Page 1

MODEL 2411B

2MS/s Arbitrary Waveform Generator

Operation Manual 810029-CD

Rev. D

Publication Date: November 2005

Page 2

The Tegam 2411B is a high resolution 2 MS/s Arbitrary Waveform Generator with

optional Windows® based waveform creation capability. The updated front panel

and the optional WaveWork

TM

Pro +. waveform creation software make the 2411B the

easiest way to create and output the waveforms you need. The additional channels

needed for multi-phase applications can be met with a simple connection between

two or more 2411Bs. It’s combination of bench-top and system features, GPIB (optional) and RS232 (standard) interfaces and the integrated software which is optional and

runs under Windows make this waveform generator package a versatile tool useful to

create your waveforms for mechanical simulation, engine simulation, medical electronics, modulated sine wave applications and many more applications.

Lab-quality performance

z20 commonly used waveforms front-panel selectable

zContinuous or triggered output--5 standard modes

z16-bit high-fidelity waveforms--0.005% THD (typical) at 2kHz

zHigh resolution output up to 2 MS/s

zVery large waveform memory--64k words

zLoop and link up to 100 waveforms (Sequence option)

Convenient bench-top features

zUpdated front panel includes control knob and back-lighted LCD

zCursor Control of amplitude, offset, sample clock and frequency.

zPortable, small profile package

System features

zRS-232 included

zWaveform creation software under Windows available

z4 programmable Sync pulses per waveform

TEGAM 2411B

2 MS/s Arbitrary Waveform Generator

Page 3

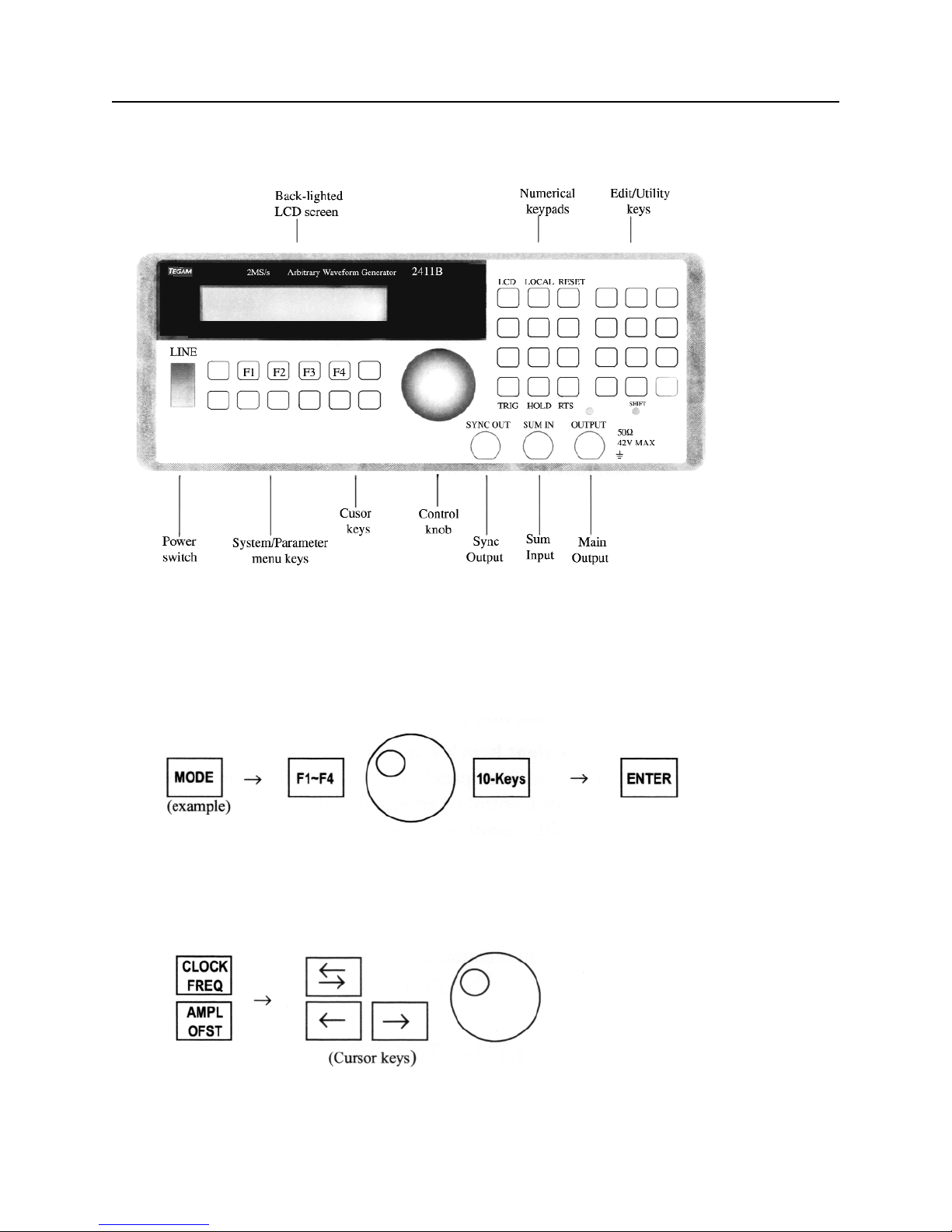

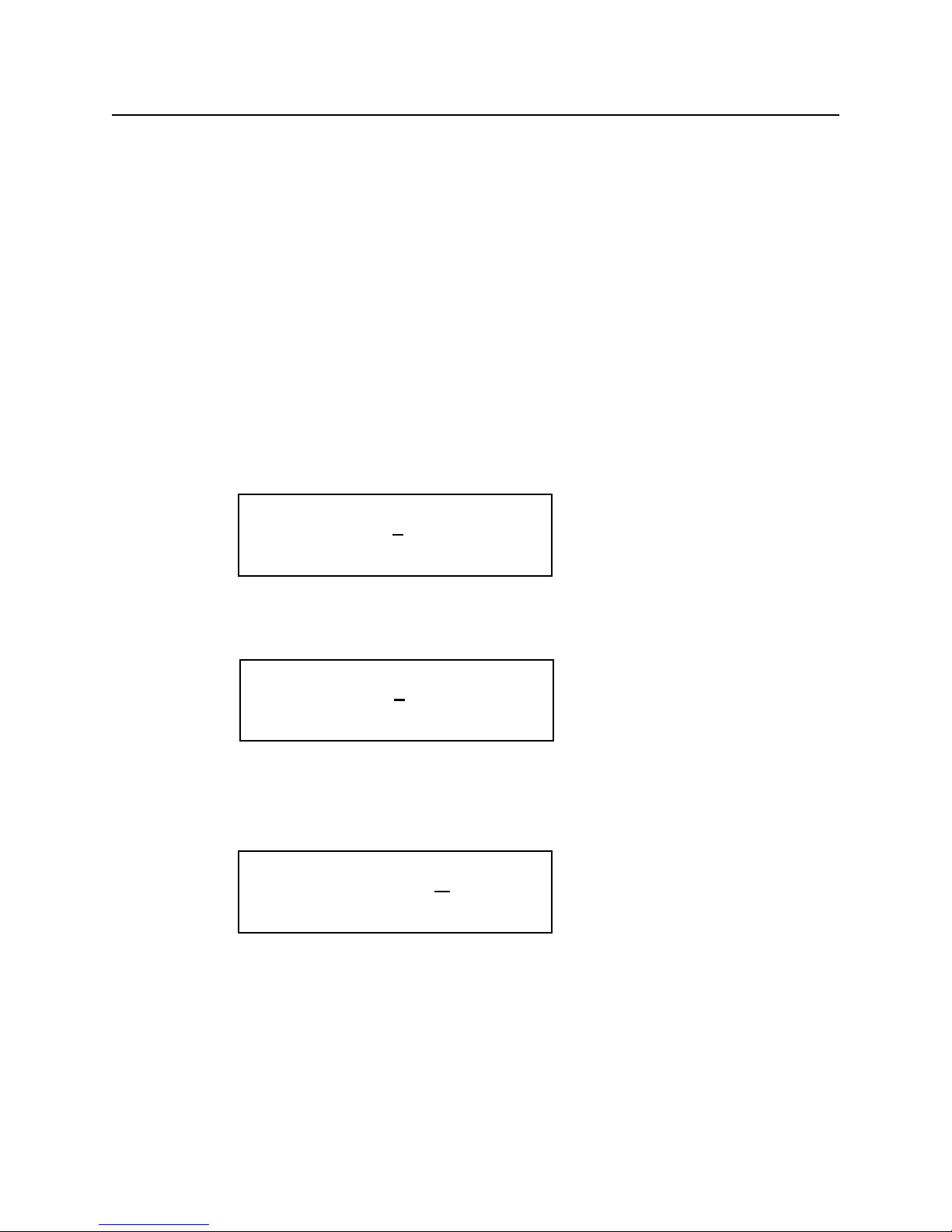

The Front Panel

Front-Panel Entry

Press one of the System/Parameter menu keys or the Utility/Edit menu keys, and use soft keys

(F1~F4), knob or 10-keys to make selection. Then, press ENTER key.

Use the CLOCK/FREQ or AMPL/OFST key and the knob to make parameter changes. Use double

arrow key to switch parameter selection.Use arrow keys to select digits and ranges.

II

Page 4

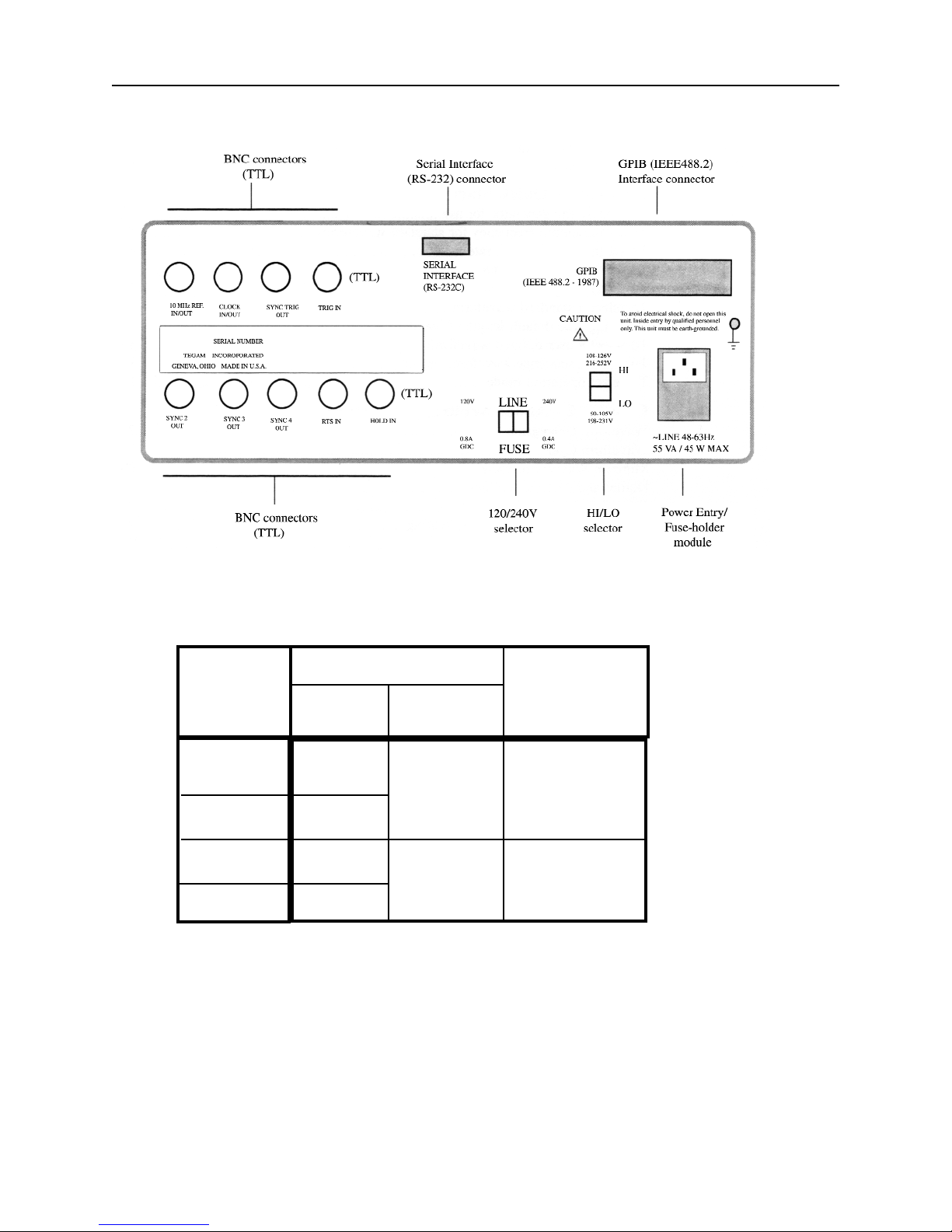

The Rear Panel

III

Mains

Voltage

Range (V)

Power Mains Setting

Hi / Lo Range Fuse Rating

Selector Selector

90 ~ 105

108 ~ 126

198 ~ 231

216 ~ 252

Lo

120V 0.8A GDC

Hi

Lo

240V 0.4A GDC

Hi

Page 5

Table of Contents

The Front Panel...........................................................................................................................II

Front Panel Entry.........................................................................................................................II

The Rear Panel / Power Mains Setting......................................................................................III

Technical Specification.............................................................................................................VII

In This Manual........................................................................................................................VIII

Chapter 1 - Quick Start

To prepare the generator for use.............................................................................................1 - 2

To set the output frequency for standard waveforms.............................................................1 - 3

To set the sample clock rate....................................................................................................1 - 4

To set the output amplitude.....................................................................................................1 - 5

To set the output offset voltage...............................................................................................1 - 6

To select a standard waveform...............................................................................................1 - 7

To change the default length of standard waveform..............................................................1 - 8

To select a user-defined waveform.........................................................................................1 - 9

To select a sequence waveform (option)...............................................................................1 -10

To select operating mode.......................................................................................................1-12

Chapter 2 - About Arbitrary Waveforms

Waveform Generation.............................................................................................................2 - 2

Waveform Cycle..................................................................................................................... 2 -2

More on Waveform Cycle...................................................................................................... 2 -3

Digital and Analog Scaling.....................................................................................................2- 3

Other Considerations...............................................................................................................2- 3

Examples-Digital and Analog Scaling....................................................................................2 - 4

Waveform Types.....................................................................................................................2- 5

Sync Pulse...............................................................................................................................2- 6

Sync Outputs...........................................................................................................................2- 7

2411B Block Diagram.............................................................................................................2- 8

Chapter 3 - Front-Panel Menu Operation

Parameter Control

MODE menu............................................................................................................ 3 - 2

Sample Clock and Frequency (SCLK/FREQ) menu...............................................3 - 2

Amplitude/Offset (AMPL/OFST) menu..................................................................3 - 2

Function (FUNC) menu............................................................................................3 - 3

OUTPUT menu........................................................................................................3 - 4

Waveform Setup.....................................................................................................................3 - 4

Waveform Edit.................................................................................................................... ...3 - 4

System Control........................................................................................................................3 - 5

Default Settings.......................................................................................................................3 - 6

Standard Waveform List......................................................................................................... 3- 9

Chapter 4 - Waveform Creation System

Components............................................................................................................................4 - 2

User Interface.........................................................................................................................4 - 2

Memory Organization

Introduction..............................................................................................................4 - 4

Default Partitioning.................................................................................................4 - 4

Waveform Numbering..............................................................................................4 -4

Changing Waveform Block Length.........................................................................4 - 4

Waveform Number Block Length............................................................................4 - 5

Deleting Waveform..................................................................................................4 - 5

Inserting New Waveform numbers..........................................................................4 - 5

IV

Page 6

Table of Contents

Waveform Creation Using Front Panel

Introduction...............................................................................................................4 - 6

Line Mode................................................................................................................4 - 6

Vertex Mode............................................................................................................ 4 - 9

Math Operation........................................................................................................4-13

Examples.................................................................................................................4-14

Sequence Generator (Option)

Introduction...............................................................................................................4-17

Programming a Sequence.........................................................................................4-17

Deleting a Sequence.................................................................................................4 -18

Adding a Step into an Existing Sequence................................................................4-18

Deleting a Step from an Existing Sequence.............................................................4-19

Modyfying a Step within an Existing Sequence......................................................4-19

WaveWorks Pro Software (Option)........................................................................................4- 20

Chapter 5 - Multi-Instrument Operation

Basic Connection.....................................................................................................................5- 2

Multiple Phase Connection......................................................................................................5- 3

Multiple Phase Operation........................................................................................................5-4

Multiple Phase Setup...............................................................................................................5-6

Chapter 6 - Performance Verification

Introduction..............................................................................................................................6-2

Test Equipment Required.........................................................................................................6-2

Verification Test.......................................................................................................................6-2

Verification Test Sheet.............................................................................................................6-4

Chapter 7 - Remote Interface Operation

Introduction..............................................................................................................................7-2

To set the GPIB address..........................................................................................................7- 2

To set the RS-232 parameters..................................................................................................7- 3

RS-232 Adapter Cables...........................................................................................................7- 4

Before sending commands......................................................................................................7-5

Command Features

Command Execution.................................................................................................7- 5

Waveform Selection..................................................................................................7- 6

Waveform Deletion...................................................................................................7 - 6

Command Set..........................................................................................................................7- 7

Reset and Default Values...................................................................................................... 7-14

RS-232 Programming Example.............................................................................................7 -16

GPIB Programming Example................................................................................................7-18

Chapter 8 - Advanced Remote Operation

RS-232 Overview

Introduction...............................................................................................................8- 2

Interface Requirements.............................................................................................8 - 2

Verifcation of Communication..................................................................................8- 3

Command Syntax......................................................................................................8- 3

Common Commands.................................................................................................8- 3

Event Register and Status and Error Reporting........................................................8-4

Functional Syntax Elements......................................................................................8-4

V

Page 7

Table of Contents

GPIB (optional) (IEEE-488.2) Overview

Introduction................................................................................................................8-7

Common Commands.................................................................................................8-8

Status and Event Registers........................................................................................ 8-9

Functional Elements - Syntax and Nomenclature...................................................8 - 11

Error Reporting........................................................................................................8-12

Data Formats

Decimal Numeric Program Data..............................................................................8 -13

Arbitrary Block Program Data.................................................................................8 -14

Remote Command Set

Introduction..............................................................................................................8 -15

Command Sequence..................................................................................................8-15

Command Execution................................................................................................8 -15

Command Set Hierarchy...........................................................................................8-16

Stacked Queries........................................................................................................8-16

Command Set............................................................................................................8 -17

Waveform Editing Principles..................................................................................................8-19

Waveform Memory Format

Decimal Waveform Download.................................................................................8- 21

Binary Waveform Download....................................................................................8-22

Example....................................................................................................................8-23

Binary Download Test Program for GPIB...............................................................8-25

Arbitrary Sync Pattern Programming

Overview.................................................................................................................. 8-28

Start/Length Sync Programming..............................................................................8-28

Block Sync Programming.........................................................................................8 -29

Combined Waveform and Sync Programming.........................................................8-30

Single Point Sync Query...........................................................................................8-31

Multiple Point Sync Query.......................................................................................8- 31

Sequence Generator Operation (Option)

Add Sequence...........................................................................................................8-33

Auto Sequence..........................................................................................................8-33

Sequence...................................................................................................................8-33

Sequence Burst.........................................................................................................8-34

Sequence Burst Number...........................................................................................8-34

Appendix

Menu Logic Tree

Standard Waveshape Equations

Amplitude/Offset Graph

Index

Warranty

VI

Page 8

Techical Data Sheet

TEGAM 2411B 2MS/s Arbitrary Waveform Generator

VII

Output Waveforms

Up to 100 High-Definition User-defined Waveforms,

Standard Waveforms: Sine, Square, Triangle, ±Sawtooth,

DC, ±Pulse, ±Exponential, AM, SCM, FM, Lin/Log

Sweep, Sin x/x (Sine), Gaussian, Haversine, Circle,

Noise.

4 programmable sync pulses per waveform.

Sequence Generator (Optional)

Waveform: Transient-free Loop and Link

Repetitions: Loop: 1,048,575 times Link: 100 waveforms

Program: 1000 Steps total

File: 100 Sequences

Waveform

Storage: 100 waveforms

Resolution:

Horizontal Points: 65,504 max., 16 min.

Vertical Points: 16 bits, 65,536 (-32768 to +32767)

Sample Rate:

Range: 0.1 Hz to 2MHz (10s to 500ns)

Resolution: 4 digits

Accuracy:±50ppm

Transition Time: <150ns

(Tested with square wave, filter off, 10Vp-p, 50Ω

termination.)

THD + Noise: -86dB typical (2kHz sinewave)

(Tested with 80kHz measurement bandwidth, 2 MHz

clock, sinewave, 1000 points, filter on. full amplitude, 50Ω

termination.)

Amplitude and Offset

Range

Resolution Accuracy

±1.00 to 10V 10mV 1 % of setting + 20mV

±100mV to 999mV 1mV 3% of setting + 5mV

±10mV to 99.9mV 100mV 5% of setting + 1mV

(Tested with 1kHz sinewave plus DC offset, 50

Ω

source

impedance, open circuit.)

Selectable Analog Filter

Cutoff: 700kHz, 7th order; 40kHz, 3rd order

Operational Modes

Continuous: Output runs continuously between selected

memory address locations

.

Triggered: Output at start point until triggered, then runs

once.

Gated: As triggered except output is continuous until gate

signal ends.

Burst: Each trigger outputs a preprogrammed number of

waveforms from 1 to 1,048,575.

Toggled: Alternate triggers gate the output waveform.

Master-Slave: For multi-unit operation.

Cont-Sync: multiple units run continuously in sync with

the master unit

Trig-Sync: multiple units run in sync with the master unit

for one cycle when the master unit is triggered.

Trig-Sequence: a tail-chasing mode between the master

and the slave unit initiated by triggering the master unit.

Outputs

Output: Front-panel main waveform output, 50Ω

impedance.

Sync Outputs: Front-panel TTLsync output, 50Ω

impedance plus 3 rear-panel TTL outputs.

Programmable.

Clock Out: Rear-panel AWG waveform sample clock

output (TTL). x2 sample clock.

Reference Out: Rear-panel internal 10MHz reference

output (TTL).

Sync Trigger Out: Triggers additional units

Inputs

Trigger Input: Rear-panel TTL trigger input for trig-

gered,gated, burst, toggled and master-slave modes.

External TTL Sample Clock Input:< 4MHz

Reference In: Rear-panel 10MHz reference input will

phase lock the internal crystal-controlled oscillator.

Trigger Sources

External Trigger Input

Manual Trigger

Waveform Creation Tools (Option)

Software:

WaveWorks Pro+ for Windows

Operating System: Windows 2000, 98 or 95.

PC Requirements: 486DX or better with 4MB RAM

space

Interface: COM port or National Instrument AT-GPIB

card (or equivalent)

Standard Function: 30

Math Operation:

Operators: 13

Transfer Functions: 20

Sequence Creation (optional hardware required)

Waveform Analysis:

Frequency Domain: FFT and IFFT: up to 500th

harmonic, graphic display and

tabulation

Time Domain: Waveform and Digital Pattern

Edit: Point, Vertex and Harmonics (FFT, IFFT).

Computer Interface

RS-232C: 19.2kBaud. max.

GPIB (optional): IEEE Std. 488.2-1987

General

Stored Settings: 31

Temperature Range: +23 °C ± 3°C for specified oper-

ation. Operates 0°C to +50°C. Storage -20°C to +60°C.

Dimensions: 11.5cm (4.53 in.) H; 25.8cm (10.14 in.)

W; 30cm (11.81 in.)D.

Weight: 5.0kg (11 Ibs)

Power: 55VA; 45W (max) 100/120/220/240 VAC. +5%,

-10%; 48 to 63 Hz.

Weight and dimensions are approximate. Errors and omissions excepted. Prices and specifications subject to change without notice. TEGAM

is the registered trademark of TEGAM, Inc.

© Copyright 2000 TEGAM Inc. All rights reserved.

Page 9

Quick Start:

Chapter 1 will prepare you to use the basic parameters of the arbitrary waveform generator

within a short time.

About Arbitrary Waveforms: Chapter 2 provides you the basic concept of arbitrary waveform genera-

tion.

Front-Panel Menu Operation: Chapter 3 describes the front-panel menu operation.

Waveform Creation System: Chapter 4 describes the overview of waveform creation system.

Multi-Instrument Operation: Chapter 5 describes the basic connection and the multiple unit operation

for multiphase applications. You will leam about the hardware connections and the available masterslave mode.

Performance Verification: Chapter 6 describes the procedure to verify the2411B specification.

Remote Interface Operation: Chapter 7 describes the remote interfaces. You will leam how to send

simple commands over RS-232 or GPIB. The detail command list is included in this chapter.

Advanced Remote Operation: Chapter 8 describes in details the remote interfaces. It is intended for

use by experienced systems programmers to control every feature of the 2411B from both RS-232 and

GPIB.

In this manual

VIII

Page 10

1

Quick Start

Page 11

Chapter 1 Quick Start

To prepare the generator for use

To prepare the generator for use

The following steps will help you verify that the generator is ready for use.

1. Check the list of supplied items.

Verify that you have received the following items with your arbitrary waveform generator.

• One power cord

• One serial interface cable

• The instrument operation manual on CD ROM.

2. Check the power mains voltage setting on the rear-panel.

Verify that the mains voltage is set to the range for your location. You can verify the setting by observing the position of the slide switches on the rear panel. Refer to the rear panel diagram on page III.

3. Connect the power cord and turn on the generator.

The generator power switch is located at the lower left corner of the front-panel. The front-panel display

will light up and indicate the name, the model number and the firmware version release level.

4. Press OUTPUT button, select ON (F1 softkey) and then press ENTER.

The LED above OUTPUT connector turns on. Now, the generator output is on.

5. Connect a BNC cable from the OUTPUT connector to an oscilloscope input.

Terminate the cable at the oscilloscope input with 50Ω load.

6. Connect a BNC cable from the front panel SYNC OUT connector to the external sync input of

the oscilloscope.

Make an adjustment to the oscilloscope to synchronize the output waveform on the display.

1-2

Page 12

Chapter 1 Quick Start

To set the output frequency for standard waveforms

To set the output frequency for standard waveforms.

At the initial power-on, the generator output is turned off. Be sure to follow the step 4 of the page 1-2 if

you have not yet turned on the generator output. The following steps will show you how to change the

output frequency to 12kHz. Remember that the output frequency is computed as shown.

Waveform Frequency = [(Sample Clock) / (Waveform Length)]*(Number of Cycles in the Waveform Frame)

1. Press SCLK (Sample Clock) / FREQ (Frequency) button. Then, press double arrow button to

exchange the parameters.

The displayed frequency is either the power-on value or the previously selected

2. Enter the magnitude of the desired frequency.

Use the right-arrow button to place the cursor under the selected digit. Turn the knob to set the digit to

2. The frequency will indicate 12.00 kHz.

3. Select the desired frequency range.

Use the right-arrow button to place the cursor under the multiplier (k). Turn the knob counterclockwise

to switch the range by a decade.

1-3

FREQ= 10.00 kHZ

SCLK= 10.00 MHz

FREQ= 12.00 kHZ

SCLK= 12.00 MHz

FREQ= 1.200 k

HZ

SCLK= 1.200 MHz

Page 13

Chapter 1 Quick Start

To set the sample clock rate

To set the sample clock rate.

At the initial power-on, the generator outputs a free-running sine wave at 10kHz with an amplitude of

5.0 V peak-to-peak (into 50Ω termination) after the output is turned on. The following steps will show

you how to change the sample clock rate of a user-defined waveform or an optional sequence. The output frequency of any waveform is:

Waveform Frequency = [(Sample Clock) / (Waveform Length)]*(Number of Cycles in the Waveform Frame)

1. Press FUNC (function) key and select a user-defined waveform, WAV#. Select WAV#0 and press

ENTER.

The default length of a user-defined waveform is 2000 points.

2. Press SCLK/FREQ (Sample Clock/Frequency) button.

The displayed sample clock is either the power-on value or the previous sample clock rate selected.

3. Enter the magnitude of the desired sample clock rate.

Use the right-arrow button to place the cursor under the selected digit. Turn the knob to set the digit to

2.

4. Select the range of the desired frequency.

Use the right-arrow button to place the cursor under the multiplier (M). Turn the knob counterclockwise

to switch the range by a decade. Observe the output frequency has changed by a decade.

1-4

SCLK= 10.00 MHZ

FREQ= 5.000 kHz

SCLK= 12.00 MHZ

FREQ= 6.000 kHz

SCLK= 1.200 MHZ

FREQ= 600.0 Hz

Page 14

Chapter 1 Quick Start

To set the output amplitude

To set the output amplitude

At the initial power-on, the generator outputs a cw sine wave at 10 kHz with an amplitude of 5V peakto-peak (into 50Ω termination) after the output is turned on. The following steps will show you how to

change the amplitude to 2.5V peak-to-peak.

1. Press AMPL/OFST (Amplitude/Offset) button.

The displayed amplitude is either the power-on value or the previous amplitude selected.

2. Select the digit you are going to modify.

Use the left-arrow button to place the cursor under the selected digit.

3. Enter the magnitude of the desired amplitude

Turn the knob counter clockwise to set the digit to 2.

4. Enter the magnitude of the desired amplitude.

Use the right-arrow button to place the cursor under the selected digit. Turn the knob to set the digit to 5

to change the magnitude.

1-5

AMPL= 5.000 V

OFST= 0.000 V

AMPL= 5.000 V

OFST= 0.000 V

AMPL= 2.000 V

OFST= 0.000 V

AMPL= 2.5

00 V

OFST= 0.000 V

Page 15

Chapter 1 Quick Start

To set the output offset voltage

To set the output offset voltage.

At the initial power-on, the generator outputs a cw sine wave at 1 kHz with an offset voltage of 0 V

(into 50Ω termination) after the output is turned on. The following steps will show you how to add 1.0

V offset to the output.

1. Press AMPL/OFST button twice or press the double arrow button to exchange the

parameters.

2. Select the digit and enter the desired offset voltage.

Use the left-arrow button to place the cursor under the number 0. Turn the knob to select the desired offset voltage. You must observe some restrictions for the magnitude of the offset voltage. The sum of the

offset and peak amplitude can not exceed ±5 volts when terminated with 50Ω.

1-6

OFST= 0.0

00 V

AMPL= 2.500 V

OFST = 1.000 V

AMPL = 2.500 V

Amplitude and DC Offset Ranges

TEGAM 2411B utilizes unique combinations of the input and output

attenuators for the output amplifier in order to accomplish the optimized

signal attenuation. Therefore, if DC offset is applied to the signal, the

following restrictions must be observed.

Amplitude Range

Legal Amplitude+DC Offset Limits

1V ~ 10.2V Amplitude + | DC Offset | < 10.4V

100mV ~ 999mV Amplitude + | DC Offset | <

1.00V

10mV ~ 99mV Amplitude + | DC Offset | <

100mV

Page 16

Chapter 1 Quick Start

To select a standard waveform

To select a standard waveform.

At the initial power-on, the generator outputs a free-running sinewave at 1 kHz after the output is turned

on. The following steps will show you how to select another standard waveform.

1. Press FUNC (function) button.

Select standard waveforms by pressing STDW (standard wave). The default length is set to 1000 points.

2. Use the right and left arrow buttons to view the selection menu.

Select one of the 20 standard waveforms.

3. Press SIN (sinewave) button to select parameter(s).

Use the double arrow button to exchange the parameters. Press the waveform button again to select

more parameters if available.

4. Turn the knob or key in the parameters on the 10-key to enter parameters.

1-7

FUNC:

wav# seq# STDW view

FUNC:STDW:

SIN squ tri saw+

FUNC:STDW:

am scm fm hsin

N=1.00 P=0.000

SIN squ tri saw+

Page 17

Chapter 1 Quick Start

To change the default length of standard waveform

To select a standard waveform (continued)

5. Press ENTER button to set parameters.

Note: the standard waveform data is recomputed after the parameters are changed. It may take a fraction of a second to several seconds to compute and draw the new waveshape. The time to draw the

waveform depends on the sample length and type of waveform selected.

To Change the default length of standard waveform.

The default length of 1000 points will create the maximum frequency of 2kHz sinewave. If higher frequency is required, the default length must be changed. The minimum length is 16 points.

1. Press SETUP button.

2. Press STDW (F2 soft key).

The display indicates standard waveform is located at the memory address of 10000 and the length is

1000. The 2411B automatically select the waveform memory location.

3. Press LEN (F4 soft key).

4. Turn the knob or key in the length on the 10-key to enter new length. Then, press OK (F3 soft

key).

1-8

SETUP:

WAV# STDW SEQ#

01000@10000 STDW

SYNC LEN

free=54504 L=1000

OK CANC

Page 18

Chapter 1 Quick Start

To select a user-defined waveform

To select a user-defined waveform.

At the initial power-on with the factory setting, the generator outputs free-running sinewave at 10 kHz

after the output is turned on. The following steps will show you how to select a user-defined arbitrary

arbitrary waveform. All user-defined waveforms must be created on the PC and downloaded to the

2411B using WaveWorks Pro or other software, or created using the edit utility prior to the selection.

However, we have loaded the first five user-defined waveform locations with sample waveforms for

your verification.

1. Press FUNC (function) button.

2. Press WAV# (F1 soft key).

If the waveform does not contain any data, it will not be displayed.

3. Press the knob to select one of the user-defined waveforms.

If the waveform does not contain any data, it will not be displayed.

4. Press ENTER button to select the user-defined waveform.

Whenever an asterisk is displayed on the LCD screen, the parameter selection is pending. You must

press ENTER button to complete the selection.

1-9

FUNC:

wav# seq# STDW view

*WAV# = 0

WAV# seq# stdw view

*WAV# = 2

WAV# seq# stdw view

WAV# = 2

WAV# seq# stdw view

Page 19

Chapter 1 Quick Start

To select a sequence waveform

To select a sequence waveform. (option)

The following steps will show you how to select a sequence waveform. The sequence generator option

must be installed in the 2411B prior to proceeding with the following steps. All user-defined waveforms

must be created on the PC and downloaded to the 2411B by using WaveWorks Pro or must be created

using the internal EDIT function before making the sequence selection. However, we have pre-loaded

the first five user-defined waveforms with the sample waveforms. We will utilize these waveforms to

demonstrate the sample sequence.

1. Press FUNC (function) button.

2. Press SEQ# (F2 soft key).

Turn the knob to select the desired Sequence waveform number. Press ENTER button. You will be able

to view the sequence waveform, unless you have already altered the sequence steps.

3. Turn the knob to select one of the user-defined waveforms.

If the sequence does not contain any data, it will not be displayed.

1-10

FUNC:

wav# seq# STDW view

*SEQ# = 0

wav# SEQ# stdw view

*SEQ# = 2

wav# SEQ# stdw view

Page 20

Chapter 1 Quick Start

To select a sequence waveform

To select a sequence waveform (continued)

4. Press ENTER button to select the sequence waveform.

Whenever an asterisk is displayed on the LCD screen, the parameter selection is pending. You must

press ENTER button to complete the selection.

Note: Each SEQ# may contain up to 4096 steps, use up to 1000 user-defined waveforms which may be

repeated up to 1,000,000 repetitions.

1-11

SEQ# = 2

wav# SEQ# stdw view

Page 21

Chapter 1 Quick Start

To select a operating mode

To select operating mode

The following steps will show you how to select an operating mode and output one cycle of a sinewavewhen a trigger signal is applied. The 2411B is initially set to CONT (continuous) mode.

1. Select a standard waveform.

See page 1-7 for the procedure.

2. Press MODE key to change the operating mode.

Press TRIG (F2 soft key) to select trigger mode.

3. Press ENTER button to select the mode.

Whenever an asterisk is displayed on the LCD screen, the parameter selection is pending. You must

press ENTER button to complete the selection.

4. Press SHIFT button and then press TRIG button (number 0 on 10-key) to output a single cycle

of a sinewave.

Please note the LED light will turn on when SHIFT button is pressed. While the SHIFT light is on, the

keypad will not function as a 10-keypad. Press again to disable the SHIFT button.

Note:

If you apply a single trigger pulse to the TRIG IN (TTL level) on the rear BNC connector, you can also

output a single cycle of a sinewave.

By selecting UTIL (UTILITY) button and then selecting TGEN (Trigger GENerator) (F4), you may

activate the internal trigger generator. When the internal generator is not in use, make sure that the triggert generator is set to OFF. Otherwise, it may interfere with other operation modes.

1-12

*MODE

cont TRIG gate brst

MODE:

cont TRIG gate brst

Page 22

Page 23

2

About Arbitrary W aveforms

Page 24

Chapter 2 About Arbitrary Waveforms

Waveform Generation

Waveform Generation

In an arbitrary waveform generator, you will define a waveform, using either the standard functions or

custom profile data files to load waveform memory. A set of start and stop addresses which correspond

to a waveform memory location is assigned with a waveform number. An address generator sequentially

presents data values from the specified memory location to the digital-to-analog converter (DAC). The

precision DAC converts the data into analog voltage values. This series of sequential voltage levels

describes the output waveform with the frequency determined by the sample clock rate divided by the

number of samples in the waveform. Changing the sample clock rate causes the address generator to

change the speed at which the data is presented to the DAC, thereby changing the output frequency.

The waveforms you create are a series of data points consisting of X- and Y-axis values. For 16-bit generators, such as the TEGAM 2411B, the Y values between +32767 and -32768 are used. In describing

the first point, 0, is given a Y value. The next point has another Yvalue, and so on up to the last address

in your waveform. This series of points make up the waveshape.

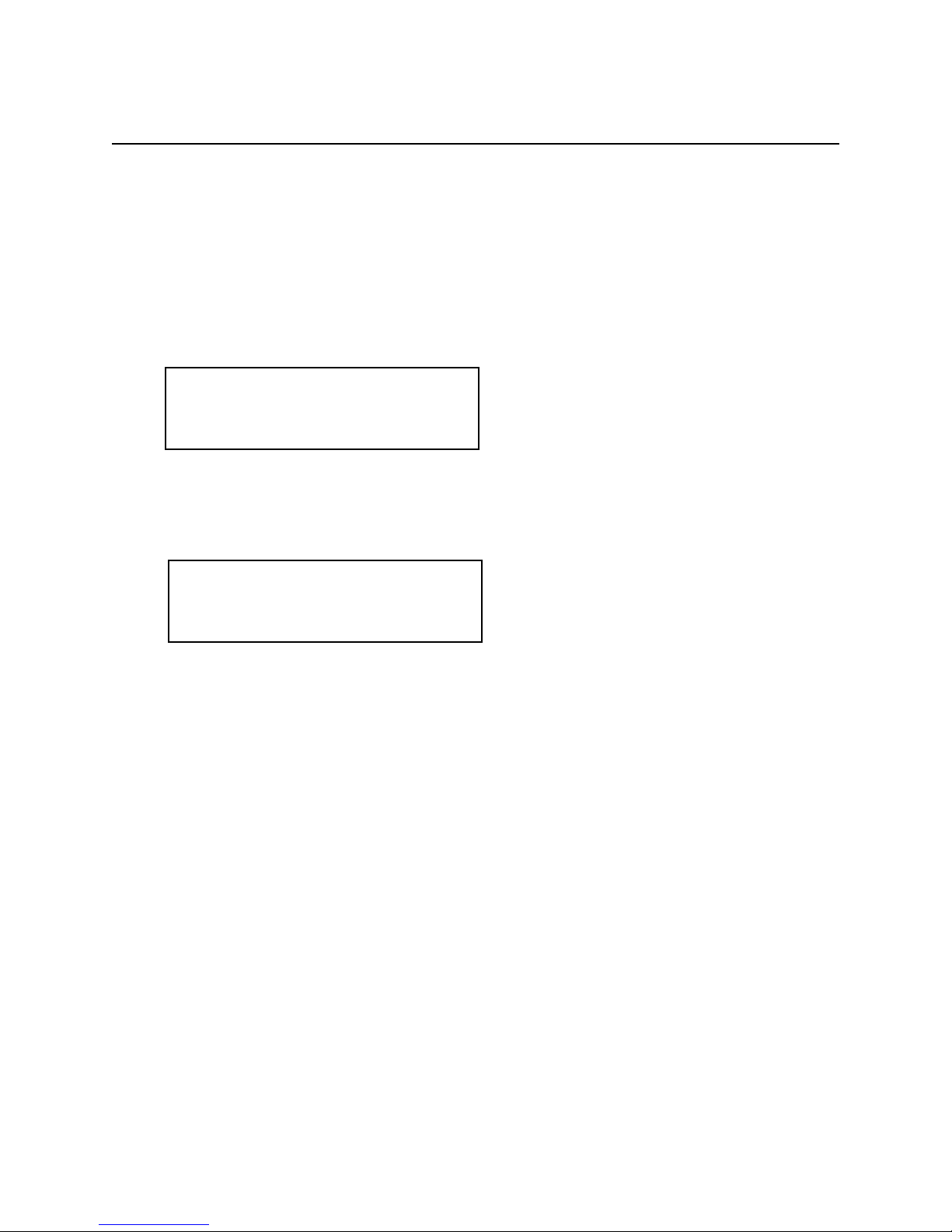

Waveform Cycle

All the data points in the specified waveform memory location make up one waveform cycle. The waveform generator will output all the points in the waveform at the sample clock rate specified. The resulting frequency is equal to the sample clock rate divided by the number of data points in the waveform. If

more than one cycle of the waveshape is entered into a waveform, the output frequency will be a multiple of one waveform generator cycle. For example, if you create a waveform with 3 triangle wave cycles

using the same number of data points and the sample clock rate, the frequency will be 3 times higher.

2-2

Page 25

Chapter 2 About Arbitrary Waveforms

More on Waveform Cycle

More on Waveform Cycle

TEGAM’s 2411B arbitrary waveform generator may sample the data points up to a maximum of 2

MS/s. The maximum frequency of the output is determined by the sample rate divided by the number of

points. For a 2 MHz arbitrary waveform generator with a waveform length of 1000 points, the upper frequency limit appears to be 2 kHz, since 2 MS/s / 1000 = 2 kHz. However, if you repeat the segment,

such as a sinewave, up to the minimum required number of samples (4 samples/segment), you can replicate up to 250 segments within the waveform length of 1000 points. Then, the output frequency of the

sinewave will be 500 kHz, since 2 kHz x 250 = 500 kHz.

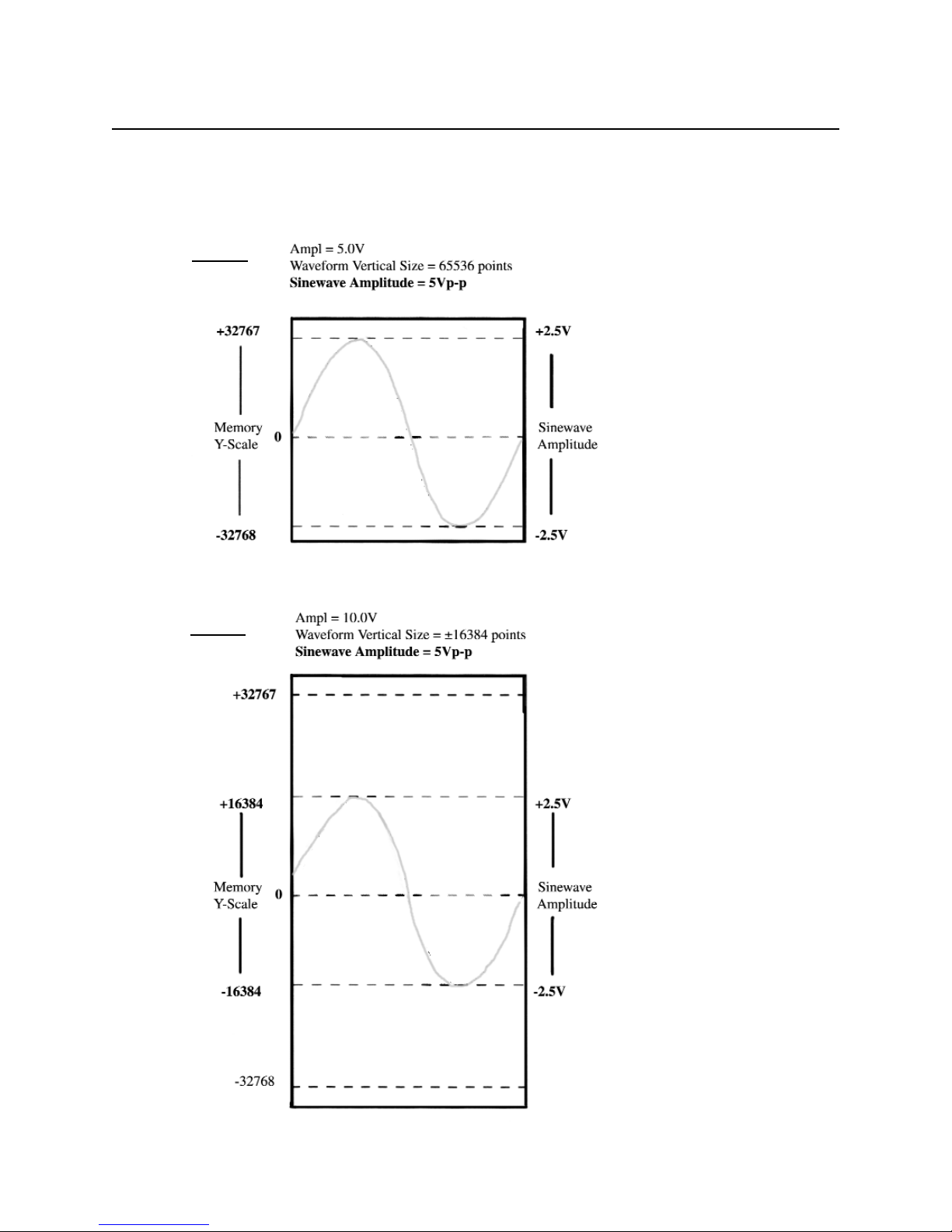

Digital and Analog Scaling

Whenever possible range the Y-values of a waveform between -32768 to +32767 in the memory to

obtain maximum resolution and to maintain the desired dc integrity of the signal. WaveWorks Pro allows

you to normalize any waveform in its Y values by a simple command. For instance, if you have a

sinewave in the waveform window that ranges from -32768 to +32767 you can specify the output at 5

volts peak-to-peak. Automatically the -32768 relative amplitude will be scaled to -2.5 volts and the

+32767 relative amplitude will be scaled to +2.5 volts. The sinewave will be centered around zero volts.

The desired output voltage may be set on the front panel of the generator or on the Download Setup

form before the waveform is sent to the 2411B. If you set the output amplitude to 10 volts peak-to-peak

and then you download a waveform with Y-values between +16384 and -16384, you have the same

+/-2.5 volt sinewave output. It is very important to understand the differences between digital scaling

and analog scaling. See the following page for the illustration.

Other Considerations

The Y values of the starting and ending points in your waveform can cause unexpected discontinuities if

they are not the same value. The waveform generator output will jump from the ending value to the

starting value of each cycle. If you are using the sequence generator in an arbitrary waveform generator,

the ending value of a waveform will jump to the starting value of the next waveform in the sequence.

For a smooth, transient-free waveform output, be sure the starting and ending values are the same for a

single waveform and the starting and ending values of adjacent waveforms are the same for a

sequenced waveform.

2-3

Page 26

Chapter 2 About Arbitrary Waveforms

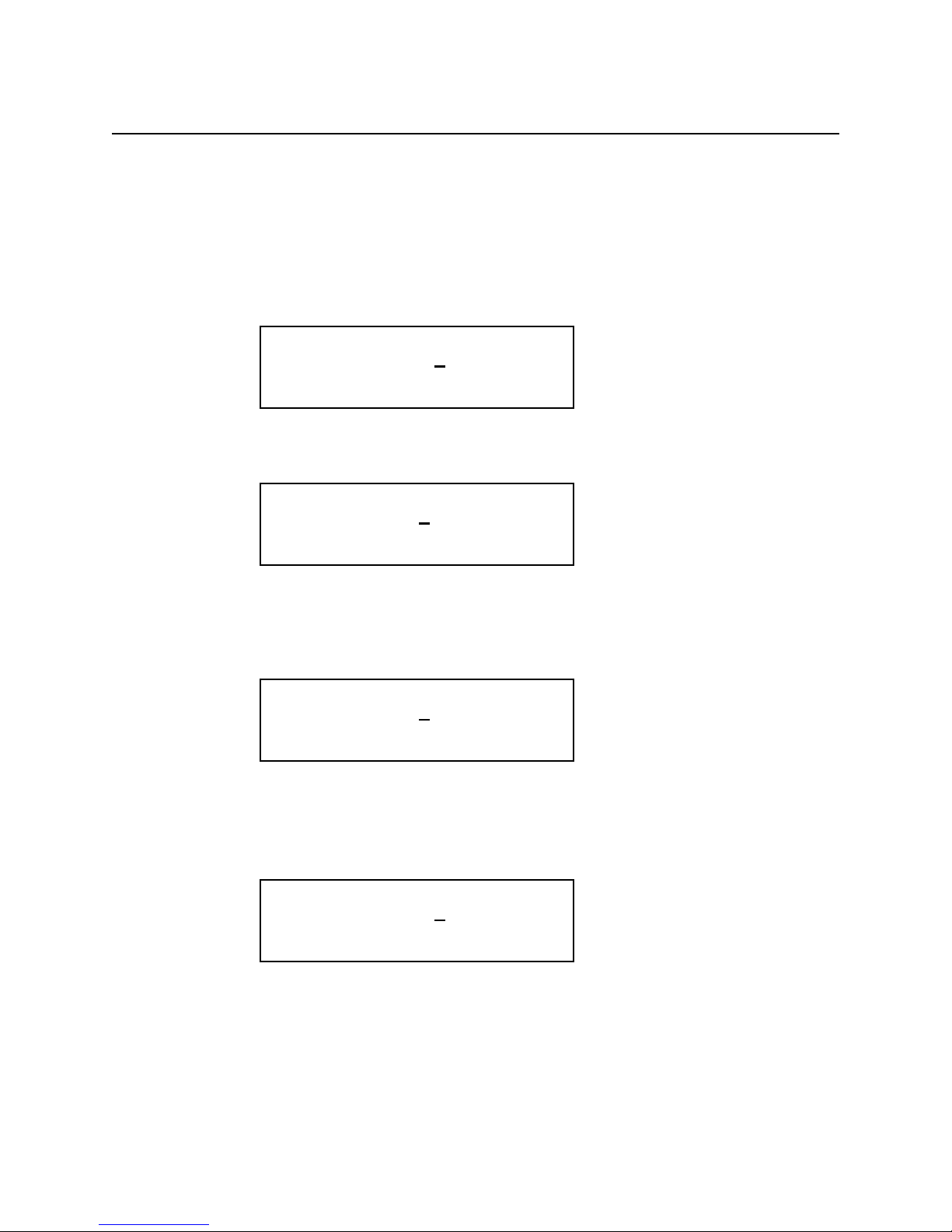

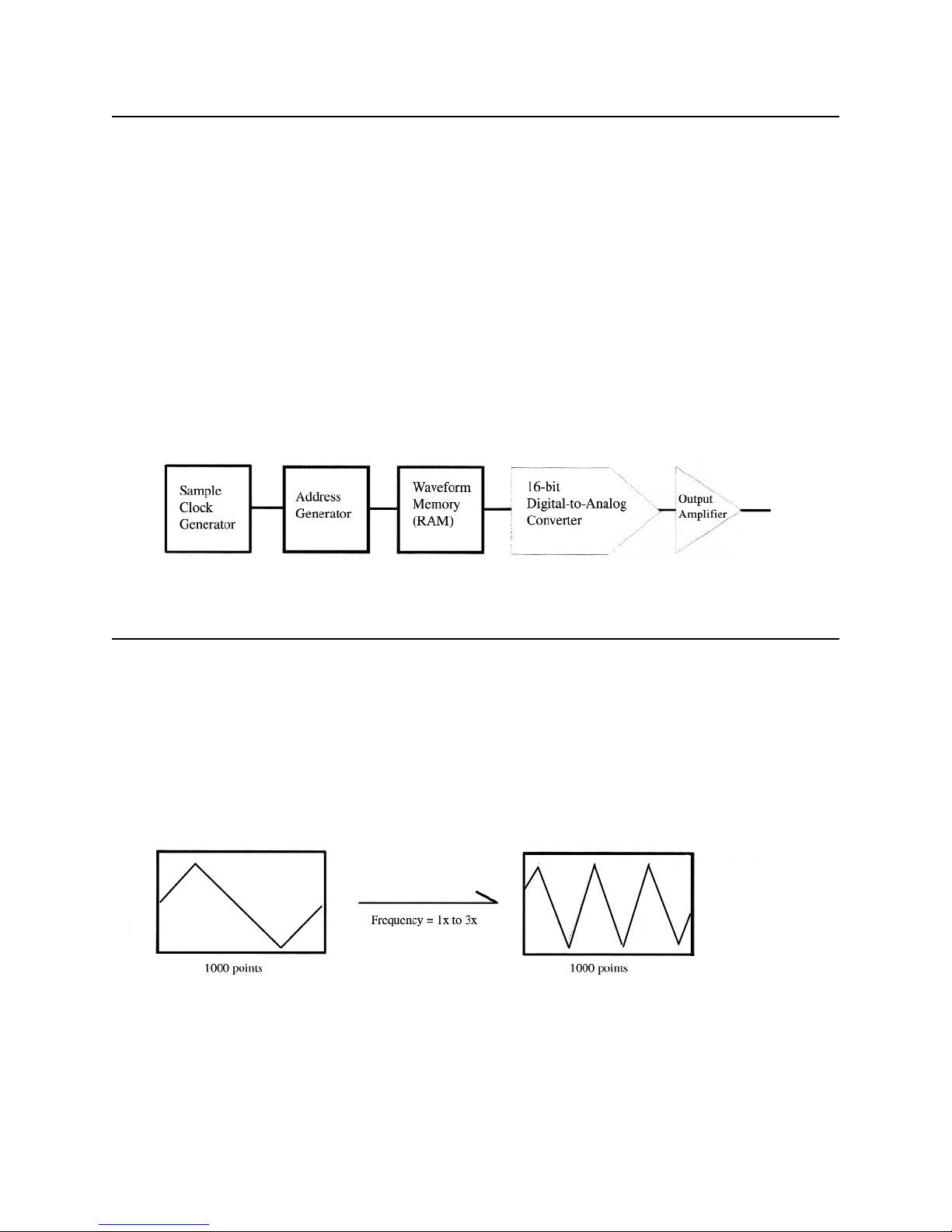

Examples - Digital and Analog Scaling

Examples - Digital and Analog Scaling

Both case 1 and case 2 produce the same output amplitude with different

vertical resolution.

2-4

Case 1

Case 2

Page 27

Chapter 2 About Arbitrary Waveforms

Waveform Types

Waveform Types

TEGAM 2411B arbitrary waveform generators can create two types of waveforms, namely standard

waveforms and user-defined waveforms. In addition, if you have installed the optional Sequence

Generator in the 2411B, you may loop and link up to 100 user-defined waveforms.

Standard Waveforms

You may access 20 commonly used standard waveforms from the front panel. These waveforms are not

available for the sequence generator from the front panel.

User-defined Waveforms (Arbitrary Waveforms)

You must create user-defined waveforms on a PC and download them to the memory of the 2411B or

you must create them using the EDIT mode. You may use the optional WaveWorks Pro + software to

create user-defined waveforms. User-defined waveforms are utilized to create sequence steps in the

optional sequence operation.

Sequence Waveforms (Optional)

You can create a virtual waveform using the user-defined waveforms in the waveform memory and

repeating the waveforms any number of times without increasing the size of the waveform memory.

Each step is defined with one of the user-defined waveforms and the number of repetition of this waveform. You may create up to 1000 steps utilizing up to 100 user-defined waveforms in each sequence

waveform.

Waveform Memory

Sequenced Waveform

Example:

Step 1) WAV#02, 2 times; Step 2) WAV#01, 1 time; Step 3) WAV#03, 3 times

2-5

Page 28

Chapter 2 About Arbitrary Waveforms

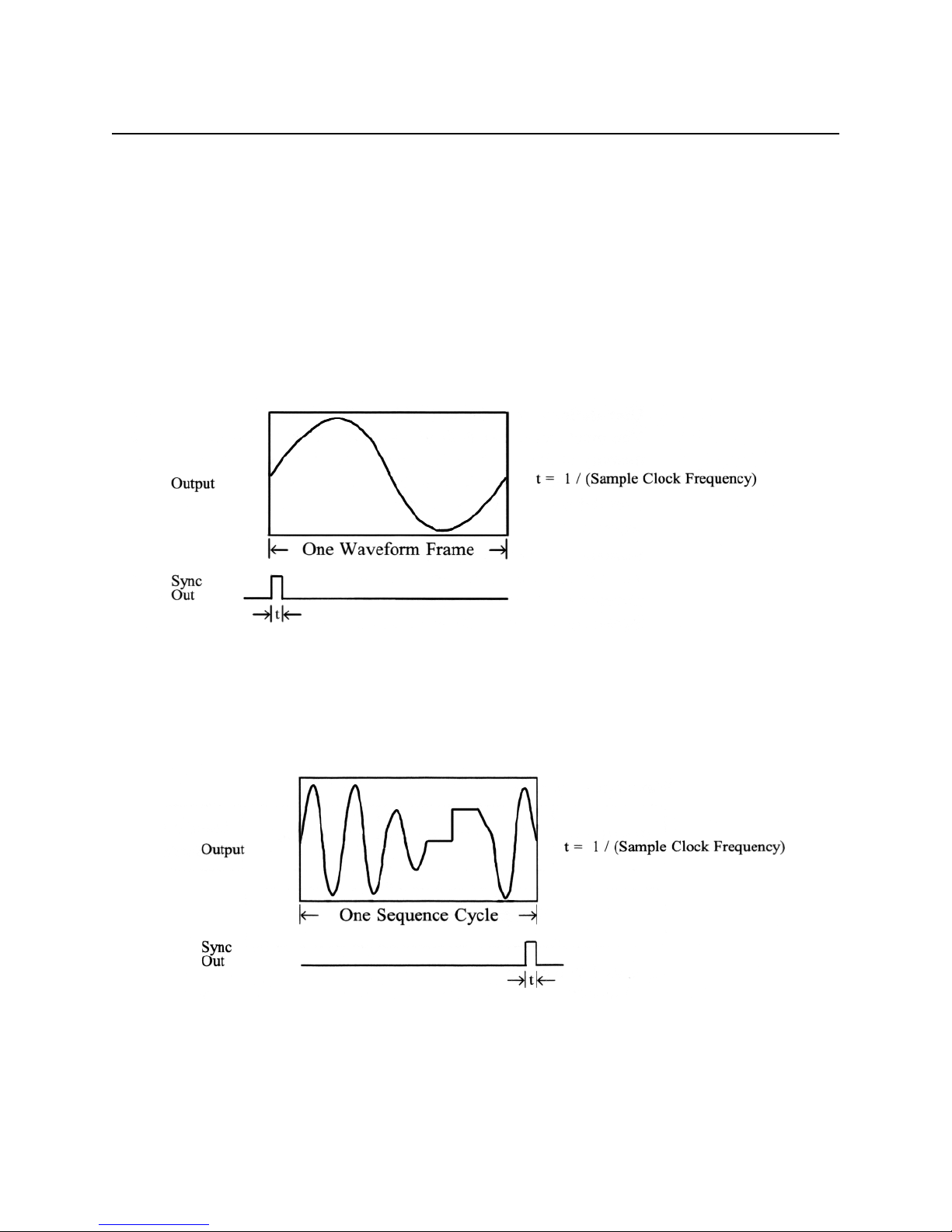

Sync Pulse

Sync Pulse

Four sync pulses are provided to synchronize the generator output waveform to trigger an external system, such as an oscilloscope.

For standard and user-defined waveforms, the sync pulse is typically placed at the start

of the waveform frame. For sequence waveforms, the sync pulse is placed at the end to indicate

the sequence completion. The detail description of the programmable sync is given in chapter 8.

Standard and User-defined Waveforms

Sequence Waveforms

Note:

If you programmed only one step in a sequence, the sync pulse appears at the start of the

waveform.

2-6

Page 29

Chapter 2 About Arbitrary Waveforms

Sync Outputs

Sync Outputs

The 2411B is unique in having extremely flexible sync waveform features. Each of the four

sync signals may be programmed via the remote interfaces to any binary valued pattern equal in

length to the waveform with which each is associated. The electrical outputs are all TTL.

In addition to providing virtually infinite pattern flexibility using the remote programming interfaces, the

sync signals have a second set of functional features. Each of the following sync signals may be programmed from the front panel or from the remote interface.

Sync 1 - Is located on the front panel where it may be set to End Pulse (a pulse of sample clock duration

occurring during the last sample of the waveform), or be set to Programmable Address (a pulse having a

start address and a length).

Sync 2 - Is located on the rear panel where it may be set to Programmable Address ( a pulse having a

start address and a length). Sync 2 has no secondary function.

Sync 3 - Is located on the rear panel where it may be set to Run (a high-level during the period of time

the waveform is being samples), or be set to Programmable Adddress (a pulse having a start address and

a length.)

Sync 4- Is located on the rear panel where it may be set to End Block (a pulse of sample clock duration

occurring during the last sample of each step in the sequence), or be set to Programmable Address (a

pulse having a start address and a length).

2-7

CAUTION: Remotely programmed sync

patterns are overwritten if the user uses

the front panel to edit the sync signal.

Page 30

Page 31

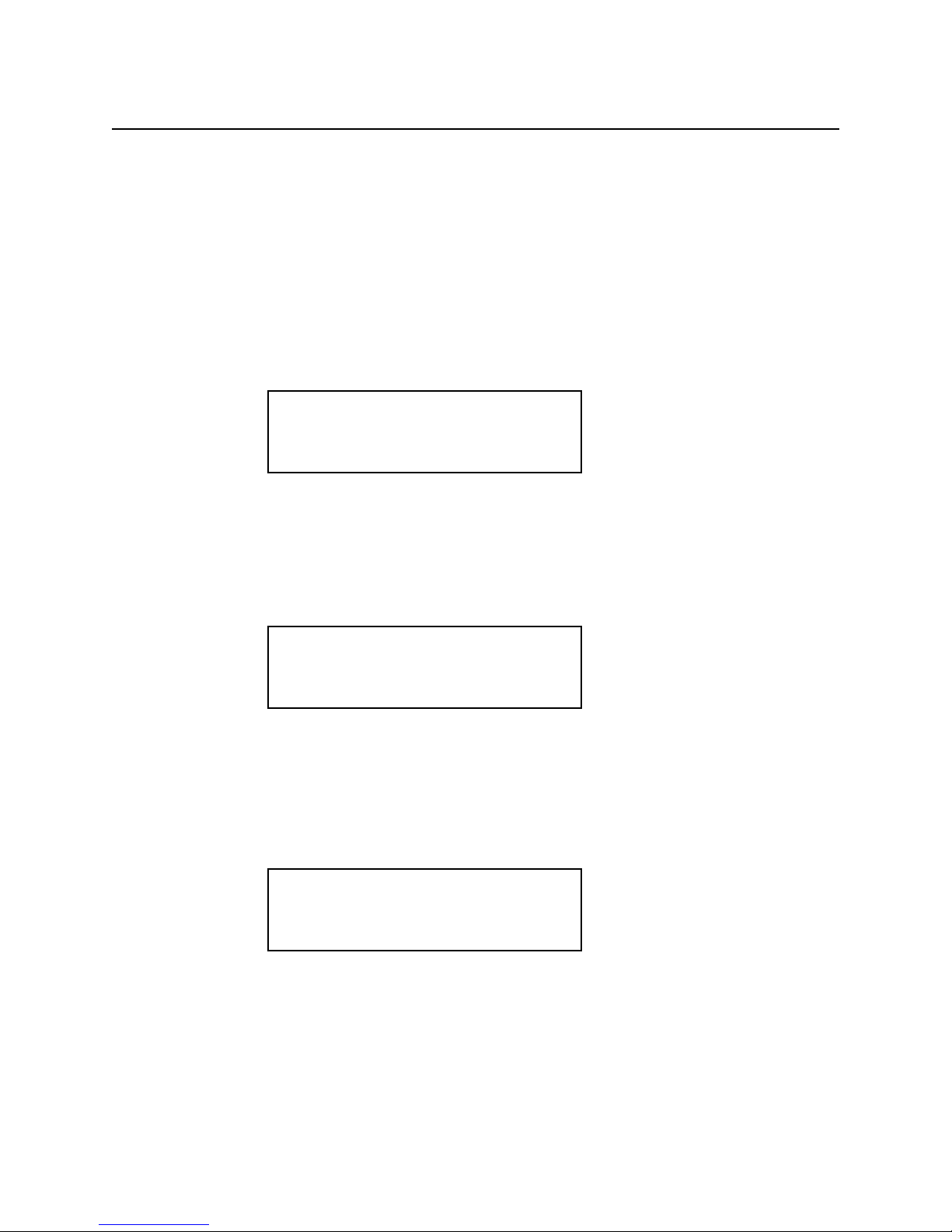

Chapter 2 About Arbitrary Waveforms

2411B Block Diagram

2-8

Block Diagram

Page 32

3

Front-Panel Menu Operation

Page 33

Chapter 3 Front-Panel Menu Operation

Parameter Control

Parameter Control

A: MODE menu

1. CONT (Continuous): Select the continuous waveform output.

2. TRIG (Trigger): Select the triggered waveform output. Output one waveform

frame when a trigger signal is applied.

3. GATE: Select the gated waveform output. Output multiple waveform

frames as long as the trigger input signal is high or the manual

button is pressed down.

4. BRST (Burst): Select the burst mode. Output multiple number of waveform

frames set by the burst cycle parameter when a trigger signal is

applied. The number of burst cycles may be set between 1 and

1,048,575.

Note: The Burst mode is not available for sequence wave form.

5. TOGL (Toggle): Select the toggle mode. Output multiple waveform frames when a

trigger signal is applied and then return to the quiescent state when the

second trigger signal is applied.

B: CLOCK/FREQ menu

1. CLOCK (Sample Clock) Sets the sample clock rate of the waveform frame.

CLOCK (Sample Clock) applies for WAV#, SEQ# and STDW.

2. FREQ (Frequency) Set the frequency of the waveform frame.

FREQ (Frequency) applies for WAV# and STDW only.

C: AMPL/OFSTmenu

1. AMPL (Amplitude) Sets the amplitude of the waveform frame.

2. OFST (Offset) Set the dc offset voltage of the waveform frame.

Note: See Chapter 2 to review the digital amplitude and offset settings.

3-2

1: CONT 2: TRIG 3: GATE 4: BRST 5:TOGL

Page 34

Chapter 3 Front-Panel Menu Operation

Parameter Control (continued)

D: FUNC (Function) menu

1: WAV# Select a user-defined arbitrary waveform by the waveform number (0~99).

2: SEQ# Select a user-defined sequence waveform by the sequence number (0~99).

3: STDW Select a standard waveform.

4: VIEW Select the left and right memory addresses to view the waveform memory

contents. You may specify and select ALL, SEG1, SEG2 or SEG3.

Note: The sequence generator option must be installed to select sequence waveforms.

Sequence waveform is not available in burst mode.

D3: STDW (Standard Waveform)

1: SIN (Sine) Select sine wave.

2: SQR (Square) Select square wave.

3: TRI (Triangle) Select triangle wave.

4: SAW+ (Sawtooth+) Select positive-going ramp wave.

5: SAW- (Sawtooth-) Select negative-going ramp wave.

6: DC Select DC level.

7: EXP+ (Exponential+) Select positive-going exponential wave.

8: EXP- (Exponential-) Select negative-going exponential wave.

9: AM Select AM (Amplitude Modulation) wave.

10: SCM Select SCM (Suppressed Carrier Modulation) wave.

11: FM Select FM (Frequency Modulation) wave.

12: HSIN (Haversine) Select haversine wave.

13: SUN (Sweep Linear) Select linear sweep wave.

14: SLOG (Sweep Log) Select log sweep wave.

15: PLS+ (Pulse+) Select positive-going pulse wave.

16: PLS- (Pulse-) Select negative-going pulse wave.

17: GAUS (Gaussian Pulse) Select Gaussian pulse wave.

18: SX/X (Sine X/X) Select (sine x)/x (or SINC) wave.

19: CIRC (Circular) Select semi-circular wave.

20: NOIS (Noise) Select random noise wave.

3-3

1: WAV# 2: SEQ# 3: STDW 4: VIEW

1: SIN 2: SQR 3: TRI 4: SAW+ 5: SAW- 6: DC 7: EXP+ 8: EXP9: AM 10: SCM 11: FM 12: HSIN 13: SLIN 14: SLOG 15: PLS+ 16: PLS-

17: GAUS 18: SX/X 19: CIRC 20: NOIS

Page 35

Chapter 3 Front-Panel Menu Operation

Waveform Setup

E: OUTPUT menu

1: ON Turn the generator output on.

2: 40K Turn 40kHz low pass filter on.

3: 700K Turn 700kHz low pass filter on.

4: SYNC Select the sync mode of SYNC 1, SYNC 3 and SYNC 4.

5: STRG (Sync Trigger) Select sync trigger operation mode (Series or Parallel)

6: DEGL (Deglitcher) Turns on or off deglitcher.

Waveform Setup (Refer to Chapter 4 for detail operations.)

SETUP menu

1: WAV# (Waveform Number) Select, allocate or delete a user-defined waveform and set up

the waveform length and the parameter of 4 sync pulses.

2: STDW (Standard Wave) Select the standard waveform and set up the length and the

parameter of 4 sync pulses.

3: SEQ# (Sequence Number) Select, create or delete a sequence waveform and edit the

sequence steps.

Waveform Edit (Refer to Chapter 4 for detail operations.)

EDIT menu

1: LINE Line mode creates a line segment of a user-defined waveform using

START, ANCHOR and CHORD commands.

2: VRTX (Vertex) VRTX (Vertex) mode creates a user-defined waveform using two anchor

points and a vertex. This mode allows to insert a standard function, and

scale and offset a portion of the waveform.

3: MATH Math mode allows the user to mathematically operate on existing

waveforms. Addition, subtraction and multiplication are available on two

selected user-defined waveforms.

3-4

1: WAV# 2: STDW 3: SEQ#

1: ON 2: 40K 3: 700K 4: SYNC 5: STRG 6: DEGL

1: LINE 2: VRTX 3: MATH

Page 36

Chapter 3 Front-Panel Menu Operation

System Control

System Control

A: UTIL (Utility) menu

1: SCLK Select the sample clock source.

2: RCLK Select the reference clock source and make a fine adjustment to the

internal reference clock.

3: TGIN Select the trigger type for multi-phase or single unit operations.

4: TGEN Select the internal trigger generator and the trigger rate.

5: MBST Select and display the monitor burst count.

6: GPIB Set the GPIB bus address (0-30).

7: R232 Set the RS232 serial interface parameters.

B: LOCAL Select the front panel control when the instrument is in remote

mode. Press SHIFT

button and then press LOCAL (or number 8 key)

C: STOR/RECL Store and recall 31 sets of the 2411B status. Press ENTER to activate the recalled set

tings.

D: RESET Reset the 2411B. Press SHIFT button and then press RESET (or number 9 key). Select

either ALL or CURR.

E: RTS Return to start address. Press SHIFT button and then press RTS (or number +/- key).

F: HOLD Hold the output at the current level until released. Press SHIFT button and then press

HOLD.

G: TRIG Manual trigger button. Initiates GATE, TRIG, BURST and TOGGLE mode.

H: LCD Adjust the LCD screen viewing angle. Press SHIFT button and

then press LCD. Turn knob to adjust viewing angle.

3-5

1: SCLK 2: RCLK 3: TGIN 4: TGEN 5: MBST 6: GPIB 7: R232

Page 37

Chapter 3 Front-Panel Menu Operation

Default Settings

Default Settings

Important: by holding RESET key (or number 9 key on the 10-key pad) down while turning the

LINE switch on, you can reset the 2411B settings to the factory defaults. If you want to save the wave-

form data, be sure to back up in a PC using WWP Pro + or an appropriate software before resetting the

2411B.

Front-panel button Defaults

UTILity Defaults

3-6

Buttons Factory Defaults

MODE CONT

FUNC STDW (SIN)

CLOCK

FREQ

SCLK=1.000MHz

FREQ=1.000kHZ

AMPL

OFST

AMPL=5.000 V

OFST=0.000 V

OUTPUT output and filters off

Buttons Defaults

SCLK INT

RCLK INT

TGIN ASYNC

MBST n=3

GPIB GADR=16

TGEN

OFF

R232

BAUD=1.2K,

PAR=NONE,

BITS=8D1S

HAND=SW

Page 38

Chapter 3 Front-Panel Menu Operation

Default Settings (continued)

Default Settings (continued)

User-Defined Waveform Defaults

Optional Sequence Waveform Defaults

3-7

WAV#

SIZE

Type

Sync Location

1 2 3 4

0

2000

Triangle

0 0 0 0

1

2000

DC 0V

0 0 0 0

2

2000

Pulse

0 0 0 0

3

2000

DC 0V

0 0 0 0

4

2000

DC 0V

0 0 0 0

SEQ# Step WAV# Repeat

0

10 0 2

20 2 1

30 0 3

1

10 1 2

20 3 4

30 4 6

2

50 1 2

60 3 4

70 4 6

Page 39

Chapter 3 Front-Panel Menu Operation

Default Settings (continued)

Standard Waveform Default Settings (continued)

Default settings are listed in the following tables. The limits are shown in parenthesis.

3-8

Function Parameters Range Defaults

Sine (SIN)

Phase 0.000~360.000° 0.000°

Number of Cycles 0.01~1000.00 1.00

Square (SQU)

Number of Cycles 1 ~ 1000 1

Duty Cycle 1~100% 50%

Triangle (TRI) Number of Cycles 1 ~ 1000 1

Number of Cycles 1~1000 1

Sawtooth

(SAW+/-)

Duty Cycle 1~100% 100%

DC

DC -32768~

+32767

0

Exponential

(EXP+/-)

Time Constant 0.01~20.00 5

Amplitude

Modulation

(AM)

Carrier Frequency 1~10000 20

Modulation 1~10000 1

Modulation Index 0~200% 100%

Modulation Phase 0~360° 0°

Carrier Phase 0~360° 0°

Suppressed

Carrier

Modulation

(SCM)

Carrier Frequency 1~1000 20

Modulation Freq. 1~1000 1

Modulation Phase 0~360° 0°

Carrier Phase

0~360° 0°

Haversine

(HSIN)

Number of Cycles

0.01 ~ 1000.00

1.00

Linear Sweep

(SLIN)

Begin 1 ~ 1000 1

End 1 ~ 1000 10

Log Sweep

(SLOG)

Begin 1 ~ 1000 1

End 1 ~ 1000 10

Pulse

(PLS+/-)

Delay 0~100% 0%

Rise Time 0~100% 10%

High Time 0~100% 30%

Fall Time 0~100% 10%

Number of Cycles 1~1000 1

Gaussian

(GAUS)

Exponent 0.01 ~ 20.00 2

Sine X/X (SX/X)

Number 4.00 ~ 1000.00 5.50

Circle (CIRC)

Number of Cycles 0.01 ~ 1000.00 1.00

Phase 0.01 ~ 360.00° 0.00°

Page 40

Chapter 3 Front-panel Menu Operation

Standard Waveform List

Standard Waveform List

The following list shows you the standard waveforms available from the 2411B front panel and in the

optional WaveWorks Pro software. You can create a standard waveform in WaveWorks Pro and download it to an arbitrary waveform location. Now, you can select the customized standard waveform from

the front panel as a user-defined waveform.

3-9

2411B

WaveWorks Pro

Sine

Square

Triangle

Sawtooth (+/-)

DC

Exponential (+/-)

AM

SCM

FM

Haversine

Linear Sweep

Log Sweep

Pulse (+/-)

Gaussian

Sine(X)/X

Circle

Noise

Sine Cosine

Square Squine

Triangle Lines

Ramp Steps

DC Binary FSK

Exponential Binary PSK

AM NTSC

SCM PAL

FM PWM

Pulse1 VHR Pulse

Cont Sweep Burst Sweep

Step Sweep Digital Noise

Pulse 2 FIR_LPF

Gaussian Han(SinX/X)

Sin(X)/X Comb

Cardiac

Analog Noise

Page 41

4

Waveform Creation System

Page 42

Chapter 4 Waveform Creation System

Components

Components

The following components are required for the 2411 B waveform creation system.

• Model 2411B Arbitrary Waveform Generator

• WaveWorks Pro + Wavform Creation Software

• RS-232 Cable

It is recommended that you install the optional WaveWorks Pro + in a PC equipped with the following

minimum configuration. For more details, see page 1-3 of the WaveWorks Pro manual.

• IBM (or compatible) PC , 16MB memory

• 2MB free harddisk space. Windows 95 or higher operating system

Recommendation

It is recommended that you try operating WaveWorks Pro + software using the PC

asynchronous serial port (COM port) since you do not have to have the specified

GPIB card and software installed in your PC. Follow the installation instruction

on page 1 -4 of the WaveWorks Pro + manual.

User Interface

When the system is completely installed, the following interfaces are used to

control the waveform creation system.

Front Panel (2411B)

This is used primarily to select and control the hardware parameters, such as mode, sample clock rate,

amplitude, offset, and waveform selection. 20 standard waveforms may be created from the front panel.

Arbitrary waveforms and sequence waveforms can be edited from the front panel.

Waveform Windows (WaveWorks Pro +)

The WaveWorks Pro +, which runs under Windows, is the main interface for waveform creation tasks.

You can create up to 32 standard waveforms and unlimited number of arbitrary and sequence waveforms

using Point Edit and Waveform Math.

You may also analyze and edit the waveforms using the FFT and Digital Pattern Generator while

exchanging the ASCII data with other applications. Once the communications link is established

between the PC and the waveform generator, downloading a waveform is as simple as selecting the

download waveform location and clicking the OK button.

4-2

Page 43

Chapter 4 Waveform Creation System

User Interface for the Waveform Creation System

4-3

Page 44

Chapter 4 Waveform Creation System

Memory Organization-Introduction

Memory Organization

Introduction

This section explains how the waveform memory is organized, the system of waveform numbering, how

default memory segments can be changed, and how standard functions can be inserted.

Default Partitioning

The total available waveform memory is 65,504 points. The memory is initially divided into partitions to

provide easy programming of 6 different waveforms. Five blocks of 2000 points each occupy the first

10K of memory. In addition, one of 20 standard waveforms can be readily recalled from the Function

menu and downloaded to 1000 points of memory from 10k to 11k. (A sinewave is the default Standard

Wave.)

Waveform Numbering

The first 5 blocks of memory are assigned Waveform Numbers. Additional Waveform Numbers can be

assigned (up to total of 100, depending on the number of points). Waveform Numbers are used to access

the memory blocks for initial waveform programming and to recall the waveforms later. Waveform

Numbers are arrayed in the memory in ascending order. Figure below shows the default waveform numbers and partitioning.

Waveform Numbers and Memory Partitions

Changing Waveform Block Length

Standard Wave

The standard wave memory can be changed from its default value of 1000 points. (Minimum

waveform length is 16 points.)

4-4

START START START START START START START

0 2000 4000 6000 8000 10000 11000

WAV#0 WAV#1 WAV#2 WAV#3 WAV#4 STDW Avaiable MemorySpace

System

1999 3999 5999 7999 9999 10999 65503

65535

Stop Stop Stop Stop Stop Stop Stop

Page 45

Chapter 4 Waveform Creation System

Memory Organization-Waveform Number Block Lengths (continued)

Memory Organization-Changing Waveform Block Length (continued)

1) Press SETUP key.

2) Press STDW softkey (F2). The display indicates the present length of the standard wave and

the address where it begins in memory.

3) Press LEN softkey (F4). The display indicates the available free memory.

4) Select desired standard wave length with edit knob or keypad. (Do not attempt to exceed the

amount of memory available.)

5) Press OK (F3) to enter change or CANC (F4) to cancel.

6) Press ENTER.

Waveform Number Block Length

The waveform length of the numbered blocks can be changed from their default values of 2000

points. (Minimum waveform length is 32 points.)

1) Press SETUP key.

2) Press WAV# softkey (Fl).

3) Select Waveform Number with edit knob. The display indicates the present length and start

address of the waveform.

4) Press LEN softkey. The display indicates the available free memory.

5) Select desired waveform block length with edit knob or keypad. (Do not attempt to exceed

the amount of memory available.)

6) Press OK to enter change or CANC to cancel.

Deleting Waveform

A waveform which is no longer needed can be deleted from memory as follows:

1) Press SETUP key.

2) Press WAV# softkey.

3) Select Waveform Number with edit knob.

4) Press DEL softkey.

5) Press OK to delete or CANC to cancel.

Inserting New Waveform Numbers

Unused Waveform Numbers can be activated as follows:

1) Press SETUP key.

2) Press WAV# softkey.

3) Press NEW softkey.

4) Screen will show all unused Waveform Numbers when edit knob is turned. Select desired

number.

5) Move waveform length to right side of display with double-arrow key and set desired length

with edit knob or keypad.

(New waveform cannot be longer than available free memory.)

6) Press OK to insert new Waveform Number or CANC to cancel.

4-5

Page 46

Chapter 4 Waveform Creation System

Waveform Creation using Front Panel-Introduction

Waveform Creation using Front Panel

Introduction

This section explains how to create arbitrary, non-standard waveshapes. These custom waveforms can be

created a segment at a time using LINE or VERTEX edit modes. Each step in the waveform construction may be viewed on an oscilloscope connected to the instrument output. Arbitrary and standard

waveforms can be interspersed. More complex waveforms can be created by adding, subtracting, and

multiplying any two standard or arbitrary waveforms that have been previously stored in memory.

NOTE: Define waveform number block length before creating an arbitrary waveshape.

Line Mode

With the line editing mode, waveforms are created a segment at a time from a left-hand start or anchor

point. Aline is drawn from the start point or anchor to a "vertex" point which is positioned to the right.

The vertex becomes a new anchor and the process is interactively repeated until the new arbitrary waveform is completed. This process is illustrated in page 4-8. All or any portion of a selected waveform

block can be edited. Editing begins at the start point. Astart point can be placed at any X and Y position

within the selected waveform block. Alternatively, a left anchor can be positioned at any X address, but

the Y value follows that of any previously programmed waveform (or baseline if no waveform was programmed).

Editing From Start Point

1) Press EDIT key.

2) Press LINE softkey (Fl).

3) Select Waveform Number using edit knob or keypad (press ENTER after using keypad).

4) Arbitrary waveform construction can begin at any point within the selected waveform number

block. Press STRT softkey (Fl).

5) Use edit knob or keypad to select X and Y addresses to start waveform editing within the

selected block. Use double-arrow key to move each active parameter to right side of display.

(Remember to press ENTER if keypad is used.)

6) Press OK (F3) to store start point or CANC (F4) to cancel.

7) Press ANCH softkey (F2).

8) Use double-arrow key to move Right Anchor (AR) to right side of

4-6

Page 47

Chapter 4 Waveform Creation System

Waveform Creation using Front Panel-Line Mode

Line Mode (continued)

LCD. Use edit knob or keypad to select X address for the end of the

edited portion of the waveform.

9) Press OK (F3) to store right anchor or CANC (F4) to cancel.

Editing From Left Anchor

1) Press EDIT key.

2) Press LINE softkey (Fl).

3) Select Waveform Number using edit knob or keypad (press ENTER after using keypad).

4) Arbitrary waveform construction can begin at any X address within the selected waveform num-

ber block. Press ANCH soft key (F2). (If the Start Point is to be uniquely defined, see previous

section.)

5) Use double-arrow key to move Left Anchor (AL) to right side of display. Use edit knob or keypad to select X address. (Remember to press ENTER if keypad is used.)

6) Use double-arrow key to move Right Anchor (AR) to right side of LCD. Use edit knob or key-

pad to select X address for the end of the edited portion of the waveform.

7) Press OK (F3) to store anchors or CANC (F4) to cancel.

Creating Line Segments

1) Press CHRD (chord) softkey (F3). (Set anchors first per previous section.)

2) Use edit knob, keypad or optional mouse to select X and Y addresses for the destination of the

first line segment (chord). If the mouse is used, LCD readouts will continually indicate mouse

position.

3) When the desired position is reached, press OK (F3) and the line segment will be stored. Press

CANC (F4) to cancel.

4) Create the next line segment by again using the knob or keypad to set the next X-Y coordinate,

as before.

5) Continue adding line segments up to the limit established in step 5 of Editing from Start Point

section.

4-7

Page 48

Chapter 4 Waveform Creation System

Waveform Creation using Front Panel-Line Mode

Line Mode Waveform Creation and Editing

4-8

Page 49

Chapter 4 Waveform Creation System

Waveform Creation using Front Panel-Vertex Mode

Vertex Mode

With the vertex editing mode, waveforms are created by establishing two anchor points at selected

addresses, positioning a vertex in the active region between the two anchors and then connecting the

vertex to the anchors with two line segments. The vertex mode also permits waveform scaling and the

insertion of standard functions. Vertex editing is illustrated in page 4-10.

1) Press EDIT key.

2) Press VRTX softkey (F2).

3) Select Waveform Number using edit knob or keypad (press ENTER after using keypad).

Selecting Left and Right Anchor Points

1) Press ANCH softkey (F3).

2) Set left anchor (AL) X value using edit knob or keypad. Press ENTER if keypad is used.

3) Use double-arrow key to move right anchor (AR) to right side of LCD. Set right anchor X

value using edit knob, keypad or optional mouse.

4) Press OK (F3) to store anchors or CANC (F4) to cancel.

NOTE

The difference between the left and right anchors is limited to 8000

points or the waveform length, whichever is less.

Selecting Vertex Point

1) Press ADDV softkey (Fl).

2) Set vertex X and Y values using edit knob, keypad or optional mouse.

3) When the desired position is reached, press OK (F3) and the two line segments will be

stored. Press CANC (F4) to cancel.

4) Continue adding anchors and vertices until the waveform is completed.

Scaling

Scaling allows any portion of a waveform designated by the left and right anchors to be scaled in

amplitude and offset.

1) Select anchors as in page 4-6.

2) Press SCAL softkey (F2).

3) Set digital amplitude (DA) and digital offset (DO) values for selected portion of waveform

using edit knob or keypad. Observe changes on output oscilloscope. Use double-arrow key to

select active parameter.

4) Press OK (F3) to store the scaled waveform or CANC (F4) to cancel.

4-9

Page 50

Chapter 4 Waveform Creation System

Waveform Creation using Front Panel-Vertex Mode

Vertex Mode Waveform Creation and Editing

4-10

Page 51

Chapter 4 Waveform Creation System

Waveform Creation using Front Panel-Vertex Mode

Vertex Mode (continued)

NOTE

The digital amplitude default value is 65535. The

available range of settings is ±131071. A negative

setting inverts the edited waveform portion. Rescaling amplitude from the default value of 65535

to the maximum value of 131071 doubles the output

amplitude. Steps 1-4 above can be repeated as

necessary to enlarge small signals.

CAUTION

The waveform will be clipped if the scaling factors

exceed the 65535 points available in the waveform

memory.

Smoothing

A smoothing factor may be applied to any part or all of a waveform. It is computed as a moving average

over a specified number of samples.

1) Select anchors as in Selecting Left and Right Anchor Points section.

2) Press either the left or right arrow key.

3) Press SMOO softkey (F3).

4) Select the number of samples to be averaged (up to 250) using the edit knob or keypad.

5) Press SHOW softkey (F2) to preview.

6) Press CANC softkey (F4) to cancel.

7) Press OK softkey (F3) to store smoothed waveform.

Inserting Standard Functions

Any one of 20 standard functions can be inserted between the left and right anchors.

1) Select anchors as in Selecting Left and Right Anchor Points section.

2) Press INSF softkey (F4).

3) Select desired standard waveshape by pressing softkey. Use left and right arrow keys to view

all 20 waveshapes. Access any desired ancillary functions by pressing the right arrow (->)

softkey (Fl).

4) Press SHOW softkey ( F2) to preview selection.

5) Press CANC softkey (F4) to cancel selection.

6) Press OK softkey (F3) to store selection.

4-11

Page 52

Chapter 4 Waveform Creation System

Waveform Creation using Front Panel-Vertex Mode

Vertex Mode (continued)

Summing Standard Functions

Any one of the 20 standard functions can be algebraically summed to any part

or all of any other standard function.

1) Select the first standard waveshape as in previous section.

2) If the second standard waveshape is to be summed to only a portion of

the first standard waveshape, reposition the anchors as described in

previous section.

3) Press either the left or right arrow key.

4) Press SUMF softkey (Fl).

5) Select desired standard waveshape by pressing softkey. Use left and right arrow keys to

view all 20 waveshapes. Access any desired ancillary functions by pressing the --> softkey

(Fl). (Reduce the digital amplitude value as necessary to prevent clipping.)

6) Press SHOW softkey (F2) to preview summed waveforms.

7) Press CANC softkey (F4) to cancel.

8) Press OK softkey (F3) to store summed waveforms.

Dump Function

Dump Function permits a standard waveform to be conveniently loaded into the entire length of

a Waveform Number without specifying left and right anchors. Thus, standard waveforms can

be inserted in Waveform Numbers with lengths greater than 8000 points.

1) Select the desired Waveform Number.

2) Press either the left or right arrow key.

3) Press DMPF softkey (F2).

4) Select desired standard waveshape by pressing softkey. Use left and right arrow keys to

view all 20 waveshapes. Access any desired ancillary functions by pressing the --> soft

key (Fl).

5) Press DO softkey (F2) to store the waveform in memory and permit further changes or

press OK softkey (F3) to store waveform and return to previous menu.

CAUTION

It is not possible to preview a function when

using Dump Function. Both the DO and OK

commands above will cause the new waveform to write over any previous waveforms.

4-12

Page 53

Chapter 4 Waveform Creation System

Waveform Creation using Front Panel-Math Operations

Waveform Creation using Front Panel-Vertex Mode (continued)

Move

The Move commands allow a section of a waveform as defined by the left and right anchors to

be copied and pasted into another section of the same or another Waveform Number.

1) Select the desired Waveform Number.

2) Press either the left or right arrow key.

3) Press MOVE softkey (F4).

4) Set left and right anchors to the waveform section to be copied.

5) Press COPY softkey (Fl).

*6) Press LAST key.

*7) Set Waveform Number to receive pasted section.

*8) Press MOVE softkey (F4).

9) Set left and right anchors to the destination waveform section.

10) Press PSTE softkey (F2).

* These steps may be omitted if copy and paste are within the same Waveform Number.

NOTE

The pasted waveform will be truncated if the destination

waveform section has fewer points than the original.

Math Operations

Math operations permit the contents of any two Waveform Numbers of equal size to be algebraically

added, subtracted or multiplied together. Complex composite signals can thus be created, such as shaped

tone bursts, amplitude modulation, etc. To enter the Math Mode:

1) Press EDIT key.

2) Press MATH softkey (F3).

Selecting Math Function

The three math functions have the following forms:

A*B (Multiply; output amplitude normalized to full-scale waveform memory.)

A+B (Add; output amplitude divided by two.)

A-B (Subtract; output amplitude divided by two.)

4-13

Page 54

Chapter 4 Waveform Creation System

Waveform Creation using Front Panel-Examples

Waveform Creation using Front Panel-Math Operation (continued)

To select one of the math functions:

1) Press OP softkey (F2).

2) Press the softkey for the desired math function. The selected function will be capitalized.

Selecting Waveform Numbers

Waveform Numbers to be combined must be selected and a destination assigned for the combined waveform. (To assign a destination Waveform Number, refer to page 4-5.)

1) Press the arrowhead softkey (Fl).

2) The displayed equation has the following form:

Destination Waveform ## = Waveform ## (*,+ or -) Waveform ##.

3) Define each Waveform Number by moving the arrowhead to each location in the equation

and selecting a Waveform Number with the edit knob or keypad (followed by ENTER).

4) Press the DO softkey (F4) after the three Waveform Numbers have been assigned. The result

is visible at the output.

CAUTION

Be sure only equal-length waveform blocks

are combined using a math function. The

destination waveform may be larger.

Examples

Waveform editing in the Model 2411B is so flexible that often the same

complex waveform can be created several different ways. For example, let us

construct a waveform described by the equation: A= sin cot + 1/6 sin Scot. (It

is presumed that the waveform lengths are at the default values of LEN = 2000.)

Insert and Sum Functions

1) Press SETUP key.

2) Press WAV# softkey (Fl).

3) Press NEW softkey (F3) to select a new Waveform Number.

4) Press OK softkey (F3).

5) Press EDIT key.

6) Press VRTX softkey (F2).

7) Press ANCH softkey (F3). Set AL (Left Anchor) = 0 and AR (Right Anchor) = 1999.

4-14

Page 55

Chapter 4 Waveform Creation System

Waveform Creation using Front Panel-Examples

Examples (continued)

8) Press OK softkey (F3).

9) Press INSF softkey (F4).

10) Press SIN softkey (Fl).

11) Set P (Phase) = 0.000 and N (Number) = 1.00.

12) Press --> softkey (F 1).

13) Set DO (Digital Offset) = 0 and DA (Digital Amplitude) = 65,535.

(A full-amplitude signal is obtained with DA = 65,535.)

14) Press OK softkey (F3). Observe that the fundamental frequency (sin cot) at the waveform

peaks.

15) Press either left or right arrow key.

16) Press SUMF softkey (F 1).

17) Press SIN softkey (Fl).

18) Set Phase = 0.000 and Number = 3.00.

19) Press --> softkey (Fl).

20) Set DO (Digital Offset) = 0 and DA (Digital Amplitude) = 10,923.

(Scaling of the amplitude adjusts for the 1/6 amplitude coefficient.)