Page 1

PS-CAL®

Power Sensor Calibration Software

10 T

EGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

Instruction Manual

PN# PS-CAL-900

Publication Date: February, 2018

REV. B

Page 2

TEGAM is a manufacturer of electronic test and measurement equipment for metrology, calibration, and

production test. We also provide repair, calibration, and other support services for a wide variety of test

and measurement equipment including RF power sensor calibration systems, RF attenuation measurement

systems, ratio transformers, arbitrary waveform generators, micro-ohmmeters, LCR meters, handheld

temperature calibrators, thermometers, humidity and temperature control devices, and more.

TEGAM also repairs and calibrates test and measurement equipment formerly manufactured by ElectroScientific Industries (ESI), Gertsch, Keithley Instruments, Lucas Weinschel, and Pragmatic Instruments. A

complete list can be viewed on our Product Service Directory at www.tegam.com

For more information about TEGAM and our products, please visit our website at www.tegam.com

contact one of our customer service representatives at sales@tegam.com or 800-666-1010.

: or

10 TEGAM Way,

Geneva, Ohio 44041

Telephone: (440) 466-6100

Fax: (440) 466-6110

E-mail: sales@tegam.com

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

Page 3

Section Page

I. License Agreement

II. Installation

III. Workstation Configuration

IV. Operating I nstructions

Table of Contents

Agreement ......................................................................................... 1-1

Overview............................................................................................ 2-1

Installing .NET Framework.................................................................... 2-1

Installing VISA Libraries ....................................................................... 2-1

Installing PS-CAL ................................................................................ 2-1

First Run ............................................................................................ 2-1

Measurement Methodology Selection ..................................................... 3-1

Station Configuration ........................................................................... 3-1

Editing Calibration Data for Standards ................................................... 3-2

Editing Power Sensor Data ................................................................... 3-2

Editing Power Splitter Data ................................................................... 3-4

Editing Thermistor Mount Data .............................................................. 3-5

Creating a Data Template ..................................................................... 4-1

Loading a Calibration Template ............................................................. 4-3

Setting Additional Parameters ............................................................... 4-3

Running a Calibration .......................................................................... 4-5

Saving Calibration Data........................................................................ 4-6

Uploading Ca libration Data ................................................................... 4-6

Printing a Calibration Label ................................................................... 4-7

Printing a Calibration Report ................................................................. 4-8

Batch Mode Operation .......................................................................... 4-9

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

Page 4

!

!

l

O

Off

Safety Information & Precautions:

The following safety information applies to both operation and service personnel. Safety precautions and

warnings may be found throughout this instruction manual and the equipment . These warnings may be in

the form of a symbol or a written statement. Below is a summary of these precautions.

Terms in This Manual:

CAUTION statements identify conditions or practices that could result in damage to the equipment or

other property.

WARNING statements identify conditions or practices that could result in personal injury or loss of life.

Terms as Marked on Equipment:

CAUTION indicates a personal injury hazard not immediately accessible as one reads the marking, or a

hazard to property including the equipment itself.

DANGER indicates a personal injury hazard immediately accessible as one reads the marking.

Symbols:

As Marked in This Manual:

This symbol denotes where precautionary informa t io n may be found.

As Marked on Equipment:

CAUTION – Risk of Danger

DANGER – Ri sk of El ectr ic Shock

Earth Ground Terminal

On

Frame or Chassis Terminal

Earth Ground Terminal

Alternating Current

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

Page 5

Section I – License Agreement

License

This License Agreement (Agreement) is a legal agreement between you the Customer (either an individual

or a single entity) and Cal Lab Solutions, Inc. for the software product contained in this package and

online or electronic documentation and may include associated media and printed materials (S OFTWARE

PRODUCT or SOFTWARE). By installing, copying, or otherwise using the SOFTWARE PRODUCT, you agree

to be bound by the terms of this Agreement. If you do not agree to the terms of this Agreement, do not

install or use the SOFTWARE PRODUCT.

1. GRANT OF LICENSE.

This Agreement grants you certain limited, non-exclusive rights. Ca l Lab So lutions, Inc. reserves all rights

not expressly granted to you. This software is licensed for unlimited use at the company’s location as

identified by Customer as the ship-to location of the software. There are no limitations to the number of

client workstations that can run this software at a single company location.

2. COPYRIGHT.

All rights, title, and copyrights in and to the SOFTWARE PRODUCT (including, but not limited to, any

images, photographs, animations, video, audio, music, text, and "applets" incorporated into the

SOFTWARE PRODUCT) and any copies of the SOFTWARE PRODUCT are owned by Cal Lab Solutions, Inc.

or its suppliers. The SOFTWARE PRODUCT is protected by copyright la ws and international treaty

provisions. Therefore, you must treat the SO FTWARE PRODUCT like any other copyrighted material,

except that you may make one copy of the SOFTWARE PRODUCT solely for backup or archival purposes.

You may not copy the printed materials accompanying the SOFTWARE PRODUCT.

3. DESCRIPTION OF OTHER RIGHTS AND LIMITATIONS.

a. Limitations on Reverse Engineering, Decompilation, and Disassembly. You may not reverse engineer,

decompile, or disassemble the SOFTWARE PRODUCT, except and only to the extent that such activity is

expressly permitted by applicable law notwithstanding this limitation.

b. Rental. You may not rent or lease the SOFTWARE PRODUCT.

c. Software Transfer. This software is licensed to a single company; you may not transfer, sell or

redistribute this software to any parties outside your company or organization.

d. Termination. Without prejudice to any other rights, Cal Lab Solutions, Inc. may terminate this

Agreement if you fail to comply with the terms and co nd itions of this Agreement. In such event, you must

destroy all copies of the SOFTWARE PRODUCT and all of its comp onent parts.

4. EXPORT RESTRICTIONS.

You agree that neither you nor your customers intend to or will, directly or indirectly, export or transmit

(a) the SOFTWARE PRODUCT or related documentation and technical da ta , or (b) your Application as

described in Section 1 of this Agreement (or any part thereof), or process, or service that is the direct

product of the SOFTWARE PRODUCT to any country to which such export or transmission is restricted by

any applicable U.S. regulation or statute, without the prior written consent, if required, of the Bureau of

Export Administration of the U.S. Department of Commerce, or such other governmental entity as may

have jurisdiction over such export or transmission.

5. U.S. GOVERNMENT RESTRICTED RIGHTS.

The SOFTWARE PRODUCT and documentation are provided with RESTRICTED RIGHTS. Use, duplication, or

disclosure by the Government is subject to restrictions as set forth in subparagraph (c)(1)(ii) of The Rights

in Technical Data and Computer Software clause at DFARS 252.227-7013 or subparagraphs (c)(1) and (2)

of the Commercial Computer Software - Restricted Rights at 48 CFR 52.227-19, as applicable.

Manufacturer is Cal Lab Solutions, Inc., a Colorado company.

6. MISCELLANEOUS.

If you acquired this product in the United States, this Agreement is governed by the laws of the State of

Colorado. Should you have any questions concerning this Agreement, or if you desire to contact Cal Lab

Solutions, Inc. for any reason, please contact our website at http://www.CalLabSolutions.com

sales@callabsolutions.com.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

1-1

or

Page 6

Section II – Installation

Installation Overview

In order to run the PS -Cal software all of the supporting software and hard w a re must first be installed on

the workstation. Along with the PS-Cal software, all of the required software is shipped on the PS-Cal CD.

On the CD you will find the following files and directories: PS-Cal.exe, SetupPS-Cal.msi, setup.exe, PSCAL-900.pdf (most current revision), licenseAgreement.pdf, changelog.pdf, and R&S Files-.

Installing .Net Framework

PS-Cal requires Microsoft .Net® 4.0 Framework or higher. If necessary, update the workstation .Net

installation at microsoft.com.

Installing Proper VISA Libraries

PS-CAL is designed to work will any VISA library. Use the manufacturer VISA installations for your

hardware requ irements.

Example: If using National Ins truments GPIB-USB-HS you would need the National Instruments VISA

libraries.

Installing PS-CAL

Once .Net Framework and VISA libraries are installed, use the Setup.exe found on the PS-CAL installation

disk to install the PS-Cal software.

First Run

Power sensor calibration templates must be installed before using PS-Cal. When running PS-Cal for the

first time, select Tools -> Generate Blank Templates. PS-Cal will generate blank templates for all

supported sensors and display a notification once it completes its process.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

2-1

Page 7

Section III – Work St a tion Configuration

Measurement Methodology Selection

PS-Cal allows for multiple power sensor calibration methodologies. When using with TEGAM hardw are the

RFBridge_MultiRun methodologies should be used.

Station Configuration

PS-Cal maintains a station configuration file on the local hard drive storing a list of the standards used and

the VISA resource string / GPIB address of the standard.

To open the station configuration file, select Configuration -> Edit Configuration

The Available Drivers list on the left hand side contains a list of all the standard s this version of PS-Cal

supports. The Configured Drivers list on the right lists all the standards configured on this station. This

list contains the name of the driver followed by the instance of the driver. The instance of the driver is

used to distinguish instruments in configuration us ing two or more standards of the same type. For

example, if the station is configured with two TEGAM 1830A’s, the Configured Drivers list would contain

two configuration lines, “TEGAM 1830A” and “TEGAM 1830A”.

Note: Only the standards listed in the Configured Drivers list are available for use in PS-Cal. All

drivers must be configured before they are available in the template configuration wizards.

The Driver Details section of the form shows the configuration details for this instrument. Each driver

must be configured with an Instance and Resource String.

The Instance must contain a number that uniquely identifies the driver / instrument. Typically, the first

instrument used is 1 and any other instruments of the same type are 2, 3, 4, etc.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

Figure 3.1 Station Configuration

3-1

Page 8

Section III – Work St a tion Configuration

The Resource String is a standard VISA resource string. The Resource String defines how PS-Cal will

communicate with the instrument. Typically, instrument communication is d one over the GPIB bus, but

PS-Cal is able to communicate with instruments via Ethernet, USB and RS-232. The VISA resource string

is a strictly formatted string. GPIB configured instruments are formatted as follows:

GPIB<Card Number>::<GPIB Address>::INSTR.

Note: Refer to the National Instruments VISA documentation for configuration formats for Ethernet , RS232 and USB instruments.

The second tab on the Station Configuration form also contains a list of global station variables. PS-Cal

uses the variables as global variables to set values, custom configurations and execution options.

Figure 3.2 Station Variables

After the Station Configuration has been edited, the data can be saved back to the configuration files

by pressing the Save and Close button.

Editing Calibration Data for Standards

The exact data required for each standard varies depending on the Measurement Methodology being used

and configuration of the test station. PS-Cal has a set of forms to help users manage the calibration data

associated with the station’s standards.

Editing Power Sensor Data

To edit calibration data files for a power sensor standard select Configuration -> Edit Standard Data > Power Sensor in the menu. PS-Cal opens a file dialog box.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

3-2

Page 9

Section III – Work St a tion Configuration

By default, the Power Sensor Calibration Data files are stored in the “C:\PS-Cal_V4\Standards\” directory.

If you are creating Data files for the first time, you can load a blank data file from the “C:\PSCal_V4\_Blank Templates\” directory.

Navigate to the directory where the data file is stored for the sensor file you wish to edit or view, select

the file, and then press Open.

Figure 3.3 Editing Power Sensor Data

PS-Cal loads the data into a Power Sensor Data Edit form. This form allow s the user to update the rho

and cal factor data, each with their own tab on the edit form. The exact data that m ust be entered varies,

depending on the measurement methodology used to test the UUT power sensors. Refer to the

Measurement Methodology to determine exactly what data is required. When in doubt, enter data in all

the data fields.

Figure 3.4 Editing Power Sensor Data GUI

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

3-3

Page 10

Section III – Work St a tion Configuration

When finished editing the data, press the Save button to save the data back to disk. Once the data is

saved, press the Close button to exit the form.

Editing Power Splitter Data

To edit calibration data files for a power Splitter standard, select Configuration -> Edit Standard Data > Power Splitter in the menu. PS-Cal opens a file dialog box. By default, the Power Splitter Calibration

Data files are stored in the “C:\PS-Cal_V4\Standards\” directory. If you are creating Data files for the first

time, you can load a blank data file from the “C:\PS-Cal_V4\_Blank Templates\” directory (see Creating

Templates for more information). Navigate to the directory where the data file is stored for the splitter file

you wish to edit or view, then press Open.

Figure 3.5 Editing Power Splitter Data

PS-Cal will load the data into a Power Splitter Data Edit form. This form allows the user to update the

header, S11, S22, S33, S21 and S31 data, each with their own tab on the form. The exact data that must

be entered varies depending on the measurement methodology used to test the UUT power sensors.

Refer to the Measurement Methodology section to determine exactly what data is required. When in

doubt enter all the data fields.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

Figure 3.6 Editing Power Splitter GUI

3-4

Page 11

Section III – Work St a tion Configuration

When finished editing the data, press the Save button to save the data back to disk. Once the data is

saved, press the Close button to exit the form.

Editing Thermistor Mount Data

To edit calibration data files for a power splitter standard, select Configuration -> Edit Standard Data > Bolometer \ Mount in the menu.

Figure 3.7 Editing Thermistor Mount Data

PS-Cal opens an edit form with three tabs on the top, Load Data, Import Data and New Data. The

Load Data tab allows the user to load existing PS-Cal formatte d data f iles from the hard drive for editing.

The Import Data tab allows the user to import data from various formats and converts the format to a

PS-Cal compatible format. The New Data tab allows the user to create a blank data file.

To load a TEGAM-formatted data file, select Import Data. In the Data Format field, select TEGAM.dat.

Click the Import Dat button, navigate to the Standards directory in the resulting dialog box. Select the

appropriate TEGAM data file and click Open.

PS-Cal will import the information from the selected data file. To ve rify the data, click the Data tab to see

the imported values.

Click Save to save the data as a PS-Cal-compatible file.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

3-5

Page 12

Section IV - Operatin g Inst ru ct ions

Creating a Calibration Template

PS-Cal is a template-driven calibration package. This allows you to create several calibrat ion

configurations and s ave each configuration as a separate template. To recall a configuration in the future,

simply load the appropriate template.

Blank templates are created in PS-Cal by clicking Tools -> Create Blank Templates. These bl a n k

templates are stored in the “C:\PS-Cal_V4\_Blank Templates\” directory.

Figure 4.1 Creating a Calibration Template

The first step in creating a calibration template is to open a blank template. In the PS-CAL menu, select

File -> Load and navigate to the “C:\PS-Cal_V4\_Blank Templates\” directory. Select the blank

template of the power sensor model you are creating a calibration template for and press Open.

PS-Cal reads the required tests from the blank temple and prompts you for details on the Measurement

Methodology and standards you will use for this calibration. The required test steps for each power sensor

vary based on the manufacturer’s written requirements. PS-Cal prompts you through the calibration steps

including rho, cal factors, linearity, and EEPROM read / write.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

4-1

Page 13

Section IV - Operatin g Inst ru ct ions

Figure 4.3 Select a Compatible

Figure 4.2 Select a Measurement Method

In the Select Measurement Method form, PS-Cal displays a list of available Measurement Met hodologies

in the top section. As you select each Measurement Methodology, PS-Cal updates the lower section of the

form with the details of the Measurement Methodo logy . Once you have decided on the Measurement

Methodology, select it and press Continue.

NOTE: For Cal Factor tests using the TEGAM 1806(x) Type IV Power Meters or the 1830A RF Thermistor

Power Meter, select from the RFBridge_Multirun methodologies.

Since each Measurement Methodology has differing standard requirements, PS-Cal prompts you for each

standard required by the Measurement Methodology. In the Select Compatible Driver form, PS-Cal

displays a list of configured instruments/drive rs compatible with Measurement Methodology. If you do not

see your standard/driver in the list, it may not be configured. You can edit the station configuration by

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

Driver

4-2

Page 14

Section IV - Operatin g Inst ru ct ions

pressing the Station Configuration button (see section on Station configuration). Once you have

decided on the driver you want to use, select it and press Continue.

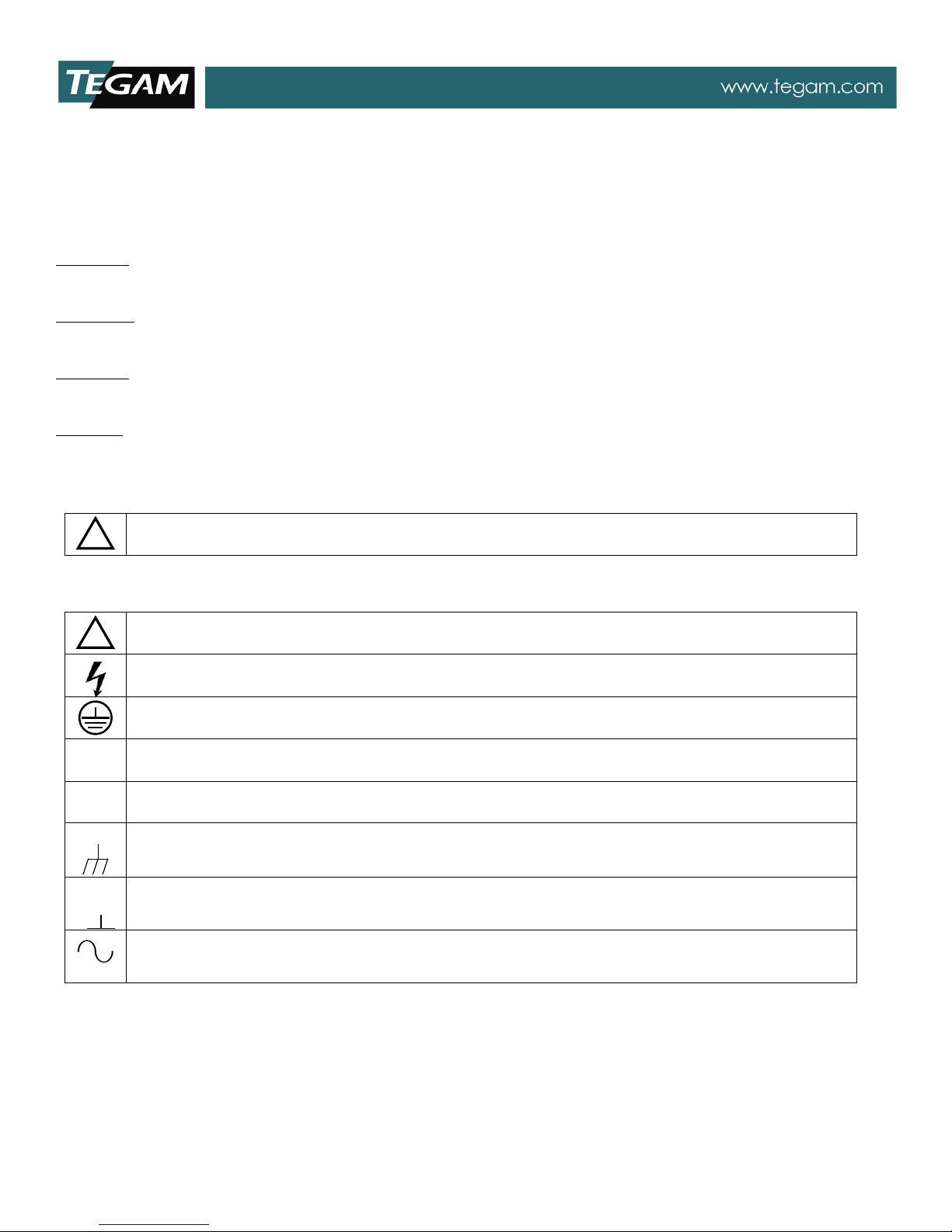

After all the Standards have been selected in PS-Cal, you are prompted to set the test parameters for the

test group. These parameters configure the specific options of the test methodology allowing you to fine

tune the specifics of each test methodology. For specifics on each option, see the supporting test

methodology documentation.

Note: Test parameters are editable after the template has been configured. Most test methodologies have

a PARAM button which loads the parameters window.

PS-Cal repeats this process of selecting the Measurement Methodology and Drivers until all Measurement

Methodologies and drivers have been configured.

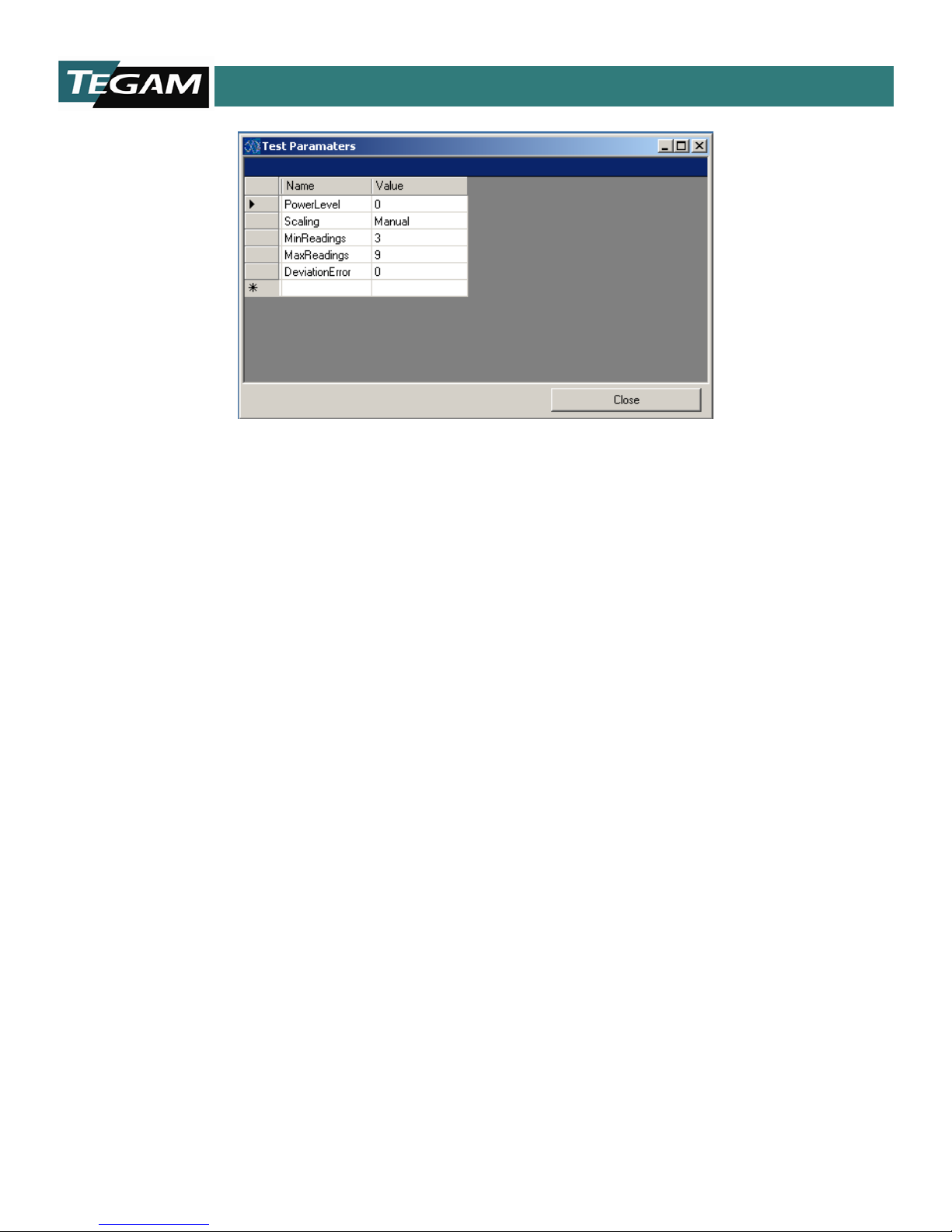

Loading a Calibration Template

To load a calibration template in the PS-CAL menu, select Calibration Template -> Load and navigate

to the “C:\PS-Cal_V4\Calibration Templates\” directory. Select the calibration template of the power

sensor you are calibrating and then press Open.

Setting Additional Parameters in the Calibration Template

After creating a calibration template, there are some additional parameters and data that may need to be

updated. The parameters set variables defining how PS-Cal performs the calibratio n, and they vary with

each test methodology. Though these variables can be set a nd upda ted a t a ny time, for consistency, we

recommend that you update them when the template is first created, and if they are modified later, that

you save the updates back to the template file.

For each test in the power sensor template there is a parameters button on the screen. The parameters

window is opened by pressing the “Param.” button. Simply update the value in the value column and

press Close.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

Figure 4.4 Load a Calibration Template

4-3

Page 15

Section IV - Operatin g Inst ru ct ions

Figure 4.5 Configuring Parameters

In addition to the parameters data, the following values ma y need to be updated before the calibration

template is saved:

1) Uncertainties By default, PS-Cal calculates on the measurement uncertainties and updates the

column if the column contains “- -. “ If you would like PS-Cal to report uncertainties that are on

your scope, you can updat e this column and save the changes back to the template. This will force

PS-Cal to use your uncertainties on all reports.

2) OnLabel For many power sensors that have a calibration label, the calibration template can test

more frequencies than fit on the label. Under the C a l Factor test there is an OnLabel column.

This column controls what frequencies will be printed on the calibration label and the data can be

updated with Yes and No values. PS-Cal ignores this data for power sensors that do not require a

printed Cal Factor label.

Once all the data and parameters are set in the power sensor template, save the template to update it

with the changes. See “Saving a Calibration Template. “

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

4-4

Page 16

Section IV - Operatin g Inst ru ct ions

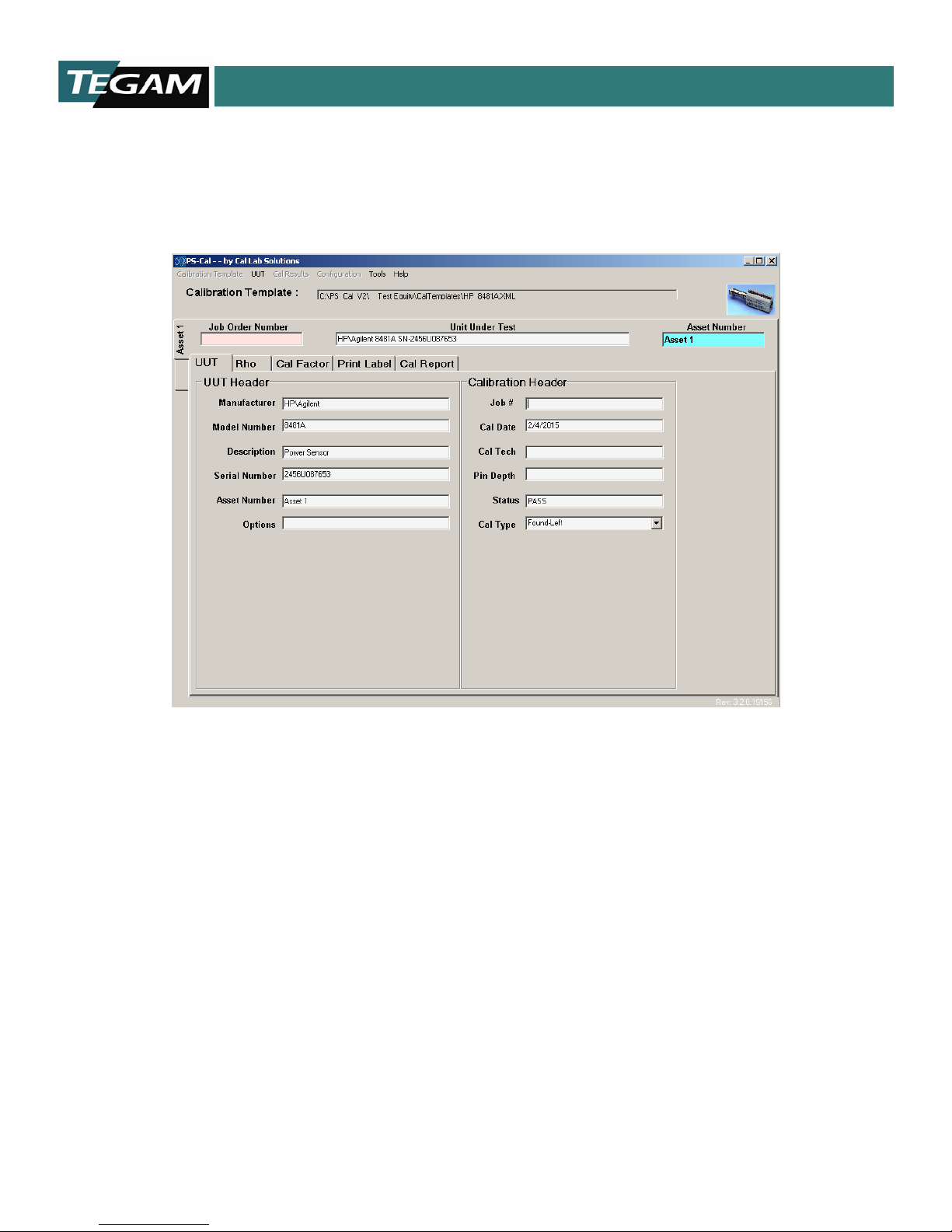

Running a Calibration

Once a power sensor template is loaded, PS-Cal displays one tab for each required test step. The exact

steps required for each power sensor and each measurement methodology vary. These tabs are loaded in

order of operation from left to right.

Figure 4.6 Running a Calibration

Two default tabs are loaded with every power sensor. The first is the UUT tab containing information

about the Unit Under Test (UUT, also known as Device Under Tes t, DUT) and the work order. Data such

as the UUT Serial number, Asset number, Job number, and the Calibration Technician (Cal Tech) w ho

performed the calibration must be updated on this tab.

The last tab is the Cal Report tab, which is used to print the report data for the calibration. Onc e all the

steps between the UUT tab and the Cal Report tab have been completed, the data is ready to print.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

Figure 4.7 Calibration Default Tabs

4-5

Page 17

Section IV - Operatin g Inst ru ct ions

Under each test procedure tab, there is a button bar w ith a button for each of the steps required to

complete that calibration step. Like the tabs, the buttons are organized in step order from left to right.

The exact buttons that appear on the form varies with each test methodology.

Figure 4.8 Calibration GUI

These buttons are enabled and disabled as required by the test procedure. A button remains disabled until

necessary prerequisite steps are performed. For example, the Cal button is turned off until the Configure

Station button has been pressed and the configure station operation has been completed. Then PS-Cal

turns on the Cal button and allows you to go to the next step in the calibration process.

Another button to make a special note of is the Halt button. This button is used to halt the application.

For example, if for some reason something was not hooked up correctly or you just need to stop the

program, simply press the Halt button and PS-Cal will stop executing the calibration steps and reset all

the standards to a safe state.

Saving Calibration Data

After you have completed a calibration (or at any point during the calibration), you can save the

calibration data to disk. We recommend you save your calibration data often, to prevent loss of data due

to a power outage or power failure.

To save your cal ibration data

1. Select UUT -> Save As and navigate to the “C:\PS-Cal_V4\CalResults\” directory.

2. Enter the file name of the calibration data you are saving (we recommend you use a standard

naming conventions of either <JobNumber>.xml or <AssetNumber><CalDate>.xml).

3. Press Save.

Uploading Calibration Data

If the sensor has an EEPROM (Electronic, Erasable Programmable Read Only memory), you can upload the

calibration data to the sensor.

To upload the calibration data:

1. Click the Upload Data tab.

2. Click the Download Data button. This brings up the data for viewing. You will also see the word

“Ready!” indicating that the data is now available for upload to the EEPROM on the sensor.

3. Click the Save/Backup Sensor Data to File button. This makes sure that the data is saved, in

case there is a malfunction with the sensor prior to uploading.

4. Select whether to upload the data for

a. Header

b. Cal Factors

c. Linearity

5. Click the Upload Cal Data button. A dialog box prompts you to cycle the power on the power sensor.

Note: to test that the data uploaded correctly, after cycling power on the sensor, with the sensor still

connected, click the Download Data button.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

4-6

Page 18

Section IV - Operatin g Inst ru ct ions

Printing a Calibration Label

If the sensor is a non-EEPROM based sensor (it does not have an Electronic, Erasable Programmable Read

Only memory), it may require a calibration label to be printed. In order to print the calibration label you

must have a compatible label printer. Once all the calibration steps have been completed the power

sensor calibration label is ready to be printed.

To print the calibration label:

6. Select the Print Label tab of the power sensor being calibrated. Under this is a report viewer tool

used to generate the label. PS-Cal supports several different label sizes.

7. Select the report size from the drop down.

8. Press the Run Report button. PS-Cal presents a print view of the report in the Report Viewer

window.

9. To print the report, press the Print button.

Note: If the report is generating a two page label, remove test points from the label by editing the

OnLabel under the Cal F ac t ors tab. Columns that contain “Yes” in the OnLabel field will be

printed on the label.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

4-7

Page 19

Section IV - Operatin g Inst ru ct ions

Printing the Calibration Report

Once all the steps of a calibration are completed, the results of the calibration are ready to be printed.

The last tab on the form is the Cal Report tab, which combines all the data from each tab into one single

report.

Figure 4.9 Print Calibration Report

To print the Calibration Report:

1. Select the Cal Report tab

2. Press the Run Report button. PS-Cal presents a print view of the report in the Report Viewer

window.

3. To print the report, press the Print button.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

Figure 4.10 Calibration Report Preview

4-8

Page 20

Section IV - Operatin g Inst ru ct ions

PS-CAL in Batch Mode

PS-Cal is able to calibrate power sensors in batch mode. Though PS-Cal can only calibrate a single sensor

at a time, Batch Mode allows the operator to configure that station to test one power sensor, and then use

that configuration to calibration the next sensor in the batch. This process saves time, because many

power sensor calibration configuration steps are time consuming.

Figure 4.11 Batch Mode

To use PS-Cal in Batch Mode:

1. Click on UUT in the menu bar

2. Select New.

This adds an Asset tab.

3. Label the tab by selecting it, and then selecting the UUT tab, and entering the asset number in the

Asset Number field.

4. The new asset tab is now labeled.

You can now select the newly added asset by clicking its tab along the left. Configuration information and

data collected on one power sensor is shared with all the power sensors that are open.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

4-9

Loading...

Loading...