INSTRUCTION MANUAL

TECSYSTEMS S r. I.

Exclusive Canadian Distributor

EL Switchgear & Control Inc

Ph: 1 800 463 1275 Fax 1 519 753 5755

E Mail elsc@on.aibn.com

February 19, 2007

T154

P4 V3 1. 2C

1

R3 T154 Table of contents

Introduction...........................................................................................3

Mounting...............................................................................................3

Dimensions ...........................................................................................3

Controls.................................................................................................4

Screen Displays ...................................................................................4

Screen Messages...................................................................................5

Light Test..............................................................................................5

Control Power.......................................................................................5

Wiring...................................................................................................6

Inputs ....................................................................................................7

Outputs..................................................................................................7

Programming ........................................................................................8

Pictorial.................................................................................................10

Technical Specifications .......................................................................11

Testing ..................................................................................................12

Warranty...............................................................................................12

Troubleshooting....................................................................................13

Options..................................................................................................14

Approvals..............................................................................................14

T154 Instruction Manual P4 V3 1.2C

February 19, 2007

Exclusive Canadian Distributor

EL Switchgear & Control Inc

Ph: 1 800 463 1275 Fax 1 519 753 5755

E Mail elsc@on.aibn.com

February 19, 2007

2

Introduction The T154 Temperature Monitor will monitor and control up to four, three-

wire RTD inputs. All input channels may be user programmed for two

separate outputs with a range of 0 to 240°C (32 to 464°F). The set points are

common to all channels. The unit is microprocessor based which offers

application flexibility, and easy integration to a variety of applications

including electric motors; electric and diesel generators; all types of

transformers; electric cables; and industrial and chemical processes. ANSI 49

covers the thermal protection provided.

The unit is intended for semi-flush mounting with hardware provided.

Installation and set-up is simple using the universal power supply 24 to 240V

AC or DC and functional user controls and display.

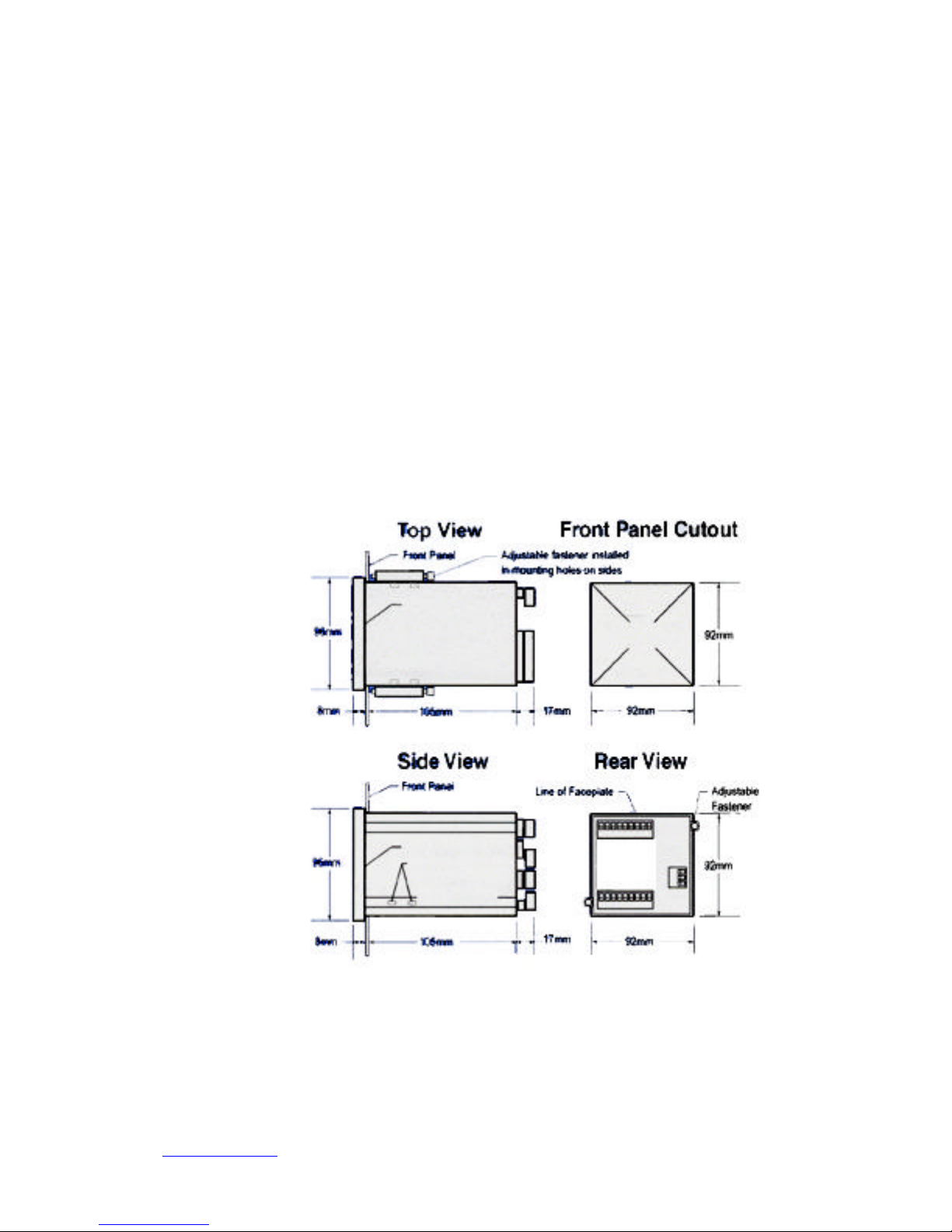

Mounting T154 is designed for semi-flush panel mounting. Mounting hardware is

included with each unit. The panel cutout dimension is 92 x 92mm (3.62 in. x

3.62 in.).

Dimensions Ref Figure 1

96 x 96 x 127 mm (3.78 x 3.78 x 5.51 in.)

Exclusive Canadian Distributor

EL Switchgear & Control Inc

Ph: 1 800 463 1275 Fax 1 519 753 5755

E Mail elsc@on.aibn.com

February 19, 2007

Figure 1

3

Controls All functional controls and displays are located on the front of the unit. The

unit has six input keys, two having dual functions. These are PRG/SET and

ENT/RESET. Keys may be categorized as, programming, screen display, and

test.

Programming keys are located at the bottom of the unit and may be identified

by the blue type. These are PRG, ENT, UP (symbol) DOWN (symbol). The

screen display may be changed by the DISPLAY MODE key located to the

right side of the display, identified by the yellow type. The TEST key is

located beside the display mode key, identified by white type. When the test

provision is enabled the SET and RESET keys are activated, with the PRG

and ENT keys disabled.

Screen Displays EACH ACTIVE CHANNEL HAS FOUR ASSOCIATED LED’S,

INDICATING STATUS. TRIP, ALARM, FAN, OR FAULT, THE LED

COLOURS ARE INTERPRETED AS FOLLOWS

Green

Displays the active channel 1-2-3 or 4

Yellow

-The associated channel has exceeded the alarm trip set point, and the alarm

output relay has changed state

-The fan relay has been ener gized

Red

-The associated channel has exceeded the trip set point and the trip output

relay has changed state.

-Indication of a fault condition

All messages and operating parameters are displayed on the screen. The

DISPLAY MODE key controls the operating mode of the screen display

allowing any one of four modes to be selected: scan, auto , man, or Tmax.

An illuminated yellow LED at the top of the display indicates the active mode

and pressing the DISPLAY MODE key toggles the four different modes. The

different modes display the following information:

Scan

Each channel is scanned for approximately three seconds during which the

actual temperature of that channel is displayed

Auto

All active channels are scanned, but only the temperature of the hottest

channel is displayed on the screen. This mode does not affect protection.

Man

Each channel may be viewed manually by pressing the UP or DOWN key.

The information displayed on the screen will be that of the channel whose

green LED is lit. All active channels are still scanned but only the temperature

of the selected channel is displayed. This mode does not affect protection.

Tmax

This value is logged in memory and is the maximum temperature recorded on

any active input channel. The temperature value is shown and the channel is

identified.

Exclusive Canadian Distributor

EL Switchgear & Control Inc

Ph: 1 800 463 1275 Fax 1 519 753 5755

E Mail elsc@on.aibn.com

February 19, 2007

4

Screen Messages The main LED screen displays a variety of messages some of which only

appear during programming or as a result of component or unit failure. During

the course of normal operation the following screen display indi cates a fault

condition:

• FOC: Fault open circuit - RTD input to one or more channels has open

circuited. LED illumination is provided showing fault relay indication,

and the affected channel is identified

• FCD: Fault sensor reading - RTD signal is erroneous. This is a

programmable feature that is enabled by the user. Sensitivity is user

selectable from 1(low) to 30 (high) This determines response time

The controller decides if the signal input from the RTD is accurate. The

fault relay will trip if a signal input is determined to be wrong. The sensor

must be replaced. To reset the fault relay push RESET until RST appears

on the main display

• FCC: Fault short circuit - RTD is short -circuited. The RTD has failed or the

RTD selection and the unit are not compati ble. The cause is the result of

lower resistance across the input than the unit is calibrated for. Indication

of this problem is provided by fault relay LED indication. The main

display will show FCC and a channel is identified If all alarm and trip

LED’s illuminate with fault indication, the probability is, the RTD’s are

not compatible with the unit

All other messages pertain to program or test functions, which are described

under programming or test.

Light Test This test is conducted automatically after completion of programming or

viewing programmed information. It is intended to provide visual indication

of all illuminated LED’s and their operation.

It is advisable to carry out this test on a regular basis to ensure all lamps are

functioning normally. Pressing the TEST key at any time allows the user to

test all lamps.

If any lamp is not functioning the unit must be returned for repair.

Control Power The T154 has a universal power supply. It can be supplied with 24 to 240V

AC or DC without respect to polarities.

The ground cable must be fixed to terminal # 41

ATTENTION: The unit may be damaged by over voltage

when power is supplied directly from the secondary of the

transformer it is monitoring. This may occur when the 240V is

obtained directly from the secondary winding and there are

fixed capacitors online. Use a control circuit transformer, with

a secondary voltage of 24 to 120V AC or DC to avoid

damage.

ATTENTION: Disconnect the power supply to the T154

when conducting insulation testing with an AC or DC HiPot.

Exclusive Canadian Distributor

EL Switchgear & Control Inc

Ph: 1 800 463 1275 Fax 1 519 753 5755

E Mail elsc@on.aibn.com

February 19, 2007

5

Failure to do so may result in damage to the unit.

Wiring Terminal blocks are located at the rear of the unit for all input channels (4),

output relays (4) and control power.

The terminal blocks are removable for ease of wiring

Wiring connections are shown in Figure 2

Figure 2

Wiring (Cont.) Sensor wiring and routing

All sensor wiring must be:

• Separated from power wiring;

• Shielded cable with twisted conductors;

• Have a cross section of 0.5mm (22AWG);

• Be twisted conductor if no shield;

• Have tinned or silvered conductors;

• Be firmly fixed in the terminal board.

Exclusive Canadian Distributor

EL Switchgear & Control Inc

Ph: 1 800 463 1275 Fax 1 519 753 5755

E Mail elsc@on.aibn.com

February 19, 2007

6

Inputs The T154 will accept three or four, three-wire RTD inputs.

The standard unit is calibrated for 100 -ohm, platinum RTDs.

The T154 may also be ordered for use with 100 or120-ohm, nickel RTDs.

Channels 1-2-3 must have inputs connected or the unit will read an open

circuit with the FOC message displayed, and the fault relay tripped. In

applications with less than three channels connected, a resistor of 100 ohms or

more must be connected across the open channel. This will eliminate nuisance

tripping of the fault relay. The display will show a value for the unused

channel, which is based on resistance vs. temperature for 100 ohm platinum

RTD’s. To select a resistance value corresponding to a temperature value, a

100 ohm resistor is equivalent to 0°C. Each 3.89 ohms (minus .01 per

increment) is equivalent to 10°C. Ensure this does not interfere with the alarm

or trip set points. Always choose a fixed resistance to provide a value lower

than the set point values on the active channels.

Applications with transformers requires the RTD’s to be connected in

sequence for best performance, i.e. Winding 1-2-3 connected to channels 1-23

Channel 4 is a programmable option. This channel m ay be enabled/disabled in

the program mode.

Outputs The standard version of the T154 incorporates four output relays. These are:

Trip, Alarm, Fault and Fan.

• Alarm , Trip & Fault relays are single -pole, double throw, fan relays are

SPST.

• The Alarm, and Tri p relays may be programmed with individual

temperature set point values All channels will respond to the

programmed values.

• The Fan relay may be programmed with an ON and Off set point

temperature value. The operation is selected in program mode. Two

choices are offered; one based on RTD inputs connected to channels 1,2

or 3 or; controlled by an RTD connected to channel 4. The fan relay

incorporates a fan test procedure this is selected in program mode. This

feature allows automatic cycling of the fans five minutes of a selected

hourly interval from one to ninty nine hours. To disable this feature enter

ooo

• The alarm and trip relays will change contact state when the set- point

temperature value is reached. This value must be present for a minimum

of four seconds in excess of 1 degree C above the set-point threshold

• The Fault relay is activated when the unit senses a defective component or

failure of the relay. This relay changes contact state when the unit is

powered on line. Resetting this relay requires repair, replacement or

correction of components. Resetting the fault relay is affected by the FCD

program selection, refer to SCREEN MESSAGES for more detail..

• Output relays are controlled by set-point thresholds for alarm trip and fan

relays. Each channel surveys the temperature independently, and the

hottest channel will cause the relays to trip when the threshold is

exceeded. The reset function requires all channels to drop one degree C

below the trip thresholds and the relays reset automatically.

Exclusive Canadian Distributor

EL Switchgear & Control Inc

Ph: 1 800 463 1275 Fax 1 519 753 5755

E Mail elsc@on.aibn.com

February 19, 2007

7

Programming Getting started

Programming the T154 is simple and requires no special tools. The set point

values for alarm, trip and fan control should be at hand.

The unit will automatically step through each program sequence and upon

completion will repeat each step or may be returned to normal operation.

The program sequence is as follows;

1) Input alarm temperature value for all channels, range 0-240°C (32 -464°F)

2) Input trip temperature value for all channels, range. 0-240°C (32 -464°F)

3) Select channel four; yes or no. If YES set alarm & trip set points

Note: set point values for this channel are independent of channels 1-2 or 3

This channel would normally be used with fan operation.

4) Select fan operation; NO or (YES) select channels 1-2-3 or 4

5) Set the fan ON temperature. High temperature

6) Set the fan OFF temperature. Low temperature

7) Select fan test interval, 5 minutes of xxx (1 – 99 hrs) or disable by entering

000

8) Select FCD; NO. If YES, set sensitivity 1 to 30

Higher numerical values offer faster response time under fault conditions

Push ENT key to return to normal operation

Unit will perform light test and return to normal operation.

Programming Sequence

1) To begin programming, press the PRG key for approximately seven

seconds. After this inter val the main screen display will present the

message PRG. The unit will then advance to the first program selection,

and the yellow PROG light above the PRG key will illuminate. After each

selection press the PRG key to advance to the next selection. At any time

during the program sequence you may discontinue by pressing the ENT

key. To enter programming again you must repeat the sequence above.

2) To review the entered values, momentarily press the PRG key and continue

to do so advancing to each programmed value. If the yellow LED is not

on, no program changes are possible

3) After advancing to any program selection, use the up/down keys to enter

your selection, or set point value.

During the programming sequence a timer allows 60 seconds for any input. If

time elapses and no input is made the unit reverts to normal operation.

As the unit advances to each of the program selections the main LED screen

will display a message or set point value.

When entering set point values for all selections, green, yellow and red

LED’s will illuminate providing reference to the functions and channels.

End of program

Exclusive Canadian Distributor

EL Switchgear & Control Inc

Ph: 1 800 463 1275 Fax 1 519 753 5755

E Mail elsc@on.aibn.com

February 19, 2007

8

Programming (Cont.)

4) Select fan operation

Exclusive Canadian Distributor

EL Switchgear & Control Inc

Ph: 1 800 463 1275 Fax 1 519 753 5755

E Mail elsc@on.aibn.com

February 19, 2007

Enter Program Values

1) Input set point temperature value for alarm

Screen display: numerical value, yellow alarm LED flashing, green chn

indicators 1-2-3

Action: Scroll up/down, using up down keys

Options: 0-240°C (32-464°F)

Complete: Press PRG —Advance

Discontinue: Press ENT

2) Input set point temperature value for trip

Screen display: numerical value, red trip LED flashing green chn

indicators 1-2-3

Action: Scroll up/down using up-down keys

Options: 0-240°C (32-464°F)

Complete: press PRG -Advance

Discontinue: Depress ENT

3) Select channel 4

Screen display: YES

Action: Scroll up/down using up-down keys

Options: Yes / No

IF YES: Set alarm & trip temperatures specific to chn 4 repeat steps 1& 2

Complete: press PRG -Advance

Discontinue: press ENT

Screen display: NO Yellow fan LED flashing

Action: Scroll up/down using up-down keys

Options: NO , or choice of channel 1-2-3 or 4

Select channels 1-2-3 or 4 using up down keys. Green channel indicators

will change. Press PRG to select.

Enter fan ON temperature (high) press PRG set value. Press PRG

Enter fan OFF temperature (low) press PRG set value. Press PRG

Set fan test interval Hfn (1hr to 99 hrs) Press PRG set value, or ooo to

disable

Complete: Press PRG - Advance

Discontinue: Press ENT

5) Select FCD operation

Screen Display: FCD flashing, NO , or numeric value ( NO, is factory

default)

Action: Scrol l up/down using up-down keys

Options: NO (disable feature) or 1 to 30 to enable feature

Numeric value represents response time 1=slow 30=fast

Complete: Press PRG -Advance

Discontinue: Press ENT

END OF PROGRAM

PRESS PRG to return to step #1

Or ENT to return to normal operation

9

Pictorial

Exclusive Canadian Distributor

EL Switchgear & Control Inc

Ph: 1 800 463 1275 Fax 1 519 753 5755

E Mail elsc@on.aibn.com

February 19, 2007

10

TECSYSTEM S.r.i

TECHNICAL SPECIFICATIONS

Auxiliary Power Supply

• Rated voltage 24-240 Vac-dc

• Maximum ratings 20.270 Vac-dc

• Vdc with reversible polarities

Inputs

• Four inputs RTD PT 100 sensors – 3

wires

• Removable rear terminals

• Input channels protected against

electromagnetic noises and spikes

• Sensors length cables compensation up

to 500 m (1 mm²)

Tests and Performances

• Assembling in accordance with CE rules

• Protection against electrical and

magnetic noises: CEI-EN500812/50082-2

• Dielectric strength 2500 Vac for 1 min.

from relays to sensors, relays to power

supply, power supply to sensors

• Accuracy: ± 1% full scale, ± 1 digit

• Ambient operating temperature -20ºC to

60ºC (-4ºF to 140ºF)

• Humidity 90% non-condensing

• ABS self -extinguishing housing

NORYL 94VO

• Frontal in polycarbonate IP54

• Burden 3Va

• Data storage 10 years minimum

• Digital linearity of sensors signal

• Self-diagnostic circuit

• Opt. Protection treatment of electronic

part

• Opt. frontal plastic protection

Dimensions

• 96 x 96mm (3.78 x 3.78 in.) – DIN

N43700-Prof. 127 mm deep 5.51” (with

rear terminals)

• panel cutout 92 x 92mm (3.62 x 3.62)

Communication

• Not available

Outputs

• Three alarm relays (Alarm -Trip-Fan)

• One-alarm relay for sensor fault or wo rking

anomaly (FAULT)

• Output contacts capacity: 5A-250Vac res.

• Arranged for output relays test

Display and Data Management

• One display, 13mm (0.5 in.) high 3 digit with 3

digit for displaying temperatures

• LED for displaying reference channel

• Eight LEDs indicating alarm or trip

• LED indicating fault, LED indicating fan

• Temperature monitoring from 0-240°C (32 -

464°F)

• Separate alarm and trip values

• Sensors diagnostic (Fcc-Foc-Fcd)

• Program entry by frontal push button

• Automatic output from programming cycle after

1 min. of no operation

• Wrong programming automatic display

• Programmed data call out

• Possibility of setting manual channel scanning

or hottest channel

• Maximum temperatures storage

Exclusive Canadian Distributor

EL Switchgear & Control Inc

Ph: 1 800 463 1275 Fax 1 519 753 5755

E Mail elsc@on.aibn.com

February 19, 2007

11

Testing All relays may be tested using the following procedure:

1) Press and hold the TEST key for 7 seconds. The main screen display will

flash TST and then default to an active test of the fault relay

2) Release the test key when the yellow test on LED illuminates. The screen

display will show OF F and the red LED indicating fault relay is

illuminated.

3) Test the fan, fault, alarm or trip relay. Use the Scroll up/down keys to make

the selection. The screen display will show the relay selected for testing.

LED’s illuminate identifying the relay being tested. Press the SET (white

print) key and check for contact operation. To reset press the RESET

(white print) key.

4) To discontinue operation and revert to normal operation, press the TEST

key.

At the start of the test, a timer is automatically initiated which reverts the unit

to normal operation if no inputs are detected for a period of five minutes

Temperature Simulation

Connect fixed or variable resistors across all channels to simulate RTD inputs.

All resistors must be connected to the input channel using the three

terminations provided. This is achieved by terminating the resistor to the two

lowest termination numbers of each channel with a jumper from the middle to

highest number

Example Channel #1

Termination #’s 13-14-15

Connect the resistor across 13-14

Connect the jumper from 14-15

Repeat for channels two, three. and four

The resistance values for all inputs must be variable between 100 and 200

ohms.

Connect the T154 to a suitable power supply.

Set the resistance value to a corresponding temperature value for the RTD

type being used. All RTD’s have published resistance vs temperature values

For 100 ohm platinum a resistance value of 175.84 ohms will yield 200ºC A

resistance of 138.50 ohms yields a temperature of 100ºC Check to verify the

readings on the main display.

The unit is completely functional with the resistors connected, and complete

evaluation is possible by following the instruction manual.

Warranty The T154 is warranted for a period of 12 months from date of shipment.

Warranty is lim ited to repair or replacement of the defective product and no

contingent liabilities will be accepted.

Warranty will be voided if the unit is found to be tampered with or it has been

damaged as a result of incorrect input or power supply connections, or is

damaged as a result of transitory over voltages.

Freight expense is not covered under warranty.

Exclusive Canadian Distributor

EL Switchgear & Control Inc

Ph: 1 800 463 1275 Fax 1 519 753 5755

E Mail elsc@on.aibn.com

February 19, 2007

12

Troubleshooting

Problem Causes / Solution

The unit will not switch on, with control power

energized

The sensor is damaged The fault relay closes and the fault LED

The fault relay has tripped , and the main screen

is displaying FOC/FCC

Check the terminal block for correct installation

Check for voltage at terminal block

switches on. The red LED of the respective

channel is illuminated. A message is displayed.

FOC- sensor open

FCC- sensor is short circuited

Check the sensor connections.

Look for damaged sensors.

Replace damaged sensor

When switching the unit on-off, alarm and trip

relays energize

All the sensors are displaying FCC Wrong wiring connections

The temperature indicated by one, or more

channels is wrong

Sudden operation of trip relay, with normal

operating temperature,

One channel caused the occurance

With a power supply of 24VDC the unit,

switches off and will not switch back on

Strong electrical noise is being picked up on the

power line.

Install a transient suppressor (PT73)

Check to ensure the shield of the sensor cable is

connected to the panel ground

Install shielded cable, or twist the sensor

conductors

The terminal block is upside down

RTD’s are not compatible

The sensors are defective.

Check the sensor resistance for compatability,

with your unit.

The unit is calibrated incorrectly

Return for repair

Sensor defective FCD

Replace the sensor

Check the input voltage is between

20-24VDC

Reconnect to a stable source of power Return if

unit does not respond

Exclusive Canadian Distributor

EL Switchgear & Control Inc

Ph: 1 800 463 1275 Fax 1 519 753 5755

E Mail elsc@on.aibn.com

February 19, 2007

13

Options • Protective display cover

• 120 or 100 ohm nickel RTD input

Approvals • Assembled in accordance with CE rules.

• Protection against electrical and magnetic noises CEI-EN50081-2/50082-2

• C-UL approval, File No, 190427

Exclusive Canadian Distributor

EL Switchgear & Control Inc

Ph: 1 800 463 1275 Fax 1 519 753 5755

E Mail elsc@on.aibn.com

February 19, 2007

14

Loading...

Loading...