Page 1

TECUMSEH

T E C H N I C I A N ' S H A N D B O O K

This manual covers engine models:

ECV100 - 120, H22 - 80, HH40 - 70, HHM80, HM70 - 100,

HMSK70 - 110, HMXL70, HS40 - 50, HSK30 - 70, HSSK40 - 50,

HT30 - 35, HXL35, LAV30 - 50, LEV80 - 120, TNT100 - 120,

TVM125 - 220, TVXL170 - 220, TVS75 - 120, TVXL105 - 115,

V40 - 80, VH40 - 70, V60 - 70, VM70 - 100

Model numbers are located on the engine shroud.

3 TO 11 HP

4-CYCLE

L-HEAD

ENGINES

ENGINES & TRANSMISSIONS

Page 2

CONTENTS

CHAPTER 1 GENERAL INFORMATION ......................................................................................................1

ENGINE IDENTIFICATION ............................................................................................................................1

INTERPRETATION OF MODEL NUMBER....................................................................................................1

SHORT BLOCKS ...........................................................................................................................................2

FUEL ..............................................................................................................................................................2

ENGINE OIL...................................................................................................................................................3

TUNE-UP PROCEDURE .............................................................................................................. .................3

STORAGE......................................................................................................................................................4

CHAPTER 2 AIR CLEANERS ......................................................................................................................5

GENERAL INFORMATION ............................................................................................................................5

OPERATION ..................................................................................................................................................5

COMPONENTS..............................................................................................................................................5

TROUBLESHOOTING OR TESTING ............................................................................................................5

SERVICE .......................................................................................................................................................6

DISASSEMBLY PROCEDURE ......................................................................................................................6

POLYURETHANE-TYPE FILTER ELEMENT ................................................................................................6

PAPER-TYPE FILTER ELEMENT .................................................................................................................6

CHAPTER 3 CARBURETORS AND FUEL SYSTEMS .................................................................................7

GENERAL INFORMATION ............................................................................................................................7

OPERATION ..................................................................................................................................................8

FUEL PRIMERS.............................................................................................................................................8

IMPULSE FUEL PUMPS................................................................................................................................9

FLOAT STYLE CARBURETORS ................................................................................................................... 9

DIAPHRAGM (PRESSURE DIFFERENTIAL) CARBURETORS....................................................................9

COMPONENTS............................................................................................................................................10

CARBURETOR IDENTIFICATION...............................................................................................................11

DUAL SYSTEM CARBURETORS................................................................................................................11

SERIES 1 CARBURETORS.........................................................................................................................11

SERIES 3 & 4 CARBURETORS ..................................................................................................................11

DIAPHRAGM CARBURETORS ...................................................................................................................11

SERIES 6 CARBURETORS 4-CYCLE.........................................................................................................12

SERIES 8 .....................................................................................................................................................12

SERIES 9 .....................................................................................................................................................12

SERIES 10 (EMISSION) ..............................................................................................................................12

SERIES 11 ...................................................................................................................................................12

SERIES 11 BRIDGED..................................................................................................................................13

NON-TECUMSEH CARBURETORS -- DELLORTO CARBURETOR.........................................................12

ENGINE TROUBLESHOOTING CHART .....................................................................................................13

CARBURETION TROUBLESHOOTING CHART.........................................................................................14

TESTING......................................................................................................................................................15

SERVICE .....................................................................................................................................................15

CARBURETOR PRE-SETS AND ADJUSTMENTS .....................................................................................15

FINAL ADJUSTMENTS (NON-EMISSION ENGINES).................................................................................16

NON-ADJUSTABLE CARBURETOR ...................................................................................................... .....16

DISASSEMBLY PROCEDURE ....................................................................................................................17

FLOAT STYLE CARBURETORS ........................................................................................................ .........17

DIAPHRAGM CARBURETORS ...................................................................................................................19

FLOAT ADJUSTING PROCEDURE.............................................................................................................19

INSPECTION ...............................................................................................................................................20

ASSEMBLY ....................................................................................................................... ...........................21

STANDARD SERVICE CARBURETORS ....................................................................................................24

CHAPTER 4 GOVERNORS AND LINKAGE...............................................................................................26

GENERAL INFORMATION ..........................................................................................................................26

OPERATION ................................................................................................................................................26

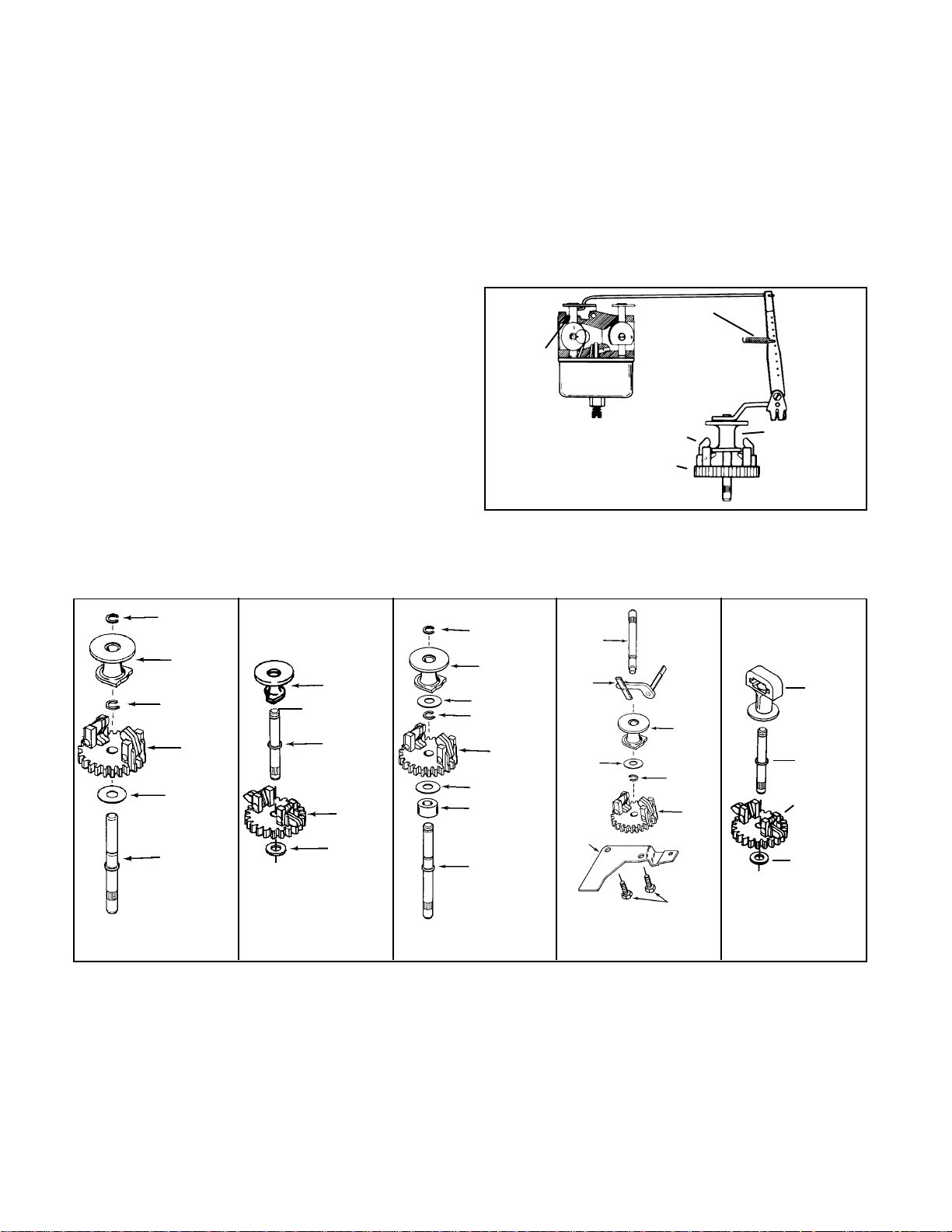

INTERNAL COMPONENTS (VARIOUS STYLES).......................................................................................26

TROUBLESHOOTING .................................................................................................................................26

ENGINE OVERSPEEDING ..........................................................................................................................27

ENGINE SURGING......................................................................................................................................27

C Tecumseh Products Company

1998

i

Page 3

SERVICE .....................................................................................................................................................27

GOVERNOR ADJUSTMENT .......................................................................................................................27

GOVERNOR ADJUSTMENT PROCEDURE FOR SHORT BLOCK INSTALLATIONS ...............................27

GOVERNOR GEAR AND SHAFT SERVICE ...............................................................................................28

SPEED CONTROLS AND LINKAGE ...........................................................................................................29

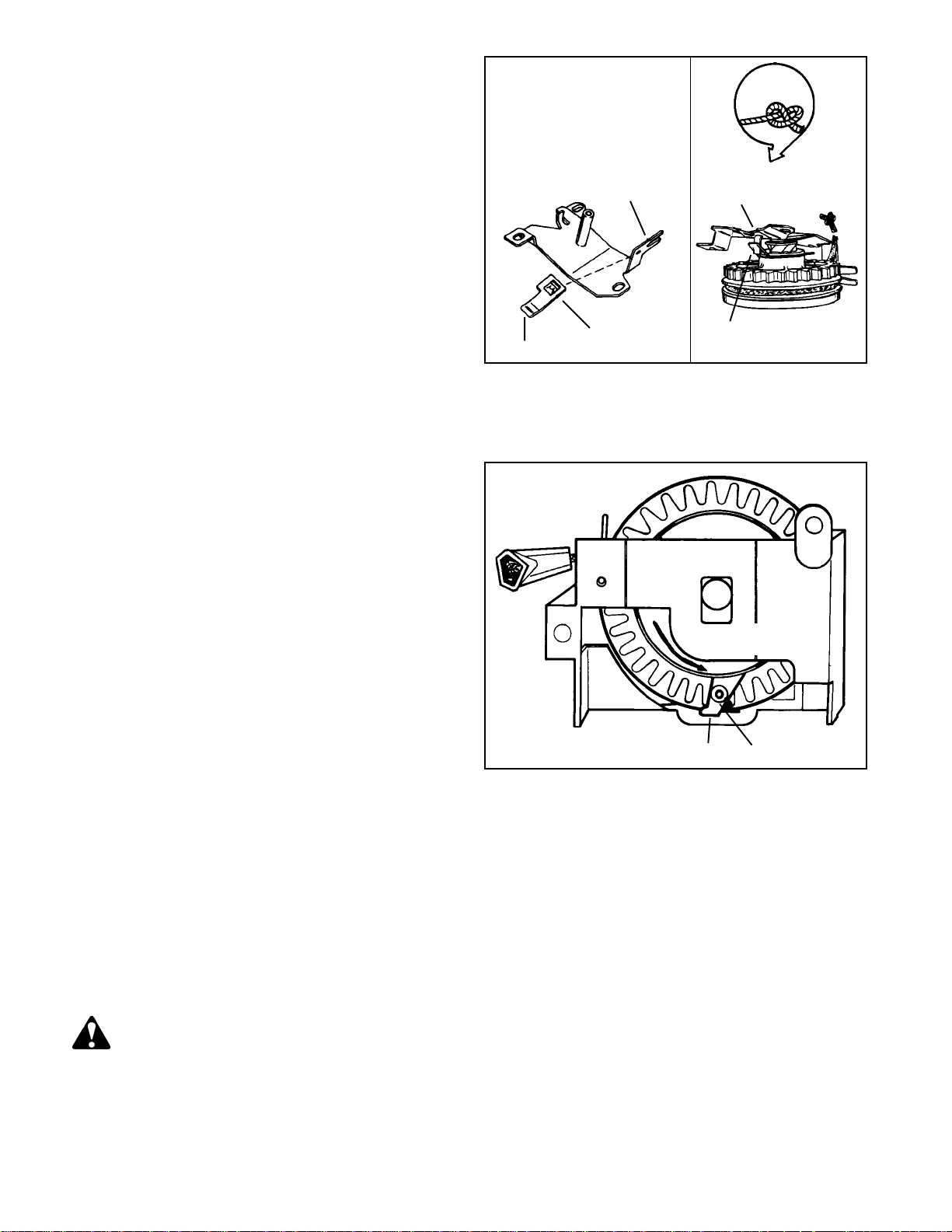

CHAPTER 5 REWIND STARTERS .............................................................................................................35

GENERAL INFORMATION ..........................................................................................................................35

OPERATION ................................................................................................................................................35

COMPONENTS............................................................................................................................................35

SERVICE .....................................................................................................................................................35

ROPE SERVICE ..........................................................................................................................................35

RETAINER REPLACEMENT .......................................................................................................................36

STYLIZED REWIND STARTER (TVS, HM, TVM, TVXL), AND STAMPED STEEL STARTER

(HM, VM, TVM, TVXL).............................................................................................................................36

STYLIZED REWIND STARTER WITH PLASTIC RETAINER ......................................................................37

STANDARD STAMPED STEEL AND CAST ALUMINUM STARTER (HM, VM) ..........................................38

VERTICAL PULL STARTER HORIZONTAL ENGAGEMENT TYPE ...........................................................39

VERTICAL PULL STARTER VERTICAL ENGAGEMENT TYPE .................................................................40

CHAPTER 6 ELECTRICAL SYSTEMS .....................................................................................................42

GENERAL INFORMATION ..........................................................................................................................42

OPERATION ................................................................................................................................................42

STARTING CIRCUIT AND ELECTRIC STARTERS ....................................................................................42

CHARGING CIRCUIT ..................................................................................................................................42

CONVERTING ALTERNATING CURRENT TO DIRECT CURRENT ..........................................................43

HALF WAVE RECTIFIER SINGLE DIODE ..................................................................................................43

FULL WAVE RECTIFIER BRIDGE RECTIFIER...........................................................................................43

COMPONENTS............................................................................................................................................43

BATTERY.....................................................................................................................................................43

WIRING........................................................................................................................................................43

ELECTRICAL TERMS..................................................................................................................................44

BASIC CHECKS...........................................................................................................................................45

TROUBLESHOOTING ELECTRICAL STARTER CIRCUIT FLOW CHART ................................................46

TROUBLESHOOTING ELECTRICAL CHARGING CIRCUIT FLOW CHART..............................................47

TESTING PROCEDURE..............................................................................................................................48

STARTING CIRCUIT....................................................................................................................................48

CHARGING CIRCUIT ..................................................................................................................................48

VOLTAGE REGULATIONS..........................................................................................................................56

LOW OIL SHUTDOWN SWITCHES ............................................................................................................56

SERVICE .....................................................................................................................................................57

12 VOLT OR 120 VOLT ELECTRIC STARTERS WITH EXPOSED SHAFT ...............................................57

12 VOLT D.C. OR 120 VOLT A.C. ELECTRIC STARTERS WITH THE STARTER GEAR UNDER

THE CAP ASSEMBLY.............................................................................................................................57

INSPECTION ...............................................................................................................................................58

CHAPTER 7 FLYWHEEL BRAKE SYSTEMS.............................................................................................59

GENERAL INFORMATION ..........................................................................................................................59

OPERATION ................................................................................................................................................59

BOTTOM SURFACE SYSTEM ....................................................................................................................59

INSIDE EDGE SYSTEM ..............................................................................................................................60

COMPONENTS............................................................................................................................................60

SERVICE .....................................................................................................................................................61

FLYWHEEL REMOVAL ...............................................................................................................................61

BRAKE LEVER AND PAD ...........................................................................................................................61

IGNITION GOUNDOUT TERMINAL ............................................................................................................61

STARTER INTERLOCK SWITCH ....................................................................................................... ......... 62

CONTROL CABLE ....................................................................................................................................... 62

BRAKE BRACKET REPLACEMENT ...................................................................................................... .....62

CHAPTER 8 IGNITION ................................................................................................................................63

GENERAL INFORMATION ..........................................................................................................................63

OPERATION ................................................................................................................................................63

SOLID STATE IGNITION SYSTEM (CDI) ....................................................................................................63

MAGNETO IGNITION SYSTEM (POINTS) ..................................................................................................63

ii

Page 4

IDENTIFICATION OF TECUMSEH IGNITION SYSTEMS ...........................................................................64

COMPONENTS............................................................................................................................................64

IGNITION TROUBLESHOOTING ................................................................................................................66

TESTING PROCEDURE..............................................................................................................................67

SERVICE .....................................................................................................................................................68

SPARK PLUG SERVICE.............................................................................................................................. 68

CONDITIONS CAUSING FREQUENT SPARK PLUG FOULING ................................................................68

IGNITION TIMING PROCEDURE ...................................................................................................... .......... 68

SERVICE TIPS.............................................................................................................................................71

CHAPTER 9 INTERNAL ENGINE AND CYLINDER ...................................................................................72

GENERAL INFORMATION ..........................................................................................................................72

OPERATION ................................................................................................................................................72

4-CYCLE ENGINE THEORY .......................................................................................................................72

LUBRICATION SYSTEMS ...........................................................................................................................73

COUNTERBALANCE SYSTEMS.................................................................................................................73

COMPONENTS............................................................................................................................................74

ENGINE OPERATION PROBLEMS.............................................................................................................75

TESTING...................................................................................................................................................... 77

ENGINE KNOCKS .......................................................................................................................................77

ENGINE OVERHEATS ................................................................................................................................77

SURGES OR RUNS UNEVENLY ................................................................................................................77

ENGINE MISFIRES......................................................................................................................................77

ENGINE VIBRATES EXCESSIVELY ...........................................................................................................78

BREATHER PASSING OIL ..........................................................................................................................78

EXCESSIVE OIL CONSUMPTION ...................................................................................................... ........78

LACKS POWER ...........................................................................................................................................78

SERVICE .....................................................................................................................................................79

DISASSEMBLY PROCEDURE ....................................................................................................................79

CYLINDERS.................................................................................................................................................81

CYLINDER HEADS......................................................................................................................................82

PISTONS, RINGS AND CONNECTING RODS ...........................................................................................82

CRANKSHAFTS AND CAMSHAFTS ...........................................................................................................84

VALVES .......................................................................................................................................................85

CRANKCASE BREATHERS ........................................................................................................................86

CYLINDER COVER, OIL SEAL, AND BEARING SERVICE ........................................................................87

CRANKSHAFT BEARING SERVICE ...........................................................................................................88

COUNTERBALANCE SERVICE ..................................................................................................................89

FLYWHEEL SERVICE .................................................................................................................................89

CHAPTER 10 ENGINE SPECIFICATIONS .................................................................................................90

FOUR CYCLE TORQUE SPECIFICATIONS ...............................................................................................91

ENGINE SPECIFICATIONS STANDARD POINT IGNITION .......................................................................93

SOLID STATE AND EXTERNAL IGNITION.................................................................................................97

CHAPTER 11 EDUCATION MATERIALS AND TOOLS...........................................................................102

DECIMAL / FRACTION CONVERSIONS................................................................................................. .. 105

SEARS CRAFTSMAN CROSS REFERENCE SUPPLEMENT INCLUDED IN BACK OF BOOK

iii

Page 5

CHAPTER 1 GENERAL INFORMATION

ENGINE IDENTIFICATION

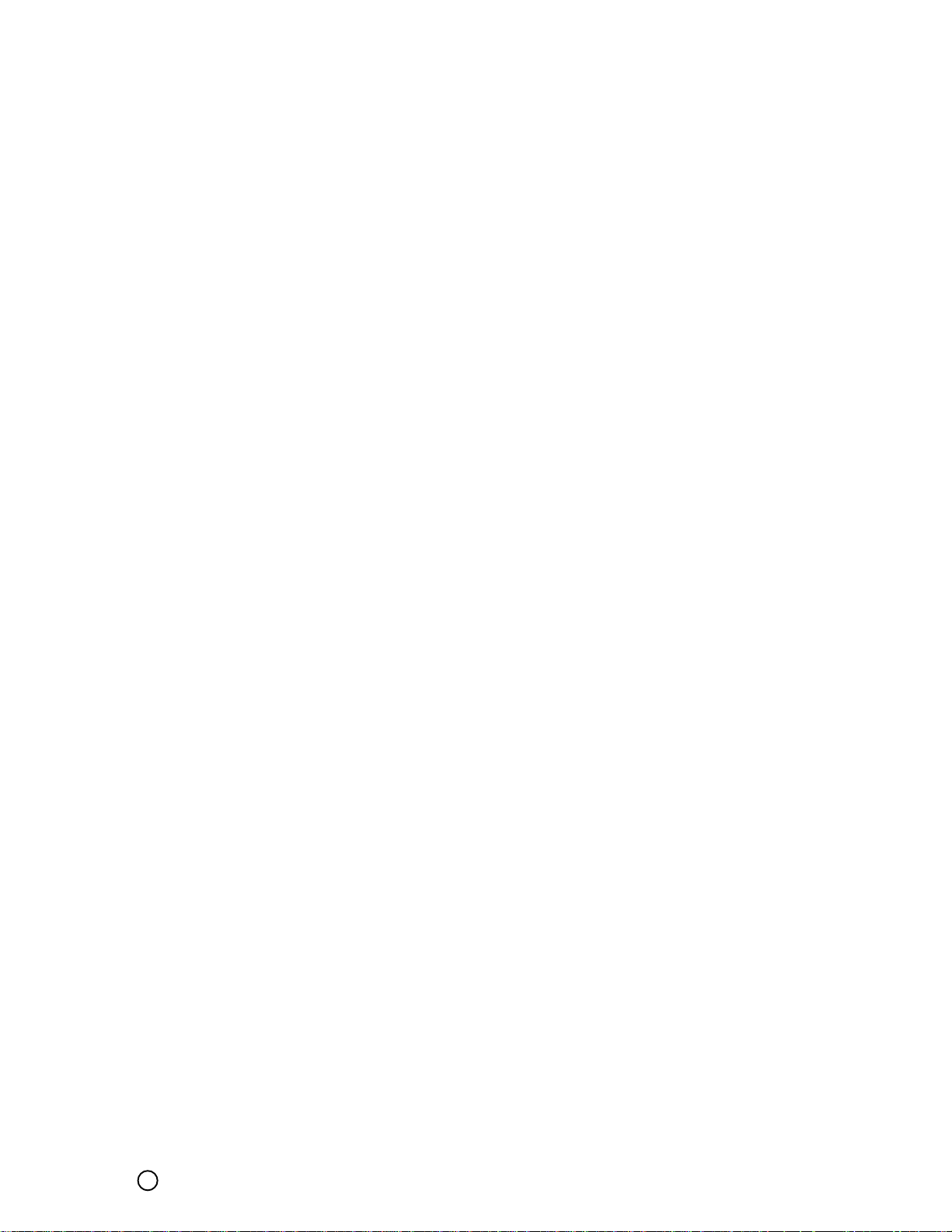

Tecumseh engine model, specification, and serial

numbers or (date of manufacture, DOM) are stamped

into the blower housing or located on a decal on the

engine in locations as illustrated (diag. 1 & 2).

NOTE: On some LEV engines, a cover bezel must be

removed to provide access to the identification decal

(diag. 1).

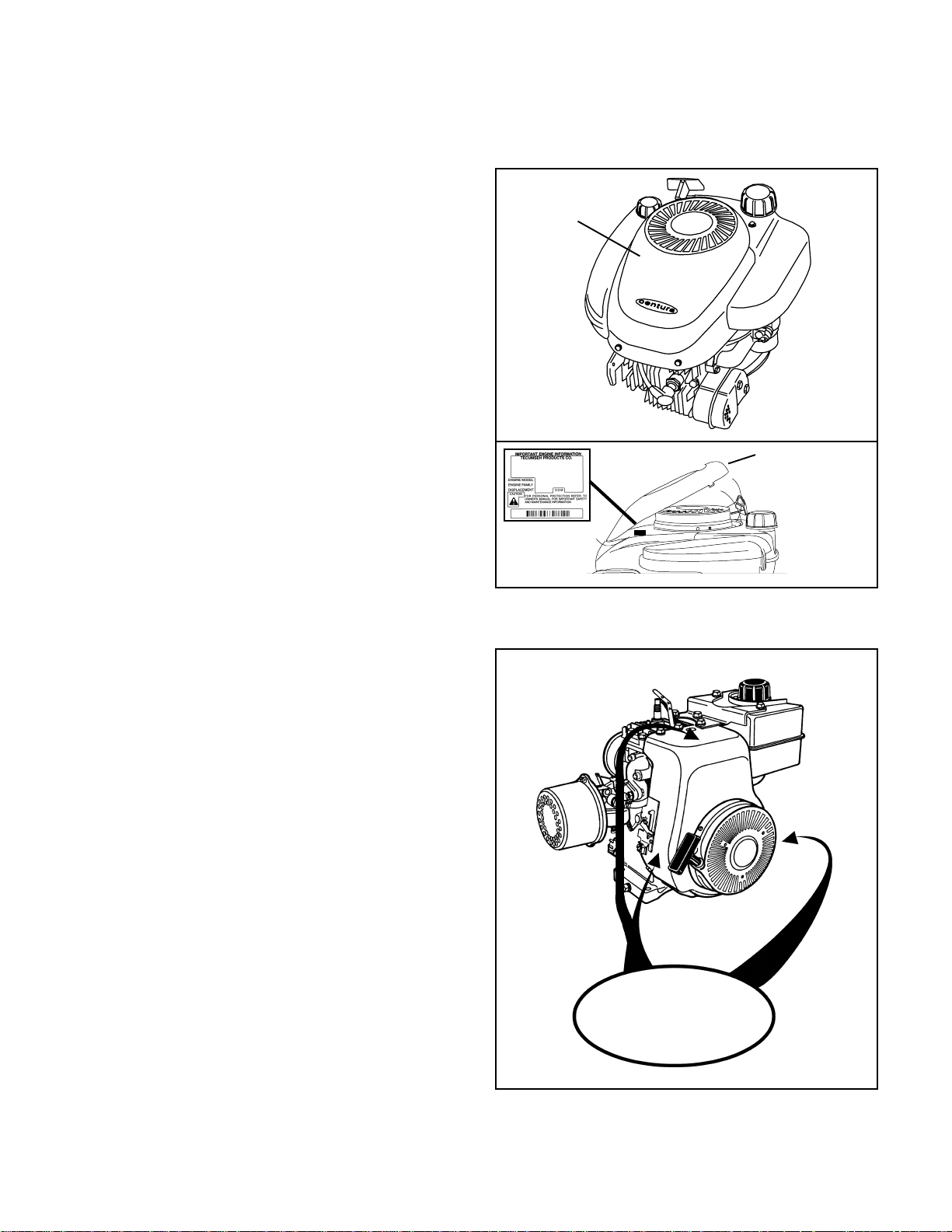

The engine identification decal also provides the

applicable warranty code and oil recommendations (diag.

3).

Emissionized engines that meet the California Air

Resource Board (C.A.R.B.) or the Environmental

Protection Agency (E.P.A.) standards will include

additional required engine information on the engine decal

(diag. 3).

INTERPRETATION OF MODEL NUMBER

The first letter designation in a model number indicates

basic type of engine.

V - Vertical Shaft

LAV - Lightweight Aluminum Vertical

VM - Vertical Medium Frame

TVM - Tecumseh Vertical (Medium Frame)

VH - Vertical Heavy Duty (Cast Iron)

TVS - Tecumseh Vertical Styled

TNT - Toro N’ Tecumseh

ECV - Exclusive Craftsman Vertical

TVXL - Tecumseh Vertical Extra Life

LEV - Low Emissions Vertical

H - Horizontal Shaft

HS - Horizontal Small Frame

HM - Horizontal Medium Frame

HHM - Horizontal Heavy Duty (Cast Iron) Medium Frame

HH - Horizontal Heavy Duty (Cast Iron)

ECH - Exclusive Craftsman Horizontal

HSK - Horizontal Snow King

COVER BEZEL

MODEL AND

D.O.M. NUMBER

DECAL

LOCATED

UNDER COVER

(IF SO EQUIPPED)

PRESS IN AND LIFT

HERE TO RELEASE

COVER

Ç

1

HS50 67355H SER 4091D

2

1

Page 6

The number designations following the letters indicate

the horsepower or cubic inch displacement.

The number following the model number is the

specification number. The last three numbers of the

specification number indicate a variation to the basic

engine specification.

The serial number or D.O.M. indicates the production

date.

Using model LEV115-57010B, serial 8105C as an

example, interpretation is as follows:

LEV115-57010B is the model and specification number

LEV Low Emissions Vertical

115 Indicates a 11.5 cubic inch displacement

57010B is the specification number used for properly

identifying the parts of the engine

8105C is the serial number or D.O.M. (Date of

Manufacture)

8 first digit is the year of manufacture (1998)

105 indicates calendar day of that year (105th day

or April 15, 1998)

C represents the line and shift on which the

engine was built at the factory.

FUEL REGULAR UNLEADED

OIL, SAE 30 (BELOW 32oF SAE 5W30)

LEV115 57010B (D)

STP185U1G1RA

8105C

THIS ENGINE MEETS 1995-1998

CALIF. EMISSION REGULATOR FOR

ULGE ENGINES AS APPLICBLE

FUEL: REGULAR UNLEADED OIL: USE SEA30

LEV115 57010B (D)

STP185U1G1RA

8105C

Engine Family: Engine Tracking Information

3

SHORT BLOCKS

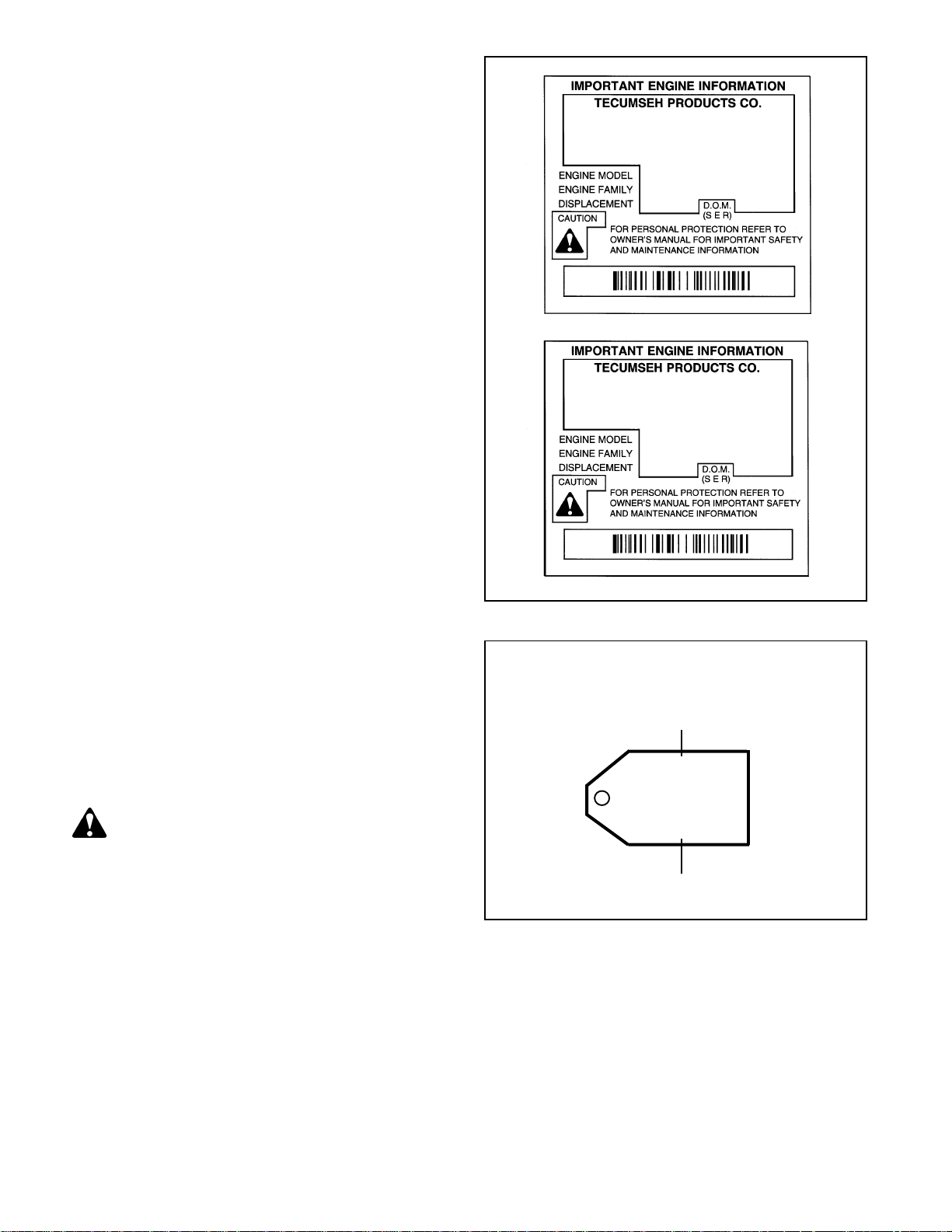

SHORT BLOCK IDENTIFICATION TAG

New short blocks are identified by a tag marked S.B.H.

(Short Block Horizontal) or S.B.V. (Short Block Vertical).

Original model identification numbers of an engine should

SBV OR SBH IDENTIFICATION NUMBER

always be transferred to a new short block for correct

parts identification (diag. 4).

THIS SYMBOL POINTS OUT IMPORTANT

SAFETY INSTRUCTIONS WHICH IF NOT

SBV-2316

SER 4291

FOLLOWED COULD ENDANGER THE

PERSONAL SAFETY OF YOURSELF AND

OTHERS. FOLLOW ALL INSTRUCTIONS.

SERIAL NUMBER

4

FUEL

Tecumseh strongly recommends the use of fresh clean unleaded regular gasoline in all engines. Unleaded gasoline

burns cleaner, extends engine life and promotes better starting by reducing build-up of combustion chamber deposits.

REFORMULATED AND OXYGENATED FUELS

Reformulated fuels containing no more than 10% Ethanol, 15% MTBE, 15% ETBE or premium gasoline can be used

if unleaded regular gasoline is not available. Leaded fuel may be used in countries where unleaded fuel is not available.

NEVER USE FUEL CONTAINING METHANOL.

2

Page 7

ENGINE OIL

Use a clean, high quality detergent oil. Be sure original container is marked: A.P.I. service SF thru SJ. The use of

multigrade oil may increase oil consumption under high temperature, high load applications.

NOTE: DO NOT USE SAE10W40 OIL.

For summer (above 32°F, 0oC) use SAE 30 oil part # 730225 (1 quart, .946 liter container) in high temperature, high

load applications.

S.A.E.10W30 is an acceptable substitute.

For winter (below 32°F, 0oC) use S.A.E. 5W30 oil part # 730226 (1 quart, .946 liter container)

S.A.E.10W is an acceptable substitute.

S.A.E. 0W30 should only be used when ambient temperature is below 0oF, -18oC.

CAPACITIES: EUROPA MODELS

Engine Model Oz. mL. Oz. mL.

LAV30-50, TVS75-120, LEV80-120 21 630 Vantage 21 630

ECV100-120, TNT100-120 21 630 Prisma 21 630

V & VH50, 60, 70 27 810 Synergy 21 630

TVM 125, 140 27 810 Synergy "55" 27 810

TVM & TVXL 170, 195, 220 32 960 Spectra 21 630

VM70, 80, 100 32 960 Futura 21 630

VH100 50 1500 Centura 21 630

H & HSK30, 35, HS & HSSK40, 50 21 630 HTL 21 630

H, HH & HSK50, 60, 70 19 570 BVS 21 630

HM & HMSK70, 80, 100 26 720 BH Series 21 630

Geo Tech Series 35-50 21 630

Oil Change Intervals. Change the oil after the first two (2) hours of operation and every 25 hours thereafter, or more

often if operated under dusty or dirty conditions, extreme temperature, or high load conditions.

Oil Check. Check the oil each time the equipment is used or every 5 hours. Position the equipment so the engine is

level when checking the oil.

CAUTION: REMOVE THE SPARK PLUG WIRE BEFORE DOING ANY SERVICE WORK ON THE ENGINE.

Oil Change Procedure: Locate the oil drain plug. On some units this plug is located below the deck through the

bottom of the mounting flange. Other units drain at the base of the engine above the deck or frame. If access to the

drain plug is restricted by the equipment it may be necessary to drain the oil by tipping the mower in a position that

would allow the oil to drain out of the fill tube.

On units that the drain plug is accessible, remove the plug and allow the oil to drain into a proper receptacle. Always

make sure that drain oil is disposed of properly.

Once the oil is drained, reinstall the plug and fill the engine with new oil to the proper capacity.

TUNE-UP PROCEDURE.

The following is a minor tune-up procedure. When this procedure is completed, the engine should operate properly.

Further repairs may be necessary if the engine's performance remains poor.

CAUTION: REMOVE THE SPARK PLUG WIRE BEFORE DOING ANY SERVICE WORK ON THE ENGINE.

1. Service or replace the air cleaner as needed.

2. Inspect the level and condition of the oil and change or add oil as required.

3. Remove the blower housing and clean all dirt, grass or debris from the intake screen, cylinder head, cylinder

cooling fins, carburetor, governor levers and linkage.

4. Make sure the fuel tank, fuel filter and fuel line are clean. Replace any worn or damaged governor springs or

linkage. Make the proper governor adjustments and carburetor presets where required.

3

Page 8

5. When replacing the spark plug, consult the parts breakdown for the proper spark plug to be used in the engine

being serviced. Set the spark plug gap to .030" (.762 mm) and install the spark plug in the engine. Tighten the

spark plug to 15 foot pounds of torque (20.4 Nm). If a torque wrench isn’t available, screw the spark plug in as far

as possible by hand, and use a spark plug wrench to turn the spark plug 1/8 to 1/4 turn further if using the old spark

plug, or 1/2 turn further if using a new spark plug.

6. Make sure all ignition wires are free of abrasions or breaks and are properly routed so they will not rub on the

flywheel.

7. Properly reinstall the blower housing, gas tank, fuel line and air cleaner assembly if removed.

8. Make sure all remote cables are properly adjusted for proper operation. See chapter 4 under "Speed Controls and

Linkage".

9. Reinstall the spark plug wire, add fuel and oil as necessary, and start the engine.

STORAGE: (IF THE ENGINE IS TO BE UNUSED FOR 30 DAYS OR MORE)

CAUTION: NEVER STORE THE ENGINE WITH FUEL IN THE TANK INDOORS , IN ENCLOSED POORLY

VENTILATED AREAS WHERE FUEL FUMES MAY REACH AN OPEN FLAME, SPARK OR PILOT LIGHT

AS ON A FURNACE, WATER HEATER, CLOTHES DRYER OR OTHER GAS APPLIANCE.

Gasoline can become stale in less than 30 days and form deposits that can impede proper fuel flow and engine

operation. To prevent deposits from forming, all gasoline must be removed from the fuel tank and the carburetor. An

acceptable alternative to removing all gasoline is adding a fuel stabilizer to the gasoline. Fuel stabilizer (such as

Tecumseh's Part No. 730245) is added to the fuel tank or storage container. Always follow the mix ratio found on the

stabilizer container. Run the engine at least 10 minutes after adding the stabilizer to allow it to reach the carburetor.

CAUTION: THE USE OF SOME ANTI-ICING ADDITIVES MAY CREATE A METHANOL FUEL BLEND. DO

NOT USE ADDITIVES THAT CONTAIN METHANOL. FUEL CONDITIONERS THAT CONTAIN ISOPROPYL

ALCOHOL IS RECOMMENDED.

Draining the Fuel System:

CAUTION: DRAIN THE FUEL INTO AN APPROVED CONTAINER OUTDOORS, AND AWAY FROM ANY

OPEN FLAME OR COMBUSTION SOURCE. BE SURE THE ENGINE IS COOL.

1. Remove all gasoline from the fuel tank by running the engine until the engine stops, or by draining the fuel tank by

removing the fuel line at the carburetor or fuel tank. Be careful not to damage the fuel line, fittings, or fuel tank.

2. Drain the carburetor by pressing upward on the bowl drain (if equipped) which is located on the bottom of the

carburetor bowl. On carburetors without a bowl drain, the carburetor may be drained by loosening the bowl nut on

the bottom carburetor one full turn. Allow to completely drain and retighten the bowl nut being careful not to

damage the bowl gasket when tightening.

3. If "Gasohol" has been used, complete the above procedure and then put one half pint of unleaded gasoline into

the fuel tank and repeat the above procedure. If Gasohol is allowed to remain in the fuel system during storage,

the alcohol content will cause rubber gaskets and seals to deteriorate.

Change Oil: If the oil has not been changed recently, this is a good time to do it.

Oil Cylinder Bore:

1. Disconnect the spark plug wire and ground the wire to the engine. Remove the spark plug and put 1/2 ounce

(14 ml) of clean engine oil into the spark plug hole.

2. Cover the spark plug hole with a shop towel.

3. Crank the engine over slowly several times.

CAUTION: AVOID SPRAY FROM SPARK PLUG HOLE WHEN SLOWLY CRANKING ENGINE OVER.

4. Install the spark plug and connect the spark plug wire.

Clean Engine: Remove the blower housing and clean all dirt, grass or debris from the intake screen, cylinder head,

cylinder cooling fins, carburetor, governor levers and linkage.

4

Page 9

CHAPTER 2 AIR CLEANERS

GENERAL INFORMA TION

The air cleaner is the device used to eliminate dust and dirt

from the air supply . Filtered air is necessary to assure that

abrasive particles are removed before entering the carburetor

and combustion chamber. Dirt allowed into the engine will

quickly wear the internal components and shorten the life

of the engine.

Tecumseh engines use either a polyurethane or a papertype air filter system. A polyurethane pre-cleaner or a flocked

screen may be used in conjunction with the main filter.

Snow King® engines do not use an air filter.

Extremely dirty conditions may require more frequent filter

cleaning or replacement.

OPERATION

The outer cover encapsulates the air filter element(s) and

prevents large particles from entering the filter box. Air is

filtered through the pre-cleaner or flocked screen (if equipped)

and the polyurethane or paper filter element. Pre-cleaners

or flocked screens provide additional air cleaning capacity .

In T ecumseh's Kleen Aire® system, air is drawn in through

a rotating screen or recoil cover to be centrifugally cleaned

by the flywheel before the air is drawn into the air filter.

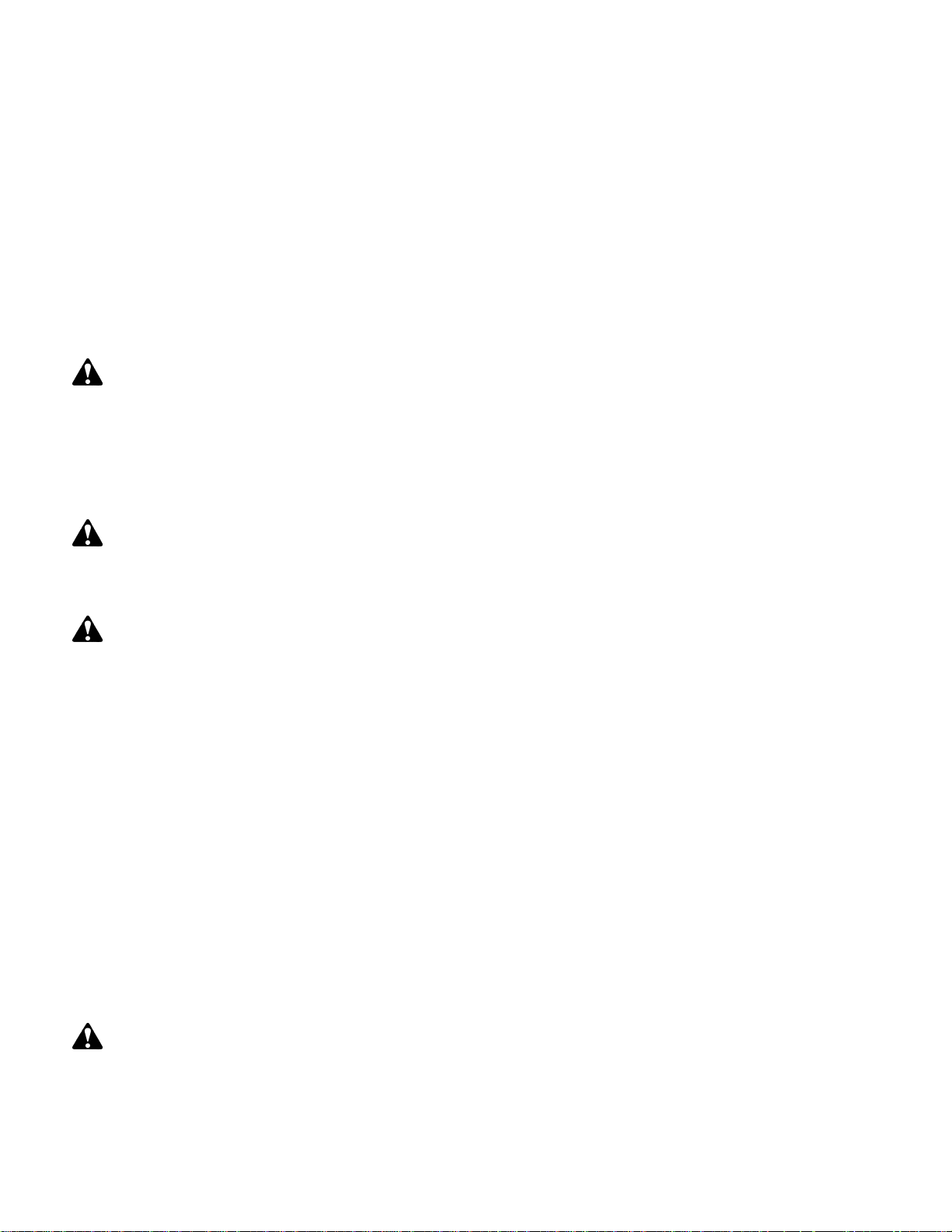

COMPONENTS

The cover holds the filter element and prevents large debris

from entering the filter element.

The polyurethane wrap pre-filter is used on XL or XL/C

engine models with paper filter elements.

(diag 1 & 2)

COVER

POLYURETHANE

WRAP

SEALING NUTS

PAPER

ELEMENT

AIR CLEANER

BODY

1

The paper or polyurethane filter element is the main

filter to trap dust and dirt. Dry-type paper elements have

treated paper folded for increased surface area and rubberlike sealing edges. The polyurethane filter uses an oil film

to trap fine particles found in dust.

The flocked screen is used as an additional filter on XL or

XL/C engine models that use a polyurethane filter element.

TROUBLESHOOTING OR TESTING

If the engine's performance is unsatisfactory (needs

excessive carburetor adjustments, starts smoking

abnormally , loses power), the first engine component to be

checked is the air cleaner. A dirt restricted or an oil soaked

element will cause noticeable performance problems. A

polyurethane element may be cleaned following the service

procedure listed under "Service" in this chapter. A papertype air filter should only be replaced. A paper-type element

cannot have an oil film present on the paper. Follow the

procedure listed in the "Service" section of this chapter for

replacement. Re-try the engine after filter replacement or

service. If the problem persists after filter service, see

Chapter 9 under "Engine Operation Problems" for additional

causes.

COVER

AIR CLEANER

BODY

FOAM

ELEMENT

FLOCKED SCREEN

2

5

Page 10

SERVICE

Service on the polyurethane element (cleaning and oiling) is recommended every three months or every twenty five

operating hours, whichever comes first. Extremely dirty or dusty conditions may require daily cleanings.

The paper filter element should be replaced at least once a year or more frequently if operated in dusty or dirty conditions.

NOTE: NEVER RUN THE ENGINE WITHOUT THE COMPLETE AIR CLEANER ASSEMBLY INSTALLED ON THE

ENGINE. AL WA YS REPLACE THE FIL TER ELEMENT WITH THE PROPER TECUMSEH ORIGINAL REPLACEMENT

PART.

DISASSEMBLY PROCEDURE

1. Unlock the tabs or remove the screws, wingnuts or

snaps holding the air cleaner cover in place.

2. Remove the hex nuts holding the element down if

equipped. New nuts are supplied with a new filter and

MUST be used for proper sealing.

3. Clean the excess contaminants out of the air cleaner

body before removing the old element.

4. Remove the old element and the polyurethane pre-

cleaner if equipped.

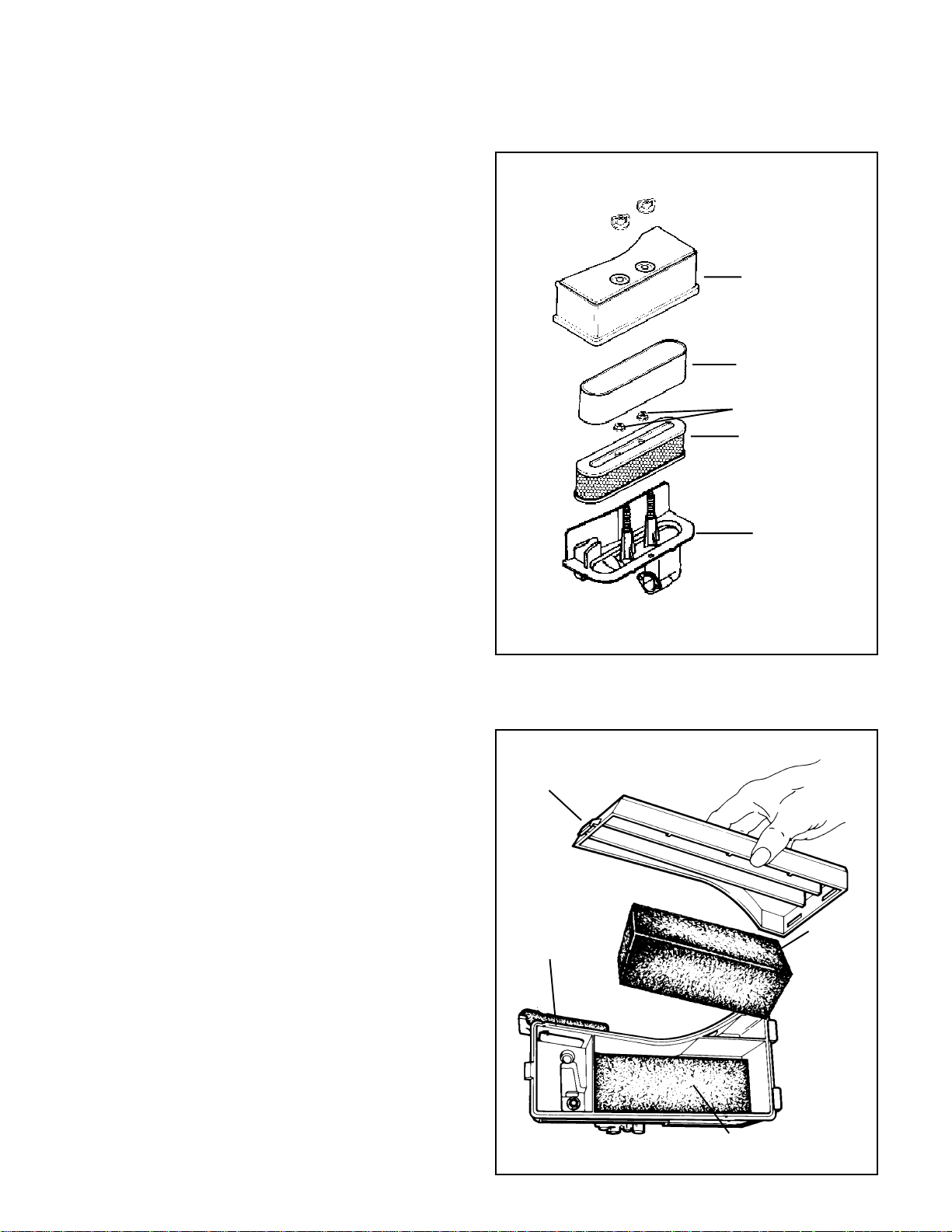

5. On air cleaners that use a flocked screen under the

polyurethane element, remove the air cleaner assembly

from the carburetor before removing the flocked screen.

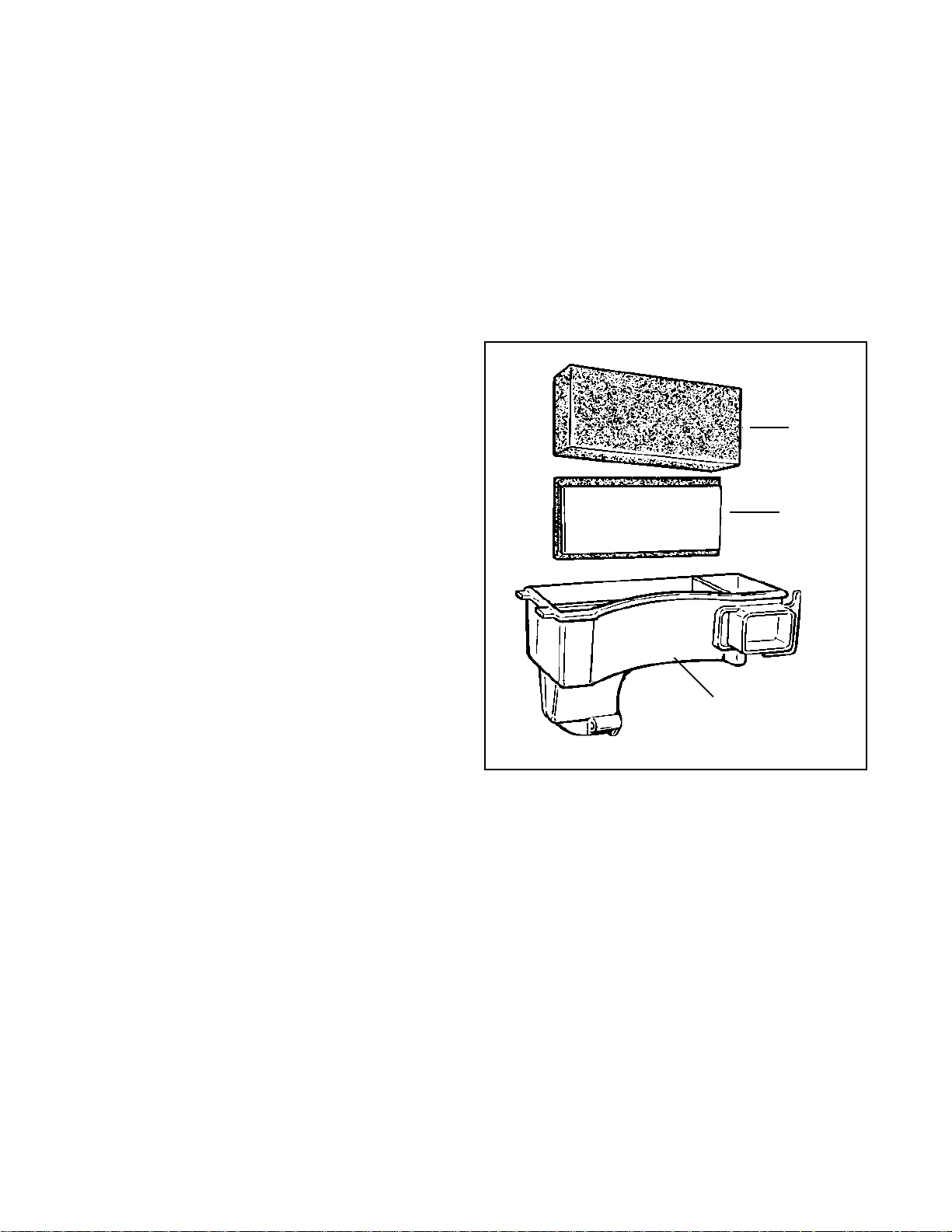

This prevents dirt from entering the carburetor (diag 3).

FOAM

ELEMENT

1/2" (12.7 mm)

FOAM

WITH FLOCKED

SCREEN

ATTACHED

6. Clean the inside of the cover and body , remove the old

gasket between the carburetor and the air cleaner

assembly.

7. Reinstall the air cleaner assembly using a new gasket.

8. Use the reverse procedure for reassembly. When

installing the foam polyurethane pre-cleaner, make sure

the seam is installed to the outside to prevent gaps

AIR CLEANER

BODY

between the paper element and the pre-cleaner.

3

POLYURETHANE-TYPE FILTER ELEMENT

This type of air filter can be serviced when restricted with dust or dirt. Wash the filter or pre-cleaner in a liquid detergent

and water solution until all the dirt is removed. Rinse in clear water to remove the detergent solution. Squeeze the

element (do not twist) to remove the excess water. W rap the element in a clean cloth and squeeze it (do not twist) until

completely dry .

Re-oil the element by applying engine oil and squeezing it vigorously to distribute the oil. Roll the element in a cloth and

squeeze it (do not twist) to remove the excess oil.

Clean the air cleaner housing and cover being careful not to allow dirt to fall into the carburetor or intake pipe.

PAPER -TYPE FILTER ELEMENT

Paper type air filter elements can only be serviced by replacement. Do not attempt to clean a paper filter element.

6

Page 11

CHAPTER 3 CARBURETORS AND FUEL SYSTEMS

GENERAL INFORMA TION

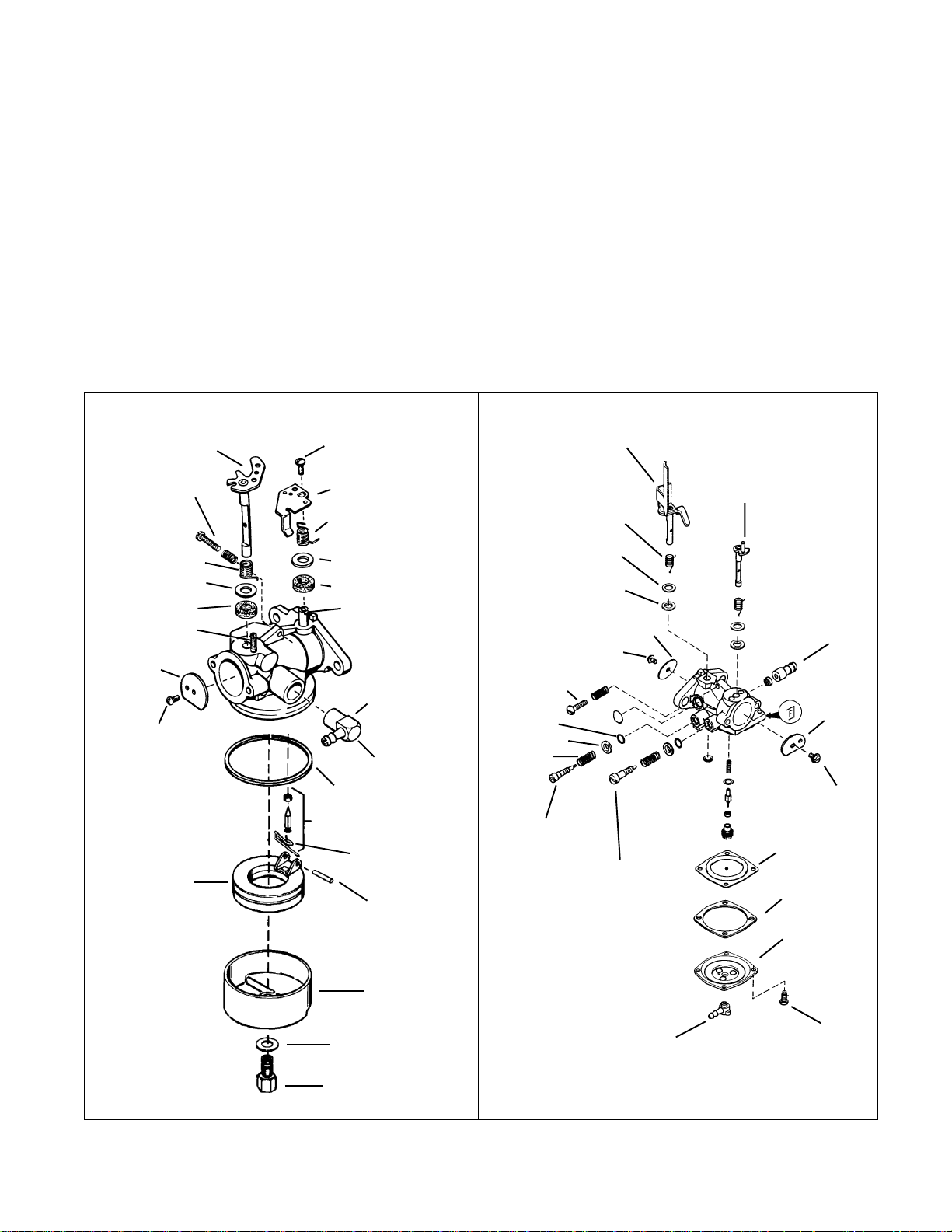

Tecumseh uses two basic types of carburetors, float and diaphragm type carburetors. Float type carburetors use a

hollow float to maintain the operating level of fuel in the carburetor. Diaphragm type carburetors use a rubber-like diaphragm.

One side is exposed to intake manifold pressure and the other side to atmospheric pressure. The diaphragm provides the

same basic function (maintaining the proper fuel level in the carburetor) as the float.

An advantage of the diaphragm carburetor over the float style is that the diaphragm carburetor will allow the engine to

operate at a greater degree of tiltability .

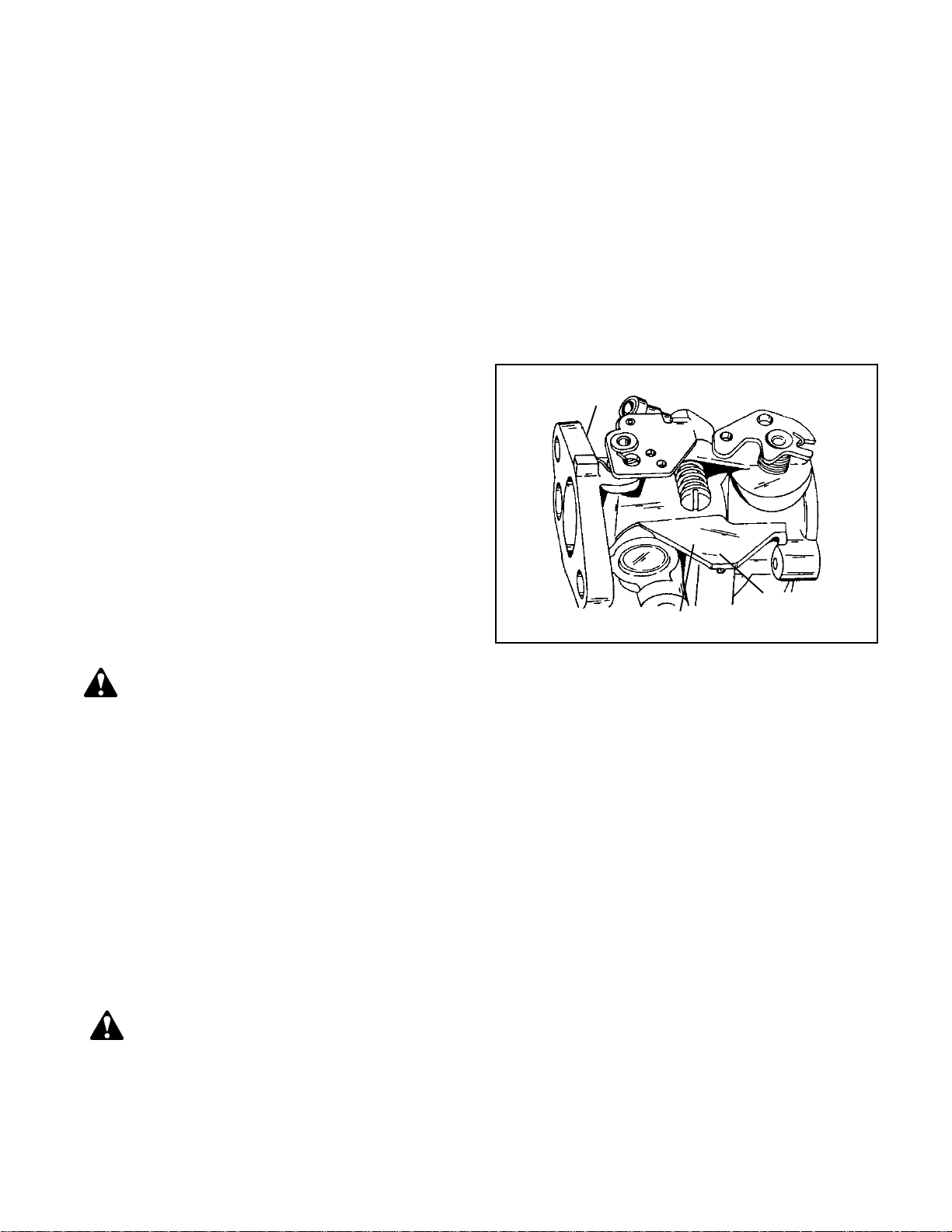

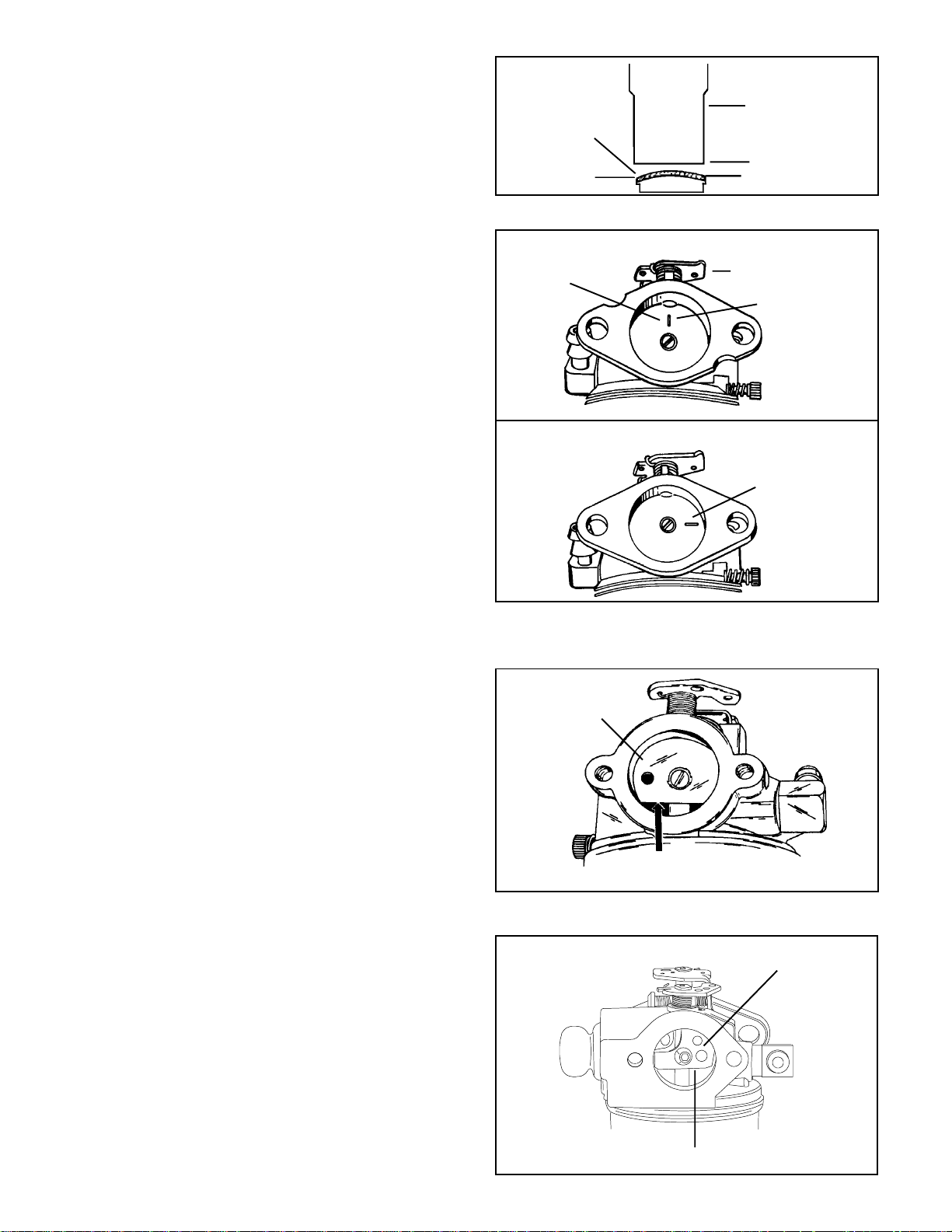

T ecumseh carburetors are identified by a manufacturing number and date code stamped on the carburetor as illustrated

(diag. 1).

When servicing carburetors, use the engine model and

specification number to obtain the correct carburetor part

number. An alternate method of finding the correct

carburetor part number is to use the manufacturing number

stamped on the carburetor and convert this number to a

part number. In the carburetor section of the Master Parts

ALTERNATE LOCATION

FOR MANUFACTURING

NUMBER

8

9

4

F

5

Manual, Microfiche Catalog or computer parts look-up

system, a cross reference chart will convert a carburetor

manufacturing number to a T ecumseh part number .

Complete carburetor replacement may be accomplished

89 4F5

with a standard service carburetor. A standard service

carburetor is a basic carburetor that may require the use

of original carburetor parts or additional new parts to adapt

to the specification. An instruction sheet is provided with

the new service carburetor or see “SERVICE” in this chapter .

MANUFACTURING

NUMBER

CARBURETOR

DATE CODE

1

CAUTION: DRAIN THE FUEL INTO AN APPROVED CONT AINER OUTDOORS, AND AW A Y FROM ANY OPEN

FLAME OR COMBUSTION SOURCE. BE SURE THE ENGINE IS COOL.

NOTE: Todays fuels can cause many problems in an engines performance, due to the fuels quality and short shelf life.

Always check fuel as a primary cause of engine performance.

1. Remove the air filter, heater box, or air cleaner assembly if applicable to visually check that the choke shutter

completely closes or check to see if fuel comes out of the main nozzle during priming.

2. If the fuel flow from the tank is adequate and no fuel is evident during priming, the carburetor will need to be

removed for service. See “Service” in this chapter or consult the “Carburetion Troubleshooting” chart to diagnose

carburetor symptoms. Improper fuel flow indicates the fuel, fuel line, filter or tank require cleaning or replacement.

3. Check the engine compression using a commercially available compression tester and follow the tester’s

recommended procedure. Low compression, a dry spark plug, adequate fuel flow, and a known good functional

carburetor indicates an internal engine problem exists. See under “Troubleshooting.”

4. A wet spark plug indicates fuel is being supplied by the carburetor. The engine may be flooded by a restricted

air filter, carbon shorted or defective spark plug, excessive choking or over priming, improperly adjusted or

defective carburetor. With the spark plug removed and a shop towel over the spark plug hole, turn the engine

over slowly 3 or 4 times to remove excess gasoline from the engine cylinder.

CAUTION: KEEP ALL COMBUSTIVE SOURCES AWAY. AVOID THE SPRAY FROM THE SPARK PLUG

HOLE WHEN CRANKING THE ENGINE OVER.

5. Replace the air filter if restricted or oil soaked. Replace the spark plug if questionable. Install the spark plug and

high tension lead and try to start the engine.

6. If the engine floods and fails to start, the carburetor will require service. See the proceeding “Carburetion

Troubleshooting” chart for additional causes. If the carburetor is functioning properly the problem may be ignition

timing related. See “Troubleshooting" under "Ignition”.

7

Page 12

OPERATION

In the “CHOKE” or “START” position, the choke shutter is closed and the only air entering the engine enters through

openings around the shutter. As the engine starts to rotate, downward piston travel creates a low air pressure area (or

vacuum) above the piston. Higher pressure (atmospheric) air rushes into the engine and fills this low pressure area. Since

the majority of the air passage is blocked by the choke shutter, a relatively small quantity of air enters the carburetor at

an increased speed. The main nozzle and both idle fuel discharge ports are supplying fuel due to the low air pressure in

the engine intake. Maximum fuel flow through the carburetor orifices combined with the reduced quantity of air that

passes through the carburetor, make a very rich fuel mixture which is needed to start a cold engine.

At engine IDLE speed, a relatively small amount of fuel is required to operate the engine. The throttle is almost completely

closed. Fuel is supplied through the primary idle-fuel discharge orifice.

NOTE: Dual system carburetors do not have an idle circuit.

During INTERMEDIA TE engine operation, a second orifice is uncovered as the throttle shutter opens, and more fuel is

allowed to mix with the air flowing into the engine.

During HIGH SPEED engine operation, the throttle shutter is fully opened. Air flows through the carburetor at high speed.

The venturi, which decreases the size of the air passage through the carburetor, further accelerates the air flow . This high

speed movement of the air decreases the air pressure at the main nozzle opening. Fuel is forced out the main nozzle

opening due to the difference in the air pressure on the fuel in the carburetor bowl and the reduced air pressure at the main

nozzle opening.

For the fuel to flow, the carburetor bowl must be either

vented externally or internally . Some internally vented float

style carburetors use a tygon tube and a vent within the air

intake. This tube must be present for the carburetor to

operate properly (diag. 2).

Air is bled into the main nozzle and through the air bleed

located in the air horn. This mixes the fuel and air prior to

the fuel leaving the main nozzle. Atomization occurs as

the fuel mixture contacts the fast moving air stream. This

mist then flows into the intake of the engine.

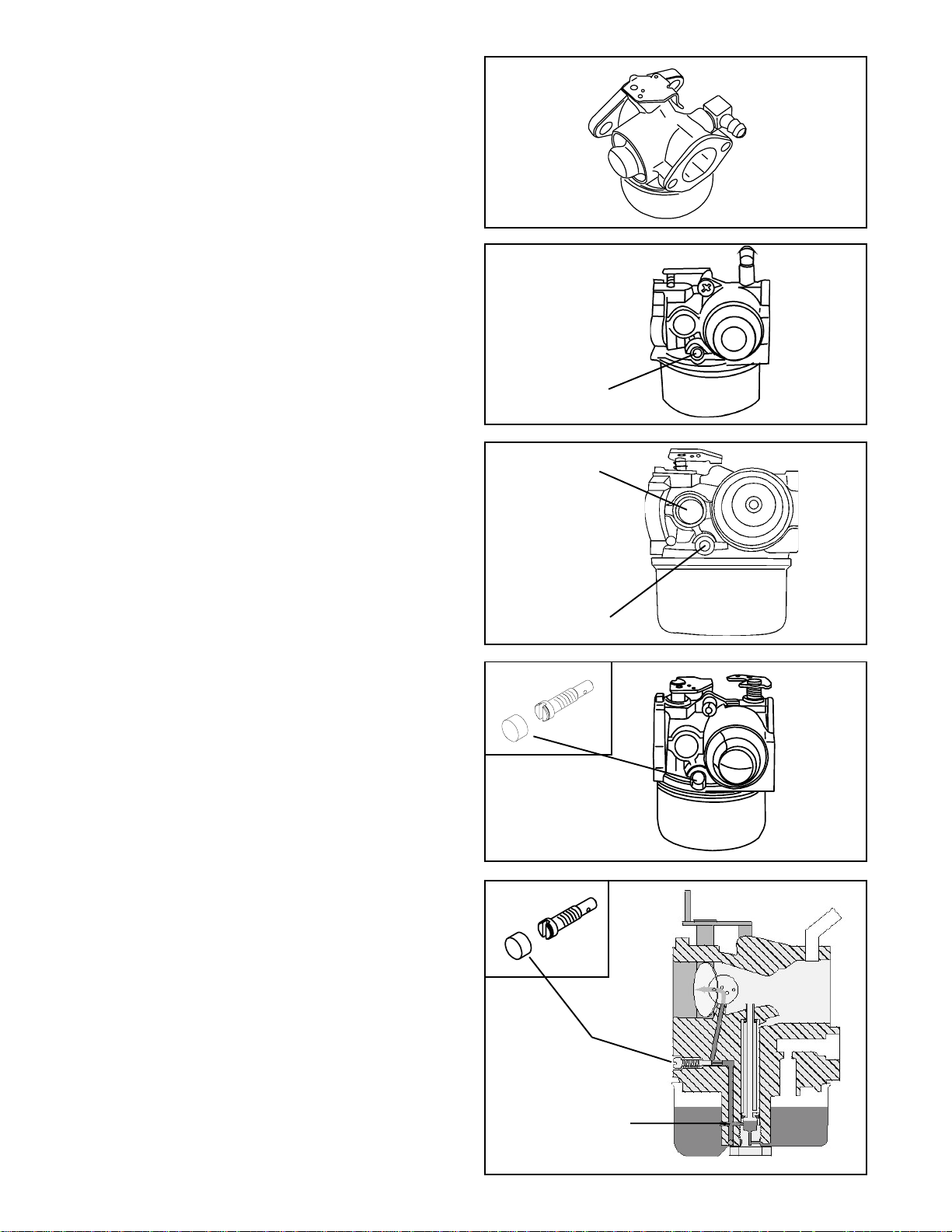

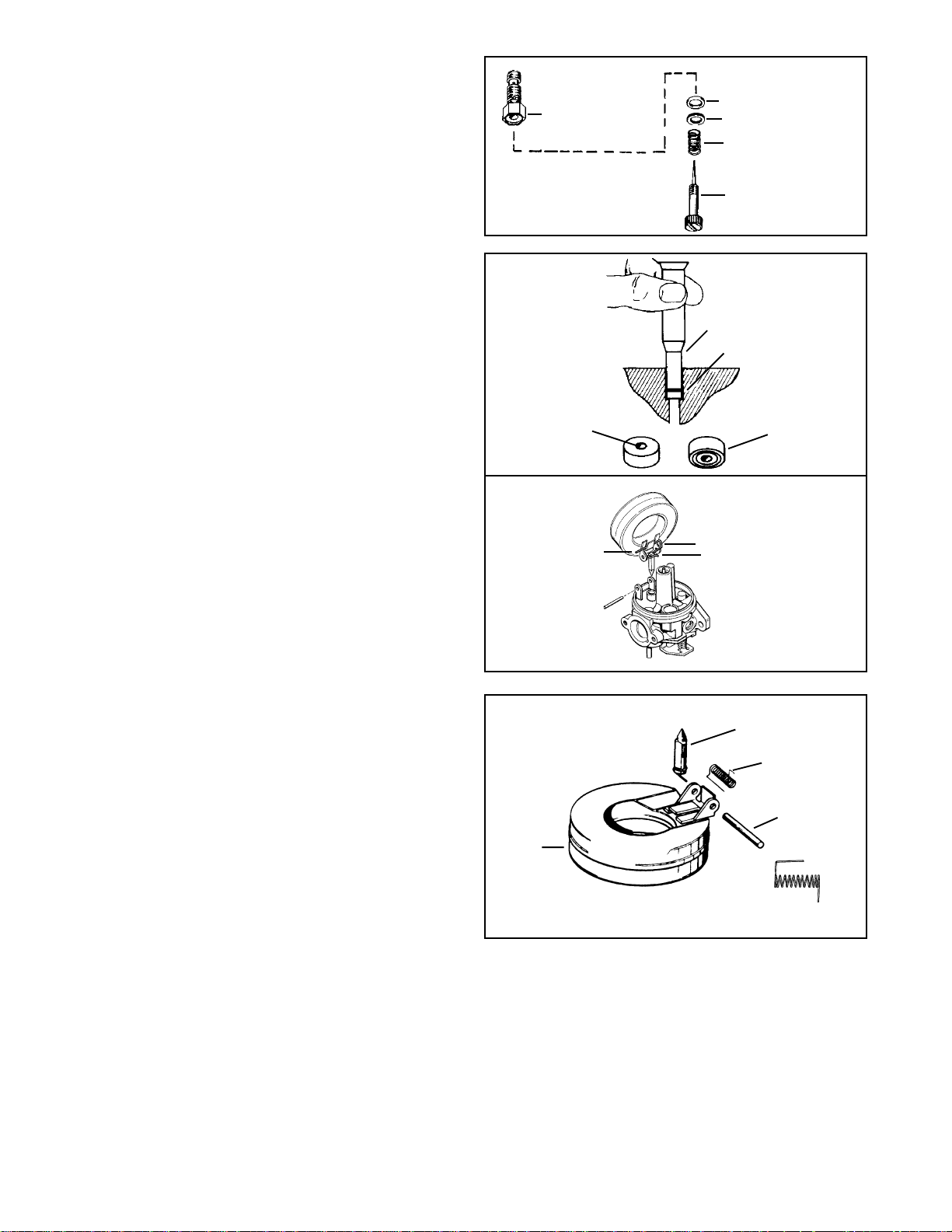

FUEL PRIMERS

Primers may be mounted remotely or as an integral part of

the carburetor. The basic function of the primer is to supply

a charge of air to the carburetor main well, or carburetor

bowl. On diaphragm carburetors it displaces fuel directly

into the carburetor venturi. This displaced fuel provides a

rich mixture necessary for engines to start easily on the

first or second attempt (diag. 3 & 4).

Primers must be vented either internally (a passage in the

carburetor air horn prior to the venturi) or externally (through

a hole in the primer bulb). The vent allows air to fill the

primer bulb after the primer bulb is released. On diaphragm

carburetors a one way valve in the body prevents the fuel

from being forced back into the fuel tank.

Two different methods are used to prime float style

carburetors, leg prime and bowl prime. The leg prime

system is used only on the dual system carburetor. Air is

forced into the center leg of the carburetor, which then forces

an enriched mixture of fuel up the main nozzle. The bowl

prime method is used on Series 6, 8, 9 and 10 carburetors

and is distinguished by a stepped or hour glass shaped

primer bulb. A good seal of the primer bulbs center lip is

critical to assure that a full charge of air reaches the bowl.

Also critical is a tight seal around the float bowl.

TYGON TUBE

LOCATION

BOWL PRIME

PRIMER BULB

3

PRIMER BULB

MAIN NOZZLE

EMULSION

TUBE

MAIN JET

2

4

NOTE: Never re-use a bowl gasket.

8

5

Page 13

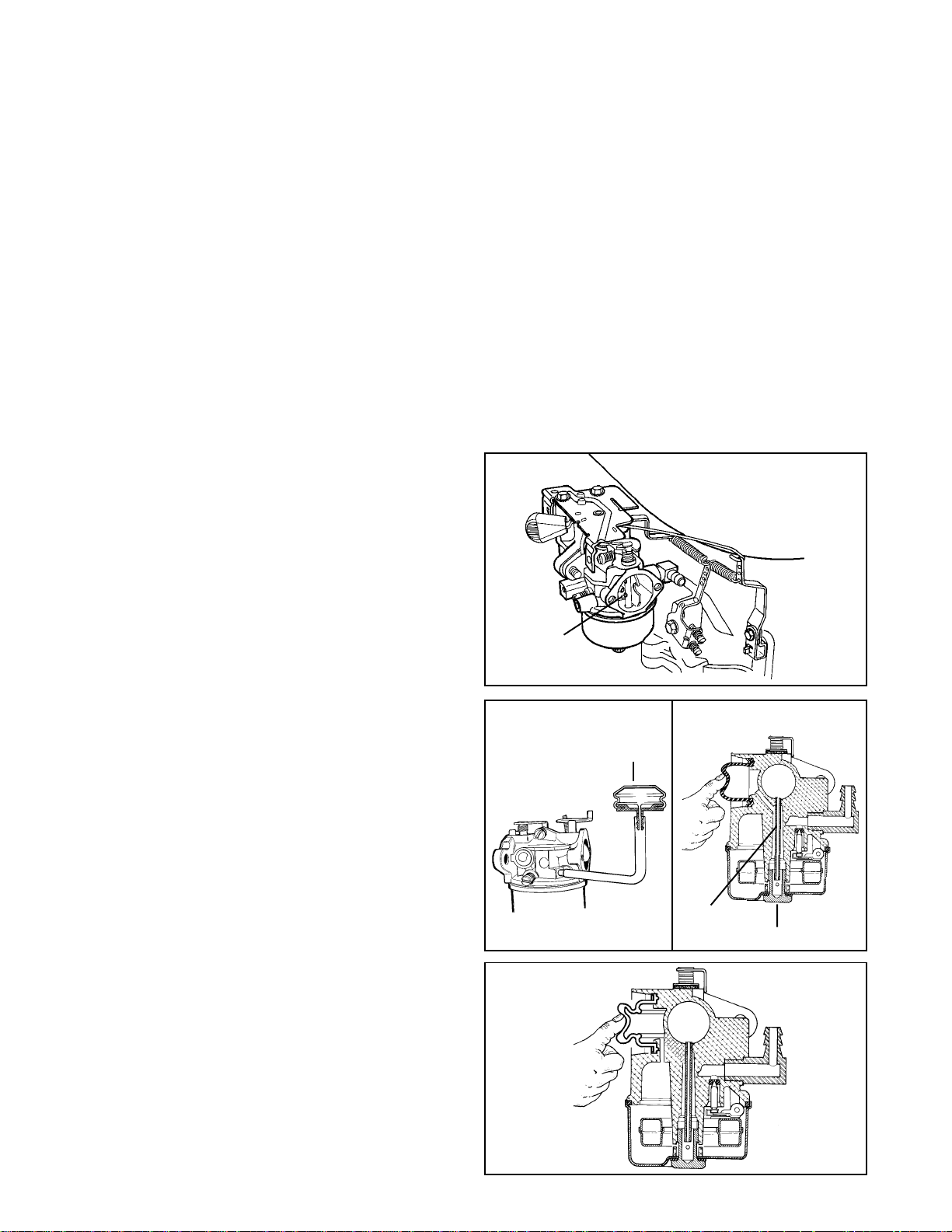

IMPULSE FUEL PUMPS

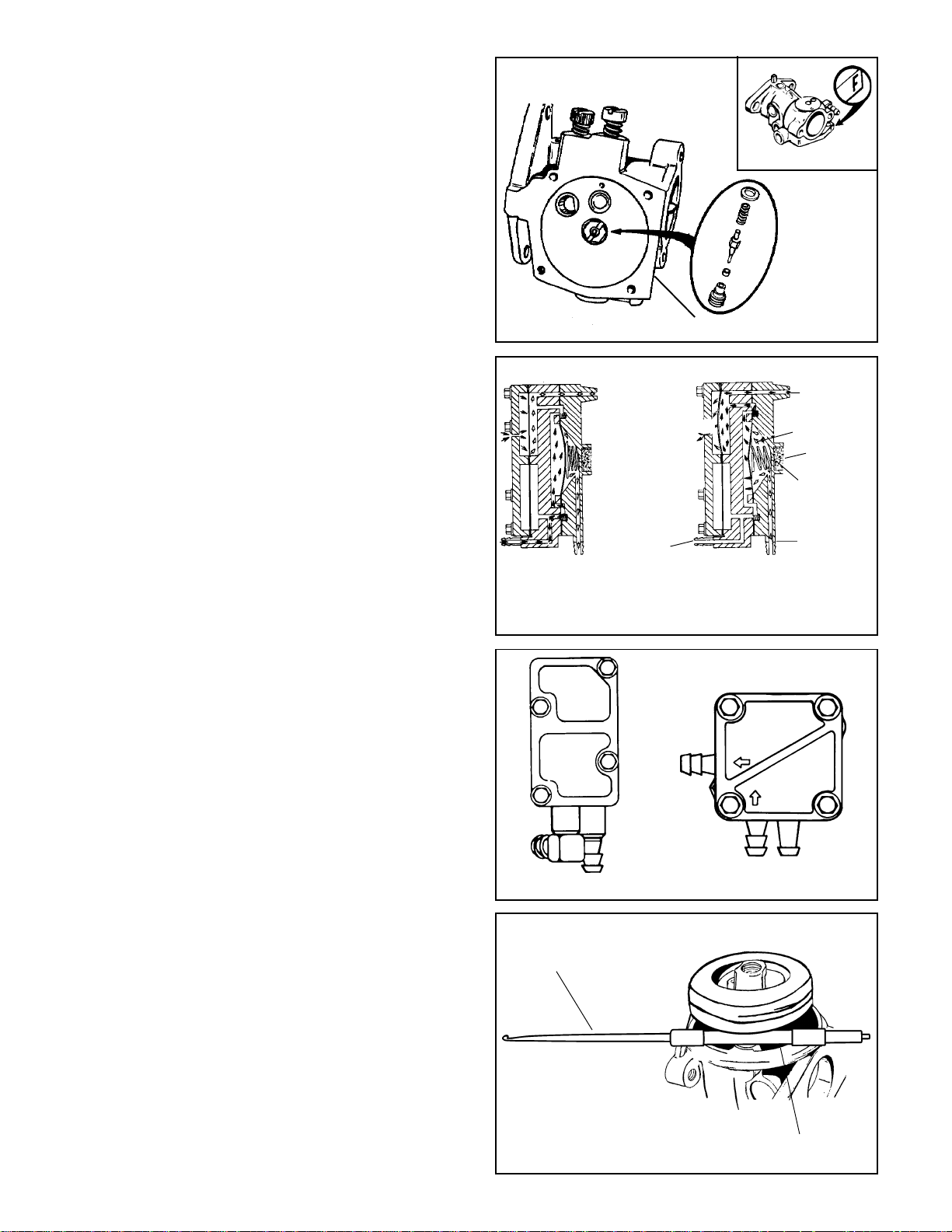

Impulse fuel pumps may either be mounted externally onto

the carburetor fuel inlet or remotely mounted. These pumps

are connected in the fuel line between the fuel supply and

the carburetor or directly to the fuel inlet.

Impulse fuel pumps are operated by crankcase impulses

created by the up and down movement of the piston. A

hose called a pulse line connects the fuel pump diaphragm

chamber to the crankcase and transmits these impulses

to the pump diaphragm. The impulses actuate the

diaphragm and flap valves to lift the fuel from the fuel tank

to the carburetor (diag. 6).

6

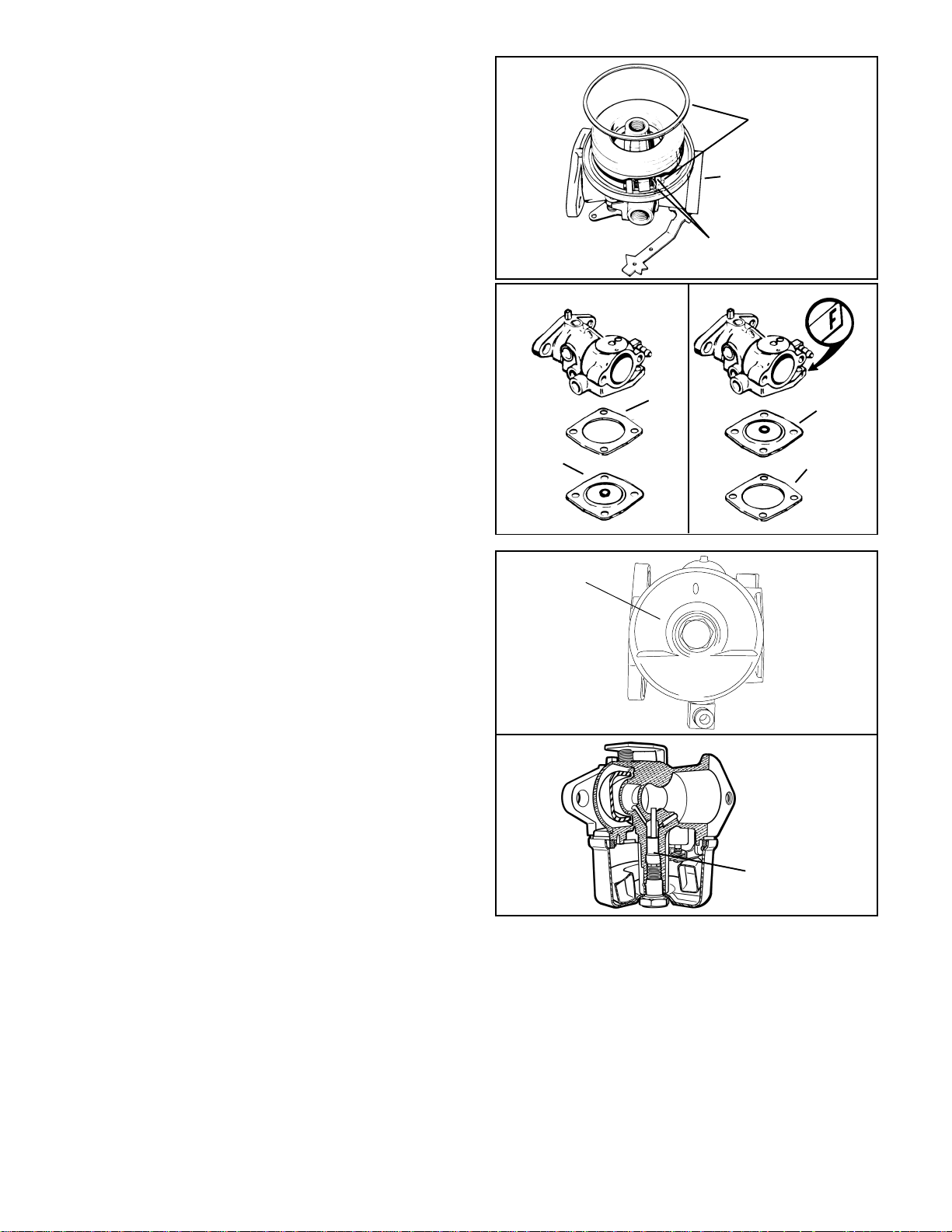

FLOAT STYLE CARBURETORS

A float is used to maintain the operating volume of fuel in

the carburetor bowl. As the fuel is used by the engine, the

fuel volume in the carburetor bowl drops and the float moves

downward. This allows the inlet needle valve to move off

the sealing seat. Fuel flows by gravity or a pulse pump into

the fuel bowl. As the fuel volume in the bowl again rises, it

raises the float. This upward float motion moves the inlet

needle valve to the closed position. When the needle

contacts the seat, the fuel flow is stopped. The tapered

end of the inlet needle varies the fuel flow rate so that the

fuel volume in the carburetor bowl will remain constant (diag.

7). The float height is set according to the service procedure.

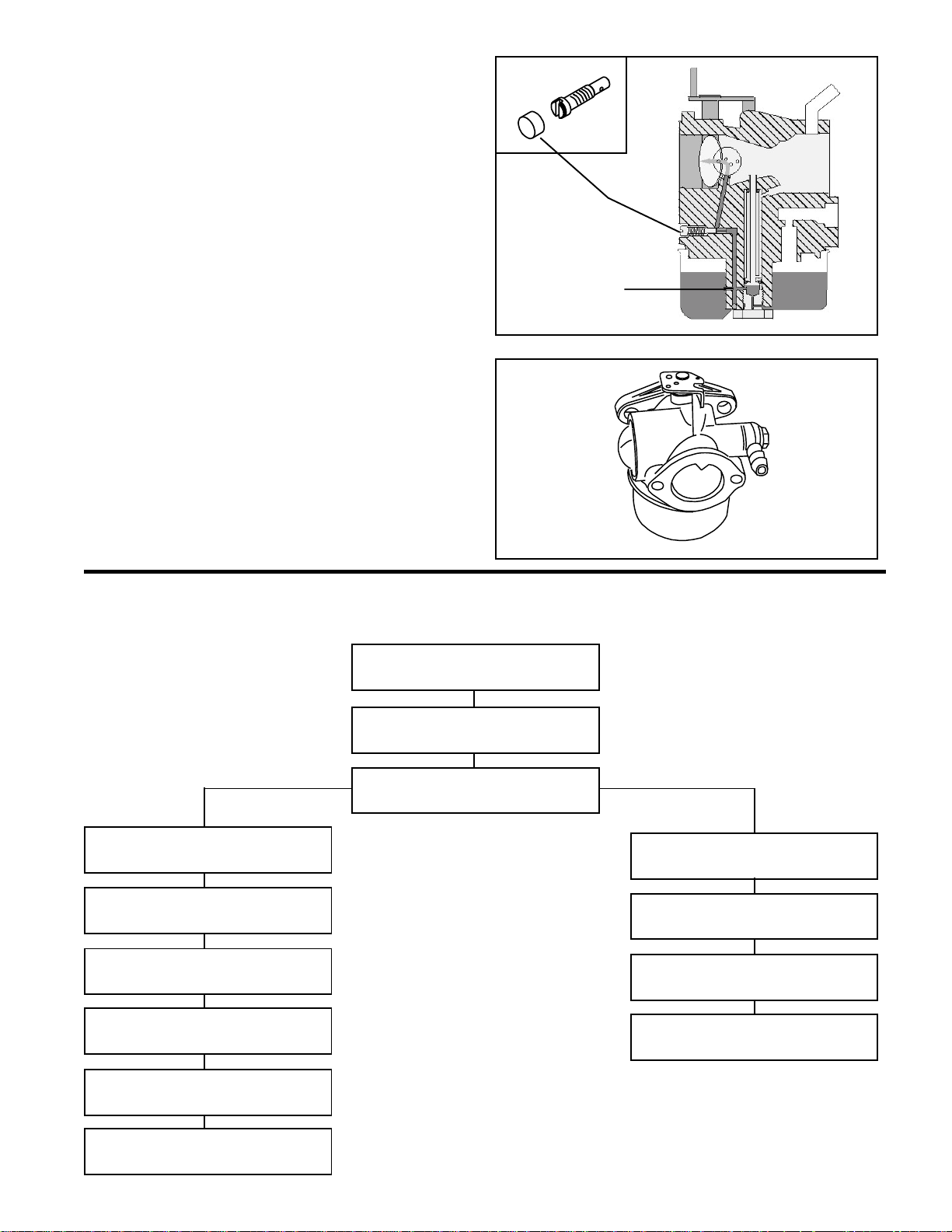

DIAPHRAGM (PRESSURE DIFFERENTIAL)

CARBURETORS

This type of carburetor uses a rubber-like diaphragm which

is exposed to intake manifold pressure on one side and to

atmospheric pressure on the other. Tecumseh diaphragm

carburetors use the diaphragm as a metering device. As

the intake manifold pressure decreases due to downward

piston travel, the atmospheric pressure on the vented side

of the diaphragm moves the diaphragm against the inlet

needle. The diaphragm movement overcomes the spring

tension on the inlet needle and moves the inlet needle off

the seat. This permits the fuel to flow through the inlet

valve to maintain the correct fuel volume in the fuel chamber.

The inlet needle return spring closes the inlet valve when

the pressure on the diaphragm equalizes or a pressure

higher than atmospheric exists on the intake side (upward

piston travel). The diaphragm meters a correct fuel volume

in the fuel chamber to be delivered to the mixing passages

and discharge ports (diag. 8).

IDLE AND

PROGRESSION

HOLES

THROTTLE

SHUTTER

IDLE

ADJUSTMENT

MAIN NOZZLE

EMULSION

TUBE

THROTTLE

SHUTTER

IDLE

ADJUSTMENT

IDLE AIR

BLEED

MAIN

ADJUSTMENT

CHECK BALL

MAIN AIR

BLEED

CHOKE

SHUTTER

INLET NEEDLE

AND SEAT

FLOAT

7

CHOKE

SHUTTER

NEEDLE AND

SEAT ASSEMBLY

A main or idle adjustment needle may be replaced by an

internally fixed jet on some models.

The main nozzle contains a ball check valve. The main

purpose of this ball check is to eliminate air being drawn

down the main nozzle during idle speeds and leaning the

idle mixture.

An advantage of the diaphragm carburetor over the float

system is that the diaphragm carburetor increases the angle

that the engine may be operated at.

MAIN

ADJUSTMENT

DIAPHRAGM

8

9

Page 14

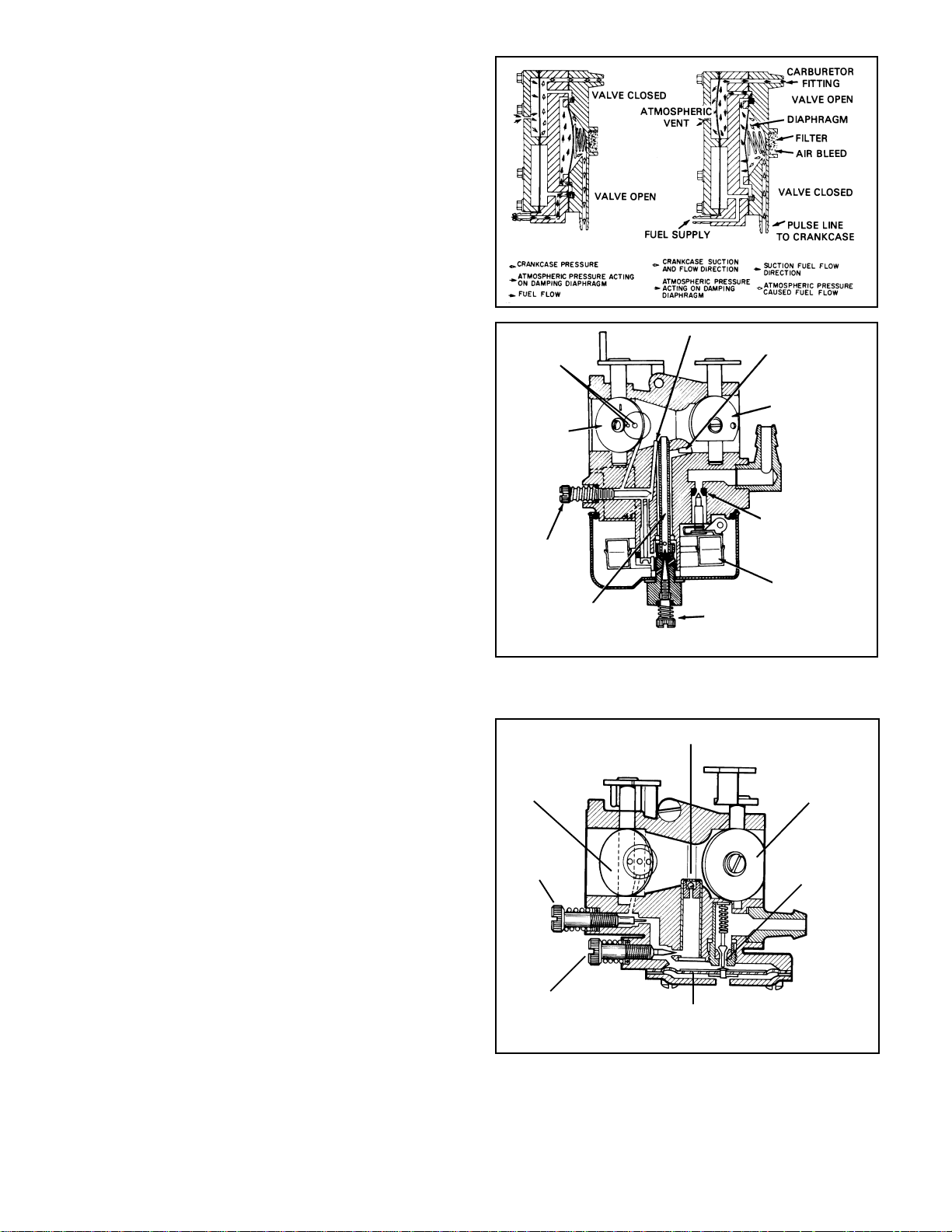

COMPONENTS

Loosen screw until it just clears throttle

lever, then turn screw in 1 turn.

Place detent reference mark to proper

location.

Check spring for return action and binding.

Remove welch plug and blow air

through air passages.

Remove adjustment screw. T o adjust

20° slant engines, the engine must be

mounted in its normal 20° slant position.

Check ball is not serviceable on some

models.

*NON METALLIC ITEMS - CAN BE DAMAGED

BY HARSH CARBURETOR CLEANERS

Blow air through passage.

Check shaft for looseness or binding.

Shutter must be positioned with detent

reference marks on top parallel with

shaft and to the right or 3 o'clock position.

Check spring for return action

and binding.

Remove idle adjustment screw. Check

needle tip and condition of "O" ring.

Remove welch plug and blow out all

passages.

NOTE: On models which have metering

rods, do not install idle adjustment screw

with carburetors upside down, as pin

will obstruct movement of adjustment

screw causing damage

*NON METALLIC ITEMS - CAN BE DAMAGED

BY HARSH CARBURETOR CLEANERS

IDLE AND INTERMEDIATE

AIR BLEED

THROTTLE SHAFT AND LEVER

THROTTLE SHUTTER

DETENT

REFERENCE MARK

THROTTLE SHAFT

RETURN SPRING

IDLE AND INTERMEDIATE

ORIFICES

IDLE AND INTERMEDIATE

FUEL CHAMBER (COVERED

WITH WELCH PLUG)

IDLE AND INTERMEDIATE

FUEL MIXTURE PASSAGE

*IDLE ADJUSTMENT SCREW

AND "O" RING

ATMOSPHERIC VENT

SOFT BAFFLE PLUG

IDLE AND INTERMEDIATE

FUEL TRANSFER PASSAGE

METERING ROD OR PIN IN

FUEL TRANSFER PASSAGE

BALL PLUG

CUP PLUG

IDLE AND INTERMEDIATE

FUEL TRANSFER PASSAGE

IDLE AND MAIN FUEL PICK UP ORFICE

10

IDLE SPEED ADJUSTMENT SCREW

THROTTLE SHAFT AND LEVER

DETENT REFERENCE MARK

ON THROTTLE SHUTTER

THROTTLE SHUTTER

THROTTLE SHAFT

RETURN SPRING

IDLE PROGRESSION

HOLE

IDLE AIR BLEED

*IDLE MIXTURE

ADJUSTMENT

SCREW AND "O"

RING (If Present)

*MAIN MIXTURE

ADJUSTMENT

SCREW AND "O"

RING (If Present)

WELCH PLUG (If Present)

*MAIN NOZZLE CHECK BALL (If Present)

IDLE

(DO NOT REMOVE)

CHOKE SHAFT AND LEVER

CHOKE SHUTTER

MAIN NOZZLE

*INLET

FITTING

SCREEN

*INLET

FITTING

*INLET SEAT

GASKET

*INLET NEEDLE

SEAT AND

SPRING

ASSEMBLY

*DIAPHRAGM GASKET

*DIAPHRAGM

ATMOSPHERIC VENT HOLE

IDLE SPEED ADJUSTMENT

MAIN NOZZLE

(EMULSION TUBE)

CHOKE SHAFT

AND LEVER

CHOKE PLATE

HIGH SPEED

AIR BLEED

INLET

FITTING

*INLET NEEDLE

AND SEAT

*FLOAT BOWL

GASKET

FLOAT

SHAFT

NUT AND MAIN ADJUSTMENT SEAT

*MAIN ADJUSTMENT SCREW AND

"O" RING SEAL

INLET

NEEDLE CLIP

(If Present)

IDLE FUEL TRANSFER PASSAGE

AND ANNULAR GROOVE

FLOAT

FLOAT BOWL

*GASKET

Check shaft for binding. Position shutter opening towards inlet fitting side or

air horn.

Blow air through passage.

Part of inlet fitting. If fuel is restricted,

clean or replace fitting.

Bulb primer models have Viton* one

way valve, in or behind fitting.

Remove and replace.

Proper installation of assembly is important.

Gasket and diaphragm sequence may

be reversed on some models. Head of

rivet must touch inlet needle. Rivet is

hooked into inlet needle control lever on

some models.

Hole must be clean. On models with

bulb primer, vent hole is very small and

is located off center.

Loosen screw until it just clears throttle

lever, then turn screw in one turn.

Removable on emission carbs. nonmetallic only.

Check shaft for binding position opening to bottom of air horn.

Blow air through passage. Do not remove restrictor if present.

Proper installation is important.

Replace.

Must hook over float tab.

Check float for leaks or dents. Clean

bowl and adjust float level position gasket or gaskets.

If the carburetor is used on a 20° slant

engine, the engine must be in its normal

20° slanted position for adjustment.

Check needle for damage and "O" ring

for cracks. Clean all passages in nut

with compressed air.

9

10

Page 15

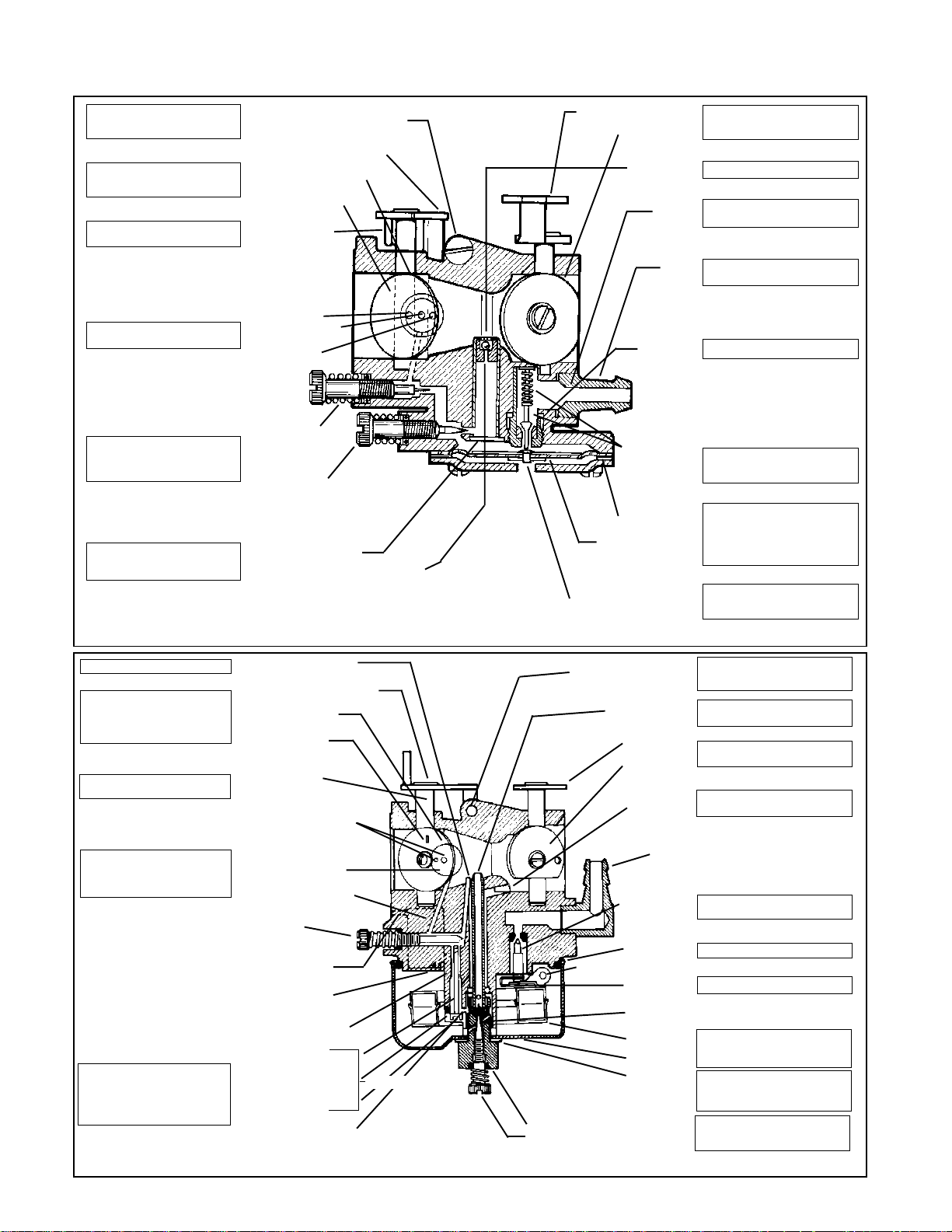

CARBURETOR IDENTIFICATION

Tecumseh has a variety of carburetors. To help identify

these carburetors here are some simple procedures to

follow.

DUAL SYSTEM CARBURETORS

The easiest way to identify the dual system carburetor is

by the presence of a large primer bulb located on the side

of the carburetor. The absence of adjustment needles help

to identify the carb as well. The dual system carburetor is

used on 4-cycle vertical crankshaft rotary mower engines.

(diag. 1 1).

SERIES 1 CARBURETORS

Series 1 carburetors come in a variety of styles. They are

used on both 2 and 4 cycle vertical and horizontal shaft

engines in the 2 through 7 h.p. range. It is a float style

carburetor with a smaller venturi than the Series 3 and 4

carburetors. Some will have an adjustable idle and main

and others will have a fixed main with an adjustable idle.

There are also some fixed speed applications that will only

have a fixed main system and the idle system will not be

drilled. (diag. 12).

11

12

NOTE: Emissionized carburetors will have a fixed jet.

SERIES 3 & SERIES 4 CARBURETORS

Series 3 and 4 carburetors are generally used on 8 through

12.5 horsepower 4-cycle engines. The venturi size of these

carburetors are larger than Series 1 and Dual System

Carburetors. The quickest way to identify these carburetors

is by the presence of bosses on each side of the idle mixture

screw. To identify the Series 3 from a Series 4, view the

carburetor from the throttle end. The Series 3 has (1) screw

securing the throttle plate and the Series 4 uses (2) screws.

(diag. 13 - 15)

DIAPHRAGM CARBURETORS

The diaphragm carburetors are unique. These carburetors

can be operated at a more severe angle than float style

carburetors. They still require that the fuel supply be located

in a position that allows it to be gravity fed. Its most

distinctive feature is the lack of a fuel bowl. (diag. 16).

BOSSES

SERIES 3

14

SERIES 4

13

15

NOTE: Emissionized carburetors will have a fixed jet.

16

11

Page 16

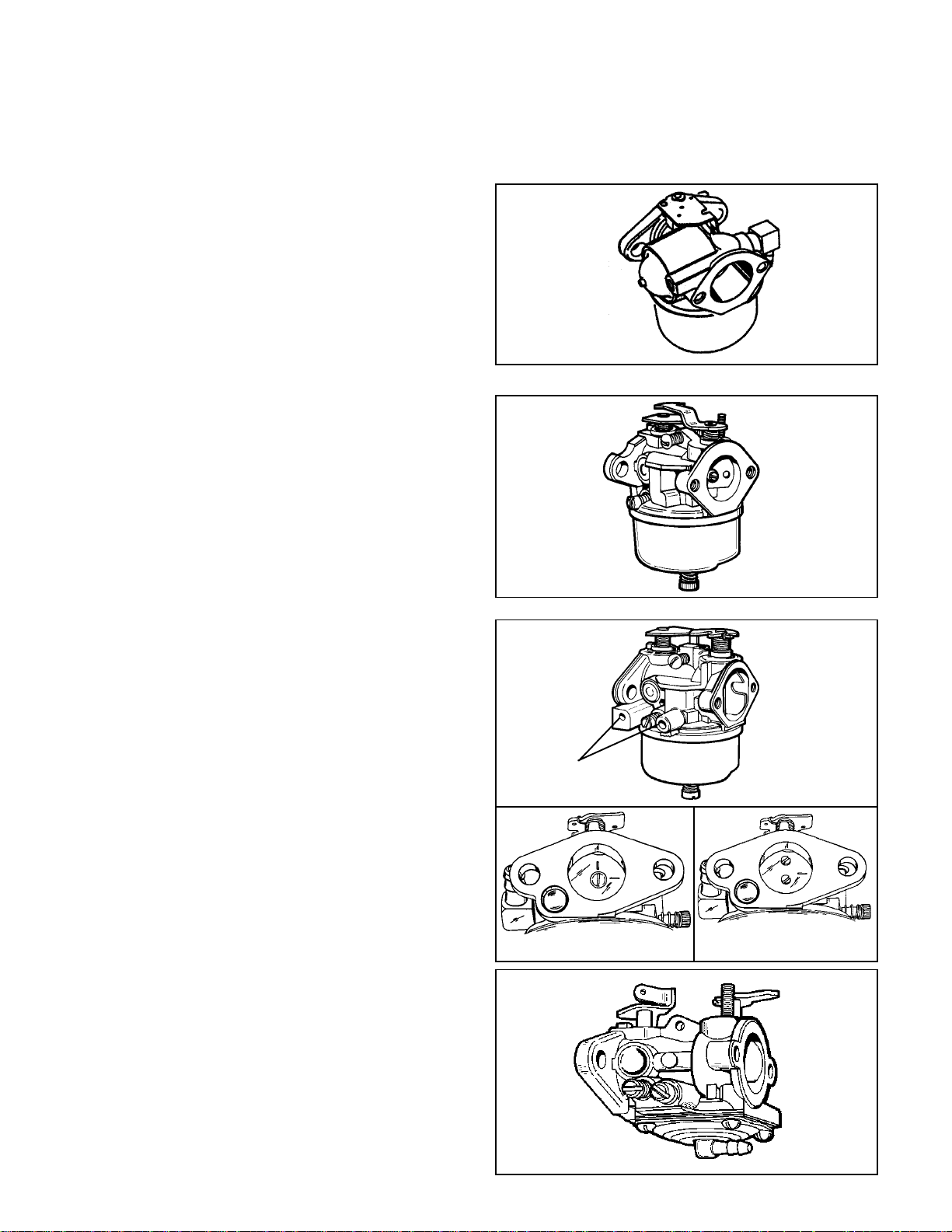

SERIES 6 CARBURETORS 4-CYCLE

Series 6 carburetors are used on 2 and 4-cycle engines.

They have a larger venturi than the dual system carburetor

and use a simple fixed idle system. Series 6 carburetors

used on both vertical and horizontal applications are

nonadjustable. The 4 cycle version pictured has a stepped

primer bulb. (diag. 17).

SERIES 8

The Series 8 carburetor has both a fixed main and idle

circuit. The fixed idle system uses a restricted jet that

meters the fuel. The idle restrictor jet will be capped to

prevent access unless removed. The fixed main jet is part

of the bowl nut. A ball plug is visible from the bottom, which

seals the metering passage. This carburetor also has a

serviceable main nozzle emulsion tube. It also has a

stepped primer bulb to assist in starting. (diag. 18)

SERIES 9

GREY

CAPPED FIXED

JET

MIXING WELL

CAST BUT NOT

MACHINED

17

18

The Series 9 carburetor uses the same body as the Series

8 but has a simple fixed idle system, identical to the one

used on the Series 6 carburetor. It has the idle discharge

port located at the 7 o'clock position on the throttle end of

the carburetor. Identify this carburetor by the stepped primer

bulb, the presence of a non-drilled idle mixing well and a

serviceable main nozzle emulsion tube. (diag. 19)

SERIES 10 (EMISSION)

The Series 10 carburetor is identical to the Series 8

carburetor with the addition of a choke to assist in cold

weather starts. It also has a fixed idle and main. The idle

restrictor jet is capped to prevent access unless the cap is

removed. The fixed main jet is part of the bowl nut. A ball

plug is visible from the bottom, which seals the metering

passage. This carburetor also has a serviceable main nozzle

emulsion tube and a stepped primer bulb to assist in

starting. (diag. 20)

SERIES 11

The Series 11 carburetor is used on most LEV model

engines. This carburetor contains a patented autoenrichment system for improved starting and performance

of a cold engine. The system contains a fuel well that is

filled as part of the priming procedure and emptied as the

engine runs in the first minute. This added fuel provides

smooth operation of today’s emission grade engines. The

carburetor can be identified externally by the BLACK

colored restrictor cap (diag. 21). Internally the standard

Series 1 1 is identified by the plugged passage as shown.

IDLE JET

CAST BUT NOT

MACHINED

BLACK CAP

19

20

12

HOLE PLUGGED

21

Page 17

SERIES 11 BRIDGED

Externally this carburetor looks identical to the standard

series 11 with the black restrictor cap. The difference is

internal through the addition of a second idle feed passage

with a restrictor as shown. This extra passage improves

run quality during light load engine operation (diag. 22).

BLACK CAP

ADDED

RESTRICTOR

NON-TECUMSEH CARBURETORS

DELLORTO CARBURETOR

The Dellorto carburetor is similar to the dual system

carburetor. It has no adjustments and has a primer assist

start. It has a noncorrosive float and the needle is viton

tipped, eliminating the viton seat found in the dual system

carburetor. The angle of the fuel inlet is adjustable and

attached to the carburetor body with a banjo bolt. This

carburetor is used on some TVS rotary lawnmower

engines.

ENGINE

TROUBLESHOOTING

Engine Will Not Start

Check For Spark

22

23

Wet Dry

Check If Spark Plug Is Wet or Dry

Defective Spark Plug Check Fuel Supply and Fuel

Cap Vent

Restricted Air Filter Restriction in Fuel System

(filter, screen)

Improper or Stale Fuel Carburetion Problem

Sheared or Partially Sheared

Flywheel Key Poor Compression

Carburetion Problems Due to

Flooding, Over Priming, etc.

Ignition System

13

Page 18

AIR SYSTEM

PROBLEMS

CARBURETION

TROUBLESHOOTING

START IDLE ACCELERATE HIGH SPEED

Will

Not

Run at

High

Speed

Low

Power

Hunts at

High

Speed

Runs with

Needle

Closed

Hard

Starting

Fuel Leak

at

Carburetor

Engine

Floods

Will Not

Idle

Rich Idle

Idles with

Needle

Closed

Hunts Erratic

Idle

Idles

Fast Lean

Will Not

Accelerate

Over Rich

Acceleration

Hesitates

Engine

Overspeeds

Plugged Air Filter

Leaky Carburetor

Gasket

Throttle or Choke

Shafts Worn

Choke Not

Functioning

Properly

Plugged

Atmospheric Vent

Air Bleed

Restricted

Damaged or

Leaky "O" Rings

DIAPHRAGM

SYSTEM

PROBLEM

Damaged

Diaphragm

Stuck or Dirty Ball

Check

Diaphragm

Upside Down

Á

Á

Á

Á

Á

ÁÁ

Á

Á

Á

Á

Á

Á

ÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

ÁÁ Á Á

Á

ÁÁ

Á

Á

ÁÁÁÁ

ÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

FUEL SYSTEM

PROBLEM

Plugged Tank

Filter or Vent

Fuel Pick-up

Restricted

Idle Port

Restricted

Damaged

Adjustment

Needles

Incorrect Float

Height

Main Nozzle

Restricted

Dirty, Stuck

Needle and Seat

Fuel Inlet Plugged

14

Á

ÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

ÁÁ

Á

Á

Á

Á

Á

Á

ÁÁ

ÁÁ

Á

Á

Á

ÁÁÁ

ÁÁ

ÁÁ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Page 19

TESTING

1. After repeated efforts to start the engine using the procedure listed in the operator’s manual fail, check for spark by

removing the high tension lead and the spark plug. Install a commercially available spark plug tester and check for

spark. If spark is evident and acceptable, proceed to step 2. If no or weak spark, see Chapter 8 under "T esting".

2. Visually inspect the spark plug for a wet condition indicating the presence of gasoline in the cylinder .

3. If the spark plug is dry, check for restrictions in the fuel system before the carburetor. If the spark plug is wet,

continue with step # 7. Check to see if the fuel cap vent is open. With a proper draining receptacle, remove the fuel

line clamp on the carburetor fuel inlet and pull the fuel line off the fitting to examine the fuel flow and fuel condition.

4. Remove the air cleaner element or air cleaner assembly to visually check that the choke shutter completely closes

or check to see if fuel comes out from the main nozzle during priming.

5. If the fuel flow is adequate and no fuel is evident during priming, the carburetor will need to be removed for service. See

“Service” in this chapter or consult the “Carburetion Troubleshooting” chart if other problems exist. Improper fuel flow

indicates the fuel, fuel line, filter or tank require cleaning or replacement.

6. Check the engine compression using a commercially available compression tester and follow the tester’s recommended

procedure. Low compression, a dry spark plug, adequate fuel flow, and a known good functional carburetor indicates

an internal engine problem exists. See Chapter 9 under “Engine Operation Problems.”

7. A wet spark plug indicates fuel is being supplied by the carburetor. The engine may be flooded by a restricted air filter ,

carbon shorted or defective spark plug, excessive choking or over priming, improperly adjusted or defective carburetor,

or the wrong ignition timing. With the spark plug removed and a shop towel over the spark plug hole, turn the engine

over slowly 3 or 4 times to remove excess gasoline from the engine cylinder.

CAUTION: KEEP ALL COMBUSTIVE SOURCES AWAY. AVOID THE SPRAY FROM THE SPARK PLUG

HOLE WHEN CRANKING THE ENGINE OVER.

8. Replace the air filter if restricted or oil soaked. Replace the spark plug if questionable. Install the spark plug and high

tension lead and retry starting the engine.

9. If the engine floods and fails to start, the carburetor may require service. See the preceding “Carburetion Troubleshooting”

chart for additional causes. If the carburetor is functioning properly the problem may be ignition timing related. See

Chapter 8 under “Ignition Troubleshooting.”

SERVICE

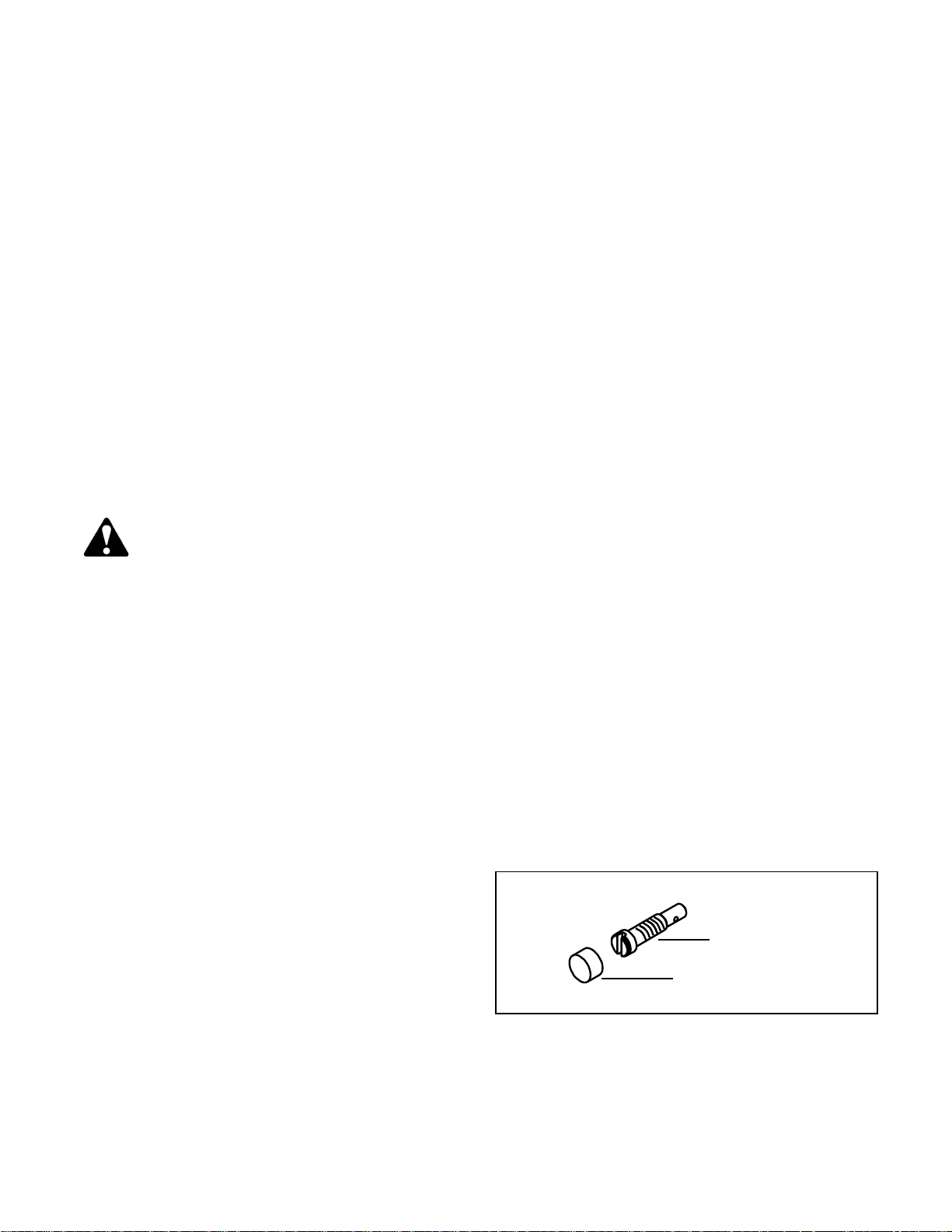

CARBURETOR PRE-SETS AND ADJUSTMENT

NOTE: EMISSION GRADE CARBURETORS HA VE FIXED IDLE AND MAIN JETS. THE ABSENCE OF THE ADJUSTING

SCREW INDICA TES A FIXED JET OR RESTRICTOR AND NO ADJUSTMENT IS NECESSARY . THE IDLE RESTRICTOR

ON AN EMISSIONS CARBURETOR APPEARS AS AN ADJUST ABLE SCREW. THIS IS NOT ADJUSTABLE AND

MUST REMAIN TIGHT FOR PROPER OPERA TION.

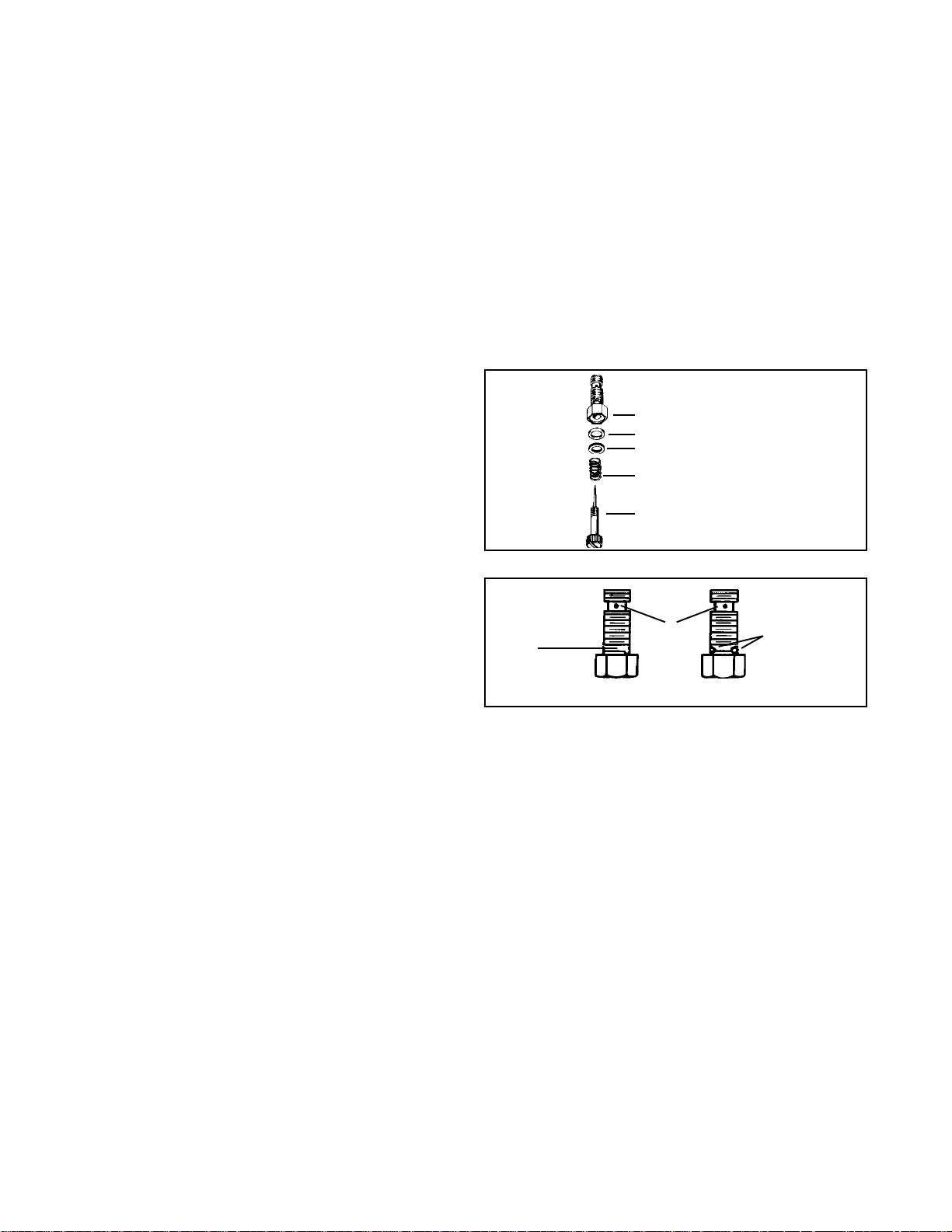

The idle on an emission is metered using a threaded

restrictor (see Illustration). Proper torque of this screw is

critical and should be torqued to 5-8 in. lbs. or .5 to 1 nm,

if not, it may vibrate loose. When the restrictor is placed in

the idle circuit passage it is capped with a tamper resistant

plastic cap. Tampering is considered the rejetting or

modification through resizing of the jet. If the jet is

removed for cleaning it must be recapped to prevent

tampering when it is re-installed.

IDLE RESTRICTOR

CAP

Before adjusting any mixture screws the necessary carburetor presets should be made. Check for the proper governor

adjustments as outlined in Chapter 4. Identify the correct carburetor model and manufacturer to find locations of the high

and low speed adjustment screws. Check the throttle control bracket for proper adjustment allowing a full choke shutter

position. See Chapter 4 under "Speed Controls and Linkage". Check to see if the normal maintenance procedures have

been performed (oil changed, fresh fuel, air filter replaced or clean). Consult microfiche card #30 to find the correct R.P .M.

settings for the engine, or consult Service Bulletin #107 for the revised safety specification for rotary type power lawn

mowers. Start the engine and allow it to warm to operating temperature. The carburetor can now be adjusted.

15

Page 20

PRE-SETS AND ADJUSTMENTS

(TECUMSEH AND WALBRO

CARBURETORS)

NOTE: OVERTIGHTENING WILL DAMAGE THE T APER

PORTION OF THE NEEDLE. All adjustments should be

made with the carburetor in the operating position.

Turn both the main and idle mixture adjusting screws in

(clockwise) until finger tight.

Now back the mixture screws out (counterclockwise) to

Engine Model

All models with float-type

carburetors

All models with diaphragm-type

carburetors

Carburetor Model Number

LMH

WHG & LME

LMK

Tecumseh Carburetors

Main Pre-set

1-1/2 turn 1 turn

1 turn 1 turn

Walbro Carburetors

1-1/2 turn

1-1/4 turn

Fixed

Idle Pre-set

1-1/2 turn

1-1/4 turn

1 turn

obtain the pre-set figure in the chart shown at right.

FINAL ADJUSTMENTS (NON EMISSION ENGINES)

Start the engine and allow it to warm up to normal operating temperature (3 - 5 minutes). Set the speed control to the

HIGH or FAST position. From the recommended preset position, turn the main mixture adjustment screw in (clockwise)

slowly until the engine begins to run erratic (lean). Note the position of the screw. Now , turn the screw out (counterclockwise)

until the engine begins to run erratic (rich). Turn the screw in (clockwise) midway between these two positions. This will

be the best setting. (diag. 24, 25 & 26).

Set the speed control to the IDLE or SLOW position. Adjust the idle mixture screw following the same procedure used to

adjust the main mixture adjustment screw.

TECUMSEH CARBURETORS

DIAPHRAGM

26

IDLE MIXTURE

SCREW

SERIES 1

MAIN MIXTURE

SCREW

24

IDLE MIXTURE

SCREW

SERIES 3 & 4

MAIN MIXTURE

SCREW

IDLE MIXTURE

25

SCREW

MAIN MIXTURE

SCREW

If further adjustment is required, the main adjustment should be made under a loaded condition.

If the engine stops or hesitates while engaging the load (lean), turn the main mixture adjusting screw out (counterclockwise)

1/8 turn at a time, testing each setting with the equipment under load, until this condition is corrected.

If the engine smokes excessively (rich), turn the main adjusting screw in (clockwise) 1/8 turn at a time, testing each

setting with the equipment under load, until this condition is corrected.

After the main mixture screw is set, move the speed control to the IDLE or SLOW position. If the engine does not idle

smoothly , turn the idle mixture screw 1/8 turn either in (clockwise) or out (counterclockwise) until engine idles smoothly .

Recheck the high and low R.P.M. setting and adjust as necessary.

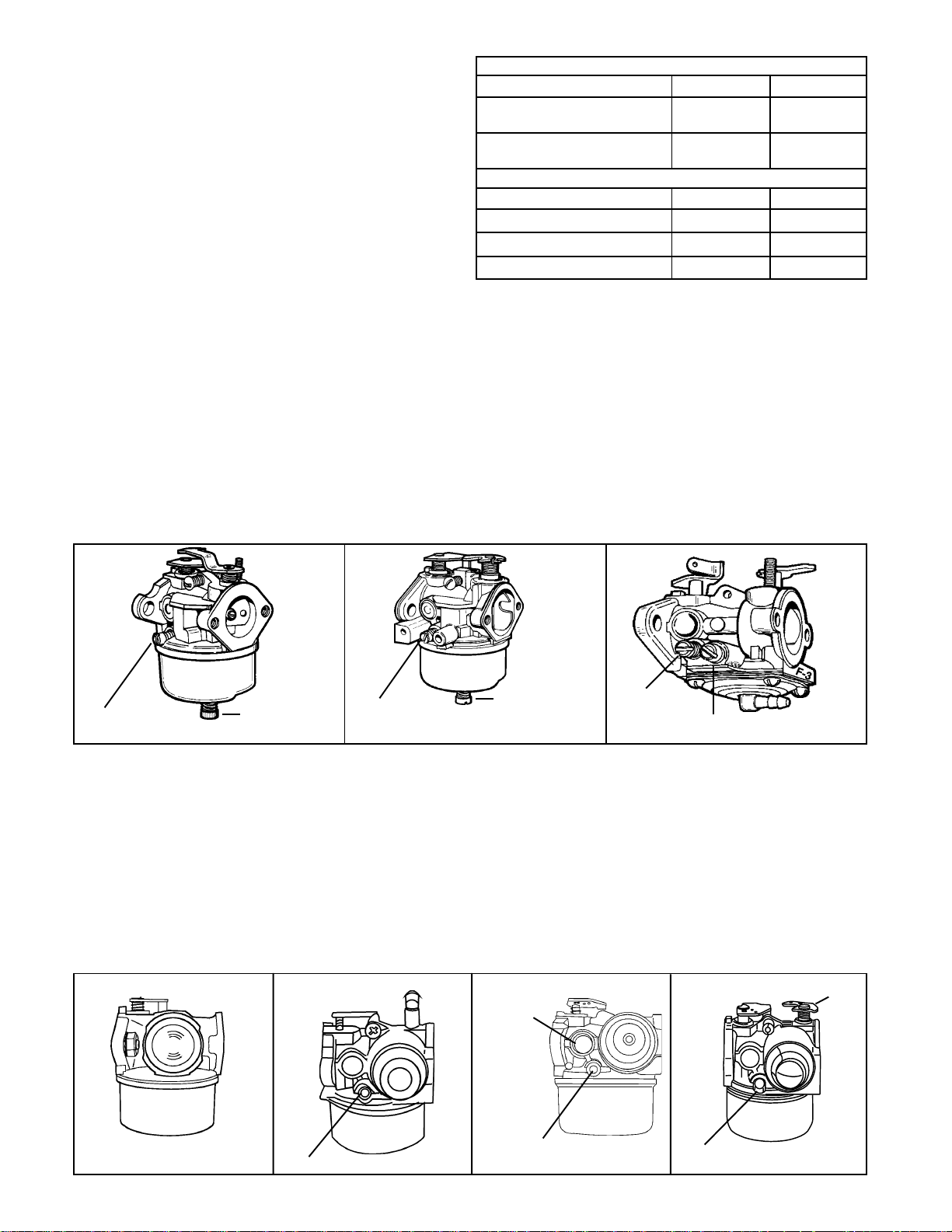

NON-ADJUSTABLE CARBURETORS

DUAL SYSTEM AND SERIES 6

SERIES 8, 11 & BRIDGED 11

MIXING WELL

CAST BUT

NOT

MACHINED

SERIES 9

SERIES 10

CHOKE

NON-ADJUSTABLE

PRIMER NO CHOKE

16

CAPPED FIXED JET

27

28

CAST BUT NOT MACHINED

IDLE JET

29

CAPPED IDLE

RESTRICTOR

30

Page 21

DISASSEMBLY PROCEDURE

NOTE: Engines which are identified as compliant with CARB (California Air Resources Board) or EPA (US

Environmental Protection Agency) regulations can NOT be changed from the factory settings unless specifically

authorized.

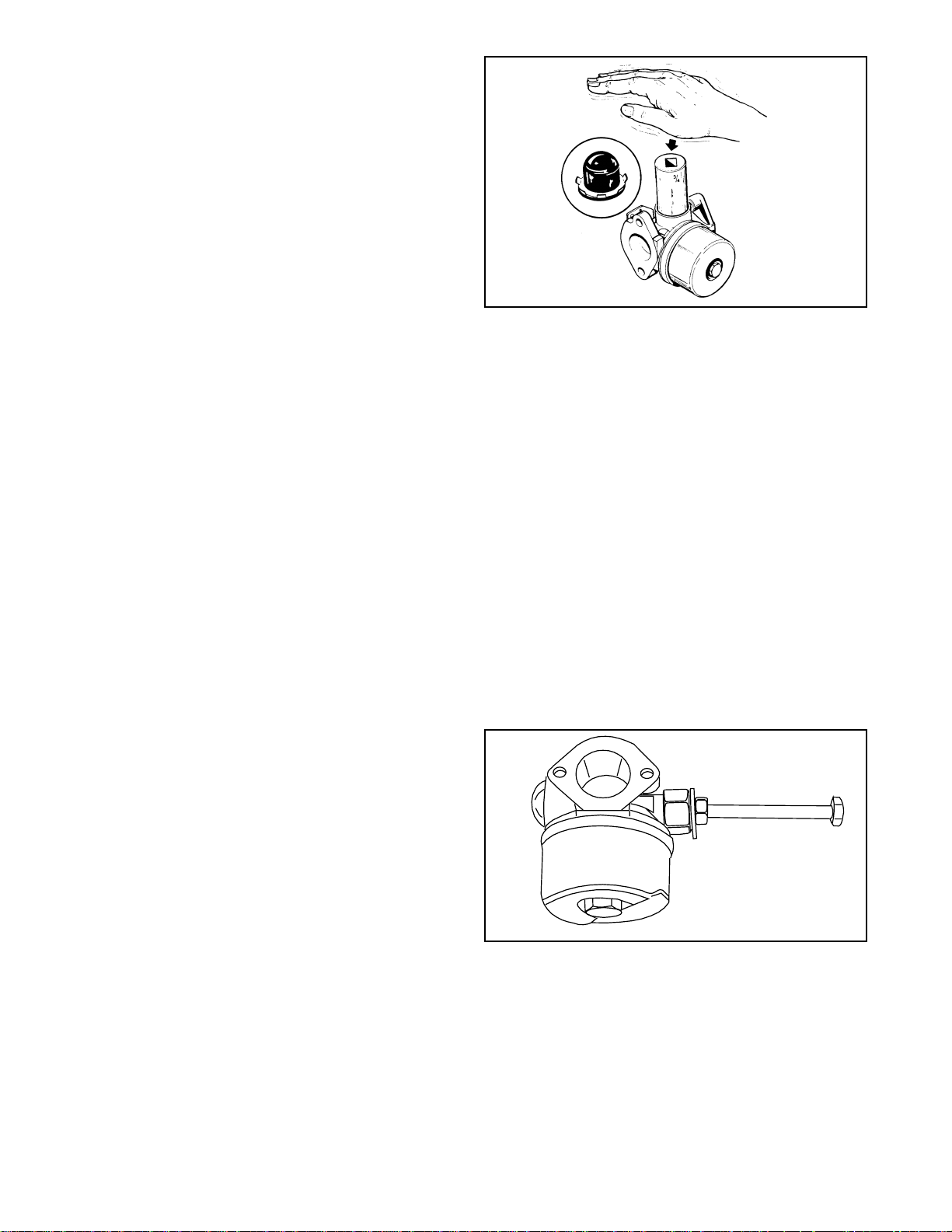

FLOAT STYLE CARBURETORS

1. Note or mark the high and low mixture adjusting screws

to aid in reassembly (if applicable). Remove the high

speed adjusting screw, bowl nut, and float bowl.

Remove the idle mixture screw assembly .

2. Note the position of the spring clip on the inlet needle

and float, the long end of the clip must face toward the

choke end of the carburetor. Remove the float hinge

pin with a needlenose pliers. Some carburetors use a

float dampening spring to aid the inlet valve in

maintaining a steady position during rough service

applications. Note the position of the hooks before

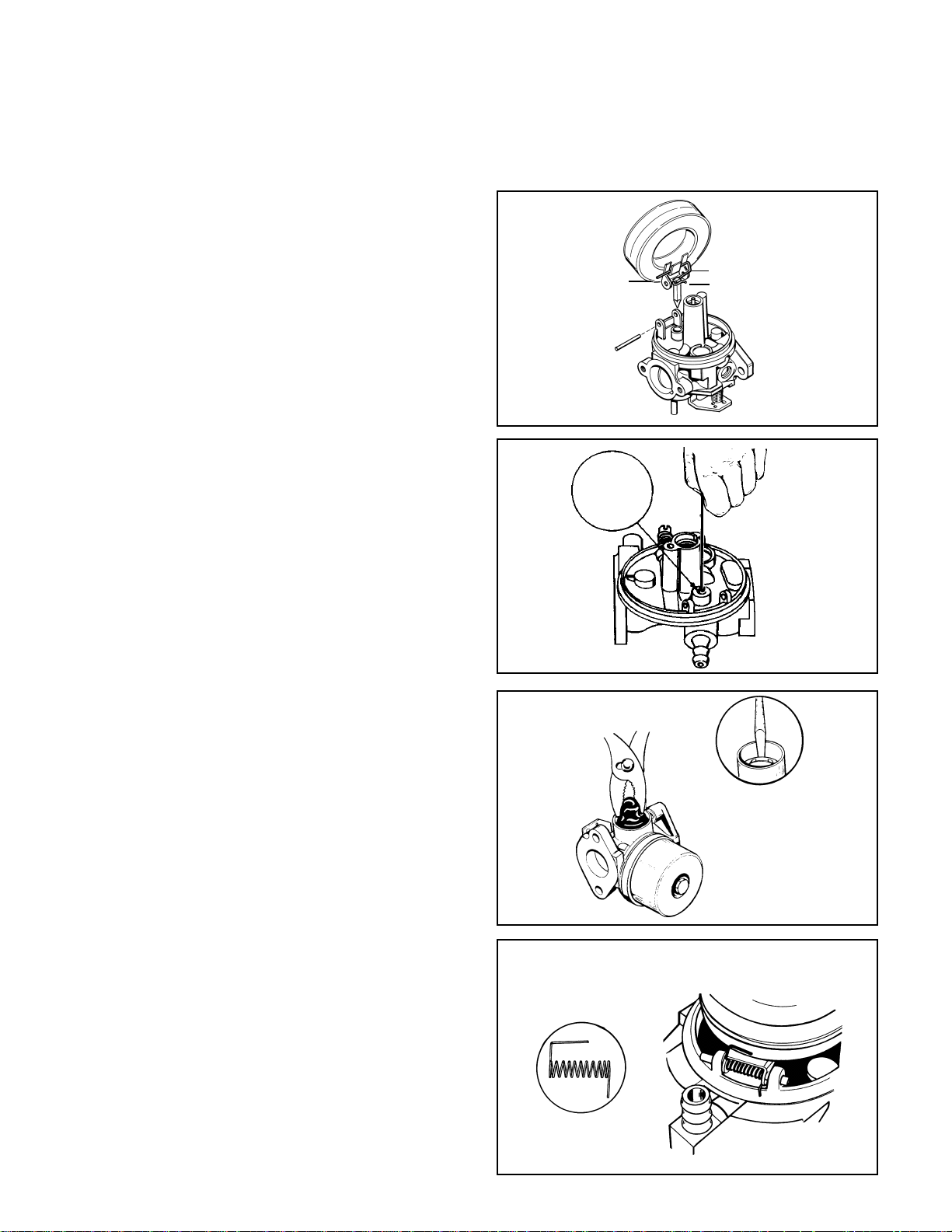

removing the float hinge pin (diag. 31).

3. Remove the float, clip, and inlet needle.

LONG END OF CLIP

TOWARD CHOKE

CHOKE

END

CLIP

OPEN END OF CLIP

THROTTLE

END

31

4. Remove the inlet needle seat using the Tecumseh

carburetor tool #670377 as shown. Push the hook

through the hole in the center of the seat to remove it.

(diag. 32).

5. Note or mark the action of the choke and throttle

shutters, and/or the hook points of the choke or throttle

return spring, or seal retainer springs located on the

top of the choke and/or throttle shaft. Remove the

throttle shutter, throttle shaft, choke shutter, springs

and choke shaft by removing the screw(s) that attach

the throttle or choke shutter to the shaft inside the air

horn.

6. Remove the primer bulb (if equipped) by grasping it

with a pliers and pulling and twisting out of the body .

Remove the retainer by prying and lifting it out with a

screwdriver. Do not re-use the old bulb or retainer (diag.

33).

7. Some T ecumseh float style carburetors have a damper

spring which is installed as shown. (diag. 34)

Use carb. tool

# 670377

32

33

34

17

Page 22

8. Remove all welch plugs if cleaning the carburetor.

Secure the carburetor in a vise equipped with protective

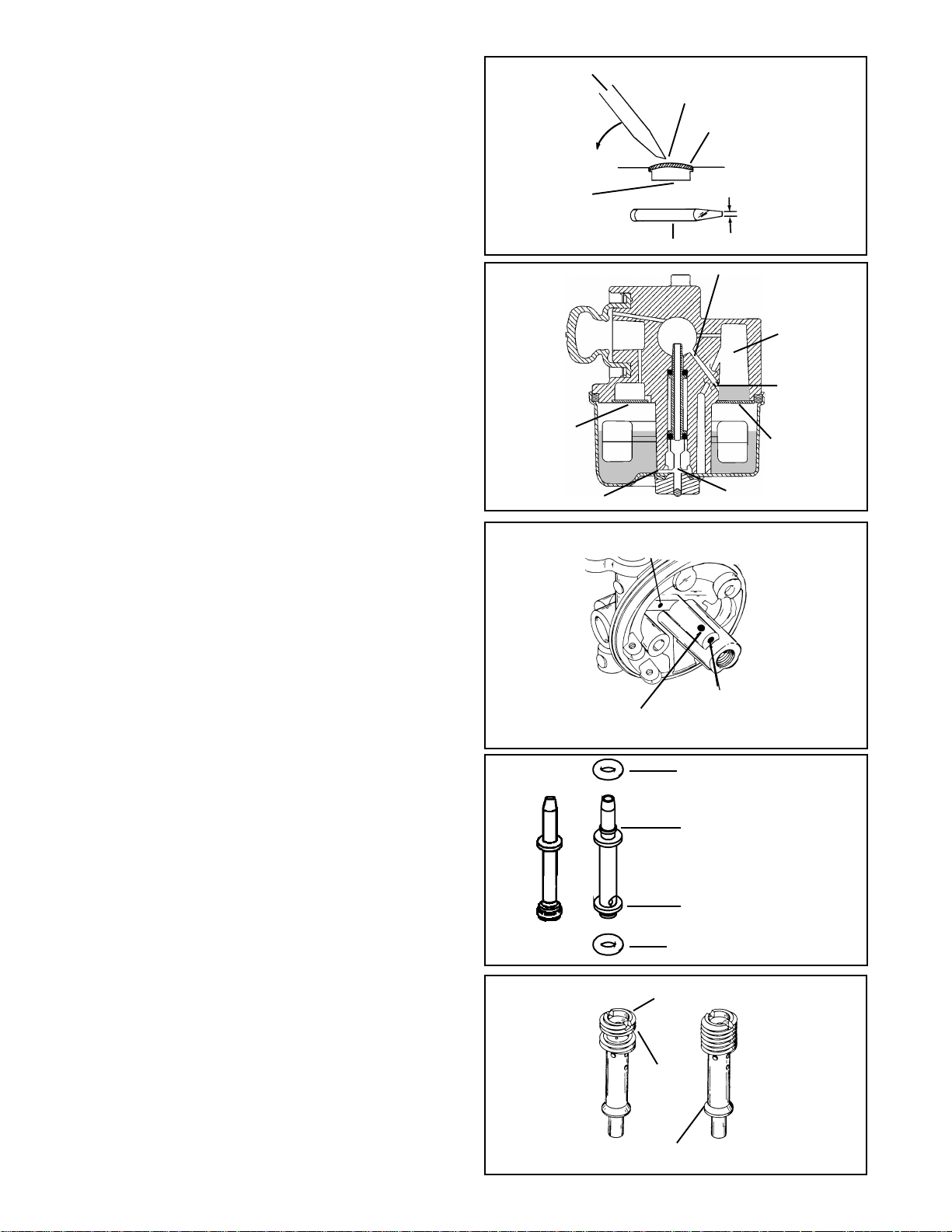

jaws. Use a small chisel sharpened to a 1/8"

(3.175 mm) wide wedge point. Drive the chisel into the

plug to pierce the metal, then push down on the chisel

to pry the plug out of the hole (diag. 35).

NOTE: DO NOT REMOVE ANY BALL OR CUP PLUGS

(diag. 37).

SMALL CHISEL

PRY OUT

PLUG

DO NOT ALLOW

CHISEL POINT

TO STRIKE

CARBURETOR

BODY OR

CHANNEL

REDUCER

PIERCE PLUG WITH TIP

WELCH PLUG TO BE

SMALL CHISEL

REMOVED

ABOUT 1/8"

(3.175 mm)

WIDE

35

9. Note the direction of the inlet fitting. If necessary the

inlet fitting can be removed. (See page 24).

10. The main nozzle on Series 8 and Series 9 carburetors

can be removed by pressing the tube outward from the

venturi thru the center leg. This nozzle is non-metallic

and has an "O" ring seal on the top and bottom end of

the tube. Do not remove a main nozzle that is made of

brass from any Tecumseh carburetor. These are

pressed in at the factory to a specific depth. When

removing the nozzle, the top "O" ring may not come

out with the tube. The "O" ring must be removed and

placed on the nozzle before it is placed back into the

center leg or it will not seal properly . (diag. 38)

11. Servicing the standard series eleven and bridged

model.

When servicing the series eleven DO NOT soak it in