USER GUIDE

RADION 8140

Automatic sprayer control

Software version 1.05

Safety information

TeeJet Technologies is not responsible for damage or physical harm caused by failure to adhere to the following safety

requirements. As the operator of the vehicle, you are responsible for its safe operation. The Radion 8140 in combination with any

assisted/auto steering device is not designed to replace the vehicle’s operator. Do not leave a vehicle while the Radion 8140 is engaged.

Ensure the area around the vehicle is clear of people and obstacles before and during engagement. The Radion 8140 is designed to support

and improve efciency while working in the eld. The driver has full responsibility for the quality and work related results. Disengage or

remove any assisted/auto steering device before operating on public roads.

iii

98-01467-EN R1

Radion 8140 automatic sprayer control

Table of Contents

NO.1 POWER ON, SWITCHES 1

Boom sections & Switches ........................................................................................................................................1

NO.2 OPERATION SCREEN 2

Operation menu ..............................................................................................................................................................................................2

Information bar ...............................................................................................................................................................................................3

Regulation modes ..........................................................................................................................................................................................3

Manual regulation mode ............................................................................................................................................3

NO. 3 GO TO HOME 4

1 SET UP THE LOCAL CULTURAL SETTINGS 4

2 SET UP THE JOB PARAMETERS 4

Establish preset target application rates ....................................................................................................................4

3 SET UP THE MACHINE 5

Operation ..........................................................................................................................................................................................................5

Implement parameters .................................................................................................................................................................................6

Section configuration .................................................................................................................................................6

Nozzle preset setup ..................................................................................................................................................6

Establish nozzle presets ............................................................................................................................................7

Calibrations .......................................................................................................................................................................................................7

NO. 4 START NEW JOB OR CONTINUE JOB 9

Jobs ......................................................................................................................................................................................................................9

SENSOR CALIBRATIONS 10

Implement speed sensor .........................................................................................................................................10

Flow sensor.............................................................................................................................................................10

Liquid pressure sensor ............................................................................................................................................ 11

Fill flow sensor ........................................................................................................................................................13

Tank level sensor ....................................................................................................................................................14

OPERATION SCREEN 17

INFORMATION BAR 17

Selectable information .............................................................................................................................................................................. 17

Application rate ............................................................................................................................................................................................ 18

Select target application rate ...................................................................................................................................18

Target rate percentage increase/decrease ...............................................................................................................19

Change application rate step ...................................................................................................................................19

iv

www.teejet.com

Radion 8140 automatic sprayer control

NOZZLE SELECTION 20

Selecting the current nozzle ....................................................................................................................................20

Presetting nozzles ...................................................................................................................................................20

TANK 21

ALARM WARNING 21

PRESSURE GAUGE 22

BOOM SECTIONS & SWITCHES 22

ALARM CONFIGURATIONS 23

1

98-01467-EN R1

Radion 8140 automatic sprayer control

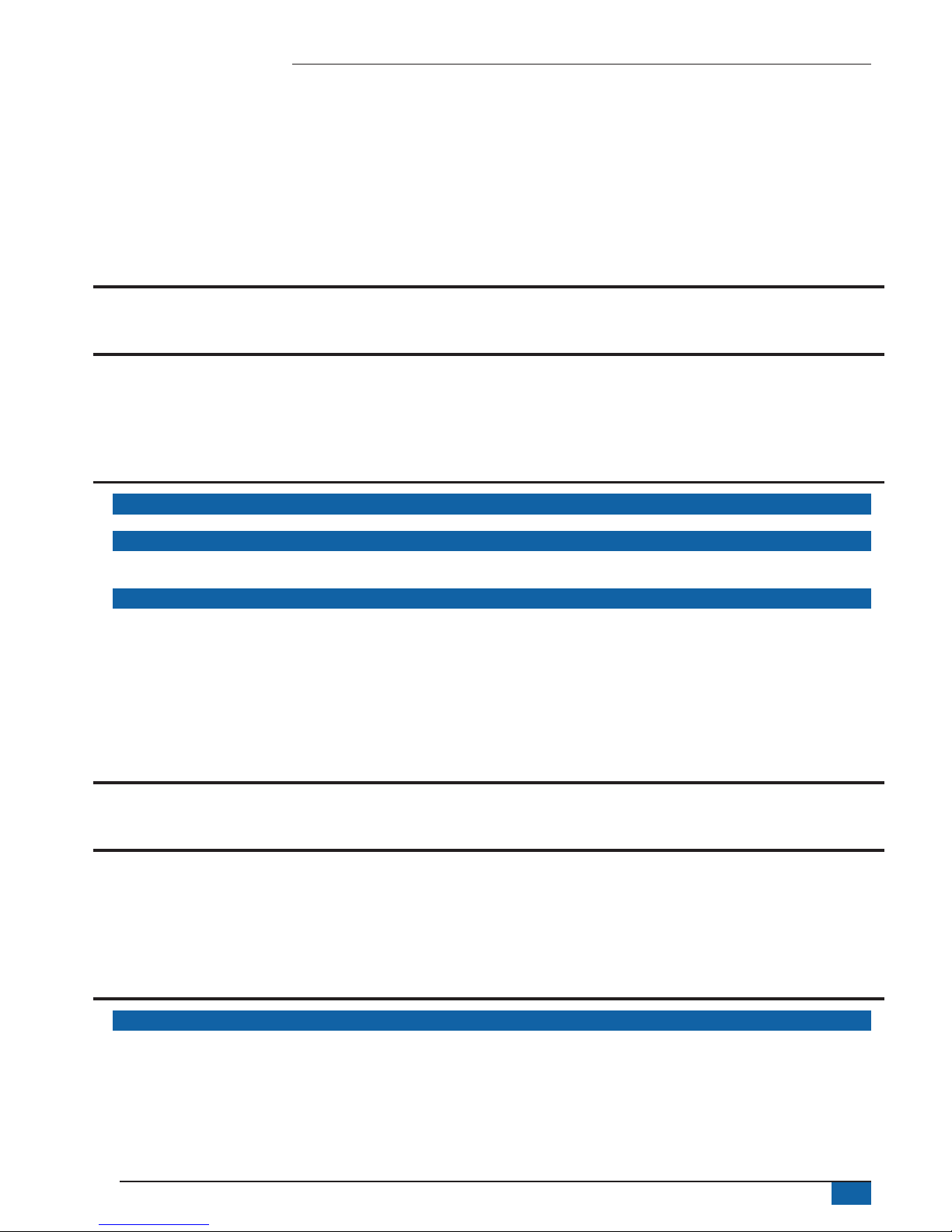

NO.1 POWER ON, SWITCHES

Integrated RAM mount

(assembly required)

Power button

USB port with rubber cover

Speed cable connection

Main cable connection

Serial connection

Master switch

Bright touch screen

CAN connection

Boom section controls

(switches 1 to 5 or 1 to 7 or 1 to 9,

depends on console)

Power On/Off Button

On – Press the POWER button to power on the console. Upon

power up, the Radion will begin its start up sequence. Once start up

is complete, the Operation screen appears.

Off – Press the POWER button . On the conrmation screen to

acknowledge shut down mode, press Yes to power off the console.

WARNING! Wait 10 seconds before restarting the console.

Boom sections & Switches

The console operates with nine (9), seven (7) or ve (5) section

switches (depending on console model) and one (1) Master switch.

Each section switch is associated with one of up to the same number

of sections on the boom and illustrated on the Operation screen.

►Switches – control individual boom sections

◄On – Flip the switch up

◄Off – Flip the switch down

►Master switch – opens/closes the main product valves and

enables/disables power to individual boom section on/off

switches

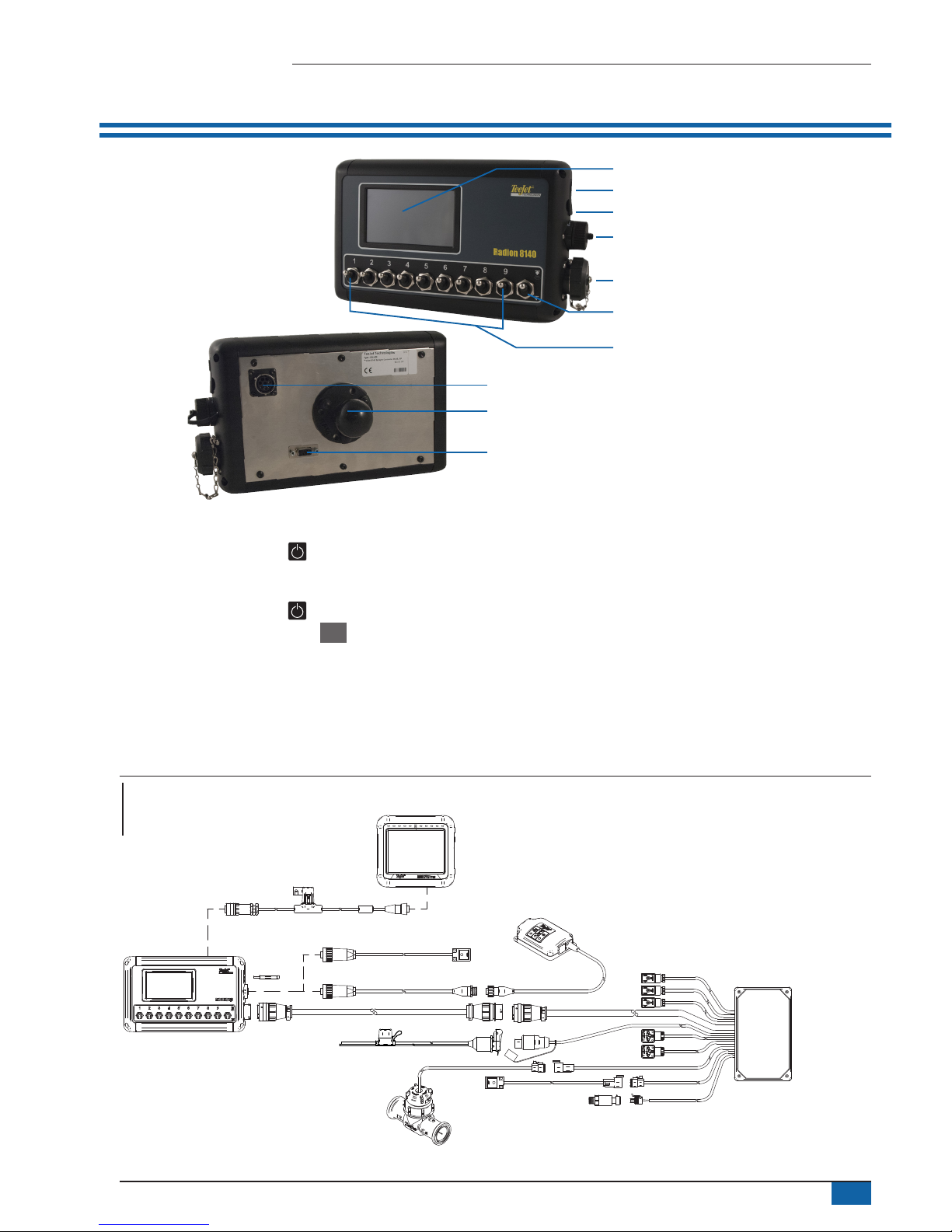

Figure 1: System diagram

Radion 8140 sprayer controller

(available in 5 sections,

7 sections or 9 sections)

98ET05-S13-4

Extension for

main cable, 4 m

Spray cable -

flow/pressure/speed

199-315: 5 section, 8 m

199-311: 7 section, 8 m

199-319: 9 section, 8 m

* Unlock code necessary to activate

the BoomPilot function, contact TeeJet Technologies.

** Only one speed source at the same time.

Flow meter

Pressure sensor

570-001: 10 bar ¼ NPT

570-002: 25 bar ¼ NPT

96ET10-8D **

Speed sensor

proximity, 8 m

96ET14 Cable,

battery to COBO,

4 m

98-50139

USB stick

99ET017-6** Speed sensor proximity, 6 m

90-02371 GPS speed sensor

198-669 ** GPS speed adapter cable

Matrix Pro console

Cable, BoomPilot adapter cable,

Radion to Matrix Pro

197-100*: Direct

197-101*: CAN/power/data cable

Radion

Matrix Pro & BoomPilot

Optional Accessory

2

www.teejet.com

Radion 8140 automatic sprayer control

NO.2 OPERATION SCREEN

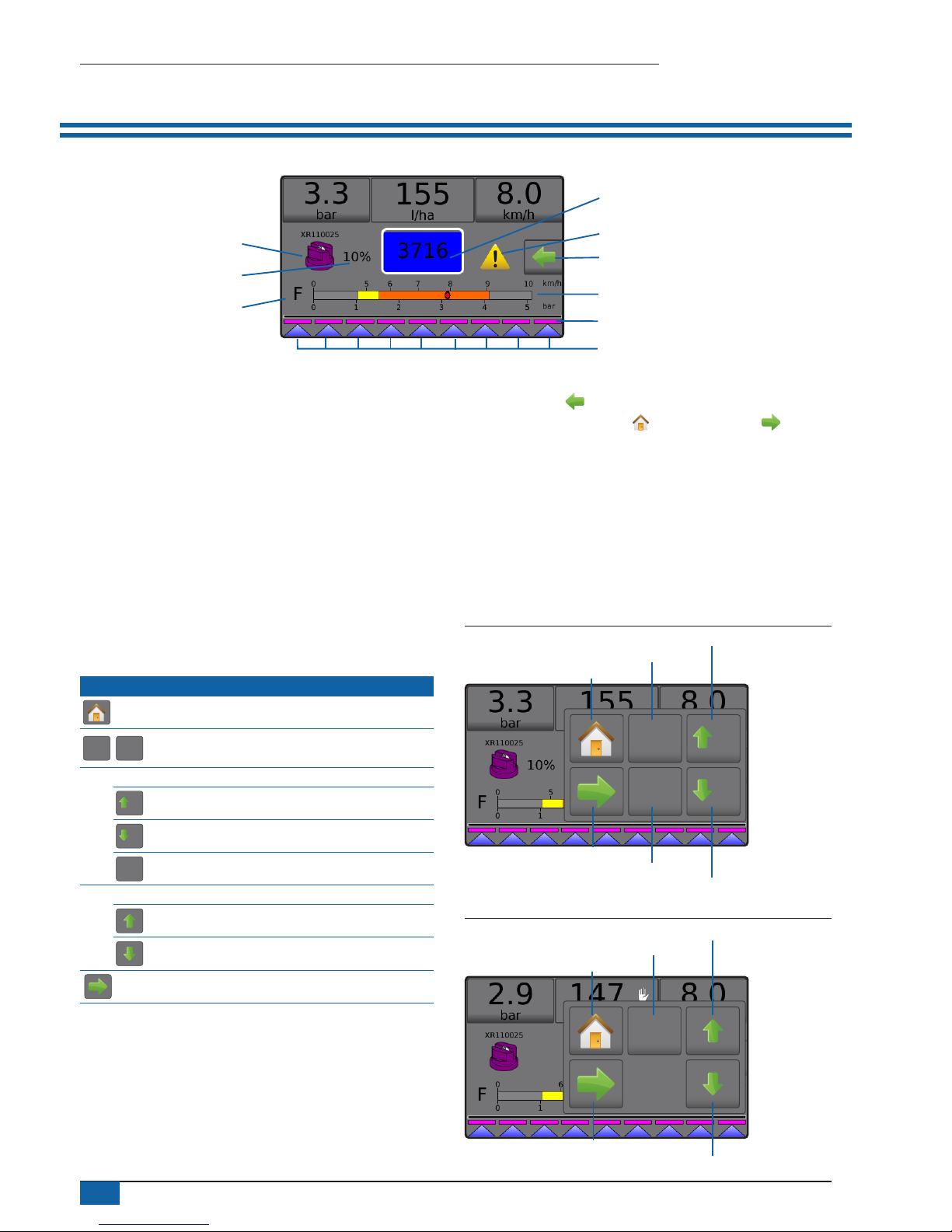

Boom sections

Spray status

Pressure gauge

Current nozzle

Information bar

Current droplet size

Tank contents / lling options

Alarm warning

Options tab

Application rate change

►Information bar – displays application rates and selectable

information

►Current nozzle – displays current nozzle and accesses ve (5)

preset nozzle types

►Application rate change – displays rate changes (if in

Automatic regulation mode)

►Tank – displays remaining tank contents and accesses lling

options

◄Filling – establishes actual/desired tank material/density

►Alarm warning – displays active alarm conditions

►Options tab – accesses the Operation menu

◄Displays Home button , Close Menu button ,

regulation modes and target rate options

►Pressure gauge – displays current pressure range compared

with recommended pressure range

◄Droplet size – displays selected droplet size

►Boom sections – displays congured boom sections

◄Spray status – displays active/inactive for section

Operation menu

The Options tab is always available on the Operation screen. This

tab accesses the Operation menu where the Home button, regulation

modes and target rate options display.

Operation menu buttons

Home

Auto

reg

Man

reg

Change between automatic/manual regulation

modes

Automatic regulation mode

5%

Target rate boost percent increase

5%

Target rate boost percent decrease

0%

Return to target rate

Manual regulation mode

Regulation valve manual open

Regulation valve manual close

Close menu

Figure 2: Options tab – Automatic mode

0%

Man

reg

5%

5%

Regulation mode

Target rate reset

Boost/step percent increase

Boost/step percent decrease

Home

Close menu

Figure 3: Options tab – Manual mode

Auto

reg

Regulation mode

Valve open

Valve close

Home

Close menu

3

98-01467-EN R1

Radion 8140 automatic sprayer control

Information bar

The information bar displays:

►Application rate – displays the actual application rate or target

application rate and accesses the preset target application

rates options menu.

►Selectable information – displays user-selected information

including volume applied, ow rate, ow pressure, speed, total

area applied and job number.

Figure 4: Information bar

Selectable information Selectable information

Application rate

Target application rate

Manual mode

Regulation modes

Automatic regulation mode will automatically adjust the application

rate based on the current speed in reference to the target rate. The

target rate can be adjusted using the Boost/step percent increase/

decrease buttons

5%/5%

on the Operation menu. Preset

application rates dene up to three (3) target rates for product being

applied per hectare/acre. These can be toggled using the Application

rate section on the Information bar on the Operation screen.

Manual regulation mode will retain an established regulation valve

setting regardless of speed. The regulation valve setting can be

adjusted using the Regulation valve open/close buttons on

the Operation menu.

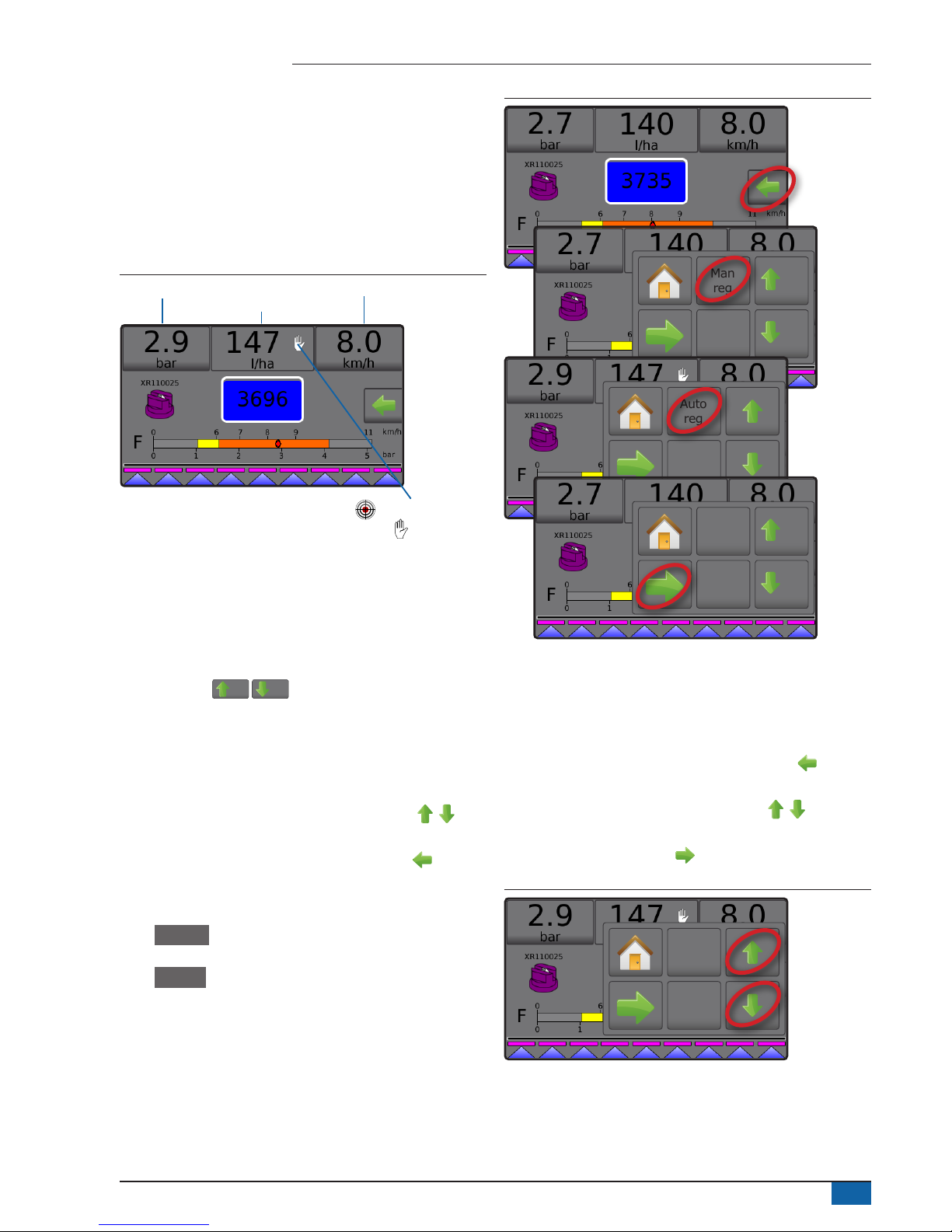

1. From the Operation screen, press the OPTIONS tab to display

the Operation menu.

2. Select from:

► Auto reg to change from Manual regulation mode to

Automatic regulation mode:

► Man reg to change from Automatic regulation mode to

Manual regulation mode:

NOTE: The Regulation button displays the regulation mode that may

be selected not the active regulation mode.

Figure 5: Regulation options: Automatic / Manual

0%

Man

reg

5%

5%

Auto

reg

0%

Man

reg

5%

5%

Manual regulation mode

Manual regulation mode will retain an established regulation valve

setting regardless of speed.

To open/close the valve:

1. From the Operation screen, press the OPTIONS tab to display

the Operation menu.

2. Press the Regulation valve open/close buttons to

manually turn the valves on/off.

3. Press the Close menu button .

Figure 6: Manual regulation mode

Auto

reg

4

www.teejet.com

Radion 8140 automatic sprayer control

NO. 3 GO TO HOME

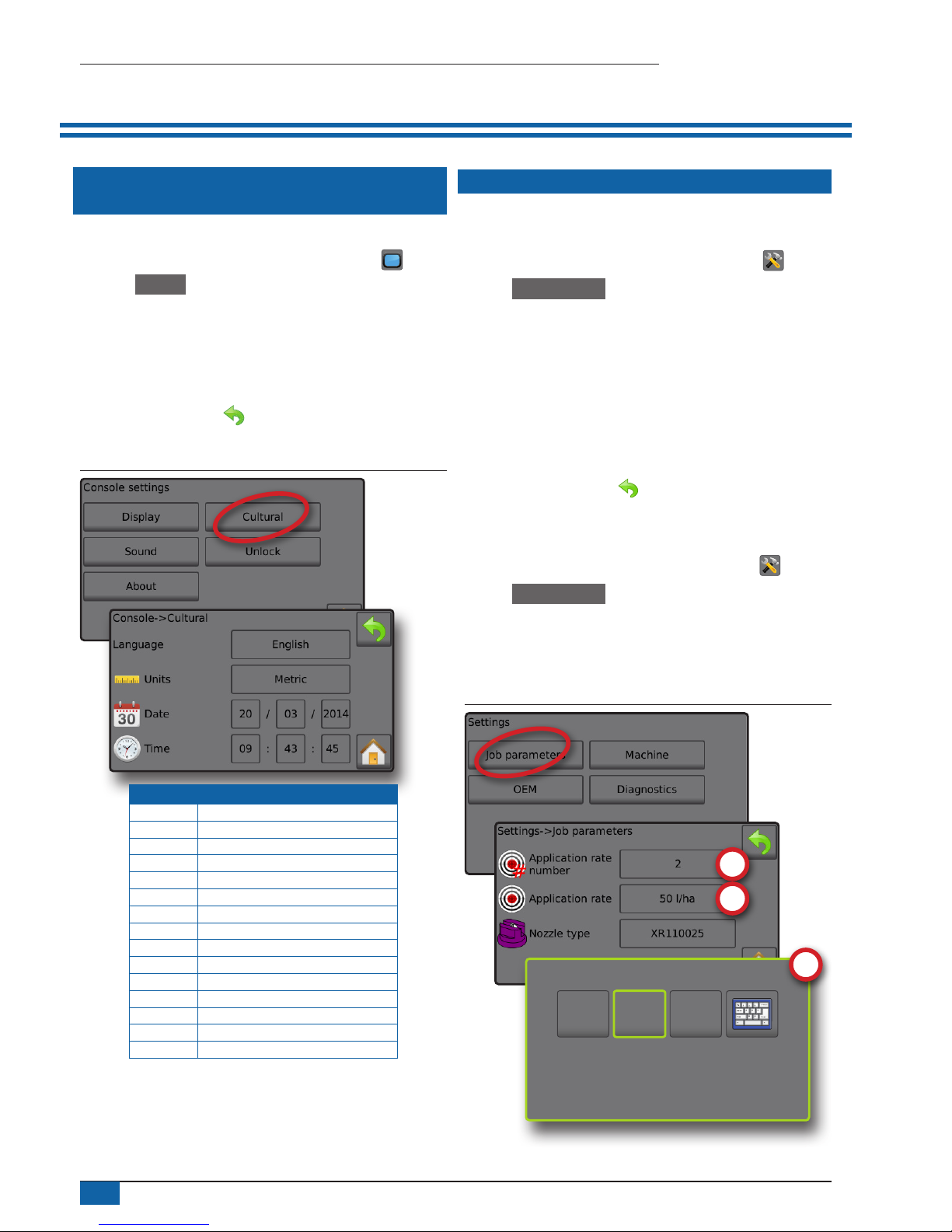

1 SET UP THE LOCAL CULTURAL

SETTINGS

Cultural congures language, units, date and time settings.

1. From the Home screen, press the CONSOLE button .

2. Press Cultural .

3. Select from:

►Language – denes the system language

►Units – denes the system measurements

►Date – establishes the date

►Time – establishes the time

4. Press RETURN arrow to return to the main Console settings

screen.

Figure 7: Cultural options

Code Language

cs Czech

da Danish

de-DE German

en-GB English (international)

en-US English (USA)

es-ES Spanish (Europe)

es Spanish (Central/South America)

fr-FR French

hu Hungarian

it-IT Italian

nl Dutch

pl Polish

pt-BR Portuguese (Brazil)

ru Russian

sk Slovak

NOTE: Some languages listed may not be available on the console.

2 SET UP THE JOB PARAMETERS

Job parameters congures the target application rate settings and

current nozzle. Selections are also active on the Operation screen.

1. From the Home screen, press the SETTINGS button .

2. Press Job parameters .

3. Press a setting value to adjust settings as needed.

◄ Target application rate number – species up to three (3)

target application rate presets from which to select

◄ Target application rate – denes the target rate of product to

apply for the selected number (these settings will be the same

for all active jobs)

◄ Nozzle type – selects the current nozzle type from the ve (5)

nozzle presets

4. Press the RETURN arrow to return to the main Settings

screen.

Establish preset target application rates

1. From the Home screen, press the SETTINGS button .

2. Press Job parameters .

3. Select Application rate number 1 .

4. Select an application rate to be associated with number 1.

5. Repeat steps 3 and 4 for Application rate numbers 2 and 3.

Figure 8: Establish preset target application rate 2

225

l/ha

50

l/ha

100

l/ha

5

98-01467-EN R1

Radion 8140 automatic sprayer control

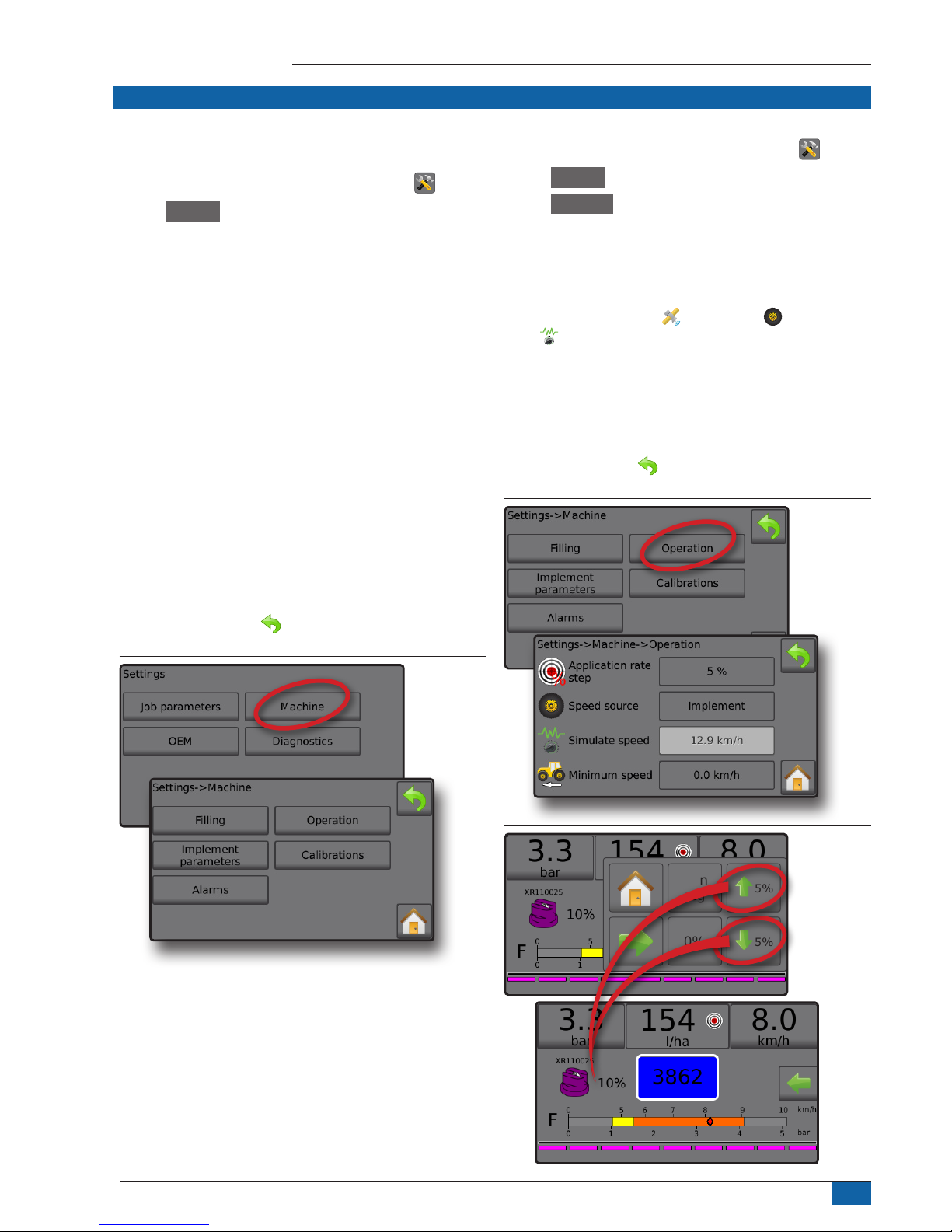

3 SET UP THE MACHINE

Machine congures machine settings. Options include Filling,

Operation, Implement parameters, Calibrations and Alarms.

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Select from:

►Filling – establishes the amount of actual and desired material

in the tank and the density of that material

►Operation – establishes application rate step, speed source,

simulated speed and minimum speed

►Implement parameters

◄ Section conguration – sets the number of nozzles on

the boom which determines the spraying width during

application

◄ Nozzle preset setup – establishes options for up to ve (5)

nozzles including series, capacity, low/high pressure limits,

reference ow and reference pressure

◄ Regulation parameters – adjusts valve calibration and

nozzle spacing and selects a regulation mode

►Calibrations – establishes either manual/automatic settings

of the Implement speed sensor, Flow sensor, Liquid pressure

sensor, Fill flow sensor and Tank level sensor

►Alarms – establishes alarms on/off and sets their trigger levels

4. Press RETURN arrow to return to the main Settings screen.

Figure 9: Machine

Operation

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Press Operation .

4. Press setting value to adjust settings as needed:

◄Application rate step – the percent of increase/decrease boost

of the active application rate at which the product is applied

◄Speed source – selects whether to base the machine speed

on input from the CAN , an Implement or a Simulated

source

◄Simulated speed – establishes a speed for using the

Simulated speed source

◄Minimum speed – establishes the minimum forward speed at

which the system should automatically switch the main valve

off

5. Press RETURN arrow to return to the Machine screen.

Figure 10: Operation

Figure 11: Application rate step on Operation screen

0%

Man

reg

5%

5%

6

www.teejet.com

Radion 8140 automatic sprayer control

Implement parameters

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Press Implement parameters .

4. Select from:

►Section conguration – sets the number of nozzles on the

boom which determines the spraying width during application

►Nozzle preset setup – where up to ve (5) sets of nozzle

options can be established to set the nozzle series, capacity,

low/high pressure limit, reference ow and reference pressure

►Regulation parameters – where adjustments to the valve

calibration, nozzle spacing and regulations mode can be

established

5. Press RETURN arrow to return to the Machine screen.

Figure 12: Implement parameters

Section configuration

Section conguration sets the number of nozzles on the boom which

determines the spraying width during application.

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Press Implement parameters .

4. Press Section conguration .

5. Press setting value to adjust settings as needed:

◄Section number – establishes the current section number to

which changes can be made. Sections are numbered from left

to right while facing in the machine forward direction

◄Number of nozzles – establishes the number of nozzles in the

current section number

◄Copy section – sets all Number of nozzles counts to the same

count for all boom sections based upon the current Section

number

◄Section width – displays the width for the current section

6. Press RETURN arrow to return to the Implement parameters

screen.

Establish number of nozzles

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Press Implement parameters .

4. Press Section conguration .

5. Select Section number .

6. Set the number of nozzles for the selected section number.

7. Repeat steps 5 and 6 for additional Section numbers as available.

8. OPTIONAL: If all sections have the same number of nozzles,

press Copy to set all sections to the current number of

nozzles.

Figure 13: Establish number of nozzles

Nozzle preset setup

Nozzle preset setup establishes up to ve (5) sets of nozzle options

setting the nozzle type, capacity, low/high pressure limit, reference

ow and reference pressure.

NOTE: Settings on both screen 1 and screen 2 are specific to the

currently selected Nozzle preset number.

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Press Implement parameters .

4. Press Nozzle preset setup .

5. Press setting value to adjust settings as needed:

◄Nozzle preset (number)

◄Nozzle series

◄Nozzle capacity

◄Factory settings

◄Low pressure limit

◄High pressure limit

◄Reference ow

◄Reference pressure

6. Press RETURN arrow to return to the Implement parameters

screen.

7

98-01467-EN R1

Radion 8140 automatic sprayer control

Establish nozzle presets

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Press Implement parameters .

4. Press Nozzle preset setup .

5. Select Nozzle preset number 1 .

6. Select Nozzle series .

7. Select Nozzle capacity .

8. Repeat steps 5, 6 and 7 for Nozzle preset numbers 2 to 5.

9. OPTIONAL: Press NEXT PAGE arrow to adjust the

settings for Low pressure limit, High pressure limit, Reference ow

and Reference pressure. Each of these settings are specic to the

current nozzle preset number.

Figure 14: Establish nozzle presets

Calibrations

For detailed instructions on sensor calibrations, see the Sensor

calibrations section of this guide.

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Press Calibrations .

4. Select from:

►Implement speed sensor – establishes the wheel impulses

over a specied distance

►Flow sensor – establishes the impulses per litre through the

Flow sensor

►Liquid pressure sensor – establish the maximum pressure limit

and no pressure calibration for the liquid pressure sensor

◄Calibrate each option in the following order:

No pressure

Maximum pressure

►Fill ow sensor – establishes the impulses per litre through the

Fill ow sensor

►Tank level sensor – establishes the empty, minimum and

maximum levels for the tank and calibrates the tank shape

◄Calibrate each option in the following order:

Empty tank

Minimum tank level

Maximum tank level

Tank shape

5. Press the RETURN arrow to return to the Machine screen.

Figure 15: Calibrations – Tank level sensor and Fill flow sensor

8

www.teejet.com

Radion 8140 automatic sprayer control

SETTINGS MENU STRUCTURE

| | | |

Job parameters Machine OEM Diagnostics

Application rate number Filling Sensor presence Test inputs

Application rate Actual content Flow sensor Implement wheel sensor

Nozzle type *Full tank Liquid pressure sensor Tractor wheel sensor

Density type Fill ow sensor Supply voltage

Density factor Tank sensor Flow sensor

Implement speed sensor Desired content Implement parameters Fill ow sensor

Calibration number Automatic lling Number of sections Liquid pressure sensor

Automatic calibration Operation Circulation Tank level sensor

*Flow sensor Application rate step Section conguration Valve setup Remote master signal

Calibration number Speed source Section number Regulation valve type Master switch

Low ow limit Simulate speed Number of tips Section valve type Section switches

High ow limit Minimum speed Copy section Section valve behaviour Test outputs

Automatic calibration Implement parameters Section width Tank setup Liquid valve PWM duty cycle

*Liquid pressure sensor Calibrations Nozzle preset setup Maximum tank content Master valve

No pressure Alarms Nozzle preset Minimum tank content Fill valve

No pressure calibration Minimum tank content Nozzle series Automatic lling Section number

Maximum pressure Flow/pressure cross check Nozzle capacity Automatic lling offset Section valve state

Maximum pressure Section output low Factory settings Regulation details All sections off

Reference pressure Low pressure limit Minimum regulation pressure Test boompilot

Automatic calibration High pressure limit Maximum regulation pressure Connection

*Fill ow sensor Reference ow Regulation valve time Mode

Calibration number Reference pressure Minimum regulation voltage Section input

Automatic calibration Regulation parameters Regulation deadband Alarm log

*Tank level sensor Course value calibration Regulation valve capacity Save alarm log

Empty tank Fine value calibration Regulation start delay

Automatic calibration Nozzle spacing Manual regulation speed

Minimum tank level Regulation mode Restrictor plate ow

Minimal tank level Clear totals

Automatic calibration Area counter

Maximum tank level Volume counter

Maximum tank level Time counter

Automatic calibration Clear all total counters

Tank shape Import/export calibrations

Maximum tank level

Start calibration

Import/export calibrations

OEM menu is password protected.

*Menu settings directly related to fitted OEM equipment.

9

98-01467-EN R1

Radion 8140 automatic sprayer control

NO. 4 START NEW JOB OR CONTINUE JOB

The Data option, provides an overview of various system

counters including job counters, campaign counters and total

counters. From Data options screens, export as either PDF or

CSV reports.

6. From the Home screen, press the DATA button

7. Select from:

►Jobs – displays, deletes and reports on job information

►Campaign – displays and deletes campaign information

►Totals – displays all counter information

►CSV – compiles a CSV report of counters for all jobs, and for

the campaign and console totals, then saves reports to a USB

drive

Figure 16: Data management options

Jobs

One of up to ten (10) jobs may be selected to view job information.

The current job, displayed/active on the Operation screen, may be

exported as a PDF report.

Job information includes:

◄Job number of information displayed

◄Current date

◄Applied area

◄Volume of material applied

◄Distance travelled

◄Time travelled

1. From the Home screen, press the DATA button .

2. Press Jobs .

3. Press Job number to view information for a different job.

◄Enter any number to display another job

4. Press RETURN arrow to return to the main Data screen.

Figure 17: Job data

Job data report

The PDF button compiles active job information to be exported as a

PDF report.

1. From the Home screen, press the DATA button .

2. Press Jobs .

3. Select the job from which to create a report.

4. Insert USB drive into the console and wait for PDF button

PDF

to

activate.

5. Press PDF button

PDF

.

6. Press RETURN arrow to return to the main Data screen.

NOTE: The PDF icon

PDF

is not available for selection (greyed out)

until a USB drive is inserted properly.

Figure 18: Job data

10

www.teejet.com

Radion 8140 automatic sprayer control

SENSOR CALIBRATIONS

Implement speed sensor

The Implement speed sensor establishes the wheel impulses over

a specied distance. Establish the value manually or automatically

calibrate the value.

►Calibration number –

◄Automatic calibration will determine the number of impulses

counted while driving 100 metres and convert the calibration

number to the correct units.

◄Manual calibration, enter the calibration number in impulses

per 100 meters

►Automatic calibration – establishes the impulses using the

automatic calibration function.

Figure 19: Implement speed sensor

Implement speed sensor automatic calibration

1. Press Calibrate to start an automatic sensor calibration.

2. Drive a distance of 100 metres.

3. Press Done when complete.

To cancel the calibration, press Cancel , RETURN arrow or the

Home button .

The counted wheel impulses will be displayed during the automatic

calibration.

Flow sensor

The Flow sensor establishes the impulses per litre. Establish the

value manually or automatically calibrate the value.

►Calibration number – enter the amount of impulses counted

while running 1 litre of water through the ow sensor. Use

Automatic calibration to calculate impulses automatically.

Manual calibration establishes the calibration and limits based

on user-entered values.

►Low ow limit – enter the ow sensors low limit value.

►High ow limit – enter the ow sensors high limit value.

►Automatic calibration – establishes the calibration and limits if

the number of impulses per litre for the ow meter is unknown

or to make sure the value is correct.

►Impulse count – shows the number of impulses during

calibration. Minimum of 10 impulses needed to do a

calibration.

►Collected volume – enter the volume passed through the

ow sensor during the calibration. Once encoded, a new ow

sensor calibration value is calculated.

►Master switch status / Cancel – shows if the Master switch is

off or on .

Press the Cancel to cancel the calibration and return to the

Flow sensor screen.

Figure 20: Flow sensor

11

98-01467-EN R1

Radion 8140 automatic sprayer control

Flow sensor automatic calibration

1. Press Calibrate to enter automatic calibration mode.

2. Prepare to collect the ‘medium’ via the Flow sensor (minimum

100 litres).

3. Make sure the controller is in manual mode and ow is not

regulated down.

4. Turn on the Master switch to start ow and calibration.

◄Impulses counted display during the automatic calibration

5. Once at the minimum 100 litres has distributed, turn off

Master switch to stop calibration.

6. Press the Collected volume value .

7. Enter the precise volume which passed through the ow sensor

during the calibration.

Once encoded, a new ow sensor calibration value is calculated.

To cancel the calibration, press Cancel , RETURN arrow or the

Home button .

Figure 21: Automatic calibration

Liquid pressure sensor

The liquid pressure sensor settings establish the maximum pressure

limit and no pressure calibration for the liquid pressure sensor.

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Press Calibrations .

4. Press Liquid pressure sensor .

5. Calibrate each option in the following order:

No pressure

Maximum pressure

6. Press RETURN arrow to return to the Calibrations screen.

Figure 22: Liquid pressure sensor

No pressure

Liquid pressure sensor->No pressure establishes the calibration

while NO pressure is applied to the liquid pressure sensor.

1. Remove all pressure from the system.

2. Press Calibrate to record a new calibration value and nalise the

calibration.

NOTE: Manual calibration is not available.

Figure 23: Liquid pressure sensor->No pressure

12

www.teejet.com

Radion 8140 automatic sprayer control

Maximum pressure

Liquid pressure sensor->Maximum pressure establishes the

maximum allowed pressure limit for the liquid pressure sensor.

The automatic calibration is based on the recommended maximum

pressure level and a tested reference pressure level.

►Maximum pressure – enter the maximum allowed pressure

limit for the liquid pressure sensor. Use Automatic calibration

to calculate the maximum pressure automatically.

►Reference pressure – enter the pressure value used as

reference for the actual liquid pressure sensor calibration.

The reference pressure can be changed, but not while in the

calibration mode.

►Automatic calibration – if the maximum pressure is not known,

or to make sure the value is correct, automatic calibration

establishes the calibration.

►Complete calibration – apply constant reference pressure to

the sensor. Press “Done” when complete.

►Master switch status / Pressure adjustment –

Shows if the Master switch is off or on .

Press the UP/DOWN arrows to increase/decrease

the pressure until reaching and maintaining the reference

pressure.

►Minimum/maximum pressure bar – illustrates the change in

pressure from minimum to maximum.

Figure 24: Liquid pressure sensor->Maximum pressure

Maximum pressure automatic calibration

IMPORTANT: Make sure all section valves are open before opening

the Master valve; otherwise, the pressure could build and

damage the system.

1. Press the Reference pressure value .

2. Enter the pressure value used as reference for the actual liquid

pressure sensor calibration.

3. Press Calibrate to start an automatic calibration of the sensor.

4. Turn on Master switch .

5. Press the UP/DOWN arrows to increase/decrease the

pressure until reaching and maintaining the reference pressure.

6. Apply constant reference pressure to the sensor.

7. Press Done when complete.

8. Turn off Master switch to stop calibration.

To cancel the calibration, press the RETURN arrow or the Home

button .

Figure 25: Automatic maximum pressure

13

98-01467-EN R1

Radion 8140 automatic sprayer control

Maximum pressure manual calibration

1. Press the Maximum pressure value .

2. Enter the maximum allowed pressure limit for the liquid pressure

sensor.

Figure 26: Manual maximum pressure

Fill flow sensor

The Fill ow sensor establishes the impulses per litre. The Fill ow

value can be established manually or automatically calibrated.

►Calibration number – enter the amount of impulses counted

while running one (1) litre of water through the Fill ow

sensor. Use Automatic calibration to calculate the impulses

automatically. Manual calibration establishes the calibration

and limits based on user entered values.

►Automatic calibration – establishes the calibration if the

number of impulses per litre for the Fill ow meter is unknown,

or to make sure the value is correct.

►Impulse count – number of impulses calculated during

automatic calibration.

►Collected volume – enter the collected volume.

►Automatic calibration done – to complete the automatic

calibration, press “Done” when collected volume has been

entered.

Figure 27: Fill flow sensor

Fill flow sensor automatic calibration

1. Press Calibrate to enter automatic calibration mode.

2. Prepare to collect the ‘medium’ via the Fill ow sensor (minimum

of 100 litres).

3. Turn on Master switch to start ow.

4. Press START CALIBRATION button .

◄Impulses counted display during automatic calibration

5. Once the desired amount has distributed, press the STOP

CALIBRATION button .

6. Turn off the Master switch .

7. Press the Collected volume value .

8. Enter the precise volume passed through the Fill ow sensor

during the calibration.

9. Press Done to complete the automatic calibration.

To cancel the calibration, press RETURN arrow or the Home

button .

14

www.teejet.com

Radion 8140 automatic sprayer control

Figure 28: Fill flow sensor automatic calibration

Tank level sensor

Tank level sensor establishes the empty, minimum and maximum

levels for the tank and calibrates the tank shape. Tank level sensor

calibration settings can be exported to a USB drive and recalled for

future use.

NOTE: Manual calibration is not available for any Tank level sensor

calibrations.

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Press Calibrations .

4. Press Tank level sensor .

5. Calibrate each option in the following order:

Empty tank

Minimum tank level

Maximum tank level

Tank shape

6. Press RETURN arrow to return to the Calibrations screen.

Figure 29: Tank level sensor

15

98-01467-EN R1

Radion 8140 automatic sprayer control

Empty tank – Automatic calibration

Empty tank establishes the empty tank value.

IMPORTANT: The tank should be completely empty.

1. Press Calibrate to record a new calibration value and nalise the

calibration.

◄The low-high graph should be empty

Figure 30: Tank level sensor – Empty tank

Minimum tank level – Automatic calibration

Minimum tank level establishes the minimum level of water on the

tank sensor.

IMPORTANT: Make sure the tank is filled with the contents displayed

on the screen. The amount displayed is established in

Settings->OEM->Tank setup->Minimum tank content.

1. Press Calibrate to record a new calibration value and nalise the

calibration.

◄The low-high graph should display approximately 5% full

Figure 31: Tank level sensor – Minimum tank level

Maximum tank level – Automatic calibration

Maximum tank level establishes the maximum level of water on the

tank sensor.

IMPORTANT: Ensure the tank is filled with the contents displayed on

the screen. The amount displayed is established in Settings

-

>OEM->Tank setup->Maximum tank content.

1. Press Calibrate to record a new calibration value and nalise the

calibration.

◄The low-high graph should display 100% full

Figure 32: Tank level sensor – Maximum tank level

16

www.teejet.com

Radion 8140 automatic sprayer control

Tank shape – Automatic calibration

Tank shape establishes the tank shape.

1. Flip Master switch to start calibration.

◄Tank level sensor graph will go from high to low as the

calibration proceeds

◄When Calibration progress graph reaches 100%, calibration

will record a new calibration value and nalise the calibration

To pause the calibration process, ip the Master switch.

To cancel the calibration, press RETURN arrow or press the

Home button .

Figure 33: Tank level sensor – Tank shape

Import / export

Tank level sensor calibration settings can be exported to USB drive

and recalled for future use.

NOTE: The import/export buttons are not available for

selection and are greyed out until a USB drive is inserted

properly.

To import the calibration settings:

1. Insert USB drive.

2. Press IMPORT button .

To export the calibration settings:

1. Insert USB drive.

2. Press EXPORT button .

NOTE: Only one (1) tank calibration settings file can be saved on

a USB drive at one time. If there is an existing file it will be

overwritten.

Figure 34: Tank level sensor – Import/export

17

98-01467-EN R1

Radion 8140 automatic sprayer control

OPERATION SCREEN

INFORMATION BAR

The information bar displays user selected information and

application rate information.

Figure 35: Information bar

Selectable information Selectable information

Application rate

Selectable information

Selectable information displays user-selected information.

1. Press either the left or right Selectable information section.

2. Select one (1) of six (6) available options to display for each side

(options depend upon equipment in use).

►Volume applied – displays volume applied for the current job

number

►Flow rate – displays current ow rate

►Flow pressure – displays current ow pressure

►Speed – displays vehicle speed

►Area applied – displays applied area for the selected job

number

►Job number – displays the current job number

Figure 36: Selectable information

Figure 37: Selectable information options

3450

l

0.2

l/min

20.0

bar

50

ha

5

Job No.

9.0

km/h

Flow rate

Job number

Volume applied

Area applied

Flow pressure

Speed

Selecting a job number

One of up to ten (10) jobs may be selected to view job information.

1. From the Operation screen, press the OPTIONS tab .

2. Press the HOME button .

3. From the Home screen, press the DATA button .

4. Press Jobs .

5. Press Job number to select current job number.

6. Press the HOME button .

7. From the Home screen, press the OPERATION button .

Figure 38: Selecting a job number

0%

Man

reg

5%

5%

18

www.teejet.com

Radion 8140 automatic sprayer control

Application rate

Application rate displays or give access to:

►Application rate – while application is active, displays the

actual application rate

►Target application rate – while application is inactive, displays

the target rate of product to apply.

◄Automatic regulation mode – Target application rate symbol

will be active

Use the Boost/step percent increase/decrease

buttons

5%/5%

to adjust the target application rate

◄Manual regulation mode – manual regulation symbol will

remain active

►Preset target application rates options menu – denes the

target rate of product to apply for the selected number. These

settings will be the same for all active jobs. Range is 0 to

6,554 litres/hectare.

Select target application rate

1. Press the Application rate section.

2. Select one (1) of up to three (3) preset application rates.

Figure 39: Select target application rate

140

l/ha

225

l/ha

180

l/ha

Change preset target application rate

The selected target rate can be changed either on the Operation

screen or in Settings->Job parameters.

Operation

1. Press the Application rate section.

2. Select the target application rate to be changed.

3. Press KEYBOARD button .

4. Select an application rate.

NOTE: Value must be between 0 and 6,554 litres/hectare.

Figure 40: Application rate number

140

l/ha

225

l/ha

180

l/ha

140

l/ha

225

l/ha

180

l/ha

Application rate (l/ha)

1 2 3

165

Clear

4 5 6 <--

7 8 9

0 . +/-

140

l/ha

225

l/ha

165

l/ha

19

98-01467-EN R1

Radion 8140 automatic sprayer control

Settings

1. From the Home screen, press the SETTINGS button .

2. Press Job parameters .

3. Select Application rate number 1 .

4. Select an application rate to be associated with number 1.

5. Repeat steps 3 and 4 for Application rate numbers 2 and 3.

Figure 41: Establish preset target application rate 2

225

l/ha

50

l/ha

100

l/ha

Target rate percentage increase/decrease

Target rate boost/step percent increase/decrease buttons increase/

decrease the application target rate per the established percentage

set in the Settings->Machine->Operation setup screen under

Application rate step.

Figure 42: Target rate boost/step percent

Increase/decrease percentage

1. From the Operation screen, press the OPTIONS tab to display

the Operation menu.

2. Press the Boost/step percent increase/decrease

buttons

5%/5%

to adjust application rates.

3. Press the Close menu button .

Return to preset target rate

1. From the Operation screen, press the OPTIONS tab to display

the Operation menu.

2. Press 0% to return to the preset target rate.

3. Press the Close menu button .

Figure 43: Application rate step

0%

Man

reg

5%

5%

Change application rate step

Application rate step is the percent of increase/decrease boost of the

active application rate at which the product is applied. Range is 1 to

20%.

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Press Operation .

4. Press Application rate step value .

5. Select an application rate step.

6. Press RETURN arrow to return to the Machine screen.

Figure 44: Operation

20

www.teejet.com

Radion 8140 automatic sprayer control

NOZZLE SELECTION

Nozzles must be preset to be available for current nozzle selection. Presets allow saving of up to ve (5) nozzles for quick recall.

Selecting the current nozzle

1. From the Operation screen, press the CURRENT NOZZLE to

display the Preset nozzle menu.

2. Select a nozzle type from among ve (5) nozzle presets.

NOTE: Current nozzle can also be selectable on the

Settings->Job parameters screen.

Figure 45: Nozzle type on Operation screen

XR110025

XR11001

TT11004

XR110015 XR8001

Presetting nozzles

Nozzle preset setup establishes up to ve (5) sets of nozzle options

setting the nozzle type, capacity, low/high pressure limit, reference

ow and reference pressure. For more information see Settings->

Machine->Implement parameters->Nozzle preset setup.

1. From the Home screen , press the SETTINGS button .

2. Press Machine .

3. Press Implement parameters .

4. Press Nozzle preset setup .

5. Select Nozzle preset number 1 .

6. Select Nozzle series .

7. Select Nozzle capacity .

8. Repeat steps 5, 6 and 7 for Nozzle preset numbers 2 to 5.

9. OPTIONAL: Press NEXT PAGE arrow to adjust the

settings for Low pressure limit, High pressure limit, Reference ow

and Reference pressure. Each of these settings are specic to the

current nozzle preset number.

Figure 46: Establish nozzle presets

21

98-01467-EN R1

Radion 8140 automatic sprayer control

TANK

Tank displays or give access to:

►Actual content – displays the current volume of content in

the tank. Manual adjustment is directly relate to OEM tted

equipment. The volume cannot be manually adjusted if a Tank

sensor is active.

►Tank lling – establishes the amount of actual and desired

material in the tank and the density of that material. Options

displayed directly relate to OEM tted equipment. Different

options will be available depending upon if a Tank sensor or

Fill ow sensor is active. See Settings->Machine->Filling for

additional information.

1. Press TANK

100

.

2. Press setting value to adjust settings as needed:

◄Actual content (unavailable when Tank sensor is active)

◄Full tank (unavailable when Tank sensor or Fill ow sensor is

active)

◄Density type

◄Density factor (available when Density type is Fertiliser)

◄Desired content (available when Tank sensor or Fill ow

sensor is active)

◄Automatic lling (available when Tank sensor or Fill ow

sensor is active)

3. Press RETURN arrow to return to the Operation screen.

Figure 47: Tank filling

ALARM WARNING

If there is an active alarm, an Alarm warning icon will appear next to

the Tank. For a list of Alarm message codes see Appendix C – Alarm

congurations.

1. Press ALARM WARNING icon to display a list all active

alarms.

Figure 48: Active alarm warning list

Set up alarms

1. From the Home screen, press the SETTINGS button .

2. Press Machine .

3. Press Alarms .

4. Press setting value to adjust settings as needed:

◄Minimum tank content

◄Flow/pressure cross check (alarm active only when both a

Flow sensor and Liquid pressure sensor are active)

◄Section output low

5. Press RETURN arrow to return to the Machine screen.

Figure 49: Alarms

22

www.teejet.com

Radion 8140 automatic sprayer control

PRESSURE GAUGE

The Pressure gauge displays current pressure compared with the

recommended pressure range. Pressure sensor options are used to

enter the sensor manufacturer maximum pressure rating and to set

high and low user-determined pressure alarms.

Figure 50: Pressure gauge example

Speed

Pressure

Current working

pressure

Recommended pressure range

Current droplet size

Recommended pressure range

Displays the recommended pressure range for the selected nozzle.

The pressure range will change depending upon the selected

nozzle, target application rate (including boost/step percent increase/

decrease) and working speed.

IMPORTANT! Always refer to the recommended pressure range as

failure to do so may result in uneven spray patterns.

Current working pressure

Displays the current working pressure.

NOTE: This pressure range should not exceed the recommended

pressure range.

IMPORTANT! Always refer to the recommended nozzle pressure

values when setting nozzle pressure.

Current droplet size

A single nozzle can produce different droplet size classications

at different pressures. The colours displayed in the recommended

pressure range are directly associated with the current droplet

sizes. The droplet size displays as one (1) of eight (8) classication

categories.

Table 1: Droplet size chart

Category Symbol Colour code

Extremely ne XF Violet

Very ne VF Red

Fine F Orange

Medium M Yellow

Coarse C Blue

Very coarse VC Green

Extremely coarse XC White

Ultra coarse UC Black

BOOM SECTIONS & SWITCHES

The console operates with nine (9), seven (7) or ve (5) section

switches (depending on console model) and one (1) Master switch.

Each section switch is associated with one of up to the same number

of sections on the boom and illustrated on the Operation screen.

►Switches – control individual boom sections

◄On – Flip the switch up

◄Off – Flip the switch down

►Master switch – opens/closes the main product valves and

enables/disables power to individual boom section on/off

switches

◄Cannot be activated outside of the Operation screen

►Boom sections spray status – displays the status of the

section switches in association to the master switch. Number

of sections shown is established in Settings-> OEM->

Implement parameters.

◄Section on, master switch on – spray is blue

◄Section off, master switch on – spray is white

◄Master switch off – spray not shown

Figure 51: Master switch, 9 section switches

Master switchSection switchs

Figure 52: Boom sections

Boom section spray status

Master switch off

Section on, master switch on Section off, master switch on

23

98-01467-EN R1

Radion 8140 automatic sprayer control

ALARM CONFIGURATIONS

Code Message / condition Possible solution Console path

1 No ow impulses

Check ow sensor from test menu. Check components and

programming steps related to ow.

Settings->Diagnostics->Test inputs (1)->

Flow sensor

2 Low liquid pressure

Check ow sensor from test menu. Check components and

programming steps related to ow.

Settings->Machine->Implement parameters->

Nozzle preset setup (2) or Settings->Machine->

Calibrations or Settings->Diagnostics->Test inputs

(2)->Liquid pressure sensor

4 Calibration error

Check components and programming steps related to

implement or process registering a calibration error.

Settings->Machine->Calibrations - check sensors

5

Density not equal to water

(1 kg/l or 8.34 lb/gal)

Select Water for tank contents or change fertiliser density No..

Check components and programming steps related to content.

Operation->Filling (1) or Settings->Machine->

Filling (1)

6 Below minimum speed

Increase speed. Check components and programming steps

related to speed.

Settings->Machine->Operation or Settings->

Machine-> Calibrations->Implement speed sensor

7 Pressure based

Check components and programming steps related to

implement or process registering a pressure error.

Settings->Diagnostics->Test inputs or Settings->

Machine->Implement parameters->Nozzle preset

setup (2)

8 Low ow

Increase speed. Check or clean nozzles. Check components

and programming steps related to ow.

Settings->Diagnostics->Test inputs or Settings->

Machine->Implement parameters->Nozzle preset

setup (2)

9 Tank almost empty

Rell tank. Check all components and programming steps

related to contents.

Operations->Tank->Filling (1) or Settings->

Machine-> lling (1) and (2) or Settings->

Machine-> Alarms-> Minimum tank contents

10 Target rate impossible to reach

Select a new target rate. Use larger nozzles. Check

components and programming steps related to rates.

Operation->Target rates or Settings->Job

parameters

11 Actual rate too high

Select a lower target rate. Check components and

programming steps related to rates.

Operation->Target rates or Settings->Job

parameters

12 Minimum regulation pressure

Check components and programming steps related to

pressure.

Settings->Machine->Implement parameters->

Regulation parameters

13 Maximum regulation pressure

Check components and programming steps related to

pressure.

Settings->Machine->Implement parameters->

Regulation parameters

14 Pressure too low

Check components and programming steps related to

pressure.

Settings->Machine->Implement parameters->

Nozzle preset setup (2)

15 Pressure too high

Check components and programming steps related to

pressure.

Settings->Machine->Implement parameters->

Nozzle preset setup (2)

16 Pressure/ow check Check components and programming steps related to ow.

Settings->Diagnostics->Test inputs or Settings->

Machine->Calibrations

19 Liquid pressure too low

Check ow sensor from test menu. Check components and

programming steps related to pressure.

Settings->Machine->Implement parameters->

Nozzle preset setup (2) or Settings->Machine->

Calibrations or Settings->Diagnostics->Test inputs

(2)->Liquid pressure sensor

20 Liquid pressure too high

Check ow sensor from test menu. Check components and

programming steps related to pressure.

Settings->Machine->Implement parameters->

Nozzle preset setup (2) or Settings->Machine->

Calibrations

21 No speed signal Check components and programming steps related to speed.

Settings->Machine->Calibrations->Implement

speed sensor

31 Work not possible

34 Save error Insert or reset a USB device if saving to a USB port.

36 CAN speed missing

Check GNSS source for power/satellite reception. If no

GNSS source, change speed source. Check components and

programming steps related to speed.

Settings->Machine->Operation->Speed source

45 BoomPilot unit not responding Check BoomPilot for power. Test BoomPilot under test menu. Settings->Diagnostics->Test BoomPilot

46 BoomPilot unit in manual mode

Current operation mode is different than standard operation. If

this is undesired, change mode to automatic under test menu.

Settings->Diagnostics->Test BoomPilot

47 Not all sections on

Current operation mode is different than standard operation. If

this is undesired, check section switches are ipped up (ON).

Check sections under test menus. Congure sections. Check

components and programming steps related to power.

Settings->Diagnostics->Test outputs (2) or

Settings-> Diagnostics->Test inputs (3)->Section

switches or Settings->Machine->Implement

parameters->Section conguration

49 Section output failure Check components and programming steps related to sections. Settings->Diagnostics->Test outputs (2)

50 Master output failure

Check Master switch if ipped up (ON). Check all components

and programming steps related to Master switch.

Settings->Diagnostics->Test inputs (3)->Master

switch

51 Fill valve output failure

Check ll valve under test menus. Check components and

programming steps related to ll valve.

Settings->Diagnostics->Test outputs (2)->Fill valve

52 Low supply voltage Check voltage supply under Diagnostics. Settings->Diagnostics->Supply voltage

www.teejet.com

RADION 8140

USER GUIDE

98-01467-EN-A4 R1 English International

© TeeJet Technologies 2016

Copyrights

© 2016 TeeJet Technologies. All rights reserved. No part of

this document or the computer programmes described in

it may be reproduced, copied, photocopied, translated, or

reduced in any form or by any means, electronic or machine

readable, recording or otherwise, without prior written

consent from TeeJet Technologies.

Trademarks

Unless otherwise noted, all other brand or product names

are trademarks or registered trademarks of their respective

companies or organizations.

Limitation of Liability

TEEJET TECHNOLOGIES PROVIDES THIS MATERIAL

“AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER

EXPRESSED OR IMPLIED. NO COPYRIGHT LIABILITY

OR PATENT IS ASSUMED. IN NO EVENT SHALL TEEJET

TECHNOLOGIES BE LIABLE FOR ANY LOSS OF

BUSINESS, LOSS OF PROFIT, LOSS OF USE OR DATA,

INTERRUPTION OF BUSINESS, OR FOR INDIRECT,

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES

OF ANY KIND, EVEN IF TEEJET TECHNOLOGIES HAS

BEEN ADVISED OF SUCH DAMAGES ARISING FROM

TEEJET TECHNOLOGIES SOFTWARE.

NO.1 POWER ON

NO.2 OPERATION SCREEN

NO. 3 GO TO HOME

1 SET UP THE LOCAL CULTURAL SETTINGS

2 SET UP THE JOB PARAMETERS

3 SET UP THE MACHINE

1) Operation

2) Implement parameters

3) Verify sensor calibrations

NO. 4 START NEW JOB OR CONTINUE JOB

Loading...

Loading...