Page 1

V-TWIN

TECUMSEH

ENGINE

Small Engine Parts

Page 2

TABLE OF CONTENTS

CHAPTER 1. GENERAL INFORMATION

CHAPTER 2. AIR CLEANERS

CHAPTER 3. CARBURETORS AND FUEL SYSTEMS

CHAPTER 4. GOVERNORS AND LINKAGE

CHAPTER 5. ELECTRICAL SYSTEMS

CHAPTER 6. IGNITION

CHAPTER 7. INTERNAL ENGINE AND DISASSEMBLY

CHAPTER 8. ENGINE ASSEMBLY

CHAPTER 9. TROUBLESHOOTING AND TESTING

CHAPTER 10. ENGINE SPECIFICATIONS

All rights reserved. No part of this book may be reproduced or transmitted, in any form or by any

means, electronic or mechanical, including photocopying, recording or by any information storage and

retrieval system, without permission in writing from Tecumseh Products Company Training Department

Manager.

Copyright © 2000 by Tecumseh Products Company

i

Page 3

TABLE OF CONTENTS

GENERAL INFORMATION

Engine Identification ................................................................................................1-1

Interpretation of Engine Identification ......................................................................1-1

Short Blocks ............................................................................................................1-2

Fuels........................................................................................................................1-2

Engine Oil ................................................................................................................1-3

Basic Tune-Up Procedure .......................................................................................1-4

Storage....................................................................................................................1-4

AIR CLEANERS

General Information.................................................................................................2-1

Operation.................................................................................................................2-1

Components ............................................................................................................2-1

Troubleshooting and Testing....................................................................................2-1

Service.....................................................................................................................2-2

(by subject)

Page

CARBURETORS AND FUEL SYSTEMS

General Information.................................................................................................3-1

Float Style Carburetors............................................................................................3-1

Operational Circuits Series 7 Carburetor.................................................................3-1

Testing .....................................................................................................................3-3

Carburetor Disassembly Procedure ........................................................................3-5

Inspection ................................................................................................................3-7

Carburetor Re-Assembly .........................................................................................3-7

Throttle Shaft and Plate...................................................................................3-7

Choke Shaft and Plate.....................................................................................3-8

Fuel Bowl Assembly ........................................................................................3-8

Impulse Fuel Pumps................................................................................................3-9

Impulse Fuel Pump Service...........................................................................3-10

GOVERNORS AND LINKAGE

General Information.................................................................................................4-1

Operation.................................................................................................................4-1

Troubleshooting.......................................................................................................4-1

Engine Speed Adjustments .....................................................................................4-1

Engine Overspeed...........................................................................................4-2

Engine Surging ................................................................................................4-2

Governor Service

Static Adjustment - Governor ..........................................................................4-2

Governor Gear and Shaft Service ...................................................................4-3

Governor Shaft Replacement ..........................................................................4-3

ii

Page 4

TABLE OF CONTENTS (continued)

Speed Controls and Linkage ...................................................................................4-3

Synchronizing the Carburetors ................................................................................4-4

Choke Synchronization............................................................................................4-5

ELECTRICAL SYSTEMS

General Information.................................................................................................5-1

Operation.................................................................................................................5-1

Converting Alternating Current to Direct Current.....................................................5-2

Components

Battery ............................................................................................................5-2

Wiring..............................................................................................................5-2

Condition.........................................................................................................5-2

Wire Gauge.....................................................................................................5-2

Electrical Terms .......................................................................................................5-3

Basic Checks...........................................................................................................5-3

Charging Circuit.......................................................................................................5-4

3 Amp D.C. 5 Amp A.C. Alternator .........................................................................5-4

Diode Replacement ........................................................................................5-4

Checking the System......................................................................................5-5

16 Amp Alternator System with External Regulator.................................................5-5

Troubleshooting Electrical Charging Circuit Flow Chart ..........................................5-6

Voltage Regulators ..................................................................................................5-7

Fuel Shut-Down Solenoids ......................................................................................5-7

Low Oil Pressure Sensor Testing.............................................................................5-7

Starting Circuit .........................................................................................................5-8

Testing Procedure Starting Circuit ..................................................................5-8

Troubleshooting Electrical Starter Circuit Flow Chart .....................................5-9

Electric Starter Service ..........................................................................................5-10

12 Volt Electric Starter ..................................................................................5-10

Inspection and Repair...................................................................................5-11

Brush Holder.................................................................................................5-12

Brush Replacement ......................................................................................5-12

Page

IGNITION

General Information.................................................................................................6-1

Operation

Solid State Ignition System (CDI) ............................................................................6-1

Components ....................................................................................................6-1

Testing Procedure............................................................................................6-2

Service

Spark Plug Service ..........................................................................................6-3

Conditions Causing Frequent Spark Plug Fouling...........................................6-3

Ignition Timing .........................................................................................................6-3

Service Tips.............................................................................................................6-4

iii

Page 5

TABLE OF CONTENTS (continued)

INTERNAL ENGINE AND DISASSEMBLY

General Information.................................................................................................7-1

Lubrication Systems ................................................................................................7-1

Disassembly Procedure...........................................................................................7-1

Disassembly of Cylinder Heads...............................................................................7-4

Valves ..............................................................................................................7-5

Valve Guides ...................................................................................................7-5

Valve Springs...................................................................................................7-6

Push Rods .......................................................................................................7-6

Valve Seats......................................................................................................7-6

Internal Engine Component Inspection

Cylinders..........................................................................................................7-7

Pistons.............................................................................................................7-8

Rings ...............................................................................................................7-9

Connecting Rods ...........................................................................................7-10

Crankshafts and Camshafts ..........................................................................7-11

Mechanical Compression Release ................................................................7-12

Valve Lifters ...................................................................................................7-13

Crankcase Breather.......................................................................................7-13

Cylinder Cover...............................................................................................7-13

Page

ENGINE ASSEMBLY

Engine Assembly.....................................................................................................8-1

TROUBLESHOOTING AND TESTING

Engine Knocks.........................................................................................................9-1

Engine Overheats....................................................................................................9-1

Surges or Runs Unevenly........................................................................................9-1

Engine Misfires ........................................................................................................9-1

Engine Vibrates Excessively....................................................................................9-2

Breather Passing Oil................................................................................................9-2

Excessive Oil Consumption.....................................................................................9-2

Lack Power..............................................................................................................9-2

ENGINE SPECIFICATIONS

TVT691 Engine Specifications...............................................................................10-1

Torque Specifications ............................................................................................10-3

Service Tool List ....................................................................................................10-4

iv

Page 6

CHAPTER 1. GENERAL INFORMATION

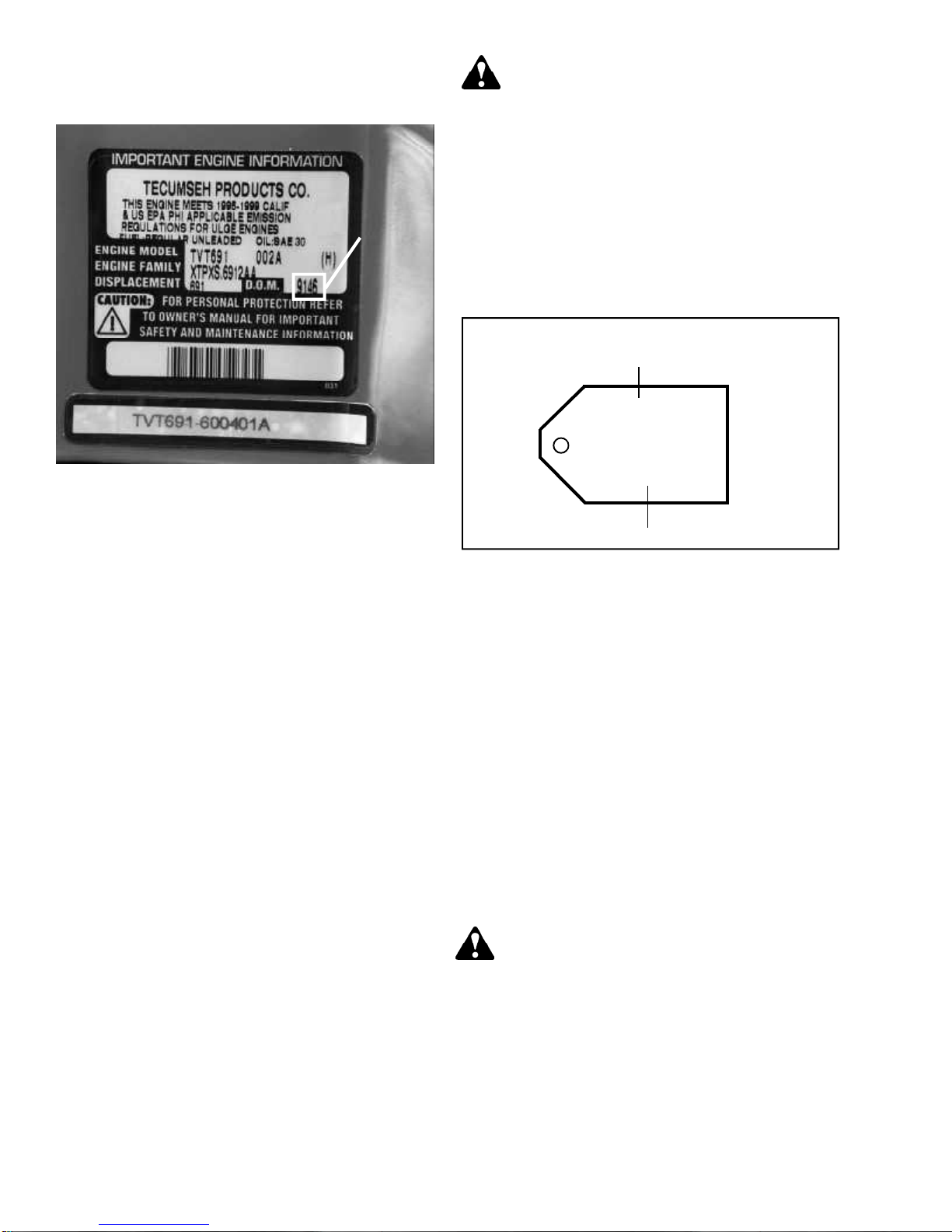

ENGINE IDENTIFICATION

Tecumseh engine model, specification, and date of

manufacture (D.O.M.) are located on decals attached to

the blower housing of the engine. The engine

identification decal also provides the applicable warranty

code, oil and fuel recommendations, EPA (Environmental

Protection Agency) and C.A.R.B. (California Air Resource

Board) Emission Compliance Information. (Illust. 1-1)

The group of numbers following the model number is

the specification number. The last three numbers

indicate a variation to the basic engine specification.

(Illust. 1-3)

SPECIFICATION

NUMBER

1-3

1-1

INTERPRETATION OF ENGINE

IDENTIFICATION

The letter designations (TVT) in a model number

indicate the basic type of engine.

The number designations following the letters (691)

indicate the basic engine model displacement in CC’s

(cubic centimeters). (Illust. 1-2)

ENGINE

MODEL

NUMBER

The letter in parenthesis on the engine information decal

is the warranty code identification number. This letter

designates the length of time the engine is under

warranty. A cross-reference may be found in the service

warranty policy of the master repair manual or the engine

operator’s manual. (Illust. 1-4)

WARRANTY

IDENTIFICATION

NUMBER

1-4

1-2

1-1

Page 7

The D.O.M. (date of manufacture) indicates the

production date of the engine by year and numerical day.

(Illust. 1-5)

DATE OF

MANUFACTURE

(D.O.M.)

1-5

This symbol points out important safety

INSTRUCTIONS, WHICH IF NOT FOLLOWED,

could endanger the personal safety of YOU and

others. Follow all instructions.

SHORT BLOCKS

New short blocks are identified by a tag marked S.B.V.

(Short Block Vertical) located on the engine block. When

a short block repair is made, it is vital both the original

engine and short block numbers are present on the

repaired product for correct future parts identification.

(Illust. 1-6)

SBV OR SBH IDENTIFICATION NUMBER

SHORT BLOCK IDENTIFICATION TAG

SBV- 564A

SER 5107

Using model TVT691-600401A D.O.M. 9146 as an

example, the interpretation is as follows:

TVT691- Is the model number.

60041A Represents the specification number used for

properly identifying the parts of the engine.

TVT Tecumseh Vertical Twin.

691 Indicates the displacement in cubic

centimeters.

9146 Is the D.O.M. (Date of Manufacture) formerly

serial number.

9 Is the last digit in the year of manufacture

(1999).

146 Indicates the calendar day of that year (146th

day or May 26th of 1999).

A,B,C A letter following the D.O.M. number

represents the line, shift and plant in which

the engine was built.

Emissionized engines that meet the California Air

Resource Board (C.A.R.B.) or the Environmental

Protection Agency (EPA) standards will include additional

required engine information on the engine decal.

NOTE: To maintain the best possible emission

performance, use only Genuine Tecumseh Parts.

SERIAL NUMBER

1-6

FUELS

Tecumseh Products Company strongly recommends the

use of fresh, clean, unleaded regular gasoline in all

Tecumseh engines. Unleaded gasoline burns cleaner,

extends engine life, and promotes good starting by

reducing the build up of combustion chamber deposits.

Unleaded regular, unleaded premium or reformulated

gasoline containing no more than 10% Ethanol, 15%

MTBE or 15% ETBE may be used.

Leaded fuel is not available in the United States and

should not be used if any of the above options are

available.

Never use gasoline, fuel conditioners, additives or

stabilizers containing methanol, white gas, or fuel blends,

which exceed the limits, specified above for Ethanol,

MTBE, or ETBE because engine/fuel system damage

could result.

CAUTION: THE USE OF SOME ANTI-ICING

ADDITIVES MAY CREATE A METHANOL FUEL

BLEND. DO NOT USE ADDITIVES THAT

CONTAIN METHANOL. FUEL CONDITIONERS

THAT CONTAIN ISOPROPYL ALCOHOL CAN

BE USED IN CORRECT MIXTURE RATIOS.

Regardless of which of the approved fuels are used, fuel

quality is critical to engine performance. Fuel should

not be stored in an engine or container more than 30

days prior to use. Time may be extended with the use of

a fuel stabilizer like TECUMSEH, part number 730245.

See “STORAGE” instructions in this Manual, Operators

Manual, or Bulletin 111.

1-2

Page 8

ENGINE OIL

TECUMSEH FOUR-CYCLE ENGINES REQUIRE THE

USE OF CLEAN, HIGH QUALITY DETERGENT OIL.

Be sure original container is marked: A.P.I. service “SF”

thru “SJ” or “CD”.

TECUMSEH RECOMMENDS USING ONE OF THE

FOLLOWING FOUR CYCLE OILS THAT ARE

SPECIALLY FORMULATED TO TECUMSEH

SPECIFICATIONS.

DO NOT USE SAE 10W40 OIL.

FOR SUMMER (Above 320 F) (0oC) USE SAE 30 OIL.

PART 730225

Use SAE 30 oil in high temperature, high load

applications. Using multigrade oil may increase oil

consumption.

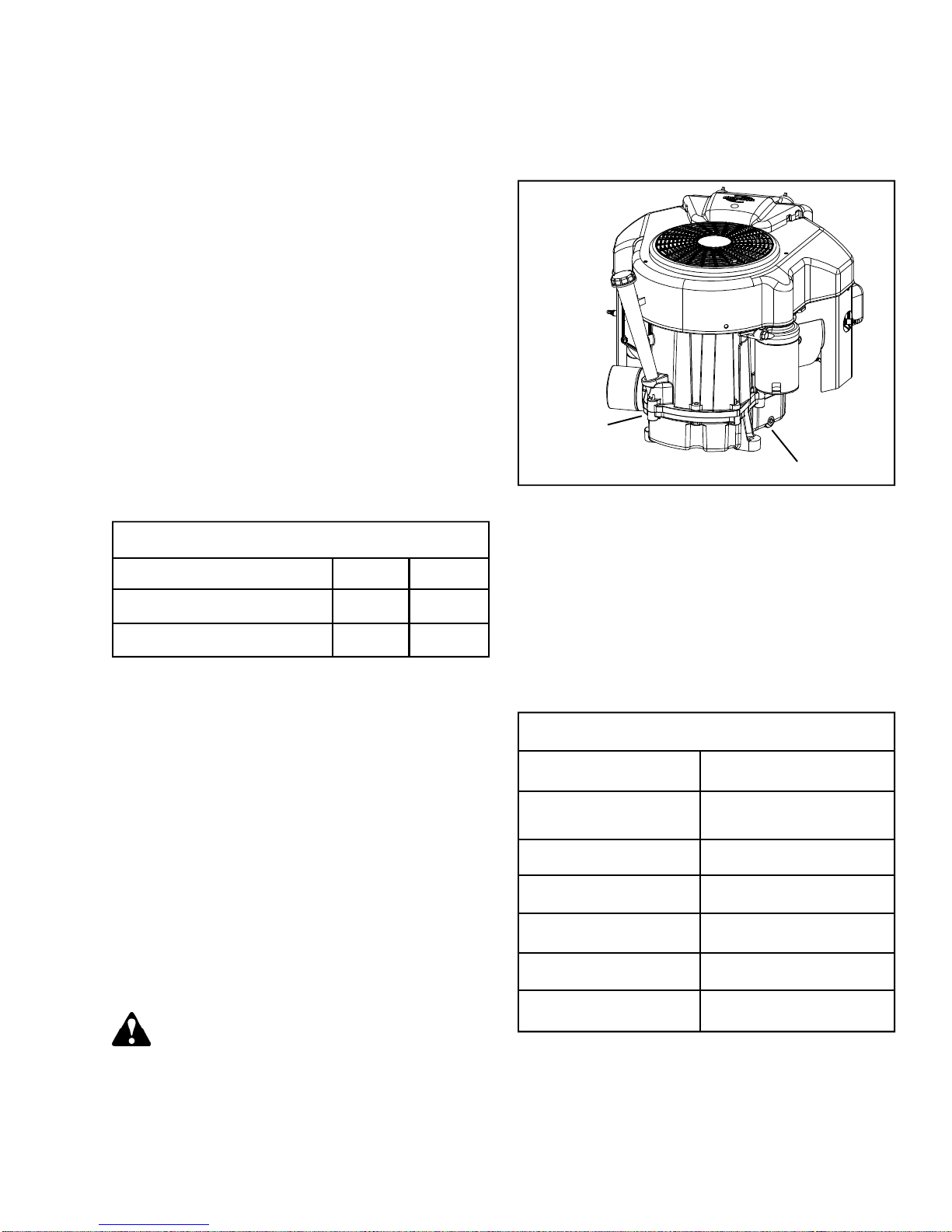

Oil Change Procedure: Locate the oil drain plug in the

mounting flange. The drain plug or cap on most units is

located above the frame in one of the locations shown.

(Illust. 1-7) The oil filter if equipped, can be removed

with a commercially available filter wrench.

FOR WINTER (Below 320F) (0oC) USE SAE 5W30 OIL.

PART 730226

(SAE 10W is an acceptable substitute.)

(BELOW 00F (-18oC) ONLY): SAE 0W30 is an

acceptable substitute.

Oil Capacity

Engine Model oz. ml.

TVT691 with Filter 80 2366

TVT691 Oil Only 72 2129

Change oil and filter after the first two operating hours.

Standard oil change intervals are every 50 hours. Oil

filter changes are recommended every 100 operating

hours.

Oil Change Intervals: Change the oil and filter after

the first 2 hours of operation. Thereafter oil change

intervals are every 50 hours. Oil and oil filter changes

are requested every 100 operating hours. Service should

be performed more often if operated under extremely

dusty or dirty conditions. The oil and filter (if equipped)

should be changed yearly if operated less than 100 hours.

Oil Check: Check the oil each time the equipment is

used or every five-(5) hours of operation. Position the

equipment so the engine is level when checking the oil

level.

CAUTION: A TWIN CYLINDER ENGINE MAY

START AND RUN ON ONLY ONE CYLINDER.

ALWAYS DISCONNECT BOTH SPARK PLUG

WIRES FROM THE SPARK PLUGS AND

GROUND TO THE DEDICATED RETAINING

POSTS LOCATED ON THE VALVE COVER

BOXES BEFORE ATTEMPTING ANY SERVICE

OR MAINTENANCE WORK ON THE ENGINE OR

EQUIPMENT.

ALTERNATE

LOCATION

STANDARD OIL DRAIN PLUG LOCATION

NOTE: An oil change is best performed after the engine

is warm.

Remove the oil plug or cap and allow the oil to drain into

a proper receptacle. Always make sure that drain oil and

filter are disposed of properly. Contact your local

governing authorities to find a waste oil disposal site.

Once the oil is drained, reinstall the drain plug and fill the

engine with new oil to the proper capacity.

1-7

BASIC MAINTENANCE CHART

Pre-filter (Dry Poly) Clean every 25 hours

Air filter (Paper Element) Replace every 100 hours of

operation

Oil change Every 50 hours or annually

Oil filter Every 100 hours or

annually

Spark plug replacement Every 100 hours or

annually

Clean cooling fins Every 200 hours or

annually

Fuel Filter (Replace) Every 100 hours or

annually

1-3

Page 9

BASIC TUNE-UP PROCEDURE:

NOTE: Today’s fuels can cause many problems in an

engines performance due to the fuel quality and short

shelf life (as little as 30 days). Always check fuel as a

primary cause of poor engine performance before

performing any other service.

The following is a minor tune-up procedure. When this

procedure is completed, the engine should operate

properly. Further repairs may be necessary if the engine’s

performance remains poor.

CAUTION: REMOVE THE SPARK PLUG WIRES

AND ATTACH TO THE DEDICA TED RET AINING

POSTS BEFORE DOING ANY SERVICE WORK

ON THE ENGINE.

1. Service or replace the air cleaner. See Chapter 2

under “Service”.

2. Inspect the level and condition of the oil, change or

add oil as required.

3. Remove the blower housing and clean all dirt, grass

or debris from the intake screen, Cylinder head,

cooling fins, carburetor, governor levers and linkage.

4. Check that the fuel filter, fuel tank, and fuel line are

clean. We recommend replacing the fuel filter every

100 hours or annually.

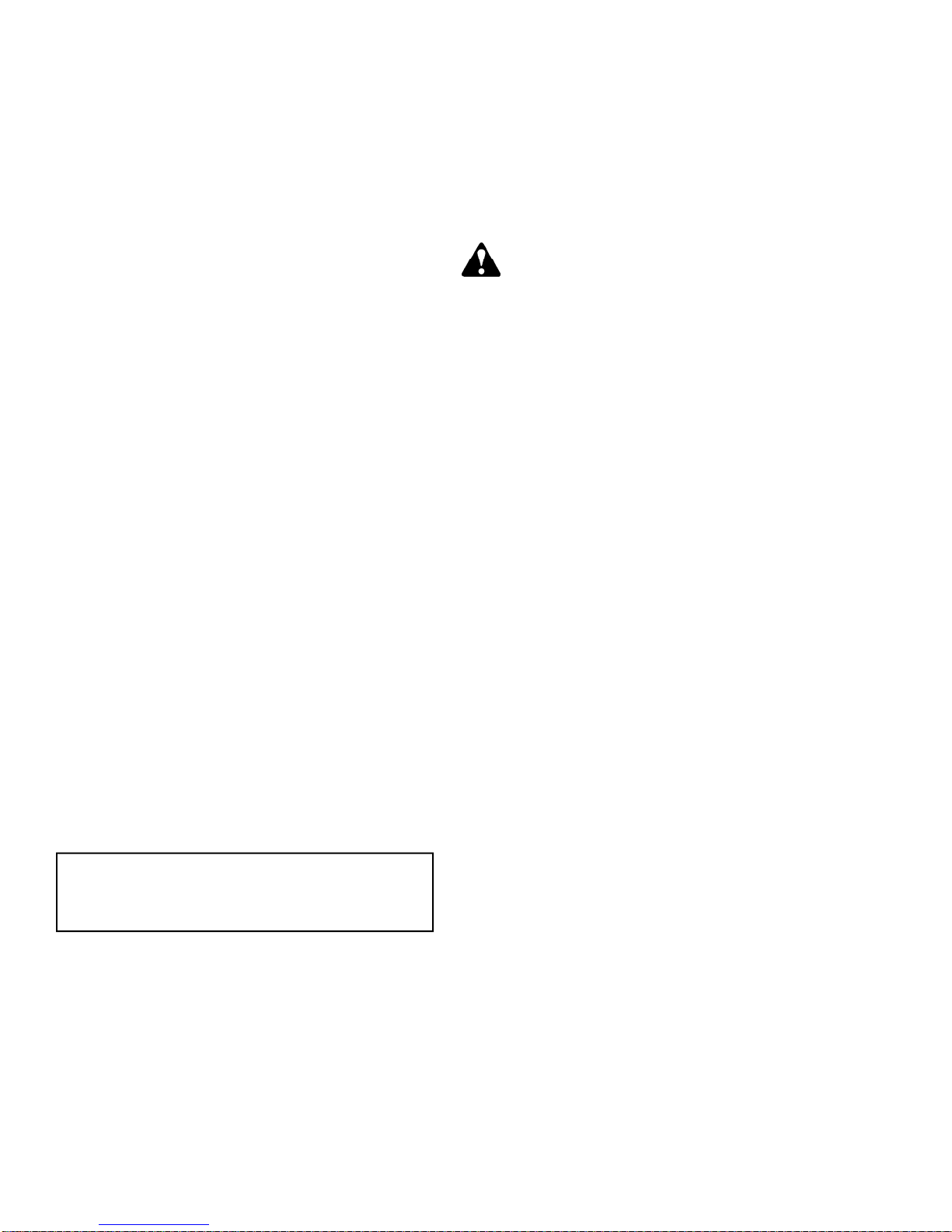

5. Replace the spark plugs every 100 hours or annually,

consult the parts breakdown for the correct spark

plug to be used. Set the spark plug gap (.030") (.762

mm) and install the plug, being careful not to cross

thread. Tighten the spark plug to 21 foot pounds

(28 Nm) of torque. If a torque wrench is not

available, turn the spark plug in as far as possible

by hand, then use a spark plug wrench to turn the

plug 1/2 turn further. If installing a used plug, only

1/8 to 1/4 turn after seat is needed. Note: The correct

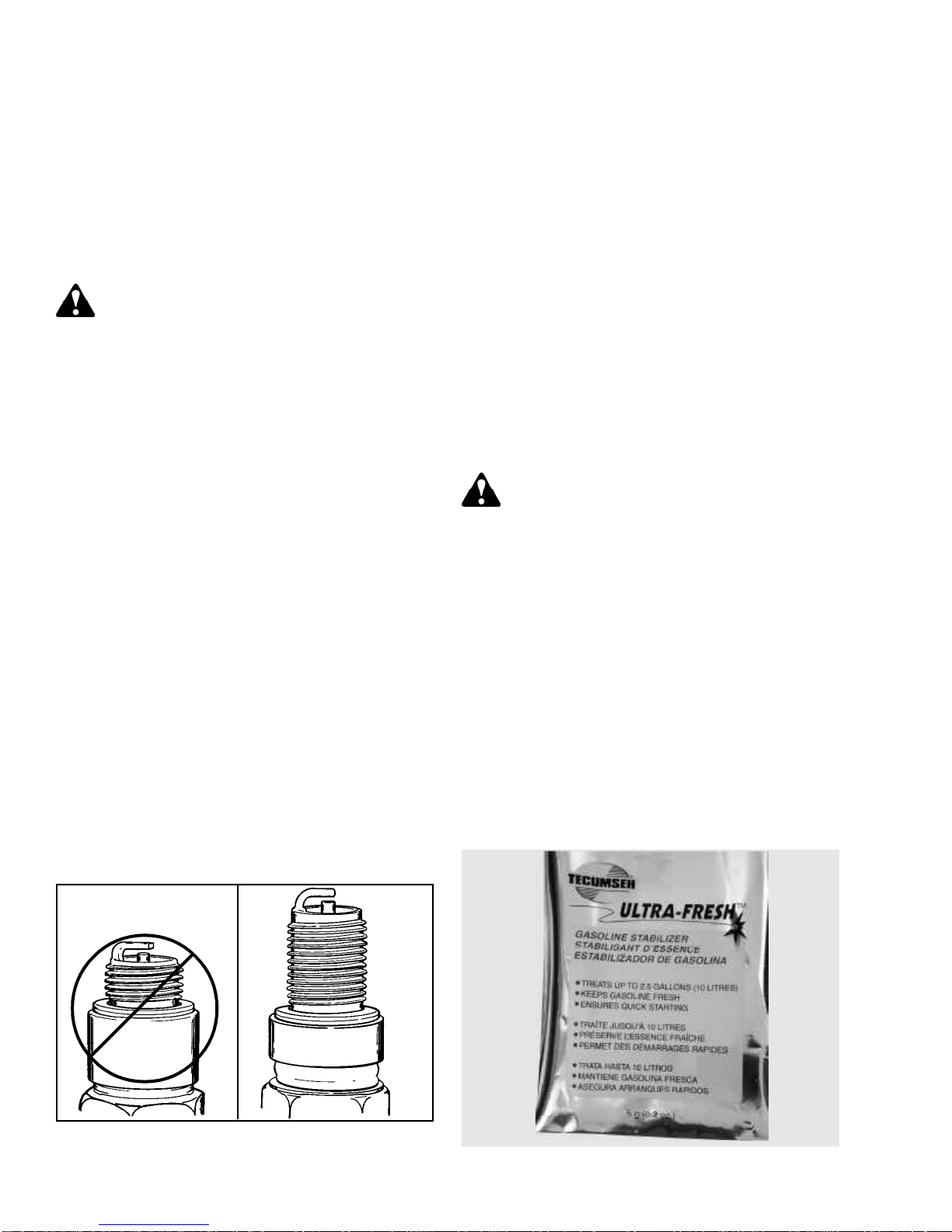

plug reach must be used see (Illust. 1-8).

6. Make sure all ignition wires are free of abrasions or

breaks and are properly routed so they will not rub

on the flywheel.

7. Completely clean the cooling fins, intake screen and

linkages of all dirt and debris. Reinstall the blower

housing, fuel tank, fuel line, and air cleaner assembly

if removed. Be careful not to pinch any of the

wires upon re-assembly.

8. Make sure all remote cables are correctly routed and

adjusted for proper operation. See Chapter 4, under

“Speed Controls and Linkage”.

9. Reinstall the spark plug wires, add fuel and oil as

necessary, start the engine.

STORAGE

(IF THE ENGINE IS TO BE UNUSED FOR 30 DAYS

OR MORE)

CAUTION: NEVER STORE THE ENGINE WITH

FUEL IN THE TANK INDOORS OR IN

ENCLOSED, POORLY VENTILATED AREAS,

WHERE FUEL FUMES MAY REACH AN OPEN

FLAME, SPARK OR PILOT LIGHT AS ON A

FURNACE, WATER HEATER, CLOTHES

DRYER OR OTHER GAS APPLIANCE.

Gasoline can become stale in less than 30 days and

form deposits that can impede proper fuel flow and engine

operation. To prevent deposits from forming, all gasoline

must be removed from the fuel tank and the carburetor.

An acceptable alternative to removing all gasoline, is by

adding Tecumseh fuel stabilizer, part number 730245,

to the gasoline. Fuel stabilizer is added to the fuel tank

or storage container. Always follow the mix ratio found

on the stabilizer container. Run the engine at least 10

minutes after adding the fuel stabilizer to allow it to

reach the carburetor. (Illust. 1-9)

STANDARD

PLUG

1-4

OHV

1-8

1-9

Page 10

CHAPTER 2. AIR CLEANERS

GENERAL INFORMATION

The air cleaner is the device used to eliminate dust and

dirt from the air supply. Filtered air is necessary to assure

that abrasive particles are removed before entering the

combustion chamber. Dirt allowed into the engine will

quickly wear the internal components and shorten engine

life.

The TVT series engine uses a paper-type air filter system

and also has a dry foam pre-filter.

Extremely dirty conditions require more frequent pre-filter

cleaning or paper element replacement.

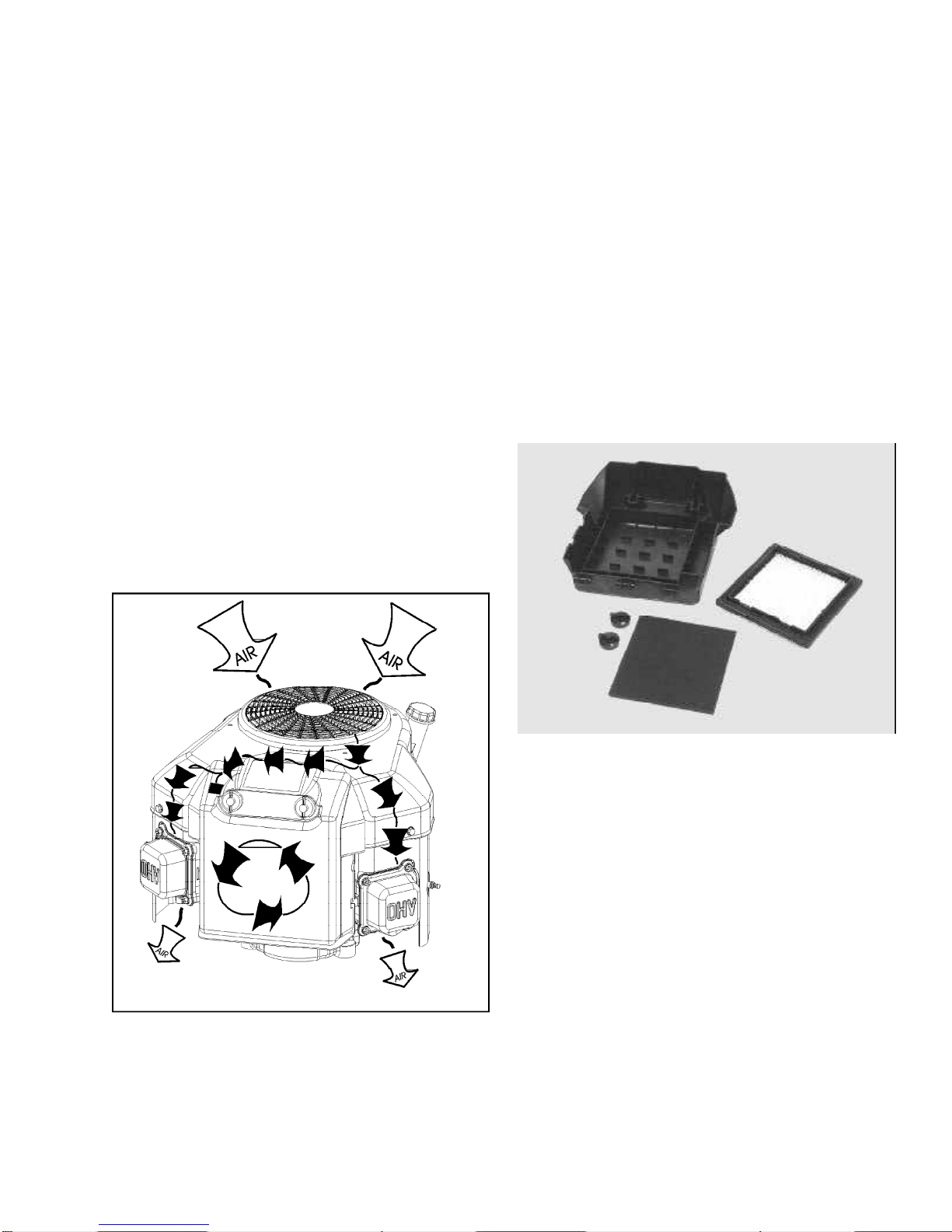

OPERATION

The air filter cover secures and seals the paper filter

element in place. The cover also prevents large particles

from entering the filter body and completes the KleenAire® circuit. The air is first filtered through the flywheel

and blower housing then enters the air filter cover. It

travels through the pre-filter then the paper filter element.

Pre-filters typically extend the paper filter life.

(Illust. 2-1)

COMPONENTS

The cover holds the poly pre-cleaner and clamps the

paper filter in place, creating a dirt tight seal. The cover

also prevents large debris from entering the filter body.

The pre-cleaner is made of a polyurethane foam and

designed to pre-filter the air prior to it passing through

the paper filter. This added stage, assures the operator

of maximum air filtering and extends paper filter life.

The paper filter element is the main filter to stop

impurities from entering the engine. This dry-type element

is pleated paper for increased surface area maximizing

its life. The filter has rubberized edges to assure sealing.

(Illust. 2-2)

2-1

2-2

TROUBLESHOOTING AND TESTING

If the engine’s performance is unsatisfactory (runs

unevenly, starts smoking abnormally or loses power),

the first engine component(s) to be checked are the air

filter(s). A dirt restricted or oil soaked filter will cause

noticeable performance problems. Polyurethane pre-filter

can be cleaned following the service procedure listed

under “Service” in this chapter. A paper-type air filter can

only be replaced NEVER attempt to clean a paper filter.

The paper-type filter must not have any oil film or residue

present. Should the paper have a brown tint it may have

been damaged by an excessively oiled pre-filter or

crankcase breather problems. Follow the procedure listed

in the “Service” section of this chapter for filter

replacement or cleaning.

2-1

Page 11

SERVICE

Cleaning of the polyurethane pre-filter element is

recommended every twenty-five (25) operating hours or

(3) months, whichever comes first. Extremely dirty or

dusty conditions may require daily cleanings.

2. Remove the paper filter. Note: Paper filters must be

replaced NEVER attempt to clean a paper filter.

3. Remove the polyurethane pre-cleaner from the

cover.

NOTE: Do not oil the pre-filter, paper element damage

can occur.

The paper filter element should be replaced once a year

or every 100 operating hours, more often if used in

extremely dusty conditions.

NOTE: Never run the engine without the complete air

cleaner assembly installed on the engine. Always replace

the filter element with a Tecumseh original replacement

part to maintain proper filtration, emissions compliance

and long engine life.

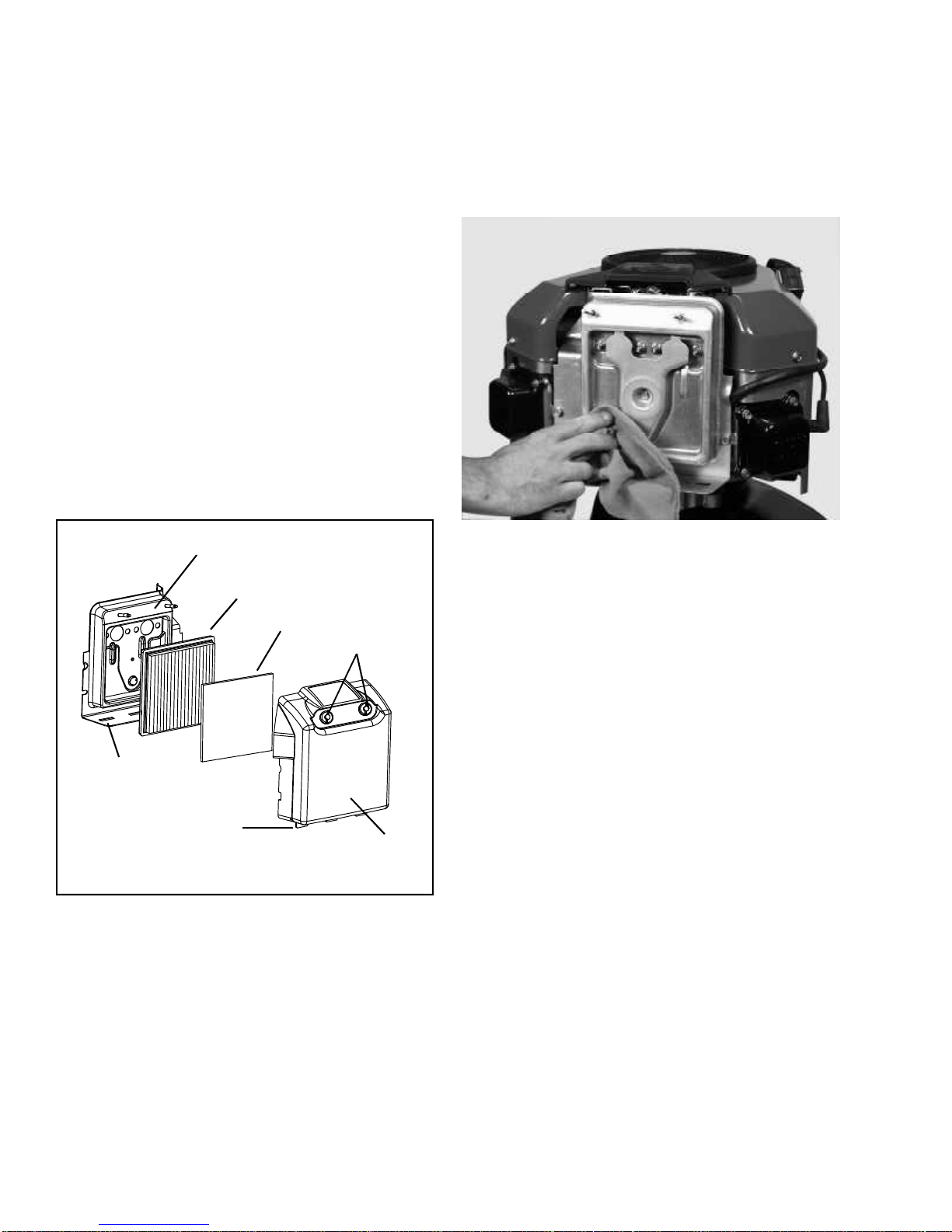

Disassembly Procedure

1. Remove the wing nuts holding the air cleaner cover

in place. Swing the cover out, then lift to remove.

(Illust. 2-3)

BODY

(ATTACHED TO ENGINE)

PAPER FILTER

FOAM PRE-FILTER

WING NUTS (2)

4. Wipe or wash out the air filter cover and base. (Illust.

2-4)

2-4

5. Service the polyurethane pre-filter element by

washing in liquid dish soap and warm water until

clean. Squeeze out the excess water (Never Twist).

Finish drying the element by squeezing it in a dry

cloth or paper towel.

SLOTS

TABS

COVER

2-3

NOTE: DO NOT OIL THE PRE-FILTER IT MUST

BE INSTALLED DRY TO PREVENT SATURATION

OF THE PAPER FILTER ELEMENT.

6. Install the pre-cleaner and new air filter in the cover.

Replace the filter cover and tighten the wing nuts,

be careful not to over-tighten it. Note: The air filter

system on all models can be upgraded to include

the pre-cleaner if the OEM did not originally request

one.

2-2

Page 12

CHAPTER 3. CARBURETORS AND FUEL SYSTEMS

GENERAL INFORMATION

The TVT engine uses two series seven (7) float type

carburetors. This carburetor uses a choke enrichment

system to provide easy cold engine starting. To comply

with emission standards, the carburetor idle and highspeed fuel mixtures are non-adjustable. Carburetor

cleaning and related fuel system service is covered in

this chapter.

FLOAT STYLE CARBURETORS

A float is used to maintain the operating level of fuel in

the carburetor bowl. As the engine consumes fuel, the

fuel level in the carburetor bowl drops and the float moves

downward. This allows the inlet needle valve to move off

the sealing seat, and fuel to enter the carburetor float

bowl. As the fuel level in the bowl rises, it elevates the

float. This upward float motion moves the inlet needle

valve to the closed position. When the needle contacts

the seat, the fuel flow is stopped. The tapered end of the

inlet needle varies the fuel flow rate keeping the supply

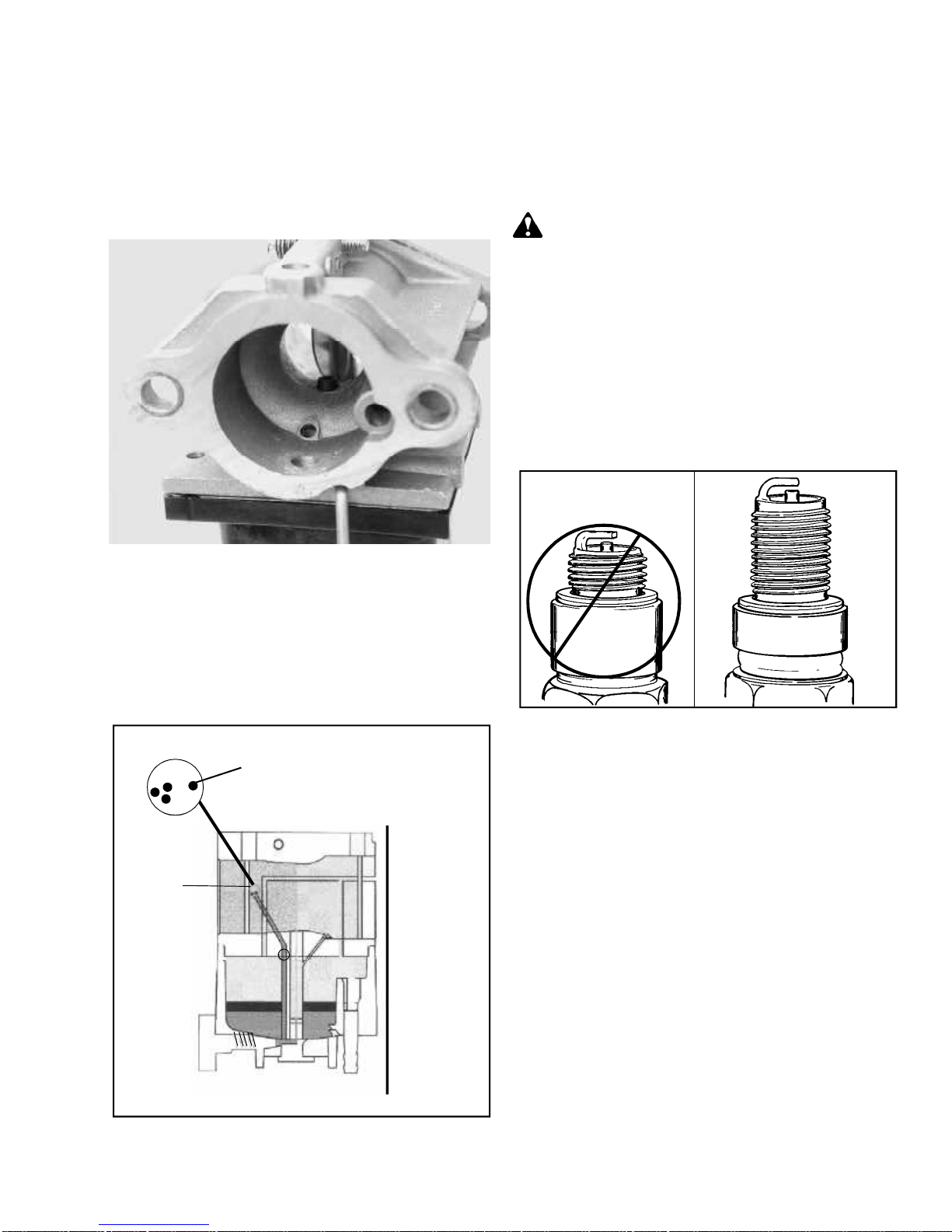

constant. (Illust. 3-1) The float height on the series 7

carburetor is fixed and may not be adjusted.

OPERATIONAL CIRCUITS SERIES 7

CARBURETOR

SERIES 7

IDLE

PRIMARY

IDLE MIXING

WELL

IDLE

RESTRICTOR

IDLE/TRANSFER

FUEL

PASSAGE

IDLE PROGRESSION HOLES

IDLE

AIR BLEED

SPRING

MAIN JET

ATMOSPHERIC

VENT PASSAGES

MAIN NOZZLE

AIR BLEED

3-2

INLET

NEEDLE

3-1

NOTE: Gravity fed systems must have the bottom of

the fuel tank no lower than the fuel inlet of the carburetor.

When servicing carburetors, use the engine model and

specification number to obtain the correct carburetor part

number or parts. An alternate method is to use the

manufacturing number stamped on the carburetor.

Convert this number to a service part number in Div. 5

carburetor section of the Master Parts Manual. This

method can also be used in microfiche and computer

parts look-up systems.

Choke Circuit: In the “CHOKE”/“START” position, the

choke shutter is closed, and the only air entering the

engine, enters through openings around the shutter. As

the starting device cranks the engine over, the pistons

travel downward on the intake stroke, creating a lowpressure area in the cylinder. High-pressure

(atmospheric) air rushes into the cylinder to fill the lowpressure area created.

Since the choke shutter blocks the majority of the air

passage, a relatively small quantity of air enters the

carburetor. The main nozzle and idle fuel discharge ports

are all supplying fuel at this point. This is due to the

increased low air pressure in the intake system of the

engine. A maximum fuel flow through the carburetor

orifices combined with the reduced quantity of air that

passes through the carburetor, creates a very rich fuel

mixture needed to start a cold engine.

3-1

Page 13

Governed Idle Circuit: The TVT series engine uses a

governed idle system. In the low speed throttle position,

engine speed is being maintained by the governor NOT

the idle speed adjustment screw. The governed idle

system improves throttle response when the engine load

changes. The relatively small amount of fuel/air mixture

is supplied through the primary idle orifice location under

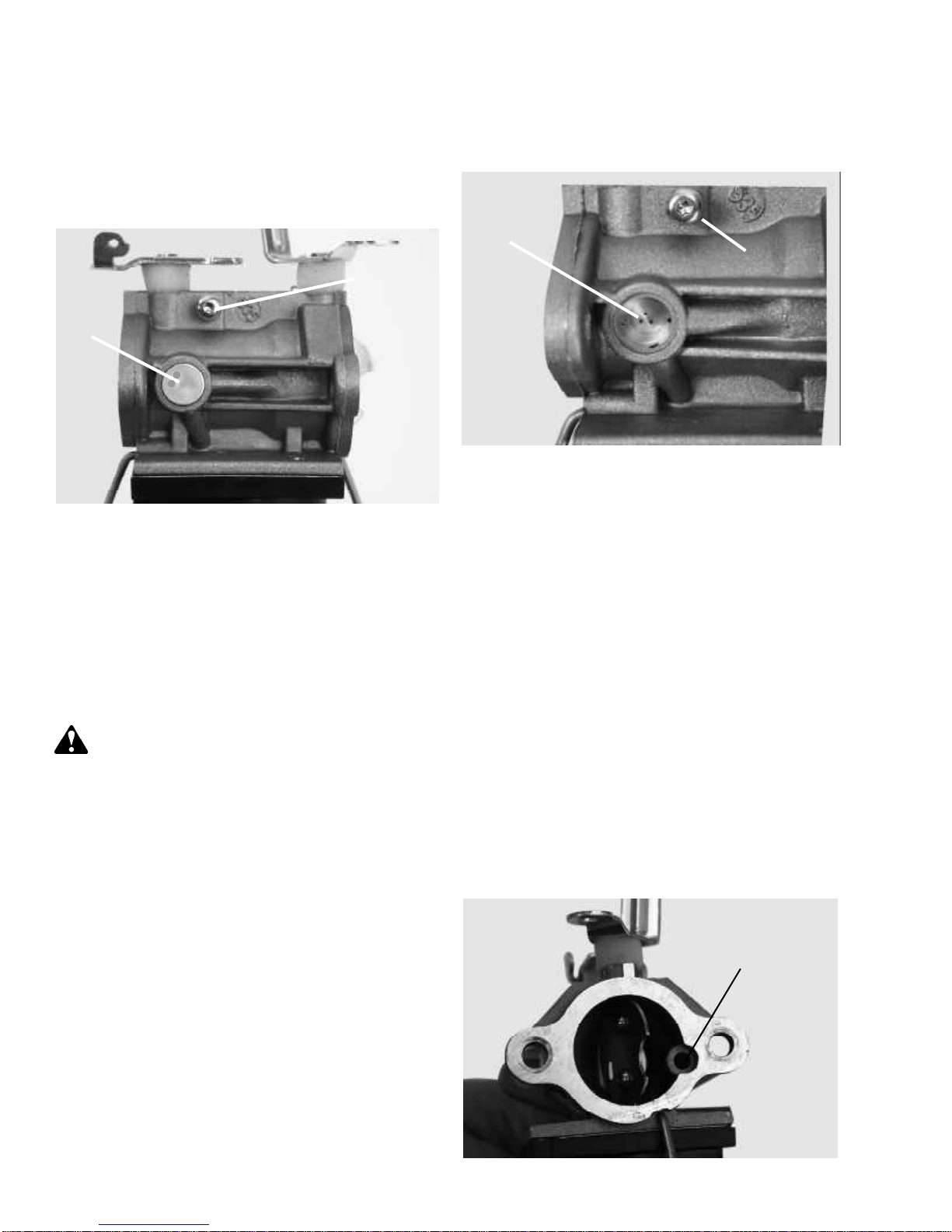

the idle mixing well welch plug. (Illust. 3-3)

IDLE SPEED

ADJUSTMENT

IDLE

MIXING

WELL

SCREW

3-3

True Idle: The idle speed adjustment screw on governed

idle engines perform as a stop to prevent complete

closure of the throttle plate. This partial open throttle

position is required for good starting performance. The

idle adjustment screw is set 600 RPM lower than the

governed idle speed. (Found on microfiche card #30 or

the computer parts look-up systems.) See governed

speed adjustment procedure Chapter 4.

CAUTION: DUAL CARBURETORS MUST BE

PROPERLY SYCRONIZED. DO NOT ADJUST

IDLE SPEED SCREW WITHOUT PROPER

SYNCHRONIZATION.

Transfer/Intermediate Circuit: During Intermediate

engine operation or light loads, additional orifices are

uncovered in the idle mixing well, as the throttle shutter

opens. The fuel being released from these jets is already

pre-mixed (atomized) with air prior to entering the air

stream in the venturi of the carburetor. When the fuel

enters the air stream it further mixes with the air which

maximizes combustibility.

Idle Mixing Well: The idle mixing well of the carburetor

contains a series of metering holes. These metering holes

are the primary and secondary idle circuit as well as the

idle air bleed hole. Proper servicing of the carburetor

requires removal of the welch plug and cleaning of these

metering holes. (Illust. 3-4)

IDLE

MIXING WELL

IDLE SPEED

ADJUSTMENT

SCREW

3-4

High Speed Circuit: During HIGH-SPEED engine

operation, the throttle shutter is opened beyond the idle/

transfer discharge ports. Air is flowing through the

carburetor(s) at a high rate. The venturi, which decreases

the size of the air passage through the carburetor, causes

the airflow to further accelerate. This rapidly moving air

creates a low-pressure area at the main nozzle (Emulsion

Tube) discharge opening.

Using air that is channeled to the emulsion tube through

the main nozzle air bleed, a mixture of fuel and air is

drawn up the emulsion tube.

The addition of air creates an atomized mixture before

being discharged into the venturi. Fuel flow is created

by the difference in the atmospheric air pressure on the

fuel in the carburetor bowl and the main nozzle opening.

Atmospheric Vent: For the fuel to flow out of the

carburetor, the bowl must be vented to atmospheric

pressure. The internal vent is located at the 4 o’clock

position from the choke end of the carburetor. (Illust.

3-5) This passage should be checked for blockage if

engine performance is in question.

ATMOSPHERIC

VENT

3-2

3-5

Page 14

Main Nozzle Air Bleed: Air is bled into the main nozzle

through the main nozzle air bleed passage located in

the 6 o’clock position of the carburetor’s choke end. (Illust.

3-6) This passage allows air to mix with the fuel traveling

up the main nozzle creating a pre-atomized mixture. The

fuel is then released into the venturi from the nozzle tip.

Atomization occurs as the fuel mixture contacts the fast

moving air stream in the venturi and flows into the intake

of the engine.

TESTING

1. Should repeated efforts to start the engine using the

procedure listed in the operator’s manual fail, check

for spark by removing the high-tension lead. Install

an ignition tester and check for spark. If the spark is

bright blue and consistent, proceed to step 2. If no

or irregular spark see Chapter 6 under “Testing”.

CAUTION: KEEP ALL COMBUSTIVE SOURCES

AWAY. AVOID THE SPRAY FROM THE SPARK

PLUG HOLE WHEN CRANKING THE ENGINE

OVER AND MAKE SURE THE PLUG WIRES ARE

PROPERLY GROUNDED TO THE DEDICATED

RETAINING POSTS.

2. Remove and visually inspect the condition of each

spark plug, a wet condition indicates the presence

of gasoline in the cylinder. Although this indicates

fuel is present the fuel condition regarding its

combustibility should always be checked.

NOTE: Check plug for correct reach. (Illust. 3-8)

3-6

Low Speed Idle Air Bleed: The low speed circuit of the

carburetor has an idle air bleed passage which performs

the same function as the high-speed air bleed. It premixes fuel and air prior to entering the throat of the

carburetor. This passage is located in the idle mixing

well (Illust. 3-7)

LOW SPEED

IDLE AIR BLEED

IDLE MIXING

WELL

PLUG

OHVSTANDARD

3-8

3. If either spark plug is dry, check for restrictions in

the fuel system, which supplies that cylinder. If both

plugs are dry check the fuel supply system and

continue with step #4. If the spark plug is wet,

continue with step # 8.

4. Dry Spark Plug: Begin by checking the fuel cap for

proper atmospheric venting. With the fuel cap in place

and tightened, remove the fuel line prior to the pump

allowing fuel to flow into a proper receptacle. Allow

at least 1 gallon of fuel to flow out, noting the rate of

flow. If it remains consistent the vent is performing

properly. Re-connect the fuel line(s) to the pump.

3-7

NOTE: Today’s fuels can cause many problems in

engine performance due to the fuels quality and short

shelf life. Always check fuel as a primary cause of

engine poor performance.

5. Remove the air filter, visually check the choke

shutter(s) operation for complete closure when the

throttle or independent choke control are in the full

choke position.

3-3

Page 15

6. Fuel Supply If the fuel flow to the carburetors is

adequate and no fuel is evident at either spark plug,

the carburetor bowl(s) will need to be removed for

service. See “Service” in this chapter or consult the

“Carburetor Troubleshooting” chart to diagnose

carburetor symptoms. Improper fuel flow indicates

the fuel, fuel line, filter or tank require cleaning or

replacement.

7. Compression Test Most Tecumseh engines include

a compression relief system. These systems make

publishing compression values impractical. However,

following is a cylinder compression balance test,

which can be preformed to help diagnose a possible

compression concern.

1. Remove air filter cover, air filter and both spark

plugs

2. Ground out the spark plug wires to the engine.

3. Install a compression tester into either of the

spark plug holes of the cylinder head.

8. Wet Plug(s) A wet spark plug indicates fuel is being

supplied by the carburetor. A restricted air filter,

carbon shorted or defective spark plug, excessive

choking or a defective carburetor, may have flooded

the engine. With the spark plug(s) removed and the

plug wire(s) grounded to the dedicated retaining

posts, place a shop towel over the spark plug hole.

Turn the engine over very slowly by hand to remove

excess gasoline from the engine cylinder.

CAUTION: KEEP ALL COMBUSTIVE SOURCES

AWAY. AVOID THE SPRAY FROM THE SPARK

PLUG HOLE WHEN CRANKING THE ENGINE

OVER AND MAKE SURE THE PLUG WIRES

ARE PROPERLY GROUNDED TO THE

DEDICATED RETAINING POST.

9. Replace the air filter if restricted or oil soaked, if the

paper filter has a brown color it may have been

damaged by oil and should be replaced. Replace

the spark plug if questionable then install the spark

plugs and high tension leads. Attempt to start the

engine.

4. Turn engine over until the highest reading is

recorded on the compression tester.

5. Write down the reading, remove the compression

tester install it into the remaining cylinder head

and repeat.

Compare the two readings. The difference between

the two cylinders should not exceed 20%. Example:

Cyl #1 90 PSI, Cyl #2 75 PSI. There is 15-PSI

difference between cylinders. Divide this number (15)

into the highest compression reading (90) giving a

17% difference between cylinders. A difference

above 20% or an extremely low compression reading

(below 50 PSI) will require further leak testing or

cylinder head removal for inspection.

Cylinder #1 Cylinder #2 Difference %

90 psi - 75 psi = 15 psi ÷ 90 = 17%

10. If the engine floods and fails to start, the carburetor(s)

will require service. See the “Carburetor

Troubleshooting” chart for additional causes. If the

carburetor is functioning properly the problem may

be ignition or timing related. Reference

“Troubleshooting” under “Ignition” for further

assistance.

3-4

Page 16

CARBURETOR DISASSEMBLY

PROCEDURE

Before performing any carburetor service check the

throttle/choke control(s) for proper adjustments. Make

sure the unit is reaching full choke shutter position on

both carburetors.

NOTE : The series seven carburetor uses FIXED IDLE

AND MAIN JETS AND SHOULD BE SERVICED ONLY

BY QUALIFIED TECHNICIANS TO PREVENT

DAMAGE. It is a violation of both the U.S. EPA and CARB

regulations to modify the carburetor from the original

factory jetting unless specifically authorized.

CAUTION: DRAIN THE FUEL INTO AN

APPROVED CONTAINER OUTDOORS, AND

AWAY FROM ANY OPEN FLAME OR

COMBUSTION SOURCE. BE SURE THE ENGINE

IS COOL.

1. Remove the fuel line. Use care not to damage the

float bowl or retainer. Disconnect the wires from the

fuel shut-off solenoids. Release the float bowl retainer

bail. The float bowl assembly may now be removed

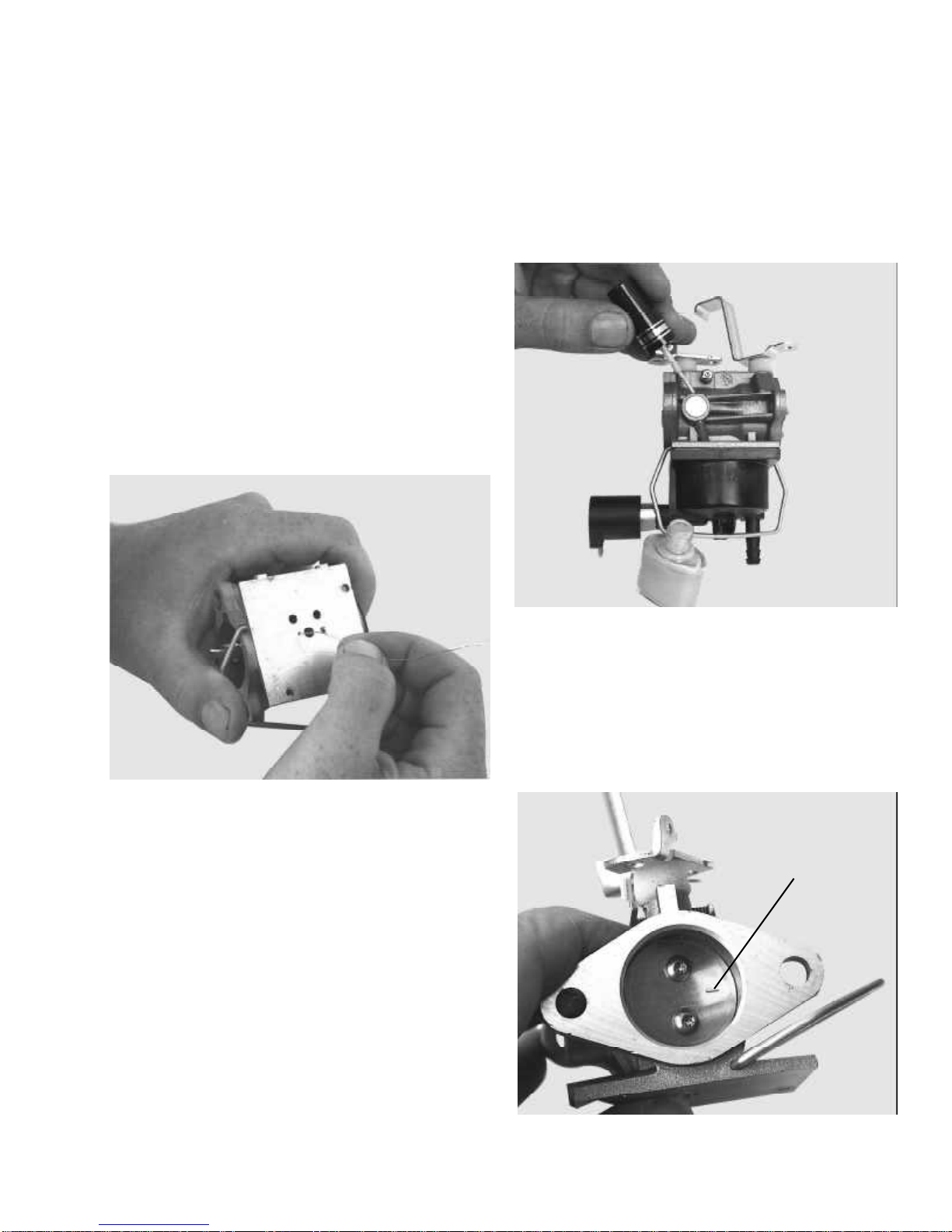

by pulling straight down. (Illust. 3-9)

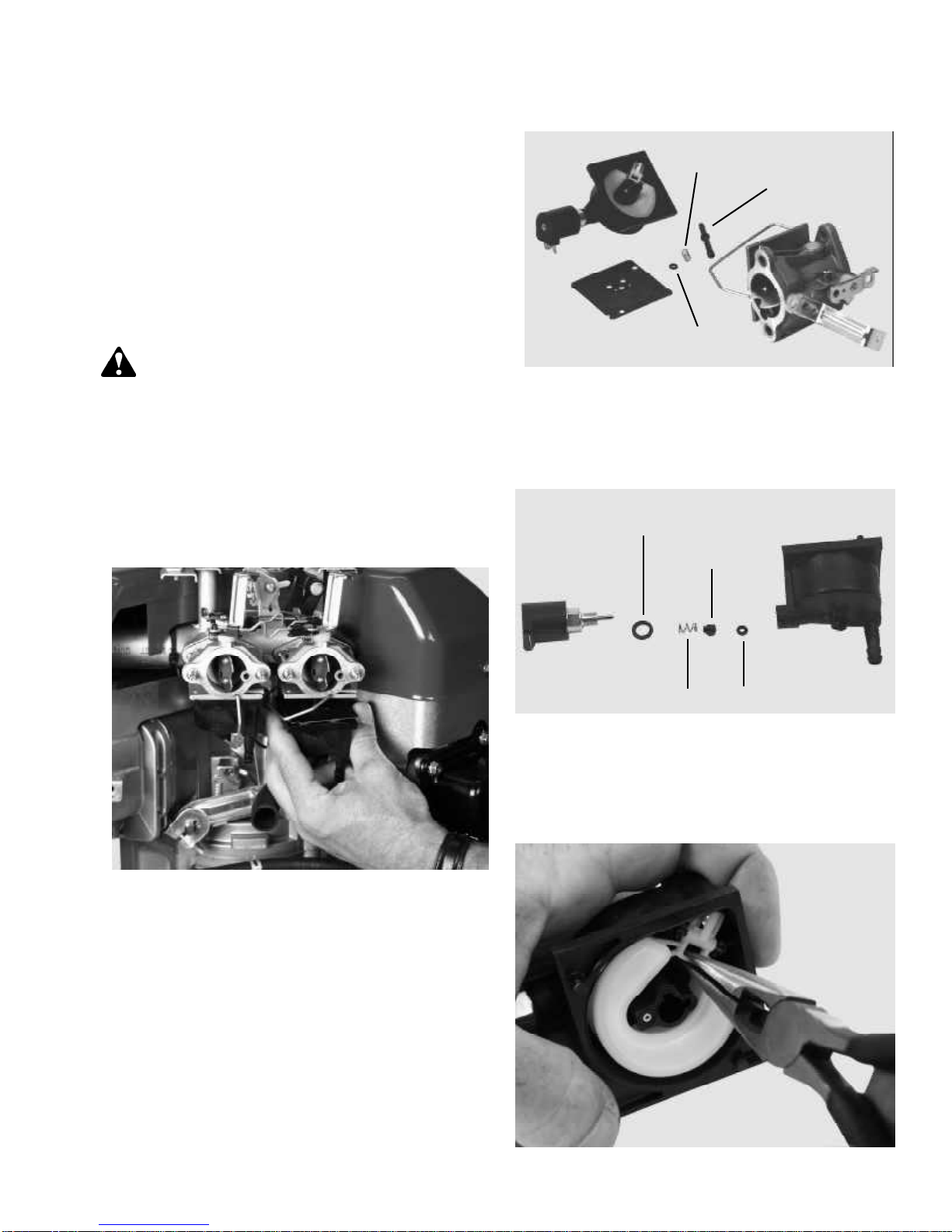

2. Remove the main nozzle (Emulsion) tube, “O” ring,

and spring located in the center leg of the float bowl.

(Illust. 3-10)

SPRING

O-RING

MAIN NOZZLE

(EMULSION TUBE)

3-10

3. Next remove the bowl drain screw or fuel shut off

solenoid and gasket. Remove the spring, metering

jet, and “O” ring. (Illust. 3-11)

SOLENOID

GASKET

METERING

JET

3-9

SPRING

O-RING

3-11

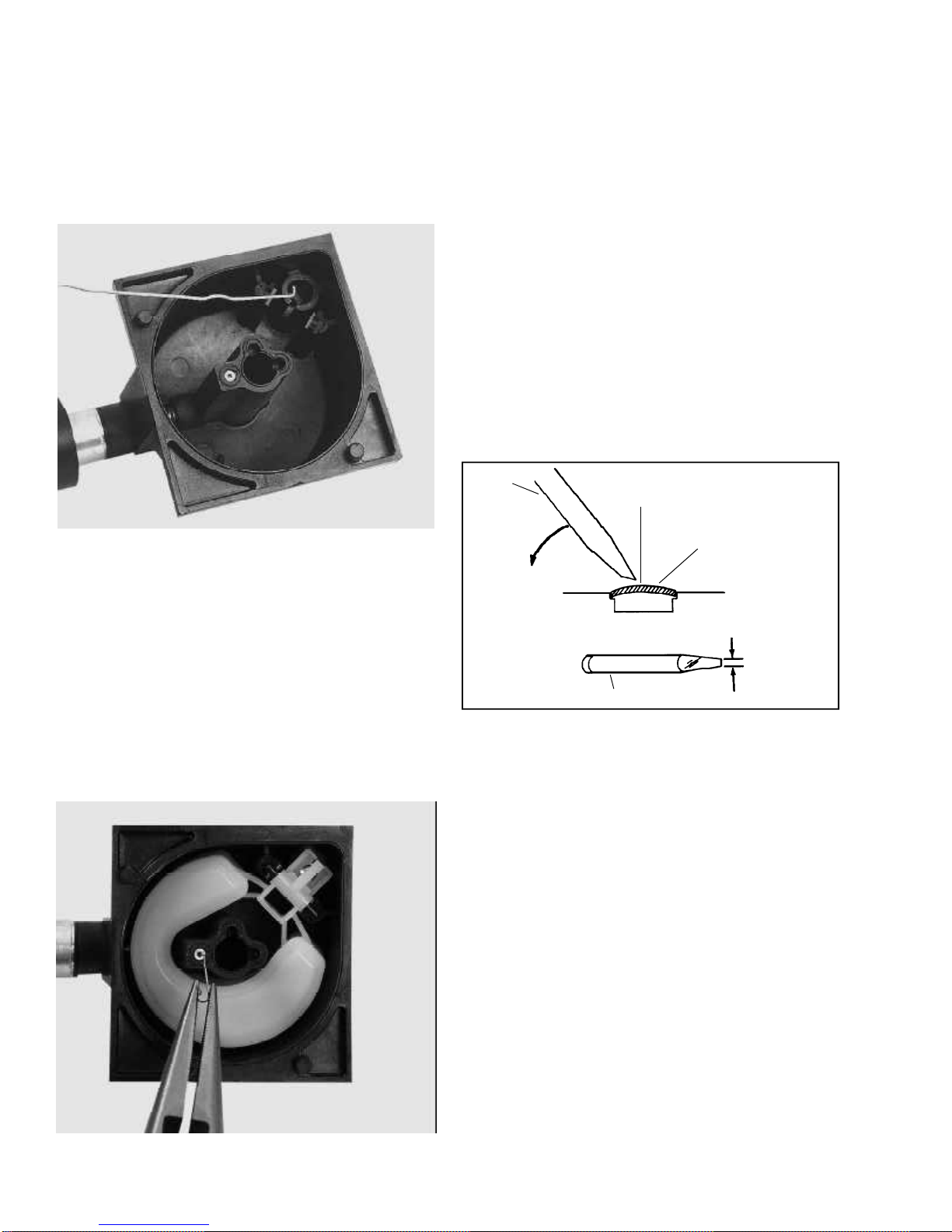

4. Float removal is done by grasping the cross-brace

on the float with needle nose pliers. Then pulling in a

horizontal motion to release the float assembly. (Illust.

3-12) Removal by any other method may cause

damage.

3-12

3-5

Page 17

5. Remove the inlet needle seat using a No. 4 crochet

hook or a paper clip with a 3/32" (2.38 mm) hook

end. Push the hook through the hole in the center of

the seat and pull out to remove it. NOTE: A metal

retaining ring may be present on top of the seat to

aid in its retention, this will come out with the seat. If

a ring is present or comes with the new seat reinstall

it. (Illust. 3-13)

NOTE: Before removing the main carburetor body,

mark or sketch the choke and throttle linkage

connection points. Also MARK THE EDGES OF THE

THROTTLE AND CHOKE SHUTTERS. THE

SHUTTERS HAVE BEVELED EDGES AND MUST

BE INSTALLED IN THE ORIGINAL POSITION.

7. Use a Torx T-10 to remove the choke and throttle

shutters. Remove the throttle shaft, choke shaft and

return springs.

8. Welch plug Removal: Secure the carburetor in a vise

equipped with protective jaws. Use a small chisel

sharpened to a 1/8" (3.175 mm) wide wedge point .

Drive the chisel into the plug to pierce the metal and

push down on the chisel prying the plug out of the

hole. (Illust. 3-15)

NOTE: Be careful not to drive the chisel through the

plug damaging the metering holes underneath.

3-13

6. Idle Restrictor: The idle restrictor is located to the

side of the center leg in the fuel bowl. (Illust. 3-14)

Clean the passage using a piece of wire (maximum

.015, .0006 mm), carburetor spray and compressed

air, verify it is open. If the restrictor remains plugged

it can be serviced by replacement of the float bowl

assembly only.

NOTE: New service fuel bowls come with the

restrictor installed.

SMALL

CHISEL

PRY OUT

PLUG

DO NOT ALLOW

CHISEL POINT

TO STRIKE

CARBURETOR

BODY OR

CHANNEL

REDUCER

PIERCE PLUG

WITH TIP

SMALL CHISEL

WELCH PLUG TO

BE REMOVED

ABOUT 1/8”

(3.175 mm)

WIDE

3-15

3-6

3-14

Page 18

INSPECTION

After careful disassembly of the carburetor, clean the

carburetor body and float bowl with solvent, or spray

carburetor cleaner. Wearing eye protection, use

compressed air and soft tag wire to clean internal

carburetor passages. (Illust. 3-16) Examine the float for

cracks or leaks. Check the float hinge bearing surfaces

for wear, as well as the tab that contacts the inlet needle.

Examine the throttle, choke shaft, and carburetor body

at the bearing points and holes into which the linkage is

fastened. If dust seals are present, check the seal

condition and for correct placement next to the carburetor

body. If the condition of any of these parts is worn or

questionable replace them. The float can be checked

for leakage by submersion in a clear jar filled with hot

water. If any air bubbles are noted the float must be

replaced.

NOTE: DO NOT INTERCHANGE MAIN NOZZLES OR

METERING JETS FROM OTHER CARBURETORS.

CARBURETOR RE-ASSEMBLY

WELCH PLUGS

To install a new welch plug, secure the carburetor in a

vise equipped with protective jaws. Place the welch plug

into the mixing well pocket with the raised portion up.

With a punch equal to the size of the plug-hole, flatten

the plug. Do not dent or drive the center of the plug below

the top surface of the carburetor. After installation of the

welch plug, seal the outer diameter with fingernail polish.

(Illust. 3-17)

3-16

3-17

THROTTLE SHAFT AND PLATE

When reassembling the throttle plate on a series 7

carburetor, it is important that the marking on the plate

be in the 3 o’clock position facing out with the throttle

plate closed. (Illust. 3-18)

3 O’CLOCK

POSITION

3-18

3-7

Page 19

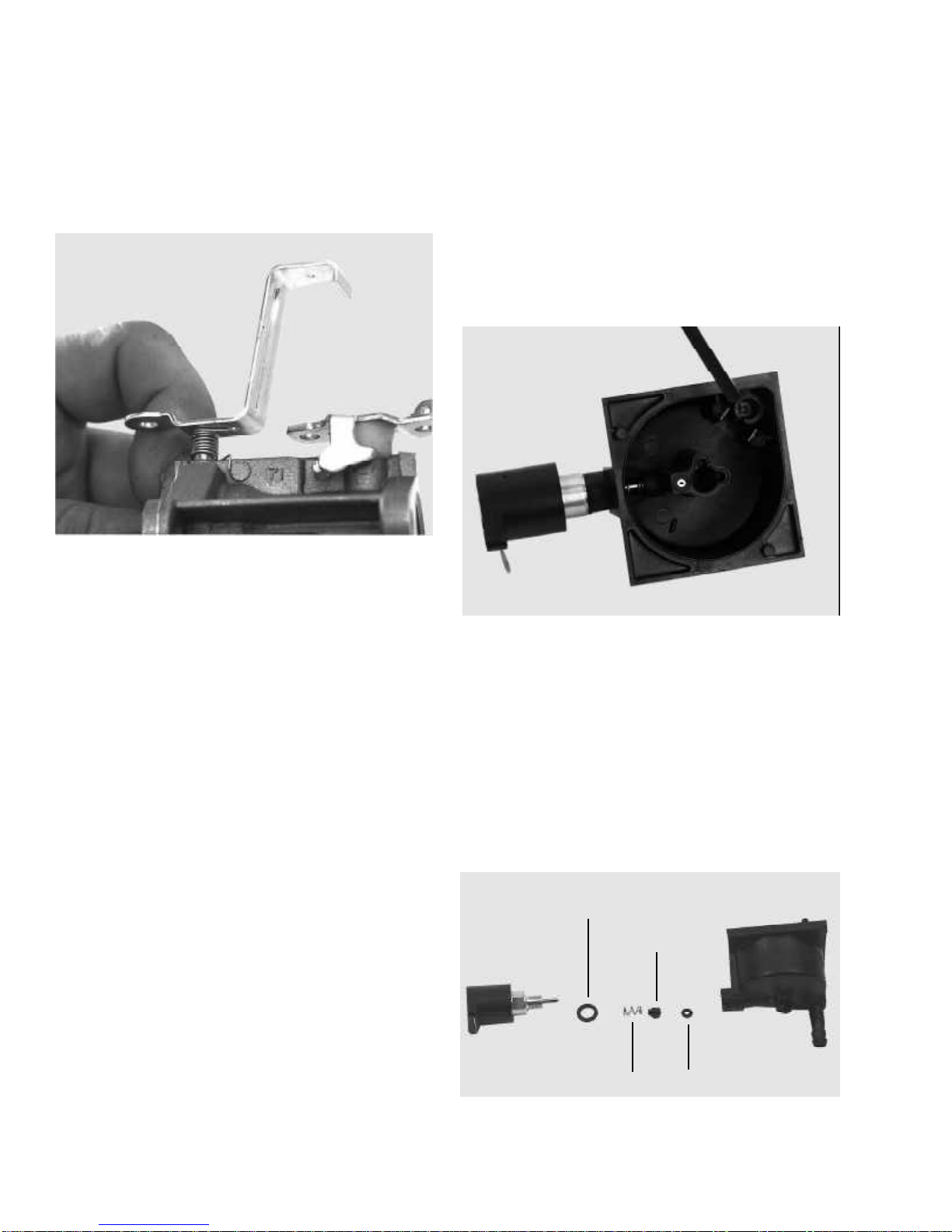

CHOKE SHAFT AND PLATE

Install the choke return spring on the choke shaft with

the squared end up and hooked into the notch on the

arm. Work the dust shield up around the spring and insert

the choke shaft into the carburetor body. Rotate the shaft

counterclockwise until the tang on the spring rests against

the left side center boss on the carburetor body. (Illust.

3-19)

FUEL BOWL ASSEMBLY

Inlet Needle & Seat

When servicing the fuel bowl assembly, a new needle

and seat should always be installed to reduce the

possibility of leakage.

Make sure the seat cavity is clean. Moisten the seat

with oil and insert the seat with the grooved side down

and away from the inlet needle. Press the seat into the

cavity using a 5/32” (3.969 mm) an Allen wrench or a

flat punch, making sure it is firmly seated. (Illust. 3-20) If

the new needle and seat contains a retainer install it on

top and in contact with the seat.

3-19

Always use new shutter screws part 650506 when

reinstalling a shutter plate. Install the screws so they

are slightly loose. Apply light downward pressure on the

shaft and rotate it clockwise to seat the shutter in the

bore, then tighten the shutter screws. Check for binding

by rotating the shaft. If necessary, adjust the shutter by

loosening and repositioning, then retighten the screws.

3-20

Main Jet Assembly

Install a new O-ring in the main jet cavity (verify the

original o-ring has been removed). Place the spring over

the shoulder of the main jet and insert into the cavity

with the main jet towards the o-ring. Next install a new

fiber gasket on the bowl drain screw or fuel shut-off

solenoid and tighten to 25-30 In. lbs. (2.83 - 3.4 Nm).

(Illust. 3-21)

SOLENOID

GASKET

METERING

JET

3-8

SPRING

O-RING

3-21

Page 20

Main Nozzle (Emulsion Tube)

Place the main nozzle tension spring into the cavity of

the float bowl. Apply a small amount of oil to the o-ring

on the main nozzle and insert it into the float bowl cavity.

Float Installation

Install the float with a new inlet needle and float hinge

pin onto the float bowl assembly. Carefully push the hinge

pin into the retaining post using a small flat blade

screwdriver. Check the float movement for complete

travel.

IMPULSE FUEL PUMPS

11

1

10

4

7

NOTE: EMISSIONIZED ENGINES OPERATED WITHIN

THE UNITED STATES MAY HAVE HIGH ATTITUDE

JETS AVAILABLE, CONSULT SERVICE BULLETIN

110 FOR INFORMATION.

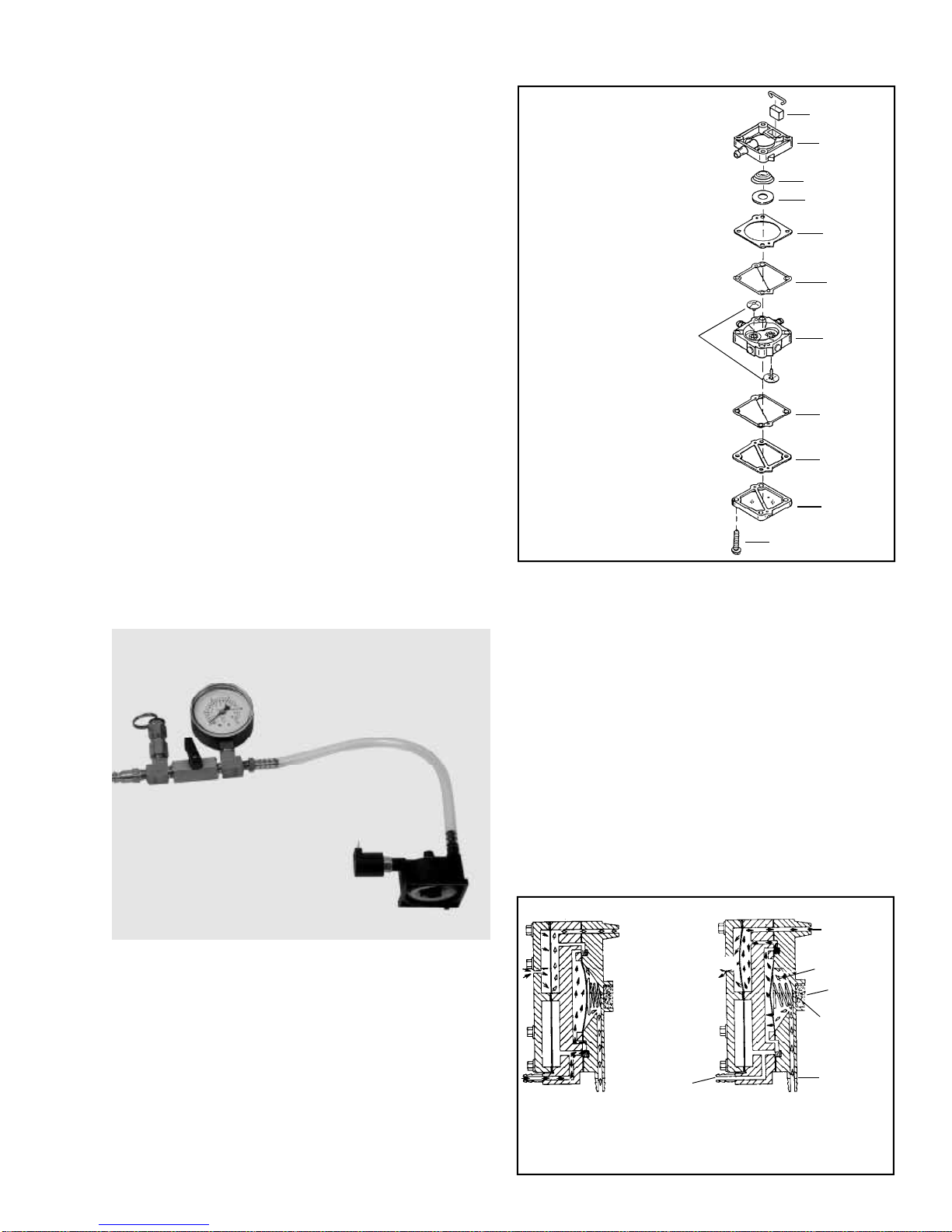

Final Checks

Test the inlet needle and seat sealing using Tecumseh

service kit 670340 or a similar pop-off tester. To test the

pop off pressure remove the float bowl, float and inlet

needle. Place a drop of fuel on the seat and reinstall the

needle and float. Hook up the pressure tester and apply

approximately 6-9 PSI of pressure or until the needle

pops off the seat. Slowly release the pressure to not

less than 1 ½ PSI. The needle should seat between

1 ½ - 6 PSI for a minimum of five minutes. If the minimum

1 ½ PSI cannot be maintained the needle and seat will

need to be serviced. (Illust. 3-22)

11

5

1 - Body, Impulse

2 - Body, Pump

3 - Cover, Pump

4 - Bearing, Spring

5 - *Valve, Check (2)

6 - *Gasket, Pump Cover

7 - *Diaphragm, Pump (2)

9 - Screw, 1-1/4" (4)

10 - *Spring, Pressure

11 - *Filter, Air

9

2

8

6

3

3-23

Impulse fuel pumps are externally mounted in the fuel

circuit between the fuel supply and the carburetor. A fuel

pump must be used if the fuel supply outlet is lower than

the bowl inlet. There MUST be a in-line fuel filter installed

prior to the pump to prevent system damage.

Impulse fuel pumps are operated by positive and

negative pressure pulsation in the crankcase, which are

created by the up, and down movement of the piston. A

hose called a pulse line, connects the fuel pump

diaphragm chamber to the crankcase and transmits the

pulses to the pump diaphragm. These impulses actuate

the diaphragm creating the pumping action to lift the

fuel from the fuel tank to the carburetor(s). (Illust. 3-24)

The pump body contains check valves, which open and

close preventing the fuel from going backwards from

the pump.

Fuel Bowl Retaining Bail

The retainer bail must hold adequate pressure on the

float bowl to prevent air or fuel leakage during operation.

When re-installed, the force should be adequate to

securely clamp the bowl to the body of the carburetor. If

damage occurred upon bowl removal replace the bail.

3-22

VALVE CLOSED

CRANKCASE PRESSURE

ê

ATMOSPHERIC PRESSURE ACTING

á

ON DAMPING DIAPHRAGM

FUEL FLOW

á

ATMOSPHERIC

VENT

FUEL SUPPLY

CRANKCASE SUCTION AND

ê

FLOW DIRECTION

ATMOSPHERIC PRESSURE

ACTING ON DAMPING

á

DIAPHRAGM

CARBURETOR

FITTING

VALVE OPEN

DIAPHRAGM

FILTER

AIR BLEED

VALVE

CLOSED

PULSE LINE

TO CRANKCASE

SUCTION FUEL FLOW

á

DIRECTION

ATMOSPHERIC PRESSURE

ê

CAUSED FUEL FLOW

3-24

3-9

Page 21

Fuel Pump Testing: The maximum lift is 24 inches

(610 mm). A fuel pump may be tested with our leak test

kit part number 670340 or a commercially available low

pressure gauge. Connect the low pressure gauge to the

fuel inlet fitting. Apply no more than 5 PSI (.35 Bar) of

pressure. The air pressure should pass freely through

the pump and out of the fuel outlet fitting. Next, attach

the low pressure gauge to the fuel outlet fitting. Apply

less than 5 PSI (.35 Bar) of pressure. Turn off the air

valve and watch for any pressure drop. The fuel pump

should hold a maximum of 5 PSI (.35 Bar) for one minute.

NOTE: Do not exceed 5 PSI (.35 Bar) of pressure or

fuel pump damage may occur.

CAUTION: DRAIN ALL FUEL INTO AN

APPROVED CONTAINER OUTDOORS, AND

AWAY FROM ANY OPEN FLAME OR

COMBUSTION SOURCE. BE SURE THE

ENGINE IS COOL.

NOTE: A crankcase overfilled with engine oil can affect

pump operation by splashing oil over the pulse line

passage causing erratic pump operation.

IMPULSE FUEL PUMP SER VICE

The valve type impulse pump can be serviced using the

following procedure.

1. Remove the pump from the engine noting its exact

mounting location and position.

4. Clean the body parts with solvent and blow out all

passages using compressed air.

5. After drying all parts, install the new check valves

with the face of the valve facing the raised portion of

the passage. (Illust. 3-26) After installation, cut off

the extended portion of the check valve stems flush

with the pump body.

3-26

6. Install the diaphragms against the center portion of

the body with the gaskets against the outside covers.

The parts can only be assembled one way without

damage.

2. Note or mark the pump body alignment by lightly

scribing lines at various mating joints. Remove the

four screws and disassemble the pump.

(Illust. 3-25)

3-25

3. Remove the gaskets, diaphragms, check valves,

springs and air filter. (If equipped).

7. Install the spring bearing on the new spring and place

into position. (Illust. 3-27)

8. Assemble the body sections, install the retaining

screws, and torque the screws to 12 - 16 inch

pounds (1.36 - 1.81 Nm).

9. Install new filter in pump cavity if present.

3-27

NOTE: Retain the spring bearing. A replacement is

not supplied in the fuel pump kit.

3-10

Page 22

CHAPTER 4. GOVERNORS AND LINKAGE

GENERAL INFORMATION

The TVT engine is equipped with an internal mechanical

governor. The governor’s function is to maintain a R.P.M.

setting when engine loads are added or taken away. This

chapter includes governor assembly linkage illustrations

to aid in governor or speed control assembly.

OPERATION

As the speed of the engine increases, the weights on

the governor gear move outward from centrifugal force

lifting the governor spool. The contact between the spool

and governor rod causes the attached outer governor

lever to push the solid link and close the throttle plate.

When the engine speed decreases, the lower centrifugal

force allows the governor weights to be pulled in by the

governor spring. The governor rod rotates and the solid

link moves the throttle plate to a more open position.

(Illust. 4-1)

ENGINE SPEED ADJUSTMENTS

Before attempting to set the governed high or low RPM

speeds, locate the recommended RPM setting according

to the engine model and specification numbers. These

specifications can be located on microfiche card # 30 or

the computerized parts look-up system.

Start the engine and allow it to warm up to normal

operating temperature (3 - 5 minutes). Set the speed

control to the low speed position. Check the governed

idle speed (not true idle). Adjustment is made by

bending the governor spring bracket upward to increase

the idle RPM or downward to lower idle RPM.

(Illust. 4-2)

GOVERNED IDLE

SPRING BRACKET

THROTTLE

GOVERNOR

SHAFT

WEIGHTS

GOVERNOR

SPOOL

GOVERNOR

SPRING

GOVERNOR

LEVER

GEAR

4-1

TROUBLESHOOTING

Engine overspeed must be corrected immediately, before

serious engine damage occurs. Erratic engine operation

where the governor is suspect, may be the result of other

engine system problems. Hunting (engine R.P.M. surging

up and down) can be an indication of fuel starvation or

an air leak. Low power (engine will not hold RPM under

load) can indicate, fuel, ignition or internal concerns. Use

the following procedure to diagnose a suspected

governor problem.

4-2

Set the speed control to the HIGH or FAST position.

Check engine speed. To adjust, bend the tang on the

control lever upward to increase high speed R.P.M. or

downward to lower high speed R.P.M. (Illust. 4-3)

4-3

4-1

Page 23

ENGINE OVERSPEED

1. If the engine runs wide open (faster than normal),

shut the engine off immediately.

2. Check the condition of the external governor shaft,

linkage, governor spring, and speed control assembly

for breakage or binding. Correct or replace binding

or damaged parts.

3. Follow the governor static adjustment procedure and

reset the governor - see “Service” in this chapter.

4. Start the engine. Be ready to shut the engine off if

an overspeed condition still exists. If the problem

persists, attempt to hold the solid link between the

governor arm and the carburetor throttle plate in one

position. If this controls the condition, the engine will

require disassembly to inspect the governor gear

assembly for damage, binding, or wear. See Chapter

7 under “Disassembly Procedure”.

5. Remove the governor gear assembly. Repair or

replace as necessary.

2. If the engine R.P.M. stabilizes, re-adjust the governor

setting. Check the governor shaft, linkage, bushing

clips and spring for binding, wear, or improper

hookup. Replace as necessary. If none of these

correct the problem it may be necessary to

disassemble the engine for internal governor repair.

3. If the engine R.P.M. does not stabilize, it may require

additional checks of the fuel system, see the fuel

system trouble shooting section.

GOVERNOR SERVICE

STATIC ADJUSTMENT - GOVERNOR

With the engine stopped, loosen the screw holding the

governor lever to the governor shaft. Push the governor

lever up to move the carburetor throttle plate(s) to the

wide-open throttle position. Rotate the governor rod

counterclockwise. Hold the lever and rod in this position

while tightening the screw. (Illust. 4-5)

ENGINE SURGING

1. Try to stabilize engine R.P.M. by holding the solid

link between the bell crank lever and the carburetor

throttle plate in a fixed position using a pliers or

fingers. (Illust. 4-4)

4-4

ROTATE

å

4-5

4-2

Page 24

GOVERNOR GEAR AND SHAFT SERVICE

After the cylinder cover is removed from the engine, the

governor spool, gear, and governor shaft can be

removed. A retaining ring must be removed to allow the

gear to be removed from the shaft. (Illust. 4-6)

4-6

SPEED CONTROLS AND LINKAGE

The TVT series engine offers the adaptability of throttle

cable connection from either side of the engine. Either

cable position must pull against the governor spring force,

to increase the engines speed. NOTE: Both the upper

and lower governor spring connections, they must be

installed correctly to prevent improper operation.

(Illust. 4-7 & 4-8)

GOVERNOR SHAFT REPLACEMENT

1. Remove the spool, retaining ring, gear assembly and

washer(s).

2. Clamp the shaft in a vise and pound gently on the

flange with a wooden or plastic mallet to remove the

shaft.

NOTE: DO NOT TWIST THE SHAFT WHEN

REMOVING. THE SHAFT BOSS MAY BECOME

ENLARGED AND THE PRESS FIT WILL NOT

SECURE THE NEW GOVERNOR SHAFT.

3. Start the new shaft into the flange boss by tapping

with a soft faced hammer.

4. Apply a small amount of red loctite 271 to the lower

governor shaft and using a press or vise push the

governor shaft into the flange leaving an exposed

length of 1.196” (3.969 mm).

4-7

4-8

NOTE: Whenever the carburetor or the governor linkage

is removed or replaced, the engines governed R.P.M.’s

must be checked. Use microfiche card #30 or the

computer parts look-up systems to locate the correct

R.P.M. settings for the engine model and specification

you are repairing.

4-3

Page 25

SYNCHRONIZING THE CARBURETORS

The TVT series uses twin carburetors, which MUST be

synchronized if the linkage or carburetor body has been

disturbed. The following step by step procedures must

be followed to synchronize both the throttle and choke.

Inspect all link connectors. If excessively worn or

damaged replace them. To perform this service the

carburetors must be mounted and all linkage must be

connected.

1. Remove the control assembly cover, air cleaner

cover, air cleaner, carburetor deflector and air cleaner

body from the engine. (Illust. 4-9)

3. Manually rotate the throttle shaft on the number #2

carburetor to the idle position. Next back out the idle

R.P.M. adjustment screw until it no longer contacts

the throttle plate tang. (Illust. 4-11)

4-11

4-9

2. Remove the link connector bushing clip holding the

throttle link to the #1 cylinder carburetor.

(Illust. 4-10)

#2

#1

4. While holding the number #2 carburetor throttle shaft

in the idle position turn in the idle R.P.M. adjustment

screw to 1/4 turn past first contact. NOTE: It is

critical to find first contact of the R.P.M.

adjustment screw to the throttle plate tang.

5. With the bushing clip still detached, back out the

idle R.P.M. adjustment screw on the #1 carburetor.

Hold the throttle plate in the idle position and turn

the idle R.P.M. adjustment screw in until first contact

with the tang is made. (Illust. 4-12)

#1

CARB

4-4

4-10

4-12

Page 26

6. Connect both carburetors by attaching the link and

link connector bushing clip to the # 1 carburetor.

7. Hold the throttle plate on the #2 carburetor in the

true idle position. (Screw against the tang). NOTE:

Do not set the gap using the idle R.P.M. adjustment

screw.Use a .010” (.254 mm) feeler gauge to set

the air gap between the idle R.P.M. adjustment screw

and the throttle plate tang on the #1 carburetor. (Illust.

4-13) The throttle cross link will need to be bent

inward (toward the engine) to increase the air gap or

pulled outward to decrease. (Illust. 4-14)

CHOKE SYNCHRONIZATION

1. Engage the choke control cable of the equipment to

the full choke position.

2. Remove the control assembly cover, air cleaner

cover, air cleaner and air cleaner baffle. (Illust. 4-15)

#2 CYLINDER

#1 CYLINDER

4-15

CROSS LINK

4-13

3. Visually inspect that the choke shutter plate on the #

2 carburetor is completely closed. If the plate is not

completely closing, choke cable adjustment is

necessary.

4. Apply and hold light pressure closing the choke lever

on the #2 carburetor. Attempt to rotate or move the

choke plate on the #1 carburetor. (Illust. 4-16) If

movement can be found or the choke shutter is not

completely closing, the choke cross-link will need to

be adjusted. To adjust, bend the cross-link inward

towards the cylinder block until both choke shutters

completely close at the same time.

4-14

4-16

Re-assemble the components, ensure the cable clamps

are tight. Start the engine and allow it to warm up (3-5

minutes). Set the governed idle and top no-load RPM.

The correct RPM settings can be located on microfiche

card #30 or the computer parts look-up systems. The

use of a vibra-tach Tecumseh part #670156 or a digital

engine tachometer part #670341 will aid in this procedure.

4-5

Page 27

CHAPTER 5. ELECTRICAL SYSTEMS

GENERAL INFORMATION

The electrical system consists of three main elements:

a battery, a starting circuit, and a charging circuit. The

battery is part of both the starting and charging circuit.

Battery voltage should be checked before going into any

extensive starter or charging system checks. If a battery

has a shorted cell, overcharging can result, and the

regulator or rectifier may appear to be at fault. If a cell

has an open or high resistance connection, the electric

starter operation will be affected.

The power source used to provide the energy to turn an

electric starter motor on the TVT series is 12 volt D.C.

The 12-volt battery system requires a charging package

to maintain proper battery charge.

The starting circuit includes the battery, battery cables,

ignition switch, safety switches, starter solenoid, and the

electric starter motor.

The charging system consists of alternator charge coils,

a diode or regulator, ignition switch, flywheel magnets,

and a battery. All engines that have a charging system

will use a combination of some or all of these features.

OPERATION

Although most equipment has an electrical system that

consists of three main elements, (battery, starting circuit,

and charging circuit) they can vary in layout and design

form model to model as well as manufacturer to

manufacturer.

Within each element there are individual components

(battery, wiring, safety switches, ignition switch, solenoid,

etc.) which must be diagnosed separately. The illustration

shown (Illust. 5-1) is a basic diagram which includes some

of the elements used in an electrical system.

REGULATOR

FUSE

GREEN

MAGNETO

GROUND

12 VOLT STARTER MOTOR

SOLENOID

(+)

+

BATTERY

AMMETER

(+)

LIGHT

SWITCH

B

A

R

M

S

SAFETY

SWITCH

REGULATED

D.C. OUTPUT

SAFETY

SWITCH

FUEL SHUT-OFF

SOLENOID

SAFETY

SWITCH

5-1

5-1

Page 28

CONVERTING ALTERNATING CURRENT

TO DIRECT CURRENT

In order to charge a battery, it is necessary to convert

alternating current (A.C.) to direct current (D.C.). This is

accomplished by using a diode or rectifier. (Illust. 5-2) A

single diode makes use of only one half of the A.C. signal.

This is known as HALF WAVE RECTIFICATION. (Illust.

5-3) In certain situations it is necessary to make use of

the entire A.C. signal. To accomplish this, multiple diodes

in a bridge configuration are used to produce FULL WAVE

RECTIFICATION.

HALF WAVE RECTIFIER

(SINGLE DIODE)

ANODE

CATHODE

BAND OR OTHER

MARKING INDICATES

CATHODE END

5-2

+ VOLTAGE

A.C. INPUT

- VOLTAGE

Current flows through a diode when the anode is more

positive than the cathode. The cathode end of the diode

should point toward the battery when a diode is used

between a charging system and a battery.

Half Wave Rectifier Single Diode

The single diode allows only the positive half of the A.C.

signal through. It does not allow the negative portion

through.

Full Wave Rectifier Bridge Rectifier

The full wave rectifier makes use of the entire A.C. signal,

converting it to D.C.

COMPONENTS

BATTERY

The batteries used in conjunction with Tecumseh engines

are 12 volt lead acid or “maintenance free” style. The

chemical energy produced by the dissimilar metals of

the battery plates provides an electrical potential that is

used to power the electric starter or unit accessories.

Consult the original equipment manufacturer’s service

manual for battery size, capacities, and testing

procedure.

+ VOLTAGE

D.C. INPUT

- VOLTAGE

5-3

CONDITION: All wiring must be fully insulated, securely

fastened and free of foreign materials (such as rust and

corrosion) at the connection points. This is especially

important with the use of batteries, as much of the

potential may be lost due to loose connections or

corrosion. Remember to check the insulation on the wire.

All it takes is a pinhole for leakage to “ground out” on the

engine or frame. This is of special concern when moisture

or water is present.

WIRE GAUGE: The proper thickness of wire is

necessary in all electrical circuits. Wire diameter is

measured in increments of gauge numbers. As the gauge

number of the wire increases, the wire diameter

decreases in size. (Illust. 5-4)

THE LARGER THE NUMBER THE SMALLER THE WIRE

# 18

WIRING

The wires used in Tecumseh electrical systems are

copper stranded with an insulated coating around the

copper strands.

5-2

# 6

5-4

Page 29

1. The starter circuit wiring requires a rating of #6 or

lower gauge number.

2. The charging circuit wiring requires a #16 or lower

gauge number. (20 amp systems requires #14 or

lower gauge number).

3. The magneto circuit wiring (ground circuit) requires

#18 or lower gauge number.

INSULATORS - An insulator is a material that will not

allow an electric current to pass through it. Some of the

more common materials that are insulators are glass,

plastic, rubber, ceramics and porcelain.

BASIC CHECKS

Before going into extensive diagnostics, be sure to

perform the more basic checks first, such as:

Tecumseh Products Company’s standard wiring color

codes effective August, 1992 are as follows:

Code Product

Yellow - Alternator A.C. Leads

Red - Alternator D.C. + Leads

Brown - Alternator D.C. - Leads

Black - Alternator Ground Leads, Battery

Ground Leads

Orange - 12 Volt Starter B + Leads

Dark Green - Ignition Shut-Off Leads

NOTE: Prior to August 1992, wire codes changed

according to model and specification numbers.

ELECTRICAL TERMS

1. Battery not fully charged or defective.

2. Terminals or connections that are loose or corroded.

3. Cracked insulation or broken wires grounding out.

4. Improper wire connections.

5. Defective ignition switch.

6. Properly functioning Operator Presence System.

(Safety Interlocks)*

7. Proper valve lash affecting compression relief.

*NOTE: All lawn and garden tractors built after July of

1987 are required to have an operator presence system.

Many came equipped with such a system prior to this

date. If the tractor is “cutting out” or will not start, these

switches are a PRIMARY area to check.

ALTERNATOR - An alternator consists of coils of wire

wound around a metal lamination stack. When a magnet

is moved past the coils, a current is induced in the coils.

In general, the greater the number of coils and magnets

in the flywheel, the greater the output of the alternator.

RECTIFIERS and DIODES - Charging a battery requires

the A.C. (alternating current) produced by the alternator

be changed to D.C. (direct current). This is accomplished

by using a diode or rectifier.

REGULATOR/RECTIFIERS - This combines a regulator

with a rectifier. The regulator controls the amount of

current flowing to the battery based on the electrical

system need. The rectifier changes the alternating current

to direct current.

CONDUCTORS - A conductor is a material that allows

an electric current to pass through it. All metals are

conductors of electricity, but some are better conductors

than others. Silver, copper and gold are some of the

better known conductors.

5-3

Page 30

CHARGING CIRCUIT

The charging system works independently of any manual

controls. The engine needs to be running to produce an

electric current flow. When a conductor (alternating coils)

cuts the magnetic field generated by the magnets in the

flywheel, a current is induced in the alternator coil. The

permanent magnets in the flywheel have a magnetic field

in which the lines of magnetic force run from the North

Pole to the South Pole. As the flywheel rotates and the

position of the magnets change, the direction of the

magnetic field changes or alternates. The alternating coils

are wound in different directions to allow current to flow

as an A.C. waveform. (Illust. 5-5)

ROTATION OF FLYWHEEL

A wire harness (part 36588) may be added to the 3 Amp

D.C. / 5 Amp A.C. charging system to power an electric

clutch without the use of a battery. Test the charging

system using the applicable “Checking the System”

procedure listed in this section. Test the diode in the

harness by using a continuity test. (Illust. 5-6) Continuity

should exist in one direction only. Replace the diode if

continuity exists after reversing tester leads or no

continuity is found.

IF BULB DOES NOT LIGHT OR LIGHTS WHEN

POLARITY IS REVERSED, DISCARD DIODE.

5-6

5-5

CHARGING CIRCUIT

The charging systems used on the TVT engine is best

identified by obtaining the engine model and specification

number from the engine. Consult a Tecumseh dealer or

a parts manual to correctly identify the charging system.

Many of the tests require running the engine and

measuring alternator output with a voltmeter. When

making voltage tests with the engine running, it is not

necessary to take readings at all of the listed R.P.M.’s.

Checking at one of the speeds is sufficient.

In some cases an open circuit D.C. check cannot be

made. A SCR (Silicon Controlled Rectifier) is located in

the circuit which requires a minimum “turn on” voltage

to allow it to conduct. Without the battery in the circuit

this “turn on” voltage is not present. The SCR “senses”

this and there will be no D.C. output from the regulator/

rectifier.

Each charging system has its own testing procedure.

Test the charging system using the applicable procedure

found on the following pages.

DIODE REPLACEMENT

To replace the diode, disconnect at the plug (spade

terminal) and cut the wire on the opposite end of the

diode at the solderless (crimped) connector. Remove

1/4” (6.35 mm) of insulation from the cut end of the wire

and twist the strands together. Place the solderless

connector from the new diode onto the exposed 1/4” (6.35

mm) wire and crimp the connector with a standard

electricians pliers. Reconnect the plug end or spade

connector.

NOTE: DO NOT USE ACID CORE SOLDER. BE

CAREFUL NOT TO APPLY HEAT DIRECTLY TO THE

DIODE. USE HEAT SHRINK.

New heat shrink tubing can be installed by slipping over

the wires and heating with a heat gun. If this is not

available, tape the diode and connections with electrical

tape.

3 AMP D.C. 5 AMP A.C. ALTERNATOR

This unit combines a 3 Amp D.C. system used to charge

a battery with a 5 Amp A.C. system used for lighting.

Located in the red wire of the harness is a diode, which

converts the alternating current to direct current for

charging the battery. The yellow wire provides the A.C.

voltage for the lighting circuit.

5-4

Page 31

CHECKING THE SYSTEM: To check the system,

disconnect the plug and measure the D.C. voltage at the

red wire terminal. Measure the A.C. voltage at the yellow