Page 1

TEGAM Inc.

Model 1806

Dual Type IV Power Meter

MODEL 1806

Instruction Manual

PN# IM140-CD

Publication Date October 2011

REV. J

©1999, TEGAM, Inc.All rights reserved.

NOTE: This user’s manual was as current as possible when this product was manufactured. However,

products are constantly being updated and improved. Because of this, some differences may occur between

the descriptions in this manual and the product received. Please refer to www.tegam.com

of this manual.

for future updates

Page 2

Page 3

i

Table of Contents

SECTION I

GENERAL INFORMATION

Scope of Manual .......................................................................................................................................... 1-1

Purpose and Use of Equipment ................................................................................................................... 1-1

Specifications ........................................................................................................................................... 1-1

Items Supplied ........................................................................................................................................... 1-2

SECTION II

INSTALLATION

Unpacking and Inspection ........................................................................................................................... 2-1

Preparation for Reshipment or Storage ........................................................................................................ 2-1

Power, Environmental, and Mounting Requirements .................................................................................. 2-1

Installation ........................................................................................................................................... 2-2

Power Input Connector and Voltage Selector/Fuse Assembly (XF1) ........................................... 2-2

AC Power Input Connector ................................................................................................ 2-2

Voltage Selector/Fuse Subassembly .................................................................................. 2-2

Selection of Proper Fuse/Circuit Board for XF1 ............................................................... 2-2

SECTION III

OPERATION

General Operating Considerations ............................................................................................................... 3-1

Front Panel Meters, Indicators, Switches and Connectors .......................................................................... 3-1

Front Panel Connectors ................................................................................................................. 3-1

BOLOMETER Mount Bias Connectors (TP3 and TP4) .................................................... 3-1

Mount SENSE Lead Connectors (TP1 and TP2) ............................................................... 3-1

TEMPERATURE CONTROL Connector (J5) .................................................................. 3-1

VOLTMETER Connectors (TP5 and TP6) ....................................................................... 3-3

Front Panel Meters ........................................................................................................................ 3-3

BOLOMETER Current Meter (M1) .................................................................................. 3-3

TEMPERATURE CONTROL Meter (M2) ....................................................................... 3-3

Front Panel Indicators ................................................................................................................... 3-3

ON Indicator (DS1) ........................................................................................................... 3-3

STANDBY Indicator (DS2) .............................................................................................. 3-3

100-Ohm Operational Indicator (DS4) .............................................................................. 3-3

200-Ohm Operational Indicator (DS5) .............................................................................. 3-3

ERROR Indicator (DS3) .................................................................................................... 3-4

Model 1806 Switches .................................................................................................................... 3-4

Power Switch (S1) ............................................................................................................. 3-4

100/200-Ohm OPERATING RESISTANCE Switch (S2) ................................................ 3-4

FLOAT/GROUND Switch (S3) ........................................................................................ 3-4

RF Power Level Measurement .................................................................................................................... 3-4

RF Power Measurement Wi th DVM Only .................................................................................... 3-5

RF Power Measurement With DVM and Reference Voltage Generator ....................................... 3-5

SECTION IV

PRINCIPLES OF OPERATION

Introduction ........................................................................................................................................... 4-1

Principle of DC Substitution ....................................................................................................................... 4-1

Precision Power Measurement System ........................................................................................................ 4-1

Self-Balancing Bridge Circuits .................................................................................................................... 4-2

Page 4

ii

Power Measurements .................................................................................................................... 4-3

RF Power Level Calculation .............................................................................................. 4-4

Controlli ng Thermisto r Mount Int ernal Te mperature .................................................................................. 4-4

Temperature Control Board .......................................................................................................... 4-5

Model 1806 Power Supply .......................................................................................................................... 4-5

Power Supply Electrical Confi guration ......................................................................................... 4-5

Power Supply Application, Transformation, and Isolation ........................................................... 4-5

Motherboard ........................................................................................................................................... 4-6

Front Panel PC Board .................................................................................................................................. 4-6

Measurements Using a Reference Voltage Source ...................................................................................... 4-6

Precision Measurement System Errors ........................................................................................................ 4-7

Calculating Model 1806 Accuracies ............................................................................................................ 4-8

SECTION V

MAINTENANCE

Introduction .......................................................................................................................................... 5-1

Preventive Maintenance ............................................................................................................................. 5-1

Troubleshooting Procedures ........................................................................................................................ 5-1

Specification Tests ........................................................................................................................ 5-1

Power-Up Operational Test ............................................................................................... 5-2

Bolometer Current Meter Test ........................................................................................... 5-3

Bridge Noise Test .............................................................................................................. 5-4

Bridge Balance Test ........................................................................................................... 5-4

Temperature Control ..................................................................................................................... 5-5

Corrective Maintenance and Recalibration ................................................................................................. 5-6

Initial Setup ................................................................................................................................... 5-6

Power Supply Assembly Test and Recalibration .......................................................................... 5-7

Bridge Board Circuitry Test and Recalibration ............................................................................. 5-8

Bolometer Current Meter Cali bration ................................................................................ 5-8

Calibration of Internal Resistance ...................................................................................... 5-9

Bridge Circuit Amplifier Gain Test ................................................................................... 5-9

Factory Maintenance ................................................................................................................................. 5-10

List of Illustrations

Model 1806 Dual Type IV Power Meter .................................................................................................... 1-1

Model 1806 Dimensions (Top/Front View) ................................................................................................ 1-3

Model 1806 Dual Type IV Power Meter Rear Panel Voltage Selector/Fuse Assembly.............................. 2-3

Model 1806 Operational Voltage Selection Process ................................................................................... 2-4

Model 1806 Dual Type IV Power Meter Front Panel Meters, Indicators, Switc hes and Connectors.......... 3-2

Location of Digital Voltmeter in T ypical Test Configuration ..................................................................... 3-5

Location of Reference Voltage Generator in Typical Test Configuration ................................................... 3-6

Functional Block Diagram of Precision Power Measurement System ........................................................ 4-2

Simplified Schematic of Precision Power Measurement System ................................................................ 4-3

Simplified Schematic of Model 1806 Temperature Control Board ............................................................. 4-4

Use of Reference Voltage Generator in Typical Test Configuration ........................................................... 4-6

Graph of Typical Bridge Errors With and Without Reference Voltage Generator ...................................... 4-7

Power-Up Ope rational Test Configuration .................................................................................................. 5-2

Bolometer Current Meter Test Configuration ............................................................................................. 5-3

Bridge No ise Test Configuration ................................................................................................................. 5-4

Bridge Balance Test Configuration ............................................................................................................. 5-5

Initial Test and Calibration Configuration ................................................................................................... 5-6

Page 5

iii

LIST OF TABLES

Model 1806 Dual Type IV Power Meter Specifications ............................................................................. 1-2

Model 1806 Line-Voltage Fuse Requirements ............................................................................................ 2-2

Comparison of Voltmeter Errors When Reference Voltage Generator Is and Is Not Used ......................... 4-8

Required Test and Calibration E quipment .................................................................................................. 5-1

Power Supp ly Line Regulation Test ing ....................................................................................................... 5-8

Page 6

iv

Page 7

Instruction Manual Section I

1-1

Dual Type IV Power Meter, Model 1806 General Information

SECTION I GENERAL INFORMATION

SCOPE OF MANUAL

This manual contains operation and maintenance information for the TEGAM Model 1806

Dual Type IV Power Meter shown in Figure 1-1. This information is in five sections that

outline general information, installation, operation, principles of operation and maintenance.

Discussions throughout this manual concerning use of the Model 1806 treat it as a stand-alone

item. The TEGAM System IIA Automatic Power Meter Calibration System manual contains

information for use, operational role, and cabling of the Model 1806 within a power sensor

calibration system.

Figure 1-1 Model 1806 Dual Type IV Power Meter

PURPOSE AND USE OF EQUIPMENT

The TEGAM Model 1806, in conjunction with an external thermistor mount and a digital

voltmeter (DVM), forms a precision power measurement system that measures microwave

power within the frequency bandwidth of the thermistor mount. The primary application of

this system is for power sensor calibration. The Model 1806 contains two Type IV Bridge

circuits and two thermistor mount temperature controllers. Each Type IV Bridge circuit

operates at a dc resistance of either 100 or 200 ohms which is front-panel selectable. A

complete power measurement system includes an accurate DVM and some means of offsetting

the DVM to measure small voltage changes more accurately. This offsetting voltage source or

reference voltage generator (RVG) becomes increasingly important when measuring power

levels below a few milliwatts. The Model 1806 is designed for use with a temperaturestabilized thermistor mount (100 or 200 ohms) and a DVM with a 6.5 digit, or higher,

resolution.

The Model 1806 contains two self-balancing Type IV Bridge circuits that pass current through

a bolometer mount while sensing the voltage across the mount which defines the resistance of

the bolometer at its dc terminals. This process eliminates lead errors associated with

Wheatstone Bridges. Therefore, the Model 1806 suits applications such as power

measurement and insertion loss measurement applications, requiring high accuracy and

computer control.

The role of the Model 1806 within the TEGAM System IIA Automatic Power Meter

Calibration System is to measure precisely RF and microwave power applied to terminating

standards in order to transfer the calibration factor of one standard to another. The System IIA

is an IEEE Bus compatible system designed to calibrate feedthrough and terminating power

sensors in the .01 to 18.0 GHz frequency range.

SPECIFICATIONS

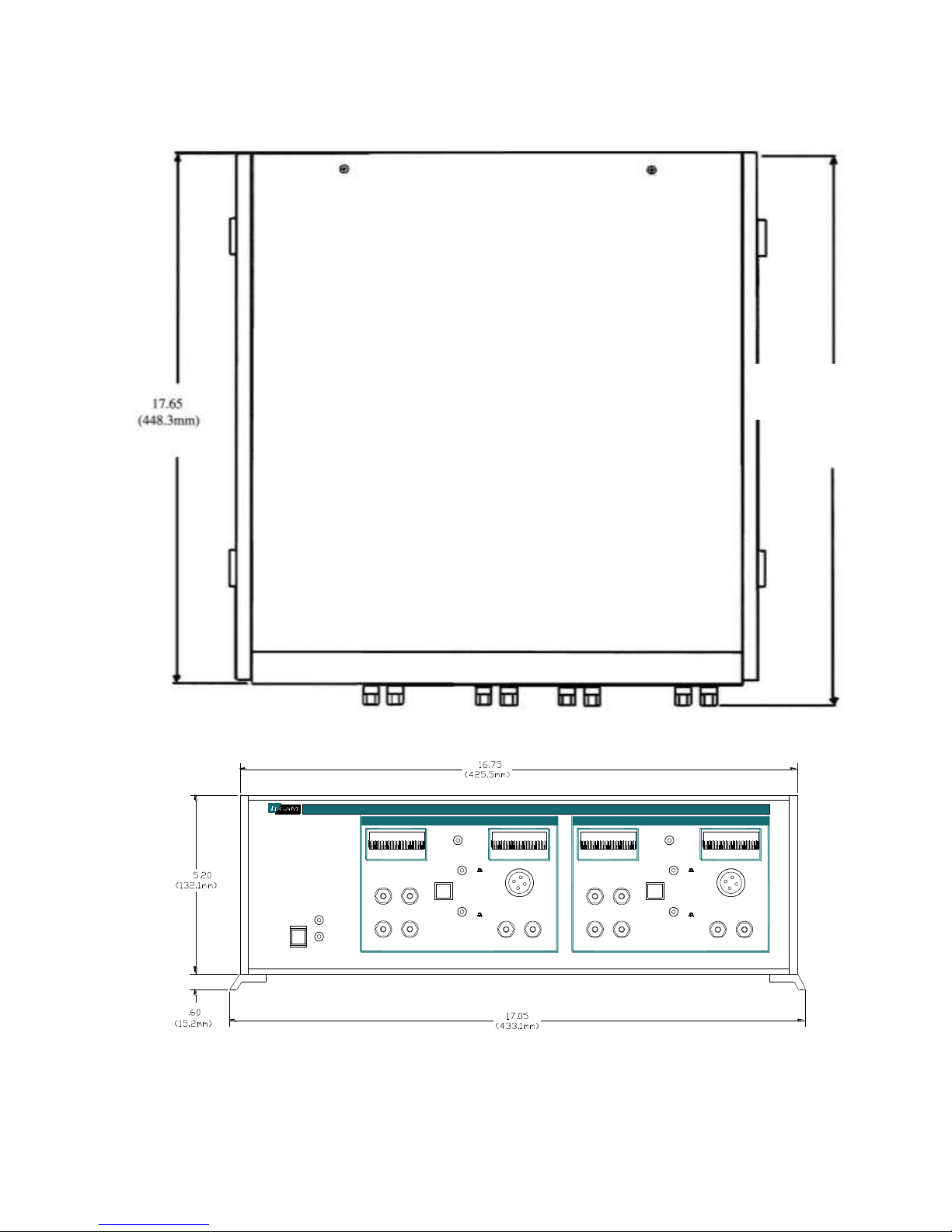

Table 1-1 contains the electrical, physical, and environmental specifications for the

Model 1806. Figure 1-2 contains an outline drawing and design dimensions.

Page 8

Instruction Manual Section I

1-2

RF Power Measurement Range:

10 W to 25 mW

Substitution Bridge Accuracy:

0.003%

Power Measurement Accuracy:

0.03% + 2W when using an HP 3458A Voltmeter

Bias Power Temperature

Sensitivity:

2 W/C/hr

Ambient Temperature Dynamic

Range:

+12C to + 32C

(54°F to 90°F)

Mount Warm-up Time:

2 hrs. to achieve + 60°C (140°F) nominal operating

temperature

Loop Gain:

80 dB minimum

Open Loop Frequency Response:

0.1 Hz

Thermistor Mount Temperature

Control Indicator Operating

Range:

Temperature meter with marked operating point

Bolometer Mount Bias Current

Indicator Resolution:

0.1 mA

Power Requirements:

100/120/220/240 VAC, (+5%, -10%) 25W, 48-62 Hz

Dimensions:

18.35 in. (466.1 mm) L x 17.05 in. (433.1 mm) W x 5.80 in

(147.3 mm) H

Constructions:

Cabinet or standard rack mount

Weight:

Net: 16 lbs. (7.26 kg)

Shipping: 20 lbs. (9.07 kg)

Dual Type IV Power Meter, Model 1806 General Information

Table 1-1 Model 1806 Dual Type IV Power Meter Specifications

ITEMS SUPPLIED

The following items are supplied with the TEGAM Model 1806 Dual Type IV Power Meter:

1. Assembly AC Power Cable, P/N 068-21, 1 ea.

2. Assembly Temperature Control Cable, P/N 138-477, 2 ea.

3. Assembly Mount Bias Cables, P/N 138-526, 2 sets ea.

4. Model 1806 Instruction Manual (IM-140), 1 ea.

5. Shorting Link, P/N 138-495, 4 ea. (installed on front panel)

OPTIONAL ACCESSORIES

The following items can be purchased separately and are needed to perform

calibration service on the 1806.

1. Assembly Extender Board, P/N 138-439, 1 ea.

2. Printed Circuit Card Pullers, P/N 139-1141, 2 ea.

Page 9

Instruction Manual Section I

1-3

18.35

(466.1mm)

CONTROL

TEMPERATURE

ERROR

100

OPERATING

RESISTANCE

200

VOLTMETERSENSE

BOLOMETER

CURRENT

BOLOMETER

O

I

POWER

OFF

ON

STAND BY

VOLTMETER

100

ERROR

CURRENT

BOLOMETER

RESISTANCE

OPERATING

200

BOLOMETER

SENSE

TEMPERATURE

CONTROL

Dual Type IV Power Meter, Model 1806 General Information

Figure 1-2 Model 1806 Dimensions (Top/Front)

Page 10

Instruction Manual Section I

1-4

Dual Type IV Power Meter, Model 1806 General Information

Page 11

Instruction Manual Section II

2-1

Dual Type IV Power Meter, Model 1806 Installation

SECTION II INSTALLATION

UNPACKING AND INSPECTION

TEGAM ships the Model 1806 cushioned between molded-in-place expanded plastic pads in a

double-walled carton. Upon unpacking the equipment, retain the shipping container and

packing material until the equipment has been thoroughly inspected and it is ensured that

reshipment is not necessary. Perform the following initial inspection:

a. Carefully look at the outside of the shipping container for discoloration, stains, charring,

or other signs of exposure to excessive heat, moisture, or liquid chemicals. Check for any

physical damage to the shipping container such as dents, snags, rips, crushed sections or

areas, or similar signs of excessive shock or careless handling.

b. With the equipment and any accessory package removed from the shipping container,

check each item against the packing list or items supplied list. If any items are missing,

contact the factory or the manufacturer’s local representative.

c. Carefully inspect the equipment looking for dents, deep scratches, damaged or loose

pushbuttons or knobs, or any other signs of physical abuse or careless handling.

If damage is found, forward an immediate request to the delivering carrier to perform an

inspection and prepare a concealed damage report. Do NOT destroy any packing material

until it has been examined by an agent of the carrier. Concurrently, report the nature and

extent of damage to TEGAM giving equipment model and serial numbers, so that necessary

action can be taken. Under U.S. Shipping regulations, damage claims must be collected by the

consignee; do NOT return the equipment to TEGAM until a claim for damages has been

established.

PREPARATION FOR RESHIPMENT OR STORAGE

RESHIPMENT

Perform the following procedures when reshipping an instrument or component:

DO NOT return any instrument or component to TEGAM without receiving prior factory

authorization (RMA Number).

Use the best available packing materials to protect the instrument during reshipment.

When possible, use original shipping container and packing materials.

a. Wrap the instrument in sturdy paper or plastic;

b. Place the wrapped instrument in a strong shipping container and place a layer of shock-

absorbing material (3/4 inch minimum thickness) around all sides of the unit to provide a

firm cushion and to prevent movement inside the container;

c. If shipping the unit for service, attach a tag to indicate:

1. Model and serial numbers,

2. Service required,

3. Description of malfunction,

4. Return address,

5. Authorization to conduct repairs; and

Thoroughly seal the shipping container and mark it FRAGILE.

STORAGE

Storage of the unit is possible for extended periods without incurring damage to internal

circuitry if the instrument is packaged according to the instructions above. The safe limits for

storage environment are:

Temperature: -67 to + 167 F (-55 to + 75 C)

Humidity: 95%

Altitude: 40,000’ (12,192M)

Page 12

Instruction Manual Section II

2-2

Dual Type IV Power Meter, Model 1806 Installation

POWER, ENVIRONMENTAL AND MOUNTING REQUIREMENTS

TEGAM supplies a detachable, three-conductor power cord for connecting an ac power

source of 48 to 62 Hz at line voltages of 100, 120, 220, or 240 volts +5%, -10% to the

Model 1806. This ac power source supplies the Model 1806 with all operational power

required. The Model 1806 requires no other external power.

The Model 1806 operates within its specifications at an ambient temperature of +12 C to

+32 C. Operating beyond these limits could affect the accuracy of this unit and damage

internal circuitry.

TEGAM ships the Model 1806 with four plastic feet and a tilt stand mounted on the

bottom of the unit for bench use; however, the Model 1806 is also rack-mountable. To

rack-mount the unit, first remove the four plastic feet and the tilt stand on the bottom of

the unit. Next, remove the rear panel trim and slide the side panels out. Then, remove

the side trim and install rack adapters on the left and right sides of the Model 1806. Reattach the rear panel trim to the unit while leaving the side panels off. When rack

mounting the unit, ensure access to the rear panel so that rear panel connections can be

made. The unit may now be mounted into a standard rack.

INSTALLATION

Installation of the Model 1806 consists of rack mounting or bench configuring the unit,

selecting the proper line-voltage fuse and circuit board, and connecting the unit to the desired

ac power source that matches the fuse and circuit board.

POWER INPUT CONNECTOR AND VOLTAGE SELECTOR/FUSE ASSEMBLY (XF1)

Assembly XF1 is in the lower right-hand corner of the rear panel of the Model 1806. This

assembly contains a three-prong ac power input connector and a voltage selector circuit

board/fuse assembly. The design of XF1 prevents use of the voltage selector/fuse assembly

while an ac power cord is connected to the ac power input connector. Disconnect the power

cord and slide the protective plastic window to the left to change the line fuse and printed

circuit (PC) board. This arrangement eliminates the possibility of electric shock to operating

personnel.

Power source voltages of sufficient current to constitute a HAZARD to operating

personnel exist at the voltage selection PC board and line fuse. Ensure that the power

cord is DISCONNECTED prior to changing line voltage selection or line fuse.

AC Power Input Connector

This connector, located on the left side of XF1, is a plug-type, prong-insert connector with

three conductors for connection of the 100/120/200/240 volt ac power cord (P/N 068-21) to the

power supply assembly within the Model 1806. Arrangement of the conductors and keying of

the insertion area prevent an incorrect connection. This connector also passes the ground

current of the Model 1806 when the ac power cord is plugged into a grounded wall outlet.

When the wall outlet contains two insertion slots, use a three-prong-to-two-prong adaptor.

Voltage Selector/Fuse Subassembly

The voltage selector/fuse subassembly on the right side of XF1 reconfigures the Model 1806

for different operational voltages. This subassembly contains a line fuse and a voltage selector

PC board. Replacement of the fuse and proper selection of the voltage selector PC board

change the operational power requirement to ac voltages of either 100, 120, 220, or 240 volts

at 48 to 62 Hz. Refer to the following paragraph for the proper fuse/PC board selection.

Selection of Proper Fuse/Circuit Board for XF1

TEGAM ships the Model 1806 configured for 120-volt operation. Table 2-1 lists fuse

requirements for other available operational voltages. Figure 2-2 depicts the procedure,

including outline steps, for removal of the line voltage fuse, selection of the proper line-voltage

PC board, and replacement of the fuse.

Page 13

Instruction Manual Section II

2-3

Operational Line Voltage

Fuse Requirement

100 volts +5%, -10% at 48 to 62 Hz

0.75 Amp Slo-Blo

120 volts +5%, -10% at 48 to 62 Hz

0.75 Amp Slo-Blo

220 volts +5%, -10% at 48 to 62 Hz

0.4 Amp Slo-Blo

240 volts +5%, -10% at 48 to 62 Hz

0.4 Amp Slo-Blo

Dual Type IV Power Meter, Model 1806 Installation

Page 14

2-4

Figure 2-1 Model 1806 Dual Type IV Power Meter Rear Panel Voltage Selector/Fuse Assembly

FLOAT/GROUND

Switch (S3)

Power Input

Connector and

Voltage

Selector/Fuse

Assembly (XF1)

Instruction Manual Section II

Dual Type IV Power Meter, Model 1806 Installation

Page 15

Instruction Manual Section II

2-5

VOLTAGE SELECTION PROCESS

STEP PROCESS

1. Pull to the back and left on the fuse pull lever to eject the fuse.

2. Remove the voltage selector circuit board from the module by pulling it out carefully.

3. Position the voltage selector circuit board so that the desired voltage appears readable

(right-side-up) on the left-hand side of the wafer as it faces you. The “X” on the board in

the diagram depicts this location.

4. Slide the board back into the module as shown in the diagram with the desired voltage

still appearing as set in step 3.

5. Replace the fuse with the proper fuse according to Table 2-1. Re-insert the new fuse by

placing it in the fuse brackets.

Figure 2-2 Model 1806 Operational Voltage Selection Process

Dual Type IV Power Meter, Model 1806 Installation

Page 16

Instruction Manual Section III

Dual Type IV Power Meter, Model 1806 Operation

SECTION III OPERATION

GENERAL OPERATING CONSIDERATIONS

Operation of the Model 1806 consists of: (1) cabling the unit to the device for testing, (2)

selecting the proper voltage fuse and circuit board, (3) grounding or ungrounding the Model

1806, (4) selecting the proper operating resistance, (5) monitoring several indicators and

meters located on the front panel of the unit, (6) using a digital voltmeter (DVM) or a DVM

and a reference voltage generator (RVG) to measure substituted dc bias, and (7) calculating the

amount of RF power. The Model 1806 contains two identical Type IV Bridge circuits (Bridge

A and Bridge B) with individual sets of controls and indicators. Two black outlined squares

on the front panel separate each set of controls and indicators for each bridge. Figure 3-1

depicts these bridge control panels. Since both bridge circuits perform identical functions,

Section III discusses operation of Bridge A only. Operation of Bridge B is exactly the same as

Bridge A operation. Operation of these bridges may occur individually or simultaneously.

Figure 3-1 also shows the front panel location of meters, indicators, switches and connectors

that control the operations of the Model 1806. Refer to this figure throughout the discussion in

Section III.

The TEGAM System II Automatic Power Meter Calibration System manual contains

information about typical power meter calibration procedures.

FRONT PANEL METERS, INDICATORS, SWITCHES & CONNECTORS

The Model 1806 contains a Power Switch that controls power for the entire unit. Two

indicators located next to the switch show the Model 1806 power status. As shown in Figure

3-1, each bridge control panel contains two meters, three dual binding post connectors, one

temperature control connector, three light-emitting diode (LED) indicators, and an operating

resistance switch.

FRONT PANEL CONNECTORS

The front panel of the Model 1806 contains fourteen connectors, seven connectors for each

bridge. The following paragraphs discuss connectors contained in Bridge A only. Bridge B

connectors have functions identical to those in Bridge A. Refer to Figure 3-1 for locations of

all connectors.

Bolometer Mount Bias Connectors (TP3 and TP4)

Bolometer Mount Bias Connectors TP3 and TP4 are spade-lug connecting posts that pass dc

current applied by the Model 1806 to and from a thermistor mount (typically Model 1110).

The location of TP3 and TP4 is in the lower left-hand corner of Bridge A above the Mount

SENSE Lead Connectors. The red connector is for positive dc bias current and the black

connector is for dc bias current return.

Mount SENSE Lead Connectors (TP1 and TP2)

Mount SENSE Lead Connectors TP1 and TP2 are spade-lug type connecting posts located in

the lower left-hand corner of Bridge A. Voltage present at TP1 and TP2 is proportional to the

effective dc current passing through the thermistor element. Use of the voltage potential

present at TP1 and TP2 reduces errors associated with lead resistance.

Temperature Control Connector (J5)

The location of TEMPERATURE CONTROL Connector J5 is in the center-right of Bridge A.

This connector is a four-pin threaded connector that links a temperature controller within the

Model 1806 to a heater which stabilizes the internal temperature of the thermistor mount. The

TEMPERATURE CONTROL Meter M2 indicates current present at this connector.

3-1

Page 17

Instruction Manual Section III

Figure 3-1 Model 1806 Dual Type IV Power Meter Front Panel Meters, Indicators, Switches, and Connectors

Dual Type IV Power Meter, Model 1806 Operation

3-2

Page 18

Instruction Manual Section III

Dual Type IV Power Meter, Model 1806 Operation

Voltmeter Connectors (TP5 and TP6)

VOLTMETER Connectors TP5 and TP6 are spade-lug connecting posts. Placement of these

connectors is in the lower right-hand corner of either bridge (shown in Figure 3-1 on Bridge

B). TP5 and TP6 complete the dc path between the Model 1806 and a digital voltmeter with a

6.5-digit resolution. DC voltage present at TP5 and TP6 is equivalent to the voltage across the

thermistor element. The red connector is for positive (+) dc power and the black connector is

for negative (-) dc power.

FRONT PANEL METERS

The front panel of the Model 1806 has four analog meters, two for each bridge. They are the

TEMPERATURE CONTROL Meter and the BOLOMETER CURRENT Meter. The

following discussion of Bridge A meters applies equally to Bridge B meters. Figure 3-1 shows

the location of front panel meters.

Bolometer Current Meter (M1)

The Bolometer Current Meter M1 is in the upper left-hand corner of Bridge A. M1 measures,

with a resolution of .1 mA, the thermistor bias current level applied through the Model 1806

Bolometer Mount Bias Connectors.

Temperature Control Meter (M2)

Temperature Control Meter M2 is in the upper-right-hand corner of Bridge A. M2 indicates a

dc voltage level that is proportional to the current applied through Temperature Control

Connector J5 to a heater bridge in the thermistor mount. The green area on M2 indicates that

the thermistor mount is in the correct temperature range.

FRONT PANEL INDICATORS

The Model 1806 contains eight front-panel LED indicators. Each bridge control on the Model

1806 contains three indicators and the overall unit control contains two indicators. This

assortment of LEDs varies in color from yellow to green to red. Each indicates either an ON

or OFF condition. Figure 3-1 also shows the location of front panel indicators.

ON Indicator (DS1)

The location of DS1 is in the lower left-hand corner just to the right of the POWER Switch S1.

This green indicator illuminates when the Model 1806 POWER Switch is in the ON position

indicating supply of operational power to the unit and availability of all operations.

Standby Indicator (DS2)

The DS2 indicator location is just below indicator DS1 in the lower left-hand corner of the

front panel. This yellow indicator illuminates when the Model 1806 POWER Switch is in the

STANDBY position and power is being applied to the unit. Illumination of DS2 indicates that

partial power is supplied to the unit and test functions such as changing the bridge operating

resistance or monitoring bridge bias are not available.

100 Ohm Operational Indicator (DS4)

Each bridge circuit on the Model 1806 contains indicator DS4 in the center of the bridge

control panel (shown in Figure 3-1 on Bridge B). This green indicator illuminates when the

OPERATING RESISTANCE Switch S2 sets the bridge circuitry for 100 Ohm operation.

200 Ohm Operational Indicator (DS5)

Each bridge circuit on the Model 1806 also contains indicator DS5 below DS4 on the front

panel (shown in Figure 3-1 on Bridge B). This green indicator illuminates when the

OPERATING RESISTANCE Switch S2 sets the bridge circuitry for 200 Ohm operation.

3-3

Page 19

Instruction Manual Section III

Dual Type IV Power Meter, Model 1806 Operation

Error Indicator (DS3)

Each bridge on the Model 1806 contains one red DS3 indicator between meters M1 and M2 at

the top of the bridge control panel. ERROR indicator DS3 illuminates for any condition

preventing the Type IV Bridge circuit from balancing.

MODEL 1806 SWITCHES

The Model 1806 uses two front panel switches and one rear panel switch during individual

bridge operation. Switch S1, located on the front panel, selects ON/OFF/STANDBY power

requirements for the entire Model 1806. Each bridge control panel on the Model 1806

employs one switch S2 for selecting the bridge circuit operating resistance. Figure 3-1 depicts

the location of front panel switches. The rear panel of the Model 1806 contains one switch S3

for grounding or ungrounding the Model 1806 depending on the ground state of the thermistor

and DVM used with the Model 1806.

Power Switch (S1)

The Model 1806 POWER Switch S1 controls operational power. S1 is in the lower left-hand

corner of the front panel next to the ON Indicator DS1. S1 is a three-position toggle switch

that completes, extends, or terminates power to the Model 1806. In the uppermost position, S1

extends power to the entire circuitry within the Model 1806 that enables all unit operations. In

the middle position, S1 places the Model 1806 in a STANDBY mode for warm-up.

STANDBY mode applies only necessary power to heat the Model 1806 and associated

thermistor mounts. When switched to the lowest position, S1 terminates power to the Model

1806.

Ensure that input connector and voltage selector/fuse assembly are set for the proper voltage

before switching the POWER Switch (S1) to ON or STANDBY; otherwise, damage may

result to internal circuitry.

100/200 Ohm Operating Resistance Switch (S2)

Each bridge on the Model 1806 contains a two-position, push-button OPERATING

RESISTANCE Switch S2. The location of this switch is in the center of each bridge control

panel. The position of S2 configures individual bridge circuitry for either 100- or 200-ohm

operation. Depending on the position of this switch, either the 100 ohm or 200 ohm

operational indicator will be illuminated. When using a 100 ohm thermistor mount, set S2 to

the in position for 100 ohm operation and to illuminate operational indicator DS4. When using

a 200 ohm thermistor mount, set S2 to the out position for 200 ohm operation and to illuminate

operational indicator DS5.

Float/Ground Switch (S3)

FLOAT/GROUND Switch S3 is a two-position, toggle switch located on the rear panel

directly above the Power Input Connector and Voltage Selector/Fuse Assembly XF1 (refer to

Figure 2-1). S3 grounds or ungrounds (floats) the Model 1806 depending on whether or not

the thermistor and DVM are grounded. The up position of S3 grounds the Model 1806. The

down position of S3 floats the Model 1806. If either the thermistor mount or DVM or both are

grounded, place the FLOAT/GROUND Switch in the FLOAT position. When both bridges

are used, if any external voltage measuring instrument is grounded, place the

FLOAT/GROUND Switch in the FLOAT position.

RF POWER LEVEL MEASUREMENT

The Model 1806 is one component in a precision measurement system that measures RF power

in terms of a dc voltage change across the Model 1806 bridge circuit. This system measures

the voltage change with a digital voltmeter (DVM) with a 6.5 digit resolution – or the same

DVM and reference voltage generator (RVG) when the applied RF power level is small (a few

milliwatts). The following paragraphs describe these two methods of measurement.

3-4

Page 20

Instruction Manual Section III

[(V1)

2

- (V

2

)2]

R0

Pdc

K1

Dual Type IV Power Meter, Model 1806 Operation

RF POWER MEASUREMENT WITH DVM ONLY

The Precision Measurement System does not measure the RF power level directly. Instead, a

DVM measures dc voltages before and after the application of RF power to the Model 1806

bridge. This necessitates calculation of the RF power level using data obtained from the DVM

measurements.

To calculate the RF power level applied to the thermistor element, configure the Model 1806

and the DVM according to Figure 3-2 and measure the voltage across the bridge with the

DVM before the application of RF power, V1. Then measure the voltage across the bridge

after applying RF power and record that measurement as V2. Determine the RF power level

using the following equations:

First, calculate the level of proportional dc substituted power from the operating resistance and

DVM readings with the equation:

Pdc =

Where:

V

V

R

P

Next, calculate the applied RF power level using the mount calibration factor and the level of

dc substituted power:

PRF =

Where:

P

P

K

1

2

0

dc

RF

dc

1

= DVM reading across the bridge in the absence of RF power,

= DVM reading across the bridge with RF power applied, and

= Mount operating resistance (100 or 200 ohms)

= dc substituted power which is proportional to the applied RF power

= Level of RF power applied to the terminating thermistor,

= Level of proportional dc substituted power from previous equation, and

= Terminating Mount calibration factor directly traceable to NIST

___________________

_________

Figure 3-2 Location of Digital Voltmeter in Typical Test Configuration

RF POWER LEVEL MEASUREMENT WITH DVM AND

REFERENCE VOLTAGE GENERATOR

When the applied RF power level becomes small, change of voltage across the bridge also

becomes very small. In this situation, even a high-accuracy voltmeter magnifies measurement

3-5

Page 21

Instruction Manual Section III

(2V

1

– V

D

2

+ V

D

1

) x (V

D

2

– V

D

1

)

R0

Dual Type IV Power Meter, Model 1806 Operation

uncertainties because the large DVM measurement scale has limited resolution. Use of a

reference voltage generator, like the one in Figure 3-3, minimizes voltmeter uncertainties by

enabling use of a measurement scale that has better resolution.

When a reference voltage generator is used with the DVM, calculation of the RF power level

requires a different process. First, adjust the reference voltage generator to an output power

level approximately equal to the Model 1806 bridge output measured by a DVM when no RF

power is applied. Ensure stabilization of the RVG output throughout the entire measurement

period. Next, record the DVM reading with no RF power applied to the bridge and the doublepole, double-throw switch in the “Measure V

” position. This value is (V

1

). Switch the DVM

1

to a scale with improved resolution for smaller power levels. Record the DVM reading with

no RF power applied and the double-pole, double-throw switch in the “Measure V

” position.

D

This reading is the difference between the Model 1806 bridge output and the setting of the

reference voltage source (VD1). Finally, apply RF power to the bridge and record the

voltmeter reading with the double-pole, double-throw switch in the “Measure V

” position.

D

This value is the difference between the Model 1806 output and RVG output including the

proportional RF power effect on the bridge circuit (VD2). Use these values and the following

method to calculate the applied level of RF power.

First, determine the level of dc substituted power using the measurements taken above with the

equation:

Pdc =

______________________________

Where:

V

V

R

P

V

dc

= Model 1806 bridge output measured by DVM with no RF power applied,

1

= Difference between 1806 bridge output with no RF applied and RVG output,

D1

= Difference between 1806 bridge output with RF applied and RVG output

D

2

= Mount operating resistance, and

0

= Proportional amount of dc substituted power.

Next, apply the mount calibration factor to find the level of RF power using the second

equation in the “RF POWER MEASUREMENT WITH DVM ONLY” section above.

Figure 3-3 Location of Reference Voltage Generator in Typical Test Configuration

3-6

Page 22

Instruction Manual Section IV

4-1

Pdc

K1

PRF

Pdc

Dual Type IV Power Meter, Model 1806 Principles of Operation

SECTION IV PRINCIPLES OF OPERATION

INTRODUCTION

This section contains information that describes the basic circuitry and functions of the Model

1806 Dual Type IV Power Meter - the major component in a precision power measurement

system that measures high-frequency or microwave power in the .01 to 18 GHz range. The key

role of the Model 1806 within this system is the realization of the principle of dc substitution.

It also provides temperature stabilization of up to two mounts each associated with one of the

two bridges.

The Model 1806 contains a power supply assembly and five printed circuit (PC) boards. The

five PC boards are the temperature control board, two bridge boards, a front panel board, and a

motherboard. The functions of each of these boards are detailed in this section.

PRINCIPLE OF DC SUBSTITUTION

The Model 1806 uses the principle of dc substitution to provide a measure of RF power. DC

substitution refers to the measurement of RF power according to the amount of dc power that

must be substituted for the RF power in a bolometer in order to cause equivalent thermal

effects. This principle extends to the determination of terminating thermistor mount calibration

factors (ratio of substituted dc power to the power incident on the thermistor mount) by the

following formulas:

PRF =

K1 =

Where:

PRF = the RF power incident on the terminating mount.

Pdc = the dc substituted power as measured at the Model 1806.

K1 = the measured or known calibration factor for the terminating mount.

RF power measurements are traceable to a primary laboratory standard in cases where the

terminating thermistor mount has been calibrated by NIST.

_______

_______

PRECISION POWER MEASUREMENT SYSTEM

The Model 1806 Dual Type IV Power Meter, the NIST-calibrated TEGAM Model 1110

Terminating Mount, a reference voltage generator, and a digital voltmeter with a 6.5 digit

resolution combine to provide the precision power measurement system shown in the

functional block diagram in Figure 4-1. This system features one of the two Model 1806

closed-loop, self-balancing Type IV Bridge circuits consisting of two legs--a precision

resistance leg (100 or 200 ohms) and a leg linked to a thermistor element in the Model 1110. A

thermistor is a type of bolometer whose resistance decreases as a function of increasing heat

associated with ambient temperature or applied power.

This system also features the Model 1806 temperature control circuitry that temperature

stabilizes the thermistor mount. This eliminates changes in the thermistor element's resistance

due to ambient temperature changes and thus isolates the causes of thermistor variation to the

application of RF and dc power only.

An IEEE - 488 bus-compatible controller controls DVM measurements across the precision

resistance leg of the Model 1806 bridge circuit. A reference voltage generator (RVG) increases

the accuracy of the DVM measurements when the RF power level is below a few milliwatts.

Page 23

Instruction Manual Section IV

4-2

Dual Type IV Power Meter, Model 1806 Principles of Operation

Figure 4-1 Functional Block Diagram of Precision Power Measurement System

SELF-BALANCING BRIDGE CIRCUITS

The Model 1806 contains two identical bridge circuits on individual PC boards that perform dc

substitution independently from each other. Figure 4-2 shows a simplified schematic of one of

the two bridge boards circuits depicting its interaction with system components internal and

external to the Model 1806.

Each self-balancing bridge circuit, in a closed-loop configuration, consists of two legs: a

precision resistance leg (l00-ohm or 200-ohm) and a leg containing a thermistor element. The

precision resistance leg maintains a constant effective resistance value of either 100 or 200

ohms depending on the bridge operating resistance selection. When the thermistor mount is

temperature stabilized by the Model 1806 temperature controller, thermistor resistance varies

solely due to the application of RF and dc power.

Each leg uses an operational amplifier (U1 or U2) to sense voltage imbalances and to drive

transistors (Q1 and Q2) to correct them. The power supply assembly provides isolated 15 volt

biasing to each op-amp. Since the voltage differential at the input stage of op amp U2 is

negligibly small, it provides a virtual common reference to op amp U1 (i.e., it acts as a virtual

common ground since the voltage approaches zero with respect to either ground). This forces

the current through the thermistor to equal the current through the precision resistance leg.

The application of RF power to the thermistor element creates a decrease in the voltage drop

across the thermistor element due to its negative temperature coefficient. This decreased

voltage drop in turn creates an unbalanced bridge condition. When resistance in the thermistor

element leg of the bridge changes due to the application of RF power, op amp U1 senses a

voltage difference between Va and Va' and causes Va' to equal Va. When Va' equals Va, the

voltage across the thermistor element leg equals the voltage across the precision resistance leg.

Also, the closed loop circuit configuration maintains equal current throughout the bridge. Since

the voltage and current throughout the circuit is equal, the resistance in both halves is also

equal. Therefore, when the thermistor mount's temperature is stabilized and RF power is

applied, a change in voltage across the precision resistance leg is proportional to the amount of

RF power applied to the themistor mount.

Page 24

Instruction Manual Section IV

4-3

V2

R

Dual Type IV Power Meter, Model 1806 Principles of Operation

Figure 4-2 Simplified Schematic of Precision Power Measurement System

POWER MEASUREMENTS

The precision measurement system measures RF power in terms of a voltage change across the

precision resistance leg. The digital voltmeter measures voltage across the precision resistance

leg before the application of RF power (V1) and after the application of RF power (V2). The

difference, V2 – V1, indicates the change in voltage across the precision resistance leg due to

the application of RF power. The RF power introduced to the thermistor is directly

proportional to the change in dc power across the precision resistor. The change in dc power is

calculated by the formula:

Pdc =

Where:

Pdc = the change in dc power across the precision resistor

V2 = change in voltage across the precision resistor (V

R = resistance value of precision resistor

______

2

2

– V

1

)

2

Page 25

Instruction Manual Section IV

4-4

[(V

1

)

2

- (V

2

)

2

]

R0

K1

Pdc

Dual Type IV Power Meter, Model 1806 Principles of Operation

RF Power Level Calculation

The Model 1806 measures high-frequency or microwave power in terms of a dc voltage

change. The system does not measure the RF power level directly. Instead, it measures dc

voltages before and after the application of RF power using a DVM or a DVM and an RVG.

The difference between these voltages is proportional to the RF effect on the thermistor's

resistance and is calculated in terms of dc substituted bias required to rebalance the bridge as

follows:

Pdc =

Where:

V1 = DVM reading across the precision resistance leg in the absence of RF power,

V2 = DVM reading across the precision resistance leg with RF power applied,

R0 = Mount operating resistance (100 or 200 ohms), and

P

power

The dc effect is translated into an RF power level using the mount calibration factor according

to this equation:

P

Where:

P

P

K

= DC power across precision resistance which is proportional to the applied RF

dc

= Level of RF power applied to the thermistor,

RF

= Level of proportional dc substituted power from previous equation, and

dc

= Terminating Mount calibration factor which is directly traceable to NIST.

1

_______________

_____

=

RF

CONTROLLING THERMISTOR MOUNT INTERNAL TEMPERATURE

When the Model 1806 operates in conjunction with a thermistor mount, a temperature sensitive

device, it must eliminate or minimize the effects of changes in the ambient temperature upon

the thermistor in order to provide precise measurements. The Model 1806 temperature control

board accomplishes this by raising the mount's internal temperature to a level higher than the

ambient temperature and maintaining that level by controlling the current applied to the

mount's internal heater element. This prevents any thermistor imbalance due to ambient

temperature change. Therefore, all temperature changes are due to the application of RF and dc

power. The temperature controller maintains the temperature of one or two external

temperature-stabilized thermistor mounts above the ambient temperature.

Figure 4-3 Simplified Schematic of Model 1806 Temperature Control Board

Page 26

Instruction Manual Section IV

4-5

Dual Type IV Power Meter, Model 1806 Principles of Operation

TEMPERATURE CONTROL BOARD

The temperature control board performs three basic functions: the control of current applied to

the mount heater, indication of the mount temperature by a front panel meter, and illumination

of a balanced-state indicator LED on the temperature control board (window indicator) Refer

to Figure 4-3 for the following discussions concerning the temperature control circuit The

temperature control board controls current to the thermistor mount heater element which is a

thermal bridge configuration. U1, a high-gain amplifier with excellent offset drift

characteristics, senses imbalances across the thermal bridge located in the temperaturestabilized feedthrough thermistor mount via inputs 2 and 3. This thermal bridge, which is

composed of two types of resistance with differing temperature coefficients, balances at

approximately 60C. U1/U2 interaction provides a varying response to thermal bridge

imbalances according to the relationship between the voltage differential inputs. U1/U2

amplifies an imbalance signal from a cold thermal bridge that forces the series pass transistor

Q3 to pass a current proportional to the imbalance signal. This current drives the mount heater

to restore thermal bridge balance. As the thermal bridge nears the steady-state condition, Q3

causes DS1 to illuminate. If the mount is cold, DS1 does not illuminate since the Darlington

pair configuration made up by U2-2 and Q4 is not in a conducting state. U1/U2 responds to an

imbalance signal from an overheated mount by turning off Q3 so that it passes no current to

the heater or DS1.

Transistor Q2 and Resistor R16 combine to provide circuit protection by limiting current in the

event of an output short circuit.

Throughout this process, the TEMPERATURE CONTROL Meter M2 senses the balance state

of the thermistor heater element. This control meter contains a marked green operating range

that indicates the operating point for thermistor mount temperature stabilization.

MODEL 1806 POWER SUPPLY

The power supply assembly transforms the ac power input into six different power sources for

the varying operations of the Model 1806 while completely isolating those supplies for bridge

circuitry biasing. These power supplies consist of + 5-volt and + 20-volt operational power

supplies and four completely isolated + 15-volt bridge board biasing power supplies. The + 5volt control signal enables front panel controls and is applied only when the Model 1806 is in

the ON mode. The + 20-volt potential powers the temperature control circuitry in both

STANDBY and ON modes. The four isolated + 15-volt supplies bias bridge board circuitry in

the STANDBY and ON modes of operation.

POWER SUPPLY ELECTRICAL CONFIGURATION

The power supply electrical configuration uses transformers and a network of full-wave

rectifiers, capacitive filters, and three-terminal voltage regulators to produce the six power

sources needed for Model 1806 operation.

POWER SUPPLY APPLICATION, TRANSFORMATION, & ISOLATION

To produce the six required voltages, the power supply assembly contains two transformers.

One transformer contains dual secondary windings that supply the voltages for the + 5-volt and

+20-volt supplies. The other transformer has four center-tapped secondaries that supply four

15-volt bridge biasing supplies. The power supply assembly isolates the four 15-volt circuits

by using a transformer with primary-to-secondary and secondary-to-secondary isolation. The

power supply circuitry applies these voltages to a network of full-wave rectifiers and

capacitive filters in order to smooth out ripple effects. A series of three-terminal regulators

control the 15volt supplies while two individual variable regulators control the +5-volt and +

20-volt supplies.

When in the STANDBY position, the front panel Power Switch turns off the + 5-volt supply,

thus, disabling front panel switches. When in the ON position, the front panel Power Switch

allows power to all front panel switches.

Page 27

Instruction Manual Section IV

4-6

Dual Type IV Power Meter, Model 1806 Principles of Operation

MOTHERBOARD

The motherboard within the Model 1806 routes power between the power supply assembly and

temperature control board, the bridge board, and the front panel board. The motherboard

contains only simple conductor paths.

FRONT PANEL PC BOARD

The front panel PC board extends the circuitry of the temperature control board, the power

supply assembly, the bridge boards, and the mother board to front panel meters, indicators, and

switches. The front panel PC board contains several electrical components.

MEASUREMENTS USING A REFERENCE VOLTAGE SOURCE

When the applied RF power level becomes small, the change in voltage across the precision

resistance also becomes very small. In this situation, even a high-accuracy digital voltmeter

magnifies measurement uncertainties because the measured voltages differ only slightly and

the DVM has a limited resolution. Use of a reference voltage source, like the one in Figure 4-4,

minimizes voltmeter uncertainties by employing a measurement scale with improved

resolution.

Figure 4-4 Use of Reference Voltage Generator in Typical Test Configuration

The RVG increases measurement accuracy by reducing the voltage output across the precision

resistance by a known amount so that the measurement can be made on a scale with better

resolution. This change takes place because the RVG output and the Model 1806 output are in

opposition when measuring with the double-pole, double-throw switch in the “Measure V

position (refer to Figure 4-4). For example, when the RVG switch is in the “Measure V

position, the connection poles between the DVM and the Model 1806 are aligned and a direct

bridge output reading by the DVM occurs. When the double-pole, double-throw switch is in

the "Measure VD" position, the connection is re-aligned so that the RVG output voltage

opposes the Model 1806 output voltage. This allows only the voltage difference caused by the

introduction of RF power to the Model 1806 bridge to remain. The small reduction of bridge

outputs with and without the application of RF power by the opposition of the reference

voltage generator enables DVM readings on a smaller scale with a wider resolution. This

provides readings of greater accuracy. Since the output difference between the RVG and

Model 1806 with no RF power applied is known (V

difference between the two devices when RF power is applied (V

RF-generated voltage difference (V), which is used to calculate Pdc in the following

equations:

”

D

”

1

), it can be subtracted from the

D

1

). This process leaves the

D

2

Page 28

Instruction Manual Section IV

4-7

1

(2V

1

– V

D

2

+ V

D

1

) x (V

D

2

-V

D

1

)

R0

Dual Type IV Power Meter, Model 1806 Principles of Operation

V

2

= (2V

– V

1

D

+ V

2

D

) x (V

1

-V

D

)

D

2

1

Pdc =

Where:

V = Change in voltage across the precision resistance leg of the Model 1806

bridge,

V1 = Model 1806 bridge output reading with no RF power applied,

V

V

= Difference between Model 1806 output with no RF power applied and

D

1

reference voltage generator,

= Difference between Model 1806 output with RF power applied and reference

D

2

voltage generator,

R0 = Mount operating resistance, and

P

dc

= Proportional amount of dc substituted power

_______________________________

PRECISION MEASUREMENT SYSTEM ERRORS

Precision measurement system errors are due largely to the inaccuracy of the external voltagemeasuring equipment. However, servo errors dependent on power level such as those caused

by amplifier offset and finite gain, amplifier input bias currents, and the nominal resistance of

the precision resistor do occur. Figure 4-5 depicts typical bridge errors over a 30 mW RF

power range with and without a reference voltage generator. Figure 4-5 shows values obtained

when using a typical coaxial dual-element thermistor with an ohms-per-watt coefficient of

1300 and a bias current of 12.8 mA. Because this type of mount experiences a dual-element

substitution error, the normal maximum RF power level is 10 mW. However, the graph in

Figure 4-5 extends beyond this level to illustrate better the nature of errors.

Table 4-1 offers a comparison of voltmeter errors when a reference voltage source is used and

not used over a 0.1-to-10 mW power range.

Figure 4-5 Graph of Typical Bridge Errors With and Without Reference Voltage Generator1

Neil T. Larsen, A New Self-Balancing DC-Substitution RF Power Meter, IEEE TRANSACTIONS ON INSTRUMENTATION

AND MEASUREMENT, VOL. IM-25 NO.4, December 1976, page 345.

Page 29

Instruction Manual Section IV

4-8

Power in

mW

V1 Range

V2 Range

Percent Error With

RVG Use

Percent Error

Without RVG Use

0.100

10.0000

10.0000

0.1552*

23.1772

0.200

10.0000

10.0000

0.0914*

11.5746

0.300

10.0000

10.0000

0.0702*

7.7071

0.400

10.0000

10.0000

0.0595*

5.7734

0.500

10.0000

10.0000

0.0532*

4.6131

0.600

10.0000

10.0000

0.0489*

3.8396

0.700

10.0000

10.0000

0.0459*

3.2871

0.800

10.0000

10.0000

0.0436*

2.8727

0.900

10.0000

10.0000

0.0419*

2.5504

1.000

10.0000

10.0000

0.0405*

2.2926

2.000

10.0000

10.0000

0.0341*

1.1323

3.000

10.0000

10.0000

0.0442**

0.7455

4.000

10.0000

10.0000

0.0400**

0.5520

5.000

10.0000

10.0000

0.0376**

0.4359

6.000

10.0000

10.0000

0.0359**

0.3585

7.000

10.0000

10.0000

0.0348**

0.3032

8.000

10.0000

10.0000

0.0339**

0.2617

9.000

10.0000

10.0000

0.0333**

0.2294

10.000

10.0000

10.0000

0.0328**

0.2035

V

OFF

2

200

Dual Type IV Power Meter, Model 1806 Principles of Operation

Table 4-1 Comparison of Voltmeter Errors When Reference Voltage Generator Is and Is Not Used

*VD Range = .1000V

**VD Range = 1V

CALCULATING MODEL 1806 ACCURACIES

The specification for the Model 1806 Dual Type IV Bridge is given as: Substituted DC Power

Accuracy: 0.03 2% W.

The actual Model 1806 bridge is accurate to better than 0.003 up to 25mW. This means that

the voltages measured across the 200 Ohm resistor in the self-balancing bridge give the bias

power in the thermistor mount to better than 0.003%. Accuracy is lost when the

specifications of the voltmeter used to measure this voltage are taken into account.

For example, consider the Fluke Model 8506A digital voltmeter. It has a 6-1/2 digit display

with quoted specifications after 90 days of 0.001% 8 counts in the 10 Volt range.

Consider the bias of the thermistor beads with no RF power present.

0.030 =

Where V

V

is the voltage across the 200 Ohm resistor.

OFF

OFF

_______

= 2.44949 V

Page 30

Instruction Manual Section IV

4-9

Dual Type IV Power Meter, Model 1806 Principles of Operation

If the incident RF causes the bias to drop by 1 mW, i.e., the dc Substitution power is 1 mW,

then:

V1 = 2.40832V

The 0.001% figure in the voltmeter accuracy, and the 0.003% for the 1806 are linear, and

always in the same direction. The ability to correctly measure the 1 mW is thus directly

affected by both. The 8 counts part of the accuracy can be of any sign or value within these

limits, and is a function of the nonlinearity of the voltmeter.

Thus, in the worst case, the V

could be read as 2.44957 V, i.e., 2.44949+0.00008 and V1 as

OFF

2.40824 V., i.e., 2.40832-0.00008.

The former gives an initial bias power of 30.002 mW and the latter a bias power after RF

substitution of 28.998 mW. The measurement answer would thus be 1.004 mW, i.e., a 0.4%

error. A similar calculation for a 10 mW substituted power gives 0.04% from this alone. This

error is far greater than either the voltmeter reference accuracy or the 1806 bridge accuracy.

Page 31

Instruction Manual Section IV

4-10

Dual Type IV Power Meter, Model 1806 Principles of Operation

Page 32

Instruction Manual Section V

5-1

EQUIPMENT

EQUIPMENT

SPECIFICATlONS

Voltmeter (DC Null Detector)

Range:

Sensitivity of Smallest Scale:

Input Impedance:

Accuracy:

30V

10%V

100 K or greater (resistive)

2% of full scale

General purpose oscilloscope

Bandwidth

10 MHz

Dual Type IV Power Meter, Model 1806 Maintenance

SECTION V MAINTENANCE

INTRODUCTlON

This section contains maintenance and troubleshooting information for the TEGAM Model

1806 Dual Type IV Power Meter, including preventive maintenance, troubleshooting

procedures, and corrective maintenance and recalibration.

PREVENTIVE MAINTENANCE

While the Model 1806 requires little preventive maintenance, it should not be subjected to

physical abuse, severe mechanical shock, high humidity, or operating temperatures outside the

specification range (refer to Table 1-1). The unit should be kept free of excessive dirt and dust,

as these can interfere with normal heat dissipation and connector functions. Care should be

taken to prevent physical strain on the interconnecting cables, as damage here may not always

be apparent.

To remove dirt or dust, use a slightly dampened lint-free cloth. Avoid use of cleaning solvents.

Interior dust may be blown out using a low-pressure air blower. Occasionally check external

cables and connectors for signs of cracked insulation and bent or worn pins.

TROUBLESHOOTING PROCEDURES

Where the 1806 in question is a component of a System II Automatic Power Meter Calibration

System, troubleshooting procedures herein assume completion of system level diagnostics. The

System II manual contains these diagnostics. When the System II manual refers further

diagnostics to this manual, follow the specification tests and then perform the appropriate

calibration procedures. Inability to resolve the problems using an accurate voltmeter with

these procedures indicates that an uncalibrated thermistor mount or a burned-out thermistor

element may be the source of problems. For further information on these situations, refer to the

repair manual for TEGAM Models F1109 and M1110 Temperature Stabilized Coaxial

Thermistor Mounts.

This section provides a series of operational checks that ensure that the unit is working

properly. When out-of-specification conditions are found, note the problem area and continue

the audit procedures. When all the audit procedures are completed, perform all of the

corrective maintenance and recalibration procedures indicated in “Corrective Maintenance and

Recalibration” later in this section. Testing and recalibrating the Model 1806 requires the use

of several items not supplied with the unit. Table 5-1 lists this equipment.

SPECIFICATION TESTS

This section provides a series of operational tests that check the Model 1806 for possible outof-specification conditions. These operational tests are: (1) a power-up operational test, (2) a

bolometer current meter test, (3) a bridge noise test, and (4) a bridge balance test. This process

draws attention to specific circuits as probable sources of unit malfunctions. When an out-ofspecification condition is revealed, refer to the calibration procedures to correct the problem.

Table 5-1 Required Test and Calibration Equipment

Page 33

Instruction Manual Section V

5-2

Four-terminal 100 ohm resistance standard

0.01% or better

DC milliammeter

Range:

Sensitivity:

Accuracy:

30 mA

.1 mA

2%

Temperature-stabilized thermistor mount

Resistance:

Bias Requirement:

200 ohms

30 mW

Decade resistance box or multi-turn potentiometer

Adjustment Range:

Resolution:

0 to 100 ohms

0.1%

1N914 silicon diode or its equivalent

Variac

Line Voltage Requirement:

Adjustment Range:

117 Vac

105 to 130 Vac

PC Extender Board

Tegam P/N 138-439

PC Board Puller

Tegam P/N 139-1141

Dual Type IV Power Meter, Model 1806 Maintenance

Power Up operational Test

The power-up operational test ensures that the Model 1806 power supply circuitry, bridge

meters, and indicators are working properly. Figure 5-1 shows the power-up test configuration

and cabling procedure. The Model 1806 Dual Type IV Power Meter has two bridges (Bridge A

and Bridge B) that have identical circuitry. The following procedure should be repeated for

both bridges. To test the Model 1806 power supply, perform the following:

A. Cable the test configuration according to Figure 5-1 and the following steps:

1. Install a shorting link (P/N 138-495) between the Model 1806 red, positive Bolometer

Mount Bias Connector (TP3) and the Model 1806 blue, positive SENSE Connector

(TP1).

2. Install a shorting link (P/N 138-495) between the Model 1806 black, negative

Bolometer Mount Bias Connector (TP4) and the Model 1806 white, negative SENSE

Connector (TP2).

3. Set the Bridge OPERATING RESISTANCE Switch (S2) to 200 ohms (the out

position), and

4. Set the Model 1806 rear panel FLOAT/GROUND Switch (S3) to the FLOAT position;

B. Turn the Model 1806 POWER Switch (S1) to the ON and STANDBY positions and

ensure that:

1. The ON (green) and STANDBY (yellow) Power Indicators (DS1 and DS2,

respectively) illuminate while the switch is in the ON or STANDBY positions,

2. The ERROR Indicators (DS3) are lit (red) for both bridges, and

3. Depression of the OPERATING RESISTANCE Switch (S2) triggers the operational

Resistance Indicators (DS4 and DS5) to indicate the corresponding bridge impedance

(100 or 200 ohms); and

C. Turn the Model 1806 POWER Switch (S1) to the OFF position.

Figure 5-1 Power-up Operational Test Configuration

Page 34

Instruction Manual Section V

5-3

Dual Type IV Power Meter, Model 1806 Maintenance

Bolometer Current Meter Test

This test ensures that the BOLOMETER CURRENT Meter (M1) indicates the correct dc bias

level applied by the Model 1806 to the bolometer mount. Perform this test for both bridges.

Figure 5-2 illustrates the cabling arrangement of the BOLOMETER CURRENT Meter test.

A. Configure the test arrangement according to Figure 5-2 and the following steps:

1. Install a shorting link (P/N 138-495) between the Model 1806 red, positive

BOLOMETER Mount Bias Connector (TP3) and the Model 1806 blue, positive

SENSE Connector (TP1),

2. Install a shorting link (P/N 138-495) between the Model 1806 black, negative

BOLOMETER Mount Bias Connector (TP4) and the Model 1806 white, negative

SENSE Connector (TP2),

3. Connect the anode of the 1N914 diode to the Model 1806 red, positive BOLOMETER

Mount Bias Terminal (TP3),

4. Connect the cathode of the 1N914 diode to the 100-ohm adjustable resistor,

5. Connect the 100-ohm resistor's other terminal to the negative terminal of the dc

milliammeter,

6. Connect the dc milliammeter's positive terminal to the Model 1806 black, negative

BOLOMETER Mount Bias Connector (TP4),

7. Set the Model 1806 OPERATING RESISTANCE Switch (S2) to 100 ohms (the in

position), and

B. Turn the Model 1806 POWER Switch (S1) to the ON position;

C. Adjust the external adjustable resistor to obtain 30 mA of current as indicated on the

BOLOMETER CURRENT Meter (M1);

D. Ensure that the dc milliammeter reading is 30 mA 1 mA; and

E. Ensure that the front panel ERROR Indicator (DS3) remains dark throughout the entire

test except for momentary flashes when changing the bridge operating resistance settings.

Figure 5-2 Bolometer Current Meter Test Configuration

Page 35

Instruction Manual Section V

5-4

Dual Type IV Power Meter, Model 1806 Maintenance

Bridge Noise Test

The bridge noise test employs an oscilloscope to measure bridge noise. The bridge noise test

ensures that the Model 1806 bridge does not source noise that would disrupt measurements or

bridge balance capability. Perform this test for both Bridge A and Bridge B.

A. Configure the test arrangement according to Figure 5-3 and the following steps:

1. Install a shorting link (P/N 138-495) between the Model 1806 red, positive

BOLOMETER Mount Bias Connector (TP3) and the Model 1806 blue, positive

SENSE Connector (TP1),

2. Install a shorting link (P/N 138-495) between the Model 1806 black, negative

BOLOMETER Mount Bias Connector (TP4) and the Model 1806 white, negative

SENSE Connector (TP2),

3. Connect the anode of the 1N914 diode to the Model 1806 red, positive BOLOMETER

Mount Bias Connector (TP3),

4. Connect the cathode of the 1N914 diode to the to the Model 1806 black, negative

BOLOMETER Mount Bias Connector (TP4),

5. Connect the oscilloscope's positive and negative terminals to the Model 1806

VOLTMETER Terminals (TP5 and TP6), respectively,

6. Set the Model 1806 OPERATING RESISTANCE Switch (S2) to 100 ohms (the in

position), and

B. Turn the Model 1806 POWER Switch (S1) to the ON position; and

C. Ensure that the oscilloscope indicates approximately 1 mV peak-to-peak amplitude with

no short-term bursts or large peak transients.

Bridge Balance Test

The bridge balance test checks the Model 1806 bridge circuitry balance at a 30 mW 1 mW

operating bias. Figure 5-4 shows this test configuration. Perform this test for Bridge A and B.

Figure 5-3 Bridge Noise Test Configuration

Page 36

Instruction Manual Section V

5-5

V

1

2

200

Dual Type IV Power Meter, Model 1806 Maintenance

A. Configure the test arrangement according to Figure 5-4 and the following steps:

1. Connect the bolometer mount's positive mount bias connector to the Model 1806 red,

positive BOLOMETER Mount Bias Connector (TP3),

2. Connect the bolometer mount's negative mount bias connector to the Model 1806

black, negative BOLOMETER Mount Bias Connector (TP4),

3. Connect the bolometer mount's positive mount bias connector to the Model 1806 blue,

positive SENSE Connector (TP1),

4. Connect the bolometer mount's negative mount bias connector to the Model 1806

white, negative SENSE Connector (TP2),

5. Remove any shorting links from either bridge between the Model 1806 BOLOMETER

Mount Bias Connectors (TP3 and TP4), and the Model 1806 SENSE Connectors (TP1

and TP2),

6. Connect the digital voltmeter's positive and negative terminals to the Model 1806

VOLTMETER Terminals (TP5 and TP6), respectively,

7. Connect the bolometer mount's temperature control connector to the Model 1806

TEMPERATURE CONTROL Connector (J5) via a temperature control cable (P/N

138-477), and

8. Set the Bridge OPERATING RESISTANCE Switch (S2) to 200 ohms (the in

position);