TeeJet Technologies Aeros 9040 User Manual

AEROS 9040

USER MANUAL

Software version 4.31

Copyrights

© 2017 TeeJet Technologies. All rights reserved. No part of this document or the computer programs described in it may be reproduced, copied,

photocopied, translated, or reduced in any form or by any means, electronic or machine readable, recording or otherwise, without prior written

consent from TeeJet Technologies.

Trademarks

Unless otherwise noted, all other brand or product names are trademarks or registered trademarks of their respective companies or organizations.

Limitation of liability

TEEJET TECHNOLOGIES PROVIDES THIS MATERIAL “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESSED OR IMPLIED.

NO COPYRIGHT LIABILITY OR PATENT IS ASSUMED. IN NO EVENT SHALL TEEJET TECHNOLOGIES BE LIABLE FOR ANY LOSS OF

BUSINESS, LOSS OF PROFIT, LOSS OF USE OR DATA, INTERRUPTION OF BUSINESS, OR FOR INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES OF ANY KIND, EVEN IF TEEJET TECHNOLOGIES HAS BEEN ADVISED OF SUCH DAMAGES ARISING FROM

TEEJET TECHNOLOGIES SOFTWARE.

Safety information

TeeJet Technologies is not responsible for damage or physical harm caused by failure to adhere to the following safety requirements.

As the operator of the vehicle, you are responsible for its safe operation.

The Aeros 9040 in combination with any assisted/auto steering device is not designed to replace the vehicle’s operator.

Do not leave a vehicle while the Aeros 9040 is engaged.

Be sure that the area around the vehicle is clear of people and obstacles before and during engagement.

The Aeros 9040 is designed to support and improve efciency while working in the eld. The driver has full responsibility for the quality and work

related results.

Disengage or remove any assisted/auto steering device before operating on public roads.

Aeros 9040 eld computer

Table of contents

CHAPTER 1 INTRODUCTION 1

Product upgrades available ........................................................................................................................................................................1

SYSTEM COMPONENTS 1

Aeros 9040 console ........................................................................................................................................................................................1

Buttons .....................................................................................................................................................................2

RealView® camera ...........................................................................................................................................................................................2

Additional information .................................................................................................................................................................................2

BASIC SCREEN USE 3

Bottom tab keys ........................................................................................................................................................3

Unavailable options when job is active ......................................................................................................................3

Console screen colours .............................................................................................................................................4

Simple or advanced mode .........................................................................................................................................4

Warnings and information pop-ups ............................................................................................................................5

Setup option information ...........................................................................................................................................5

Drop-down menu selections ......................................................................................................................................5

Scrolling screens .......................................................................................................................................................5

Keyboard entry screen ..............................................................................................................................................6

Next page .................................................................................................................................................................6

Checkboxes ..............................................................................................................................................................6

HOMESETUPGUIDANCE FULL SCREENIMPLEMENT INTRODUCTIONGNSSRATE CONTROLAPPENDIX

CHAPTER 2 JOBS / HOME SCREEN 7

Simple mode .............................................................................................................................................................7

Advanced mode ........................................................................................................................................................7

SIMPLE MODE 8

New job ..............................................................................................................................................................................................................8

Continue job .....................................................................................................................................................................................................8

Close job ............................................................................................................................................................................................................8

ADVANCED MODE 8

New job ..............................................................................................................................................................................................................8

Start job .............................................................................................................................................................................................................. 8

Close job ............................................................................................................................................................................................................8

CHAPTER 3 FULL SCREEN VIDEO VIEW 9

Camera snapshot ......................................................................................................................................................................................... 10

VSM camera options ................................................................................................................................................................................... 10

CHAPTER 4 SYSTEM SETUP 11

Overview ......................................................................................................................................................................................................... 11

98-05304-EN R2

i

Aeros 9040 eld computer

CONFIGURATION 12

Implement ...................................................................................................................................................................................................... 13

Single section setup ...............................................................................................................................................13

Section(s) with ISOBUS sprayer/spreader setup ......................................................................................................14

Multiple sections with SDM/SFM setup ....................................................................................................................15

Droplet size monitor ................................................................................................................................................16

HOME SETUP GUIDANCEFULL SCREEN IMPLEMENTINTRODUCTION GNSS RATE CONTROL APPENDIX

Nozzle selection ......................................................................................................................................................16

Reverse sense options ............................................................................................................................................17

Mapping and guidance ............................................................................................................................................................................. 17

Mapping and guidance [console only] ......................................................................................................................17

Mapping and guidance using an external lightbar ....................................................................................................18

User entered mapping location ................................................................................................................................19

GNSS ................................................................................................................................................................................................................. 20

Video ................................................................................................................................................................................................................ 21

Sensors ............................................................................................................................................................................................................ 21

Input/output module pressure sensor.......................................................................................................................22

Nozzle ow monitor ................................................................................................................................................................................... 23

ISOBUS ............................................................................................................................................................................................................. 23

Product ............................................................................................................................................................................................................ 24

AutoSteer ........................................................................................................................................................................................................ 25

FieldPilot [using a SCM] ..........................................................................................................................................25

FieldPilot Pro / UniPilot Pro [using a SCM Pro] ........................................................................................................25

Tilt correction ................................................................................................................................................................................................ 27

DATA MANAGEMENT 28

Job data ........................................................................................................................................................................................................... 28

Transfer ..................................................................................................................................................................29

Manage ...................................................................................................................................................................29

Reports ............................................................................................................................................................................................................ 31

Options (Job mode) .................................................................................................................................................................................... 32

Machine settings .......................................................................................................................................................................................... 33

Transfer ..................................................................................................................................................................33

Manage ...................................................................................................................................................................34

CONSOLE 35

About ............................................................................................................................................................................................................... 35

Display ............................................................................................................................................................................................................. 36

Cultural ............................................................................................................................................................................................................ 36

Audio volume ................................................................................................................................................................................................ 37

Demo GNSS ................................................................................................................................................................................................... 37

Restart Demo GNSS ...............................................................................................................................................38

Feature unlock .............................................................................................................................................................................................. 38

TOOLS 39

Upload software ........................................................................................................................................................................................... 39

Extras ................................................................................................................................................................................................................ 40

ii

www.teejet.com

Aeros 9040 eld computer

CHAPTER 5 GNSS RECEIVER CONFIGURATION 41

GNSS ................................................................................................................................................................................................................. 41

GNSS type ..............................................................................................................................................................42

GNSS port...............................................................................................................................................................42

Programme .............................................................................................................................................................44

PRN ....................................................................................................................................................................... 44

Show refresh GNSS position button ........................................................................................................................45

GNSS glossary ............................................................................................................................................................................................... 45

CHAPTER 6 IMPLEMENT SETUP 47

Multiple section output modules .......................................................................................................................................................... 47

IMPLEMENT TYPE 48

Section numbers .....................................................................................................................................................48

Straight ............................................................................................................................................................................................................ 48

Single section .........................................................................................................................................................48

Multiple sections with SDM or SFM .........................................................................................................................49

Multiple sections with ISOBUS sprayer setup ..........................................................................................................50

Spreader – TeeJet ......................................................................................................................................................................................... 51

Single section .........................................................................................................................................................51

Multiple sections .....................................................................................................................................................52

Spreader – OEM ............................................................................................................................................................................................ 54

Single section .........................................................................................................................................................54

Multiple sections .....................................................................................................................................................54

Staggered ....................................................................................................................................................................................................... 55

Multiple sections .....................................................................................................................................................55

HOMESETUPGUIDANCE FULL SCREENIMPLEMENT INTRODUCTIONGNSSRATE CONTROLAPPENDIX

APPLICATION OR WORKING WIDTH 57

Single section .........................................................................................................................................................57

Multiple sections .....................................................................................................................................................57

ISOBUS SPRAYER OFFSETS 58

Self-propelled – front mount ....................................................................................................................................58

Self-propelled – rear mount .....................................................................................................................................59

Three point hitch – front mount ................................................................................................................................59

Three point hitch – rear mount ................................................................................................................................60

Trailed – always rear mount ....................................................................................................................................61

IMPLEMENT LATERAL OFFSET DISTANCE ADJUSTMENT 62

GNSS offset adjustment calculation.........................................................................................................................62

Implement lateral offset adjustment .........................................................................................................................63

REVERSE SENSE 64

Reverse on guidance screens .................................................................................................................................64

NOZZLE SELECTION 65

Preset .....................................................................................................................................................................65

Current nozzle .........................................................................................................................................................66

98-05304-EN R2

iii

Aeros 9040 eld computer

DROPLET SIZE MONITOR 66

Setup ................................................................................................................................................................................................................ 66

Enable/disable DSM ................................................................................................................................................66

Nozzle selection / current nozzle .............................................................................................................................66

Input/output module pressure sensor.......................................................................................................................66

Operation ....................................................................................................................................................................................................... 67

HOME SETUP GUIDANCEFULL SCREEN IMPLEMENTINTRODUCTION GNSS RATE CONTROL APPENDIX

BOOMPILOT SECTION CONTROL 68

CHAPTER 7 GUIDANCE AND MAPPING 69

GUIDANCE BAR 74

Status bar ...............................................................................................................................................................67

Guidance bar ..........................................................................................................................................................67

Overview ......................................................................................................................................................................................................... 69

Screens options ............................................................................................................................................................................................ 70

Navigation activity & Boom status ...........................................................................................................................74

Selectable Information.............................................................................................................................................74

STATUS BAR 75

Status/information screens ...................................................................................................................................................................... 76

NAVIGATION SCREENS 78

Vehicleview ................................................................................................................................................................................................... 78

Fieldview ........................................................................................................................................................................................................ 79

RealView guidance ...................................................................................................................................................................................... 80

GUIDANCE MODES 81

Straight AB guidance.................................................................................................................................................................................. 81

Curved AB guidance ................................................................................................................................................................................... 81

Adaptive curve AB guidance ................................................................................................................................................................... 81

Circle pivot guidance ................................................................................................................................................................................. 81

Last pass guidance ...................................................................................................................................................................................... 81

NextRow guidance ...................................................................................................................................................................................... 82

No guidance .................................................................................................................................................................................................. 82

GUIDELINES 82

Marking A and B points ............................................................................................................................................................................. 82

A+ nudge feature ....................................................................................................................................................83

Next guideline feature ............................................................................................................................................................................... 84

Last pass guidelines .................................................................................................................................................................................... 84

NextRow guidelines .................................................................................................................................................................................... 85

Azimuth degree ........................................................................................................................................................................................... 85

RETURN TO POINT 86

Marking a return point .............................................................................................................................................86

Delete the return point .............................................................................................................................................86

Guidance to a return point .......................................................................................................................................86

iv

www.teejet.com

Aeros 9040 eld computer

BOOMPILOT 87

No Section control module ...................................................................................................................................................................... 87

ISOBUS sprayer ............................................................................................................................................................................................. 88

ISOBUS spreader .......................................................................................................................................................................................... 89

With TeeJet section control module and switchbox or ISM ......................................................................................................... 90

With TeeJet section control module ..................................................................................................................................................... 90

CURVED LOOKAHEAD 90

REFRESH GNSS POSITION 91

NOZZLE FAULT RESET 91

BOUNDARIES AND POLYGONS 92

Boundaries ..................................................................................................................................................................................................... 92

Establishing an exterior or interior boundary ...........................................................................................................92

Delete last marked boundary ...................................................................................................................................94

Boundary on status bar ...........................................................................................................................................94

Polygons ......................................................................................................................................................................................................... 94

Establishing a polygon ...........................................................................................................................................94

Delete last marked polygon .....................................................................................................................................95

MAPPING OPTIONS 96

Polygon mapping ........................................................................................................................................................................................ 96

Rate control mapping ................................................................................................................................................................................ 96

APPLICATION CONTROL OPTIONS 97

HOMESETUPGUIDANCE FULL SCREENIMPLEMENT INTRODUCTIONGNSSRATE CONTROLAPPENDIX

ZOOM IN/OUT 97

Vehicleview ................................................................................................................................................................................................... 97

Fieldview ........................................................................................................................................................................................................ 97

PAN MODE 98

REALVIEW SPECIFIC OPTIONS 98

RealView guidance options ..................................................................................................................................................................... 99

Camera snapshot ......................................................................................................................................................................................... 99

VSM camera options ................................................................................................................................................................................... 99

CHAPTER 8 RATE CONTROL 101

Ready for operation ..................................................................................................................................................................................102

ISOBUS configuration options ............................................................................................................................... 102

NAVIGATION SCREEN OPTIONS 103

Guidance bar ........................................................................................................................................................103

Current pressure ...................................................................................................................................................103

98-05304-EN R2

v

Aeros 9040 eld computer

Application control options ....................................................................................................................................103

Mapping options .................................................................................................................................................... 104

MAPPING OPTIONS 104

Coverage map .............................................................................................................................................................................................105

Polygons map .............................................................................................................................................................................................105

Prescription map ........................................................................................................................................................................................106

HOME SETUP GUIDANCEFULL SCREEN IMPLEMENTINTRODUCTION GNSS RATE CONTROL APPENDIX

Application and target rate maps .......................................................................................................................................................106

Application map ...................................................................................................................................................106

Target rate map ..................................................................................................................................................... 107

Colour range selection ..........................................................................................................................................107

APPENDIX A SYSTEM CONFIGURATIONS 109

APPENDIX B AEROS CONSOLE MENU SETTINGS 112

APPENDIX C UNIT SPECIFICATIONS 116

APPENDIX D SETTING RANGES 116

APPENDIX E UTM COORDINATES AND ZONES 117

vi

www.teejet.com

Aeros 9040 eld computer

CHAPTER 1 INTRODUCTION

The Aeros 9040 eld computer allows the management of multiple connected modules plus GNSS mapping, guidance, FieldPilot®,

BoomPilot®, ISOBUS Rate Control, Nozzle Flow Monitor, and data collection in a single console using CAN bus technology. This replaces

multiple consoles in the cab with one robust system.

Product upgrades available

• FieldPilot® Pro auto steering

• Fieldware® Link enhanced data organization application

HOMESETUPGUIDANCE FULL SCREENIMPLEMENT GNSSRATE CONTROLAPPENDIX INTRODUCTION

• UniPilot® Pro assisted steering

• BoomPilot® automated boom section control

• Tilt gyro module

• Video selection modules for up to 8 cameras

• External GNSS receiver or antenna upgrades

• Pressure sensor interface kit for droplet size monitor

• ISOBUS rate control

• Reverse sense module

• Nozzle ow monitoring

SYSTEM COMPONENTS

Aeros 9040 console

The Aeros 9040 is designed to provide years of service under typical agricultural operating conditions. A tight tting enclosure, combined

with rubber covers for all connectors mean that typical dusty environments will not cause operational problems. While occasional splashing

of water will not damage the unit, the Aeros 9040 is not designed for direct exposure to rain. Take care not to operate the Aeros 9040 in wet

conditions.

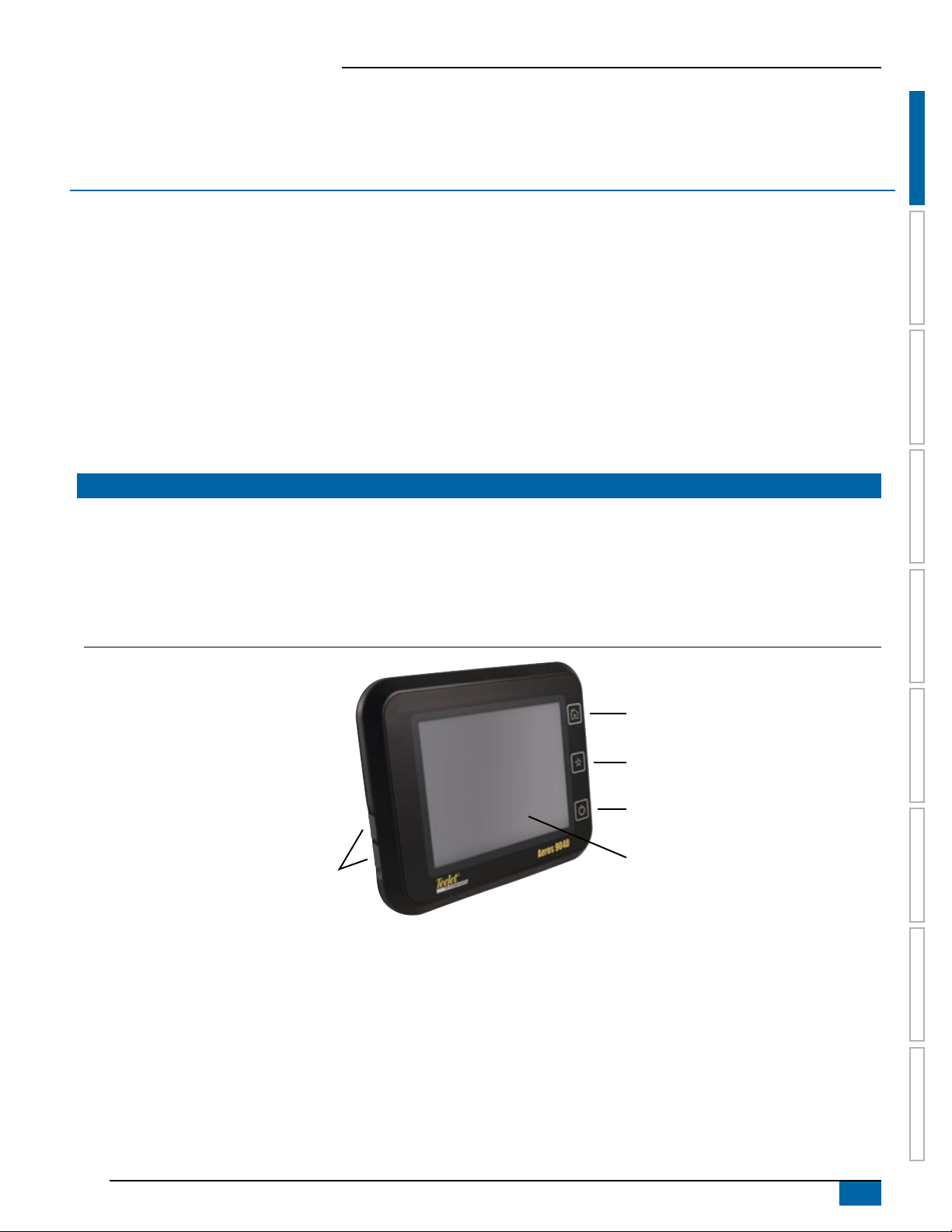

Figure 1-1: Aeros 9040 console front

Home button

Favorites button

USB ports with rubber covers

Power button

Bright touch screen

98-05304-EN R2

1

Aeros 9040 eld computer

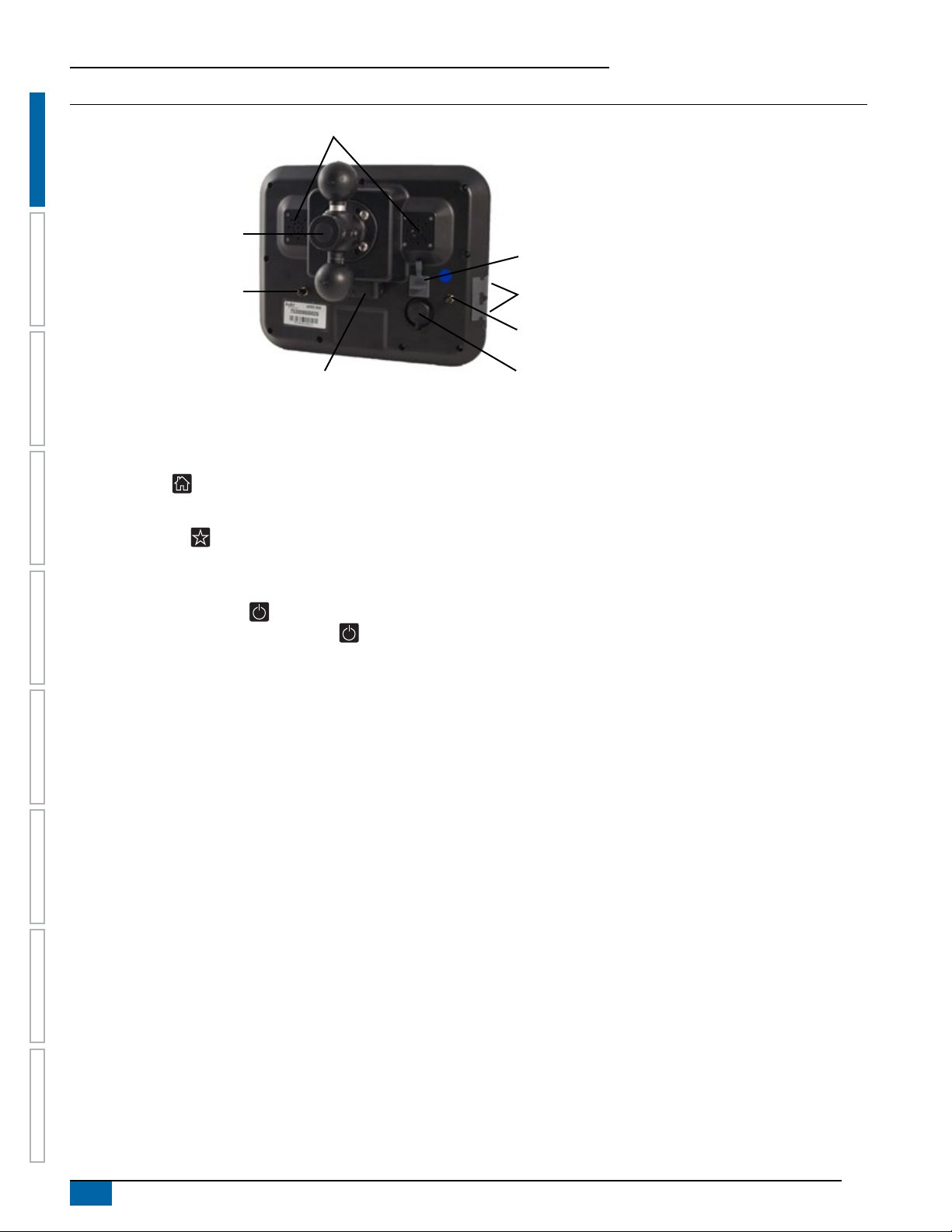

Figure 1-2: Aeros 9040 console back

Speakers

Integrated RAM mount

HOME SETUP GUIDANCEFULL SCREEN IMPLEMENTGNSS RATE CONTROL APPENDIXINTRODUCTION

(assembly required)

Speed digital (LAN) connection

with rubber cover

WiFi antenna connection

Power connection

USB ports with rubber covers

GNSS antenna connection

Camera connection

with rubber cover

Buttons

Home

The Home button provides a shortcut to the Home screen.

Favorites

The Favorites button provides a shortcut to a frequently used console bottom tab. To assign a tab to the button, navigate to that tab’s

screen, then press and hold the Favorites button until it beeps.

Power on/off

On – Press the POWER button to power on the console. Upon power up, the Aeros will begin its start up sequence.

Off – Press and briey hold the POWER button until a conrmation screen acknowledges shut down mode.

WARNING! Wait 10 seconds before restarting the console.

RealView® camera

The TeeJet Technologies RealView camera allows video images to be displayed on the Aeros screen. The camera can be pointed forward to

enable RealView guidance over video, or it can be positioned to view other operational aspects of your equipment. The camera is equipped

with a exible RAM mount, integral sun shade and provides infrared illumination, allowing clear video images even in dark conditions.

Additional information

All changes are saved automatically.

The console needs to be cycled off and back on when changing or attaching equipment to the Aeros system.

Start up sequence

The console takes approximately two-three minutes to power up. During this time a series of screens will be displayed, LEDs will power on

and off, and brightness levels will uctuate. Once the power up sequence has completed, the Home screen will appear.

Recommended antenna installation

The GNSS antenna should be mounted as far forward as possible on top of the cab on a metal surface of at least 10 cm × 10 cm.

USB ports

Only one USB port can be used at any given time.

2

www.teejet.com

Aeros 9040 eld computer

BASIC SCREEN USE

The Aeros 9040 can be used as a simple current job system or advanced multi-job system. Regardless of which mode the console is in, the

basic screen functions are the same.

• Bottom tabs and side tabs access the various screens and sub-screens

• Warnings and information pop-ups inform user of console activities and details on setup or guidance functions

• Setup options can easily be set using the drop-down menus or keyboard entry screens

To quickly nd a setup feature, see “Aeros console menu settings” in this manual.

Bottom tab keys

The bottom tab keys are always available on screen. These keys

give access to jobs, setup options, and navigation.

Home/job screen

System setup

Vehicle view guidance

Field view guidance

RealView guidance or

RealView camera full screen video view

NOTE: RealView Guidance options are only available with a

camera installed on the system.

ISOBUS universal terminal

Figure 1-3: Bottom tab keys

0.00

ha

0.0

0.0

km/h

3.5

(bar)

Unavailable options when job is active

When a job is active some setup options are unavailable: see “Aeros

console menu settings” in this manual.

Figure 1-4: Examples of unavailable options

HOMESETUPGUIDANCE FULL SCREENIMPLEMENT GNSSRATE CONTROLAPPENDIX INTRODUCTION

98-05304-EN R2

3

Aeros 9040 eld computer

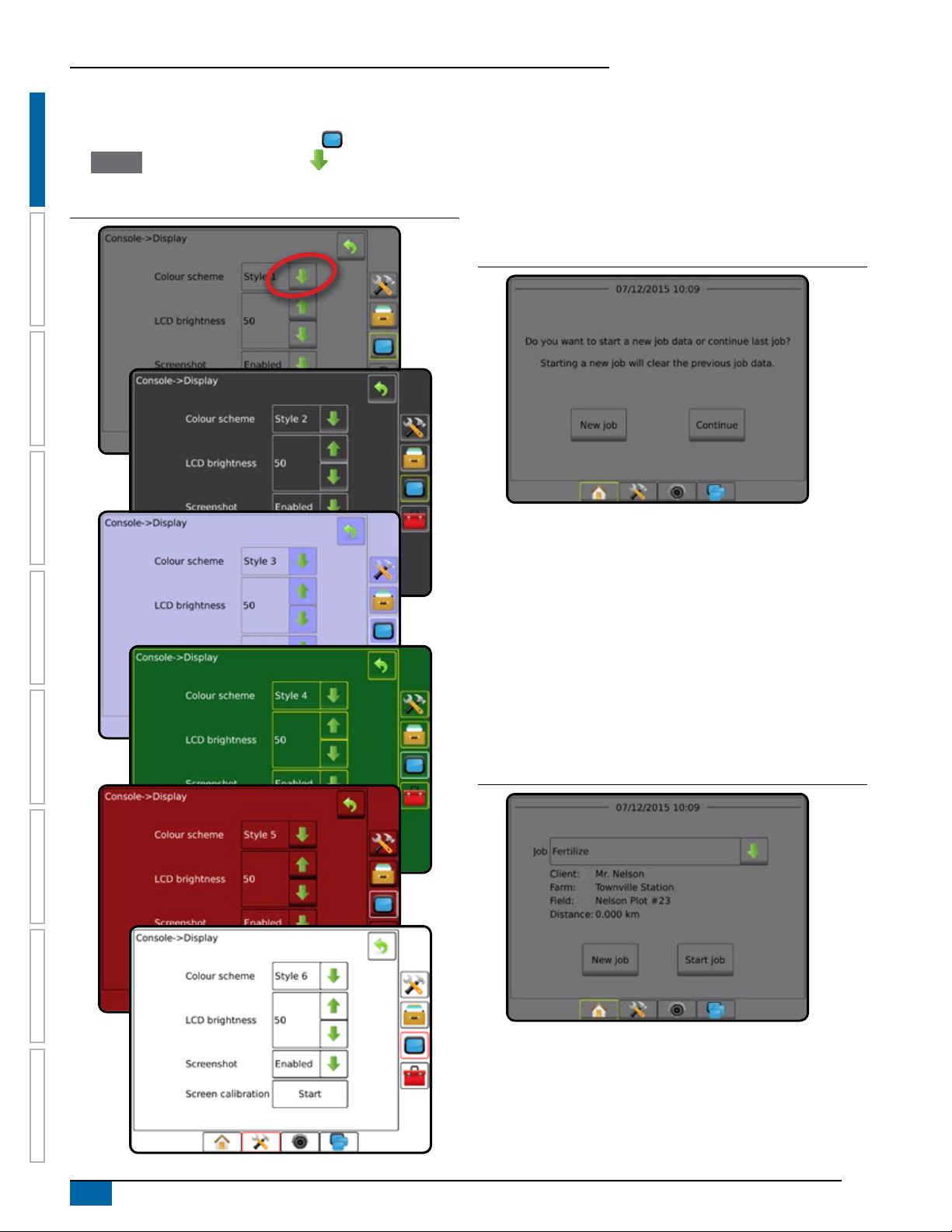

Console screen colours

The console is available in six colour schemes. From the System

setup bottom key, press CONSOLE side tab and enter

the Display options. Press DOWN arrow to access the Colour

scheme options to select colour mode.

Figure 1-5: Colour schemes

HOME SETUP GUIDANCEFULL SCREEN IMPLEMENTGNSS RATE CONTROL APPENDIXINTRODUCTION

Simple or advanced mode

To change between simple mode and advanced mode, see the

conguration chapter under Data –> Options.

In simple mode, only one job will be available at a time. Only

bounded area and coverage areas are displayed on the home

screen. Only the current job is available for saving in Reports. Use

with Fieldware Link is not available.

Figure 1-6: Simple mode home screen

In advanced mode, more than one job will be available at any time.

Client, farm, eld and job names; bounded and coverage areas;

application time; and distance from selected job are displayed on the

home screen. All saved job proles can be exported as a PDF, SHP

or KML le to a USB drive using Data -> Reports.

Client information, farm information, eld information, and

prescription maps can only be inputted using Fieldware Link. A job

name can only be edited using Fieldware Link.

A user can duplicate jobs for reuse of guidelines, boundaries, applied

data, prescription map and/or polygons using Fieldware Link or

Data -> Job data -> Manage in the console.

Figure 1-7: Advanced mode home screen

4

www.teejet.com

Aeros 9040 eld computer

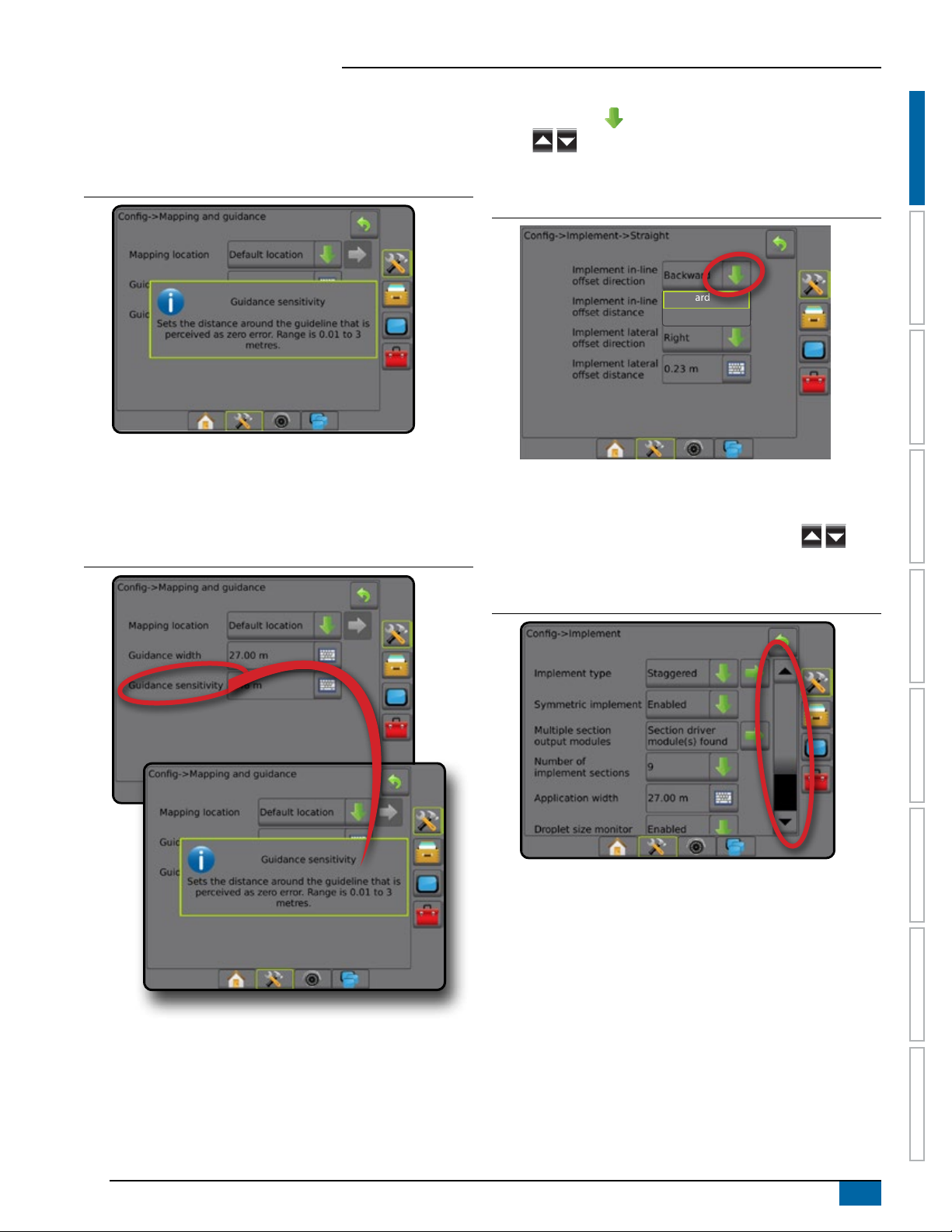

Warnings and information pop-ups

A pop-up warning or information box will be displayed for

approximately ve (5) seconds. To remove the information box, tap

anywhere on the screen.

Figure 1-8: Example of information text box

Setup option information

Press the option’s icon or option’s name of any menu item to display

a denition and range values of that item. To remove the information

box, press anywhere on the screen.

Figure 1-9: Example of information text box

Drop-down menu selections

Press DOWN arrow to access the options. Use the UP/DOWN

arrows or slide bar if necessary to scroll through the extended

list. Select the appropriate option. To close the list without selecting an

option, tap anywhere on the screen outside the drop-down menu.

Figure 1-10: Example of drop-down menu

HOMESETUPGUIDANCE FULL SCREENIMPLEMENT GNSSRATE CONTROLAPPENDIX INTRODUCTION

Backward

Forward

Scrolling screens

Some screens have more information or options that are visible

beyond the current screen. Use the UP/DOWN arrows or

slide bar to access additional options or information not currently

visible on the screen.

Figure 1-11: Example of scrolling screen

98-05304-EN R2

5

Aeros 9040 eld computer

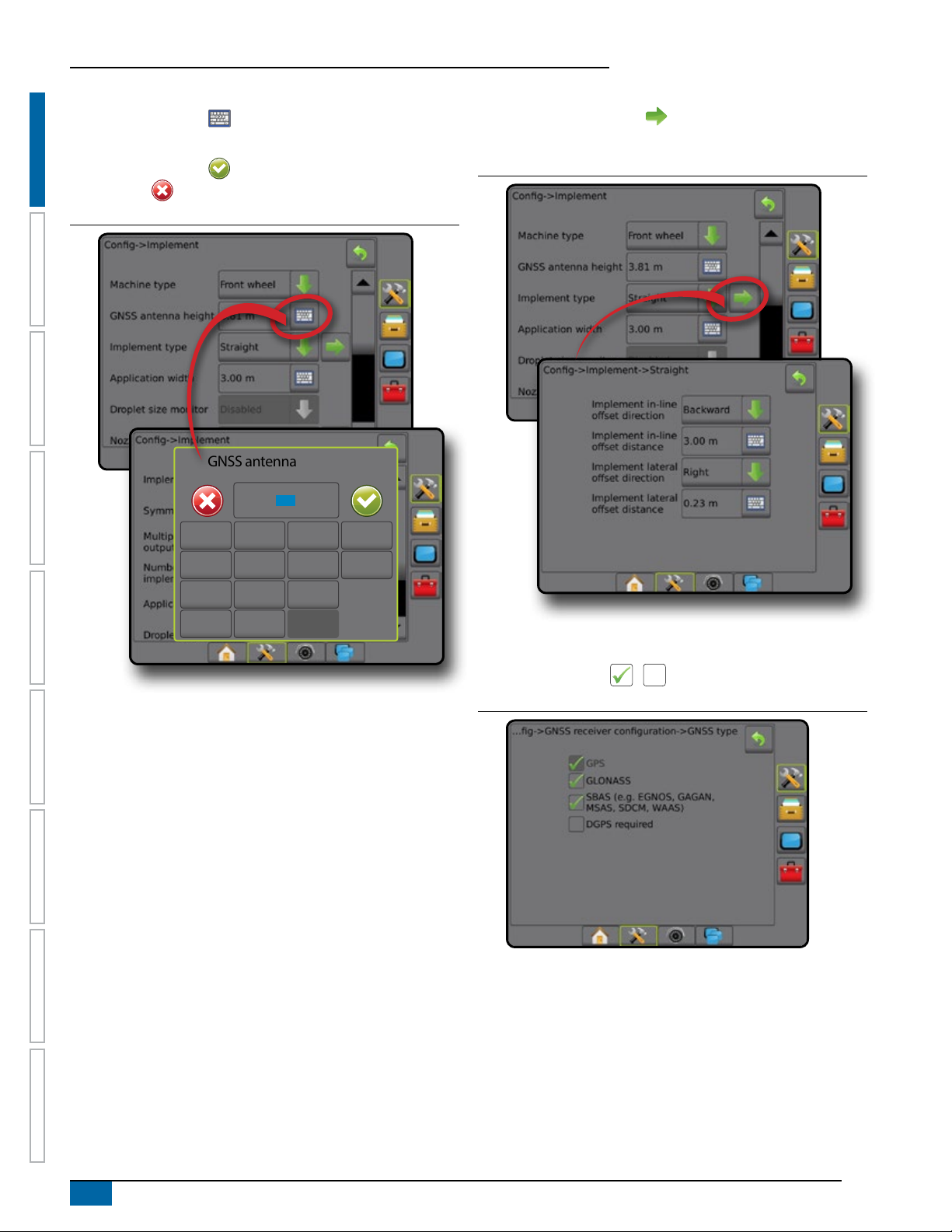

Keyboard entry screen

Press the KEYPAD icon . Use the numeric keypad to enter

a value.

Press the ACCEPT icon to save the settings or the

CANCEL icon to leave the keypad without saving.

Figure 1-12: Example of keyboard

HOME SETUP GUIDANCEFULL SCREEN IMPLEMENTGNSS RATE CONTROL APPENDIXINTRODUCTION

GNSS antenna height (m)

3.50

1 2 3

Next page

Press the NEXT PAGE arrow to set up additional options for the

selected item.

Figure 1-13: Example of next page

Clear

4 5 6 <--

7 8 9

0 . +/-

Checkboxes

Press the CHECKBOX / to select or deselect.

Figure 1-14: Example of checkboxes

6

www.teejet.com

Aeros 9040 eld computer

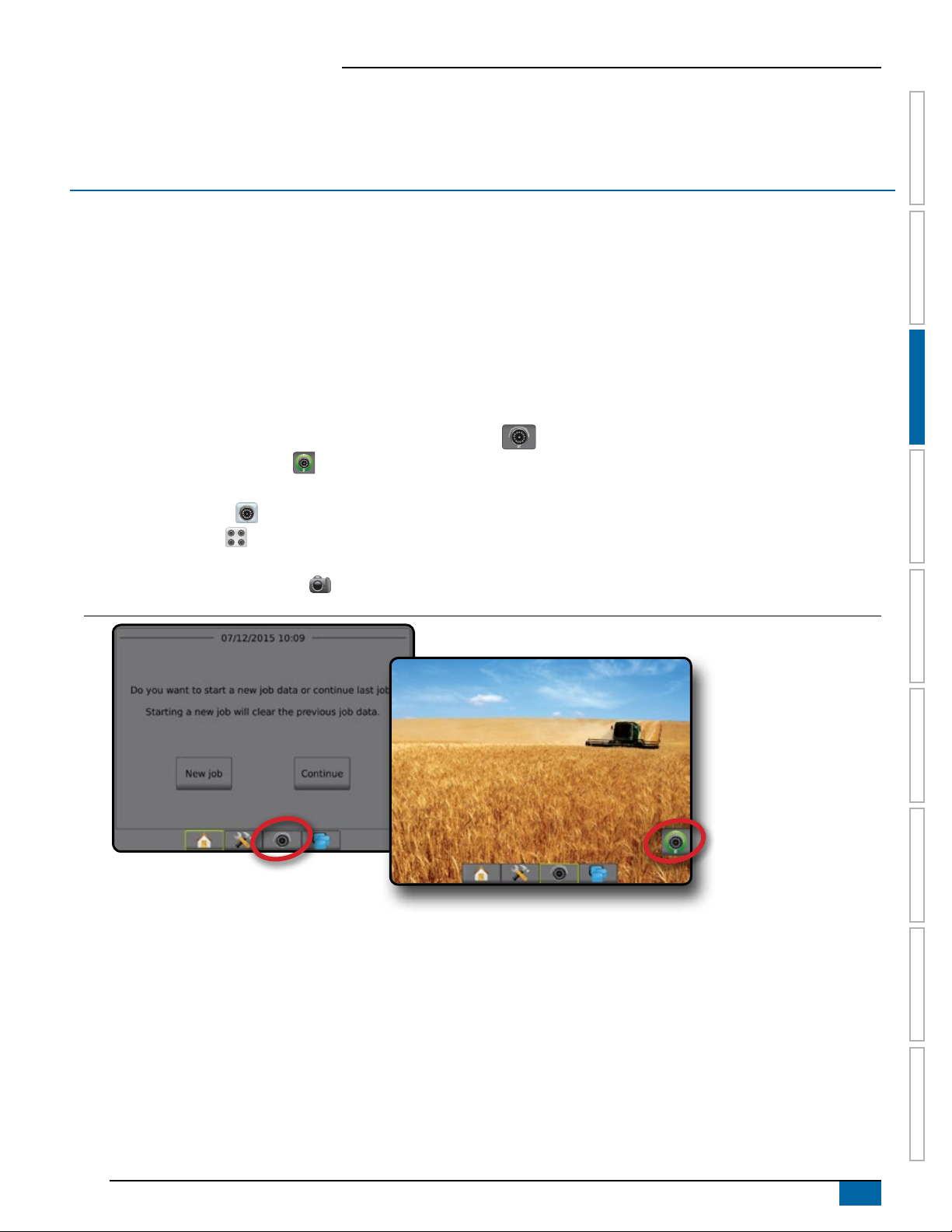

CHAPTER 2 JOBS / HOME SCREEN

Once the power up sequence has completed and the console is receiving GNSS, the Home screen will appear with the option to start a new

job or continue an existing job.

Setup for the specic machine and its components must be completed before starting a job. Once a job is

active, some setup options can no longer be changed. See “Aeros console menu settings” in the appendix of this manual.

To change between simple and advanced mode, go to Data-> Options-> Job mode in the System setup.

Simple mode

In simple mode, only one job will be available at a time. Only

bounded area, coverage areas, and application time are displayed

on the home screen. Only the current job is available for saving in

Reports. Use with Fieldware Link is not available.

Figure 2-1: Simple mode home screen

Advanced mode

In advanced mode, more than one job will be available at any time.

Client, farm, eld and job names; bounded and coverage areas;

application time; and distance from selected job are displayed on the

home screen. All saved job proles can be exported as a PDF, SHP

or KML le to a USB drive using Data -> Reports.

Client information, farm information, eld information, and

prescription maps can only be inputted using Fieldware Link. A job

name can only be edited using Fieldware Link.

A user can duplicate jobs for reuse of guidelines, boundaries, applied

data, prescription map and/or polygons using Fieldware Link or

Data -> Job data -> Manage in the console.

Figure 2-2: Advanced mode home screen

SETUPGUIDANCE FULL SCREENIMPLEMENT INTRODUCTIONGNSSRATE CONTROLAPPENDIX HOME

98-05304-EN R2

7

Aeros 9040 eld computer

SIMPLE MODE

Once the power up sequence has completed, the Home screen will

appear with the option to start a new job or continue an existing job.

The console must have GNSS before starting or continuing a job.

New job

Starting a new job will clear the previous job data.

To start a new job:

1. On the Home screen , press New job .

The console will jump to Vehicle View.

Continue job

To continue the existing job:

1. On the Home screen , press Continue .

The console will jump to Vehicle view and begin providing navigation

information.

Distance

SETUP GUIDANCEFULL SCREEN IMPLEMENTINTRODUCTION GNSS RATE CONTROL APPENDIXHOME

If a selected job is in a UTM zone other than the current or adjacent

UTM zone, “Out of range” will be displayed next to Distance, and

Continue will be disabled.

NOTE: For more information, see the UTM zone appendix.

If a selected job has no recorded information, Distance will show “No

data”.

Close job

To close a job:

1. On the Home screen , press Close job .

To create a report of the job when closing a job:

1. Insert a USB drive into the USB port of the console.

2. On the Home screen , press Close job .

3. Select:

►Yes – to create a report of the last job

►No – to return to the Home screen without saving

ADVANCED MODE

Once the power up sequence has completed, the Home screen will

appear with the option to start a new job or continue an existing job.

The console must have GNSS before starting or continuing a job.

New job

Starting a new job will clear the previous job data.

To start a new job:

1. On the Home screen , press New job .

2. Press:

►Yes – to automatically generate a name

►No – to enter a name using the on screen keyboard

Client, farm, and eld information are inputted using Fieldware Link.

The console will jump to Vehicle view.

Start job

The Aeros 9040 is programmed with a eld nder tool to assist the

user in nding the job closest to the vehicle’s location. With GNSS

acquired, the job pick list will be updated every ten seconds. During

this update, the list of jobs is sorted by distance and the closest two

jobs are displayed on the top of the list. The remaining jobs are listed

beneath these.

To continue the existing job:

1. On the Home screen , press DOWN arrow to access the

list of jobs saved in the console.

2. Select the job name to be started/continued.

3. Press Start job .

The console will jump to Vehicle View and begin providing navigation

information.

Distance

If a selected job is in a UTM zone other than the current or adjacent

UTM zone, “Out of range” will be displayed next to Distance, and

Start job will be disabled.

8

www.teejet.com

NOTE: For more information, see the UTM zone appendix.

If a selected job has no recorded information, Distance will show “No

data”.

Close job

To close a job:

1. On the Home screen , press Close job .

To create a report of the job when closing a job:

1. Insert a USB drive into the USB port of the console.

2. On the Home screen , press Close job .

3. Select:

►Yes – to create a report of the last job

►No – to return to the Home screen without saving

Aeros 9040 eld computer

CHAPTER 3 FULL SCREEN VIDEO VIEW

RealView full screen video view allows live video input to be displayed. View video feed(s) and setup cameras without GNSS available.

Options for RealView guidance are not available on this screen.

►Single camera – a single camera is directly attached to the console

►Video selection module – if a Video Selection Module (VSM) is installed on the system, two (2) video options are available:

• One camera view – one of up to eight camera inputs can be selected to change the view of the video input.

• Split camera view – one of two sets of four camera inputs (A/B/C/D or E/F/G/H) can be selected to divide the screen into four

separate video feeds.

To adjust the camera view [reverse, upside down], go to Setup-> Conguration-> Video.

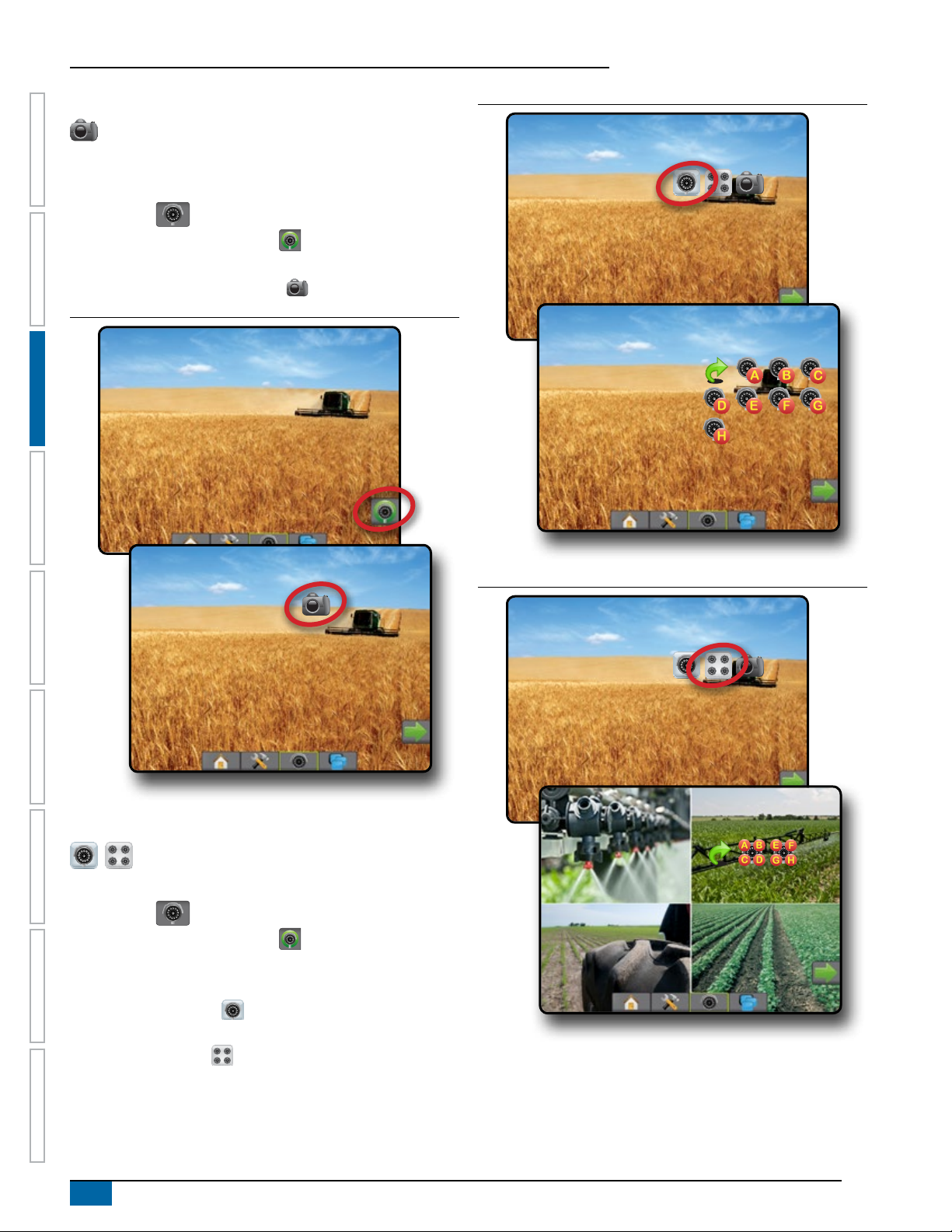

To enter Full screen video mode:

1. Press REALVIEW CAMERA FULL SCREEN VIDEO VIEW bottom tab .

2. Press REALVIEW OPTIONS tab to display RealView options.

3. Select from:

►Single camera view [VSM only] – one (1) of up to eight (8) camera inputs can be selected to change the view of the video input

►Split camera view [VSM only] – one (1) of two (2) sets of four (4) camera inputs (A/B/C/D or E/F/G/H) can be selected to divide the

screen into four separate video feeds

►RealView camera image capture – saves a still photo of the current view on the screen to a USB drive

Figure 3-1: RealView full screen video view

HOMESETUPGUIDANCE IMPLEMENT INTRODUCTIONGNSSRATE CONTROLAPPENDIX FULL SCREEN

98-05304-EN R2

9

Aeros 9040 eld computer

Camera snapshot

RealView camera snapshot saves a still photo of the current

view on the screen to a USB drive.

1. Insert USB drive.

2. Press REALVIEW CAMERA FULL SCREEN VIDEO VIEW

bottom tab .

3. Press REALVIEW OPTIONS tab to display RealView

HOME SETUP GUIDANCEIMPLEMENTINTRODUCTION GNSS RATE CONTROL APPENDIXFULL SCREEN

options.

4. Press CAMERA SNAPSHOT icon .

Figure 3-2: RealView camera full screen video view

Figure 3-3: Single camera selection with VSM

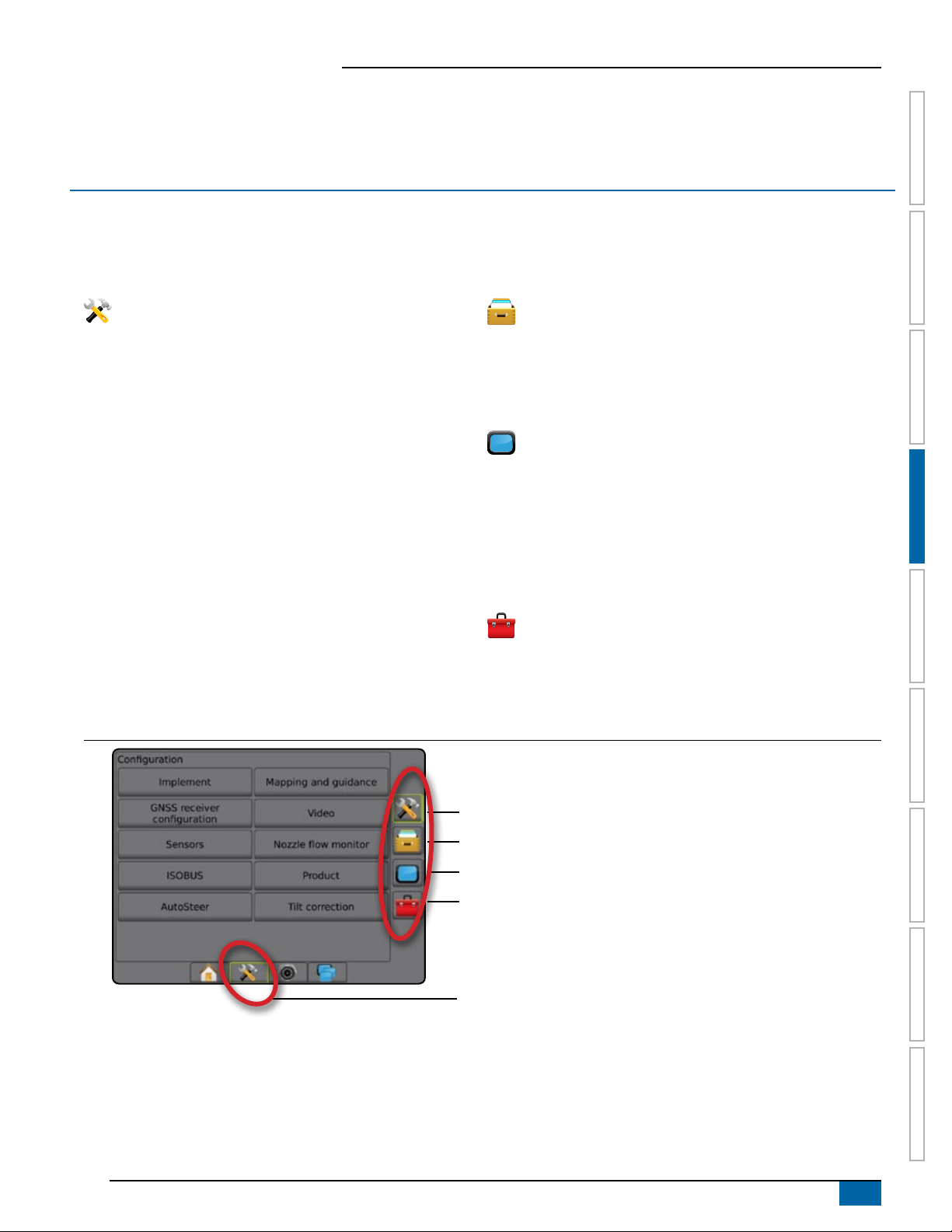

VSM camera options

If a Video selection module (VSM) is installed on the

system, two (2) video options are available:

1. Press REALVIEW CAMERA FULL SCREEN VIDEO VIEW

bottom tab .

2. Press REALVIEW OPTIONS tab to display RealView

options.

3. Select from:

►Single camera view – one (1) of up to eight (8) camera

inputs can be selected to change the view of the video input.

►Split camera view – one (1) of two (2) sets of four (4)

camera inputs (A/B/C/D or E/F/G/H) can be selected to divide

the screen into four separate video feeds.

Figure 3-4: Select split view with VSM

10

www.teejet.com

Aeros 9040 eld computer

CHAPTER 4 SYSTEM SETUP

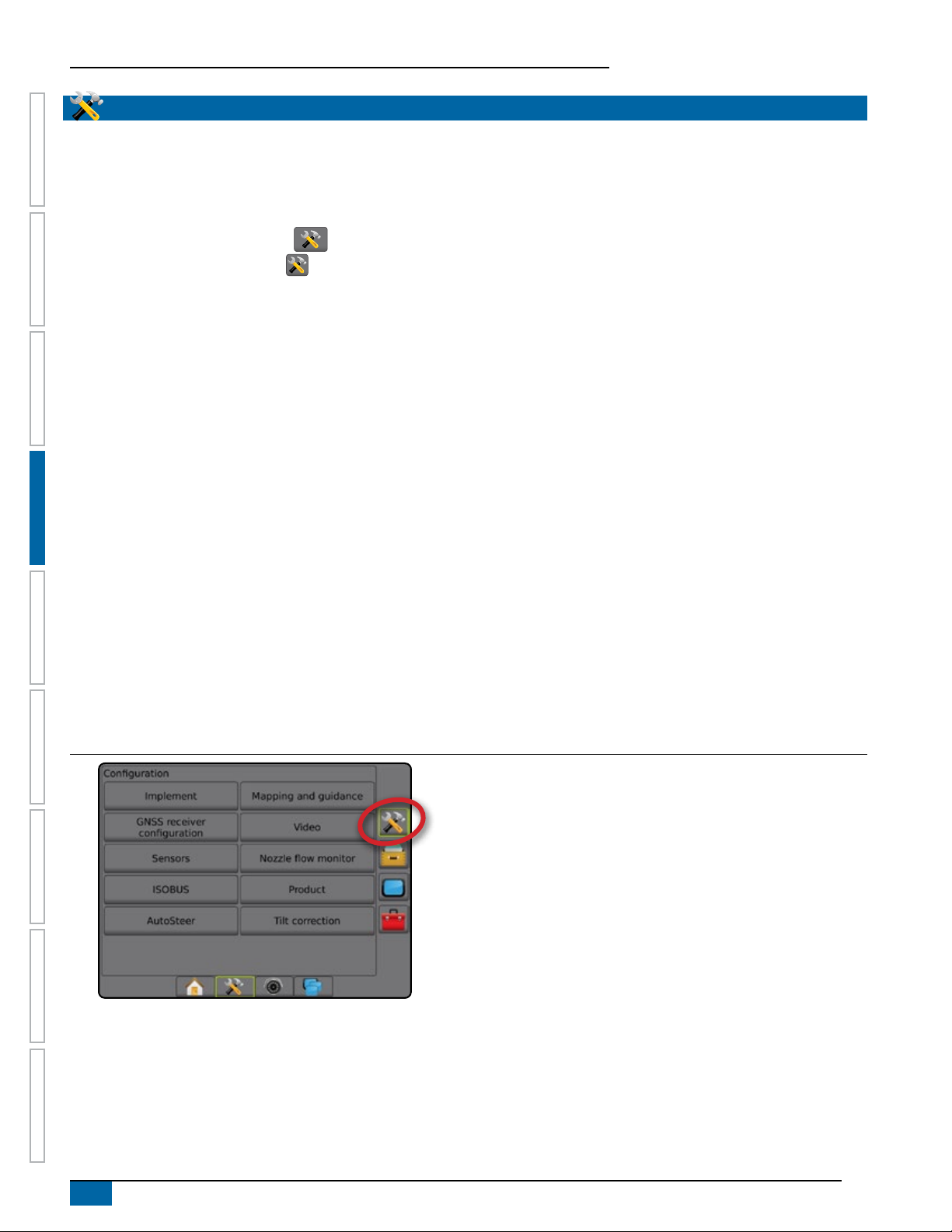

System Setup is used to congure the console, the machine and its implements. Four side tabs access options for Machine/Implement

Conguration, Data management, Console settings, and Tools.

Overview

Four side tabs access setup options for:

Conguration

• Implement (straight, spreader, or staggered implement

congurations; nozzle selection information including droplet

size monitor, reverse conguration)

• Mapping and Guidance (mapping location, guidance sensitivity,

external lightbar)

• GNSS receiver conguration

• Video conguration

• Sensors (Input/output module (IOM) pressure sensor)

• Nozzle ow monitor

• ISOBUS conguration

• Product conguration

• AutoSteer

◄FieldPilot (valve setup, steering settings, valve test, valve

diagnostics, steering wheel sensor, steering angle sensor)

◄FieldPilot Pro / UniPilot Pro (manage vehicle, calibrations,

adjustments, select qi values, transport mode, service mode)

• Tilt correction

HOMEGUIDANCE FULL SCREENIMPLEMENT INTRODUCTIONGNSSRATE CONTROLAPPENDIX SETUP

Data management

• Job data (transfer, manage)

• Reports

• Options (job mode)

• Machine settings (transfer, manage)

Console settings

• About (system information)

• Display

• Cultural

• Audio volume

• Demo GNSS

• Feature unlock

Tools

• Upload software

• Extras (calculator, units converter)

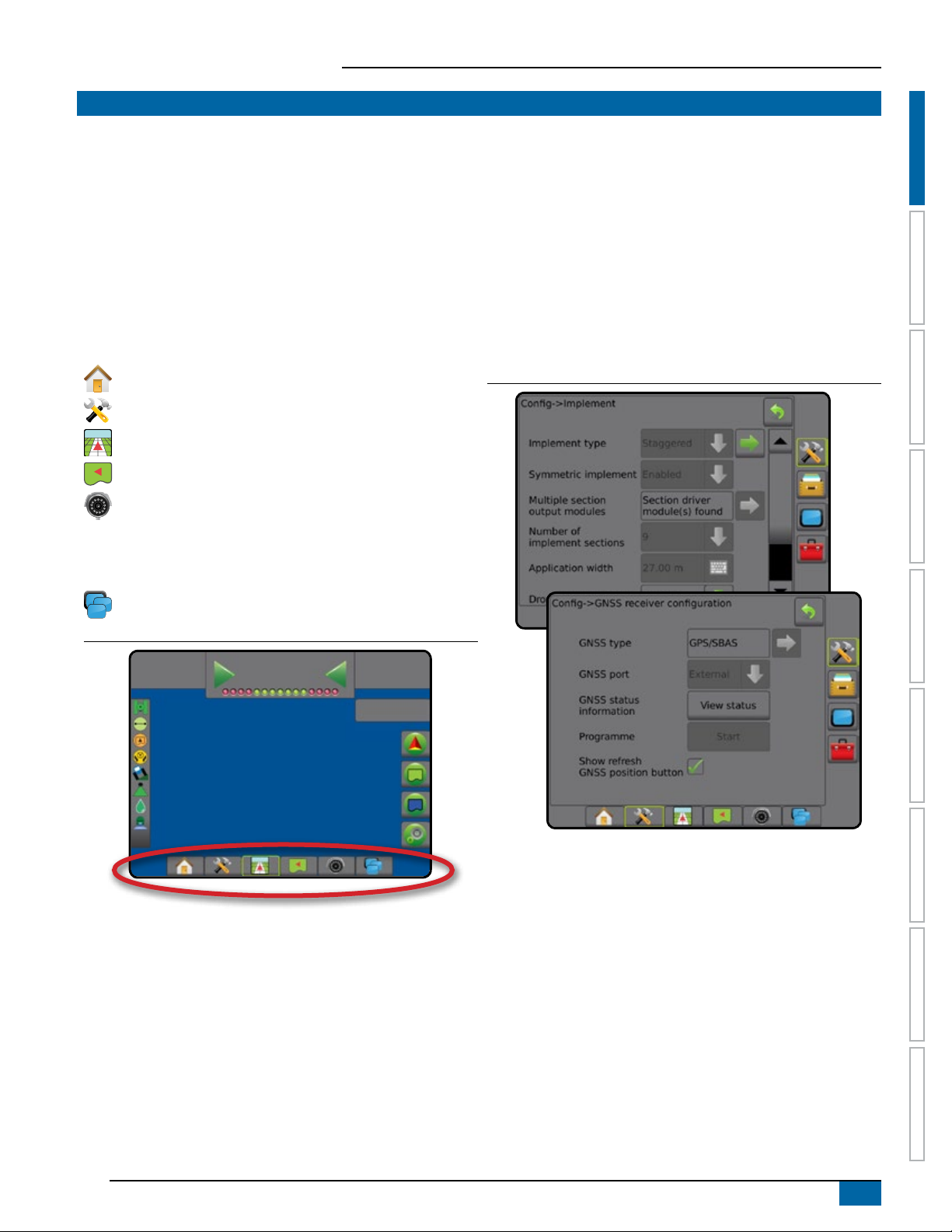

Figure 4-1: Setup options

Side tabs

Conguration side tab

Data management side tab

Console settings side tab

Tools side tab

System setup bottom tab

98-05304-EN R2

11

Aeros 9040 eld computer

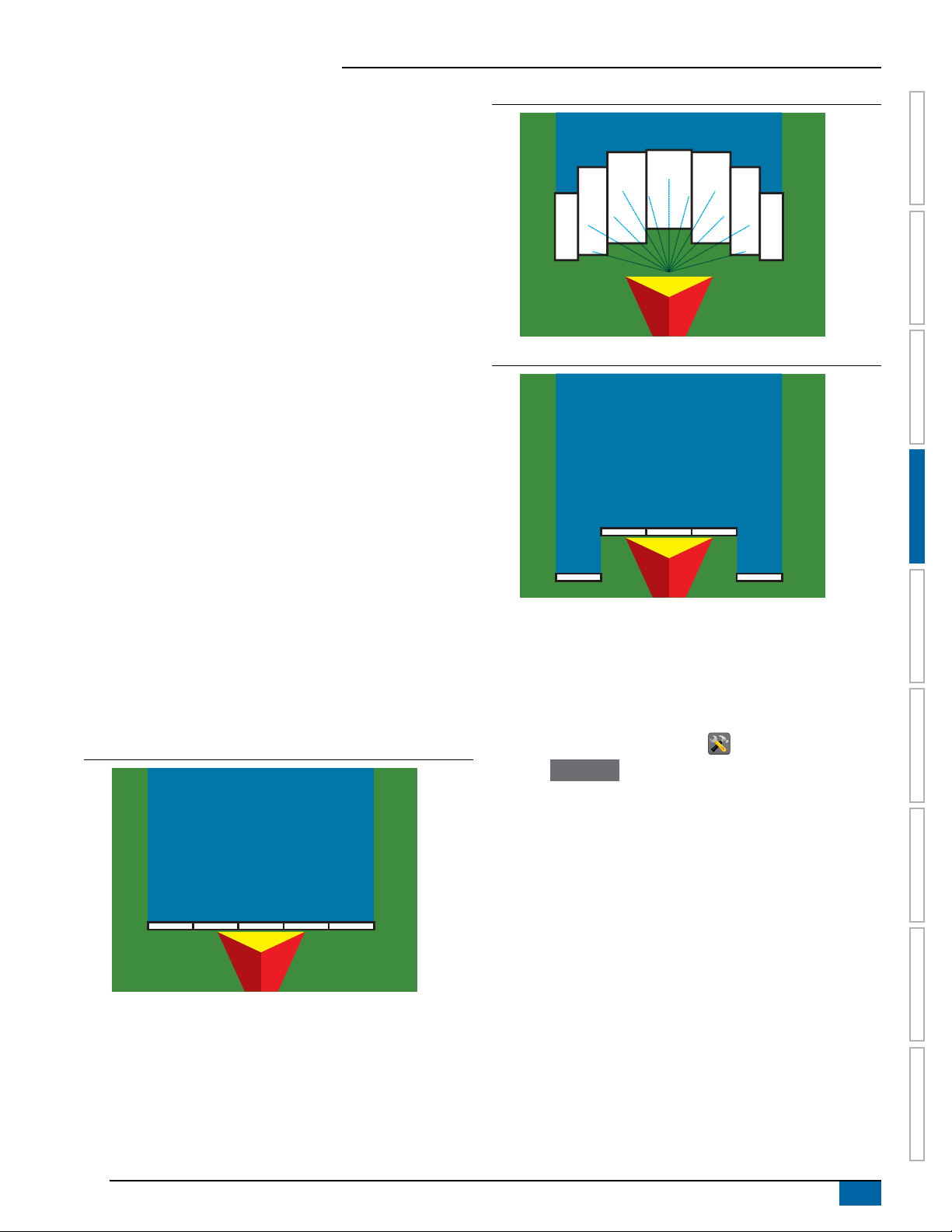

CONFIGURATION

Conguration is used to congure the system components including

implements, guides, steering, monitors and sensors.

NOTE: Feature availability will vary depending on the devices

available and unlocked on the Aeros 9040 system.

1. Press SYSTEM SETUP bottom tab .

HOME GUIDANCEFULL SCREEN IMPLEMENTINTRODUC TION GNSS RATE CONTROL APPENDIXSETUP

2. Press CONFIGURATION side tab .

3. Select from:

►Implement – used to set (as appropriate) machine type,

GNSS antenna height, implement type, symmetric implement

layout, section output modules, number of implement

sections, application/working width, droplet size monitor,

nozzle selection, nozzle spacing, BoomPilot start mode,

reverse sense module

● In Straight mode – in-line/lateral implement offset direction/

distance, overlap percentage, implement delay on/off time

● In Spreader mode:

TeeJet – antenna to disks distance, lateral implement offset

direction/distance, overlap percentage, delay on/off times,

spread offset distance, section offset distances, section

lengths

OEM – antenna to disks distance, lateral implement offset

direction/distance, start/stop distance, section start/stop

offset distances

● In Staggered mode – in-line/lateral section 1 offset

direction/distance, overlap percentage, delay on/off times,

section offsets

Figure 4-2: Configuration options

►Mapping and guidance – used to congure the mapping

location, guidance width, guidance sensitivity (cross track

error) and/or an optional external lightbar module (ELM)

►GNSS – used to establish GNSS type, port, and PRN, as well

as to view GNSS status information

►Video – used to set up individual cameras

►Sensors – used to establish pressure sensor settings

►Nozzle ow monitor – used to establish nozzle conguration,

and to establish and calibrate ow limits and alarm behavior

for nozzle ow monitors

►ISOBUS – used to select information for broadcast over the

ISOBUS, and in troubleshooting

►Product – used to congure product name, tank/bin volumes,

target application rates, increment for adjusting target rates,

and colour mapping maximum/minimum rate limits and

corresponding display colours

►AutoSteer – used to enable/disable and calibrate assisted/

auto steering

● FieldPilot – used to establish valve setup settings, steering

settings, steering wheel and steering angle sensor settings,

and to perform valve tests or valve diagnostics

● FieldPilot Pro / UniPilot Pro – used to manage vehicle

settings, calibrate sensors, select QI values, as well as

establish transport mode and service mode

►Tilt correction – used to enable/disable and calibrate the tilt

correction function, and improve application on hilly or sloped

terrain

12

www.teejet.com

Aeros 9040 eld computer

Implement

Implement setup is used to establish the various settings associated

with straight mode, spreader mode, or staggered mode. Available

settings will vary depending on the specic equipment present in the

system.

This section includes setup options for these implement

congurations:

►Single section

►Section(s) with ISOBUS sprayer/spreader setup

►Multiple sections with Section driver module or Switch function

module

NOTE: For more information, see the Implement chapter of this

manual.

Implement type

Implement type selects the type of application pattern that most

closely represents your system.

● In Straight mode – the boom sections have no length and are

on a line a xed distance from the antenna

● In Spreader mode – a virtual line is created in line with the

delivery disks from which the application section or sections can

vary in length and can be at different distances from the line

(availability depends on the specic equipment in the system)

● In Staggered mode – a virtual line is created in line with

section 1 from which the application section or sections have

no length and can be at different distances from the line

(availability depends on the specic equipment in the system)

NOTE: For more information, see "Implement type" in the Implement

chapter of this manual.

Figure 4-3: Implement type – Straight

Figure 4-4: Implement type – Spreader

HOMEGUIDANCE FULL SCREENIMPLEMENT INTRODUCTIONGNSSRATE CONTROLAPPENDIX SETUP

Figure 4-5: Implement type – Staggered

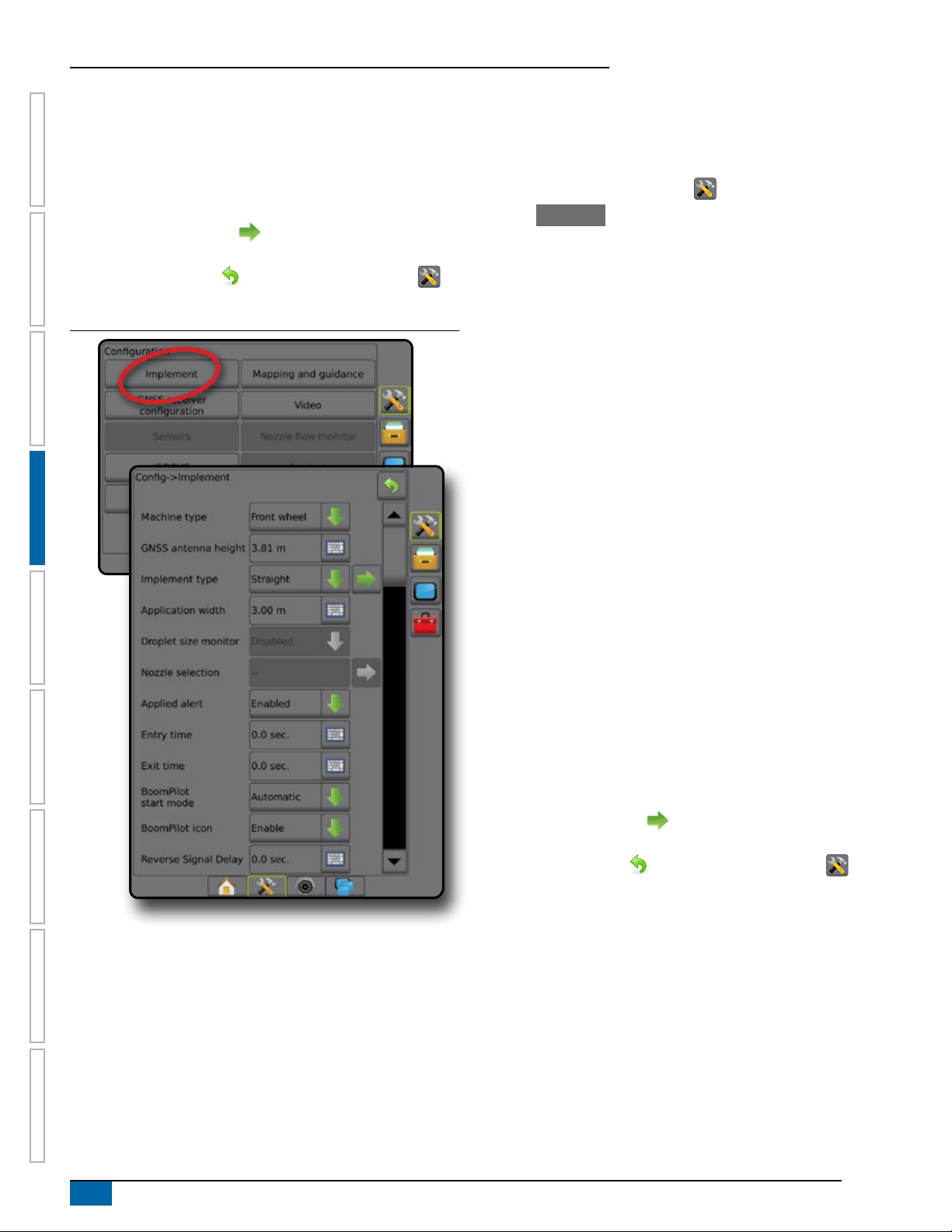

Single section setup

Single section setup is used when a SmartCable, Section driver

module (SDM), or Switch function module (SFM) is not on the

system (that is, no section control is present). The entire boom or

delivery area is considered to be one section.

1. Press CONFIGURATION side tab .

2. Press Implement .

3. Select from:

►Machine type [when available] – used to select the type of

machine that most closely represents your machine

►GNSS antenna height [when available] – used to measure the

height of the antenna from the ground

►Implement type – used to select the layout of the sections for

the applied product location

►Working width [Spreader implement type] – used to enter the

total width of the implement

►Application width [Straight implement type] – used to enter the

total width of the implement

►Droplet size monitor [when available] – used to enable droplet

size monitoring for up to ve preselected sprayer tips

►Nozzle selection [when available] – used to select the type of

sprayer nozzle (series and capacity) for determining droplet

size information

98-05304-EN R2

13

Aeros 9040 eld computer

►Applied alert – used to establish an alert to signal when

exiting or entering an applied area

►BoomPilot start mode – used to establish whether BoomPilot

will be controlled by speed or by the BoomPilot icon

►BoomPilot icon – used to activate the guidance screen icon

for manually controlling on-screen application painting

4. Press NEXT PAGE arrow to set up specic implement

HOME GUIDANCEFULL SCREEN IMPLEMENTINTRODUC TION GNSS RATE CONTROL APPENDIXSETUP

options. See the Implement chapter for details.

5. Press RETURN arrow or CONFIGURATION side tab to

return to the main Conguration screen.

Figure 4-6: Implement – Single section setup

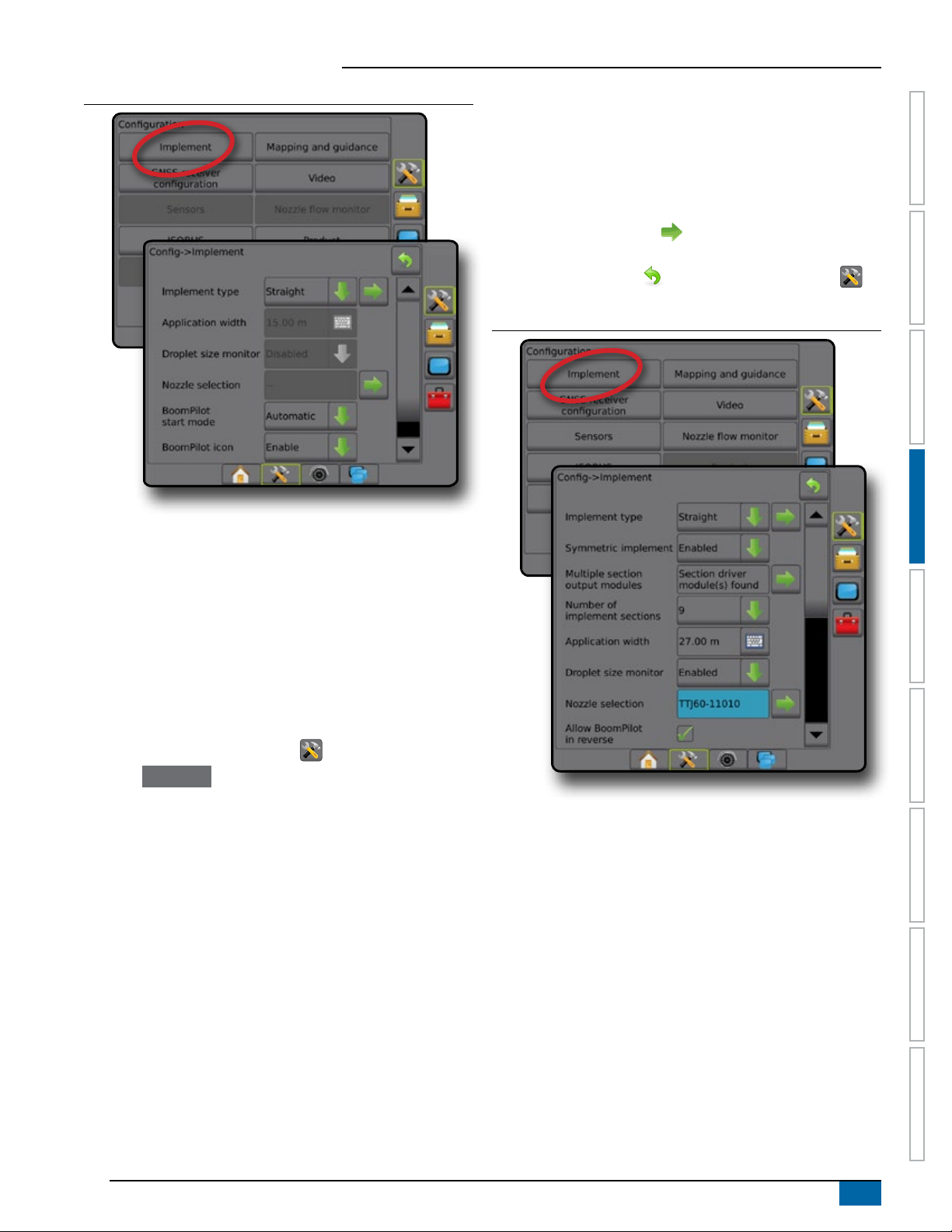

Section(s) with ISOBUS sprayer/spreader setup

Some Implement options are completed on the ISOBUS ECU. When

these options are also available in the Implement setup section, they

will be greyed out or unavailable.

1. Press CONFIGURATION side tab .

2. Press

3. Select from:

4. Press NEXT PAGE arrow

5. Press RETURN arrow or CONFIGURATION side tab to

Implement .

►Machine type [when available] – used to select the type of

machine that most closely represents your machine

►GNSS antenna height [when available] – used to measure the

height of the antenna from the ground

►Implement type – used to select the layout of the sections for

the applied product location

►Application width [Straight implement type completed on

ISOBUS ECU] – used to display the total width of the

implement as entered on the ISOBUS sprayer

►Working width [Spreader implement type completed on

the ISOBUS ECU] – used to display the total width of the

implement as entered on the ISOBUS spreader

►Droplet size monitor [available only with Pressure sensor

interface kit] – used to enable droplet size monitoring for up to

ve sprayer tips

►Nozzle selection [Straight implement type completed on the

ISOBUS ECU] – used to display the type of sprayer nozzle as

entered on the ISOBUS sprayer

►Applied alert – [only available without a switchbox] used to

establish an alert to signal when exiting or entering an applied

area

►BoomPilot start mode – used to control BoomPilot

automatically by speed, or manually by BoomPilot icon

►BoomPilot icon – used to activate icon for manually controlling

BoomPilot

to set up specic implement

options. See the Implement chapter for details.

return to the main Conguration screen.

14

www.teejet.com

Aeros 9040 eld computer

Figure 4-7: Implement – with ISOBUS setup

►Working width [Spreader implement type] – used to enter the

total width of the implement

►Droplet size monitor [when available] – used to enable droplet

size monitoring for up to ve preselected sprayer tips

►Nozzle selection [Straight or Staggered implement type] –

used to select the type of sprayer nozzle

4. Press NEXT PAGE arrow to set up specic implement

options. See the Implement chapter for details.

5. Press RETURN arrow or CONFIGURATION side tab to

return to the main Conguration screen.

Figure 4-8: Implement – Multiple sections with SDM or SFM setup

HOMEGUIDANCE FULL SCREENIMPLEMENT INTRODUCTIONGNSSRATE CONTROLAPPENDIX SETUP

Multiple sections with SDM/SFM setup

Multiple sections with SDM/SFM setup is used when a Section driver

module (SDM) or switch function module (SFM) is on the system.

The boom or delivery area can include up to 15 sections of varying

width and (in spreader mode) length. Additional options available

with an SDM include application overlap, application delay, and

staggered mode.

The Switch function module enables manual and automated control

of up to 20 sections.

1. Press CONFIGURATION side tab .

2. Press

3. Select from:

Implement .

►Machine type [when available] – used to select the type of

machine that most closely represents your machine

►GNSS antenna height [when available] – used to measure the

height of the antenna from the ground

►Implement type – used to select the layout of the sections for

the applied product location

►Symmetric implement – used to establish if sections are

paired and therefore share the same width, offset, and length

values

►Multiple section output modules – used to enable use of

multiple section output modules on the CAN bus

►Number of implement sections – used to select the number of

implement sections

►Application width [Straight or Staggered implement type] –

used to enter the total width of all sections of the implement

98-05304-EN R2

15

Aeros 9040 eld computer

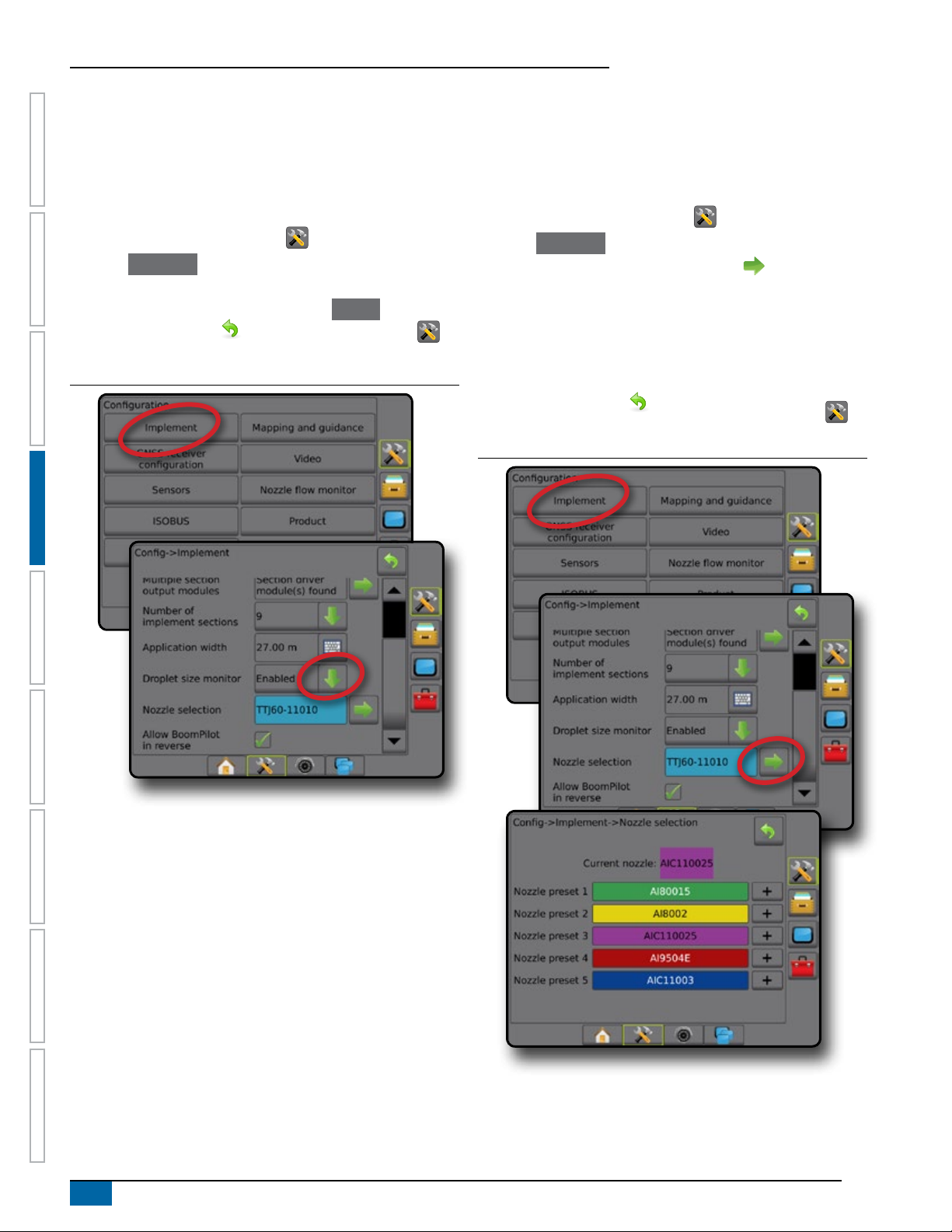

Droplet size monitor

When the system includes a Pressure sensor interface kit (PSIK),

Droplet size monitor can be enabled/disabled. The DSM then

becomes available on the operation screens.

NOTE: For more information, see "Droplet size monitor" in the

Implement chapter of this manual.

1. Press CONFIGURATION side tab .

HOME GUIDANCEFULL SCREEN IMPLEMENTINTRODUC TION GNSS RATE CONTROL APPENDIXSETUP

2. Press

3. Select if Droplet size monitor is enabled or disabled. (If enabling,

4. Press RETURN arrow or CONFIGURATION side tab to

Figure 4-9: Droplet size monitor

Implement .

also read displayed information and press

return to the main Conguration screen.

Accept .)

Nozzle selection

Nozzle selection enables up to ve (5) tips to be preset for quick

recall, and the current nozzle to be selected.

NOTE: For more information, see "Nozzle selection" in the

Implement chapter of this manual.

1. Press CONFIGURATION side tab .

2. Press

3. Press Nozzle selection NEXT PAGE arrow

4. Select from:

5. Press RETURN arrow

Figure 4-10: Nozzle selection

Implement .

.

►Nozzle preset 1-5 – selects up to ve (5) tips for quick recall,

and selected the current nozzle for determining droplet size

information

►Current nozzle – displays the current nozzle

or CONFIGURATION side tab to

return to the main Conguration screen.

16

www.teejet.com

Aeros 9040 eld computer

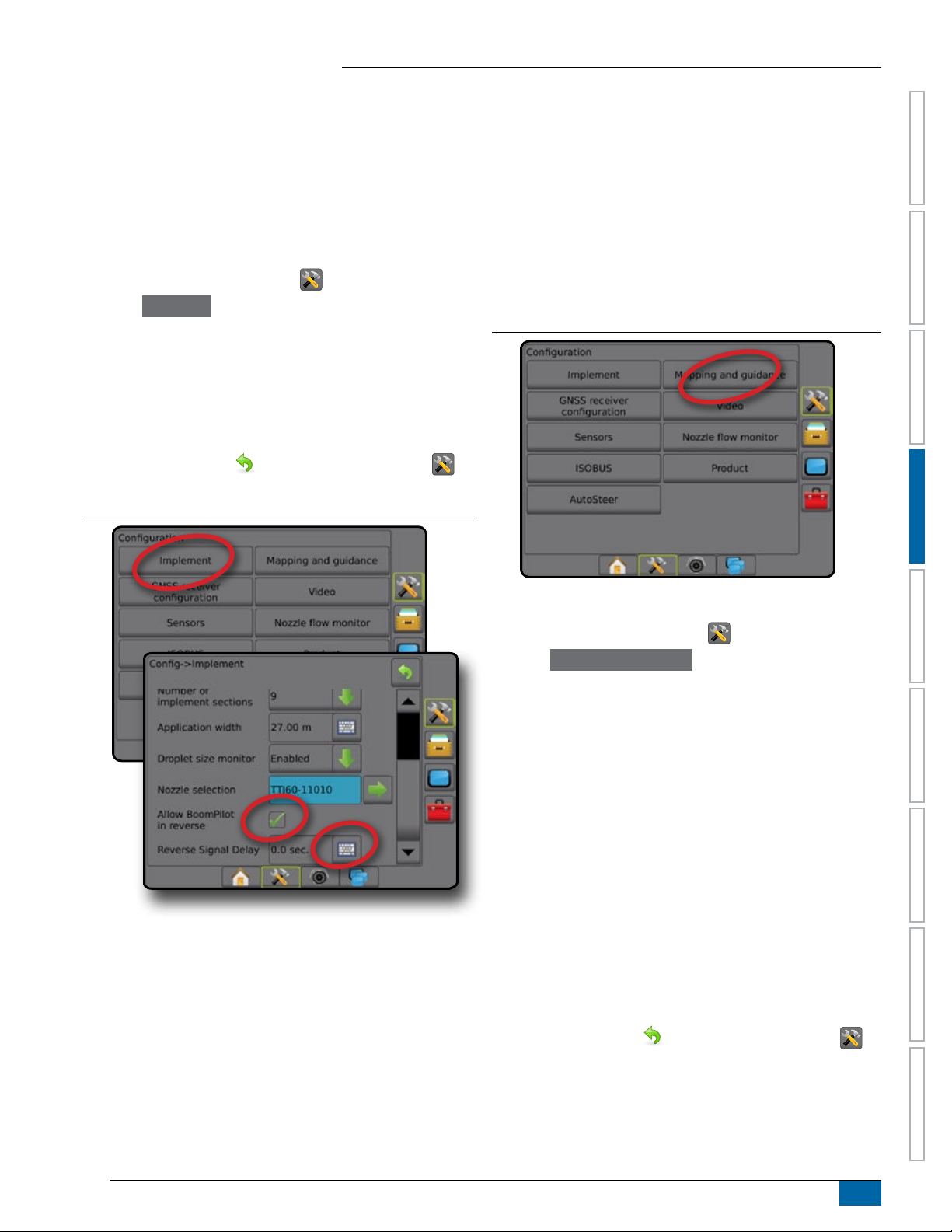

Reverse sense options

Reverse sense options are used when adding a Reverse sense

module or SCM Pro (Steering control module Pro for FieldPilot

Pro/UniPilot Pro) to any conguration.. This allows for application

mapping and control, and on-screen guidance when traveling in

reverse.

NOTE: For more information, see "Reverse sense" in the Implement

chapter of this manual.

1. Press CONFIGURATION side tab .

2. Press

3. Select:

4. Press RETURN arrow

Figure 4-11: Reverse sense

Implement .

►Allow BoomPilot in reverse [when available] – used to enable

BoomPilot function while traveling in reverse

►Reverse signal delay – used to set the delay when going

from forward to reverse or reverse to forward, after which the

vehicle icon on a navigation screen changes direction

or CONFIGURATION side tab to

return to the main Conguration screen.

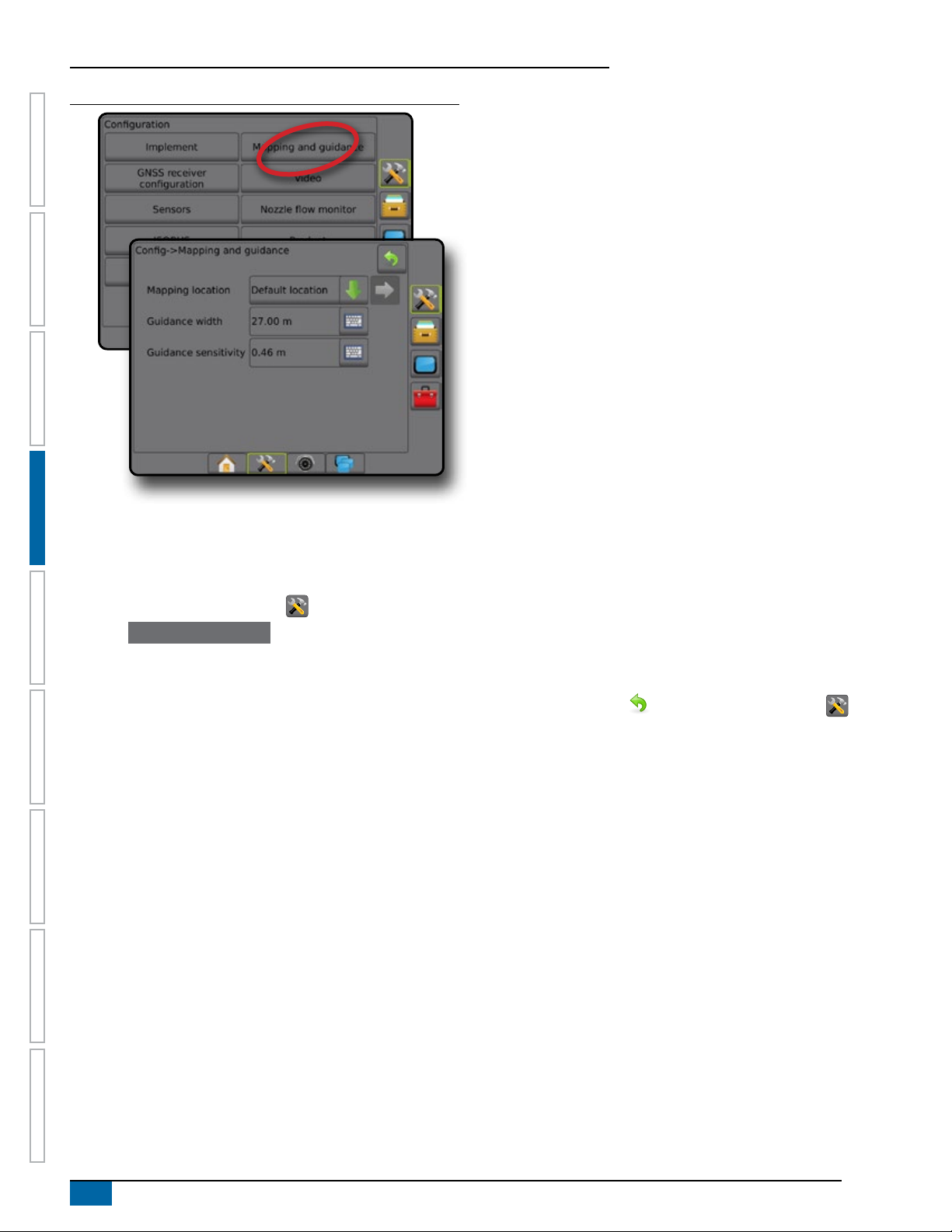

Mapping and guidance

Mapping and guidance options are used to congure the mapping

location, guidance width, guidance sensitivity (cross track error) and/

or an optional external lightbar module (ELM).

● Mapping and guidance [console only] – used to congure the

mapping location, guidance width and guidance sensitivity/

cross track error shown on the on screen guidance bar

● Mapping and guidance [using an external lightbar] – used to

congure an optional external lightbar module (ELM) which

provides additional guidance information.

Figure 4-12: Mapping and guidance

HOMEGUIDANCE FULL SCREENIMPLEMENT INTRODUCTIONGNSSRATE CONTROLAPPENDIX SETUP

Mapping and guidance [console only]

1. Press CONFIGURATION side tab .

2. Press Mapping and guidance .

3. Select:

►Mapping location – establishes the location from which the

boundary or polygon will be mapped.

● Default location – While creating an exterior boundary or

polygon, the line will be to the exterior of the outermost

active section. While creating an interior boundary, the line

will be to the interior of the innermost active section. If no

sections are active, the boundary will be marked to the end

of the outermost section.

● User entry – in-line and lateral offset from the GNSS

antenna directions and distances can be specied by the

user. Up to ve (5) user entries can be created. See "User

entered mapping location" for details.

►Guidance width – used to set the distance between guidelines

►Guidance sensitivity – sets the distance around the guideline

that is perceived as zero error.

4. Press RETURN arrow

return to the main Conguration screen.

or CONFIGURATION side tab to

98-05304-EN R2

17

Aeros 9040 eld computer

Figure 4-13: Mapping and guidance

HOME GUIDANCEFULL SCREEN IMPLEMENTINTRODUC TION GNSS RATE CONTROL APPENDIXSETUP

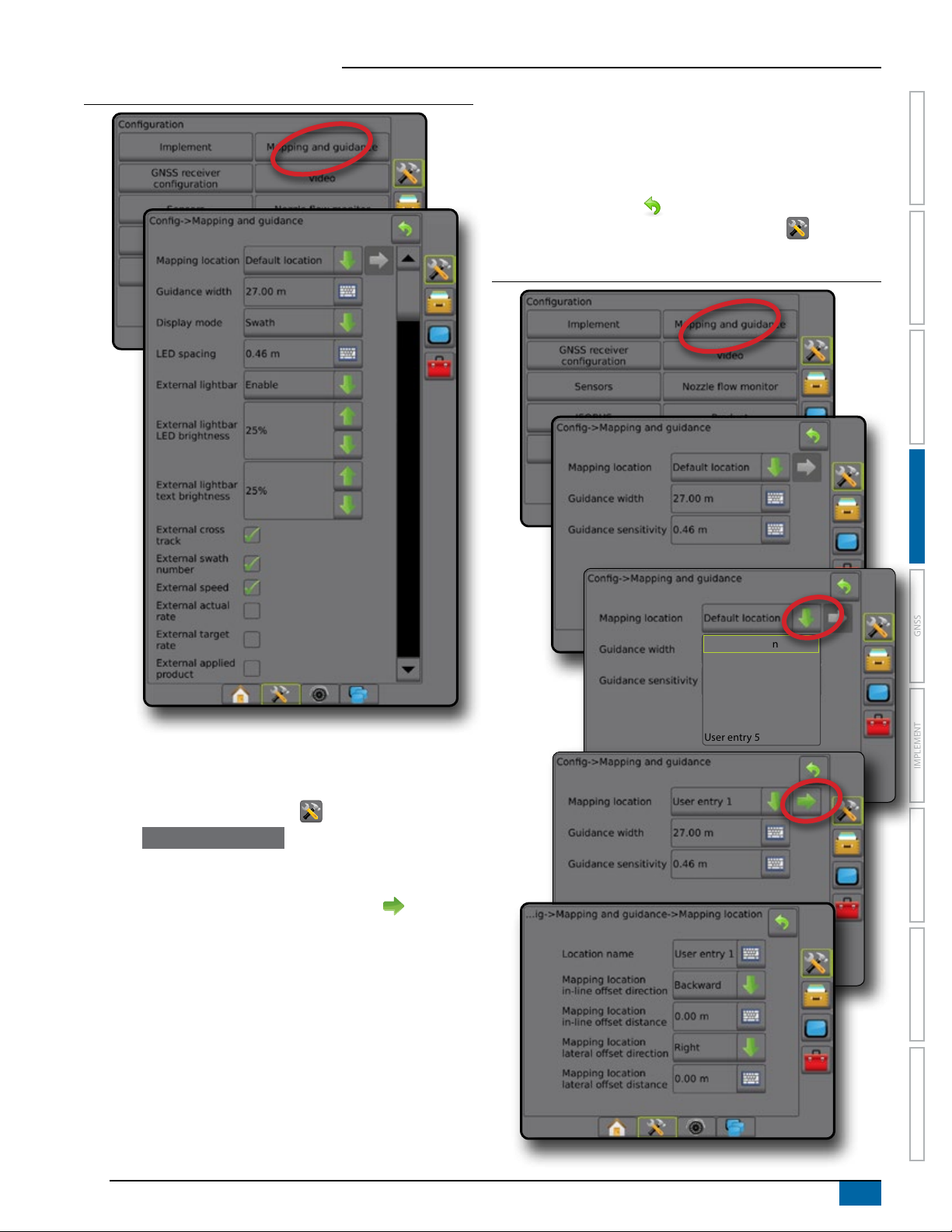

Mapping and guidance using an external lightbar

Additional conguration options are available when using an external

lightbar.

1. Press CONFIGURATION side tab .

2. Press Mapping and guidance .

3. Select from:

►Mapping location – establishes the location from which the

boundary or polygon will be mapped.

● Default location – While creating an exterior boundary or

polygon, the line will be to the exterior of the outermost

active section. While creating an interior boundary, the line

will be to the interior of the innermost active section. If no

sections are active, the boundary will be marked to the end

of the outermost section.

● User entry – in-line and lateral offset from the GNSS

antenna directions and distances can be specied by the

user. Up to ve (5) user entries can be created. See "User

Entered Mapping Location" for details.

►Guidance width – used to set the distance between guidelines

►Display mode – when External lightbar is "enabled",

determines whether the lightbar represents the swath or

vehicle

● When set to "swath", the LEDs represent guideline location

and the moving LED represents the vehicle

● When set to "vehicle", the center LED represents vehicle

location and the moving LED represents the guideline

►LED spacing –

● When External lightbar is "enabled", sets the distance

away from the guideline or vehicle each illuminated LED

represents

● When External lightbar is "disabled", sets the distance

around the guideline that is perceived as zero error

►External lightbar – enable/disable use of the external lightbar

4. With the External lightbar module (ELM) enabled, select from:

►External lightbar LED Brightness – adjusts the brightness of

the external lightbar LEDs

►External lightbar text brightness – adjusts the brightness of

the external lightbar text

►External cross track – enable/disable display of cross track

error information on the external lightbar

►External swath number – enable/disable display of swath

number information on the external lightbar

►External speed – enable/disable display of speed information

on the external lightbar

►External actual rate [available with rate control] – enable/

disable display of actual rate information on the external

lightbar

►External target rate [available with rate control] – enable/

disable display of target rate information on the external

lightbar.

►External applied product [available with rate control] – enable/

disable display of applied product information on the external

lightbar

5. Press RETURN arrow or CONFIGURATION side tab to

return to the main Conguration screen.

18

www.teejet.com

Aeros 9040 eld computer

Figure 4-14: Mapping and guidance with external lightbar

the mapping location while facing in the machine’s forward

direction

►Mapping location lateral offset distance – used to dene the

lateral distance from the centreline of the machine to the

mapping location

6. Press RETURN arrow to return to the Mapping and

Guidance screen or CONFIGURATION side tab to return to

the main Conguration screen.

Figure 4-15: User entered mapping location

HOMEGUIDANCE FULL SCREENIMPLEMENT INTRODUCTIONGNSSRATE CONTROLAPPENDIX SETUP

User entered mapping location

Mapping location establishes the location from which boundary and

polygon mapping will take place.

1. Press CONFIGURATION side tab .

2. Press Mapping and guidance .

3. Select user entry location from the Mapping Locations dropdown options.

4. Press MAPPING LOCATION NEXT PAGE arrow

the selected specic mapping location options.

5. Select:

►Location name – used to enter the name of the mapping

location for the current user entry selected

►Mapping location in-line offset direction – used to select

whether the mapping location is located in front of or behind

the GNSS antenna as the vehicle moves in a forward direction

►Mapping location in-line offset distance – used to dene the in-

line distance from the GNSS antenna to the mapping location

►Mapping location lateral offset direction – used to select

the lateral direction from the centreline of the machine to

to set up

Default location

User entry 1

User entry 2

User entry 3

User entry 4

User entry 5

98-05304-EN R2

19

Aeros 9040 eld computer

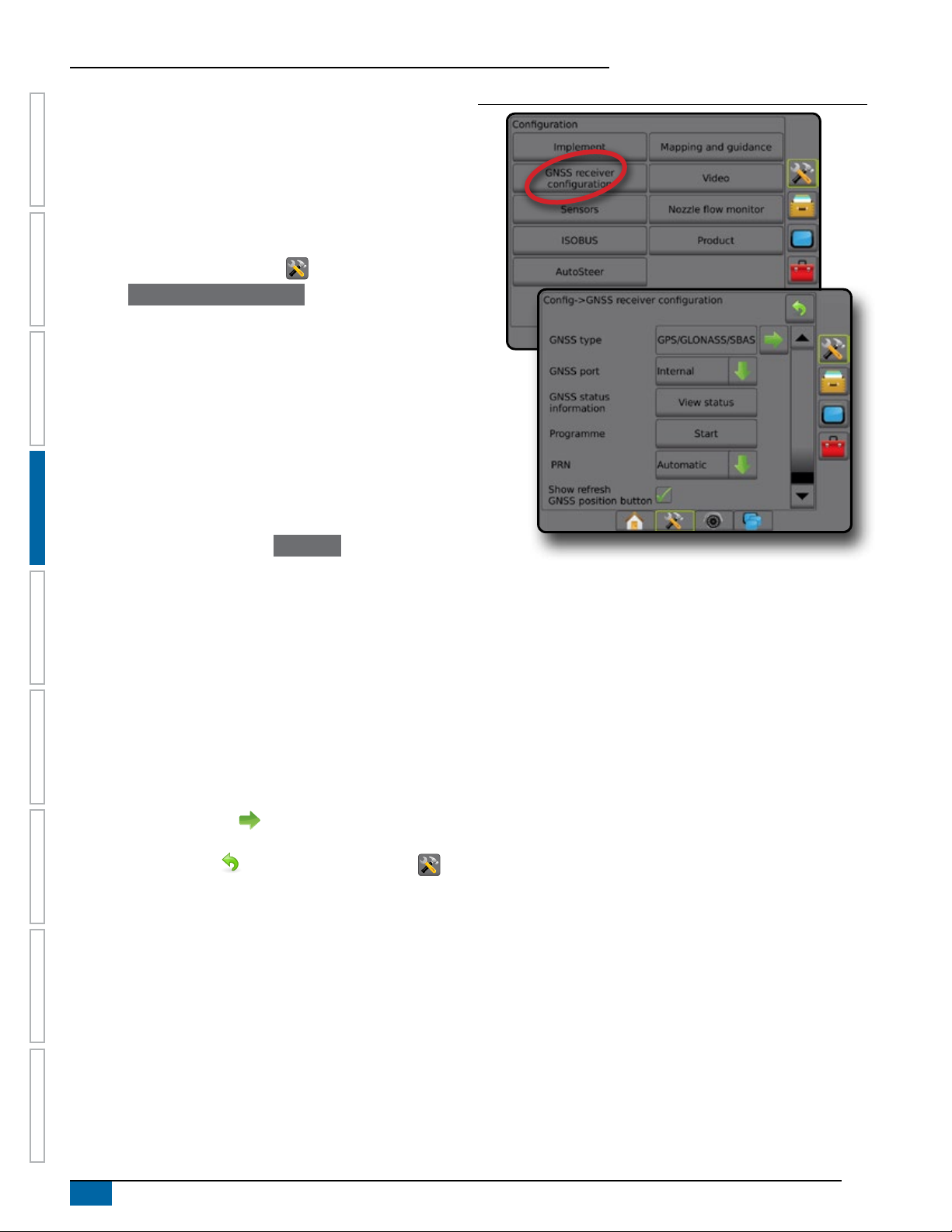

GNSS

GNSS is used to congure GNSS type, GNSS port, and PRN, as

well as to view GNSS status information.

NOTE: For more information, see the GNSS chapter of this manual.

These settings are required for assisted/auto steering, tilt

sensor operation, and rate control functionality, as well as

HOME GUIDANCEFULL SCREEN IMPLEMENTINTRODUC TION GNSS RATE CONTROL APPENDIXSETUP

proper implement operation.

1. Press CONFIGURATION side tab .

2. Press GNSS receiver conguration .

3. Select from:

►GNSS type – sets to accept GNSS source transmissions:

GPS, GLONASS, SBAS (with or without DGPS required)

►GNSS port – sets GNSS communication port to either internal

or external

►GNSS status information – displays current GNSS status

information

►Program – only TeeJet support technicians should use this

feature

►PRN – selects the rst of two possible SBAS PRN's to provide

SBAS correction data. Set to Automatic for automatic PRN

selection.

►Alternate PRN – when PRN is not automatic, allows possible

selection of a second SBAS PRN to provide correction data

►Show refresh GNSS position button – establishes if the

refresh GNSS position button is available on the guidance

screens.

NOTE: Activating the refresh while in a job will cause a

momentary interruption in the relay of GNSS data. This

will most likely result in sections already on in automatic

BoomPilot mode to go off for a short period of time.

Figure 4-16: GNSS options

PRN not shown

PRN options are only available with SBAS GNSS type selected.

The refresh should not be done during active application.

4. Press NEXT PAGE arrow to set up the selected specic

GNSS options.

5. Press RETURN arrow or CONFIGURATION side tab to

return to the main Conguration screen.

20

www.teejet.com

Aeros 9040 eld computer

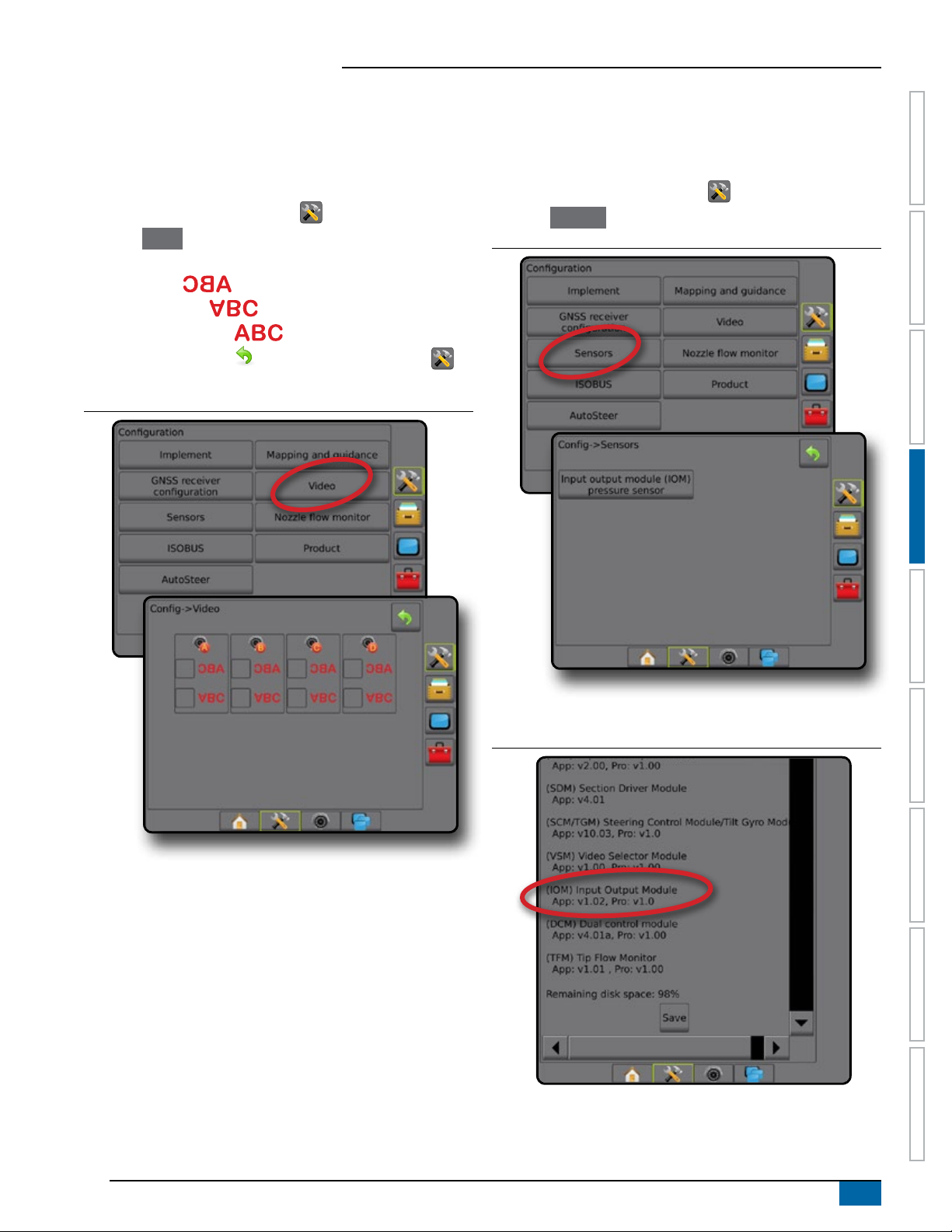

Video

Video setup is used to set up a single directly connected camera

or individual cameras while using an eight (8) channel or four (4)

channel Video selector module (VSM). Up to 8 cameras can be

congured if a VSM is installed.

1. Press CONFIGURATION side tab .

2. Press Video .

3. Select the appropriate check box(es):

►Reverse –

►Upside down –

For normal video view un-check all check boxes.

4. Press RETURN arrow or CONFIGURATION side tab to

return to the main Conguration screen.

Figure 4-17: Video with 4 channel VSM options

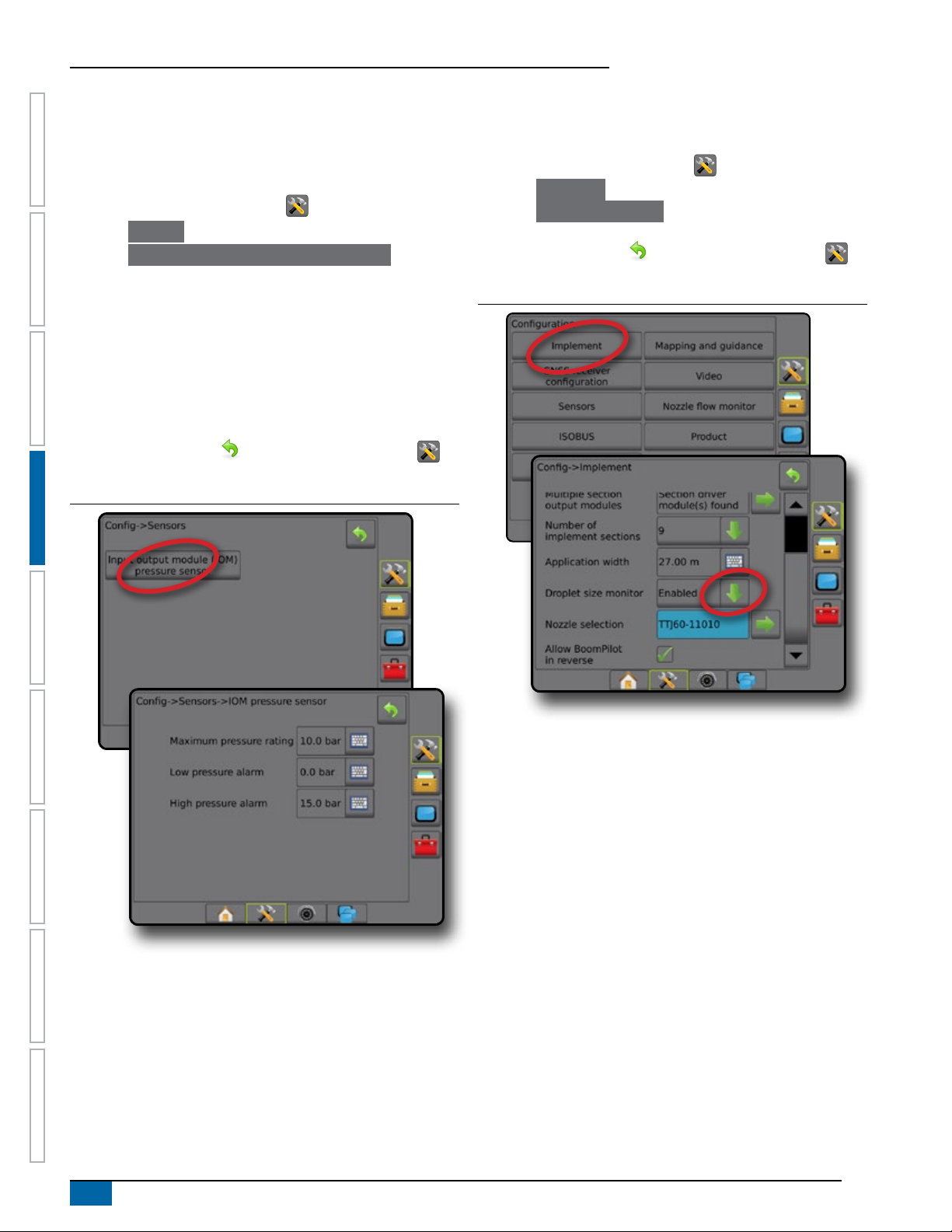

Sensors

When a Pressure sensor interface kit (specically, an Input output

module (IOM)) is on the system, options to set up and congure the

sensor will be available.

1. Press CONFIGURATION side tab .

2. Press Sensors .

Figure 4-18: Sensors

HOMEGUIDANCE FULL SCREENIMPLEMENT INTRODUCTIONGNSSRATE CONTROLAPPENDIX SETUP

Video setup unavailable

If a camera or VSM is not connected, setup options will not be

available.

The Pressure sensor interface kit is recognized on the console about

screen as an Input/output module (IOM).

Figure 4-19: Input/output module

Sensors unavailable

If a Pressure sensor interface kit is not installed, setup options will

not be available.

98-05304-EN R2

21

Aeros 9040 eld computer

Input/output module pressure sensor

When a Pressure sensor interface kit is present, pressure sensor

options are used to enter the sensor manufacture's maximum

pressure rating and set high and low user determined pressure

alarms.

1. Press CONFIGURATION side tab .

2. Press

HOME GUIDANCEFULL SCREEN IMPLEMENTINTRODUC TION GNSS RATE CONTROL APPENDIXSETUP

3. Press

4. Select from:

5. Press RETURN arrow or CONFIGURATION side tab to

Figure 4-20: Input/output monitor pressure sensor options

Sensors .

Input output module (IOM) pressure sensor .

►Maximum pressure rating – used to establish the maximum

pressure rating of the pressure sensor as recommended by

the manufacturer

►Low pressure alarm – used to enter the user determined low

pressure point at which the alarm will sound

►High pressure alarm – used to enter the user determined high

pressure point at which the alarm will sound

return to the main Conguration screen.

Droplet size monitor

If a Pressure sensor interface kit is being used, the Droplet size

monitor options will be available.

1. Press CONFIGURATION side tab .

2. Press

3. Press

4. Select if droplet size monitor is enabled or disabled.

5. Press RETURN arrow or CONFIGURATION side tab to

Figure 4-21: Droplet size monitor

Implement .

Droplet size monitor .