TECSYSTEM S.r.l.

20094 Corsico (MI)

Tel.: +39-024581861

Fax: +39-0248600783

NT210 K

TPL503

INSTRUCTION MANUAL

ENGLISH

1MN0079 REV. 0

operates with ISO9001:2008 certified quality system

“Translations of the original instructions”

http: //www.tecsystem.it

R. 1.5 31/01/18

2

NT210 K

PAGE

1) SAFETY REQUIREMENTS

…………………………………..

4

2) ACCESSORIES

…………………………………..

5

3) TECHNICAL SPECIFICATIONS

…………………………………..

6

4) TPL503 SENSOR INSTALLATION PROCEDURE

…………………………………..

8

5) FRONT PANEL

…………………………………..

10

DISPLAY

…………………………………..

11

CHECKING THE WORK PROGRAM

…………………………………..

—

LED TEST

…………………………………..

—

ALARM RELAY TEST

…………………………………..

—

ALARM RELAY SILENCING (AL1)

…………………………………..

—

5) INSTALLATION

…………………………………..

12

6) ELECTRICAL CONNECTIONS

…………………………………..

13

NT210

…………………………………..

—

POWER SUPPLY

…………………………………..

14

ALARMS AND VENTILATION

…………………………………..

—

COOLING FAN CONTROL

…………………………………..

15

FAN TEST

…………………………………..

TPL503 CONNECTIONS

…………………………………..

—

PROGRAMMED DATA DIAGNOSTICS

…………………………………..

—

TEMPERATURE MEASUREMENT (T)

…………………………………..

—

PRESSURE MEASUREMENT (P)

…………………………………..

16

PRESSURE SENSOR ZEROING

…………………………………..

—

LEVEL MEASUREMENT (L)

…………………………………..

—

7) PROGRAMMING

…………………………………..

17

NOTES ON THE FCD FUNCTION

…………………………………..

19

NOTES ON THE FPS FUNCTION

…………………………………..

—

INTRODUCTION

First of all we wish to thank you for choosing to use a TECSYSTEM product and recommend you read this instruction

manual carefully: You will understand the use of the equipment and therefore be able to take advantage of all its

functions.

ATTENTION! THIS MANUAL IS VALID AND COMPLETE FOR THE NT210 K VERSION COMBINED WITH THE

TRANSPARENT TPL503 SENSOR.

3

NT210 K

PAGE

8) RS485 MODBUS OPTION

…………………………………..

20

INTRODUCTION TO THE MODBUS INSIDE

…………………………………..

—

OPERATING NOTES

…………………………………..

—

DATA TRANSMISSION ON MODBUS NETWORK

…………………………………..

—

RS485 ELECTRICAL CONNECTIONS

…………………………………..

—

DATA FRAME

…………………………………..

—

DATA PACKET

…………………………………..

—

FUNCTION CODE

…………………………………..

21

CODE 3(10).

…………………………………..

—

CODE 16(10).

…………………………………..

—

NOTES FOR REMOTE PROGRAMMING

…………………………………..

—

ERROR CODES (exception code)

…………………………………..

—

POLLING FREQUENCY

…………………………………..

—

MODBUS MAPPING TABLE

…………………………………..

22

CRC CALCULATION

…………………………………..

29

PARAMETER DESCRIPTION

…………………………………..

—

ALGORITHM

…………………………………..

—

12) WARRANTY REGULATIONS

…………………………………..

—

13) TROUBLESHOOTING

…………………………………..

30

14) EQUIPMENT DISPOSAL

…………………………………..

—

15) USEFUL CONTACTS

…………………………………..

—

4

NT210 K

SAFETY REQUIREMENTS

Read the manual carefully before starting to use the control unit. Keep the instructions for future reference.

Do not open the device, touching any internal components can cause electric shock. Contact with voltage over

50 Volts can be fatal. To reduce the risk of electric shock, do not dismantle the back of the device for any reason.

Moreover its opening would void the warranty.

Before connecting the device to the power supply, make sure that all the connections are correct. Always

disconnect the unit from the supply before any cabling modification.

Any intervention on the equipment must be entrusted to a qualified repair engineer

Failure to comply with these instructions can cause damages, fires or electric shock, and possible serious

injuries!

POWER SUPPLY

The NT210 K series has UNIVERSAL power supply, i.e. it can be supplied by 24 to 240 Vac-Vdc, irrespectively of polarity

in Vdc.

Before using it, make sure the power cable is not damaged, kinked or pinched. Do not tamper with the power cable.

Never disconnect the unit by pulling the cable, avoid touching the pins. Do not carry out any connecting/disconnecting

with wet hands. To disconnect the device, do not use objects such as levers. Immediately disconnect the device if you

smell burning or see any smoke: contact technical service.

LIQUIDS

Do not expose the equipment to splashes or drops, do not position it in places with humidity exceeding 90% and never

touch with wet or humid hands during storms. If any liquid penetrates the control unit, disconnect it immediately and

contact technical service.

CLEANING

Disconnect the power cable before cleaning the control unit, use a dry cloth to dust it, without any solvent or detergents,

and compressed air.

OBJECTS

Never insert any objects into the cracks of the control unit. If this happens, disconnect the control unit and

contact an engineer.

USE RESERVED TO QUALIFIED PERSONNEL

The purchased goods are a sophisticated electronic device that is totally unsuitable to be used by non-qualified

personnel. Any intervention must be carried out by a specialist engineer.

ACCESSORIES

The use of non-original accessories or spare parts might damage the unit and endanger users' safety. In the event of

faults, contact technical service.

LOCATION

Install the control unit indoors, in a place protected from water splashes and sun rays. Do not place near heat sources

exceeding the parameters stated in this manual. Position on a stable surface, far from any possible vibrations. Position

the unit as far as possible from any intense magnetic fields.

REPAIRS

Do not open the control unit. For any fault, always use qualified personnel. The opening of the control unit and/or the

removal of the series identifying label entails the automatic forfeiture of the warranty. The Warranty seal is applied to all

devices, any attempt to open the unit would break the seal and cause the consequent automatic forfeiture of the warranty.

TECHNICAL INFORMATION

Mail: ufficiotecnico@tecsystem.it — tel: 02/4581861

ATTENTION:

5

NT210 K

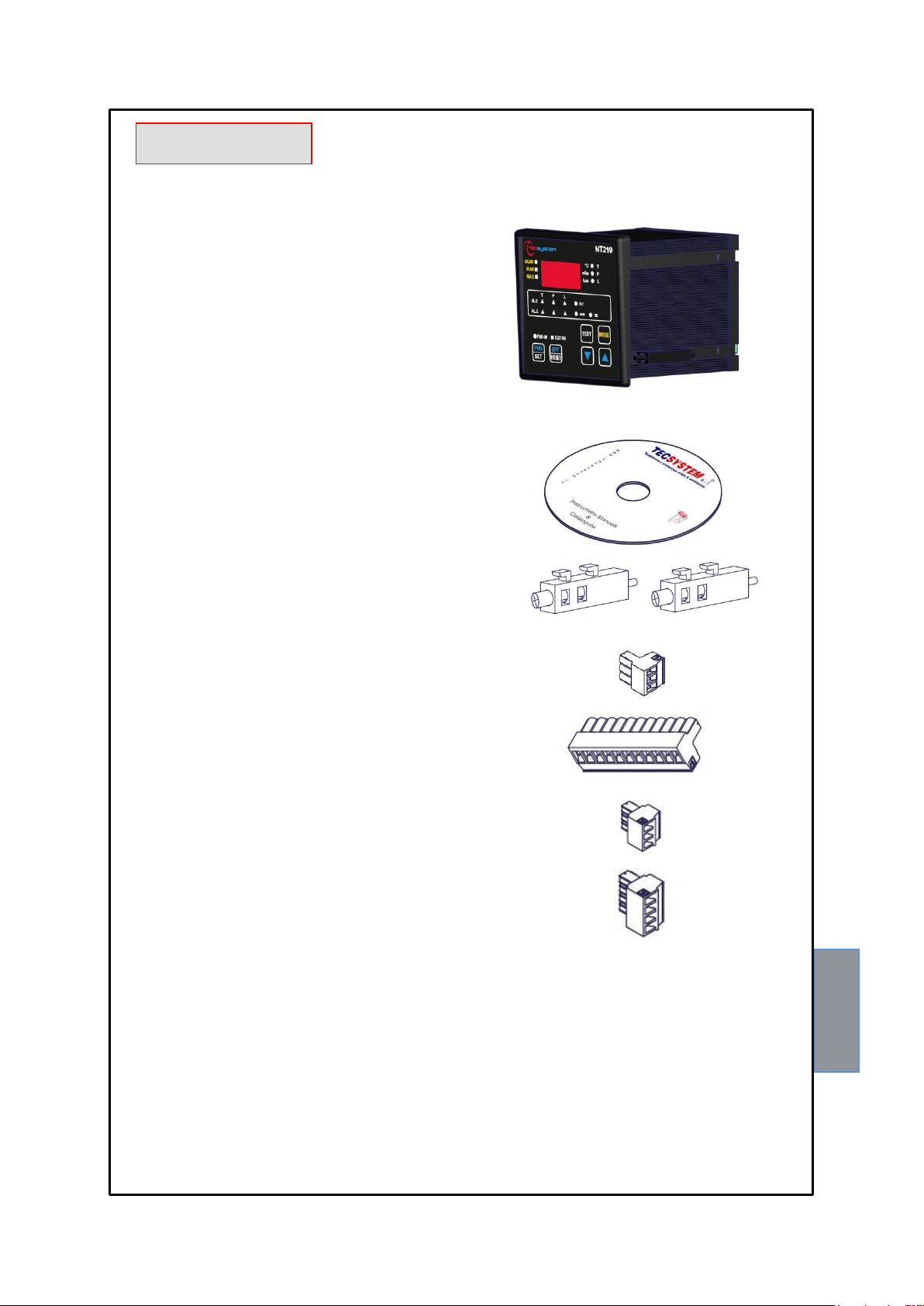

ACCESSORIES

The following objects are present inside the box:

Control unit

Instruction manual CD

2 blocks for panel mounting

1 supply terminal 3 poles pitch 5

Code: 2PL0367- Screws tightening torque 0.5Nm

1 relay terminal 11 poles pitch 5

Code: 2PL0359 - Screws tightening torque 0.5Nm

1 RS485 terminal 3 poles pitch 3.81

Code: 2PL0366 - Screws tightening torque 0.25Nm

1 TPL503 sensor Tecsybus terminal 4 poles pitch 3.81

Code: 2PL0368 - Screws tightening torque 0.25Nm

1MN0030 REV. 1

ATTENTION: always install the device using the terminals included in the pack. The use of terminals

other than those included with the control unit might cause malfunctions.

6

NT210 K

TECHNICAL SPECIFICATIONS

NT210 K

POWER SUPPLY

Supply rated values

24-240 Vac-Vdc (50/60Hz)

Supply min/max values

20-270 Vac-Vdc (50/60Hz)

Vdc with reversible polarities

●

INPUTS

Digital input for the connection with the TPL503 sensor

●

OUTPUTS

2 alarm relays (ALARM AND TRIP) SPDT

●

1 fault sensor or operating failure (FAULT) relay SPDT

●

Output relay with 5A-250Vca-res COSФ=1 contacts.

●

Ventilation management relay SPST

FAN

Power-link output (9Vdc 100 mA max.) to feed the TPL503 sensor.

●

COMMUNICATION

RS485 Modbus RTU serial output

●

DIMENSIONS

100x100 mm– din43700-depth 131mm (terminal block included)

Hole 92 x 92 mm

TEST AND PERFORMANCE

Construction in compliance with CE regulations

●

Protection from electrical interference EN 61000-4-4

●

Dielectric strength 1500 Vac for 1 minute between relays and supply, relays and power-link,

relays and RS485 input, power-link and supply, RS485 input and supply.

●

Ambient operating temperature from –20°C to +60°C

●

Humidity 90% non-condensing

●

Housing NORYL 94 _V0

●

Absorption 5VA

●

Data storage: 10 years minimum

●

IP65 polycarbonate front film

●

Electronic protection only on customer's request

Option

DISPLAY AND DATA MANAGEMENT

1 x 13 mm display with 3 digits to display T-P-L values and messages

●

3 LEDs to show the displayed oil temperature (°C), pressure (mbar) and level.

●

6 LEDs to show the T-P-L alarm status

●

7

NT210 K

TECHNICAL SPECIFICATIONS

NT210 K

1 LED to show the correct connection of RS485 with TPL503

●

Temperature control: from 0°C to + 120°C

●

Oil pressure reading: from -400 to 500 mbar (DEP indication for negative value)

●

Oil pressure controls: from 0 mbar to 500 mbar

●

Level control in 3 modes (FULL - ALARM - TRIP ).

●

2 alarm thresholds (AL.1/AL.2) for temperature, pressure and level.

●

1 threshold for the quick increase of the programmable pressure (FPS)

●

1 threshold for the quick increase of the programmable pressure (FCD)

●

2 thresholds for ventilation ON-OFF control, controlled by the oil temperature

●

Incorrect programming warning

●

Selection of the data display mode between automatic and manual scan and memory.

●

Maximum temperature and pressure memory recorded since the last reset

●

Front alarm reset button

●

Sensor fault diagnostics (FLT)

●

TPL503 TECHNICAL SPECIFICATIONS

TPL503

POWER SUPPLY

Direct connection to the Power-link source of the NT210 K control unit.

9VDC 100mA max

MEASURED QUANTITIES

Oil temperature: from –20 to +120°C

●

Resolution: ±1°C

●

Accuracy: ±1% full scale value

●

Oil pressure: from -400 to 500 mbar

●

Resolution: ±10 mBar

●

Accuracy: ±2% full scale value

●

Level in 3 modes (FULL - ALARM - TRIP ).

●

TEST AND PERFORMANCE

T.P.L. parameter management in compliance with the IEC EN 50216-3/A standard

●

Protection from electro-magnetic interference IEC EN 61000-4-4

●

Dielectric strength 2500 Vac for 1 minute

●

Operating temperature of the electronic part: -20°C to + 85°C

●

Self-diagnosis circuit of the T-P-L sensors.

●

Maximum cable length: 40 m (4 wires AWG22/24, shielded, impedance 120 ohm)

●

Pressure sensor resistant to the corrosion of mineral oil.

●

8

NT210 K

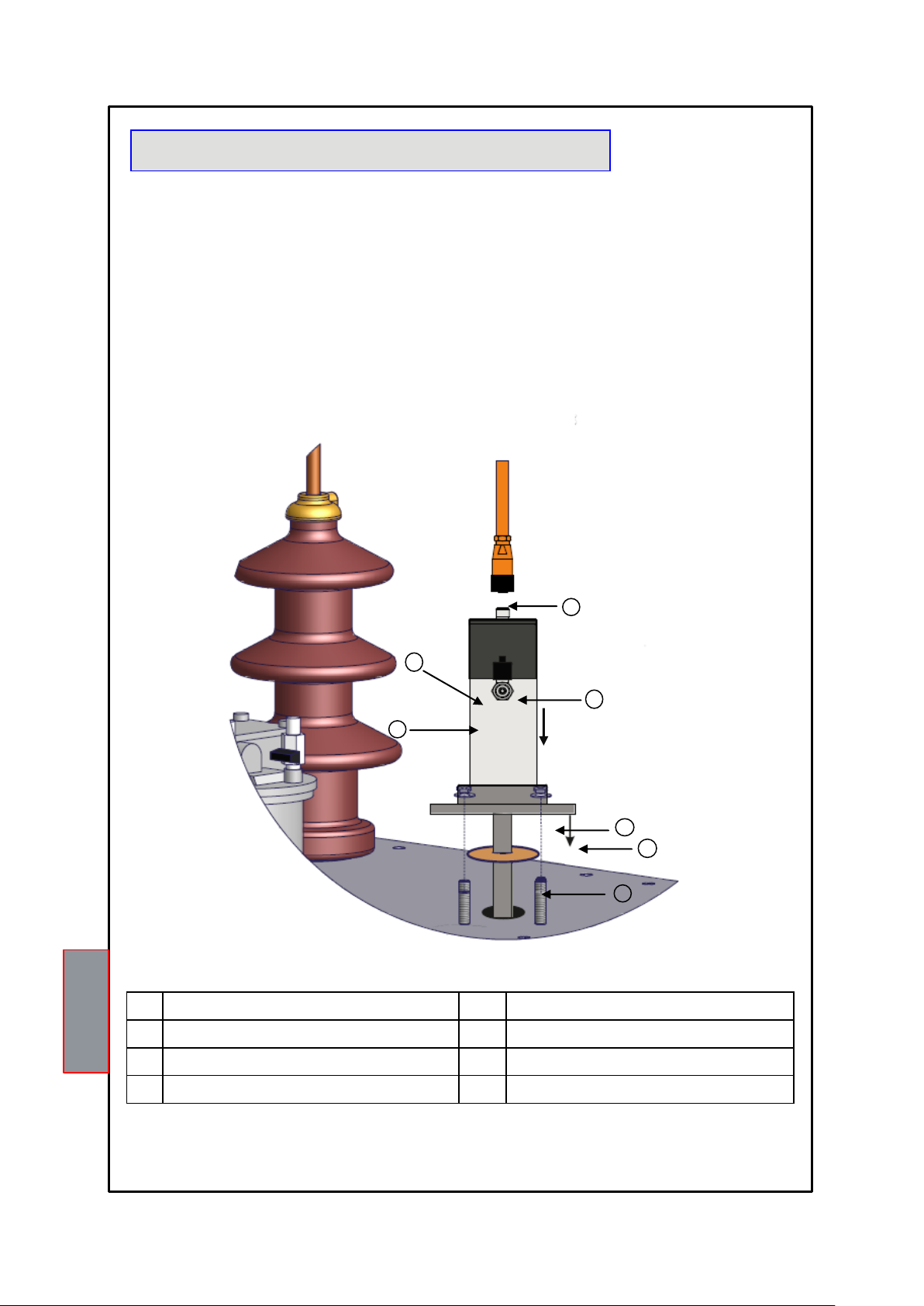

1)

Cork- rubber gasket

5)

Air release tap

2)

TPL503 sensor base

6)

Air release tap plug

3)

Flange fixing bolts and washers

7)

TPL503 data and supply cable

4)

TPL503 sensor and closing gasket OR

1MN0073 REV. 2

2

3

6

4

7

NOTE: The sensor stem is inserted 10cm inside of the transformer, the TPL503 must not interfere with other internal

elements; In addition w e suggest always to respect the safety distance between the sensor and the live parts of the

monitored machine .

INTRODUCTION

The TPL503 sensor is fitted on the transformer cover in oil sealed box with integral filling.

The installation method is described below just for information purposes; the installer is fully responsible for the

installation.

INSTALLATION PRECAUTIONS

The transformer must be disconnected.

The transformer dielectric fluid must be at ambient temperature (about 20°C).

The level of dielectric fluid must be slightly below the transformer cover.

The TPL503 hole on the transformer must be open .

The installing area of the sensor must be free from welding or painting residue and perfectly clean.

The cork- rubber gasket, TPL base, must adhere fully to the support surface (note: replace the gasket every time it is

removed to the TPL base)

NECESSARY TOOLS

A 13x13mm spanner

A 5mm Allen wrench (inbus)

9

NT210 K

STEP BY STEP DESCRIPTION pictures on page 8.

NOTE: Bolts and washers for securing the sensor are not supplied by Tecsystem.

1) Following the suitably sized hole centering on the transformer fixing pins: insert the cork rubber (1) and mounting the

TPL503 base (2) into the appropriate hole in the transformer cover.

2) Insert the 4 washers (3) in the fixing pins.

3) Insert the bolts (3) onto the fixing pins and screw them in, use the 13x13 spanner, tighten but without straining

(strength recommended 8 Nm).

4) Check that the air release tap (5) is OFF.

5) Filling/Finish to fill the transformer.

6) Insert OR ring on the TPL503 base and tightening the TPL503 sensor (4) immediately over the base to its end.

7) Remove the plug on the air release tap (6), use the 5mm Allen wrench (tighten but without straining).

8) Remove the protection cap on the data / supply connector.

9) Connect the data / supply cable (7), tighten the connector manually (TPL503 connection on page 15).

10) Open the release tap (6), position ON, until the oil shows no air bubbles (sensor air bleeding), turn the tap to the OFF

position. Repeat the operation until all the air is released.

Attention: bleeding must be carried out taking into consideration the transformer operating conditions, with the

transformer switched off and a temperature of about 20°C (or ambient); the installer or maintenance engineer takes full

responsibility for this operation.

11) Insert the tap plug (6) and screw fully in, using the 5mm Allen wrench.

12) Zero the pressure sensor, see page 16.

13) With the transformer switched off, checking the values displayed by the control unit:

Temperature (ambient) - Pressure (000) - Level (full)

14) Mark the closing TPL503 sensor (4) with a label.

NOTES ON THE ASSEMBLY

The installation of the sensor must be carried out by a specialized engineer following the above procedure carefully.

For a correctly working of the system, the oil level must be in line with the release tap (6).

The end of the stem (temperature measurement) is placed 10cm below the transformer cover.

Before starting the transformer, always check the bolts are tightened and bleed the air.

The bolts loosening or the presence of air in the system might cause malfunctioning.

The presence of air bubbles might affect the level reading, therefore it is necessary to check there is no air in the system.

Filling or topping up the oil must be done with the transformer switched off and cold (ambient temperature about 20°C).

10

NT210 K

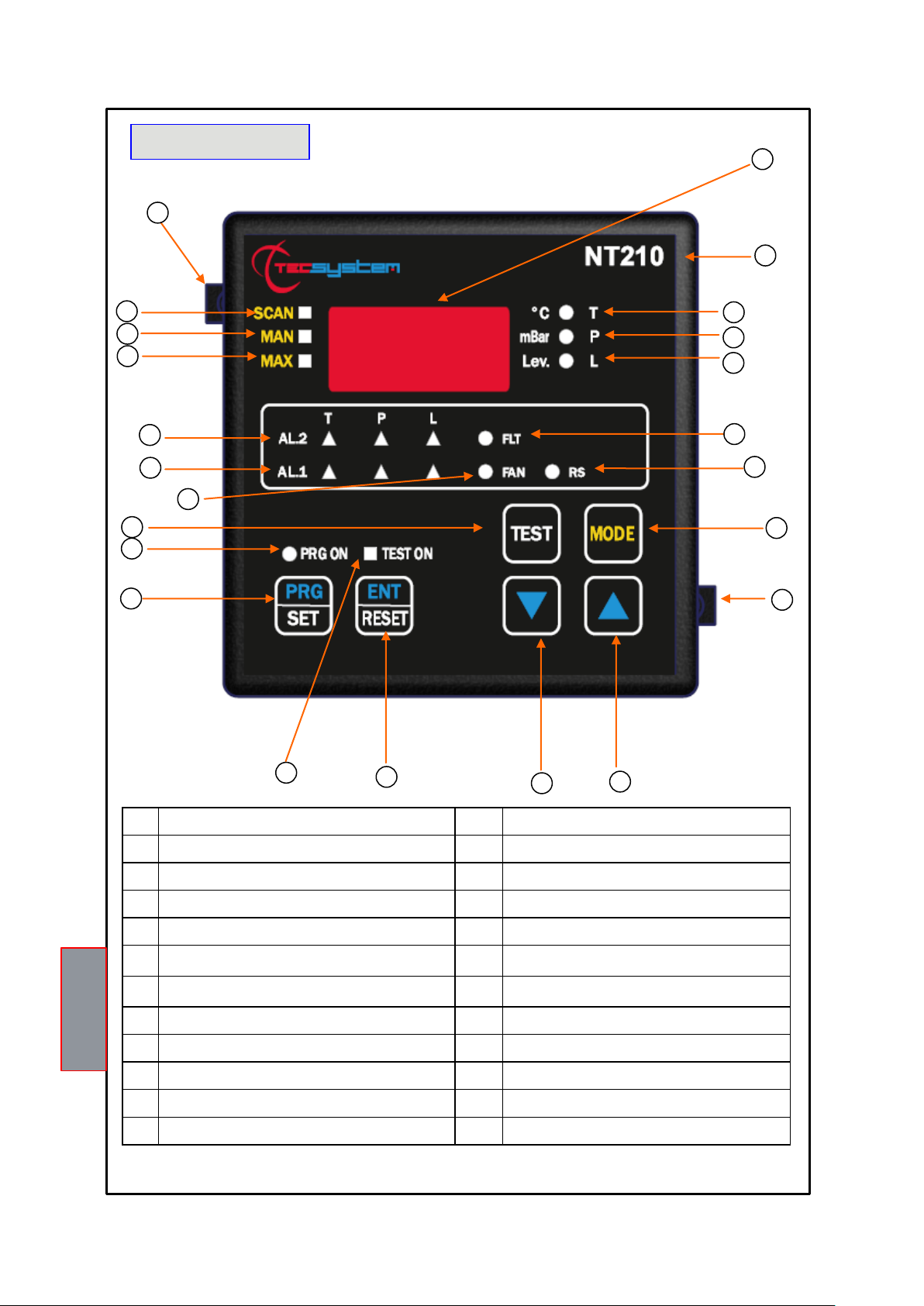

FRONT PANEL

1)

3-digit display

13)

Relay ON test (yellow) LED

2)

Control unit series

14)

Programming button

3)

Temperature display (green) LED

15)

PRG ON (yellow) LED

4)

Pressure display (green) LED

16)

LED/relay test button

5)

Level display (green) LED

17)

FAN warning (green) LED

6)

FAULT warning (red) LED

18)

T-P-L alarm activation AL1 (red) LED

7)

RS communication (TPL503) (green) LED

19)

T-P-L alarm activation AL2 (red) LED

8)

Scanning mode selection button

20)

T-max mode selection (red) LED

9)

Fixing block

21)

Man mode selection (yellow) LED

10)

UP button

22)

Scan mode selection (yellow) LED

11)

DOWN button

23)

Fixing block

12)

Enter/Reset button

1 2 3 4 5

6 7 8 9 10

11

12

13

15

14

16

17

18

19

20

21

1MN0079 REV. 0

22

23

11

NT210 K

If one of the LEDS does not work, please return the control unit to TECSYSTEM for repair.

DISPLAY

Pressing the MODE button, the display viewing modes are set:

SCAN: the unit displays the T-P-L values scanned (every 2 seconds)

MAN: manual reading of the T-P-L values using the up/down buttons

T.MAX: the unit displays the maximum temperature and pressure values reached, the minimum level recorded

and the possible alarms or faults that have occurred after the last reset.

Select the channels with , zero the values with RESET.

CHECKING THE WORK PROGRAM

To check the set protection levels, press the PRG button briefly.

Vis appears for 2 seconds, confirming you have entered viewing mode.

By pressing the PRG button repeatedly, all the previously set values are scrolled through in sequence.

After 1 minute's keyboard inactivity, the programming viewing procedure is automatically abandoned.

To end viewing, press the ENT button.

LED TEST

We recommend the unit LEDs are tested regularly.

For this operation press the TEST button briefly, all the displays light up for 2 seconds.

ALARM RELAY TEST

This function allows carrying out a test of the relay operation without having to use supplementary equipment.

To start the test procedure, keep the TEST button pressed for about 5 seconds: TST is displayed for 2 seconds, confirming

you have entered the Relay Test mode.

The flashing LED shows the relay to be tested, select the desired LED with the sliders.

Press the SET and RESET buttons to energise and de-energise the relay to be tested, ON-OFF appears on

the display. After 1 minute's keyboard inactivity, the RELAY TEST procedure is automatically abandoned. To

end the RELAY TEST procedure, press the TEST button.

AL1 ALARM RELAY SILENCING

If you wish to silence the ALARM, press the RESET button: the relay is de-energised and the AL1 LED, that was ON,

starts flashing.

Silencing is automatically disabled when the temperature goes below the alarm threshold.

12

NT210 K

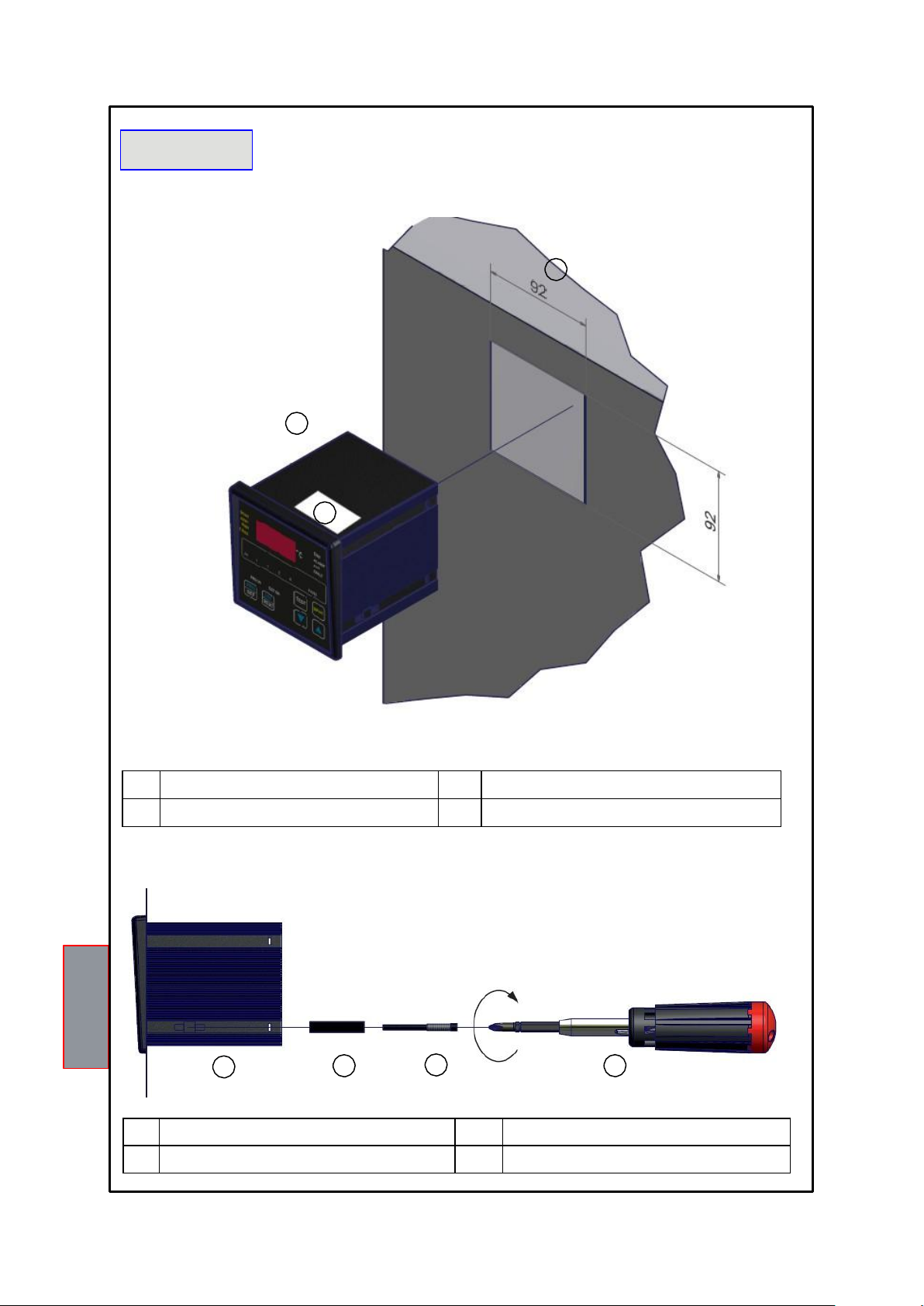

1

1)

Control unit

2)

Panel hole dimensions (+0.8mm tolerance)

3)

Identification label

1)

Control unit

3)

Fixing screw

2)

Fixing block

4)

Crosshead screwdriver #1X100mm

MOUNTING

Drill a 92 x 92 mm hole in the panel sheet.

2

1

3

1MN0007 REV. 0

Fix the unit securely with the blocks supplied.

1 2

3

4

1MN0008 REV. 0

13

NT210 K

1)

Power supply (24-240 Vac-dc 50/60Hz)

3)

RS485 Output

2)

Relays (ALARM-TRIP-FAULT-FAN)

4)

TPL503 sensor connection

ELECTRICAL CONNECTIONS

1 2 3 4 1MN0053 REV. 0

RELAY CONNECTION EXAMPLE

SENSOR CONNECTION

Output relay with 5A-250Vac-res COSФ=1 contacts

LIGHT

SIGNAL

SYSTEM

STOP

AUDIO

SIGNAL

NT210 K

NOTE: Carry out the electrical connections on the removable terminal blocks only after disconnecting them from the unit.

Connector

Connector connection colours:

1.

+ RS white

2.

+ PWL brown

3.

- PWL black

4.

- RS Blue

Note: with the power to the unit ON, the FAULT relay switches, contacts 8-9 open (NO) and 7-9 closed (NC), read paragraph

ALARMS AND VENTILATION page 14

FAULT 8-9 NC: ALARM FAULT OR POWER OFF FAULT 7-9: NC POWER ON

7 8 9

7 8 9

14

NT210 K

To protect the control unit from line overvoltages, we recommend using the electronic PT-73-220 surge limiter,

designed by TECSYSTEM S.r.l. specifically for this purpose.

Alternatively we recommend 24 Vac or, even better, 24 Vdc supply voltages are adopted.

IMPORTANT WARNING

Before carrying out the insulation test of the electrical panel the control unit is installed on, disconnect it from the power supply

to prevent it from being seriously damaged.

POWER SUPPLY

The NT210 K control unit has UNIVERSAL power supply, i.e. it can be supplied by 24 to 240 Vac-Vdc, (50/60 Hz)

irrespectively of polarity in Vdc (terminals 40-42).

This is obtained thanks to the use of a tested power supply unit, newly designed and manufactured, that frees installers from

worrying about the correct Vac and Vdc supply.

Earth must always be connected to terminal 41.

When the unit is supplied directly by the secondary of the transformer to be protected, it can be burnt out by strong

overvoltages.

This happens if the main switch is closed and the transformer has no load (blank test). The above is much more

obvious when the voltage of 220 Vac is taken directly from the bars of the transformer secondary and there is a fixed

bank of capacitors to correct the power factor of the transformer itself.

If an existing control unit must be replaced with a new one, to guarantee its correct and safe operation, the

sensor/relay/supply connecting terminals must be replaced with the new terminals supplied.

ALARMS AND VENTILATION

When the control unit is in one of the modes mentioned below, it does not monitor the temperature and the relays are all

blocked.

Vis. programming display

PRG Programming.

Relay test.

The ALARM and TRIP relays switch only when the set temperature, pressure and level thresholds are exceeded.

The FAULT relay switches when the unit is powered, contacts 7-9 closed (NC) and 8-9 open (NO), and holds till one

of the following events takes place:

Data storage fault (Ech message).

TPL503 sensor fault:

1. ER0 -> communication error between TPL503 and NT210 K

2. ER1 -> faulty TPL503 internal temperature sensor

3. ER2 -> TPL503 electronic card temperature > than 85°C

4. ER3 -> TPL503 electronic card temperature < than -20°C

5. FLT T -> faulty oil temperature sensor

6. FLT P -> faulty pressure sensor

7. FCD -> quick increase in oil temperature (exceeding x °C/sec)

8. FPS -> quick increase in oil pressure (exceeding x mbar/sec)

Insufficient supply voltage.

During the power on reset after programming (PRG) of the control unit (local or via Modbus).

NOTE: do not connect the FAULT relay to the transformer tripping circuit to avoid unwanted system interruptions.

The FAN contact can be used to control the cooling fans or it can be inserted into the air conditioning system of the

room where the transformer is located.

NOTE: always disconnect the unit before performing any electrical connections.

15

NT210 K

COOLING FAN CONTROL

The NT210 K unit can control the cooling system of the oil temperature of the operating machine (i.e. ON at 80°C - OFF

at 70°C).

FAN TEST

By programming (HFn), it is possible to have the fans operating 5 minutes every "xxx" hours, regardless of the column

or ambient temperature values (i.e.: with HFn=001 the fans are activated for 5 minutes every hour).

This function aims at verifying the operation of the fans and their control apparatus periodically in periods when they

would not be used for a long time.

Setting 000 as a value inhibits the function.

TPL503 CONNECTIONS

The TPL503210 is fitted with an M12 IEC 947-5-2 connector that must be connected to the control unit with the cable

supplied, electrical connections are shown on page 13.

The signals present are power (POWER LINK) and data output (RS485). Note: All the

cables transferring signals must:

be separated from the power cables

be shielded cables with twisted conductors

have at least 0.5 mm² section

be twisted if there is no shield

be firmly fixed inside the terminal boxes

PROGRAMMED DATA DIAGNOSTICS

In case of failure of the internal memory or alteration of the programmed data, at start-up Ech is displayed

with the relative warning of the Fault contact.

In this case, for safety reasons, the default parameters are loaded automatically (see the programming table on pages

17 and 18 according to the model purchased).

Eliminate the Ech message by pressing RESET and enter the desired values.

Finally switch the unit off and back on to check the memory works correctly, if it is damaged Ech will be displayed again

(send the control unit to TECSYSTEM srl for repair).

TEMPERATURE MEASUREMENT (T)

The reading of the temperature takes place using an RTD Pt100 sensor placed at the end of the stem.

When the temperature exceeds the set pre-alarm threshold by 1°C (AL.1) the ALARM relay switches and the ALARM

LED comes ON while T. is displayed.

When the temperature exceeds the set alarm threshold by 1°C (AL.2) the TRIP relay switches and the TRIP LED comes

ON while T. is displayed.

As soon as the temperature goes back to values equal to or lower than the threshold set for the

ALARM and TRIP relays to switch, these relays deenergise and the relative LEDs switch off.

If the FCD function is activated and the set temperature increase speed is exceeded, the FAULT relay switches and

FCD is displayed on the screen.

With FCD the ALARM and TRIP functions are inhibited. Press

RESET to cancel FCD.

16

NT210 K

Level value

Display

Gas formation / loss

FULL (3)

0 cm³/90 cm³

ALARM /AL1 (2)

100 cm³/180 cm³

TRIP /AL2 (1)

190 cm³ and more

PRESSURE MEASUREMENT (P)

The pressure reading is made by a sensor placed under the head, through the specially provided opening.

The reading range of the sensor is -400 to + 500 mbar, the display negative values is made by indication DEP

and the relative value of depressure.

Setting for ALARM and TRIP contains just the positive value 0 to + 500 mbar.

When the pressure exceeds the set pre-alarm threshold (AL.1) by 10mbar the ALARM relay (AL1) switches, the

ALARM LED (AL1) comes on and P. is displayed. When the temperature exceeds the set pre-alarm threshold (AL2)

by 10 mbar, the TRIP(AL2) relay switches, the TRIP LED comes on and P. is displayed.

As soon as the pressure goes back to values equal to or lower than the threshold set for the ALARM and

TRIP relays to switch, these relays deenergise and the relative LEDs switch off.

If the FPS function is activated and the set pressure increase speed is exceeded, the FAULT relay switches and

FPS is displayed on the screen. In this case the ALARM and TRIP functions are always active.

PRESSURE SENSOR ZEROING

To benefit from the precision offered by the electronic pressure sensor, we recommend the scale value is zeroed

before starting the transformer that must be cold and stable at ambient temperature (±20°C):

1) Press the MODE button and go to MAX mode

2) Press MODE again without releasing it for 6 seconds until the control unit is reset.

This operation will allow compensating for any reading tolerances due to differences in altitude or transformer filling

pressure.

For the system to be operating correctly the transformer must be cold.

LEVEL MEASUREMENT (L)

The level sensor measures quantity of oil into the sensor TPL503 case; the reading is expressed in three different

modes:

When the level reaches 0 (L2 threshold activated), alarm AL2 is triggered due to the minimum level being exceeded

and the TRIP relay switches.

By enabling the Alarm function or AL1 (YES), see programming on page 17, the alarm relay is triggered when the

level reaches the loss value of 100 cm³, with NO the function is disabled.

By enabling the Trip function or AL2 (YES), see programming on page 17, the trip relay is triggered when the level

reaches the loss value of 190 cm³, with NO the function is disabled.

The TPL503 must be installed so that the base end position corresponds to the minimum level below the

transformer cover, below which the warning must be triggered and the transformer tripped.

IMPORTANT WARNING

The stated oil volume/level values refer to the use of mineral oils with the following density: 888 Kg/m³ at the

temperature of 15°C (mineral oil general specifications).

The presence of air bubbles inside the transformer is identified as formation of gas which can cause a decrease in the

level indication and the activation of the Alarm and Trip signals.

17

NT210 K

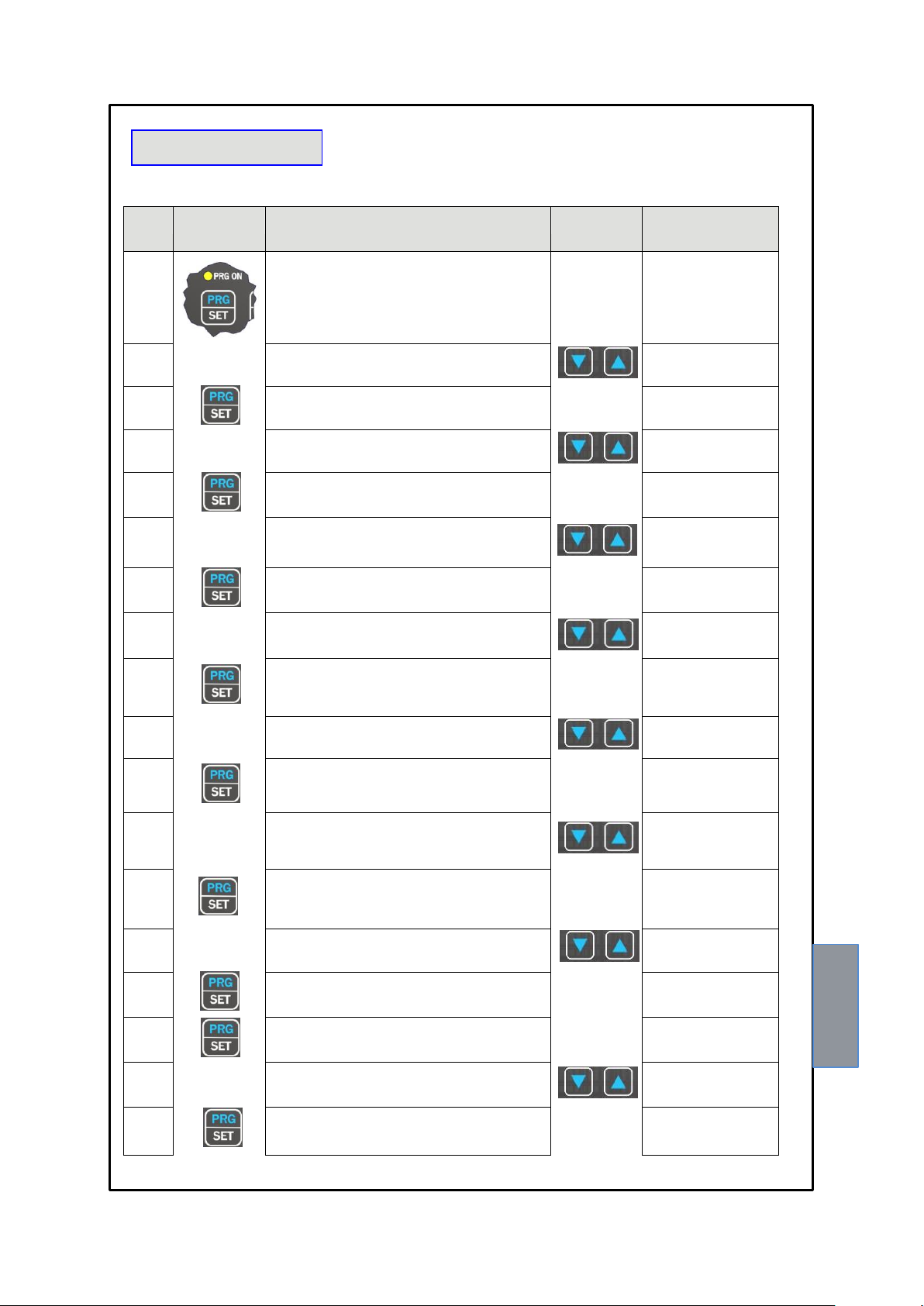

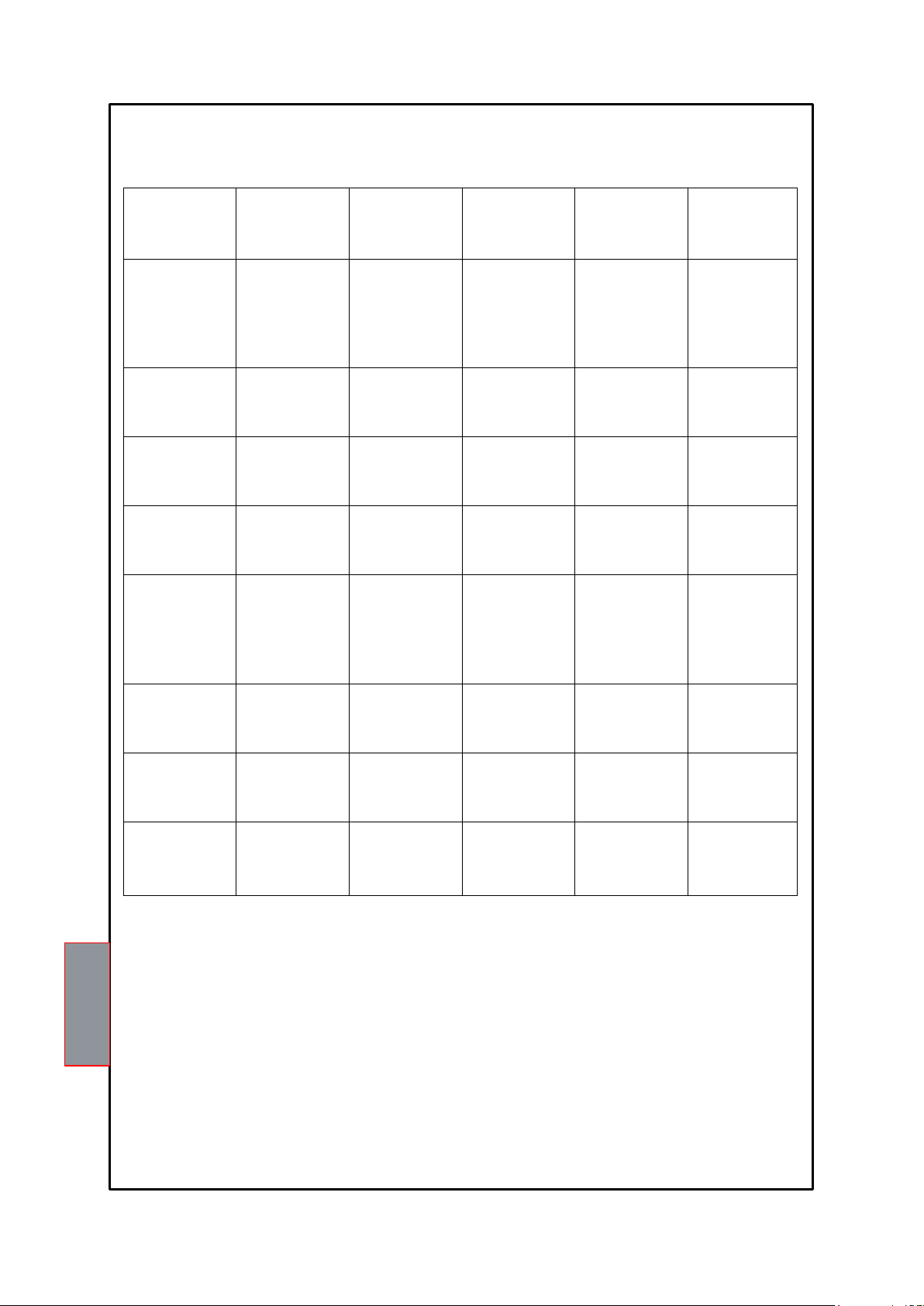

STEP PRESS

EFFECT

PRESS NOTES

1

Keep the PRG button pressed till the PRG-ON LED lights

up. After PRG the temperature ALARM (AL1) threshold is

displayed

2

Set the desired threshold

Default 80°C

3

The temperature TRIP (AL2) threshold is displayed.

4

Set the desired threshold

Default 90°C

5

The pressure ALARM (AL1) threshold is displayed

6

Set the desired threshold

Default 100mbar

7

The pressure TRIP (AL2) threshold is displayed.

8

Set the desired threshold

Default 200mbar

9

The level/gas ALARM (AL1) threshold is displayed

10

Select YES or NO

Default NO

11

The level/gas ALARM (AL2) threshold is displayed

12

Select YES or NO

Default YES

13

The Fan LED flashes and Yes/No is displayed

14

Select YES or NO

Default YES

15

ON is displayed

16

The ON threshold of the FANS is displayed

Default 70°C

17

Set the desired threshold

18

OFF is displayed

PROGRAMMING

NT210 K

18

NT210 K

19

The OFF threshold of the FANS is displayed

Default 60°C

20

Set the desired threshold

21

HFN is displayed

Cyclical test of the fans for 5

minutes every "n" hours

22

Display 000

Default 000= function disabled

23

Set the desired number of hours

Default 000

24

FCD <> "datum" is displayed

Fault due to quick temperature

increase (°C/sec) Default NO

25

Set the desired value (see page 19)

Default no "function excluded"

26

FPS <> "datum" is displayed

Fault due to quick pressure

increase (mbar/sec) Default NO

27

Set the desired value (see page 19)

Default no "function excluded"

28

ADR <> "datum" is displayed

Modbus address Default 001

29

Set the desired address

From 1 to 255

30

BDR <> "datum" is displayed

Modbus transmission speed

Default 9.6 Kb/s

31

Set the desired speed

From 2.4 Kb/s to 38.4 Kb/s

32

PAR <> "datum" is displayed

Parity bit selection

Default NO

33

Set the desired speed

None (No), Even (EVE), Odd

(ODD)

34

END is displayed

End of programming

35

Storing the settings and exiting programming

Err: incorrect programming of

the LED values (note 2)

36

Return to step 1

1)

It is possible to go back to the previous step by pressing the MODE button.

2)

If, when pressing ENT, "Err" is displayed, it means that one of the following errors have been made:

ALARM ≥ TRIP or FAN-OFF ≥ FAN-ON. Press PRG to go back to step 1 and correct the data.

3)

After 1 minute's keyboard inactivity programming is abandoned without saving the data.

4)

At the end of programming the FAULT relay is disabled till the control unit is restarted.

5)

During programming the control unit does not control/protect the monitored machine.

19

NT210 K

ATTENTION:

We recommend you check the control unit before starting the device.

The default parameters set by TECSYSTEM might not suit your requirements.

Programming the device is the end user’s responsibility: the set alarm thresholds and the

enabled functions described in this manual must be checked (by a specialized technician)

referring them to the application and system characteristics on which the control unit is

installed.

NOTES ON THE FCD FUNCTION

The NT series equipment boasts an innovative control function combined with the dynamic status of the Pt100 sensor

inside the TPL503.

Activating FCD, the control unit analyses the increase in temperature ∆T (*) recorded in a second (°C/sec).

Enabling the function, the user can select the value (∆T) from a minimum of 1°C/sec (2°F) to a maximum of 30°C/ sec.

(54°F). If the value sensed is higher than the value set by the user, the control unit inhibits the possible activation of the

ALARM and TRIP alarms and switches the FAULT relay (7-8-9), displaying the message "Fcd fault".

Example: if we set the function to 5°C, FAULT for FCD will switch only if the control unit senses an increase in ∆T of

over 5°C in a second on the monitored system.

Setting "no" disables the FCD function.

When a channel is in FAULT for FCD, the Alarm and Trip warnings are inhibited; therefore only the quick temperature

increase is highlighted.

Press Reset to delete the FCD warnings on all channels and reset the FAULT relay.

Possible FCD applications

Identification of a possible induced disturbance on the sensor line

If the installation instructions are not complied with (see TPL503 connections on page 15), any disturbance on the Pt100

sensor line may cause false readings or anomalous alarms.

Setting the FCD function in a temperature range of between 1°C and 10°C (5°C recommended), the effects caused by

false readings can be suppressed and the alarm relay activation can be prevented, as shown above.

Corrective actions: check the installation of the sensor extension cable is in line with the instructions given in the

paragraph on the TPL503 connections on page 15.

Identification of a sensor fault or faulty connection

In case of a faulty connection or sensor fault, a quick positive or negative variation in temperature might occur, leading

to the system tripping or the alarms of the monitored system to be triggered.

In this specific case we recommend the FCD function to be set in a temperature range of between 10°C and 20°C.

(*) The ΔT value shows the temperature range for each second.

NOTES ON THE FPS FUNCTION

Activating the FPS function it is possible to monitor quick increases in pressure.

If the pressure exceeds the set value in a second, the FAULT relay switches and FPS is displayed on the pressure

channel.

This increase can be set in steps of 10 mbar up to a maximum of 200 mbar.

Sensitivity is controlled by the value set, setting "no" disables the FPS function. Excessively low values might cause

warnings too often, while excessively high values would do the opposite.

In case of FPS, the relative Alarm and Trip thresholds are always monitored. Press Reset to delete the FPS warnings

and reset the FAULT relay.

20

NT210 K

MODBUS RS485 OUTPUT OPTION

INTRODUCTION TO THE MODBUS INSIDE MODULE

The MODBUS INSIDE expansion module is embedded in the control unit and allows transferring data on an RS485

network with MODBUS RTU protocol.

OPERATING NOTES

For the module to work correctly, the set-up parameters of the RS485 network must be set: address, baud rate, parity bits.

See programming steps 28 to 33 as shown in the table on page 18.

The serial communication of the temperature control unit is active only when the NT210 K is in temperature control

mode in one of the modes provided (Scan, Man and T.Max).

When other functions such as programming, programming display and relay test are activated, the ModBus

communication is temporarily disabled.

DATA TRANSMISSION ON MODBUS NETWORK

The MODBUS INSIDE internal module allows connecting the NT210 K control unit to an RS485 network with ModBus

RTU protocol. In order to read/write data remotely, read the paragraph notes for remote programming on page 21.

Note: the module is always in slave mode.

The NT210 K control unit communicates with the network only when it is in temperature reading mode, while it is inactive

when it is in the following modes: display, programming and relay test.

RS485 ELECTRICAL CONNECTIONS

As to the signal cable to use in order to guarantee correct network operation, follow standard EIA RS485 that

recommends the use of a 24AWG pair.

The pair that connects all the units in RS485 might require a 120 ohm terminating resistor on the last unit of the series.

Connect the pair taking polarities into account and lay the network avoiding to create tight bends or ring windings so as not

to change the line impedance. Place always the cable away from the power cable.

If necessary, the terminal for the GND earth connection is available.

DATA FRAME

The frame in asynchronous transmission consists of: 1 start bit, 8 data bits, 1 parity bit (even or odd if parity has been

set) and 1 stop bit.

The allowed Baud rates are: 2400, 4800, 9600, 19200, 38400.

Where unspecified, the length of the words (DATA) is 16 bits.

DATA PACKET

A complete sequence of request/answer consists of the following: Master request:

SLAVE ADDRESS - 1 byte

FUNCTION CODE - 1 byte

DATA - variable, depends on the function code

CRC - 2 bytes

Slave request:

SLAVE ADDRESS - 1 byte

FUNCTION CODE - 1 byte

DATA - variable, depends on the function code

CRC - 2 byte

21

NT210 K

FUNCTION CODE

The ModBus module supports the following function codes:

3(10): - holding register reading

16(10): - multiple register writing

If ModBus receives a message and the presence of a CRC error is confirmed, no answer is given.

CODE 3(10).

Request:

Slave address, code 3(10), Starting address HI, Starting address LO, Number of Point HI, Number of Point LO, Crc LO, Crc

HI.

Answer:

Slave address, code 3(10), Byte count, Data HI, Data LO……., Crc LO, Crc HI.

CODE 16(10).

Request:

Slave address, code 16(10), Starting address HI, Starting address LO, Number of Point HI, Number of Point LO, Byte count,

Data HI, Data LO……., Crc LO, Crc HI.

Answer:

Slave address, code 16(10), Starting address HI, Starting address LO, Number of Register HI, Number of register LO, Crc

LO, Crc HI.

The writable registers contain the following data: Alarm, Trip, Fan-on, Fan-off.

So the possible starting addresses are: 00-17 for alarm and fan, 00-25 for the Trip thresholds. The Number of Point LO

parameter can be set only to 8.

If a writing request is sent to an address other than the above, ModBus shall answer with an error code 02 (incorrect data

address).

If a writing request is sent for more than 8 registers (Number of point LO), ModBus will not be able to accept the

request and will not answer, so the request will time out.

NOTES FOR REMOTE PROGRAMMING

If an NT210 K needs to be programmed, it is necessary to remember that the Temperature, Pressure and Level alarm

settings must be modified selecting 8 registers at a time (registers 00-17, 00-18 ......... 00-24).

The same must be remembered for the Trip thresholds (registers 00-25, 00-26 ......... 00-32) and for each quantity measured

(Temperature, Pressure, Level).

Note: the Alarm level thresholds must be programmed in the register number 20 selecting 2 for active the function. The Trip

level thresholds must be programmed in the register number 28 selecting 1 for active the function.

Also in the remote programming stage via ModBus it is necessary to consider that the Alarm thresholds must be lower than

the Trip thresholds and that the Fan-on thresholds must be higher than the Fan-off thresholds.

If an attempt is made to set these thresholds incorrectly, the NT210 K control unit will not set and store the data, so the data

of the previous programming will not be changed.

Before restarting ERR is displayed.

After sending a writing request the control unit will take about 1" to store the data in eeprom; while storing the ModBus

module will not be able to process any other requests.

If the programming request is successful, the control unit resets automatically and loads the new values. Before restarting

PRG is displayed.

ERROR CODES (exception code)

If the request is incorrect, ModBus will answer with modified codes and codified errors as follows:

1. Unsupported function code

2. Incorrect data address

3. Incorrect data (i.e. length)

POLLING FREQUENCY

The maximum time to answer a call never exceeds a second, so we recommend shorter polling frequencies are not

adopted. In multi-device RS485 lines, interrogated in sequence, it may be useful to enter a delay between polls in relation

to: the number of connected devices, the communication speed, and the number of readings registers.

22

NT210 K

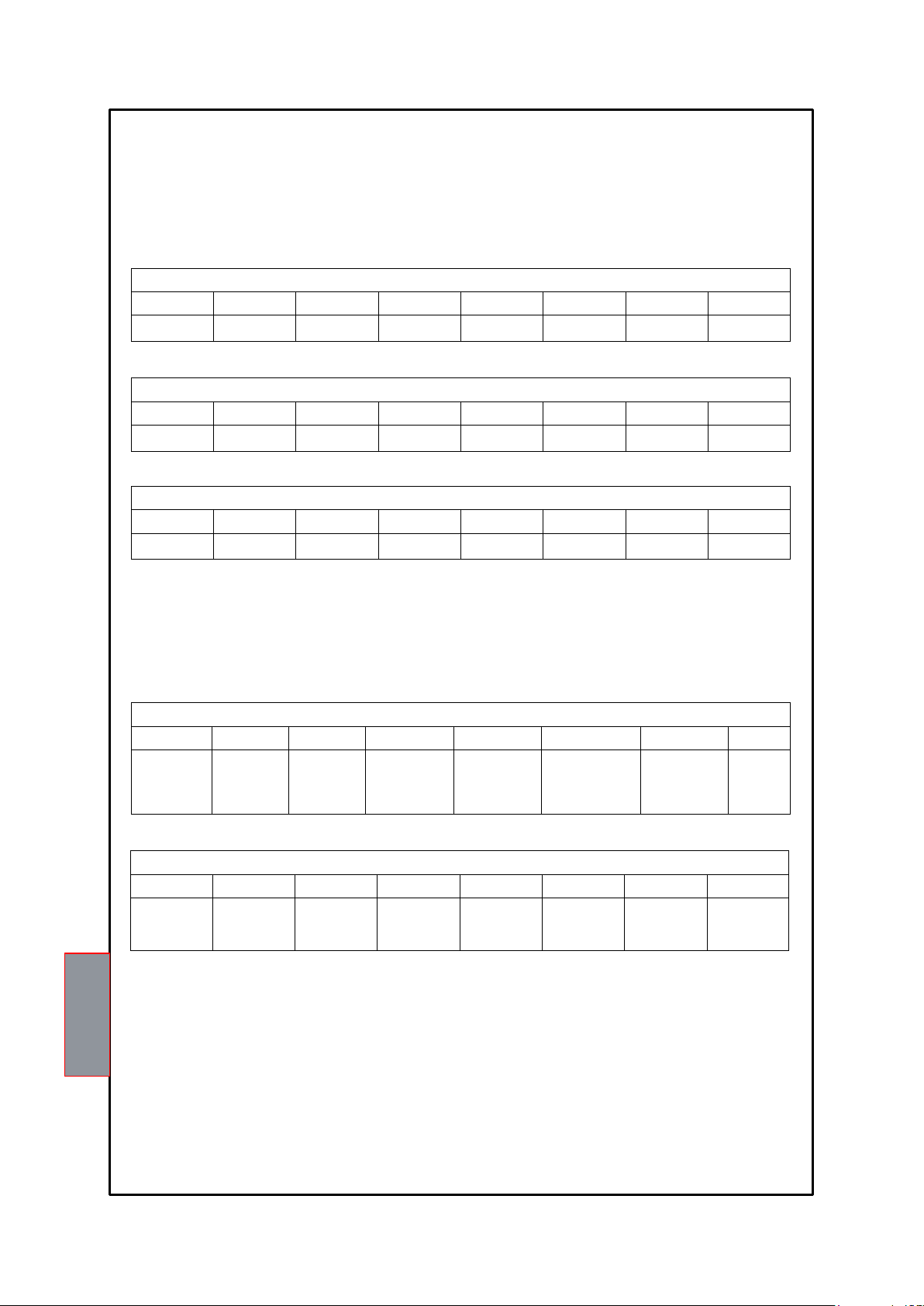

Address HI (10)

Address LO (10)

Data HI

Data LO

Primary tables

Notes

00

01

00

Oil temperature

Holding register

Temperature

Range

-40+120°

DATA LO

-50(10 )

00

02

00

Oil pressure HI

Holding register

mbar see note

page 22.

00

03

00

Oil pressure LO

Holding register

mbar see note

page 22.

00

04

00

Oil level

Holding register

1-2-3, see level

indication page 16.

00

05

00

TPL503 sensor

temperature

Holding register

Temperature

Range

-40+120°

DATA LO

-50(10 )

00

06

00

Not used

Holding register

00

07

00

Oil pressure

Holding register

mbar/10 see note

page 22.

00

08

00

Not used

Holding register

NOTE: The pressure is readable in the form of mB of 0 to 500 bytes of HI (register 2) and LO byte (register 3).

Or it is available in the form of mBar / 10 (single byte register 7).

The sign is present in bit 6 of the flag FLG_GEN register 49 (HI + sign pressure, LO sign - and then depressure).

MODBUS MAPPING TABLE

23

NT210 K

Address HI (10)

Address LO (10)

Data HI

Data LO

Primary tables

Notes

00 09 00

Oil temperature

status

Holding register

See note 1

on page 27

00 10 00

Oil pressure

status HI

Holding register

00 11 00

Oil level status

Holding register

00 12 00

Not used

Holding register

00 13 00

Not used

Holding register

00 14 00

Not used

Holding register

00

15

00

Not used

Holding register

00 16 00

Not used

Holding register

00 17 00

Oil Temperature

Set Alarm

Holding register

°C

00 18 00

Oil Pressure HI

Set Alarm

Holding register

mbar 00 19 00

Oil Pressure LO

Set Alarm

Holding register

mbar

00 20 00

Oil Level

Set Alarm

Holding register

2 = enabled

0 = disabled

00 21 00

Fan On

Holding register

°C

00 22 00

Fan Off

Holding register

°C

00 23 00

Oil Pressure

Alarm

Holding register

mbar/10

00 24 00

Not used

Holding register

24

NT210 K

Address HI (10)

Address LO (10)

Data HI

Data LO

Primary tables

Notes

00 25 00

Oil Temperature

Trip

Holding register

°C

00 26 00

Oil pressure Trip

HI

Holding register

mbar

00 27 00

Oil pressure Trip

LO

Holding register

mbar

00 28 00

Oil level Trip

Holding register

1 = enabled

0 = disabled

00 29 00

Oil pressure Trip

Holding register

mbar/10

00 30 00

Not used

Holding register

00 31 00

Not used

Holding register

00 32 00

Not used

Holding register

00 33 00 Hfn

Holding register

See page 15

00 34 00 Fcd

Holding register

See page 19

00 35 00 Fps

Holding register

See page 19

00 36 00

Not used

Holding register

00 37 00

Not used

Holding register

00 38 00

Not used

Holding register

00 39 00

Not used

Holding register

00 40 00

Not used

Holding register

NOTE :AL1 = ALARM, AL2 = TRIP.

25

NT210 K

Address HI (10)

Address LO (10)

Data HI

Data LO

Primary tables

Notes

00

41

00

Oil T.max

Holding register

Temperature

Range

-40+120°

DATA LO

-50(10 )

00 42 00

P.max HI

Holding register

mbar 00 43 00

P.max LO

Holding register

mbar 00 44 00

Oil minimum

level

Holding register

1-2-3, see level

indication page 16.

00 45 00

Oil

Temperature

alarm history

Holding register

See note 2 on

page 28.

00 46 00

Oil Pressure

alarm history

Holding register

00 47 00

Oil Level

alarm

history

Holding register

00 48 00

Not used

Holding register

00 49 00

FLG_GEN

Holding register

See note 3 on

page 28.

00 50 00

FLG_GEN2

Holding register

00 51 00

Not used

Holding register

00 52 00

Not used

Holding register

00 53 00

Not used

Holding register

00 54 00

Not used

Holding register

00 55 00

Not used

Holding register

00 56 00

Not used

Holding register

26

NT210 K

Address HI (10)

Address LO (10)

Data HI

Data LO

Primary tables

Notes

00 57 00

Not used

Holding register

00 58 00

Not used

Holding register

00 59 00

Not used

Holding register

00 60 00

Not used

Holding register

00 61 00

Not used

Holding register

00 62 00

Not used

Holding register

00 63 00

Not used

Holding register

00 64 00

Not used

Holding register

00 65 00

Not used

Holding register

00 66 00

Not used

Holding register

00 67 00

Not used

Holding register

00 68 00

Not used

Holding register

00 69 00

Not used

Holding register

27

NT210 K

Address HI (10)

Address LO (10)

Data HI

Data LO

Primary tables

Notes

00 70 00

Not used

Holding register

00 71 00

Not used

Holding register

00 72 00

Not used

Holding register

00 73 00

Not used

Holding register

00 74 00

Not used

Holding register

00 75 00

Not used

Holding register

00 76 00

Not used

Holding register

00 77 00

Not used

Holding register

00 78 00

Not used

Holding register

00 79 00

Not used

Holding register

00 80 00

Not used

Holding register

OIL TEMPERATURE STATUS

B7

B6

B5

B4

B3

B2

B1

B0

TRIP

ALARM

FREE

FAN

FREE

FREE

FCD

FREE

OIL PRESSURE STATUS

B7

B6

B5

B4

B3

B2

B1

B0

TRIP

ALARM

FREE

FREE

FREE

FREE

FPS

FREE

OIL LEVEL STATUS

B7

B6

B5

B4

B3

B2

B1

B0

TRIP

ALARM

FREE

FREE

FREE

FREE

FREE

FREE

TPL503 210 TEMPERATURE STATUS

B7

B6

B5

B4

B3

B2

B1

B0

FREE

ER3

ER2

FLT-P

ER1

FREE

FREE

FLT-T

NOTE 1: STATUS REGISTER

The status register contains information on the status of the alarms of the channel it refers to. Each bit

represents a flag that is active only when its value is 1.

28

NT210 K

OIL TEMPERATURE ALARM MEMORY

B7

B6

B5

B4

B3

B2

B1

B0

TRIP

ALARM

FREE

FAN

FREE

FREE

FREE

FREE

OIL PRESSURE ALARM MEMORY

B7

B6

B5

B4

B3

B2

B1

B0

TRIP

ALARM

FREE

FREE

FREE

FREE

FREE

FREE

OIL LEVEL ALARM MEMORY

B7

B6

B5

B4

B3

B2

B1

B0

TRIP

ALARM

FREE

FREE

FREE

FREE

FREE

FREE

FLG_GEN: GENERAL FLAGS

B7

B6

B5

B4

B3

B2

B1

B0

FREE

PRES/DEP

FREE

SYSTEM

FLAG

ECH

EE- PROM

ERR

FAN TEST IN

PROGRESS

ALARM1

RESET

SYSTEM

FLAG

FLG_GEN2: GENERAL FLAGS

B7

B6

B5

B4

B3

B2

B1

B0

FREE

SYSTEM

FLAG

SYSTEM

FLAG

SYSTEM

FLAG

ErO

TPL503

timeout

SYSTEM

FLAG

SYSTEM

FLAG

SYSTEM

FLAG

NOTE: The pressure is readable in the form of mB of 0 to 500 bytes of HI (register 2) and LO byte (register 3).

Or it is available in the form of mBar / 10 (single byte register 7).

The sign is present in bit 6 of the flag FLG_GEN register 49 (HI + sign pressure, LO sign - and then depression).

NOTE 2: ALARM HISTORY REGISTER

The status register contains information on the storage of the alarms of the channel it refers to.

Each bit represents a flag that is active only when its value is 1.

NOTE 3: GENERAL FLAG REGISTER

The general function register contains information on the enabling of general functions

29

NT210 K

WARRANTY REGULATIONS

NOTE 4: TPL503 STATUS FLAG

Each bit represents a flag that is active only when its value is 1.

When the flag is active it means the sensor, even if powered, is not working because no circulating current is sensed

(presence of no-load voltage). The sensor is very likely faulty or incorrectly connected.

CRC CALCULATION

This protocol includes 2 CRC-16 bytes in each transmission. The characteristic polynomial (11000000000000101B) is

used for the calculation and the result is "hung" at the end of the packet. The polynomial is used in reverse order with the

most significant bit suppressed because useless for the purpose of the calculation.

PARAMETER DESCRIPTION

A - 16bit AL

register - A low

part AH - A high

part i,j - METERS

(+) - EXCLUSIVE OR

Di - Datum of the «i»th frame of the packet

N - number of bytes in the packet excluding the 2 of

the CRC G - Polynomial: 1010-0000-0000-0001

shr - shift to the right

ALGORHITHM

1) 0xFFFF -> A

2) 0 -> i

3) 0 -> j

4) Di (+) AL -> AL

5) j +1 -> j

6) shr A

7) if carry then G (+) A -> A

8) if NOT j=8 then go to 5

9) i +1 -> i

10) if NOT i = N then go to 3

11) A -> in CRC (the result is in order L,H)

The purchased product is covered by manufacturer's or seller's warranty as per the "Tecsystem s.r.l.'s General

Conditions of Sale" available at www.tecsystem.it and/or the purchase agreement drawn up.

Said Warranty is valid only when the Product fails due to reasons attributable to TECSYSTEM srl, such as manufacturing

faults or faulty components.

The Warranty is invalid when the product is tampered with / modified, connected incorrectly, causing voltages outside the

permitted limits, non-compliant with the use and installation technical specifications, as described in this instruction

manual.

The Warranty is always ex our Corsico works, as stated in the "General Conditions of Sale".

30

NT210 K

TROUBLESHOOTING

CAUSES AND SOLUTIONS

The control unit does not switch on and the

supply to terminals 40-42 is correct.

Check that: the connector is correctly inserted into its housing, the

wires are tightened, there is no evidence of burning on the

connectors. Disconnect the power supply, carry out the above and

reconnect.

On startup "ECH" is displayed

Strong disturbance has damaged the data in the memory. See the

paragraph Programmed data diagnostics on page 15.

The display shows ER0

Check the connecting cable between the TPL503 sensor and the

NT210 K control unit: the connector must be fully pushed in, the

wires must be tightened.

The main switch has been tripped unexpectedly.

Check the T.P.L. values recorded in MAX, check the oil level in the

transformer.

FCD or FPS warning.

See the FCD or FPS function on page 19.

Contact TECSYSTEM Technical Department if the problem persists.

USEFUL CONTACTS

EQUIPMENT DISPOSAL

European directives 2012/19/EC (WEEE) and 2011/65/EC (RoHS) have been approved to reduce electrical and

electronic waste and promote the recycling and reuse of the materials and components of this equipment, cutting down

on the disposal of the residues and harmful components of electrical and electronic materials

All the electrical and electronic equipment supplied after 13 August 2005 is marked with this symbol, pursuant

to the European directive 2002/96/EEC on electrical and electronic waste (WEEE). Any electrical or electronic

equipment marked with this symbol must be disposed of separately from normal domestic waste.

Returning used electrical devices: contact TECSYSTEM or the TECSYSTEM agent for information on the correct

disposal of the devices.

TECSYSTEM is aware of the impact its products have on the environment and asks its customers active support in the

correct and environmentally-friendly disposal of its devices.

TECHNICAL INFORMATION: ufficiotecnico@tecsystem.it

COMMERCIAL INFORMATION: info@tecsystem.it

Loading...

Loading...