Page 1

1750

High Speed Programmable

Microohmmeter

MODEL 1750

NOTE: This User’s Manual was as current as possible when this product was manufactured. However,

products are constantly being updated and improved. To ensure you have the latest documentation,

refer to www.tegam.com.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

Instruction Manual

PN# 1750-900-01

Publication Date: April 2017

REV. S

Page 2

TABLE OF CONTENTS

TABLE OF CONTENTS

1 INSTRUMENT DESCRIPTION

Instrument Description ............................................................................ 1-1

Feature Overview .................................................................................... 1-1

Accessories Sheet ................................................................................... 1-4

Performance Specifications ....................................................................... 1-5

Accuracy ........................................................................................... 1-6

Measurement Times ........................................................................... 1-7

Reference Current Modes ......................................................................... 1-9

Miscellaneous Specifications ..................................................................... 1-10

Test Lead Requirements ........................................................................... 1-12

Broken Lead Detection ............................................................................. 1-14

2 PREPARATION FOR USE

Unpacking & Inspection ............................................................................ 2-1

Safety Information & Precautions .............................................................. 2-1

Terms in this Manual .......................................................................... 2-1

Terms as Marked on Equipment ........................................................... 2-1

Symbols ............................................................................................ 2-2

Grounding the Equipment .................................................................... 2-2

Danger Arising from the Loss of Ground ................................................ 2-2

Use the Proper Fuse ........................................................................... 2-2

Do not Use in Explosive Environments .................................................. 2-2

Do not Operate without Covers ............................................................ 2-3

Preventive Maintenance ...................................................................... 2-3

Line Voltage Selection ......................................................................... 2-4

3 QUICK START INSTRUCTIONS

General .................................................................................................. 3-1

Power the Unit ........................................................................................ 3-1

Factory Settings ...................................................................................... 3-1

Customizing Parameter Settings ................................................................ 3-2

Test Lead Requirements ........................................................................... 3-2

Measuring Resistances Greater than 200kΩ ................................................ 3-2

4 OPERATING INSTRUCTIONS

Basic Operation ....................................................................................... 4-1

Default Parameters .................................................................................. 4-1

Front Panel Description ............................................................................ 4-2

Rear Panel Description ............................................................................. 4-3

Display Modes ......................................................................................... 4-4

Resistance Mode ................................................................................ 4-5

Figure 4.5 Over Range or Open Lead Condition ...................................... 4-5

Open Lead Detection .......................................................................... 4-5

Reading Hold ..................................................................................... 4-6

Absolute Comparator Mode .................................................................. 4-7

% Comparator Mode ........................................................................... 4-8

Navigating the Menus .............................................................................. 4-9

Keypad Functionality .......................................................................... 4-9

Figure 4.8 Menu ................................................................................. 4-9

Ranges .................................................................................................. 4-10

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

I

Page 3

TABLE OF CONTENTS

TABLE OF CONTENTS

Trigger Modes ......................................................................................... 4-11

Delay Time ............................................................................................. 4-11

Display Mode .......................................................................................... 4-12

Absolute Comparator Limits ...................................................................... 4-12

% Compare Limits ................................................................................... 4-13

Communication Interface ......................................................................... 4-13

Store Setup ............................................................................................ 4-14

Recall Setup ........................................................................................... 4-14

Line Frequency ....................................................................................... 4-14

PIN Function ........................................................................................... 4-15

Calibration .............................................................................................. 4-15

Auto Correct ........................................................................................... 4-15

The PIN Function ..................................................................................... 4-16

Enabling or Disabling the PIN Function .................................................. 4-16

Changing a PIN Number ...................................................................... 4-16

Disabling an Unknown PIN ................................................................... 4-16

5 PROGRAMMING & INTERFACING

Interfacing to the 1750 ............................................................................ 5-1

Front Panel ............................................................................................. 5-1

Figure 5.1 Lemo Connector .................................................................. 5-1

Rear Panel .............................................................................................. 5-2

Trigger Input Connector ...................................................................... 5-2

Trigger Out Connector ........................................................................ 5-3

Using the Trigger Outputs ................................................................... 5-4

Connector J8 .......................................................................................... 5-5

RS232 Communication ............................................................................. 5-8

RS232 Settings .................................................................................. 5-8

RS232 Interface Command Summary ................................................... 5-9

RS232 Device Dependent Commands Supplementary Information ............ 5-11

Table 5.4 –RS232 Status Command Summary ....................................... 5-12

RS232 Hierarchy of Commands ............................................................ 5-13

Power Up and Device Clear Defaults .......................................................... 5-13

Reading Via RS232 Interface ............................................................... 5-14

IEEE-488.1 / GPIB Operation .................................................................... 5-15

GPIB Command Summary ................................................................... 5-16

GPIB Device Dependent Commands Supplementary Information .............. 5-18

Serial Polling ...................................................................................... 5-19

Self Test ........................................................................................... 5-21

Hierarchy of GPIB Commands .............................................................. 5-21

Power Up and Device Clear Defaults ..................................................... 5-23

Reading from the IEEE-488 Bus ........................................................... 5-23

Sample Programs ............................................................................... 5-24

6 SERVICE INFORMATION

Cleaning ................................................................................................. 6-1

Calibration Procedure ............................................................................... 6-1

Calibration Verification Procedure ......................................................... 6-3

Performance Verification Procedure ...................................................... 6-4

Internal Jumpers ..................................................................................... 6-5

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

(continued)

II

Page 4

TABLE OF CONTENTS

TABLE OF CONTENTS (continued)

Calibration Enable Jumper ................................................................... 6-5

RS232/RS422 Configuration Jumper ..................................................... 6-5

Figure 6.1 Internal Jumpers ................................................................. 6-5

Repair Parts ............................................................................................ 6-6

Instructions for Fuse Replacement ........................................................ 6-6

Figure 6.2 Fuse and Filter Assemblies ................................................... 6-6

Troubleshooting ...................................................................................... 6-7

No Display ......................................................................................... 6-7

Reading Drifts .................................................................................... 6-7

Unstable Reading ............................................................................... 6-7

Preparation for Repair or Calibration Service ............................................... 6-8

Expedite Repair and Calibration Form ........................................................ 6-9

Warranty ................................................................................................ 6-10

Warranty Limitations .......................................................................... 6-10

Statement of Calibration ..................................................................... 6-10

Contact Informat ion ........................................................................... 6-10

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

III

Page 5

INSTRUMENT DESCRIPTION

SECTION 1

INSTRUMENT DESCRIPTION

The Model 1750 is a highly versatile, precision digital Microohmmeter designed to provide unmatched

measurement speed and accuracy for production test and quality control applications up to 23 MΩ.

The 1750 microohmmeter automatically rejects thermal and electromagnetic line noise to provide error

free measurements for micro Ohm measurements down to 100 nΩ resolution. The 1750 also

incorporates a single command set to make integration easy for IEEE-488, RS-422 and RS-232

applications.

FEATURE OVERVIEW

The 1750 microohmmeter is desi gn ed a s a c omp l ete bu ndl ed s olu ti on for a wi d e vari ety of r esi stan ce

measurement applications. Listed below are some of the features.

0.02% Basic Accuracy with 4½ digit resolution

The 1750 microohmmeter is de signed to perf orm resi stance m easurem ents wi th a 0.02% basic

accuracy. The 4 ½ digit display produ ces readi ngs from 100 nΩ resolution to 23 MΩ maximum

resistance values.

Bipolar Test Si gnal Eliminat es Thermal EMF errors

The unit is designed to eliminate junction EMFs by introducing a bipolar test signal, which when

combined with digital signal processing, produce an accurate resistance measurement minus

thermal offset errors.

Closed Box Calibration

Full digital calibration is performed within minutes without having to make any internal

adjustments. A calibration enable/disable jumper is accessible by removing the top panel. All

adjustments are made digitally.

Programmable Delay Mode

Settling times are programmable from 1-250 ms to allow measurements of devices with extended

time constants.

Continuous and One-Shot Triggering

The 1750 microohmmeter provides two user-selectable, trigger modes, One-Shot and Continuous

for greater flexibility and optimization of test processes.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

1-1

Page 6

INSTRUMENT DESCRIPTION

Selectable Reference Currents from 100 nA – 1 A

For power sensi ti ve appl ica tion s such as fuse s a nd resi st ors, mu lti pl e test cur rent select ion s a re

available.

Percent or Absolute Comparator with HI-GO-LO contact and TTL outputs

The 1750 microohmmeter d esign m akes it easy to integra te into n ew or existi ng desi gns. There

are three compar ator outputs which doub le as output b ins 1, 2, and 3. The 1750 inter face include s

relay and TTL outputs for comparator and bin functions.

Rear Panel TTL & Relay outputs for PLCs and interfacing

In addition to GPIB and RS232 interfaces, the 1750 provides a variety of TTL and relay contact

I/O’s designed to make integrating the 1750 into a test stand as versatile as possible.

1 year calibration cycle (after initial 6 month calibration)

After the initial 6 month calibration, the recommended calibration interval for the 1750 is every

twelve months.

10 Preset Storage Locations

Storage location 0 is reserved for recalling factory default settings. Locations 1-9 are user

definable and may be program med manually or via communicat ion interf aces. Thes e settings a re

stored in non-volati le RAM locations.

Fast Mode for high-sp eed measurement

Fast Modes allow speedy measurements of up to 100 reading per second. The time to first reading

is approximately 12 ms, faster than any other Ohmmeter in the mar ke t. This is o btained by us ing

a patent pending DSP technique developed by TEGAM.

½ Rack Width

Two 1750 microohmmeter uni ts are able to be rack mounted, side-by-side, in a standard 19”

rack without modification to the 1750 case.

Manual or Auto Ranging

User defined ranging allows AUTO range or 19 user-selectable ranges of resistance and test

current. All ranges have a 15% over-ranging capability.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

1-2

Page 7

INSTRUMENT DESCRIPTION

Auto- Correct Function

The auto- correct function compensates for tim e or temp erature d rift b y readin g high ac curacy

internal references and automatically calculating correction coefficients for all ranges. During this

software correction process, the 1750 will delay one reading for 50 ms. The auto correct routine

is performed at power up, after 30 seconds of operation, after 30 minutes of operation, and after

every 65,536 “delayed trigger” readings, (approximately 2 hours).

High Noise Immunity

Built in line cycle integration in combination with shielded test lea ds produce exception al noise

rejection.

GPIB, RS232, or RS-422 Communication Interfaces

Standard GPIB, RS232, or RS422 user-selectable interfaces are standard communications for all

1750 units. A simple command sets ease the task of integration while the use of device dependent

commands allows for specialized function execution.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

1-3

Page 8

INSTRUMENT DESCRIPTION

connection to components under test.

Kelvin Klip™ replacements for construction

ACCESSORIES SHEET

17501- Kelvin Klip™ Leads

Provides a solid four- terminal

These clips are particularly usef ul for

manual resistance measurement.

Cable length – 3 ft.

17504 – Kelvin Pr obe s

These probes are excellent for

making four-wire surface resistance

measurements on films and other flat

metallic surfaces. Each probe has two

spring-loaded, replaceable tips that

are easily removed and replaced.

Cable length – 3 ft.

17502- Spade Lug Ada pter

Used for connections between the

1750 front panel LEMO and existing

test fixtures.

Cable length – 3 ft.

17503-Sorting Fixture

This sorting fixture allows for

efficient four-wire measur ement of

leaded parts. The test fixture

features spring action contacts for

easy insertion and removal of test

components.

Cable length – 3 ft.

17505 - Male LEMO Connector

For the repair or construction of 1750

test leads.

& Strain Relief

17507 – Large Kelvin Klip™

Leads

Provides a solid 4-terminal connection

KK100- Kelvin Klip™ Rebuild Kit

or repair of Kelvin Klip leads.

to large components hat cannot be

measured with conventional Kelvin

clips. It is robust in construction,

ensuring a firm grip. Used for

connection with large bolts, cables,

plates, etc.

Cable length – 8 ft.

17510 –Chip Tweezers

Four-terminal tweezers make solid

connections to chip components in

manual sorting applications. Capacity of

jaws is 12.7 mm (0.5 in.). Contact tips

are replaceable (part no. 47422)

Cable length – 5 ft.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

1583 - GPIB (IEEE-488) Cables

1583-3 – 1-meter GPI B buss cable

1583-6 – 2-meter GPI B buss cable

1583-9 – 3-meter GPI B buss cable

1-4

CA-22-36 – RS-232 Straight

Cable 9 pin

Male to Female DB9 straight cable used

to connect the 1750 to a PC via RS-

232.

Cable length – 3 ft.

Page 9

INSTRUMENT DESCRIPTION

PERFORMANCE SPECIFICATIONS

The advertised specifications of the model 1750 are valid under the following conditions:

1. The instrument must be calibrated using the methods and intervals as described in the calibration

section of this user’s manual.

2. The instrument must be in an environment, which does not exceed the limitations as defined under

“Environmental” in the Miscellaneous Specifications in Section 1.

3. T he un i t i s all ow ed to w arm up for a pe ri od of a t lea st 3 0 mi nu tes bef o re me asu rem en ts ar e ta ken .

A warm-up p eriod of 60 min utes is re commend ed after exposur e to or sto rage in a high humidity,

(non-condensing), environment .

4. T he Kelvin seri es lead resi stances must not exceed th e limitati ons as defined in Table1.1 o r Table

1.7.

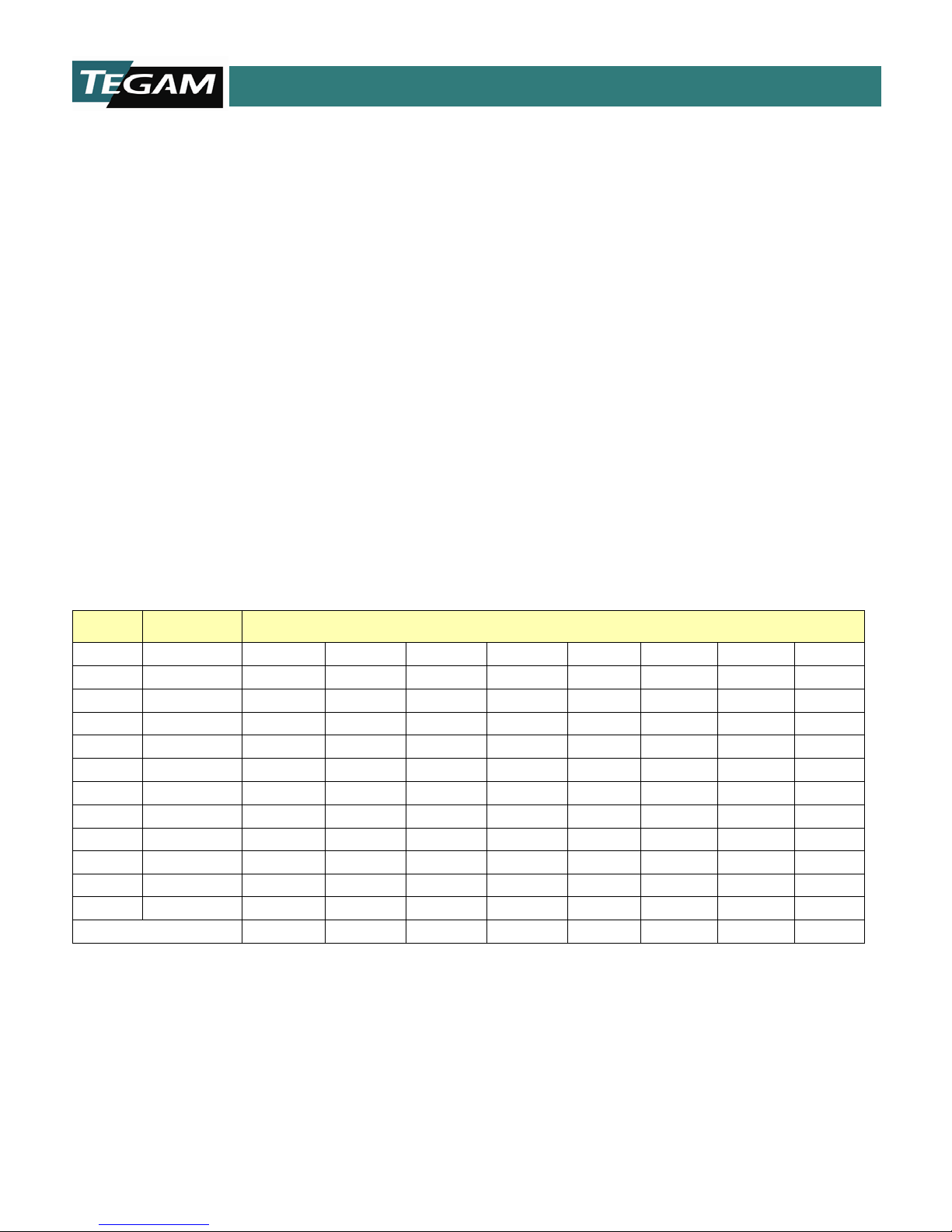

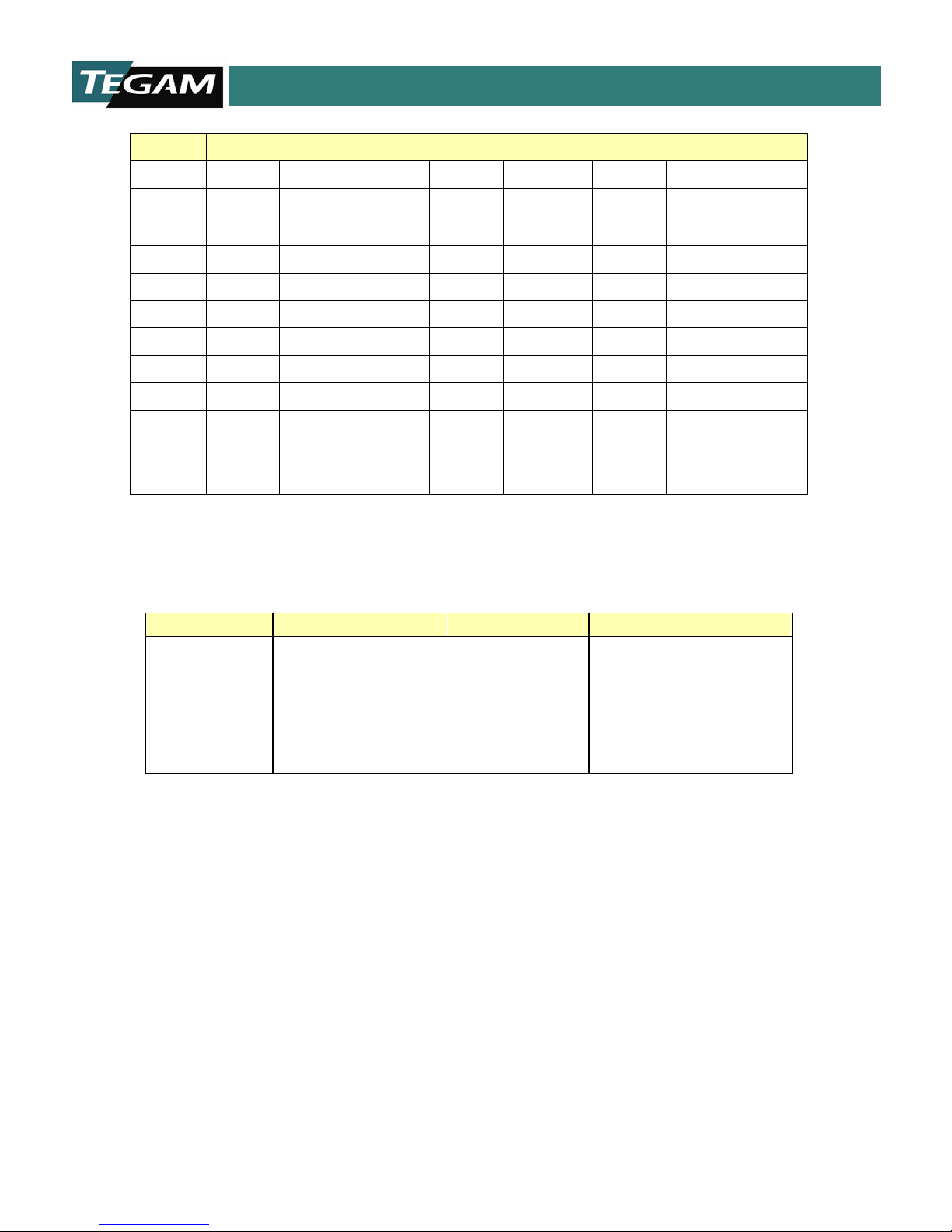

Table 1.1 below is a summary of the ranges and resi stances available with the model 1750. It also

shows the full-scale voltage for each of the reference current ranges. The default ranges are printed in

BOLD. Absol ute maximum lead resist ances for each of the refe rence curren t ranges ar e included on

the bottom row. If these absolute maximum lead resistances are exceeded then significant error will be

introduced into the measurement.

RANGE RESOLUTION

REFERENCE CURRENT

1 A 100 mA 10 mA 1 mA 100 μA 10 μA 1 μA 100 nA

2 mΩ 100 nΩ 2 mV

20 mΩ 1 μΩ 20 mV 2 mV

200 mΩ 10 μΩ 200 mV 20 mV

2 Ω 100 μΩ 200 mV 20 mV

20 Ω 1 mΩ 200 mV 20 mV

200 Ω 10 mΩ 2 V 200 mV 20 mV

2 kΩ 100 mΩ 2 V 200 mV

20 kΩ 1 Ω 2 V 200 mV

200 kΩ 10 Ω 2 V

2 MΩ 100 Ω 2 V

20 MΩ 1 kΩ 2 V

Max. Lead Resistance 500 mΩ 5 Ω 50 Ω 100 Ω 100 Ω 100 Ω 100 Ω 100 Ω

Table 1.1: Full Scale Voltage as a Function of Reference Current

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

1-5

Page 10

INSTRUMENT DESCRIPTION

.02%+5ct

.02%+4ct

.02%+5ct

.02%+2ct

.02%+4ct

.02%+2ct

.02%+4ct

.02%+2ct

.02%+4ct

.02%+2ct

.02%+2ct

.02%+4ct

.02%+2ct

.02%+2ct

.02%+2ct

.02%+2ct

.02%+2ct

.04%+2ct

.04%+2ct

NA

NA

NA

.05%+5ct

NA

.05%+5ct

NA

.05%+5ct

NA

.05%+5ct

.05%+5ct

NA

.05%+5ct

.05%+5ct

.05%+5ct

NA

NA

NA

NA

Table 1.2 summarizes the accuracy specifications for the model 1750, in the delayed mode.

RANGE REFERENCE CURRENT

1 A 100 mA 10 mA 1 mA 100 μA 10 μA 1 μA 100 nA

2 mΩ

20 mΩ

200 mΩ

2 Ω

20 Ω

200 Ω

2 kΩ

20 kΩ

200 kΩ

2 MΩ

20 MΩ

Table 1.2: Delayed Mode Accuracies with Respect to Reference Current

(±) ACCURACY; 18-28 °C (64.4-82.4 °F); 1 YEAR (after initial 6 month cycle ).

In the fast mode, the published accuracy for all reference current ranges is +/- (0.05% + 5 counts).

These accuracies are displayed in Table 1.3. Fast Mode is not available for all range s. If the unit is in

Fast Mode and a range is selected that Fast Mode is not ava ilable, then the instrument will default to

Delayed mode.

RANGE REFERENCE CURRENT

1 A 100 mA 10 mA 1 mA 100 μA 10 μA 1 μA 100 nA

2 mΩ

20 mΩ

200 mΩ

2 Ω

20 Ω

200 Ω

2 kΩ

20 kΩ

200 kΩ

2 MΩ

20 MΩ

Table 1.3: Fast Mode Accuracy with Respect to Reference C urre nt

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

1-6

Page 11

INSTRUMENT DESCRIPTION

.004%rdg

+1 count

.004%rdg

+.5 counts

.004%rdg

+1 count

.002%rdg

+.1 counts

.004%rdg

+.5 counts

.002%rdg

+.1 counts

.004%rdg

+.5 counts

.002%rdg

+.1 counts

.004%rdg

+.5 counts

.002%rdg

+.1 counts

.002%rdg

+.1 counts

.004%rdg

+.5 counts

.002%rdg

+.1 counts

.002%rdg

+.1 count

.002%rdg

+.1 count

.002%rdg

+.1 counts

.002%rdg

+.1 counts

.008%rdg

+.5 counts

.008%rdg

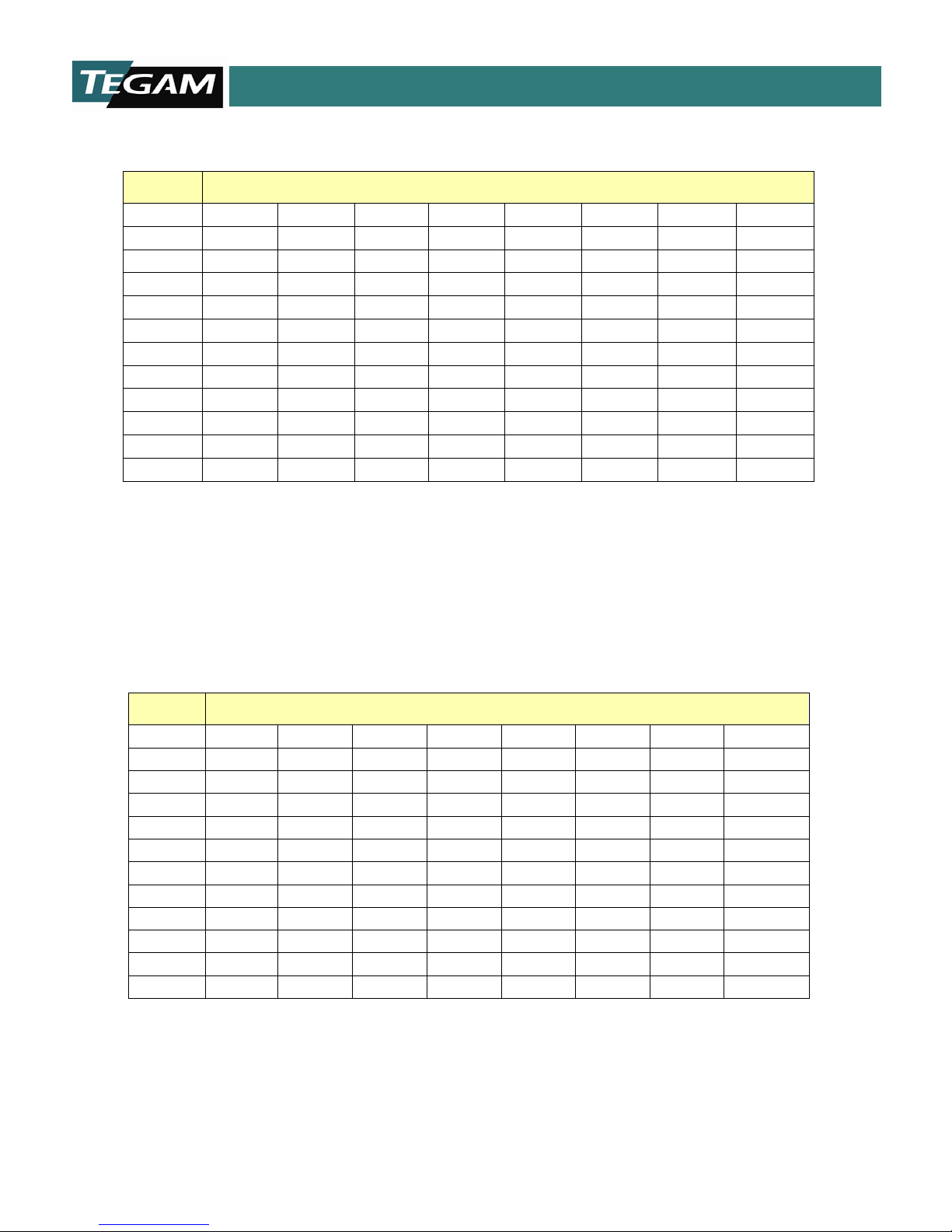

MEASUREMENT TIMES

READING RATE

TIME TO FIRST READING

FAST MODE

10ms

100 Readings/ s

12 ms

DELAYED MODE

DELAY=1 ms

36 ms

27 RDG/s

38 ms

DELAY=5 ms

45 ms

22 RDG/s

47 ms

DELAY=10 ms

55 ms

18 RDG/s

57 ms

Delayed Mode

=

2 X (Line Period + Programmed Delay + Process Time)

RANGE REFERENCE CURRENT

2 mΩ

20 mΩ

200 mΩ

2 Ω

20 Ω

200 Ω

2 kΩ

20 kΩ

200 kΩ

2 MΩ

20 MΩ

1 A 100 mA 10 mA 1 mA 100 μA 10 μA 1 μA 100 nA

+.5 counts

Table 1.4: Table of Temperature Coefficients

+/- Temperature Coefficient / °C

(0-18 °C & 28-50 °C; 32-64.4 °F & 82.4-122 °F)

Table 1.5: Measurement Times

Table 1.5 provides approximations of me asurement times and reading rates for delaye d and fast modes.

Note that the time to first reading is longer than subsequent re adings. Examples are provided for various

delay settings. The Delayed Mode Measurement Time is calculated by the following equation:

Measurement

Where the Line Period is 1/f, f = (50 or 60 Hz) and the Programmed Delay Time may range from 1mS

to 250 ms. The Process Time is the time required to process the read data and is equal to about 1.9

ms.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

1-7

Page 12

INSTRUMENT DESCRIPTION

2 mΩ

D

20 mΩ

D D

200 mΩ

D, F D

2 Ω

D, F D

20 Ω

D, F D

200 Ω

D, F

D, F D

2 kΩ

D, F

D, F

20 kΩ

D, F D

200 kΩ

D

2 MΩ

D

20 MΩ

D

RANGE REFERENCE CURRENT

1 A 100 mA 10 mA 1 mA 100 μA 10 μA 1 μA 100 nA

Table 1.6: Table of Trigger Modes

In Table 1.6, the availability of Fast, (F), or Delayed, (D), Mode Triggering is i ll ustrat ed. Del ayed mod e

is available for each of t h e 1 9 resistance / reference cu r ren t ran ges. The Fa st T riggering m ode is limited

to 8 of the ranges.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

1-8

Page 13

INSTRUMENT DESCRIPTION

+

REF

0 A

SAMPLE

SAMPLESAMPLE

SAMPLE

SAMPLES FOR HIGH AND LOW STATES ARE TAKEN

FOR 32 CYCLES, THEN A READING IS PROCESSED.

THE PROCESS IS REPEATED CONTINUOUSLY.

READING COMPLETE

+

REF

0 A

SAMPLE

SAMPLE

SAMPLE

SAMPLE

CONTINUOUS SAMPLES ARE TAKEN FOR 32 CYCLES,

THEN A READING IS PROCESSED

READING COMPLETE

+

REF

0 A

- REF

A

A

A

A

ACB

B

B

B

B

C

C

CD D

SAMPLE

COMPLETE READING

SAMPLE

COMPLETE READING

SAMPLE

SAMPLE

+

REF

0 A

- REF

A

ACBB C D

SAMPLE

COMPLETE READING

SAMPLE

+

REF

0 A

- REF

A

A BBC

C D

SAMPLE

COMPLETE READING

SAMPLE

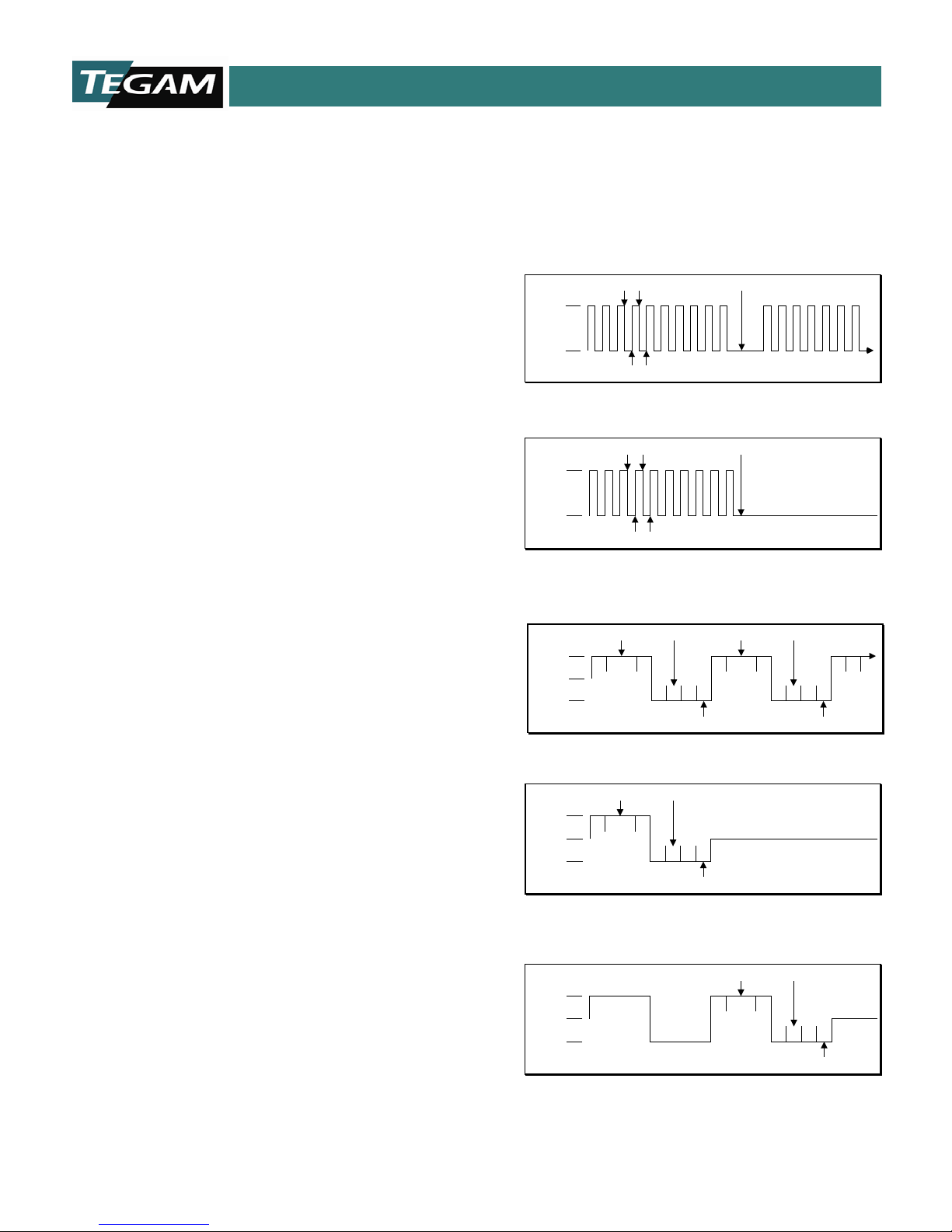

Fast Continuous:

Readings are taken towards the end of each +REF/ 0A state.

The test signal is an alternating reference current from + REF

to 0A, with automatic thermal and noise rejectio n.

Fast One-Shot:

This mode must receive an external trigger and is a shortened

version of the Fast Continuous mode. A total of 64 data

samples are taken. 32 samples on + cycles and 32 samples

on the 0 Ampere cycles. These samples are digitally processed

to produce reading

Delayed Continuous:

Continuous Alternating refer ence current from + REF to

“A” represents the programmable delay time from 1 to 250 mS.

“B” represents the line cycle time

Cycle

“C” is the time required for broken lead detection to take p lace

“D” is when the reading is processed and updated

Delayed One-Shot

Alternating reference current from + REF to – REF.

Triggering via GPIB, RS232 or rear trigger input will cause a

single cycle of reference curren t .

Delayed One-Shot

(Triggered Via Front Panel)

Alternating reference current from + REF to – REF.

Triggering via the front panel. Once trigg er e d , two reference

cycles are released of which the latter pulse will be used to

take the actual reading.

REFERENCE CURRENT MODES

There are several types of pulses available for making measurements. Below is a summary of

characteristics for each type of trigger mode and the sequence of events that occur during an actual

measurement.

Integration)

- 1/f (Sampled Input for Line

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

– REF.

.

1-9

Page 14

INSTRUMENT DESCRIPTION

MISCELLANEOUS SPECIFICATIONS

Display Modes:

• Resistance; Absolute Comparator; % Comparator

Digital Inte rfaces:

• IEEE-488

• RS-232

• RS-422

• External Trigger Input, and Reading Done TTL Outputs - BNC Connectors

Display:

• 4½ Digit alpha numeric readout; 2 X 16 Characters, Dot Matrix Display with backlight

Measurement Method:

• 4 terminal Kelvin connection to DUT.

Input Connector:

• Heavy Duty Type LEMO Connector for signal integrity and long life.

Input Protection:

• ± 15 V Continuous.

• Maximum Common Mode Input Voltage is 42 V peak.

Overload Current:

• Delayed Mode: 100% Overshoot, <25 μs

• Fast Mode: 200% Overshoot, < 30 μs

Noise Rejection:

• 60 dB Typical at Line Frequency

Maximum Open Circuit Compliance Voltage, (Typical):

Closed circuit compliance voltages are much lower; see Table 1.1, Full Scale Voltage as a

Function of Reference Current

• 18 Vp-p maximum (1 mA-1 A Test Current)

• 14 Vp-p maximum (100 nA-100 uA Test Current)

Environmental:

• Operating Temperature: 0 to 50 °C (32 to 122 °F), <80% RH; (Non-Condensing)

• Storage Temperature: -35 to 60 °C (-31 to 140 °F), <90% RH (Non-Condensing)

EMC:

• EN 61326-1:2013

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

1-10

Page 15

INSTRUMENT DESCRIPTION

MISCELLANEOUS SPECIFICATIONS (Continued)

Dimensions:

• Depth: 13.0” (33.0 cm)

• Width: 8.50” (21.6 cm)

• Height: 5.20” (13.2 cm)

Weight:

• 9.25 lbs (4.20 kg)

Rear Interface Relay Cont act Sp eci fications:

The relay contact I/Os are rated at 125 VAC @ 500 mA or 30 VDC @ 1 A.

Calibration:

Calibration of the 1750 is permitted via the front panel with no internal a d justments.

Calibration requires the temporary placement of a jumper, P9 to the J9 position.

AC Power Requirements:

Input: <100 VA, 108-132 VAC or 216-264 VAC, at 50/60 Hz.

Fuse:

• For 108-132 V Operation; use 0.8 A @ 250 V, 5X20 mm, fast acting, TEGAM PN#FU-800

• For 216-264 V Operation; use 0.5 A @ 250 V, 5X20 mm, fast acting, TEGAM PN#FU-500

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

1-11

Page 16

INSTRUMENT DESCRIPTION

V

REFERENCE

CURRENT

SOURCE

VOLTAGE

SENSE

DUT

= SERIES LEAD RESISTANCE

CONTACT

POINTS

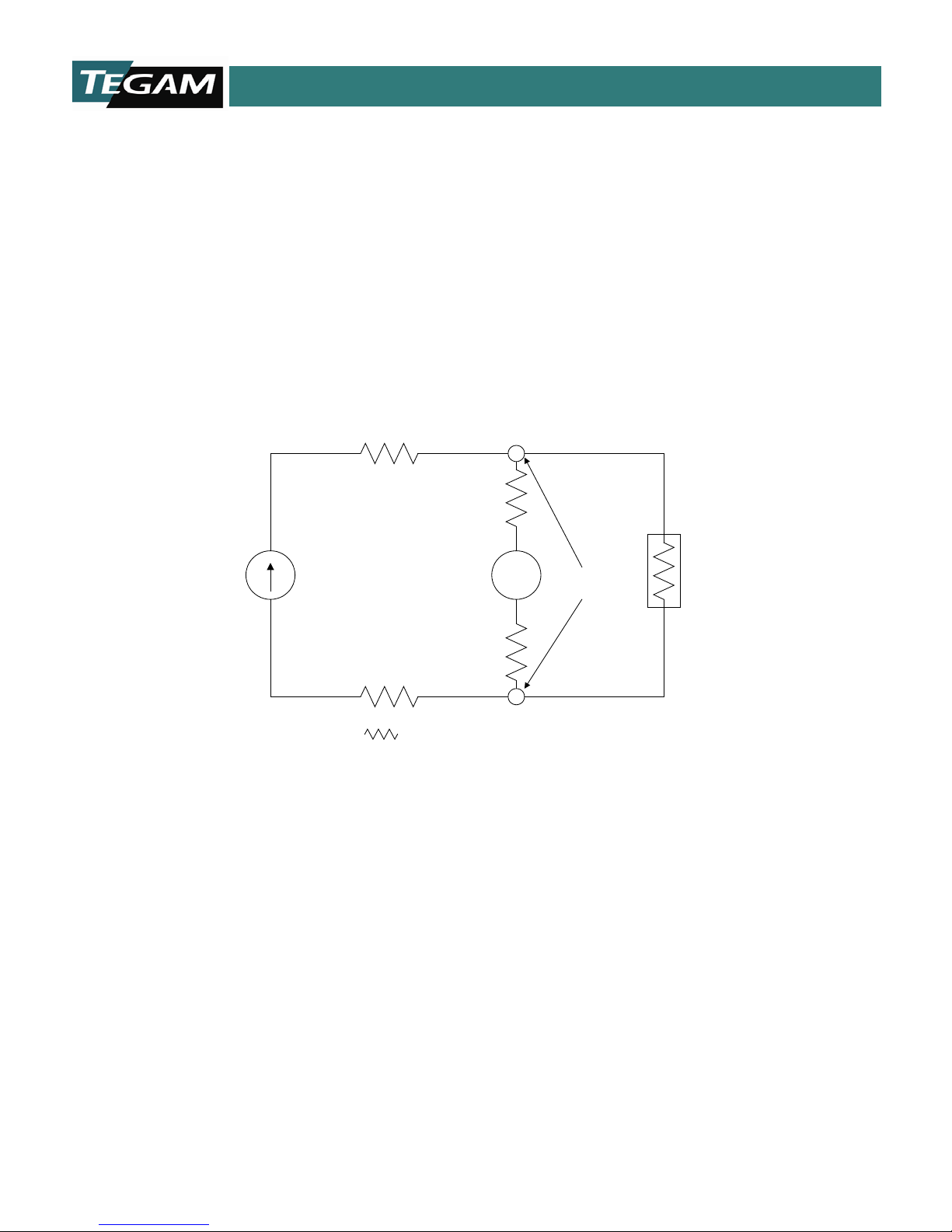

TEST LEAD REQUIREMENTS

From the factory, the 1750 microohmmeter is equipped with the choice of either 17501 Kelvin Klips or

17502 Kelvin Spade Lugs. These are both 4-wire Kelvin input cables. Four-wire Kelvin-type cables must

be used with the 1750 in order to obtain an accurate resistance measurement.

The Kelvin measurement technique allows for a much more accurate reading over the two wire method.

This is because it eliminates l ead resistance. Thi s i s d on e by designatin g two o f th e f ou r con du ctors as

source lead s. These sou rce leads p rovide th e precisi on test curren t that wil l be referen ced in ma king

the resistance measurement. Since current is the same throughout a series circuit, the lead resistance

of the test leads will not have any effect on the reference current.

Figure 1.1: Electrical Representation of a typical Four-Wire Kelvin Measurement

The other two conductors are designated as voltage sense leads. These leads originate from high

impedance, v olt measurem ent circuit . When these l eads are termi nated at the poi nts of contact, an

exact resis ta n ce r ea d ing may be cal cu lated by the 175 0 m icroprocesso r . Th e s eries lead resistance of

the volta ge s ens e l eads i s neg l igi ble w i th resp e ct t o t he hi gh i mp edan ce of t he vol t age m ea sur ement

circuitry within the 1750 microohmmeter.

Four-wire Kelvin measurements are mainly used for low resistance measurements where lead

resistance er ro rs must be elimi nated.

Even though the four-wire Kel vin measurement minimizes th e effect that l ead resistance h as on the

overall measurement, there is a maximum allowable lead resistance. If this value is exceeded, then the

resulting measurement will be erroneous. The test current source dictates this limitation and lead

resistance limits are based on the amount of reference current that is flowing. The table below

summarizes these limitations.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

1-12

Page 17

INSTRUMENT DESCRIPTION

REFERENCE CURRENT 1 A 100 mA 10 mA 1 mA 100 μA 10 μA 1 μA 100 nA

MAXIMUM LEAD RESISTANCE 500 mΩ 5 Ω 50 Ω 100 Ω 100 Ω 100 Ω 100 Ω 100 Ω

Table 1.7: Maximum Allowable Lead Resistance (per lead).

To assure measurement accuracy, the above lead resistance limits should not be exceeded.

In order to make accurate measurements on resistances greater than 200 kΩ, it is highly recommended

that the GROUND terminal, located on the rear panel, be connected to the DUT test fixture shield. The

test fixture shield must surround the DUT.

Also, for resistance measurements greater than 200 kΩ, the programmable delay time should be set to

a minimum of 100 ms to allow adequate settling of the reference current.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

1-13

Page 18

INSTRUMENT DESCRIPTION

V + -

Positive Kelvin Loop

Negative Kelvin Loop

DUT

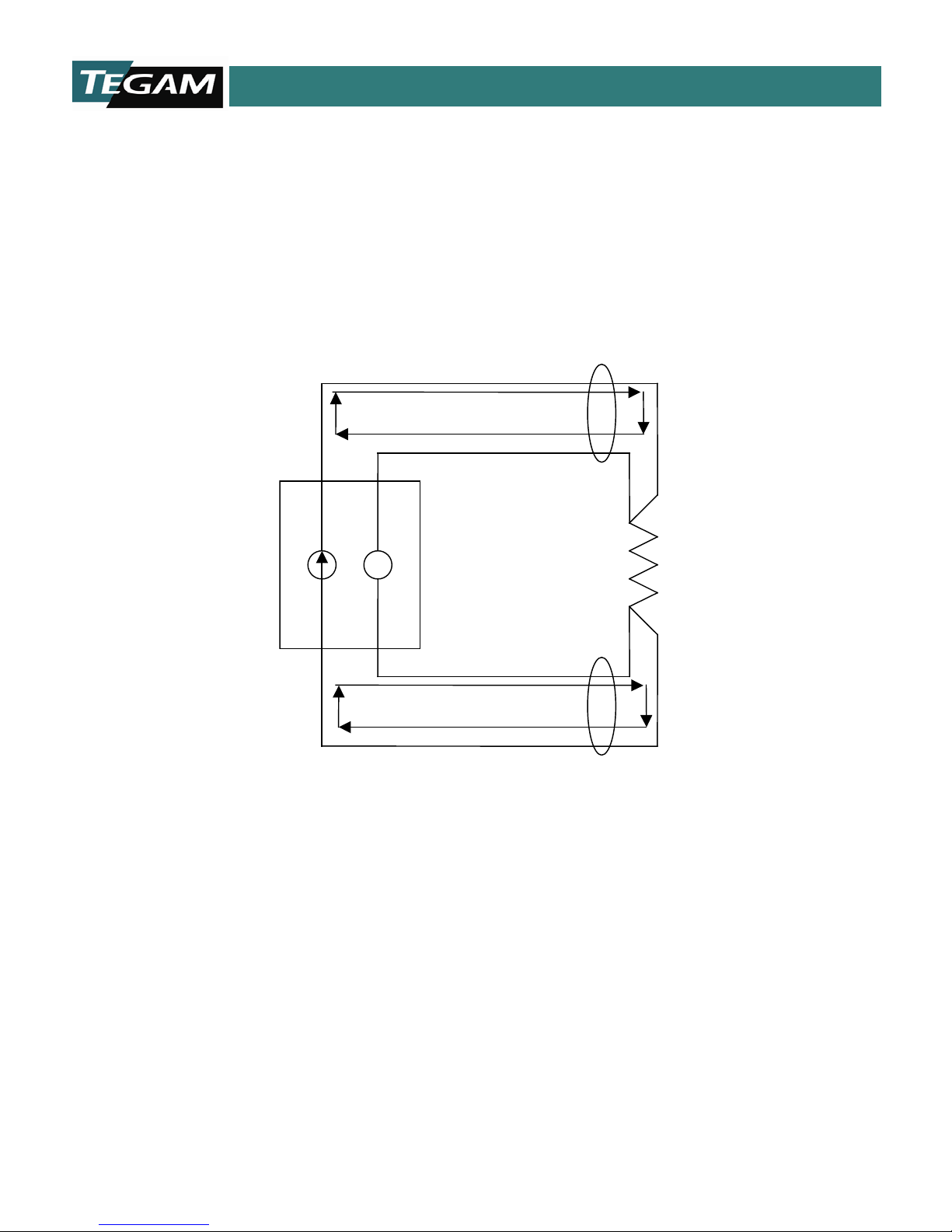

BROKEN LEAD DETECTION

A broken lead detection feature is enabled for ranges below 200 Ω when operating in either of the two

Delayed trigger modes. This feature is a function of the firmware and detects an open circuit by

monitoring the test current characteristi cs. The ill ustrati on below r epresents the Kel vin lea ds and th e

connection acros s a d evi ce u nd er test. Not e tha t th ere are t hr ee loop s drawn wi th the a rrows . Each of

these arrows shows the continuity test that is effectively performed by firmware during each read cycle.

If either the negative Kelvin loop, Positive Kelvin loop, or connection between the leads is broken, then

a broken lead state will be detected and the message “*****” is displayed on the LCD.

Fig 1.2: Continuity Test Paths for Broken Lead Detection

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

1-14

Page 19

PREPARATION FOR USE

!

SECTION 2

PREPARATION FOR USE

UNPACKING & INSPECTION

Each 1750 microohmmeter is put through a series of electrical and mechanical inspections before

shipment to the customer. Upon receipt of your instrument unpack all of the items from the shipping

carton and inspect for any damage that may have occurred during transit. Report any damaged items

to the shipping agent. Retain and use the original packing material for reshipment if necessary.

Upon Receipt, inspect the carton for the fo llowing items:

Model 1750 Precision Microohmmeter

Model 1750 User’s Manual

Either one of the following: 17501 Kelvin Klips™ or 17502 Spade Lug Adapter

SAFETY INFORMATION & PRECAUTIONS

The following safety information applies to both operation and service personnel . Safety precautions

and warnings may be found throughout this instruction manual and the equipment. These warnings

may be in the form of a symbol or a written statement. Below is a summary of these precautions.

Terms in This Manual

CAUTION statements identify conditions or practices that could result in damage to the equipment or

other property.

WARNING statements apply conditions or practices that could result in pers onal injury or loss of life.

Terms as Marked on Equipment

CAUTION indicates a personal injury hazard not immediately accessible as one reads the marking, or a

hazard to property including the equipment itself.

DANGER indicates a personal injury hazard immediately accessible as one reads the marking.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

2-1

Page 20

PREPARATION FOR USE

! !

!

SAFETY INFORMATION & PRECAUTIONS (Continued)

Symbols

As Marked in This Manual:

This symbol denotes where precautionary information m ay be found.

As Marked on Equipment:

Attention – Please refer to the instruction manual.

Power ON/OFF switch

Danger – High or hazardous Voltage

Earth Ground Terminal

Grounding the Equipment

This product is grounded through the grounding conductor of the power cord. To avoid electrical shoc k

or other potential safety hazards, plug the po wer cord into a properly wir ed receptacle before using this

instrument. The proper grounding of this instrument is essential for safety and optimizing instrument

operation.

Danger Arising from Loss of G round

If the connection to ground is lost or compromise d, a floating potent ial could develop in the instrument.

Under these conditions all accessible parts, including insulating parts s uch as keypads and buttons could

develop a hazardous voltage and put the user at risk.

Use the Proper Fuse

To avoid fire hazard, use only the correct fuse type as specified for the AC power supply in the

“Miscellaneous Specifications” or “Repair Parts” sections of this manual.

Refer fuse replacement to qualified service personnel.

Do Not Use in Explosive Environments

The 1750 microohmmeter is not designed for operation in explosive environments.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

2-2

Page 21

PREPARATION FOR USE

!

Do not Operate without Covers

This device should be operated with all panels and covers in place. Operation with missing panels or

covers could result in personal injury.

Preventive Maintenance

Preventive maintenance performed on a regular basis will improve the reliability of this instrument.

It may include cleaning (please refer to Section 6), visual inspection, or even monitoring the operating

environment.

FOR QUALIFIED SERVICE PERSONNEL ONLY

SERVICING SAFETY SUMMARY

Do Not Service Alone

Do not perfo rm servi ce or adj ustm ent on th is produ ct unl ess anoth er per son cap able of renderi ng first

aid is present. In stallati on and mai ntenance proc edures des cribed in this man ual are to be p erformed

by qualified service personnel only.

Use Care Wh en Servicing with Power On

Dangerous voltages may exist at several points in this product. To avoid personal injury or damage to

this equipment, avoid touching exposed connections or components while the power is on. Assure that

the power is off when removing panels, soldering, or replacing co m ponents.

Power Source

This product is intended to connect to a power source that will not apply more than 250 V

the supply conductors or between either supply conductor and ground. A protective ground connection

by way of the grounding conductor in the power cord is essential for safe operation.

between

RMS

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

2-3

Page 22

PREPARATION FOR USE

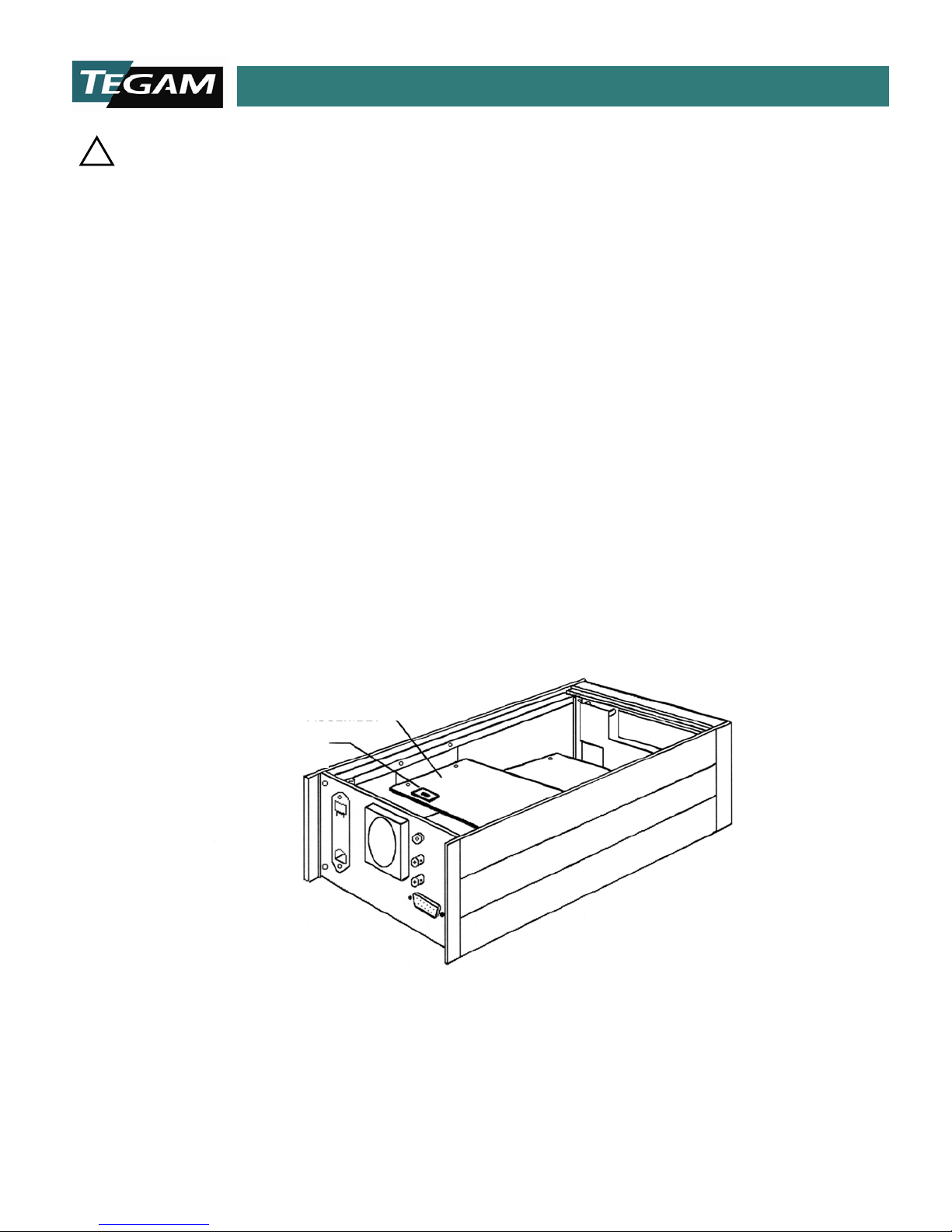

!

LINE SELECTOR

671175400

LINE VOLTAGE SELECTION

CAUTION: DO NOT APPLY POWER TO THE INSTRUMENT BEFORE READING THIS SECTION:

Unless other wise specified, the M odel 1750 microohmmeter i s delivered from TE GAM with its power

supply set for 120 V, 60 Hz operation. However, the 1750 design allows it to operate under 120/240

V @ 50/60 Hz op erati on. It is recomm ended th at th e li ne vol tage, f requ ency setti ng an d fus e typ e be

verified before powering the unit.

The following procedure describes the steps necessary to change the 1750 power settings from factory

default settings to 240 VAC @50 Hz.

1. Verify that there is no power connected to the unit. Remove the top co ve r.

2. Change the line selector switch on the power supply printed circuit board from 120 VAC to 240

VAC. The switch is located toward the rear panel of the 1750 on the top most PCB board. Refer

to the figure below:

3. Replace the top cover and connect the 1750 to its power source. Power the unit by depressing

the power switch located on the front panel.

4. Press the [MENU/CLEAR] key then press the 50/60 Hz key, (Key #1). Scroll the menu by pressing

either the [▲] or [▼] keys. Once 50Hz is displayed on the LCD then press [ENTER]. The 1750 is

now set for 240 VAC @ 50 Hz operation .

POWER SU PPLY

ASSEMBLY

SWITCH

Fig 2.1: Line Voltage Selection Location

NOTE: The 1750 microohmmeter uses line cy cle in t egrat ion in order to p rev ent in ter fer enc e f rom a ff ectin g the

instrument read ings . F or p rop er rea d ing s, th e f req uen cy se tting of th e in stru men t mu st m atc h th e lin e su pply .

You can change th e frequency setting simply by follow ing the instructions in step #4.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

2-4

Page 23

QUICK START INSTRUCTIONS

Parameter

Setting

Parameter

Setting

1

Range

2 Ω @100 mA

8

Communication

*RS232

2

Trigger

Delay Continuous

9

Store Setup

-

3

Delay Time

111 ms

10

Recall Setup

-

4

Display Mode

Resistance

11

Line Frequency

60 Hertz

5

Compare Limits

19999; 00000

12

PIN Function

*Disabled

6

% Compare Limits

10.00%; 10.00%

13

Calibration

*Disabled

7

Nominal

10000

SECTION 3

QUICK START INS TR UCTIONS

GENERAL

The Model 1750 microohmmeter is a versatile product, which can be used in many different

configurations. De pending on the applicat ion, there are configur ations of the 1750 microohmmeter that

will help optimize te st cond itions invo lving acc uracy, me asurement speed, and v ersatility. The bes t way

to maximize the effectiveness of a pro duct and test setup is by ha ving a thorough unders tanding of the

instrumentation and the test parameters, which can a ffect the readings.

The Quick Start section is designed to give the user a general i n st ru ct i on s et for the speedy setup a n d

measuremen t of resista nce values . Whenever additi onal informat ion is app licable, a r eference w ill be

made to other parts of this manual so that the user, at their discretion, can decide whether or not to

pursue ad d itional informa t io n .

POWER THE UNIT

The power supply of the Model 1750 is designed for 50-6 0 Hz operat ions and a v olt age ran ge of 1 08132 & 216-264 VAC. Review the line voltage selection procedure on page 2-4 before proceeding.

Power the unit and allow at least 30 minutes for the unit to warm up. Make sure that the safety

precautions on pages 2-2 and 2-3 hav e be en re vi ewed an d un der sto od. Ve ri fy th at t h e en vi ron men tal

conditions, listed on page 1-10 are met.

FACTORY SETTINGS

Before perfor ming t he actual resistance m easuremen t, there a re a num ber of test paramet ers, whic h

must be defined. The factory settings can be used for most general resistance measurements.

The 1750 microohmmeter is shipped from the factory with instrument settings as follows:

These settings can be recalled by sending a device clear command via RS232, RS422 or GPIB interface.

* When a device clear command is sent via communications interface, this value does not change.

CUSTOMIZING PARAM ETER SETTINGS

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

Table 3.1: Factory Default Settings

3-1

Page 24

QUICK START INSTRUCTIONS

The 1750 factory settings are usually adequate to meet the needs of most manual, low inductance,

resistance measurement applications. However, in high-speed, automated resistance measurement, it

is often desirable to optimize the instruments settings to obtain the highest accuracy and throughput.

For this rea son, t he Mod el 175 0 offers 13 user -defin ed test p aramet ers. In-depth information for any

of these Setup options may be found in Section 4, O perating I nstruct ions. Before changing any o f these

factory default settings, it is highly recommended that Section 4 is thoroughly reviewed and understood.

Special attention should be directed toward allowing adequate settling times for high resistance

measurement applications and defining the proper reference current in fuse testing applications.

The front keypad is setup for ma ximum functionality. Each key has multiple functions assigned to it.

These funct ions are l abeled acc ording t o their pri mary and se condary functions . To access the Setup

options, simply press the [MENU] button on the front panel. The message “

appear on the screen. From this display, you can access any of the 11 menu options labeled with teal

text located below the key. Pressing any of these buttons will allow yo u to access the instrume nt’s Sub Menu for entering custom settings. You can modify instrume nt Sub-settings by either pressing the [▲]

or [▼] scroll keys or by manually entering a numeric value.

See Section 4 for an in depth description of the keypad functionality and how to store and recall custom

settings.

TEST LEAD REQUIREMENTS

The Model 1750 microohmmeter measures resistance by using the four-wire Kelvin technique. This type

of measurem ent virtually elimi nates lead resistanc e error. A set of Kelvi n Klip™ leads or Spade Lu g

Adapters are supplied with the new instrument. In addition, optional sorting fixture or Kelvin Probes

are available. These accessories are designed to function with the Model 1750 in all operating currents

and ranges.

In certain applications, the need arises for a custom assembled test connection or fixture. When

constructing a solution of this type, detail has to be directed towards the maximum allowable series

lead resistan ce. There is a speci fic series lead resi stance limit estab lished for each cu rrent range. If

these limits are exceeded, a significant amount of error may be introduced into the measurement.

Detailed information on Kelvin-type measurements an d lea d re sist ance er ror m ay b e foun d in Section

1 under the “Test Lead Requirements” section. See Table 1.7 for maximum allowable series lead

resistances.

MEASURING RESISTANCES LARGER THAN 200KΩ

For stable resi stance mea surements on resista nces greater t han 200 kΩ, it is recommended that the

GUARD terminal on the rear panel be conn ected to th e DUT te st fi xture GR OUND t ermi nal . The actu al

resistance being measured should be shielded within a grounded test fixture.

If it is unknown whether the test circuit is inductive or capacitive in nature, the delay time should be

set to a minimum of 100mS in order to allow adequate measurement settling time. This settling time

should be increased as the measured resistance value is increased.

Menu Number?” will

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

3-2

Page 25

OPERATING INSTRU CTIONS

SECTION 4

OPERATING INSTRUCTIONS

BASIC OPERATION

The Model 1750 microohmmeter is a highly versatile product, designed for use in many different

applications. There are ideal configurations of the 1750 microohmmeter for each type of application.

These configurations optimize test conditions while enhancing accuracy, measurement speed, and

versatility.

In order to maximize the effectiveness the 1750’s operation the user should have a thorough

understanding of the instruments operation.

This section is designed to give the user an in depth description of the numerous parameters and

operating modes available from the Model 1750. The user will be e xpose d to additiona l topics that wil l

enhance the integration of the Model 1750 into their application.

DEFAULT PARAMETERS

Each unit is delivered from the factory with predefined test parameters and mode s. These pred efined

settings are intended for general-purpose resistance measurement and ease of use.

Section 3, Quick Start Instructions, contains information on factory default settings.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

4-1

Page 26

OPERATING INSTRU CTIONS

Liquid C rystal Display - Indicates the resistance

either HOLD the measurement when operating in Co ntinuo us

for factory use only.

Power Switch – Powers the 1750.

]

High Speed Programmable Micro-Ohmmeter Model 1750

High Speed Programmable Micro-Ohmmeter Model 1750

Liquid Crystal

Local Mode

Kelvin Input

Comparator

MENU Selection

Power Switch

Parameter

Hold/Manual

Numeric

Communication

FRONT PANEL DESCRIPTION

Display

Keypad

Trigger Key

Figure 4.1: Front Panel Layout

Menu Enter

Key

Status LEDs

Output LEDs

Key

LEMO Connector

Key

measurement, resistance range, comparator settings,

communication type, and other operating conditions. See

“Display Modes” in this Section for details of displ ay

operation.

Numeric Keypad – Numeric keypad includes 0-9 keys for

entering values for menu items, delay times or

comparator/bin limits.

Hold/Manual Trigger Key – This key allows the user to

Trigger Modes or to TRIGGER a reading in the One-Shot

Modes. It also functions as the scroll up, [▲], key when the

unit is in parameter mode.

Parameter Menu Enter Key – The [ENTER] key is used for

inputting parameter settings for any of the menus or for

storing numerical data.

Local Mode K e y –Pressing this key permits the user to

access front panel controls while the unit is operating in

remote mode. The unit returns to remote mode from local

mode after receiving a command from the GPIB or RS232

interface.

The local key also functions as the scroll down, [▼], key

when the menu mode is selected.

If the internal calibration jumper is enab le d , pres s ing this

button will switch the 1750 into debug mode. This feature is

Kelvin Input LEMO Connector – Heavy Duty Input

Connector for Kelvin Klips™, Spade Lug Adap ter, Ke lvin

Probes or Test Fixture using 5 conductor, male LEMO.

Menu Scroll Keys – The scroll keys will allo w the

navigation of the Menu Screens by pressing either the [▲

or [▼] keys.

Menu Selection Key – Pressing this key will toggle the

function of the numeric keypad for accessing and defining

instrument parameters.

Comparator Output LEDs - LEDs indicate status of

comparator after measurement cycle. LED status

corresponds to comparator relay and TTL outputs on rear

panel connector, J8.

Communication Stat us LED s – Indicate the error and

status of communications RS232, RS422 & GPIB.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

4-2

Page 27

OPERATING INSTRU CTIONS

20 CFM maximum airflow. Operation is 5

V @ 240 mA.

REAR PANEL DESCRIPTION

Figure 4.2: Rear Panel Layout

BNC Reading Done TTL Output – Open Collector TTL

Output. Output is at +5 V until a complete reading cycle

has occurred. A negative going pulse occurs for about 4 .25

ms then the output state returns to +5 V.

BNC Trigger TTL Input – A TTL low into this input will

activate a trigger command. A trigger will also occur if the

input is shorted to ground via relay or other contact for a

minimum of 10 ms.

J8 – Relay and TTL I/O Conn ec tor – See Section 5,

Interfacing to the PC for pin out details.

VAC Input – 120 /2 40 V @ 50/6 0 Hz , power input. Line

fuse is accessible through this input.

GPIB (IEE-488.2) Port - See Section 5, Interfacing to

the PC for pin out details.

RS232 Port - See Section 5, Interfacing to the PC for

pin out details.

RS422 Port - See Section 5, Interfacing to the PC for

pin out details.

Guard Terminal – Banana connection to the 1750 test

signal current source (common), typically us ed for

reducing noise in high resistance, (>20 kΩ)

measurements.

Cooling Fan –

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

4-3

Page 28

OPERATING INSTRU CTIONS

Digital Software

Version

Product

Identification

DISPLAY MODES

When the power key is depressed, AC power is applied to the 1750. During the power cycle, the

1750 operating system initiates and the display will show the product identif icat ion information. The

1750 dig ita l so ft war e re vis ion s a ppe ar be low the pr odu ct id ent if icat ion. Th is dis pla y w ill b e v isib le fo r

about two sec onds an d then the 175 0 will resume op erati on und er the sam e set-up paramet ers a s

when it was last turned off.

Tegam Model 1750

Revision 2.XX

Figure 4.3: Initialization Display

After initialization, the 1750 microohmmeter will display one of three t ypes of displ ays, Resistance,

Absolute Comparator, or % Comparator. The particular display mode will be dependent upon the

mode that the 1750 was operating in before the last power down. The following sections will describe

each of the display modes and their respective display fields.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

4-4

Page 29

OPERATING INSTRU CTIONS

Resistance Reading

0.1750 mΩ

Ref. I= 1Amp

Indication of Over

Reading Hold

*.**** m

Ref. I= 1Amp h

Reference Current

Resistance Mode

The 1750 factory default setting is the Resistance Mode. Below is a representation of the Resistance

Mode display and a brief description of each of the display fie lds.

Resistance Reading

This field is reserved for display of the resistance measurement value or status. There are 4 ½ digits

of resolution for all ranges of resistance and test currents. The reading is updated once every

measurement cycle in the Continuous Trigger Mode. The actual cycle time of the continuous mode is

dependent on whether the unit is in Delayed Continuous or Fast Continuous Mode. Refer to Section

1, for detai led timing diagrams a nd a formula for cal culating total measurement times. When the

1750 is operating in the Delayed One-Shot or Fast One-Shot Mode, the resistance reading is updated

one measur ement cycle aft er a manual trigger is recei ved. These ac tual measurem ent times may

also be determined by referencing Section 1.

Range or Open Lead

Open Lead Detection

The 1750 includes an Open Lead Detection feature, which is active in the 20 Ω, 2 Ω, 200 mΩ, 20

mΩ, and 2 mΩ ranges. It verifies the continuity of the test leads and contacts when the 1750 is

operating in either of the two delayed trigger modes, (Delayed Continuous or Delayed Trigger). The

Kelvin measurement technique requires that four wires be used in making a measurement. If any of

these leads or a combination of these leads is open, then the instrument shall display “

which is the equivalent of an ov er range co nditio n. For RS23 2 and GPI B op era tion, the unit w ill s e nd

a “2.9999” ASCII string, which is also the equivalent of an over range condition.

Condition

Figure 4.5: Over Range or Open Lead Condition

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

Figure 4.4: Resistance Mode

Ω

4-5

Status

*****”,

Page 30

OPERATING INSTRU CTIONS

Reading Hold

When the [HOLD/TRIGGER] button is pressed, the most current reading may be latched and held on

the LCD until the [HOLD/TRIGGER] button is pressed again. The status of the reading hold feature

is indicated on the lower left hand corner of the LCD. An “h” indicates a hold condition. This feature

is only functional in the Continuous Trigger Modes.

One Shot Trigger

When the 1750 microohmmeter is operated in the One-Shot Trigger Mode, an “S” will appear in place

of the “h” in the LCD lower right hand corner. This symbol notates that the instrument is in the One

Shot mode an d requires ext ernal trigg ering from th e front panel , communicati ons interface o r the

BNC TTL trigger input on the rear panel.

Resistance Range and Reference Current

There are 19 possible resistance and reference current range combinations that the 1750 will operate

under. The pr esent reference cur rent level is di splayed on the bottom of t he LCD. Once the u ser

becomes more familiar with the display, the actual resistance and reference current combination c an

be determined by observing the placement of the decimal point on the reading and the indicated

reference current level. When the 1750 is in AUTO RANGE mode, then the AUTO RANGE LED on the

right hand side of the front panel will be illuminated.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

4-6

Page 31

OPERATING INSTRU CTIONS

H=20000 L=10000 h

*.**** M

High Absolute

Low Absolute

Absolute Comparator Mode

In the Absolute Comparator Display Mode, the screen will look like the Resistance Display Mode

except that the reference current indication is replaced by two additional fields of data. On the left

side is the high limit, absolute value. On the right side is the a bsolute low, comparator limit.

Comparator Limit

Ω

Comparator Limit

Figure 4.6: Absolute Comparator Mode

The above display indicates that the meter is in the 2 MΩ range. The high limit is set to 20,000

counts of ful l sca l e, whi ch i s 2 MΩ. The low limit is set to 10,000 counts, which is the equivalent to

1 MΩ in this scale. Note that the comparator limits are programmed in counts rather than Ohmic

units. This mean s that the comparat or resistance val ues are determi ned by both the act ive range

and the user defined limit values.

High & Low Absolute Comparator Limit

Fields indicate the user-defined upper and lower limits for the absolute comparator function. If the

measured resistance reading exceeds the high limit, and the comparator mode is active, then the

corresponding “HI” state will transfer to the Compar ator State LED. If the current re ading falls o n or

between the HI and LO comparator limits, then the “GO” LED becomes illuminated. And finally, if the

reading falls below the low limit then the “LO” comparator output is activated. The TTL and Relay

comparator outputs in the rear panel follow the front panel comparator LED states. All comparator

outputs are disabled when the 1750 is operating in the resistance mode.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

4-7

Page 32

OPERATING INSTRU CTIONS

H10.00% L10.00% h

**.***MΩ N10.000

Resistance

High %

Nominal Value

Low %

Comparator Limit

% Comparator Mode

Reading

Comparator Limit

Figure 4.7: % Comp arator Mode

High% & Low% Absolute Comparator Limit

The % Comparator Display Mode is similar to the Ab solute Com parator Mode in that the use r defines

the upper and lower limits of the resistance measurement. However, these limits are defined in terms

of a high and low percentage of a nominal value instead of an absolute value. The comparator state

is indicated by the front panel LEDs and is transferred to the TTL and Relay outputs of the rear panel.

Nominal Resistance V al ue

In the upper right-hand corner of the display, the user-defined nominal value is dis played. High an d

low % compa rator values are calcul ated by the 17 50 from the user-defined nominal value. In the

illustration above, the nominal value is set for 10 MΩ. The high limit is set for all readings abo ve 11.0

MΩ, (10 M+1 M) and the low limit is set for all readings below 9 MΩ (10 M-1 M).

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

4-8

Page 33

OPERATING INSTRU CTIONS

Resistance Range Short Cut

(Primary Function)

Numeric Function

(Secondary Function)

MENU OPTION

(Secondary Function)

2 mΩ @ 1A

-

AUTO CORRECT

20 mΩ @ 1A

-

PIN ACCESS

200 mΩ @ 1A

-

% COMPARATOR

2 Ω @ 100mA

1

50/60 Hz

20 Ω @ 10mA

2

STORE

200 Ω @ 10mA

3

RECALL

2 kΩ @ 1mA

4

INTERFACE

20 kΩ @ 100μA

5

DELAY

200 kΩ @ 10μA

6

COMPARATOR

2 MΩ @ 1μA

7

TRIGGER

20 MΩ @ 100nA

8

REFERENCE

AUTO

9

DISPLAY

Menu

Number?

NAVIGATING THE MENUS

Keypad Functionality

Each button on the keypad has one primary function and up to two secondary functions. The table

below summarizes the functions of each button on the front panel keypad. These buttons are

highlighted in white on the 1750 front panel. Each key is labeled with its primary and secondary

functions. The primary function of each button is a short cut to the instrument’s d efault resis tance

and reference current ranges. Secondary functions are enabled by pressing the [MENU] key. The 1750

secondary functions permit numeric data entry or the selection of instrument parameters.

Table 4.1: Summary of Keypad Functionality

From the main display, press the [MENU] key. The instrument display should look like the illustration

below:

Figure 4.8: Menu

This message prompts the user to select one of the 12 buttons on the keypad. Pressing one of the

keys allows access for modifying or enabling instrument parameters . Refer to the Keypad Functionality

Table above and the following section in order to navigate the menu.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

4-9

Page 34

OPERATING INSTRU CTIONS

MENU/CLEAR

200m Ohm@1A

2m Ohm@1A

200m Ohm@100mA

200K Ohm@10uA

20M Ohm@100nA

20K Ohm@100uA

200 Ohm@100uA

200 Ohm@1mA

200 Ohm@10mA

2 Ohm@10mA

REFERENCE

20mOhm@100mA

2M Ohm@1uA

20K Ohm@10uA

2K Ohm@100uA

2K Ohm@1mA

2 Ohm@100mA

20 Ohm@10mA

20 Ohm@1mA

20m Ohm@1A

AUTO

RANGES

From the main menu, the user can access any of the default instrument resistance range settings by

pressing t he co rresp on di n g ran ge key. If AUT O ra nge i s s el ected , th e m ete r wi l l a utoma ti call y sel ect

the best defau lt re sistan ce rang e setti ng for th e resist ance bei ng mea sured . Only 1 1 of the t otal 20

ranges are available when using the shortcut keys or AUTO range.

In AUTO range mode, if the reading is at or below 10% of 20,000 counts, then the instrument will

switch to the next lower ran ge. If th e mea su re men t i s at or abov e 10 1 % of 20 ,00 0 cou nts , t hen the

instrument will select the next higher range.

In manual mode, each range is capable of measuring from 0 to 22,999 counts before over rang ing.

The diagram below maps all of the avai l abl e resi st ance ra ng e set ti ng s. Th ese s etti n gs a re acc essi b le

by pressing the [MENU] key then the [REFERENCE] key. The ranges may be explored by repeatedly

pressing the [REFERENCE] key or by scrolling the

displayed. Pressing the [ENTER] key will enable the range setting. Def ault range settings are shaded.

TRIGGER MODES

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

[▲] or [▼] keys un til the desired range setting is

4-10

Page 35

OPERATING INSTRU CTIONS

MENU/CLEAR

TRIGGER

Delay One Shot

Fast One Shot

Delay Continuous

Fast Continuous

MENU/CLEAR DELAY Delay (1-250 mS)

There are f our selectab le Trigger Modes: Fast Continu ous, Fast One S hot, Delay ed Continu ous and

Delayed One Shot.

The Fast modes are not as accurate as the Delayed modes but are able to generate an initial reading

in about 12 ms. Note that Fast Mode is not availabl e for al l ra nges. See T abl e 1.6 fo r a su mma ry of

which ranges apply.

Delayed Modes are generally more accurate than the Fast Modes and allow the user to program

settling times. When the instrument is in the Delayed Mode, the broken wire function is also enabled

for all ranges below 200 Ω.

Continuous Trigger Modes are controlled interna lly and produce a continuous reading on the display.

One Shot tri gger m odes requ ire ext ernal tri ggerin g for each m easur ement. T his i s done by shorti ng

the BNC tri gger input in the rear panel, software command via GPIB, RS232, or RS422, or manually

pressing the [HOLD/TRIGGER] button on the front panel.

Press the [MENU/CLEAR] button > [TRIGGER] then select the desired trigger mode. Enable the

selected trigger mode by pressing [ENTER].

DELAY TIME

This parameter applies only when the instrument is in either Delayed One Shot or Delayed Continuous

Modes. The Delayed Modes allow the user to program settling times from 1 to 250 ms. Simply type in

a numerical value into the entry field and hit [ENTER] to save the new delay time.

Allowing a lon ger set tli ng peri od al lows the D elayed Mod es to p rodu ce a m ore a ccura te rea ding . Thi s

is a commonly used feature for measuring high resistances or components with a slight inductive

characteristic.

DISPLAY MODE

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

4-11

Page 36

OPERATING INSTRU CTIONS

MENU/CLEAR DISPLAY

Compare

% Compare

Resistance

MENU/CLEAR COMPARATOR

High 00000-22999

Low 00000-22999

Three select ab le options a r e av ailable for t he displ ay ty p e. These are Resistance, C omp arator, a n d %

Comparator.

Selecting either of the Comparator Display Modes will enable the Comparator LED’s on the front Panel

and their respective outputs on the rear panel.

ABSOLUTE COMPARATOR LIMITS

Comparator limits are entered i nto the 1750 in cou nts. Because the 1750 is a 4½ digit meter, the

maximum entered value would be 22999 counts. The lowest possible entry would be 00000. For the

high limit, any va lue less t han the hig h limit va lue may be entere d for the low limit and any l imit lowe r

than the high limit may be entered as the lower limit.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

4-12

Page 37

OPERATING INSTRU CTIONS

MENU/CLEAR

% COMPARATOR

Nominal 00000-22999

Low 00.00-99.99%

High 00.00-99.99%

RS232

GPIB

(IEEE-488.2)

RS422

MENU/CLEAR

INTERFACE

GPIB

ADDRESS

% COMPARATOR LIMITS

For the % comparator, there are three programmable parameters; Upper % Limit, Lower % Limit, and

the Nominal Value. Values 00.00 through 99.99% may be entered for the upper and lower %

comparator limits. The nominal value is entered from 00000 – 22999, in counts.

COMMUNICATION INTERFACE

GPIB, RS232 or RS422 communication is selected from this menu option. When the GPIB

communication mode is selected (by pressing the [ENTER] key once), an additional screen will appear

to allow a new GPIB address to be entered. Enter a new GPIB address by typing a number from 01 to

30 and pressing [ENTER]. The existing address may be retained by simply pressing [ENTER].

There are no user-defined settings available for the RS232 or RS422 communication modes.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

4-13

Page 38

OPERATING INSTRU CTIONS

MENU/CLEAR STORE

Select Memory

Location 1-9

MENU/CLEAR RECALL

Select Memory

Location 1-9

MENU/CLEAR

50/60HZ

60 Hertz

50 Hertz

STORE SETUP

Accessing this menu will allow the user to store the curre nt instrument se tting s int o a me mor y locat ion

from 1-9. Comparator and GPIB settings are included.

RECALL SETUP

Recalls setups from 1-9.

LINE FREQUENCY

In this menu, the user selects either 50 or 60 Hz operation for line cycle integration.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

4-14

Page 39

OPERATING INSTRU CTIONS

MENU/CLEAR

PIN Function

(unmarked key)

Enter PIN (3 digits)

MENU/CLEAR

[0]

ARE YOU SURE?

SEE CHAPTER

VI FOR

DETAILED

CALIBRATION

INSTRUCTIONS

PIN FUNCTION

Enter the PIN # to either enable or disable the PIN lockout function. Refer to the section on PIN f unction

located in this Section.

CALIBRATION

The Pin function must be disabled in order to access this menu. In addition, an internal calibration

jumper must b e i n pl ace to enab l e th e cal i brat ion of this instrument. See section 6, on calibration for

an in depth description of calibration functions p rocedures.

AUTO CORRECT

The 1750 microohmmeter has an auto-correction feature that allows internal compensation of the

instrumen t for temperat ure chan ges in t he operati ng environ ment. In e arlier fi rmware revi sions, th e

auto correction feature was user-selectable. Cu rrently, al l 1750 uni ts have this feature enabled and

the user cannot modify the feature.

This feature does NOT compensate for changes in resistance of the DUT due to ambient temperature

changes.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

4-15

Page 40

OPERATING INSTRU CTIONS

THE PIN FUNCTION

Because the 1750 has a significant number of measurement parameters that are user defined and may

have an impact on measurement accuracy, a lockout feature is supplied with each 1750. This lockout

feature is r eferred to as a PIN function, whi ch prevents unauth orized access to i nstrument setti ngs

critical to the operation of the 1750. It also prevents an operator from accidentally changing the

instrument settings. The PIN function may be enabled or disabled by a user provided that the correct

code is entered to gain access to the PIN menu. The instrument settings which are protected by the

PIN function are as follows; Resistance Ran g e, Trigger Mode, Dela y T ime, Commu n ication Mo de, Line

Frequency, and access to the Calibration menu.

Enabling or Disabling the PIN Function

To enable the PIN function, follow the steps below:

a) Press the [MENU/CLEAR] key then press the [0] key.

b) You will be prompted to enter a three-digit PIN code. Enter the three-digit code and press enter.

(Use the [MENU/CLEAR] key to erase numbers if necessary).

NOTE: The 1750 is shipped fr om the factory with a PIN of “555”

c) If the PIN function is off, then you will be prompted “Turn PIN ON?” If the PIN function is ON,

then you will be prompted “Turn PIN OFF?” To acknowledge turning the PIN function on or off,

simply press the [ENTER] key. A Message will appear on the display to acknowledge the PIN

functions new state b efore returning to the 1 750s main display.

d) If you choose not to ch ange the state of the PIN function, then simply press the [MENU/CLEAR]

key to prompt an error message. This will exit the PIN menu and return to the main display.

Changing a PIN Number

To change an existing PIN Number, follow the steps below:

a) Press the [MENU/CLEAR] key then press the [0] key.

b) You will be prompted to enter a three-digit PIN code. Enter the three-digit code and press enter.

(Use the [MENU/CLEAR] key to erase numbers if necessary).

c) If the PIN function is off, then you will be prompted “Turn PIN ON?” If the PIN function is ON,

then you will be prompted “Turn PIN OFF?”

d) Press the “0” key and the message, “Change PIN # ?” will appear on the screen.

e) Press the [ENTER] key and a new screen appears. This screen will show the old PIN number.

f) The PIN number is changed by keying in the new PIN numbers and pressing [ENTER]. You can

escape this screen without changing the old PIN number by pressing [MENU/CLEAR] > [ENTER].

(Use the [MENU/CLEAR] key to erase numbers if necessary).

To Disable an Unknown PI N

In case an unkn o wn P IN n um ber n eeds to b e di sa bled , a “b ack d oo r” h as b een c reat ed t o by pa ss th e

PIN function. To bypass the PIN function, simply enter the code, [9][9][9], as the PIN number . Upon

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

4-16

Page 41

OPERATING INSTRU CTIONS

entering this code, you will be prompted to disable the PIN function. Pressing [ENTER] will unlock the

PIN function.

NOTE: This “back door” will only allow the Pin function to be disabled. The only way to reactivate the PIN

function is to enter the original PIN code. Contact TEGAM for support in reactivating the PIN number if it is

permanently lost.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

4-17

Page 42

PROGRAMMING AND INTERFACING

SECTION 5

PROGRAMMING AND INTERFACING

INTERFACING TO THE 1750

This section provides detailed information about the model 1750 electrical interfaces and their

functional ity. It will p rovide all of th e necessary inf orma t ion required t o integrate th e 1 7 50 easily in t o

a working test stand. Only one communication int erface ma y be u sed at a tim e. The 175 0 is shi pped

from the factory with a default RS232 communications setting. To change the communicat ions setting,

refer to the menu navigation chart on page 4-13.

The command sets for the RS232, RS422 and GPIB communication are virtually identical. However,

because of the minor differences, this section separates RS232 and RS422 from GPIB to simplify the

description of operating principles.

FRONT PANEL

The Model 1750 uses a four-wire, Kelvin type connection to make resistance measurements. This Kelvin

connection is located o n the instruments front panel. There are five connections used on this connec tor.

Two source leads, which send the bipolar test current through the DUT, two voltage sense leads that

detect the voltage drop across the DUT, and a shield connection for protection against exter nal electrical

interference. The orientation of the front panel LEMO connector is illustrated below:

NOTE: When cons tructing c ustom test lea ds for a test fixtu re etc., th e maximum allow able lead r esistan ce

limits must not be exceeded. Refer to Table 1.7 in Section 1 for a summary of maximum lead resistance

limits for each of the reference current ranges. Use shielded cabl e, grounded on one en d only, to minim ize

external interference. Also, take special care in assuring proper contact to the DUT when taking

measurements.

10 TEGAM WAY • GENEVA, OHIO 44041 • 440-466-6100 • FAX 440-466-6110 • sales@tegam.com

Figure 5.1: Lem o Con n ector

5-1

Page 43

PROGRAMMING AND INTERFACING

REAR PANEL

RS232, RS422 and GPIB communication ports are standard features of the Model 1750. Th ese ports

are located in the rear panel of the unit. In addition to the RS232, RS422 and GPIB connectors, there