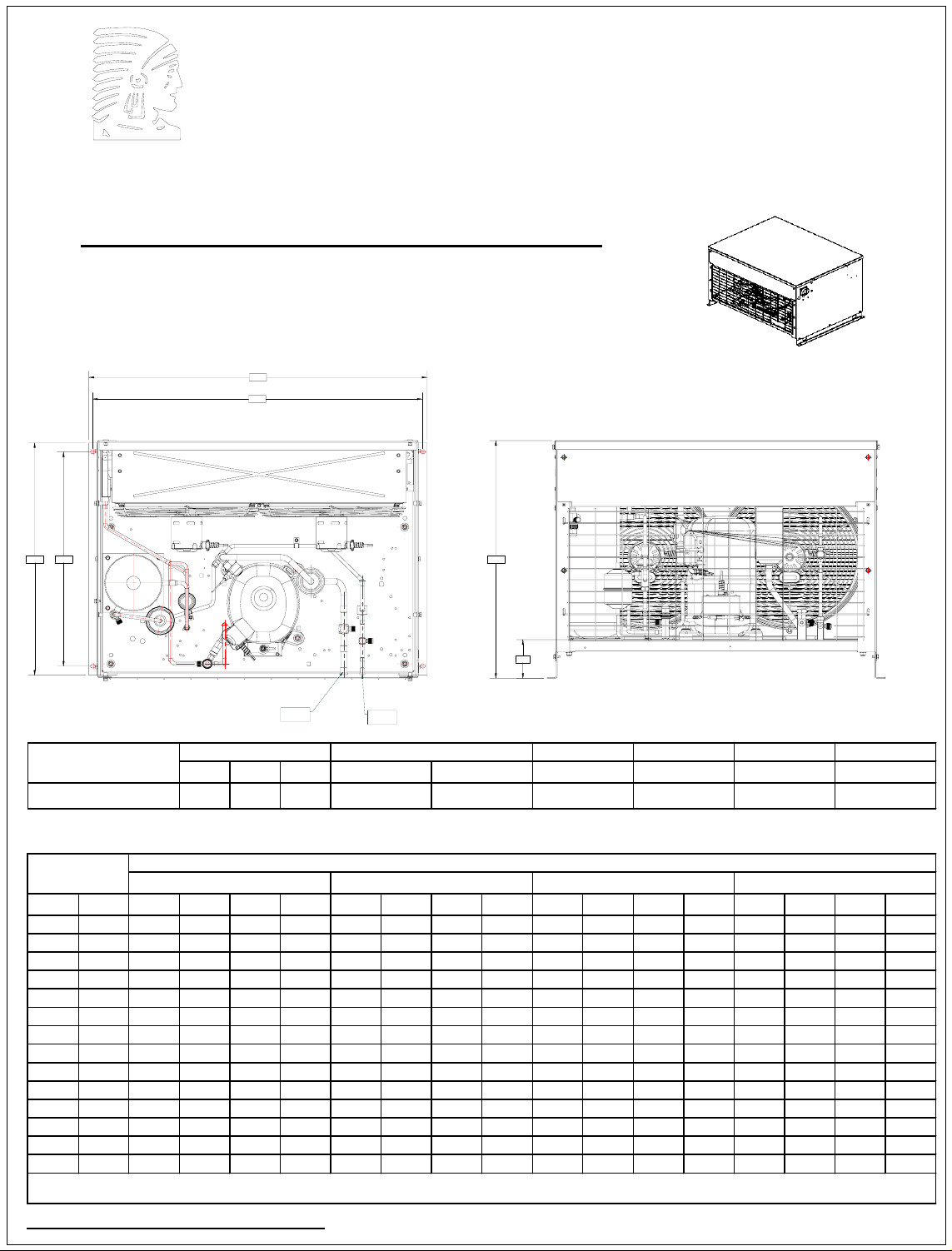

Tecumseh AWA9490ZXTHN Performance Data Sheet

TECUMSEH HERMETIC

CONDENSING UNIT

Model AWA9490ZXTHN

BOM 32L1902-2E

Air Cooled 1 HP

Application Commercial Temp

AWA9490ZXTHN

TPC___REV 1

March 21, 2012

26.08

4.24

LIQUID

3/8" SWEAT

Suctio n Liquid

5/8 3/8 20.16

90% @ 90

o

F

SCFM Oz. Lbs.

1800 38.6 320

A ir flow Oil C h . G r o s s weight

Refrigerant R404A

36.25

35.38

23.5025.50

Model

A W A949 0Z XTH N

Dim. E nclo sur e(inch)* Line connections Pump down

LWH

31.50 40.50 26.75

SUCTION

5/8" SWEAT

*) Enclosure Mounting Holes, 38.5 x 25.5

Factory charge 20 psig d ry air,

Evap orator

o

Psig BTUH Watts Head Cond T BTUH Watts Head Cond T BTUH Watts Head Cond T BTUH Watts H ead Cond T

F

MUST BE EVACUATED

Ambient Temeratures

o

80

F95

o

F100

o

F110

o

-10 23.2 4800 1 30 0 206 91 3700 123 0 25 1 105 3300 1200 268 109 250 0 1150 3 06 11 9

-5 27.5 5900 135 0 2 08 91 4600 128 0 25 5 105 4100 12 60 27 2 110 3 20 0 1210 3 10 120

0 32.1 7300 1 41 0 211 92 5700 135 0 25 8 106 5200 1330 276 111 410 0 1290 3 14 12 1

5 37.0 8800 1 48 0 214 93 7000 144 0 26 2 107 6400 1420 280 112 520 0 1380 3 18 12 2

10 42.4 10500 1560 217 94 8400 1530 267 109 7700 1520 284 113 6400 1490 322 123

15 48.2 12300 1650 221 96 9900 1630 271 110 9200 1620 289 115 7700 1610 327 124

20 54.5 14 100 173 0 2 26 97 115 00 173 0 27 7 111 107 00 1730 295 116 910 0 1730 333 125

25 61.2 16 000 181 0 2 31 99 131 00 184 0 28 3 113 122 00 1840 301 117 1050 0 1850 3 39 126

30 68.4 17 900 189 0 2 38 101 148 00 194 0 29 0 115 138 00 1950 308 119 1190 0 1980 3 45 128

35 76.1 19 700 196 0 2 45 103 163 00 203 0 29 7 117 152 00 2050 315 121 1320 0 2100 3 53 130

40 84.4 21 500 201 0 2 53 105 178 00 211 0 30 6 119 166 00 2150 323 123 1440 0 2210 3 61 131

45 93.2 23 100 205 0 2 62 107 191 00 218 0 31 5 121 179 00 2230 333 125 1550 0 2310 3 70 133

50 1 03 .0 24600 207 0 2 72 110 203 00 224 0 32 5 1 24 189 00 2290 343 128 1640 0 2390 3 80 135

55 1 13 .0 25800 208 0 2 83 113 212 00 227 0 33 7 1 26 198 00 2340 354 130 1700 0 2460 3 91 138

Performance @ 6 0 H z ; R et urn G a s Te m p erature 2 0

o

F max superheat above 20oF evap, 40oF max below 20oF evap ; --- SubCooling 5oF

F

PRELIMINARY PERFORMANCE DATA

E

r

y

2

)

p

e

6

e

AWA9490ZXTHN

TPC___REV 1

March 21, 2012

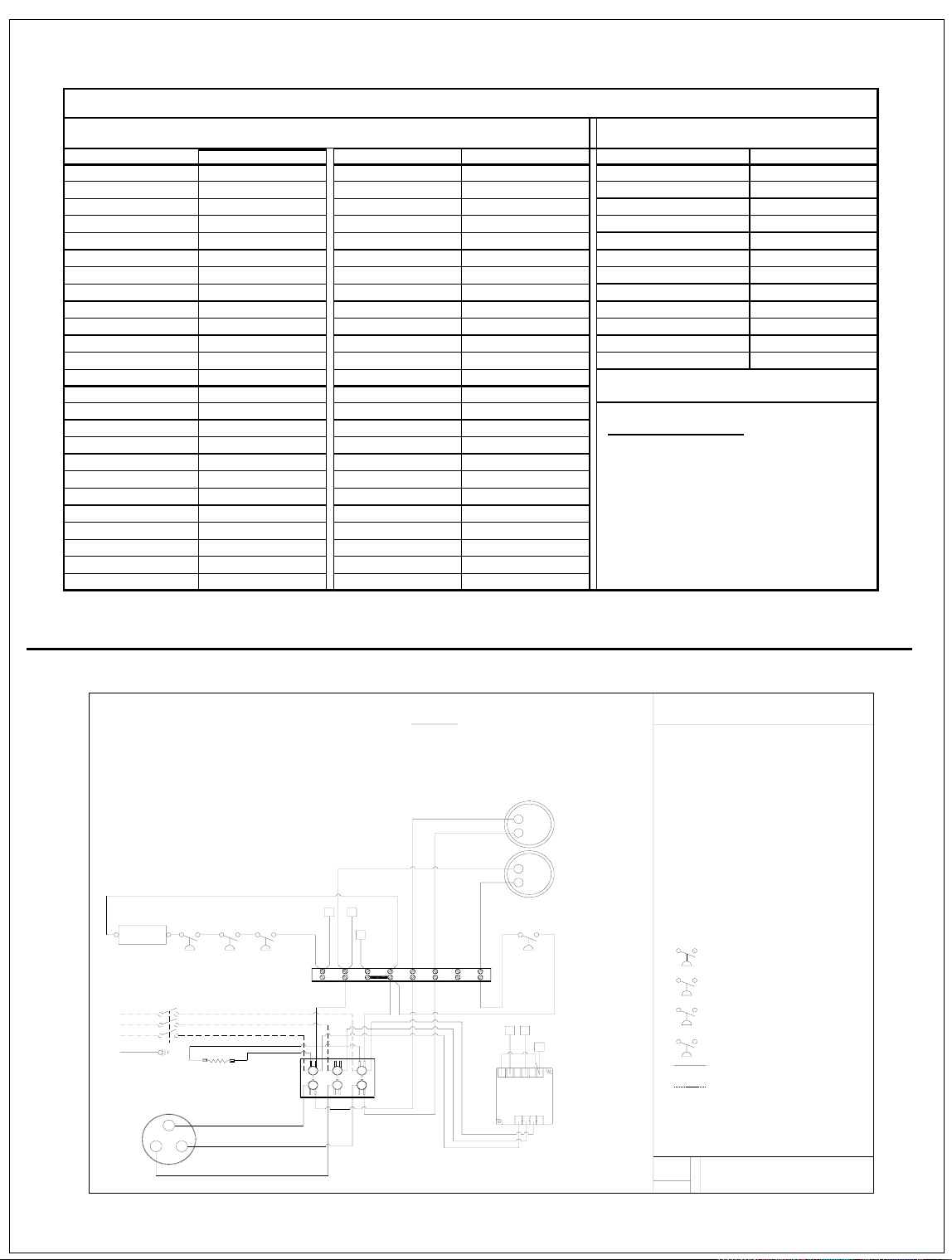

Pa rts/Sp ecifications

STANDARD OPTIONAL

Unit BOM 32L1902-2

Unit MODEL A WA9490ZX THN

Refrigeration RANGE -10°F to 45°F Fan Blade 51568 Defrost Clock (Tn option)

Design Pressure Low 181 Fan Guard 70831 Defrost Heaters Contactor

Desig n P r essure High 450 Shroud 70648-2 Re c . Heater (R op tion)

Volts - HZ - Ph 200- 230V 3~ 60HZ So lenoid Valve (loose)

Voltage Range 180 - 254 High Pr essure switch 8409 5-2 L Disconnect (D option)

Min. Circuit Ampa city 9.94 Low Pressu re Control 8402 6-2

Ma x. F use Size 15 Du al P r essure Conrol Wiring w ith F option W D 23-2AT2

Compressor MOD EL AW616RT-121 -A2 Co ndenser 50855-1

Compressor B OM AWA9490 ZXT He ad Ma ster V alv e 70083-1 Phase Mo nitor, ICM 402 900 -10026

Com

ressor LR A 51 Ch eck V alv

Compressor RLA 4.70 Process Valv

OverLoad Suction Valve 56500-10K

Relay E En clos ure

Run Capacitor Receiver 51099-2L R Receiver Heater

Run Capacitor Rating Receiver Qty 1 A Adjustable fan control

Start Ca pac i tor Accumulator F Fixed fan C ontrol

Start Ca pac i tor R ating Liquid Filter 70081-3 T1 D efrost tim er opt ion

Contactor 91014B Sight Glass 70084 T2 Defrost timer & Defrost Heaters Contactor

Un it D raw ing DG U 1 91 8 -L3 0 5 S So len oid liqu id Va lv e (su p plie d lo ose )

Wiring D iagram WD2 3-2F M CrankC ase H ea ter 91 022-1

Fan Moto

Fan Motor Qt

810F050C 20 Fix.Fan Switch #1 (F opt.)84132-01

Fix.Fan Switch #2 (F opt.

Fan Mo to r RLA 0. 7 Adjus. Fa n C trl. (A opt .)

Wiring w ith A o ptio n

5662

BOM INDEX DESCRIPTION

Liquid Valve 56500-K06

32xYYYY- 2ERA(F)TnDS

Suc tion Filter 70822-6 S D D iscon nect

NOTES

FIELD WIRING NOTES

1. ALL FIELD WIRIN G M UST BE DONE IN C O M PLIANCE WITH ALL

APPLICABLE LOCAL AND NATIONAL CODES.

2. CONNECT INCOMING POWER LEADS FROM POWER SUPPLY

TO L1, L2, AND L3 IN COMPRESSOR CONTACTOR OR TO L1, L2 AND L3 IN

DISCONNECT SWITCH (IF PROVIDED). USE COOPER CONDUCTORS

ONLY. (EMPLOYER DES CONDUCTEURS DE CUIVER SEULEMENT.)

PROVIDE EQUIPMENT GROUNDING CONDUCTOR.

USE 75°C (MIN.) WIRING

GENERAL NOTES:

A. CONTACTOR COIL CIRCUIT IS FACTORY CONNECTED TO 230 V SOURCE IN

PANEL AS SHOWN

B. COMPRESSOR EQUIPPED WITH AN INTERNAL OVERLOAD PROTECTOR.

ALLOW TIME FOR RESET.

AFC

ADJUSTABLE FAN CONTROL

LP

LOW PRESSURE CONTROL

HP

HIGH PRESSURE SWITCH

D.T.

DISCHARGE THERMOSTAT

FACTORY COMPONENTS

OPTIONAL FACTORY COMPONENTS

CONDENSING UNIT WIRING, 230V 60Hz 3 Ph,

fixed fan control,

PHASE MONITOR OPTION

-

REVISION

WD23-2FM

AUG. 18, 2009

POWER SUPPLY

230-60-3

COMPRESSOR

CONTACTOR COIL

see note A

L3L2T3

L1 T1

COMPRESSOR

TERMINAL

IMPORTANT:

COMPRESSOR EQUIPPED WITH AN INTERNAL OVERLOAD

PROTECTOR. ALLOW TIME FO R RESE T.

USE COPPER CONDUCTORS ONLY.

(EMPLOYER DES CONDUCTEUERS DE CUIVER

SEULEMENT.)

FAN 1

FAN 2

TO "Y-OUT"

AT PHASE

HP LP

T2

GRD

S

CRANK CASE

HEATER

C

R

BLACK

RED

YELLOW

MONITOR

D.T.

TERMINAL

BOARD

T1L1T2

TO "230 VAC"

A

B

AT PHASE

MONITOR

TO "C"

C

AT PHASE

MONITOR

L1

P1

L2 L3 T3T1 F1 F2

L2

L3

T3

TO "P1"

AT TERMINAL

BOARD

Y Y-

A

OUT

ICM402

3 PHASE

MONITOR

L1 L2 L3

FFC

TO "L2"

AT TERMINAL

C

BOARD

C115

VAC

TO "L1"

B

AT TERMINAL

BOARD

230

VAC

Loading...

Loading...