Page 1

TEGAM Inc.

Model 3550

42.0Hz-5.00MHz

Fully Programmable

LCR Meter

© Copyright 2004, TEGAM, Inc. All rights reserved.

NOTE: This user’s manual was as current as possible when this product was manufactured. However, products are

constantly being updated and improved. Because of this, some differences may occur between the descriptions in this

manual and the product received. Please refer to www.tegam.com for future updates of this manual.

Model 3550 Programmable LCR Meter Instruction Manual a

MODEL 3550

Instruction Manual

PN# 3550-900-01CD

Publication Date April 2004

REV. B

Page 2

Model 3550 Programmable LCR Meter Instruction Manual b

Page 3

Table of Contents

I INSTRUMENT DESCRIPTION............................................................................1-1

Instrument Description ........................................................................... 1-1

Feature Overview ................................................................................... 1-1

3550 Options and Accessories .................................................................. 1-4

Performance Specifications ...................................................................... 1-5

Table 1.1 – Model 3550 Measurement Range Limits ............................... 1-5

Table 1.2 – Model 3550 Measurement Frequencies ................................. 1-7

Table 1.3 – Model 3550 Measurement Amplitudes .................................. 1-7

Table 1.4 – Model 3550 Amplitude Accuracies ....................................... 1-8

Table 1.5 – Model 3550 Measurement Ranges ....................................... 1-8

Table 1.6 – Typical Analog Measurement Times ..................................... 1-9

Table 1.7a – Absolute Comparator Operation......................................... 1-11

Table 1.7b – Percentage Comparator Operation ..................................... 1-11

Table 1.8 – Numeric Displays and Annunciators ..................................... 1-11

Formulas and Measurement Accuracy........................................................ 1-13

Table 1.9 – Series and Parallel Equivalent Circuit Measurements .............. 1-14

II PREPARATION FOR USE ..................................................................................2-1

Unpacking and Inspection........................................................................ 2-2

Safety Information and Precautions .......................................................... 2-2

Servicing Safety Summary ...................................................................... 2-4

Line Voltage and Fuse Selection ............................................................... 2-5

III QUICK START INSTRUCTIONS .........................................................................3-1

Power the Unit ....................................................................................... 3-2

Instrument Settings................................................................................ 3-2

Table 3.1 – Factory Default Settings .................................................... 3-2

Table 3.2 – Control Command Summary............................................... 3-3

Table 3.3 – Shift Function Summary .................................................... 3-4

Instrument Setup for Basic Measurements ................................................. 3-5

Table 3.4 – Settings Summary ............................................................ 3-5

Setting the Absolute Comparator.............................................................. 3-6

Setting the Percent Comparator ............................................................... 3-7

IV OPERATING INSTRUCTIONS............................................................................4-1

Basic Operation...................................................................................... 4-2

Default Parameters................................................................................. 4-2

Precautions ........................................................................................... 4-2

Measurement Tips .................................................................................. 4-2

Making Measurements that are Sensitive to Voltage and Current.............. 4-2

Measuring Earth Grounded Test Pieces ................................................. 4-2

Measurement Circuit Modes ................................................................ 4-3

Table 4.1 – Relationship Between Series and Parallel Equivalent Circuits ... 4-3

Negative Capacitance or Inductance Readings ....................................... 4-4

Zero Correction of Parasitic Impedance ................................................ 4-4

Table 4.2 – Short and Open Null Connections ........................................ 4-4

Model 3550 Programmable LCR Meter Instruction Manual c

Page 4

Table of Contents

IV OPERATING INSTRUCTIONS CONT’D...............................................................

Measurement Tips ..................................................................................

Test Lead Requirements..................................................................... 4-5

Figure 4.1a – Four-Wire Kelvin Measurement ........................................ 4-5

Figure 4.1b – Proper Application of Four Wire Kelvin Measurement ........... 4-5

Measurement Signal Levels................................................................. 4-6

Series or Parallel Circuit Modes............................................................ 4-6

Auto range Switching Threshold .......................................................... 4-6

Display Resolution ............................................................................. 4-6

AC Resistance of Coils with Cores ........................................................ 4-6

Front Panel Description ........................................................................... 4-7

Figure 4.2 – Front Panel Layout........................................................... 4-7

Power Switch.................................................................................... 4-8

Circuit Mode Panel............................................................................. 4-8

Trigger Panel .................................................................................... 4-8

Zero Panel ....................................................................................... 4-9

Range Selection Panel........................................................................ 4-9

Shift Key.......................................................................................... 4-10

Frequency Set Mode........................................................................ 4-10

Test Voltage Set Mode..................................................................... 4-11

Test Current Set Mode..................................................................... 4-11

Averaging Set Mode ........................................................................ 4-12

Key Lock Mode ............................................................................... 4-12

Comparator buzzer Function............................................................. 4-13

Trigger Delay Time.......................................................................... 4-13

Comparator Functions Mode ............................................................. 4-14

Defining Spot Frequencies for Zero Adjustments ................................. 4-14

RS-232C Settings Mode ................................................................... 4-15

Correction Frequency Limit Setting Mode............................................ 4-16

Spot Correction Mode (Open Correction) ............................................ 4-16

Spot Correction Mode (Short Correction) ............................................ 4-16

Unknown Terminals Panel................................................................... 4-17

Table 4.3 – Unknown Terminals........................................................... 4-17

Comparator Limit Set Panel ................................................................ 4-17

The Guard Terminal ........................................................................... 4-17

Remote Interface Status LEDs............................................................. 4-18

Panel Selector Switch......................................................................... 4-18

Panel Display LED.............................................................................. 4-18

Display A Parameter Selection Key....................................................... 4-18

Display A ......................................................................................... 4-18

Bin Display LED................................................................................. 4-18

Comparator State Annunciators........................................................... 4-19

Sample LED (Trigger Status)............................................................... 4-19

Comparator ON/OFF Switch ................................................................ 4-19

Display B Parameter Selection Key....................................................... 4-19

Display B ......................................................................................... 4-19

Model 3550 Programmable LCR Meter Instruction Manual d

Page 5

Table of Contents

IV OPERATING INSTRUCTIONS CONT’D...............................................................

Front Panel Description Cont’d ............................................................

Display C Measurement Panel ............................................................. 4-20

Table 4.4 – CV/CC Indicators .............................................................. 4-21

Display C ......................................................................................... 4-21

Enter Key......................................................................................... 4-21

Rear Panel Description ............................................................................ 4-22

Figure 4.3 – Rear Panel Layout............................................................ 4-22

Making Accurate Measurements ............................................................... 4-23

Connections to the Device Under Test .................................................. 4-23

3-Terminal Measurement.................................................................... 4-23

4 or 5-Terminal Measurements............................................................ 4-23

Test Fixture Selection ........................................................................ 4-24

Table 4.4 – Impedance and Frequency Limitations of Kelvin Klip Leads ..... 4-24

Table 4.5 – Impedance and Frequency Limitations of the SMD Test Fixture 4-25

Zero Corrections ............................................................................... 4-26

Table 4.6 – Zero Correction Limits ....................................................... 4-26

Figure 4.4 – Terminal Connections for Zero Correction............................ 4-27

Equivalent Circuits............................................................................. 4-28

Table 4.7 – Equivalent Circuit Relationships .......................................... 4-29

Operating the 3550 ................................................................................ 4-30

Preparation ...................................................................................... 4-30

How to Perform a Zero Correction........................................................ 4-30

Measuring L, C, and R........................................................................ 4-31

Measuring |Z| and |Y|........................................................................ 4-33

Measuring D, Q, Rs, Rp, G, X, B, and LJ................................................. 4-34

The Comparator..................................................................................... 4-35

Important Notes for the Absolute and Comparator Functions ................... 4-35

Absolute Value Settings...................................................................... 4-36

Percent Value Settings ....................................................................... 4-37

Bin Operation ................................................................................... 4-39

Figure 4.5 – Sequenced Bin Sorting ..................................................... 4-39

Figure 4.6 – Nested Bin Sorting........................................................... 4-40

Outputting the Comparator’s Results.................................................... 4-41

Audible Buzzer Operation ................................................................... 4-41

Model 3550 Programmable LCR Meter Instruction Manual e

Page 6

f

Table of Contents

V PROGRAMMING AND INTERFACING ................................................................5-1

Interfacing to the 3550 ........................................................................... 5-2

Control I/O Connector............................................................................. 5-2

Inputs ............................................................................................. 5-2

Figure 5.1 – Input Schematic .............................................................. 5-2

Outputs ........................................................................................... 5-3

Figure 5.2 – Output Schematic ............................................................ 5-3

Timing Diagrams............................................................................... 5-4

Figure 5.3a – Test Busy Operation ....................................................... 5-4

Figure 5.3b – Measure End Operation................................................... 5-4

Figure 5.3c – GO/NO-GO Operation ..................................................... 5-4

Table 5.1 – Connector Pin Designations ................................................ 5-5

Table 5.2 – Control I/O Function Summary ........................................... 5-6

Sample Diagram of External Connections to Sequencer........................... 5-7

RS-232C ............................................................................................... 5-8

Interface Cable ................................................................................. 5-8

Input Format .................................................................................... 5-8

Table 5.3a – Command Summary........................................................ 5-11

Table 5.3b – Command Summary cont’d .............................................. 5-12

Table 5.3c – Command Summary cont’d............................................... 5-13

Table 5.4 - Comparator Instructions..................................................... 5-14

Data Output Format for Measurement Settings ...................................... 5-15

Table 5.5a – Data Output Code Functions ............................................. 5-16

Table 5.5b – Data Output Code Functions cont’d .................................... 5-17

Monitor Output Format....................................................................... 5-18

Table 5.6c – Monitor Output Code Functions.......................................... 5-21

Table 5.6b – Monitor Output Code Functions cont’d ................................ 5-22

RS-232C Hardware and Computer Settings ........................................... 5-23

Sample Programs for RS-232C ............................................................ 5-23

The GPIB Interface (Optional) .................................................................. 5-28

General Description of GPIB................................................................ 5-28

Primary Specifications of GPIB ............................................................ 5-28

Table 5.7 – GPIB Functions ................................................................. 5-28

Installation of the GPIB Board ............................................................. 5-29

Figure 5.4a – Rear View ..................................................................... 5-29

Figure 5.4b – Side View ..................................................................... 5-30

Figure 5.4c – Top View....................................................................... 5-30

Front Panel Status LEDs ..................................................................... 5-31

Local Key Switch ............................................................................... 5-31

GPIB Switches .................................................................................. 5-31

Delimiter Output Formats ................................................................... 5-31

Output Status Bits for Service Requests................................................ 5-31

Figure 5.5 – GPIB Status Bits.............................................................. 5-31

Additional Notes for Using the GPIB Interface ........................................ 5-31

Programming Examples...................................................................... 5-33

Model 3550 Programmable LCR Meter Instruction Manual

Page 7

Table of Contents

VI SERVICE INFORMATION..................................................................................6-1

Warranty .............................................................................................. 6-2

Warranty Limitations .............................................................................. 5-2

Statement of Calibration ......................................................................... 6-2

Contact Information ............................................................................... 6-2

Repair Parts .......................................................................................... 6-3

Troubleshooting .................................................................................... 6-4

Preparation for Repair or calibration Service............................................... 6-5

Expedite Repair and calibration Form ........................................................ 6-6

Performance Verification Procedure........................................................... 6-7

Model 3550 Calibration Adjustment Procedure ............................................ 6-12

VII APPENDIX .......................................................................................................A.1

Setting the Constant Voltage Mode ........................................................... A.3

To Enable the Constant Voltage Mode................................................... A.3

Calculating the maximum Allowable Constant Voltage Setting.................. A.3

Setting the Constant Current Mode ........................................................... A.4

Calculating the maximum Allowable Constant Current Setting.................. A.4

Basic Measurement Accuracy Tables ......................................................... A.5

Table A.1 – Basic Accuracy Table ......................................................... A.5

Table A.2 – Basic Accuracy Table [0.01V to 0.04V]................................. A.6

Table A.3 – Basic Accuracy Table [0.05V to 0.10V]................................. A.7

Table A.4 – Basic Accuracy Table [0.11V to 0.20V]................................. A.8

Table A.5 – Basic Accuracy Table [0.21V to 0.45V]................................. A.9

Table A.6 – Basic Accuracy Table [0.46V to 1.00V]................................. A.10

Table A.7 – Basic Accuracy Table [1.01V to 5.00V]................................. A.11

LC Impedance Calculation Chart ............................................................... A.12

Error Codes ........................................................................................... A.13

Model 3550 Programmable LCR Meter Instruction Manual g

Page 8

Model 3550 Programmable LCR Meter Instruction Manual h

Page 9

Instrument Description

INSTRUMENT DESCRIPTION

PREPARATION FOR USE

QUICK START INSTRUCTIONS

OPERATING INSTRUCTIONS

PROGRAMMING & INTERFACING

SERVICE INFORMATION

APPENDIX

Page 10

Model 3550 LCR Meter Instruction Manual Instrument Description

Instrument Description

The Model, 3550, is a high-speed LCR Meter capable of measuring Inductance (L), Capacitance(C),

Resistance (R), Absolute Impedance (|Z|), Absolute Admittance (|Y|), Dissipation factor (D),

Quality (Q), Serial Equivalent Resistance (Rs), Parallel Equivalent Resistance (Rp), Conductance

(G), Reactance (X), Susceptance (B), and Phase Angle (LJ). It has a wide measurement range, and

includes full adjustability of Measurement Frequency and Measurement Signal Level. It also

features Automatic adjustment for Zero Correction, Range Switching, and Series and Parallel Mode

Switching.

The basic comparator function of the 3550 is extended to allow sorting of components to up to 10

different bins. Up to 9 panels worth of measurement settings can be stored in the instrument’s

non-volatile memory for convenient recall. The instrument can perform a complete measurement

including a comparator judgment in as little as 40ms.

The 3550 has standard RS-232C and Control I/O Connector Interfaces with the availability of an

optional GPIB Interface. The Control I/Os are optically isolated thus making the instrument ideal

for noise immunity.

Feature Overview

The 3550 Programmable LCR Meter offers a complete solution for a wide variety of specialized LCR

measurement applications. Listed below are some of the features.

High Speed

The measurement time, including data display, zero correction, and comparator function is

approximately 40 milliseconds.

Extended Frequency Range

The Measurement Frequency can be adjusted between 42.0Hz - 5.00MHz.

Programmable Test Voltage and Current

The test signal level can be adjusted between 10mV to 5.00V in the constant voltage mode

and from 10µA to 99.99mA in the constant current mode.

Voltage & Current Monitor

The voltage at the test piece terminals and the current, which is flowing through the test

piece, can be displayed up to 3 significant digits.

1-2

Page 11

Model 3550 LCR Meter Instruction Manual Instrument Description

Feature Overview cont’d:

1

/2 Digits Resolution

4

"DISPLAY A" (L, C, R, |Z|, |Y|), and "DISPLAY B" (D, Q, R

up to 4

1

/2digits.

GO/NO-GO COMPARATOR

For L, C, R, |Z|, |Y|, D, Q, R

, RP, G, X, B, and LJ, upper and lower limit values can be set

S

for 9 items (10 categories), for up to 9 panels of settings.

Series or Parallel Equivalent Circuit Mode

When in "Auto" mode, Parallel or Series Equivalent Circuit measurements are automatically

determined by the active measurement range. In manual range, the Parallel or Series

Equivalent Circuit mode are user selectable.

, RP, G, X, B, LJ) can both display

S

Front Panel Key Lock

The Key Switch on the front panel can be set to lock the instrument settings for protection

against accidental changes.

Automatic Zero Correction of Parasitic Impedance

Performing Open and Short Circuit Zeroing cancel the offset errors caused by Stray

Capacitance, Stray Conductance, Residual Inductance, and Residual Resistance.

Non-Volatile Memory

All measurement settings such as the Zero Correction Values, Comparator Limits, Panel

Settings etc. are stored in non-volatile memory and are retained in the event of power loss.

Remote Operation

The TEGAM Model 3550 provides standard RS-232C and I/O Control Connector interfaces

for remote operation. There is an optional GPIB (IEEE-488) interface available for purchase.

1-3

Page 12

Model 3550 LCR Meter Instruction Manual Instrument Description

3550 Options and Accessories

2005B - Chip Tweezers (5ft)

This four-terminal tweezer set makes

solid connections to chip components

in manual sorting applications.

Capacity of jaws is 12.7mm (0.5

in.). The 2005B Chip Component

Tweezer Set includes a 1.5m (5 ft)

cable for connection to the

2150/2160. Contact tips are

replaceable. P/N 47422.

47422 Chip Tweezer

Replacement Kit

Tweezer tips are intended to last

100,000 to 500,000 operations. An

optional tip replacement kit includes

12 replacement tips, 2 screws and 1

wrench.

3510-Radial Lead Adapter

This sorting fixture allows for efficient

four-wire measurement of leaded parts.

The test fixture features spring action

contacts for easy insertion and removal

of test components.

47454 – Kelvin Klips

Kelvin Klips allow solid four-terminal,

Kelvin connections to leaded

components. The jaws are assembled

with hardened gold-plated, beryllium

copper, which ensures low contact

resistance, low thermal emf to copper,

high corrosion resistance, and long

service life. An alligator clip is provided

allowing connection of a passive guard.

The assembly includes a 5 ft (1.5m)

cable for connection to the 3525.

KK100- Kelvin Klip™ Rebuild

Kit

Kelvin Klip™ replacements for

construction or repair of Kelvin Klip

leads.

GPIB (IEEE-488) Cables

1583-3 – 1-meter GPIB buss cable

1583-6 – 2-meter GPIB buss cable

1583-9 – 3-meter GPIB buss cable

3505 – GPIB Interface

3550-900-01 – User’s ManualHard Copy

3511 - SMD Test Fixture

Available for performing three

terminal measurements on surface

mount devices. Connects directly to

the front panel of the 3550. Use the

3511 for medium and high

impedance measurements.

1-4

NOTE: Under certain measurement

conditions, Kelvin Klips can cause a loss

of measurement accuracy. Fixtures

3510, 3511, or 2005B chip tweezers are

recommended for the following

component values:

C<100pF; L < 100µH; R > 1Mƻ

Page 13

Model 3550 LCR Meter Instruction Manual Instrument Description

Performance Specifications

The advertised specifications of the model 3550 are valid under the following conditions:

1. The instrument must be verified and/or adjusted using the methods and intervals as

described in the calibration section of this user’s manual.

2. The instrument must be in an environment, which does not exceed the limitations as

defined under “Environmental” in the Miscellaneous Specifications section.

3. The unit is allowed to warm up for a period of at least 30 minutes before measurements

are taken. A warm-up period of 60 minutes is recommended after exposure to or storage in

a high humidity, (non-condensing), environment.

4. Only TEGAM-manufactured Kelvin Klips™, Tweezers and other test fixtures are used with

this device during measurements.

Measurement Parameters:

Inductance (L), Capacitance(C), Resistance(R), Impedance (|Z|), Admittance (|Y|),

Dissipation Factor (D), Quality (Q), Equivalent Series Resistance (R

Resistance (R

), Conductance (G), Reactance (X), Susceptance (B), and Phase Angle (LJ).

P

), Equivalent Parallel

S

Measurement Ranges

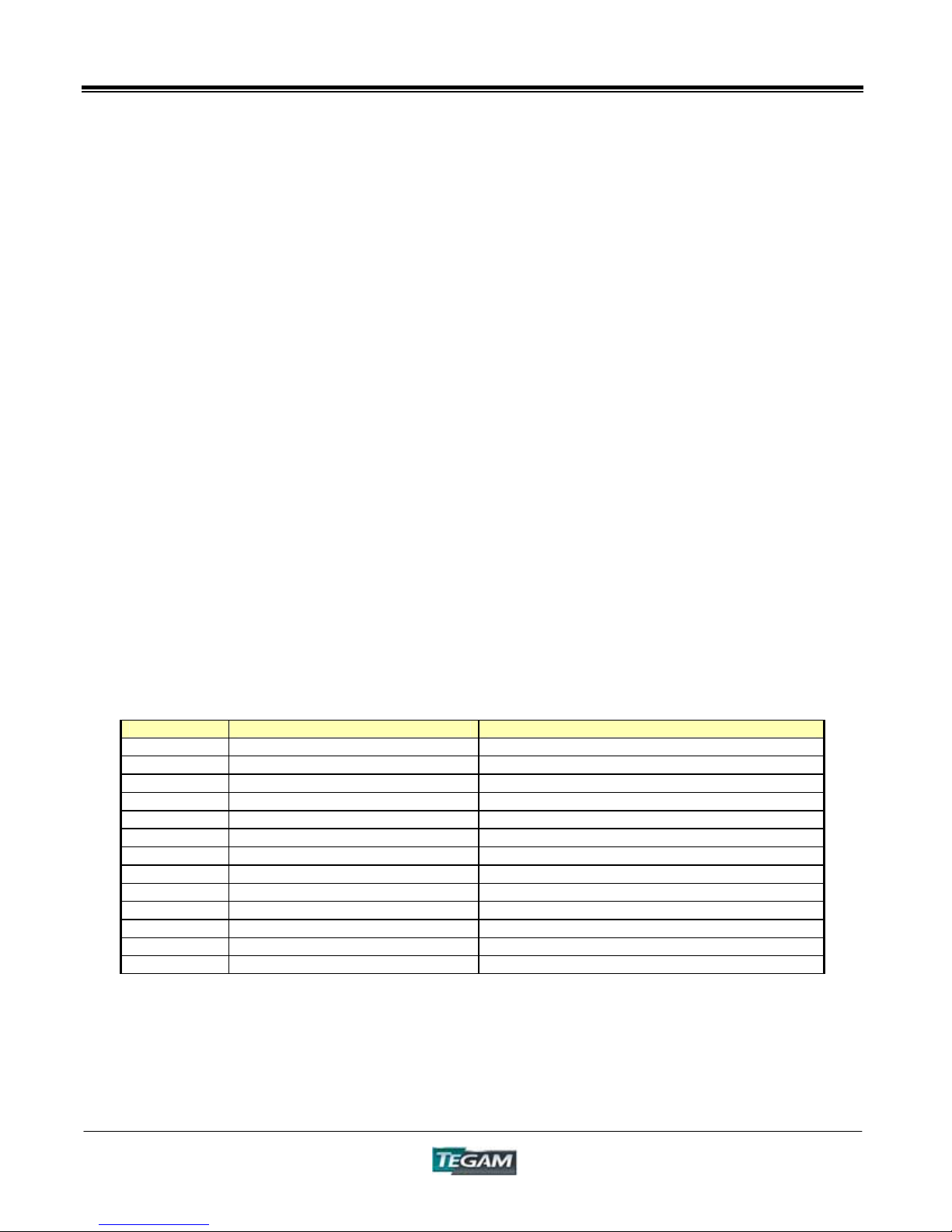

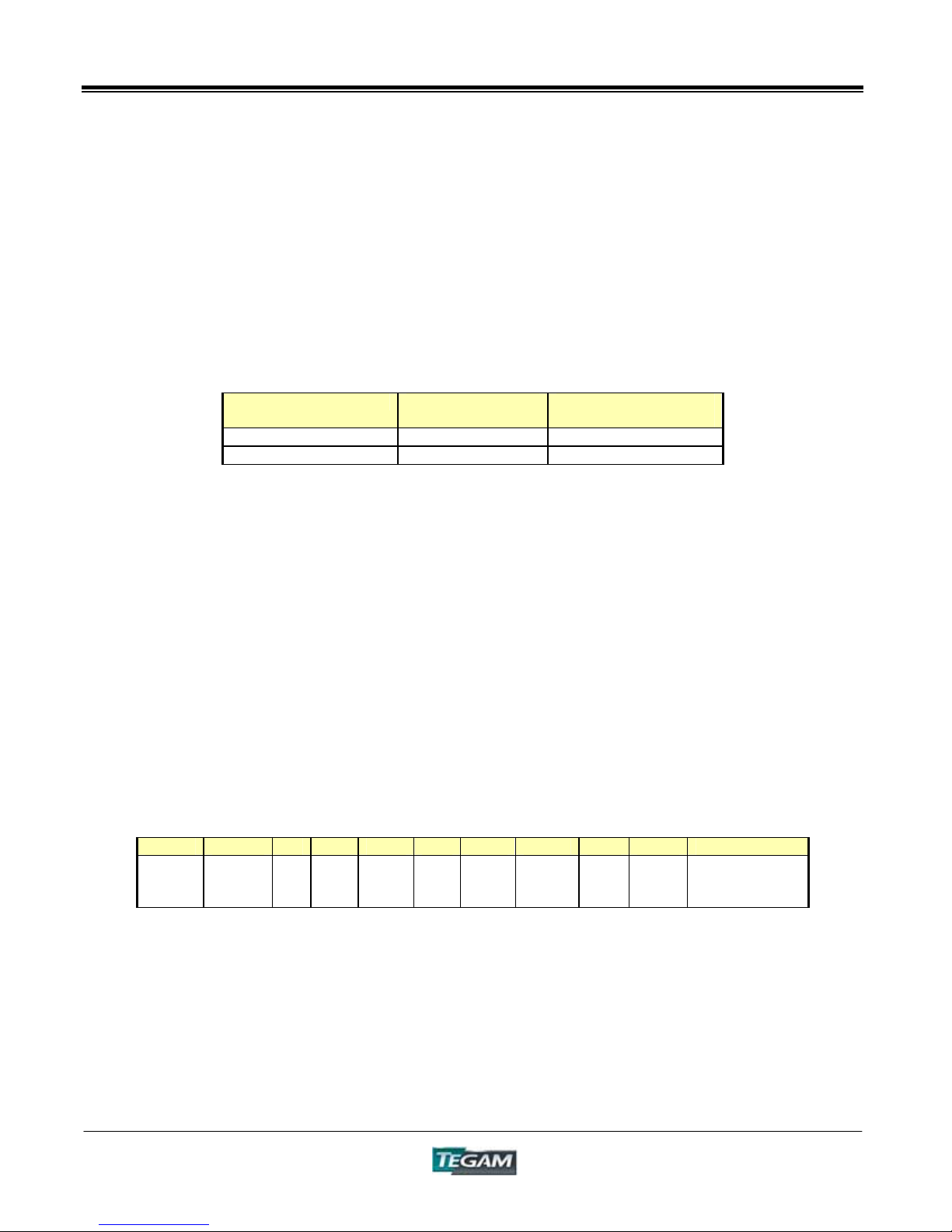

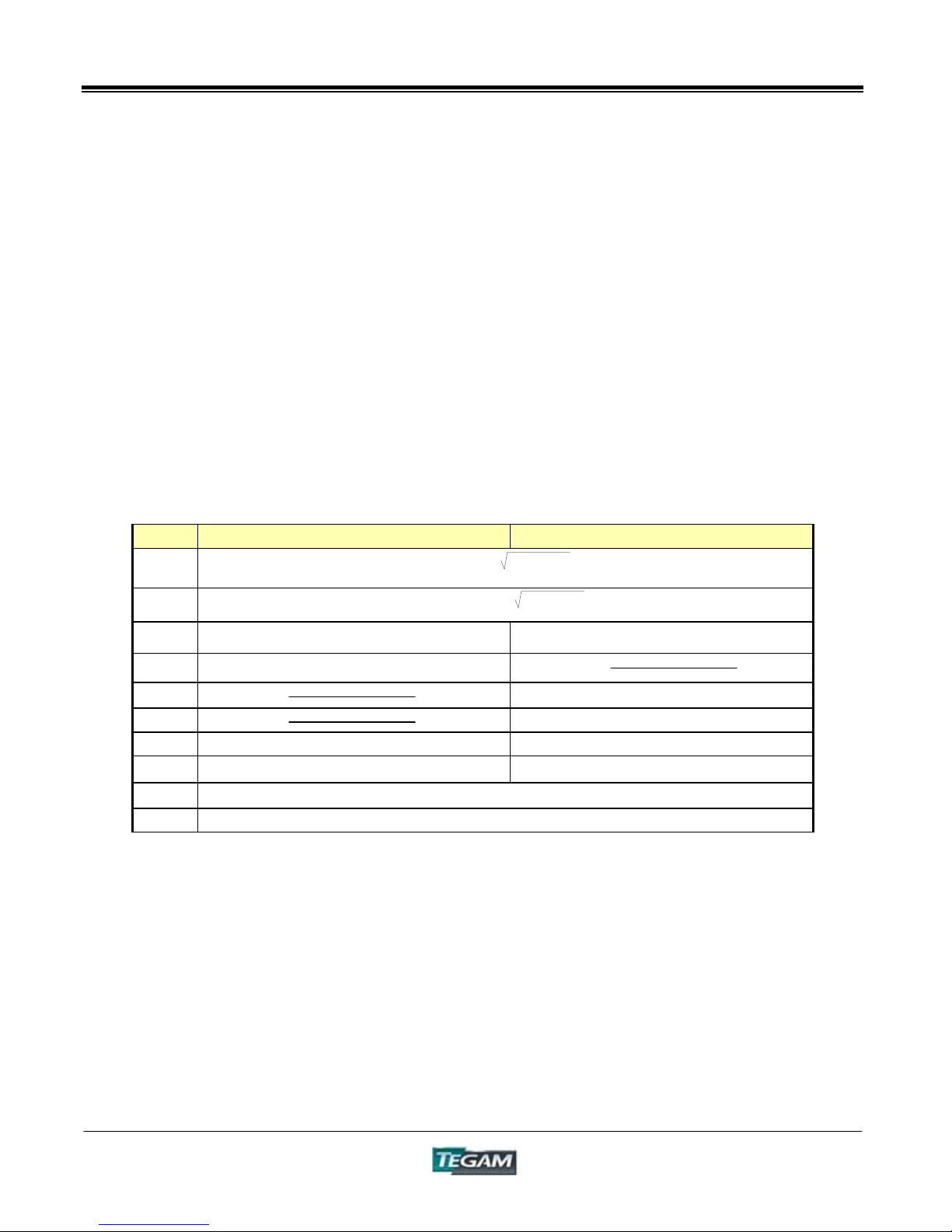

Table 1.1 – Model 3550 Measurement Range Limits

Parameter Low Limit High Limit

L 320.0nH (At: 10ƻ 5MHz) 0.7500MH(At: 199.99Mƻ 42Hz) (LJ=90°)

C 0.160pF (At: 100kƻ 5MHz) 0.037F(At: 100mƻ 42Hz) (LJ=-90°)

R 0.01mƻ 199.99Mƻ

|Z| 0.01mƻ 199.99Mƻ

|Y| 5.000nS(199.99Mƻ) 100.00S(100mƻ)

D 0.0001 9.999

Q 0.1 1999.9

R

S

R

P

G 5.000nS(199.99Mƻ) 100.00S(100mƻ)

X 0.01mƻ 199.99Mƻ

B 5.000nS(199.99Mƻ) 100.00S(100mƻ)

LJ -180.00° 180.00°

0.01mƻ 199.99Mƻ

0.01mƻ 199.99Mƻ

NOTE: The Measurement Range is dependent on the Measurement Frequency. The figures in

parentheses are DUT impedance values.

1-5

Page 14

Model 3550 LCR Meter Instruction Manual Instrument Description

Performance Specifications cont’d:

Basic Accuracy

0.1%

Display Specifications:

x Numeric Display (DISPLAY A)

1

L, C, R, |Z|, |Y| (4

x Numeric Display (DISPLAY B)

D, Q, R

, RP, G, X, B, LJ (41/2 digits)

S

x Numeric Display (DISPLAY C)

Frequency, Voltage, Current, Terminal Voltage, Terminal Current, PANEL (3 digits)

x Unit Prefix Display (DISPLAY A)

p, n, µ, m, k, M

/2 digits)

x Unit Prefix Display (DISPLAY B)

n, µ, m, k, M

x Unit Display (DISPLAY A)

F, H, ƻ, S

x Unit Display (DISPLAY B)

ƻ, S, deg

x Unit Display (DISPLAY C)

Hz, kHz, MHz, V, mA

Switch Indicator Lamps

x RANGE – AUTO; UP; DOWN

x CIRCUIT MODE – AUTO; SER; PRL

x SHIFT

x DISPLAY C – V; I; CV/CC

x TRIGGER - INT; MAN/EXT

x SAMPLE

1-6

Page 15

Model 3550 LCR Meter Instruction Manual Instrument Description

Performance Specifications cont’d:

Measurement Frequency

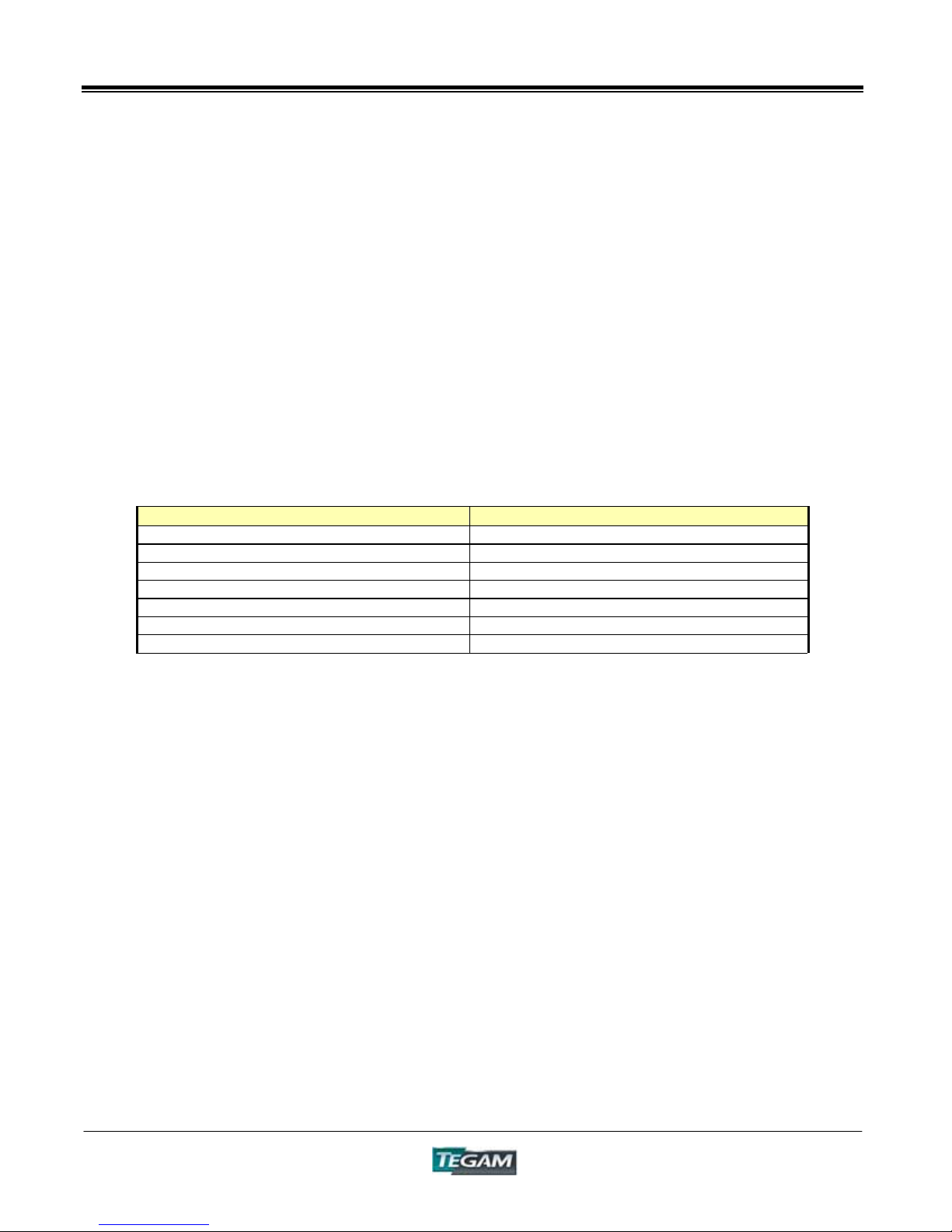

Table 1.2 – Model 3550 Measurement Frequencies

Frequency Range Resolution

42.0Hz ~99.9Hz 0.1Hz Steps

100Hz~999Hz 1Hz Steps

1.00kHz~9.99kHz 10Hz Steps

10.0kHz~99.9kHz 100Hz Steps

100kHz~999kHz 1kHz Steps

1.00MHz~5.00MHz 10kHz Steps

Measurement Frequency Accuracy

±0.01%

Measurement Signal Level

Table 1.3 – Model 3550 Measurement Amplitudes

Frequency Range Test Voltage

Range

42.0Hz~1.00MHz 0.01~5.00Vrms 0.01~99.99mArms

1.01MHz~5.00MHz 0.05~1.00Vrms 0.05~20.00mArms

Test Current Range

Open Terminal Voltage Mode

x Increment/Resolution 0.01V Steps

x Max. Shorting Current 99.99mA (Dependent on Measurement Frequency)

Fixed Voltage Mode

x Increment/Resolution 0.01V Steps

x Max. Shorting Current 99.99mA(Dependent on Measurement Frequency)

Fixed Current Mode

x Increment/Resolution 0.01mA Steps

x Max. Shorting Current 99.99mA(Dependent on Measurement Frequency)

1-7

Page 16

Model 3550 LCR Meter Instruction Manual Instrument Description

Performance Specifications cont’d:

Monitor Functions

Voltage Monitor 0.00V~5.00V

Current Monitor 0.00mA~99.99mA

Settings and Monitor Accuracy

Table 1.4 – Model 3550 Amplitude Accuracies

Frequency Range Test Voltage

Accuracy

42.0Hz~4.00MHz ±(10%+10mV) ±(10%+10µA)

4.01MHz~5.00MHz ±(20%+10mV) ±(20%+10µA)

Signal Source Impedance

50ƻ ±10%

Test Current

Accuracy

Measurement Circuit Modes

x Auto/Manual Circuit Selection

x Parallel Equivalent Circuit Mode

x Series Equivalent Circuit Mode

Range

Measurement Range is determined by the DUT’s absolute impedance |Z|. There are 9 total ranges

selectable in either AUTO or MANUAL modes. Measurement parameters (L, C, R, etc.) are

calculated from actual test voltage and current values.

Table 1.5 – Model 3550 Measurement Ranges

Range 1 2 3 4 5 6 7 8 9 AUTO

Upper

Limit

|Z|

100mƻ 1ƻ 10ƻ 100ƻ 1kƻ 10kƻ 100kƻ 1Mƻ 10Mƻ 100mƻ~10Mƻ

1-8

Page 17

Model 3550 LCR Meter Instruction Manual Instrument Description

Performance Specifications cont’d:

Measurement Time

Open Terminal Voltage Mode

When the Measurement Frequency is 10kHz, no averaging, the range is held constant, RS-232C is

OFF and the Comparator is ON, the shortest measurement time is 18ms.

Typical Analog Measurement Times

Conditions: Averaging= 1, range held, RS-232C is OFF, and Comparator ON:

Table 1.6 – Typical Analog Measurement Times

Test Frequency Typical Analog Measurement Time

42Hz 624ms Max.

120Hz 221ms Max.

1kHz 31ms Max.

10kHz 18ms Max.

100kHz 30ms Max.

1MHz 25ms Max.

5MHz 21ms Max.

About the Typical Analog Measurement Time

The Typical Analog Measurement Time is dependent upon the Measurement Frequency. For ranges

42.0Hz~750Hz, and 10.1kHz~19.0kHz, Typical Analog Measurement Time will exceed 40 ms.

For other frequencies, 40ms will not be exceeded.

(Conditions: Averaging = 1, range held, RS-232C is OFF, and Comparator ON)

Fixed Voltage/Fixed Current Mode

The measurement time can be up to 4X the time of the Open Terminal Voltage Mode.

Average Mode

The user can define from 1~100 averages.

1-9

Page 18

Model 3550 LCR Meter Instruction Manual Instrument Description

Performance Specifications cont’d:

Measurement Terminals

x 2 – BNC Source Terminals

x 2 – BNC Detect Terminals

x 1 – Guard Banana/Binding Post

Parasitic Impedance Correction

Open Correction 1kƻ or higher Impedance

Short Correction Less than 1kƻ Impedance

Programmable Delay Time

Measurements will be started after a trigger is detected from the front panel, Control I/O

Connector or RS232C interface. The delay time setting is user-definable and ranges from

0~10 seconds in 1ms increments.

GO/NO-GO Limits Comparator/Binning

Absolute Value

x Absolute Settings must fall within the Measurement Ranges of DISPLAY A and DISPLAY B.

x Comparator Settings must be applied to existing preset panels.

x Up to 9 programmable bins (1-9) may be defined. Bin 0 is reserved for measured values

that fall outside of the limits.

x User may program the High or Low limits of DISPLAY A and DISPLAY B to be ignored.

Percent Value

x Percent Settings must fall within the Measurement Ranges of DISPLAY A and DISPLAY B.

x Limit Values of 00000~999.99 % for both DISPLAY A and DISPLAY B

x Comparator Settings must be applied to existing panels.

x Up to 9 programmable bins (1-9) may be defined. Bin 0 is reserved for measured values

that fall outside of the limits.

x User may program the High or Low limits of DISPLAY A and DISPLAY B to be ignored.

1-10

Page 19

Model 3550 LCR Meter Instruction Manual Instrument Description

Performance Specifications cont’d:

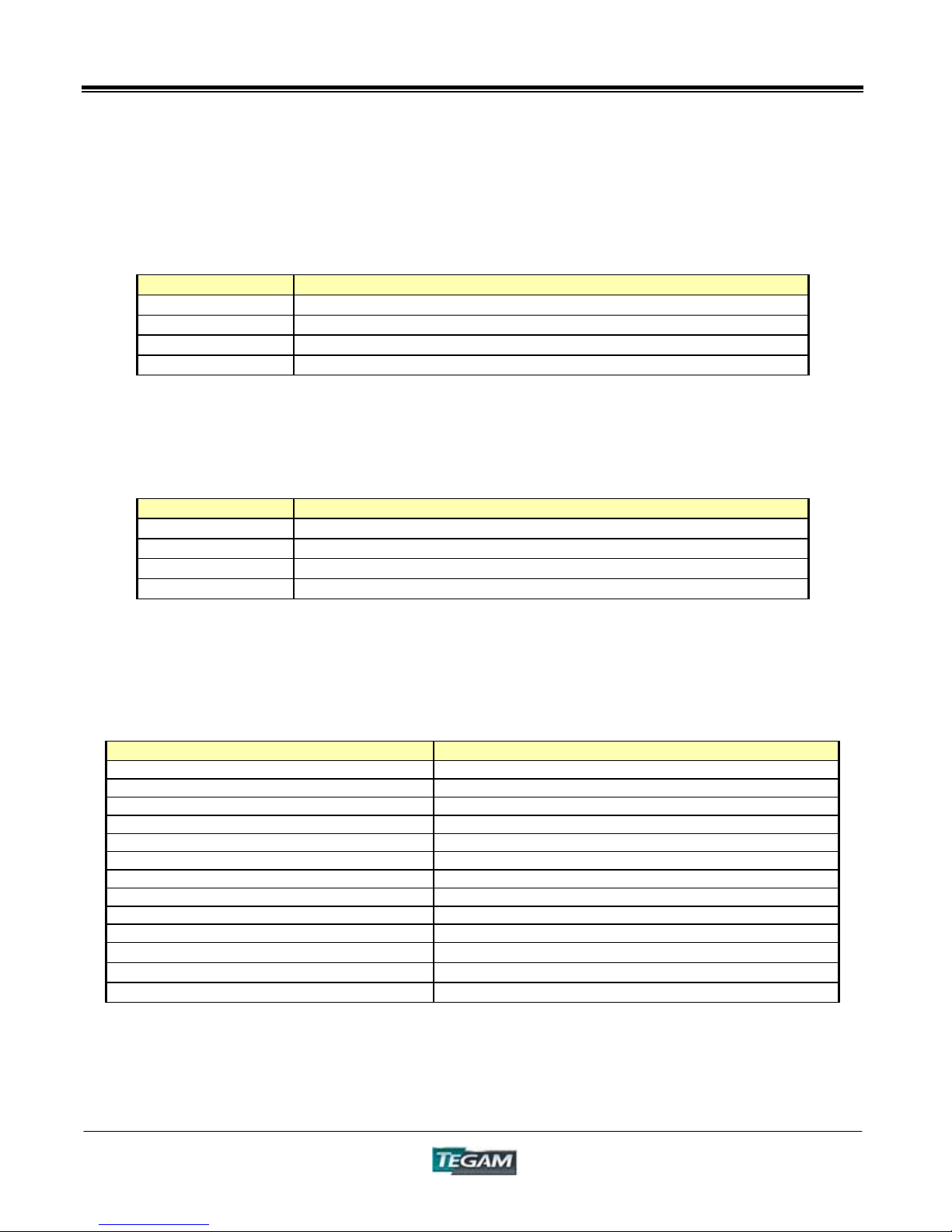

Comparator/Binning: Absolute Limits Operation

Table 1.7a – Absolute Comparator Operation

Operation Function

Bins 1~9 "LOW LIMIT" Measurement Value "HIGH LIMIT"

LO Measurement Value < "LOW LIMIT"

HI "HIGH LIMIT" < Measurement Value

TOTAL GO When both DISPLAY A and DISPLAY B are not LO or HI

Comparator/Binning: Percent Limits Operation

*The location of the decimal point affects the % comparator/binning values.

Table 1.7b – Percentage Comparator Operation

Operation Function

Bins 1~9 "LOW LIMIT" Measurement Value "HIGH LIMIT"

LO Measurement Value < "LOW LIMIT"

HI "HIGH LIMIT" < Measurement Value

TOTAL GO When both DISPLAY A and DISPLAY B are not LO or HI

Displays

Table 1.8 – Numeric Displays and Annunciators

Display Display Description & Range

Numeric DISPLAY A -19999 ~ 19999 (4-1/2 digits)

Numeric DISPLAY B -19999 ~19999 (4-1/2 digits)

Unit Prefix Annunciators for DISPLAY A p, n, µ, m, k, M

Unit Prefix Annunciators for DISPLAY B n, µ, m, k, M

Unit Annunciators for DISPLAY A F, H, ƻ, S

Unit Annunciators for DISPLAY B ƻ, S, deg

Comparator Limit LOW & HIGH Pushbuttons

Comparator Enabled ON Pushbutton

Comparator State LO-HI (For DISPLAY A & B)

Comparator Total GO TOTAL GO LED

BIN 0-9 Seven Segment LED Display

PANEL 0-9 Seven Segment LED Display

GPIB Status SRQ, LTN, TLK, RMT

1-11

Page 20

Model 3550 LCR Meter Instruction Manual Instrument Description

Performance Specifications cont’d:

Digital Interfaces

RS-232C Standard interface

GPIB Optional Interface

Control I/O Standard Interface Connector

External Control Signals

CONTROL PANEL/EXT, EXT TRIGGER, PANEL No. (Isolated)

External Output Signals

MEASURE END, ERROR, DISPLAY A HI, DISPLAY A LO, DISPLAY A GO, DISPLAY B LO, DISPLAY B HI,

DISPLAY B GO, TOTAL GO, TOTAL NO-GO, BIN (Optically Isolated)

Audible Buzzer

Can be set to turn ON with GO or NO-GO comparator state; or it can be disabled.

Panel Presets

9 panel presets including comparator settings can be programmed into non-volatile

memory.

Front Panel Key Lock

Protects accidental changing of front panel settings all panel keys except the Manual

Trigger are disabled.

Environmental

Operating Temperature = 5°C~40°C (41°F~104°F) <80%RH Non-Condensing

o Accuracy specifications are based on temperature conditions within 23°C±5°C

(73.4°F±9°F).

o For temperatures exceeding 23°C±5°C and still within the operating temperature,

the margin of error will be 2 times larger.

Power Source

x Operating Voltage=100/120/220/240V AC ±10%(MAX250V)

x Power Frequency=50/60Hz

x Maximum Power Usage=40VA

Dimensions

Width: 9.84” (250mm)

Height: 5.83” (148mm)

Depth: 15.74” (400mm)

Weight

Approximately 15.4lb (7kg)

1-12

Page 21

Model 3550 LCR Meter Instruction Manual Instrument Description

Formulas and Measurement Accuracy

Parameters and Formulas

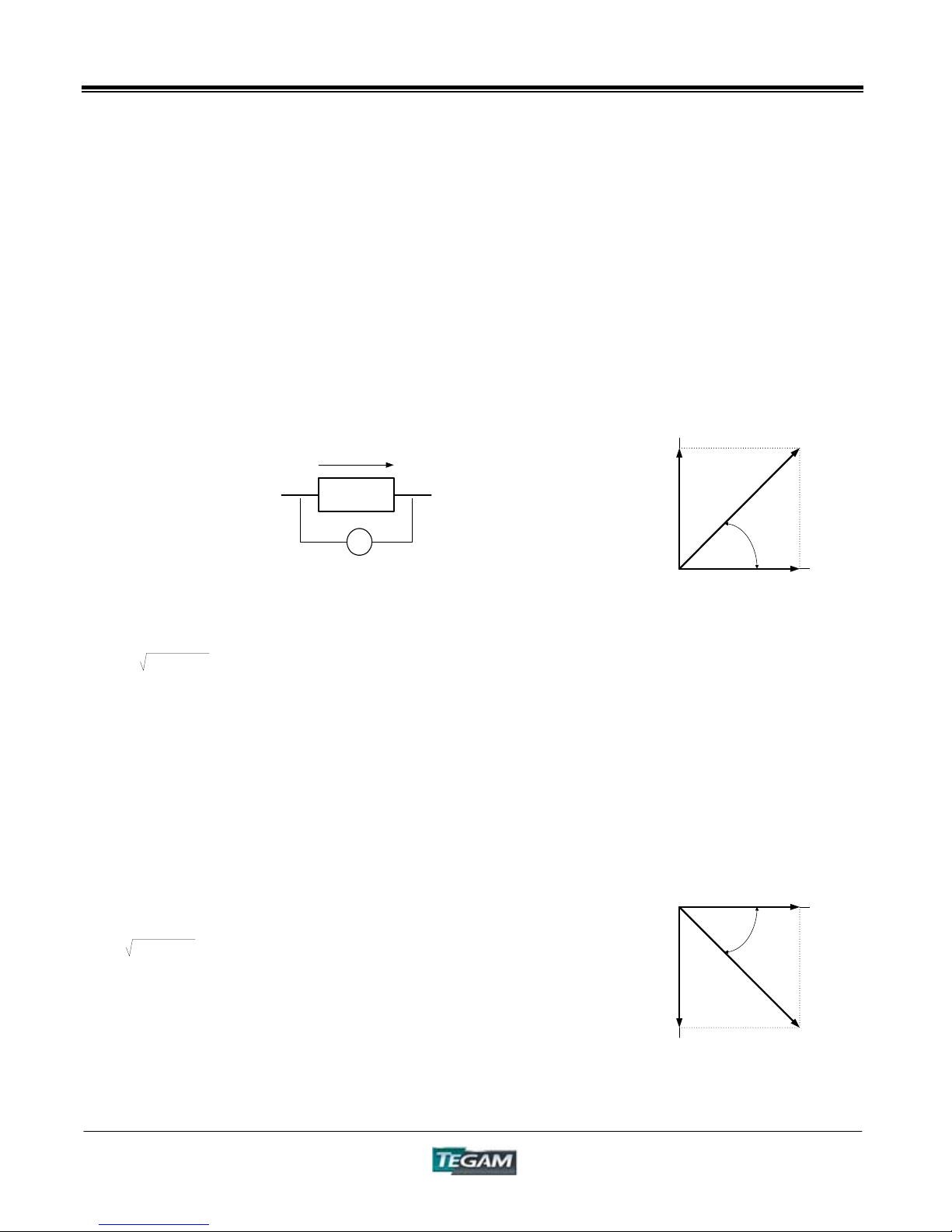

Generally speaking, the characteristics of circuit components can be evaluated in terms of

impedance (Z).

The 3550 LCR Meter measures the voltage and current components of the circuit in relation to the

alternating signal of the measurement frequency, and uses these values to calculate impedance

(Z) and phase angle (LJ).

Displaying impedance (Z) in a complex notation as below allows us to determine the following

values.

I

Z

Z

jX

Z=R+jX

LJ = TAN

|Z| =

-1

X/R

R2 +X

V

Z =V / I

2

IMAGINARY NUMBERS

ș

R

REAL NUMBERS

Z: Impedance (ƻ)

LJ: Phase Angle (deg)

R: Resistance (ƻ)

X: Reactance (ƻ)

|Z|: Absolute Value of Impedance (ƻ)

Depending on the properties of the DUT, Admittance (Y), which is the inverse of Impedance (Z),

may be used to calculate parameter values instead. Admittance (Y), like Impedance (Z) can be

represented in complex notation in order to calculate the following values.

Y=G+jB

ĭ= TAN

|Y|=

-1

(B*G)

G2 +B

2

Y: Admittance (S)

REAL NUMBERS

jB

G

ij

G: Conductance (S)

B: Susceptance (S)

|Y|: Absolute value of Admittance (S)

IMAGINARY NUMBERS

Y

1-13

Page 22

Model 3550 LCR Meter Instruction Manual Instrument Description

Formulas and Measurement Accuracy cont’d:

The 3550 calculates the various measurement values using the inter-terminal voltage (V) applied

to the DUT (device under test) terminals, the current (I) that occurs in relation to the voltage, the

Phase Angle (LJ) of (V) and (I), and the Angular Velocity (ǔ) of the measurement frequency.

These factors are used in the formulas below to determine values for the measurements made by

the TEGAM 3550.

Note: The Phase Angle is based on Impedance (Z). In order to base the Phase Angle on

Admittance (Y), add a "-" sign to the Impedance value to negate it.

Thus, ij for Admittance will be ij=-LJ.

Table 1.9 – Series and Parallel Equivalent Circuit Measurements

Item Series Equivalent Circuits Parallel Equivalent Circuits

Z

|Z| = V/I( )

R2 +X

2

|Y| = 1/|Z|( )

R

X

Y

RS = ESR = | |Z|cosLJ | RP = EPR = | 1/(|Y|cosLJ) | = 1/G

X = |Z| sinLJ

G

B

L

C

D

Q

*** ij is the Phase Angle of Admittance: ij = -LJ

, CS, RSrepresent the L, C, R measurements for series equivalent circuits.

L

S

, CP, RPrepresent the L, C, R measurements for parallel equivalent circuits.

L

P

LS = X/ǔ LP = 1/(ǔ*B)

CS = 1/(ǔ*X) CP = B/ǔ

D = 1/tanLJ = 1/Q

Q = tanLJ = 1/D

G2 +B

2

|Y|cosLJ ***

B = |Y|sinLJ ***

1-14

Page 23

Model 3550 LCR Meter Instruction Manual Instrument Description

Measurement Accuracy

The impedance of the DUT is either the actual measured value or a value, which is derived from

the formulas below:

If LJ=90° ĺ |Z| = ǔL

If LJ= -90° ĺ |Z| = 1/ǔC

If LJ=0° ĺ |Z| = R

Voltage Level Accuracy Limit

See the Measurement Accuracy Tables located in the Appendix. The tables contain formulas for

calculating the Voltage Level Accuracies.

1-15

Page 24

Model 3550 LCR Meter Instruction Manual Instrument Description

1-16

Page 25

Preparation for Use

INSTRUMENT DESCRIPTION

PREPARATION FOR USE

QUICK START INSTRUCTIONS

OPERATING INSTRUCTIONS

PROGRAMMING & INTERFACING

SERVICE INFORMATION

APPENDIX

Model 3550 LCR Meter Instruction Manual 2-1

Page 26

Model 3550 LCR Meter Instruction Manual Preparation for Use

Unpacking & Inspection:

Each 3550 is put through a series of electrical and mechanical inspections before shipment to the

customer. Upon receipt of your instrument unpack all of the items from the shipping carton and

inspect for any damage that may have occurred during transit. Report any damaged items to the

shipping agent. Retain and use the original packing material for reshipment if necessary.

Upon Receipt, inspect the carton for the following items:

Model 3550 General Purpose, Programmable LCR Meter

Model 3550 User’s Manual CD

Power Cord

!

Safety Information & Precautions:

The following safety information applies to both operation and service personnel. Safety

precautions and warnings may be found throughout this instruction manual and the equipment.

These warnings may be in the form of a symbol or a written statement. Below is a summary of

these precautions.

Terms in This Manual:

CAUTION statements identify conditions or practices that could result in damage to the equipment

or other property.

WARNING

life.

Terms as Marked on Equipment:

CAUTION indicates a personal injury hazard not immediately accessible as one reads the marking,

or a hazard to property including the equipment itself.

DANGER

statements apply conditions or practices that could result in personal injury or loss of

indicates a personal injury hazard immediately accessible as one reads the marking.

2-2

Page 27

Model 3550 LCR Meter Instruction Manual Preparation for Use

!

Safety Information & Precautions Cont’d:

Symbols:

As Marked in This Manual:

!

This symbol denotes where precautionary information may be found.

As Marked on Equipment:

!

Caution – Risk of Danger

Danger – Risk of Electric Shock

Earth Ground Terminal-

On

l

O

Grounding the Equipment

This product is grounded through the grounding conductor of the power cord.

WARNING:

properly wired receptacle before using this instrument. The proper grounding of this instrument is

essential for safety and optimizing instrument operation.

Off

Chassis Terminal

Alternating Current

Earth Ground Terminal / Guard

To avoid electrical shock or other potential safety hazards, plug the power cord into a

Danger Arising from Loss of Ground

WARNING:

in the instrument. Under these conditions all accessible parts, including insulating parts such as

keypads and buttons could develop a hazardous voltage and put the user at risk.

If the connection to ground is lost or compromised, a floating potential could develop

2-3

Page 28

Model 3550 LCR Meter Instruction Manual Preparation for Use

!

Use the Proper Fuse

To avoid fire hazard, use only the correct fuse type as specified for the AC power supply in the

“Preparation for Use”” or “Service” sections of this manual. Please note that the fuse rating for 100

& 120-volt operation is different than the rating for 200 & 240-volt operation. Information about

the proper fuse type is also printed on the rear panel of the instrument.

Refer fuse replacement to qualified service personnel.

Do Not Use in Explosive Environments

WARNING: The 3550 is not designed for operation in explosive environments.

Do not Operate Without Covers

WARNING:

missing panels or covers could result in personal injury.

This device should be operated with all panels and covers in place. Operation with

FOR QUALIFIED SERVICE PERSONNEL ONLY

Servicing Safety Summary:

!

Do Not Service Alone

Do not perform service or adjustment on this product unless another person capable of rendering

first aid is present.

Use Care When Servicing with Power On or Off

Dangerous voltages may exist at several points in this product. To avoid personal injury or

damage to this equipment, avoid touching exposed connections or components while the power is

on. Assure that the power is off by unplugging the instrument when removing panels, soldering, or

replacing components.

WARNING:

present throughout the instrument even when the instrument is in the OFF state.

Always unplug the instrument and wait 5 minutes before accessing internal components.

Power Source

This product is intended to connect to a power source that will not apply more than 250V RMS

between the supply conductors or between either supply conductor and ground. A protective

ground connection by way of the grounding conductor in the power cord is essential for safe

operation.

The instrument power source is electronically controlled meaning that there is power

2-4

Page 29

Model 3550 LCR Meter Instruction Manual Preparation for Use

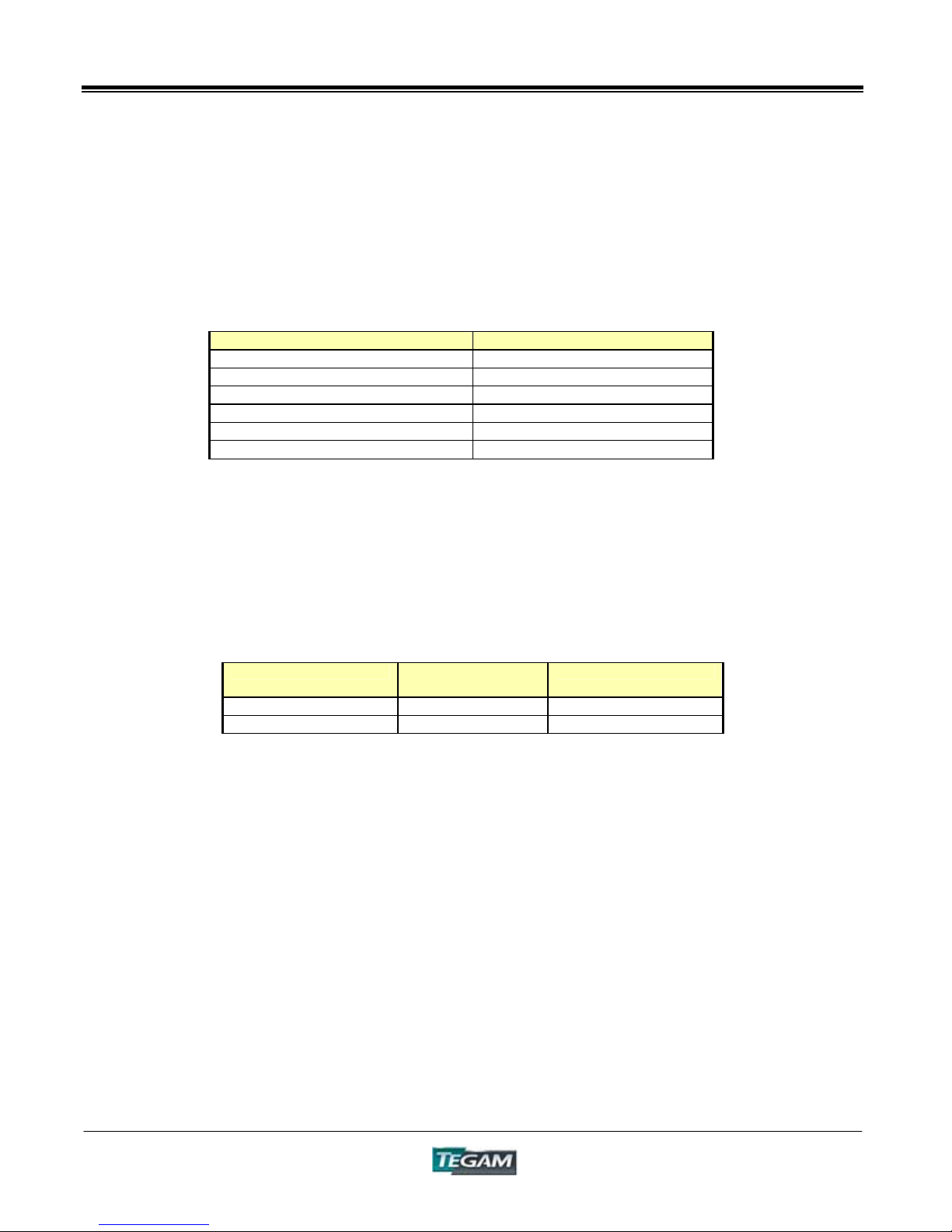

Line Voltage & Fuse Selection:

!

CAUTION: DO NOT APPLY POWER TO THE INSTRUMENT BEFORE READING THIS SECTION:

Unless other wise specified, the Model 3550 is delivered from TEGAM with its power supply set for

120V, 60 Hz operation. However, the 3550 design allows it to operate under 100, 120V, 220 or

240V @ 50/60 operation. It is strongly recommended that the line voltage and fuse size be

verified before powering the unit.

First, determine the supply voltage that the instrument will be operating under and verify that the

supply voltage does not fall outside of the allowable ranges in the table below:

LINE VOLTAGE RANGE FUSE SIZE

100/120V 90~132VAC 1A

220/240V 198~250VAC 0.5A

Make sure that the proper fuse size is installed.

Next, verify that the jumper block in the rear panel of the instrument is securely plugged into the

correct position. There are four positions that the block may be set to. Set the jumper block to

point to one of the four voltage settings. You can remove the jumper block by pulling it from the

jumper socket.

120V240V

220V 100V

Unit set for 120VAC Operation 50/60Hz

The instrument is ready for power up. Proceed to “Quick Start Instructions” for continued

operation.

2-5

Page 30

2-6

Page 31

Quick Start Instructions

SPECIFICATIONS

PREPARATION FOR USE

QUICK START INSTRUCTIONS

OPERATING INSTRUCTIONS

PROGRAMMING & INTERFACING

SERVICE INFORMATION

APPENDIX

Model 3550 LCR Meter Instruction Manual 3-1

Page 32

Model 3550 LCR Meter Instruction Manual Quick Start Instructions

The Model 3550 is a versatile product, which can be used in many different configurations.

Because of its ability to measure a large number of impedance parameters under a dynamic range

of test frequencies, amplitudes, and configurations, its is highly recommended that the entire

“Operating Instructions” Section of this manual be reviewed to insure proper use of this

equipment.

This Quick Start section is designed to give the user a general instruction set for the speedy setup

and measurement of impedance values where arbitrary measured values are needed and accuracy

is not critical. Whenever additional information is applicable, a reference will be made to other

parts of this manual so that the user, at their discretion, can decide whether or not to pursue

additional information.

Power the Unit

The power supply of the Model 3550 is designed for 50-60 Hz operations and a voltage range of

90-250 VAC. It is assumed that the “Preparation for Use” section of this manual has been read an

understood and the line voltage and fuse settings have been verified to be correct.

Power the unit by depressing the pushbutton located on the lower right corner of the front panel.

Allow at least 30 minutes for the unit to warm up and verify that the unit will be operated in its

specified operating environment described on page 1-12.

Instrument Settings

Factory Default Settings

Before performing an actual impedance measurement, there are a number of test parameters,

which must be defined. The factory default settings can be used for most general-purpose

measurements.

The 3550 is shipped from the factory with default settings as follows:

Table 3.1 – Factory Default Settings

Parameter Setting Parameter Setting

1 DISPLAY A Capacitance 9 Communications *RS232

2 DISPLAY B Dissipation Factor 10 Trigger INT

3 DISPLAY C Frequency 11 PANEL 0

4 Comparator Data Cleared 12 Circuit Mode AUTO

5 Comparator OFF 13 Range AUTO

6 Zero Correction Data Cleared 14 LOCK OFF

7 Test Frequency 1kHz 15 Test Voltage 1.00 V

8 Measurement Mode Open Terminal

Voltage

* not storable in a setup location.

At any time during use, you may recall these default settings by pressing the [MAN/EXT] key while

powering the unit.

NOTE: When the unit is reset to factory defaults, user-defined comparator settings and zero

correction factors will be lost.

3-2

Page 33

Model 3550 LCR Meter Instruction Manual Quick Start Instructions

Table 3.2a – Control Command Summary

1 Change measure item of DISPLAY A A

Commands

Display

2 Change measure item of DISPLAY B B

3 Show measure frequency on DISPLAY C FREQ

4 Show terminal voltage on DISPLAY C V

5 Show measure. current on DISPLAY C I

6 Change panel number 0-9

Basic Commands

7 Change measurement frequency FREQ ĺ DISPLAY C's UP and DOWN

8 Change measurement voltage V ĺ DISPLAY C's UP and DOWN

9 Carry out open correction OPEN

10 Carry out short correction SHORT

11 Change to auto range RANGE's AUTO

12 Change to auto circuit mode CIRCUIT MODE's AUTO

13 Change to fixed voltage mode V ĺ CV/CC

14 Change the fixed voltage setting

15 Change to fixed current mode I ĺ CV/CC

16 Change the fixed current setting

Applied Commands

17 Raise the range RANGE's UP

18 Lower the range RANGE's DOWN

19 Parallel equivalent circuits mode PRL

20 Serial equivalent circuits mode SER

21 Measure with continuous trigger INT

22 Measure with manual (single shot) trigger MAN/EXT ĺ MAN/EXT ĺ MAN/EXT ĺ

23 Set comparator lower limit LOW

24 Set comparator upper limit HIGH

25 Turn comparator on ON

26 Move cursor forward in setting mode

27 Move cursor backward in setting mode

28 Set measurement frequency SHIFT ĺ 0 ĺ Frequency Value ĺ ENTER

Commands

Shift

29

30 Set current for fixed current mode SHIFT ĺ 2 ĺ Current Value (mA) ĺ ENTER

31 Set number of measurements SHIFT ĺ 3 ĺ Number Setting ĺ ENTER

Set voltage for measurement or fixed voltage

mode

When V and CV/CC LED are flashing,

DISPLAY C's UP and DOWN

When I and CV/CC LED are flashing

DISPLAY C's UP and DOWN

SHIFT ĺ 1 ĺ Voltage Value (V) ĺ ENTER

3-3

Page 34

Model 3550 LCR Meter Instruction Manual Quick Start Instructions

Table 3.2b – Control Command Summary cont’d

32 Release Key Lock SHIFT ĺ 4 ĺ 0 ĺ ENTER

33 Lock Key SHIFT ĺ 4 ĺ 1 ĺ ENTER

34 No buzzer for decision SHIFT ĺ 5 ĺ 0 ĺ ENTER

35 Buzzer for GO decision ON SHIFT ĺ 5 ĺ 1 ĺ ENTER

36 Buzzer for NO GO decision ON SHIFT ĺ 5 ĺ 2 ĺ ENTER

37 Set start delay time SHIFT ĺ 6 ĺ delay time (ms) ĺ ENTER

38 To use absolute value comparator SHIFT ĺ 7 ĺ 0 ĺ ENTER

Shift Commands

39 To use percent comparator SHIFT ĺ 7 ĺ 1 ĺ ENTER

40 Set 1st spot correction frequency SHIFT ĺ 8 ĺ 1 ĺ frequency value ĺ ENTER

41 Set 2nd spot correction frequency SHIFT ĺ 8 ĺ 2 ĺ frequency value ĺ ENTER

42 Set 3rd spot correction frequency SHIFT ĺ 8 ĺ 3 ĺ frequency value ĺ ENTER

43 Set low frequency of correction SHIFT ĺ - ĺ 1 ĺ frequency value ĺ ENTER

44 Set high frequency of correction SHIFT ĺ - ĺ 2 ĺ frequency value ĺ ENTER

45 Do spot or open correction SHIFT ĺ OPEN

46 Do spot or open correction SHIFT ĺ SHORT

47 Change RS-232C baud rate SHIFT ĺ 9 ĺ 1 ĺ Setting ĺ ENTER

48 Change RS-232C data length setting SHIFT ĺ 9 ĺ 2 ĺ Setting ĺ ENTER

49 Change RS-232C parity setting SHIFT ĺ 9 ĺ 3 ĺ Setting ĺ ENTER

50 Change RS-232C stop bit setting SHIFT ĺ 9 ĺ 4 ĺ Setting ĺ ENTER

3-4

Table 3.3 - Shift Function Summary

SHIFT 0 Set measurement frequency

SHIFT 1

SHIFT 2 Set current for fixed current mode

SHIFT 3 Set number of measurements

SHIFT 4 Set key lock

SHIFT 5 Set buzzer

SHIFT 6 Set start delay time

SHIFT 7 Set comparator mode

SHIFT 8 Set spot correction frequency

SHIFT 9 Set RS-232C communication parameters

SHIFT - Set correction frequency limits

SHIFT OPEN Do spot open correction

SHIFT SHORT Do spot short correction

Set voltage for measure voltage/fixed

voltage mode

Page 35

Model 3550 LCR Meter Instruction Manual Quick Start Instructions

Instrument Setup for Basic Measurements

To perform basic measurements with the Model 3550, perform the steps below: Refer to

“Operating Instructions” for more details about specific commands or functions of the 3550.

NOTE: The numerals in parentheses reference the Control Command Tables on the previous pages. The

letters in parentheses reference the Settings Summary below:

Perform an open and closed circuit zero correction {Normal correction (9,10), Frequency

limit correction (F), or Spot correction (E)} on the test leads or fixture.

Set DISPLAY A measurement parameters (1)

Set DISPLAY B measurement parameters (2)

Set measurement frequency (7 or 28)

Set measurement mode {Voltage (8 or 29), Constant Voltage (A), or Constant Current (B)}

Set the comparator limits and operation if necessary {Absolute Comparator (C) or Percent

Comparator (D)}

Set the trigger mode {Continuous (21) or One-Shot (22) trigger}

Table 3.4 - Settings Summary

To use fixed voltage

A

mode

To use fixed current

B

mode

To use absolute

C

value comparator

To use percent

D

comparator

To use spot

E

correction

To use frequency

F

limit correction

Set voltage for fixed voltage mode (14 or 29)

Change to fixed voltage mode (13)

Set current for fixed current mode (16 or 30)

Change to fixed current mode (15)

Select absolute value comparator (38)

Set comparator lower limit value (23)

Set comparator upper limit value (24)

Turn comparator ON (25)

For comparator setting details, see absolute value

comparator setting instructions.

Select percent comparator (39)

Set comparator lower limit value (23)

Set comparator upper limit value (24)

Turn comparator ON (25)

For comparator setting details, see percent

comparator setting instructions.

Set spot correction frequency (40~42)

Carry out spot-open correction (45)

Carry out spot-short correction (46)

Set upper frequency limit for correction (44)

Set lower frequency limit for correction (43)

Carry out open correction (9)

Carry out short correction (10)

3-5

Page 36

Model 3550 LCR Meter Instruction Manual Quick Start Instructions

Setting the Absolute Comparator

To set the Absolute Value Comparator, following the procedure below:

1. Select either the upper or lower comparator limit.

To input an upper limit, press [HIGH]

To input a lower limit, press [LOW]

2. Input the BIN No.

After the [HIGH] or [LOW] key is pressed, the BIN LED will begin to flash. Use keys [1]~[9]

to designate the number.

3. Input a limit value for DISPLAY A

After selecting the bin number, use the cursor to highlight DISPLAY A.

Enter the 5-digit upper or lower value using the keys [1]~[9]. When this is complete, the

decimal point will flash.

Press [DP] to move the decimal point to the position of the setting value.

Use the cursor [Ź] to highlight the unit. Here, each time [UNIT] is pressed, the unit will

change. Designate the unit for the Nominal value.

4. Input a limit value for DISPLAY B

When the setting for DISPLAY A is complete, use the cursor [Ź] to highlight DISPLAY B.

Enter the 5 digits, decimal point and unit as done for DISPLAY A.

If the setting is a negative value, use the cursors keys, [Ź] or [Ż] to highlight the 1

of DISPLAY B.

Press [-] to negate the value.

5. Finalize the Comparator Settings

If defining an upper limit, press [HIGH] to complete the setting.

If defining a lower limit, press [LOW] to complete the setting.

To input settings for other bins, repeat the steps above.

6. Invalidating the DISPLAY A or DISPLAY B Comparator settings.

To invalidate the settings, take the cursor, [Ź] or [Ż], to any digit location in DISPLAY A or

DISPLAY B. Then press [IGNORE] to invalidate the settings of DISPLAY A or DISPLAY B.

NOTES:

The comparator can only be set using panels [1]~[9]. [0] is not used.

The above procedure applies only to the Absolute Value Comparator. The procedure for

setting the Percent Comparator is different. Before attempting to set the Absolute

Comparator limits, verify that the 3550 is in the Absolute Comparator Mode.

After setting the limit values for the comparator, the measurement parameters for

DISPLAY A and DISPLAY B cannot be changed. The measurement parameters must be

defined before the comparator is set.

For DISPLAY B, there are no units for D,Q, or LJ.

st

digit

3-6

Page 37

Model 3550 LCR Meter Instruction Manual Quick Start Instructions

Setting the Percent Comparator

To set the Percent Comparator, follow the procedure below.

The upper and lower limit for the nominal value are the same. For the threshold values, different

values for the upper and lower limit must be set. In order to proceed, the 3550 must be in the

percent comparator mode.

1. Select the Upper or Lower Limit to Enter the % Comparator Mode

To input the Nominal value, press the [HIGH] key. (The [LOW] key may also be pressed to

enter the % Comparator Set Mode)

2. Select the Nominal Value Input Mode

To input the Nominal Value, press [0] when the first digit of DISPLAY C is flashing.

3. Input the BIN No.

After selecting the Nominal Value Input Mode, use the cursor [Ź] to highlight the bin

number, and then press [1]~[9] to select the desired bin.

4. Set the Nominal Value for DISPLAY A

After inputting the bin number, use the cursor, [Ź] to highlight DISPLAY A. Enter a 5 digit

Nominal Value for DISPLAY A using keys [0]~[9]. (NOTE: The 1

st

digit, is restricted to only a

“1” or “0” setting.)

When this is complete, the decimal point will flash. Press [D.P] to move the decimal point to

the desired position. Then, use the cursor [Ź] to highlight the unit. Press the [UNIT] key

until the required unit annunciator is lit. This designates the measurement unit for the

Nominal value.

5. Input the Nominal Value for DISPLAY B

When the setting for DISPLAY A is complete, use the cursor [Ź] to highlight DISPLAY B.

Enter the 5 digits, decimal point and unit just as in DISPLAY A.

If the setting is to be a negative value, use cursors [Ź] or [Ż] to highlight the 1

st

DISPLAY B then press [-] to negate the value.

6. Completing the Nominal Value Setting

Press the [HIGH] key to finalize the Nominal Value Setting for the % Comparator.

(If the [LOW] key was pressed to enter into the % Comparator Mode then press it instead of

the [HIGH] key to exit the mode and finalize the settings.)

7. Set an Upper or Lower Limit for the % Threshold Values

To input an upper limit threshold value, press the [HIGH] key. Press the [LOW] key to set

the lower limit threshold value. Then, highlight the first digit of DISPLAY C and press [1].

digit of

3-7

Page 38

Model 3550 LCR Meter Instruction Manual Quick Start Instructions

Setting the Percent Comparator

8. Input the BIN No.

After selecting the threshold value input mode, use the cursor key, [Ź] to highlight the bin

LED, and then press [1]~[9] to select the desired bin.

9. Input the Threshold Value for DISPLAY A

After entering the bin number, use the cursor key [Ź] to highlight DISPLAY A.

Enter the 5-digit threshold value for DISPLAY A using keys [0]~[9]. (The setting range is

from 000.00%~199.99%)

10. Input the Threshold Value for DISPLAY B

Enter the 5-digit threshold value for DISPLAY B using keys [0]~[9]. (The setting range is

000.00%~199.99%)

11. Finalizing the Setting

To finalize an upper limit, press [HIGH] or press [LOW] to finalize a low limit setting.

NOTE: Whether a high or low limit %comparator setting is defined is determined in step 7.

To input settings for other bins, return to Step 1 and repeat the process.

12. Invalidating the DISPLAY A or DISPLAY B Percent Comparator settings

To invalidate the settings, for threshold values, simply enter the Threshold Percent

Comparator Set Mode and move the cursor to any segment in DISPLAY A or DISPLAY B. Then

press [IGNORE] to invalidate the % comparator settings for that DISPLAY.

NOTES:

The comparator can only be set using panels 1~9. 0 cannot be used.

This procedure is only for the percent comparator setting. Note that the procedure for the

absolute value comparator is different.

Make sure the comparator mode is set for “Percent Mode” otherwise the procedure will not

work correctly.

After setting the limit values for the comparator, the measurement parameters for DISPLAY

A and DISPLAY B cannot be changed. This means that the measurement parameters must

be defined before the comparator settings.

For DISPLAY B, there are no units for D,Q, or LJ.

3-8

Page 39

Operating Instructions

INSTRUMENT DESCRIPTION

PREPARATION FOR USE

QUICK START INSTRUCTIONS

OPERATING INSTRUCTIONS

PROGRAMMING & INTERFACING

SERVICE INFORMATION

APPENDIX

Model 3550 LCR Meter Instruction Manual 4-1

Page 40

Model 3550 LCR Meter Instruction Manual Operating Instructions

Basic Operation

The Model 3550 is a fully programmable LCR meter, designed for use in many different low and

high frequency applications. There are ideal configurations of the 3550 for each type of

measurement. These configurations optimize test conditions while enhancing accuracy and

measurement speed. In order to maximize the effectiveness the 3550, the user should have a

thorough understanding of the instrument’s operation along with a basic knowledge of LCR

measurement techniques. This section will provide the user with the necessary information to

make accurate and repeatable measurements.

Default Parameters

Each unit is delivered from the factory with predefined settings intended for general-purpose LCR

measurement and ease of use. Chapter III, Quick Start Instructions, contains information on

factory default settings.

!

CAUTION:

NEVER APPLY DIRECT CURRENT TO THE MEASUREMENT TERMINALS

Never apply direct voltage to the measuring terminals. When testing capacitors, always make

sure that they are fully discharged otherwise damage to the instrument will result.

NEVER MEASURE COMPONENTS IN A POWERED CIRCUIT

If you are measuring components, which are integrated into circuit boards, always check that

power is disconnected from the circuit before taking measurements. When measuring

transformers, always verify that no induced voltage is present before making connections.

Measurement Tips

Making Measurements that are Sensitive to Voltage and Current

The measured values of many components such as core-filled coils, layered ceramic capacitors etc.

are dependent upon the applied level of test current or voltage. In applications where the test

signal must remain constant, it is recommended that the range of the 3550 be manually set.

In the event that AUTO Range must be used, then operation of the 3550 in the “Constant Current”

or “Constant Voltage” Mode will maintain signal levels while allowing range adjustments.

Measuring Earth-Grounded Test Pieces

The L-side (L

FORCE

& L

point of the internal amplifiers. The L-side is a high-impedance point with zero electrical potential.

These terminals cannot be directly connected to Earth Ground. Measurement of devices with one

lead tied to earth ground is not recommended.

) of the measurement terminals is set up to be the virtual grounding

SENSE

4-2

Page 41

Model 3550 LCR Meter Instruction Manual Operating Instructions

R

R

R

R

Measurement Tips cont’d:

Measurement Circuit Modes

When the Measurement Circuit Mode is set to "AUTO", the Parallel Mode (PRL) or the Serial Mode

(SER) is automatically selected by the instrument based on the Measurement Range. The

measurement range is determined by the instrument by the magnitude of |Z| with no regards to D

or Q of the DUT.

Thus, the measured values of a component will vary depending on whether series or parallel

equivalent circuit modes are used. The relationship between series and parallel equivalent circuit

measurements is illustrated in Table 4.1.

Table 4.1: Relationship Between Series and Parallel Equivalent Circuit Values

Equivalent Circuit

Mode

(SER)

Ls

L

(PRL)

G

L

(SER)

C

S

C

(PRL)

G

C

As a general rule, when measuring components where the reactive component is high, >10kƻ

then the parallel equivalent mode should be used as parallel leakage becomes more significant to

the measurement.

For low reactance components, <10ƻ the series equivalent mode should be used since lead

resistance becomes more significant to the reading than parallel leakage.

For measurements of component values that fall somewhere in between, follow the manufacturer’s

recommendations.

Dissipation

Factor: D

R

D =

D =ZLPG

D =ZCSR

D =

=

Z

L

S

=

=

G

=

Z

C

P

1

Q

1

Q

1

Q

1

Q

Conversion Formula

P LD1L

S L

L

P C

C

S CD1C

2

1

2

D1

1

2

D1

2

2

G

D

S

R

D

P

G

D

S

D

R

P

1

2

D1

2

1

2

G

D1

2

1

2

D1

2

1

2

G

D1

4-3

Page 42

Model 3550 LCR Meter Instruction Manual Operating Instructions

Measurement Tips cont’d:

Negative Capacitance or Inductance Readings

If a capacitor is connected to the 3550 while in the inductance measurement mode or if an

inductor is connected to the 3550 while in the capacitance mode, a negative sign will appear in the

display. The negative sign in the capacitance mode indicates an inductive measurement. The

negative sign in the inductance mode indicates a capacitive measurement.

If the resonant frequency of a DUT is reached, a “-“ sign will appear in the display.

Zero Correction of Parasitic Impedance

"Open Correction" is for the purpose of compensating for the stray capacitance and stray

conductance of cables or test fixtures. Executing an "Open Correction" procedure on the test

leads of fixture before measurement of high impedance DUTs improves measurement accuracy.

"Short Correction" compensates for the residual inductance and resistance of cables or test

fixtures. Performing a "Short Correction" procedure on cables or test fixture before measurement

of low impedance DUTs improves measurement accuracy.

If the condition or position of a cable or test fixture changes, you MUST carry out Zero Correction

to compensate for the change. When performing a Zero Correction, keep hands and metallic

objects away from the cable or fixture.

Connection

Terminal

Only

5-Terminal

Kelvin

Klips™

Table 4.2: Short and Open Null Connections

Open Correction Short Correction

Correct Incorrect Correct Incorrect

G L H

G L H

G L H G L H G L H

G L H G L H G L H

L

H

F

F

L

H

S

S

L

H

F

L

H

S

Insulator

F

S

L

F

H

F

H

L

S

S

L

H

L

F

S

H

S

F

4-4

Page 43

Model 3550 LCR Meter Instruction Manual Operating Instructions

T

Measurement Tips cont’d:

Test Lead Requirements

Four-wire Kelvin-type cables or fixtures must be used with the 3550 in order to obtain accurate

impedance measurements. The Kelvin measurement technique allows significant accuracy

advantage over the two-wire method. This is because it virtually eliminates lead resistance and

inductance and reduces stray capacitance between the source and sense leads.

Two of the four conductors are designated as source leads. These source leads provide the

precision test current that will be referenced in making the resistance measurement. Since current

is the same throughout a series circuit, the lead resistance of the test leads will not have any

effect on the level of reference current.

The other two conductors are designated as voltage sense leads. These leads originate from a high

impedance, volt measurement circuit. When these leads are terminated at the points of contact,

an exact resistance reading is calculated by the 3550’s microprocessor. The series lead resistance

of the voltage sense leads is negligible due to the high impedance of the voltage measurement

circuitry within the 3550.

Figure 4.1a: Four-Wire Kelvin Measurement

Z

S

VOLTAGE

REFERENCE

CURRENT SOURCE

H

FORCE/LFORCE

SENSE

H

SENSE/LSENSE

Z

S

V

CONTACT

POINTS

Z

DUT

Figure 4.1b: Proper Application of Four Wire Kelvin Measurement

H

S

H

L

L

F

S

F

L

F

L

S

HSH

F

DUT DUT

CORRECT INCORREC

4-5

Page 44

Model 3550 LCR Meter Instruction Manual Operating Instructions

Measurement Tips cont’d:

Measurement Signal Levels

Measurement signal levels are adjustable between 0.01V~5.00V. It is recommended that the

voltage level be kept at a high value (usually 1V or larger) to avoid potential stability problems

associated with test frequency, device impedance and noise.

Series or Parallel Circuit Modes

The "CIRCUIT MODE" should always be "AUTO" mode, unless there is a special circumstance that

requires otherwise. The 3550 is in the AUTO circuit mode when the pushbutton’s LED is

illuminated. Manually setting the circuit mode should only be done in special circumstances where

series or parallel measurement is necessary even if some discrepancy is known to occur.

Auto Range Switching Threshold

When using Auto Range for measurement, the relationship between the switching direction and

indicated switching values are as follows: (When Dissipation Factor: D=0)

Range UP When|Z|19999 counts

Range DOWN When|Z| 17999 counts

As the dissipation factor, D increases then these threshold values will change.

Display Resolution

The absolute impedance, |Z| of the DUT determines the range of the 3550. All subsequent

measurements will display with a resolution that is consistent with the instrument’s current range

setting.

AC Resistance of Coils with Cores

In most cases the AC resistance of a coil with no core at low frequencies is the same as the DC

resistance. This is not the case for coils with high permeability cores such as ferrite or iron. Higher

permeability will promote core losses from an AC signal causing the resistance measurement to

appear larger than it would be for a DC measured resistance value. Therefore, an inductance

measurement taken at 42Hz (the lowest frequency setting of the 3550) will not necessarily reflect

a DC equivalent resistance value.

4-6

Page 45

Model 3550 LCR Meter Instruction Manual Operating Instructions

Front Panel Description

Front Panel Layout

15

17

12

10

11

8

6

14

16

18 20

22

21

2

9

Except for the "POWER" switch, a buzzer will be sounded whenever the function of a switch is

changed.

7

13 19

Figure 4.2: Front Panel layout

34 5

1

4-7

Page 46

Model 3550 LCR Meter Instruction Manual Operating Instructions

Front Panel Description cont’d:

1 - [POWER] Switch – [POWER]

With the power switch in the down state, power is applied to the 3550 and in the up state power is

off. When the power is turned on, the remaining operational switches will retain the same status

as they had before the power was previously turned off.

If the power is turned on while simultaneously pushing the [MAN/EXT] Key, the machine will

return to its factory default settings.

2 "CIRCUIT MODE" Panel - [AUTO] [SER] [PRL]

This panel contains the keys used for setting the Series or Parallel Equivalent Circuit Mode. When

verifying incoming component values it is usually good practice to consult the manufacturer for the

recommended test mode.

In general, parallel mode is used when the reactance of a device is large. Parallel mode should be

used when a capacitor’s leakage or an inductor’s core losses significantly affects the reading.

Series mode is recommended for small reactance measurements in capacitors and inductors where

series lead resistance must be considered and leakage and core losses become negligible.

x [AUTO] – When this key is illuminated, the instrument is in AUTO equivalent circuit mode.

This means that the 3550 will automatically select either series or parallel equivalent circuit

mode based on the impedance of the DUT. It does not necessarily mean that the correct

equivalent circuit mode will be selected.

x [SER] – Series equivalent circuit mode is typically desirable for low reactance

measurements. This is because Rs or series resistance becomes more significant than

parallel resistance to the measured value.

x [PRL] – Parallel equivalent circuit mode is often more effective for measurement of

impedances with high reactive components. This is because in a capacitor or inductor with

a high reactance, the parallel leakage is more significant to the measured value.

3 "TRIGGER" Panel - [INT] [MAN/EXT]

Select either an internal or external trigger by pressing either the [INT] or [MAN/EXT] key. The