Page 1

Blast Chillers/Freezers

BLC3, BLC5, BLC10, BLC14

Users manual UK 1

0

Page 2

1

Page 3

CONTENT

ENGLISH

1.REGULATIONS AND GENERAL INSTRUCTIONS .................................................................................. 1

1.1 General information ................................................................................................................................... 1

1.2 Replacement of Parts ................................................................................................................................ 1

1.3 Description of the Applianc e ..................................................................................................................... 1

1.4 Features Plate............................................................................................................................................. 2

2. SAFETY.................................................................................................................................................... 3

3.RECOMMENDATIONS FO R USE ............................................................................................................ 4

Prolonged Inactivity .......................................................................................................................................... 4

Blast chilling Cycle ............................................................................................................................................ 5

Shock freezing Cycle ........................................................................................................................................ 5

4.CLEANI NG AND MAINTENAN CE ............................................................................................................ 6

4.1 Recommendations for Cleaning and Mainten ance ............................................................................... 6

4.2 Routine Maintenan ce ................................................................................................................................. 6

4.3 Extraordinary maintenance ....................................................................................................................... 6

5.TROUBLE SHOOTING ............................................................................................................................. 8

6. INSTALLATION ........................................................................................................................................ 9

6.1 Packing And Unpacking ............................................................................................................................ 9

6.2 Installation ................................................................................................................................................... 9

6.3 Electric Power Supply Connection ........................................................................................................ 10

6.4 Inspection .................................................................................................................................................. 10

7.DISPOAL OF THE APPLIANCE ............................................................................................................. 11

8.REFRIGERANT RECHNICAL CARD ..................................................................................................... 11

XB570L BLAST CHI LL& FR EEE ZE R CONT RO LL ER ............................................................................. 12

9. General Features ................................................................................................................................... 12

10. Mounting & Instal lation ......................................................................................................................... 12

1 1. Electrical Connections .......................................................................................................................... 12

11.1 PROBES CONNECTION ...................................................................................................................... 13

12. Connections ......................................................................................................................................... 13

13. Frontal panel......................................................................................................................................... 13

14. QUICK START ...................................................................................................................................... 13

14.1 DISPLAY .................................................................................................................................................. 13

14.2 KEYBOARD IN STAND-BY .................................................................................................................. 14

14.3 KEYBOARD WHEN A CYCLE 1,2,3,4 IS RUNNING ....................................................................... 15

14.4 KEYBOARD WHEN THE HOLDING CYCLE IS RUNNING ( H) ..................................................... 16

14.5 OTHER KEYS......................................................................................................................................... 16

14.6 HOW TO START A MANUAL DEFROST .......................................................................................... 17

14.7 OTHER FUNCTIONS OF KEYBOARD .............................................................................................. 17

14.8 MEANING OF THE LEDS’ .................................................................................................................... 17

15. How To Select A Cycle ......................................................................................................................... 18

15.1 HOW TO MODIFY A CYCLE ............................................................................................................... 18

16. Parameters ........................................................................................................................................... 18

PROBES .......................................................................................................................................................... 19

1

Page 4

DISPLAY AND MEASUREMENT UNIT ...................................................................................................... 19

DIGITAL INPUTS ............................................................................................................................................ 19

AUXILIARY RELAY CONFIGURATION ...................................................................................................... 20

SECOND REL AY MANAGEMENT ............................................................................................................... 20

AUXILIARY RELAY MANAGEMENT ........................................................................................................... 21

DEFROST ........................................................................................................................................................ 21

FANS ................................................................................................................................................................ 21

TEMPERATU RE ALARMS............................................................................................................................ 22

CYCLE LOG .................................................................................................................................................... 22

OTHER ............................................................................................................................................................. 22

17. How A Cycle Is Done ........................................................................................................................... 22

17.1 CONFIG URABLE CYCLE PARAMETERS ........................................................................................ 23

17.2 HOW TO USE THE INSERT PROBES .............................................................................................. 23

17.3 EXAMPL E OF A B L AST CHILLER CYCLE. ...................................................................................... 23

18. Installation and mounti ng ..................................................................................................................... 25

18.1 CUT OUT ................................................................................................................................................. 25

18.2 MOUNTING............................................................................................................................................. 25

19. XB07PR - Printer (opti onal) ................................................................................................................. 26

19.1 PRINTER DIMENSIONS ...................................................................................................................... 26

19.2 PRINTER MOUNTING .......................................................................................................................... 26

19.3 CONNECTION TO THE XB570L – XB07PR ..................................................................................... 27

20. Electrical connection s .......................................................................................................................... 27

20.1 PROBE CONNECTIONS ...................................................................................................................... 27

21. TTL Serial line ...................................................................................................................................... 27

22. Use of the programmi ng “ HOT KEY” ................................................................................................... 27

22.1 DOWNLOAD (FROM THE “HOT KEY” TO THE INSTRUMENT) .................................................. 27

22.2 UPLOAD (FROM THE INSTRUMENT TO THE “HOT KEY”) .......................................................... 28

23. ALARM SIGNALS ................................................................................................................................ 28

24. Technical data ...................................................................................................................................... 29

25. Standard Value of the cycles ............................................................................................................... 29

26. Standard Values of the parameters ..................................................................................................... 30

2

Page 5

1.REGULATIONS AND GENERAL INSTRUCTIONS

1.1 General information

This manual has been designed by the manufacturer to provide the necessary inf ormation to those who

are authorized to interact with the appliance.

The persons receiving the inf ormation must read it caref ul ly and apply it strictly.

Reading the information contained in this document will allow the user to prevent risks to personal health

and safety.

Keep this manual for the entire operating life of the equipment in a place which is well-known and easily

accessible, so that it is always available when its consultation beco me s necessary.

Particular symbols have been used to highlight some parts of the text that are very important or to

indicate some important specifications. Their meanings are given below:

Indicates important information regarding safety. Behave appropriately so as not to risk the health

and safety of persons or cause damage.

Indicates particularly important t echnical information that must not be ignored

1.2 Repl ac em ent of Parts

Activate all envisioned safety devices b ef or e car r ying out any replacement intervention.

In particular, deactivate the electrical power supply using the differential isolating switch.

All responsibility is declined for injury to persons or damage to com ponents deriving from the use of

non-original spare parts and interventions which could modify the safety requisites,without authorization

of the manufacturer .

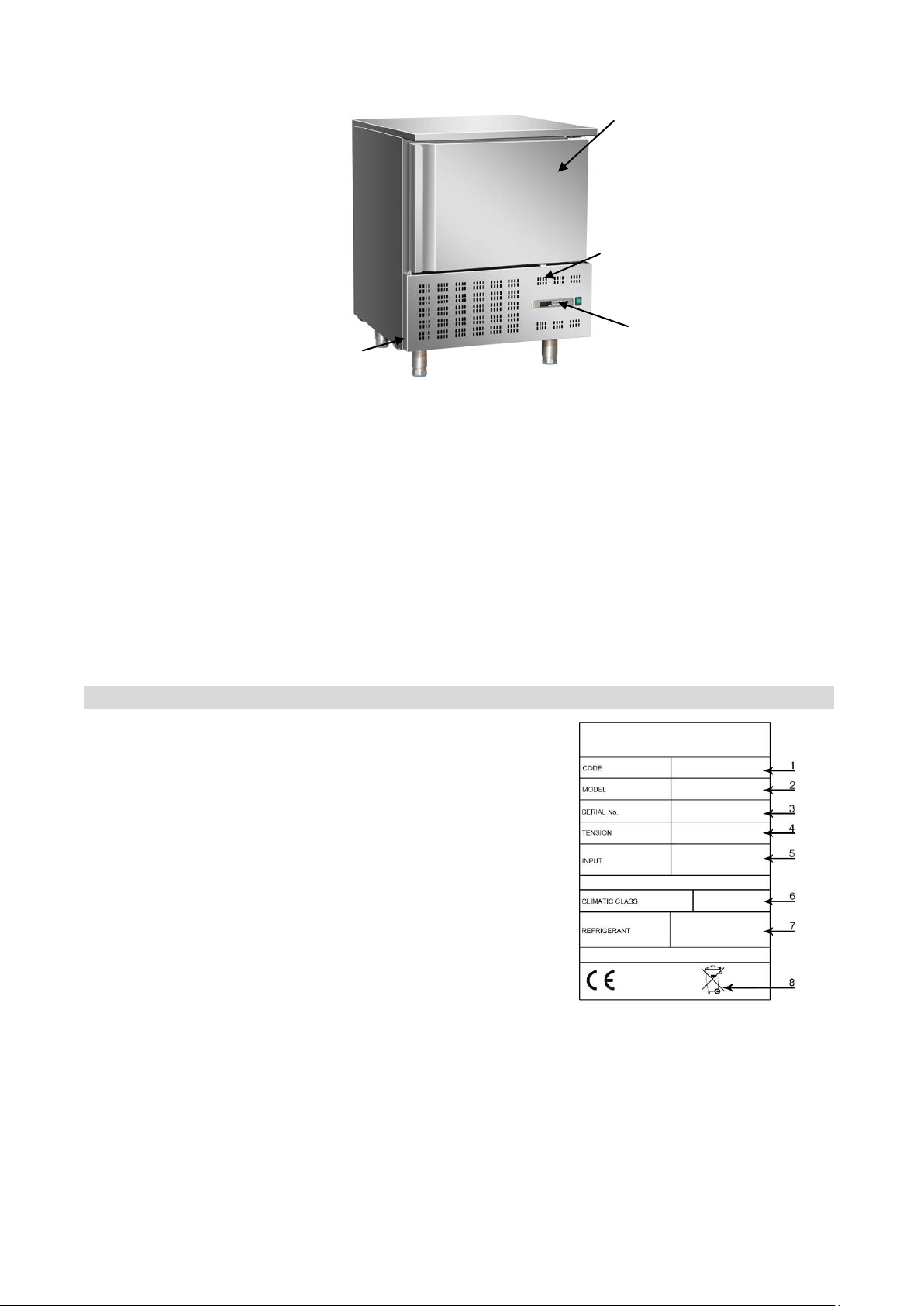

1.3 Descript ion of the Appliance

The Blast chiller & freezer, from now on defined as applian ce, has been designed and built t o c ool and/or

freeze foodstuffs in t he professional catering ambit.

1) Condensation area: it is pos itioned in the lower part and is characterized by t he pr es ence of the

condensing unit.

2) Electric area: it is positioned in the lower part of the appliance and contains the control and power

supply components as well as electric wiring.

3) Evaporation area: it is situated inside the refrigerated compartment in the rear and is characterized

by the evaporating unit.

4) Storage area: it is situated inside the re frig er ated compartment and is destined for the cooling and/or

freezing of foodstuffs.

1

Page 6

3-4

1

2

A

The lower part is also distinguished by a control panel (A) that allows access t o t he electric parts; there is

a vertically-opening door in the front, which closes the refrigerated comp ar tment hermetically .

Depending on requirements, the appliance is produced in several ver sions.

BLC3 BLAST CHILLER/FREEZER

Model suitable to contain 3 trays with blast chilling capacity of 12kg and 8 kg in shock freezing.

BLC5 BLAST CHILLER/FREEZER

Model suitable to contain 5 trays with blast chilling capacity of 18k g and 14kg in shock freezing.

BLC10 BLAST CHILLER/FREEZER

Model suitable to contain 10 trays with blast chilling capacity of 40kg and 28 kg in shoc k freezing.

BLC14 BLAST CHILLER/FREEZER

Model suitable to contain 14 trays with blast chilling capacity of 55kg and 38kg in shock fre ezing.

1.4 Features Plate

The identification plate shown is applied directly onto

the appliance. It st at es t he reference and all indications

indispensable for workin g in safety.

(1) Appliance code

(2) Description of the Appliance

(3) Serial number

(4) Power supply voltage and frequ enc y

(5) Electrical absorption

(6) Climatic class

(7) Type and Amount of refrigerant gas

(8) WEEE symbol

2

Page 7

2. SAFETY

It is recommended to carefully read the instructions and warnings contained in this manual before

using the appliance. The informat io n c ontained in the manual is fundamental for the safety of use and for

machine maintenance.

Keep this manual carefull y so that it can be Consulted when necessary.

The electric plant has been designed in compliance with the IEC EN 60335-2-89 and EN 60335-1

standard.

Specific adhesives highlight the presence of mains voltage in the proximity of areas(however

protected)with risks of an electrical nature.

Before the connection, ensure the presence of an omni polar switch with minimum contacts opening

equal to 3 mm in the mains pow er supply upst ream from the applianc e (requested for appliances supplied

without plug to connect to the fi xed plant).

In the design and construction phase, the manufacturer has paid particular attention to the aspects that

can cause risks to safety and health of persons that interact with the appliance.

Carefully read the instructions stated in the manual supplied and those applied directly to the machine,

and particularly r espec t t hose r egarding Safety.

Don’t tamper or eliminate the installed safety devices. Failure to comply with this requisite can Lead to

serious risks for personal health and safety.

It is recommended to simulate some test manoeuvers in order to identify the controls, in particular those

relative to switch-on and sw it ch-off and their main functions.

The appliance is only destined for the use for which it has been designed; any other use must be

considered improper.

The manufacturer declines all liability for any damage to objects or injury to persons owing to

improper or incorrect use.

All maintenance interventions that require precise technical skill or particular ability must be

performed exclusively by qualified staff.

When using the appliance, never obstruct the air inlet when the appliance is on,so as not to

compromise its per formance and safety.

Never stretch the power cabl e.

In order to guarantee hy giene and pr ot ect t he food stuffs from contaminatio n, t he e lements that come into

direct or indirect contact with the foodstuffs must be cleaned very well along with the surrounding

areas .These operations must only be performed using detergents that can be used with foodstuffs,

3

Page 8

avoiding inflammable products or those that contain substa nces that are harmful to personal health.

In the case of prolonged inactivity, as well as disconnecting all the supply lines, it is necessary to

accurately clean all inter nal and external par ts of the appliance.

3.RECOMMENDATIONS FOR USE

Prolonged Inact ivity

If the appliance remains inactive for a long period, proceed as follows

1. Use the automatic isolating switch to deactivate connection to the main electrical line.

2. Clean the appliance and surrounding areas thoroughly.

3. Spread a thin layer of cooking oi l onto t he stainless steel surfaces

4. Carry out all maintenance operations

5. Leave the doors ajar to prevent the formation of mould and /or unpleasant odour.

Recommendations for normal use

In order to ensure correct use of the appliance, it is good practice to apply the following

recommendations:

Do not obstruct the zone in front of the condensing unit in order to favour heat disposal from the

condenser to a maximum.

Always keep the front of the con denser clean.

Do not insert foodstuffs t hat ar e we ll abov e the t e m perature of 65 ℃. As well as initially overloading the

machine it can make protections intervene that prolong temperature descent times. If possible , a brief

external period is useful to lower the temperature t o ac ceptable values.

Check the planarity of the app lia nce r est surface.

Do not stack the materials to be preserved in contact with the internal walls .so blocking the

circulation of air , which gu arantees un iformity of the interna l temperatur e of the refrigerate d compar tment .

There must be a suffici ent sp ace b etw een the ba sin s and t ray s used in ord er to guarant ee a sufficient

flow of cold air on the entire pr oduct. Therefore avoid the following positions of trays and/or basins stated

below.

Never obstruct the inlet of t he evaporator fans.

Products that are more difficult to chill because of their composition and size shoul d be placed in the

centre.

Limit the number of times and the duration of time the doors are opened.

Blast chilling data r efer to stand ard product s ( low fat cont ent )with a th icknes s below 5 0 mm: ther efore

avoid overlaying products or the insertion of pieces with a much higher thickness, This would ,in fact,

lead to an extension of blast chilling times .Always distribute the product well on the trays or basins or in

the case of thick pieces decrease the amount to blast chill.

4

Page 9

After blast chilling/shock freezing the product, it can be stored in a preservation cabinet after having

℃

℃

been duly protected .A tag should be applied describing the contents of the product, blast chilling/shock

freezing date and exp iry d at e. When the pr oduct has been bl ast ch ille d it must be pr es erv ed at a c onstant

+2

temperature of

-20

。

,while if it has been shock frozen it must be preserv ed at a const ant t emperat ure of

The chiller should be used for st or age for short periods only.

T o preve nt bacterial co ntaminati on or contami nation of any other bi ological na ture,

the needle probe must be disinfected af ter use.

To extract the product that has undergone blast chilling or shock freezing ,always wear gloves to

protect the hands ,as “bur ns” m ay occur form the cold.

Blast chilling Cycle

With this operating modality the chiller keeps the temperature of the refrigerating compartment close to

zero during the entire chill i ng pr ocess in

order to ensure a gradual drop in the temperature of the product to +3℃。In this way ,ice crystals do not

form on the surface of the product .This blast chilling method should be used preferably for products that

are not packed and whose physical/organoleptic characteristics could be damaged by the formation of

superficial ice (e.g. fish)

Shock freezing Cycle

With this blast chilling modality the blast chiller maintains the temperature at a negative value below

-18℃,which is the end te mperatur e of shoc k freez ing .For shoc k freezing t o be succes sful and fast, food

should be in small pieces, especiall y if it has a high fat content. The largest pieces should be placed in

central trays .If it takes longer than standard time to shock freeze and the sizes cannot be reduced,

decrease the quantity and precool the chiller compartment by starting an empty shock freezing cycle

before shock freezing the pr oduct.

5

Page 10

4.CLEANING AND MAINTENANCE

4.1 Recommendations fo r Cleaning and Maintenance

Activate all envisioned safet y dev ices before car ry ing out any mainte nan ce int erv entions, I n par ticu lar,

deactivate the electrica l power supply using the automatic isolating switch.

4.2 Routine Maintenance

Routine maintenance consists of dai ly cleaning of all the parts which can into contact with foodstuffs and

the periodic maintenance of the burners, nozzles and draining pipes.

Correct maintenance allows the user to maximize performance levels and operating life and constantly

maintain safety r equirements.

Do not spray the applianc e w ith dir ect j ets of water or using high pressure appliances.

Do not use iron wool. brushes or scrapers to clean the stainless steel as ferrous particles could be

deposited which ,on oxidiz ing, could lead to rust.

To remove hardened residues, use wooden or plastic spatulas or abrasive rubber pads.

During long periods of inactivity , spread a protective layer on all stainless steel surfaces by wiping them

with a cloth soaked in Vaseline oil and airing the roo ms p er iodically .

Do not use products which contain substances which are harmful and dangerous for personal health

(solvents. petrol et c)

At the end of the day it is advisable to clean:

the cooling compartment

the appliance

4.3 Extraordinary maintenance

Have the following operati ons c arr ied out periodically by specialized staff:

Check the perfect sealing of the door gaskets and replace them if necessary.

Check that the electric connections have not loosened.

Check the efficiency of the heating element resistance.

Check functioning of the board and probes.

Check the efficiency of the electrical system.

Clean the evaporator.

Clean the condenser.

Cleaning the evaporator

Clean the evaporator periodically.

6

Page 11

As the fins of the evaporator are very sharp. always wear protectiv e gloves for the next phases .Only

a brush must be used for cleaning :do not use jets of liquid or sharp instruments.

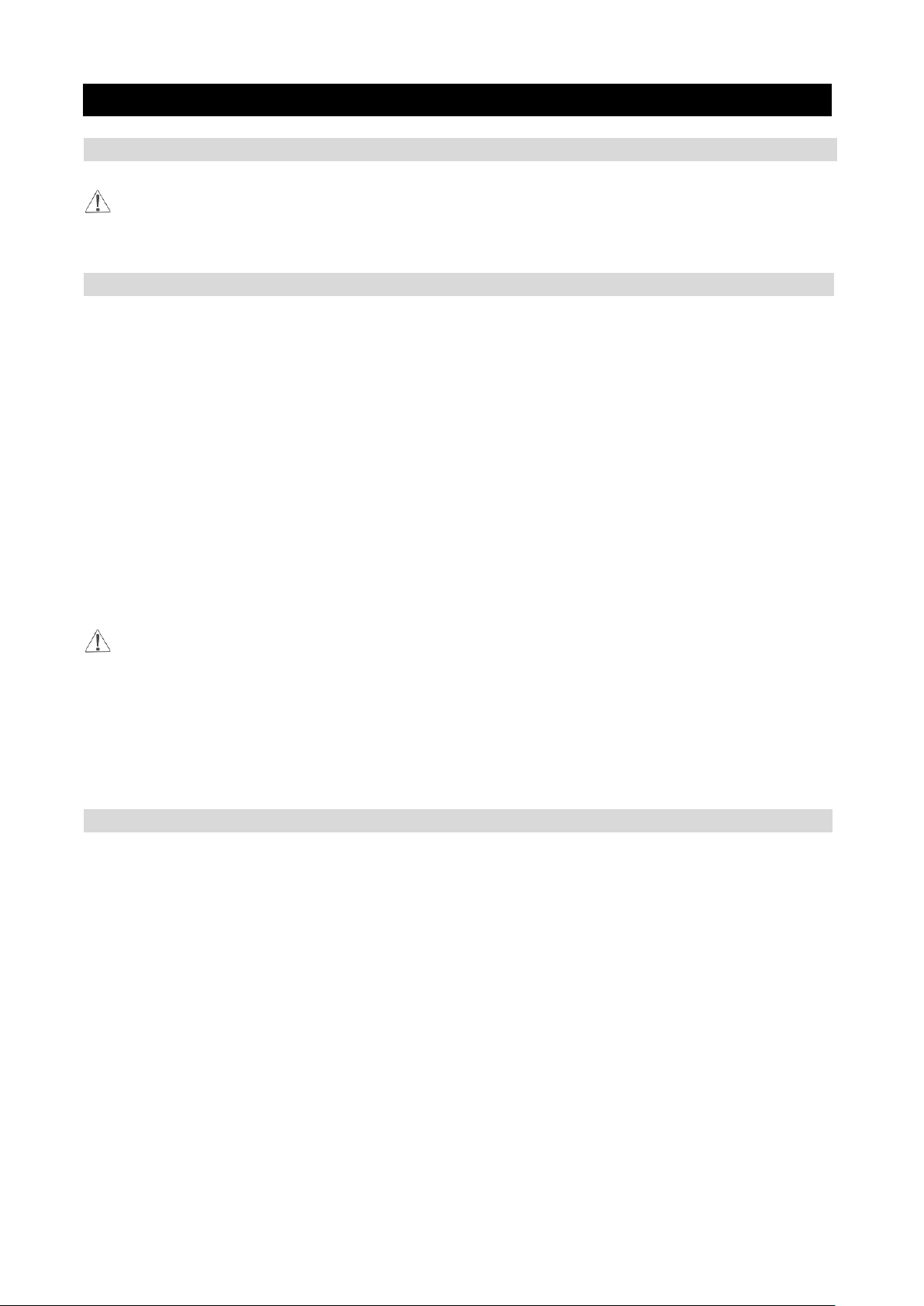

To access the evaporator procee d as f ollows:

1. Open the do or ( A) of the appliance.

2. Loosen the t w o sc r ew s ( B)on the right of the deflector.

3. Remov e t he r unner s(C)

4. Turn the deflector(D) to the left.

Clean the condenser

Clean the condenser periodically

As the fins of the condenser are very sharp, always wear protective gloves for the next phases. Use

protective masks and glas ses in the presence of dust

Whenever the condenser has a deposi t of dust in correspondence with the fins, this can be removed

using a suction device or with a brush applied, using a vertical movement along the direction of the fins.

No other instruments must be used, which may deform the fins and therefore the efficiency of the

appliance.

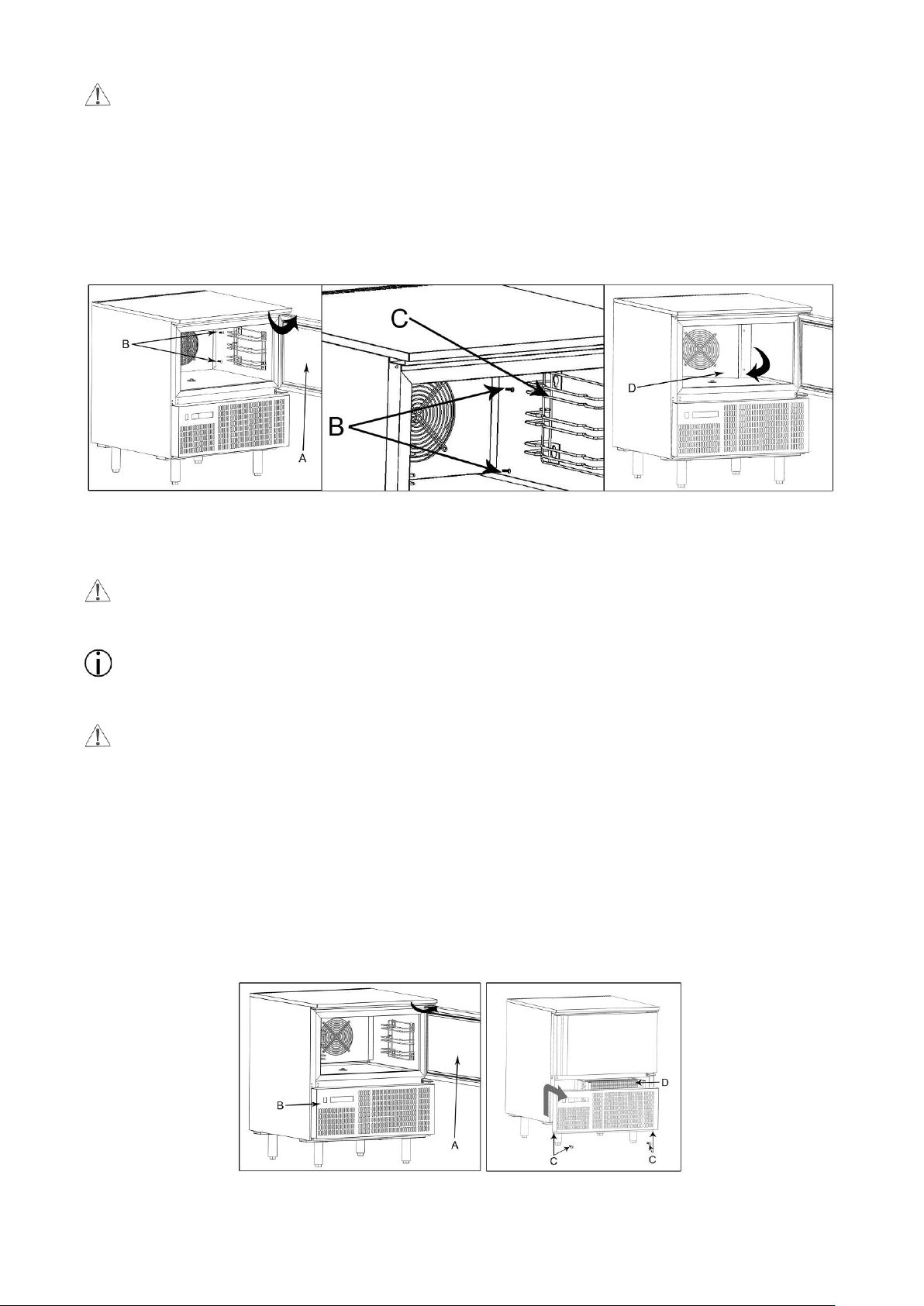

To clean, proceed as follows:

1. Open the door (A) of the appliances.

2. Remove the lower panel(B) from the technical compartment: to do this, remove the screw

fasteners(C)

3. It is now possible to clean the finned part of the condenser (D) using suitable tools and protecti on

devices.

4. After cleaning, close the control panel an d f ix it with the screws removed beforehand.

7

Page 12

5.TROUBLE SHOOTING

centre

centre

centre

The information shown below aims to help with the identification and correction of any anomalies and

malfunctions which could occur duri ng use. So me of these pr oblems can be re solved by the user. For the

others, precise skill is req uir ed and they must therefore only be carried out by qualified staff.

Problem

The refrigerator unit does not

start

The refrigerator unit funct i ons

continuously, cooling

insufficiently

Causes Solutions

Check the power supply cabl e

No voltage

Check the correct connect ion o f

Other causes

contact the after-sales centre

Room too hot Air the environment

Dirty condenser Clean the condenser

Insufficient door sealing Check the gaskets

Insufficient quantity of

refrigerant gas

Check fuses

the appliance

If the problem persists,

Contact the after -sales

The refrigerator unit does not

stop

Presence of ice inside the

evaporator

Appliance noise Persistent vibrations

Condenser fan at a standstill

Evaporator fan standstill

Probe faulty

Circuit board fault

Contact the after -sales

Contact the after -sales

centre

Contact the after -sales

centre

Contact the after -sales

Carry out a defrosting cy cl e

possibly with the door open

If the problem persists,

contact the after-sales centre

Check there is no contact

between the appliance and

other objects inside or outside

8

Page 13

6. INSTALLATION

6.1 Packing And Unpacking

Handle and install the appliance respecting the information provided by the manufacturer, shown directly

on the packaging, on t he appliance and in this man ual.

The lifting and transportation system of the packaged product envisions the use of a fork -lift truck or a

pallet stacker. W hen using these, particular attention must be paid to balancing the weight in order to

prevent the risk of overtur nin g( avoid excessive tilting!).

ATTENTION: When inserting the lifting device, pay attention to the power supply cable and the

position of the feet.

The packaging is m ade of cardboard and the pallet of plywood. A series of symbols is printed on the

cardboard packagin g which highl ights, i n accordanc e with internat ional st anda rds, the prov isions to w hich

the appliances are subjected during loading, unloading, transport and storage.

On delivery, check that the packaging is intact and has not undergone any damage during tr ansportation.

The transportation company must be notified of any damage immedi at ely.

The appliance must be unpacked as soon as possib le to chec k that it is int act and unda maged. Do not cut

the cardboard with sharp tools so as not to damage to the steel panels underneath.

Pull the cardboard pa ckaging upwards.

After having unp acked the appliance, check that the features correspond to those requested in the or der ;

Contact the dealer imm ediately if there are any anomalies.

Packaging elements (nylon bags, polystyrene foam, staples…) must not be left within reach of

children.

Remove the protective PV C fil m from the internal and external walls, avoiding the use of metal tools.

6.2 Installation

All the installation phases must be considered, from the moment of creation of t he general plan.

The installation area must be equipped with all power supply and production residue drainage

connections and must be suitably lit and respect current laws regarding hygiene and sanitary

requirements.

The performance of the appliance is guaranteed with a room temperature of 32℃. A higher

9

Page 14

temperature can compromise its performance and, in more serious cases, cause the appliance’s

protections to start up.

Therefore, consider t he m ost cr itical r oo m cond itio ns t hat can be rea che d in t h at posit ion be fore ma king a

choice.

Level the appliance by act ing on the individual feet.

This appliance can only be instal led and operate in rooms which are permanently ventilated, in order

to guarantee correct operation.

Connect and leave for a certain peri od of time (at least 2 hours) before checking functioning. During

transport it is probable that the compressor lubricant oil has entered the refrigerant circuit blocking the

capillary: as a consequence the appliance will function for a certain peri od of time without producing cold

until the oil has returned to the compressor.

ATTENTION: the appliance requires the mini m um functioning spaces, as shown in the attachments.

The defrosting water and the water that forms at the bottom of the refrigerating compartment during

operation or during periodical internal cleaning must be drained through a prearranged hose with a

minimum diameter 3/4 connected to the hose at the bottom of the chiller.

A drai n t r ap should also be guaranteed. The drain must be in comp lia nce with S tandards in force.

6.3 Electric P ower Supply Connection

Connection must be carried out by authorized and qualified staff, respecting the current laws regarding

the subject and using app r opr iate prescribed material.

Before connecting the appliance to the electric mains, check that the voltage and the frequency

correspond to the dat a stated on the registration plate applied in the rear of t he appliance.

Before connection, ensure the presence of a relevant differential switch with adequate power in the

mains power supply, upstream from the appliance, i n order to protect the appliance from overloads or

short circuits

6.4 Inspection

The appliance is delivered in conditions such that it can be st ar ted-up by the user.

This functionality is guaranteed by passing the tests (electric inspection-functional inspection,

appearance inspection) and relative certification through the specific att achments.

At least the following should be checked after installation:

Check the electric connec tions.

Check the functionality and efficiency of drains.

Check that there are no to ols or mater ials lef t in the app liance th at could jeo pa rdize it s funct ionality or

even damage the machine.

Have the appliance perfor m at least one complete chill blasting/shock freezing cycle.

10

Page 15

7.DISPOAL OF THE APPLIANCE

This appliance is marked in compliance with the 2002/96/EC European Directive. WASTE

ELECTRICAL AND ELECTRIC EQUIPMENT (WEEE).

By assuring that this product is dis posed of correctly , the user contributes to preventing the potentia l

negative consequences on the environment and health.

The

product must not be treated as domestic waste but must be taken to suitable collection points for the

recycling of electric and el ect r onic appliances.

Dispose of it following local regulations regard ing waste disposal.

For further information regarding the treatment, recovery and recycling of this product, contact the

relevant local office, the domest ic w aste coll ection serv ice or the shop w here the product was pur chas ed.

symbol found on the product or on the accompanying documentation indicates that this

8.REFRIGERANT RECHNICAL CARD

The refrigerant used in the machine is R404a fluid. Below find the components of the fluid:

PENTAFLUOROETANE (HFC R125)44%

ETHANE 1, 1, 1-TRIFLUORO (HFC R143A)52%

ETHANE 1, 1, 1, 2 TERAFLUORO (HFC R134A)4%

IDENTIFICATION OF DANGERS

The rapid evaporation of the liquid can cause freezing. The inhalation of high concentrations of vapour

can cause irregular heartbeat, short term narcotic effects (including vertigo , headache and mental

confusion), fainting and d eat h.

Effects to the eyes: Freezing or cold bur ns caused by contact with the liquid.

Effects on the skin: Freezing or cold bur ns caused by contact with the liquid.

Effects of ingestion. Ingest ion is n ot considered a means of exposure.

FIRST AID

Eyes: In the case of contact, wash the eye well using a l arge amount of water for at least 15 minutes.

Consult a doctor.

Effects on the skin: Wash with water for at least 15 minutes after excessive contact. If necessary, cure

freezing by gently warming the area in question. Consult a doctor in the case of irritation.

Ingestion: Ingestion is not considered a means if exposure.

Inhalation: If large concentrations are inhaled, go into the open air, Keep the person calm. If the

person cannot breath, perform artificial respiration. If respiration is difficult, apply oxygen.

Consult a doctor.

11

Page 16

XB570L

BLAST CHILL&FREEEZER CONTROLLER

9. General Features

The series XB has been creat ed f or fast chilling or freezing goods a ccor ding to international food safety

standards.

There are FOUR types of cy cles:

The CYCLES: Cy1, Cy2, Cy3, Cy4 are pre-set according to the m ost common cycles used in food -

safety applications; the user can select one of them according to his own requirement s and modify

it as he wants.

Any cycle can be manually terminated before the normal.

Any cycle can use the insert probe, it measures the internal temperature of the product.

During the Cycle there are no defrosts and the fans are always on, a defrost cycle can be done

before any freezing cycle.

The cycle is divided up to 3 phases c ompletely configurable by the user.

Each instrument is provided with an output for remote display XR REP, which s how s t he

temperature of cabinet s or goods.

The XB570L controller is provided with internal real time clock and can be connected t o t he

XB07PR printer. This means that a report, which includes all the main features of cycle, can be

printed: start and end of the cycle, length of t he cycle , loggi ng of the te mperatur e of the c abinet an d

goods.

10. Mounting & Installation

Model XB570L is a contro l ler panel mounted, hole dims 150x31 mm, and fixed wit h t he scr ew s . The

ambient operating temperature range is 0÷60°C. Avoid locations subject to heavy vibration, corrosive

gases or excessive dirt. T he same applies to the probes. E nsur e ventilation around the instrument.

11. Electrical Connections

The instruments are provided with a screw terminal block to connect cables with a cr oss s ect i on up to

2,5mm² for probes and digital input.

Spade on 6,3mm heat-res istant wiring for supply and loads. Before connecting cabl es make sure the

power supply co mplies wit h the instrume nt’s requir ement s. Separat e the input connectio n cables fro m the

power.

supply cables, from the outputs and the power connections. Do not excee d the maximum current

allowed on each relay, in case of heavier loads use a suitable external relay.

12

Page 17

11.1 PROBES CONNECTION

The probes shall be moun t ed with t he bulb upwar ds t o prev ent da mages d ue t o casu al liqu id infi ltrat ion. I t

is recommended to place the thermostat probe away from air streams to corr ectly measure the average

room temperature. Place the defrost termin at io n pr obe among the evaporator fins in the coldest place,

where most ice is formed, far from heaters and fro m the w ar me st place during defrost, to prevent

premature defrost ter m ination.

12. Connections

13. Frontal panel

14. QUICK START

14.1 DISPLA Y

The upper display shows the t emp er at ur e of the room probe.

The lower display shows the temperature of the inserts probe or the co unt down timer. To pass to the

one insert probe to the an ot her one use the DOWN key.

DISPLAY

Temperature.

Timer or insert probe

Alarm and status icons.

If an icon or LED is on, the correspondent

Function is enabled.

If an icon or LED is flashing, the correspondent

function is delayed.

13

Page 18

14.2 KEYBOARD IN STAND-BY

HOW TO SELECT A CYCLE:

Push and release the (3) key till the desired

cycle is selected.

HOW TO START A CYCLE: Push and release

the START/ST OP

button (2). Il The

correspondent yellow L E D is switched on..

HOW TO TEMPORARI LY STOP THE

RUNNING CYCLE.

1. Press and release the

key.

2. The compressor and the fan wi l l be stopped

for the PAU time (see par am et er s list) and

the flashing message “Stb” will be displayed.

3. To restart the cycle press and release the

key, the cycle will restart from the some

point at which it was interrupt ed.

4. In any case the cycle autom at ically restarts

after the PAU time.

HOW TO STO P A CYCLE: hold pushed the

START/STOP

button (2) till the yellow LED

will be switched off.

HOW TO SET THE TI ME (RT C)

Hold pushed the DOWN key (5) till the Min

label is displayed.

Use the UP and DOWN KEY to browse the

parameters.

TO MODIFY: push the SET button and then

the UP and DOWN keys.

TO CONFIRM : push the SET button.

TO EXIT THE RTC MENU: Push together

SET + UP keys or wait 5 sec.

1. HOW DISPLAY / MODIFY THE SET

POINT OF THE HOLDING PHASE

TO DISPLAY: Push and release the SET key In this exemplum the

(6), the holding set point of the selected cycle holding set point of the

is displayed for 5 sed.. cycle 1 is modified.

TO MODIFY: while the set point is displayed

hold pushed the SET key till the HdS label start

flashing. Use the UP and DOWN key to modify

the value. TO CONFIRM: push the SET key to

confirm the value and exit.

14

Page 19

HOW MODIFY A CYCLE:

1. Push the key (6) for several seconds

till the first parameter (CyS) is displayed.

2. Use the UP and DOWN keys to browse the

parameters.

3. To modify a parameter push the SET key

and use the arrow keys.

5. Confirm the new value by pushing the

SET key.

6. The new value is recorded even if the

programming is exited by t im e out.

14.3 KEYBOARD WHEN A CYCLE 1,2,3,4 IS RUNNING

DISPLAY TEMPERATURES:

The upper display shows the temperature of

the thermostat probe The bottom display

shows the temperature of a insert probe (if

enabled) or the count down t imer .

By pushing the DOWN key the probes iP1, iP2,

iP3 and the count down timer are displayed in

sequence.

PHASE DISP LAY: pushing the UP key the

running phase is displayed.

HOW TO DISPLAY THE REGULATION

SET POINTS

By pushing the SET key the follow i ng

information are displayed in sequence:

- rSI = Room set point

- iSI = Stop phase set point, referred to the

insert probe

- Back to the room temperat ur e.

HOW TO MODIFY THE ROOM SET

POINT

While rSI or iSI are displayed hold pushed the

SET key till the rSi or iSi label start flashing

and LED near the SET key is turned on..

Use the arrow key to modify the value and the

SET key to confirm it.

15

Page 20

14.4 KEYBOARD WHEN THE HOLDING CYCLE IS RUNNING (H)

HOW TO DISPLA Y THE HOL DI NG

(REGULATION) SET POINT

While the holding cycle is running, (H icon

lighted), push the SET key and the holding set

point is displayed on the UPPER display while

the SETH label on the bottom display

HOW TO MODIFY THE ROOM SET

POINT

While SETH is displayed hold pushed the SET

key till the SETH label star t s flashing and LED

near the SET key is turne d on. .

Use the arrow key to modify the value and the

SET key to confirm it.

TO CONFIRM AND EXIT: push again the SET

key

14.5 OTHER KEYS

LIGHT (4): push the LIGHT (4) key to switch

the light on and off. The status of the light is

monitored by the yellow LED upper the key.

AUX (8): push the AUX (8) key to switch the

auxiliary on and off. The s t at us of the auxiliary

relay is monitored by the yellow LED upper

the key.

PRINTER / H (7) : push t he PRINTER key when

the keyboard is connected to the controller, to

enabled/ disable the printer.

PRINTER CONFIGURATION MENU

Push the PRINTER (7) key for few seconds to

enter the printer configur at ion menu.

The itP, label is displayed, use the ARROW

keys to browse the parameters

To modify: push the SET key and t hen the

ARROW keys.

To confirm: push t he SET key

To exit the Printer menu: Push together

SET + UP keys or wait 5 sec

16

Page 21

14.6 HOW TO START A MANUAL DEFROST

put into “Pr1” (user level) by pressing “SET + ▼”.

LED

MODE

ACTION

- Anti-short cycle delay enabled

- Activation delay active

H

H

Assure that none cycle is act iv e or the hold mode is running.

1. Hold press the UP key fro few seconds.

NOTE: The defrost will not be done if the te mp er at ure detected by the evaporator probe is higher than

EdF (stop defrost temperature) par ameter.

14.7 OTHER FUNCTIONS OF KEYBOARD

+

To lock & unlock the keyboar d P on/PoF

To enter the programming mod e when the controller is

+

in stand-by

Each parameter present in the Pr2 c an be removed or

To return to the previous menu.

+

14.8 MEANING OF THE LEDS’

A series of light points on the front panels is used to monitor the loads controlled by the instr ument. Each

LED function is described in the following table.

ON

Flashing

- Compressor enabled

- Programming Phase (f lashing with LED

)

①②③④

①②③④

AUX –AUX2 ON

ON

Flashing

ON

Flashing

ON

Flashing

ON

- Fans enabled

- Programming Phase (f la s hin g with LED )

- Defrost active

- Drip time ac tive

- Freezing cycle 1, 2, 3, 4 or hold mode active

- Instrument temporarily stop

- Alarm signalling

- Aux or Aux2 enabled

17

Page 22

15. How To Select A Cycle

1. Push the to move among the cycles C1, C2, C3, C4 and the holding cycle. The related symbol on

the display will be lighted and t he cycle will be selected.

NOTE: to pass from a cycle to another one simply push t he

mode.

HOLD PHASE: To select H symbol pushing the

Cycles are pre-set with the fo llowing values:

1. Cy1: for fast chilling and conservation of foods ( har d + soft c hill).

2. Cy2: for chilling and fast freezing avoiding ice skin (hard + soft + freezing cycle).

3. Cy3: for fast freezing (fast freezing + freezing cycle)

4. Cy4: for direct fast fr eezing (only fast freezing cycle)

5. HLd: hold mode function

6. dEF: for starting a manual defrost

2. Now the cycle is memorized and can be activated.

15.1 HOW TO MODIFY A CYCLE

1. Verify that none cycle is r unnin g. If one cycle is running stop it by pushing the key for 3s.

2. Push the

to move among the cycles C1, C2, C3, C4 and the holding cycle. The relate d symbol on

.

key when the controller is in sta nd–by

the display will be lighted and t he cycle will be selected

3. Hold push the

cycle (CyS) with its value.

4. Use the UP and DOWN keys to browse the parameters.

5. To modify a parameter push the SET key and use the arrow keys.

6. Confirm the new value by pushing the SET key.

7. The new value is recorded even if the programming is exited by time out.

TO exit: wait 30s or push the SET+UP keys.

key for several seconds till the display will show t he f irs t parameter of the selected

16. Parameters

Hy Intervention differential for set point: (0,1 ÷ 12,0 /0,1°C/1°F), always pos itiv e. Co mpress or cut I N is

Set Point Plus Differential (Hy). Compressor cut OUT is when the temperature r eaches the set point.

AC Anti-short cycle delay: (0÷30 min) min imum int erv al between t he c ompre ssor s top an d the following

restart.

PAU Time of stand by: (0 ÷ 60min) after this time the controller restart t he cyc le.

PFt Maximum acceptable durat io n of power f ailur e: (0 ÷ 250 min) if power failure duration is less than

PFt, the cycle restarts from the same point at which it was stopped otherwise the cycle restar ts from

18

Page 23

the beginning of the current phas e.

Con Compressor ON time with faulty probe: (0÷ 2 55 m in) t ime during which the compressor is active

in case of faulty thermo st at probe. With COn=0 compressor is always OFF

COF Compressor OFF time with faul ty probe: (0÷255 min) time during which the compressor is off in

case of faulty thermostat probe. With COF=0 compressor is a lw ays active

PROBES

rPO Thermostat probe calibration (-12,0 ÷ 12,0; res. 0,1 °C / 1°F)

EPP Evaporator probe p r esence (not present in the XB350C): (no / YES) no: not present (timed

defrost); YES: pr esent (end defrost )

EPO Evaporator probe calibration (not prese nt in the XB350C): (-12,0 ÷ 12,0; res. 0,1 °C / 1°F)

i1P Insert probe 1 presence (no / YES) no: not present; YES: present.

i1o Insert probe 1 calibrat i on (-12,0 ÷ 12,0; res. 0,1 °C /1°F)

i2P Insert probe 2 presence (no / YES) no: not present; YES: present.

i2o Insert probe 2 calibration (-12,0 ÷ 12,0; res. 0,1 °C /1°F)

i3P Insert probe 3 presence (no / YES) no: not present; YES: present.

i3o Insert probe 3 calibrat i on (-12,0 ÷ 12,0; res. 0,1 °C /1°F)

rEM End cycle probe selecti on. ( iPt, rP). It sets which probe stops teh the cycle, thermostat probe or

insert probe.

iPt = insert probe;

rPt =thermostat probe

NOTE, with rEM = rPt wh en t he cycles are done by temperature, the rSi values are used as

stop of the cycle.

DISPLAY AND MEASUREMENT UNIT

CF Temperature measurement unit: ° C =Celsius; °F =Fahrenh eit

rES Resolution (for °C): in: integer; de: with decimal point

Lod Upper display visualization: select which pro be is shown by the upper display:

rP = Thermostat probe

EP = Evaporator probe

rEd Remote dis play, X-REP, visualization: select which probe is displayed by the X-REP:

rP = Thermostat probe; EP = Evaporator probe; tiM: cycle count down; i1P = insert pr obe 1; i2P =

insert probe 2; i3P = insert pr obe 3.

DIGITAL INPUT S

d1P: Door switch input pol ari ty (25-26): (OP÷CL)selec t if the digital input is activ at ed by opening or

closing the contact. OP= open ing; CL=closing

odc Compress or a nd fan status when open door:

no = normal;

Fan = Fan OFF;

CPr = Compressor(s) OFF;

F_C = Compressor(s) and fan OFF.

doA Open door alar m delay:(0÷254min,nu) delay between the det ection of the open door condition and

its

19

Page 24

alarm signalling: the flashi ng m essage “dA” is displayed. If doA=nu the door alarm will be not

Holding

signalled.

dLc Stop count do wn of the r unning cy cl e with door op en y = count down is stopped w ith door openi;

n= count down goes on with door open;

rrd Regulation restart with door open alarm: y = count down and regualtion restart w hen door open

alarm is signalled.; n = compressor and fans stay according to the odc parameter when door open

alarm is signalled.

d2F(EAL, bAL,) Second digital input configurati on ( 2 6 -27): EAL: external alarm; bAL: serious alarm,

regulation is stopped.;

d2P: Configurable digital input polarity ( 2 6 -27): (OP÷CL)select if the digital input is activated by

opening or closing the con t act. OP= opening; CL=closing

did Time delay for digital input alarm:(0÷255 min.) If d2F=EAL or bAL (external alarms), “did”

parameter defines the t i m e del ay between the detection and the successive signalling o f the alarm.

AUXILIARY RELAY CONFIGURATION

oA1 First auxiliary r el ay configuration (7-8):

ALL: alarm; Lig: light; AuS: Second thermostat; tMr: auxiliary r elay enabled by keyboard

C2: Second compressor: it always is switched on during the Cycles, during the holding depends on

the 2CH parameter

oA2 First auxiliary r el ay configuration (1-2):

ALL: alarm; Lig: light; AuS: Second thermostat; tMr: auxiliary r elay enabled by keyboard

C2: Second compressor: it always is switched on during the Cycles, during the holding depends on

the 2CH parameter

oA3 First auxiliary r el ay configuration (9-10)

ALL: alarm; Lig: light; AuS: Second thermostat; tMr: auxiliary relay enabled by keyboard

C2: Second compressor: it always is switched on during the Cycles, during the holding depends on

the2CH parameter

SECOND RELAY MANAGEMENT

2CH Compressors set t ing during the holding phase : (used only if one OAi =C2)

The second compressor is alway s switched on durin g the phase s, duri ng the h olding de pends on this

parameter.

The 2CH sets which comp r essor is used during the holding phase.

Second compressor oper at es on set + OAS. (whit set= set loaded during the holding phase of each

cycle). It starts oAt min. after the first compressor

The following table shows how it works:

2CH =C1 C1 on;

2CH =C2 C2 on

2CH =1C2 C1 on; C2 On

OAt Second compressor switching on delay: (0÷255 min) time de lay between the switching on of the

first and second compressor.

OAS Set point for se cond compressor (-50÷50; ris.1 ° C/ 1° F) This set point is a differential add to the

set point of the first compressor .

20

Page 25

ES. OAS=0 the set point of t he second compressor s the same set point of the first compr essor.

OAS=5 the set point of the second compressor is SET (of first c ompressor) + 5;

OAS=-5 the set point of the second compress or is S ET (of first compressor) - 5;

OAH Differential for second compr essor: (-12.0÷12,0; ris.0,1°C/1°F, alway s ¹ 0) second compressor

cut IN is SETH+OAS+OAH. Second compressor c ut out is when the temperature SETH+OAS.

OAi Probe selection for the second compressor: rP =Thermostat probe; EP = Evaporator probe; tiM:

cycle count down; i1P = insert pr obe 1; i2P = ins er t probe 2; i3P = insert probe 3.

AUXILIARY RELAY MANAGEMENT

OSt AUX output timer: (0÷255 min) time in which the AUX out put stays ON. It is used when oA1 or oA2

or oA3 = tMr. With oAt = 0 the AUX r el ay is switched on and off only manually.

OSS Set point for AUX output, used when oA 1 or oA2 or oA3 = AUS (-50÷50; ris.1 °C/ 1°F)

OSH Differential for AUX output: (-12.0÷12,0; ris.0,1°C/1°F, always ¹0) Intervention differential for the

set point of the AUX output, with OAH<0 the action is for heating, w ith OAH>0 it is for cooling.

COOLING, OSH >0: AUX output cut IN is OSS+OAH. Second compressor cut out is when the

temperature SETH+OAS.

HEATING, OSH <0: second compressor cut IN is OSS-O AH. Second compressor cut out is w hen the

temperature OSS

OSi Probe selec t ion for the second compressor: rP =Thermostat pr obe; EP = Evaporator probe; tiM:

cycle count down; i1P = insert pr obe 1; i2P = ins er t probe 2; i3P = insert probe 3.

DEFROST

tdF Defrost type (not present in the XB350C): (rE= electrical heater; in = hot gas).

IdF Interval between def r ost cycles: (0.1÷ 24.0; res. 10 min) Determines the time interval between the

beginning of two defrost c ycles. (with 0.0 the defrost is disabled)

dtE Defrost termination temperature: (-50÷50 °C/°F) Sets the temperatur e m easured by the evaporator

probe, which terminates the defrost. Used only if EPP =YES

MdF Maximum length for defrost: (0÷255 min) When EPP = no (timed defrost) it sets the defrost

duration, when EPP = YES (defrost termination based on temperature) it sets t he ma x i m um length

for defrost.

dFd Temperatur e displayed during defrost: (rt , it, SEt, dEF) rt: real temperature; it: temperat ur e at

the start of defrost; SEt: set point; dEF: “dEF” message

Fdt Drip time: (0 ÷ 60 min) Time interval between reaching defrost termination temperature and the

restoring of the controllers ' normal operation. This time allows the evaporator to eli m inate water

drops that might have for me d during defrost.

dAd Defrost dis pl a y time out: (0÷120 min) Sets the maximum time between the end of defrost and

the restarting of the real roo m temperature display.

FANS

FnC Fans operat i ng mode during the holding phase:

o-n = continuous mode, O FF during defrost;

C1n= runs in parallel with the first compressor, OFF during defrost;

C2n= runs in parallel with the second com pr essor, OFF during defrost;

21

Page 26

Cn= runs in parallel with compressors, OFF during defrost;

o-Y = continuous mode, on dur ing defrost;

C1y= runs in parallel with t he first compressor, on during defrost;

C2y= runs in parallel with the second compressor, on during defrost;

Cy= runs in parallel with compressors, on during defrost;

FSt Fan stop temperature: (-50÷50°C/°F; res. 1°C/1° F).It used o nly if the E PP = yES. If the tem peratur e.

detected by the evaporato r pr obe is above FSt fans are stopped. It serves to avoid blowing warm air

in the room.

AFH Differential for the stop temperature and for the alarm (0.1 ÷ 25.0 °C; ris.0.1°C/1°F) Fans carry

on working when the temperature reaches th e FSt-AFH value, the temperature alarm rec overs when

the temperature is AFH degrees bel ow the alarm set.

Fnd Fan delay after defrost: (0 ÷ 255 min) The time int erval between end o f defrost and ev aporator fa ns

start.

TEMPERATURE ALARMS

ALU MAXIMUM temperature alarm (it is used only during t he holding phase): (1 ÷ 50 °C/°F) When

the “SET+ALU” temperatu r e is reached the alarm is enabled, (possibly after the “ALd” de lay t ime).

ALL Minimum tem per at ure al arm (i t i s used only during the holding phase): (1÷ 50°C/1° F) When the

“SET-ALL” temperature is reached the al arm is enabled, (possibly after t he “ ALd” delay time).

ALd Temperature alarm delay (it is used only dur ing the holding phase): (0÷255 m in) t i me interval

between the detection of an al arm condition and alarm signalling.

EdA Temperature alarm delay at the end of defro st (it is used only during the holdi ng phase): (0 ÷

255 min) Time interval betw een the detect ion of the temper ature alar m condit ion at the end of defro st

and alarm signalling.

tbA Silencing alarm relay: (Yes= silencing buzzer and alar m rel ay, no= only buzzer silencing).

CYCLE LOG

tCy duration of the last cycle (readable only);

tP1 duration of first phase of the la s t cycle (readable only);

tP2 duration of second phase of the last cycle (readabl e only ) ;

tP3 duration of third phase of the last cycle (readable only);

OTHER

Adr Address for RS485: (1 ÷247)

bUt Buzzer activation at t he end of the cycle (0÷60s; w ith 0 t he buzzer is on till a key is pushed)

tPb Kind of probe: it sets the kind of probe used:

ntc = NTC o Ptc = PTC.

rEL Release code (reada ble onl y)

Ptb Parameter code (readable only)

17. How A Cycle Is Done

1. Every programmable cycle Cy1, Cy2, Cy3 or Cy 4 can be divided into up to 3 phases usua l ly called:

• hard chill

22

Page 27

• soft chill

• freezing cycle

2. For each phase there are 3 par ameters.

iS1, (iS 2, iS 3): Set point related to the insert pr obes that stops the current phase.

rS1, (rS2, rS3): set point of the room temperature for each phase.

Pd1, (Pd2, Pd3): the maximum durat ion time for eac h phase.

Hds : set point of the hold phase at the end of the whol e cycle.

There are also 3 parameters:

first one concerning the cycle way of doing the cy cle: by t emperature or by t ime, t he other two ar e related

to the defrost. These are dbC = defrost before cycl e, dbH = defrost before holding (at the end of the

cycle).

17.1 CONFIGURABLE CYCLE PARAMETERS

cyS Cycle setting: tEP = by temperature. the cycle is done according to the rEM parameter; tiM: timed

cycle, based on the Pd1, Pd2, Pd3 parameters.

dbc (yes/no) Defro st before the cycle

iS1 (-50÷50°C;1°C/1°F) Inser t Probe Set point: when the temperature m easured by the three insert

probes reaches this valu e the first phase is ended.

rS1(-50÷50°C; 1°C/1°F) R oom probe S et point for t he first phase: it prev ents te mperatur e from rea ching a

too low value during the hard cycle.

Pd1 (OFF÷4.0h;10 min)Maximum time for first phase

iS2 (-50÷50°C; 1°C/1°F) Insert probe set point when the temperature measured by t he t hr ee insert

probes reaches this valu e the second phase is ended.

rS2 (-50÷50°C; 1°C/1°F) Room probe Set point for the second phase: it prevents temperature from

reaching a too low value dur ing the second phase.

Pd2 OFF÷4.0h; res. 10 min Maximum time for second phase.

iS3 (-50÷50°C; 1°C/1°F) Insert Probe Set point to stop the third (and last ) phase: when the temperature

measured by the three insert pr obes r eaches this value the third phase is ended.

rS3 (-50÷50°C; 1°C/1°F) Room probe Set point for the third (and last) phas e: it prevents temperature

from reaching a too low value during the third (and last ) phas e.

Pd3 (OFF÷4.0h; 10 min) Maximum time for the third phase.

dbH (yes / no) def rost before the hold phase

HdS (-50÷50 - OFF; 1 °C / 1°F) Set point of the holding phase. With “OFF” the hold phase is dis abled.

IMPORTA NT NO TE: If the duration time of a ph as e is set at the OFF value, the corresponding phase is

disabled. E.g. If Pd3= 0FF the third phas e of the cycle is not active.

17.2 HOW TO USE THE INSERT PROBES

By means the insert probe , t he interna l temperature of products can be checked. This measur e is us ed t o

end the various phase of the cycle. A special internal function detect if the inset pr obe is not used, in this

case the cycle is made by time

17.3 EXAMPLE OF A BLAST CHILLER CYCLE.

The following drawing explains how a Blast Chiller cycle can be done.

23

Page 28

17.3.1 First phase: “Hard chill”.

It is normally used to fast chill h ot foods. E.g. from 80°C / 170°F to 20°C / 70°F

During “Hard Chill”, both compressor and fan are always on unt il the rS1 temperature is r eached. At

this point compressor i s tu rned o n end off s o as to k eep the t em peratur e o f th e roo m at t he rS1 value.

“Hard Chill” ends when th e t emp er ature measured by the 3 insert probes reach the iS1 value.

17.3.2 Second phase: “Soft chill”.

The Soft Chill starts when the Hard Chill ends. I t is used t o pr event thin layer of ice from forming on

the product. The Soft Chill lasts unti l the temperature measured by the 3 insert probes reach t he set

point iS2 (usually 4 or 5°C).

During Soft Chill the temp erature of the ro om is regu lated by t he ambient prob e with the set point rS2

(normally at 0 or 1 °C / 32 or 34°F). When the box temperature r eaches the rS2 value compressor is

turned on end off so as to keep the te mp er at ur e of the box at this value.

17.3.3 Third phase: “Fre ezi ng cycle”.

Freezing Cycle: used to fast freeze foods.

The Freezing Cycle starts when the Soft Chill ends. During the “Freezing Cycle” bot h compressor

and fan are always on until the rS3 t emperature is reached. At t his point compressor and fans ar e

turned on end o ff so as t o keep th e temp erature of t he roo m at the rS3 value (normally some degrees

below iS3).

Freezing Cycle ends when the temperature measured by the 3 insert probes reach the iS3 value

(normally -18°C / 0°F), in any case it ends when the maximum time Pd1 + Pd2 + Pd3 has expired.

17.3.4 End of the Bl as t Chill cycle and starting of the Hold Mode.

When one of the three inser t pr obes r eaches the iS3 value the values End followed by t he i1 P or i2P

or i3P are shown on the display.

Cycle ends when all the probes h av e reache d the iS 3 value. A signa l is gener at ed: buz z er and alarm

relay is turned ON, the display s how s t he message “End” alternating with the room temperature.

The alarm automatically stops after the “but” time or by pressing any keys.

At the end of the cycle the controller can start the “Hold mode” keeping the room temper at ur e at t he

value set in HdS parameter.

If HdS = OFF, the machine is turned OFF.

NOTE1: with dbH = yES a defrost is done before the holding phase.

NOTE2: If the end cycle temperature iS3 is not reached in the maximum time Pd1+Pd2+Pd3 the

24

Page 29

instrument keep on working, but the alarm mes sage “OCF” is given.

18. Installation and mounting

Instruments XB570L shall be mounted on vertical panel, in a 150x31 mm hole, and fixed using two

screws ø 3 x 2mm. To obtain an IP65 pr ot ection grade use the front panel rubber gasket (mo d. RG-L).

The temperatur e rang e allowed for correc t operat ion is 0 - 60 °C. Avoid places subject to str ong vibrat ions,

corrosive gases, excess iv e dir t or humidity. The same reco m me ndations apply to probes. Let the air

circulate by the cooling holes.

18.1 CUT OUT

18.2 MOUNTING

25

Page 30

19. XB07PR - Printer (optional)

The XB570L is designed t o w or k with t he XB07PR.

The XB07PR kit is compos ed by:

1. Printer

2. Power adapter

3. Connecting cables

19.1 PRINTER DIMENSIONS

19.2 PRINTER MOUNTING

SCREW FIXING PANEL CUT OUT

26

Page 31

19.3 CONNECTION TO THE XB570L – XB07PR

20. Electrical connections

The instruments are provided with screw terminal block to connect cables with a c ros s sect ion up to 2,5

mm2 for the digital and analo gue i nput s . Relays and power supply have a Fast on connection (6,3mm).

Heat resistant cables have to be used. Before connecting cables make sure the power supply complies

with the instrument’s requirements. Separate the probe cables from the power supply cables, from the

outputs and the power connec t i ons. Do not exceed the maximum current allowed on eac h r elay, in case

of heavier loads use a suitabl e ex t er nal relay.

N.B. Maximum current allowed for al l t he loa ds is 20A.

20.1 PROBE CONNECTIONS

The probes shall be moun t ed with t he bulb upwar ds t o prev ent da mages d ue t o casu al liqu id infi ltration. I t

is recommended to place the thermostat probe away from air streams to corr ectly measure the average

room temperature.

21. TTL Serial line

The TTL connector allows, by means of the ext ernal modu le TTL/ RS 485, to connec t the unit to a netw or k

line ModBUS-RTU compatible as the DIXEL monitoring syste m X J500 (Version 3.0).

The same TTL connector i s used to upload and download the parameter list of the “ HOT KEY“.

22. Use of the programming “HOT KEY”

The Wing units can UPLOAD or DOWNLOAD the parameter list from its own E2 inter nal memory to the

“Hot Key” and vice-versa.

22.1 DOWNLOAD (FROM THE “HOT KEY” TO THE INSTRUMENT)

1. Turn OFF the instrument by means of the ON/OFF key, remove the TTL seria l cable if pres ent, insert

the “Hot Key” and then turn the Wing ON.

27

Page 32

2. Automatically the parameter list of the “Hot Key” is downloaded into the Wing memory, the “DoL”

Mess

Cause

Outputs

“EE”

Alarm output ON; Compressor output according to

temperature control on fa ns.

Alarm output ON; Other outputs unchanged; The cycle is

“rtC”

Real Time Clock data lost

Alarm output ON; Other outputs unchanged;

Alarm output ON; Other outputs unchanged; The date and

“HA”

“LA”

Fast freezing interrupte d by

Alarm output ON; The freezing cycle restart from the same

long power failure

Alarm output ON; The freezing cycle restart from the

current phase.

Max duration of the cycle is

“EA”

External alarm

Alarm output ON; Other outputs unchanged.

“CA”

Serious external alar m

Alarm output ON; Other outputs OFF.

“dA”

Door open alarm

Alarm output ON; Other outputs unchanged.

message is blinking. After 10 seconds the instrument will restart working wit h t he new par ameters.

3. Turn OFF the instrument remove the “Hot Key”, plug in the T TL serial cable, then turn it ON ag ain .

At the end of the data transfer ph ase t he instrument displays the following messages:

“end “ for right progra m ming. The instrument starts regularly with the new programm ing.

“err” for failed programming. In this case turn the unit off and then on if you want to restart the dow nlo ad

again or remove the “Hot key” to abort the operation.

22.2 UPLOAD (FROM THE INSTRUMENT TO THE “HOT KEY”)

1. Turn OFF the instrument by means of the ON/OFF key and re m ove the TTL serial cable if present;

then turn it ON again.

2. When the Wing unit is ON, insert the “Hot key” and push o key; the "uPL" message appears.

3. Push “SET” key to start the UPLOAD; the “uPL” message is blinking.

4. Turn OFF the instrument remove the “Hot Key”, plug in the T TL serial cable, then turn it ON ag ain .

At the end of the data transfer ph ase t he instrument displays the following messages:

“end “ for right progra m ming.

“err” for failed programming. In this case push “SET” key if you want to restart the program m in g again or

remove the not programm ed “ H ot key”.

23. ALARM SIGNALS

Data or memory failure Alarm output ON; Other output s unchanged

“rPF”

“EPF”

“i1P”

“i2P”

“i3P”

“rtF”

“FF”

“PFA”

Thermostat Probe failure

Evaporator Probe failure

Insert probe 1, 2, 3, failure

Real Time Clock failure

Maximum temperature al arm Alarm output ON; Other outputs unchanged

Minimum temperature alarm Alarm output ON; Other outputs unchanged.

shortpower failure

Fast freezing interrupte d by

parameters “COn” and “C OF”

Alarm output ON; Defrost t er m ination is timed; No

made by time

the duration of the cycle a r e not available.

point at which was interrupted.

“OCF”

expired

Alarm output ON; Other outputs unchanged. In any case

the cycle ends when the fi nal temperature is reached

28

Page 33

24. Technical data

CyS =

iS2 =

Pd3

dbC =

rS2

dbH

iS1 = 8°C

Pd2 = 3.0 h

HdS = 2°C

rS1= -10°C

iS3 = 5°C

Pd1 = 2.0 h

rS3=+2°C

CyS =

iS2

Pd3

dbC = no

rS2

iS1

Pd2

rS1

iS3

Pd1 = 2.0 h

rS3=-28°C

Housing: self extinguishing ABS.

Case: frontal 185x38 mm; depth 70mm;

Mounting: panel mounting in a 15 0x 31mm panel cut-out

Frontal protection: IP65

Connections: Screw terminal block £ 2,5mm² wiring.

Power supply: 230Vac, ±10%

Power absorption: 5VA max.

Display: dual display

Inputs: 5 PTC or NTC probes

Relay outputs:

compressor: relay SPST 20(8)A or 8(3) A, 250 Vac

defrost:: relay 8(3)A, 250Vac

fans: relay SPST 8(3)A, 250Vac

Light : relay SPST 16(6)A, 250Vac

Aux1 : relay SPST 8(3)A, 250Vac

Aux2 : relay SPST 16(6)A , 250Vac

Serial output: RS232 serial output for X B07PR printer connection

Serial output: T TL serial output for monitoring system (MODBUS-RTU) protocol

Data storing: on the non-volatile memory (EEPROM).

Operating temperature: 0÷60 °C.

Storage temperature: -30÷85 °C.

Relative humidity: 20÷85% (no condensing)

Measuring range: -55÷50 °C

Resolution: 0,1 °C or 1 °F (selectable).

Accuracy of the controller at 25° C : ±0, 3 °C ±1 digit

25. Standard Value of the cycles

Cy1: for fast chilling and conservation of foods at positive temperature

tEP

not

Cy2: for chilling and fast freezing of fo ods with holding

tEP

= 10°C

= -10°C

5°C

=+2°C

= 5°C

= -2°C

= 3.0 h

=-18°C

29

= OFF

= yes

= 4.0 h

dbH = YES

HdS =-21°C

Page 34

Cy3: direct fast freezing with holding

CyS =

iS2

Pd3

dbC =

rS2

iS1

Pd2

rS1

iS3

Pd1

rS3

CyS = tEP

iS2=-18°C

Pd3 = OFF

dbC = not

rS2=-28°C

dbH = no

iS1 =-18°C

Pd2 =OFF

HdS = OFF

rS1

iS3

Pd1

rS3

Lab

Description

Values

Level

Set

Hy

AC

PAU

PFt

Con

COF

Compressor OFF time wit h fau lty probe

10

Pr2

rPO

Thermostat probe calibration

0.0

Pr2

EPP

Evaporator probe presence

YES

Pr2

EPO

Evaporator probe calibration

0.0

Pr2

i1P

Insert probe 1 presence

YES

Pr2

i1o

i2P

i2o

i3P

i3o

rEM

CF

Temperature measureme nt unit

°C

Pr2

rES

Resolution (for °C):

in

Pr2

Lod

Local display

rP

Pr2

rEd

d1P

Odc

dOA

dLc

rrd

d2F

Second digital input funct ion

EAL

Pr2

tEP

no

= -18°C

=-30°C

= 4.0

Cy4: direct fast freezing without holding

=-30°C

= 4.0

=-18°C

=-28°C

=OFF

=-18°C

=-28°C

=-18°C

=-28°C

26. Standard Values of the parameters

Set point 3 - - differential 4.0 Pr1

Anti-short cycle delay 2 Pr2

Time of stand by 20 Pr2

Maximum acceptable dur at ion of power failure 15 Pr2

Compressor ON time with fau lt y probe 10 Pr2

= 4

dbH = yes

HdS = -21°C

Insert probe 1 calibration 0.0 Pr2

Insert probe 2 presence n Pr2

Insert probe 2 calibration 0 Pr2

Insert probe 3 presence n Pr2

Insert probe 3 calibration 0 Pr2

Probe selection to stop chil ling c ycle iPt Pr2

Remote display rP Pr2

Door switch polarity cL Pr2

Open door control F-C Pr2

Open door alarm delay 5 Pr2

Stop count down of running cycle y Pr2

Regulation restart after door open alarm Y Pr2

30

Page 35

Lab

Description

Values

Level

d2P

Second digital input polar i ty cL Pr2

did

oA1

oA2

oA3

2CH

OAt

Second compressor switching on delay

3

Pr2

OAS

Set point for second compr essor

0

Pr2

OAH

Differential for second compressor

2.0

Pr2

OAi

Probe selection for second compressor

rP

Pr2

OSt

OSS

OSH

OSi

tdF

IdF

dtE

Defrost termination temperature

6

Pr2

MdF

Maximum length for defrost

20

Pr2

dFd

Temperature displayed during defrost

set

Pr2

Fdt

Drip time

2

Pr2

dAd

Defrost display time out

20

Pr2

FnC

FSt

AFH

Fnd

ALU

ALL

Minimum temperature alarm

30

Pr2

ALd

Temperature alarm delay

15

Pr2

EdA

Alarm delay after defrost

30

Pr2

tbA

Silencing alarm relay

YES

Pr2

tCy

tP1

tP2

tP3

Adr

bUt

tPb

Type of probe

ntc

Pr2

rEL

Release code (readable only)

2.0

Pr2

Ptb

Parameter code (readable only)

1

Pr2

Time delay for digital input alarm 5 Pr2

First configurable relay function tMr Pr2

Second configurable re lay function ALL Pr2

Third configurable relay function Lig Pr2

Compressor setting during the holding C1 Pr2

Auxiliary output timer 0 Pr2

Set point for auxiliary output 0 Pr2

Differential for auxiliary output 2.0 Pr2

Probe selection for auxiliary output rP Pr2

Defrost type in Pr2

Interval between defrost cycles 6.0 Pr2

Fan operating mode o_n Pr2

Fan stop temperature 15 Pr2

Differential for the stop temp er at ur e and for the alarm 10 Pr2

Fan delay after defrost 2 Pr2

MAXIMUM temperature alarm 30 Pr2

Duration of last cycle - - - Pr1

Duration of first phase of the last cycle - - - Pr1

Duration of second phase of the last cycle - - - Pr1

Duration of third phase of t he last c ycle - - - Pr1

Address for RS485: 1 Pr2

Buzzer activation at the end of the cycle 30 Pr2

31

Page 36

32

Loading...

Loading...