Tecumseh ROTARY COMPRESSORS HG, ROTARY COMPRESSORS RG, ROTARY COMPRESSORS RK, RK, RG Installation And Operation Manual

...Page 1

MANUAL

INSTALLATION AND OPERATION

Rotary Compressors

RK, RG and HG

Page 2

2

General Information 5

The working principle of the Rotary Compressor 5

Range 6

Performance 7

Voltage and range of operation 7

1.4.1 Single phase 7

1.4.2 Three phase 7

Dimensions and connections 8

Mountings 8

Oil type 8

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

Operating Range 9

Operating envelope 9

Operating compression ratio 9

Operating pressure differential 9

2

2.1

2.2

2.3

Temperature Criteria 10

Ambient temperature 10

Discharge temperature 10

Motor temperature 10

Return gas temperature 10

3

3.1

3.2

3.3

3.4

General Recommendations 11

System requirements 11

Pipework design 11

4.2.1 Pipework design advice/guidance 11

4.2.2 Connections 14

4.2.3 Flexible connections 14

4.2.4 Velocity within pipework and heat exchangers 14

4.2.5 Capillaries 16

Refrigerant charge 21

4.3.1 Advice for installers 21

4.3.2 Refrigerant charge 21

Starting 21

4.4.1 Frequency of starts 21

4.4.2 Start-up pressure 21

4

4.1

4.2

4.3

4.4

Page 3

3

Security 23

Pressure 23

Electrical 23

Declaration of incorporation 23

5

5.1

5.2

5.3

Appendices 25

Documents 25

Contacts 25

6

6.1

6.2

General Recommendations (continued)

Liquid return whilst operating 22

Liquid migration during prolonged shutdown 22

4.6.1 Band heaters 22

4.6.2 Non-return valves 22

Purging refrigerant from the system 22

4

4.5

4.6

4.7

Page 4

Page 5

General Information

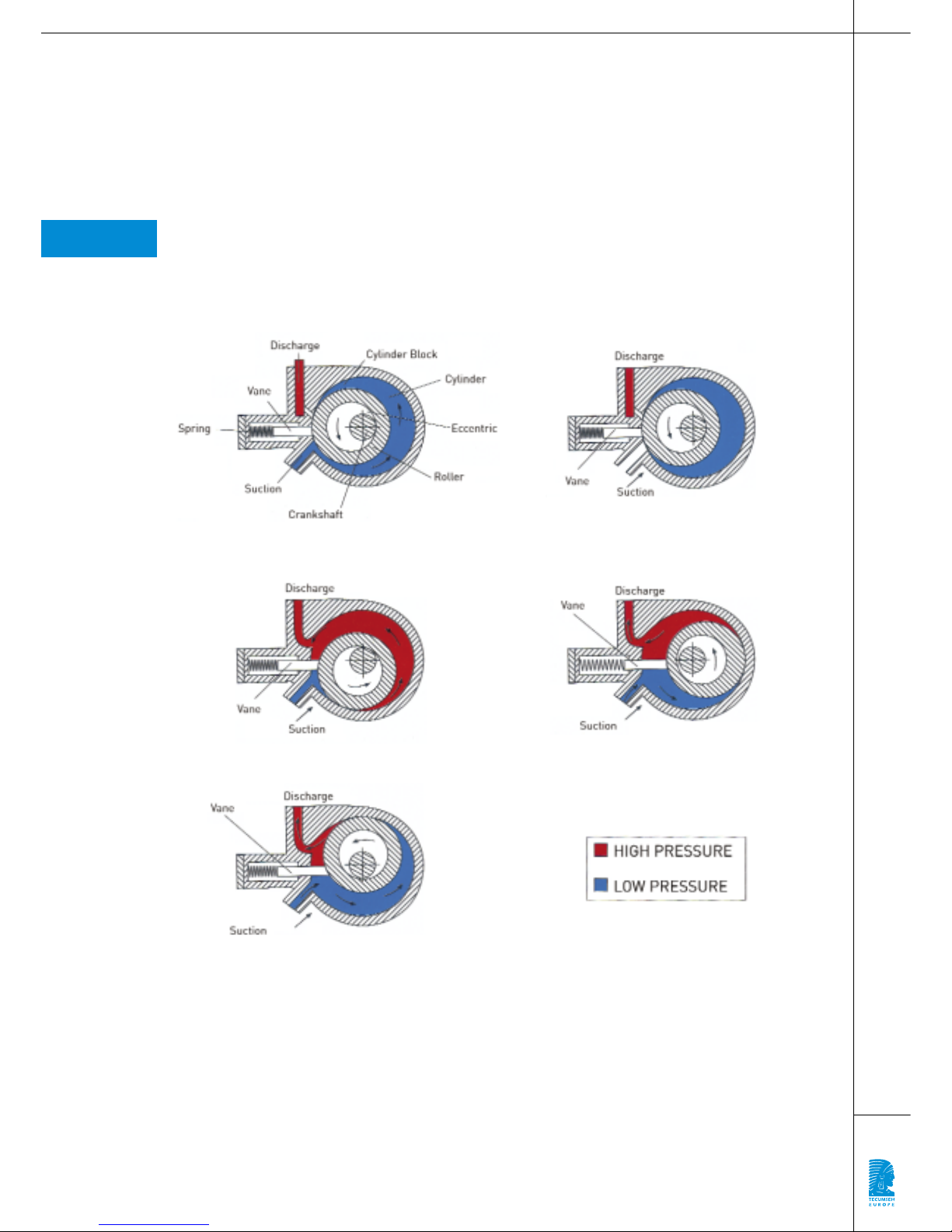

The working principle of the Rotary Compressor

Rotary compressors are ‘high pressure shell’ type compressors. The suction on these compressors

is taken directly into the compression chamber. Gas compressed in the compression chamber is

discharged into the compressor casing. It should be noted that from a cold start-up, high pressure shell

type compressors take longer to reach their normal operating pressure in the compressor shell. This

is partly due to the larger volume of the compressor casing and partly as a result of refrigerant being

trapped in the oil. Any refrigerant in the oil has to completely evaporate before condensing pressure can

reach its operating level.

1

1.1

5

Tecumseh Europe with its long experience of compressor development has introduced

a range of rotary compressors for air conditioning and commercial refrigeration.

This operating manual has been designed to help you correctly install this compressor

range in your applications.

1|Names of the different pieces 2|End of suction and the start of compression

3|Start of compression and suction 4|Compression and suction

5|Compressed gas exit

Page 6

6

1.2

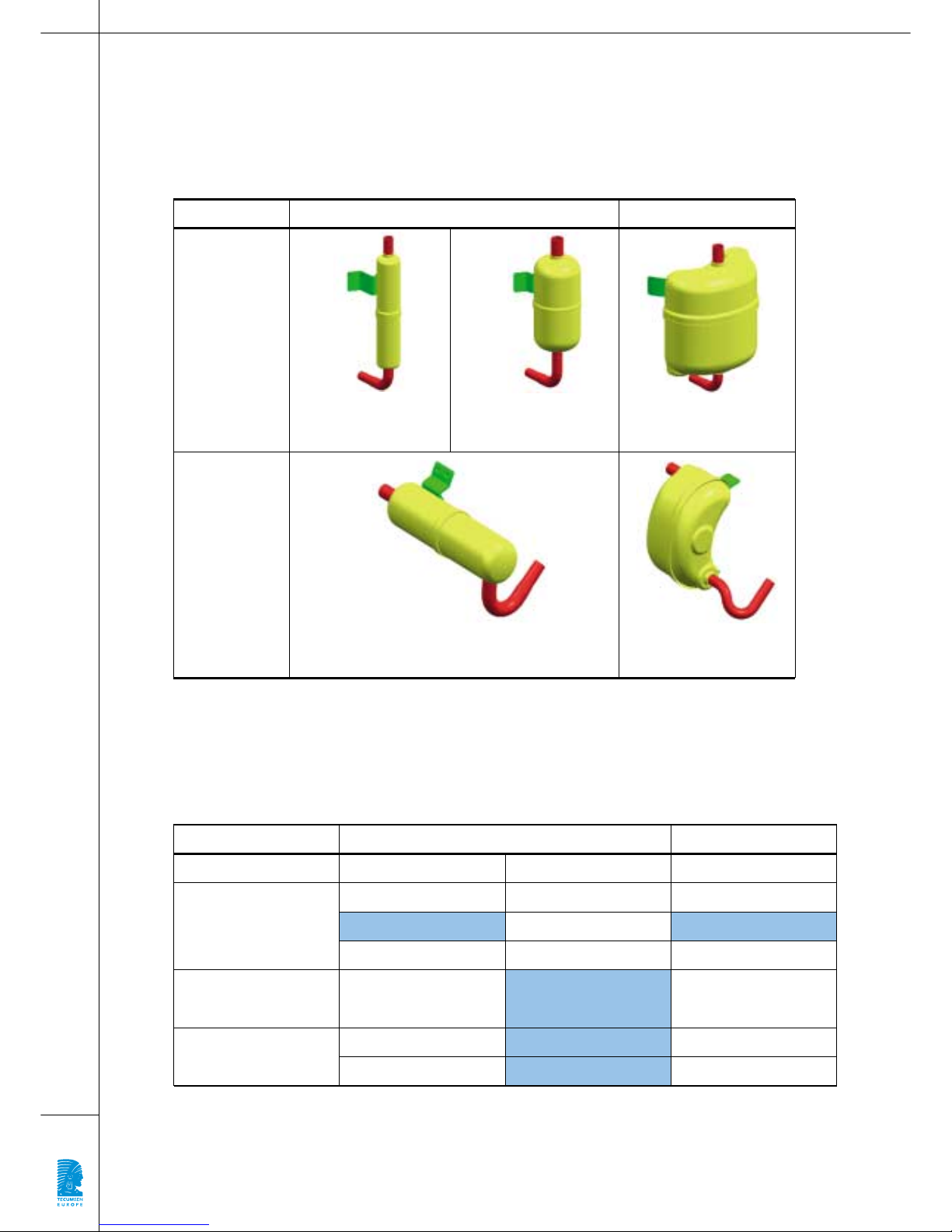

Sucking bottle

Excessive refrigerant, oil or impurity in the suction chamber of the compressor can result in mechanical

damage. As a result, all our compressors are fitted with an accumulator equipped with a filter.

Please note that overcharging with refrigerant is one of the major causes of damage to the compressor.

It is important to check the amount of refrigerant being used is correct.

Range

Application

VERTICAL HORIZONTAL

Air Conditioning

or Heat Pump

RG range, accumulator

capacity > 100 cm

3

RK range, accumulator

capacity > 160 cm

3

RG range, accumulator

capacity > 680 cm

3

HG range, accumulator

capacity > 405 cm

3

HG range, accumulator capacity > 70 cm

3

Commercial Refrigeration

Low Back Pressure

RG RK HG

R22 R22 R22

R134a

R407C R407C R407C

Commercial Refrigeration

High Back Pressure

R134a R134a

R404A R404A

VERTICAL

AIR CONDITIONING COMMERCIAL

HORIZONTAL

R404A R404A

Page 7

7

Performance

Please refer to the Technical Data Sheets for information on compressor performance.

Voltage and range of operation

The voltage range of the rotary compressors corresponds to the standard ranges defined by Tecumseh

Europe. See the General Catalogue for more information.

Start-up should never be carried out when the electrical cover has been removed.

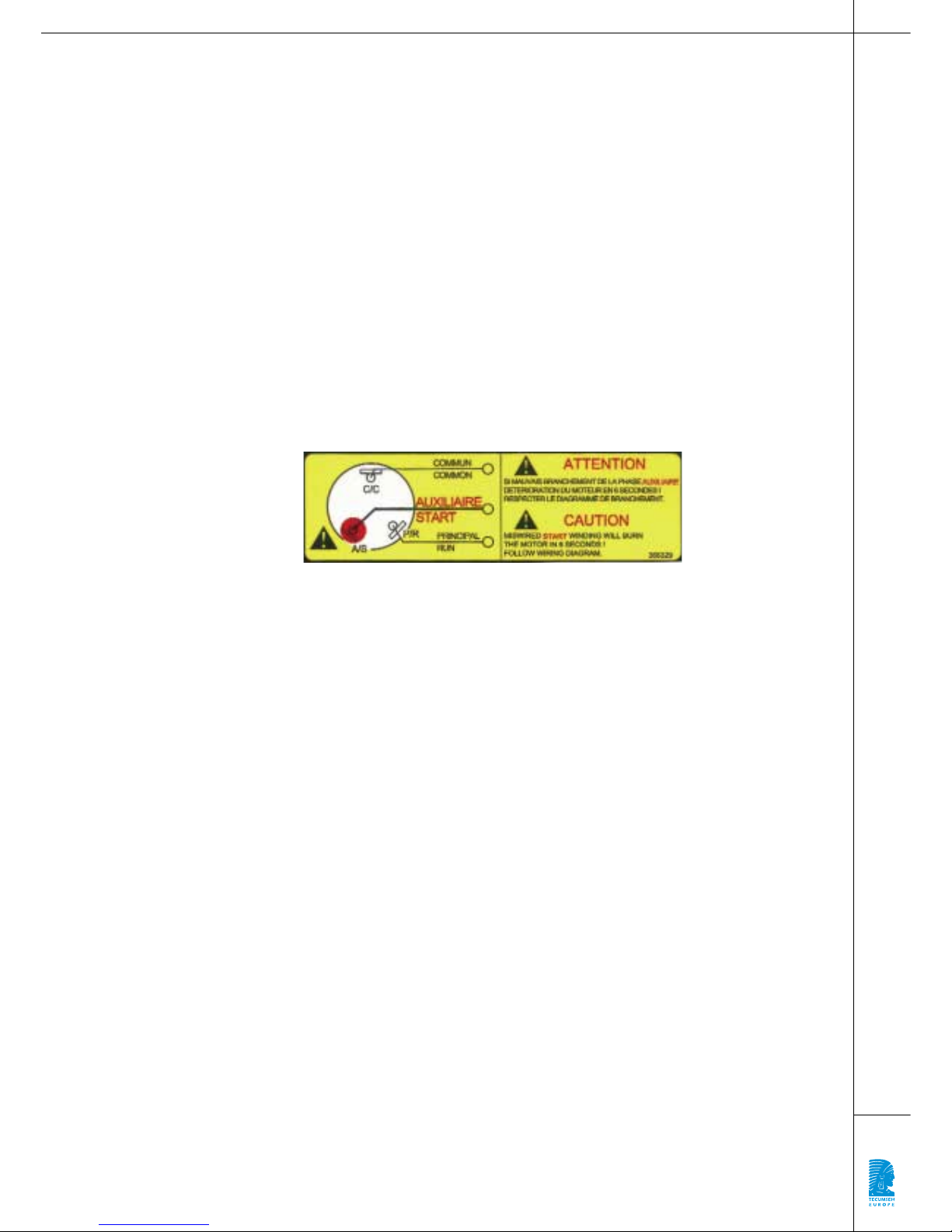

1.4.1 Single phase

Single phase compressor motors are two pole asynchronous and they are designed to be used with

different types of starting method depending on the application (PSC, CSR, CSIR).

Please ensure the starting mode follows that specified on the Technical Data Sheet for each product.

We recommend the use of components specified by Tecumseh Europe.

For wiring instructions, follow the diagram supplied with the compressor.

Ensure that the start and run windings are connected correctly otherwise damage to the motor will

result (see label below).

1.4.1.1 Motor protection

The motor is protected by an externally mounted temperature and current sensitive overload. It is imperative that the overload protector is connected as it cuts off the power supply to the compressor if a fault

occurs. For wiring instructions, follow the wiring diagram supplied with the compressor.

1.4.2 Three phase

All rotary compressors which have a model number beginning with a letter ‘T’ are equipped with a three

phase motor.

Three phase motors are wired in star, and the resistance measured between two terminals corresponds

to the resistance of that coil.

Ensure that each compressor conforms to the information given on the Technical Data Sheet.

We recommend the use of components specified by Tecumseh Europe.

For wiring instructions, follow the diagram supplied with the compressor.

1.4.2.1 Phase control

Care should be taken when connecting three phase rotary compressors to ensure that the direction of

rotation is correct as rotation occurs in one direction only.

ATTENTION: If the rotational direction is incorrect, the compressor will not refrigerate and the life of the

product will be reduced. However, a short test period will not cause damage.

To ensure correct rotation we recommend the use of our phase detector reference number 8 535 136,

which is listed in our Spare Parts and Accessories Catalogue.

1.4.2.2 Protection of the motor

The motor is protected from overheating by an external overload protector which must be connected.

This device has a single contact and cannot be wired into the three phase electrical supply of the compressor (a three phase motor can only operate with a minimum of 2 active phases). The protector should

therefore be wired into the control circuit of the compressor so that it cuts the power supply if a fault

occurs. For wiring instructions, see the electrical diagram supplied with the compressor.

For further information on protecting the compressor against high current, please contact the technical

application department at Tecumseh Europe.

1.3

1.4

Page 8

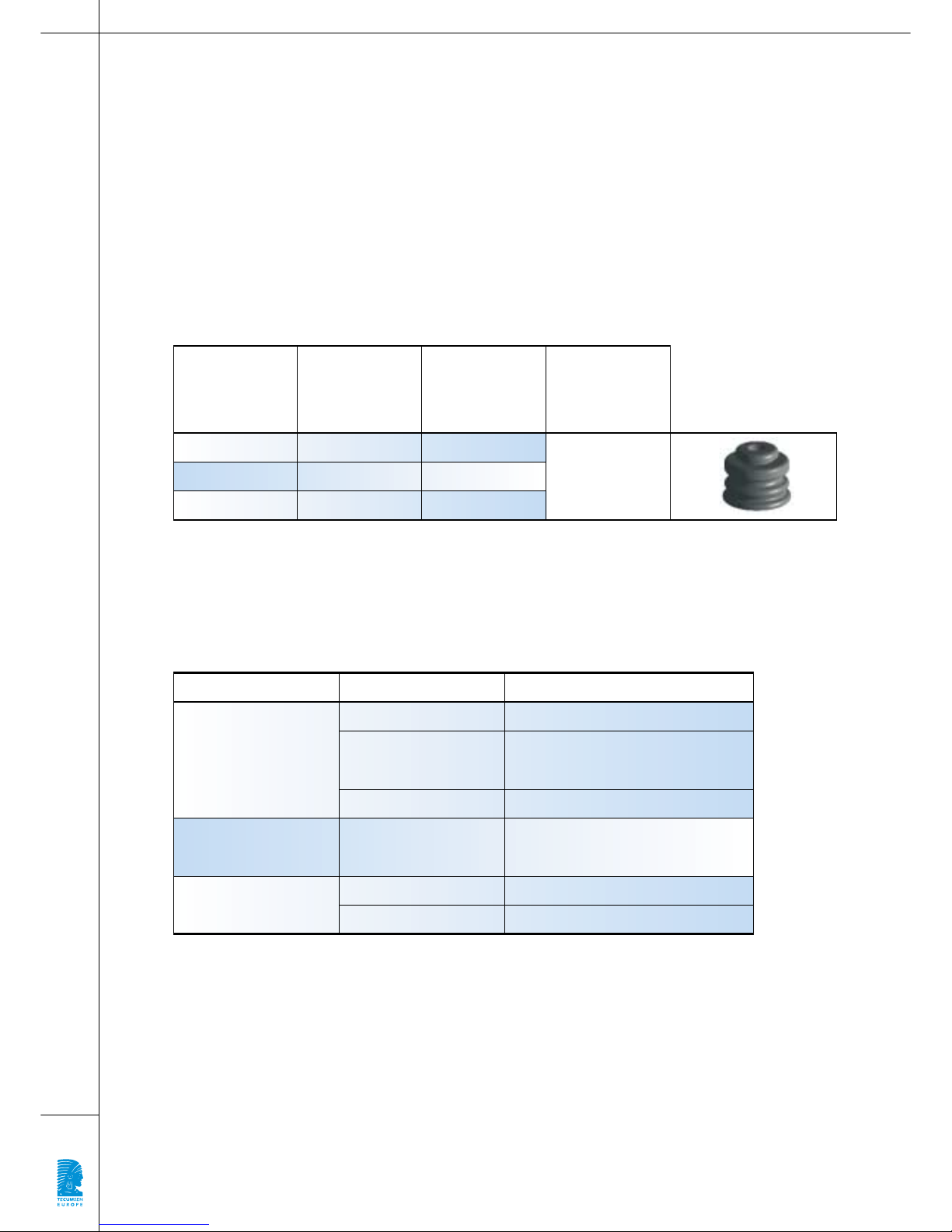

8

RG

STANDARD

MOUNTING

STANDARD

PLAY

HG

4 feet 8 682 025

3 feet 8 682 021

RK

1.5

1.6

1.7

RANGE

MAXIMUM

TORQUE

SETTINGS

3 feet 8 682 021

13.8 Nm to 17.9 Nm

(10 to 13 ft.lbs)

Air Conditioning

or Heat Pump

REFRIGERANT OIL

APPLICATION

R22 Alkyl Benzene

R134a Polyolester

R404A Polyvinyl ether

R134a Polyolester

R404A Polyvinyl ether

Commercial Refrigeration

Low Back Pressure

Commercial Refrigeration

High Back Pressure

Short pipe run* (<3,6m): Alkyl Benzene

Long pipe run* (≥3,6m): PVE

R407C

Dimensions and connections

The dimensions and the position of the connections are given in our Technical Data Sheets.

The compressors can tolerate an angle of tilt of +/- 7° for vertical models and +5°/0° for horizontal versions.

Mountings

We recommend the fitting of anti-vibration mounting feet as specified by Tecumseh Europe (see table

below).

Natural or synthetic rubber products bearing weight for long periods tend to loose their shape. This

occurs more quickly when they are subject to an excessive loading and/or heat. Anti-vibration mounting

feet should be regularly checked to ensure optimal operation of the installation and replaced where

necessary to ensure the sound level does not increase.

The length of the AV mount insert used allows the mounts to function correctly and prevents overtightening.

Specific mounts can be supplied for applications where greater vibration reduction is required. For further

information, contact your local representative.

Oil type

* Short or long pipe run: Distance between the condenser and the evaporator.

The design of the rotary compressors is such that an oil change or the addition of oil should not be

carried out.

We strongly advise against adding oil to the refrigeration system whether the pipework is long or short.

Page 9

9

Operating Range

Operating envelope

The operating envelope is in accordance with EN 12 900, with a superheat of 10K for air conditioning

and heat pump applications, and return gas of 20°C for all other applications (See diagrams in

the appendices).

For more information please refer to the Technical Data Sheet for each product.

Operating compression ratio

The operating compression ratio is the ratio between absolute condensing and evaporating pressures.

It is essential to adhere to the maximum values listed in the following table.

Exceeding these values will reduce the working life of the compressor or even cause a breakdown.

Operating pressure differential

The operating pressure differential corresponds to the difference between absolute discharge and suction pressure. Maximum levels are listed in the table below. Exceeding these values will reduce the working life of the compressor or even cause a breakdown.

2

2.1

2.2

2.3

Air Conditioning

or Heat Pump

REFRIGERANT COMPRESSION RATIO

APPLICATION

R22 7

R134a 15.8

R407C 7

R404A 8

R134a 15.8

R404A 22

Commercial Refrigeration

Low Back Pressure

Commercial Refrigeration

High Back Pressure

Air Conditioning

or Heat Pump

REFRIGERANT PRESSURE DIFFERENTIAL (BAR)

APPLICATION

R22 22

R407C 23.5

R134a 23

R404A 25

R134a 23

R404A 27.1

Commercial Refrigeration

Low Back Pressure

Commercial Refrigeration

High Back Pressure

Page 10

10

Temperature Criteria

Ambient temperature

The compressors have been designed to operate in the following ambient temperatures (with forced

air cooling).

Comment:

For air conditioning applications operating in high ambient conditions, see our tropical range. These

products use R-134a and have an evaporating temperature range of –10°C to +30°C, and a condensing

temperature range of +30°C to +80°C for a temperature of 55°C.

Discharge temperature

The maximum discharge temperature is 127°C. This temperature can be measured by soldering a

thermocouple onto the discharge pipe 5 cm from the compressor and insulating it for 10 cm.

Motor temperature

All our single phase rotary compressors are supplied with an external overload protector. The maximum

permitted operating temperature is 130°C which is measured by the resistance variation method.

Resistance variation method: Leave the application switched off in a constant temperature

(temperature t1) for at least 8 hours. Measure the motor winding resistance R1at this temperature t1.

With three phase motors, measure the resistance between 2 electrical supply terminals to the compressor.

Run the application in the most difficult conditions foreseeable, switch off the machine and immediately

measure the new motor winding resistance (R2). With three phase motors, measure the resistance

between the 2 terminals used before.

The new temperature t2can easily be calculated using the following equation:

t1& t2are given in degrees Celsius.

Return gas temperature

A minimum superheat of 10K is necessary between the evaporating temperature and suction temperature

at the inlet of the compressor. However, it is necessary to control superheat to prevent exceeding the

maximum return gas temperature for the compressor and the compressor motor (see sections 3.2 and 3.3).

3

3.1

3.2

3.3

3.4

Air Conditioning

or Heat Pump

AMBIENT TEMPERATURE

46°C

43°C

Commercial Refrigeration

Page 11

11

General Recommendations

System requirements

Rotary compressors are ‘direct suction’. The suction gas enters directly into the compression chamber.

The suction accumulator incorporates a filter to protect the compressor against dirt and debris entering

the pump.

It is essential that all necessary precautions are taken to ensure the system is kept clean during

installation and service e.g. purge the system with Nitrogen whilst brazing.

Pipework design

The function of the pipework is to allow the refrigerant to circulate through the system components in

such a way as to provide optimum operating conditions, i.e.:

> Limited pressure drop,

> Velocity is sufficient to entrain the oil,

> Ensure that the compressor is protected against the return of liquid refrigerant particularly when

the installation is switched off.

> A full head of liquid refrigerant at the expansion device.

As in all refrigerating systems using hermetic compressors, some of the oil from the compressor

circulating within the system is entrained with the refrigerant. The amount varies according to the operating conditions of the installation. No additional components e.g. oil separator, oil coolers etc. are

required to assist with oil control in rotary compressor systems.

However, it is essential to ensure the oil return to the compressor otherwise its working life may be

shortened and its performance affected.

All pipework in the refrigerating system must be designed to return oil to the compressor. The design

must prevent oil being trapped in the pipework, the system components and the heat exchangers.

Refrigeration best practice must be respected.

Due to the difficulty of controlling the return of oil in a multi-evaporator system, we advise that the

rotary compressors should only be used in a single circuit system.

4.2.1 Pipework design advice/guidance

4.2.1.1 Suction pipework

Suction pipework returns refrigerant gas to the compressor from the evaporator. The main factors

to consider are:

> A partial refrigerant charge caused by a leak or incomplete charging will cause a reduction in

compressor capacity due to the lower suction pressure,

> Reduce the return gas superheat in order to limit the discharge temperature,

> Ensure that the refrigerant velocity is sufficient to return the oil to the compressor which has a small

oil charge,

> Prevent refrigerant entering the compressor during either the running or off cycles. The possibility

of any liquid slugs of oil entering the compressor during the running must also be prevented.

In practice, suction lines are generally designed for pressure drops of no more than 1°C saturated temperature.

4

4.1

4.2

Page 12

12

1 - If the compressor is located higher than the

evaporator, the oil return to the compressor must

be guaranteed. Oil traps at the beginning of the

suction risers must be used and the pipe line velocity must be sufficient to ensure oil flow in suction

risers. A smaller size oil trap could be used before

the suction riser.

2 - When the compressor is on the same level or

lower than the evaporator, we recommend that

swan neck suction line is used where the top of the

swan neck is above the evaporator, whether the

suction exit of the evaporator is at the top or bottom.

This is to prevent the gravitational flow of refrigerant to the compressor during the off cycle.

On the other hand, an oil trap should not be used

close to the suction of the compressor to prevent

oil/refrigerant slugs (or a mixture of both) reaching

the compressor.

3 - The above design can be simplified by using a

“pump down” control system.

This system requires the installation of a solenoid

valve (LLSV) prior to the expansion device (EXV).

The compressor is controlled by a low pressure

switch. Before pump down can occur, the solenoid

valve must be closed in order to pump out the evaporator and transfer the refrigerant to the high

pressure side. As the low pressure in the suction

reaches the cut off point of the low pressure switch,

the pressure switch stops the compressor.

Liquid cannot therefore accumulate at the suction

of the compressor.

The suction piping then drops directly towards the

compressor.

4.2.1.1.1 Discharge pipework

The discharge pipework carries refrigerant gas compressed by the compressor to the condenser.

The main factors to consider are:

> Minimum pressure drop,

> The velocity is sufficient to take the oil to the condenser even when there is only a partial charge,

> Ensure that liquid (oil, refrigerant or both) does not migrate towards the compressor during the off cycle.

In practice, discharge piping can be designed for a pressure drop of up to 1°C at saturation temperature.

Pressure drop in the discharge pipework can cause a slight reduction in capacity as the compressor has

to operate at a discharge pressure higher than the condensing pressure.

Riser

Suction pipework

Pump down

Page 13

13

If the installation is such that the compressor is

the coldest part of the system (i.e. has the lowest

temperature), a non-return valve must be fitted

close to the condenser to isolate the condenser

from the compressor.

The valve is also an advantage during start-up

where a large pressure differential may occur.

(see § 4.4.2)

4.2.1.1.2 Liquid pipework

The liquid line supplies liquid refrigerant to the expansion device from the condenser/receiver. When

sizing a liquid line the main factors to consider are:

> The re-heating of the duct,

> Minimum pressure drop.

In this part of the system, because the oil and refrigerant are miscible, oil flow does not present any

particular problems. However, attention must be paid to ensuring there is a constant supply of liquid to

the expansion device. Under no circumstances must the refrigerant be heated and pressure changes in

the pipework must be prevented.

If liquid refrigerant experiences a pressure below its saturation pressure, it will vaporize within

the pipework.

To ensure the expansion device functions correctly, the pressure of the liquid reaching it must be sufficiently high, and preferably, slightly subcooled. It is essential to restrict the pressure drop in the pipework for the following reasons:

> To prevent a reduction in the mass flow through the expansion device,

> To prevent partial vaporization of the liquid refrigerant prior to the expansion device (pressure drop

higher than subcooling).

The components fitted to the liquid line such as the filter drier, solenoid valve, liquid line sight glass also

cause varying pressure drops.

The pressure drop in this pipework must not exceed 0.5°C.

4.2.1.1.3 Positioning of accessories on the liquid line

The diagrams below show the normal position of accessories on the liquid line.

The filter drier must be positioned next to the

expansion device to prevent clogging by impurities.

It should be installed in a vertical position with the

outlet downwards to ensure constant liquid supply

to the expansion device.

The liquid sight glass should be positioned between

the drier and the expansion device in order to indicate that:

> Liquid / vapour is present,

> The level of risedual humidity.

Discharge pipework

Liquid line - position of accessories

Page 14

4.2.2 Connections

The rotary compressors have copper connections. The positioning of connections is given in the

Technical Data Sheets. Please note the following:

• Brazing should be carried out using an inert gas (Nitrogen).

• Protect paintwork while brazing by covering the accumulator and compressor with a damp cloth.

Do not allow the flame to come in contact with paintwork.

• Brazing of the connections must comply with the recommendations of the Standard NF EN 378-2.

• Carry out pipe cutting and bending operations carefully in order to prevent dust and swarf contaminating

the system.

Care should be taken to ensure that flux does not contaminate the system.

4.2.3 Flexible connections

Rotary compressors do not have internal mounting springs, in contrast to the majority of hermetic compressors. The internal design and external mountings are designed to reduce vibration. However, some

vibration is transmitted to the suction and discharge pipework. We therefore recommend using flexible

connections to prevent vibration being transmitted to the rest of the installation.

We recommend using annealed copper pipe rather than hard drawn.

A suggested design of flexible connections for this range of compressors and their applications is

shown in the diagrams in the Appendices (see p. 25).

The general design of the pipework can be adjusted according to your equipment. The recommended

suction loop of 3/8 inch and 1/4 inch discharge should be adhered too.

Great care should be taken when designing the system and correct refrigeration practices must be followed to ensure the oil return to the compressor.

4.2.4 Velocity within pipework and heat exchangers

To ensure correct running of the installation and to assure the working life of the compressor, it is

recommended that pipework be calculated using the velocities shown in the table below.

Anti-vibration loops are used to provide a very flexible pipework system which absorbs vibration. The velocity

in the AV loops should not exceed that stated in the table.

A minimum velocity of 8 m/s is necessary in any vertical risers, suction or discharge to ensure adequate

oil return to the compressor.

The velocity within the heat exchangers should not drop below 3 m/s to guarantee oil return.

The table page 21 lists the velocities for different internal diameter pipework and compressor models.

The choice of pipework should therefore be made for a particular model of compressor and specified

type of connection (suction, discharge or liquid pipework) in accordance with the velocity ranges recommended in the above table.

In the case of the heat exchangers, the number of circuits can be defined on the basis of the refrigerant

velocity circulating in the tubes, taking as reference the value calculated at the suction for the evaporator

and at the discharge for the condenser.

14

Connections

SUCTION DISCHARGE

LIQUID

Minimum Maximum Minimum Maximum Minimum Maximum

25 m/s 25 m/s

4 m/s 15 m/s 4 m/s 15 m/s 0.3 m/s 1 m/s

3 m/s 10 m/s

3 m/s 8 m/s

Anti-vibration loops

Pipework

Evaporator

Condenser

Page 15

15

Refrigerant velocity in the suction pipework (in m/s)

HG/RG2426Z

HG/RG2432Z

HG/RG2436Z

HG/RG2446Z

HG/RG4467Z

HG/RG4480Z

68

Suction Discharge Liquid

10 12 14 16 3 5 7 9 11 3 5 7 9 11

CAPILLARY - INTERNAL DIAMETER (mm)

13.7 7.7 4.9 3.4 2.5 1.9 6.7 2.4 1.2 0.7 0.5 0.61 0.22 0.11 0.07 0.05

16.2 9.1 5.8 4.1 3.0 2.3 7.9 2.8 1.5 0.9 0.6 0.73 0.26 0.13 0.08 0.05

17.9 10.1 6.4 4.5 3.3 2.5 8.7 3.1 1.6 1.0 0.6 0.80 0.29 0.15 0.09 0.06

23.3 13.1 8.4 5.8 4.3 3.3 11.3 4.1 2.1 1.3 0.8 1.04 0.38 0.19 0.12 0.08

14.6 8.2 5.2 3.6 2.7 2.0 18.5 6.6 3.4 2.1 1.4 1.70 0.61 0.31 0.19 0.13

17.4 9.8 6.3 4.3 3.2 2.4 22.1 7.9 4.1 2.5 1.6 2.03 0.73 0.37 0.23 0.15

19.9 11.2 7.2 5.0 3.7 2.8 25.3 9.1 4.6 2.8 1.9 2.32 0.84 0.43 0.26 0.17

24.7 13.9 8.9 6.2 4.5 3.5 31.3 11.3 5.7 3.5 2.3 2.88 1.04 0.53 0.32 0.21

14.2 8.0 5.1 3.6 2.6 2.0 16.0 5.7 2.9 1.8 1.2 0.66 0.24 0.12 0.07 0.05

17.2 9.7 6.2 4.3 3.2 2.4 19.3 7.0 3.5 2.1 1.4 0.80 0.29 0.15 0.09 0.06

19.2 10.8 6.9 4.8 3.5 2.7 21.6 7.8 4.0 2.4 1.6 0.90 0.32 0.16 0.10 0.07

25.0 14.1 9.0 6.2 4.6 3.5 28.1 10.1 5.2 3.1 2.1 1.17 0.42 0.21 0.13 0.09

18.1 10.2 6.5 4.5 3.3 2.6 21.2 7.6 3.9 2.4 1.6 1.05 0.38 0.19 0.12 0.08

29.8 16.7 10.7 7.4 5.5 4.2 34.7 12.5 6.4 3.9 2.6 1.72 0.62 0.32 0.19 0.13

38.3 21.6 13.8 9.6 7.0 5.4 44.8 16.1 8.2 5.0 3.3 2.21 0.80 0.41 0.25 0.16

17.6 9.9 6.3 4.4 3.2 2.5 21.5 7.7 3.9 2.4 1.6 1.53 0.55 0.28 0.17 0.11

19.8 11.1 7.1 5.0 3.6 2.8 24.2 8.7 4.4 2.7 1.8 1.72 0.62 0.32 0.19 0.13

22.3 12.5 8.0 5.6 4.1 3.1 27.3 9.8 5.0 3.0 2.0 1.94 0.70 0.36 0.22 0.14

24.5 13.8 8.8 6.1 4.5 3.5 30.0 10.8 5.5 3.3 2.2 2.13 0.77 0.39 0.24 0.16

17.7 10.0 6.4 4.4 3.3 2.5 21.7 7.8 4.0 2.4 1.6 1.54 0.56 0.28 0.17 0.11

19.2 10.8 6.9 4.8 3.5 2.7 23.5 8.4 4.3 2.6 1.7 1.67 0.60 0.31 0.19 0.12

23.0 12.9 8.3 5.7 4.2 3.2 28.1 10.1 5.2 3.1 2.1 2.00 0.72 0.37 0.22 0.15

24.5 13.8 8.8 6.1 4.5 3.5 30.0 10.8 5.5 3.3 2.2 2.13 0.77 0.39 0.24 0.16

27.9 15.7 10.0 7.0 5.1 3.9 34.1 12.3 6.3 3.8 2.5 2.43 0.87 0.45 0.27 0.18

34.0 19.1 12.2 8.5 6.2 4.8 41.5 14.9 7.6 4.6 3.1 2.96 1.06 0.54 0.33 0.22

38.9 21.9 14.0 9.7 7.1 5.5 47.6 17.1 8.7 5.3 3.5 3.39 1.22 0.62 0.38 0.25

17.7 10.0 6.4 4.4 3.3 2.5 24.0 8.6 4.4 2.7 1.8 1.54 0.55 0.28 0.17 0.11

19.8 11.1 7.1 4.9 3.6 2.8 26.7 9.6 4.9 3.0 2.0 1.72 0.62 0.32 0.19 0.13

21.0 11.8 7.6 5.3 3.9 3.0 28.4 10.2 5.2 3.2 2.1 1.83 0.66 0.34 0.20 0.14

24.9 14.0 9.0 6.2 4.6 3.5 33.7 12.1 6.2 3.7 2.5 2.16 0.78 0.40 0.24 0.16

17.3 9.7 6.2 4.3 3.2 2.4 23.4 8.4 4.3 2.6 1.7 1.50 0.54 0.28 0.17 0.11

19.9 11.2 7.2 5.0 3.7 2.8 26.8 9.7 4.9 3.0 2.0 1.72 0.62 0.32 0.19 0.13

22.6 12.7 8.1 5.7 4.2 3.2 30.6 11.0 5.6 3.4 2.3 1.96 0.71 0.36 0.22 0.15

25.0 14.1 9.0 6.2 4.6 3.5 33.7 12.1 6.2 3.7 2.5 2.17 0.78 0.40 0.24 0.16

27.9 15.7 10.0 7.0 5.1 3.9 37.6 13.5 6.9 4.2 2.8 2.42 0.87 0.44 0.27 0.18

32.4 18.2 11.7 8.1 6.0 4.6 43.8 15.8 8.0 4.9 3.3 2.81 1.01 0.52 0.31 0.21

37.9 21.3 13.6 9.5 7.0 5.3 51.1 18.4 9.4 5.7 3.8 3.29 1.18 0.60 0.37 0.24

HG/RG4492Z

HG/RG4512Z

HG/RG4445Y

HG/RG4450Y

HG/RG4460Y

HG/RH4476Y

RK5450Y

RK5480Y

RK5512Y

RGA5480C

RGA5492C

RGA5510C

RGA5512C

RK5480C

RK5490C

RK5512C

RK5510C

RK5515C

RK5513C

RK5518C

RGA5480E

RGA5492E

RGA5510E

RGA5512E

RK5480E

RK5490E

RK5510E

RK5512E

RK5513E

RK5515E

RK5518E

Page 16

16

4.2.5 Capillaries

Capillaries are currently used as expansion devices in small refrigeration installations as they are:

> Easy to use,

> Inexpensive,

> Reliable: there are no moving parts,

> Permits the use of low starting torque compressors, provided pressure equalization can be achieved

during the off cycle.

However, selecting the appropriate capillary always requires great care and some experimentation may

be necessary if one does not have a thorough knowledge of the behaviour of the different parts of the

system and the factors which affect the way they function.

Capillaries must allow the correct amount of refrigerant to flow to the evaporator. The main factors

determining flow are:

> Evaporating temperature,

> Condensing temperature,

> The temperature of subcooled liquid entering the capillary.

As these parameters vary according to the application, it is very difficult to determine a capillary which

gives optimum performance across the range of operation when either running continuously or cycling,

at start-up or during pull down. The selection of a capillary will therefore always be the result of a compromise between these different criteria.

It is wrong to think that the selection of a capillary is based purely on the use of a mathematical formula. As an example, a variation of 10K in condensing temperature results in approximately a 5K variation in evaporating temperature.

If the diameter of your capillary is not listed in the tables (p. 18-19-20), the length can be calculated

from the nearest diameter provided that it does not exceed the diameter of your capillary by

+/-0.2 mm (0.008 inch).

, where D1 is the available diameter and L1 the new length to be calculated.

D2 and L2 are respectively the recommended diameter and length listed in the tables (p. 18-19-20).

The tables give the recommended internal diameters and capillary length.

Note that a laboratory test with a longer capillary may give better results. However, if these parameters

were to be generally applied, problems would occur in a number of applications. A variation of 1/10 th in

the diameter will affect the length of the capillary.

It is essential to use capillary line specified as ‘calibrated for refrigeration’ when selecting

your capillaries.

Capillary lengths from 1.5 m up to 3 m are considered to provide the best performance.

A capillary tube that is too short increases the risk of hunting. A capillary tube that is too long will not

allow the operating conditions to change and will require longer for the system to equalize. This will be

problematic in systems where the cycle time is short. In addition, the pull down time will be longer.

It is important to highlight the effect the charge of refrigerant has on the operation of systems with

capillary tube. A different charge weight of refrigerant is required for each capillary. It is therefore

essential to test the capillary / refrigerant charge combination when carrying out validation tests. If different capillaries are tested with the same charge, the results will differ.

Page 17

> Insufficient charge results in low evaporation temperature, causing a reduction in cooling and only

partial use of the heat exchange surface of the evaporator,

> Excessive charge can cause excessive discharge pressure, overloading of the compressor, liquid

slugging to the compressor as well as reducing the capacity of the evaporator.

The use of a liquid / suction line heat exchanger made from the capillary tube and suction pipework

will produce:

> A 5% increase in performance,

> Greater reliability by reducing the likelihood of liquid / wet gas slugs.

It is even more effective when the contact, i.e. the heat exchange surface, is as long as possible or

when more than one capillary is used (2 capillaries are preferable to 1).

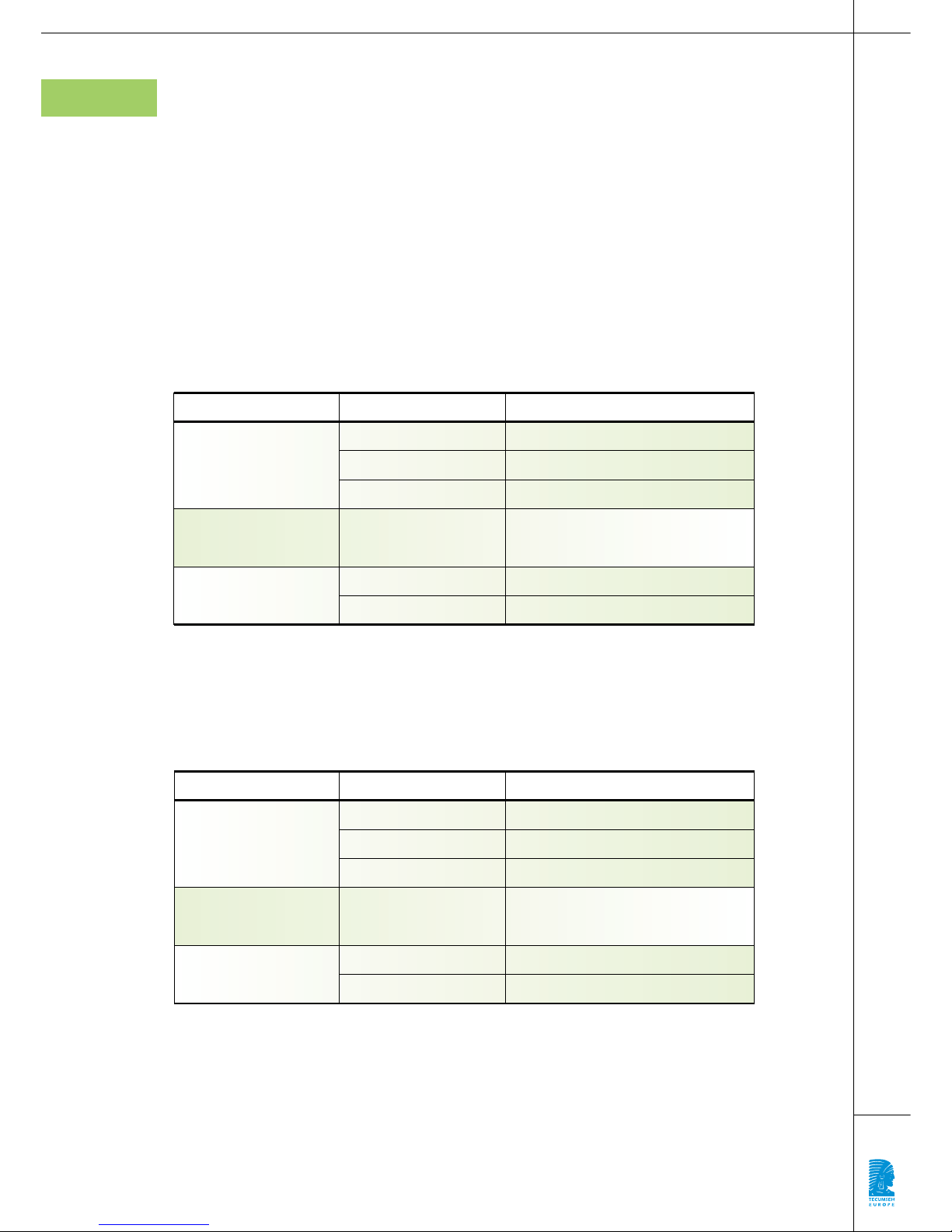

The diagrams below show the different types of heat exchange which can be used.

4.2.5.1 Testing a capillary

In the case of mass produced equipment, testing may be necessary due to slight manufacturing

variations in the internal diameter, roundness and internal finish of the capillary.

Select a capillary of the appropriate dimensions for the installation using the tables and test it

in the refrigeration system. It is then easy to obtain identical capillaries for other installations of the

same type.

17

Capillary soldered

to the suction line

Capillary fixed onto

the suction line

by aluminium tape

Coaxial

Page 18

18

For this procedure use a cylinder of dry Nitrogen (or other source of dried and filtered compressed

air) fitted with a manual pressure regulator to ensure a constant pressure of, for example, 14 bar.

A capillary of the same dimensions as the one already tested in the system is fitted between pressure

gauges 1 and 2. This will be used as the reference capillary.

The calibrated capillary is fitted to the outlet of pressure gauge 2. This is the reference datum capillary.

Adjust the manual regulating device, take a reading of the pressures indicated.

For example: pressure gauge 1, 14 bar; pressure gauge 2, 7.8 bar.

These levels represent the reference pressure level. Maximum sensitivity is obtained with a pressure

from pressure gauge 2 equal to half the reading from pressure gauge 1.

Then replace the reference tube with the capillary to be checked. Adjust the manual regulating device

to read 14 bar on pressure gauge 1.

- If the tube to be checked is identical to the reference capillary, pressure gauge 2 will give a reading

of 7.8 bar.

- If the pressure reading from pressure gauge 2 is above 7.8 bar, the capillary is too resistant and must

therefore be shortened.

- If the pressure reading from pressure gauge 2 is lower than 7.8 bar, the capillary is not suitable for

this application.

NOTE: the pressure values 14 and 7.8 bar are arbitrary and are used only as an example. It is not recommended, however, to work below 5 bar on pressure gauge 1.

4.2.5.2 LBP R404A applications

In tables listing capillary size, ‘2x’ refers to parallel capillaries.

The grey cells refer to cabinet applications with product temperatures in the region of -20°C. The

other cells are deep freeze cabinet applications with product temperatures in the region of -30°C.

HG/RG2426Z

HG/RG2432Z

0.8 mm 0.036” 1 mm 0.042” 1.2 mm 0.049” 0.052” 0.054”

CAPILLARY - INTERNAL DIAMETER

2x3m 1.5m 4m

2x3m 2m 3.5m

2x1.5m 2x2.5m 3m 3.5m

2x2.5m 2x3.5m 1.5m 2.5m

2x2m 2x3m 2.5m 3m

2x2m 2x3m 2.2m

2x2m 1.5m 1.8m 2.5m 3m

2x2m 2x3m 1.5m 3.5m

HG/RG2436Z

HG/RG2446Z

Page 19

19

4.2.5.3 MHBP R404A applications

The grey cells refer to bottle cooler cabinet applications operating at +5°C evaporation temperature

and +50°C condensing temperature. The other cells refer to an application operating around -10°C

evaporation temperature and +45°C condensing temperature. All MHBP applications should come within

these two operating envelopes.

4.2.5.4 HBP R134a applications

The operating envelope is +5°C evaporation temperature +50°C condensing temperature, with 0K subcooling.

HG or

RG4467Z

HG or

RG4480Z

0.042" 1.2 mm 0.049" 0.050" 0.052" 0.054"

0.059"

1.5 mm

0.064"

0.069" 0.075" 2 mm .080'' 2.2 mm

CAPILLARY - INTERNAL DIAMETER

2x2m 2x2.5m 2x3m 2x3.5 1.4m 2m 3m 3.8m

2x2m 1.4m 1.7m 1.80 2m 2.5m 3.5m

2x1.4m 2x1.8m 2x2.m 2x2.5m 2x3.5m 1.5m 2.4m 2.8m

2x2m 2x3.5m 2x3.9m 1.5m 1.9m 2.6m 3.5m

2x1.5m 2x1.6m 2x2.2m 2x2.9m 2m 2.3m 2.6m 3.5m

2x2.3m 2x2.9m 2x3.6m 1.5m 2m 3.2m

2x2m 2x2.9m 1.7m 1.9m 2.6m

2x1.7m 2x2.1m 2x2.2m 2x2.5m 2x2.7m 2x3.3m 1.5m 2.1m 3.2m 3.8m

HG or

RG4492Z

HG or

RG4512Z

HG/RG4445Y

HG/RG4450Y

0.042''/

1.067mm

1.2 mm 0.049" 0.052" 0.055" 0.049” 0.064" 0.069"

CAPILLARY - INTERNAL DIAMETER

2x1.5m 1.5m 2.1m 2.6m 3.5m

2x3m 2x3.5m 1.5m 1.8m 2.5m

2x2.5m 2x3.5m 1.5m 2.m 3.m

2x1.7m 2x2m 2x2.5m 2x3m 1.4m 2.m 3.m

HG/RG4460Y

HG/RH4476Y

Page 20

20

4.2.5.5 A/C R22 applications

The operating envelope is +5°C evaporation temperature and +50°C condensing temperature,

with 0K subcooling.

4.2.5.6 A/C R407C applications

The operating envelope is +5°C evaporation temperature and +50°C condensing temperature

(Mid/Mid), with OK subcooling.

HG/RG5480E

HG/RG5492E

HG/RG5510E

HG/RG5512E

1.0 mm 0.042" 1.2 mm 0.049" 0.052" 0.055"

0.059"/

1.5mm

0.064"

0.069" 0.075" 2 mm 2.2mm

2x1.8m 2x2.7m 2x3.2m 1.5m 2m 2.8m

2x2.3m 2x2.7m 1.7m 2.3m 3.3m

2x2.3m 2x2.7m 2m 2.7m

2x2.3m 2x2.8m 2m 3m

2x1.9m 2x2.9m 2x3.4m 1.7m 2.2m 3m

2x2.3m 2x2.7m 1.7m 2.3m 3.3m

2x2.2m 2x2.6m 1.9m 2.6m

2x2.3m 2x2.8m 2m 3m

2x1.9m 2x2.3m 2.5m 3m

2x1.7m 2x2.4m 2x3.2m 2.4m 3.5m

2x1.9m 2x2.6m 1.7m 2.8m

RK5480E

RK5490E

RK5510E

RK5512E

RK5513E

RK5515E

RK5518E

HG/RG5480C

HG/RG5492C

HG/RG5510C

HG/RG5512C

1.0 mm 0.042" 1.2 mm 0.049" 0.052" 0.055"

0.059"/

1.5mm

0.064"

0.069" 0.075" 2 mm 2.2mm

2x1.4m 2x2.2m 2x2.6m 1.2m 1.6m 2.2m

2x1.8m 2x2.2m 1.4m 1.8m 2.6m

2x1.8m 2x2.2m 1.6m 2.2m

2x1.8m 2x2.2m 1.6m 2.4m

2x1.5m 2x2.3m 2x2.7m 1.4m 1.8m 2.4m

2x1.8m 2x2.2m 1.4m 1.8m 2.6m

2x1.8m 2x2.0m 1.5m 2m

2x1.8m 2x2.2m 1.6m 2.4m

2x1.5m 2x1.8m 2m 2.4m

2x1.4m 2x1.9m 2x2.6m 1.9m 2.8m

2x1.5m 2x2.0m 1.4m 2.2m

RK5480C

RK5490C

RK5510C

RK5512C

RK5513C

RK5515C

RK5518C

CAPILLARY - INTERNAL DIAMETER

CAPILLARY - INTERNAL DIAMETER

Page 21

21

Refrigerant charge

4.3.1 Advice for installers

After pulling a vacuum in the system, break the vacuum by using the refrigerant specified on the

compressor identification plate. Charge into the liquid line between the condenser and the expansion

device an amount of refrigerant below that of the nominal charge so that the pressure is above

atmospheric pressure. The remaining refrigerant can then be charged in vapour form into the suction

line while the compressor is running. To prevent liquid refrigerant entering directly into the compressor, connect to the suction accumulator inlet if fitted and use an expansion device, either a capillary or

orifice, to restrict the flow.

4.3.2 Refrigerant charge

If refrigerant migration is a problem, use the following recommended charges:

• 700 gms maximum for RG and HG compressors,

• 800 gms maximum for RK compressors.

We strongly recommend reducing charge weight as much as possible by designing a system with a low

internal volume (e.g. by using high efficiency heat exchangers, low internal volume heat exchangers,

short pipe runs or removing the liquid receiver when not essential...).

The refrigerant gas passes through the suction of the compressor into the compression chamber,

where it is compressed and discharged into the compressor shell. This leads to a higher compressor

shell temperature than in low pressure shell compressors.

When charging do not use the temperature of the compressor shell as a guideline for a full charge.

High pressure shell compressors take longer to reach normal operating pressure when starting from

cold than low pressure shell compressors. This is due to the additional volume of the compressor

casing and refrigerant being entrained in the oil. Condensing pressure will only reach the operating

level if the entrained refrigerant evaporates completely.

Starting

Never switch on a compressor when under vacuum, an electric arc can occur inside the compressor.

4.4.1 Frequency of starts

Under no circumstances should 10-12 starts per hour be exceeded. Where this is the case an anti-short

cycle or time delay relay must be fitted.

4.4.2 Start-up pressure

A maximum pressure differential of 6 bar between discharge and suction pressure is acceptable

at start-up for commercial high start torque compressors.

If the pressure differential is above the recommended level due to design factors, a non-return valve

in the discharge pipework near the compressor will allow the pressure differential to return to an

acceptable level within 3 minutes.

This recommendation is also valid for refrigeration systems fitted with an expansion valve.

Systems fitted with a capillary do not require a non-return valve as pressure equalization occurs via

the capillary.

4.3

4.4

Page 22

22

Liquid return whilst operating

Liquid migration during prolonged shutdown

Liquid migration to the compressor can occur during transport of a factory charged system or during

prolonged shutdown. The refrigerant is trapped in the compressor shell.

It can be prevented by ensuring that:

> With the compressor stopped, the temperature of the lower housing is above the ambient by 5°C,

> With the compressor running, the temperature of the lower housing is above the condensing

temperature by 5°C.

See below for possible solutions.

4.6.1 Non-return valves

Non-return valves must be fitted. They can be useful when starting where a high pressure differential

exists. (see § 4.4.2 Start-up pressure).

4.6.2 Pump Down

Pump Down stores liquid refrigerant in the high pressure side of the refrigeration system. In this case

the use of a non-return valve is obligatory.

4.6.3 Band heaters

For the RGA and RK ranges, we recommend band heater reference number 8 583 024 listed in our Spare

Parts and Accessories CD-Rom.

The band heater should be fitted onto the lower part of the compressor (above the pipe connecting the

accumulator and the compressor). Plan to switch on tension only when compressor's stop.

For HGA range, we recommend our self-adhesive cartridge reference number 8 583 015, componant

in our Spare Parts & Accessories CD-Rom. This self-adhesive cartridge is self regulating and can wired

in permanentely.

Purging refrigerant from the system

Use a refrigerant recovery unit when removing refrigerant from the system.

The flow rate should be reduced to a minimum to prevent oil in the system being entrained.

All the pressure coupling connections for controls or refrigerant recovery must allow oil to flow back

into the main pipe work for return to the compressor, otherwise oil will be lost from the system.

4.5

4.6

4.7

POTENTIAL CAUSES SOLUTIONS

• Compressor running with a dirty or partially blocked

evaporator filter > 1

• Expansion valve orifice too large

or stuck open > 1 - 2

• Insufficient air flow > 2

• Re-circulation of air to the evaporator > 2

• Overcharging with refrigerant > 3 - 4

1.Carry out adequate maintenance.

2.Correct installation design.

3.Check that the appropriate liquid receiver

is being used.

4.Reduce the charge.

Page 23

23

Security

Pressure

Rotary compressors comply with the Pressure Equipment Directive 97/23/CE.

They are classified under Class I, pressurized containers i.e. they are not required to have specific

labelling with regard to the PED.

Electrical

These compressors comply with the Low Voltage Directive 73/23/CE.

The applicable standards are:

• CEI335-1 [EN 60 335-1]

• CEI 335-2-34 [EN 60 335-2-34]

Most models are certified by NF, VDE, CCA, UL & CSA. Please contact Tecumseh Europe for more information.

Declaration of incorporation

The compressors are defined as for installation in machines according to the Machinery Directive

89392CE appendix II B, and the Pressure Equipment Directive 97/23/CE 97/23/CE.

A Declaration of incorporation is available on our website at www.tecumseh-europe.

5

5.1

5.2

5.3

Page 24

Page 25

25

Appendices

Documents

Application Envelope High Back Pressure Commercial 26

Application Envelope Low Back Pressure Commercial 26

Application Envelope Air Conditioning 26

Anti-Vibration Piping for HGA Commercial Refrigeration Compressors 27

Anti-Vibration Piping for HGA Air Conditioning Compressors 27

Anti-Vibration Piping for RGA Air Conditioning Compressors 27

Anti-Vibration Piping for RK Air Conditioning Compressors 27

Contacts

Customer Technical Support:

Tel. +33 (0) 4 74 82 21 04

Fax: +33 (0) 4 74 82 24 89

Email: technical.support@tecumseh-europe.com

Website: http://www.tecumseh-europe.com

6

6.1

6.2

Page 26

26

Figure 1|Application Envelope High Back Pressure (HBP)

for Rotary Compressors RG & HG

Figure 2|Application Envelope Low Back Pressure

for Rotary Compressors RG & HG

Figure 3|Application Envelope Air Conditioning

Evaporating Temperature (C°)

Evaporating Temperature (C°)

Evaporating Temperature (C°)

Condensing temperature (°C) Condensing temperature (°C) Condensing temperature (°C)

Page 27

27

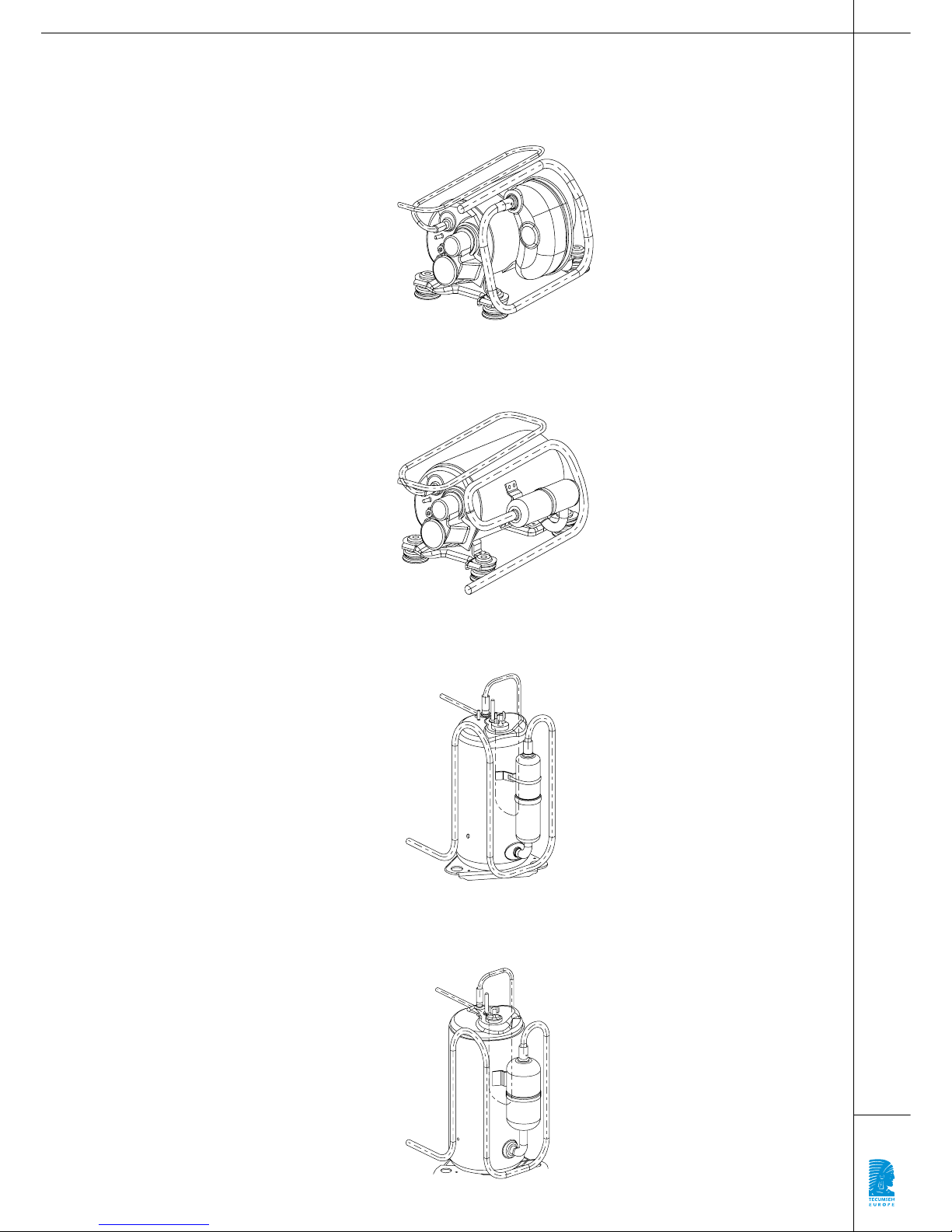

Figure 4|Anti-Vibration Piping for HGA

Commercial Refrigeration Compressors

Figure 5|Anti-Vibration Piping for HGA

Air Conditioning Compressors

Figure 6|Anti-Vibration Piping for RGA

Air Conditioning Compressors

Figure 7|Anti-Vibration Piping for RK

Air Conditioning Compressors

Page 28

www.tecumseh-europe.com

Longueur d’Onde - 07.2004

Loading...

Loading...