COLD WEATHER

CWT INDIRECT HEATING BOILER

OPERATOR MANUAL | EVAPORATOR VERSION | 2016

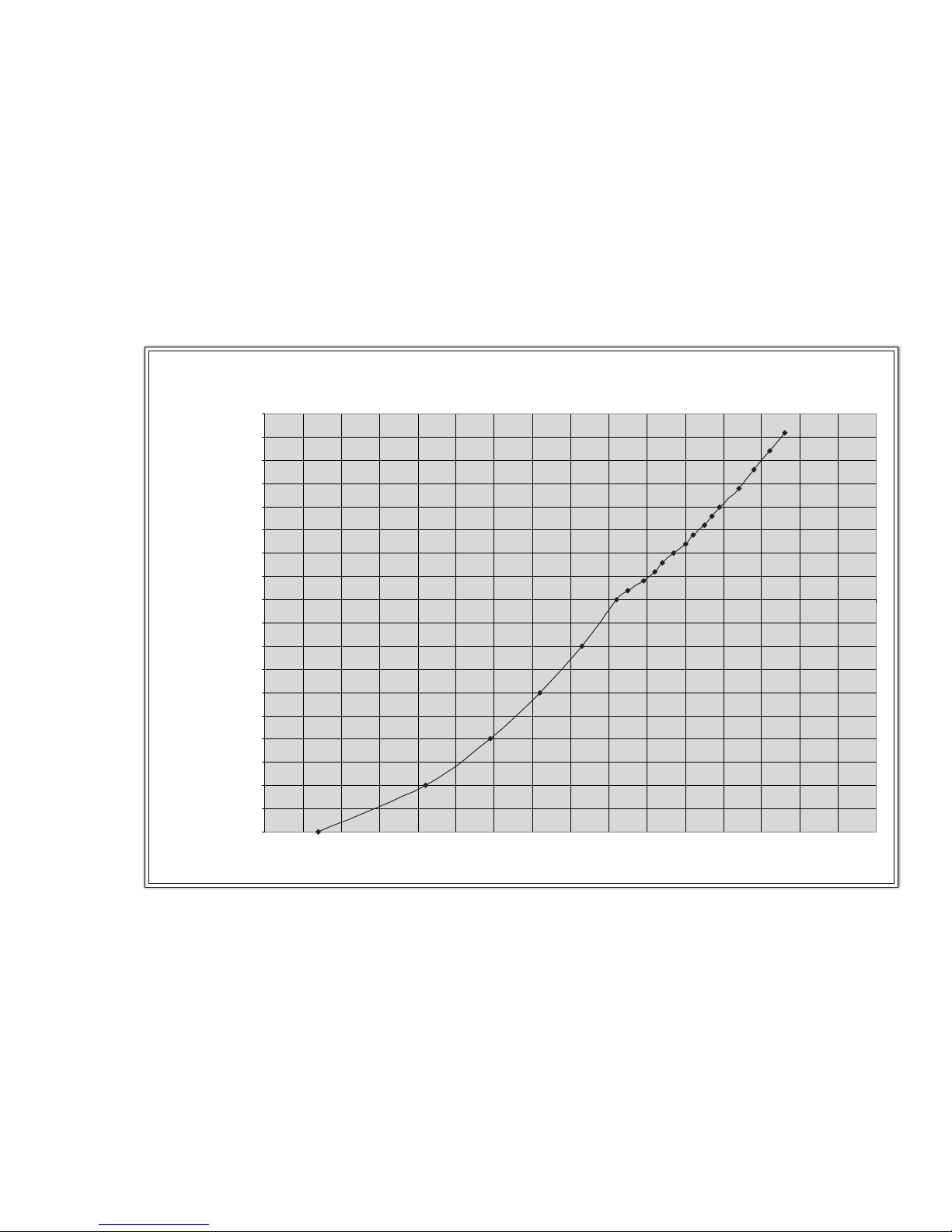

Boiling Point of Water at various Pressures Gauge Pressure

(Vacuum and Positive Pressure)

20

17.5

15

12.5

10

7.5

5

2.5

0

-2.5

-5

-7.5

-10

-12.5

-15

-17.5

-20

-22.5

Steam Pressure (positive in PSI -negative in INHG)

-25

120 130 140 150 160 170 180 190 200 210 220 230 240 250 260 270 280

Boiling Point of Water Temperature Deg F

Low Vacuum Range

(Possible Leak)

Strong Vacuum

(Healthy Unit)

To use this chart correlate the

steam temperature gauge vs. the vacuum gauge reading.

For service

scan the QR code,

or call

(780) 875-2530

WARNING:

If the information in this manual is not followed exactly, a fire or explosion may result

causing property damage, personal injury, or loss of life.

Do not store or use gasoline or other flammable vapours and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS

= Do not try to light any appliance.

= Do not touch any electrical switch; do not use any phone in your building.

= Immediately call your gas supplier from a neighbour’s phone. Follow the gas supplier’s

instructions.

= If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency, or the gas

supplier.

Page 2

PN :: HEA -EVA P-MA NUAL-016 | 20170316

CWT (Cold Weather Technologies)

is an indirect-heater product line of

Tecvalco Ltd.

Niagara Falls, Ontario CANADA

Toll Free: 1 (866) 317-0131 | www.tecvalco.com

MODEL NUMBER: ____________________________________________

SERIAL NUMBER: _____________________________________________

COLD W E ATHER

IMPORTANT NOTES:

1) The installation must conform to the requirements of the authority having jurisdiction or, in the

absence of such requirements, to the National Fuel Gas Code, ANSI Z223.1/NFPA 54 and/or

CAN/CSA B149.1, Natural Gas and

Propane Installation Code.

2) Where required by the authority having jurisdiction, the installation must conform to the

Standard for Controls and Safety Devices for Automatically Fire Boilers, ANSI/ASME CSD-1.

3) Placement of the C WT DLH unit should be such that there are no combustibles or any

combustible construction within three feet (3’) of boiler, vent stack, and steam piping. Boiler unit

must not be installed on combustible floors.

4) The equipment shall be installed in accordance with the current Installation Code for Gas

Burning Appliances and Equipment, and applicable State Regulations for the class; which should

be carefully followed in all cases. Authorities having jurisdiction should be consulted before

installations are made.

5) The heater and its individual shutoff valve must be disconnected from the gas supply piping

system during any pressure testing of that system at test pressures in excess of ½ psi (3.5 kPa).

The heater must be isolated from the gas supply piping system by closing its individual manual

shutoff valve during any pressure testing of the gas supply piping system at test pressures equal

to or less than ½ psi (3.5 kPa).

6) The heater shall be installed such that the gas ignition system components are protected from

water (dripping, spraying, rain, etc.) during appliance operation and service.

7) Provisions for combustion and ventilation air in accordance with the section “Air for Combustion

and Ventilation,” of the National Fuel Gas Code, ANSI Z223.1/NFPA 54, or Clause 8.2, 8.3 or 8.4

of Natural Gas and Propane Installation Code, CAN/CSA B149.1, or applicable provisions of the

local building codes.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

8) This heater is not connected / serviced as a common venting system.

9) Vent clearances will be for the Authority having Jurisdiction to determine the correct dimensions

for their site clearances.

10) ANSI Z21.13/CSA 4.9 requires a sediment trap to be installed upstream of the fuel train. End

users will need to make accommodation for a sediment trap in your piping upstream of fuel train.

11) Manual main shutoff valve location: The manual main shutoff valve is located before the Fisher

HSR regulator on the fuel train.

CAUTION: Label all wires prior to disconnection when servicing controls.

Wiring errors can cause improper and dangerous operation.

All wiring indicated within this manual shall be done in accordance with the NEC “National

Electrical Code” for US applications.

Verify proper operation after servicing.

This manual and the instructions outlined within apply to all CWT Evaporator Models

ranging from DLH-70 to DLH-4620

Page 3

FOREWORD

Foreword

Thank you for purchasing a Cold Weather Technologies (CWT) Natural Gas

Indirect Heating Boiler. The following manual has been simplified to give both

technical and non-technical owners and operators a detailed and thorough

understanding of CWT Natural Gas Indirect Heating Boiler operation. Detailed

installation diagrams and pictures can also be found inside this manual. These

diagrams will serve you well as a reference for the unit and its materials.

Please note: it is essential that all wiring and piping be installed in accordance

with this manual

The boiler is designed to operate on natural gas. However, please ensure that the

fuel gas used in your application is the same gas that is specified on the heater

model and rating plate.

Some components in the Instrumentation might have been changed or

replaced due to market availability at the time when this manual was

prepared. However, a changed component does not affect the overall

capability of the CWT Natural Gas Indirect Heater. With proper care and

regular maintenance, the heater should provide years of trouble–free service.

Please take a few moments and read through the manual carefully. Keep the

manual in a safe place where it can be easily located if needed.

We welcome any suggestions from customers to help improve this product line,

please feel free to call Tecvalco.

The CWT boiler and its components are designed, fabricated, tested and

inspected in accordance to the laws, codes, statutes and regulations for use in

the Province of Alberta, Canada. The end user is responsible for ensuring that

CWT complies with all Federal, Municipal, Provincial, State and Local laws,

Codes, Statutes and Regulations prior to installation of the unit, and

application of permits, licenses, certificates and authorizations thereof.

Page 4

Warning: This manual must be read in its entirety before installation of this

product. Installation and commissioning must be performed by a qualified

technician and adhere to the safety standards. Failure to do so will result in

personnel injury or property damage

PN :: HEA -EVA P-MA NUAL-016 | 20170316

TABLE OF CONTENTS

Table of Contents

Installation, operating and service manual SECTION A

Quality control documentation SECTION B

CAD drawings SECTION C

Material Safety Data Sheets SECTION D

PN :: HEA -EVA P-MA NUAL-016 | 20170316

Page 5

SECTION A CONTENTS

(A) Installation, operating and service manual

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . Page 8

2. Site preparation, delivery and installation . . . . . . . . . Page 10

2.1 Prior to receiving the boiler . . . . . . . . . . . . . . . . Page 10

2.2 Upon receiving the boiler . . . . . . . . . . . . . . . . Page 11

3. Installation procedures . . . . . . . . . . . . . . . . . . . Page 12

4. Components and controls overview . . . . . . . . . . . . . Page 15

4.1 Evaporator section . . . . . . . . . . . . . . . . . . . Page 15

4.1.1 Swordfish burners (burner manifold or burner tray) . . . . Page 15

4.1.2 Pilot and thermopile assembly . . . . . . . . . . . . . . Page 16

4.1.3 The fintube assembly (primary heat exchanger) . . . . . . Page 17

4.1.4 The control box . . . . . . . . . . . . . . . . . . . . . Page 18

4.1.5 Wiring diagrams . . . . . . . . . . . . . . . . . . . . Page 21

4.1.6 Flame or flash back arrestors . . . . . . . . . . . . . . Page 27

4.1.7 Robertshaw gas valve . . . . . . . . . . . . . . . . . . Page 28

4.1.8 High temperature ESD switch . . . . . . . . . . . . . . . Page 29

4.1.9 Discharge temperature . . . . . . . . . . . . . . . . . Page 30

4.1.10 Ignitor box and hand-held sparker . . . . . . . . . . . . Page 31

4.1.11 The high-pressure switch and shutdown . . . . . . . . . . Page 32

4.1.12 Temperature control (line temperature control) . . . . . . . Page 33

4.1.13 Burst disk and burst disk holder . . . . . . . . . . . . . Page 36

4.1.14 Fisher HSR regulator . . . . . . . . . . . . . . . . . . . Page 37

4.1.15 Pressure gauge WIC (inches of water column) . . . . . . . Page 38

4.1.16 Fisher 289H relief valve . . . . . . . . . . . . . . . . . Page 38

4.1.17 Fuel train drawing . . . . . . . . . . . . . . . . . . . . Page 39

4.1.18 Pressure vacuum gauge . . . . . . . . . . . . . . . . . Page 41

4.1.19 High-pressure coil gauge . . . . . . . . . . . . . . . . Page 42

4.1.20 Liquid level gauge . . . . . . . . . . . . . . . . . . . . Page 43

4.1.21 Exhaust vent . . . . . . . . . . . . . . . . . . . . . . Page 44

4.2 Condenser section (heat exchanger) . . . . . . . . . . . Page 45

4.2.1 The heat exchanger can . . . . . . . . . . . . . . . . . Page 46

4.2.2 The high-pressure process coil . . . . . . . . . . . . . . Page 47

5. Start-up procedure . . . . . . . . . . . . . . . . . . . . . . Page 49

Page 6

6. Typical operation . . . . . . . . . . . . . . . . . . . . . . . Page 50

6.1 Recommended control settings . . . . . . . . . . . . . . Page 51

6.2 Tuning the CWT boiler . . . . . . . . . . . . . . . . . . Page 52

6.3 Cycles . . . . . . . . . . . . . . . . . . . . . . . . . Page 52

PN :: HEA -EVA P-MA NUAL-016 | 20170316

7. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . Page 54

7.1 Maintenance schedule . . . . . . . . . . . . . . . . . . Page 54

7.2 Cleaning the flame arrestor . . . . . . . . . . . . . . . Page 55

7.3 Swordfish burner clean up . . . . . . . . . . . . . . . . Page 55

7.4 Inspecting and cleaning the fin tubes . . . . . . . . . . . Page 54

7.5 Glycol sample procedure . . . . . . . . . . . . . . . . Page 57

7.6 Testing the thermopiles . . . . . . . . . . . . . . . . . Page 58

7.7 Procedure for testing high-pressure shut down . . . . . . . Page 59

7.8 Procedure to find possible leaks . . . . . . . . . . . . . . Page 60

7.9 Pulling vacuum . . . . . . . . . . . . . . . . . . . . . Page 60

7.10 Replacing damaged burst disk . . . . . . . . . . . . . . Page 61

7.11 Drawing glycol into the system . . . . . . . . . . . . . . Page 62

7.12 Recommended glycol volumes . . . . . . . . . . . . . . Page 62

7.13 Glycol characteristics . . . . . . . . . . . . . . . . . . Page 62

7.14 Gas bundle removal . . . . . . . . . . . . . . . . . . . Page 63

7.15 Boiler checklist . . . . . . . . . . . . . . . . . . . . . Page 64

8. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . Page 66

8.1 Heater inspection checklist usage . . . . . . . . . . . . . Page 66

8.2 Common problems and possible solutions . . . . . . . . Page 67

8.3 Potential zero-flow application . . . . . . . . . . . . . . Page 69

SECTION A CONTENTS

9. Optional equipment and accessories . . . . . . . . . . . . Page 70

9.1 High temperature shut down . . . . . . . . . . . . . . . Page 70

9.2 High temperature shut down installation drawing . . . . . Page 71

10. Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 73

11. Spare parts list . . . . . . . . . . . . . . . . . . . . . . . . Page 77

12. Equipment warranty - repair and return procedure . . . . . Page 80

Appendix A - CWT 140 Evaporator Packing List . . . . . . . . . . . . Page 82

Appendix B - CWT 315 Evaporator Packing List . . . . . . . . . . . . Page 83

Appendix C - CWT 385 Evaporator Packing List . . . . . . . . . . . . Page 84

Appendix D - CWT 770 Evaporator Packing List. . . . . . . . . . . . Page 85

Appendix E - CWT 140 Exhaust Stack Drawing . . . . . . . . . . . . Page 86

Appendix F - CWT 315 Exhaust Stack Drawing . . . . . . . . . . . . Page 87

Appendix G - CWT 385 Exhaust Stack Drawing. . . . . . . . . . . . Page 88

Appendix H - CWT 770 Exhaust Stack Drawing . . . . . . . . . . . . Page 89

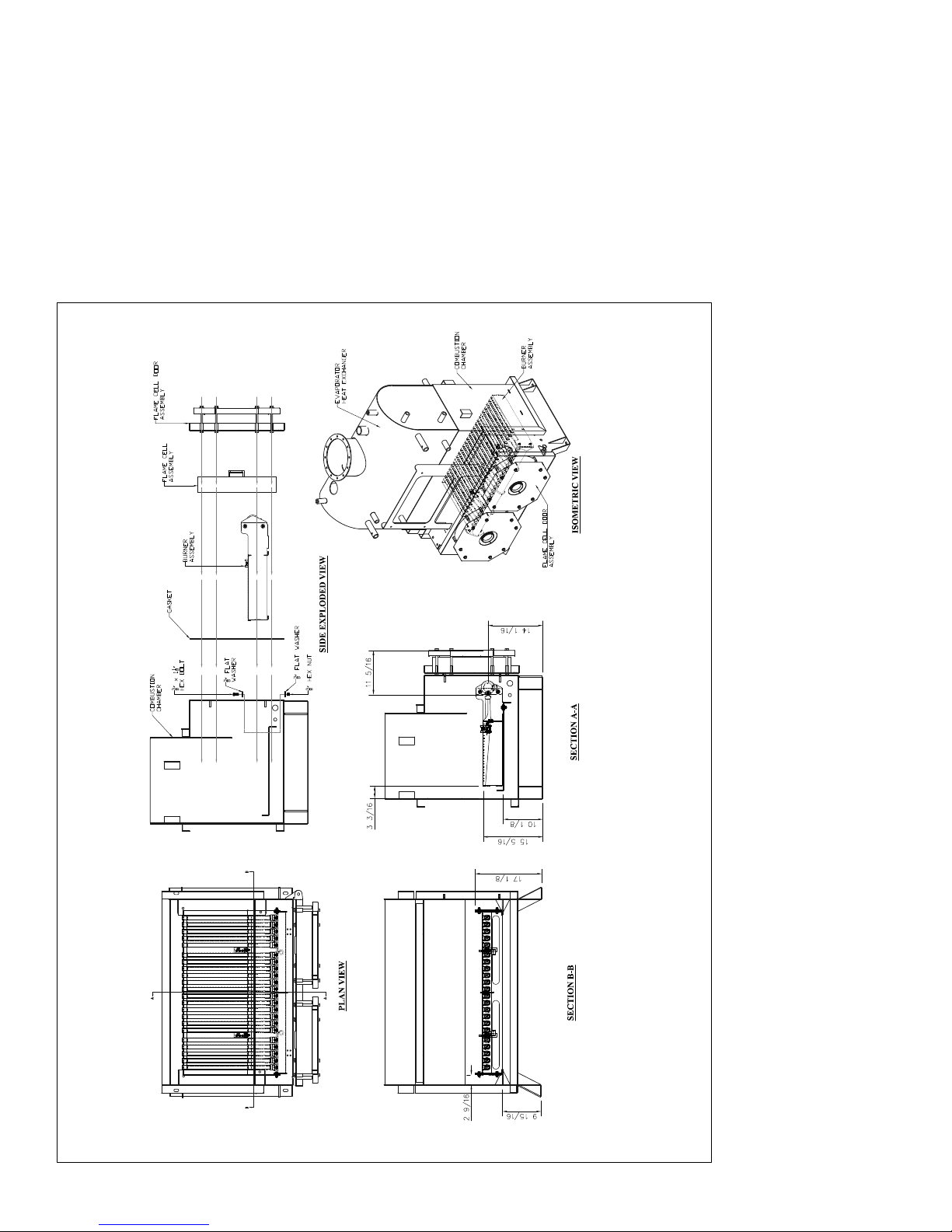

Appendix I - DLH 140 Burner Assembly and Cross-section drawings Page 90

Appendix J - DLH 315 Burner Assembly and Cross-section drawings Page 92

Appendix K - DLH 385 Burner Assembly and Cross-section drawings Page 94

Appendix L - DLH 770 Burner Assembly and Cross-section drawings Page 96

Appendix M - CWT 140 Fuel Gas Train . . . . . . . . . . . . . . . Page 98

PN :: HEA -EVA P-MA NUAL-016 | 20170316

Page 7

INTRODUCTION

1. Introduction

Cold Weather Technologies (CWT), a product line of Tecvalco Ltd., has developed the Heat Driven Loop

(HDL) technology for a variety of applications for the purpose of heating process fluids and gases in the oil and

gas industries. Conventional line heaters utilize heat transfer from a natural draft flame arrested burner system

immersed in a glycol bath. The CWT utilizes the energy released when steam changes from a vapor to a

condensed state (Known as the “Latent Heat of Vaporization” shown in figure 1.1). The HDL operates with high

thermal efficiency without any moving mechanical components or external power.

The HDL is comprised of three main components, the low-pressure evaporator, the condenser (heat exchanger) and the high pressure coil. The unit is collectively known as the CWT Natural Gas Indirect Heating Boiler.

In the evaporator, the mixture of water and glycol is heated to a point at which the water is separated from the

glycol, creating steam. In the heat exchanger, the steam produced from the evaporator condenses on the process

coils and the energy from the condensing steam is then transferred to the gas in the coils. This separation of

components has two advantages. Firstly, the evaporator can be utilized for multiple coil/heat exchanger

combinations, and multiple evaporators may be attached to a heat exchanger for large boilers. Secondly, because

the medium being heated is physically isolated from the combustion process, long term maintenance and safety

issues are effectively controlled.

Typically a vacuum is drawn on the boiler prior to shipment, removing all the excess air from the evaporator and heat exchanger. The vacuum is important for two main reasons. First, under vacuum the water will begin

to boil at a temperature as low as 45°C/113ºF, allowing for fast heat transfer to the heat exchanger. Second, the

system will have no air in it reducing corrosion and eliminating the need to “Top Up” the glycol volume during

operation.

As the gas passes through the process coil the flow will accept the energy from the steam in the condenser.

With increased flow more energy will be accepted and the internal pressure of the heating system will be

decreased or maintained in a vacuum state. At low flow conditions the heating system will increase in pressure up

to a point of which either flow is increased through the station or a safety shut down/set point is reached on the

CWT boiler.

If your system is running in or near a positive state please correlate the pressure against the unit

discharge temperature graph at the front of this manual. Your heating system should always return to a vacuum

state when cooled down.

Page 8

PN :: HEA -EVA P-MA NUAL-016 | 20170316

125 / 257

Temperature (C/F)

100 / 212

75 / 167

50 / 122

LATENT HEAT

Heat required to change

1lb (500g) of ice at -50 degrees C (-58 degrees F) to 1lb (500g) of steam at 104 degrees C (219 degrees F) at 1 atmopsheric condition

GAS

Phase changes from liquid to vapour with no change in temperature

[Latent Heat of Vapourization]

Temperature rises from 0 to 100 (Celsius)

25 / 77

0 / 32

Phase changes from solid to liquid with no change in temperature [Latent Heat of Fusion}

Temperature rises from -50 to 0 (Celsius)

-25 / -13

0 / 0

-50 / -58

Energy (Joules/BTU)

21,101 / 200

42,202 / 400

63,303 / 600

84,404 / 800

105,505 / 1,000

The latent heat exchanged from the steam as it condenses into liquid water to

the natural gas inside the high-pressure coil is the key to heat exchange in our

HDL system. A 50/50 propylene glycol/water or ethylene glycol/water mixture is

used in all HDL systems for freeze protection and corrosion inhibition along with

minimum oxidation.

126,606 / 1,200

LIQUID

SOLID

147,707 / 1,400

168,808 / 1,600

(Figure 1.1)

PN :: HEA -EVA P-MA NUAL-016 | 20170316

Page 9

SITE PREPARATION AND DELIVERY

2. Site preparation and delivery

2.1 Prior to receiving the boiler

In preparation for the receipt of the boiler the following should be performed:

2.1.1 Tecvalco recommends that the boiler be levelled (a solid pad or base

should be completed before arrival of the unit).

Note: Please follow all local jurisdictions and codes to design a proper foundation. In addition the equipment shall be installed in accordance with those installation regulations in force in the local area where the installation is to be made.

These shall be carefully followed in all cases. Authorities having jurisdiction should

be consulted before installations are made.

The reason for a solid base is to ensure the integrity of the HDL (Heat Driven

Loop), the boiler depends on gravity for the water to return from the heat

exchanger to the evaporator. If the foundation slopes the wrong way it puts undue

stress on the high pressure flanges and the condensed returning water will be

trapped and will “pocket” at the far end of the heater. In this situation the Heat

exchange process (HDL) is disrupted as no steam can be generated and the glycol

can overheat.

2.1.2 A thermowell should be installed in the gas piping downstream of the reg-

ulators (depends on application) and this thermowell will receive the probe for the

gas temperature control. It is the end user’s responsibility to select, and notify

Cold Weather Technologies of, the appropriate thermowells prior to shipping

the heating boiler (see section 3.1 for thermowell sizings). The thermowell must

be in contact with the flow of gas to operate the system properly.

2.1.3 The CWT evaporator fuel supply operates on an inlet fuel pressure of 5

psi or less, depending on the model of the heater. Regulating and fuel supply metering equipment on the fuel train is the sole responsibility of the end user. It is also

the end user’s responsibility to ensure that an adequate fuel supply is available.

(This fuel supply must be clean and dry pipeline quality natural

gas or propane.)

Page 10

PN :: HEA -EVA P-MA NUAL-016 | 20170316

SITE PREPARATION AND DELIVERY

2.2 Upon arrival of your new CWT heating boiler at site

The CWT boiler is typically shipped completely charged with heat transfer fluid and

on vacuum (depends on size of heater).

2.2.1 Check for any damage to the evaporator body and heater exchanger.

2.2.2 Unload the boiler using lift points (lugs) on the skid as shown on the lifting

diagram provided by Tecvalco and place on pad or on preferred base

(Section 2.1.1). The heater should be level throughout the entire lift process.

2.2.3 Open the shipping crate to ensure all loose shipped items were sent and

received in good order. (There will be a check list of parts in side the crate.) The

packing list for our standard CWT models can be found in the Appendix at the end

of this manual.

2.2.4 Check burner section for loose bolts, miss aligned burners, proper burner

tray placement, loose gas line fittings and foreign debris from the manufacturing

and shipping process.

2.2.5 Check the vacuum on the heater to make sure it is still established.

Note: If any of the above points are not satisfactory please contact

Tecvalco immediately.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

Page 11

INSTALLATION PROCEDURES

IM POR TANT:

All wiring must be done in

accordance with the current

Canadian Electrical Code

3. Installation procedures

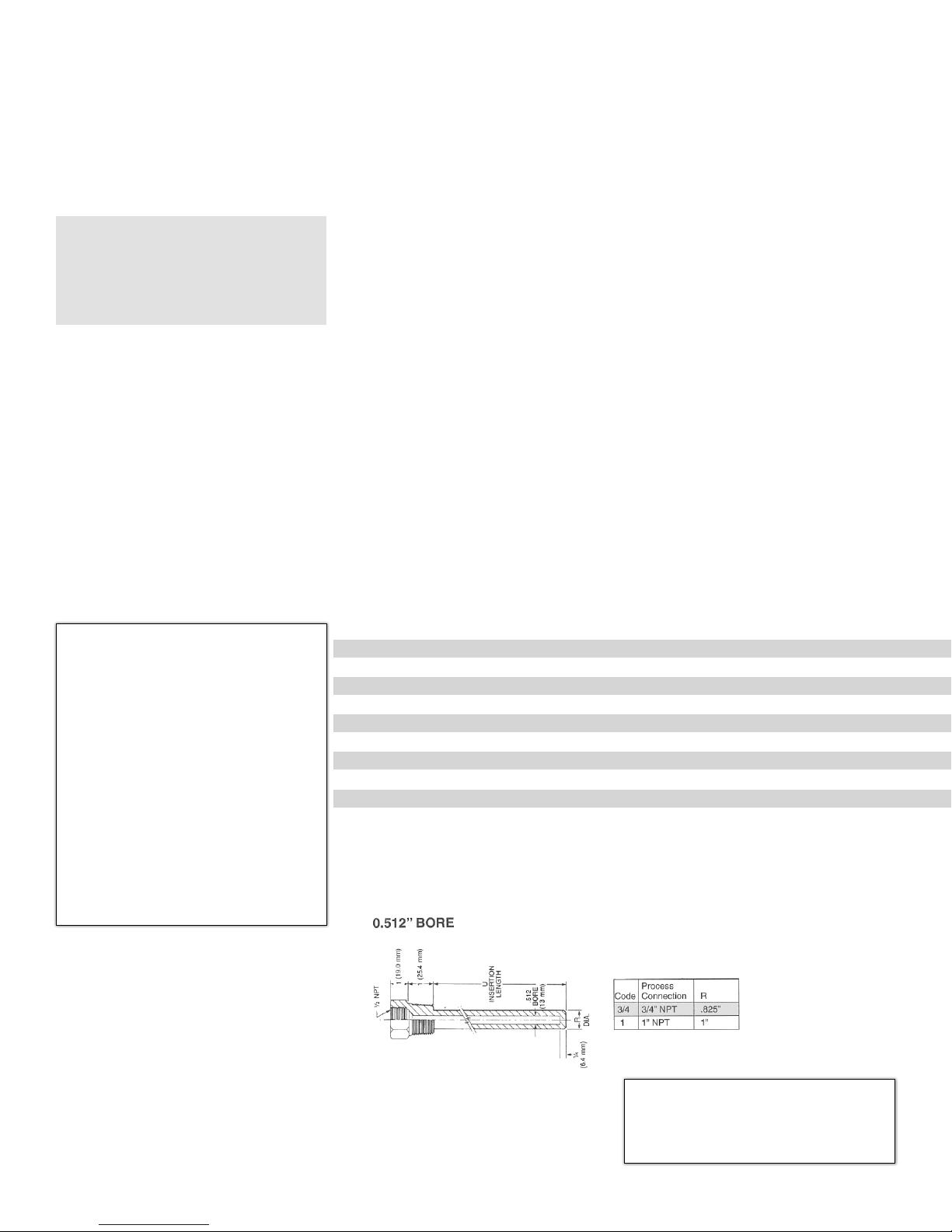

3.1 Place thermowells in downstream gas piping just past the meter station.

The line temperature probe is typically placed immediately after the last pressure

regulation in the facility. Place thermowells as close as possible to meter

station. The probe requires a thermowell with a minimum internal bore of .512

inches (13mm). Tecvalco can supply the appropriate thermowell upon request.

Length will depend on pipe size and collar used on pipe. This information will be

required in order to send proper length.

It is also recommended to install a temp gauge on the piping next to the

Line Temp Controller to ensure the Temp Controller is always calibrated correctly

(Reading the proper temperature)

NOTE: It is suggested that a barrier be created within this conduit prior to the

thermowell in the high pressure line.

Use the following table to select the appropriate thermowell, and notify Tecvalco

Industries of the part number.

Heater size Number of

(BTU in 1000’s) thermowells

140 1

385 1

770 (single) 1

770 (2-385) 2

1155 (3-385) 3

1540 (2-770) 2

2300 (3-770) 3

3100 (4-770) 4

4600 (6-770) 6

Figure 3.1a

Note: One thermowell per evaporator.

CWT Part Numbers Description

THR-SS-.75-.5-4-.512 3/4” NPS x 1/2” x 2.5” U Length x .512 Bore

THR-SS-.75-.5-5-.512 3/4” NPS x 1/2” x 3.5” U Length x .512 Bore

THR-SS-.75-.5-6-.512 3/4” NPS x 1/2” x 4.5” U Length x .512 Bore

THR-SS-.75-.5-8-.512 3/4” NPS x 1/2” x 6.5” U Length x .512 Bore

THR-SS-.75-.5-9-.512 3/4” NPS x 1/2” x 7.5” U Length x .512 Bore

THR-SS-1-.5-2-.512 1” NPS x 1/2” x 1” U Length x .512 Bore

THR-SS-1-.5-4-.512 1” NPS x 1/2” x 2.5” U Length x .512 Bore

THR-SS-1-.5-5-.512 1” NPS x 1/2” x 3.5” U Length x .512 Bore

THR-SS-1-.5-6-.512 1” NPS x 1/2” x 4.5” U Length x .512 Bore

• It is suggested the tip of the thermowell be in the middle of the pipe, or beyond in smaller

pipes.

• Please ensure that proper components and procedures are used for the pressure piping.

• It is suggested that appropriate thermally conductive heat transfer compound be used.

Page 12

Page 12

NOTE: All customers should select

components and materials based upon

applicable engineering standards.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

INSTALLATION PROCEDURES

PN :: HEA -EVA P-MA NUAL-016 | 20170316

Figure 3.1b

Page 13

Page 13

INSTALLATION PROCEDURES

Figure 3.3

3.2 Connect the fuel supply line to the fuel train on the evaporator. Be sure to

check local codes. The CWT evaporator operates on a max inlet fuel pressure of

20 psig to the Fisher HSR.

HE ATER SIZE MAXIMUM PSI MINIMUM PSI

140,000 Btu/hr Heater 5 1

385,000 Btu/hr Heater 5 3

770,000 Btu/hr Heater 5 5

Based on a Fisher HSR Regulator with a 1/2” Orifice

3.3 If supplied with a boiler having multiple evaporators, run cable from the

terminal remote box (see figure 3.3) to the remote box.

3.4 To install the line temperature control switch, refer to figure 3.1.1b.

3.5 Place B-Vent exhaust stack on evaporator (see section 4.1.21 for images of

the B-Vent exhaust stack):

• Remove exhaust stack blind or cover.

• Keep stack gasket that is in place to be re-used with the B-Vent

stack.

• Place rain cap on exhaust stack section (use screws).

• Place exhaust stack sections together if necessary (use screws).

• Place exhaust stack on evaporator (lifting equipment maybe

needed).

• Use bolts from cover to secure the evaporator

(evaporator size 140 will not require bolts).

• Install stack temperatue gauge provided in the field crate.

Page 14

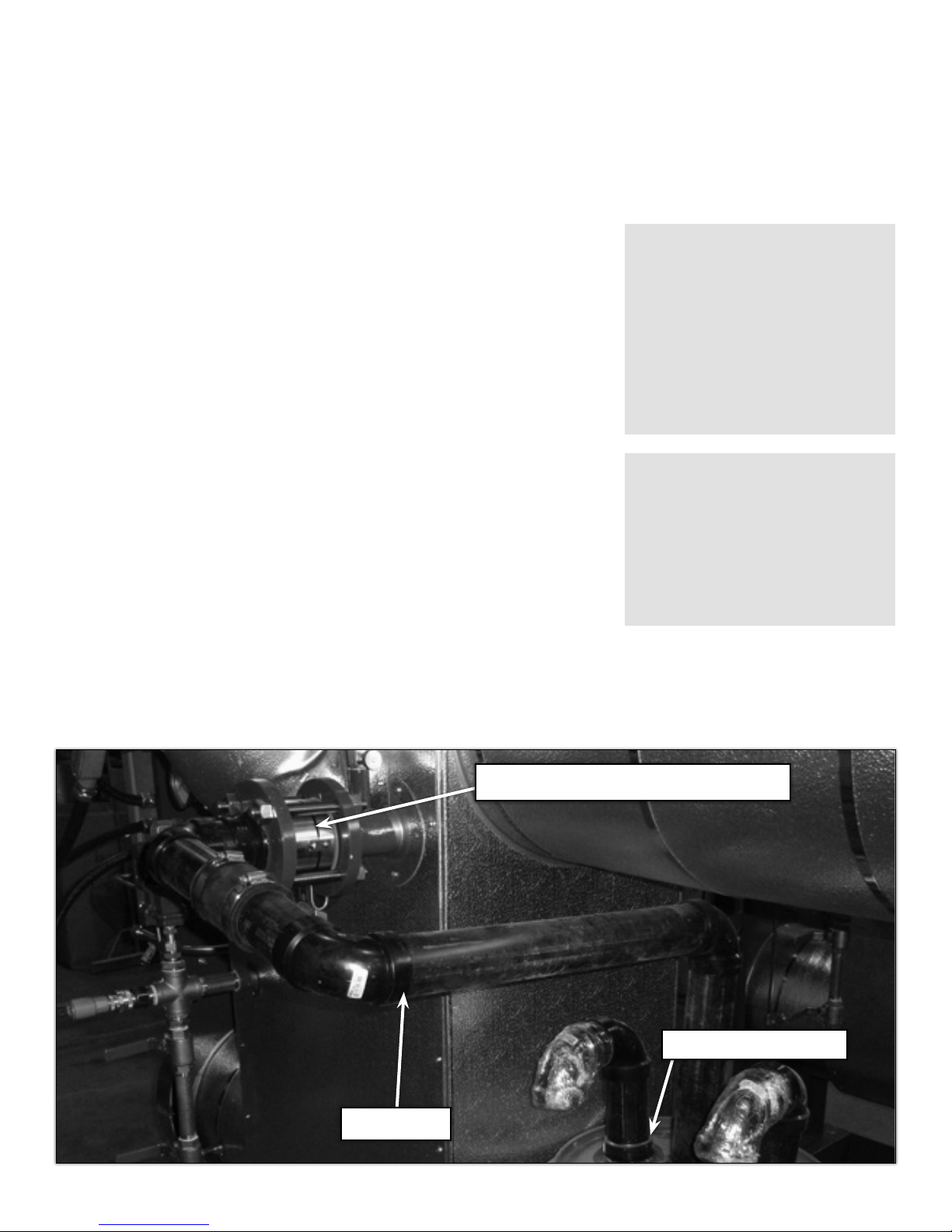

Figure 3.6

3.6 Pressure gauges to be placed in valves located on coil (See figure 3.6)

3.7 When completed all parts from crate should be used

3.8 Note: Tecvalco highly recommends insulating gas piping from heater coil

outlet, up to the pipe where the downstream thermo-probe be installed.

3.9 Ready for pre-start up, start-up and run procedure.

Note: Please confirm all connections are tight and sealed.

3.10 Vent installation

Vent Installations shall be in accordance with “Venting of Equipment” of the

National Fuel Gas Code, ANSI Z223.1/NFPA 54, or “Venting Systems and

Air supply for Appliances” of the Natural Gas and Propane Installation Code,

CAN/B 149.1, or applicable provisions of the local building codes.

Type of Vent: “B” Gas Vent. For stack assembly limitations, please look at

Appendix E to H.

a. Slide the vent stack assembly into the stack support bracket.

Lock stack in place.

b. Safely climb on a step ladder and place the stack support bracket

onto the stack flange located on top of the boiler as show on

pa ge 81.

c. Use 1/2 inch Grade 5 bots and nuts provided to securely bolt the

vent stack.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

COMPONENTS, SAFETIES, AND CONTROLS

4. Components, safeties, and controls

The CWT evaporator is equipped with a number of safety systems that protect

personnel and equipment. These systems function automatically without the need

for constant supervision; however, some of the systems may require manual

start-up after a shut down. A thorough examination of the device should be

performed to determine the cause of any shut down. Activation of a safety shut

down may be a signal that maintenance is needed for the device. Contact Tecvalco

if the cause of the shut down is unknown.

The controls on the CWT operate on the energy provided by the thermopiles

located near the continuous pilot. The power provided passes through a circuit that

contains the various switches, as illustrated in the following pages.

In general, safety and control is quite simple; if any of the switches open, the circuit

will be broken and the main burner will shut down; if the pressure switch or the

ESD open both the main burner and the pilot will be extinguished and a manual

restart will be required.

4.1 Evaporator section:

The firebox contains the burners, burner manifold, burner tray, Ignitor/thermopile

assembly and the pilot and main fuel lines.

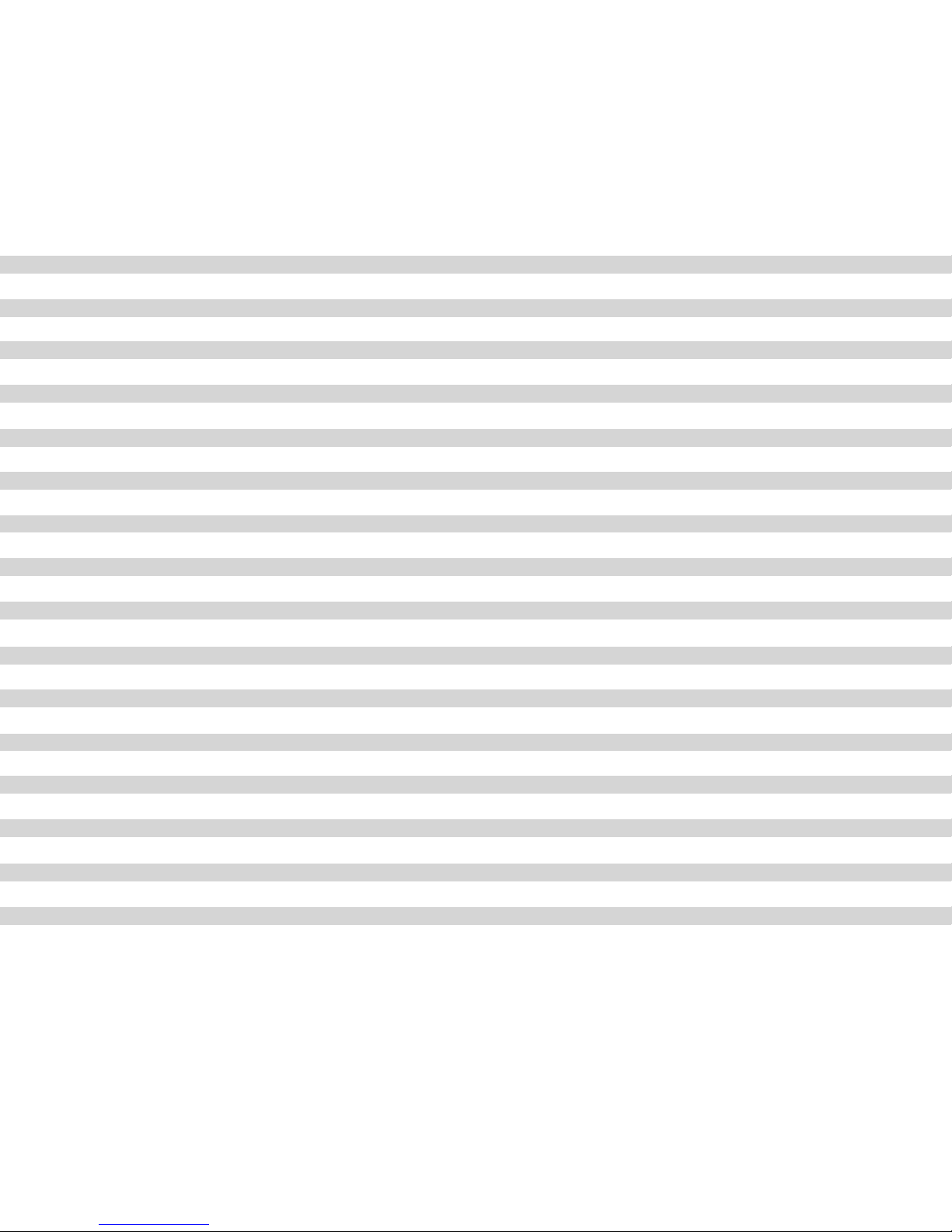

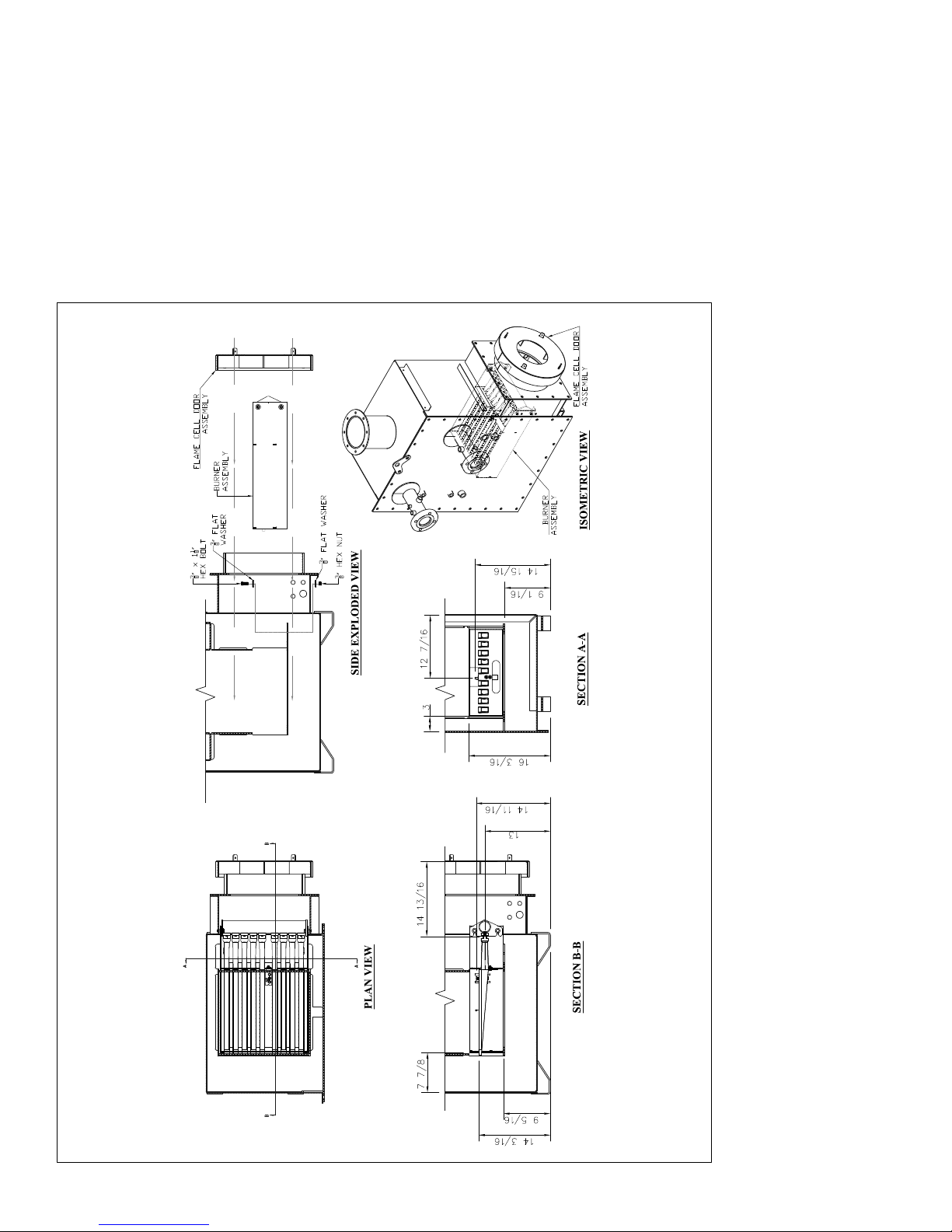

4.1.1 Swordfish burners (burner manifold or burner tray)

The burners are referred to as “swordfish burner”. Each burner is capable of a

maximum firing rate of 35,000 Btu/hr, at 14 inch w.c. and #45 orifices. They sit in

slots in the burner tray and can be equipped with a primary air adjuster (upon

customer request).

PN :: HEA -EVA P-MA NUAL-016 | 20170316

Figure 4.1.1a -

Page 15

COMPONENTS, SAFETIES, AND CONTROLS

The burner manifold is connected to the main fuel line and

distributes the incoming fuel gas evenly to the burner.

Figure 4.1.1 -

The burner tray for 770,000 Btu’s, which contains

22 swordfish burners, one split manifold and

four thermocouples on two pilot assemblies.

Each swordfish burner generates 35,000 Btu’s per hour:

• 140,000 (Btu’s)= 4 swordfish burners

• 385,000 (Btu’s)= 11 swordfish burners

• 770,000 (Btu’s)= 22 swordfish burners

4.1.2 Pilot and thermopile assembly

The pilot and thermopile assembly consists of two 700 mV thermopiles, a pilot

burner, and a sparker.

Page 16

(Figure 4.1.2)

NOTE: The pilot orifice should be stamped with the part number BL22N for natural

gas applications and 22LP for propane applications.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

COMPONENTS, SAFETIES, AND CONTROLS

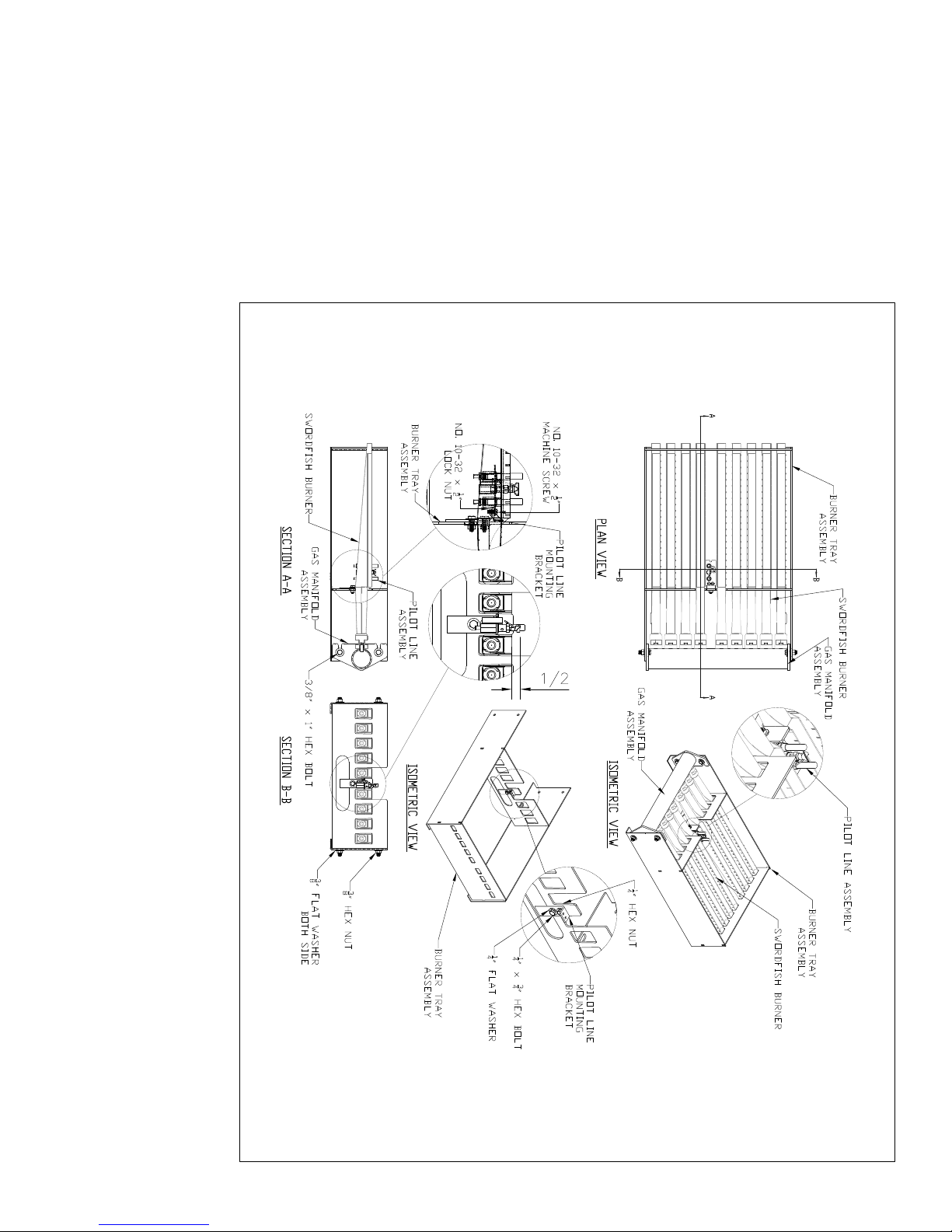

4.1.3 The fintube assembly (primary heat exchanger)

The fintubes are located above the burners and span the width of the firebox. The

flue gas passes through the fins and exit through the flue and stack. As the heated

flue gas pass through the fintubes they heat the water-glycol mixture and cause the

water to boil, generating steam.

(Figure 4.1.3)

(Figure 4.1.3a)

The photo above shows the primary heat exchanger with the side (saddle) tank

open. The heat transfer fluid sits in the saddle tanks and fins as the combustion

products pass upward, through the fins.

NOTE: The internal design is different for different models.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

Page 17

COMPONENTS, SAFETIES, AND CONTROLS

4.1.4 The control box

The control box is attached to the evaporator and houses the various controls and

safeties for the CWT heating unit. Included are the Robertshaw gas valve, the

switches for high steam temperature (labelled “discharge temp”) and high glycol

temperature (labelled “ESD”). Also included are the ignition box and a gauge to

indicate main fuel line pressure downstream of the gas control valve. The gas line

temperature control, while usually remote from the boiler, is also connected to the

control box and system control logic.

Please refer to figures (4.1.4a and 4.1.4b) for control box instrumentation layout

Page 18

PN :: HEA -EVA P-MA NUAL-016 | 20170316

COMPONENTS, SAFETIES, AND CONTROLS

1 2

3

4

Components

1) Discharge temp

2) High temperature ESD

3) 4x4x2 CWT Ignitor box

4) Pilot gas line - 1/4” 304SS tubing

5) Fuel pressure gauge

6) Robertshaw type 7000 MVR gas valve

7) 3/4” tubing

Portable hand held ignitor (not shown)

6

5

7

(Figure 4.1.4a) CWT standard control box 140,385

models

PN :: HEA -EVA P-MA NUAL-016 | 20170316

Page 19

COMPONENTS, SAFETIES, AND CONTROLS

33

1

5 5

2

4 4

2

1

6 6

7 7

(Figure 4.1.4b) CW T standard control box

770 model

No. Components

1) Discharge temp

2) High temperature ESD

3) 4x4x2 CWT Ignitor box

4) Pilot gas line - 1/4” 304SS tubing

5) Fuel pressure gauge

6) Robertshaw type 7000 MVR gas valve

7) 3/4” tubing

Portable hand held ignitor (not shown)

Page 20

PN :: HEA -EVA P-MA NUAL-016 | 20170316

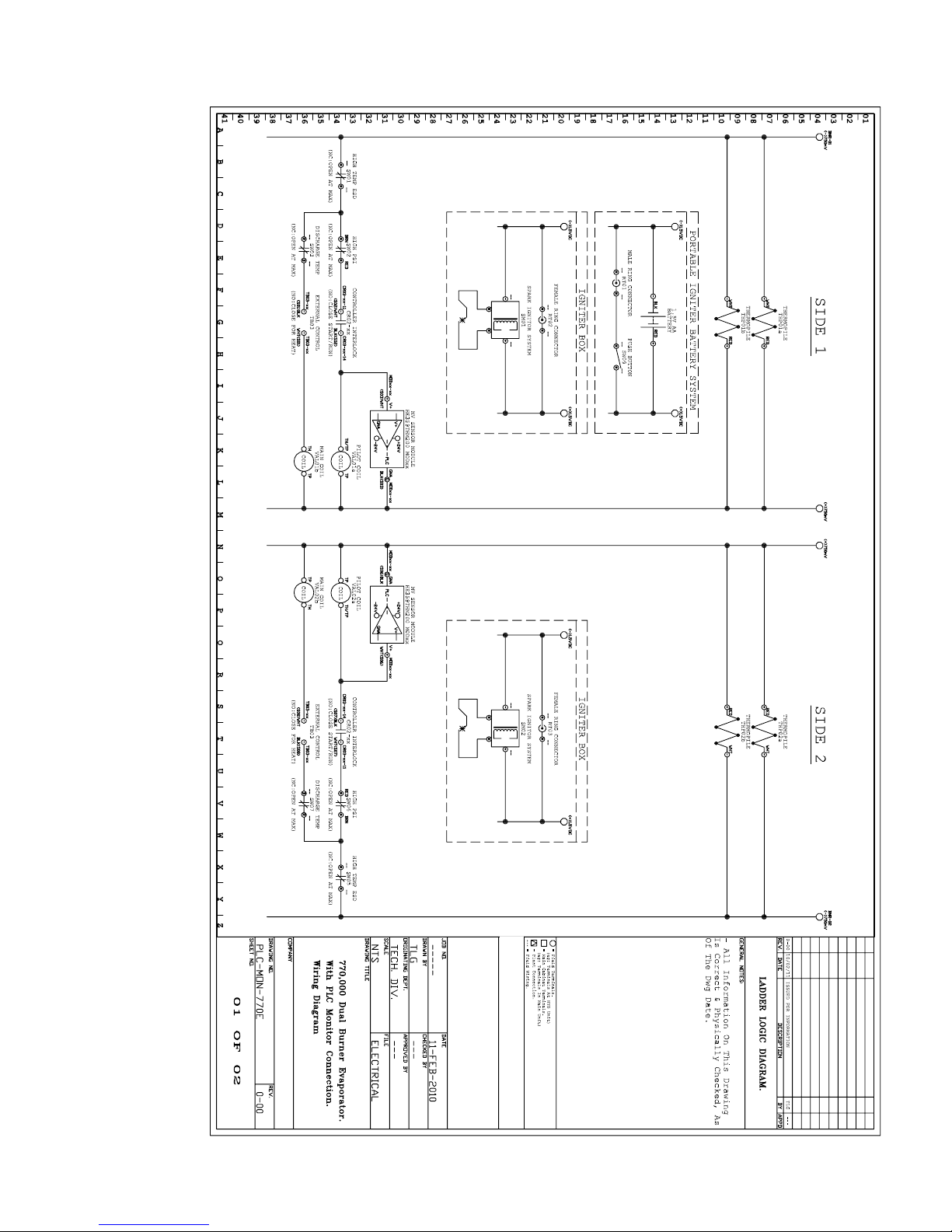

4.1.5 Wiring diagrams

COMPONENTS, SAFETIES, AND CONTROLS

PN :: HEA -EVA P-MA NUAL-016 | 20170316

Bill of material

1 Pressure switch

2 Temperature switch

3 Emergency shut-down device

4 Electronic ignition housing

5 Robertshaw millivolt gas valve

6 Temperature switch (-15 to 35C)

7 High temperature switch (0 to 100F)

8 Temperature switch (15 to 75F)

9 Temperature switch (55 to 175F)

(Figure 4.1.5a) CWT standard

control box layout schematics

140,315 and 385

Page 21

COMPONENTS, SAFETIES, AND CONTROLS

Page 22

Page 22

(Figure 4.1.5b)

PN :: HEA -EVA P-MA NUAL-016 | 20170316

COMPONENTS, SAFETIES, AND CONTROLS

PN :: HEA -EVA P-MA NUAL-016 | 20170316

(Figure 4.1.5c)

Page 23

Page 23

COMPONENTS, SAFETIES, AND CONTROLS

Page 24

Page 24

(Figure 4.1.5d)

PN :: HEA -EVA P-MA NUAL-016 | 20170316

COMPONENTS, SAFETIES, AND CONTROLS

PN :: HEA -EVA P-MA NUAL-016 | 20170316

(Figure 4.1.5e)

Page 25

Page 25

COMPONENTS, SAFETIES, AND CONTROLS

Page 26

Page 26

(Figure 4.1.5f)

PN :: HEA -EVA P-MA NUAL-016 | 20170316

COMPONENTS, SAFETIES, AND CONTROLS

4.1.6 Flame or flashback arrestors

It is a simple safety device, which quenches the flame from escaping to the outside

after burner housing. Ensure you are following local codes and regulations in

the use of a flame arrestor.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

(Figure 4.1.6)

Page 27

Page 27

COMPONENTS, SAFETIES, AND CONTROLS

4.1.7 Robertshaw gas valve

The Robertshaw gas valve is the primary fuel control on the boiler. The current

generated by the thermopiles in the continuous pilot powers the valve. The valve has

three settings: off, pilot, and on. When the valve is in the on position it will respond to

the controls in thermostats in the circuit and the unit will operate.

The pressure regulating process of the Robertshaw gas valves are bypassed. The

pressure regulating for the units is performed by the supplied Fisher HSR regulators.

WARNING: The Robertshaw gas valve is not intended for operation at higher

than 14.0” W.C. (.5 psi) supply gas pressure. Exposure to higher supply pressure

may cause damage and could result in fire.

Pilot tube connection

Gas valve top knob

Pilot adjustment (under cap)

Page 28

(Figure 4.1.7)

NOTE: Please refer to Technical Manual section for detailed product information.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

COMPONENTS, SAFETIES, AND CONTROLS

4.1.8 High temperature ESD switch

The high-temp ESD thermostat monitors and responds to the temperature of the

glycol/water mixture in the evaporator. It is set at 230°F (110°C).

When the temperature of the solvent (glycol/water) rises above the dial setting, the

contacts open, thereby opening the electrical contact and shutting the Robertshaw

valve.

This switch acts as one of the emergency shut downs; it will shut off the gas to both

the pilot and the main burner and requires an operator to reset before relighting.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

(Figure 4.1.8)

NOTE: Please refer to Technical

Manual section for detailed product

information.

Page 29

COMPONENTS, SAFETIES, AND CONTROLS

4.1.9 Discharge temperature switch

The discharge temperature thermostat monitors the temperature of the steam in

the evaporator. It is generally set between 175°F/79.44°C and 200 °F/ 93.3 °C in

natural gas applications. If the steam temperature in the evaporator exceeds this

set point the switch will open the main gas valve in the Robertshaw gas valve. The

pilot will remain lit. The steam chamber temperature will have to cool enough to

clear the deadband of the switch before it closes and allows the evaporator to fire

again. This can occur in situations where the load on the evaporator is very low.

The gas temperature probe can call for heat in response to ambient, when the unit

fires there is little or no flow and therefore little or no heat exchange. The

evaporator will rapidly heat up and the steam temperature in the unit will reach the

discharge temperature switch set point.

(Figure 4.1.9)

NOTE: Please refer to Technical Manual section for detailed product information.

Page 30

PN :: HEA -EVA P-MA NUAL-016 | 20170316

COMPONENTS, SAFETIES, AND CONTROLS

4.1.10 Ignitor box and hand-held sparker

The ignition box assembly consists of a receiver in the control panel and a separate

hand-held sparker. Inside the sparker is an AA battery.

NOTE: Before lighting the evaporator, it is mandatory to test the atmosphere first

for combustible gases around the unit.

Receiver

PN :: HEA -EVA P-MA NUAL-016 | 20170316

Hand held sparker

(Figure 4.1.10)

Page 31

COMPONENTS, SAFETIES, AND CONTROLS

4.1.11 The high pressure switch and shutdown

The evaporator is equipped with a high-pressure shutdown switch. This switch

will shut off the main and the pilot fuel if the pressure in the boiler reaches

5 psig. The main burner and the pilot are extinguished. Once the unit has cooled

enough for the pressure to drop below 5 psig, the pilot will require to be lit

manually.

Page 32

(Figure 4.1.11)

NOTE: Please refer to technical manual section for detailed product information.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

COMPONENTS, SAFETIES, AND CONTROLS

4.1.12 Temperature control (line temperature control)

The line temperature control monitors the temperature of the gas in the

downstream gas piping.

It is generally set between 0°C (32°F) and 5°C (41°F) in natural gas applications.

If the gas temperature in the downstream gas piping falls below this set point the

switch will close, allowing gas to flow to the main burner, generating steam for

heat transfer.

Once the heated gas passing the line temp controller has exceeded its set point.

The contacts will open which stops the gas flowing to the main burners.

If low or zero gas flow situations exist we suggest installing the probe near the

outlet of the high-pressure coil (refer to section 8.5).

The temperature set point must then be increased to account for the pressure drop

through the gate station.

(As a general rule, a 100 Psi drop in pressure will result in drop of 7°F (-13.9°C) of

temperature).

NOTE: Please refer to technical manual section for detailed product information.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

Page 33

COMPONENTS, SAFETIES, AND CONTROLS

4.1.12a 140 / 315 / 385 heater line temperature controller (T675A switch)

As the temperature of the controlled medium falls below the set point less

differential, the T675A switch makes terminals R to B and energizes a normally

closed solenoid valve to provide heat. Figure 4.1.12a.1 shows the operation of the

T675A. Figure 4.1.12a.2 shows the location of the adjustment dial on models with

an adjustable differential.

Controller comes in F or C.

(Fi gur e 4.1.12a.1)

(Figure 4.1.12a.2)

R

B

(Figure 4.1.12a.3)

Page 34

PN :: HEA -EVA P-MA NUAL-016 | 20170316

COMPONENTS, SAFETIES, AND CONTROLS

4.1.12b 770 heater line temperature controller (T678A switch)

When the temperature at the sensing element rises above the set point of the

controller, the switch on the right makes R to W. Should the temperature continue

to rise through the preselected inter stage differential of the controller, the switch

on the left will make R to W.

Conversely, on a temperature fall, the switch on the left makes R to B,

providing first step switching. If the temperature continues to fall, the switch on the

right makes R to B to provide sequencing of equipment.

The T678A temperature controller has an adjustable inter stage differential. The set

point adjustment knob determines the temperature at which the right switch operates. The left switch can be adjusted to operate from 3 to 10 degrees F (1.7 to 5.6

degrees C) (or 3.6 to 12 degrees F (2.0 to 6.7 degrees C) on some models) above

the point of operation of the right switch. An illustration depicting the operation of

the T678A is shown in figure 4.1.14b.1. The inter stage differential is adjusted by

turning the star wheel with a narrow screwdriver inserted into the rectangular hole

in the chassis (figure 4.1.14b.2).

Controller comes in F or C.

B

R

PN :: HEA -EVA P-MA NUAL-016 | 20170316

2

1

B

(Fi gur e 4.1.12b.1)

R

(Figure 4.1.12b.3)

(Figure 4.1.12b.2)

Page 35

COMPONENTS, SAFETIES, AND CONTROLS

4.1.13 Burst disk and burst disk holder

The CWT Heater is designed to operate below 15 psig. If the pressure in

the boiler reaches 15 psig the rupture disk will fail and the pressure will be

released. The rupture disk is located above the fluid level in the unit so most of

what will be released will be steam. The small amount of glycol that would be

carried along will be collected in the containment system.

Note: For the new graphite gaskets, a 3M High Strength 90 Spray Adhesive Clear

must be used on all bonding surfaces.

There are a few different styles of rupture discs used in the past on CWT Line

Heaters. The most current one is shown in figure 4.1.13a and 4.1.13b.

(Figure 4.1.13a) Burst disk.

Older style rupture discs can be changed out to the new graphite rupture disc with

minor alterations to the old style discs and piping.

Page 36

(Figure 4.1.13b) Burst disk with holders.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

COMPONENTS, SAFETIES, AND CONTROLS

4.1.14 Fisher HSR regulator

Pressure reducing regulator is to regulate gas and dependant on the end users gas

usage. Vent as per local codes. Maximum inlet supply pressure is 20 psi with

the .5” orifice that are installed.

(Figure 4.1.14)

The following table is using a HSR with .5 inch orifice.

Inlet pressures and standard cubic feet per hour for each heater assembly:

BOILER SIZE INLET PRESSURE REQUIRED SCFH

140 5 psig 200

385 5 psig 480

770 (Single) 5 psig 1050

770 (2-385) 5 psig 960

1155 (3-385) 5 psig 1440

1.54 (2-770) 5 psig 2100

2.3 (3-770) 5 psig 3150

3.1 (4-770) 5 psig 4200

4.6 (6-770) 5 psig 6300

(Table 4.1.14)

PN :: HEA -EVA P-MA NUAL-016 | 20170316

Page 37

COMPONENTS, SAFETIES, AND CONTROLS

4.1.15 Fuel pressure gauge IWC (inches of water column)

(Figure 4.1.15)

Pressure measurements in inches of water column

1 psi = 27.68 inches of water column, so 0.45 psi would be

z27.68 * 0.45 = 8.3 inches of water column

WARNING: The Robertshaw gas valve is not intended for operation at higher

than 14.0” W.C. (.5 psi) supply gas pressure. Exposure to higher supply pressure

may cause damage and could result in fire.

4.1.16 Fisher 289L relief valve

This valve is set to relieve excess gas pressure at .5 psi. Vent as per local codes.

Page 38

(Figure 4.1.16)

PN :: HEA -EVA P-MA NUAL-016 | 20170316

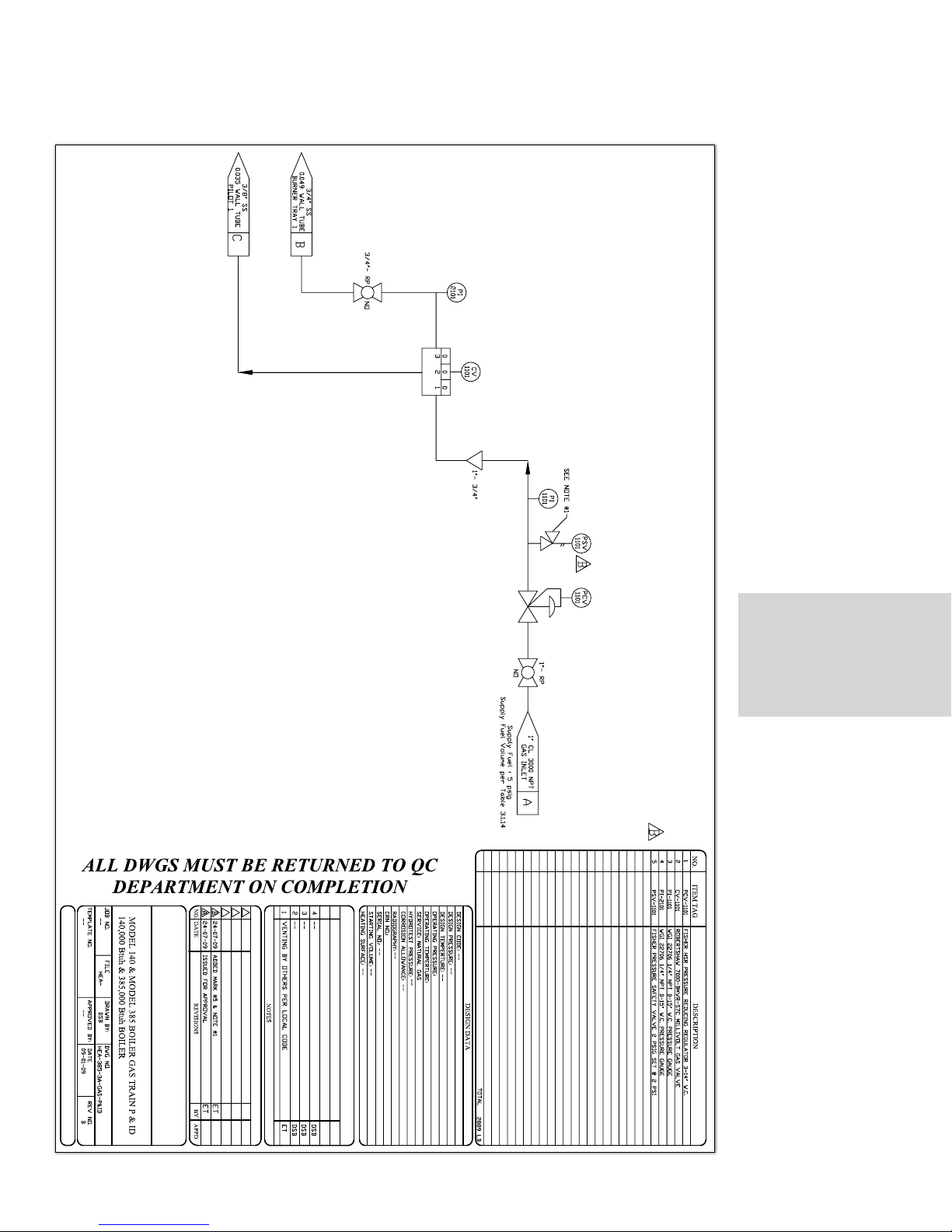

4.1.17 Fuel train drawing

COMPONENTS, SAFETIES, AND CONTROLS

Fuel gas assembly

drawings can be

found in Appendix M.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

P&ID Drawing for 140 and 385 (Figure 4.1.17a)

Page 39

COMPONENTS, SAFETIES, AND CONTROLS

Page 40

P&ID Drawing for 770 (Figure 4.1.17b)

PN :: HEA -EVA P-MA NUAL-016 | 20170316

4.1.18 Pressure vacuum gauge

COMPONENTS, SAFETIES, AND CONTROLS

The vacuum gauge indicates the strength of vacuum. When the unit has a steam

temperature of less that 60 degrees Celsius, the gauge should be in the range of

–20 to –28 inches HG.

Note: Heat transfer efficiency will increase with high vacuum.

Note: Ensure that the needle valve is fully open (during operation) or fully

closed (during maintenance), needle valves that are partially open or

closed can leak and cause the unit to lose vacuum.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

(Figure 4.1.18)

Page 41

COMPONENTS, SAFETIES, AND CONTROLS

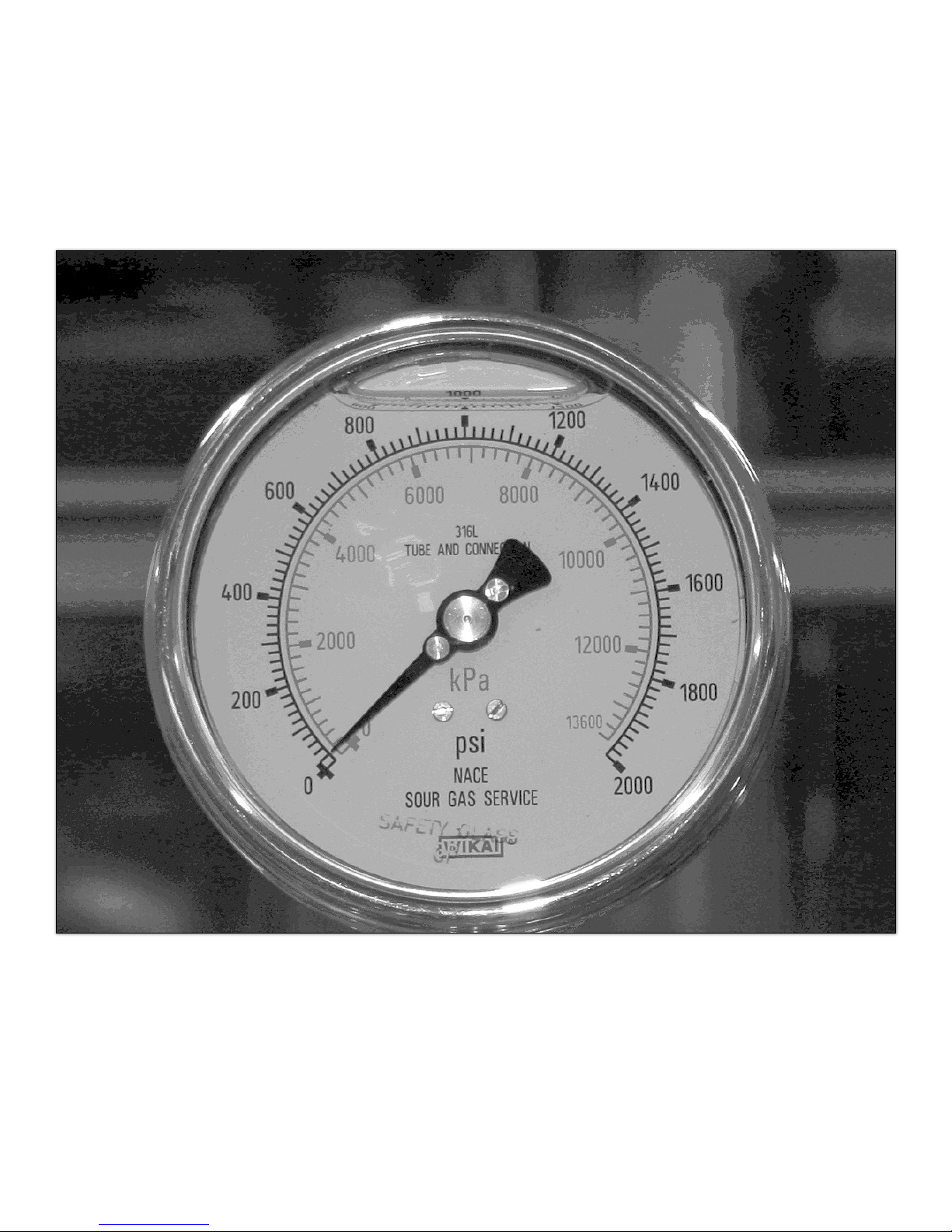

4.1.19 High pressure coil gauge

Page 42

(Figure 4.1.19)

Picture of pressure gauge above is the standard pressure gauge CWT uses on inlet

and outlet of high pressure coils to determine the gas pressure. For Compressed

Natural Gas (CNG) applications, the supplied gauge will have a scale to 5000

psig.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

4.1.20 Liquid level gauge

COMPONENTS, SAFETIES, AND CONTROLS

Heat transfer fluid (50/50 water glycol mix)

(Figure 4.1.20)

Pictured above is the liquid level gauge, which indicates the availability of the heat

transfer fluid in the system. The level gauge is not meant to indicate proper working level; it is only for indication that there is fluid in the system.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

Page 43

COMPONENTS, SAFETIES, AND CONTROLS

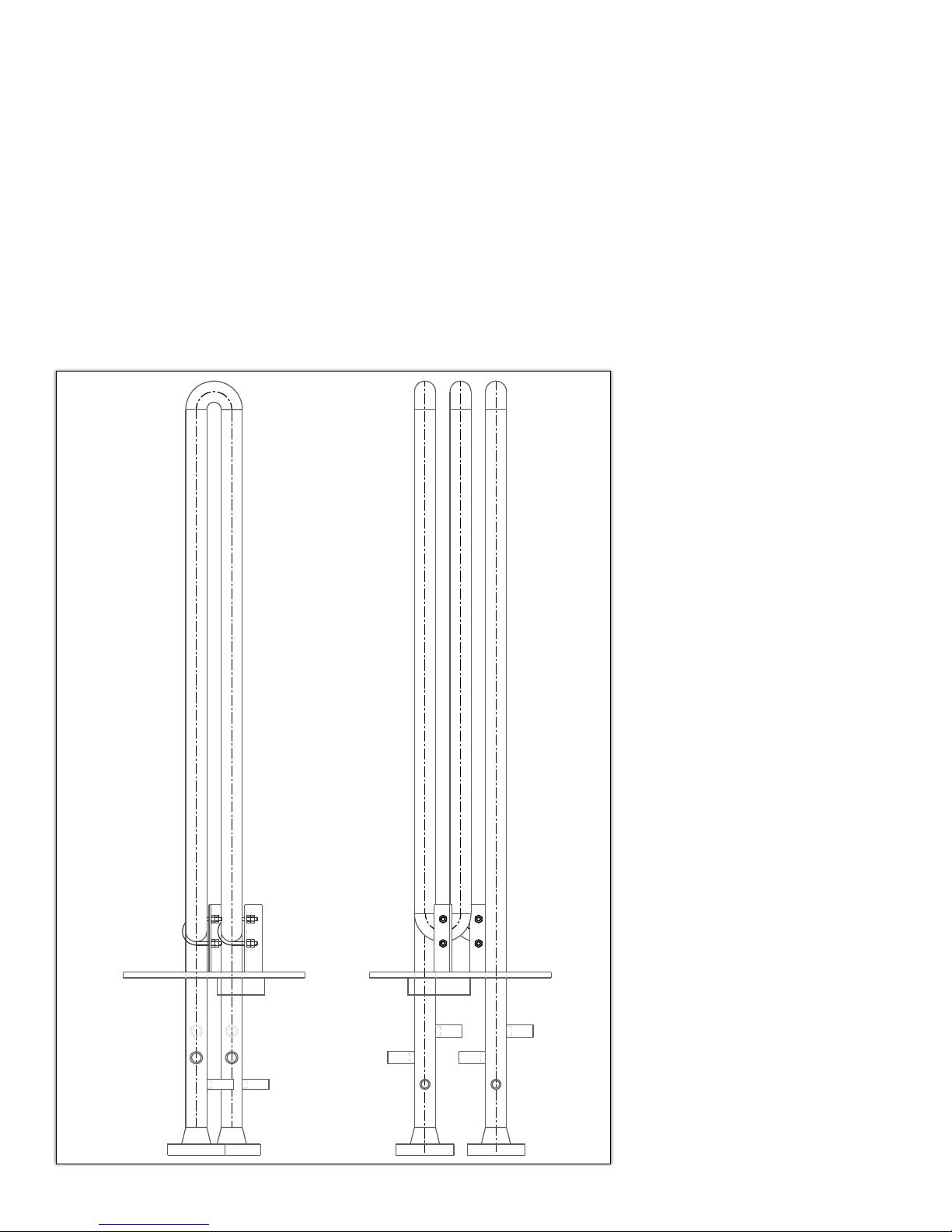

4.1.21 Exhaust vent

The exhaust stack cap supplied with the CWT heater is a residential, B-Vent style

stack cap. They come in six inch, eight inch, or 12 inch, depending on the

evaporator model.

The six inch stack has a high-wind stack cap with bird screen, while the eight and

12 inch stacks are both equipped with the bird screen.

Stacks are to be cleaned out (blown out) periodically as part of the routine

maintenance. B-vent stacks are double-walled galvalume and can dent very easily.

Proper care when installing the vent stack should be taken to prevent damage.

For assembly information please refer to Appendix E, F, G, and H.

B-vent for 140,000 BTU evaporator

6 inch

Page 44

B-vent for

315,000 / 385,000 BTU

B-vent for 770,000 BTU evaporator

12 inch

evaporator

8 inch

PN :: HEA -EVA P-MA NUAL-016 | 20170316

COMPONENTS, SAFETIES, AND CONTROLS

4.2 Condenser section (heat exchanger)

The condenser or heat exchanger is the part of the CWT Heater where the steam

condenses on the pressure coil that contains the cold gas. When the steam

contacts the cold pipe it releases latent heat by condensing to water. The water

falls back to the evaporator section by gravity. The energy released as the steam

condenses to water is significant. Just as it takes a significant amount of energy

to convert water to steam, a large amount of energy is released when the steam

condenses back to water. The inlet and outlet of the high-pressure piping is not

defined, either flow direction will result in an acceptable heat exchange.

Gas outlet/inlet

Gas inlet/outlet

(Figure 4.2)

PN :: HEA -EVA P-MA NUAL-016 | 20170316

Page 45

COMPONENTS, SAFETIES, AND CONTROLS

4.2 .1 The heat exchanger can

The condenser/heat exchanger can contains the pressure coil and provides the

vessel in which the steam is allowed to condense on the coil.

Inside the condenser can (photo below) the receivers at the far end support the coil.

Receivers to support the coil

Steam inlet

Condensate (water) outlet

Page 46

(Figure 4.2.1)

PN :: HEA -EVA P-MA NUAL-016 | 20170316

COMPONENTS, SAFETIES, AND CONTROLS

4.2.2 High-pressure process coil

The high-pressure coil is the device that contains the gas to be heated. It is a

registered pressure device built and certified in accordance with ASME B31.3

(pressure piping). The coil is typically a serpentine device as pictured below,

the cylindrical coils are helical spiral coils and adjacent to it are standard

high-pressure coils.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

Page 47

COMPONENTS, SAFETIES, AND CONTROLS

Support

Page 48

(Figure 4.2.2) Note the nubs on the end of the coil.

These provide support and grounding for the coil inside the can

NOTE: High pressure coils are rated for: -20°F to 400°F (-29°C to 240°C).

For low temp applications: -50°F to 400°F (-45°C to 204°C).

PN :: HEA -EVA P-MA NUAL-016 | 20170316

START-UP PROCEDURE

5. Start-up procedure

Prior to start-up the unit combustion chamber and all gas fittings should be checked for gastightness and proper placement

as shifting can occur during shipping. All connections should be checked and verified by a gas fitter prior to supplying gas

to the unit. Deficiencies or issues should be recorded and noted, items requiring warranty or further investigation should be

relayed back to the Tecvalco factory immediately. On start up in very cold weather the boiler coil might be quite cold. Ensure

the unit is warmed up to higher than 0°C (32ºF) prior to pressuring up the coil. If the boiler is down in very cold weather and

there is no gas flow passing through the unit, the boiler should be isolated and the pressure reduced.

WARNING: Test atmosphere around the heater prior to lighting (procedure also on control box door). If an explosive mixture

exists locate and shut off the source of the fuel and ensure the flame arrestor is in place and secure.

1. Open main gas ball valve on the fuel gas supply.

2. Turn Robertshaw control valve to the “PILOT” position.

3. Depress pilot button.

4. Insert hand held ignitor into the ignition box in the control cabinet and depress the button, while still depressing the pilot

button. This causes a spark to jump across the pilot assembly. You should hear the sparking. Once the pilot lights you

will no longer hear the spark. It may take several minutes for the natural gas to reach pilot area, due to the length of fuel

gas supply line and the amount of trapped air.

5. Hold pilot button down for 30 seconds and then release.

6. Look through the site glass to confirm the pilot remained lit. If not, check that the valves on the fuel supply are open and

return to step four. If this problem persists press the reset on the ESD control and try again or check fuel gas

7. With established pilot turn Robertshaw control to the “ON” position.

8. Change the setting of the line temperature switch to force heater to light. The main gas control valve should open and

the heater should light.

On first light you may

get a slight burst of gas

because of air in line.

Turn to pilot for a

second and then back

to on. If the main burner

does not light, confirm

that all the dial type

switches are calling for

heat.

9. Once the evaporator is

operating, examine the

flame and note any

instability.

10. Use the CWT Line

Heater checklist

inspection form

(section 7.15) to record

the initial data.

11. For 385,000 and

770,000 Btu/hr:

Allow 5 minute

complete shutoff

before attempting to

re-fire.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

Page 49

TYPICAL OPERATION

6. Typical operation

During the first operating cycle of the heater, allow the system to run. Monitor the

pressure, the discharge temperature and the level of heat transfer fluid in the sight

glass. During initial start up and during normal operation the level of heat fluid will

vary widely in the sight glass.

While the system is warming up, you will hear clattering and clanking inside the

evaporator, which is normal and due to thermal expansion of steel inside the

system and steam being percolated out of the glycol quickly. This should stop once

the heater reaches a temperature range of approximately 125 deg. F to 150 deg. F.

Once the evaporator is warm (the main flame bed turns on and off to keep the gas

warm) note the duration of the on and off cycles and the maximum and

minimum temperatures reached. The season and gas flow will determine the cycle

times; slow flow means long cycles and high flow mean short cycles. Use the

attached Inspection sheet (section 7.15)

If the evaporator appears not to be warming gas sufficiently consider increasing

the fuel pressure. Insufficient fuel gas will cause the unit to run constantly, and will not

heat properly. If the heater cycles off and on it has sufficient energy to heat the gas.

To achieve low flow rate setting, while burner is in operation, turn the knob

on the Robertshaw gas valve to reduce the input. The minimum and maximum

allowable inlet pressures are indicated on the rating plate inside the control

panel.

Page 50

PN :: HEA -EVA P-MA NUAL-016 | 20170316

6.1 Recommended control settings

CONTROL MINIMUM MAXIMUM RECOMMENDED

Steam (discharge) 76°C/170°F 95°C/200°F Start out at 170°F and

temperature (°C/°F) increase as the process

requires so that heater

control is by the line

temperature controller

and not the discharge

temperature controller.

The maximum setting is

20 0 °F.

ESD shutdown (°C/°F) 110°C/230°F 110°C /230°F Operate at 110º C/

230°F. If this trips

contact CWT.

TYPICAL OPERATION

Pressure switch 5 Psi/ 5 Psi/ This switch is factory set

(psig/kpa) 34.4KPa 34.4 KPa to 5 psig.

Line temperature 0°C/32°F 5°C / 41°F Depending on the

(°C/°F) conditions and the nature

of the gas set this as

required

(About 2°C/ 35°F)

OPTIONAL

Gas bundle outlet 24°C / 75°F 43°C / 110°F Depending on the

temperature (°C/°F) season. Summer 24°C /

(High Temp Shut Down) 75°F Winter 43°C/110°F

(Table 6.1)

Note: When multi-heating boilers are used on a heat exchanger, the line

temperature switches should be rotated, so that the single boiler is not always

the lead unit.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

Page 51

TYPICAL OPERATION

6.2 Tuning the CWT Heater

The CWT Heater has a significant advantage over conventional systems in that it

has a high turndown capability. A CWT evaporator can run with fuel inlet

pressures varying between 3.5” WC (0.13 psi) and 14” WC (0.52 psi). This allows

the operator to set the cycle time of the boiler to best fit the load. Ideally, a

perfectly tuned heater would run 100 per cent of the time on the coldest day of the

year. In practice, a well-tuned Evaporator will typically cycle three to four times per

hour. Cycle time is determined by firing rate and load. The “on”, or firing, portion

of the cycle can be controlled by the firing rate. If the firing rate is increased this

will shorten the “on” part of the cycle. Flow and pressure drop through the station

controls the “off” part of the cycle.

Some general rules for tuning include:

• If possible, set the firing rate during high station load conditions and

let the boiler stabilize (warm up) before continuing.

• Fire at a high enough rate that the boiler will cycle at least three

times per hour.

• Fire at a high enough rate to ensure the stack temperature exceeds

130°C (266º F). Below this point incomplete combustion may occur

and “raining” may occur in the stack.

• Fire at a low enough rate that the stack temperature does not exceed

250°C (482º F). Above this would impair the boiler or stack.

• Obtain a combustion analysis and optimize the combustion.

Observe the flame and address any lifting and/or hunting. Consult Tecvalco for

advice.

6.3 Cycles

The CWT boiler normally operates with cycles on and off (figure 6.3a). The

nature of the cycle depends on the firing rate and load as well as the set points on

the controls primarily the gas temperature control. (See section 6.1)

When the boiler fires in response to a call for heat by the gas temperature control

the evaporators begin the process of boiling the water. As the steam

temperature and pressure increase more heat is delivered to the process gas.

Eventually the temperature of the gas reaches the set point of the gas

temperature control and the main burner shuts down. Upon shutdown, a large

amount of energy remains in the evaporator and the temperature of the gas will

continue to climb for some time (depending on the load). As a result the heater

tends to overshoot the set point by a few degrees. Similarly when the heater is off,

and the temperature is falling, when the gas line temperature control reaches the

set point (plus the dead-band) it will call for heat and the evaporator will fire. It

might undershoot the set point before the evaporator catches up.

Page 52

PN :: HEA -EVA P-MA NUAL-016 | 20170316

1 0 .0

G as Tem p (H eat er Off) G as Te m p (Hea ter F irin g)

Heater Off

Heater Firing

1

2

3

5

6

8

TYPICAL OPERATION

Gas Temperature Profile with CWT Line Heater (Illustrative Purposes Only)

8 . 0

7

6 . 0

4 . 0

2 . 0

Gas Temperature (°C)

0 . 0

-2 .0

4

-4 .0

-6 .0

0 1 2 3 4 5 6 7 8 9 10 1 1 1 2 1 3 14 1 5 1 6 1 7 1 8 1 9 2 0 21 22 2 3 2 4 2 5 26 27 2 8

PN :: HEA -EVA P-MA NUAL-016 | 20170316

(Approx. 8min)

(Approx. 5min)

Time

(Figure 6.3a)

Page 53

MAINTENANCE

WARNING:

Inspections and tests

included in this section may be

regulated by local, Federal, or

other jurisdictions. Please

review all applicable codes

and regulations prior to

conducting any activities on

CWT equipment.

7. Maintenance

WARNING: Never perform maintenance on the boiler when under operation or

hot. Please ensure that the unit is shut and cooled down for 25 minutes, and that all

fuel gas to the device has been shut off prior to performing any maintenance

operation.

ALWAYS assume that there is pressure in the system.

7.1 Maintenance schedule

It is suggested that the boiler should undergo a complete inspection, maintenance

and cleaning at least semi-annually (spring and fall). Use the following maintenance

checklist in conjunction with the CWT inspection sheet (section 7.15). The inspection can be done in connection with maintenance and can begin with a boiler that is

operating; however sufficient time should be available to allow the evaporator to cool

prior to the maintenance activities.

WARNING:

Performing pressure tests on

the system can be hazardous,

and should only be performed

by trained professionals.

Contact Tecvalco if you have

any questions.

WARNING:

Keep boiler area clear and free

from combustible materials,

gasoline and other flammable

vapors and liquids

Page 54

Service inspections

a. A poor adjusted or malfunctioning appliance can deposit soot and other

debris which can enter the vent system. The vent should be visually inspected at

least annually for the presence of deposits of soot or debris. Blow air through the

stack till no debris.

b. The heater must be periodically inspected by a qualified serviceman or

Tecvalco service technicians.

Inspection Checklist

qTake pictures of the complete heater.

qRecord heater serial number and coil serial number.

qShut heater off and let it cool down.

qEnsure vacuum is between -20 inches and -26 inches.

qCheck the glycol level in the sight glass.

qOpen the burner box door and take pictures of burner tray and burner box.

qRemove stack and take pictures of stack walls and top of fin tubes.

qRemove burner tray gas line and disconnect the pilot assembly by removing

the nut and drop the pilot assembly to the bottom of the combustion chamber.

qWhen burner tray is removed take pictures of bottom of fin tubes. If possible,

do a visual inspection.

qUse an air compressor to blow off top and bottom of fin tubes.

qOnce complete, do a visual inspection. If not clean, then repeat.

qUse a vacuum cleaner to clean up the bottom of burner box and, if possible,

the top of the fin tubes.

qTake pictures of cleaned-out burner box and top of fin tubes.

qClean burners from tray with air and check orifices to see if they are clean.

This may require disassembly.

qClean flame arrestor cell with air, or a water/soap solution until all openings

are free and clear.

qReassemble burner tray and install back in burner box. Hook up gas line and

pilot assembly. Ensure burner tray placement is proper. If required, contact

Tecvalco Ltd. personnel.

qCheck wires in burner box for defects. If necessary, replace.

qClose up burner box area, ensuring gaskets are properly in place.

qIf heater has cooled down enough, take glycol samples.

qWhen complete, relight heater using start-up procedure.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

qOnce heater is up to temperature function test each switch, for temperature

controllers calibration please use a dry block.

qDischarge temperature switch. 170-200°F / 76-95°C. Set at required

temperature for process.

qHigh temperature ESD switch. 230°F / 110°C. Will require relight.

qLine temperature control switch. Set to desired temperature.

qPressure switch. Set at 5 psi.

qCheck millivolt readings.

qCheck temperature of gas at station outlet, as well as in and out of the coil

qCheck fuel pressure, in inches WC.

qCheck steam and stack temperature.

qPerform combustion analysis, if possible.

WARNING: Do not obstruct the flow of combustion and ventilation air.

7.2 Cleaning the flame arrestor

The flame arrestor on the evaporator should be inspected and cleaned at least semiannually in order to ensure that it is in good working order and that enough air is

provided to support proper combustion. In some cases more frequent cleaning may

be required. (Locations where large amounts of dust are present or

environmental factors). It is important to note that a clogged flame arrestor can

fail as a safety device and result in hazardous situations. Therefore, it is very important to clean the arrestor on a regular basis.

a. Ensure the evaporator is off prior to removing the flame arrestor.

b. Remove the flame arrestor and examine the cell – make sure that it is

not damaged.

c. Examine the gasket around the flange and ensure it is intact and in

good condition.

d. Use compressed air or nitrogen to blow out any dust or contaminants

that might be in the weave of the cell.

e. While the flame arrestor is removed inspect the burners – look

specifically for signs of scale and or soot.

f. Replace the flame arrestor; ensure that the cell fits tightly against

the back flange.

MAINTENANCE

SEMI-ANNUAL

WARNING:

Inspections and tests

included in this section may be

regulated by local, Federal, or

other jurisdictions. Please

review all applicable codes

and regulations prior to

conducting any activities on

CWT equipment.

SEMI-ANNUAL

7.3 Swordfish burner clean-up

For detailed assembly drawings, refer to Appendix I, J, K, and L.

1. Turn gas valve to pilot, then turn off main gas. Let cool.

2. Open heater door and disconnect main gas flex from burner

manifold. Unhook pilot gas line at Hylok fitting and remove burners

if possible. Disconnect pilot bracket from burner tray. This will allow

operator to remove the burner tray without having to disconnect the

wires.

3. Remove burners from unit.

4. Check the burner venturi ports are free of foreign particles (dust, lint

and debris).

5. Clean burners with bristle brush and/or vacuum cleaner. DO NOT

alter burner ports or pilot location.

6. If the fin tubes need to be inspected and cleaned go to section 7.4.

7. Reinstall burners in unit. Make sure front and rear of burners are

positioned correctly in burner support brackets.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

The burner tray can be difficult

to remove as the combustion

chamber walls can slightly warp

due to heat. In this case, the walls

inside may be required to be

pushed get with a spreader bar to

accomodate burner tray removal,

WARNING:

Performing pressure tests on

the system can be hazardous,

and should only be performed

by trained professionals.

Contact Tecvalco if you have

any questions.

Page 55

MAINTENANCE

WARNING:

Inspections and tests

included in this section may be

regulated by local, Federal, or

other jurisdictions. Please

review all applicable codes

and regulations prior to

conducting any activities on

CWT equipment.

7.4 Inspecting and cleaning the fin tubes

The fin tubes should be inspected and cleaned semi-annually. It is suggested that

this be done before and after peak times (spring and fall, possibly).

1. Complete steps 1 to 3 of swordfish burner clean-up (7.3).

3. The stack will need to be turned to the side or removed for inspection

and cleaning of the top of the fin tubes.

SEMI-ANNUAL

4. Once the burner tray and stack have been removed, take pictures of

the fine tubes above and below, if possible. Note any problem areas

and contact Tecvalco.

5. Use an air compressor or compressed air to blow out the fin tubes

from the top down and then from the bottom up. Clean up any

particles from bottom of the heater and any scale still on the top of

the fin tubes. If needed, use a mirror to help in the inspection.

6. When cleaning is complete take pictures to note improvements.

7. Replace the stack and burner tray.

WARNING:

Performing pressure tests on

the system can be hazardous,

and should only be performed

by trained professionals.

Contact Tecvalco if you have

any questions.

Page 56

PN :: HEA -EVA P-MA NUAL-016 | 20170316

MAINTENANCE

7.5 Glycol sample procedure

Most CWT heaters are equipped with a double valve system, which will allow you

to take a glycol sample without losing an appreciable amount of vacuum.

The procedure is as follows:

1. Take the sample when the heater is cold, in summer if possible.

During operation the water and glycol separate and a sample will

have an unrepresentatively high amount of glycol.

2. Open the top valve and wait for 30 seconds.

3. Close the top valve and open the bottom to obtain the sample, close

the bottom valve

4. Repeat steps (2) and (3) at least two times. Such process would purge

and remove the fluid standing in the low spot and to get a sample.

5. Open the top valve.

6. Open the bottom valve for 3 seconds only. This allows the system

to pour back and bring fluid into the sample leg. Close both valves

7. Repeat steps 2 and 3 and obtain the required sample.

8. Note the vacuum pressure when complete.

9. For older Series II 140s with a temperature probe in the

sample port, sample times will be much greater.

10. NOTE: Glycol samples are acceptable if they meet the customers’

minimum freezing points.

SEMI-ANNUAL

Top valve

PN :: HEA -EVA P-MA NUAL-016 | 20170316

Bottom valve

(Figure 7.5)

Page 57

MAINTENANCE

NOTE: If through age or failure the

thermopiles can no longer generate

the power to operate the gas valve

they can be replaced quite simply. In

this case all the thermostats, controls

and safeties would shutdown.

SEMI-ANNUAL

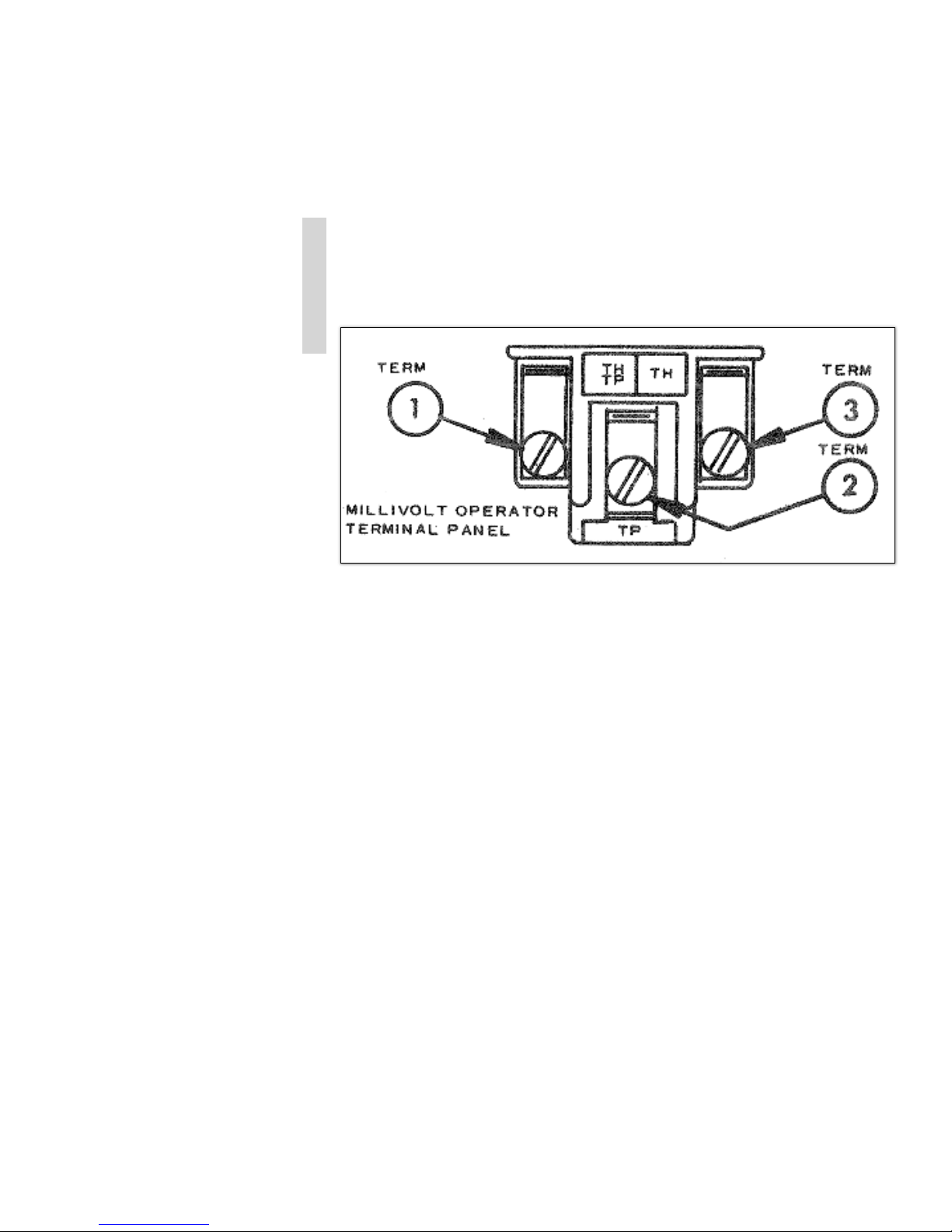

7.6 Testing the powerpiles

Test the powerpile assembly using the following procedure:

NOTE: Use a voltmeter set at 1000 mV

(Figure 7.6)

Test 1 – Complete system

Connect to terminals 2 and 3. Ensure the thermostats are calling for heat (turn

them up). Power should be >100 mV. The main burner should fire. If the voltage

>100 mV but the valve does not open replace the valve. If the power is <100 mV

proceed to test 2.

Test 2 – Thermopile output

Connect to terminals 1 and 2. The thermostats should not be calling for heat (turn

them down). The main burner is off the voltage should be > 325 mV. If it is less

replace the thermopiles.

Test 3 – System resistance

Connect to terminals 1 and 3. The thermostats should be calling for heat. The

main burner should be on. The reading should be < 80mV. If the reading is more,

clean the contacts and cycle the thermostats (to clean contacts).

Test 4 – Pilot dropout

Connect to terminals 1 and 2. Hold the pilot until the power level stabilizes. Shut

the pilot off and note at which point the magnet drops (should be between 120

and 30 mV (falling). If the dropout does not occur or occurs outside these points

replace the gas valve.

Page 58

PN :: HEA -EVA P-MA NUAL-016 | 20170316

MAINTENANCE

7.7 Procedure for testing high-pressure shutdown

1. Testing pressure switch (shutdown setting check).

2. Turn Robertshaw gas valve to off position. Give heater .5 hour to cool.

3. Close bottom valve (3) completely.

4. Remove plug from top valve (2), (releasing vacuum from the just

switch section, not all of unit).

5. Will require a pump or other to pressure test switch.

6. Unplug wire from terminal 1 on Robertshaw gas valve and wire from

high temperature ESD leading to pressure switch and connect

multimeter to wires (set meter at continuity). Add pressure and note

where contact closes.

7. Switch should cut out at set point of 2.5 psig- 5 psig (if settings

correct, reconnect the wires, replace plug, open valves turn

boiler back on. Valves must be ither opened all the way, or closed all

the way - otherwise the packing can leak.

SEMI-ANNUAL

WARNING:

Inspections and tests

included in this section may be

regulated by local, Federal, or

other jurisdictions. Please

review all applicable codes

and regulations prior to

conducting any activities on

CWT equipment.

Top Valve (2)

PN :: HEA -EVA P-MA NUAL-016 | 20170316

WARNING:

Performing pressure tests on

the system can be hazardous,

and should only be performed

by trained professionals.

Contact Tecvalco if you have

any questions.

Bottom Valve (3)

(Figure 7.7)

Page 59

MAINTENANCE

WARNING:

Inspections and tests

included in this section may be

regulated by local, Federal, or

other jurisdictions. Please

review all applicable codes

and regulations prior to

conducting any activities on

CWT equipment.

WARNING:

Performing pressure tests on

the system can be hazardous,

and should only be performed

by trained professionals.

Contact Tecvalco if you have

any questions.

7.8 Procedure to find possible leak

When required, the following checklist can be used to track down possible leaks.

qTurn heater off and let cool for one hour. This needs to be done or steam will

leave the system).

qRemove vacuum from system.

qDrain the gylcol from the system. Barrels will be required for this, so be sure

to check the size of system for the amount needed.

qUsing an air compressor, pressure system up to 10 psi MAX.

qSoap all fittings and areas that might be affected, including pressure relief

system.

qInspect areas for bubbles. Testing may require up to an hour.

qFix problem areas.

qRe-pull vacuum to -24 to -30 inches.

qPull in proper amount of glycol. Note, new glycol may be required, as old

fluid may have lost its water.

qRestart heater using start-up procedure.

7.9 Pulling vacuum (when required)

1. When pulling vacuum the unit must be empty. Sucking gylcol through

the vacuum pump can wreck the pump seals, etc.

2. Drain heater completely or make sure heater is drained.

3. Ensure that the system is cool and that neither the main burner nor

the pilot is running.

4. Connect the vacuum compressor (suction side) to the evaporator

vacuum valve.

5. Turn on the compressor, and then open the valve.

6. Continue evacuation of air until the vacuum gauge reaches –26”Hg.

(The higher the vacuum that is achieved in the system, the more

efficiently the system will operate).

7. Once sufficient vacuum is achieved, close the vacuum valve and shut

down the compressor. Remove the compressor connections and

re-install vacuum valve cap.

8. Record the pressure and temperature reading on the evaporator.

9. Allow unit to stand for 30 minutes.

10. Check to see if the pressure or temperature has dropped or varied

in any way.

11. If the pressure has increased with no change in temperature, there

is a leak in the system. If neither of the settings has changed,

proceed to the trouble shooting section.

NOTE: If there has been a vacuum leak on the heater you should assume

that much of the water in the fluid has been lost – in these cases it is

prudent to drain and replace the fluid.

Page 60

PN :: HEA -EVA P-MA NUAL-016 | 20170316

MAINTENANCE

7.10 Replacing damaged burst disk

When required, the following can be performed to replace a damaged burst disk.

1. Remove ABS pipe off burst disk holder and containment, then

remove ruptured disk by taking out all studs and nuts on holder.

2. Make sure sealing surfaces on both parts of holder are clean and

free of scaring, grooves, or debris. (If needed use steel wool to

clean).

3. When reinstalling disk make sure holders are evenly spaced all the

way around, and hand tighten studs equally.

4. All graphite rupture discs should be torqued as per the following

sequence:

a. First Pass: 5ft lbs

b. Second Pass: 10ft lbs

c. Third Pass: 15ft lbs

d. Fourt Pass (repeat three times): 22ft lbs

(NOTE: For HPX 90 style rupture disc and holder (SS): When

tightening use torque wrench, first pass should be 20ft lbs using

cross pattern, second pass use 65ft lbs making sure spacing is equal

all the way around for units installed with rupture disc holder.

5. Reinstall ABS pipe to disk holder and containment.

WARNING:

Inspections and tests

included in this section may be

regulated by local, Federal, or

other jurisdictions. Please

review all applicable codes

and regulations prior to

conducting any activities on

CWT equipment.

WARNING:

Performing pressure tests on

the system can be hazardous,

and should only be performed

by trained professionals.

Contact Tecvalco if you have

any questions.

(Note: For HPX 90 syle rupture discd holder (SS) (Note: For older style painted

rupture disc holders use a torque setting of 30ft lbs on first pass and 40ft lbs on second pass)

Burst disk holder containing burst disk

Containment system

ABS pipe

PN :: HEA -EVA P-MA NUAL-016 | 20170316

Page 61

MAINTENANCE

7.11 Drawing glycol into system

New water-glycol mixture should be used when adding fluid to a system, or for

new installs.

1. Remove the cap from the vacuum fitting.

2. Attach a vacuum hose to the fitting on the valve.

3. Insert the free end of the hose into the container of fluid mixture.

4. Open the valve to draw in fluid.

5. Close valve when the proper volume of fluid is drawn.

NOTE: Do not allow air to enter the system.

7.12 Recommended glycol volumes

The recommended glycol-water volumes for the CWT boiler are as follows. In

every case, when the evaporator is operating there should be fluid in the site glass.

If not please contact Tecvalco.

Heater Style Recommended fill volume 50/50

in Litres in Gallons

140 Integral 40 10.5

315 MK5 68 17. 9

385 MK6 95 25.09

770 160 42.2

( Ta b l e 7.11)

NOTE: Glycol volumes may change according to evaporator size

7.13 Glycol characteristics

The glycol in the CWT heating system is designed for freeze protection only. An

easy on-site check periodically can identify if the glycol needs to be changed. The

two main properties to look at are:

1) Freeze protection: ensure the glycol has adequate freeze protection

for the lowest anticipated ambient temperature for your installation

region.

Page 62

Page 62

2) PH: a pH higher than 11.5 can start to corrode internals in the CWT

system. Any pH higher than 11.5 constitutes a glycol change-out.

PN :: HEA -EVA P-MA NUAL-016 | 20170316

7.14 The gas bundle removal

When required by local jurisdictions and codes, the high-pressure coil should

be removed and inspected (this period might also vary depending on company

policy). Prior to removing the coil, contact Tecvalco for a replacement gasket and

recommended bolt torque values.

1. Ensure the heater is off and cooled. Pilot extinguished, Robertshaw

gas valve to off and main gas valve shut and locked out.

2. Carefully remove the insulation around the coil flange.

3. Ensure that no pressure exists in the unit.