PRINTED IN U.S.A.

Page 1

181-657-14

THIS ENGINE IS EQUIPPED WITH A FEDERALLY MANDATED MECHANISM WHICH STOPS THE ENGINE. DO NOT INTERFERE WITH OR BYPASS THIS MECHANISM. PARTS

TECUMSEH SERVICE OUTLET. IN THE EVENT THE

OPERATOR’S

MANUAL

and MAINTENANCE INSTRUCTIONS for

TECUMSEH

MODELS

THIS SYMBOL POINTS OUT IMPORTANT SAFETY INSTRUCTIONS WHICH IF NOT FOLLOWED COULD ENDANGER THE PERSONAL SAFETY

AND/OR PROPERTY OF YOURSELF AND OTHERS. READ AND FOLLOW ALL INSTRUCTIONS IN THIS MANUAL AND ANY PROVIDED WITH

THE EQUIPMENT ON WHICH THIS ENGINE IS USED BEFORE ATTEMPTING TO OPERATE YOUR TECUMSEH ENGINE.

THESE SYMBOLS

MAY APPEAR ON

THE ENGINE:

OF THE MECHANISM MAY BE SUBJECT TO WEAR AND MUST BE CHECKED ONCE A YEAR BY AN AUTHORIZED

MECHANISM FAILS FOR ANY REASON, YOU MUST NOT USE THE ENGINE UNTIL CORRECTED BY A TECUMSEH SERVICE OUTLET.

FAST SLOW

California Proposition 65 WARNING: The engine exhaust from this product contains chemicals

known to the State of California to cause cancer, birth defects or other reproductive harm.

ENGINES WHICH ARE CERTIFIED TO COMPLY WITH CALIFORNIA

AND U.S. EPA EMISSION REGULATIONS FOR ULGE ENGINES, are

certified to operate on regular unleaded gasoline, include the following

emission control system(s): EM, TWC (if so equipped); Do not include any

user adjustable features - therefore no other adjustments are needed.

OIL & FUEL RECOMMENDATIONS

TO OPERATE ENGINE, YOU WILL NEED THE FOLLOWING:

ÀÀ A CLEAN, HIGH QUALITY, DETERGENT OIL.

Be sure original container is marked:

A.P.I. service “SF” - “SJ”.

FOR SUMMER (ABOVE 320F; 00C) USE SAE30 OIL.

Tecumseh specially formulated oil is available at any Authorized

Tecumseh Service Outlet. Order as part number 730225.

FOR WINTER (BELOW 320F; 00C) USE SAE 5W30 OIL.

Tecumseh specially formulated oil is available at any Authorized

Tecumseh Service Outlet. Order as part number 730226.

DO NOT USE SAE 10W40 OIL.

USING MULTIGRADE OIL WILL INCREASE OIL CONSUMP-

TION.

OIL SUMP CAPACITY: 21 ounces (1-1/4 U.S.

pints) .62 liter.

ÁÁ A FRESH, CLEAN, UNLEADED REGULAR, UNLEADED

PREMIUM, OR REFORMULATED AUTOMOTIVE GASOLINE ONLY. DO NOT USE LEADED GASOLINE.

NOTE: DO NOT USE GASOLINE CONTAINING METHANOL

(WOOD ALCOHOL). Gasoline containing up to 10% ethanol or grain

alcohol (“Gasohol”), or up to 15% MTBE (Methyl Tertiary Butyl

Ether), may be used but requires special care when engine is unused

for extended periods.

See “STORAGE” instructions on Page 5.

NOTE: Use clean oil and fuel and store in approved, clean, covered

containers. Use clean fill funnels.

Never use “stale” gasoline left over from last season or

stored for long periods.

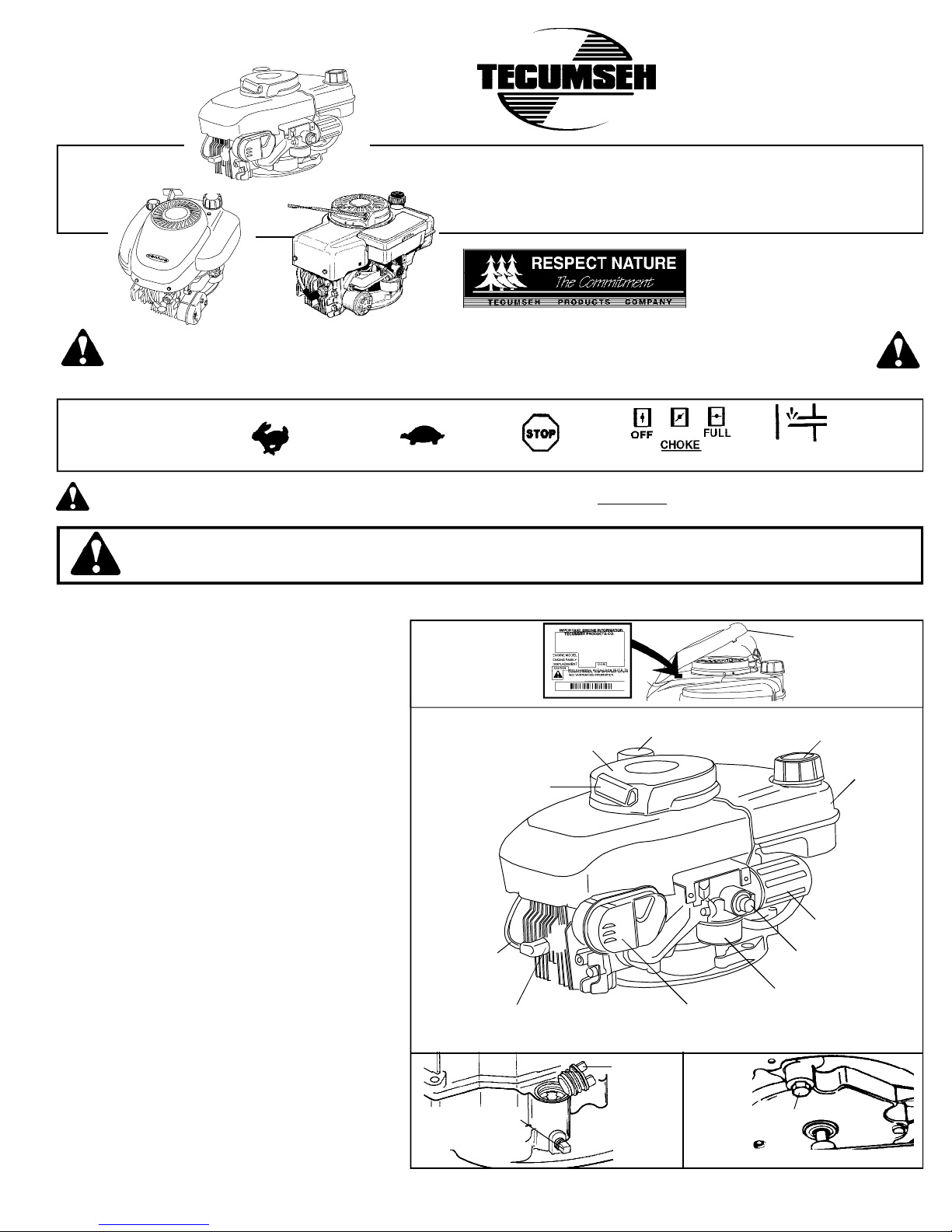

MODEL AND

D.O.M. DECAL

LOCATED

UNDER COVER

(IF SO EQUIPPED)

RECOIL STARTER

STARTER HANDLE

SPARK PLUG

WIRE

SPARK PLUG

OIL DRAIN PLUG

(IF SO EQUIPPED)

OIL FILL PLUG AND DIPSTICK

(IF SO EQUIPPED)

OIL FILL

PLUG

(IF SO

EQUIPPED)

Figure 1

LEV80

LEV100

LEV115

LEV120

TVS90

TVS100

TVS105

TVS115

TVS120

ROTARY MOWER ENGINEROTARY MOWER ENGINE

WITH BRAKE ASSIST

VERTICAL CRANKSHAFT

AIR COOLED FOUR-CYCLE

PRIMER

9-1-98 181-657-14

PRESS IN AND LIFT

HERE TO RELEASE

COVER

FUEL FILL CAP

FUEL

TANK

AIR CLEANER

PRIMER

(IF SO EQUIPPED)

CARBURETOR

MUFFLER

OIL DRAIN PLUG

BOTTOM OF ENGINE

BEFORE STARTING

ÀÀ READ ALL INSTRUCTIONS PROVIDED WITH THE

EQUIPMENT ON WHICH THIS ENGINE IS USED.

ÁÁ FILL OIL SUMP OR CHECK OIL LEVEL:

IMPORTANT: To avoid engine damage never run engine unless:

- Oil level is between “FULL” and “ADD” marks on dipstick (if

so equipped).

- Oil level is to overflow point in oil fill hole on engine without a

dipstick.

- Oil fill plug is tightened securely into oil fill tube or hole.

CHECK OIL LEVEL OFTEN DURING ENGINE BREAK-IN.

A. ENGINE WITH DIPSTICK:

1. POSITION EQUIPMENT SO ENGINE IS LEVEL.

2. Clean area around oil fill plug (see Figure 1).

3. Remove oil fill plug and dipstick.

4. Wipe dipstick clean, insert it into oil fill hole and tighten securely,

remove dipstick. If oil is not up to“FULL” mark on dipstick, add recommended oil. POUR SLOWLY. Wipe dipstick clean each time oil

level is checked.

IMPORTANT: DO NOT FILL ABOVE “FULL” MARK ON DIPSTICK.

5. Install oil fill plug and dipstick, tighten securely.

B.ENGINE WITHOUT DIPSTICK:

1. POSITION EQUIPMENT SO ENGINE IS LEVEL.

2. Clean area around oil fill plug (see Figure 1).

3. Remove oil fill plug.

4. If oil level is not up to overflow point in oil fill hole, add recommended

oil. POUR SLOWLY.

5. Install oil fill plug, tighten securely.

See “MAINTENANCE” section for further oil instructions.

ÂÂ FILL FUEL TANK:

A. Clean area around fuel fill cap, remove cap.

B. Add “UNLEADED” regular gasoline, slowly, to fuel tank. Use a funnel

to prevent spillage.

IMPORTANT: NEVER MIX OIL WITH GASOLINE

C. Install fuel fill cap and wipe up any spilled gasoline.

NEVER FILL FUEL TANK INDOORS. NEVER FILL FUEL TANK

WHEN ENGINE IS RUNNING OR HOT. DO NOT SMOKE WHEN

FILLING FUEL TANK.

NEVER FILL FUEL TANK COMPLETELY. FILL TANK TO 1/2'’

BELOW BOTTOM OF FILLER NECK TO PROVIDE SPACE FOR

FUEL EXPANSION. WIPE ANY FUEL SPILLAGE FROM ENGINE

AND EQUIPMENT BEFORE STARTING ENGINE.

ANY LIQUEFIED PETROLEUM (LPG) OR NATURAL GAS FUEL

SYSTEM MUST BE LEAKPROOF AND MEET ALL APPLICABLE

CODES AND REGULATIONS.

ÃÃ CHECK THE FOLLOWING:

A. BE SURE EQUIPMENT IS IN NEUTRAL GEAR WITH CLUTCHES,

BELTS, CHAINS AND SAFETY SWITCHES DISENGAGED. (FOLLOW EQUIPMENT MANUFACTURER’S INSTRUCTIONS.) THIS

SHOULD PLACE ANY SAFETY SWITCHES IN SAFE STARTING

POSITION.

B. Be sure spark plug wire is attached to spark plug (see Figure 1).

C. Be sure any ignition switch and/or control lever on engine or equip-

ment is in “ON”, “RUN” or “START” position.

STARTING

NEVER RUN ENGINE INDOORS OR IN ENCLOSED, POORLY VENTILATED AREAS. ENGINE EXHAUST CONTAINS CARBON MONOXIDE, AN ODORLESS AND DEADLY GAS.

KEEP HANDS, FEET, HAIR AND LOOSE CLOTHING AWAY FROM

ANY MOVING PARTS ON ENGINE AND EQUIPMENT.

WARNING TEMPERATURE OF MUFFLER AND NEARBY AREAS

MAY EXCEED 1500F (650C). AVOID THESE AREAS.

NOTE: See equipment manufacturer’s instructions for control positions

which correspond to engine control positions in Figures 2 and 4.

ÀÀ ENGINE WITH PRIMER

1) Move control lever (figure 2) to “FAST” or “START” (see equipment

manufacturer’s instructions).

2) The carburetor on your engine has been completely adjusted at the

factory. When starting a cold engine, push primer bulb firmly with your

thumb 5 times, allowing primer bulb to return completely to original

position between pushes. Repeat the above for each starter operation as necessary.

NOTE: DO NOT USE PRIMER TO RESTART A WARM ENGINE

AFTER A SHORT SHUTDOWN.

3) Operate mower control to release engine brake.

4)

a) RECOIL STARTERS: Grasp starter handle (figure 3) and pull rope

out slowly until you feel drag. Let rope rewind slowly. Pull rope

with rapid, full arm stroke. Return rope slowly to original position.

NOTE: If engine fails to start after three pulls, repeat steps 2-3

above.

b) ELECTRIC STARTERS: Crank engine.

NOTE: If engine does not start after five seconds of cranking, stop

and repeat steps 2-3 above.

NOTE: If equipped with a snap-in control as shown, no adjustment

is required.

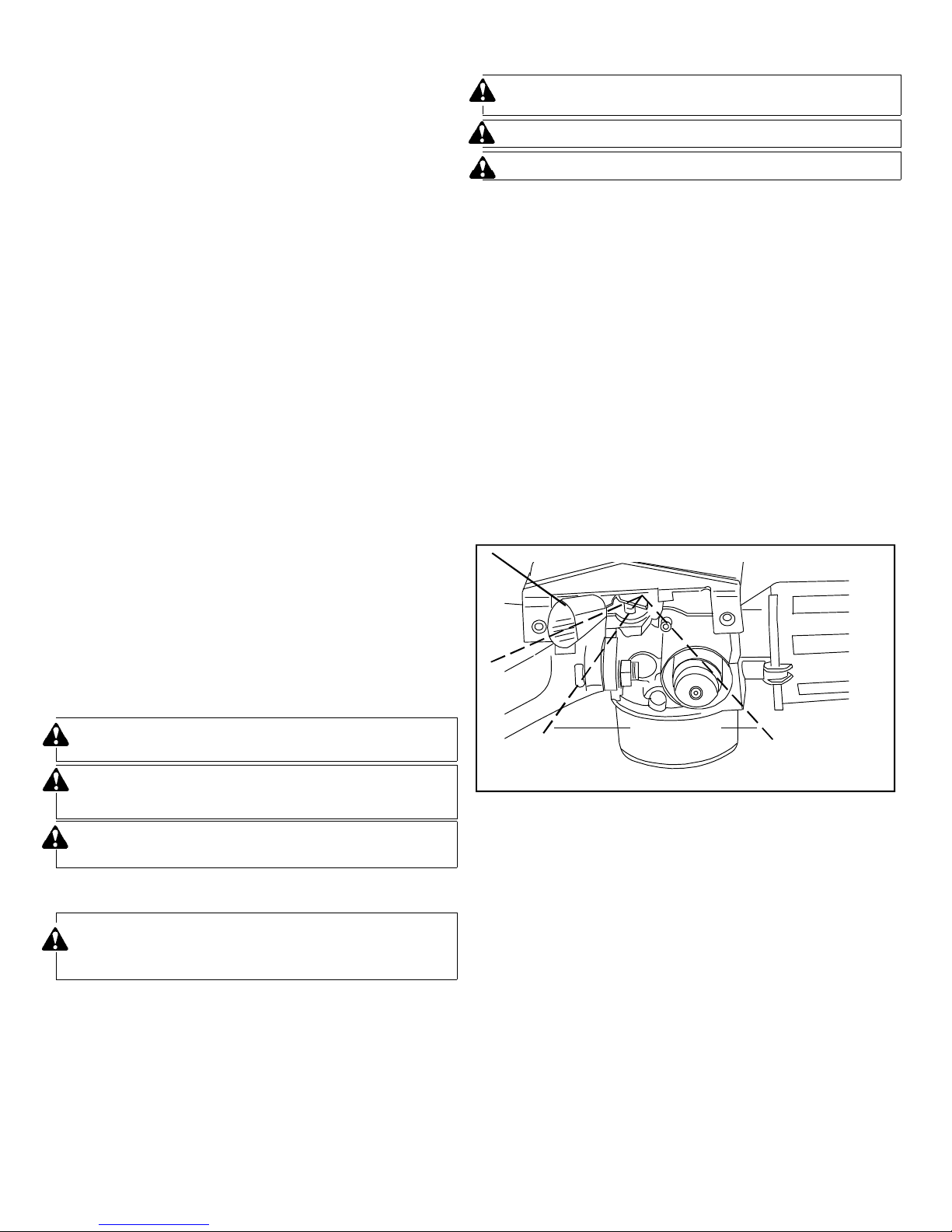

CONTROL LEVER

STOP

START

FAST

IDLE

"RUN" RANGE

Figure 2

ÁÁ ENGINE WITHOUT PRIMER

1) Move control lever (figure 4) to “CHOKE” or “START” (see equipment

manufacturer’s instructions).

NOTE: If restarting a warm engine after a short shutdown, move

control lever to “FAST” instead of “CHOKE”.

2)

a) RECOIL STARTERS: Grasp starter handle (figure 3) and pull rope

out slowly until you feel drag. Let rope rewind slowly. Pull rope with

rapid, full arm stroke. Return rope slowly to original position.

b) ELECTRIC STARTERS: Operate mower control to release engine

brake; crank engine.

3) When engine starts, move control lever to “FAST” and then to desired

speed in “RUN” range. If engine falters, move control lever to

“CHOKE”, then to “FAST”, then to desired speed in “RUN” range.

NOTE: RECOIL STARTERS: If engine fails to start after three pulls,

move control lever to “FAST” and pull starter rope again.

NOTE: If engine fires, but does not continue to run, move control lever

to “CHOKE” and repeat steps 2-3 until engine starts. Do not crank an

electric starter for more than five seconds each attempt.

Page 2 181-657-14

C). AVOID THESE AREAS.

STARTING (Continued)

ENGINE WITH PRIMER AND CHOKE

1) Move control lever (figure 4) to “CHOKE” or “START” (see equipment

manufacturer’s instructions).

NOTE: If restarting a warm engine after a short shutdown, move control

lever to “FAST” instead of “CHOKE”.

2) When starting a cold engine, push primer bulb firmly with your thumb 3

times, allowing primer bulb to return completely to original position

between pushes.

NOTE: Do not use primer to restart a warm engine after a short shutdown.

3) Operate mower control to release engine brake.

4)

a) RECOIL STARTERS: Grasp starter handle (figure 3) and pull rope out

slowly until you feel drag. Let rope rewind slowly. Pull rope with rapid,

full arm stroke. Return rope slowly to original position.

NOTE: If engine fails to start after three pulls, repeat steps 2-3 above.

b) ELECTRIC STARTERS: Crank engine.

NOTE: If engine does not start after five seconds of cranking, stop and

repeat steps 2-3 above.

NOTE: If equipped with a snap-in control, as shown, no adjustment is

required.

5) When engine starts, move control lever to “FAST” and then to desired

speed in “RUN” range. If engine falters, move control lever to “CHOKE”,

then to “FAST”, then to desired speed in “RUN” range.

NOTE: If engine fires, but does not continue to run, move control lever to

“CHOKE” and repeat steps 2-4 until engine starts.

STARTER HANDLE

TYPICAL

ROPE GUIDE

Figure 3

CONTROL LEVER

MOWER

CONTROL

RETAINING POST

SPARK PLUG WIRE

Figure 5

MAINTENANCE

WARNING: TEMPERATURE OF MUFFLER AND NEARBY

AREAS MAY EXCEED 1500F (65

0

ÀÀ OIL LEVEL:

Check oil level every five (5) operating hours and before each use. See

“FILL OIL SUMP OR CHECK OIL LEVEL’’ on Page 2.

ÁÁ CHANGE OIL:

Change oil after first two (2) operating hours and every 25 operating

hours thereafter, more often if operated in extremely dusty or dirty

conditions. Change oil while engine is still warm from recent running.

A. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG AND

ATTACH IT TO RETAINING POST (see Figure 5).

B. Clean area around oil drain plug (see Figure 6).

C. Position equipment so engine oil drain plug is lowest point on

engine.

D. Remove oil drain plug and oil fill plug to drain oil.

E. Install oil drain plug and tighten securely.

F. Fill oil sump with recommended oil. See “OIL & FUEL RECOMMEN-

DATIONS’’ on Page 1 and “FILL OIL SUMP OR CHECK OIL

LEVEL” on Page 2.

G. Install oil fill plug and tighten securely.

H. Wipe up any spilled oil.

SPARK PLUG

STOP

IDLE

"RUN" RANGE

Figure 4

STOPPING

ÀÀ See mower manufacturer’s instructions.

ÁÁ AFTER ENGINE IS STOPPED:

A. DISCONNECT SPARK PLUG WIRE FROM SPARK PLUG AND

ATTACH IT TO RETAINING POST (see Figure 5).

B. TURN IGNITION SWITCH KEY (IF SO EQUIPPED) TO “OFF”

POSITION AND REMOVE KEY FROM SWITCH, THIS WILL

REDUCE THE POSSIBILITY OF UNAUTHORIZED STARTING

OF ENGINE WHILE EQUIPMENT IS NOT IN USE.

NEVER STORE ENGINE WITH FUEL IN TANK INDOORS OR IN

ENCLOSED, POORLY VENTILATED AREAS, WHERE FUEL

FUMES MAY REACH AN OPEN FLAME, SPARK OR PILOT

LIGHT AS ON A FURNACE, WATER HEATER, CLOTHES DRYER OR OTHER GAS APPLIANCE.

START

FAST

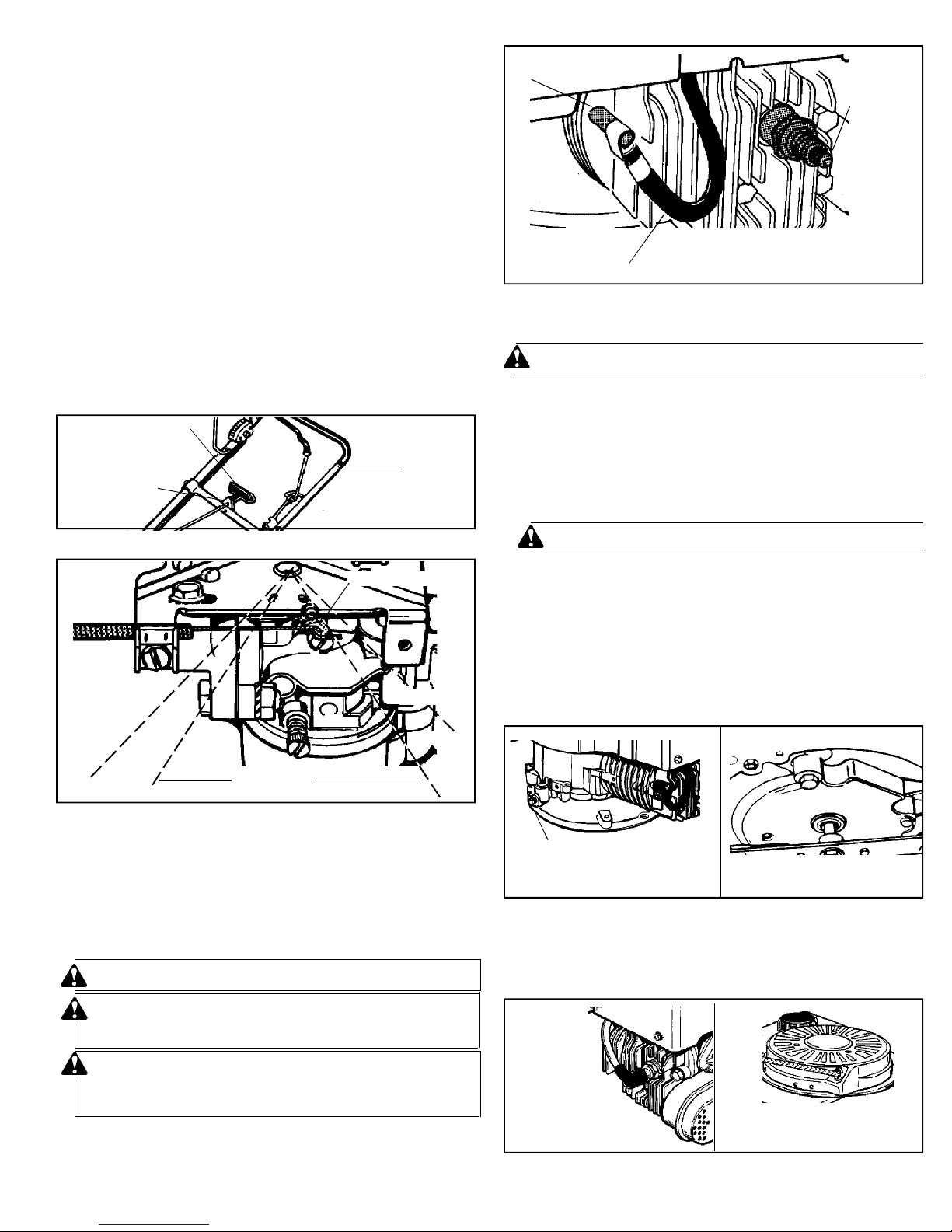

OIL DRAIN PLUG

CHOKE

OIL DRAIN PLUG (IF SO

EQUIPPED)

BOTTOM OF ENGINE

Figure 6

ÂÂ COOLING SYSTEM (see Figure 7):

IMPORTANT: Frequently remove grass clippings, dirt and debris from

cooling fins, air intake screen and levers and linkage. This will help

ensure adequate cooling and correct engine speed.

COOLING

FINS

Figure 7

Page 3 181-657-14

AIR INTAKE SCREEN

5.

AIR CLEANER E

Page 4 181-657-14

MAINTENANCE (Continued)

ÃÃ AIR CLEANER:

IMPORTANT: NEVER RUN ENGINE WITHOUT COMPLETE AIR

CLEANER INSTALLED ON ENGINE.

A. TO SERVICE FILTER(S) (see Figure 8):

1. FOAM FILTER:

Clean and re-oil every three (3) months or every 25 operating

hours. Clean and re-oil daily if used in extremely dusty conditions.

a. Wash in water and detergent solution and squeeze (don’t

twist) until all dirt is removed.

b. Rinse thoroughly in clear water.

c. Wrap in a clean cloth and squeeze (don’t twist) until com-

pletely dry.

d. Saturate with engine oil and squeeze (don’t twist) to distrib-

ute oil and remove excess oil.

2. PAPER OR FOAM/SCREEN FILTERS:

DO NOT ATTEMPT TO CLEAN OR OIL FILTER.

Replace once a year or every 100 operating hours, more often

if used in extremely dusty conditions.

Replacement filters are available at any Authorized Tecumseh

Service Outlet.

B. TO REMOVE AND INSTALL FILTER(S):

1. AIR CLEANER A:

a. Remove cover by pressing in on side of body and lifting cover

upward.

b. Inspect filter for discoloration or dirt accumulation. If either is

present, service per preceding “TO SERVICE FILTER(S)”

instructions.

c. Clean inside of body and cover thoroughly.

d. Install filter(s) in body.

e. Install cover securely on body.

2. AIR CLEANER B:

a. Remove cover by pulling tab away from body while lifting

cover upward.

b. Inspect filter(s) for discoloration or dirt accumulation. If either

is present, service per preceding "TO SERVICE FILTER(S)"

instructions.

c. Clean inside of cover and body thoroughly.

d. Install foam filter(s) and paper filter (if so equipped) in body.

e. Install cover by hooking slot of cover over tab on body. Push

cover down, snapping cover onto body.

3. AIR CLEANER C:

a. Remove wing nut and cover.

b. Slide foam filter off paper filter.

c. Inspect filters for discoloration or dirt accumulation. If either

is present, service per preceding “TO SERVICE FILTER(S)”

instructions.

d. Remove nut and paper filter (if service is necessary).

e. Clean topside of base and inside of cover thoroughly.

f. Install paper filter and nut. Tighten nut finger tight and then

turn it one (1) more complete turn.

g. Slide foam filter over paper filter.

h. Install cover and wing nut. Tighten wing nut.

4. AIR CLEANER D:

a. Turn cover to the left (counterclockwise) and remove it and

filter from flange. Discard filter.

b. Clean cover and flange thoroughly.

c. Insert new filter into cover.

d. Position cover and filter against flange with tab on cover

inserted into lower left corner of slot in flange.

e. Push cover firmly against flange and turn it to the right

(clockwise) as far as it will go. Be sure retainers are locked

around flange.

a. Remove cover by pulling tab away from body while lifting

cover upward.

b. Inspect filter(s) for discoloration or dirt accumulation. If

either is present, service per preceding "TO SERVICE

FILTER(S)" instructions.

c. Clean inside of cover and body thoroughly.

d. Install paper filter in body. Install foam filter (if so equipped)

inside of cover.

e. Install cover by hooking slot of cover over the tab on the

body, push cover down, snapping cover onto the body.

6. AIR CLEANER "F"

a. Turn cover to the right (clockwise) to remove it and remove

paper filter from flange. Discard filter.

b. Clean cover and flange thoroughly.

c. Insert new paper filter into cover.

d. Line up tabs on cover with slots on flange.

e. Push cover firmly against flange and turn it to the left

(counterclockwise) until cover locks securely in place. Cover

should be in vertical position.

TAB

FOAM FILTER

FOAM/

SCREEN

FILTER (IF

SO

EQUIPPED)

PRESS HERE TO

AIR CLEANER A

TAB (LIFT HERE TO REMOVE)

COVER

SLOT

FOAM

FILTER

TAB

AIR CLEANER B

FLANGE

SLOT

AIR CLEANER D

REMOVE COVER

FILTER

TAB

COVER

TURN COVER TO THE RIGHT

(CLOCKWISE) TO TIGHTEN;

COUNTERCLOCKWISE TO REMOVE

AIR CLEANER TYPES

COVER

SLOT

FOAM

FILTER

BODY

RETAINER (2)

COVER

NUT

TAB

PAPER

FILTER

AIR CLEANER C

TAB (LIFT HERE TO REMOVE)

COVER

SLOT

FOAM

FILTER

TAB

AIR CLEANER E

SLOT

FLANGE

TURN COVER TO THE LEFT

(COUNTERCLOCKWISE) TO

TIGHTEN; CLOCKWISE TO REMOVE

AIR CLEANER F

TABS

Figure 8

FOAM

FILTER

BASE

FILTER

BODY

PAPER

FILTER

COVER

ADJUSTMENTS

(Continued)

MAINTENANCE

(Continued)

ÄÄ SPARK PLUG (see Figure 9):

This spark ignition system meets all requirements of the Canadian

Interference-Causing Equipment Regulations. This engine complies

with all current Australian and New Zealand limitations regarding

electromagnetic interference.

Check spark plug yearly or every 100 operating hours.

A. Clean area around spark plug.

B. Remove and inspect spark plug.

C. Replace spark plug if electrodes are pitted, burned or porcelain is

cracked. For replacement use Champion RJ-19LM only.

NOTE: A resistor spark plug must be used for replacement.

D. Check electrode gap with wire feeler gauge and set gap at .030 if

necessary.

E. Install spark plug, tighten securely.

ELECTRODES

.030 GAP PORCELAIN

Figure 9

ÅÅ CHECK ENGINE AND EQUIPMENT OFTEN FOR LOOSE NUTS, BOLTS

AND ATTACHMENTS AND KEEP THESE ITEMS TIGHTENED.

ADJUSTMENTS

DO NOT MAKE UNNECESSARY ADJUSTMENTS. FACTORY SETTINGS ARE SATISFACTORY FOR MOST CONDITIONS. IF ADJUSTMENTS ARE NEEDED, PROCEED AS FOLLOWS:

ÀÀ REMOTE CONTROL (see Figure 2 and Figure 10):

For satisfactory engine performance, engine and equipment control

must be adjusted properly. To check engine control adjustments,

proceed as follows:

A. Set equipment control at “FAST” and keep it in this position.

B. Loosen clamp screw so remote control cable can be moved in cable

clamp.

C. Move engine control lever into “FAST” and hold it in this position.

NOTE: Control lever is in “FAST” position when hole in control lever

and notch on control bracket are in line.

D. Tighten clamp screw securely so cable clamp will hold remote

control cable in place when equipment control is used.

The engine controls should now be adjusted correctly.

If more adjustments are needed, make them at the equipment

control (see equipment manufacturer’s instructions).

REMOTE

CONTROL

CABLE

CLAMP

SCREW

CABLE

CLAMP

Figure 10

CONTROL BRACKET

NOTCH

CONTROL LEVER

FAST POSITION

(ILLUSTRATED)

ÂÂ ENGINE SPEED:

NEVER TAMPER WITH ENGINE GOVERNOR WHICH IS FACTORY

SET FOR PROPER ENGINE SPEED. OVERSPEEDING ENGINE

ABOVE FACTORY HIGH SPEED SETTING CAN BE DANGEROUS.

CHANGING OF ENGINE GOVERNED SPEED WILL VOID ENGINE

WARRANTY.

For engine adjustments and/or repairs not covered in this “OPERATOR’S

MANUAL” see “WARRANTY & REPAIR” on Page 6.

STORAGE

NEVER STORE ENGINE WITH FUEL IN TANK INDOORS OR IN

ENCLOSED, POORLY VENTILATED AREAS, WHERE FUEL FUMES

MAY REACH AN OPEN FLAME, SPARK OR PILOT LIGHT AS ON A

FURNACE, WATER HEATER, CLOTHES DRYER OR OTHER GAS

APPLIANCE IF ENGINE IS TO BE UNUSED FOR 30 DAYS OR

MORE, PREPARE AS FOLLOWS:

À À DRAIN FUEL SYSTEM:

A. Remove all gasoline from carburetor and fuel tank to prevent gum

deposits from forming on these parts and causing possible malfunction of engine.

DRAIN FUEL INTO APPROVED CONTAINER OUTDOORS, AWAY

FROM OPEN FLAME. BE SURE ENGINE IS COOL. DO NOT

SMOKE.

B. Run engine until fuel tank is empty and engine stops due to lack of

fuel.

NOTE: If “Gasohol” has been used, complete above instructions

and then put 1/2 pint of “Unleaded” gasoline into fuel tank and repeat

above instructions.

NOTE: Tecumseh SMART STARTTM gasoline preservative and

stabilizer is an acceptable alternative in minimizing the formation of

fuel gum deposits during storage. Add stabilizer to gasoline in fuel

tank or storage container. Always follow mix ratio found on stabilizer

container. Run engine at least 10 minutes after adding stabilizer to

allow it to reach carburetor.

ÁÁ DRAIN CARBURETOR (if so equipped):

Drain carburetor by pressing upward on bowl drain (see Figure 11,

which is located below carburetor (see Figure 1).

DRAIN FUEL INTO APPROVED CONTAINER OUTDOORS, AWAY

FROM OPEN FLAME. BE SURE ENGINE IS COOL. DO NOT SMOKE.

CARBURETOR

BOWL DRAIN

Figure 11

ÂÂ CHANGE OIL:

Change oil if it has not been changed in the last three (3) months. See

“CHANGE OIL” instructions in “MAINTENANCE” section.

ÃÃ OIL CYLINDER BORE:

A. Remove spark plug. Squirt one (1) oz. (30 ml) of clean engine oil

into spark plug hole.

B. Cover spark plug hole with a rag.

C. Crank engine over, slowly, several times.

AVOID SPRAY FROM SPARK PLUG HOLE WHEN CRANKING

ENGINE OVER SLOWLY.

D. Install spark plug. Do not connect spark plug wire.

ÁÁ CARBURETOR:

If you think your carburetor needs adjusting, see your nearest AUTHORIZED TECUMSEH SERVICE OUTLET. Engine performance should

not be affected at altitudes up to 7,000 feet. For operation at higher

elevations, contact your AUTHORIZED TECUMSEH SERVICE OUTLET.

ÄÄ CLEAN ENGINE:

Remove any clippings, dirt, or chaff from exterior of engine.

ÅÅ BATTERY (if so equipped):

See equipment manufacturer’s instructions for proper storage of battery.

Page 5 181-657-14

Page 6

WARRANTY AND REPAIR

181-657-14

For engine adjustments, repairs, or warranty service not covered in this manual, contact your nearest

AUTHORIZED TECUMSEH SERVICE OUTLET. It is listed in your telephone book yellow pages under

"Engines, Gasoline."

If you have a general understanding of internal combustion engines and wish to repair and service your engine

yourself, a "TECHNICIAN'S HANDBOOK" which covers repairs and adjustments not covered in this

OPERATOR'S MANUAL is available from your AUTHORIZED TECUMSEH SERVICE OUTLET. Order as Part

No. 692509.

Tecumseh manufactures and is responsible only for the engine used on this power equipment. If repair or

service is needed for unit, other than engine, contact service source as recommended by equipment

manufacturer.

Warranty requirements for engines sold outside of the USA may vary from country to country. For warranty

details for your specific country, contact your national Tecumseh Service Distributor. If help is needed in

locating your national service distributor, you may contact Tecumseh c/o International Service Coordinator,

Engine & Transmission Group Service Division, 900 North Street, Grafton, Wisconsin USA 53024-1499.

Telephone in USA 414-377-2700.

LIMITED WARRANTY FOR NEW TECUMSEH ENGINES

For the time period shown below from the date of purchase, Tecumseh Products Company will, at its option as the exclusive remedy, either repair or replace for

the original purchaser, free of charge, any part of any new Tecumseh engine which is found, upon examination by any Tecumseh Authorized Service Outlet or by

Tecumseh’s factory in Grafton, Wisconsin, to be DEFECTIVE IN MATERIAL AND/OR WORKMANSHIP, except as provided below. This Limited Warranty DOES

NOT COVER (i) any Tecumseh engine or part(s) thereof used to power any vehicle in competitive racing and/or used on any commercial or rental track, or (ii) defects

or damage caused by alterations or modifications of new Tecumseh engines or parts or by normal wear, accidents, improper maintenance, improper use or abuse

of the product, or failure to follow the instructions contained in an Instruction Manual for the operation of the new Tecumseh engine or part. The cost of normal

maintenance or replacement of service items which are not defective shall be paid for by the original purchaser. At the time warranty service is requested, evidence

must be presented of the date of purchase by the original purchaser. Any charge for making service calls and/or for transporting any engine or part(s) thereof to and

from the place where the inspection and/or warranty work is performed is payable solely by the purchaser. The purchaser is responsible for any damage or loss incurred

in connection with the transportation of any engine or part(s) thereof submitted for inspection and/or warranty work. WARRANTY SERVICE CAN ONLY BE

PERFORMED BY A TECUMSEH AUTHORIZED SERVICE OUTLET OR BY TECUMSEH AT ITS FACTORY IN GRAFTON, WISCONSIN. Warranty service can

be arranged by contacting either a Tecumseh Authorized Service Outlet (any Tecumseh Registered Service Dealer, Tecumseh Master Service Dealer, Tecumseh

Authorized Service Distributor, or Tecumseh Central Warehouse Distributor) or by contacting Tecumseh c/o Service Manager, Engine and Transmission Group Service

Division, 900 North Street, Grafton, Wisconsin 53024-1499.

"CONSUMER USE" + "COMMERCIAL USE" ++

Warranty

Category†

(A) 90 day 90 day No Warranty No Warranty

(B) 1 Year 1 Year 1 Year 1 Year

(C) 2 Years 1 Year 1 Year 1 Year

(D) 2 Years 2 Years** 1 Year 1 Year

(E) 2 Years 2 Years 1 Year 1 Year

(H) 2 'n 10* 2 'n 10* 1 Year 1 Year

(K) 2 'n 10* 2 'n 10* 2 'n 10* 1 Year

Within U.S.A.

and Canada

AND ELECTRONIC IGNITION MODULES

ENGINE WARRANTY PERIOD

Outside U.S.A.

and Canada

Within

USA and Canada

Outside

USA and Canada

* 2 years on engine, 10 years on electronic ignition.

** 1 year for Australia/New Zealand for rotary mower engines.

+ For purposes of this warranty policy, "consumer use" shall mean consumer's personal, residential, household use by the original retail purchaser.

++ For purposes of this warranty policy, "commercial use" shall mean all other uses, including use for commercial, income producing, or rental purposes.

†The engine warranty category of your engine can be determined by review of the engine model number on the "Important Engine Information" decal. One letter in

the engine model number will be surrounded by parens (A), (B), (C), (D), (E), (H) or (K) and that letter is your engine warranty category designation. IN CALIFORNIA

ONLY, THIS EXPRESS WARRANTY IS SUPPLEMENTED BY THE TECUMSEH CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT.

THIS EXPRESS WARRANTY IS IN LIEU OF ALL OTHER EXPRESS WARRANTIES. Neither Tecumseh nor any of its affiliates makes any warranties,

representations, or promises, written or oral, as to the quality of the engine or any of its parts, other than as set forth herein. ANY IMPLIED WARRANTY OF

MARKETABILITY OR FITNESS FOR A PARTICULAR PURPOSE, TO THE EXTENT THAT EITHER MAY APPLY TO ANY TECUMSEH ENGINE OR PART(S)

THEREOF, SHALL BE LIMITED IN DURATION TO THE PERIODS OF THE EXPRESS WARRANTIES SHOWN IN THE WARRANTY PERIOD CHART ABOVE

AND TO THE EXTENT PERMITTED BY LAW ANY AND ALL IMPLIED WARRANTIES ARE EXCLUDED. IN NO EVENT WILL TECUMSEH BE LIABLE FOR ANY

INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES AND/OR EXPENSES. Some states do not allow limitations on how long an implied warranty lasts or

the exclusion or limitation of incidental or consequential damages, so the above limitation(s) or exclusion(s) may not apply to you. This Limited Warranty gives you specific

legal rights and you may also have other legal rights which vary from state-to-state.

FILL IN:

ENGINE SPEC. WARRANTY SERIAL

MODEL NUMBER PERIOD NUMBER

TECUMSEH PRODUCTS COMPANY

6-1-95

EXAMPLE: TVS90 43000K (A) 5001A

ENGINE SPEC. WARRANTY SERIAL

MODEL NUMBER PERIOD NUMBER

CALIFORNIA & US EPA EMISSION CONTROL WARRANTY STATEMENT

The U. S. Environmental Protection Agency (“EPA”), the California Air Resources Board (“CARB”) and Tecumseh Products Co.

are pleased to explain the Federal and California Emission Control Systems Warranty on your new utility or lawn and garden

equipment engine. In California, new 1995 and later utility and lawn and garden equipment engines must be designed, built

and equipped to meet the State’s stringent anti-smog standards. In other states, new 1997 and later model year engines must

be designed, built and equipped, at the time of sale, to meet the U.S. EPA regulations for small non-road engines. Tecumseh

Products Co. will warrant the emission control system on your utility or lawn and garden equipment engine for the periods of

time listed below, provided there has been no abuse, neglect, unapproved modification, or improper maintenance of your utility

or lawn and garden equipment engine.

Your emission control system may include parts such as the carburetor, ignition system and exhaust system. Also included

may be the compression release system and other emission-related assemblies.

Where a warrantable condition exists, Tecumseh Products Co. will repair your utility or lawn and garden equipment engine at

no cost to you for diagnosis, parts and labor.

MANUFACTURER’S EMISSION CONTROL SYSTEM WARRANTY COVERAGE

Emission control systems on 1995 and later model year California utility and lawn and garden equipment engines are warranted for two years as hereinafter noted. In other states, 1997 and later model year engines are also warranted for two years.

If, during such warranty period, any emission-related part on your engine is defective in materials or workmanship, the part will

be repaired or replaced by Tecumseh Products Co.

OWNER’S WARRANTY RESPONSIBILITIES

As the utility or lawn and garden equipment engine owner, you are responsible for the performance of the required maintenance listed in your Owner’s Manual, but Tecumseh Products Co. will not deny warranty solely due to the lack of receipts or for

your failure to provide written evidence of the performance of all scheduled maintenance.

As the utility or lawn and garden equipment engine owner, you should, however, be aware that Tecumseh Products Co. may

deny you warranty coverage if your utility or lawn and garden equipment or a part thereof has failed due to abuse, neglect,

improper maintenance or unapproved modifications.

You are responsible for presenting your utility or lawn and garden equipment engine to a Tecumseh Authorized Service Outlet

(any Tecumseh Registered Service Dealer, Tecumseh Authorized Service Distributor or Tecumseh Central Warehouse

Distributor) as soon as a problem exists. The warranty repairs should be completed in a reasonable amount of time, not to

exceed 30 days.

Warranty service can be arranged by contacting either a Tecumseh Authorized Service Outlet or by contacting Tecumseh

Products Co., c/o Service Manager, Engine and Transmission Group Service Division, 900 North Street, Grafton, WI 53024-

1499. Telephone 1-414-377-2700, or see your local telephone yellow pages under “Engines, Gasoline” for the name, address

and telephone number of a Tecumseh Authorized Service Outlet near you.

IMPORTANT NOTE

This warranty statement explains your rights and obligations under the Emission Control System Warranty (“ECS Warranty”)

which is provided to you by Tecumseh Products Co. pursuant to California law. Tecumseh Products Co. also provides to

original purchasers of new Tecumseh Products Co. engines. The Tecumseh Products Co. Limited Warranties for New

Tecumseh Engine and Electronic Ignition Modules (“Tecumseh Products Co. Warranty”) which is enclosed with all new

Tecumseh Products Co. engines on a separate sheet. The ECS Warranty applies only to the emission control system of your

new engine. To the extent that there is any conflict in terms between the ECS Warranty and the Tecumseh Products Co.

Warranty, the ECS Warranty shall apply except in any circumstances in which the Tecumseh Products Co. Warranty may

provide a longer warranty period. Both the ECS Warranty and the Tecumseh Products Co. Warranty describe important rights

and obligations with respect to your new engine.

Warranty service can only be performed by a Tecumseh Products Co. Authorized Service Outlet, or by Tecumseh Products

Co. at its factory in Grafton, WI. At the time of requesting warranty service, evidence must be presented of the date of sale to

the original purchaser. The purchaser shall pay any charges for making service calls and/or for transporting the products to

and from the place where the inspection and/or warranty work is performed. The purchaser shall be responsible for any

damage or loss incurred in connection with the transportation of any engine or any part(s) thereof submitted for inspection and/

or warranty work.

If you have any questions regarding your warranty rights and responsibilities, you should contact Tecumseh Products Co. at

1-414-377-2700.

Page 7

181-657-14

EMISSION CONTROL SYSTEM WARRANTY

Emission Control System Warranty (“ECS Warranty”) for 1995 and later model year California utility and lawn and garden equipment engines (for other states, 1997 and later model year engines):

A.APPLICABILITY: This warranty shall apply to 1995 and later model year California utility and lawn and garden equipment

engines (for other states, 1997 and later model year engines). The ECS Warranty Period shall begin on the date the new engine

or equipment is delivered to its original, end-use purchaser, and shall continue for 24 consecutive months thereafter.

B.GENERAL EMISSIONS WARRANTY COVERAGE: Tecumseh Products Co. warrants to the original, end-use purchaser of the

new engine or equipment and to each subsequent purchaser that each of its utility and lawn and garden equipment engines is:

1.Designed, built and equipped so as to conform with all applicable regulations adopted by the Air Resources Board pursuant to

its authority in Chapters 1 and 2, Part 5, Division 26 of the Health and Safety Code, and

2.Free from defects in materials and workmanship which, at any time during the ECS Warranty Period, will cause a warranted

emissions-related part to fail to be identical in all material respects to the part as described in the engine manufacturer’s

application for certification.

C. The ECS Warranty only pertains to emissions-related parts on your engine, as follows:

1.Any warranted, emissions-related parts which are not scheduled for replacement as required maintenance in the Owner’s

Manual shall be warranted for the ECS Warranty Period. If any such part fails during the ECS Warranty Period, it shall be

repaired or replaced by Tecumseh Products Co. according to Subsection 4 below. Any such part repaired or replaced under

the ECS Warranty shall be warranted for any remainder of the ECS Warranty Period.

2.Any warranted, emissions-related part which is scheduled only for regular inspection as specified in the Owner’s Manual shall

be warranted for the ECS Warranty Period. A statement in such written instructions to the effect of “repair or replace as

necessary”, shall not reduce the ECS Warranty Period. Any such part repaired or replaced under the ECS Warranty shall be

warranted for the remainder of the ECS Warranty Period.

3.Any warranted, emissions-related part which is scheduled for replacement as required maintenance in the Owner’s Manual,

shall be warranted for the period of time prior to the first scheduled replacement point for that part. If the part fails prior to the

first scheduled replacement, the part shall be repaired or replaced by Tecumseh Products Co. according to Subsection 4

below. Any such emissions-related part repaired or replaced under the ECS Warranty, shall be warranted for the remainder of

the ECS Warranty Period prior to the first scheduled replacement point for such emissions-related part.

4.Repair or replacement of any warranted, emissions-related part under this ECS Warranty shall be performed at no charge to

the owner at a Tecumseh Authorized Service Outlet.

5.The owner shall not be charged for diagnostic labor which leads to the determination that a part covered by the ECS Warranty

is in fact defective, provided that such diagnostic work is performed at a Tecumseh Authorized Service Outlet.

6.Tecumseh Products Co. shall be liable for damages to other original engine components or approved modifications proximately

caused by a failure under warranty of an emission-related part covered by the ECS Warranty.

7.Throughout the ECS Warranty Period, Tecumseh Products Co. shall maintain a supply of warranted emission-related parts

sufficient to meet the expected demand for such emission-related parts.

8.Any Tecumseh Products Co. authorized and approved emission-related replacement part may be used in the performance of

any ECS Warranty maintenance or repair and will be provided without charge to the owner. Such use shall not reduce

Tecumseh Products Co. ECS Warranty obligations.

9.Unapproved add-on or modified parts may not be used to modify or repair a Tecumseh Products Co. engine. Such use voids

this ECS Warranty and shall be sufficient grounds for disallowing an ECS Warranty claim. Tecumseh Products Co. shall not

be liable hereunder for failures of any warranted parts of a Tecumseh Products Co. engine caused by the use of such an

unapproved add-on or modified part.

EMISSION-RELATED PARTS INCLUDE THE FOLLOWING:

1. Carburetor Assembly and its Internal Components 4. Catalytic Muffler (if so equipped)

a) Fuel filter a) Muffler gasket (if so equipped)

b) Carburetor gaskets b) Exhaust manifold (if so equipped)

c) Intake pipe

2. Air Cleaner Assembly a) Breather connection tube

a) Air filter element

5. Crankcase Breather Assembly and its Components

3. Ignition System, including:

a) Spark plug

b) Ignition module

c) Flywheel assembly

Page 8

7.22.97 EPA/CARB

181-657-14

Loading...

Loading...