Tecumseh HXL, AV600, TCH200, AV520, HSK User Manual

...

Tecumseh

Quick Reference

Service Information

Covers Engine and Transmission Product

Form No.695933 R 7/00

Introduction

This booklet contains the quick reference and basic troubleshooting information previously found on Tecumseh wall charts

and in the Technician's Handbooks.

This booklet is designed to be used as a work bench quick

reference guide when servicing Tecumseh engines and motion

drive systems.

Technician's Note:

Tecumseh engines are manufactured to meet EPA and CARB

standards. As a technician, it is unlawful to re-calibrate or replace

a fuel nozzle or jet (bowl nut) with a part from any other carburetor

that was not originally designed for that engine. All speed adjustments must remain within the limits that are specified for each

engine and are not to exceed the maximum. This can only be

deviated from if specifically approved by Tecumseh Products,

EPA and CARB.

1

Note: Torque specifications listed should not be confused with the torque value observed on

engines which have been run.

The Torque specifications take relaxation into account so sufficient clamping force exists

after an engine has reached operating temperature.

Torques listed are intended to cover highly critical areas. More extensive torques are found

in the respective repair manual.

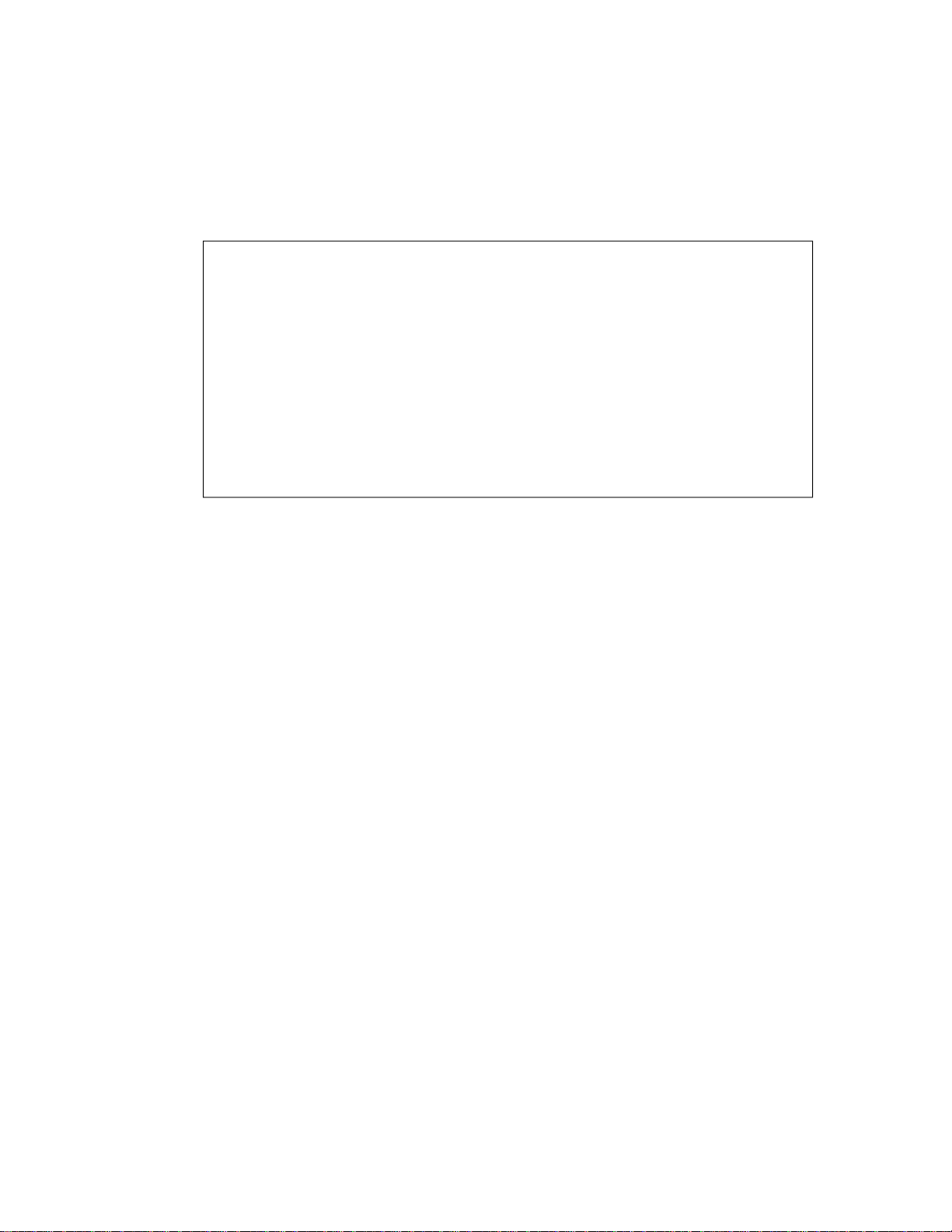

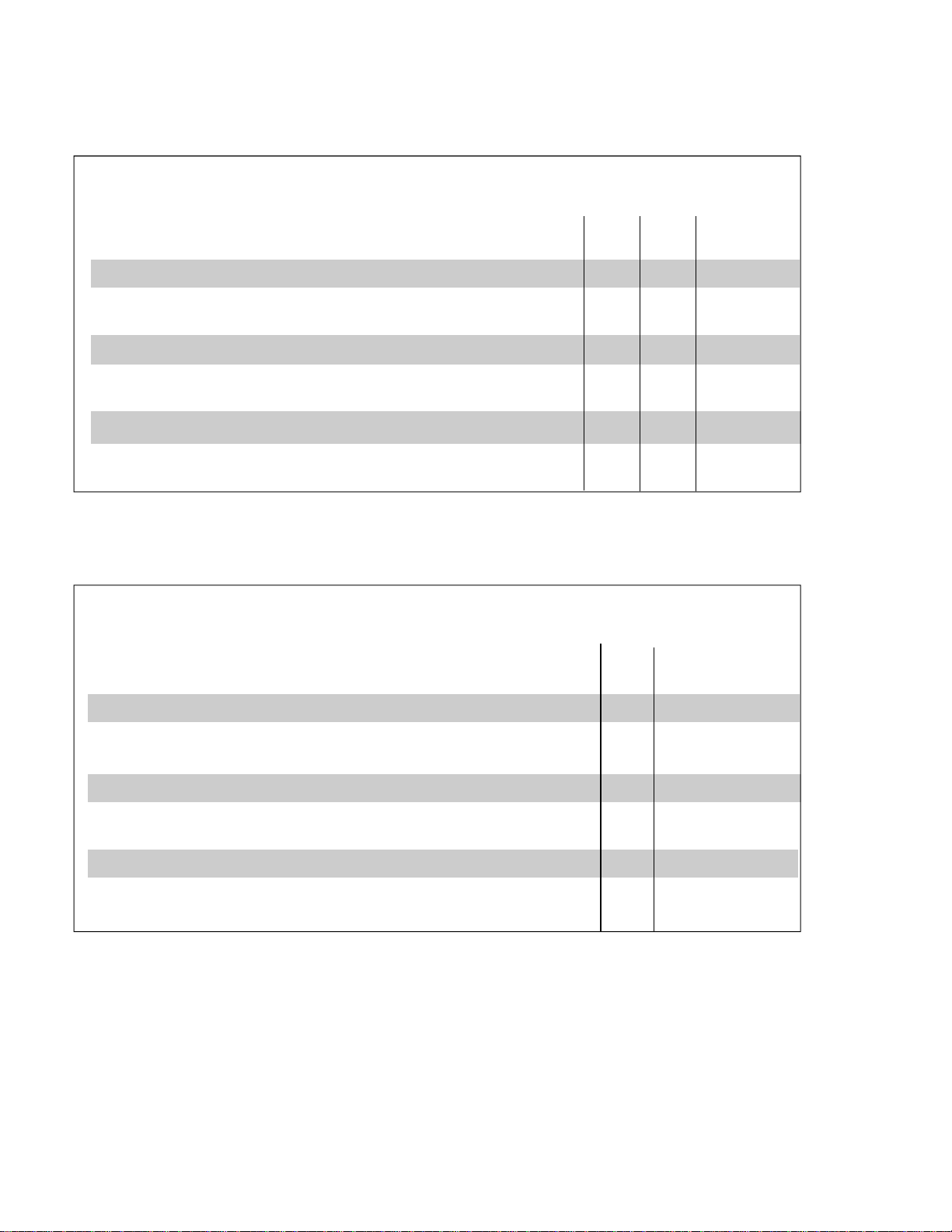

Torque Specifications

TWO-CYCLE ENGINE SERIES

840 - 850 TWO-CYCLE ENGINE SERIES

Location Inch lbs. Torque Nm Engine Designation

TVS

TVXL

HSK

HXL

Crankcase to Cylinder 120-204 13.5-23 • • • •

Flywheel Nut 360-420 41-47.5 • • • •

Adapter Plate to Cylinder 160-220 18-25 • •

TC TWO-CYCLE ENGINE SERIES

Location Inch lbs. Torque Nm Engine Designation

TC200

TC300

TCH200/

Cylinder to Crankcase 80-95 9-11 • • •

Crankcase Cover to Crankcase 70-100 8-11 • • •

Flywheel Nut 190-250 21.5-28.5 • • •

TWO-CYCLE ENGINE SERIES (AV520/600, TVS600, AH520, AH/HSK600)

Location Inch lbs. Torque Nm Engine Designation

AV520/600

TVS600

AH/HSK600

300

AH520

Connecting Rod 40-50 4.5-5.5 • • • •

Housing Base to Cylinder 80-120 9-13.5 • • • •

Cylinder Head to Cylinder 100-140 11-16 • • • •

Flywheel Nut AV Industrial (Point Ignition) 216-300 24.5-34 • •

(670 Series AV 520 and All AV 600)

Flywheel Nut (C.D. Ignition) 264-324 30-36.5 • • • •

2

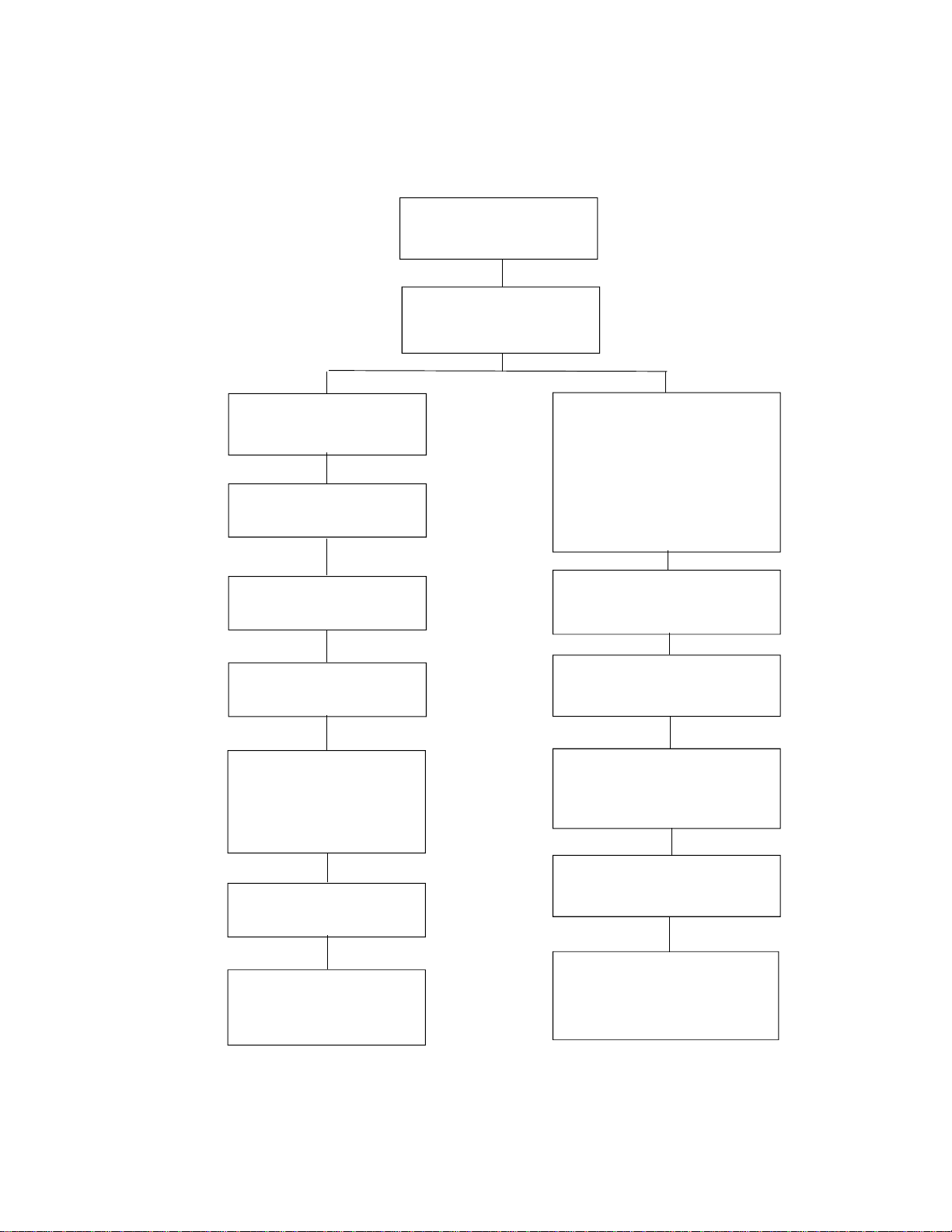

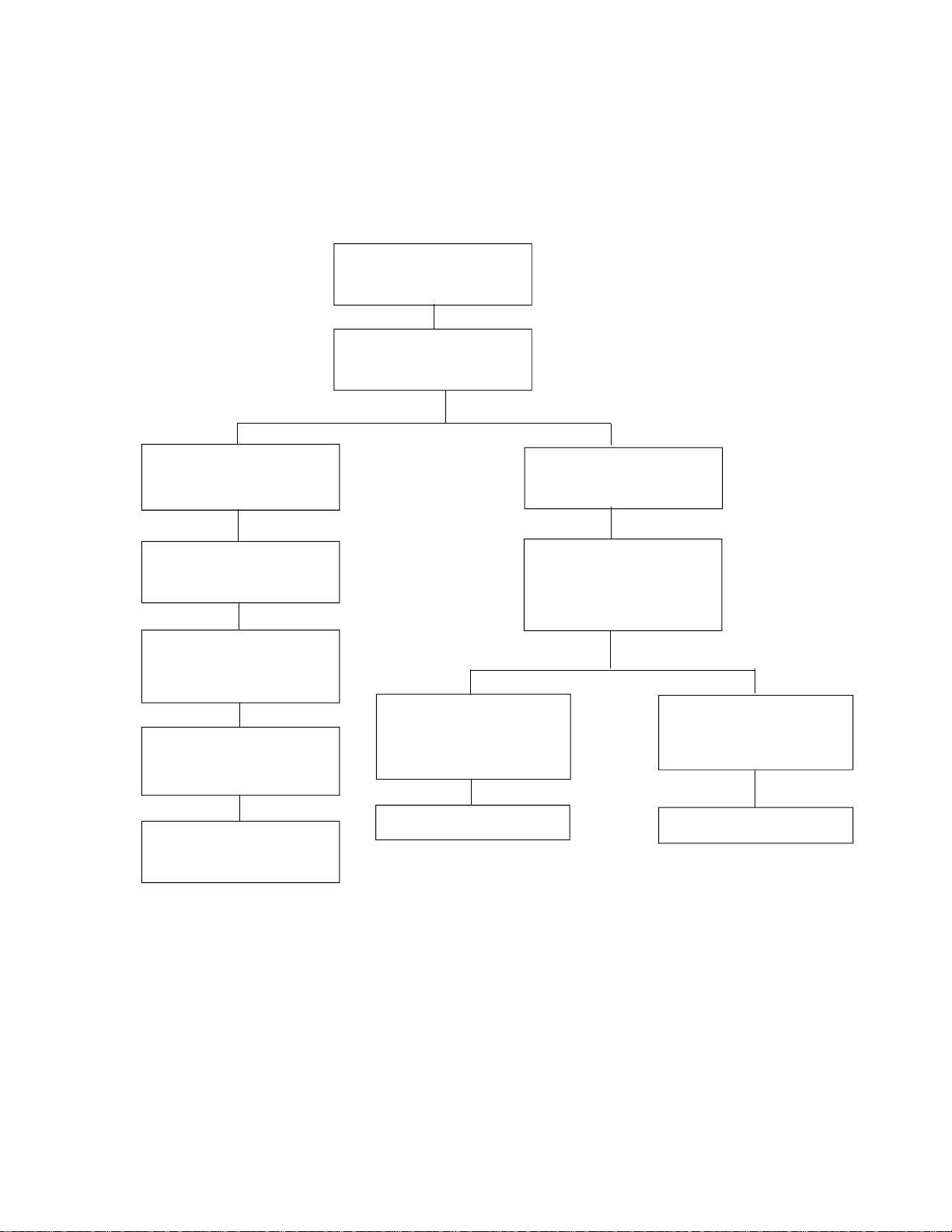

Two Cycle Troubleshooting

As an aid in troubleshooting any piece of equipment, interview the customer, and review conditions and

symptoms of the problem. Examine exterior for clues: leaks, excessive dirt, damaged or new parts.

FUEL SYSTEM

Engine Will

Not Start

Check if spark

plug is wet or dry

Wet

Dry

Defective

spark plug

Restricted

air filter

Improper fuel mix

or stale fuel

Exhaust ports

plugged

Carburetion

problems due to

flooding, over

priming, etc.*

Review with customer

priming or choking

procedure

(3-5 primes, if

equipped, waiting 2

seconds between

each prime)

Carburetion problem*

(bad bowl gasket)

Check fuel supply

and fuel cap vent

Restriction in

fuel system (filter,

screen)

Ignition System

Crankcase seals

or gaskets leaking

NOTE: Refer to Technician's Handbook for a more

detailed list of remedies.

*Carburetor Troubleshooting use Technician's

Handbook or Carburetor Troubleshooting Booklet,

Form No. 695907. Video No. 695015.

(CONTINUED ON NEXT PAGE)

Poor

compression

Damaged reed, port

plugs, seals or

gaskets

3

Two Cycle Troubleshooting - continued

IGNITION SYSTEM

Engine Will

Not Start

Check for spark

Spark

Check flywheel for

correct key, damaged

key or key adaptor

Set proper air gap on

external coil

Set proper point gap,

check condensor and

timing (if equipped)

Test coil for

intermittent or weak

spark

Check electric starter

if applicable

No Spark

Replace spark plug

Isolate engine from all

equipment (disconnect

wiring harness), repeat

Spark

Equipment problem,

check switches, wiring

and equipment

controls

Parasitic load too high

test

No Spark

Engine problem,

check for shorts or

grounds in wiring

Test ignition module

NOTE: Refer to Technician's Handbook for a more detailed list of remedies.

4

Note: Torque specifications listed should not be confused with the torque value observed on

engines which have been run.

The Torque specifications take relaxation into account so sufficient clamping force exists

after an engine has reached operating temperature.

Torques listed are intended to cover highly critical areas. More extensive torques are found

in the respective repair manual.

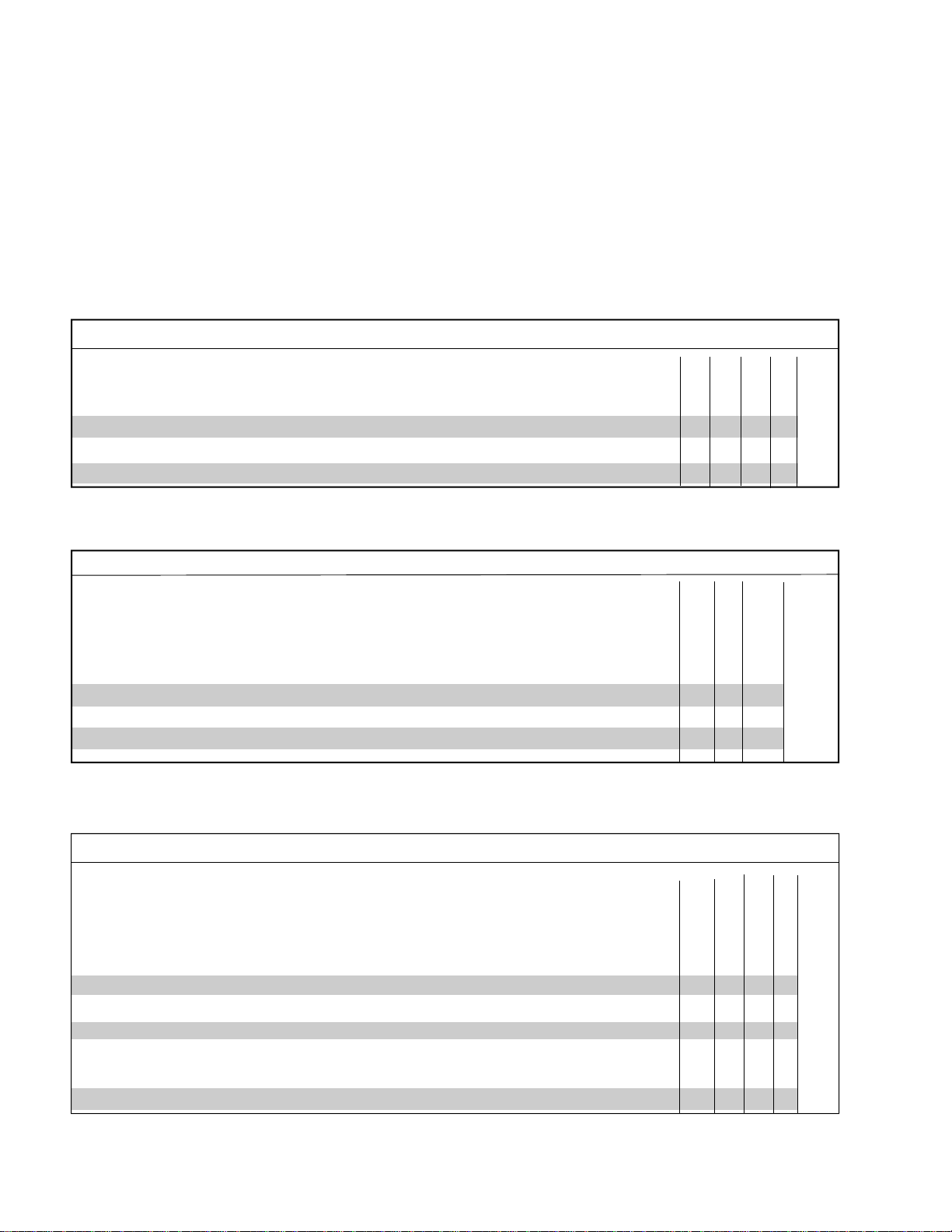

Torque Specifications

FOUR-CYCLE LIGHT FRAME ENGINE SERIES

(TVS, TNT, ECV, LAV, LEV, H, HS, OHH, OVRM and VLV)

Location Inch lbs. Torque Nm Engine Designation

TVS

TNT

ECV

LAV

H/HSK

HS/HSSK

OVRM

VLV

LEV

OHH

Rocker Arm Stud Lock Nut 100-140 11-16 • •

Connecting Rod 95-110 11-12.5 • • • • • • • • • •

Cylinder Head 160-210 18-24 • • • • •

Cylinder Head 220-240 25-27 • •

Cylinder Head 180-220 20.5-25 •

Mounting Flange or Cylinder Cover 100-130 11-14.5 • • • • • • • • • •

Flywheel Nut (Cast Iron) 500-600 42-50 • • • • • • • • • •

Flywheel Nut (Aluminum) 400-500 45-56.5 • • • • • • • • • •

FOUR-CYCLE MEDIUM FRAME ENGINE SERIES

(TVM, TVXL, H, V, HM, OVM, OVXL, OHM, OHSK and OHV)

Location Inch lbs. Nm Engine Designation

Torque

TVM & TVXL

170-195-220

HM/HMSK70-100

OVM/OVXL,

TVM125, 140

H50-60

V70

H70

Connecting Rod 160-180 18-20.5 • •

Connecting Rod 200-220 22.5-25 • • • • • •

Connecting Rod 200-240 22.5-27 •

Cylinder Head Bolts 220-240 25-27 • •

Cylinder Head Bolts 180-240 20.5-27 • •

Cylinder Head Bolts 160-210 18-24 • • • • • •

Rocker Adj. Lock Screw 65-80 7-9 •

Rocker Arm Stud Lock Nut 110-130 12.5-14.5 •

Rocker Arm Hex Jam Nut 15-20 2 • •

Rocker Arm Studs 170-210 19-24 • • •

Rocker Arm Box to Head 75-130 8.5-14.5 • •

Rocker Box Cover 15-20 2 • •

Rocker Box Cover (Four Screw) 40-65 4.5-7 • • •

Mounting Flange or Cylinder Cover 100-130 11-14.5 • • • •

Mounting Flange or Cylinder Cover 110-140 12.5-16 • • • • • •

Flywheel Nut 400-550 45-62 • • • •

Flywheel Nut (External Ignition) 600-800 68-90 • • • • • •

OHV120-125

OHSK80-130

OHM120

OHV135-145

203 Series

OHV15-17.5

OHV11-13,OHV110-

135, 206 Series

204 Series

5

Torque Specifications - continued

FOUR-CYCLE LARGE FRAME ENGINE SERIES (CAST IRON BLOCK HH, VH and OH)

Location Inch lbs. Nm Engine Designation

Torque

HH

Connecting Rod 86-110 10-12.5 • • •

Cylinder Head 180-240 20.5-27 • • •

Mounting Flange & Cylinder Cover 100-130 11-14.5 • • •

Rocker Arm Shaft to Box 180-220 20.5-25 •

Rocker Arm Box to Cylinder Head 80-90 9-10 •

Flywheel Nut 600-660 68-74.5 • • •

FOUR-CYCLE HEAVY FRAME ENGINE SERIES (V-TWIN)

Location Inch lbs. Nm Engine Designation

Torque

VH

TVT

OH

Connecting Rod 200-220 22.5-25 •

Cylinder Head Bolts 220-240 25-27 •

Rocker Arm Jam Nut 110-130 12.5-14.5 •

Rocker Arm Cover Mounting Screw 52 6 •

Mounting Flange/Cylinder Cover 240-260 27-29 •

Flywheel Nut 600-800 68-90 •

6

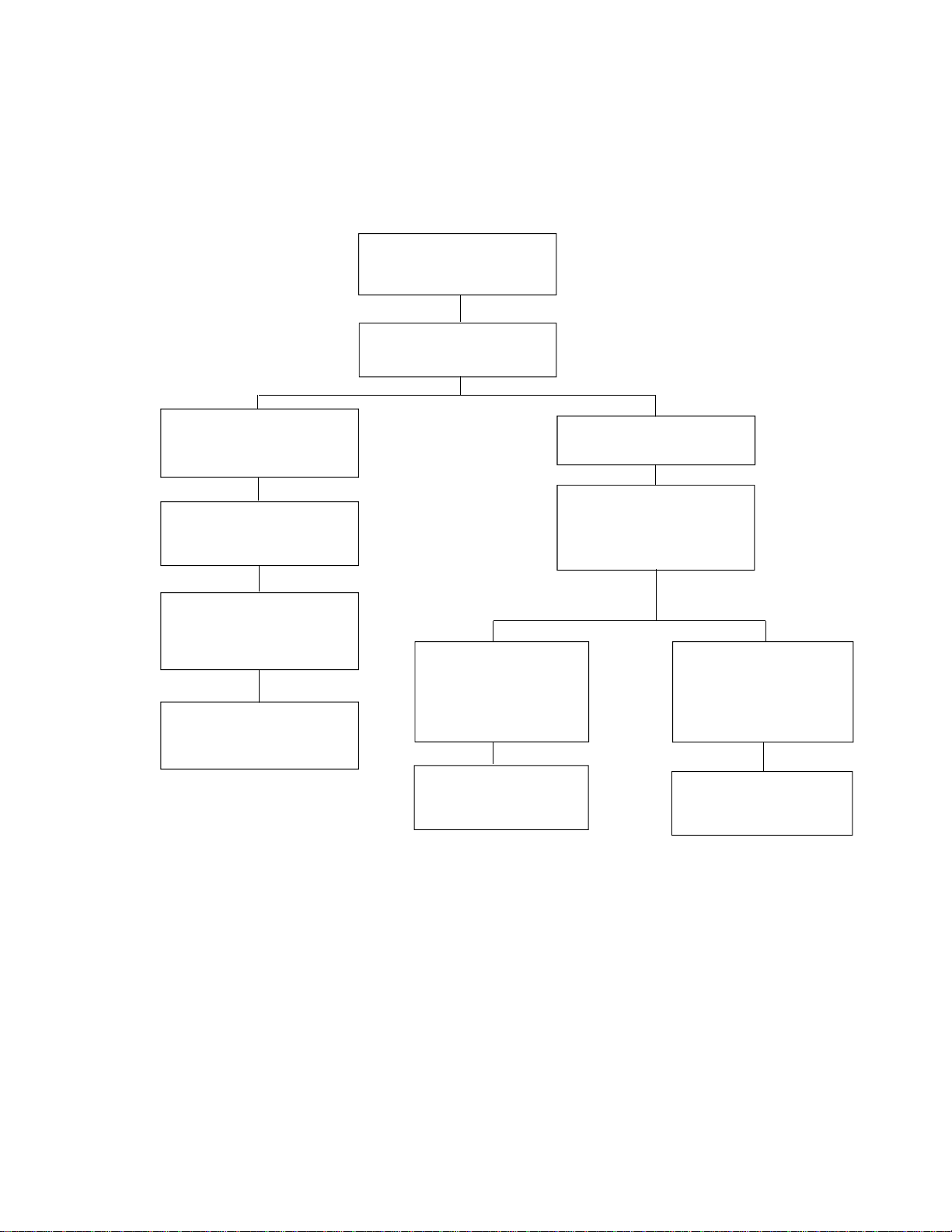

Four Cycle Troubleshooting

As an aid in troubleshooting any piece of equipment, interview the customer, and review

conditions and symptoms of problem. Examine exterior for clues: leaks, excessive dirt,

damaged or new parts.

FUEL SYSTEM

Engine Will

Not Start

Check if spark plug is

wet or dry

Wet

Defective

spark plug

Restricted air filter

Improper or

stale fuel

Carburetion problems

due to flooding, over

priming, etc.*

Ignition system

Dry

Review with the

customer proper

priming procedure

(3-5 primes, waiting

2 seconds between

each prime)

If equipped with a

choke, check for full

travel. Check throttle

cable and control for

proper adjustment.

Check fuel supply and

fuel cap vent

Restriction in fuel

system (filter)

Carburetion problem*

(bad bowl gasket)

Poor

compression

NOTE: Refer to Technician's Handbook for a more detailed list of remedies.

*Carburetor Troubleshooting, use Technician's Handbook or Carburetor Troubleshooting

Booklet, Form No. 695907. Video No. 695015.

7

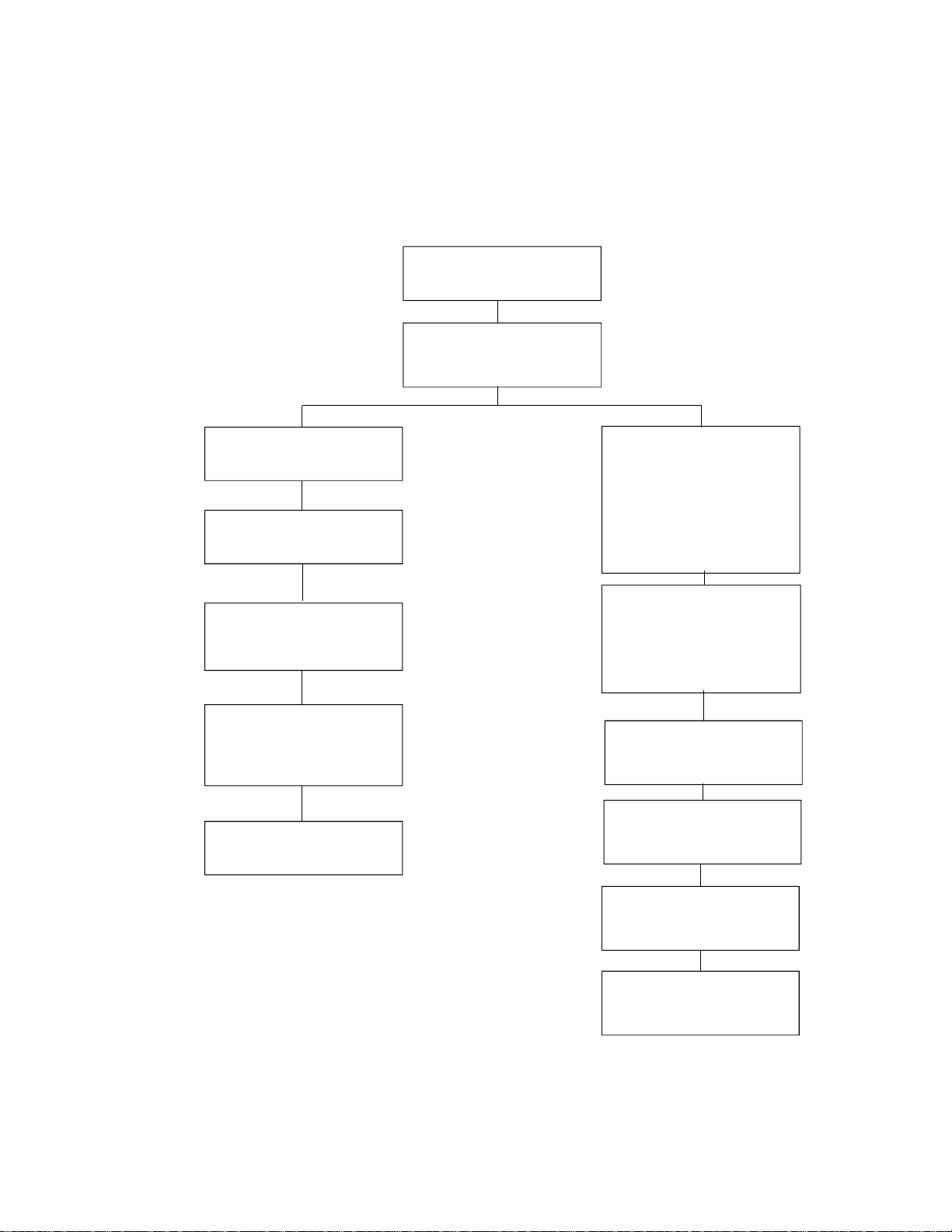

Four Cycle Troubleshooting - continued

IGNITION SYSTEM

Engine Will

Not Start

Check for

spark

Spark

No Spark

Check flywheel for

correct key, damaged

or sheared key

Set proper air gap on

external coil

Set proper point gap,

check condensor and

timing

Test coil for

intermittent or weak

spark

Isolate engine from all

equipment (disconnect

wiring harness), repeat

Spark

Equipment problem,

check switches,

wiring and

equipment controls

Parasitic load too

high

Replace spark plug

test

No Spark

Engine problem,

check for shorts or

grounds in wiring

Test ignition

module

NOTE: Refer to Technician's Handbook for a more detailed list of remedies.

8

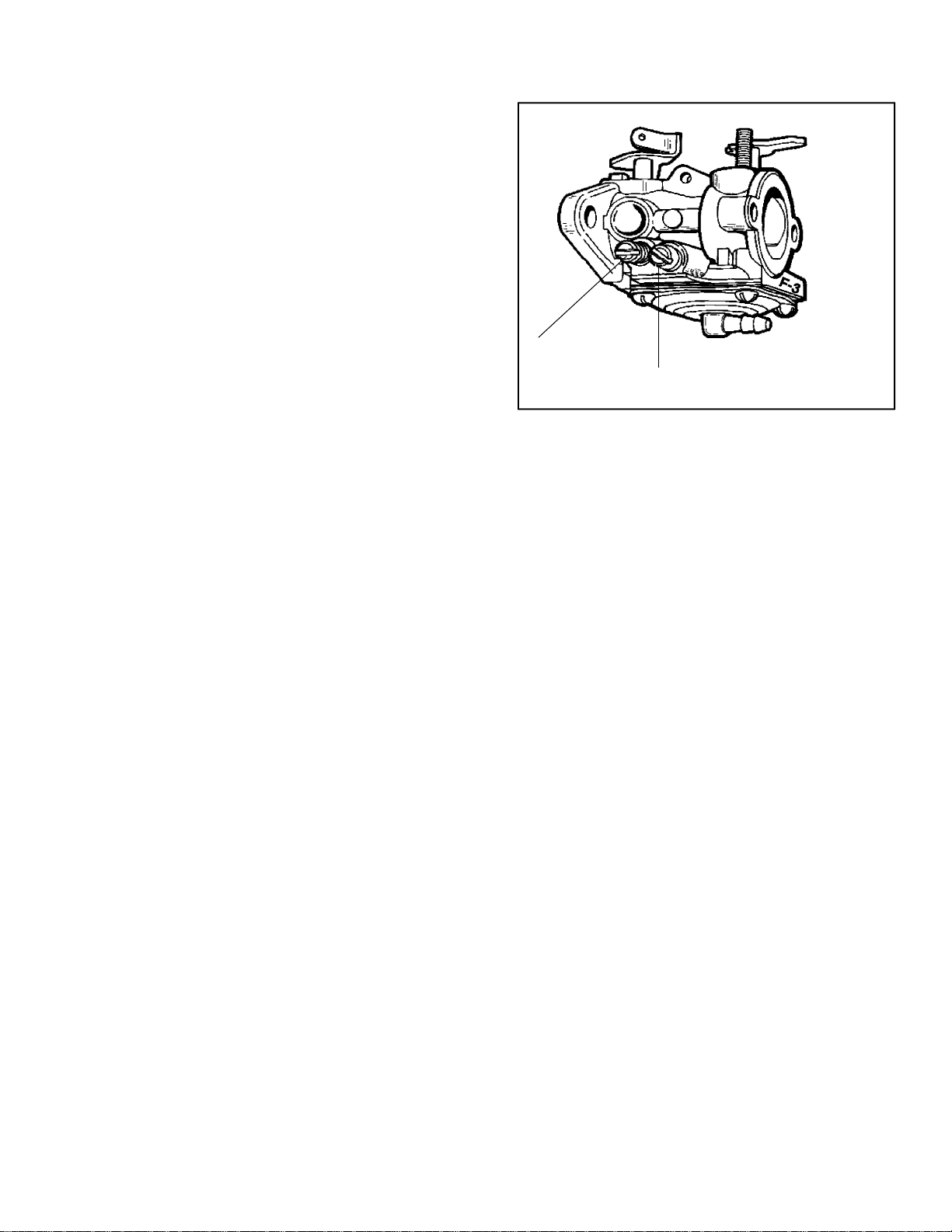

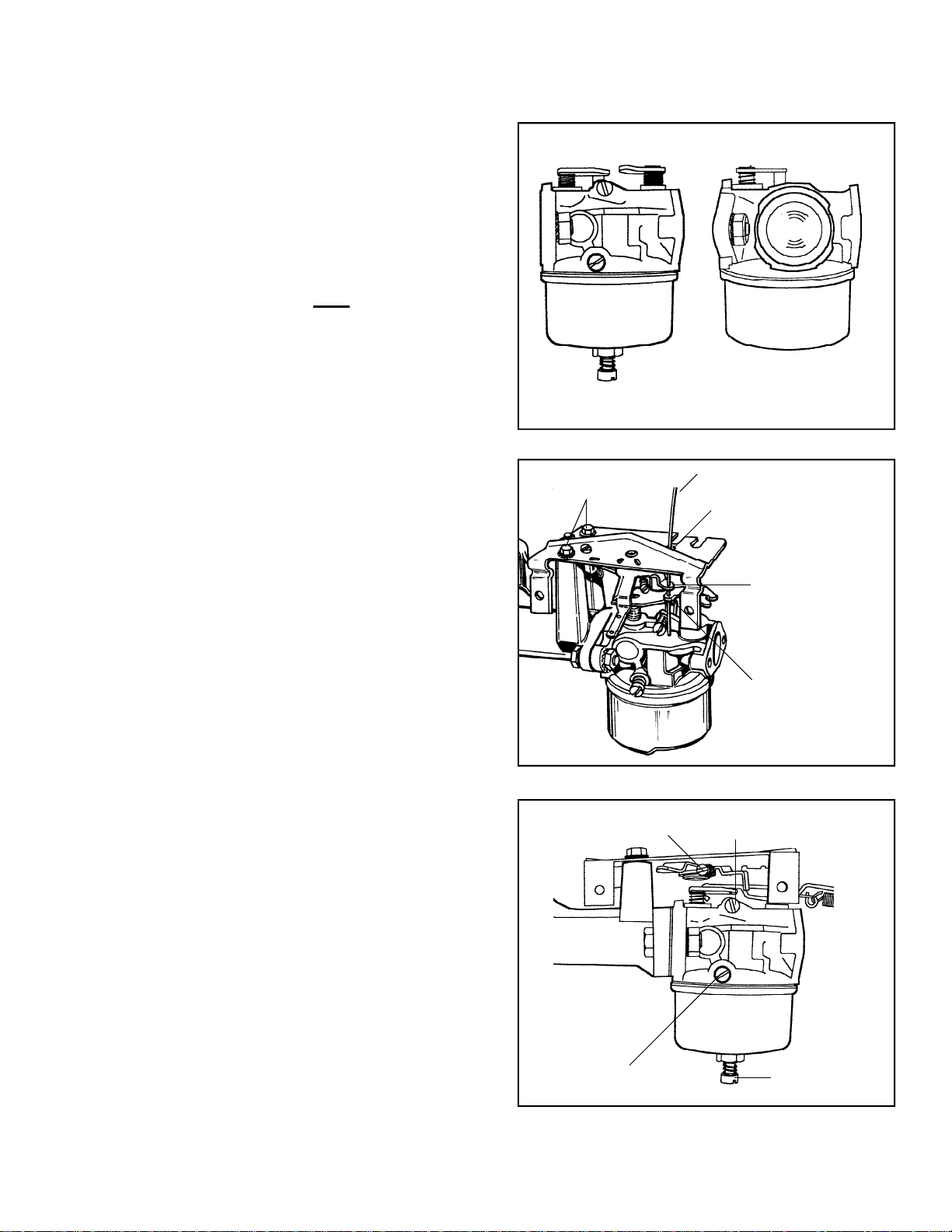

Tecumseh 2 Cycle Diaphragm Adjustments

NOTE: For meeting emission requirements, some

carburetors have fixed-main or idle jets. The

absence of the adjustment screw indicates fixed

jets and no adjustment is necessary.

Diaphragm-Dual Adjustment.

Turn mixture adjusting screws in finger tight to the

closed position, then one (1) turn out from closed

position. This setting is approximate. This will allow

the engine to be started so the carburetor can be fine

tuned.

Start the engine and let it warm up for approximately

3-5 minutes. Do not adjust the carburetor when

the engine is cold.

IDLE MIXTURE

SCREW

MAIN MIXTURE

SCREW

NOTE: If no tension

spring is present, it

may be a fixed jet.

1

Set the throttle control to idle. If it is a fixed speed

type, manually hold the throttle against the idle

speed adjustment screw.

The throttle lever must be held against the crack screw for low speed adjustments or all adjustments will

be incorrect and cause poor performance and unsatisfactory operation.

With the engine idling and throttle lever against the idle speed regulating screw, turn the low speed

adjustment screw slowly clockwise from the NORMAL setting until the engine falters. Remember this

location. Turn the screw counterclockwise until engine just starts to sputter or drops in R.P.M.. Remember

this location. Turn the screw clockwise until it is halfway between your first position where the engine

faltered and your last position where the engine started to sputter. This will be the optimum low speed setting

on your carburetor.

Next run the engine at governed speed. The high speed adjustments are made basically the same as the

low speed adjustments, with the exception of the settings being made 1/8 of a turn at a time, from the

NORMAL settings. NOTE: It may be necessary to re-check the idle mixture adjustment after performing

the high speed adjustment.

Diaphragm-Single Adjustment.

Turn the mixture adjustment screw finger tight to the closed position, then one (1) turn out from the closed

position. This setting is approximate and will allow the engine to be started so the carburetor can be finetuned.

Start the engine and let it warm up for approximately 3-5 minutes. Do not adjust the carburetor when the

engine is cold.

Set the throttle control to idle. If it is a fixed speed type, manually hold the throttle against the idle speed

adjustment screw.

NOTE: If the engine falters or stops after the choke lever is moved to the "OFF" position, open the mixture

adjusting screw 1/4 turn (counterclockwise) and restart the engine.

With the engine running, place the speed control in the "slow" position to make mixture adjustments. Turn

the mixture screw slowly clockwise from the NORMAL setting until the engine falters. Remember this

location. Turn the screw counterclockwise until the engine just starts to sputter or drops in R.P.M. Remember

this location. Turn the screw clockwise until it is halfway between your first position where the engine

faltered and your last position where the engine started to sputter. This will be the optimum setting on your

carburetor.

9

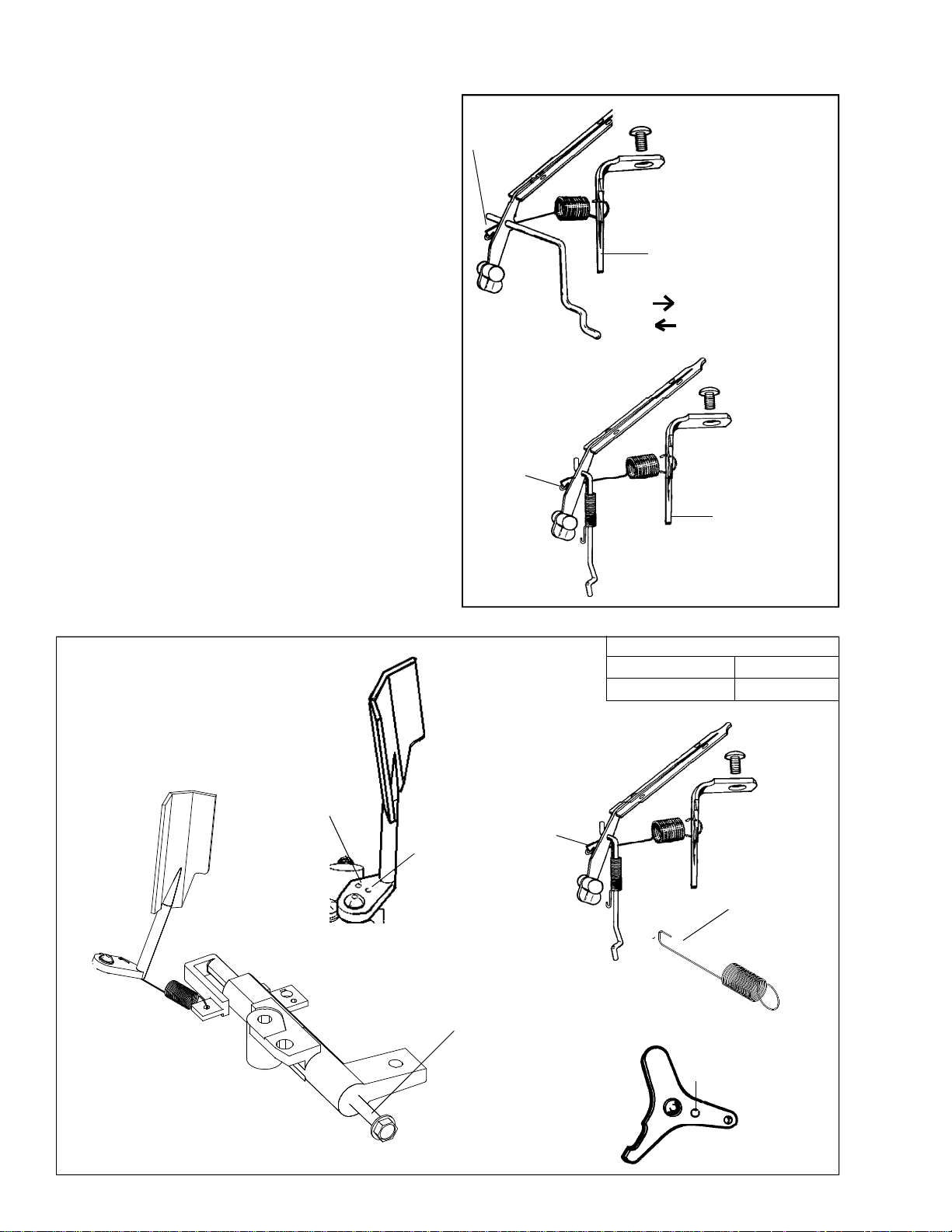

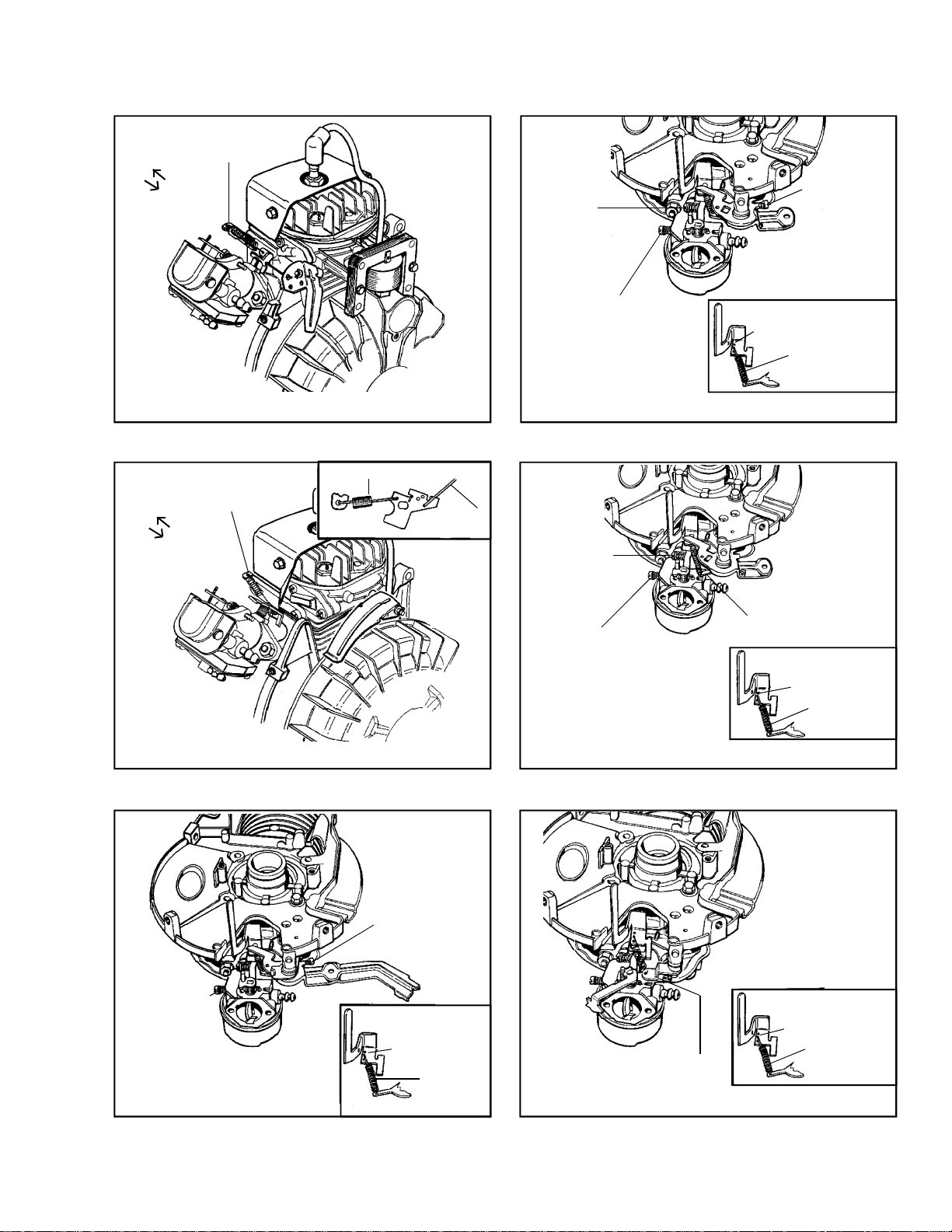

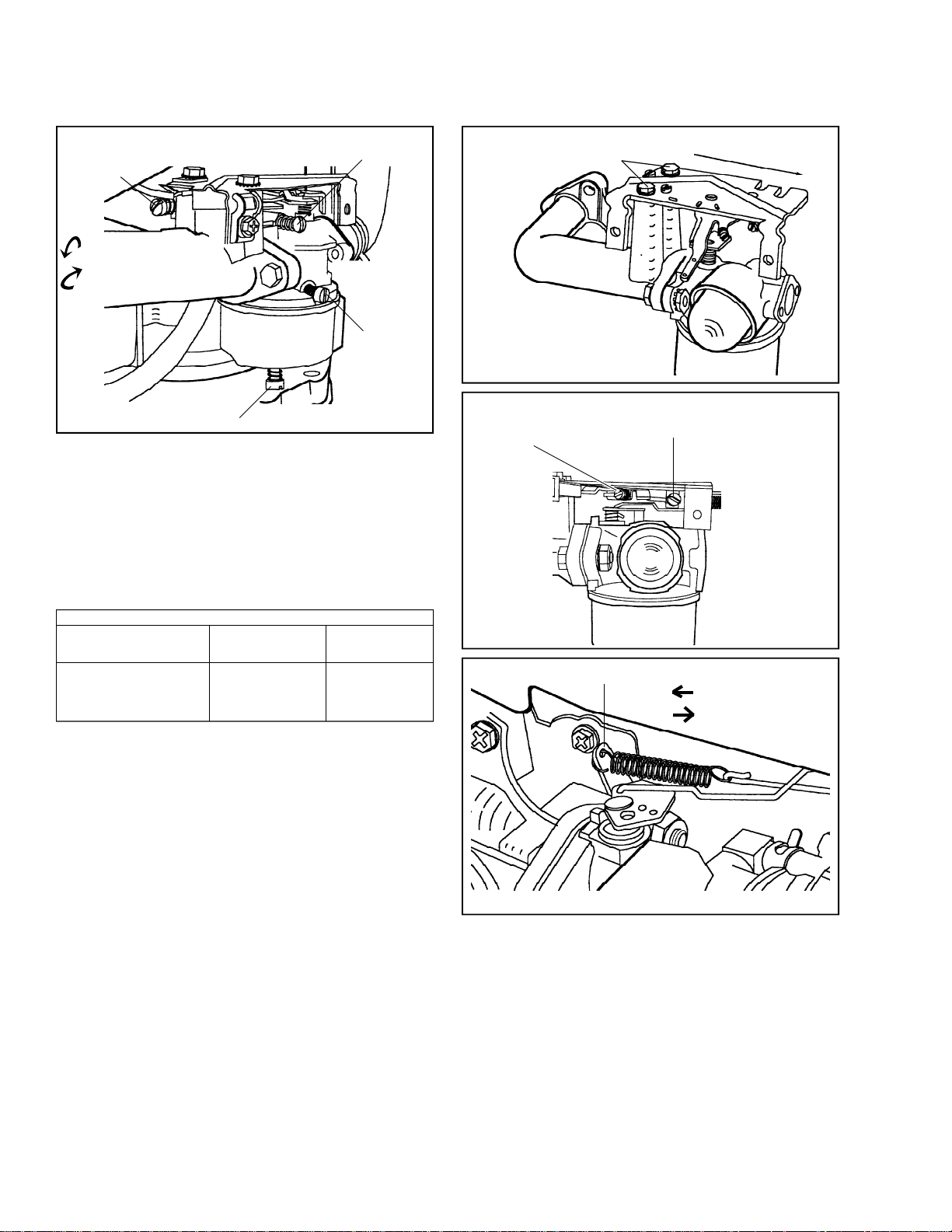

TC Series Governor Adjustment

Three different styles of governor systems are used

on TC engines. Use the following illustrations (diags.

2 and 3) to identify the governor system used and

the following procedure to adjust the governed

engine speed.

1. Allow the engine to run for at least 5 minutes to

reach operating temperature. Make sure the air

filter (if equipped) is clean and the choke is in the

off position.

2. Using a Vibratach (part# 670156) or other

tachometer, determine the engine's R.P.M. at

idle and wide open throttle. Refer to Microfiche

card 30, or a computer parts look-up program to

obtain the recommended engine speeds.

3. Using the applicable illustration, either bend the

speed adjusting lever toward the spark plug end

of the engine to decrease high speed R.P.M., or

bend the lever in the opposite direction to increase

R.P.M. On TC Type II engines, turn the speed

adjusting screw out to increase or in to decrease

engine high speed R.P.M. If the speed adjustment

screw is turned out to increase the engine R.P.M.,

the speed control lever must be moved to allow

the speed control plunger to contact the speed

adjustment screw.

4. The low speed is set by moving the throttle

control to the lowest speed position and adjusting

the low speed adjustment screw on the carburetor.

HOOK

SPRING ON

NOTCH

TYPE I

(style 2)

HOOK

SPRING ON

NOTCH

TYPE I

(style 1)

SPEED

ADJUSTING

LEVER

BEND TO INCREASE SPEED

BEND TO DECREASE SPEED

SPEED

ADJUSTING

LEVER

2

1. AIR VANE

2. BACKLASH SPRING

3. GOVERNOR LINK

4. GOVERNOR SPRING

5. MOUNTING SCREW

6. SPEED ADJUSTMENT SCREW

7. SPEED CONTROL BODY

8. SPEED CONTROL LEVER

9. SPEED CONTROL PLUNGER

SPRING

POSITION 1

TYPE II:

(style 3)

4

1

9

HIGH SPEED

GOVERNOR

ADJUSTMENT

7

6

HOOK

SPRING ON

NOTCH

POSITION 2

OUT TO INCREASE

IN TO DECREASE

Spring Color Spring Position

Orange or Green 1

Pink, Red, or Black 2

1

5

8

4

2

3

SPRING

INSERT THROTTLE

LINK AND SPRING

HERE

10

3

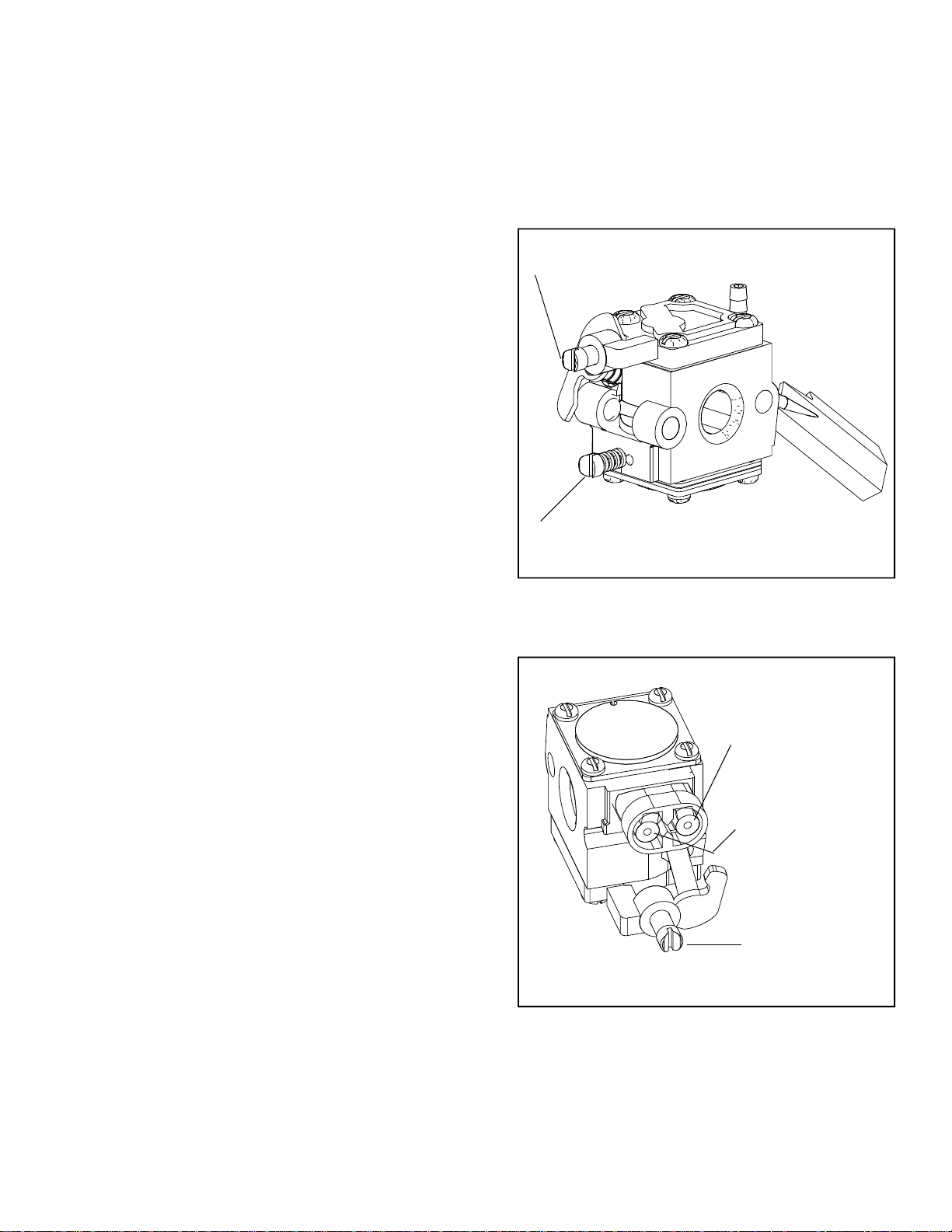

Walbro (WTA, WT) and Tillotson (HU) Diaphragm Adjustment

Carburetor Pre-Set and Adjustment

Both the Walbro and the Tillotson carburetors used

on TC engines have non-adjustable main mixture

jets. Only the idle mixture is adjustable by turning

the idle mixture screw. Use the following procedure

to pre-set the idle mixture screw. Turn the idle

mixture screw (clockwise) finger tight to the closed

position, then turn the screw counterclockwise to

obtain the proper preset (diag. 4).

Walbro Model WTA, WT 1 - 1-1/8 turns

Tillotson Model HU 1-1/4 - 1-3/8 turns

Final Idle Mixture Adjustment

Start the engine and allow it to reach normal operating

temperature (after 3-5 minutes). As the speed control

is set at the idle position, turn the idle mixture screw

slowly clockwise until the engine R.P.M. just starts

to decrease. Stop and note this screw position. Turn

the idle mixture screw slowly counterclockwise, the

engine will increase in R.P.M. Continue to slowly

turn the screw until the engine R.P.M. starts to

decrease. Note this position and turn the mixture

screw back clockwise halfway between the two

engine R.P.M. drop off positions. The idle mixture

adjustment is complete.

Some carburetors came equipped with a main

mixture adjusting screw. To adjust the main mixture,

follow the steps for idle adjustment.

IDLE SPEED ADJUSTMENT

SCREW

IDLE MIXTURE

SCREW

4

Emissionized Tillotson

Similar in design and operation, the Tillotson

emission carburetor uses a fixed main jet with an

adjustable idle. The idle circuit has a limiter cap to

prevent over richening. The cap is locked onto the

adjustment screw in a rich position, allowing only a

leaner adjustment. The main is fixed on these, which

means that the main mixture limiter is non-functional

on Tecumseh built engines (diag. 4a).

In compliance with E.P.A. and C.A.R.B. regulations

the following procedure must be followed.

NOTE: These caps can be removed for servicing

of the carburetor. Follow these steps.

1. Turn the caps clockwise until they hit the stops.

2. Remove the caps with a pointed instrument

such as an awl.

3. Then turn the screws in until softly seated, note

the number of turns. The screws must be reinstalled

to this same static setting. Replacement of the

caps is required to maintain E.P.A. and C.A.R.B.

emission compliance.

IDLE MIXTURE

LIMIT SCREW

FIXED MAIN

(MIXTURE SCREW

NOT FUNCTIONAL ON

MOST TECUMSEH

BUILT ENGINES)

IDLE SPEED

ADJUSTMENT

SCREW

4a

11

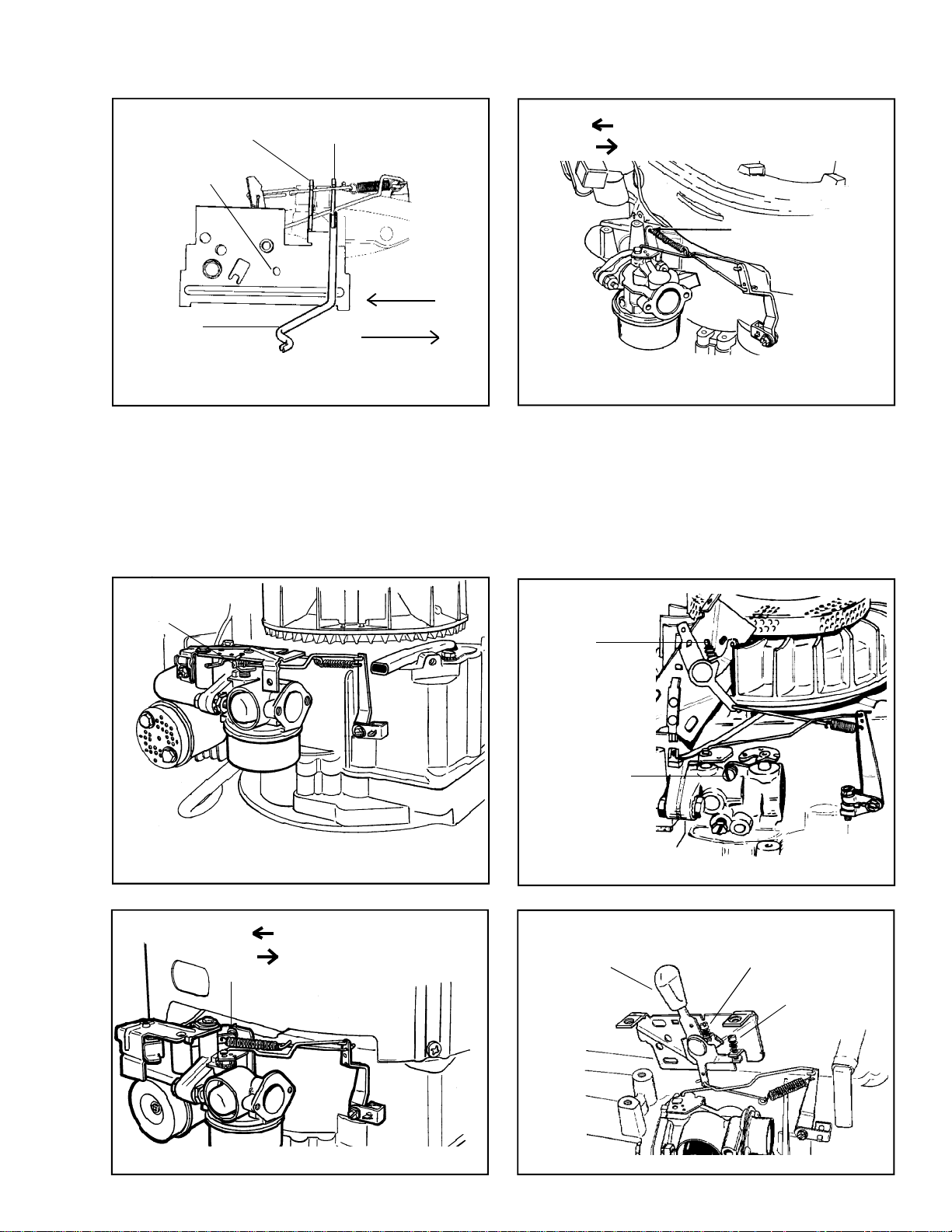

2-Cycle Engine Speed and Mixture Adjustments: TVS/TVXL840

IDLE SPEED

ADJUSTMENT

HIGH SPEED

ADJUSTMENT

5

Linkage Location

To aid in the proper reassembly of the governor

linkage, mark the linkage locations.

HOLDING

SCREW

Static Governor Adjustment

To adjust the static governor, loosen the holding

screw, rotate the governor arm and slotted shaft in

STATIC GOVERNOR

ADJUSTMENT SCREW

6

the direction that will open the throttle to the wide

open position, and then re-tighten the holding screw.

HSK/HXL840-850

IDLE RPM

ADJUSTMENT

SCREW

HIGH SPEED

RPM

ADJUSTMENT

SCREW

7

The HXL840 - 850 Series with variable speed control

have the following adjustments. Idle speed is set at

the carburetor crack screw. High speed is set with

the screw shown above. Always check Microfiche

R.P.M. adjustment of fixed speed models is done

by bending the tab as shown.

card 30 or Parts Smart computer program for

correct speed settings.

Governor and Linkage for Air Vane

BEND TAB TO

ADJUST RPM

VANE ASSEMBLY

INCREASE

DECREASE

INCREASE

DECREASE

BEND TAB

8

TO ADJUST HIGHSPEED ROTATE

CLOCKWISE TO

INCREASE

COUNTERCLOCKWISE

TO DECREASE

9

HORIZONTAL FIXED SPEED

PLASTIC AIR VANE GOVERNOR

10

Rotate sleeve clockwise to increase R.P.M., counterclockwise to decrease R.P.M.

NOTE:The sleeve is serrated to rotate in a clockwise direction and must be raised using the sleeve tabs

before it can be rotated counterclockwise.

To disassemble, remove choke shutter with needle-nose pliers; the vane assembly may then be removed

from the carburetor.

12

Governors and Linkage for Air Vane - continued

ADJUST RPM BY

LOOSENING SCREW AND

SLIDING BRACKET

INCREASE

DECREASE

IDLE RPM

ADJUSTMENT

IDLE

MIXTURE

HIGH SPEED

RPM

ADJUSTMENT

THIS HOLE NOT

PRESENT ON ALL

MODELS

SPRING

HORIZONTAL FIXED SPEED

(ALUMINUM AIR VANE GOVERNOR)

ADJUST RPM BY

LOOSENING SCREW AND

SLIDING BRACKET

INCREASE

DECREASE

HORIZONTAL FIXED SPEED

SPRING

11

GOVERNOR

LINK

13

VARIABLE SPEED-REMOTE CONTROL

IDLE RPM

ADJUSTMENT

IDLE

MIXTURE

VERTICAL ENGINE

HIGH SPEED

RPM ADJUSTMENT

THIS HOLE NOT

PRESENT ON ALL

MODELS

VERTICAL ENGINE

FIXED SPEED-REMOTE CONTROL

12

SPRING

14

IDLE RPM

ADJUSTMENTS

VARIABLE SPEED

MANUAL CONTROL

HIGH SPEED RPM

ADJUSTMENT

THIS HOLE NOT

PRESENT ON

ALL MODELS

SPRINGVERTICAL ENGINE

15

RPM ADJUSTMENT

VERTICAL ENGINE FIXED SPEED

THIS HOLE NOT

PRESENT ON ALL

MODELS

SPRING

16

13

Static Governor Adjustments

The purpose of making a static governor adjustment

is to remove all free-play between the governor

spool and the carburetor (see illustration). Any freeplay here will result in hunting/surging or erratic

running. After completing this procedure, always

re-check the engine speeds using the steps outlined

in the following pages.

SPRING

CHOKE

THROTTLE

GOVERNOR

ROD

To set the static governor, do the following:

1. Be sure the engine is stopped or damage may

occur.

2. If equipped with a throttle control, place the

throttle in the high speed position.

3. Loosen the governor clamp or screw.

4. Hold the governor arm and link in the W.O.T.

(wide open throttle) position, then rotate the

shaft or shaft/clip assembly in the same direction and tighten the screw.

5. If engine speed adjustments are needed, follow

the steps described in following pages.

Governor Shaft Pressed In Depth

NO FREE

PLAY

GOVERNOR

SPOOL

WIDE OPEN

THROTTLE

CLOSED

THROTTLE

When assembling governor shaft into a flange or cover mounting boss, refer to this chart for exposed shaft

length.

Engine Model Exposed Shaft Length

ECH 90 Mounting flange to top

ECV 100 1.319 - 1.334"

H 30, 35 (33.502 - 33.883 mm)

HS 40, 50

LAV (all)

LEV (all)

OHH (all)

OVRM (all)

TNT 100, 120

TVS (all)

VLV (all)

TVM (all) Mounting flange to top

V 50, 60, 70 1.581 - 1.596"

VH 50, 60, 70 (25.806 - 26.314mm)

HH 100, 120 Mounting flange to top

VH 100 1.016 - 1.036"

(25.806 - 26.314 mm)

Engine Model Exposed Shaft Length

H 50, 60, 70 Mounting flange to shoulder

HH 60, 70 1.283 - 1.293"

HHM 80 (32.588 - 32.842 mm)

HM 70, 80, 100

OHV 11-17 Mounting flange to top

OVM 120 1.350 - 1.365"

OVXL 120, 125 (34.290 - 34.671 mm)

OHM 90-120 Mounting flange to top

OHSK 90-130 1.085 - 1.100"

(27.559 - 27.940mm)

OH 120-180 Mounting flange to top

1.00"

(25.400mm)

TVT - V -Twin Mounting flange to top

1.196 (3.969 mm)

14

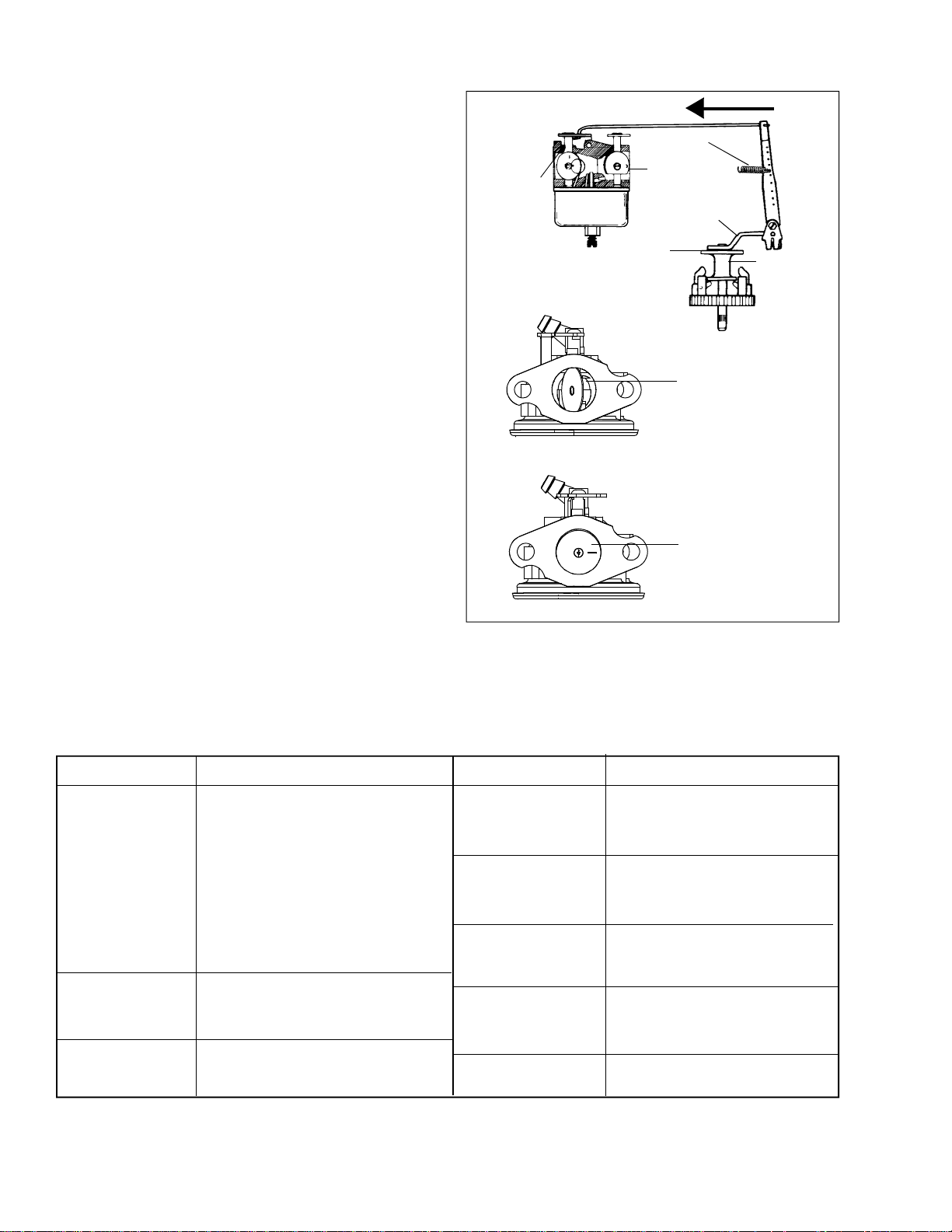

Small Frame, Vertical and Horizontal*

Models: LAV35,40,50 - H25,30,35 - HS40,50 - HSK - HSSK TNT100,120 - ECH90 - TVS75,90,105,115,120 - OVRM ALL

- ECV100,105,110,120

RETAINING

RING

Retainerless Governor System for Small

Frames*

SPOOL

RETAINING

RING

GEAR ASSY.

(GOV.)

WASHER

SHAFT

* As of August 1992, all small frame engines, including VLV40-6.75, use

a retainerless shaft. Service replacement shafts will be retainerless

for all small frame and VLV engines.

SPOOL

UPSET ROLLED

SHAFT

GEAR ASSY.

(GOV.)

WASHER

NOTE: Gear assembly must have .010 - .020 (.25 - .50 mm) end

play after shaft is installed into flange.

* As of August 1992, all small frame engines, including VLV40-

6.75, use a retainerless shaft. Service replacement shafts will

be retainerless for all small frame and VLV engines.

VLV*40, 50, 55, 60, 65, 66

TYPE I

RETAINING

RING

GEAR ASSY.

(GOV.)

SPOOL

WASHER

IDLER

GEAR

TYPE II

SPOOL

UPSET

RETAINER

SHAFT

GEAR ASSY.

(GOV.)

WASHER

.010 - .020 (.25-.50 mm)

CLEARANCE

Medium Frame Vertical

Models: TVM125, 140, 170, 195, 220 - V50,60,70 VH50,60,70

RETAINING

RING

SPOOL

WASHER

RETAINING

RING

GEAR ASSY.

(GOV.)

WASHER

SPACER

SHAFT

NOTE: Gear assembly must have .010 - .020 (.25 - .50 mm)

end play after shaft is installed into flange.

* As of August 1992, all small frame engines, including VLV40-6.75, use

a retainerless shaft. Service replacement shafts will be retainerless

for all small frame and VLV engines.

15

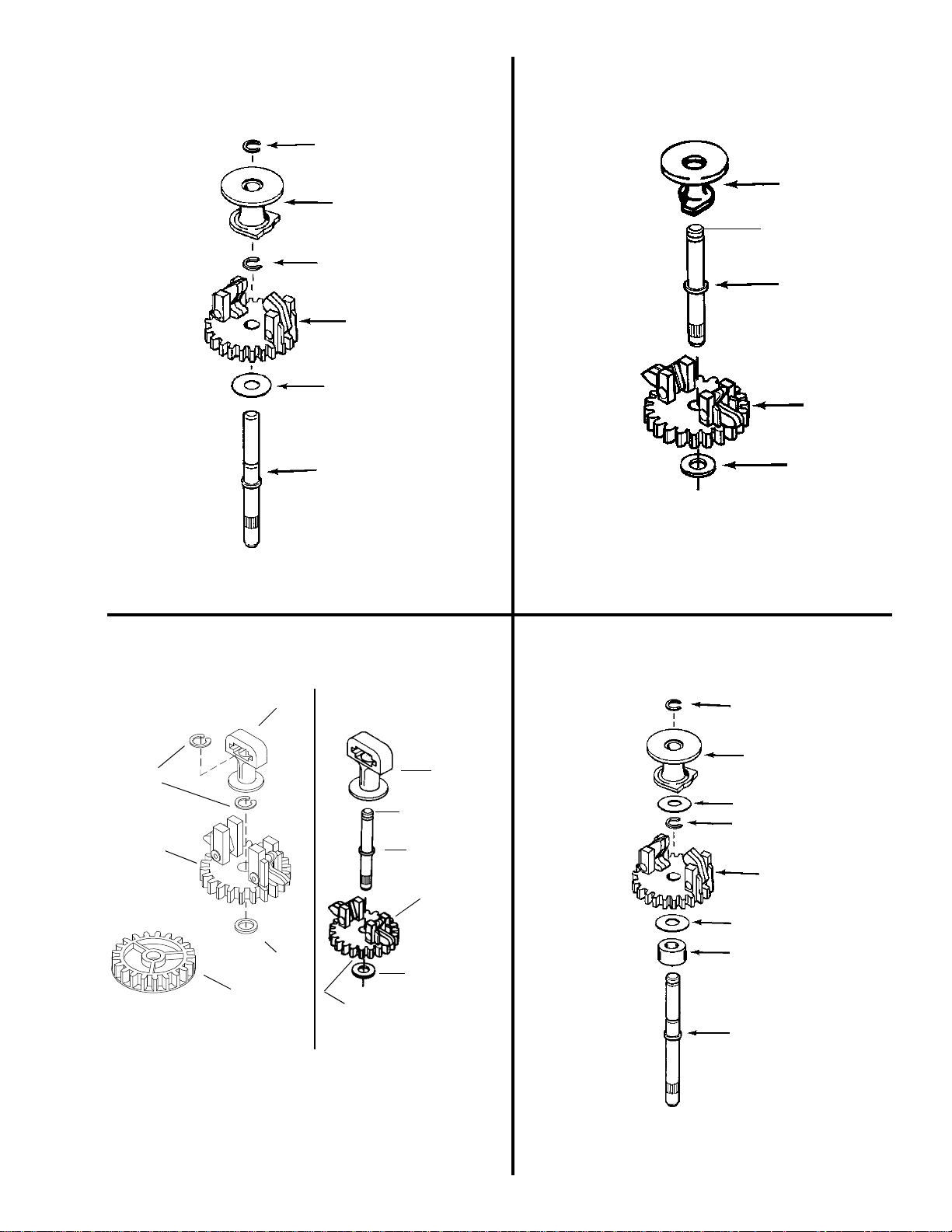

Medium Frame Horizontal

Models: HH60,70 - H50,60,70 - HM70,80,100 HMSK

SHAFT

ROD ASSY.

(GOV.)

SPOOL

OHM120 - OHSK 80-130

SPOOL

WASHER

RETAINING

RING

GEAR ASSY.

(GOV.)

WASHER

RETAINING

RING

GEAR

ASSY.

(GOV)

BRACKET

SCREWS

OVM120, OVXL120, 125 - OHV11-17

SPOOL

WASHER

RETAINING

RING

WASHER

SPACER

SHAFT

OH120, 140, 160, 180

SPOOL

GEAR ASSY.

(GOV.)

WASHER

SPACER

SHAFT

NOTE; SPACER

MAY BE PART

OF THE GEAR

ASSEMBLY.

NOTE: On models OHV13.5-17, the spacer is cast as part

of the governor gear with the washer placed below the

gear assembly.

16

WASHER

GEAR &

SHAFT

ASSY.

(GOV.)

WASHER

(CAPTURED UNDER

GEAR)

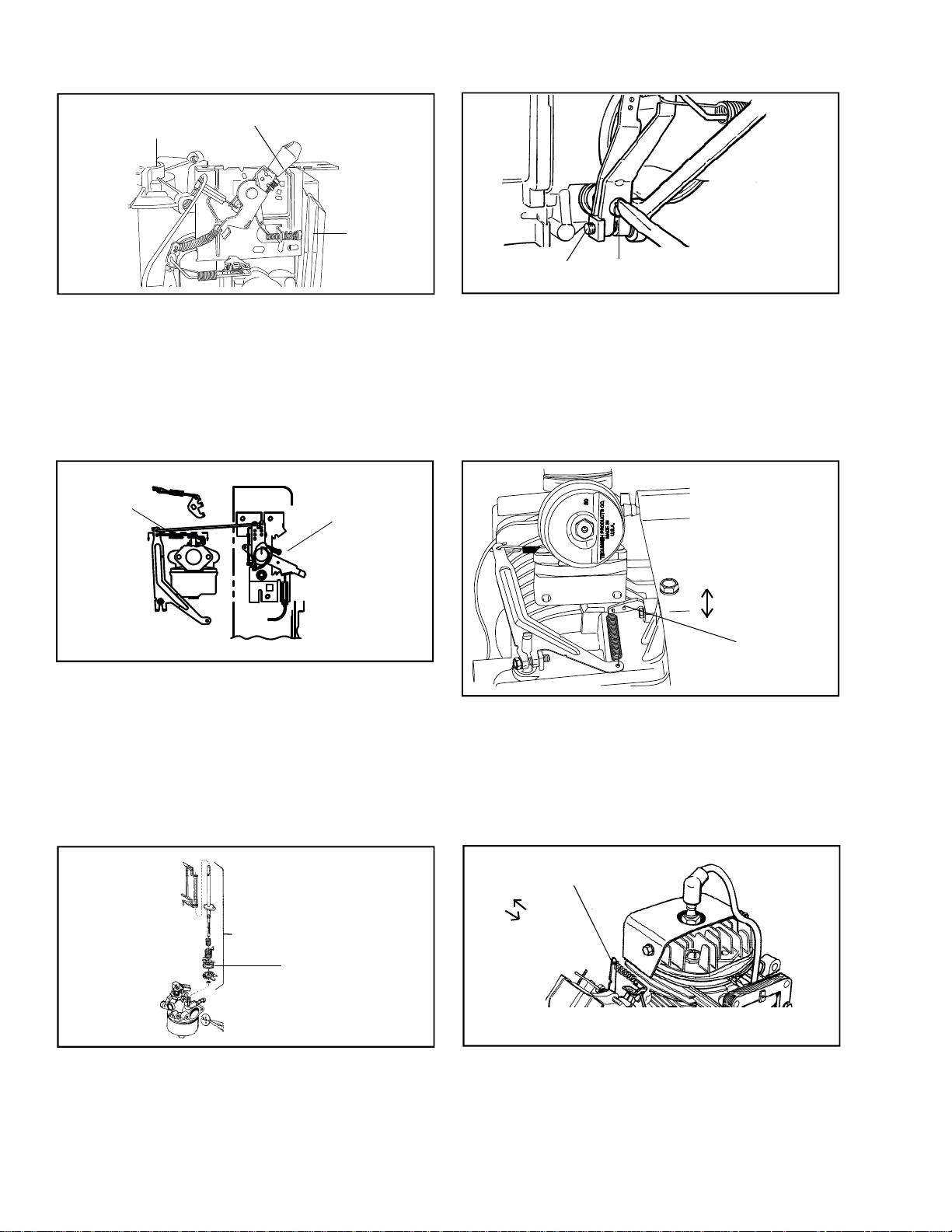

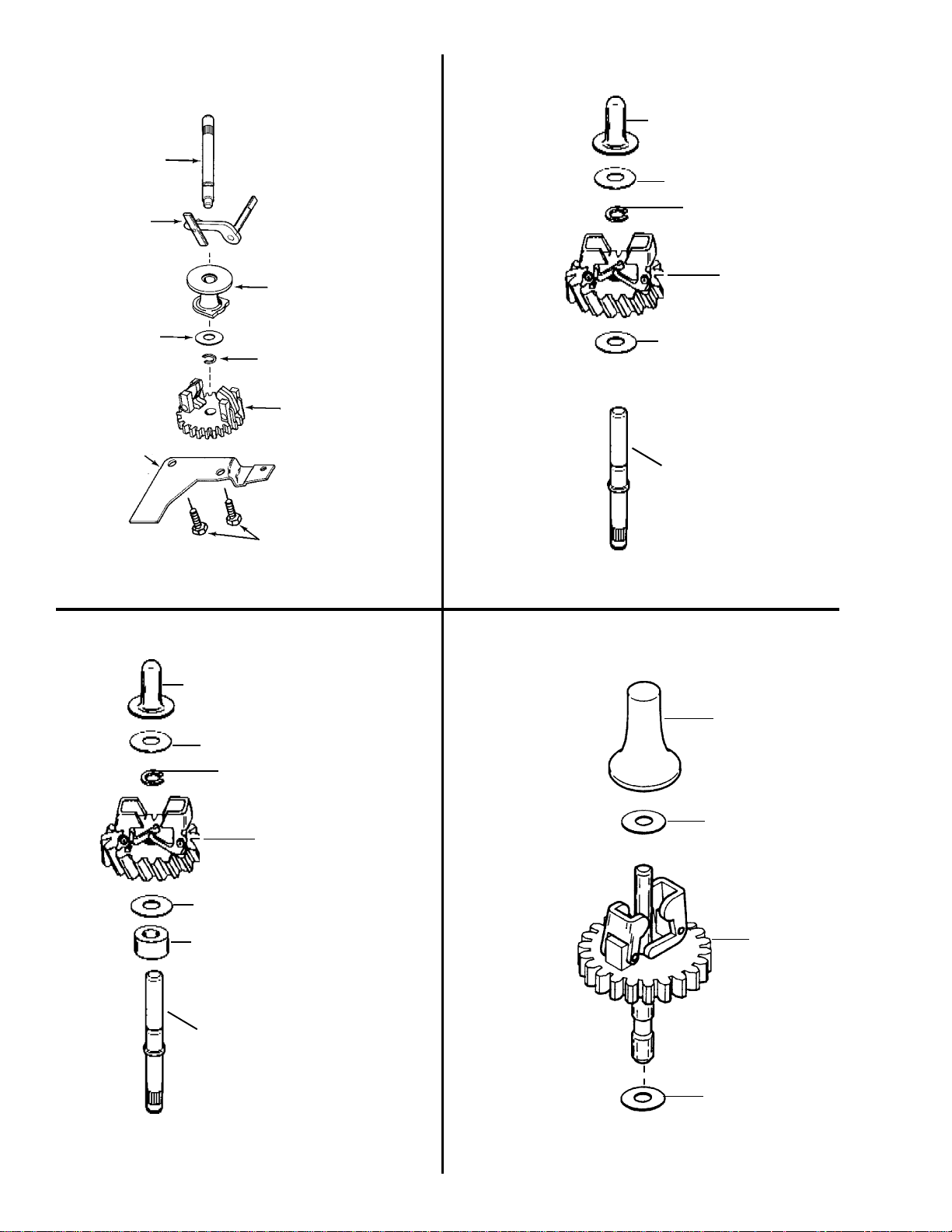

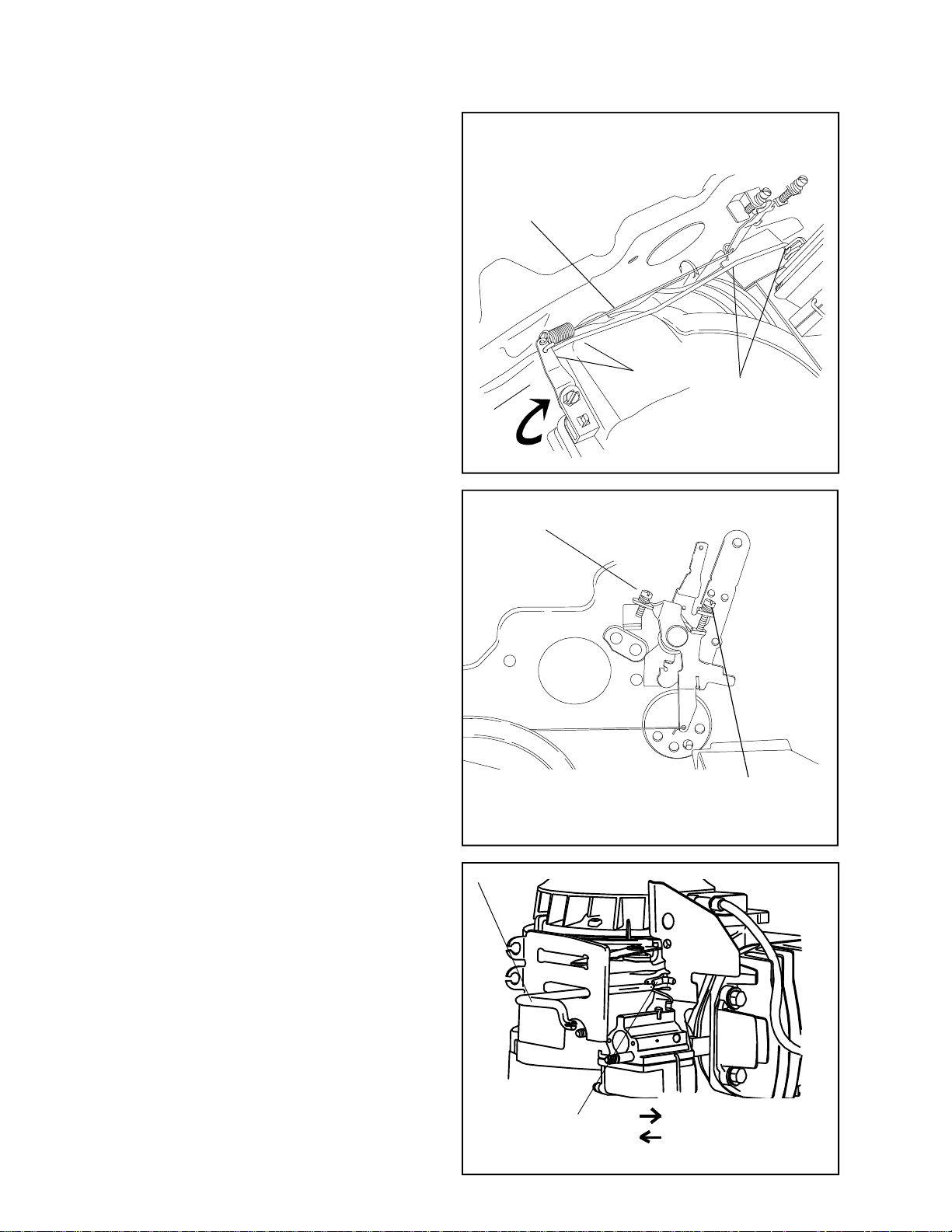

Engine Speed and Mixture

Adjustments

3-5 H.P. Vertical Shaft Engines

NOTE: Starting and operating problems may exist

when engines are used at high elevations (over

4,000 feet above sea level). In cases where a fixed

main carburetor is used, refer to Bulletin 110 for

correction. Engines which are identified as

compliant with CARB (California Air Resources

Board) or EPA (US Environmental Protection

Agency) regulations can NOT be changed from

their factory jetting unless specifically

authorized.

Before making any speed or carburetor adjustments

be sure to adjust the governor and control bracket.

See Governor Section of the Booklet.

To adjust the speed control bracket, determine

whether the carburetor is an adjustable type, then

proceed.

Some carburetors may have a choke lever which is

operated by the speed control bracket. To adjust the

speed control bracket for full choke operation, loosen

the speed control bracket mounting bolts and move

the speed control lever to the high speed/full choke

position. Next insert a small piece of wire through

the hole in the speed control bracket, choke actuating

lever, and the choke lever (diag. 18). When all three

holes are aligned tighten the mounting bolts.

Once the speed control bracket is adjusted, the

main and idle fuel mixtures can be adjusted. Start

the engine and allow it to warm up to normal operating

temperature (3 - 5 minutes). Set the speed control

to the HIGH or FAST position, then turn the main

mixture adjustment screw in (clockwise) slowly

until the engine begins to run erratic (lean). Note the

position of the screw. Now, turn the screw out

(counterclockwise) until the engine begins to run

erratic (rich). Turn the screw in (clockwise) midway

between these two positions. This will be the best

setting.

Set the speed control to the IDLE or SLOW position.

Adjust the idle mixture screw following the same

procedure used to adjust the main mixture

adjustment.

NOTE: SOME CARBURETORS HAVE FIXED

MAIN JETS. THE ABSENCE OF THE ADJUSTING

SCREW INDICATES A FIXED JET AND NO

ADJUSTMENT IS NECESSARY.

After adjusting the fuel mixtures, engine speeds can

be adjusted. The correct operating speeds are

found on Microfiche card 30 of the Tecumseh Master

Parts Manual, or the computer parts look-up program

(Part Smart). On engines with adjustable carburetors

(diag. 19 and 20) the high speed adjustment will be

in one of two places. The first location is on the

speed control lever (diag. 19).

* ADJUSTABLE

MIXTURES, CHOKE

SPEED CONTROL

MOUNTING BOLTS

HIGH SPEED

ADJUSTMENT SCREW

IDLE MIXTURE

SCREW

**NON-ADJUSTABLE

NO CHOKE

PRIMER

SMALL WIRE (DRILL BIT)

HOLE IN BRACKET

HOLE IN SPEED

CONTROL CHOKE

ACTUATING LEVER

HOLE IN CHOKE

LEVER

LOW SPEED

ADJUSTMENT SCREW

MAIN MIXTURE

SCREW

17

18

19

17

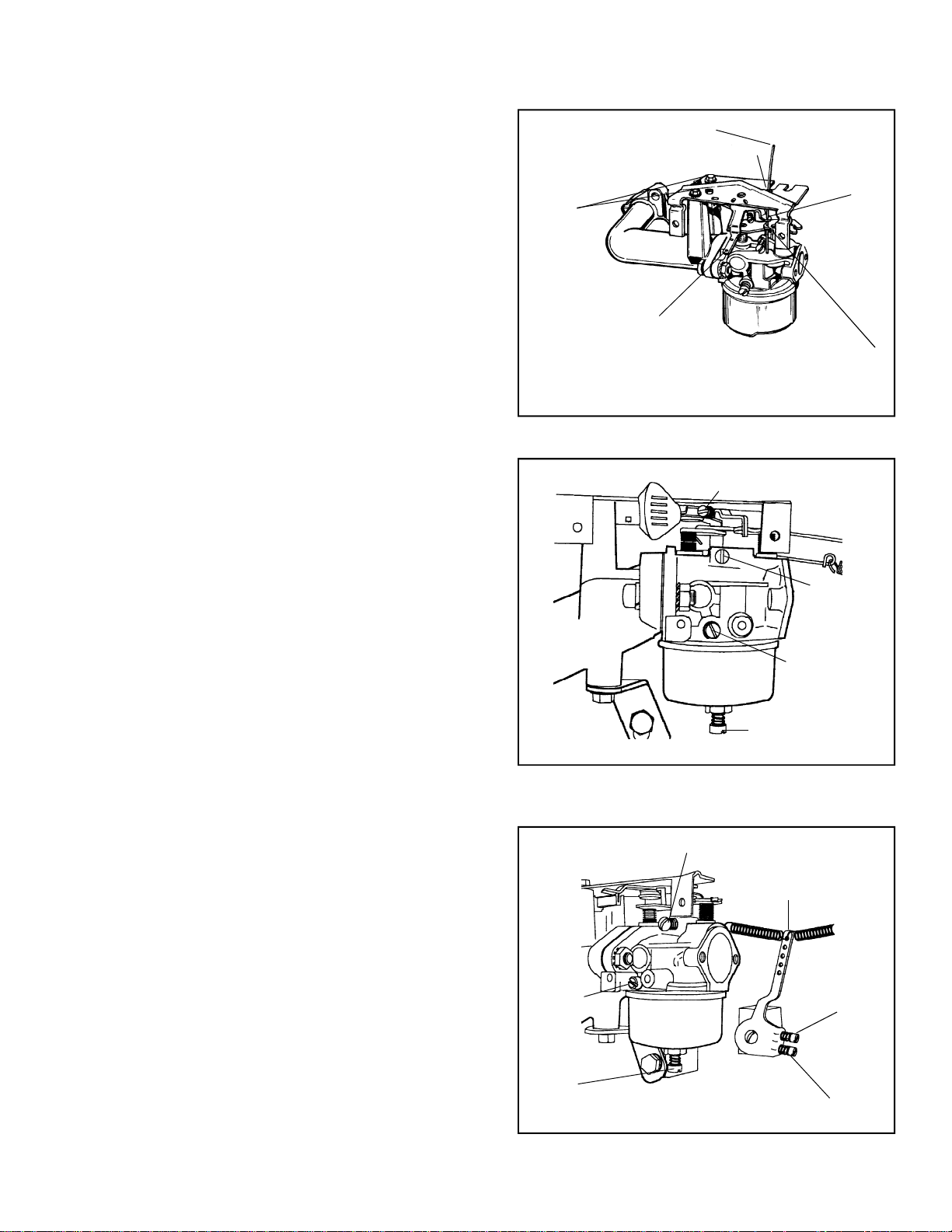

Engine Speed and Mixture Adjustments - continued

3-5 H.P. Vertical Shaft Engines

HIGH SPEED

ADJUSTMENT

SCREW

COUNTERCLOCKWISE

TO INCREASE SPEED

CLOCKWISE TO

DECREASE SPEED

MAIN MIXTURE SCREW

LOW SPEED

ADJUSTMENT SCREW

IDLE

MIXTURE

SCREW

20

The second is on a bracket located between the

blower housing and the speed control (diag. 20).

Low speed is adjusted by the throttle crack screw

on the carburetor (diag. 19 and 20).

It may be necessary to preset the carburetor mixture

screws.

Tecumseh Carburetors

Engine Model Main Pre-set Idle Pre-set

All models with

float-type carburetors 1-1/2 turn 1 turn

All models with

diaphragm-type

carburetors 1 turn 1 turn

SPEED CONTROL

MOUNTING BOLTS

HIGH SPEED

ADJUSTMENT

SCREW

21

LOW SPEED

ADJUSTMENT SCREW

22

SPEED ADJUSTMENT TAB

BEND TO INCREASE SPEED

BEND TO DECREASE SPEED

Some speed control brackets are adjusted by

loosening the speed control bracket mounting bolts

and sliding the bracket all the way to the right and retightening the mounting bolts (diag. 21). The high

speed adjustment screw is located on the speed

control lever (diag.22) Some carburetors are fixed

speed and are adjusted by bending the adjusting tab

attached to the intake manifold (diag. 23).

After setting the engine speeds recheck the fuel

mixtures, then recheck the engine speeds.

18

23

Engine Speed and Mixture Adjustments - continued

3-5 H.P. Vertical Shaft Engines

LOW SPEED TAB

HIGH SPEED

PIN POSITION

HIGH SPEED TAB

BEND TO INCREASE SPEED

BEND TO DECREASE SPEED

BEND CONTROL

BRACKET TO SET

RPM

TOOL

(670326)

SNAP IN CONTROL

DECREASE

INCREASE

24

VERTICAL ENGINES

25

GOVERNED / NON-GOVERNED IDLE

With the engine running at its lowest speed, set the governed idle at the designated R.P.M. by bending the

idle R.P.M. tab. Next set the non-governed idle by pushing the bottom of the governor lever away from the

control brackets, so the throttle lever contacts the idle speed screw. Hold the lever in this position and turn

the idle adjustment screw clockwise to increase or counterclockwise to decrease engine idle speed. The

setting on the carburetor screw should be set at 600 R.P.M. below the governed idle setting. This setting

prevents the throttle plate from closing when going from high speed R.P.M. to low speed R.P.M. If improperly

adjusted, the engine could experience an over lean condition.

HIGH SPEED RPM

ADJUSTMENT

SCREW

TVS 115 ENGINE WITH DUAL

BEND TO INCREASE SPEED

BEND TO DECREASE SPEED

SYSTEM CARBURETOR

26

HIGH SPEED

RPM

ADJUSTMENT

SCREW

IDLE SPEED

CRACK SCREW

VERTICAL SHAFT ENGINES

NOTE:

ON REMOTE CONTROL

THIS WILL NOT BE

PRESENT

27

HIGH SPEED ADJUST

LOW SPEED ADJUST

TNT 100 VERTICAL ENGINES

28

OVRM

29

19

VLV Governor and Linkage

Governor Adjustment

With the engine stopped, loosen the screw holding

the governor clamp and lever. Turn the clamp

clockwise, then push the governor lever (connected

to the throttle) to a full wide open throttle position.

Hold the lever and clamp in this position and tighten

the screw.

Linkage Installation

The solid link is always connected from the throttle

lever on the carburetor to the lower hole on the

governor lever. The shorter bend has to be toward

the governor. The governor extension spring is

connected with the spring end hooked into the upper

hole of the governor lever and the extension end

hooked through the speed control lever. To remove

the governor spring, carefully twist the extension

end counterclockwise to unhook the extension spring

at the speed control lever. Do not bend or distort the

governor extension spring (diag. 30).

Speed Controls

This engine has an adjustable speed control. Never

exceed the manufacturer's recommended speeds.

TWIST COUNTERCLOCKWISE

TO DISCONNECT

GOVERNOR SPRING

SHORT BEND

LONG BEND

30

HIGH SPEED ADJUSTMENT

COUNTERCLOCKWISE INCREASES SPEED

NOTE:Governor adjustment screw will be a Torx

head (T-10) effective August 1, 1996 for

E.C. Compliance.

Fixed Speed

High speed governor adjustment is accomplished

by bending a tab to increase and decrease engine

R.P.M. Effective August 1997 (diag. 31a).

LOW SPEED ADJUSTMENT

COUNTERCLOCKWISE INCREASES SPEED

31

TOOL 670326

20

HIGH SPEED

ADJUSTMENT

BEND TO INCREASE SPEED

BEND TO DECREASE SPEED

FIXED SPEED

31A

Engine Speed and Mixture

Adjustments

5-15 HP Vertical Shaft Engines

The first step is adjusting the speed control bracket

for full choke operation. Loosen the two speed

control bracket mounting bolts and move the control

lever to the full high speed/full choke position. Insert

a piece of wire through the hole in the speed control

bracket, the choke actuating lever, and the choke

lever (diag. 32). When all three holes are in alignment

retighten the speed control bracket mounting bolts.

SMALL PIECE OF WIRE

HOLE IN CONTROL BRACKET

MOUNTING

BOLTS

MOVE THE CONTROL

LEVER IN THE HIGH

SPEED POSITION

HOLE IN

CHOKE

ACTUATING

LEVER

HOLE IN CHOKE LEVER

32

The second step is adjusting the main and idle

fuel mixtures. Start the engine and allow it to warm

up to normal operating temperature (3 - 5 minutes).

Set the speed controls to the HIGH or FAST position,

then turn the main mixture adjustment screw in

(clockwise) slowly until the engine begins to run

erratic (lean). Note the position of the screw. Now,

turn the screw out (counterclockwise) until the

engine begins to run erratic (rich). Turn the screw

in (clockwise) midway between these two positions.

This will be the best setting.

Set the speed control to the IDLE or SLOW position.

Adjust the idle mixture screw following the same

procedure used to adjust the main mixture adjustment

screw.

NOTE: SOME CARBURETORS HAVE FIXED

MAIN JETS. THE ABSENCE OF THE ADJUSTING

SCREW INDICATES A FIXED JET AND NO

ADJUSTMENT IS NECESSARY.

The third step is setting engine speeds. The

correct engine operating speeds are listed on card

30 of the Tecumseh Master parts manual microfiche,

or the computer parts look-up program (Part Smart

or Plus One). The most common speed control

bracket (diag. 33) has the high speed adjustment

screw located on the speed control lever. The low

speed adjustment screw is the throttle crack screw

on the carburetor body. Another common speed

control is the governor override system (diag. 34).

This system has a similar speed control bracket

along with a governor adjustment lever which is

attached to the engine block. Both the high speed

and low speed adjustment screws are located on

the governor adjusting lever.

THROTTLE CRACK SCREW

IDLE

MIXTURE

SCREW

MAIN MIXTURE

SCREW

LOW SPEED

ADJUSTMENT SCREW

HIGH SPEED

ADJUSTMENT SCREW

THROTTLE

CRACK

SCREW

IDLE MIXTURE

SCREW

MAIN MIXTURE

SCREW

GOVERNOR

ADJUSTING

LEVER

HIGH SPEED

ADJUSTMENT

SCREW

33

34

21

Loading...

Loading...