Page 1

RF Coaxial Power Standards

Models 1510A and 2510A

Instruction and Service Manual

PN# 1510A/2510A-900

Publication Date: March, 2016

REV. H

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

Page 2

TEGAM is a manufacturer of electronic test and measurement equipment for metrology, calibration, and

production test. We also provide repair, calibration, and other support services for a wide variety of test

and measurement equipment including RF power sensor calibration systems, RF attenuation measurement

systems, ratio transformers, arbitrary waveform generators, micro-ohmmeters, LCR meters, handheld

temperature calibrators, thermometers, humidity and temperature control devices, and more.

TEGAM also repairs and calibrates test and measurement equipment formerly manufactured by ElectroScientific Industries (ESI), Gertsch, Keithley Instruments, Lucas Weinschel, and Pragmatic Instruments. A

complete list can be viewed on our Product Service Directory at www.tegam.com

For more information about TEGAM and our products, please visit our website at www.tegam.com

contact one of our customer service representatives at sales@tegam.com or 800-666-1010.

: or

10 Tegam Way,

Geneva, Ohio 44041

Telephone: (440) 466-6100

Fax: (440) 466-6110

E-mail: sales@tegam.com

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

Page 3

Section Page

I. Introduction

II. Preparation for Use and Installation

III. Principles of Operation

IV. Operating I nstructio ns

V. Maintenance and Servicing

VI. Preparation for Shipment

VII. Storage

Table of Contents

Purpose and functions .......................................................................... 1-1

Capabilities......................................................................................... 1-1

Performanc e ch ara cteristics .................................................................. 1-2

Environmental information ................................................................... 1-2

List of items furnished ......................................................................... 1-3

List of additional items required for operation and maintenance ................ 1-3

Preparation for calibration or repair and shipping .................................... 1-4

Expedite Repair Form .......................................................................... 1-5

Warranty information ........................................................................... 1-6

TEGAM contact information .................................................................. 1-6

Unpacking & Inspection........................................................................ 2-1

Recommended Operating Environment .................................................. 2-1

Power Measurements ........................................................................... 3-1

Principles of DC Su bstitu tion ................................................................. 3-1

Temperature Variable Resistance .......................................................... 3-1

Power Splitters ................................................................................... 3-1

Controlling Thermistor Temperature ...................................................... 3-2

Front Panel Connectors ........................................................................ 4-1

Calcu lating Calibration Factors .............................................................. 4-2

Relationship between k, gamma. And effective efficiency ......................... 4-7

Maintenance ....................................................................................... 5-1

Care and Handling of Assemblies ........................................................... 5-1

Connector Torque ................................................................................ 5-2

Connector Care an d Clea ni ng ................................................................ 5-3

Returning power standard for service..................................................... 7-1

Repacking for shipment ....................................................................... 7-1

Temperature and other environmental limitations ................................... 8-1

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

Page 4

!

!

l

O

Off

Safety Information & Precautions:

The following safety information applies to both operation and service personnel. Safety precautions and

warnings may be fo und throughout this instruction manual and the equip ment. These warnings may be in

the form of a symbol or a written statement. Below is a summary of these precautions.

Terms in This Manual:

CAUTION statements identify conditions or practices that could result in damage to the equipment or

other property.

WARNING statements identify conditions or practices that could result in per sonal injury or loss of life.

Terms as Marked on Equipment:

CAUTION indicates a personal injury hazard not immediately accessible as one reads the marking, or a

hazard to property including the equipment itself.

DANGER indicates a personal injury hazard immediately accessible as one reads the marking.

Symbols:

As Marked in This Manual:

This symbol denotes where precautionary information may be found.

As Marked on Equipment:

CAUTION – Risk of Danger

DANGER – Ri sk of El ectr ic Shock

Earth Ground Terminal

On

Frame or Chassis Terminal

Earth Ground Terminal

Alternating Current

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

Page 5

Section I – Introduction

Frequency Range

10 MHz to 50 GHz

Max Power

25 mW (+14 dBm)

RF Impedance

50 Ohms nominal

(Depends on noise floor and resolution of D C instruments)

Calibration Factor Drift

<0.5% per year

10 to 100 MHz in 10 MHz steps

35 to 50 GHz in 1 GHz steps

Thermistor DC Bias Power

Approximately 40 mW (nominal)

Thermistor Resistance at Bias

200 Ohms (set by balancer)

Temperature

Storage

-55° to +75° C (-67° to +167° F)

Purpose and Function

These Coaxial RF Power Standards are designed for the precise measurement of microwave power in the

10 MHz to 50 GHz frequency range. These standards can be configured as a Reference Standard or

Working Standard. The Working RF Power S ta ndard (or Feedthrough RF Power Standard) is a thermistor

mount with power splitter combination employed as a Feedthrough standard for the calibration of

terminating power sensors such as thermoelectric, diode and thermistor power sensors. The Reference RF

Power Standard (or Terminating RF Power Standard) is a ter m inat ing t hermistor mount used for the

calibration of Feedthrough standards and applications that require direct measurement of RF power.

Capabilities

These Coaxial RF Power Standards are designed for the calibration laboratory. These units are highly

accurate, stable with time and temperature , and are designed for use as a standard for the

characterization of calibration factors for other sen sors.

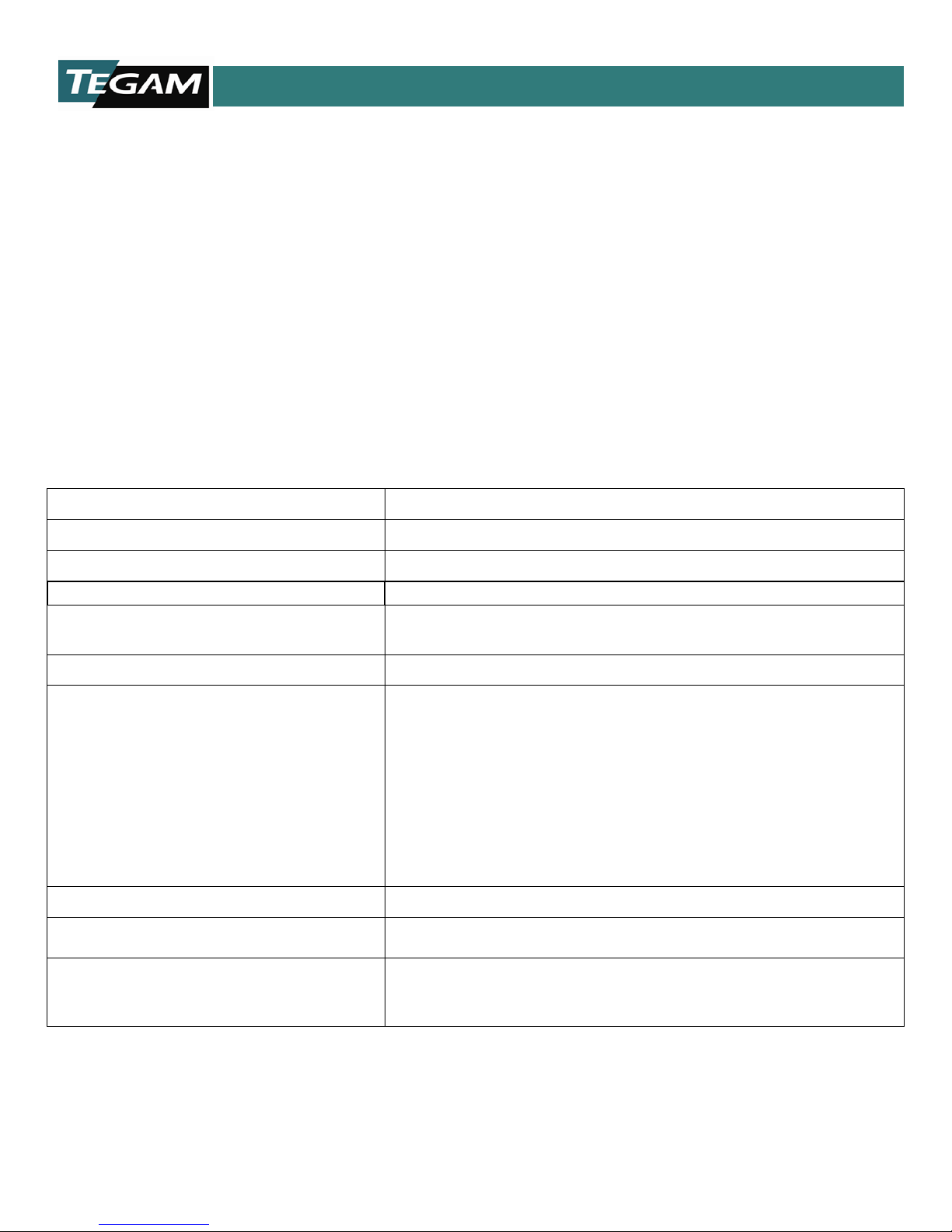

Table 1.1 General Specifications

Power Linearity

Typical Usable Range

Individual Calibration factors are

supplied standard at the following

frequencies. Inquire about

additional points.

Operating

<0.1% from 1 to 10 mW

-20 dBm to +10 dBm (0.01 to 10mW) typical

100 MHz to 2 GHz in 50 MHz steps

2 GHz to 4 GHz in 100 MHz steps

4 to 12.4 GHz in 200 MHz steps

12.75 to 18 GHz in 250 MHz steps

18 to 26 GHz in 1 GHz steps

26.5 GHz

27 to 34 GHz in 1 GHz steps

34.5 GHz

+15° to +30° C (+59° to +86° F)

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

1-1

Page 6

Section I – Introduction

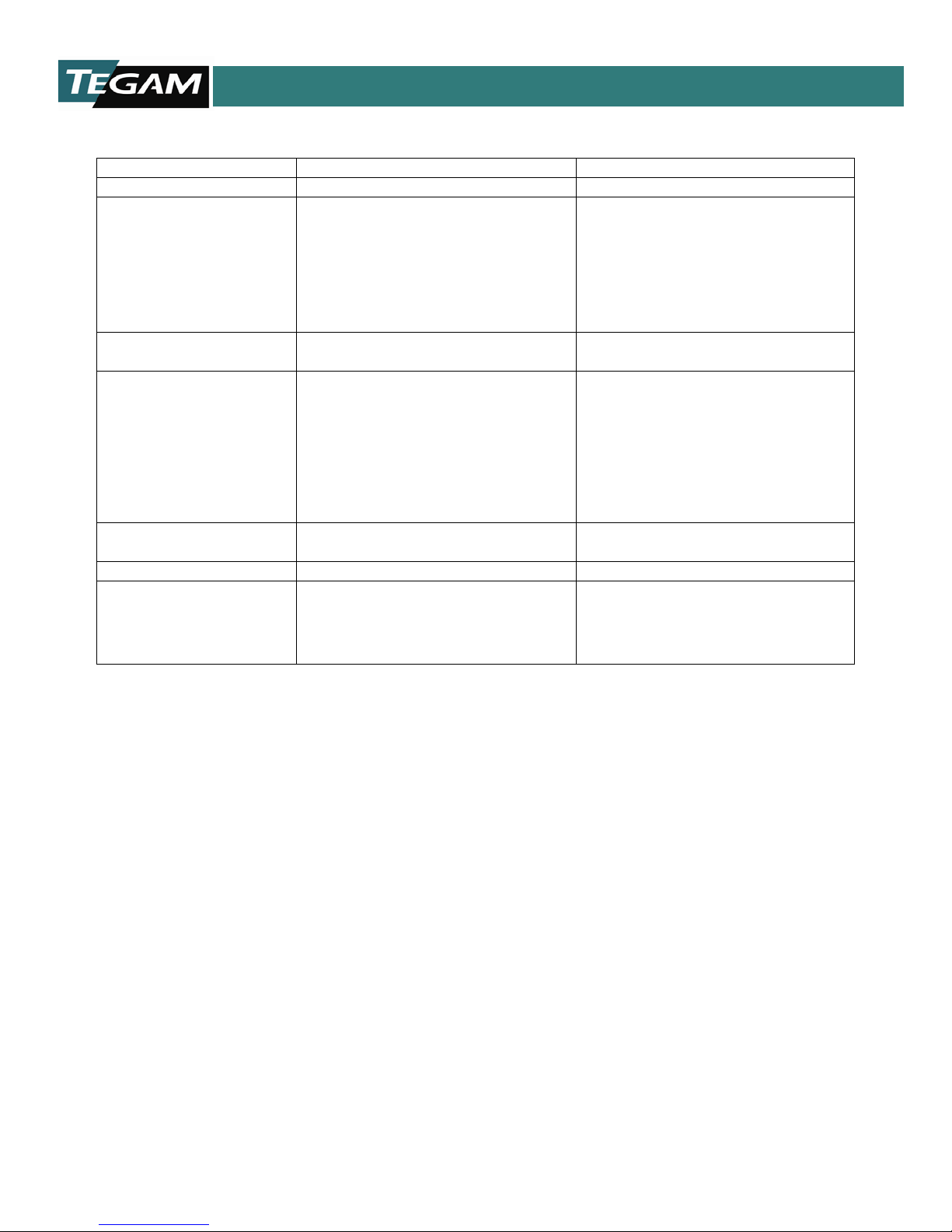

Model

2510A

1510A

Frequency Range

10 MHz to 50 GHz

10 MHz to 50 GHz

Γ

10 MHz to 100 MHz: 0.01

40 GHz to 50 GHz: 0.25

10 MHz to 100 MHz: 0.0066

Loss from Input Port

to DUT Port

11 dB (typical)

N/A

+/-1.0% from 0.01 to 0.04 GHz

+/-1.2% from 0.01 to 0.04 GHz

Connectors

APC 2.4 mm Female

APC 2.4 mm Male

Weight

2.9 kg (6.3 lb)

544.3 g (1.2 lb)

Physical Dimensions

Table 1.2 2510A/1510A Individual Specification

Typical Equivalent

Source Match

|(V/V)

|

Calibration Factor

Accuracy (typical)

Height

Width

Depth

100 MHz to 2 GHz: 0.02

2 GHz to 12.4 GHz: 0.04

12.4 GHz to 18 GHz: 0.06

18 GHz to 26.5 GHz: 0.10

26.5 GHz to 40 GHz: 0.15

+/-1.25% from 0.05 to 4.0 GHz

+/-1.5% from 4.20 to 12.0 GHz

+/-2.2% from 12.2 to 17.5 GHz

+/-2.5% from 17.75 to 26.5 GHz

+/-3.0% from 27.0 to 44.0 GHz

+/-4.0% from 45.0 to 50.0 GHz

10.5 cm (4.1 in)

21.7 cm (8.5 in)

33.8 cm (13.3 in)

100 MHz to 2 GHz: 0.0267

2 GHz to 12.4 GHz: 0.1356

12.4 GHz to 18 GHz: 0.2249

18 GHz to 26.5 GHz: 0.3200

26.5 GHz to 50 GHz: 0.3389

+/-1.4% from 0.05 to 4.0 GHz

+/-1.7% from 4.20 to 12.0 GHZ

+/-2.3% from 12.2 to 17.5 GHz

+/-2.6% from 17.75 to 26.5 GHz

+/-3.2% from 27.0 to 44.0 GHz

+/-4.2% from 45.0 to 50.0 GHz

7.2 cm (2.8 in.)

8.2 cm (3.2 in.)

13.8 cm (5.4 in.)

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

1-2

Page 7

Section I – Introduction

Item

Part Number

Technical (Operation and Maintenance) Manual

1510A/2510A-900

Calibration Cert ificate with Data

N/A

Items Included with 1510A and 2510A

Table 1.2–Packing List

Additional items (required and optional) for operation and maintenance

Required:

• TEGAM Model 1830A, 1806A, 1806, or 1805B1 RF Power Meter

o 1830A Cable (CA-21-15/48)

o 1806A Cable (CA-28-48)

o 1806 Cable (CA-29-48)

o 1805B Cable as heater only (CA-29-48)

• RF Signal Generator

o 10 MHz to 50 GHz

o Minimum power level 17 dBm at 50 GHz

• Torque Wrench

o Torque wrench, 8mm, 8 in-lbs (2510-910-01)

Optional:

• RF Amplifier

• SureCAL Software (P/N SureCAL-PM)

• Rack Mount Kit

o (Single - P/N 1830-910)

o (Dual - P/N 1830-911)

• VNA

o 2-port

o 50 GHz

• TEGAM 1510A (For calibration of TEGAM 2510A)

• Transport Cas e

o 1510 RF Power Standard (1500-910)

o 1830A, F113X & 2510A (2500-910)

• Adapters

o Coax adapter, 2.4mm (F) to 2.92mm (M) with Data (1510-911-01)

o Coax adapter, 2.4mm (F) to 3.5mm (M) with Data (1510-912-01)

o Coax Adapter, 2.4mm (M) to 2.92mm (F) with Data (2510-911-01)

o Coax Adapter, 2.4mm (M) to 3.5mm (F) with Data (2510-912-01)

o Coax Attenuator, 2.4mm (M to F) 30dB with Data (2510-913-01)

1

TEGAM models 2510A and 1510A are designed to be used with TEGAM Models 1830A, 1806A, and 1806. In

addition, the TEGAM Model 1805B can be used to heat the 2510A and 1510A with cable CA-29-48. The

1805B is for heating only and cannot be used for power measurements or biasing of the 2510A or 1510A.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

1-3

Page 8

Section I – Introduction

Preparation For Calibration Or Repair Service

Once you have verified t hat the cause for the Coaxial RF Power Standards malfunction cannot be solved in

the field and the need for repair and calibration service arises, contact TEGAM customer service to obtain

an RMA, (Returned Material Authorization), number. You can contact TEGAM customer service via the

TEGAM website, www.tegam.com

States Only).

The RMA number is unique to your instrument and will help us identify you inst rument and to addre ss the

particular service request by you which is assigned to that RMA number.

Of even importance, a detailed written description of the problem should be attached to the instrument.

Many times repair turnaround is unnecessarily delayed due to a lack of repair instructions or of a detailed

description of the problem.

This description should include inform ation such as measure ment range, and other instrument settings,

type of components being tested, are the symptoms intermittent, conditions that may cause the

symptoms, has anything changed since the last time the instrument was used, etc. Any detailed

information provided to our technicians w il l assist them in identifying and correcting the problem in the

quickest possible manner. Use a copy of the Repair a nd C alibration Service form provided on the next

page.

Once this information is prepared and sent with the instrument to our service department, we will do our

part in making sure that you receive the best possible customer service and turnaround time possible.

or by calling 440.466.6100 (All Locations) OR 800.666.1010 (United

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

1-4

Page 9

Section I – Introduction

RMA#:

Instrument Model #:

Serial

Number:

Company:

Technical Contact:

Phone Number:

Additional

Contact Info:

EXPEDITE REPAIR & CALIBRATION FORM

Use this for m to pro vide additional repair information and serv ice instructions. The Completion of this

form and including it with your instrument will ex p edite the processing and repair process.

Repair Instructions:

Evaluation Calibration Only Repair Only Repair & Calibration Z540 (Extra Charge)

Detailed Symptoms:

Include information such as measurement range, instrument settings, type of components being

tested, is the problem intermittent? When is the pro bl em most frequent?, Has anything changed with

the application since the last time the instrument was used?, etc.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

1-5

Page 10

Section I – Introduction

Warranty

TEGAM, Inc. warrants this product to be free from def ects in material and workmanship for a period of

three years from the date of shipment. During this warranty period, if a product proves to be defective,

TEGAM Inc., at its option, will either repa ir the defective product without charge for parts and labo r, or

exchange any product that proves to be defective.

TEGAM, Inc. warrants the calibration of this product for a period of 1 year from date of shipment. During

this period, TEGAM, Inc. will recalibrate any product, which does not conform to the published accuracy

specifications.

In order to exercise this warranty, TEGAM, Inc., must be notified of the defective product before the

expiration of the warranty period. The customer shall be responsible for packaging and shipping the

product to the designated TEGAM service ce nter with shipping charges prepaid. TEGAM Inc. shall pay for

the return of the product to the customer if the shipment is to a location w ithin the country in which the

TEGAM service center is located. The customer shall be responsible for paying all shipping, duties, taxes,

and additional costs if the product is transported to any other locations. Repaire d products are warranted

for the remaining balance of the original warranty, or 90 days, whichever period is longer.

Warranty Limitations

The TEGAM, Inc. warranty does not apply to defects res u lting from unauthorized modification or misuse of

the product or any part. This warra nty does not apply to fuses, batteries, or damage to the instrument

caused by battery leakage.

Statement of Calibration

This instrument has been inspected and tested in accordance with specifications published by TEGAM Inc.

The calibration of this instrument is traceable to the International System of Units (SI) through the

National Institute of Standards and Te chnology (NIST) or other recognized National Metro logy Institutes,

by comparison to equipment and standards maintained in the laboratories of TEGAM Inc.

Document publishing dates may lag produc t changes.

Visit www.tegam.com to download the late st version of this manual.

Contact Information:

TEGAM INC.

10 TEGAM WAY

GENEVA, OHIO 44041

PH: 440.466.6100

FX: 440.466.6110

EMAIL: sales@tegam.com

WEB: http://www.tegam.com

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

1-6

Page 11

Section II – Preparation for Use and Installation

Item

Part Number

Model 2510A or 1510A Coaxial RF Power

Standards

2510A or 1510A

Technical (Operation and Maintenance) Manual

1510A/2510A-900

Calibration Certificate with Data

N/A

Unpacking & Inspection

Each Coaxial RF Power Standards is put through a series of electrical and mechanical inspections before

shipment to the customer. Upon receipt of your instrument unpack all of the items fro m the shipping

carton and inspect for any damage that may have occurred during transit. Report any damaged items to

the shipping agent. Retain and use the orig ina l p a cking material for reshipment if necess a ry.

Upon Receipt, inspect the carton for the following items:

Table 2.1 Packing List

Mounting

The Model 2510A is shipped with four plastic feet mounted to the bottom cover. Whe n any of these

models are placed on a bench or table, the feet support the instrument. For rack mounting of Model

2510A use rack mount kit, (Single) P/N 1830-910 – (Dual) P/N 1830-911.

The Model 1510A is shipped without any type of rack mounting equipment the new design allows for use

as a terminating sensor and it low weight of 544.3 g (1.2 lb) reduces any stress on connectors.

Only use with Proper Equipment:

Connecting this device to any other type of circ uit or may result in permanent damage to the components.

Additionally, the heater elements used for the internal heater are designed to be used only with the heater

control circuits found in TEGAM Models 1830A, 1820B, 1806A, 1806, and 1805B. Connecting these heater

elements to any other circuit or device m ay result in damage. Contact TEGAM for any questions regarding

instruments that are compatible with these RF Powe r Sta nda rds.

Use in Proper Environment

Normal calibration laboratory practice dictates that the environment should be closely contr olled. This will

minimize errors introduced by temperature and humidity changes. A nominal temperature of +23°C

(+73.4°F) provides a good working condition. A tolerance of ±1°C gives an ideal temperature spread.

Controlled temperatures also stabilize the aging process of the standards.

CAUTION: The RF Power Standards have a specified operating temperature range of +15° to +30° C

(+59° to +86° F). Operating beyond these limits can affect the accuracy of the instruments and damage

internal circuitry.

CAUTION: When an RF Power Standard is to be stored for extended periods , pack the instrument into a

container. Place container in a clean, dry, temperature-controlled location. If instrument is to be stored in

excess of 90 days, place desiccant with items before sealing container. The safe environmental limits for

storage are -55° to +75° C (-67° to +167° F) at less than 95% non-condensing relative humidity.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

2-1

Page 12

Section II – Preparation for Use and Installation

Do Not Use in Explosive Environments

CAUTION: The 1510A and 2510A are not designed for operation in explosive environments.

Do Not Operate Without Covers

WARNING: This device should be operated with all panels and co vers in place. Operation with missing

panels or covers could result in personal injury.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

2-2

Page 13

Section III – Principles of Operat ion

BRIDGE BALANCER

SENSOR

T

T

V

OUT

Theory of RF Measurements with the 2510A and 1510A

Power Measurements

RF power is measured in terms of a power change across the precision resistance leg of a TEGAM 1830A,

1806A, 1806 Bridge Circuit. A digital voltmeter measures voltage across the precision resistance leg which

can be used to determine the power.

The total power applied to the thermistor leg (in the RF Power Standard) of the Type IV Bridge equals the

sum of both DC and RF power. The precision resistor leg only has DC power applied to it. Thus, the RF

power introduced to the thermistor is directly pro portional to the change in DC power across the precision

resistor.

Principle of DC Substitution

The RF Power Standards use the principle of DC substitution to measure RF power. DC substitution refers

to the measurement of RF power according to the amount of DC power that must be substituted for the RF

power in a bolometer in order to cause equivalent thermal effects. Since some of the RF power applied to

the input of the power standard is lost by reflection and other causes before it is applied to the thermistor

element, a calibration factor for the standard is to determine the actual level of RF power. TEGAM Coaxial

RF Power Standards are configured to prov ide a path f or RF energy via a coaxial line. DC Bias is

introduced from the Bias terminals to the thermistors.

Temperature Variable Resistance

Each RF Standard contains a pair of thermistor beads whereby the resistance changes as a function of

temperature. Thermistor bead temperature is a function of the combined DC and RF power a p plied to the

beads and the ambient temperature surrounding the beads. The level of power applied to the beads is

controlled externally. A heating element, controlled by an external controller, provides ambient

temperature stability.

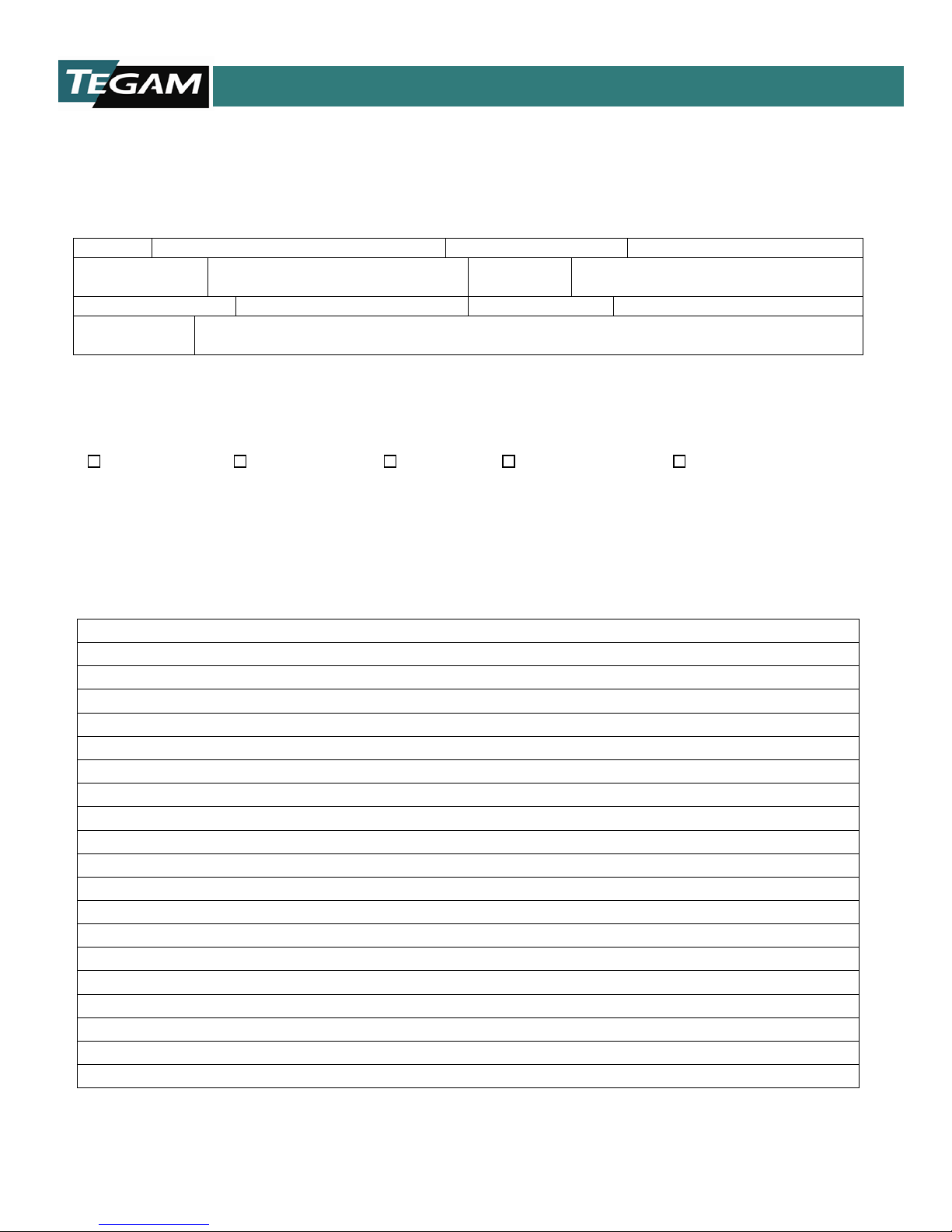

Figure 3.1 Thermistor and Bridge Balancer

Figure 3.1 depicts the thermistor assembly electrical configuration. DC biasing of the dual thermistor

beads to 100 ohms each provides a nominal 50 ohm parallel RF resistance and a 200 ohm series DC

resistance. A DC blocking capacitor and bypass capacitors isolate DC from RF signals. Filtering capacitors

provide low VSWR in the lower end of the frequency range. Application of approximately 40 mW of power

to the thermistor beads produces a 200 ohm DC resistanc e. As the power applied to the thermistor bea ds

increases, their effective resistance values decrease. This is due to the negative temperature coefficient of

the beads. Initially, the beads are DC biased to 200 ohms. Application of RF power increases the power

level present at the beads and causes the effective resistance value of the beads to drop. The bridge

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

3-1

Page 14

Section III – Principles of Operat ion

circuit of the power meter reduces DC power until the initial effective resistance value is restored (200

ohms). The total amount of DC power removed is proportional to the amount of RF power that was

introduced. Quantitatively, the total power applied to the thermistor beads equals the sum of the two

types of power.

Power Splitter

The Models 2510A contain a two-element resistive power splitter. The T-shaped divider contains a series

50 ohm resistor in each of the two legs. The test port is an APC 2.4 mm precision female connector. Use

of the splitter in a closed loop configurat ion that a p plies constant power causes the common point

(divider) to become a constant voltage point. This means the source impedance at both splitter output

ports is determined by the 50 ohm resistor and the output connector. This provides very good source

match. In addition, the power is split equally betw een the two ports.

Controlling Thermistor Temperature

Since thermistor mounts are temperature sensitive devices, it is necessary to eliminate or minimize the

effects of changes in the ambient tempera ture. This is accomplished by thermally isolating the mount,

raising its temperature with a heater element to a level higher than the ambient temperature, and

maintaining that level by means of an external temperature controller. The heater element electrical

assembly as illustrated in Figure 3.2. The proper temperature is determined by the characteristics of the

thermistor beads.

Figure 3.2 Simplified of RF Power Standards Internal Heater

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

3-2

Page 15

Section IV – Operating Instructions

General

The TEGAM RF Power Standards are designed to be employ ed as the fourth arm of a bridge configuration.

These units are designed as the sensing element in RF power calibration and measurement systems.

These systems employ other electronic elements to effect control of the measurement routines. An

example of this type of system is the TEGAM PMX50-001 Power Sensor Calibration System. Proper use of

these standards and the TEGAM PMX50-001 is further documented in other TEGAM Operation and Service

Manuals. The Working RF Power Standard (Model 2510A) are feedthrough mount-splitter combinations are

used to calibrate thermoelectric, diode, and thermistor power sensors. The Reference RF Power Standards

(Model 1510A) are terminating thermistor mounts commonly used as a reference stand a rd fo r ca librating

working standards.

Model 2510A Connector Descriptions

Figure 4.1 TEGAM 2510A Connectors

RF IN connector

APC 2.4 mm female connector connects to signal generator output. The RF power that comes in this

connector is applied equally to the DUT and the power standard. The fact that equal RF power is applied to

both the power standard and the DUT is what allows the d etermination the calibration factor of the DUT.

There is typically 6 dB nominal with a max of 10.5 db of insertion loss in the RF in path of the power

splitter, plus the loss in the standard.

BIAS VOLTAGE/Heater combination connector

A combined connect io n is used to connect the thermistor element to a DC Substitution bridge circuit and

the heater control circuit as is found in the TEGAM Model 1830A, 1806A, and 1806. The bridge operates

on the principal of DC substitution, so only DC voltages and currents are present at these terminals when

connected. In addition, the TEGAM Model 1805B can be used to heat the 2510A and 1510A with cable CA29-48.

SENSOR connector

APC 2.4 mm female coaxial connector provides the RF power to the D UT. The RF power applied to RF IN

connector is applied equally to the DUT and the internal thermistor mount. The fact that equal RF p ower is

applied to both the power standard and the DUT is what allows the calibration factor of the DUT to be

determined.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

4-1

Page 16

Section IV – Operating Instructions

Model 1510A Connector Descriptions

Figure 4.2 TEGAM 1510A Connectors

BIAS VOLTAGE/Heater combination connector

A combined connect io n i s used to connect the thermistor element to a DC Substitution bri dg e circuit and

the heater control circuit as is found in the TEGAM Model 1830A, 1806A, and 1806. The bridge operates

on the principal of DC substitution, so only DC voltages and currents are present at these terminals when

connected. In addition, the TEGAM Model 1805B can be used to heat the 2510A and 1510A with cable CA29-48.

RF INPUT connector (on the front, not shown)

APC 2.4 mm male coaxial connector where RF power to be measured is applied.

Connecting RF Power Standards

The TEGAM RF Standards are an element of a system and is not a “stand-alone” instrument. The 2510A

and 1510A RF Power Standard can only be connected to the TEGAM 1830A, 1806A, and 1806. Unlike

other TEGAM RF Power Standards, the bias and temperature are connected through one cable. To do this,

simply connect one end of the appropriate cable to the 2510A or 1510A and the other end to the

“SENSOR” and “HEA T ER” connection of the 1830A, 1806A, 1806, and 1805B. Use the appropriate cables

that meet your equipment application

The RF IN on the Working (Feedthrough) Power Standar ds is an APC 2.4 mm connector. An APC 2.4 mm

female coaxial connector is connected to the output of the chosen signal generator, which should be 50

Ohm nominal impedance. A low loss coaxial cable is recommended to a void an excessive power loss.

These Models have an additional female coaxial connector called the “SENSOR” port. This connector is

actually one of the arms of the power splitter (described in Section III Principles of Operation). The DUT is

2

.

2

When connecting to the 1806 or 1806A the FLOAT/GROUND switch should be in the FLOAT (dow n) po s ition.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

4-2

Page 17

Section IV – Operating Instructions

connected to this port for calibration. When the Wor king RF Power Standard is being calibrated, the

Reference RF Power Standard is connected to this port. This connector is an 2.4 mm female. Proper care,

cleaning, alignment, and torquing of co axial connectors should be practiced to make accurate

measurements, reduce insertion loss and extend the life of th e connectors.

The RF input on the Reference (Terminating) Power Standards (Model 1510A) is a male 2.4 mm connector

that is connected to the RF power source to be measured. Again, proper care, cleaning, alignment, and

torquing of coaxial connectors should be practiced to make accurate measurements, reduce insertion loss,

improve repeatability, and extend the life of the connectors.

Once cabling has been correctly installed, there are no further operator adjustments to be made to the RF

Power Standards. However, allow at least two hours for the heater in the RF Standard to reach its

operating temperature. Additionally, it is recommended that once the BIAS VOLTAGE terminals are

connected, the D C Substitution Bridge should be on for one hour before measurements are taken

3

.

Calculating Calibration Factors

When using a RF Power Meter with a RF Power Sensor to make a RF Power Measurement the user must

know that the measurement is accurate and there is traceability to a known standard. All diode, thermoelectric, and thermistor power sensors have calibration factors associated to particular frequencies that

are used to insure an a ccurate power measurement. Technicians and engine ers use these calibra t io n

factors when making measurements but where do these calibration factors really come from.

Calibration factor of a terminating power sensor, if it is a DC-substitution sensor, relates the change in DC

substituted power to the total RF power incident on the sensor. For this purpose, incident means all of the

RF propagating toward the sensor reference plane, including power that is subsequently reflected. On the

|

=|

signal flow diagram (figure 4.3), the incident power is

.

Calibration factor of a feed-through power calibration setup, again if the monitor is a DC-substitution

sensor, relates the change in DC substituted power in the monitor to the power delivered out of the DUT

port into a load of exactly the nominal charac teristic impedance of the system, or

feed-through DUT port as the output of a leveled generator, then the output into a perfect load is

. If we think of the

.

So for a terminating sensor (using the “M” subscript following Weinschel part numbering):

=

And for a feed-through standard, (using “F” to indicate “feedthrough”):

=

Where:

Calibration factor of the Terminating Mount

k

M =

Calibration factor of the Feed-through Moun t

k

F =

= Power measured terminating mount

P

SubM

= Power measured Feed-through mount

P

SubF

3

When connecting a 1510A or 2510A to an 1806 or 1806A; in addition to a 2 hour warm up time, operator should observe stability

in the bias voltage. Bias voltage stabil ity refers to less than 50uV change per 30 minutes as a general guideline. The error light do es

not apply when connecting the 1510A or 2510A to the 1806A.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

4-3

Page 18

Section IV – Operating Instructions

In all calibrations, calibration factors are transferred from a terminating reference, to a feed-through

stand, and then into the DUT. In some procedures, this transfer occurs all in one session, a nd in others

time is saved by transferring into the feed-through once and then using that feed-through calibration

factor to calibrate DUT for some time.

In a perfect world, the terminating sensor would present a perfect load, and then by reorganizing the

above two definitions with incident and output power equal, we would have,

=

Because power sensors are always imp erfect loads, additional analysis and sometimes correction is

required.

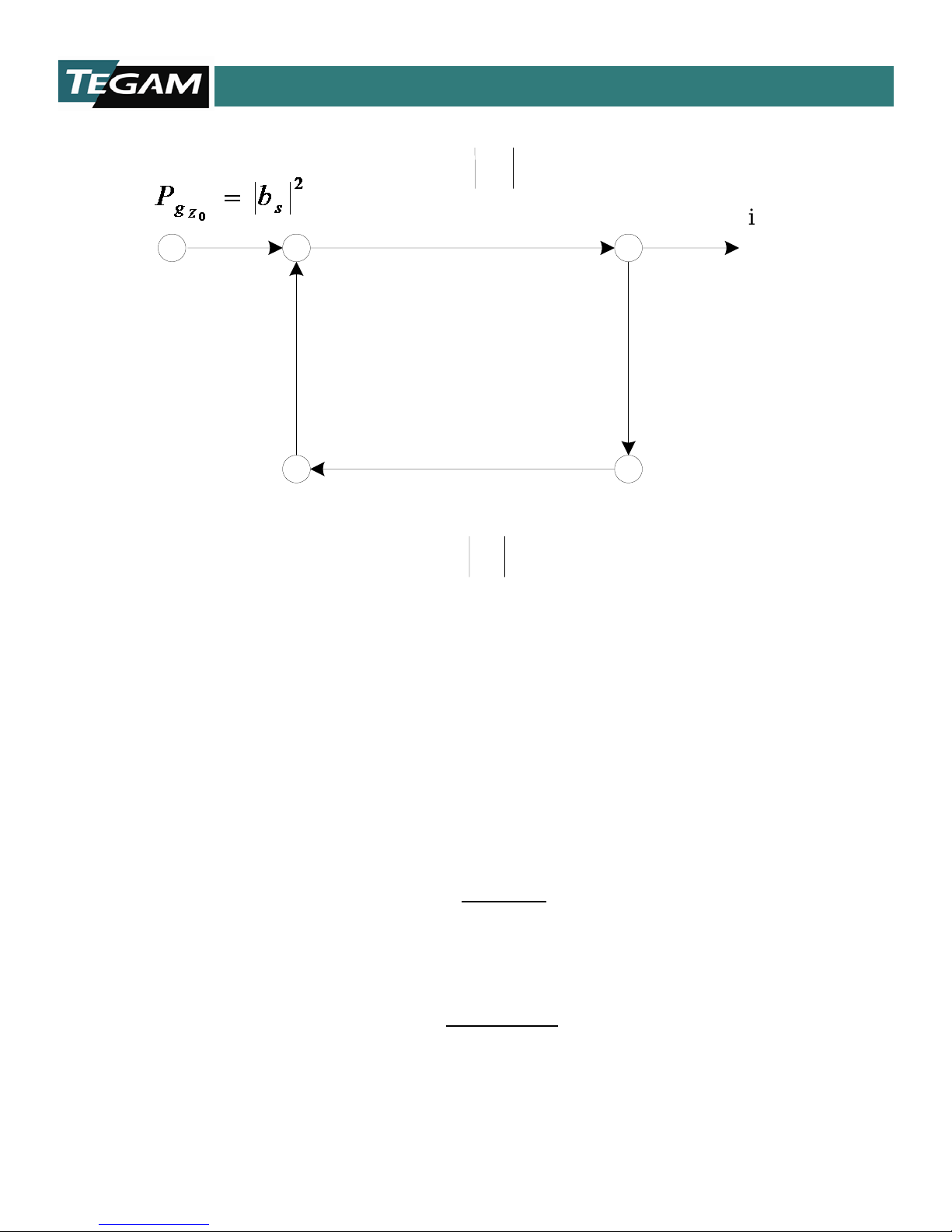

Figure 4.1 shows a signal flow diagram of two one-port devices connected together. The left-hand port is

the “output”, or “generator” port and is designated on the diagram using the subscript, “g”. The righthand port is the “input”, or “load” port and is des ignated using the subscript “l”. It’s clear from the

diagram that port reflections dominated by the Gamma vectors generally cause the power that the

generator port would output into an ideal load,

We really have to take into account the combination of reflections, or “port match” to come up with a

general understanding of calibration transfer.

Start with the signal flow diagram. In this case, a Generator “g” is represented by an ideal source “s”,

and its port reflection, and the sensor is ter med the load, “l”.

, to not be equal to the power , incident on the load.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

4-4

Page 19

Section IV – Operating Instructions

s b g

a a

r i d

P P P

−

=

Γ

2

a

P

i = 2

b

P

r

=

g Γ s g g

g

b a b

+ Γ =

b

a

=

Γ

1

1

Figure 4-3 - Signal Flow Diagram

From the diagram,

= +

But also,

= = =

So substituting the second equation into the first:

= +

And then re-arrange to collect b

Now rewrite as power, substituting in

g:

=

=|

=

1

|

, and

1

=

:

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

4-5

Page 20

Section IV – Operating Instructions

Armed with this last result, and calling the Feed-through stand (F subscript) the “generator” (g subscript)

and terminating sensor (M subscript) the “load” (l subsc ript), and substituting in the definitions for cal

factor from earlier, we get the more general equation for transferring between a feed-through and a

terminating sensor:

=

|

1

|

Where:

Calibration factor of the Terminating Mount

k

M =

Calibration factor of the Feed-through Moun t

k

F =

= Power measured terminating mount

P

SubM

= Power measured Feed-through mount

P

SubF

= Gamma Correction full vecto r da t a Terminating Mount

Γ

Μ

= Gamma Correction full vector data Feed-through Mount

Γ

Φ

Now in this general equation, the Gamma terms are the reflection scattering parameter of the respective

port noted in the subscript. Gamma is a complex vector with scalar values denoting the real and

imaginary magnitudes:

= cos + isin

In the general transfer equation, the term,

match” term. Inside the absolute value brackets, however, is a vector subtraction. Expanding out to

make the angles explicit, this becomes:

|

1

cos

|

1 ΓΓ

(

+

|

is the scalar “gamma correction” or “port

)

sin

(

+

)|

(

1

cos

1

, or the “imaginary” component.

(

cos

)

+

+

cos

(

+

))

4-6

(

+

(

+

)

sin

+

(

+

sin

))

(

+

)

Where the i represents

The absolute value, or length of a vector, is g iven by the Pythagorean formula, which is the s quare

root of the square of the magnitudes of the real and imaginary components. It’s convenien t t hat we

are looking for the square of the magnitude, so we don’t have to worry about the square root part.

Our correction term becomes the scalar,

When the squares are evaluated, this expa nds to:

1 2

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

Page 21

Section IV – Operating Instructions

Noting that if we collect the two terms beginning with

(

(

+

The term, cos

becomes,

1 2

(

+

)

+ sin

(

cos

+

(

1 2

)

+

)

is always identically equal to 1, so the final simplified equation

+

cos

Or combining this result with the general transfer equation,

=

(

1 2

If we look at the scalar result of the mismatch ter m, the “1” part is what would happen if at least one

of the ports was “perfect”, or had no reflection. In that case, one of the is zero. The right-most

element has magnitude of

ignored for most connections.

The middle part, 2

multiplied by k, the sensitivity to this change is equal to k, or about 1. In an UNCORRECTED transfer,

this part represents the probable error of the transfer. Since we can’t know the angles in an

uncorrected transfer, we let cos() ta ke its limits of +/- 1, and say that the uncer t ainty of the

uncorrected transfer is 2

probable, but it’s what the industry usually does. Unless the rhos were measured on a scalar analyzer,

we have to use manufacturer’s worst-case values.

Some common power sensor calibration practices do not always use gamma correction. An argument

could probably be made that this was a reasonable practice at lower frequencies. We typically see this at

18 GHz and lower. A value of 0 would be inserted for Γ

, which is typically so much smaller than the middle ter m tha t it can b e

)

cos(+

. That is a little pessimistic, because that is worst-case rather than

, contains the bulk of the impact of port mismatch. Since it is

This would make the formula look like:

=

, we get,

(

cos

cos

Μ

+

)

+

(

+

making that portion of the formula “1”.

)

+ sin

)

+

(

+

)

))

This revision of t he original formula assumes many things that are not ne cessarily true. Things t hat may

not necessarily show up at lower frequencies but will certainly show up at higher frequencies where

connectors change from the very rugged N-type connector to the more sensitive 3.5 mm and 2.4 mm

connectors.

By looking at Figure 4.4 we can get a practical visualization o f the relationship between calibration

factor, gamma and effective efficiency

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

.

4-7

Page 22

Section IV – Operating Instructions

Figure 4.4 - Relationship between calibration factor, gamma, and effective efficiency

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

4-8

Page 23

Section V– Maintenance and Servicing

Maintenance

Care and Handling of Assemblies

To ensure accurate measurements and optimal performance of TEGAM products, the microwave coaxial

cable assemblies used in system and test setups must be properly used and maintained. Proper

connections, rout ine i nspection of all cables, and cleaning of t he connectors are extremely important

procedures which can prolong the longevity and accuracy of equipment.

Cable Inspection

Routinely check external cables for signs of cracked insulation, dents, twists, flattening, signs of jacket

abrasion, or other sign s of abuse. Wri nkles in the j acket indi cate that the minimu m bend radi us has been

exceeded. Most often, this occurs near the marker tubes and connectors.

Also inspect the connector interfaces for the following:

• Bent pins (male).

• Bent or missing tines (female).

• Worn or chipped plating.

• Damaged or displaced dielectric inserts.

• Thread damage.

• Folded or mushroomed outer interface rims.

• Mushroomed pin shoulders (male) or tine ends

(female).

• Score lines on pins and outer interface rims visible to the unaided eye.

• Recessed or protruding pins.

It is advisable to clean the connectors prior to inspection to make subtle damage more apparent. If any of

the above is noted, repl ace the a ssemb ly b efore i ts fu rther us e resu lt s in equi pmen t dam age. Al so insp ect

the mating connectors for similar damage.

Inspect the connector interface for signs of debris.

Debris may be in the form of:

• Plating chips or ot her metal particles.

• Dust or dirt.

• Oily films.

• Other miscellaneous foreign particles.

Making Initial Connections

Exercise caution wh en mating cabl es. Poor connecti ons lead to poor system performan ce. They can al so

damage not only the cable assembly, but more significantly, front or rear panel connectors on the

equipment itself which may be more difficult to repair.

Aligning Connectors

Align the center lines of two connectors before actual mating. Male retaining nuts contain a small amount

of necessary play which may make it possible to mate the threads without the pins being properly aligned.

Pin misalignment can damage pins and dielectric inserts.

Mating Connectors

Gently mate the connectors by hand, taking care not to force the coupling nut at the slightest resistance.

It is often possible to feel whether or not the pins are mated. If the coupling nut is difficult to turn, either

the pins are not mated, the coupling nut is cross-threaded, or on e o f t h e con n e c tors has been da m ag ed b y

excess torque.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

5-1

Page 24

Section V– Maintenance and Servicing

CONNECTOR

RECOMMENDED TORQUE

APC 2.4 mm

8.0 in/lbs

Never hold a male connector coupling nut stationary while screwing a female connector into it. This

rotation can erode the plating and damage both the outer interface rim as well as the pin. If the pins

become locked, serious damage ca n res ult to both the equipment and the cable assembly.

Over-Torque

Once connectors have been properly mated, apply only the proper amount of torque. Over-torque

damages both connectors involved. Also, a connector which has been damaged by over-torque, in turn,

damages every connector to which it is subsequently mated. It usually leads to poor system performance

as well. Over-torque can cause:

• Bent pins.

• Recessed or protruding pins.

• Recessed or protruding dielectrics.

• Chipped plating.

• Damaged coupling threads.

• Coupling nut retaining ring damage.

• Mushroomed outer interface shells.

• Mushroomed pin shoulders.

Proper Torque of a APC 2.4 mm Hex Nut

To mate a connector of the hex-nut type, always use a torque w rench set to the correct torqu e value.

Tighten the connector slowly until the wrench snaps. Tightening too quickly can cause the wrench to

exceed its set limit. Do not snap the wrench more tha n once as this also causes over-torque.

Figure 6.1 Recommended APC 2.4 mm Torque

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

5-2

Page 25

Section V– Maintenance and Servicing

CLEANING CONNECTOR INTERFACES

Use the following guidelines in cleaning connector interfaces:

• Do not use chlorinated solvents including common tap water. These solvents are extremely

penetrating and sometimes ruin otherwise good devices and assemblies.

• Moisten a cotton swab with isopropyl alcohol. Roll the swab on a paper towel to remove excess.

• Use the moistened cotton swab to wipe away debris. Do not try to dissolve the debris by over-

wetting the swab.

• Repeat the cleaning process using additional swabs as necessary. If metallic particles are

embedded i n the di el ectri c, use a n eyegl a ss and a sh arp pick in an attempt to dislodge them. Swab

again.

• When satisfi ed that the interfaces a re clean , blow th em dry with dry compre ssed air, or p refera bly

dry nitrogen (pressurized spray cans work well). Do not use breath.

• Clean the mating connectors. These may be the source of the debris.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

5-3

Page 26

Section VI– Preparation for Shipment

Returning 2510A/1510A for Service

Use the information in this section if you need to return your Power Standard to TEGAM.

Package 2510A/1510A for Shipment

Use the following steps to package the Power Standard fo r sh ipment to TEGAM fo r se rv ice:

1. Fill the EXPEDITE REPAIR & CALIBRATION FORM (found in Section I) and attach it to the Power

Standard. Please be as specific as possible about the natur e of the problem. Send a copy of any or

all of the following information:

o Any error messages that appeared on the power meter display.

o Any information on the performance of the Power Standard.

2. Use the original packaging materials or a strong shipping container. The carton must be both large

enough and strong enough to accommodate the power standard and allow at least three to four

inches on all sides of the power standard for packing material.

3. Seal the shipping container securely with stro ng nylon adhesive tape.

4. Mark the shipping containe r “FRAGILE, HANDLE WI TH CARE” to ensure careful handling.

CAUTION: 2510A/1510A damage can result from using packaging materials other than those specified.

5. Retain copies of all shipping papers.

NOTE: Refer to page 1-6 of the introduction for information on how to obtain a RMA from TEGAM.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

6-1

Page 27

Section VII – Storage

Storage

When an RF Power Standard is to be stored for extended periods, pack the instrument into a container.

Place container in a clean, dry, temperature-controlled location. If instrument is to be stored in excess of

90 days, place desiccant with items before sealing container. The safe environmental limits for storage are

-55° to +75° C (-67° to +167° F) at less than 95% non-condensing relative humidity.

10 TEGAM WAY • GENEVA, OHIO 44041 440-466-6100 • FAX 440-466-6110 • www.tegam.com

7-1

Loading...

Loading...