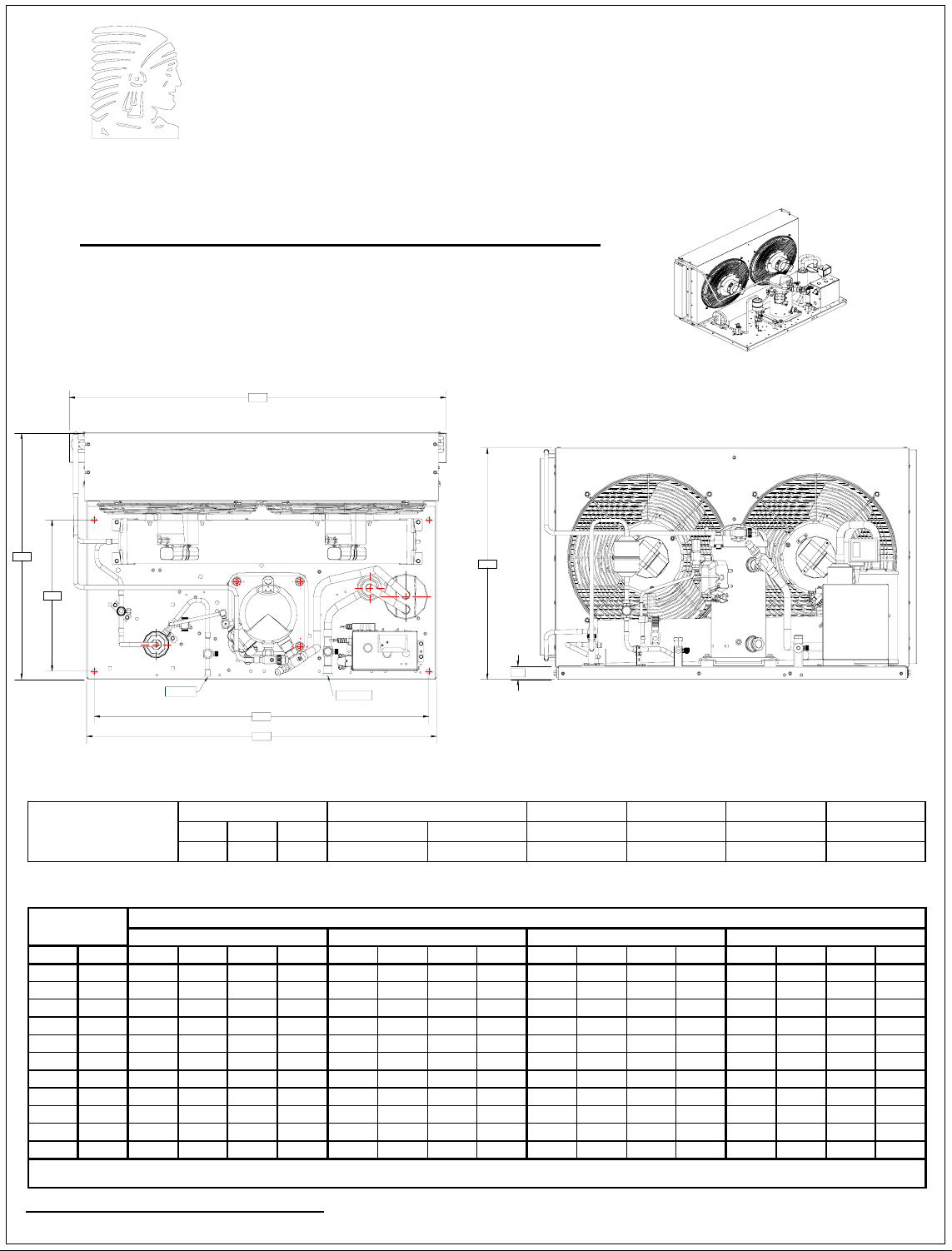

Tecumseh VSAG513ZXTXM Performance Data Sheet

d

T

TECUMSEH HERMETIC

CONDENSING UNIT

Model VSAG513ZXTXM

BOM 32T3242-2

Air Cooled 3 ¼ HP

Application Low Temp

VSAG513ZXTXM

TPC___preliminary

October 14, 2011

Refrigerant R404A

28.50

17.50

LIQUID 1/2"

VSAG513ZXTXM

44.97 28.50 26.78

*) Mounting Holes, 17.50 x 39.94

Factory charge 20 psig dry air,

Evaporator

T, °F PSIG BTUH Watts Hea

-40 5.5 6400 2720 196 87 6000 2980 223 96 5600 3240 251 104 5000 3560 286 114

-35 8.0 7300 2770 199 88 6900 3020 227 97 6400 3290 256 106 5800 3620 292 115

-30 10.7 8400 2810 202 89 7900 3070 231 98 7300 3340 260 107 6600 3680 298 117

-25 14.0 9600 2850 205 90 9000 3110 235 99 8200 3390 264 108 7500 3740 302 118

-20 17.1 10900 2900 208 91 10200 3160 238 100 9300 3440 268 109 8400 3790 306 119

-15 19.3 12300 2950 211 92 11400 3210 241 101 1050 0 3490 271 110 9500 3850 310 120

-10 24.5 13900 3010 214 93 12800 3260 244 102 1170 0 3540 275 111 10600 391 0 314 12 1

-5 28.8 15500 3080 217 94 14300 3320 248 103 13100 3600 278 112 11800 3970 317 122

0 33.5 17300 3150 221 96 15900 3380 251 104 14500 3 660 282 113 13100 4030 321 122

5 36.5 19200 3230 225 97 17600 3460 256 105 16100 3 730 286 114 14500 4100 324 123

10 43.7 21200 3320 231 99 19400 3540 260 107 17700 3810 290 115 16000 4180 328 124

Pe rfo rma nc e @ 6 0 H z , R e tur n ga s 4 0

MUST BE EVACUATED

44.97

39.94

41.78

Dimensions (inch)* Oil Ch.Line connections Air flowPum p do wn Gros s w ei gh t

LWH

80°F 90°F 100°F 110°F

Cond T BTUH Watts Head Cond T BTUHWatts Head Cond T BTUH Watts HeadCond

o

F, SubCoolin g 5oF

SUCTION 7/8"

Suction Liquid

7/ 8 Sw eat 1/ 2 Sweat

26.78

1.50

90% @ 90

33.44 4200 55

Ambient Temperatures

o

F

SCFM Lbs.Oz.

285

PRELIMINARY PERFORMANCE DATA

V

VSAG513ZXTXM

TPC___preliminary

October 14, 2011

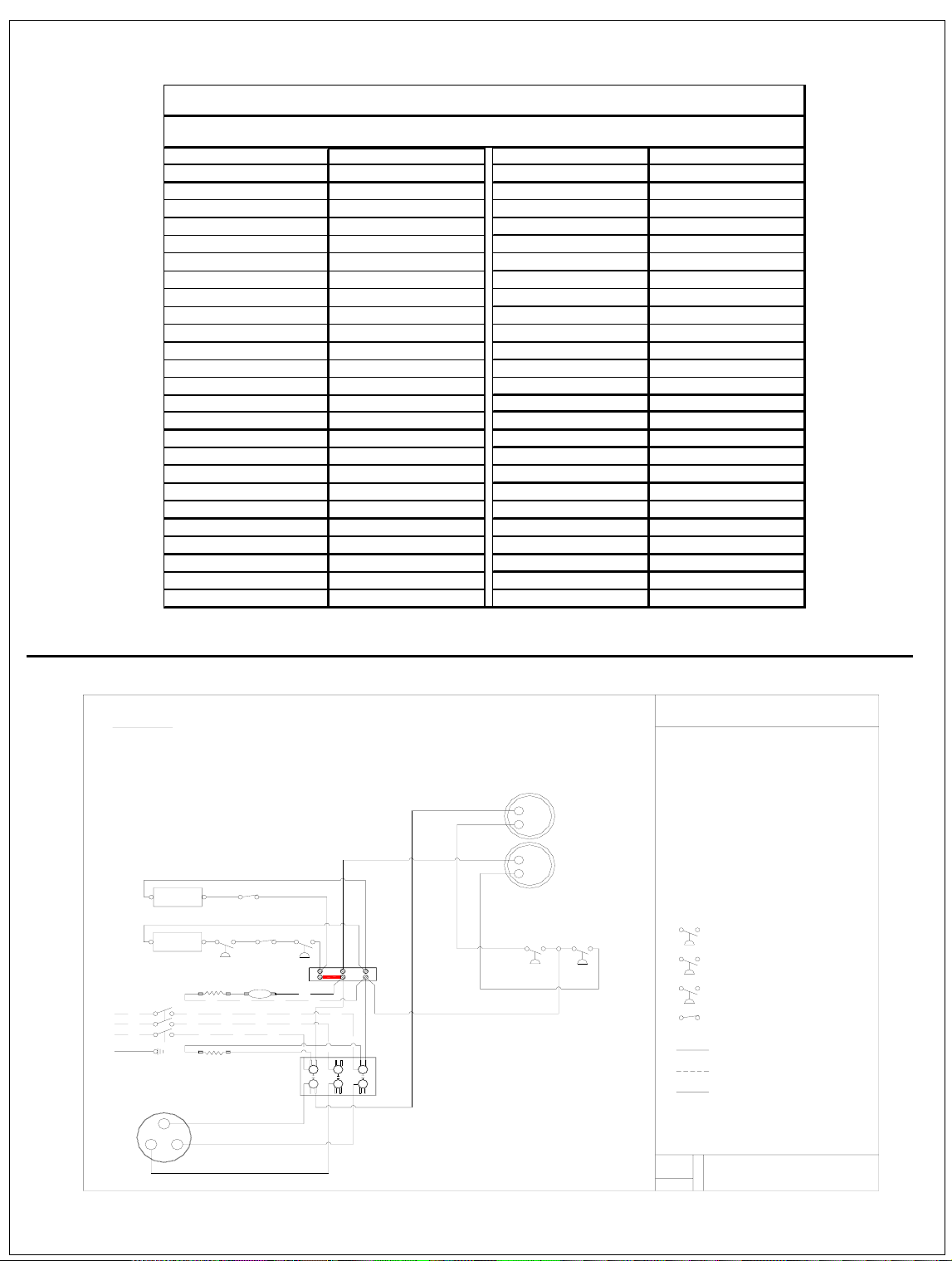

Parts/Specifications

Unit BOM 32T3242-2

Unit MODEL

SAG513ZXTXM

Fan Motor 810S186B40

Fan Motor Qty 2

Fan Motor RLA 1.9

Refrigeration RANGE -40°F to 10°F Fan Blade 51528-3

Design Pressure Low 181 Fan Guard 70832

Design Pressure High 450 Shroud 70611-1

Volts - HZ - Ph 200-230V 3~ 60HZ

Voltage Range 180 - 253 High Pressure switch 84095-2

Min. Circuit Ampacity 15.82 Low Pressure Control 84026-2

Max. Fuse Size 25 Dual Pressure Conrol

Compressor MODEL VSAG511ZXT Condenser 50785-4

Compressor BOM VS122RT-008-A4 Head Master Valve

Compressor LRA 80 Check Valve

Co mpressor RLA 9.62 Process Valve

Liquid Val v e

OverLoad INTERNAL Suction Valve 31529-2

Relay

Run Capacitor Receiver 51084

Run Capacitor Rating Receiver Qty 1

Start Capacitor Accumulator TK00042000

Start Capacitor Rating Liquid Filter 52000-164D

Cont actor 91014 B Sight Gla s s 70084-2

Suction Filter 70822-5S

Unit Drawing DGU1950- 13

Wiring Diagram WD23-2FL CrankCase Heater

IMPORTANT:

COMPRESSOR EQUIPPED WITH AN INTERNAL OVERLOAD

PROTECTOR. ALLOW TIME FOR RESET.

USE COPPER CONDUCTORS ONLY.

(EMPLOYER DES CONDUCTEUERS DE CUIVER

SEULEMENT.)

SOLENOID

POWER SUPPLY

208-230 / 60 / 3

COMPRESSOR

TERMINAL

LIQUID INJE C T IO N

COMPRESSOR

CONTACTOR COIL

L3

L2

L1

GRD

C

S

see note A

T3

T2

T1

R

COMPRESSOR CONTACTOR

NO AUXILIARY SWITCH

HP DT LP

RECEIVER

HEATER

THERMOSTAT

CRANK CASE

HEATER

BLACK

RED

YELLOW

COMPRESSOR

CONTACTOR

TERMINAL

BOARD

NOTES

FIELD WIRING NOTES

1. ALL FIEL D W IRING M U ST BE DO NE IN CO M PLIANCE W ITH ALL

APPLICABLE LOCAL AND NATIONAL CODES.

2. CONNECT INCOMING POWER LEADS FROM POW E R SUPP LY

TO L1, L2, A ND L3 IN C OMPRE SSOR C O N TACTOR OR TO L1 , L 2 A ND L3 IN

DISCONN ECT SW IT C H (IF PRO V ID E D). USE C O OPER C O N DUCTOR S

ONLY. (EMPLOYER DES CONDUCTEURS DE CUIVER SEULE ME NT.)

PROVIDE EQUIPMENT GROUNDING CONDUCTOR.

USE 75°C ( M IN .) WIRING

3. IF REQUIRED INSTALL SYSTEM REMOTE CONTROL BETWEEN P1 AND P2

FAN 1

FAN 2

FFC2

FFC1

P3

P1

P2

L1

L2 L3

T1

T3T2

IN TERMIN AL BLOC K AND RE M OVE TH E JU M PER

GENERAL NOTES:

A. CONTACTOR COIL CIRCUIT IS FACTORY CONNECTED TO 230 V SOURCE IN

PANEL AS SHOWN

B. COMPRESSOR EQUIPPED WITH AN INTERNAL OVERLOAD PROTECTOR.

ALLOW TIME FOR RESET.

FFC1 (FFC2)

FAN CONTROL 1 (2)

LP

LOW PRESSURE CONTROL

HP

HIGH PRESSURE SWITCH

DT

DISCHARGE LINE THERMOSTAT

FACTORY COMPONENTS

OPTIONAL FACTORY COMPONENTS

OPTIONAL FIELD COMPONENTS

CONDENSING UNIT WIRING, 230V 60Hz 3 Ph,

Liquid Injection Solenoid,

Fan control,

REL

REVISION

WD23-2FL

DEC 21, 2010

Loading...

Loading...