Page 1

4040A

50 MHz PXI Differential

Instrumentation Amplifier

MODEL 4040A

NOTE: This User’s Manual was as current as possible when this product was manufactured. However, products

are constantly being updated and improved. To ensure you have the latest documentation, refer to

www.tegam.com.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

Instruction Manual

PN# 4040A-840

Publication Date: June 2012

REV. E

Page 2

TABLE OF CONTENTS

TABLE OF CONTENTS

1 INSTRUMENT DESCRIPTION

Instrument Description .............................................................................1-1

Figure 1.1: Block Diagram of the 4040A .................................................1-1

Performance Specifications ........................................................................1-2

Functional Considerations ..........................................................................1-4

Frequency Response Curves ......................................................................1-5

2 PREPARATION FOR USE

Unpacking & Inspection.............................................................................2-1

Safety Information & Precautions ...............................................................2-1

Terms in this Manual ...........................................................................2-1

Terms as Marked on Equipment ............................................................2-1

Grounding the 4040A ...........................................................................2-2

Danger Arising from the Loss of Ground .................................................2-2

Do not Use in Explosive Environments ...................................................2-2

Power Source .....................................................................................2-3

3 OPERATING INSTRUCTIONS

PXI Installation ........................................................................................3-1

Front Panel Description .............................................................................3-2

4 SOFTWARE

5 SERVICE INFORMATION

Cleaning .................................................................................................5-1

Performance Verification Procedure ............................................................5-1

Computer Set-up ................................................................................5-2

CMMR ................................................................................................5-2

Offset Adjustment ...............................................................................5-4

DC Gain .............................................................................................5-6

AC Gain .............................................................................................5-7

Parts Replacement ...................................................................................5-12

Preparation for Calibration or Repair Service ................................................5-12

Expedite Repair and calibration Form ..........................................................5-13

Warranty .................................................................................................5-14

Warranty Limitations ...........................................................................5-14

Statement of Calibration ......................................................................5-14

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

I

Page 3

INSTRUMENT DESCRIPTION

SECTION 1

INSTRUMENT DESCRIPTION

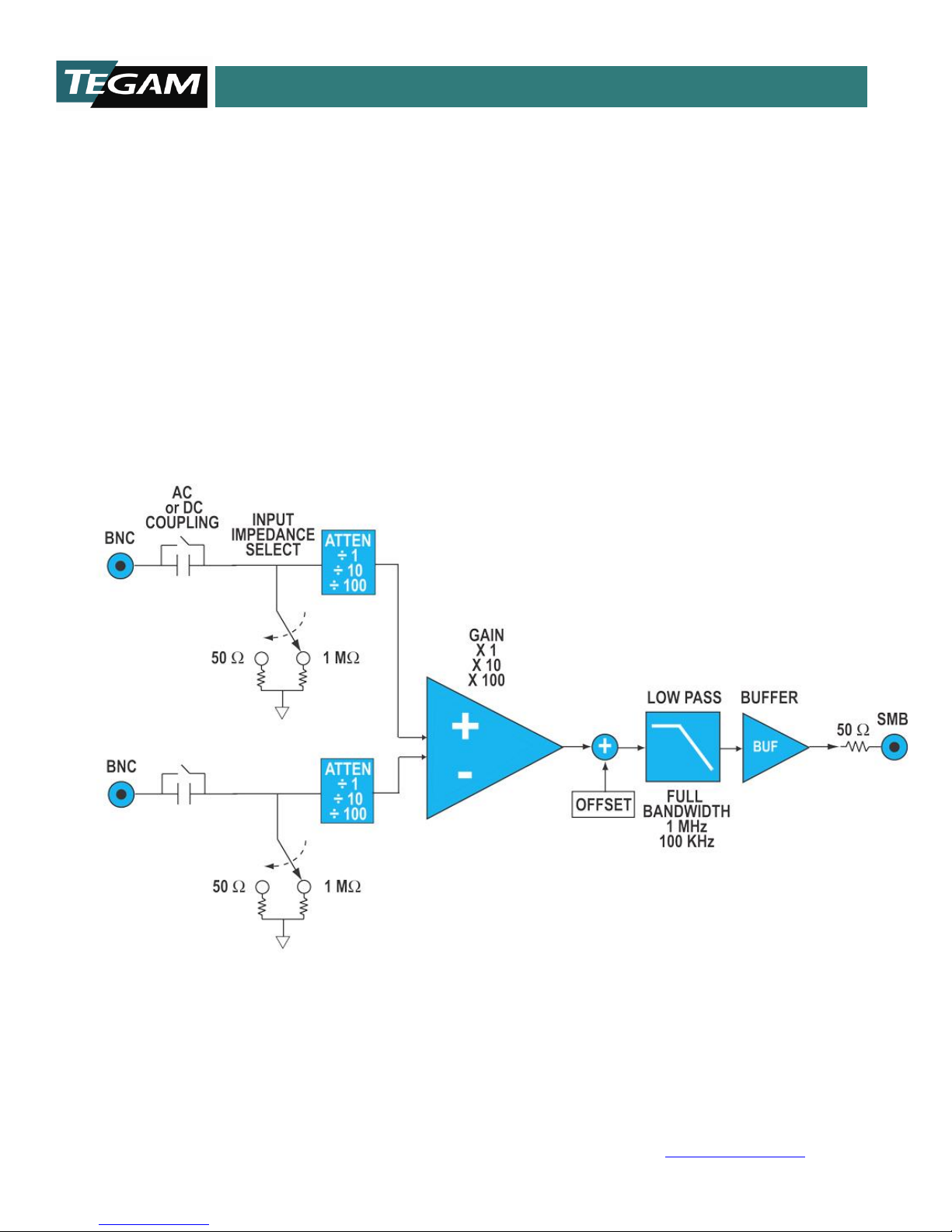

The 4040A is a single channel, differential input amplifier capable of high gain and equally high

attenuation values with a bandwidth from DC-50 MHz. The Model 4040A is capable of operating with

gains of x1, x10, and x100 in conjunction with attenuation by factors of: ÷1, ÷10, and ÷100. These

levels of gain and attenuation may be used in combination to condition a differential input signal so

that it matches the needed input of a low-level device such as a digitizer or oscilloscope. There is a

more in depth explanation contained in the specification section. In addition, the 4040A provides

programmable offset, anti-aliasing filters, input impedance and input coupling. Figure 1.1 is a block

diagram of the 4040A. The 4040A has been specifically designed to take two signals and make a valid

differential measurement by inverting one of the signals and adding the difference, this allows the user

to measure signals not referenced to local ground without compromising safety.

Figure 1.1: Block Diagram of the 4040A

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

1-1

Page 4

INSTRUMENT DESCRIPTION

Net Gain

Input

Attenuation

Internal

Amplifier

Gain

Peak AC Input

Amplitudes

(V) d per

channel

a,b,c,d

Max

Differential

Voltage (V)

w/o clipping

a,b,c,d

Max

Volts to

Chassis

a,b,c

Noise,

Referred to

Input

-3 dB

Bandwidth

÷100

÷100

X1

< 100

< 100

100 V

990 nV/√Hz

20 MHz

÷10

÷10

X1

< 10

< 10

40 V

99 nV/√Hz

20 MHz

÷10

÷100

X10

< 10

< 10

100 V

990 nV/√Hz

50 MHz 1 ÷1

X1

< 1

< 1

4 V

9 nV/√Hz

20 MHz

1

÷10

X10

< 1

< 1

40 V

99 nV/√Hz

50 MHz

1

÷100

X100

< 1

< 1

100 V

990 nV/√Hz

20 MHz

10

÷1

X10

< 0.1

< 0.1

4 V

9 nV/√Hz

50 MHz

10

÷10

X100

< 0.1

< 0.1

40 V

99 nV/√Hz

20 MHz

100

÷1

X100

< 0.01

< 0.01

4 V

9 nV/√Hz

20 MHz

a. DC Coupled, 1 MΩ input

b. AC Coupled, 1 MΩ input: DC + Peak AC not to exceed 100 V; Peak AC component not to exceed table

c. 5 Vrms max into 50 Ω

d. DAC offset adjustment to zero

PERFORMANCE SPECIFICATIONS

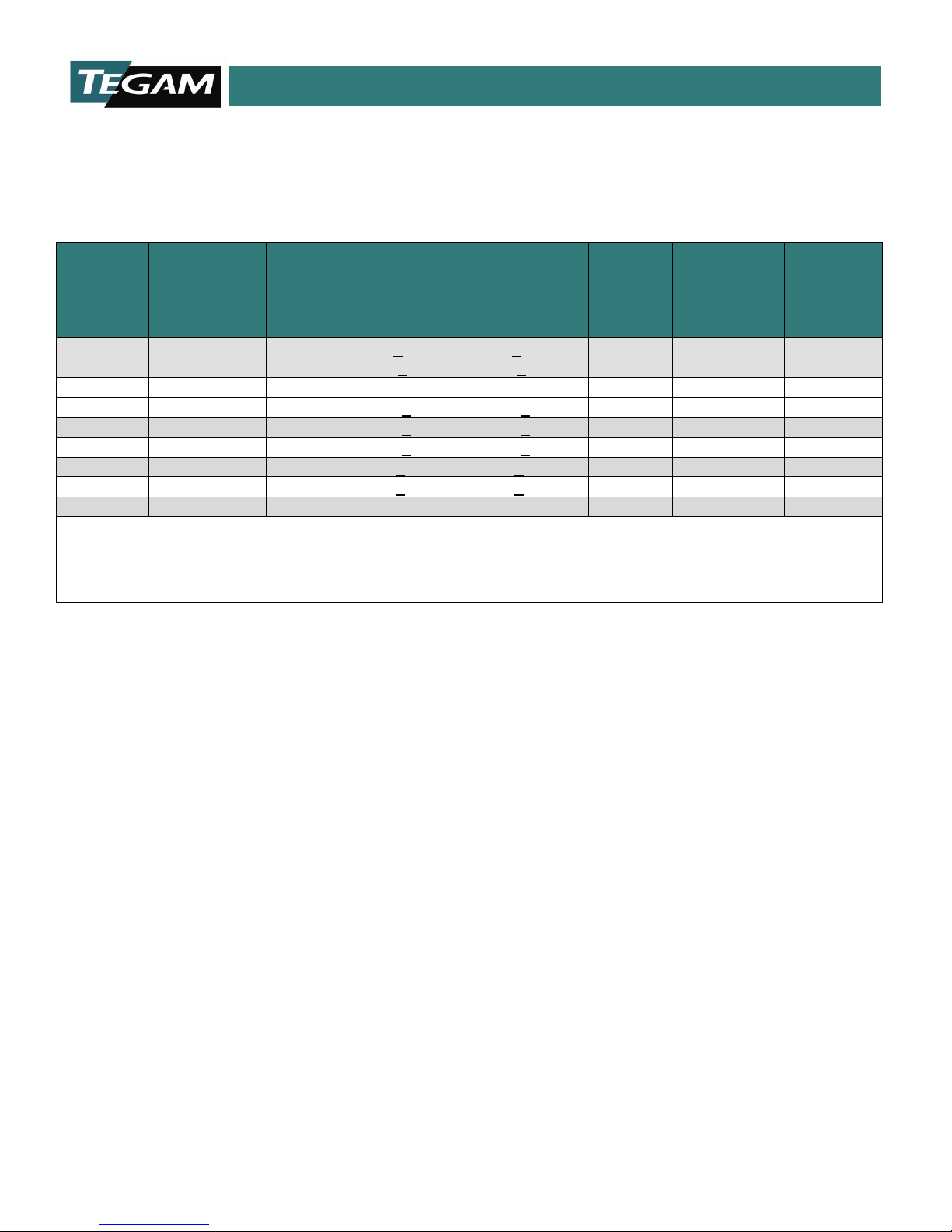

The multiple gain and attenuation settings of the 4040A interact to affect the performance in terms of

bandwidth and noise. Table 1.1 shows the various combinations and how these settings modify what

can be expected from the 4040A.

Table 1.1: Various Combination Possibilities of the 4040A

As an example, a total system gain of X1 can be achieved three different ways depending on the signal

requirements through attenuating and amplifying by different amounts. Choosing the best combination

involves trade offs in input amplitude, bandwidth and signal to noise ratio. Noise increases with higher

levels of attenuation because the noise specification is referred to the input. In relative terms the

signal to noise ratio is basically constant.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

1-2

Page 5

INSTRUMENT DESCRIPTION

Input Specifications Value Clarification

Channels Single Channel Differential Input

Gains 100, 10, 1, 0.1, 0.01

Maximum Voltage Range ±100 V DC + Peak AC

Coupling AC, DC In AC 10 Hz and above

Input Impedance 1 MΩ | | 20 pF, 50 Ω ±1%, Selectable

Input Voltage Range ±100 V For Gain 0.01 @ 1 MΩ Input Impedance

±10 V For Gain 0.1 @ 1 MΩ Input Impedance

±5 V For Gain 0.1 @ 50 Ω Input Impedance

±1 V For Gain 1

±0.1 V For Gain 10

±0.01 V For Gain 100

Connection Type BNC Jacks 50 Ω, Quantity 2

Common Mode Rejection Ratio

(CMRR) 77 dB at 60 Hz For Gain setting of x1, x10 and x100 & Attenuation

(> 50 dB at 1 MHz) setting of ÷1

57 dB at 60 Hz For Attenuation setting of ÷10

37 dB at 60 Hz For Attenuation setting of ÷100

Total Harmonic Distortion <-60 db @ 1 MHz Output 1 Vp-p into 50 Ω

DC Gain Accuracy ± (0.1% |input| + 100 µV) Offset set to 0 for Gain 10, 1, 0.1, 0.01

± (1.5% |input| + 300 µV) Offset set to 0 for Gain 100

(Basic) AC Gain Accuracy ±0.15 dB Attenuation of 1, Gain of 1,

See Figures 1.2, 1.3 and 1.4 for other settings

Over-voltage Protection ±100 V DC + Peak AC

(In Any Range)

Offset Range 0 to ± Full Scale Full Scale output of ±1 V into 50 Ω,

All Gain Ranges

Offset Resolution 38 µV per step 65,535 total DAC steps into 50 Ω

Offset Accuracy ±(0.5% of |Setting| + 300 µV) Referenced to 1 V Range

Temperature Stability ±(0.01% of |rdg| + 40 µV)/°C All Gain Ranges

Noise 9 nV/√Hz CMR=±1 V, Gain 10 and 100

Referred to Input for Frequencies >100 Hz

Rise Time ≤3.5 ns

Output Specifications Value Clarifications

Maximum Output Voltage ±1 V Single Ended into 50 Ω

Connection Type SMB Jack 50 Ω

Output Impedance 50 Ω ±1%

LP Filter, Cutoff Frequency 100 kHz, 1 MHz Single Pole Filter

Bandwidth See Table 1.1

Passband Flatness See Figures 1.2, 1.3 and 1.4 Limits off charts will not exceed ±3 dB for the

for limits Bandwidths listed in Table 1.1

Environmental

Specifications Value

Operating Temperature 0 °C to +45 °C, (32 °F to 113 °F) Ambient

Storage Temperature -20 °C to +50 °C (-4 °F to +122 °F)

Humidity Range <80% RH Non-Condensing

Warm-up Time 30 minutes

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

1-3

Page 6

INSTRUMENT DESCRIPTION

Functional Considerations

Voltage & Current Limitations

In general, the maximum input voltage of the 4040A should not exceed ±100 V (200 Vp-p) when the

input terminator is set to 1 MΩ. However, some settings will produce incorrect results at lower

voltages. This occurs when the input signal or gain setting is too high and causes the output amplifier

to clip the signal. An example of this would be measuring a 10 V signal with the gain set to x100.

Mathematically this results in a 1000 V signal which clearly exceeds the 2 Vp-p rating of the output

amplifier. See Table 1.1 for a table of appropriate input voltages for given combinations of gain and

attenuation. No damage would occur to the 4040A or to a digitizer connected to it if the input range

was exceeded, but the signal would be distorted. A signal in excess of 100 V would cause the onboard

voltage limiting circuitry to activate and also create distortion.

There are other considerations when the 4040A is configured with the 50 Ohm input termination. The

input voltage is limited to a maximum of ±5 Vrms. This is due to the power limitations of the

terminator which is 2 W. To preserve the signal integrity and bandwidth of the amplifier the 50 Ohm

terminator is protected with surface mount single use fuses.

Important: Exceeding the rating of the input in this case requires the 4040A to be returned to the

factory for service.

Frequency Characteristics

The 4040A is capable of amplifying mill-volt level signals with a bandwidth from DC to 50 MHz. Some

combinations of gain and attenuation will limit the bandwidth to 20 MHz. See Table 1.1 for a complete

list of settings and the expected bandwidth. In addition, AC coupling rolls off the low frequencies at 10

Hz.

Two anti-aliasing low pass filters are included and tuned for 100 KHz and 1 MHz. These are first order

filters that roll off at 20 dB per decade.

Offset Adjustment

The 4040A includes a programmable offset adjustment that operates on the signal after the gain

stage. The resolution of the adjustment is 38 µV and can offset the signal ±1 V which is the entire

range of the output amplifier. It is not able to effectively offset a signal that exceeds the input range of

a given gain and attenuation setting.

Selecting Gains and Ranges

The amplitude of the signal being measured is the primary consideration when selecting the

appropriate gain and attenuation settings. As an example: A 100 mV signal that is riding on 42 V can

be effectively measured with an attenuation setting of ÷100 and a gain setting of x10. This is because

the differential operation of the 4040A rejects the 42 V common mode signal and only amplifies the

difference producing an output signal of 1 V. If the signal of interest was the 42 V itself the 4040A

should be configured with an attenuation of ÷100 and a gain of x1 producing an output signal of 0.42

V. The 4040A attenuates the signal prior to amplification.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

1-4

Page 7

INSTRUMENT DESCRIPTION

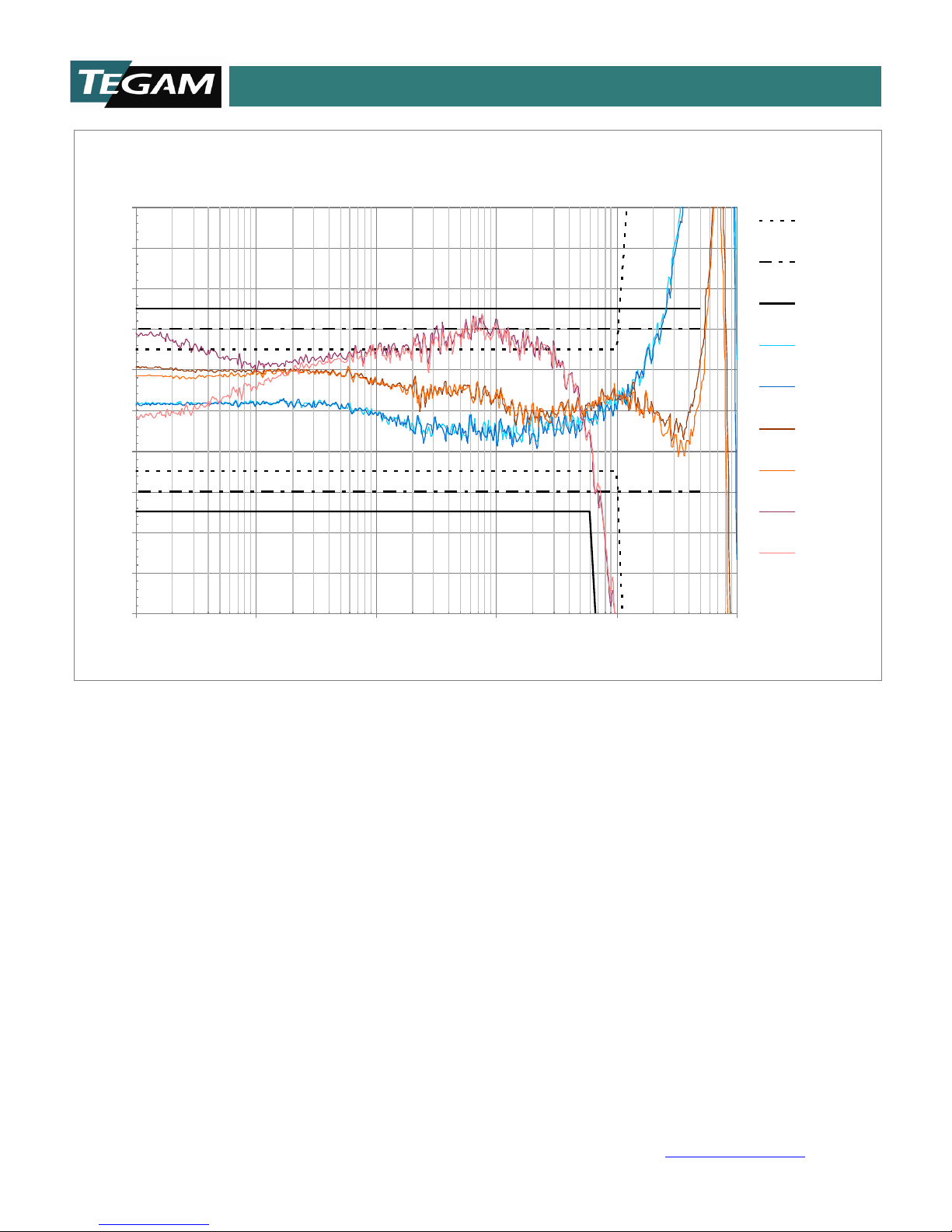

Gain Deviation from Nominal (No Attenuation)

(Typical Data and Test Limits)

-0.5

-0.4

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0.4

0.5

1.0E+03 1.0E+04 1.0E+05 1.0E+06 1.0E+07 1.0E+08

Frequency (Hz)

Gain Error (dB)

1/1 Li mit

10/1 Li mi t

100/1 Li mi t

1/1 POS

1/1 NEG

10/1 POS

10/1 NEG

100/1 POS

100/1 NEG

Figure 1.2: Frequency Response Curves

Figure 1.2 depicts the typical frequency response curves from the nominal gain values with no

attenuation applied by the 4040A. The three different black bands, above and below the curves, give

the allowable limits for passband flatness for the different gain/attenuation settings. Individual plots

are given for both the positive and negative inputs of the 4040A for all gain/attenuation settings. For

example, to find the expected passband flatness from 10 kHz to 10 MHz to achieve an inverted gain of

100, the 100/1 NEG plot would be used in conjunction with the solid black limit lines. These lines are

used because the first number is for the gain, and the second number is for attenuation, POS for

positive, and NEG for negative. The expected passband flatness would be ±0.25 dB from 10 kHz to 6

MHz and +0.25 dB to -3 dB from 6 MHz to 10 MHz.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

1-5

Page 8

INSTRUMENT DESCRIPTION

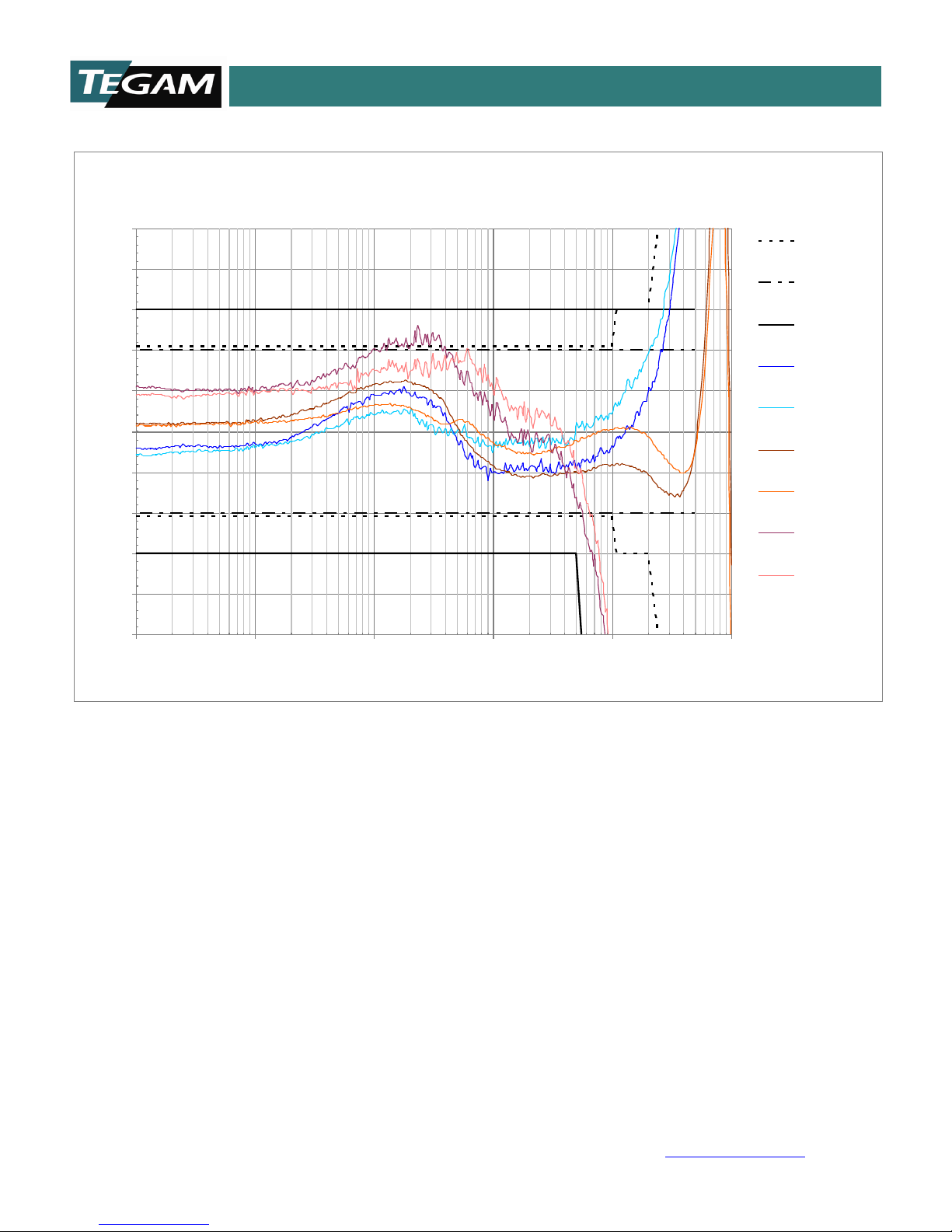

Gain Deviation from Nominal ÷10 Attenuation

(Typical Data and Test Limits)

-0.5

-0.4

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0.4

0.5

1.0E+03 1.0E+04 1.0E+05 1.0E+06 1.0E+07 1.0E+08

Frequency (Hz)

Gain Error (dB)

1/10 Li mi t

10/10 Li mi t

100/10 Limi t

1/10 POS

1/10 NEG

10/10 POS

10/10 NEG

100/10 POS

100/10 NEG

Figure 1.3 depicts the typical frequency response curves from the nominal gain values with an

attenuation of 10 applied by the 4040A. As with Figure 1.2, the three different black bands, above and

below the curves, give the allowable limits for passband flatness for the different gain/attenuation

settings. Individual plots are given for both the positive and negative inputs of the 4040A for all

gain/attenuation settings. For example, to find the expected passband flatness from 1 kHz to 7 MHz to

achieve an inverted gain of 10, the 100/10 NEG plot would be used in conjunction with the solid black

limit lines. These lines are used because the first number is for the gain, and the second number is for

attenuation, POS for positive, and NEG for negative. The expected passband flatness would be ±0.3 dB

from 1 kHz to 5 MHz and +0.3 dB to -3 dB from 5 MHz to 7 MHz.

Figure 1.3: Frequency Response Curves

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

1-6

Page 9

INSTRUMENT DESCRIPTION

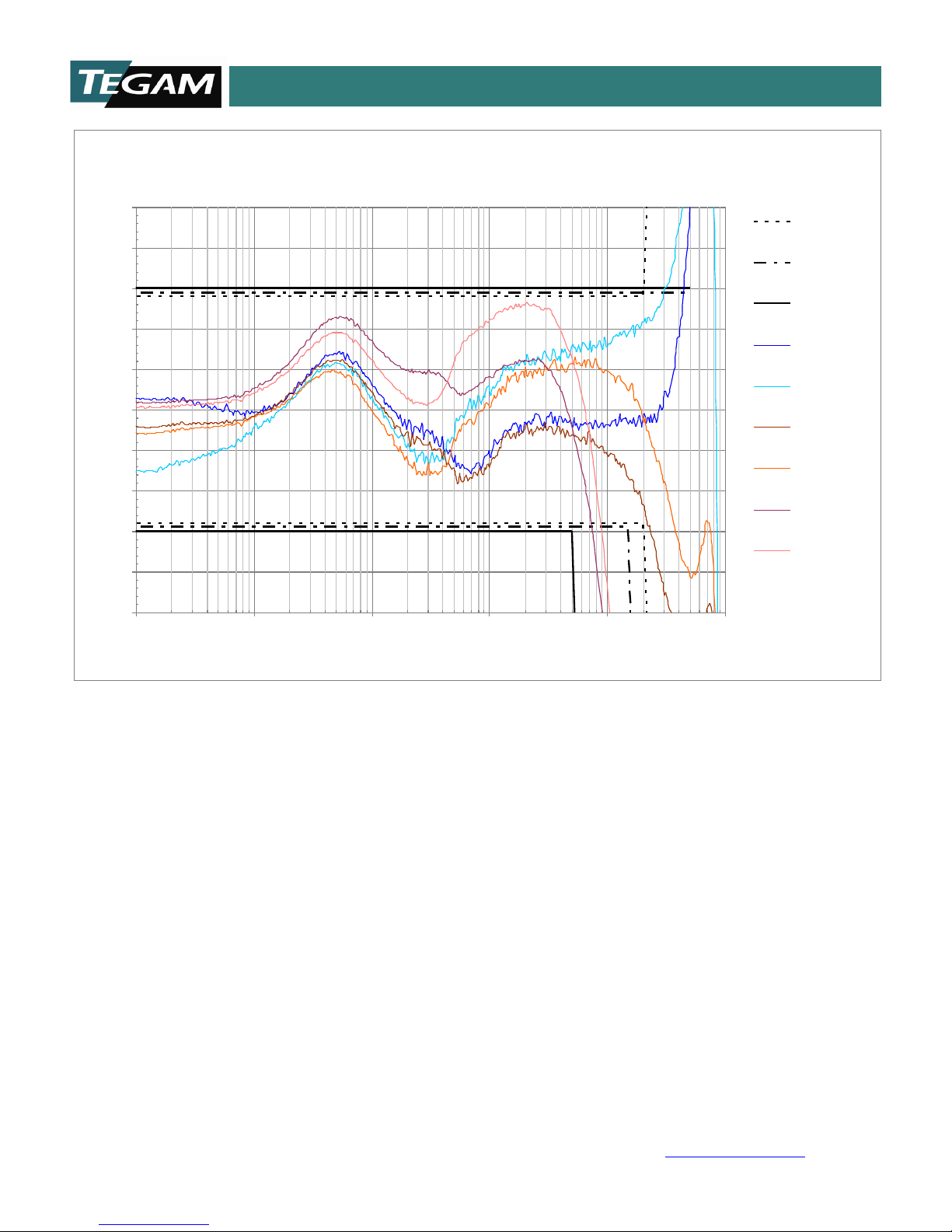

Gain Deviation from Nominal ÷100 Attenuation

(Typical Data and Test Limits)

-0.5

-0.4

-0.3

-0.2

-0.1

0

0.1

0.2

0.3

0.4

0.5

1.0E+03 1.0E+04 1.0E+05 1.0E+06 1.0E+07 1.0E+08

Frequency (Hz)

Gain Error (dB)

1/100 Li mi t

10/100 Limi t

100/100 Limi t

1/100 POS

1/100 NEG

10/100 POS

10/100 NEG

100/100 POS

100/100 NEG

Figure 1.4: Frequency Response Curves

Figure 1.4 depicts the typical frequency response curves from the nominal gain values with an

attenuation of 100 applied by the 4040A. As with Figure 1.2 & 1.3, the three different black bands,

above and below the curves, give the allowable limits for passband flatness for the different

gain/attenuation settings. Individual plots are given for both the positive and negative inputs of the

4040A for all gain/attenuation settings. For example, to find the expected passband flatness from 100

kHz to 25 MHz to achieve a gain of 1, the 100/100 POS plot would be used in conjunction with the

solid black limit lines. These lines are used because the first number is for the gain, and the second

number is for attenuation, POS for positive, and NEG for negative. The expected passband flatness

would be ±0.3 dB from 100 kHz to 5 MHz and +0.3 dB to -3 dB from 5 MHz to 20 MHz. 20 MHz is the

bandwidth limit for the 4040A in this setting. If 25 MHz is needed a setting of 10/10 or 1/1 can be

used as long as the input voltages for those ranges are not exceeded.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

1-7

Page 10

PREPARATION FOR USE

!

!

This symbol denotes where precautionary information may be found.

!

Attention – Please refer to the instruction manual.

SECTION 2

PREPARATION FOR USE

UNPACKING & INSPECTION

Each TEGAM Model 4040A is put through a series of electrical and mechanical inspections before

shipment to the customer. Upon receipt of your instrument unpack all of the items from the shipping

carton and inspect for any damage that may have occurred during transit. Report any damaged items

to the shipping agent. Retain and use the original packing material for reshipment if necessary.

Upon Receipt, inspect the carton for the following items:

(1) Model 4040A Fast PXI Instrumentation Amplifier

(1) CD including Model 4040 User’s Manual, P/N 4040-901-01A and Software Drivers, P/N 1000019

SAFETY INFORMATION & PRECAUTIONS

The following safety information applies to both operation and service personnel. Safety precautions

and warnings may be found throughout this instruction manual and the equipment. These warnings

may be in the form of a symbol or a written statement. Below is a summary of these precautions.

Terms in This Manual:

“CAUTION” A statement to identify conditions or practices that could result in damage to the

equipment, or other property.

“WARNING” A statement to identify conditions or practices that could result in personal injury or loss

of life.

Terms as Marked on Equipment:

“CAUTION” Indicates a personal injury hazard not immediately accessible as one reads the marking, or

a hazard to property including the equipment itself.

“DANGER” Indicates a personal injury hazard immediately accessible as one reads the marking.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

2-1

Page 11

PREPARATION FOR USE

!

!

!

!

Precaution

Grounding the Model 4040A

The Model 4040A is grounded through the grounding conductor of the PXI chassis power cord. The

connection shields of all the connectors are also grounded. The proper grounding of the chassis is

essential for safety and for the optimization of the Model 4040A’s operation.

WARNING

To avoid electrical shock or other potential safety hazards, plug the PXI chassis power cord into a

properly wired receptacle before using this instrument.

Use A Common Ground for All Instruments

It is very important that all instruments being used, both internal modules as well as external

instruments share a common ground. If a common ground connection is lost then improper

instrumentation readings may result, also see warning above.

Danger Arising from Loss of Ground

If the connection to ground through the PXI chassis is lost or compromised, a floating potential could

develop in the Model 4040A module. Under these conditions all accessible parts, including insulating

parts such as the front panel could develop a hazardous voltage and put the user at risk.

Do Not Use in Explosive Environments

WARNING: The Model 4040A is not designed for operation in explosive environments.

Do not Operate Unless the 4040A Module is Properly Installed

WARNING: The Model 4040A should be properly seated within an appropriate PXI chassis before use.

All PXI chassis covers and service panels should be in place before operation. Operation with empty

module slots, or removed covers could result in personal injury.

PXI Chassis:

WARNING: The power supply should be plugged in (to establish ground) but switched off before

installing the Model 4040A or any PXI module.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

2-2

Page 12

PREPARATION FOR USE

!

!

Use Care When Servicing with Power On

Dangerous voltages may exist at several points within the PXI chassis. To avoid personal injury or

damage, avoid touching exposed connections or components while the power is on. Assure that the

power is off and any cables are disconnected when removing or servicing the 4040A amplifier.

Power Source

The Model 4040A is designed to connect to a PXI Chassis and receive all operational power from the

backplane of the chassis. The Model 4040A draws 3.3 volts and 5 volts from the PXI Chassis

backplane. 3.3 DC volts are used for all TTL level functions and 5 VDC operate onboard analog

circuitry. Be aware that higher voltages exist within the PXI Chassis and it is essential that the chassis

is powered off and all cables disconnected when installing or uninstalling any PXI card. A protective

chassis ground connection by way of the grounding conductor in the power cord is essential for safe

operation.

WARNING:

DO NOT MODIFIY any configurations or connections from their original state otherwise safe operation

of this equipment may be compromised.

WARNING:

Always remember to shut off the power and wait at least 15 seconds before disconnecting or

connecting any cables to or from the Model 4040A. Ignoring this warning could result in electric shock.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

2-3

Page 13

OPERATING INSTRUCTIONS

PXI Empty Slot and Module Guides

CPCI / PXI Connector

Injector / Ejector Handle

Differential Inputs

Output (2 Vp-p Max)

SECTION 3

OPERATING INSTRUCTIONS

PXI Installation

Follow the steps below to install the Model 4040A Fast PXI Instrumentation Amplifier.

1. Make sure the power is off or turn off the power of the PXI chassis.

2. Read the manual supplied with the PXI chassis to determine which slot is available for standard

PXI modules such as the Model 4040A. Slot 1 is usually reserved for use as a hardware controller

for the overall system, or other modular device to enable PXI control.

3. Install the 4040A by inserting the module into a PXI chassis empty slot by placing the card edges

into the front module guides, guides are located on both the top and bottom of the chassis entry

location.

4. Gently apply pressure to further insert the card and finally use the injector/ejector handle on the

4040A to fully insert the card into the chassis.

5. Secure the 4040A to the chassis with the captured screw in the top of the face plate.

Figure 3.1: Installation of the 4040A into a typical multi-slot PXI chassis

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

3-1

Page 14

OPERATING INSTRUCTIONS

Connections

Both of the amplifier’s inputs require standard BNC 50 Ω connections and have an impedance of 1 MΩ

or 50 Ω. The 4040A is compatible with all signals from DC to 50 MHz and 0 to ±100 V. The output is

an SMB jack connector specified as 50 Ω with an output impedance of 50 Ω. For proper performance,

TEGAM recommends interconnection cables made of RG316-DS. RG316-DS accessory cables are

available from TEGAM in various lengths to suit your application or you may purchase them from

standard cable vendors.

Both input BNC shields are grounded to a common ground inside the Model 4040A. The BNC shield is

at the same potential as the PXI chassis ground. Figure 3.2 represents a typical connection from the

4040A to a system under test.

Figure 3.2: Typical Connection

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

3-2

Page 15

SOFTWARE

SECTION 4

SOFTWARE

VISA compliant drivers are available for LabVIEW 8, C++ and Visual Basic. Installation instructions are

contained in the Readme.txt in 4040A DRIVER zip file on the CD that is included with the 4040A. It can

also be downloaded from the website, www.tegam.com.

The 4040A driver installer does not allow customization of the installation path. The setup will create a

Tegam4040 folder in C:\Program Files\National Instruments\LabVIEW 8.2\instr.lib folder. The whole

tegam4040 folder can be copied to the instr.lib folder for later LabVIEW versions. A simple front panel

LabVIEW VI, Tegam4040 - Control [Demo].vi is included in C:\Program Files\National

Instruments\LabVIEW 8.2\instr.lib\Tegam4040\Examples folder that provides control of all of the

4040A’s settings.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

4-1

Page 16

SERVICE INFORMATION

SECTION 5

SERVICE INFORMATION

CLEANING

AVOID THE USE OF CHEMICAL CLEANING AGENTS WHICH MIGHT

DAMAGE THE UNIT. DO NOT APPLY ANY SOLVENT CONTAINING

KETONES, ESTERS OR HALOGENATED HYDROCARBONS.

Use low-velocity compressed air to blow off the accumulated dust. Hardened dirt can be removed with

a cotton-tipped swab, soft, dry cloth.

VERIFICATION PROCEDURE

Equipment Required:

Network Analyzer: Agilent 4395A or equivalent

5 ½ digit Digital Multimeter (DMM) (Qty 2): Fluke 8840A or equivalent

DC voltage source capable of 10 mV - 10 V with the capability of a switched output, BNC output

PXI Chassis: NI PXI-1033 or equivalent

Computer with required software installed; LabVIEW

Tegam 4040-Control [Demo].vi LabVIEW Application (Provided with the unit)

N-type male to N-type male adapters

N-type male to N-type male patch cable

N-type male to BNC female adapters (Qty 5)

BNC Male to BNC Male Adapter

BNC Female to BNC Female Adapter

BNC to BNC cables 3’ (Qty 3)

50 Ω ± 0.1 Ω BNC feed thru terminators (Qty 2), one to be marked with a red dot.

SMB Female to BNC Female adapter

SMB Male to BNC Female adapters (Qty 2)

Dual Banana jack to BNC Male connector

Dual Banana plug to BNC Female connectors (Qty 2)

N-Type Power-Splitter 50 Ω

Two way splitters (Qty 2)

1000 µF Non-Polarized Filter Cap (Qty 2)

Identical BNC to BNC cables as short as possible (Qty 2)

Special Instructions: UUT designates Unit Under Test.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

5-1

Page 17

SERVICE INFORMATION

3

2

Computer Set-Up

LabVIEW 4040A Front Panel Control

1. Double click on “Tegam4040A - Control [Demo].vi”.

2. From the Visa Tegam4040 I/O drop down box, select the appropriate slot of the

4040A card.

3. Press the Run Arrow button on the toolbar.

Figure 5.1: Tegam4040A - Control [Demo].vi Front Panel

A. Common Mode Rejection Ratio, Gain of 1

Note: CMRR = (differential gain dB) – (common mode gain dB), the 4395A Network Analyzer will

be displaying the common mode gain dB. The differential gain dB is equal to the gain setting of

the 4040A, example: 4040A set for 20 dB gain (gain of 10), common mode gain must be less

than -60 dB for a CMRR of less than 80 dB.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

5-2

Page 18

SERVICE INFORMATION

1 3 2

4 5 6

7

8

Figure 5.2: Connections for CMMR

1. Connect the N-type power splitter’s input to the 4395A Network Analyzer’s RF Out,

using an N-type male to male adapter.

2. Connect one end of the N-type power splitter’s output to the 4395A Network

Analyzer’s R, using an N-type patch cable.

3. Connect an N-Type to BNC Female adapter to the remaining end of the N-Type Power-

Splitter.

4. Connect the two identical short BNC to BNC cables to the “+” and “-“ inputs of the

UUT.

5. Connect the BNC “T” to both the identical BNC cables.

6. Connect a 50 Ω load to the BNC “T”.

7. Connect a BNC to BNC cable from the N-type power splitter to the 50 Ω load.

8. Connect a BNC to BNC cable to the A input of the 4395A Network Analyzer.

9. Connect a SMB male to BNC female adapter to the previously connected BNC cable

and the output of the UUT.

10. Change the setting in the Tegam4040A - Control [Demo].vi application as follows:

a) Attenuation of 1

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

5-3

Page 19

SERVICE INFORMATION

11. Change the setting on the 4395A Network Analyzer as follows:

a) Network Analyzer Mode

b) Bandwidth for 10 Hz

c) Start frequency to 50 Hz

d) Stop frequency to 70 Hz

e) Scale Reference to 20 dB/div

f) Source Power to +15 dB

g) Statistics On

12. Measure the common mode gain @ 60 Hz. Tolerance <-80 dB.

13. Change the setting in the Tegam4040A - Control [Demo].vi application as follows:

a) Gain of 10

14. Measure the common mode gain @ 60Hz. Tolerance <-60 dB.

15. Change the setting in the Tegam4040A - Control [Demo].vi application as follows:

a) Gain of 100

16. Measure the common mode gain @ 60 Hz. Tolerance <-40 dB.

17. Disconnect the setup from the UUT.

B. Offset Adjustment of UUT

Note: Do not perform this portion of the procedure until called out by any other section of this

procedure.

1. If no connections are made to the UUT’s output, then:

a) Connect the Dual Banana plug to BNC female adapter into the DMM 1 Input.

Observe Polarity.

b) Connect a 1000 µF Non-Polarized Filter Cap into the side of the previous step’s

connector.

c) Connect a BNC to BNC cable to the dual banana plug in step a.

d) Connect a SMB male to BNC female adapter to the other end of the BNC cable

connected in the previous step.

e) Connect the SMB adapter connected to the DMM 1, to the OUT of the UUT.

2. Verify the DMM 1 is set for DC voltage and Auto Range.

3. Change the “DAC” setting up or down of the “Tegam4040A - Control [Demo].vi”

program until the displayed reading of the 8840A is zero. The reading on the display of

the 8840A must be less than ±0.08 mV for all gains except 40 dB. The reading must

be less than ±0.30 mV for the 40 dB gain setting. One count (hex) is ≈ 76.3 µV

4. Disconnect the 8840A Set-up from the UUT.

1. Meas, Analyzer Type, Network Analyzer

1. Bw/Avg, 1, 0, X1

1. Start, 5, 0, X1

1. Stop, 7, 0, X1

1. Scale Ref, 2, 0, X1

1. Source, 1, 5, X1

1. Utility, Statistics on/off

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

5-4

Page 20

SERVICE INFORMATION

3 4 5

5a 6 8 9 9a

10

C. DC Gain Checks -40 dB, -20 dB & 0 dB

Figure 5.3: Connections for DC Gain

1. Turn off the output of the DC voltage source.

2. Change the setting on the DC voltage source to output 5.00 VDC.

3. Connect a two way BNC connector to the “+” input of the UUT.

4. Connect the Red 50 Ω terminator to one side of the connector in the previous step.

5. Connect a Dual Banana plug to BNC female adapter into the DMM 2 Input. Observe

Polarity.

a) Connect a 1000 µF Non-Polarized Filter Cap into the side of the previous step’s

connector.

6. Connect a BNC to BNC cable in between the DMM 2 and the unused end of the two

way BNC connector on the UUT “+” input.

7. Connect a 50 Ω terminator to the “-“ input of the UUT.

8. Connect a BNC to BNC cable in between the DC voltage source and the Red 50 Ω

terminator.

9. Connect a Dual Banana plug to BNC female adapter into the DMM 1 Input. Observe

Polarity.

a) Connect a 1000 µF Non-Polarized Filter Cap into the side of the previous step’s

connector.

10. Connect a BNC to BNC cable to the adapter connected in the previous step.

11. Connect a SMB male to BNC female adapter to the end of the BNC connected in the

previous step.

12. Connect the cable and SMB adapter to the output of the UUT.

13. Change the setting in the Tegam4040A - Control [Demo].vi application as follows:

a) Attenuation of 100

b) Gain of 1

Note: Do not disconnect any connections from the UUT for the next Step.

Note: Do not touch or move any wires after performing the next step.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

5-5

Page 21

SERVICE INFORMATION

14. Perform the Offset Adjustment of UUT section at this time skipping any steps that

say to connect or disconnect anything.

15. Press the Offset button on the DMM 2.

16. Turn on the output of the DC voltage source.

17. Measure both the DMMs displayed readings. The DMM 1 is the Voltage Out, and the

DMM 2 is the Voltage In. Calculate the percentage difference by (dividing the voltage

out by 2, divided by the gain setting (0.01,0.1,1,10,100), minus the voltage input),

divided by the voltage input. Tolerance ±0.1%

18. Turn off the output of the DC voltage source.

19. Press the Offset button on the DMM 2.

20. Change the setting in the Tegam4040A - Control [Demo].vi application as follows:

a) Attenuation of 10

21. Repeat steps 14—19.

22. Swap the two connections to the inputs of the UUT. The cables and splitter shall

remain connected to the Red 50 Ω terminator.

23. Repeat steps 13—21.

24. Set the DC voltage source to output 1.00 VDC.

25. Change the setting in the Tegam4040A - Control [Demo].vi application as follows:

a) Attenuation of 1

26. Repeat steps 14—19.

27. Swap the two connections to the inputs of the UUT. The cables and splitter shall

remain connected to the Red 50 Ω terminator.

28. Repeat steps 14—19.

D. DC Gain check 20 dB

1. Set the DC voltage source to output 0.100 VDC.

2. Change the setting in the Tegam4040A - Control [Demo].vi application as follows:

a) Gain of 10

Note: Do not disconnect any connections from the UUT for the next Step.

Note: Do not touch or move any wires after performing the next step.

3. Perform the Offset Adjustment of UUT section at this time skipping any steps that

say to connect or disconnect anything.

4. Press the Offset button on the DMM 2.

5. Turn on the output of the DC voltage source.

6. Measure both the DMMs displayed readings. The DMM 1 is the Voltage Out, and the

DMM 2 is the Voltage In. Calculate the percentage difference by (dividing the voltage

out by 2, divided by the gain setting (0.01,0.1,1,10,100), minus the voltage input),

divided by the voltage input. Tolerance ± 0.1%

7. Turn off the output of the DC voltage source.

8. Press the Offset button on the DMM 2.

9. Swap the two connections to the inputs of the UUT. The cables and splitter shall

remain connected to the Red 50 Ω terminator.

10. Repeat steps 3—8.

E. DC Gain Adjustment 40 dB

1. Set the DC voltage source to output 0.010 VDC.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

5-6

Page 22

SERVICE INFORMATION

1

2 3 6

8

5

2. Change the setting in the Tegam4040A - Control [Demo].vi application as follows:

a) Gain of 100

Note: Do not disconnect any connections from the UUT for the next Step.

Note: Do not touch or move any wires after performing the next step.

3. Perform the Offset Adjustment of UUT section at this time skipping any steps that

say to connect or disconnect anything.

4. Press the Offset button on the DMM 2.

5. Turn on the output of the DC voltage source.

6. Measure both the DMMs displayed readings. The DMM 1 is the Voltage Out, and the

DMM 2 is the Voltage In. Calculate the percentage difference by (dividing the voltage

out by 2, divided by the gain setting (0.01,0.1,1,10,100), minus the voltage input),

divided by the voltage input. Tolerance ±1.5%

7. Turn off the output of the DC voltage source.

8. Press the Offset button on the DMM 2.

9. Swap the two connections to the inputs of the UUT. The cables and splitter shall

remain connected to the Red 50 Ω terminator.

10. Repeat steps 3—8.

11. Disconnect setup from UUT.

F. Verification of 20 dB & 40 dB Attenuation

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

Figure 5.4: Connections for AC Gain

5-7

Page 23

SERVICE INFORMATION

14

15

1. Connect the N-type power splitter’s input to the 4395A Network Analyzer’s RF Out,

using an N-type male to male adapter.

2. Connect one end of the N-type power splitter’s output to the 4395A Network

Analyzer’s R, using an N-type patch cable.

3. Connect an N-Type to BNC Female adapter to the remaining end of the N-Type Power-

Splitter.

4. Connect two 50 Ω terminators to both inputs of the UUT, the one with Red, on top.

5. Connect a BNC to BNC cable to remaining N-type power splitter.

6. Connect a BNC to BNC cable to the A input of the 4395A Network Analyzer.

7. Connect a SMB male to BNC female adapter to the previously connected BNC cable.

8. Connect the two BNC to BNC cables from the 4395A together using a SMB female to

BNC female adapter.

9. Change the setting in the Tegam4040A - Control [Demo].vi application as follows:

a) Attenuation of 10

b) Gain of 1

10. Repeat the Offset Adjustment of UUT section.

11. Change the setting on the 4395A Network Analyzer as follows:

a) Bandwidth for 100 Hz

1. Bw/Avg, 1, 0, 0, X1

b) Start frequency to 1 kHz

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

Figure 5.5: Connections for AC Gain

5-8

Page 24

SERVICE INFORMATION

c) Stop frequency to 50 MHz

d) Sweep Type to Log Frequency

e) Scale Reference to 0.25 dB/div with a Reference Value of -20 dB

f) Calibrate the system

g) Stop frequency to 10 MHz

12. Disconnect the two SMB adapters from each other.

13. Remove the SMB female to BNC adapter from the BNC cable connected to the power

splitter.

14. Connect the BNC Cable from power splitter to the 50 Ω load of the “+” input of the

UUT.

15. Connect the SMB male adapter end, connected to the A of the 4395A, to the OUT of

the UUT.

16. Verify the final values for the frequency response curve to not exceed -20 dB ±0.2 dB

for the -20 dB and -40 dB ±0.3 dB for the -40 dB settings.

17. Change the setting on the 4395A Network Analyzer as follows:

a) Stop frequency to 50 MHz

18. After the cursor has swept the entire frequency, verify the frequency response curve to

not exceed -20 or -40 dB ±3 dB.

19. Change the setting on the 4395A Network Analyzer as follows:

a) Stop frequency to 10MHz

20. Swap the two loads connected to the inputs of the UUT. The cable shall remain

connected to the Red 50 Ω terminator.

21. Repeat steps 16—19.

22. Change the setting in the Tegam4040A - Control [Demo].vi application as follows:

a) Attenuation of 100

23. Change the setting on the 4395A Network Analyzer as follows:

a) Scale Reference Value of -40 dB

24. Repeat steps 16—19.

25. Swap the two loads connected to the inputs of the UUT. The cable shall remain

connected to the Red 50 Ω terminator.

26. Repeat steps 16—19.

27. Disconnect the cables from the UUT, leaving the loads connected.

G. 0 dB Gain Check

1. Change the setting in the Tegam4040A - Control [Demo].vi application as follows:

a) Attenuation of 1

2. Repeat the Offset Adjustment of UUT section.

3. Connect the two BNC to BNC cables from the 4395A together using a SMB female to

BNC female adapter.

1. Start, 1, k/m

1. Stop, 5, 0, M/µ

1. Sweep, Sweep Type Menu, Log Freq

1. Scale Ref, ., 2, 5, X1, Reference Value, -, 2, 0, X1

1. Cal, Calibration Menu, Response, Thru

2. After the Cursor has swept across the frequency span, “Press ‘Done’ if

finished with Cal” is displayed, press the Done Response button.

1. Stop, 1, 0, M/µ

1. Stop, 5, 0, M/µ

1. Stop, 1, 0, M/µ

1. Scale Ref, Reference Value, -, 4, 0, X1

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

5-9

Page 25

SERVICE INFORMATION

4. Change the setting on the 4395A Network Analyzer as follows:

a) Scale Reference Value of 0 dB

b) Source Power to -4 dB

c) Calibrate the system

5. Disconnect the two SMB adapters from each other.

6. Remove the SMB female to BNC adapter from the BNC cable connected to the power

splitter.

7. Connect the BNC Cable from the power splitter to the Red 50 Ω load connected to the

“+” input of the UUT.

8. Connect the SMB male adapter, connected to the A of the 4395A, end to the OUT of

the UUT.

9. After the cursor has swept the entire frequency, verify the frequency response curve to

not exceed 0 dB ±3 dB.

10. Change the setting on the 4395A Network Analyzer as follows:

a) Stop frequency to 10 MHz

11. Verify the final values for the frequency response curve to not exceed 0 dB ±0.15 dB.

12. Swap the two loads connected to the inputs of the UUT. The cable shall remain

connected to the Red 50 Ω terminator.

13. Verify the final values for the frequency response curve to not exceed 0 dB ±0.15 dB.

14. Change the setting on the 4395A Network Analyzer as follows:

a) Stop frequency to 50 MHz

15. After the cursor has swept the entire frequency, verify the frequency response curve to

not exceed 0 dB ±3 dB.

16. Disconnect the cables from the UUT, leaving the loads connected.

H. 20 dB Gain Check

1. Change the setting in the Tegam4040A - Control [Demo].vi application as follows:

a) Gain of 10

2. Repeat the Offset Adjustment of UUT section.

3. Connect the BNC Cable from the power splitter to the Red 50 Ω load connected to the

“-” input of the UUT.

4. Connect the SMB male adapter, connected to the A of the 4395A, end to the OUT of

the UUT.

5. Change the setting on the 4395A Network Analyzer as follows:

a) Scale Reference Value of 20 dB

6. Verify the final values for the frequency response curve to not exceed 20 dB ±0.2 dB.

7. Swap the two loads connected to the inputs of the UUT. The cable shall remain

connected to the Red 50 Ω terminator.

8. Verify the final values for the frequency response curve to not exceed 20 dB ±0.2 dB.

9. Disconnect the cables from the UUT, leaving the loads connected.

1. Scale Ref, Reference Value, 0, X1

1. Source, -, 4, X1

1. Cal, Calibration Menu, Response, Thru

2. After the Cursor has swept across the frequency span, “Press ‘Done’ if

finished with Cal” is displayed, press the Done Response button.

1. Stop, 1, 0, M/µ

1. Stop, 5, 0, M/µ

1. Scale Ref, Reference Value, 2, 0, X1

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

5-10

Page 26

SERVICE INFORMATION

I. 40 dB Gain Check

1. Change the setting in the Tegam4040A - Control [Demo].vi application as follows:

a) Gain of 100

2. Repeat the Offset Adjustment of UUT section.

3. Connect the two BNC to BNC cables from the 4395A together using a SMB female to

BNC female adapter.

4. Change the setting on the 4395A Network Analyzer as follows:

a) If the memory card with saved settings is available:

b) Scale Reference Value of 40 dB

c) Stop frequency to 20 MHz

d) Source Power to -24 dB

e) Calibrate the system

5. Disconnect the two SMB adapters from each other.

6. Remove the SMB female to BNC adapter from the BNC cable connected to Bbox1.

7. Connect the BNC Cable from the power splitter to the Red 50 Ω load connected to the

“+” input of the UUT.

8. Connect the SMB male adapter, connected to the A of the 4395A, end to the OUT of

the UUT.

9. After the cursor has swept the entire frequency, verify the frequency response curve to

not exceed 40 dB +0.25 dB, -3 dB.

10. Change the setting on the 4395A Network Analyzer as follows:

a) Stop frequency to 6 MHz

11. Verify the final values for the frequency response curve to not exceed 40 dB ±0.25 dB.

12. Swap the two loads connected to the inputs of the UUT. The cable shall remain

connected to the Red 50 Ω terminator.

13. Verify the final values for the frequency response curve to not exceed 40 dB ±0.25 dB.

14. Change the setting on the 4395A Network Analyzer as follows:

a) Stop frequency to 20 MHz

15. After the cursor has swept the entire frequency, verify the frequency response curve to

not exceed 40 dB +0.25 dB, -3 dB.

16. Disconnect the setup.

J. UUT Disconnect

1. Press the Stop button on the “Tegam4040A - Control [Demo].vi” program.

2. Remove any cables that may be still connected to the UUT.

1. Press, RECALL, 4.STA, Skip steps b—d.

1. Scale Ref, Reference Value, 4, 0, X1

1. Stop, 2, 0, M/µ

1. Source, -, 2, 4, X1

1. Cal, Calibration Menu, Response, Thru

2. After the Cursor has swept across the frequency span, “Press ‘Done’ if

finished with Cal” is displayed, press the Done Response button.

1. Stop, 6, M/µ

1. Stop, 2, 0, M/µ

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

5-11

Page 27

SERVICE INFORMATION

Parts Replacement

The Model 4040A has no user-serviceable parts. All onboard parts besides the connectors are surface

mount based (SMT). The 4040A contains multiple levels of failsafe circuitry. As a last resort, four SMT

fuses have been installed which may blow if the 4040A is used outside of its rated operating

constraints. Since all onboard fuses are SMT devices, it is not suggested that they be replaced by the

user. If you suspect that the unit has failed, please contact TEGAM Inc. for an RMA number.

Preparation for Calibration or Repair Service

Once you have verified that a malfunctioning 4040A cannot be solved in the field and the need for

repair and calibration service arises, contact TEGAM customer service to obtain an RMA, (Returned

Material Authorization), number. You can contact TEGAM customer service via the TEGAM website,

www.tegam.com or by calling 440.466.6100 (All Locations) OR 800.666.1010 (United States Only).

The RMA number is unique to your instrument and will help us identify your instrument and to address

the particular service request by you which is assigned to that RMA number. Of even greater

importance is a detailed written description of the problem that should be attached to the instrument.

Many times repair turnaround is unnecessarily delayed due to a lack of repair instructions or of a

detailed description of the problem.

This description should include information such as is the problem intermittent?, when is the problem

most frequent?, has anything changed since the last time the instrument was used?, Etc. Any detailed

information provided to our technicians will assist them in identifying and correcting the problem in the

quickest possible manner. Use the form provided on the next page.

Once this information is prepared, sent it with the instrument and RMA number to our service

department, we will do our part in making sure that you receive the best possible customer service

and turnaround time possible.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

5-12

Page 28

SERVICE INFORMATION

RMA#:

Instrument Model #:

Serial

Number:

Company:

Technical

Contact:

Phone

Number:

Additional

Contact Info:

Expedite Repair & Calibration Form

Use this form to provide additional repair information and service instructions. The Completion of this

form and including it with your instrument will expedite the processing and repair process.

Repair Instructions

Evaluation Calibration Only Repair Only Repair & Calibration Z540 (Extra Charge)

Detailed Symptoms

Include information such as measurement range, instrument settings, type of components being

tested, is the problem intermittent? When is the problem most frequent?, Has anything changed with

the application since the last time the instrument was used?, etc.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

5-13

Page 29

SERVICE INFORMATION

Warranty

TEGAM, Inc. warrants this product to be free from defects in material and workmanship for a period of

one year from the date of shipment. During this warranty period, if a product proves to be defective,

TEGAM Inc., at its option, will either repair the defective product without charge for parts and labor, or

exchange any product that proves to be defective.

TEGAM, Inc. warrants the calibration of this product for a period of 6 months from date of shipment.

During this period, TEGAM, Inc. will recalibrate any product, which does not conform to the published

accuracy specifications.

In order to exercise this warranty, TEGAM, Inc., must be notified of the defective product before the

expiration of the warranty period. The customer shall be responsible for packaging and shipping the

product to the designated TEGAM service center with shipping charges prepaid. TEGAM Inc. shall pay

for the return of the product to the customer if the shipment is to a location within the country in

which the TEGAM service center is located. The customer shall be responsible for paying all shipping,

duties, taxes, and additional costs if the product is transported to any other locations. Repaired

products are warranted for the remaining balance of the original warranty, or 90 days, whichever

period is longer.

Warranty Limitations

The TEGAM, Inc. warranty does not apply to defects resulting from unauthorized modification or

misuse of the product or any part. This warranty does not apply to fuses, batteries, or damage to the

instrument caused by battery leakage.

The foregoing warranty of TEGAM is in lieu of all other warranties, expressed or implied. TEGAM

specifically disclaims any implied warranties of merchantability or fitness for a particular purpose. In no

event will TEGAM be liable for special or consequential damages. Purchaser’s sole and exclusive remedy

in the event any item fails to comply with the foregoing express warranty of TEGAM shall be to return

the item to TEGAM; shipping charges prepaid and at the option of TEGAM obtain a replacement item or

a refund of the purchase price.

Statement of Calibration

This instrument has been inspected and tested in accordance with specifications published by TEGAM

Inc. The accuracy and calibration of this instrument are traceable to the National Institute of Standards

and Technology through equipment, which is calibrated at planned intervals by comparison to certified

standards maintained in the laboratories of TEGAM Inc.

Contact Information:

TEGAM INC.

10, TEGAM WAY

GENEVA, OHIO 44041

PH: 440.466.6100

FX: 440.466.6110

CAGE Code: 49374

WEB: http://www.tegam.com

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

5-14

Loading...

Loading...