Page 1

il

-12

I

I

0perator's

Manual

Four-0ycle

Engine

Vertical Crankshaft

Air-Cooled

l. General

Safety

Precautions

.......................

.. 1

ll. How

to Get

Service

..................

1

lll.

Oil &

Fuel

Specifications

....---...

2

lV

Before

Starling

Your

Engine

"......-.-.-.....'.'.-..-

2

V. Starting

Your

Engine

.........'.'.....

3

Vl. Stopping

Your

Engine/Short-Term

Storage

'.-.

4

Vll. Maintenance...............

'..-.....'.".

4

Vlll

Adiustments................

.......'..'... 6

lX. Seasonal

Storage

..'.'.'-'........"'.

7

X. Quick-Check

Maintenance

Chart

..."..

..........

7

Xl.

V/arranty

Informatron

'...........

' 8

181-1

215-14

(English)

8/1/00

Page 2

NO^TE

Engines

which

are certified

to comply

with

California

and

U.S. EPA

emission

regulations

for

SOhE

(Small

Off Road

Equipment),

are

certiJied'io

operate

on regular

uhteaOeO

gasotine,

and

include

the

following

emission

control

systemsi

Engine

Modification (EM),

and Three-way

Catalyst

(TWCi

ff

so

equip[ee.

Read

this

material

and the

equipment

owner,s

manual

before

using

this

engine.

Failure

to

do so

can result

in

serious

injury

or

death.

Call Tecumseh

Products

Company

at

1-262-377-2700

rt

you

have

any

questions.

AWARNING

Avoid

Carbon

Monoxide

Poisoning

Avoid

Other Fires

To

reduce

the risk

of fire,

keep

all materials

that can

burn, including

grass

and leaves,

away from

muffler

and rest

of

engine.

Stay Away

from

Hot

Surfaces

Muffler

and

other engine

parts

become

extremely

hot

during

operation

and remain

hot

after

engine

has

stopped.

To

avoid

severe

burns

on contacr.

&

All

engine

exhaust

contains

carbon

monoxide,

a

deadly

gas.

Breathing

carbon

monoxide

can

cause

headaches,

dizziness,

drowsiness.

nausea,

confusion

and eventuallv

death

Carbon

monoxide

is

a

colorless,

odorless.

tasteless

gas

which

may

be

present

even

il

you

do not

see

or smell

any

engine

exhaust.

Deadly

levels

of

carbon

monoxide

can

collect

rapidly

and

you

can

quickly

be

overcome

and

unable

to save

yourself

.

Also,

deadly levels

of

carbon

monoxide

can

linge_r

for

hours

or

days

in

enciosed

or

poorly_

ventilated

areas.

lf

you

experience

any

symptoms

of barbon

Tgloljqgpolsoning.

leave

the area

immediately, get

fresh

air,

and

SEEK

MEDICAL

ATTENTION.

To

prevent

serious

injury

or death

from

carbon

monoxide:

.

NEVER

run

engine

indoors.

Even if

you

try to

ventilate

engine

exhaust

with

fans

or

open windows

and

doors,

carbon

monoiide

can

rapidly

reach

dangerous

levels.

.

NEVER

run

engine

in

poorly-ventilated

or

partially

enclosed

areas

such

as barns,

garages,

basements,

carports,

under

dwellings,

or in

pits.

.

NEVER

run

engine

outdoors

where

engine

exhaust

can be

drawn

into

a building

through

openings

such

as windows

and

doors.

Avoid

Gasoline

Fires

Fuel vapors

are highly

flammable

and

can

explode.

Fuel

vapors

gan

spread

and be ignited

by

a spark

or flame

many

feet

away

f rom

engine.

To

prevent

injury

or death

from

fuel

fires,

follow

these

instructions:

.

Never

store

engine

with

fuel in

fuel

tank

inside

a

buildrng

with

potential

sources

of ignition

such

as

hot water

heaters

and

space

heaters.

clothes

dryers,

electric

motors,

etc.

.

Never

remove

fuel

cap or

add fuel

with

engine

running.

.

Allow

engine

to

cool

before refueling.

.

Never

fill

fuel

tank

indoors.

Fill

fuel

tank

outdoors in

a well_

ventilated

area.

.

Do

not

smoke while

refuelinq

tank.

.

Use

only

an approved

red

GnSOLtNE

container

to store

and

dispense fuel.

.

Do

not

attempt

to

pour

fuel

from

engine.

Empty

fuel

tank

by

running

engine.

stay

away from

these

areas.

Do

Not

Modify

Engine

To_av_oid

serious

injury

or death,

do

not

modify

engine in

any way.

NEVER

tamper

with factory

setting

of

engine

govbrnor.

RLinning

engine

faster

than

speed

set at factory

can be

dangerous

and wilj

voro

engrne

warranty.

Avoid

Accidental

Starts

To

prevent

accidental

starting

when

working

on

equipment,

always

disconnect

spark

plug

wire

and

attach it

securely

to retaining post.

Stay

Away from

Rotating

Parts

Never

operate

engine with

covers

or

guards

removed.

Flotating

pafts

can cause

severe

injury.

Keep

hands,

feet, hair,

jewelry

and

clothing

away

from

all moving

pans.

For

engine

adjustments,

repairs

or

warranty

service,

contact

your

nearest

Tecumseh

Service Dealer.

lt

is listed

in

vour

telephone

book

under

"Engines,

Gasoline."

A

decal located

on

your

engine

blower housing (on

some LEV

models

it may

be located

under

the

top cover

-

see right),

indicates your

engine

-,',.:--1:

.,

model

number

and the

date

of manufacture .-

-

(D

O.M

).

Please

frll in

this information

in the

spaces

below

for future

reference.

$N

-

ENGINE

MODEL:

rtq$t*lirtq;:5tF8Ti'*

A[-rr,.irri,'

i

ltn

ttr

ir

itn

D.O.M.:

lf

you

have

a

general

understanding

of

combustion

engines

and

wish

to repair

and

service

your

engrne

and/or engrne

emissjon

control

systems

yourself.

a

Technician's

Handbook

is

avarlable

from

your

Tecumseh

Servrce Dealer.

This handbook

covers repairs

and

adjustments

not

covered

within

this manual.

Order as

part

no.

692509

;ikt

181-1215-14

Page

1

Page 3

A. OIL

To operate

your

engine efficiently,

follow

the chart below.

(-1BoC

to OoC)

Below

0oF

At temperatures above 3?)F

(0

C). use of

multigrade

oil

in

ai-cooled

engines will

resLtlt in

greater

oil consumption, and

ls not recornmended.

(Multigrade

oil

will

have a number

appearing both before and after

the

"ltV,"

sut:lt as

"5W30".

etc.)

Oil sump capacity:

21

ounces

(1-5/1

6 U.S.

pints;

.62

liters)

B. FUEL

.

Use unleaded

regular,

unleaded

premium

or reformulated

automotive fuel only. DO NOT use

leaded fuel.

.

Fuel must be fresh and clean.

Never

use

fuel lett

over

from last

season or stored

for long

periods.

.

Never mix oil wrth

fuel

.

Do

nclt

use

fuel

containing

Methanol

(Wood

Alcohol). You rnay

use

fuel

containing

the foliowing, but they may require special

care

when

engine

is not used for extended

periods

(see

"Seasonal

Storage"

instructions

on

page

7).

FUEt

COMPOI{E'/T

PERCENTAGE ALLOWED

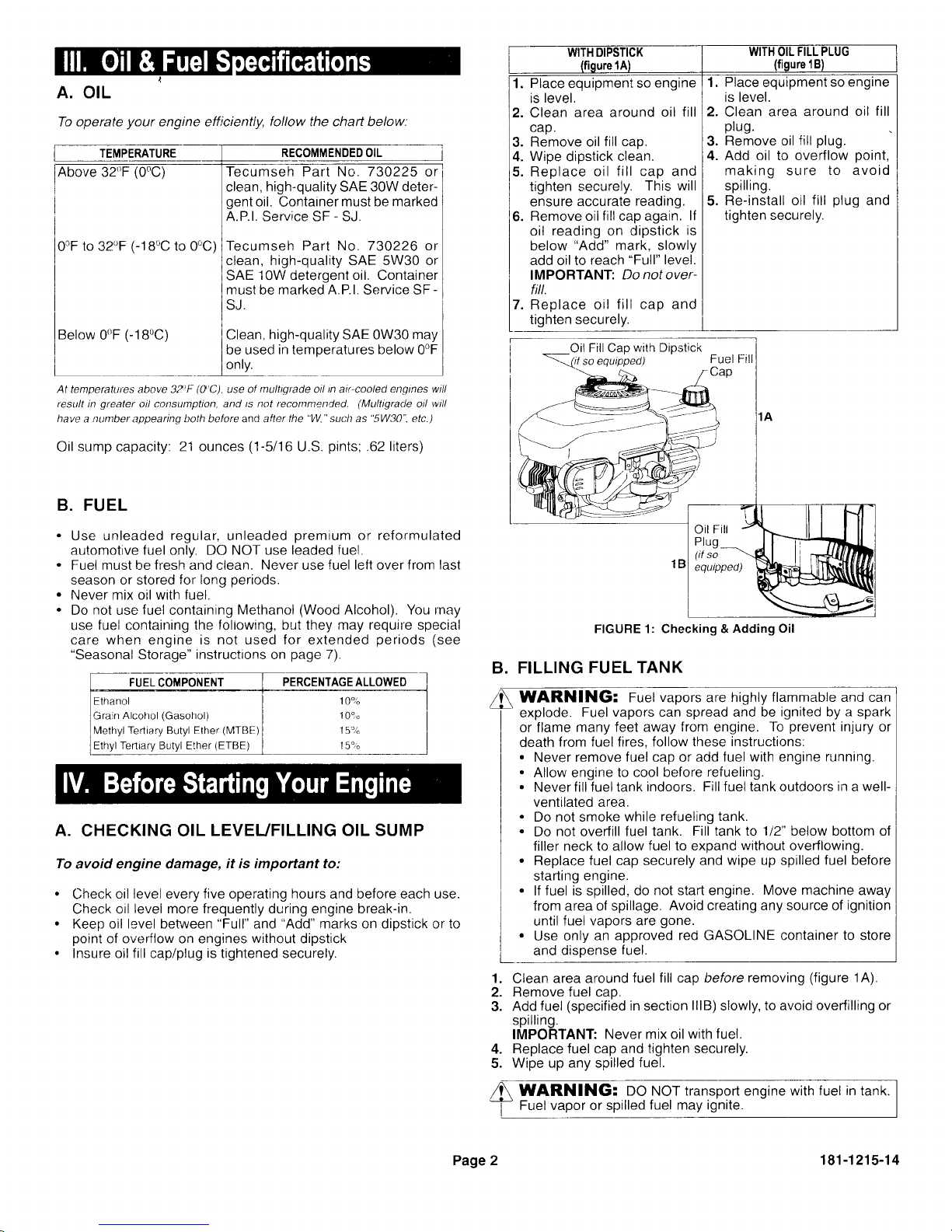

FIGURE 1: Checking &

Adding Oil

FILLING

FUEL TANK

AT4{NtrG:

ruet

vapors

are,

highly flammable and can

explode.

Fuel vapors can spread and be

ignited

by

a spark

or flame

many feet away

from

engine.

To

prevent

inlury or

death

from fuel fires, follow

these instructions:

.

Never remove

fuel

cap or

add fuel with engine

running.

.

Allow engine

to cool before

refueling.

.

Never fill fuel tank

indoors. Fill fuel tank outdoors

in a well-

ventilated area.

.

Do not smoke

while

refuelinq tank.

Do

not

overfill

fuel tank.

Fill tank to 1/2" below bottom of

filler neck to allow

fuel to expand

without

overflowing.

Replace fuel cap securely

and wipe up spilled

fuel

before

starting

engine.

lf fuel is spilled, do

not staft engine. Move

machine

away

from area of spillage.

Avoid creating any source of

ignition

until

fuel vapors are

gone.

Use

only an approved

red GASOLINE container

to

store

and

dispense

fuel.

Clean

area around

fuel f ill cap before

removing

(figure

1A).

Remove fuel cap.

Add

fuel

(specified

in section

lllB)

slowly,

to avoid overfilling or

spilling.

IMPORTANT:

Never mix oil with

fuel.

Fleplace fuel cap and

tighten securely.

Wipe up any spilled

fuel

1.

Place

equipment

so

engine

is

level.

2. Clea.n area

around

oil fill

cap.

3.

Remove oil

fill cap.

4.

Wipe

dipstick

clean.

5. Replace

oil fill cap and

tighten securely.

This will

ensure

accurate

readitrg.

6.

Remove oil

fill

cap again.

lf

oil

reading on dipstick

is

below

"Add"

mark, slowly

add oil to

reach

"Full"

level.

f MPORTANT:

Do

not

over-

fiil.

7. Replace oil

fill cap and

tighten securely.

equrpment

so engrne

B.

Ethanol

Grajn

Alcohol

(Gasohol)

Methyl Terliary Butyl Flher

([/TBF)

I

Elhyl

Tenrary

Butyl Elher

(FTBF)

10%

1

09.

15%

15",b

A. CHECKING OIL

LEVEUFILLING OIL SUMP

To

avoid engine damage,

it is important to:

.

Check

oil level every five operating hours and before each use.

Check oil

level more frequently during engine break-in.

.

Keep oil level between

"Full"

and

"Add"

marks on dipstick or to

point

of overflow on engines

without

dipstick

.

Insure oil fill cap/plug

is

tightened securely.

1.

2.

3.

4.

5.

is level.

2.

Clean

area around

oil fill

ptug.

3.

Remove oil fill

plug.

4. Add oil to overflow

point,

making sLr

re to avoid

spilling.

5.

Re-install oil

fill

plug

and

tighten securely.

'ecumseh

Part Na. 730225 or

clean,

high-quality

SAE 30W

deter-

gent

oil.

Container

must be marked

A.P.l. Service SF - SJ.

Tecumseh

Part No. 730226 or

clean, high-quality SAE 5W30 or

SAE

10W

detergent

oil.

Contarner

must

be

marked A.P.l.

Service SF

-

SJ.

Clean, high-quality SAE 0W30

may

be used

in

temperatures

below

OoF

onry.

Oil

Fill Cap

with Dipstick

s:-L-156

equipped)

WARNING:

DO NOT transport engine with

fuel in

tank

i-

Fuel vapor or spilled

fuel may ignite.

Page

2

181-1215-14

Page 4

, !''wlnNlNG:

tt

you

are unable

to

start

this engine afterl

d;

I

foliowing

instructions in this manrral,

contact

your

lecumseh

WARNING:

Never

run

engine

indoors or in

poorly-

ventilated or

partially

enclosed

areas including, but

not limited

to, barns,

garages,

basements, carports,

or under dwellings.

Carbon

monoxide

can

rapidly reach dangerous

levels,

even

when using exhaust

fans

and open doors

and windows to aid

ventilatron. When running engine. be sure

exhaust fumes are

away

irom all air intakes

including.

but

not limited to,

windows

ano ooors.

All

engine

exhaust contains carbon

monoxide, a deadly

gas.

Breathing carbon

monoxide

can cause

headaches, dizziness,

drowsiness,

nausea, confusion and eventually

death.

lf

you

experience any

of these synrptoms,

leave the

area

immediately,

get

fresh air, and seek

medical treatment. Deadly

levels

of

carbon monoxide can collect

rapidly and

you

can

quickly

become overcome and

unable to save

yourself.

Service

Dealer To

avoid

serious burn injuries or damage

to

your

engine,

DO NOT attempt tc start or

troubleshoot thts

engine

in

any other

way. For example:

.

DO NOT use starting

fluid.

.

DO NOT

spray

flammable

r",apors

into carburetor

or onto air

cleaner.

.

DO

NOT

put

flamnrable liquids into carburetor or onto air

cleaner.

.

DO NOT

crarrk engine

with spark

pluq

removed

spray from spark

plug

hole

an,J

igniie.

,ri',

WARNING: When

pullirig

starter cord,

cord can

|

''

unexpectedly

jerk

back causing seiious

irrjury.

Caref

ully follow

i

i l!.11"1191.

iq'f

yll

sta!ing enq191

!

WARNING:

Rctat,,,1

parts

ean

cause severe

nlury Keep

i

hands. feet. hair,

jewelry

aricJ clotlring away

from

all movtng

parts.

l,lever

operal.e

engirre with covers, shrouds or

guards

rPrflOVeCi

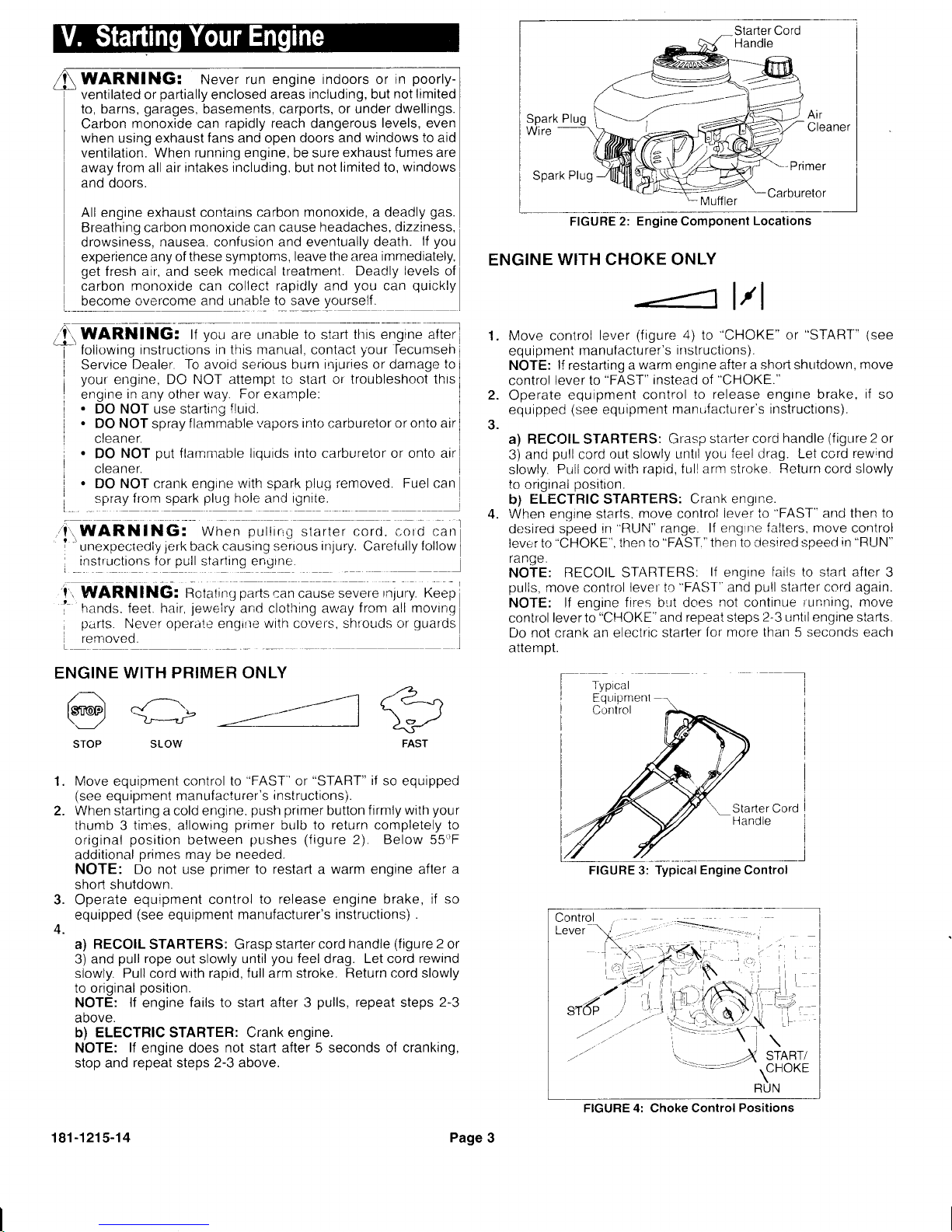

ENGINE

WITH PRIMER

ONLY

FIGURE 2:

Engine Component

Locations

ENGINE

WITH CHOKE ONLY

Move control

lever

(figure

4)

to

'CHOKE"

or

"START"

(see

equiprnent

rnanu{actu

rer's

instructions).

NOTE:

l{ restarting a

warm

engine

after a short shtrtdown,

move

control

lever to

"FAST"

instead of

"CHOKE."

Operate

equipment

control

to release engtne brake,

if

so

equipoed

(see

equipment

manrifacturer's instructions).

a) RECOIL STARTERS:

Grasp

starter coro

handle

(figure

2

or

3)

and

pull

cord out

slowly untrl

you

{eel drag. Let cord

rewind

slowly.

PLrli

cord

with

rapici, tull arm stroke

Return

cord slowly

to original

position.

b)

ELECTRIC STARTERS:

Crank engrne.

When engine starts.

move

control

lever to

'FAST"

and then

to

desired

speed

in

"HLJN"

range. lf engtne falters, move control

lever to

"CHOKE".

then to

"FAST

"

then to desired speed

in

"RUN"

range.

NOTE:

RECOIL STARTERS:

lf

enqine

fails to start alter

3

pulls,

move

control

lever to

"FAST"

and

pull

starter

cord

again.

NOTE: lf engine

fires bLtt does

not

continue

running,

move

control

lever to

"CllOKE

'

and repeat steps

2-3 until engine starts.

Do not crank an electric

stafter

for more than 5 seconcls each

attemot.

t:I

rvprcar

i

I

Fqrtipn

renl

1.

2.

3.

Fuel can

4.

STOP SLOW

(?-*

-<-.-- --l

\=-.t

FAST

Cuntrol

FIGURE 3:

Typical Engine Control

1

2.

3.

4.

Move equipment control

to

"FAST'

or

"START"

if

so equipped

(see

equipment rnanufacturer's

instructions).

When starting a cold engine.

push primer

button firmly

with

your

thumb 3 tin-res, allowing

primer

bulb

to return

completely

to

original

position

between

lrushes

(figure

2). Below 55"F

additional orimes

mav be needed,

NOTE: Do not use

primer

to

restart a warm

engine afler

a

short shutdown.

Operate

equipment control

to release

engrne

brake, if so

equipped

(see

equipment

manufacturer's instructions)

.

a) RECOIL STARTEBS: Grasp

stafter cord

handle

(figure

2

or

3)

and

pull

rope

out slowly until

you

feel drag. Let cord

rewind

slowly. Pull cord

with rapid, full

arm

stroke. Return cord slowly

to original

position.

NOTE:

lf

engine

fails to start after 3

pulls,

repeat

steps

2-3

above.

b)

ELECTRIC STARTER: Crank engine.

NOTE:

lf

engine does

not start after 5 seconds of cranking,

stop and

repeat

steps

2-3 above.

Control

FIGURE 4: Choke Control

Positions

181-1215-14

Page

3

Page 5

ENGINE

WITH PRIMER AND CHOKE

I

1.

Move

control

lever

(figure

a)

to

"CHOKE"

or

"START" (see

equipment

manufacturer's

instructions).

NOTE:

lf restafiing a warm engine after a short shutdown,

move

control

lever to

"FAST"

instead of

"CHOKE."

2. Push

primer

bulb firmly

with

your

thumb 3 times, allowing

primer

bulb

to return completely to original

position

between

pushes.

Below

550F,

additional

primes

may

be

needed.

NOTE: Do not use

primer

to restart a warm

engine

after a short

shutdown.

3. Operate

equipmerrt control to

release

engine brake,

if so

equipped

(see

equipment manufacturer's

instructions).

4.

a) REGOIL STABTERS: Grasp starter cord

handle

(figure

2 or

3) and

pull

cord out slowly until

you

feel

drag.

Let

cord

rewind

slowly.

Pull

cord with rapid,

full

arm stroke.

Return

cord slowly

to

original

position.

b)

ELECTRIC

STARTERS: Crank

engine.

NOTE: lf

engine

does not start after 5 seconds of cranking,

stop and repeat steps 2-3 above.

5.

When

engine starts,

move control lever to

"FAST"

and then to

desired speed in

"RUN"

range. lf

engine

falters, move

control

lever to

"CHOKE,"

then to

"FAST,"

then to desired speed

in

"RUN"

ran9e.

NOTE: lf

engine

fires,

but

does not continue to run, move control

lever

to

"CHOKE"

and

reoeat

steos

2-4

until enoine starts.

1.

See equipment

manufacturer's

instructions

,'N WARNINCl:

To reduce risk

of

fire, t""p

u[*rorsot"]

'

i'

nraterials

away

f rom muffler and hot engine'parls.

I

/t\

WARNING:

ruel vapors

are

highly flammable and

can

]

'

i'

explode. Fuel vapors can spread an,l'oe

ignited

by a spark

or

I

]

flame many feet

away

f rom engine. To

prevent

injury or death

i

I

from fuel

fires. never

store engine

with tuel in fuel tank insidel

j

a building

with

potential

sources of ignition such as hot waterl

| !"qlgr

glggglggEfrIllhes

dryers, ere"t'9a9lglr

9l9 -]

./tr

WARNING:

tvtuttler

and

nearbv

areas

become extremelv

;

hot dLrring operatron and remain

hot

after engine

has

stopped.

I

To avoid sevefe burns on contact, stay away f

rom

these areas.

,A

WARNING:

fo

prevent

accidental starling when rvorking

]

''it

on equipment, always disconnect

spark

plug

',iire

and xeep

ii

i

i

away from spark

plr-rg.

I

-_-_

,A-WARNIttG:

rr"r vapors are highty

ttammatrre

ano canl

''j-)

explode.

Fuel vapors

can spread and'Ue

ignited by a spark or

I

]

flame many feet

away

from engine. To

prevent

injury

or death

]

j

from fuel fires, never

store

engine with fuel in fuel tank inside

j

I

a building

with

potential

sources

of ignition such as hot water

j

i

heaters,

space

heaters, clothes dryers, electric

motors,

etc.

j

3.

4.

5.

6.

A. CHANGING

OIL

Check

oil

level

every

five

operating

hours and before

each use.

(See

"Checking

Oil Level/Filling

Oil Sump" on

page

2.)

Change

oil after

first two operating

hours and every

25

operating

hours thereafter;

more often

if

operated

in

extremely

dusty or dirty

conditions.

Engine should still be

warm from

recent use.

1. Disconnect spark

plug

wire

and

attach to

retaining

post

(figure

2. Position equipment so

engine oil drain

plug

is lowest

point

on

engrne.

Clean area

around oil drain

plug (figure

6).

Place container

under

plug

to

catch

oil

as

it

drains.

Remove oil drain

plug.

Remove oil

fill

cap/dipstick

(or

oil

fill

plug)

and drain oil

(figure

7\.

7.

Replace

oil

fill cap/dipstick

(or

oil fill

plug)

and tighten securely.

8.

Replace oil drain

plug

and

tighten securely.

9.

Wipe away any spilled

oil.

10.Add oil

(see

"Oil

&

Fuel

Specifications"

on

page

2).

FIGURE

5:

Spark Plug/Retaining

Post

FIGURE 6:

FIGURE

7:

Oil

Fill Locations

Spark

Pluq

i

.-l

Oil

Fill

Cap/Dipstick

(tf

so equpped,)

Oil

Fill Plug

ENGINE BOTTOM

Page 4

181-1215-14

Page 6

B. REMOVING DEBRIS FROM ENGINE

Before each use, remove

grass

clippings, dirt and debris from

cooling fins,

air

intake

screen and

levers

and

linkage,

to insure

adequate cooling,

correct engine speed, and to

reduce

the risk of

fire

(see

fig.

8).

Tecumseh Products

Company

recommends

you

take

your

engine to

an

Tecumseh

Service

Dealer

once a

year

for a

complete cleaning.

FIGURE

8:

Debris

Locations

C. SPARK PLUGS

Check spark

plugs

annually

or every

100

operating hours.

1.

Clean area around spark

plug.

2. Remove spark

plug.

3. Replace spark

plug

if

electrodes are

pitted.

burned, fouled with

deposits. or

if

porcelain

is cracked.

NOTE: A resistor

spark

plug

must lle

used

for replacement

(Tecumseh part

no #35395,

or Chan.rpion

RJ-1gLM).

4.

Check electrocle

gaps

with wire feeler

gauge

and

set

gaps

to

030

(0.76mm)

if necessary.

NOTE: This spark ignition

system

meets

all requirenrents of

the

Canadian

Interference-Causing

Equipment Regulations

NOTE: This

engine complies with

all current

Australian

and

New Zealand limitations

regarding electromagnetic inter-ference.

NOTE: This

engirre corrplies with the European

standard

for

safety of

garden

ec,uipment and

powered

lawnmowers

EN836,

Bevision March, 1997,

and aprrlicable sections of the EU

Machinery

Safety

Directives

truft

i

"\-oeo

to

L

FIGURE 9:Resistor

Spark Plug

D.

CLEANING/REPLACING

AIR

CLEANER

IMPORTANI Air cleaners help

prevent premature

engine wear

and failure. NEVER

rr-rn

engine

without

complete air cleaner

installed on engine.

1.

SERVICING

FILTERS

A. Foam Filter

Clean and

re-oil

every

three months

or every 25 operating

hours.

Clean

and re-oil daily if used rn

extremely dusty

conditions.

1" Wash in water and detergent solution and

squeeze

(don't

twist)

until

all dirt is removeci

2. Rinse thoroughly

in

clear

water.

3.

Wrap in a clean cloth and squeeze

(don't

twist)

until

completely dry.

4.

Saturate

with

engine

oil and

squeeze

(don't

twist) to

distribute oil and

remove

excess oil.

B. Paper or Foam Filters

Paper filter

cannot be

cleaned

and

must

be

replaced

once

a

year

or every

100

operating

hours;

more often if used

in

extremely dusty conditions.

Replacement filters

are

available at a

Tecumselr

Senvice Dealer.

2. REMOVING & INSTALLING FILTERS

\bur engine

r,vili

be

equrpped,,r,rth one oi the

following

air

cieaners.

Find the

air cleaner

which

best

resembles

yours,

and

follow the instructions which accompany it.

AIR CLEANER "A''

l

1. Remove

cover by

pressing

in

ort side of body and

lifting

cover upward.

2. Inspect f ilter f

or drscoloration

or

dirl accumulation.

lf

erther

rs

presert.

servrce

per

preceding

"Servicing

Filters"

rnstructrons.

3. Clean inside of cover

and

body thoroughly.

4. Install filter in

body.

5.

Install

cover securely on

body.

AIR

CLEANER

"B"

Paper Filter

(Optianal

1. Remove

cover by

pulling

tab

"A"

away

f rom

body while lift-

ing

cover

upward.

2. Inspect filter(s)

for

discoloration

or dirt

accumulation.

lf

either

is

nraeant

qorrrino

per

preceding

"Servicing

Filters"

rnstructions.

3. Clean

inside

of cover and

body thoroughly.

4.

Install foam filter(s)

and

pa-

per

filter

(if

so equipped)

in

body.

5.

Install cover by hooking

slot

of cover over

tab

"8"

on body.

Push

cover

down. snapping

^^r/6r ^nt^ h^rlv

,(v vvuJ.

F

f,Filter

lab

Slot

l

orcelain

I

mmi

I

Cover

L.

Felease

Button

Tccumseh Pan

. -t

No t367-15)

frtmtlffiilu

Cover-,

'

Slot-\

.h

Tab

["a"

Foam

Filterl

\-030

{o.76mm)Gap

181-1215-14

Page

5

Page 7

For satisfactory

engine

perlormance,

engine and

equipment controls

must be adjusted

Proqerly.

1.

CHOKE

CONTROL

CABLE

ADJUSTMENT

To

check

engine

choke

adiustment:

a. Set

equipment

choke at

"Fast".

b. Loosen

cable

clamp screw

so choke

cable

rnoves in cable

clamp

(figure 10).

c. Line

up hole

in choke control

lever with

notch on choke

control bracket.

This

is

"fast"

position

on engine.

d.

Hold choke

control

lever

in this

position

and tighten

cable

clamp

screw

securely.

NOTE:

lf additional

adjustments

are

needed, adjust

at

equipment

control

(see

equipment

manufacturer's

instructions).

Cable

Clamp

Choke

Cable

Cable Clamp

Choke

Control

\

Lever

("Fast"

position

:;;;;i._".::)

FIGURE'10:

Choke

Cable Adiustment

2.

CARBURETOR

Engine

performance

should

not be affected at

altitudes up

to

7,000

feet

(2,134

meters)

. For operation

at

higher elevations,

contact

your

Tecumseh

Service

Dealer.

3.

ENGINE SPEED

r Wanff

lfrG:

-to

auo,o

r"rtr.,n1rry.

N-E-ulr..

,r,np",

*,i,.'

'

I

'

factory

setting of

engine

governor.

Running engine

faster than

l

speed set

at

factory can be

dangerous

and

will void engine

I wai'ranly.

yapet

rrtet

// \\ r ll

SIOIS On

ilange.

ttecutnsen

-\yl

7.

push

cover

firmly against

Part No.

_

-1

1

i|iii,";t

coverf

I

f

lange

and

lu rn

lo

1".11

(counterclockwise) until

cover

locks securely

in

place.

Cover

should be

in

vertical

position.

Paper Filter

(Tecunseh

Part No.

#35066)

1.

Tu rn cover

to

lef t

(counterclockwise)

and

remove it and

paper

filter

from flange.

2. Discard

filter.

3. Clean

cover and

flange

thoroughly.

4. Install new

paper

filter

into

cover.

5.

Position cover

and filter

against

flange

with tab on

cover

inserted

into lower

left

corner

oi slot

in flange.

6.

Push cover

frrmly against

flange and

turn to right

(clockwise)

as

far

as

it will

go.

Be sure

retainers are

locked

around

flange.

Flange

1@%s*'

rabl/Yl,

Betainerr

L-

r

AIR CLEANER "D''

___l

,*

^/

l. Remove cover

by

pulling

tab

I

"A"

away

from body

while

lifting cover upward.

2. Inspect

filter(s)

tor

discoloration

or dirt

accumulation.

lf either

is

present,

service

per

preceding

"Servicing

Filters"

instructions.

3. Clean

inside of cover

and

body

thoroughly

Install

paper

filter

in

body.

Install

foam

filter

(if

so

equipped)

inside of body

Install

cover

by

hooking slot

7.

Screw

t,*l

Paper

Filter

lit

Foam Filter

-

|

(if

so equtpped)

.;;.

I v'

''

!,2?

t

Bodv

D

l"q,

lr'

4.

5.

6.

Foam Filter

--

(Optionai)

-/

t----

jBtt!o!t-!"

----_-]

I1.

nr.

";r"t

t" tighf

, |

(clockwise)

to

remove.

I

\-Q{t lFtange lz'

nemove

paper

filter from

,

, -^' /

llanqe

I

Uf :I

3.

Disc"ard

filter.

I

I {o*t'l A- l

labs

4.

clean

cover ancl

flange

I

I

A;i

N\rooi'diif?1ili

ouo"'r'|'ler

n'l'I

I

ouou,r,n",//

Nllt

li:B:iiffff"coverwith

I

4\

WARNING:

Never run engine

indoors or

in

poorly-J

"

.i

ve ntilated

or

partially

enclosed

areas

including, but

not limited

I

to, barns,

garages,

basements,

carports,

or under

dwellings.

I

Carbon

monoxide

can

rapidly reach dangerous

levels, even

when using

exhaust

fans and

open doors and

windows

to

aid

ventilation.

When

running engine,

be sure

exhaust

fumes are

away

from all

air

intakes including,

but

not limited to, windows

i

and doors.

i

All engine

exhaust

contains

carbon

monoxide, a

deadlv

gas

Breathing carbon

monoxide can

cause

headaches, dizziness,

drowsiness,

nausea,

confusion

and eventually

death.

lf

you

experience

any of

these symptoms,

leave the area immediately,

get

fresh air,

and seek

medical

treatment.

Deadly levels of

carbon

monoxide

can

collect

rapidly and

you

can

quickly

become

overcome

and unable

to save

vourself.

WARNING:

Rotating

pans

can cause severe

injury.

Keep

hands,

feet,

hair,

jewelry

and clothing

away

from all moving

parts.

Never operate

engine

with covers,

shrouds or

guards

removeo.

ofcoverovertab

"B"

on body.

I

Push cover

down

urtttl

it

I

snaps

into

body.

j

Page

6

181-1215-14

Page 8

lf engine is to be unused for over 30 days,

prepare

as

follows:

1. FUEL

SYSTEM

Fuel stored in the tank will

gradually

deteriorate,

leaving

gum

deposits

which will clog the carburetor or fuel system.

To

avoid

these

problems,

treat the

fuel

system

in

one of the two

following

methods:

METHOD 1: Draining

Fuel Tank

A. Run

engine until

engine stops from lack of

fuel.

WARNING! Fuel vapors are highly

flammable

and can

explode.

Fuel vapors

can spread and be

ignited

by a spark or

flame many feet away from engine.

To

prevent

injury

or death

from fuel fires,

use only an approved container

to

store and

disoense

fuel.

IYARNING:

Never run

engine

indoors

or

in

poorly-

ventilated

or

partially

enclosed areas

including,

but

not limited

to,

barns,

garages,

basements, carports, or under dwellings.

Carbon monoxide can

rapidly reach

dangerous

levels,

even

when using exhaust

fans

and open doors and

windows

to aid

ventilation. When running

engine, be sure

exhaust fumes

are

drowsiness,

nausea,

confusion and eventually death.

lf

you

experience any

of these

symptoms,

leave the area immediately.

get

fresh air, and seek medical treatment. Deadly leveis of

carbon

monoxide

can collect

rapidly and

you

can

quickly

become overcome and unable

to

save vourself

B. Drain remaining fuel

from

carburetor by

pressing

up on

bowl

drain

(if

so equipped).

FIGURE 11: Draining Carburetor

lf

"Gasohol"

has been used:

C.

Add 112

pinl

of

gasoline

into fuel tank,

and

repeat

step

"A"

and

"B"

above

METHOD

2: Adding Fuel

Stabilizer

Gasoline

preservative/stabilizer

(such

as

"Tecumseh

Gasoline

Stabilizer"),

is an acceptable alternative

in minimizing

formation

of

fuel

gum

deposits during storage.

A. Add fuel

preservative/stabilizer

according to

manufacturer's instructions.

B.

Run

engine at

least 10 minutes

after adding stabilizer

to allow it to reach carburetors.

IMPORTANT: Always follow mix ratio found on stabilizer

container. DO NOT drain stabilizer from carburetor.

ENGINE

Flemove any clippings,

dirt or chaff

from

exterior

of engrne.

orL

Change

oil if not changed

withirr the last three months

,See

"Changing

Oil"

section under

"Maintenance",

page

4).

BATTERY

ff

so equipped)

See equipment

manufacturer's

instructions for

proper

storage.

CYLINDER

BORE

1. Bemove

spark

plug

wire(f igure 12).

2.

Attach spark

plug

wire

to

retaining

post.

Remove spark

plug.

Squifi

1oz.

(30m1)

of

clean engine oil into spark

plug

hole.

Grasp starter

handle and

pull

out

slowly

2 times.

Use a

full

arm stroke.

This will distribute oil throughout the cylinder to

prevent

corrosion

during

storage.

Re-insert spark

plug.

2.

3.

4.

5.

3.

4.

5.

[-

sparx

nrL,g

---_.]

Wire

a

Retainrng

Posf

\f M--=a- l

;

-Xrcilf[Nu*'^,

\

i

\

Spark

Piuq

Clean

foam filter

Replace

paper

filter

Check

spark

plugs

l

+-

181-1215-14

PageT

Page 9

CALIFORNIA

&

US

EPA

EMISSION CONTROL

WARRANTY

STATEMENT

The U. S.

Environmental

Protection Agency

("EPA"),

the

California

Air Resources

Board

("CARB")

and

Tecumseh

Products Co.

are

pleased

to explarn

the Federal

and California

Emissron Control

Systems

Warranty on

your

new small

off-road

engine.

In

California,

new 1995 and

later small

off-road engines

must be designed,

built

and equipped

to

meet the State's

stringent

anti-smog

standards.

In other states,

new

1997 and

later

model

year

engines

must be designed, built

and equipped,

at

the time of sale,

to

meet the U.S.

EPA

regulations

for

small

non-road

engines.

Tecumseh

Products Co.

will warrant the

emission

control

system

on

your

small

off-road

engine

for the

periods

of time

listed below,

provided

there has been

no abuse,

neglect. unapproved

modification,

or

improper maintenance

of

your

small off-road

engine.

Your.emission

control

system

may include

parts

such

as the

carburetor,

ignition system and

exhaust system.

Also inclucied

may be the

conrpression

release system and

other emission-

related

assemblies.

Where a

warrantable condition

exists.

Tecumseh

Products Co.

will repair

your

small off-road

engirre

at no

cost to

you

for

dragnosrs,

parts

and

labor.

MANUFACTURER'S

EMISSION

CONTROL

SYSTEM

WARRANTY

COVERAGE

Emissron

control systems

on

1995 and

later model

year

California

small

oft-roacl engines

are

warranted

for two

years

as

hereinafter

noted.

In other states,

1997 and

later

model

year

engines

are

also

warranted

for

two

years.

lf, during such

warranty

period,

any enrission-related

part

on

your

engine

is

defective

in materials

or

workmanship,

lhe

cart

will be

repaired or

replaced by

Tecumseh

Products Co.

OWNER'S

WARRANTY

RESPONSIBILITIES

As the small

off-road

enqrne owner,

you

are

responsible

for the

performance

of the

required

maintenance

listed in

your

Owner's

Manual,

but

Tecumseh Products

Co. will not deny

warranty

solely

due

to the

lack of

receipts or

for

yorlr

failure to

provide

written

evidence

of

the

performance

of all

scheduled

maintenance.

As tl.re

small off-road

engine

cwner,

you

should,

however, be

aware

that

Tecumseh

Products Co.

may deny

you

warranty

coverage

if

your

small

off-road engine

or a

part

thereof

has failed

You are

responsible

for

presenting

your

small off-road

engine

to a

Tecumseh

Authorized

Service

Outlet

(any

Tecumseh

Registered

Service

Dealer,

Tecunrseh

Authorized

Service

Distributor

or

Tecumseh

Central

Warehouse

Distributor)

as soon

as a

problem

exists.

The

warranty

repairs

should

be

completed

in a reasonable

amount

of time,

not to exceed

30 days.

Warranty service

can

be arranged

by contacting

either

a

Tecumseh

Authorized

Service

Outlet

or by

contacting

Tecumseh

Products

Co.,

cio Service

Manager,

Engine and

Transmission

Group

Service

Division,

900

North Street,

Grafton,

Wl 53024-1499.

Telephone

1-262-377'2704,

or

see

your

local

telephone

yellow

pages

under

"Engines,

Gasoline"

for the

name,

address

and

telephone

number o{

a

Tecumseh

Authorized

Service

Outlet

near

you.

IMPORTANT

NOTE

This

warranty statement

explains

your

rights and

obligattons

under

lhe

Emission

Control

System

Warranty

("ECS

Warranty")

which is

provided

to

you

by

Tecumseh

Products

Co.

pursuant

to California

law.

Tecumseh

Products Co.

also

provides

to original

purchasers

of

new

Tecutnseh

Products

Co.

errgines.

The

Tecumseh

Products Co.

Limited

Warranties

for New

Tecumseh

Engine and

Electronic

lgnition

Modules;

("Tecumseh Prodtlcts Co.

Warranty")

which

is

enclosed

with all

new

Tecumseh

Products

Co. engines

on a

separate

sheet.

The

ECS Warranty

applies

only

to the

emission

control

system

of

your new

engine.

To the extent

that there

is any

conflict

in terrns

between

the ECS

Warranty

and

the Tecunrseh

Products Co.

Warranty. the

ECS Warranfy

shall apply

except

in any circurnstances

in which

the

Tecumseh

Products Co.

Warranty

may

provide

a lortger

warranty

period. Both the

ECS

Warranty and

ihe Tecumseh

Products Co.

Warranty

describe

important

rtghts and

obligations

wilh

respect to

your new errgine.

Warranty

servtce

can

only be

performed

by a

i-ecumseh

Products Co.

Authorized Service

Outlet,

or by

Tecumseh

Products

Co. at

its

factory

in Grafton,

Wl.

At the time

of

requesting

warranty

service.

evidence

must be

presented

of

the date

of sale

to

the original

purchaser.

The

purohaser

shall

pay

any charges

for making service

calls

and/or

for

transporting

the

products

to and

lrom

the

place where the

inspection

and/or

warranty

work

is

performed.

The

purchaser

shall

be

responsible

for any damage

or

loss

incurred

in

connection

with the transportation

of any engine

or any

part(s)

thereof

submitted

for

inspection and/or

warranty

work.

lf

you

have

any

questions

regarding

your

warranty

nghts

and

responsibilities,

you

should

contact

Tecumseh

Products

Co.

aI1-262-377'2700.

I

l

Page 8

't

81-1215-14

Page 10

EMISSION

CONTROL SYSTEM

WARRANTY

=mission Control

System

Warranty

("ECS

Warranty") for 1995

and

ater model

year

California small off-road engines

(for

other states,

1997 and later model

year

engines):

APPLICABILITY:

This warranty shall

apply

to 1995

and

later

model

year

California small off-road

engines

(for

other states,

1997

and

later

model

year

engines). The ECS Warranty Period

shall begin

on

the

date the

new

engine or equipment is delivered

to

its

original, end-use

purchaser,

and

shall

continue for 24

consecutive months thereafter.

B.

GENERAL

EMISSIONSWARRANTY

COVERAGE:

Tecumseh

Products

Co. warrants to the

original, end-use

purchaser

of the

new

enqine or equipment and to

each subsequent

purchaser

that each of

its

small off-road engines is:

1. Designed, built and

equipped so as to conform with all

applicable

regulations

adopted by the Air Flesources Board

pursuant

to its

authority

in

Chapters 1 and2, Paft

5,

Division

26

of the

Health

and

Safety

Code,

and

2. Free from

deiects

in materials

and workmanshio which.

at

any time during the ECS Warranty Period, will

cause a

warranted

emissions-related

part

to fail to be identical in

all

material respects to the

paft

as described in the engine

manufacturer's

application

for

certification

C.

The ECS Warranty

only

pertains

to emissions-related

parts

on

your

engine, as

follows:

Any warranted,

emissions-related

parts

which are nol

scheduled

for replacement

as required maintenance in

the

Owner's

Manual

shall be warranted for the ECS Warranty

Period. lf

any such

part

fails

during the ECS Warranty

Period, it

shall be

repaired

or

replaced

by Tecumseh Products

Co. according

to

Subsection 4 below. Any such

part

repaired

or

replaced

under the ECS Warranty

shall be

warranted

for

any remainder

of

the ECS Warranty Period.

Any warranted,

emissions-related

paft

which is scheduled

only

for regular inspection

as specified in the

Owner's

Manual

shall be warranted for the ECS Warranty Period.

A

statement

in

such written instructions to the

effect of

"reoair

or replace as necessary".

shall

not reduce

the ECS Warranty

Period.

Any such

part

repaired

or

replaced

under the ECS

Warranty

shall be

warranted

for the remainder of the ECS

Warranty Period.

Any warranted,

emrssions-related

paft

which is

scheduled

for replacement

as

reouired maintenance

in the

Owner's

Manual,

shall be warranted for the

period

of

time

prior

to

the first scheduled replacement

point

for

that

part.

lf the

part

fails

prior

to the first scheduled replacement, the

part

shall be repaired

or

replaced

by

Tecumseh Products

Co.

according to

Subsection 4 below.

Any

such emissions-

related

part

repaired or replaced

under the ECS Warranty,

shall be

warranted for

the remainder of the ECS Warranty

Period

prior

to the f irst

scheduled replacement

point

for

such

em

issions-related

part.

Repair or replacement of any warranted,

emissions-related

part

under this ECS Warranty

shall be

performed

at no

charge to the

owner at a

Tecumseh Authorized

Service

Outlet.

5.

The

owner shall

not be charged

for

diagnostic labor which

leads

to the determination

that a

pafl

covered by the ECS

Warranty

is in fact

defective.

provided

that such diagnostic

work is

performed

at a Tecumseh

Authorrzed

Service

Outlet.

6.

Tecumseh Products

Co.

shall be

liable for

damages to other

original engine

components or approved

moditications

proximately

caused by a

failure under warranty

of an

emission-related

part

covered by

the

ECS

Warranty.

7. Throughout the ECS Warranty

Period. Tecumseh Products

Co.

shall maintain a supply of

warranted

emission-related

parts

sufficient

to meet the expected demand for

such

emissron-related

parts.

8.

Any Tecumseh Products Co. authorized and approved

emission-related

replacement

part

may be

used

in the

performance

of any

ECS Warranty

maintenance

or repair

and will

be

provided

without charge to the olvner. Such

use

shall

not reduce Tecumseh

Products

Co. ECS Warrantv

obligations.

9. Unapproved add-on or

modif ied

parts

may not

be used to

modify

or

repair a Tecumseh

Products

Co engine.

Such

use

voids

this

ECS Warranty and sna I

be suflrcrent

grounds

for

disallowing an

ECS Wai'ranty cla m. Tecumseh Products

Co. shall

not

be

liable hereunder

for failures

of any warranted

parts

of a Tecumseh

Products

Co engine caused by the

use of

such

an unapproved add-on or

modif ied

paft.

EMISSION.RELATED PARTS

INCLUDE

THE

FOLLOWING:

1.

Carburetor

Assembly and

its Internal

Components

a)

Fuel filter

b) Carburetor

gaskets

c)

Intake

pipe

2. Air

Cleaner

Assembly

a) Air filter element

3.

lgnition System,

including:

a) Spark

plug

b)

lgnition module

c) Flywheel assembly

4. Catalytic

Muffler

(if

so equipped)

Muffler

gasket

(if

so equipped)

Exhaust manifold

(if

so equipped)

5.

Crankcase

Breather Assembly and its Components

a)

Breather

connection

tube

181-1215-14

Page 9

Page 11

Warranty

requirements

for ongines sold

outside of

the USA

may vary from country

to country.

For warranty

details

lor

your

specific country,

contact

your

national

Tecumseh

Service

Distributor.

lf help

is

needed

in locatlng

your

national servlce

distributor,

you

may

contact

Tecumseh c/o

International Service

Coordinator,

Engine

&

Transmission

Group Service

Division, 900

Nonh Street,

Grafton,

Wisconsin USA

53024-1499.

Telephone

in USA

is 262'377'2700.

For

the

time

period

shown

below

from the date of

purchase

and

sublect to

the

exceptions

and lrmitations

described

herein, Tecumseh

Products Company

will.

at

its option as

the exclusive

remedy. either

repair or

replace for the original

purchasei

,

free of charge,

any

pad

of any

new Tecumseh engine

which

is lound, uoon

examination

by

any Tecumseh

Authorized

Service Outlet

or by

Tecumseh's

factory

in Grafton,

Wisconsin, to be

DEFECTIVE

lN MATERIAL

AND/OR

WORKMANSHIP.

This

Limited Warranty

DOES NOT COVER

(i)

any

Tecumseh engine

or

part(s)

thereof

used

to

power

any

vehicle

in

competitive

racing

and/or

used

on any commerclal

or

rental

track, or

(ij)

defects or

damage

caused by alterations

or

modifications ot

new

Tecumseh engines

or

parts

or by

normal wear, accidents,

improper

maintenance,

improper use or abuse

of the

product,

or

lailure to follow

the instructions contained

in

an

Instruction

Manual

for

the operation

of

the new

Tecumseh engine or

part.

The

cost of

normal

maintenance or

replacement oJ service

items which are

not

defective

shall be

paid

for by the original

purchaser.

At the time

warranly service

is

requested,

evidence

must be

presented

of the date of

purchase

by

the original

purchaser'

Any

charge

{or making service calls

and/or

for transporting any

engine or

part(s)

thereof

to

and from

the

place

where

the inspection

and/or

warranly work

is

performed

is

payable

solely

by the

purchaser.

The

purchaser

is responsible

lor

any

damage or

loss incurred

in

connection

with

the transportation

of any engine

or

part(s)

thereoJ

submitted

lor inspection and/or

warranty

work. WABRANTY

SERVICE

CAN ONLY

BE PERFORMED

BY A TECUMSEH

AUTHORIZED

SERVICE

OUTLET.

Warrantv

service

can be arranged

by contacting

a

Tecumseh Authorized

Service Outlet

(anV

Tecumseh

Registered Seruice

Dealer,

Tecumseh Authorized

Service

Distributor, or

Tecumseh Central

Warehouse

DistributoO or by

contacting

Tecumseh c/o Service

Manager, Engine and

Transmission

Group Service

Division.

900

Nodh

Street,

Grafton. Wisconsin

USA 53024-1

499.

ENGINE

WARRANTY

PERIOD

CONSUMER

USE

+

'

2

years

on

engine,

10

years (the lirst 5

years

covering

parls

and

iabor only;

the

second

5

years

covenng

parts

o^rvr o.

e ecl'onrc

ignition

"

1

year for

A.rstralian/New

Zealano'o'

'ola'v

-ower

engines

+ For

purposes

o{

this warranty

po[cy.

co']sumer

use" shall

mean consumer's

personal,

residential.

household use

by the or

grnal

relail

purchascr'

++For

purposes

of

tnis

warranty

policy,

'corilmercial

use' shall

nlean all

other uses.

includinq use

forcommercial,

Income

productng

or

renial

purposes.

,

The engrne

warranty category

of

your

englne

can be determined

by

review ol the

enginemodel

numberonthe"lnlportantEngrneinfo'mation'decal.

Oneletterin

the engine

model numberwill

be surrounded

Lry

parens

(A)'

(B),

(C)' (D). (E),

(H)

cr

(K)

and that

letter

is

your

engine

warranty category

designatron.

lN CALIFORNIA

ONLY

THtS

EXPRESS

WARFiANTY

IS SUPPL.EMENTED

BY T!1E

TECUMSEH

CALIFORNIA

EMMISSION

CONTROL

WARFANTY

STATEMENT

THIS EXPRESS

WAFRANTY

lS lN

LIEU OF ALL OTHER

EXPRESS

WAHRANTIES.

Neither

Tecumseh

nof any

of its aflilrates

rnakes

any

lvarrantres,

represenlalrons, or

promises,

written or oral, as

to the

quality

of the engine or

any of

its

parts,

other

than as set

forth

herein. ANY

IMPLIED

WABRANTY

OF MARKETABILITY

OR

FITNESS FOR

h

pnRTIcuun

PURPoSE,

To THE EITENT

THAT EITHER

MAV APPLY

To ANY

TECUMSEH

ENGINE

OR

PART(S)

THEREOE

SHALL

BE LIMITED

IN

DURATION TO

THE PERIODS

OF

THE EXPRESS

WARRANTIES SHOWN

tN THE WARRANTY

PERIOD

CHART

ABOVE

AND

TO THE EXTENT

PERMITTED

BY LAW

AND ANY AND

ALL IMPLIED

WARRANTIES

ARE

EXCLUDED.

IN NO EVENT

WILL TECUMSEH

BE

LIABLE

FOR ANY

TNCIDENTAL,

CONSEOUENTIAL

OB SPECIAL

DAUIAGES

AND/OR EXPENSES.

Some states

do

not altow

limitations on

how long an impliecl

warranty

lasts or

the exclusion

or

limrtation oi

incidental

or conseqrlential

darnages,

so

ihe

aboVe|imitation(s)orexc|usion(s)maynotapp|ytoyoU'Th.SLimitedWarrantygiVeSyoUspeciJic|ega|rightsandyoUmaya|so|lave

to-state.

Revised

l",larch.

2000

=-

-.

rd.

-

-

-

TEGUTISEH

"The

Power

to Grow

Your

Business...

Tecumseh

products

Company.

Engine &

Transmission

Group

Service

Division.

Grafton,

Wisconsin

53024-1499'USA

leleohone:

262.377

.27 OO

181-1

215-14

(English)

8/1/00

COMMERCIAL

USE

++

WITHIN USA

Loading...

Loading...