Page 1

BLAST CHILLER/FREEZER

User Manual

EN

FR

IT

ES

PT

SL

3

13

25

37

49

61

Page 2

2

Page 3

CONTENTS

1.

2.

General information

Important safety instructions .................................................................................. 4

Unpacking and installation ..................................................................................... 4

Electrical connection .............................................................................................. 5

Start-up of the cabinet ........................................................................................... 5

Capacity ................................................................................................................. 5

Recommendations for use ..................................................................................... 5

Blast chilling cycle ................................................................................................. 6

Shock freezing cycle .............................................................................................. 6

Cleaning and maintenance .................................................................................... 6

Service ................................................................................................................... 7

Disposal ................................................................................................................. 7

Quick guide

3.

Daily quick guide ................................................................................................... 9

Thermostat XB570L / XB590L

Technical manual ................................................................................................. 73

3

Page 4

IMPORTANT SAFETY INSTRUCTIONS

1. To obtain full use of the cabinet, we recommend reading this instruction manual.

2. It is the user’s responsibility to operate the appliance in accordance with the instructions given.

3. Contact your dealer immediately in case of any malfunctions.

4. Place the cabinet in a dry and ventilated place.

5. Keep the cabinet away from strongly heat-emitting sources and do not expose it to direct sunlight.

6. Always keep in mind that all electrical devices are sources of potential danger.

7. Do not store inammable material such as thinner, gasoline etc. in the cabinet.

8. We declare that no asbestos nor any CFC are used in the construction.

9. The oil in the compressor does not contain PCB

ONLY FOR APPLIANCES WITH REFRIGERANT R290/R600a!

This appliance contains a ammable refrigerant, so make sure of good ventilation

around the appliance. Do not use mechanical devices when defrosting, this can cause

leakage of the cooling system. Do not use electrical appliances inside the refrigerated

storage compartment.

Any repair of the appliance should be carried out by a skilled technician (EN 60335-289: 2010).

UNPACKING AND INSTALLATION

Remove the wooden pallet and the packing. External surfaces are supplied with a protection foil,

which must be removed before installation.

To ensure correct function it is important that the cabinet is level. If the cabinet is supplied with legs,

these can be adjusted.

Important !

1. Do not block the ventilation holes.

2. Make sure that there is at least 15 cm. free space between the cabinet and the wall.

4

Page 5

ELECTRICAL CONNECTION

BLC3, BLC5 and BLC10 cabinets operates on 230 V/50 Hz.

BLC14 operates on 3x400 V/50 Hz.

Make sure that the cabinet is connected to a separate electrical group to avoid overload.

The wall socket should be easily accessible.

All earthing requirements stipulated by the local electricity authorities must be observed. The cabinet

plug and wall socket should then give correct earthing. If in doubt, contact your local supplier or

authorized electrician.

The main electrical connections must be done by skilled electricians.

START-UP OF THE CABINET

Before use, we recommend that the cabinet is cleaned, see the section on maintenance and

cleaning.

Important !

If the cabinet has been horizontally placed during transport, please wait 2 hours before starting up

the cabinet.

CAPACITY

BLC3 BLAST CHILLER/FREEZER

Model suitable to contain 3 trays with blast chilling capacity of 12kg and 8 kg in shock freezing.

BLC5 BLAST CHILLER/FREEZER

Model suitable to contain 5 trays with blast chilling capacity of 18kg and 14kg in shock freezing.

BLC10 BLAST CHILLER/FREEZER

Model suitable to contain 10 trays with blast chilling capacity of 40kg and 28 kg in shock freezing.

BLC14 BLAST CHILLER/FREEZER

Model suitable to contain 14 trays with blast chilling capacity of 55kg and 38kg in shock freezing.

5

Page 6

RECOMMENDATIONS FOR USE

If the appliance remains inactive for a long period, proceed as follows

1. Use the automatic isolating switch to deactivate connection to the main electrical line.

2. Clean the appliance and surrounding areas thoroughly.

3. Spread a thin layer of cooking oil onto the stainless steel surfaces

4. Carry out all maintenance operations

5. Leave the door ajar to prevent the formation of mould and / or unpleasant odour.

Do not insert foodstus that are above the temperature of 90 °C.

Do not stack the materials to be preserved in contact with the internal walls so blocking the circulation

of air.

There must be a sucient space between the trays used in order to guarantee a sucient ow of

cold air on the entire product.

Never obstruct the inlet of the evaporator fans.

Products that are more dicult to chill because of their size should be placed in the centre.

Limit the number of times and the duration of time the door are opened.

After blast chilling/shock freezing the product, it can be stored in a preservation cabinet after having

been duly protected .A tag should be applied describing the contents of the product, blast chilling/

shock freezing date and expiry date. When the product has been blast chilled it must be preserved at

a constant temperature of +2 °C while if it has been shock frozen it must be preserved at a constant

temperature of -20 °C.

The chiller should be used for storage for short periods only.

To prevent bacterial contamination or contamination of any other biological

nature, the needle probe must be disinfected after use.

6

Page 7

BLAST CHILLING CYCLE

With this operating modality the chiller keeps the temperature of the refrigerating compartment close

to zero during the entire chilling process in order to ensure a gradual drop in the temperature of the

product to +3 °C.In this way, ice crystals do not form on the surface of the product .This blast chilling

method should be used preferably for products that are not packed and whose physical/organoleptic

characteristics could be damaged by the formation of supercial ice (e.g. sh)

SHOCK FREEZING CYCLE

With this blast chilling modality the blast chiller maintains the temperature at a negative value below

-18 °C which is the end temperature of shock freezing .For shock freezing to be successful and fast,

food should be in small pieces, especially if it has a high fat content. The largest pieces should be

placed in central trays .If it takes longer than standard time to shock freeze and the sizes cannot

be reduced, decrease the quantity and precool the chiller compartment by starting an empty shock

freezing cycle before shock freezing the product.

CLEANING AND MAINTENANCE

Switch o the electrical connection at the socket.

The cabinet must be periodically cleaned. Clean the external and internal surfaces of the cabinet with

a light soap solution and subsequently wipe dry. External surfaces can be maintained using steel oil.

Do not spray the appliance with direct jets of water or using high pressure appliances.

Do not use iron wool. brushes or scrapers to clean the stainless steel as ferrous particles could be

deposited which ,on oxidizing, could lead to rust.

To remove hardened residues, use wooden or plastic spatulas or abrasive rubber pads.

Clean the condenser

Clean the condenser periodically.

As the ns of the condenser are very sharp, always wear protective gloves for the next phases.

Use protective masks and glasses in the presence of dust.

Whenever the condenser has a deposit of dust in correspondence with the ns, this can be

removed using a suction device or with a brush applied, using a vertical movement along the

direction of the ns.

No other instruments must be used, which may deform the ns and therefore the eciency of the

appliance.

7

Page 8

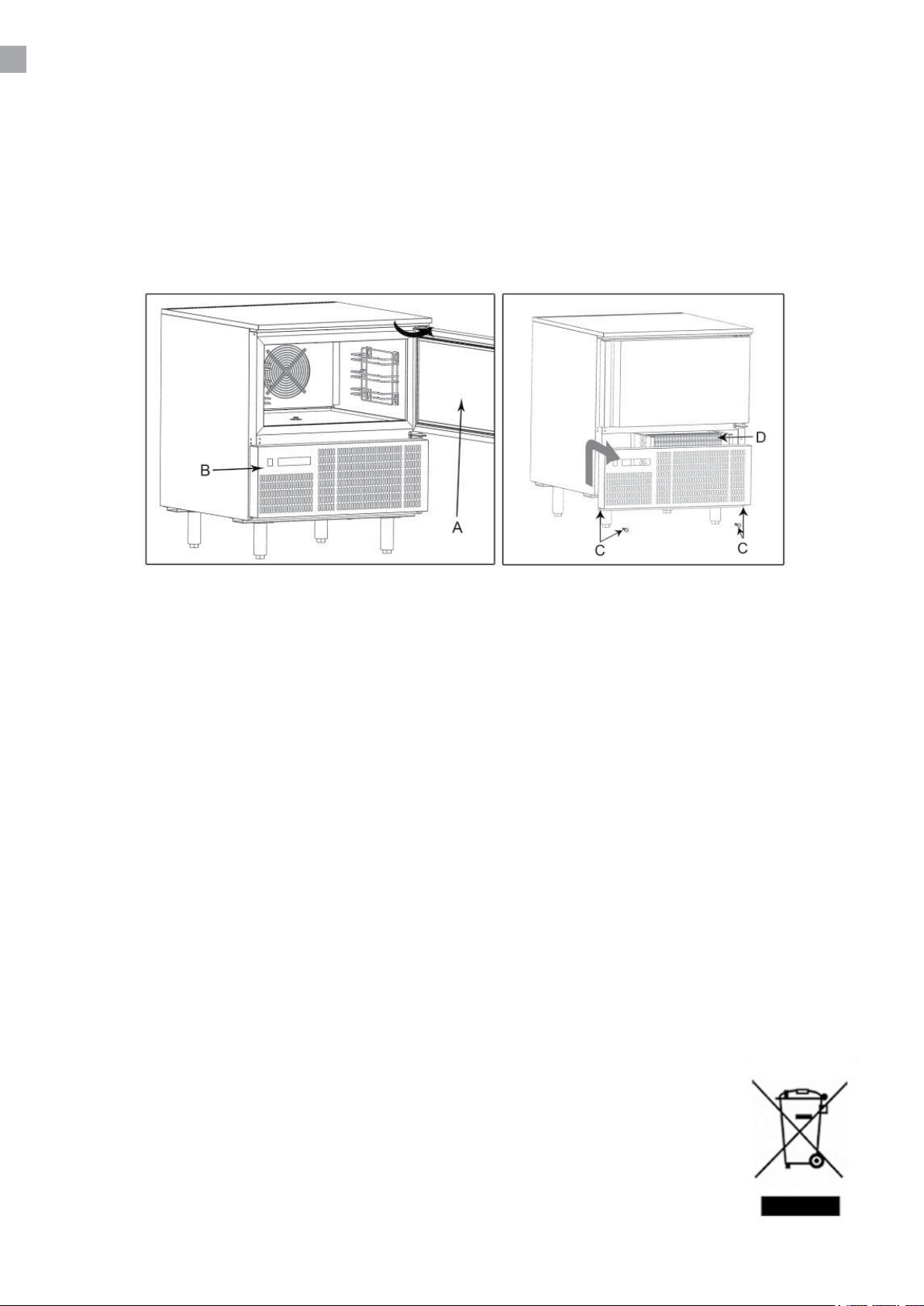

To clean, proceed as follows:

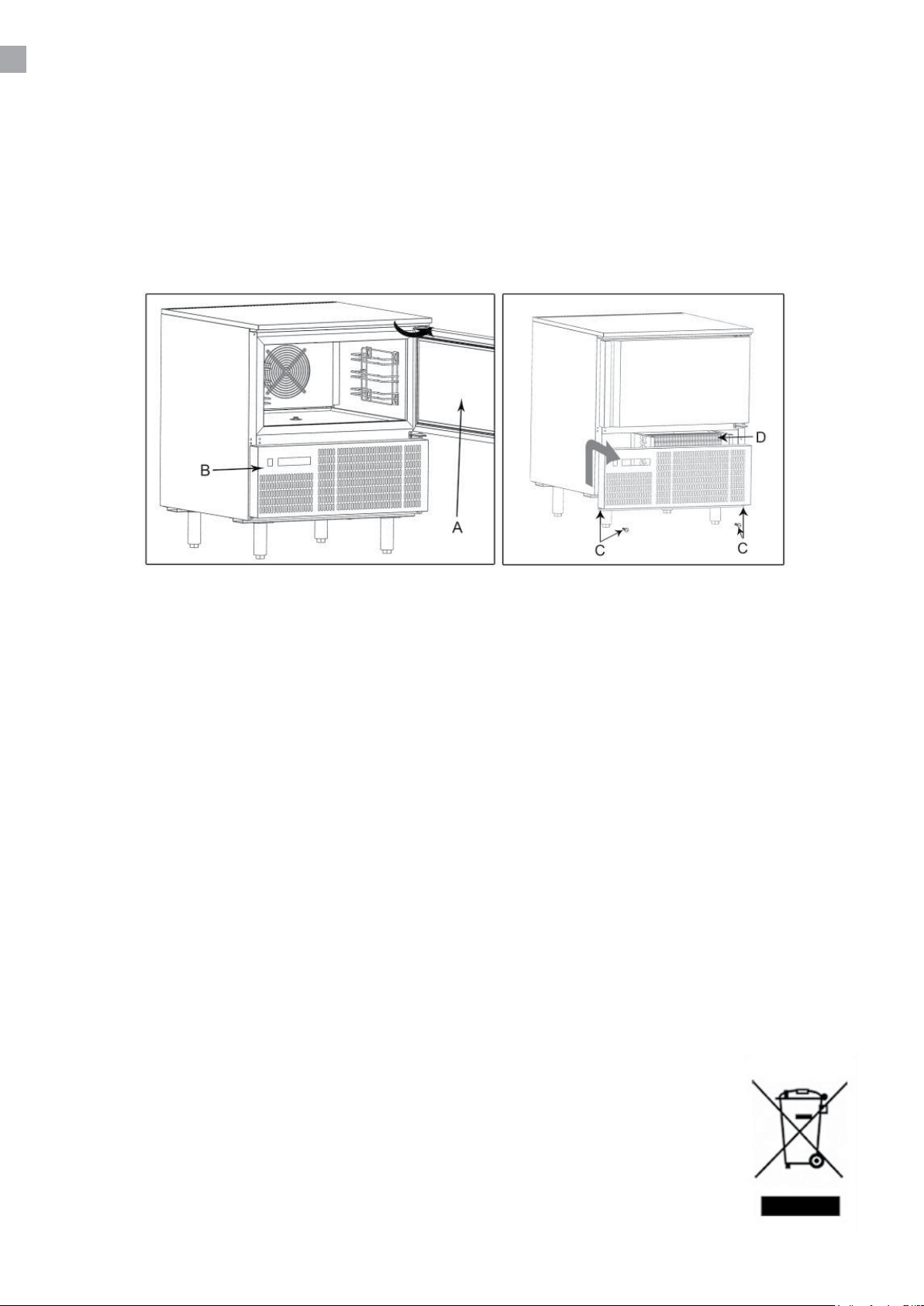

1. Open the door (A) of the appliances.

2. Remove the lower panel(B) from the technical compartment: to do this, remove the screw

fasteners(C)

3. It is now possible to clean the nned part of the condenser (D) using suitable tools and

protection devices.

4. After cleaning, close the control panel and x it with the screws removed beforehand.

SERVICE

The cooling system is a hermetically sealed system and does not require supervision, only cleaning.

If the cabinet fails to cool, check if the reason is a power cut.

If you cannot locate the reason to the failure of the cabinet, please contact your supplier. Please

inform model and serial number of the cabinet. You can nd this information on the rating label which

is placed inside the cabinet in the top right hand side.

DISPOSAL

Disposal of the cabinet must take place in an environmentally correct way. Please note existing

regulation on disposal. There may be special requirements and conditions which must be observed.

8

Page 9

QUICK GUIDE

For the daily use

9

Page 10

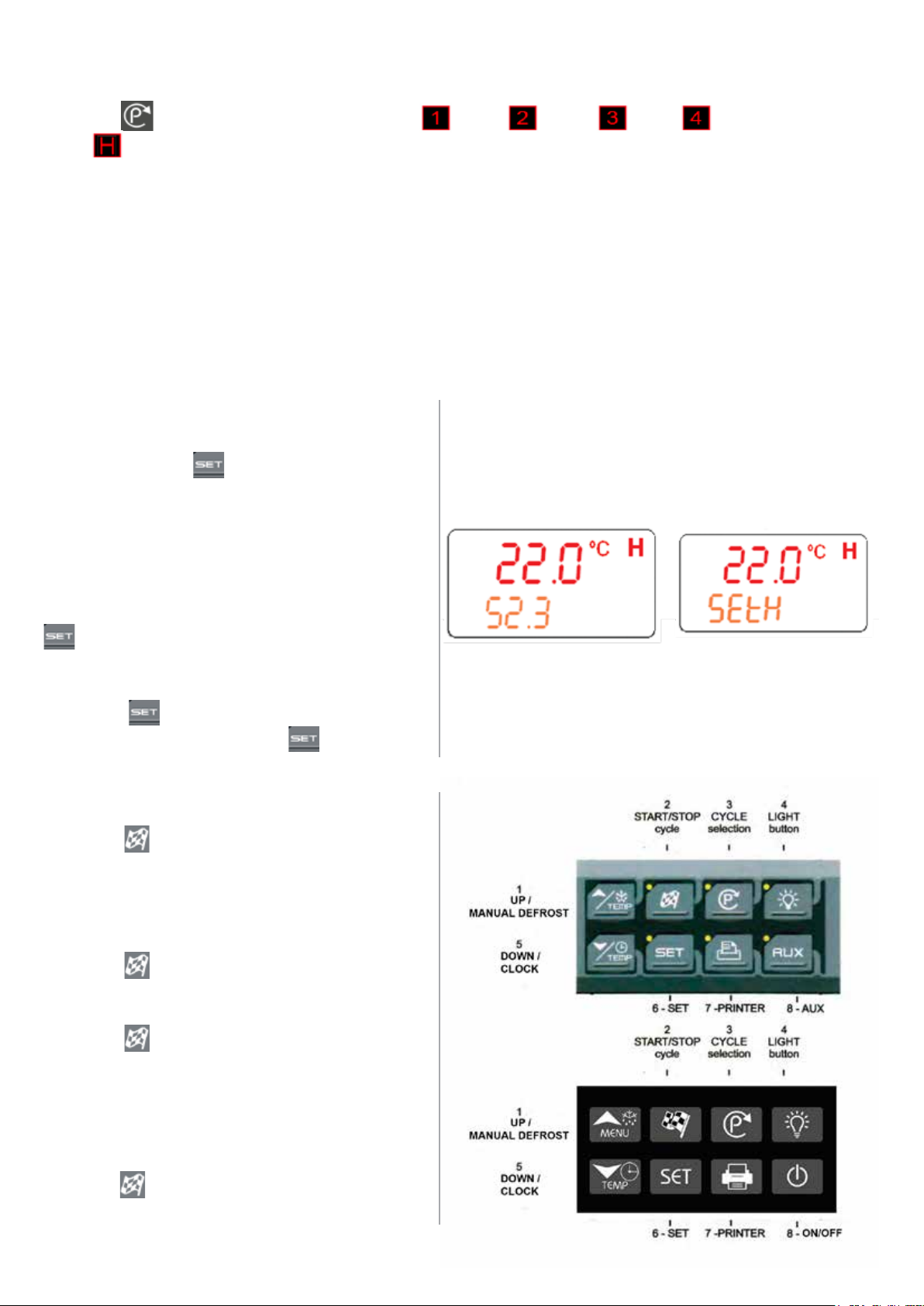

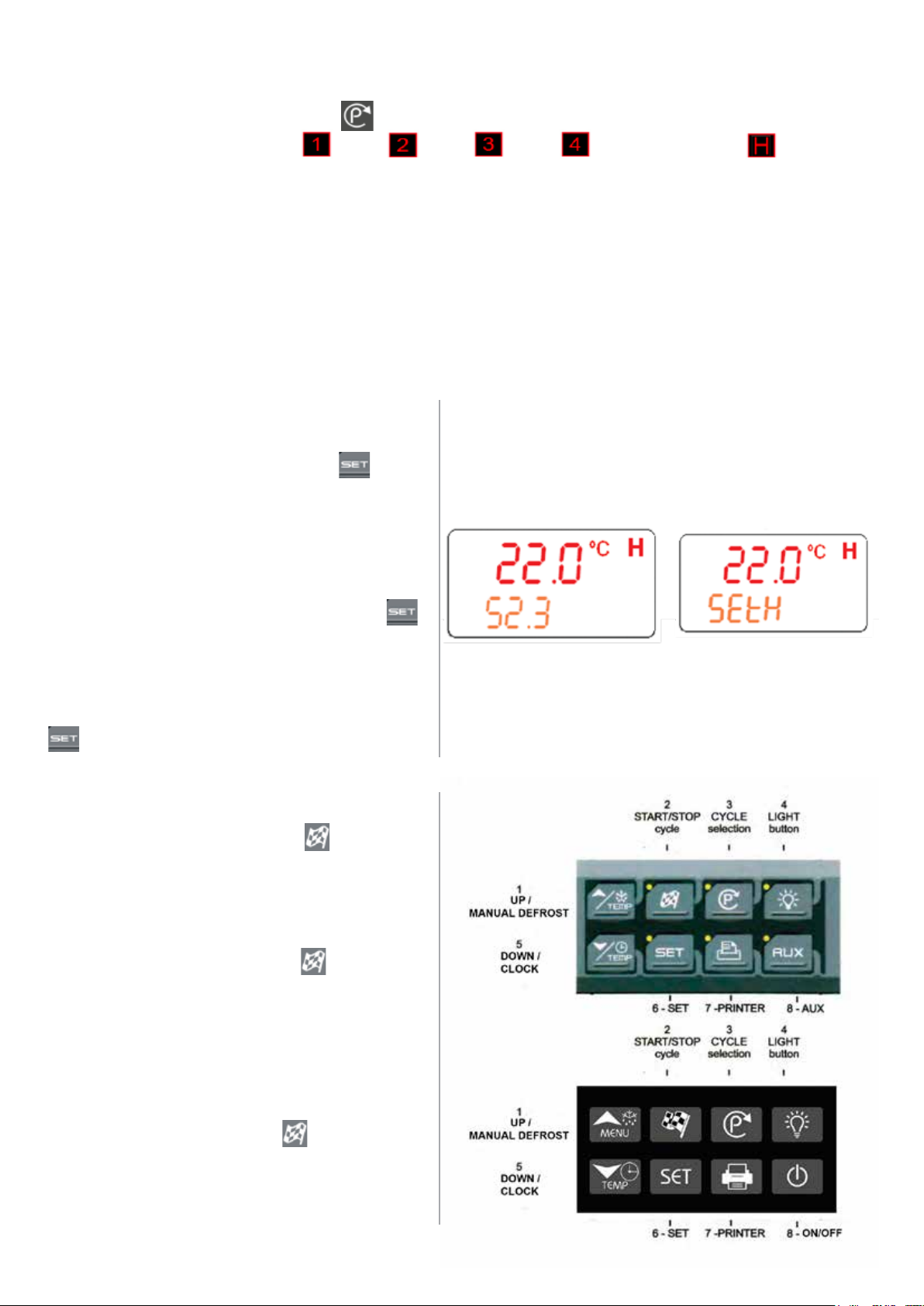

How to select a cycle

Push the to move among the cycles CY1 , CY2 , CY3 , CY4 and the holding

cycle .

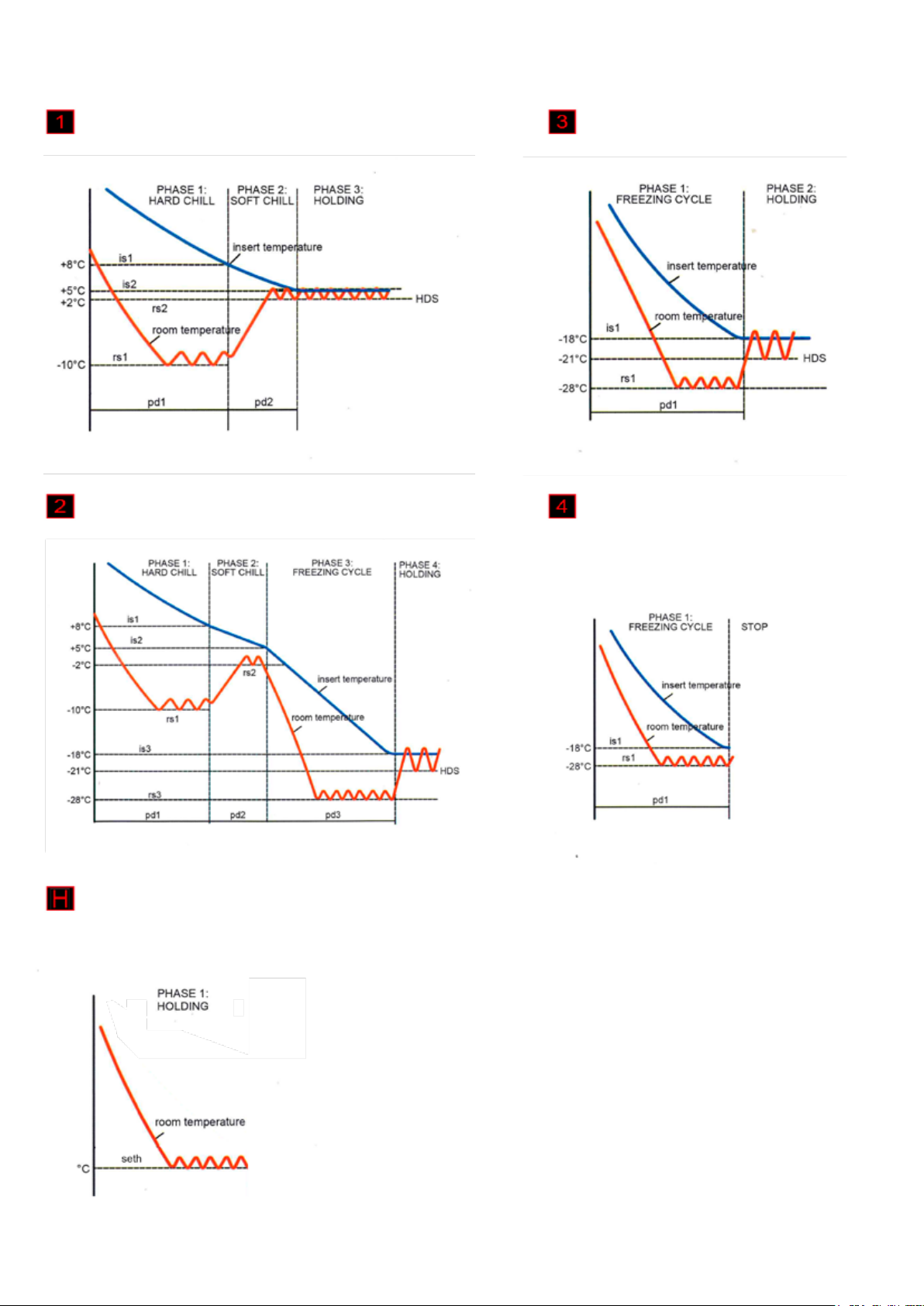

The 5 programs have the default values shown in the diagrams next page.

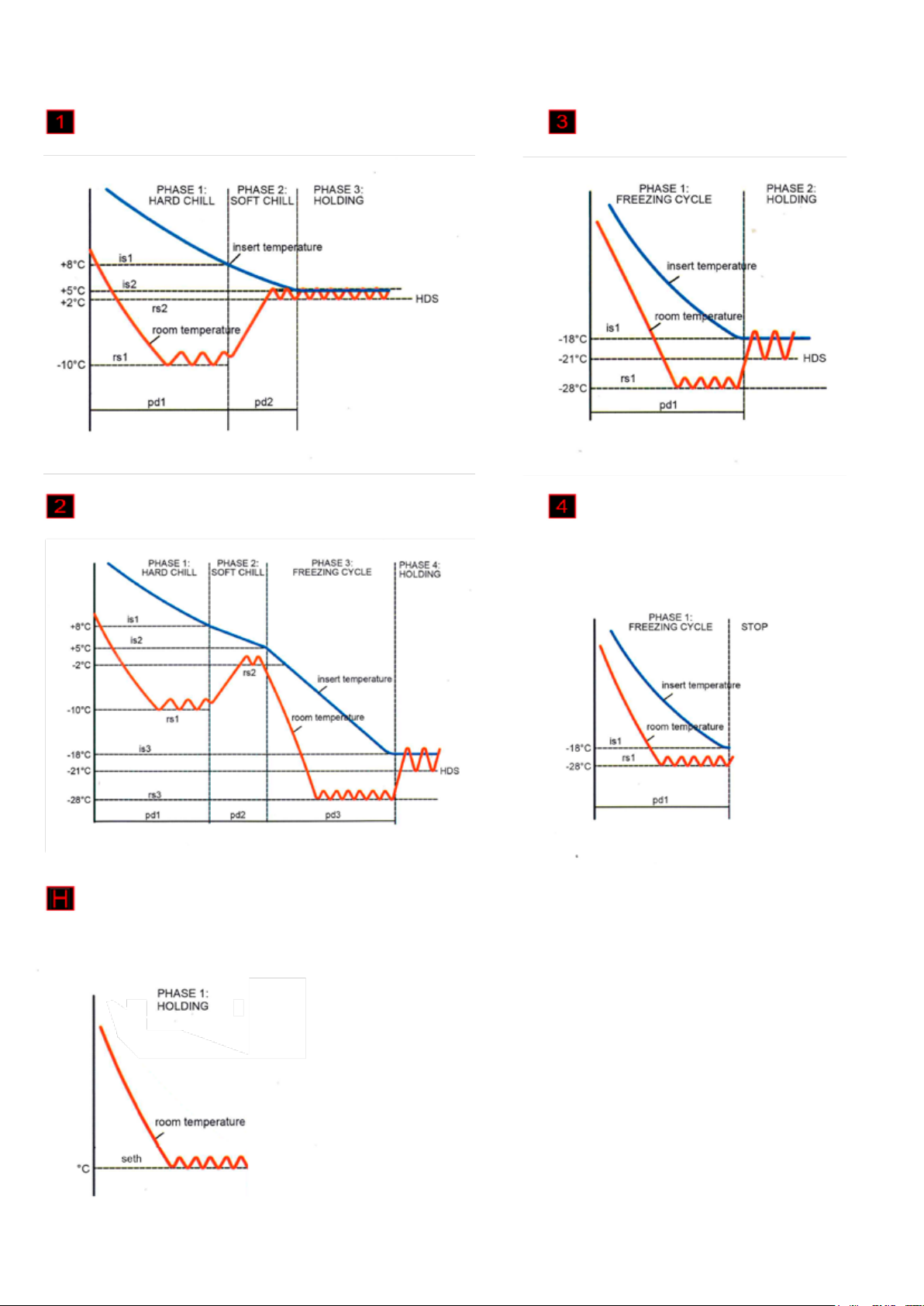

CY1: Fast chilling and conservation. (Hard + soft chilling and holding)

1.

CY2: Chilling and fast freezing. (Hard + soft chilling, freezing and holding)

2.

CY3: Fast freezing. (Fast freezing and holding)

3.

CY4: Fast freezing with alarm and stop. (Only fast freezing)

4.

H: Hold mode function. (Hard chill or freezing)

5.

dEF: For starting a manual defrost.

6.

How to display the holding SET point.

While the Holding cycle is running (H-icon

lighted), push the key.

The Holding set point is displayed on the

upper display and the SETH labels is

displayed on the bottom display.

How to modify the holding SET point.

While the SETH is displayed, hold the

key pressed until the SETH label starts

ashing.

Use the arrow keys to modify the value and

press the key to conrm.

To conrm and exit, push the key again.

How to start a cycle.

Push the key and the selected cycle starts.

The yellow display is switched on.

Compressor is delayed by 3 min.

How to pause a cycle.

Push the key and the compressor and fan

will stop.

Stb will ash in the display during the pause.

Push the key to restart the cycle from the

point of interruption.

In any case the cycle automatically restarts

after the PAU time. (See manual)

How to stop a cycle.

Hold the key pressed untill the yellow

display switch o and the cycle is stopped.

10

Page 11

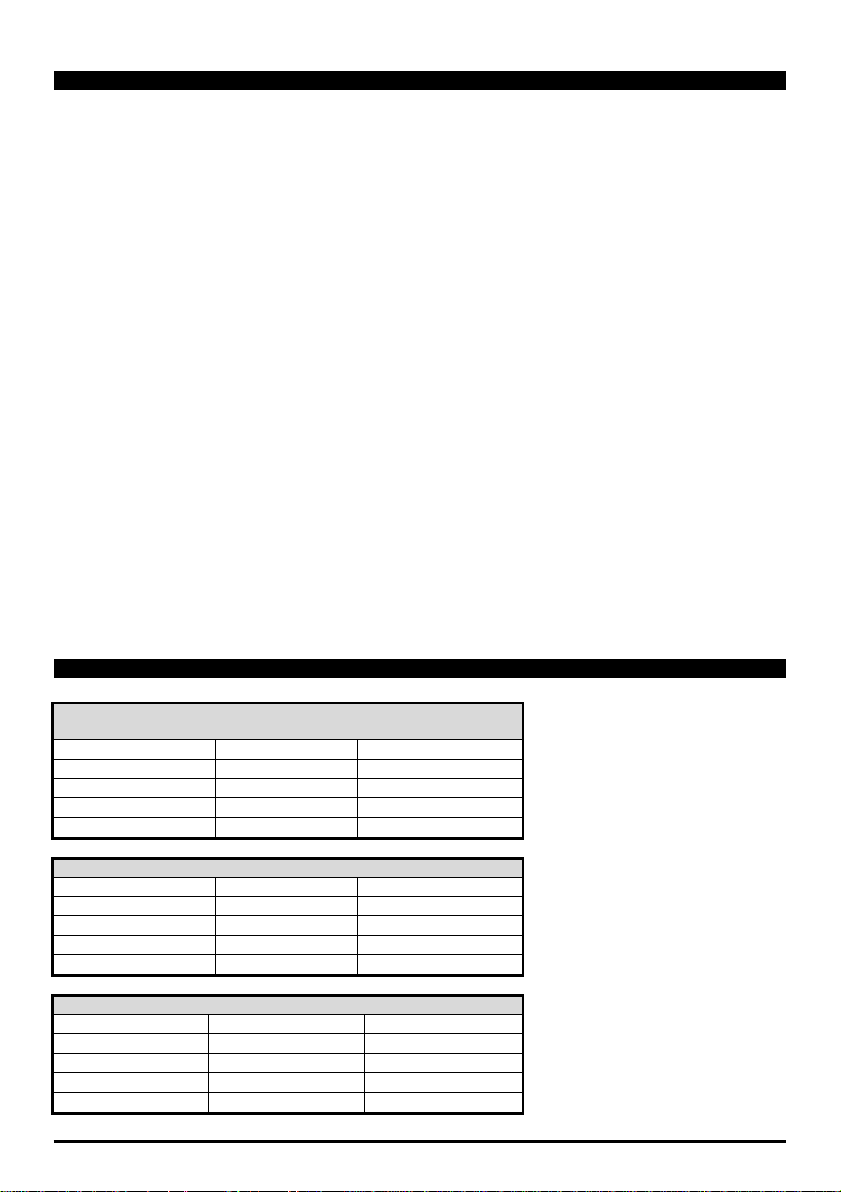

CY1: Hard chill + soft chill + holding

CY2: Hard chill + soft chill + freezing + holding CY4: Freezing cycle then stop

CY3: Freezing cycle + holding

H: Holding mode

11

Page 12

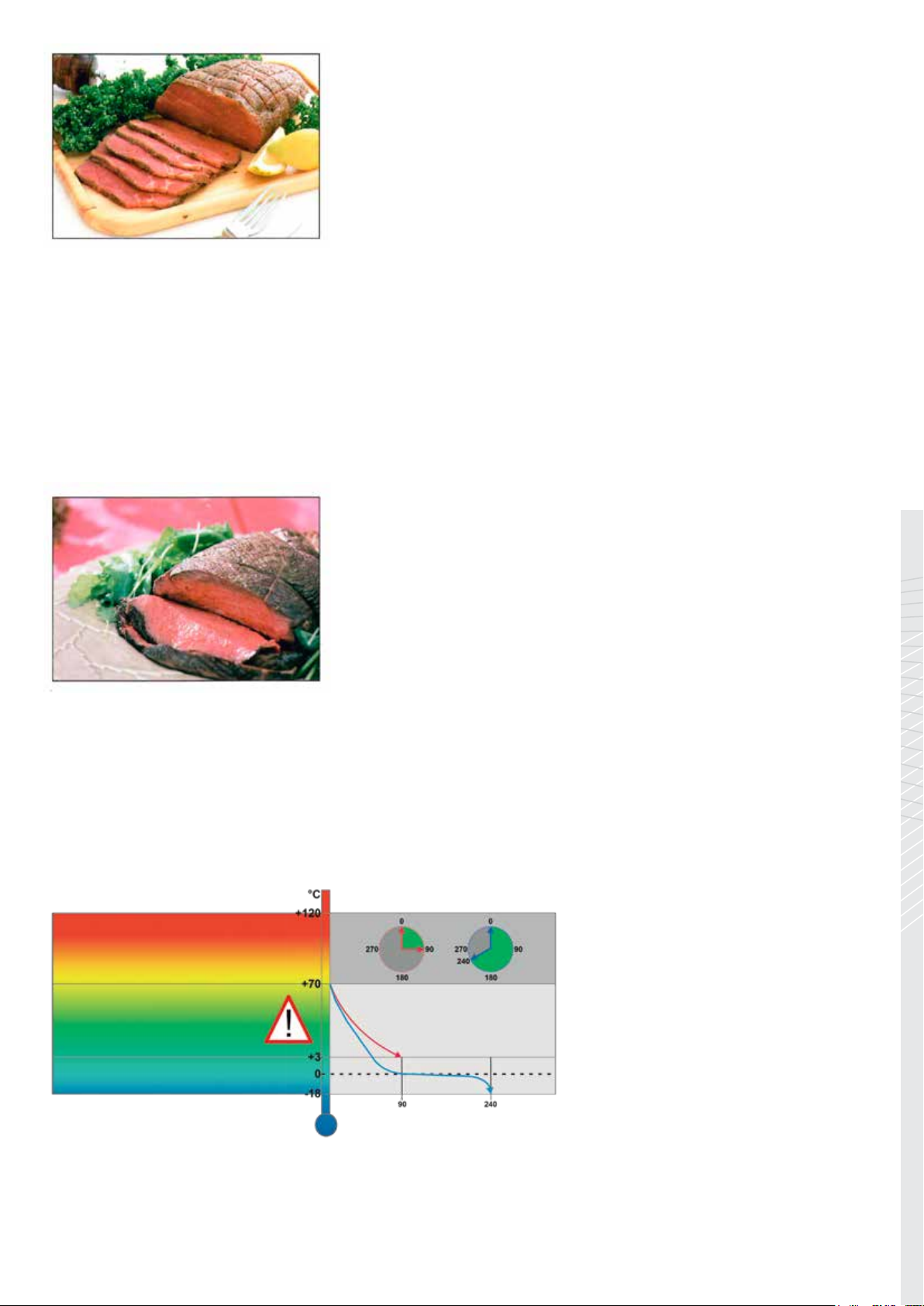

Blast Chillers

+70 °C to +3 °C

The blast chilling cycle reduce the product temperature from

+70 °C to +3 °C in 90 minuttes.

Bacterial generation is accelerating in the gap between +60 °C

and +10 °C, therefore it is essential to cool the product as fast

as possible.

Furthermore vitamins, taste and odour are preserved.

Should then be stored in normally chiller at +2 °C.

Blast Freezers

+70 °C to -18 °C

Bacterials destroyed

Bacterial acceleration

The blast freezing cycle reduce the product temperature from

+70 °C to -18 °C in 240 minuttes.

The fast reduction of the product temperature increases the

lifetime of the product.

Furthermore the quality is preserved without major loss of

weight, liquid and taste.

Should then be stored in normally freezer at -20 °C.

Bacterials in general

Chill Freeze

Bacterial reduction/

stop

rfj_191013

© TEFCOLD A/S 2019

Page 13

REFROIDISSEURS /

CONGÉLATEURS RAPIDES

Manuel d’utilisation

FR

IT

ES

PT

SL

13

25

37

49

61

Page 14

14

Page 15

SOMMAIRE

1.

2.

Informations générales

Consignes de sécurité importantes ..................................................................... 16

Déballage et installation ...................................................................................... 16

Raccordement électrique ..................................................................................... 17

Démarrage du congélateur .................................................................................. 17

Capacité .............................................................................................................. 17

Consignes d’utilisation ......................................................................................... 18

Cycle de refroidissement rapide .......................................................................... 19

Cycle de congélation rapide ................................................................................ 19

Nettoyage et maintenance ................................................................................... 19

Entretien .............................................................................................................. 20

Mise au rebut ....................................................................................................... 20

Guide rapide

3.

Guide rapide quotidien ........................................................................................ 21

Thermostat XB570L / XB590L

Manuel technique ................................................................................................ 73

15

Page 16

CONSIGNES DE SÉCURITÉ IMPORTANTES

1. Pour tirer le meilleur parti du congélateur, nous vous recommandons de lire de manuel d’utilisation.

2. L’utilisateur est responsable d’utiliser l’appareil conformément aux instructions données.

3. Contactez votre revendeur immédiatement en cas de dysfonctionnements.

4. Placez le congélateur dans un endroit sec et ventilé.

5. Conservez le congélateur à l’abri de sources de chaleur importante et ne l’exposez pas à la

lumière directe du soleil.

6. N’oubliez jamais que tous les appareils électriques sont des sources de danger potentiel.

7. Ne stockez pas de matériaux inammables tels que du diluant, de l’essence, etc. dans le

congélateur.

8. Nous déclarons n’avoir pas utilisé d’amiante ou de CFC lors de la construction.

9. L’huile dans le compresseur ne contient pas de PCB.

POUR LES ARMOIRES AVEC RÉFRIGÉRANT R290/R600a!

Ce refroissseur contient un réfrigérant inammable; assurez un endroit bien ventilé

autour de l’armoire. N’utilisez pas des outils mécaniques pour le dégivrage; cela peut

causer des fuites dans le système de refroidissement interne. N’utilisez pas des outils

électrique á l’intérieur de l’armoire.

Chaque réparation de ce réfroidisseur doit être eectué par un réparateur professionel.

(EN 60335-2-89: 2010)

DÉBALLAGE ET INSTALLATION

Retirez la palette en bois et l’emballage. Les surfaces externes sont recouvertes d’un lm de

protection que vous devez retirer avant l’installation.

Pour garantir un bon fonctionnement, il est important que le core soit horizontal. Si le core est doté

de pieds, vous pouvez les régler.

Important !

1. Ne bloquez pas les trous de ventilation.

2. Assurez-vous qu’il y a un espace d’au moins 15 cm entre le core et le mur.

16

Page 17

RACCORDEMENT ÉLECTRIQUE

Les cores BLC3-BLC5 et BLC10 fonctionnent avec 230 V/50 Hz.

Le BLC14 fonctionne avec 3x400 V/50 Hz.

Assurez-vous que le core est connecté à un groupe électrique distinct pour éviter les surcharges.

La prise murale doit être facile d’accès.

Toutes les exigences de mise à la terre stipulées par les autorités locales doivent être respectées. La

prise du congélateur et la prise murale doivent alors fournir la mise à la terre appropriée. En cas de

doute, contactez votre fournisseur local ou électricien autorisé.

Les principaux raccordements électriques doivent être eectués par un électricien professionnel.

DÉMARRAGE DU CONGÉLATEUR

Avant l’utilisation, nous vous recommandons de nettoyer le congélateur (voir la section sur la

maintenance et le nettoyage).

Important !

Si le congélateur a été placé horizontalement pendant le transport, attendez 2 heures avant de le

mettre en marche.

CAPACITÉ

REFROIDISSEURS/CONGÉLATEURS RAPIDES BLC3

Ce modèle peut contenir 3 plateaux avec une capacité de refroidissement rapide de 12 kg et de

congélation rapide de 8 kg.

REFROIDISSEURS/CONGÉLATEURS RAPIDES BLC5

Ce modèle peut contenir 5 plateaux avec une capacité de refroidissement rapide de 18kg et de

congélation rapide de 14kg.

REFROIDISSEURS/CONGÉLATEURS RAPIDES BLC10

Ce modèle peut contenir 10 plateaux avec une capacité de refroidissement rapide de 40kg et de

congélation rapide de 28 kg.

REFROIDISSEURS/CONGÉLATEURS RAPIDES BLC14

Ce modèle peut contenir 14 plateaux avec une capacité de refroidissement rapide de 55kg et de

congélation rapide de 38kg.

17

Page 18

CONSIGNES D’UTILISATION

Si l’appareil reste inactif pendant une période prolongée, procédez de la manière suivante

1. Utilisez le sectionneur automatique pour désactiver la connexion à l’alimentation électrique

principale.

2. Nettoyez bien l’appareil et les zones environnantes.

3. Étalez une ne couche d’huile de cuisine sur les surfaces en acier inoxydable

4. Réalisez toutes les opérations de maintenance

5. Laissez la porte entrebâillée pour empêcher la formation de moisissure et/ou les mauvaises

odeurs.

N’insérez pas d’aliments dont la température est supérieure à 90 °C.

N’empilez pas les éléments à préserver en contact avec les parois internes, ce qui risquerait de

bloquer la circulation de l’air.

Il doit y avoir un espace susant entre les plateaux utilisés an de garantir un débit susant d’air

froid sur tout le produit.

Ne bouchez jamais l’entrée des ventilateurs d’évaporateurs.

Les produits plus diciles à refroidir en raison de leur taille doivent être placés au centre.

Limitez le nombre et la durée d’ouverture de la porte.

Après un refroidissement/une congélation rapides du produit, vous pouvez le stocker dans un core

de préservation après l’avoir correctement protégé. Nous vous conseillons d’appliquer une étiquette

décrivant le contenu du produit, la date de refroidissement/congélation rapide et la date d’expiration.

Une fois le produit refroidi rapidement, préservez-le à une température constante de +2°C alors que

s’il il a été congelé rapidement, préservez-le à une température constante de -20°C. Le refroidisseur

doit être utilisé pour un stockage de courte durée uniquement.

Pour empêcher la contamination bactérienne ou toute autre contamination

de nature biologique, la sonde à aiguille doit être désinfectée après

utilisation.

18

Page 19

CYCLE DE REFROIDISSEMENT RAPIDE

Avec ce mode de fonctionnement, le refroidisseur maintient la température du compartiment de

réfrigération proche de zéro pendant tout le processus de refroidissement an de garantir une baisse

progressive de la température du produit jusqu’à +3°C. Ainsi, aucun cristal de glace ne se forme à

la surface du produit. Cette méthode de refroidissement rapide doit être utilisée de préférence pour

les produits non emballés et dont les caractéristiques physiques/organoleptiques pourraient être

aectées par la formation de glace supercielle (par ex. le poisson)

CYCLE DE CONGÉLATION RAPIDE

Avec ce mode de refroidissement rapide, le refroidisseur rapide maintient la température à une

valeur négative inférieure à -18°C ce qui correspond à la température nale de la congélation rapide.

Pour que la congélation rapide soit réussie et rapide, les aliments doivent être en petits morceaux,

en particulier si sa teneur en graisse est élevée. Les plus gros morceaux doivent être placés sur

les plateaux centraux. S’il faut plus de temps que le temps habituel pour la congélation rapide et

que la taille des morceaux ne peut être réduite, réduisez la quantité et refroidissez préalablement

le compartiment du refroidisseur en démarrant un cycle de congélation rapide à vide avant la

congélation rapide du produit.

NETTOYAGE ET MAINTENANCE

Coupez le raccordement électrique au niveau de la prise.

Le congélateur doit être nettoyé régulièrement. Nettoyez les surfaces externes et internes du

congélateur à l’aide d’une solution savonneuse douce puis séchez. Les surfaces externes peuvent

être entretenues à l’aide d’huile pour l’acier.

Ne pulvérisez pas l’appareil avec des jets d’eau directs ou à l’aide d’appareils haute pression.

N’utilisez pas de laine de fer, de brosses ou de racloirs pour nettoyer l’acier étant donné que des

particules ferreuses risquent de se déposer et, lors de leur oxydation, de former de la rouille.

Pour éliminer les résidus secs, utilisez des spatules en bois ou en plastique ou des tampons abrasifs

en caoutchouc.

Nettoyage du condensateur

Nettoyez le condensateur régulièrement

Comme les ailettes du condensateur sont très tranchantes, portez toujours des gants de protection

pour réaliser les étapes suivantes. Utilisez des masques et des lunettes de protection s’il y a de la

poussière

Lorsque le condensateur présente un dépôt de poussière correspondant aux ailettes, vous pouvez

l’éliminer à l’aide d’un appareil d’aspiration ou avec une brosse, en exerçant un mouvement vertical

dans le sens des ailettes.

N’utilisez aucun autre instrument susceptible de déformer les ailettes et, par conséquent, d’aecter

l’ecacité de l’appareil.

19

Page 20

Pour le nettoyage, procédez comme suit :

1. Ouvrez la porte (A) des appareils.

2. Retirez le panneau inférieur (B) du compartiment technique : pour cela, retirez les vis (C)

3. Vous pouvez maintenant nettoyer les ailettes du condensateur (D) à l’aide des outils et des

dispositifs de protection adaptés.

4. Une fois le nettoyage terminé, fermez le panneau de commande et xez-le à l’aide des vis que

vous avez retirées.

ENTRETIEN

Le système de refroidissement est un système fermé hermétiquement qui ne nécessite pas d’être

surveillé, mais uniquement d’être nettoyé.

Si le congélateur ne refroidit pas, vériez si la raison est une panne de courant.

Si vous ne pouvez pas détecter la raison de la défaillance du congélateur, veuillez contacter votre

fournisseur. Veuillez indiquer le modèle et le numéro de série du congélateur. Vous pourrez trouver

ces informations sur l’étiquette de cote énergétique placée à l’intérieur du congélateur en haut à

droite.

MISE AU REBUT

La mise au rebut du congélateur doit être eectuée dans le respect de l’environnement. Veuillez

consulter la réglementation existante sur la mise au rebut. Il peut y avoir des exigences et conditions

spéciales à respecter.

20

Page 21

GUIDE RAPIDE

Guide rapide quotidien

21

Page 22

SÉLECTIONNER UN CYCLE

Appuyer en séquence sur la touche pour sélectionner un cycle, lors de chaque pression

l’écran ache la sélection CY1 , CY2 , CY3 , CY4 , cycle de maintien .

Les 5 programmes ont les valeurs par défaut montrées dans les diagrammes page suivante.

CY1: Refroidissement rapide et début de la phase de conservation.

1.

CY2: Refroidissement rapide, surgélation rapide et début de la phase de conservation.

2.

CY3: Surgélation rapide et début de la phase de conservation.

3.

CY4: Congélation rapide avec alarme et arrêt.

4.

H: Fin du cycle de congélation et début de la phase de conservation (sélectionnable).

5.

dEF: S’assurer qu’aucun cycle ne soit actif ou que la conservation est en cours.

6.

Acheur les valeurs réglage.

Lorsqu’un maintien est sélectionné, l’icône H

allumée, en appuyant sur la touche

La valeur suivante est achée:

SETH = valeur du thermostat de la cellule en

phase de maintien.

Modication.

Avant 5 secondes, appuyer sur la touche

pendant 2 secondes, et l’inscription achée

clignotent.

Modier la valeur avec les touches èche.

Conrmer et quitter : appuyer à nouveau sur

Démarrer un cycle.

Appuyer et relâcher le bouton .

La LED jaune correspondante s’allume.

Le compresseur est retardé de 3 min.

Arrêt manuel.

Appuyer et relâcher le bouton .

la LED jaune clignote.

Le redémarrage s’eectue en appuyant sur la

touche ou automatiquement après la durée de

pause PAU.

Arrêt dénitif.

Maintenir appuyé le bouton .

La LED jaune s’éteint.

22

Page 23

CY1: Refroidissement rapide

et début de la phase de conservation

CY3: Surgélation rapide et début

de la phase de conservation

CY2: Refroidissement rapide, surgélation rapide

et début de la phase de conservation

H: Fin du cycle de congélation et début de la

phase de conservation

CY4: Congélation rapide avec

alarme et arrêt

23

Page 24

Refroidisseurs rapides

+70 °C to +3 °C

Le cycle de refroidissement rapide réduit la température du

produit de +70 °C à +3 °C en 90 minutes.

La génération bactérienne s’accélère dans l’intervalle entre

+60 °C et +10 °C ; il est donc essentiel de refroidir le produit le

plus rapidement possible.

De cette manière, les vitamines, le goût et l’odeur sont

préservés.

Après, il faut stocker les produits alimentaires dans un

refroidisseur normal à +2 °C.

Congélateurs rapides

+70 °C to -18 °C

Bactéries détruites

Accélération bactérienne

Le cycle de congélation rapide réduit la température du produit

de +70 °C à -18 °C en 240 minutes.

La réduction rapide de la température du produit augmente la

durée de vie du produit. De plus, la qualité est préservée sans

perte importante de poids, de liquide ou de goût.

Après, il faut stocker les produits alimentaires dans un

congélateur normal à -20 °C.

Bactéries en général

Refroidissement Congélateur

Réduction / arrêt bactérien

rfj_191013

© TEFCOLD A/S 2019

Page 25

ABBATTITORI/CONGELATORI

Manuale d’uso

IT

ES

PT

SL

25

37

49

61

Page 26

26

Page 27

SOMMARIO

1.

2.

Informazioni generali

Istruzioni di sicurezza .......................................................................................... 28

Disimballaggio e installazione ............................................................................. 28

Collegamenti elettrici ........................................................................................... 29

Avviamento .......................................................................................................... 29

Capacità .............................................................................................................. 29

Raccomandazioni per l’uso ................................................................................. 30

Ciclo di abbattimento ........................................................................................... 31

Ciclo di congelamento rapido .............................................................................. 31

Pulizia e manutenzione ....................................................................................... 31

Servizio assistenza .............................................................................................. 32

Smaltimento ......................................................................................................... 32

Guida rapida

3.

Guida pratica quotidiana ...................................................................................... 33

Termostato XB570L / XB590L

Libretto di istruzioni .............................................................................................. 73

27

Page 28

ISTRUZIONI DI SICUREZZA

1. Per un corretto funzionamento dell’armadio frigo consigliamo di leggere attentamente questo

manuale di istruzioni.

2. È responsabilità dell’utente utilizzare il dispositivo in conformità alle istruzioni date.

3. In caso di guasto contattare immediatamente il proprio rivenditore.

4. Posizionare l’armadio in un luogo asciutto e ventilato.

5. Tenere l’armadio frigo lontano da fonti di calore intenso e non esporlo direttamente alla luce del

sole.

6. Ricordare sempre che tutti i dispositivi elettrici sono potenziali fonti di pericolo.

7. Non conservare materiale inammabile come solventi, benzina, ecc. all’interno dell’armadio.

8. Si dichiara che durante la costruzione non sono stati utilizzati CFC o amianto.

9. L’olio nel compressore non contiene PCB.

SOLO PER APPARECCHI CON REFRIGERANTE R290/R600a!

Questo apparecchio contiene un refrigerante inammabile: assicurarsi che vi sia una

buona ventilazione intorno all’apparecchio. Non utilizzare dispositivi meccanici in fase

di scongelamento per evitare perdite del sistema di rareddamento. Non utilizzare

dispositivi elettrici all’interno del vano di conservazione refrigerato.

Qualsiasi riparazione dell’apparecchio deve essere svolta da un tecnico qualicato

(EN 60335-2-89: 2010).

DISIMBALLAGGIO E INSTALLAZIONE

Rimuovere il pallet in legno e l’imballaggio. Le superci esterne sono ricoperte da una pellicola di

protezione che deve essere rimossa prima dell’installazione.

Per garantire il corretto funzionamento è importante che l’armadio frigo si trovi in piano. L’armadio

frigo è dotato di piedini regolabili.

Importante !

1. Non ostruire i fori di ventilazione.

2. Vericare che tra l’armadio frigo e il muro vi sia uno spazio libero di almeno 15 cm.

28

Page 29

COLLEGAMENTI ELETTRICI

Gli armadi BLC3, BLC5 e BLC10 funzionano a 230 V/50 Hz.

L’armadio BLC14 funziona a 3x400 V/50 Hz.

Per evitare il sovraccarico, accertarsi che l’armadio sia collegato a un gruppo elettrico separato.

La presa a muro deve essere facilmente accessibile.

È necessario osservare tutti i requisiti di messa a terra previsti dall’ente locale per l’energia elettrica.

La spina e la presa a muro dell’armadio dovrebbero essere correttamente collegate a terra. In caso di

dubbi contattare il fornitore locale o un elettricista autorizzato.

I collegamenti elettrici principali devono essere eseguiti da elettricisti qualicati.

AVVIAMENTO

Prima dell’uso controllare che l’armadio sia pulito; consultare in merito la sezione relativa a

manutenzione e pulizia.

Importante !

Se l’armadio frigo è stato trasportato in posizione orizzontale attendere 2 ore prima dell’attivazione.

CAPACITÀ

ABBATTITORE/CONGELATORE BLC3

Il modello può contenere 3 vassoi con una capacità di abbattimento di 12 kg e 8 kg in caso di

congelamento rapido.

ABBATTITORE/CONGELATORE BLC5

Il modello può contenere 5 vassoi con una capacità di abbattimento di 18 kg e 14 kg in caso di

congelamento rapido.

ABBATTITORE/CONGELATORE BLC10

Il modello può contenere 10 vassoi con una capacità di abbattimento di 40 kg e 28 kg in caso di

congelamento rapido.

ABBATTITORE/CONGELATORE BLC14

Il modello può contenere 14 vassoi con una capacità di abbattimento di 55 kg e 38 kg in caso di

congelamento rapido.

29

Page 30

RACCOMANDAZIONI PER L’USO

Se l’apparecchio rimane inattivo per un periodo di tempo prolungato, procedere come segue.

1. Usare l’interruttore automatico di isolamento per disattivare il collegamento con la linea elettrica.

2. Pulire accuratamente l’apparecchio e le zone circostanti.

3. Applicare un sottile strato di olio da cucina sulle superci in acciaio inossidabile.

4. Eseguire tutte le operazioni di manutenzione.

5. Lasciare lo sportello socchiuso per prevenire la formazione di mua e/o odori sgradevoli.

Non riporre nell’armadio alimenti con una temperatura superiore a 90 °C.

Non appoggiare gli alimenti da conservare a contatto con le pareti interne bloccando così la

circolazione dell’aria.

Accertarsi che la distanza tra i vassoi sia tale da garantire un suciente usso di aria fredda su tutto

il prodotto.

Non ostruire l’ingresso delle ventole dell’evaporatore.

I prodotti più dicili da refrigerare per dimensioni devono essere posizionati al centro.

Limitare il numero di volte e la durata del tempo di apertura degli sportelli.

Una volta sottoposto ad abbattimento di temperatura/congelamento rapido, il prodotto può essere

conservato un armadio di conservazione. A tale scopo, esso dovrà essere debitamente protetto e

munito di etichetta indicante il contenuto, la data di abbattimento/congelamento rapido e la data di

scadenza. Dopo l’abbattimento di temperatura, il prodotto deve essere conservato a una temperatura

costante di +2°C in caso di congelamento rapido il prodotto dovrà essere conservato a una

temperatura costante di -20°C.

L’abbattitore deve essere utilizzato per la conservazione solo per brevi periodi.

Per evitare contaminazioni di natura batterica o altra natura biologica,

sterilizzare la sonda ad ago dopo l’uso.

30

Page 31

CICLO DI ABBATTIMENTO

In questa modalità operativa, l’abbattitore mantiene la temperatura dello scomparto di refrigerazione

prossima allo zero durante l’intero processo di abbattimento, assicurando così una diminuzione

graduale della temperatura del prodotto no a +3°C. In questo modo, si evita la formazione di cristalli

di ghiaccio sulla supercie del prodotto. Questo metodo di abbattimento della temperatura è da

preferirsi nel caso di prodotti non confezionati e le cui caratteristiche sico-organolettiche potrebbero

risultare compromesse dalla formazione di ghiaccio superciale (ad es. pesce)

CICLO DI CONGELAMENTO RAPIDO

In questa modalità operativa, l’abbattitore mantiene la temperatura a un valore negativo inferiore

a -18°C ovvero la temperatura nale per il congelamento rapido. Per eettuare un congelamento

rapido in maniera rapida ed ecace, il cibo deve essere inserito in piccole pezzature, specialmente

se ha un contenuto di grassi elevato. Posizionare i pezzi di dimensioni maggiori nei vassoi centrali.

Se il congelamento rapido richiede più tempo della norma e non è possibile ridurre la pezzatura

del cibo, diminuire la quantità e prerareddare lo scomparto di abbattimento avviando un ciclo di

congelamento rapido a vuoto prima di eettuare quello con il prodotto.

PULIZIA E MANUTENZIONE

Scollegare l’apparecchio dalla presa.

Il dispositivo deve essere pulito periodicamente. Pulire le superci interne ed esterne dell’armadio

con una soluzione detergente delicata e asciugare. È possibile eseguire una manutenzione delle

superci esterne in acciaio utilizzando appositi oli.

Non utilizzare getti diretti di acqua sull’apparecchio né pulitori ad alta pressione.

Non usare lana metallica né spazzole o raschiatori in ferro per pulire le parti in acciaio inossidabile

poiché le particelle ferrose che si depositano potrebbero, ossidando, causare la formazione di

ruggine.

Per rimuovere residui incrostati, usare una spatola di legno o plastica oppure una spugna in gomma

abrasiva.

Pulizia del condensatore

Pulire il condensatore periodicamente

Essendo le alette del condensatore molto alate, durante le fasi seguenti indossare sempre guanti

protettivi. In presenza di polvere, usare maschere e occhiali protettivi.

Qualora il condensatore presenti depositi di polvere in corrispondenza delle alette, rimuoverli

utilizzando un dispositivo di aspirazione o una spazzola compiendo un movimento verticale lungo

la direzione delle alette stesse.

Non utilizzare nessun altro strumento che potrebbe deformare le alette e compromettere

l’ecienza dell’apparecchio.

31

Page 32

Per la pulizia procedere come segue:

1. Aprire lo sportello (A) dell’apparecchio.

2. Rimuovere il pannello inferiore (B) dallo scomparto tecnico, a tale scopo rimuovere i le viti di

ssaggio (C).

3. Servendosi di idonei strumenti e dispositivi di protezione, è ora è possibile pulire la parte alettata

del condensatore (D).

4. Terminate le operazioni di pulizia, chiudere il quadro di comando e ssarlo con le viti

precedentemente rimosse.

SERVIZIO ASSISTENZA

Il sistema di rareddamento è un sistema chiuso ermeticamente e non richiede supervisione, è

suciente la pulizia.

Se l’armadio frigo non si raredda, controllare che non si tratti di un’interruzione di corrente.

Se non è possibile stabilire la causa del guasto, contattare il fornitore. Indicare il modello e il numero

di serie del dispositivo. Queste informazioni sono riportate sulla targhetta che si trova all’interno

dell’armadio frigo, in alto a destra.

SMALTIMENTO

L’armadio frigo deve essere smaltito in modo ambientalmente corretto. Attenersi ai regolamenti sullo

smaltimento esistenti. Potrebbero esserci condizioni e requisiti speciali da osservare.

32

Page 33

GUIDA RAPIDA

Guida pratica quotidiana

3333

Page 34

SELEZIONARE UN CICLO

Premere in sequenza il tasto per selezionare un ciclo, ad ogni pressione il display visualizza

la selezion CY1 , CY2 , CY3 , CY4 , ciclo di mantenimento .

I programmi di 5 hanno i valori di default indicati nei diagrammi pagina seguente.

CY1: Ciclo di abbattimento e conservazione a temp. positiva.

1.

CY2: Ciclo di abbattimento e surgelamento con conservazione.

2.

CY3: Ciclo di surgelamento rapido e conservazione.

3.

CY4: Ciclo di surgelamento rapido senza conservazione.

4.

H: Ciclo di mantenimento

5.

dEF: Inoltrata una richiesta di sbrinamento.

6.

Visualizzare i set de regolazione.

Quando è selezionato un mantenimento, icona

H accesa, premendo il tasto si visualizza:

- SEtH = set termostato cella in mantenimento.

Modica.

Entro 5 secondi premere il tasto set per 2

secondi, lampeggia il led del tasto e la

scritta a display.

Modicare il valore con i tasti freccia.

Conferma e uscita, premere ancora .

Avviare un ciclo.

Premere e rilasciare il pulsante .

Il corrispondente led giallo si illumina.

Compressore è ritardato di 3 minuti.

Fermata manuale.

Premere e rilasciare il pulsante , il led

giallo lampeggia. La ripartenza viene data

ripremendo il tasto o in automatico dopo il

tempo PAU.

Fermata denitiva.

Tenere premuto il pulsante , il led giallo si

spegne.

34

Page 35

CY1: Abbattimento + rareddamento controllato

+ conservazione

CY3: Surgelamento rapido +

conservazione

CY2: Abbattimento + rareddamento controllato

+ surgelamento rapido + conservazione

H: Ciclo di mantenimento

CY4: Surgelamento rapido senza

conservazione

35

Page 36

Abbattitori

+70 °C to +3 °C

Il ciclo di abbattimento a ridurre la temperatura del prodotto da

+70 °C al +3 °C a 90 minuti.

Generazione batterica sta accelerando nello spazio tra +60 °C

e +10 °C, quindi è indispensabile per rareddare il prodotto il

più velocemente possibile.

Inoltre le vitamine, il gusto e l’odore

Dovrebbe poi essere conservati in refrigeratore normalmente a + 2 °C.

Congelatori

+70 °C to -18 °C

Bacterials distrutti

Accelerazione batterica

Il ciclo di surgelazione a ridurre la temperatura del prodotto da

+70 °C a -18 °C a 240 minuti.

La rapida riduzione della temperatura del prodotto aumenta la

durata del prodotto.

Inoltre, la qualità viene conservato senza grave perdita di peso,

liquidi e gusto.

Dovrebbe poi essere conservato in congelatore normalmente a -20 °C.

Bacterials in generale

Abbattitori Congelatori

Riduzione batterica/stop

rfj_191013

© TEFCOLD A/S 2019

Page 37

ABATIDORES/CONGELADORES

Manual del usuario

ES 37

PT

SL

49

61

Page 38

38

Page 39

CONTENIDO

1.

2.

Información general

Instrucciones de seguridad importantes .............................................................. 40

Desembalaje e instalación ................................................................................... 40

Conexión eléctrica ............................................................................................... 41

Puesta en marcha de la unidad ........................................................................... 41

Capacidad ........................................................................................................... 41

Recomendaciones de uso ................................................................................... 42

Ciclo de abatimiento ............................................................................................ 43

Ciclo de congelación de choque .......................................................................... 43

Limpieza y mantenimiento ................................................................................... 43

En caso de avería ................................................................................................ 44

Eliminación .......................................................................................................... 44

Guía rápida

3.

Guía rápida diaria ................................................................................................. 45

Termostato XB570L / XB590L

Manual técnico ..................................................................................................... 73

39

Page 40

INSTRUCCIONES DE SEGURIDAD

IMPORTANTES

1. Para obtener el máximo rendimiento del armario, recomendamos la lectura de este manual de

instrucciones.

2. Es responsabilidad del usuario utilizar el electrodoméstico de acuerdo con las instrucciones

facilitadas.

3. Póngase en contacto inmediatamente con su concesionario en caso de cualquier anomalía.

4. Coloque el armario en un lugar seco y ventilado.

5. Mantenga el armario alejado de fuentes de mucho calor y no lo exponga a la luz solar directa.

6. Tenga siempre en cuenta que todos los dispositivos eléctricos pueden ser el origen de peligros

potenciales.

7. No almacene materiales inamables como disolvente, gasolina, etc., en el armario.

8. Declaramos que no se ha usado amianto ni CFC en su construcción.

9. El aceite del compresor no contiene PCB.

¡SOLO PARA LOS MODELOS QUE INCORPOREN REFRIGERANTE R290/R600a!

Este electrodoméstico contiene un refrigerante inamable. Por lo tanto, asegúrese de

disponer de una buena ventilación a su alrededor. No utilice dispositivos mecánicos

para descongelar el electrodoméstico, ya que podría causar fugas en el sistema

de refrigeración.No utilice aparatos eléctricos en el interior del compartimento de

almacenamiento refrigerado.

Deje cualquier reparación del electrodoméstico en manos de un técnico cualicado

(EN 60335-2-89: 2010).

DESEMBALAJE E INSTALACIÓN

Retire el palet de madera y el embalaje. Las supercies exteriores llevan una lámina de protección

que se debe retirar antes de la instalación.

Para asegurar un correcto funcionamiento es importante que el armario esté nivelado. Si el armario

se suministra con patas, se pueden ajustar.

¡Importante!

1. No bloquee los oricios de ventilación.

2. Asegúrese de dejar al menos 15 cm de espacio libre entre el armario y la pared.

40

Page 41

CONEXIÓN ELÉCTRICA

Los armarios BLC3-BLC5 y BLC10 funcionan con 230 V/50 Hz.

BLC14 funciona con 3x400 V/50 Hz.

Asegúrese de que el armario esté conectado a un grupo eléctrico aparte para evitar sobrecargas.

La toma eléctrica de la pared debe ser fácilmente accesible.

Se deben cumplir todos los requisitos de conexión a tierra estipulados por las empresas de

suministro eléctrico de su país. El enchufe del armario y la toma de la pared deben tener una

conexión a tierra correcta. En caso de duda, póngase en contacto con su proveedor local o un

electricista homologado.

Las conexiones eléctricas del suministro principal las deben efectuar electricistas con experiencia.

PUESTA EN MARCHA DE LA UNIDAD

Antes del uso, recomendamos limpiar el armario; remítase a la sección sobre mantenimiento y

limpieza.

¡Importante!

Si el armario se ha colocado horizontalmente durante el transporte, espere 2 horas antes de

ponerlo en marcha.

CAPACIDAD

ABATIDOR / CONGELADOR BLC3

Modelo adecuado para contener 3 bandejas con capacidad de abatimiento de 12 kg y 8 kg en

congelación de choque.

ABATIDOR / CONGELADOR BLC5

Modelo adecuado para contener 5 bandejas con capacidad de abatimiento de 18kg y 14kg en

congelación de choque.

ABATIDOR / CONGELADOR BLC10

Modelo adecuado para contener 10 bandejas con capacidad de abatimiento de 40kg y 28 kg en

congelación de choque.

ABATIDOR / CONGELADOR BLC14

Modelo adecuado para contener 14 bandejas con capacidad de abatimiento de 55kg y 38kg en

congelación de choque.

41

Page 42

RECOMENDACIONES DE USO

Si el equipo va a estar inactivo durante mucho tiempo, proceda del siguiente modo

1. Use el seccionador para desactivar la conexión con la red eléctrica.

2. Limpie a fondo el equipo y el área circundante.

3. Aplique una na capa de aceite de cocina sobre las supercies de acero inoxidable.

4. Realice todas las operaciones de mantenimiento

5. Deje la puerta entreabierta para evitar la formación de moho y/o de olores desagradables.

No introduzca alimentos a temperaturas por encima de 90 °C.

No apile los materiales que desea conservar en contacto con las paredes internas de forma que

bloqueen la circulación de aire.

Debe haber suciente espacio entre las bandejas, a n de garantizar un ujo suciente de aire frío

por todo el producto.

Nunca obstruya la entrada de los ventiladores de evaporación.

Los productos más difíciles de enfriar por su tamaño se deben colocar en el centro.

Limite el número de veces y el tiempo de apertura de la puerta.

Después de abatir/congelar el producto, se puede guardar en un armario de conservación una

vez protegido debidamente. Es conveniente colocar una etiqueta que describa el contenido del

producto, la fecha de abatimiento/congelación y la de caducidad. Si el producto se ha abatido, debe

conservarse a una temperatura constante de +2 °C, mientras que, si se ha congelado por choque,

debe conservarse a una temperatura constante de -20 °C.

El abatidor solo se debe usar para periodos cortos de conservación.

Para evitar la contaminación bacteriana o biológica de otro tipo, la sonda

de aguja se debe desinfectar después de cada uso.

42

Page 43

CICLO DE ABATIMIENTO

Con esta modalidad de funcionamiento, el abatidor mantienen la temperatura del compartimento

refrigerador cerca de cero durante todo el proceso de abatimiento para garantizar un descenso

gradual de la temperatura del producto hasta +3 °C.De este modo, no se forman cristales de

hielo en la supercie del producto. El método de abatimiento se debe usar, preferentemente, para

productos no envasados y cuyas características físicas/organolépticas pueden degradarse debido a

la formación de hielo supercial (p. ej., pescado)

CICLO DE CONGELACIÓN DE CHOQUE

Con esta modalidad de abatimiento, el abatidor mantiene la temperatura en un valor negativo

inferior a -18 °C que es la temperatura nal de la congelación de choque. Para que la congelación

de choque se produzca rápidamente y con éxito, la comida debe estar en piezas pequeñas,

especialmente si tiene un alto contenido en grasa. Las piezas más grandes se deben situar en las

bandejas centrales. Si la congelación de choque tarda más tiempo del estándar y no se pueden

reducir los tamaños, reduzca la cantidad y enfríe previamente el compartimento del abatidor

iniciando un ciclo de congelación de choque antes de congelar el producto.

LIMPIEZA Y MANTENIMIENTO

Desenchufe el equipo por la toma de corriente.

El armario se debe limpiar periódicamente. Limpie las supercies externas e internas del armario con

una solución jabonosa ligera y séquelas después con un trapo. Las supercies externas se pueden

mantener usando aceite de máquina.

No pulverice agua directamente sobre el aparato ni use aparatos de alta presión.

No use lana de acero, cepillos ni rascadores para limpiar el acero inoxidable, porque podrían

depositarse partículas ferrosas que podrían oxidarse.

Para eliminar los residuos persistentes, use espátulas de madera o plástico o esponjas de goma

abrasivas.

Limpie el condensador

Limpie el condensador periódicamente

Las láminas del condensador están muy aladas: lleve siempre guantes protectores para las

siguientes fases. Use máscara y gafas protectoras en presencia de polvo.

Siempre que el condensador tenga un depósito de polvo en la zona de las láminas, puede

eliminarlo usando un dispositivo aspirador o un cepillo aplicado en movimientos verticales a lo

largo de la dirección de las aletas.

No use ningún otro instrumento porque podría deformar las láminas y, por tanto, afectar a la

eciencia del equipo.

43

Page 44

Para limpiar, proceda como sigue:

1. Abra la puerta (A) del equipo.

2. Retire el panel inferior (B) del compartimento técnico: para ello, quite los tornillos de sujeción (C)

3. Ahora puede limpiar la parte laminada del condensador (D) usando herramientas y dispositivos

de protección adecuados.

4. Después de limpiar, cierre el panel de control y fíjelo con los tornillos que retiró previamente.

EN CASO DE AVERÍA

El sistema de refrigeración es un sistema sellado herméticamente que no requiere supervisión, solo

limpieza.

Si el armario no enfría, compruebe si el motivo es un corte de suministro eléctrico.

Si no puede encontrar el motivo de la avería del armario, póngase en contacto con su proveedor.

Indique el modelo y el número de serie del armario. Puede encontrar dicha información en la etiqueta

de características situada en el interior del armario, en el lado superior derecho.

ELIMINACIÓN

El armario se debe eliminar de forma respetuosa con el medio ambiente. Tenga en cuenta la

normativa existente en cuanto a residuos. Es posible que haya requisitos y condiciones especiales

que deban cumplirse.

44

Page 45

GUÍA RÁPIDA

Guía rápida diaria

45

Page 46

SELECCIONAR UN CICLO

Pulse la tecla para seleccionar el ciclo deseado CY1 , CY2 , CY3 , CY4 ,

ciclo de mantenimiento .

Los 5 programas tienen los valores por defecto mostrados en los diagramas de la página

siguiente.

CY1: Enfriamiento rápido y conservación a temp. positiva.

1.

CY2: Enfriamiento rápido y congelación con conservación.

2.

CY3: Congelación rápida y conservación.

3.

CY4: Congelación rápida sin conservación.

4.

H: El ciclo de mantenimiento.

5.

dEF: Activará una descongelación.

6.

Ver la temperatura de mantenimiento.

Si un ciclo de enfriamiento rápido prevé el

mantenimiento, pulse y suelte la tecla ,

y se mostrará su valor HdS, durante 5

segundos.

Para modicar la temperatura de

mantenimiento.

Pulse la tecla durante 5 s hasta que el

parámetro HdS parpadea, use las echas para

modicar el valor.

Para conrmar: pulse la tecla .

Habilitar un ciclo.

Pulse y suelte la tecla .

El led correspondiente amarillo se enciende.

El compresor se retrasa 3 min.

Paro manual.

Pulse y suelte la tecla , el led amarillo

parpadea. El arranque empieza de nuevo

pulsando la misma tecla o automáticamente

tras el tiempo PAU.

Paro denitovo.

Pulse la tecla , el led amarillo se apaga.

46

Page 47

CY1: Fuerte enfriamiento + enfriamiento suave +

mantenimiento

CY3: Ciclo de congelación +

mantenimiento

CY2: Fuerte enfriamiento + enfriamiento suave

+ ciclo de congelación + mantenimiento

H: El ciclo de mantenimiento

CY4: Finalizacion del ciclo

enfriamiento fuerte e inicio

del modo espera

47

Page 48

Abatidores

+70 °C to +3 °C

El ciclo de enfriamiento reduce la temperatura del producto de

+70 °C a +3 °C en 90 minutos.

La generación bacteriana se acelera en el intervalo entre

+60 °C and +10 °C, por lo que es esencial enfriar el producto lo

más rápido posible.

Además se conservan vitaminas, sabor y olor.

Deberá almacenarse en un enfriador normal a +2 °C.

Congeladore

+70 °C to -18 °C

Bacterianos destruidos

Aceleración bacteriana

El ciclo de congelación reduce la temperatura del producto de

+70 °C a -18 °C en 240 minutos.

La rápida reducción de la temperatura del producto aumenta la

vida útil del producto.

Además, la calidad se conserva sin grandes pérdidas de peso,

líquido y sabor.

Deberá almacenarse en un congelador normal a -20 °C.

Bacterianos en general

Abatidores Congeladore

Reducción/parada bacteriana

rfj_191013

© TEFCOLD A/S 2019

Page 49

ABATEDORES DE

TEMPERATURA /

CONGELADORES

Manual do utilizador

PT

SL

49

61

Page 50

50

Page 51

CONTEÚDO

1.

2.

Informação geral

Instruções importantes de segurança .................................................................. 52

Desembalar e instalação ...................................................................................... 52

Ligações Eléctricas .............................................................................................. 53

Arranque da arca .................................................................................................. 53

Capacidade ......................................................................................................... 53

Recomendações de utilização ............................................................................. 54

Ciclo de abatimento de temperatura .................................................................... 55

Ciclo de congelação rápida .................................................................................. 55

Limpeza e manutenção ........................................................................................ 55

Assistência Técnica ............................................................................................. 56

Eliminação ............................................................................................................ 56

Guia rápido

3.

Guia rápido diário ................................................................................................. 57

Termóstato XB570L / XB590L

Manual técnico ..................................................................................................... 73

51

Page 52

INSTRUÇÕES IMPORTANTES DE

SEGURANÇA

1. Para se obter uma utilização plena desta arca vertical, recomendamos-lhe que leia este manual

de instruções.

2. A utilização do aparelho de acordo com as instruções fornecidas é da inteira responsabilidade do

utilizador.

3. Contacte imediatamente o distribuidor em caso de avarias.

4. Coloque a máquina num local seco e ventilado.

5. Mantenha o aparelho afastado de fontes de calor intenso e não o exponha a luz solar directa.

6. Tenha sempre presente que qualquer dispositivo eléctrico é uma fonte de perigo potencial.

7. Não armazene na arca quaisquer materiais inamáveis, como diluente, gasolina, etc.

8. Declara-se que não foi usado amianto ou CFC na construção deste aparelho.

9. O óleo no compressor não contém PCB.

APENAS PARA EQUIPAMENTOS COM REFRIGERANTE R290/R600a!

Este equipamento contém um agente refrigerante inamável. Por isso, certique-se

de que existe boa ventilação em torno do mesmo. Não utilize dispositivos mecânicos

quando descongelar, pois pode provocar fugas no sistema de refrigeração. Não utilize

equipamentos eléctricos no interior do compartimento de arrumação refrigerado.

Todos trabalhos de reparação no aparelho devem ser realizados por um técnico

qualicado (EN 60335-2-89: 2010).

DESEMBALAJE E INSTALACIÓN

Retire a palete de madeira e a embalagem. As superfícies externas encontram-se revestidas com

uma película de protecção que deverá ser removida antes da instalação.

Para garantir o correcto funcionamento da arca, é importante que esta esteja nivelada. Se a arca

tiver pés, estes podem ser ajustados.

Importante!

1. Não obstruir os orifícios de ventilação.

2. Certique-se de que existem pelo 15 cm de espaço entre a arca e a parede.

52

Page 53

LIGAÇÕES ELÉCTRICAS

As arcas BLC3-BLC5 e BLC10 funcionam a 230 V/50 Hz.

A BLC14 funciona a 3x400 V/50 Hz.

Certique-se de que a arca está ligada a um grupo elétrico separado de modo a evitar sobrecarga.

A tomada de parede deverá estar facilmente acessível.

Todas as ligações à terra estipuladas pelas autoridades eléctricas locais deverão ser observadas.

A cha da arca e a tomada de parede deverão fornecer a ligação à terra adequada. Se houver

qualquer dúvida, contacte o distribuidor local ou um electricista qualicado.

ARRANQUE DA ARCA

Antes de utilizá-la, recomendamos que a arca seja limpa; consulte a secção sobre manutenção e

limpeza.

Importante!

Se a arca tiver sido colocada na horizontal durante o transporte, aguarde duas horas até ligá-la.

CAPACIDADE

ABATEDOR DE TEMPERATURA/CONGELADOR BLC3

Modelo adequado para conter 3 tabuleiros com capacidade de abatimento de temperatura de 12 kg

e 8 kg em congelação rápida.

ABATEDOR DE TEMPERATURA/CONGELADOR BLC5

Modelo adequado para conter 5 tabuleiros com capacidade de abatimento de temperatura de 18 kg

e 14 kg em congelação rápida.

ABATEDOR DE TEMPERATURA/CONGELADOR BLC10

Modelo adequado para conter 10 tabuleiros com capacidade de abatimento de temperatura de 40 kg

e 28 kg em congelação rápida.

ABATEDOR DE TEMPERATURA/CONGELADOR BLC14

Modelo adequado para conter 14 tabuleiros com capacidade de abatimento de temperatura de 55 kg

e 38 kg em congelação rápida.

53

Page 54

RECOMENDAÇÕES DE UTILIZAÇÃO

Se o dispositivo permanecer inactivo durante um longo período, proceda do seguinte modo

1. Utilize o interruptor de isolamento automático para desactivar a ligação à linha eléctrica principal.

2. Limpe bem o dispositivo e as áreas adjacentes.

3. Espalhe uma na camada de óleo de cozinha sobre as superfícies em aço inoxidável

4. Realize todas as operações de manutenção

5. Deixe a porta aberta para evitar a formação de bolor e/ou odores desagradáveis.

Não insira alimentos que se encontrem a uma temperatura superior a 90 °C.

Não empilhe os materiais a conservar em contacto com as paredes internas de modo a não bloquear

a circulação de ar.

Deve existir um espaço suciente entre os tabuleiros utilizados de modo a garantir um caudal

suciente de ar frio em todo o produto.

Nunca obstrua a entrada das ventoinhas do evaporador.

Os produtos que sejam mais difíceis de refrigerar devido ao seu tamanho devem ser posicionados

ao centro.

Limite o número de vezes e a duração do tempo que a porta estiver aberta.

Depois de abatimento da temperatura/congelação rápida do produto, este pode ser conservado

numa arca de conservação depois de ter sido devidamente protegido. Deve aplicar-se uma etiqueta

com uma descrição do conteúdo do produto, a data do abatimento de temperatura/congelação

rápida e a data de validade. Quando o produto tiver sido sujeito a abatimento de temperatura, deve

ser conservado a uma temperatura constante de +2 °C enquanto que se tiver sido submetido a

congelação rápida, deve ser conservado a uma temperatura constante de -20 °C.

O abatedor de temperatura deve ser utilizado para conservação apenas por curtos períodos.

Para impedir a contaminação bacteriana ou a contaminação de qualquer

outra natureza biológica, a sonda de agulha deve ser desinfectada após a

utilização.

54

Page 55

CICLO DE ABATIMENTO DE TEMPERATURA

Com esta modalidade de operação, o abatedor de temperatura mantém a temperatura do

compartimento de refrigeração perto de zero durante todo o processo de congelação de modo a

garantir uma descida gradual da temperatura do produto até +3 °C.Deste modo, não se formam

cristais de gelo na superfície do produto. Este método de refrigeração rápida deve ser utilizado de

preferência para produtos que não são embalados e cujas características físicas/organolépticas

podem ser danicadas pela formação de gelo na superfície (p. ex., peixe)

CICLO DE CONGELAÇÃO RÁPIDA

Com esta modalidade de refrigeração, o abatedor de temperatura mantém a temperatura a um valor

negativo inferior a -18 °C que é a temperatura nal da refrigeração rápida. Para que a refrigeração

rápida seja bem sucedida e rápida, os alimentos devem apresentar-se em pequenos pedaços,

especialmente se tiverem elevado teor de gordura. Os pedaços maiores, devem ser colocados em

tabuleiros centrais. Se demorar mais tempo do que o tempo padrão para congelação rápida e não

for possível reduzir os tamanhos, diminua a quantidade e pré-refrigere o compartimento do abatedor

de temperatura iniciando um ciclo de refrigeração rápida em vazio antes de proceder à refrigeração

do produto.

LIMPEZA E MANUTENÇÃO

Desligue a ligação eléctrica da tomada de parede.

A arca deve ser limpa periodicamente. Limpe as superfícies interna e externa da arca com

uma solução ligeiramente ensaboada e seque de seguida. As superfícies externas poderão ser

conservadas com um óleo de máquina.

Não aplique jactos de água directamente sobre o dispositivo nem utilize dispositivos de alta pressão.

Não utilize palha de aço, escovas ou raspadores para limpar o aço inoxidável devido ao risco de

depósito das partículas ferrosas que, ao oxidarem, podem provocar ferrugem.

Para remover os resíduos endurecidos, utilize espátulas de madeira ou de plástico, ou peças de

raspagem abrasivas.

Limpeza do condensador

Limpe o condensador regularmente

Visto que as aletas do condensador são muito aadas, use sempre luvas de protecção para a

fases seguintes. Na presença de poeiras, utilize máscaras e óculos de protecção

Sempre que o condensador tiver depósitos de poeiras nas aletas, é possível removê-los com um

aspirador ou uma escova aplicando um movimento vertical ao longo da direcção das aletas.

Não se devem utilizar quaisquer outros instrumentos, pois podem deformar as aletas e, por

conseguinte, diminuir a eciência do dispositivo.

55

Page 56

Para limpar, proceda do seguinte modo:

1. Abra a porta (A) dos dispositivos.

2. Remova o painel inferior (B) do compartimento técnico: para tal, remova os xadores de

parafuso (C)

3. Será agora possível limpar a parte das aletas do condensador (D) utilizando ferramentas

adequadas e dispositivos de protecção.

4. Depois de limpar, feche o painel de controlo e xe-o com os parafusos previamente removidos.

ASSISTÊNCIA TÉCNICA

O sistema de arrefecimento é hermeticamente selado e não requer supervisão; apenas limpeza.

Se a arca não arrefecer, verique se isso se deve a uma falta de electricidade.

Se não conseguir diagnosticar a causa da falha da arca, contacte o distribuidor. Informe o modelo

e o número de série da arca. Poderá encontrar esta informação na etiqueta de características

localizada na parte de dentro da arca, do lado superior direito.

ELIMINAÇÃO

A eliminação da arca deverá efectuar-se de modo ambientalmente correcto. Aquando da eliminação,

tenha em consideração a legislação existente. Poderá haver requisitos e condições especiais a

serem observados.

56

Page 57

GUIA RÁPIDO

Guia rápido diário

57

Page 58

COMO SELECCIONAR UM CICLO

Prima e liberte a tecla até o ciclo desejado ser seleccionado CY1 , CY2 , CY3 ,

CY4 função de modo de retenção

5 programas têm valores padrão apresentados nos diagramas na próxima página.

CY1: Para refrigeração rápida e conservação de alimentos.

1.

CY2: Para refrigeração e congelação rápida de alimentos.

2.

CY3: Para congelação rápida directa.

3.

CY4: Para congelação rápida directa, sem conservação.

4.

H: Função de modo de retenção.

5.

dEF: Para iniciar descongelação manual.

6.

Visualizar o ponto de denição da fase de

retenção.

Prima e liberte a tecla , o ponto de

retenção do ciclo seleccionado é visualizado

durante 5 segundos.

Modicar o ponto de denição da fase de

retenção.

Enquanto o ponto de denição é visualizado,

mantenha a tecla premida até a etiqueta

HdS car intermitente. Utilize as teclas UP

(Cima) e DOWN (Baixo) para modicar o

valor.

Para conrmar: Prima a tecla para

conrmar o valor e sair.

Como iniciar um ciclo.

Prima e liberte o botão .

Il O LED amarelo correspondente é activado.

O compressor é retardada 3 min.

Como parar temporariamente o ciclo.

Prima e liberte a tecla , o compressor

e a ventoinha serão parados durante o

período PAU (ver lista de parâmetros) e será

visualizada a mensagem “Stb” intermitente.

Para reiniciar o ciclo, prima e liberte a tecla

o ciclo reiniciará a partir de algum ponto

em que tenha sido interrompido. Em qualquer

caso, o ciclo reinicia automaticamente após o

período PAU.

Como parar um ciclo.

Mantenha o botão até o LED amarelo

apagar.

58

Page 59

CY1: Refrigeração forte + fraca + retenção

CY3: Refrigeração forte +

congelação

CY2: Refrigeração forte + fraca + congelamento

+ retenção

H: Função de modo de retenção

CY4: Para congelação rápida

directa, sem conservação

59

Page 60

Abatedores

+70 °C to +3 °C

O ciclo de arrefecimento reduz a temperatura do produto de

70 °C a + 3 °C em 90 minutos.

Geração bacteriana é acelerado no intervalo entre

60 °C e 10 °C, de modo que é essencial para arrefecer o produto

tão rapidamente quanto possível.

Além de vitaminas, paladar e olfato são preservados.

Deve ser armazenada num refrigerador normal a 2 °C.

Congeladores

+70 °C to -18 °C

Bacteriana destruída

Aceleração bacteriana

O ciclo de congelação reduz a temperatura do produto de

70 °C a -18 °C em 240 minutos.

A redução rápida da temperatura do produto aumenta a vida

útil do produto.

Além disso, a qualidade é preservada, sem grande perda de

peso, líquido e sabor.

Deve ser armazenada num congelador normais a -20 °C.

Bacterianos en general

Abatedores Congeladores

Redução/parar bacteriana

rfj_191013

© TEFCOLD A/S 2019

Page 61

HLADILNIK/ZAMRZOVALNIKA

ZA HITRO

HLAJENJE/ZAMRZOVANJE

Navodila za uporabo

SL 61

Page 62

62

Page 63

VSEBINA

1.

2.

Splošne informacije

Pomembna varnostna navodila ........................................................................... 64

Odstranjevanje embalaže in namestitev .............................................................. 64

Električna priključitev .......................................................................................... 65

Zagon omare ...................................................................................................... 65

Zmogljivost .......................................................................................................... 65

Priporočila za uporabo ........................................................................................ 66

Cikel hitrega hlajenja .......................................................................................... 67

Cikel hitrega zamrzovanja ................................................................................... 67

Čiščenje in vzdrževanje ...................................................................................... 67

Servis ................................................................................................................... 68

Odlaganje ............................................................................................................. 68

Hitri vodnik

3.

Dnevni hitri vodnik .............................................................................................. 69

Termostat XB570L/XB590L

Tehnični priročniki ............................................................................................... 73

63

Page 64

POMEMBNA VARNOSTNA NAVODILA

1. Da bi lahko v popolnosti izkoristili omaro, priporočamo, da preberete ta navodila za uporabo.

2. Uporabnik je odgovoren za uporabo naprave v skladu z navodili.

3. V primeru kakršnih koli okvar se nemudoma obrnite na svojega trgovca.

4. Omaro postavite na suho in prezračevano mesto.

5. Omara naj se nahaja stran od virov močne vročine, prav tako pa je ne izpostavljajte

neposredni sončni svetlobi.

6. Nikoli ne pozabite, da so električne naprave viri potencialne nevarnosti.

7. V omari ne hranite vnetljivega materiala, kot so razredčilo, bencin itd.

8. Izjavljamo, da konstrukcija ne vsebuje azbesta in plinov CFC.

9. Olje v kompresorju ne vsebuje polikloriranih bifenilov.

LE ZA NAPRAVE S HLADILNO TEKOČINO R600a!

Ta naprava vsebuje vnetljivo hladilno tekočino, zato v okolici naprave zagotovite dobro

prezračevanje.

Pri odtaljevanju ne uporabljajte mehanskih naprav, saj lahko povzročijo puščanje

hladilnega sistema.

Znotraj hlajenega predela za shranjevanje ne uporabljajte električnih naprav.

Vsa popravila naprave mora izvesti usposobljen tehnik (EN 60335-2-89: 2010)

ODSTRANJEVANJE EMBALAŽE IN NAMESTITEV

Odstranite leseno paleto in embalažo. Zunanje površine so zaščitene z zaščitno folijo, ki jo je treba

pred namestitvijo odstraniti.

Pomembno je, da zagotovite, da omara stoji uravnano, da zagotovite ustrezno delovanje. Če ime

omara priložene noge, jih je mogoče prilagoditi.

Pomembno!

1. Ne blokirajte odprtin za prezračevanje.

2. Poskrbite, da je med omaro in steno vsaj 15 cm prostora.

64

Page 65

ELEKTRIČNA PRIKLJUČITEV

Omare BLC3, BLC5 in BLC10 delujejo pri 230 V/50 Hz.

Omara BLC14 deluje pri 3 x 400 V/50 Hz.

Da se izognete preobremenitvi, poskrbite, da je omara priključena na ločeno električno skupino.

Stenska vtičnica mora biti zlahka dosegljiva.

Upoštevati je treba vse zahteve glede ozemljitve, določene s strani lokalnih električnih organov. Vtič

omare in stenska vtičnica morata imeti ustrezno ozemljitev. Če ste v dvomih, se obrnite na lokalnega

dobavitelja oziroma pooblaščenega električarja.

Glavne električne priključitve morajo opraviti usposobljeni električarji.

ZAGON OMARE

Pred uporabo priporočamo, da očistite omaro, glejte poglavje o vzdrževanju in čiščenju.

Pomembno!

Če je bila omara med prevozom v vodoravnem položaju, pred vklopom počakajte dve uri.

ZMOGLJIVOST

HLADILNIK/ZAMRZOVALNIK ZA HITRO HLAJENJE/ZAMRZOVANJE BLC3

Model, v katerega je mogoče dati tri pladnje, z zmogljivostjo hitrega hlajenja v višini 12 kg in

zmogljivostjo hitrega zamrzovanja v višini 8 kg.

HLADILNIK/ZAMRZOVALNIK ZA HITRO HLAJENJE/ZAMRZOVANJE BLC5

Model, v katerega je mogoče dati pet pladnjev, z zmogljivostjo hitrega hlajenja v višini 18 kg in

zmogljivostjo hitrega zamrzovanja v višini 14 kg.

HLADILNIK/ZAMRZOVALNIK ZA HITRO HLAJENJE/ZAMRZOVANJE BLC10

Model, v katerega je mogoče dati deset pladnjev, z zmogljivostjo hitrega hlajenja v višini 40 kg in

zmogljivostjo hitrega zamrzovanja v višini 28 kg.

HLADILNIK/ZAMRZOVALNIK ZA HITRO HLAJENJE/ZAMRZOVANJE BLC14

Model, v katerega je mogoče dati štirinajst pladnjev, z zmogljivostjo hitrega hlajenja v višini 55 kg

in zmogljivostjo hitrega zamrzovanja v višini 38 kg.

65

Page 66

PRIPOROČILA ZA UPORABO

Če naprava dlje časa ostane neaktivna, naredite naslednje:

1. Za deaktivacijo povezave do glavnega električnega voda uporabite samodejno ločilno stikalo.

2. Temeljito očistite napravo in okoliška območja.

3. Površine iz nerjavnega jekla premažite s tankim slojem jedilnega olja.

4. Opravite vsa vzdrževalna dela.

5. Vrata pustite priprta, da preprečite nastajanje plesni in/ali neprijetnega vonja.

V omaro ne dajajte živil, ki imajo temperaturo, višjo od 90 °C.

Živil, ki jih želite shraniti, ne zložite tako, da bi bila v stiku z notranjimi stenami omare in bi tako

preprečila kroženje zraka.

Med uporabljenimi pladnji mora biti dovolj prostora, da zagotovite zadosten pretok hladnega zraka po

celotnem izdelku.

Nikoli ne ovirajte dovoda ventilatorja uparjalnika.

Živila, ki jih je zaradi njihove velikosti težje ohladiti, dajte na sredino.

Omejite število in trajanje obdobij, ko so vrata odprta.

Ko živilo na hitro ohladite/zamrznete, ga je mogoče shraniti v omari za konzerviranje, potem ko ste ga

primerno zaščitili. Na paket namestite oznako z opisom vsebine paketa, datumom hitrega ohlajanja/

zamrzovanja in rok uporabe. Ko je izdelek na hitro ohlajen, ga morate hraniti pri stalni temperaturi +2

°C, če pa ste ga na hitro zamrznili, ga morate hraniti pri stalni temperaturi –20 °C.

Hladilnik uporabljajte le za shranjevanje za krajša obdobja.

O abatedor de temperatura deve ser utilizado para conservação apenas por curtos períodos.

Da preprečite okužbo z bakterijami oziroma okužbo kakršne koli druge

biološke narave, morate po uporabi razkužiti igelno sondo.

66

Page 67

CIKEL HITREGA HLAJENJA

V tem načinu delovanja hladilnik med celotnim procesom hlajenja ohranja temperaturo hladilnega

predala blizu ničle, da zagotovi postopen padec temperature živila na +3 °C. Na ta način se na

površini živila ne tvorijo ledeni kristali. To metoda hitrega hlajenja prednostno uporabljajte za živila,

ki niso pakirana, in katerih zične/organoleptične lastnosti bi se lahko poškodovale zaradi tvorjenja

površinskega ledu (npr. ribe).

CIKEL HITREGA ZAMRZOVANJA

V tem načinu hitrega ohlajanja hitri zamrzovalnik ohranja temperaturo pri negativni vrednosti pod

–18 °C, kar je končna temperatura hitrega zamrzovanja. Da bi bilo hitro zamrzovanje uspešno in

hitro, mora biti hrana narezana na majhne koščke, zlasti če ima visoko vsebnost maščobe. Največje