially in that order. Adjusting the current affects the

readings, so current adjustment INDEPENDENT of the

readings adjustment is not possible.

Voltage Measurement

The voltage across the resistance being measured is amplified

by U10A, U10B and U9B. The E+ and E- test jacks are the

input to this differential amplifier, and the output is connected

to the voltmeter IC U4 pins 38 and 39. R130, R131, R141,

R142, CR3 and CR4 provide overvoltage input protection.

U10A, U10B, R132, R133 and R134 provide a differential gain

of 5: the voltage between U10A pin 1 and U10B pin 7 is 5

times the voltage between E- and E+. U9B provides voltage

gain of 10, and develops its output between VREF at pin 40 of

U4 and VIN+ at pin 39 of U4. An adjustable bipolar offset

voltage is added to this output by R143 before it is applied to

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

4-2

Page 17

PRINCIPLES OF OPERATION

VIN- at pin 38 of U4. C18 and 140 are a low pass filter to

reduce noise.

The voltmeter IC U4 converts the amplified voltage across the

resistance being measured into a displayed reading. Because

the test current is precisely regulated along with the various

gains chosen in the circuit, the displayed value is directly

proportional to the resistance being measured. U4 develops a

reference voltage of 3 V between pins 8 and 40. The reference

is divided by the resistor string R31, R32, R146 and R143.

R146 provides an adjustable voltage used as the analog to

digital conversion reference to pin 44. R143 provides an

adjustable zero reading.

Display

U4 directly drives the LCD, except for the decimal points and

the LOBAT indicator. The decimal point associated with the

range selected is displayed when the range switch SW1

provides a +3.6 V signal to one of the inputs of U7. The LOBAT

signal is displayed when U2A detects the voltage at pin 40 of

U4 falls below ground. Since this pin is maintained by U4 at

the reference voltage of 3 V below the battery voltage, LOBAT

will be displayed when the battery is less than approximately

3 V.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

4-3

Page 18

MAINTENANCE

SECTION 5

MAINTENANCE

5.1 Inspection

These units should be inspected semi-annually. Cables should

be periodically inspected to make sure they are in good

condition. Check that the switches turn smoothly. Check all

four binding posts to ensure that they operate smoothly.

No other maintenance is required, other than to keep the

battery charged through power line operation. Charging

should be done for at least 14 hours after long periods

(several months) of storage or after considerable use on

battery power.

5.2 Cleaning

The instrument should be cleaned periodically, as is

necessary, using mild soap and a damp cloth, followed by a

second damp rinsing cloth.

Clean the LCD window using a soft cloth moistened with water

or "Windex" type window cleaner.

towel products as some brands may contain fibers which could

scratch the display window.

to the LCD window as it could separate from the front panel.

DO NOT use alcohol, solvents, or harsh chemicals to clean the

LCD window.

DO NOT apply significant pressure

5.3 Test Equipment and Tools Required for Calibration and

Repair

Calibration of the R1L-BIR1 is recommended on a yearly

basis, and is done at a temperature of 23 °C ± 1 °C. To obtain

best results, keep the unit at 23 °C ± 1 °C for at least 8

hours, and allow it to warm up for 30 minutes before making

any adjustments.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

5-1

DO NOT use common paper

Page 19

MAINTENANCE

CAUTION

SAFETY PRECAUTIONS MUST BE TAKEN WHEN HANDLING

THIS INSTRUMENT WHEN THE LINE CORD IS PLUGGED IN

R1 HAS BEEN REMOVED FROM ITS CASE,

TO ENSURE THAT CONTACT IS NOT MADE WITH THE AC

POWER CONNECTIONS OR OTHER POTENTIALLY HARMFUL

POINTS. FAILURE TO OBSERVE PROPER SAFETY

PRECAUTIONS MAY CAUSE SERIOUS HARM TO THE

OPERATOR AND/OR DAMAGE THE R1L-BIR1.

Precision four terminal resistors with accuracy of 0.05% or

better: 1 mΩ, 1.9 mΩ, 19 mΩ, 190 mΩ, 1.9 Ω, and 19 Ω

A standard 4 ½ digit digital voltmeter: with 2 V range, accuracy better than 0.03% of reading ±1 count.

Screwdrivers: Medium Phillips and small slotted for trim-pot adjustment.

Three 20 AWG approximately 4 inch long Bus Wires

Four 18 AWG Wires (or dual wire cable) approximately 2 feet

long with clips

5.4 Calibration

AND THE R1L-BI

A. Preparation

1. Remove the front panel assembly from the case by

removing the ten retaining screws. Retain the ten

screws for reinstallation.

2. Install a new set of approved batteries into the UUT

as required. Observe polarity.

3. Plug UUT in and turn on setting the range switch to

20Ω range, allow a 14-hour charge time. (Skip this

step if batteries have already been charged.)

4. After the UUT has been charged, unplug the UUT.

5. Allow a 10-minute COOL DOWN.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

5-2

Page 20

MAINTENANCE

NOTE: Heat from the charging circuit causes the UUT to

drift. The COOL DOWN period is only necessary if the

UUT has been charging for an extended period of time.

6. Turn the voltmeter on allowing a 10-minute warm up.

a) Set unit to measure DC voltage.

b) Set unit to Auto range.

7. Connect clip leads to the voltmeter.

B. AC Circuitry Check

1. Set the range switch to 20 Ω on the UUT.

2. Connect the voltmeter to the UUT;

a) Voltmeter Red test lead to TP1 of the UUT,

b) Voltmeter Black test lead to TP2 of the UUT.

3. Plug the UUT into AC and turn on.

4. Verify the reading on the voltmeter reads between

1.0-1.5VDC.

5. Disconnect the UUT from the AC source.

6. Disconnect the Voltmeter from the UUT.

NOTE: The UUT is to be unplugged from AC during the

remaining portions of the procedure.

C. Zero the Display

1. Set the range switch to 2 mΩ on the UUT.

2. Short out all four terminals of the UUT in the following

order, +I to –I, –I to +E, +E to –E using the three

pieces of buss wire.

3. Adjust R143 for a zero reading ±1 count on the least

significant digit as displayed by the UUT.

4. Set the range switch to the next higher range.

5. Verify a zero reading within ±1 count on the least

significant digit.

6. Repeat steps 4 and 5 for all remaining ranges.

7. Disconnect the buss wires from the UUT.

D. 2 mΩ Adjust (Main Gain Adjust)

1. Set the range switch to 2 mΩ on the UUT.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

5-3

Page 21

MAINTENANCE

2. Connect a 1.9 mΩ standard to the UUT using the clip

leads.

3. Adjust R32 for a display reading of the actual

standards value ±3 counts (±0.003 mΩ) on the

display of the UUT, typically 1.900. Allow adequate

time for any thermals to dissipate and the unit to

settle.

4. Repeat sections C-D until both values are with-in

specifications.

5. Disconnect the resistance standard.

6. Connect a 1 mΩ standard to the UUT using the clip

leads.

7. Verify that the display of the UUT displays the actual

standard value ±2 counts.

8. Disconnect the resistance standard.

NOTE: The following adjustment steps build upon each other,

and must be performed in sequence. It appears that the

connection of standards will be more convenient if the steps

are performed in reverse order, from H to E, but this will not

provide a satisfactory adjustment, as (for example) the Step

E adjustment changes the Step H reading.

E. 20 mΩ Adjust

1. Set the range switch to 20 mΩ on the UUT.

2. Connect a 19 mΩ standard to the UUT using the clip

leads.

3. Adjust R53 for a display reading of the actual

standards value ±3 counts (±0.03 mΩ) on the display

of the UUT, typically 19.00. Allow adequate time for

any thermals to dissipate and the unit to quit drifting.

4. Disconnect the resistance standard.

5. Connect a 1.9 mΩ standard to the UUT using the clip

leads.

6. Verify that the display of the UUT displays the actual

standard value ±2 counts.

7. Disconnect the resistance standard.

F. 200 mΩ Adjust

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

5-4

Page 22

MAINTENANCE

1. Set the range switch to 200 mΩ on the UUT.

2. Connect a 190 mΩ standard to the UUT using the clip

leads.

3. Adjust R51 for a display reading of the actual

standards value ±3 counts (±0.3 mΩ) on the display

of the UUT, typically 190.0. Allow adequate time for

any thermals to dissipate and the unit to quit drifting.

4. Disconnect the resistance standard.

5. Connect a 19 mΩ standard to the UUT using the clip

leads.

6. Verify that the display of the UUT displays the actual

standard value ±2 counts.

7. Disconnect the resistance standard.

G. 2 Ω Adjust

1. Set the range switch to 2 Ω on the UUT.

2. Connect a 1.9 Ω standard to the UUT using the clip

leads.

3. Adjust R49 for a display reading of the actual

standards value ±3 counts (±0.003 Ω) on the display

of the UUT, typically 1.900. Allow adequate time for

any thermals to dissipate and the unit to quit drifting.

4. Disconnect the resistance standard.

5. Connect a 190 mΩ standard to the UUT using the clip

leads.

6. Verify that the display of the UUT displays the actual

standard value ±2 counts.

7. Disconnect the resistance standard.

H. 20 Ω Adjust

1. Set the range switch to 20 Ω on the UUT.

2. Connect a 19 Ω standard to the UUT using the clip

leads.

3. Adjust R114 for a display reading of the actual

standards value ±3 counts (±0.03 Ω) on the display

of the UUT, typically 19.00. Allow adequate time for

any thermals to dissipate and the unit to quit drifting.

4. Disconnect the resistance standard.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

5-5

Page 23

MAINTENANCE

Component

U6

U4, if present, replace U6.

Remove battery cells and bend contact arms

(ref. to common) at the anode of D5, if not,

replace D5.

ables

U10/U9

If above ok, check the Kelvin cable for

if defective.

5. Connect a 1.9 Ω standard to the UUT using the clip

leads.

6. Verify that the display of the UUT displays the actual

standard value ±2 counts.

7. Disconnect the resistance standard.

5.5 Troubleshooting

Following are possible symptoms, diagnosis, and repair suggestions for use in trouble-shooting (the most likely causes are listed first).

Symptom

Faulty

Repair

Batteries

Power cord

No Display

Battery

won’t

charge

Display

reads zero

with c

connected

to a good

resistor

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

Power

switch

Connections

Batteries

Fuse

Fuse (F1)

U1

R1/R101

D5

Current o/p

Kelvin Clip

U9/U11/Q1

Check for batteries installed & polarity.

Check the power cord is plugged in.

Check the power switch is ON.

Check for a square wave between pin 4 & 40 of

inward to ensure better contact with the battery

cells.

Clean connections if required.

Try a new set of batteries.

Check fuses.

Check for 12 VDC across C1. If not check for

mains on pins 1 & 2 of U8. If not replace U8. If

ok, check for aprox. 6 VDC (ref. to common) at

the output of U1. If not, replace U1.

If above ok, check for approximately 4.5 VDC

replace R1/R101.

If above ok, check for approximately 3.6 VDC

(ref. to common) at the cathode of D5, if not,

Check for proper current o/p between +I and I.

continuity from each side to the banana plug.

If no current, troubleshoot the const. current

circuit and replace U11 or other component(s)

• sales@tegam.com

5-6

Page 24

MAINTENANCE

component(s) if defective.

If the current and cables are both ok, check the

voltage amplifier and replace U10,U9 or other

Table 2: Fault Symptoms and Repair Actions

After trouble-shooting and repair, the instrument must be recalibrated in accordance with 5.4 above. Disassembly

• First remove the line cord and any other connecting wires.

Then remove the ten screws of the top (display) panel.

Carefully lift the unit out of its cabinet. Remove the three

battery cells.

• Remove the four screws that secure the battery plate.

• Loosen the set screws in the knobs for the Power and

Range switches, and remove these knobs.

• To separate the printed circuit board from the front panel,

remove the two screws and two standoffs appearing in a

rectangular pattern around the LCD and control switches.

Remove the four nuts from the binding post connections.

Re-assembly

To reassemble the unit, repeat the above steps in reverse

order, taking care to install the lockwashers on the proper

screws.

5.6 Preparation for Shipment

The original shipping carton is not reusable.

Remove the battery cells prior to shipment (or inactive storage of 30 days or more) and package them separately. Disassemble the R1L-BIR1 as per section 5.5, and extract the negative end of the battery cells first.

Packaging must provide sufficient resilient material, in

accordance with standard packaging practices, to prevent

excessive shock to the power supply and display during

shipment.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

5-7

Page 25

MAINTENANCE

5.7 Overhaul Instructions

The R1L-BIR1 is an all solid-state unit and requires no

periodic overhaul, other than routine cleaning, inspection of

cables per section 5, and calibration per section 5.4.

However, some disassembly is required to remove and install

the batteries. This level of disassembly is detailed in section

2.2 and battery cells should be removed at the negative end

first.

Tools and test equipment used for disassembly, calibration,

and troubleshooting of the R1L-BIR1 are listed in section 5.3.

Troubleshooting suggestions are given in section 5.5.

The only component expected to require replacement is the

battery. The battery designation is listed on the Replacement

Parts List, with battery cell removal and installation

instructions given in section 2.2.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

5-8

Page 26

MAINTENANCE

Figure 3: Parts Layout

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

5-9

Page 27

MAINTENANCE

Figure 4: Digital Section

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

5-10

Page 28

MAINTENANCE

Figure 5: Analog Section

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

5-11

Page 29

MAINTENANCE

Part

Reference

Value

Description

Manufacturer

P/N

1 1 C1

220uF

CAP ALUM 220uF 35V F

EEE-1VA221UP

PANASONIC

C-328-220UF

2 6 C2 C3 C4 C21

C26 C36

0.1uF

CAP CER 50V X7R 0805

C0805C104K5R

ACTU

KEMET

C-610-0.1UF

3 1 C9

0.47µF

CAP CER 50V X7R 0805

UMK212B74

74KG-T

TAIYO YUDEN

C-610-

0.47UF

4 4 C10 C11 C12

C13

6.8uF

CAP TANT 16V 10%

EIAA

TR3A685K016C

3000

VISHAY

C-606-6.8UF

5 1 C18

1.0uF

CAP FILM(PEN) 1.0uF

100V

ECWU1105KCV

PANASONIC

C-335-1.0UF

6 1 C22

1.0uF

CAP CER 50V X7R 0805

GRM21BR71H1

05KA12L

MURATA

C-0805K-

1.0UF

7 1 C23

0.1uF

CAP FILM(PEN) 0.1uF

100V 2416

ECWU1104JC9

PANASONIC

C-630-0.1UF

8 1 C24

0.47uF

CAP FILM(PEN) 0.47uF

16V 2416

ECWU1C474JC9

PANASONIC

C-632-

0.47uF

9 1 C25

0.1uF

CAP FILM(PP) 0.1uF

250V RAD_10MM

ECWF2104JAQ

PANASONIC

C-514-0.1UF

10 1 C27

4.7uF

CAP TANT 16V EIAA

TR3A475K016C

1500

VISHAY

C-606-4.7UF

11 1 C28

10000pF

CAP CER 250VAC

RAD_7.5MM

DE2F3KH103MA

3B

MURATA

C-59510000PF

12 4 C30 C31 C32

C33

0.1uF

CAP CER 0.1UF 50V X7R

1206

C1206C104K5R

AC

KEMET

150036

13 4 C34 C35 C37

C38

0.01µF

CAP CER 0.01UF 50V

X7R 0805

C0805C103

K5RACTU

KEMET

C-61010000PF

14 4 CR1 CR2 CR3

CR4

BAV23S

DIO FAST DUAL 200V

400mA SOT-23-3

BAV23S-7-F

DIODES

INCORPORATED

DZ-228

15 1 D3

SS24

DIO SCHOTTKY 40V 2A

SMB

SS24T3G

ON

OR

DZ-157

16 1 D5

ES1B

DIO FAST 100V 1A SMA

ES1B-13-F

DIODES

INCORPORATED

DZ-172

17 1 D7

5.6V

DIO ZENER 5.6V 1W

POWERDI123

DFLZ5V6

DIODES

INCORPORATED

DZ-180

18 1 D9

1.5 AMP

DIO GP 400V 1.5A SMB

MRS1504T3G

ON

OR

DZ-130

19 1 F1

2A

FUSE 2A 125VAC/DC

2410

CB61F2A

COOPER

BUSSMANN

FU-25

20 1 J2

39-29102

CONN HEADER RIGHT

ANGLE 2X1 4.2MM

39-29-102

MOLEX

CS-22

21 1 J3

6404563

CONN HEADER

VERTICAL 1x3 2.54MM

640456-3

TE

CONNECTIVITY

CS-199

22 4 M15 M16 M17

M18

9

M-F THRD HEX STANDOFF

92700A452

McMASTERCARR

ST-318

23 1 Q2

FMB222

XSISTOR BJT NPN DUAL

40V 500mA TSOT

FMB2222A

FAIRCHILD

OR

TG-270

24 2 R1 R101

3.3

RES CARBON FILM 5%

1W MELF 0207

CMB02070X330

8JB200

VISHAYBEYSCHLAG

R-250-3.3

25 2 R2 R50

100

RES THICK FILM 1%

1/8W 0805

ERJ-6ENF1000V

RC0805FR

07100RL

PANASONIC

R-618-100

26 5 R3 R4 R34

R35 R36

10.0K

RES THICK FILM 1%

1/8W 0805

ERJ-6ENF1002V

RC0805FR

0710KL

PANASONIC

R-618-10K

Part Number: R1L-B-100

Qty

Manufacturer TEGAM P/N

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

2A

• sales@tegam.com

-23-6

-

-

SEMICONDUCT

SEMICONDUCT

SEMICONDUCT

YAGEO

YAGEO

5-12

Page 30

MAINTENANCE

27 1 R5

1.00K

RES THICK FILM 1%

1/8W 0805

ERJ-6ENF1001V

RC0805FR

071KL

PANASONIC

R-618-1K

28 1 R6

4.99

RES THICK FILM 1%

1/8W 0805

RC0805FR074R99L

YAGEO

R-618-4.99

29 5 R7 R128 R129

R141 R142

499

RES THICK FILM 1%

1/8W 0805

ERJ-6ENF4990V

PANASONIC

R-618-499

Part

Reference

Value

Description

Manufacturer

P/N

30 8 R8 R10 R134

R135 R136

R147

R162

15.0K

RES THICK FILM 0.1%

1/8W 0805

ERA-6AEB153V

PANASONIC

R-638-15K

31 4 R9 R11 R132

R133

31.6K

RES THICK FILM 0.1%

1/8W 0805

ERA6AEB3162V

PANASONIC

R-638-31.6K

32 1 R13

10.0K

RES THICK FILM 0.1%

1/8W 0805

ERA-6AEB103V

PFC

03

1739

PANASONIC

R-638-10K

33 3 R31 R137

R138

150K

RES THICK FILM 0.1%

1/8W 0805

ERA-6AEB154V

PANASONIC

R-638-150K

34 2 R32 R53

500

RES TRIMMER 1/4W 12TURN 4mm SQ SMD

3224G-1-501E

BOURNS

RP-103-500

35 1 R33

174K

RES THICK FILM 1%

1/8W 0805

ERJ-6ENF1743V

RC0805FR

07174KL

PANASONIC

R-618-174K

36 2 R43 R44

499K

RES THICK FILM 0.1%

1/8W 0805

ERA6AEB4993V

PANASONIC

R-638-499K

37 2 R45 R47

18.0K

RES THICK FILM 0.1%

1/8W 0805

ERA-6AEB183V

PANASONIC

R-638-18K

38 4 R46 R127

R130 R131

1.00K

RES THICK FILM 1%

1/4W 1206

ERJ-8ENF1001V

PANASONIC

R-515-1K

39 1 R48

1.00K

RES THICK FILM 0.1%

1/4W 1206

RG3216P-1001B-T1

SUSUMU

R-550-1.0K

40 1 R49

10K

RES TRIMMER 1/4W 12TURN 4mm SQ SMD

3224G-1-103E

BOURNS

RP-103-

10.0K

41 1 R50

100

RES METAL FILM 0.1%

1/2W AX

CMF55100R00B

EEB

VISHAY

R-169-100

42 2 R51 R143

1K

RES TRIMMER 1/4W 12TURN 4mm SQ SMD

3224G-1-102E

BOURNS

RP-103-1.0K

43 1 R52

10.0

RES WW 1% 3W AX

43F10RE

OHMITE

R-275-10

44 1 R54

1.00

RES WW 1% 5W AX

45F1R0E

OHMITE

R-341-1

45 1 R114

100K

RES TRIMMER 1/4W 12TURN 4mm SQ SMD

3224G-1-104E

BOURNS

RP-103-

100.0K

46 1 R115

13.0K

RES THICK FILM 1%

1/4W 1206

ERJ-8ENF1302V

PANASONIC

R-515-13K

47 1 R121

110K

RES THICK FILM 1%

1/4W 1206

ERJ-8ENF1103V

PANASONIC

R-515-110K

48 1 R125

154

RES THICK FILM 1%

1/4W 1206

ERJ-8ENF1540V

PANASONIC

R-515-154

49 1 R126

1.30K

RES THICK FILM 1%

1/4W 1206

ERJ-8ENF1301V

PANASONIC

R-515-1.3K

50 4 R139 R145

R158 R159

301

RES THICK FILM 0.1%

1/8W 0805

ERA-6AEB301V

PANASONIC

R-638-301

51 1 R140

49.9K

RES THICK FILM 1%

1/4W 1206

ERJ-8ENF4992V

PANASONIC

R-515-49.9K

52 1 R144

0.0

RES THICK FILM JUMPER

1/8W 0805

ERJ-6GEY0R00V

RC0805JR

070RL

PANASONIC

R-618-0

53 1 R146

3.57K

RES THICK FILM 0.1%

1/8W 0805

ERA6AEB3571V

PANASONIC

R-638-3.57K

-

YAGEO

Qty

R157

Manufacturer TEG AM P/N

-W0805LF-

-1002-B-

-

TT ELEC./IRC

YAGEO

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

5-13

-

YAGEO

SUSUMU

Page 31

MAINTENANCE

RG2012P-3571B

54 1 R150

140

RES THICK FILM 1%

1/4W 1206

ERJ-8ENF1400V

PANASONIC

R-515-140

55 1 R151

1.96K

RES THICK FILM 1%

1/4W 1206

ERJ-8ENF1961V

PANASONIC

R-515-1.96K

56 1 R152

19.6K

RES THICK FILM 1%

1/4W 1206

ERJ-8ENF1962V

PANASONIC

R-515-19.6K

57 1 R153

196K

RES THICK FILM 1%

1/4W 1206

ERJ-8ENF1963V

PANASONIC

R-515-196K

Part

Reference

Value

Description

Manufacturer

P/N

58 2 R154, R156

2.0M

RES THICK FILM 1%

1/8W 0805

ERJ-6ENF2004V

PANASONIC

R-618-2.0M

59 2 SO6 SO60

SIP-20

CONN SIL-SOCKET

0.472" STANDOFF

HEIGHT 20-POS

316-93-120-41008000

MILL-MAX

SO-314-20

60 2 SW1 SW2

2P6T

SW ROTARY DP 6-POS

C5P0206N-R

ELECTROSWITC

H

SW-419

61 2 TP1 TP2

S175146R

TP LOOP SMD

S1751-46R

HARWIN INC.

CS-122

62 1 U10

OPA218

0

IC OPAMP DUAL ZERODRIFT SOIC-8

OPA2180IDR

TEXAS

INSTRUMENTS

IC-352

63 2 U11 U9

OPA237

6

IC OPAMP DUAL LOW

NOISE SOIC-8

OPA2376AID

TEXAS

INSTRUMENTS

IC-358

64 1 U2

LMC648

2

IC OPAMP DUAL CMOS

SOIC-8

LMC6482IM/NO

PB

TEXAS

INSTRUMENTS

IC-251

65 1 U4

MAX138

IC 3.5 DIGIT ADC

W/LCD DRIVER QFP-44

MAX138CMH

MAXIM

IC-241

66 1 U5

7660

IC REGULATOR

SWITCHED CAP SOIC-8

ICL7660ACBAZ

A

INTERSIL

IC-809

67 1 U6

3.5DIGI

DISPLAY 3.5 DIGIT W/ ±

AND LOBAT IND., USE

NO BACKLIGHT

35D050-R3PBZ

FEMA ELEC.

DD-206

68 1 U7

4070B

IC QUAD 2-INPUT XOR

SOIC-14

CD4070BM96

TEXAS

INSTRUMENTS

IC-863

69 1 U8

VOF-1512

PS 12VDC 1.25A OPEN

FRAME PCB MOUNT

VOF-15-12

CUI INC

PS-128

Part Number

Part Description

Qty

UM

Manufacturer

Cage

Code

Mfg Part

BA-110

BATT,C,NICAD,3000mAh

3

EA

PANASONIC

0HF77

P-280CR

SANYO

00JU0

N-3000CR

TENERGY

55R99

20400

R1L-BR1-040

FRONT PANEL ASSY

1

EA

TEGAM, INC

49374

KAK-04

CABLE, BANANA PLUG TO KELVIN

CLIP

1

EA

TEGAM, INC

49374

BCP-10

KELV PRB, SPRING LOAD PINS

1

EA

C PETROVIC

BCP-10

BCP-10-A

PIN SET, 8 PINS, A STYLE

1

EA

CO-115

LINECORD

1

EA

VOLEX

U7112

17250-10-B1

PK-5000

POCKT POUCH R1L-BR1

1

EA

ELLIS CH

0TJ49

PK-5000

R1L-BR1-900-01

OPERATION MANUAL

1

EA

ACTIVITIES

PRESS

R1L-B-90001

R1L-B/BR-841

CD MANUAL MILITARY

AR

EA

TEGAM, INC

49374

-T5

Qty

T LCD

Manufacturer TEG AM P/N

Table 3: Parts List – Main Board Assembly

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

5-14

Page 32

MAINTENANCE

MC-1212

R1L-BR1 LABEL

1

EA

NUTRON

NAMEPLATE

30236

MC-1212

1531

CASE, R1LC-080

1

EA

AMERIPACK

0TJ49

1013

5879

TBG, N16 VINYL FBGL, GRN

AR

FT DOC-019

PRODUCT SPEC SHEET TEMP

REF

EA

Part Number

Part Description

Ref

Qty

UM

Manufacturer

Cage

Code

Mfg Part

BP-50-0

BIND POST CON GLD-PLT

BLK

BP -I,

BP

2

EA

POMONA

5D6S9

3750-0

BP-50-2

BIND POST CON GLD-PLT

RED

BP +I,

BP +E

2

EA

POMONA

5D6S9

3750-2

CS-104

CON,DUL,BINDPOST,BASE

BLK

BP +I,

+E,-I,-E

2

EA

POMONA

ELECTRONICS

5D6S9

3862

PE-2

PWR ENTRY LINEFILTER

3A

LF1 1 EA

CORCOM

38AS8

3EEA1

TYCO\TE

CONNECTIVITY

1Z830

6609000-4

FH-20

FUSE HLD PNL MNT

6.3X32MM

XF1 2 EA

LITTELFUSE

7E222

03453LF1H

FU-202

FUSE,1/4A 3AG SLOW

BLOW

F1 2 EA

LITTELFUSE

7E222

313.25

LITTELFUSE

7E222

313.250HXP

IN-7

SIL-PAD,HEATPAD TO 220

2 EA

BERGQUIST

55285

3223-07FR-90

BERGQUIST

55285

SP400-0.00700-90

WA-20

WSH,NYLON #4

Q1,U1 2 EA

THERMALLOY

13103

7721-7PPS

THERMALLOY

13103

7721-7PPSG

TEGAM, INC

49374

210117800

ITW PANCON

0K1B5

CE100F22-3-D

210108

LUG,SOLDER,#4

1 EA

KEYSTONE

ELECTRONICS

91833

908

12373

DISPLAY GASKET R1L-B

2 EA

GASKO

6R887

12373

ST-318

STNDOF,8-32X1/2"HEX

BRS Z

4 EA

MCMASTER-CARR

0KVE6

92700A452

WA-244

WSH,#8 LOCK,GLD

PLATED

4 EA

MPT FASTENER

45T10

BUY WIT NUT8/32 & WA-242

NUT-8/32GLD

NUT,HEX,8-32,GLD

PLATED

4 EA

MPT FASTENER

45T10

BUY WITH WA242 & WA-244

MS51957-13

SCR PH 4-40 X 1/4 LG

6 EA

MPT FASTENER

45T10

NON MIL EQUAL

BY DESC

440X1/2PFHBLK

SCW,PFH,4/40X1/2,SS,BL

K

2 EA

MPT FASTENER

45T10

3538

NUT,HEX,4-40

6 EA

BEAVER BOLT

OB6M9

3538

MPT FASTENER

45T10

4-40 HEX NUT

18-8

MS35338-135

WSH LOCK #4

11

EA

MPT FASTENER

45T10

NON MIL EQUAL

BY DESC

6168

WIRE,N18 STR GRN TFLN

AR

FT

BIRNBACH

71002

8518/19 GRN

Table 4: Parts List – R1L-BR1 Final Assembly

Part Number: R1L-BR1-040

-E

ELECTRONICS

ELECTRONICS

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

5-15

Page 33

MAINTENANCE

BELDEN WIRE AND

CABLE

3HXC8

83029 005100

TEGAM, INC

49374

079-145-5

TEGAM, INC

49374

600005

KN-106

KNOB,ROUND,KNURLED.6

.4MM

2 EA

MULTICOMP/SPC

75498

MC21051

CS-21

CONN,PUSH ON

1 EA

MOLEX

KB925

39012020

CS-105

CONN,TERM,FEMLE,18-24

AWG

2 EA

MOLEX

KB925

39-00-0039

ST-335

STANDOFF,4-40X3/4 HEX

4 EA

MCMASTER-CARR

0KVE6

91780A745

Part Number

Part Description

Ref

Qty

UM

Manufacturer

Cage

Code

Mfg Part

015-317

IC VOLT REG ADJ

1 EA

FAIRCHILD

SEMICONDUCTOR

4E8P4

LM317T

NATIONAL

SEMICONDUCTOR

LM317T

TG-34

XISTOR,BIPOLAR,PNP

1 EA

MOTOROLA

TIP34

ST

S

SCE76

TIP34C

TEGAM, INC

49374

079-148-8

TEGAM, INC

49374

600008

TX-20-3/16

TUBING SHRINK 3/16

AR

EA

ALPHA WIRE &

CABLE

92194

FIT221 3/16

ALLIED WIRE &

CABLE

92194

HST221-3/16

TEGAM, INC

49374

6196

MS35338-137

WSH LOCK,SPLT,#8

4 EA

TEGAM, INC

49374

50626

TEGAM, INC

49374

NAS1676C8

MPT FASTENER

45T10

NON MIL EQUAL

BY DESC

R1LBR1-319

FRONT PANEL

1 EA

AMERICAN METAL

SPECIALTIE

5JH28

R1LBR1-319

R1LBR1-320

FRONT PNLW/ OVERLAY

REF

EA

R1LBR1-321

FRONT PNL OVERLAY R1LBR1

1 EA

NUTRON

NAMEPLATE

30236

PER PRINT

R1L-B-100

PC ASSY, R1L-B

1 EA

TEGAM, INC

49374

R1L-BR1-700

FIXTURE FRNT PNL

REF

EA

DD-130

LCD DISP 3.5 DIGIT 0.5”H

IC

1 EA

FEMA ELECTRONICS

CORP

OP7Z6

35D050-T3PBZ

SW-419

SWITCH ROTARY 2 POLE

2 POS

2 EA

ELECTROSWITCH

TEGAM, INC

49374

C5P0206N-4006

SW

SW-421

SO-314-20

SOCKET ROW 20 PIN SIP

2 EA

MILL-MAX

3N087

316-93-120-41008-000

999920-000

WIR,20 AWG TFE BLACK

AR

EA

BELDEN WIRE AND

CABLE

3HXC8

83007-010

999920-008

WIR,20 AWG TFE GREY

AR

EA

BELDEN WIRE AND

CABLE

3HXC8

83007-008

ST-317

STNDOF,4-40X.25 M/F

STEEL

4 EA

MCMASTER-CARR

0KVE6

93620A430

R1L-B-200

PC ASSY R1L-B BATT BRD

1 EA

TEGAM, INC

49374

LOCTITE263

LOCTITE,263,HI

STG,THRD

AR

EA

LOCTITE

05972

263

MICROELECTROINC

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

TEGAM, INC

49374

-420

5-16

Page 34

MAINTENANCE

Number

Part Description

Qty

UM

Manufacturer

Code

Mfg Part

R1L-B-172

PCB BATTERY BRD

R1L-B

1

EA

ALPHA CIRCUITS

33TM7

R1L-B-172

BH-107

BATT HOLDER END

"C" INSUL

6

EA

KEYSTONE

ELECTRONICS

91833

87

EY-35

EYELET 3/32X0.156

12

EA

KEYSTONE

ELECTRONICS

91833

35

Part

Number

Part Description

Qty

UM

Manufacturer

Cage

Code

Mfg Part

BH-25

BATT HOLDER KEY

INSUL

3

EA

KEYSTONE

ELECTRONICS

91833

59

CS-211-3

CONN,3 PIN,IDC

INLINE

1

EA

ITW PANCON

0K1B5

CE100F22-3-C

ITW PANCON

0K1B5

CE100F22-3-D

999924000

WIR,24 AWG,TEFLON

BLK

AR

IN

BELDEN WIRE AND

CABLE

3HXC8

83003-10/BLK

999924002

WIR,24

AWG,RED,TEFLON

AR

IN

BELDEN WIRE AND

CABLE

3HXC8

83003-2(RED)

999924003

WIR,24

AWG,TFE,ORANGE

AR

IN

BELDEN WIRE AND

CABLE

3HXC8

830033(ORNG)

TX-20-3/16

TUBING SHRINK

3/16

AR

EA

ALPHA WIRE & CABLE

92194

FIT221 3/16

ALLIED WIRE & CABLE

92194

HST221-3/16

TEGAM, INC

49374

6196

ST-420

SPA, INS PCB,

NYL,.250X.260

2

EA

KEYSTONE

ELECTRONICS

91833

9029

Table 5: Parts List – R1L-BR1 Front Panel Assembly

Part Number: R1L-B-200

Part

Cage

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

Table 6: Parts List –Battery Board Assembly

• sales@tegam.com

5-17

Page 35

MAINTENANCE

Cage

Code

Cage

Code

ABBATRON HH SMITH

91967

MAXIM

1ES66

ALPHA

92194

MCMASTER CARR

OKVE6

AMERIPACK

OTJ49

MICRO COMMERCIAL

374W0

AVX

16299

MILL MAX

3N087

BELDEN

3HXC8

MOLEX

KB925

BOURNS

F0978

MOTOROLA

0G546

C&K

63HW9

MPT FASTENER

45T10

COMMERCIAL-SEE MCMASTER CARR

MULTICOMP

75498

CONCORD

18310

MULTI-CONTACT

0WCJ0

COOPER BUSSMANN

1UW16

MURATA ELECTRONICS NA

3EH09

CORCOM

38AS8

NATIONAL SEMICONDUCTOR

0G557

CUSTOM COIL

0VYL0

OHMITE

03615

DIALIGHT (DIALCO)

96312

OLDAKER

64882

DISCH-SEE TEGAM

ON SEMICONDUCTOR

59PE1

EAGLE

0MPC5

PANASONIC

0HF77

ELECTROSWITCH

8T045

PHILIPS

0TBA7

ELECTRO-TECH SYSTEMS

56541

POMONA

5D6S9

ETCHED METAL-SEE TEGAM

PPM-SEE TEGAM

FAIRCHILD SEMICONDUCTOR

4E8P4

SPRAGUE

5079

FEMA

OP7Z6

SUSUMU

SAW40

GE (MG CHEMICALS)

L3160

ST MICROELECTRONICS

SCE76

GRAYHILL

81073

TEGAM, INC

49374

HARWIN INC.

06EX9

TEXAS INSTRUMENTS

8T904

ILLINOIS CAPACITOR

74840

TYCO

Z9V34

INTERSIL CORPORATION

K0331

TYTON

3E655

KEMET ELECTRONICS

31433

VISHAY

56845

KOA

59124

VOLEX POWER CORDS

U7112

LITTLEFUSE

7E222

Manufacturer

Manufacturer

Table 7: Vendor Cage Code Directory

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

5-18

Page 36

SERVICE INFORMATION

SECTION 6

SERVICE INFORMATION

Preparation for Calibration or Repair Service

Once you have verified that the cause for R1L-BIR1

malfunction cannot be solved in the field and the need for

repair and calibration service arises, contact TEGAM customer

service to obtain an RMA, (Returned Material Authorization),

number. You can contact TEGAM customer service via the

TEGAM website, www.tegam.com

(All Locations) OR 800.666.1010 (United States Only).

The RMA number is unique to your instrument and will help us

identify you instrument and to address the particular service

request by you which is assigned to that RMA number.

Of even importance, a detailed written description of the

problem should be attached to the instrument. Many times

repair turnaround is unnecessarily delayed due to a lack of

repair instructions or of a detailed description of the problem.

This description should include information such as

measurement range, and other instrument settings, type of

components being tested, are the symptoms intermittent?,

conditions that may cause the symptoms, has anything

changed since the last time the instrument was used?, etc.

Any detailed information provided to our technicians will assist

them in identifying and correcting the problem in the quickest

possible manner. Use a copy of the Repair and Calibration

Service form provided on the next page.

Once this information is prepared and sent with the instrument

to our service department, we will do our part in making sure

that you receive the best possible customer service and

turnaround time possible.

or by calling 440.466.6100

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

6-1

Page 37

SERVICE INFORMATION

RMA#:

Instrument

Model #:

Serial Number:

Company:

Technical

Contact:

Phone

Number:

Additional

Expedite Repair & Calibration Form

Use this form to provide additional repair information and

service instructions. The Completion of this form and including

it with your instrument will expedite the processing and repair

process.

Contact Info:

Repair Instructions:

Evaluation Calibration Only Repair Only

Repair & Calibration Z540

Detailed Symptoms:

Include information such as measurement range, instrument

settings, type of components being tested, is the problem

intermittent? When is the problem most frequent?, has

anything changed with the application since the last time the

instrument was used?, etc.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

6-2

Page 38

SERVICE INFORMATION

Warranty

TEGAM, Inc. warrants this product to be free from defects in

material and workmanship for a period of three years from the

date of shipment. During this warranty period, if a product

proves to be defective, TEGAM Inc., at its option, will either

repair the defective product without charge for parts and

labor, or exchange any product that proves to be defective.

TEGAM, Inc. warrants the calibration of this product for a

period of one year from date of shipment. During this period,

TEGAM, Inc. will recalibrate any product, which does not

conform to the published accuracy specifications.

In order to exercise this warranty, TEGAM, Inc., must be

notified of the defective product before the expiration of the

warranty period. The customer shall be responsible for

packaging and shipping the product to the designated TEGAM

service center with shipping charges prepaid. TEGAM Inc. shall

pay for the return of the product to the customer if the

shipment is to a location within the country in which the

TEGAM service center is located. The customer shall be

responsible for paying all shipping, duties, taxes, and

additional costs if the product is transported to any other

locations. Repaired products are warranted for the remaining

balance of the original warranty, or 90 days, whichever period

is longer.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

6-3

Page 39

SERVICE INFORMATION

Warranty Limitations

The TEGAM, Inc. warranty does not apply to defects resulting

from unauthorized modification or misuse of the product or

any part. This warranty does not apply to fuses, batteries, or

damage to the instrument caused by battery leakage.

The foregoing warranty of TEGAM is in lieu of all other

warranties, expressed or implied. TEGAM specifically disclaims

any implied warranties of merchantability or fitness for a

particular purpose. In no event will TEGAM be liable for special

or consequential damages. Purchaser’s sole and exclusive

remedy in the event any item fails to comply with the

foregoing express warranty of TEGAM shall be to return the

item to TEGAM; shipping charges prepaid and at the option of

TEGAM obtain a replacement item or a refund of the purchase

price.

Statement of Calibration

This instrument has been inspected and tested in accordance

with specifications published by TEGAM, Inc. TEGAM, Inc.

certifies the above listed instrument has been inspected and

calibrated and meets or exceeds all published specifications

and has been calibrated using standards whose accuracies are

traceable to the International System of Units (SI) through

the National Institute of Standards and Technology (NIST) or

other recognized National Metrology Institutes.

Contact Information

TEGAM INC.

10, TEGAM WAY

GENEVA, OHIO 44041

CAGE Code: 49374

WEB: http://www.tegam.com

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110

• sales@tegam.com

6-4

Loading...

Loading...