TECWELD Sherman digitec DIGITIG 210P User Manual

USER MANUAL

V1.2 19/01/23

WELDING RECTIFIER Inverter

DIGITIG 210P

WARNING!

Before installing and commissioning, please read these instructions

1. GENERAL

Commissioning and operation of the device can be made only after a careful reading of this handbook.

Due to the continuous development of technical equipment, some of its functions can be modified and operation may differ in detail from the description

in the manual. This is not a device error, but the result of continuous progress and modification work unit.

Damage from improper handling results in a loss of warranty. Any alteration of the rectifier are prohibited and void the warranty.

2. SAFETY

Staff operating the device should have the necessary qualifications entitling them to carry out welding work:

• should have the competence in the field of electric welder MMA welding and gas-shielded,

• know the rules of safety during the operation of the power they are welding equipment and auxiliary equipment powered by electricity,

• know the safety rules when handling and installation of the cylinder of compressed gas (argon)

• know the contents of this manual and use the device for its intended purpose.

WARNING

Welding may endanger the safety of the operator and other persons in the vicinity. Therefore, when welding special precautions must be

taken. Prior to welding, refer to the applicable health and safety regulations in the workplace. During electric welding MMA and TIG has the

following hazards:

• ELECTRIC SHOCK

• ARC NEGATIVE IMPACT ON HUMAN EYES AND SKIN

• PAIRS AND GAS POISONING

• BURNS

• EXPLOSION AND FIRE HAZARDS

• NOISE

Prevention of electric shock:

• a device connected to a technically efficient electrical system in a proper security and effectiveness of neutral (additional fire protection); Check

and properly connect to the network and other devices in the workplace welder,

• current leads off with the mounted unit,

• It does not simultaneously touch the non-insulated part of the electrode holder, the electrode and the workpiece in the device housing,

• Do not use the handles and load wires with damaged insulation,

• under special hazard of electric shock (work in environments with high humidity and closed tanks) to work with the helper supporting the work of

the welder and watchful over the safety, use gloves and clothing with good insulation properties,

• if you notice any irregularities, please contact the competent people to remove them,

• It is forbidden to operate the device with the covers removed.

Preventing negative effects of electric arc on human skin and eyes:

• Use protective clothing (gloves, lab coat, shoes, leather)

• Use protective shields or helmets with properly matched filter,

• Use protective curtains of non-combustible materials, and properly selected colors wall absorbing the harmful radiation.

2

Poisoning prevention vapors and gases evolved at the time of welding of coatings for welding electrodes and evaporation of metals:

• Use ventilation and exhaust installed in limited air exchange.

• Blow fresh air when working in a confined space (tanks)

• Use masks and respirators.

Preventing burns:

• Wear suitable protective clothing and footwear to protect from burns from arc radiation and spatter,

• Avoid contamination of clothing lubricants and oils that may lead to its inflammation

Explosion prevention and fire:

• Do not operate the machine and welding in areas at risk of explosion or fire.

• Welding station should be equipped with fire-fighting equipment,

• Welding station should be located a safe distance from flammable materials.

Preventing negative effects of noise:

• Wear earplugs or other protection against noise

• Warn people about the danger nearby

WARNING!

Do not use the power source for thawing frozen pipes.

Before starting the unit:

• Check the condition of electrical and mechanical connections. It is forbidden to use the handles and the current conductors with damaged

insulation. Inadequate insulation handles and cables current danger

electric shock

• Ensure proper operating conditions, ie. To ensure proper temperature, moisture and ventilation in the workplace. Outdoors closed to protect from

rain,

• Place the charger in a place that allows its easy handling. Persons operating welder should:

• have the power to electric welding electrode welding and TIG,

• know and comply with applicable health and safety regulations when performing welding work,

• use proper, specialized protective equipment: gloves, apron, rubber boots, shield or welding helmet with a suitably selected filter.

• know the contents of this manual welder and operated in accordance with its intended purpose, Repair work may only be carried out after removing

the plug from the wall socket.

When the device is connected to the network is not allowed to touch the bare hand or by any wet clothing elements forming the welding current circuit.

It is forbidden to remove the outer casing when the device is turned on to the network. Any alteration of the rectifier on their own are prohibited and may

constitute a deterioration in security conditions.

All maintenance and repair may only be performed by authorized persons with the conditions applicable to the safety of electrical equipment. Do not

operate the welder in areas at risk of explosion or fire! Welding station should be equipped with fire-fighting equipment, After use the unit's power cord

must be disconnected from the network.

The above risks and the general safety rules is not exhaustive safety of the welder, since it does not take into account the specifics of the workplace.

They are an important complement to bench safety instructions and training and briefings given by supervisory staff.

3

3. GENERAL DESCRIPTION

The device DIGITIG 210P is used for manual welding structural steel coated electrodes (MMA method) and quality steels, copper and its alloys tungsten

inert gas (TIG). This is the inverter device, manufactured with the most technologically advanced components made in IGBT technology. Welding has an

adjustable ARC FORCE and the ability to adjust the frequency of the pulse, fall time and current powypływu gas. It allows control mode and dwutaktu

czterotaktu.

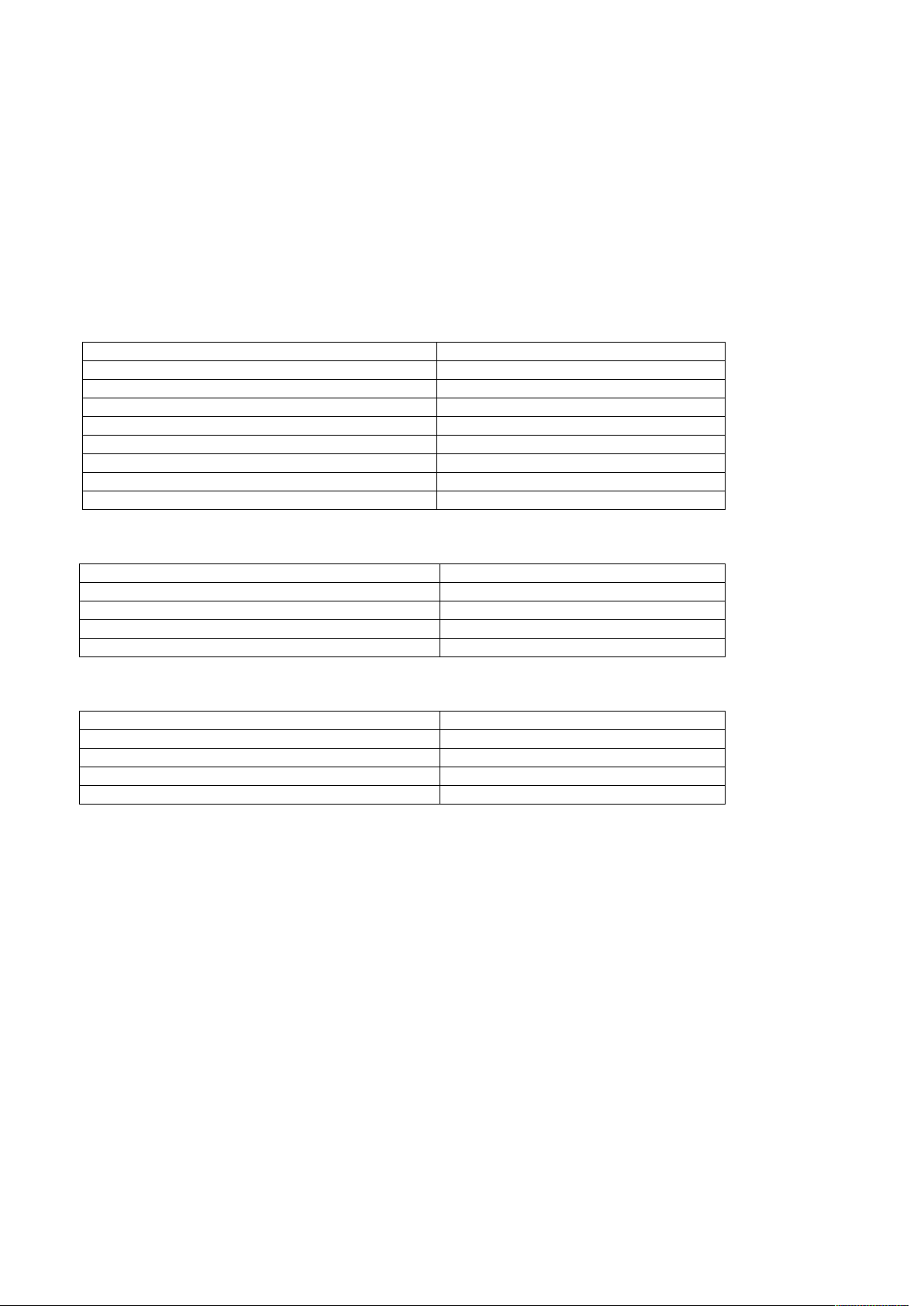

4. SPECIFICATIONS

4.1 welder

power supply AC 230V ± 10% 50Hz

Maximum power consumption MMA 8.2 kVA TIG 7.3 kVA

Rated welding current / cycle MMA: 180 A / 40% TIG 200 A / 40%

Rated voltage of no-load condition 75 V

Maximum current consumption MMA 34 A 30.5 A TIG

network security 16 And

Weight (without accessories) 7.5 kg

dimensions 430 x 168 x 312 mm

Level of security IP21S

4.1.1 range parameter adjustment

ARC FORCE 1 - 10

Post-gas 1 - 10 s

drooping current 0 - 5 s

welding current MMA: A TIG 10-180: 10-200 A

pulse rate 0.2 - 200 Hz

4.2 TIG

handle type T-26

The maximum current carrying capacity 200 A

gas flow 10-20 l / min

arc ignition Contactless (HF)

Length 4 m

Duty cycle

Duty cycle is based on a period of 10 minutes. 40% duty cycle indicates that after 4 minutes of operation of the device is required for a 6-minute break.

Duty cycle of 100% means that the machine can operate continuously without interruption.

Attention! Heating test was carried out in the ambient air temperature. Duty cycle at 20 ° C was determined by simulation.

Level of security

IP specifies the degree to which the device is resistant to entering of solid impurities and water. IP21S means that the device is suitable for use in

confined spaces and is not suitable for use in the rain.

4

Loading...

Loading...