Page 1

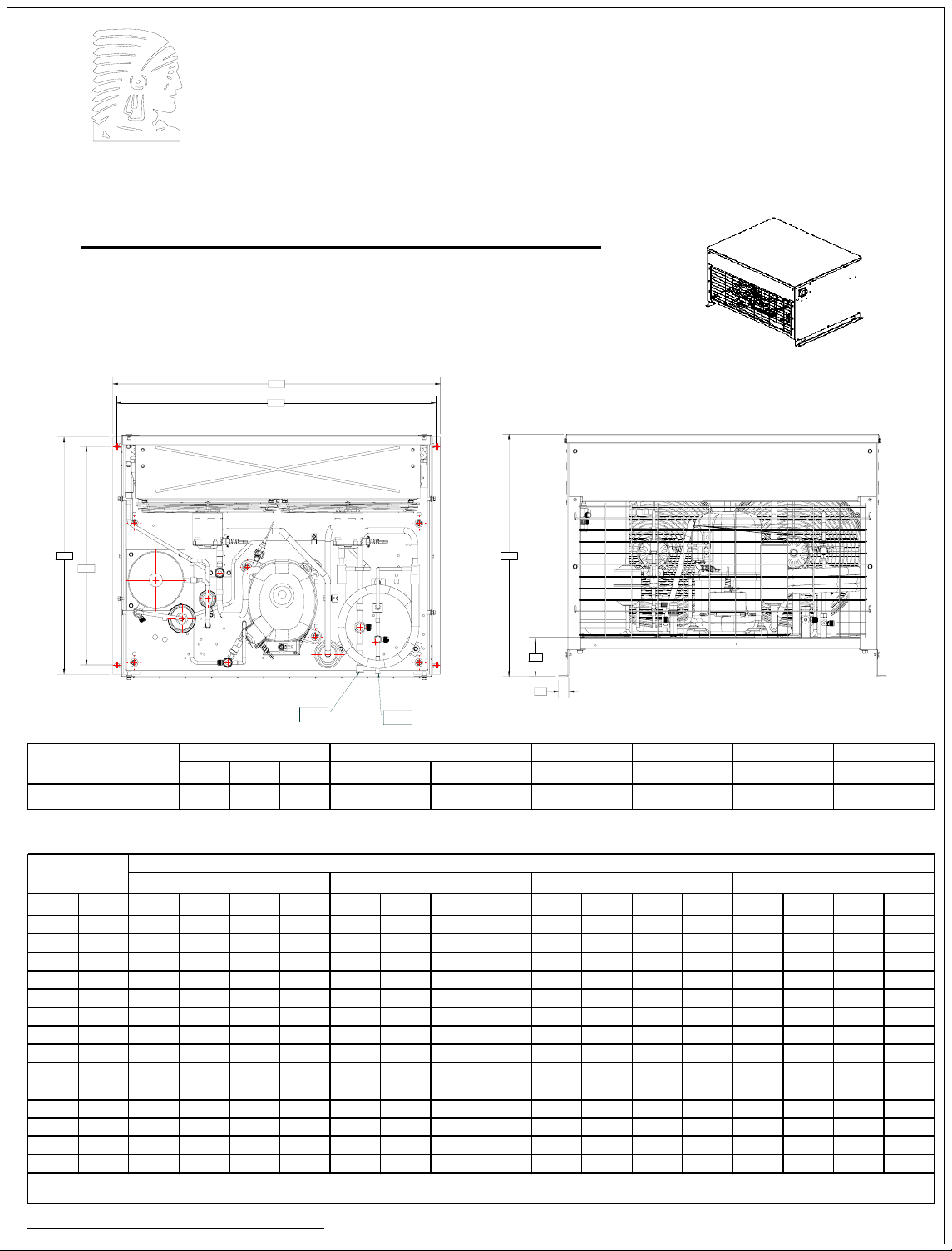

TECUMSEH HERMETIC

CONDENSING UNIT

Model AWA9517ZXTHN

BOM 32L2142-2E

Air Cooled 2 HP

Application Commercial Temp

AWA9517ZXTHN

TPC___REV 1

March 21, 2012

SUCTION

5/8" SWEAT

26.08

LIQUID

3/8" SWEAT

Suctio n Liquid

5/8 3/8 20.45

4.24

1.11

90% @ 90

o

F

SCFM Oz. Lbs.

1800 38.6 320

A ir flow Oil C h . G r o s s weight

Refrigerant R404A

36.25

35.38

25.50

23.50

Model

A W A951 7Z XTH N

Dim. E nclo sur e(inch)* Line connections Pump down

LWH

31.50 40.50 26.75

*) Enclosure Mounting Holes, 38.5 x 25.5

Factory charge 20 psig d ry air,

Evap orator

o

Psig BTUH Watts Head Cond T BTUH Watts Head Cond T BTUH Watts Head Cond T BTUH Watts H ead Cond T

F

MUST BE EVACUATED

Ambient Temeratures

o

80

F95

o

F100

o

F110

o

-10 23.2 8300 1 90 0 198 86 6900 193 0 24 4 101 6400 1930 260 106 540 0 1930 2 97 11 5

-5 27.5 9600 201 0 2 01 87 8000 205 0 24 7 102 7400 20 60 26 3 106 6 20 0 2070 3 00 116

0 32.1 11000 2120 204 88 9100 2180 250 102 8500 2190 267 107 7100 2220 303 117

5 37.0 12600 2 23 0 2 09 89 104 00 2 31 0 25 4 103 970 0 23 30 27 1 108 8 20 0 2370 3 07 118

10 42.4 14 200 235 0 2 13 90 119 00 244 0 25 9 104 111 00 2470 276 109 940 0 25 20 312 11 9

15 48.2 16 000 247 0 2 18 91 134 00 258 0 26 4 106 125 00 2610 281 110 1070 0 2680 3 18 120

20 54.5 17 900 259 0 2 24 93 151 00 272 0 27 0 107 141 00 2760 287 111 1220 0 2840 3 24 121

25 61.2 19 900 272 0 2 31 94 169 00 286 0 27 7 108 158 00 2910 294 113 1370 0 3000 3 30 122

30 68.4 22 000 286 0 2 38 96 188 00 301 0 28 4 110 177 00 3060 301 114 1540 0 3170 3 37 123

35 76.1 24 300 299 0 2 46 98 208 00 316 0 29 2 111 196 00 3220 309 116 1720 0 3340 3 45 125

40 84.4 26 700 313 0 2 55 100 230 00 332 0 30 1 113 217 00 3380 317 117 1920 0 3510 3 54 126

45 93.2 29 200 328 0 2 64 102 253 00 348 0 31 0 115 239 00 3540 327 119 2120 0 3690 3 63 128

50 1 03 .0 31800 343 0 2 74 104 277 00 364 0 32 0 1 16 263 00 3710 336 121 2340 0 3870 3 72 129

55 1 13 .0 34500 358 0 2 84 106 302 00 381 0 33 0 1 18 287 00 3880 347 122 2570 0 4050 3 82 131

o

Performance @ 6 0 H z ; R et urn G a s Te m p erature 2 0

F max superheat above 20oF evap, 40oF max below 20oF evap ; --- SubCooling 5oF

F

PRELIMINARY PERFORMANCE DATA

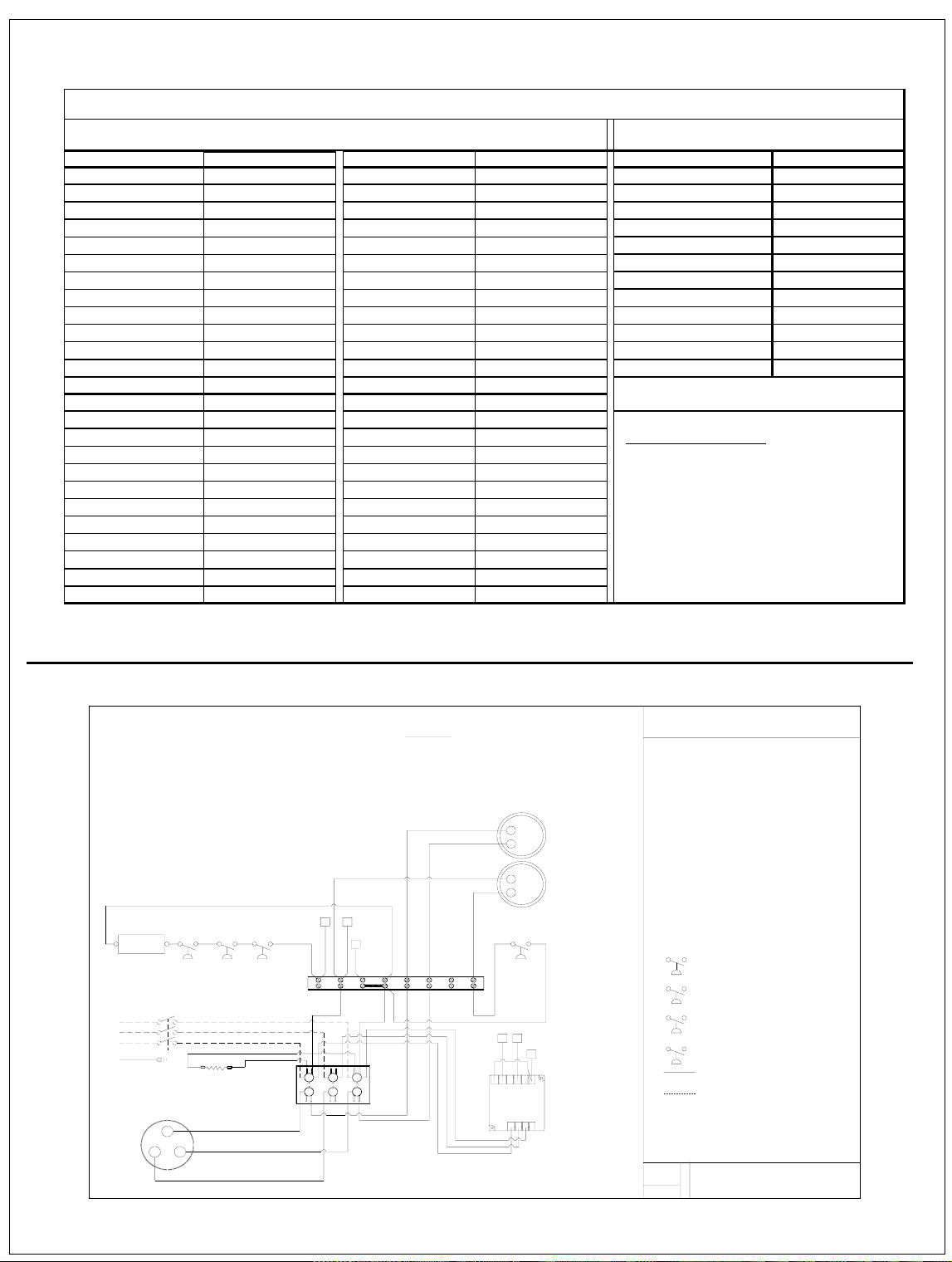

Page 2

(

y

)

p

AWA9517ZXTHN

TPC___REV 1

March 21, 2012

Pa rts/S pecifications

STANDARD OPTIONAL

Unit BOM 32L2142-2E

Unit MODEL AW A9 517ZXTHN

Refrigeration RANGE -10°F to 45°F Fan Blade 51568 Defrost Clock (Tn option)

Design Pressure Low 181 Fan Guard 70831 Defrost Heaters Contactor

Desig n P r essure High 450 Shroud 70648-2 Re c . Heater (R op tion)

Volts - HZ - Ph 20 0-230 V 3~ 60H Z So lenoid Valve (loose)

Voltage Range 180 - 254 High Pressure switch 84095-2L Disconnect (D option)

Min. Circuit Ampa city 14.03 Low Pressu re Control 84026-2

Ma x. F use Size 25 Du al P r essure Conrol Wiring w ith F option W D 23-2AT2

Compressor MOD EL AW 617R T-120-A2 Co ndenser 50858-1

Compressor BOM AWA9514ZXT Head Master Valve 70083-1 Phase monitor, ICM402 900-10026

ressor LRA 63 .4 Ch eck V alve 5662 6

Com

Compressor RLA 7.30 Process Valve 31583-1

OverLoad Suction Valve 56500-K10

Relay E Enclosure

Run Capacitor Receiver 51099-2L R Receiver Heater

Run Capacitor Rating Receiver Qty 1 A Adjustable fan control

S ta r t Capac itor A c c um u lator F Fixe d fan C ontrol

Start Ca paci tor R ating Liquid F ilter 7008 1-3 T1 D e frost timer opt ion

C o ntac tor 91014B S ight Gl a s s 70084 T2 D efrost time r & Defrost Heaters C ontac to r

Un it Draw in g D G U1 9 18-L104 S Solenoid liquid V alve (su p p lied loose)

Wiring Diagram WD2 3-2F M CrankCa se Hea ter 9102 2-1

Fan Motor 810F050C20 Fix.Fan Switch #1

Fan Motor Qt

2 F ix .Fan S witch #2 (F opt.

F opt.)84132-01

F a n Motor RLA 0. 7 A djus. Fan C tr l. (A o pt.)

Wiring w ith A option

BOM INDEX DESCRIPTION

L iqu id Va lve 56 5 00-K 06

32xY YYY - 2ERA (F )TnDS

Suction Filter 70822-6S D Disconnect

NOTES

FIELD WIRING NOTES

1. ALL FIELD WIRING MUST BE DONE IN COMPLIANCE WITH ALL

APPLICABLE LOCAL AND NATIONAL CODES.

2. CONNECT INCOMING POWER LEADS FROM POWER SUPPLY

TO L1, L2, AND L3 IN COMPRESSOR CONTACTOR OR TO L1, L2 AND L3 IN

DISCONNECT SWITCH (IF PROVIDED). USE COOPER CONDUCTORS

ONLY. (EMPLOYER DES CONDUCTEURS DE CUIVER SEULEMENT.)

PROVIDE EQUIPME NT GROUNDING COND UCT OR .

USE 75°C (MIN.) WIRING

GENERAL NOTES:

A. CONTACTOR COIL CIRCUIT IS FACTORY CONNECTED TO 230 V SOURCE IN

PANEL AS SHOWN

B. COMPRESSOR EQUIPPED WITH AN INTERNAL OVERLOAD PROTECTOR.

ALLOW TIME FOR RESET.

AFC

ADJUSTABLE FAN CONTROL

LP

LOW PRESSURE CONTROL

HP

HIGH PRESSURE SWITCH

D.T.

DISCHARGE THERMOSTAT

FACTORY COMPONENTS

OPTIONAL FACTORY COMPONENTS

CONDENSING UNIT WIRING, 230V 60Hz 3 Ph,

fixed fan control,

PHASE MONITOR OPTION

-

REVISION

WD23-2FM

AUG. 18, 2009

CONTACTOR COIL

POWER SUPPLY

230-60-3

COMPRESSOR

COMPRESSOR

see note A

L3L2T3

L1 T1

TERMINAL

IMPORTANT:

COMPRESSOR EQUIPPED WITH AN INTERNAL OVERLOAD

PROTECTOR. ALLOW TIME FOR RESET.

USE COPPER CONDUCTORS ONLY.

(EMPLOYER DES CONDUCTEUERS DE CUIVER

SEULEMENT.)

FAN 1

FAN 2

P1

T1L1T2

TO "230 VAC"

A

B

AT PHASE

MONITOR

TO "C"

C

AT PHASE

MONITOR

L1

L2 L3 T3T1 F1 F2

L2

L3

T3

TO "P1"

AT TERMIN AL

BOARD

Y Y-

A

OUT

MONITOR

ICM402

3 PHASE

L1 L2 L3

FFC

TO "L2"

AT TERMINAL

C

BOARD

115

C

VAC

TO "L1"

B

AT TERMINAL

BOARD

230

VAC

TO "Y-OUT"

AT PHASE

HP LP

T2

GRD

CRANK CASE

HEATER

C

R

S

BLACK

RED

YELLOW

MONITOR

D.T.

TERMINAL

BOARD

Loading...

Loading...