Tank-Spion Digital LX-2

Measuring an monitoring device for tank contents.

Type option: LX-2-R - with 2 relays aditionally.

Mounting and Instructions

Content:

IN GENERAL 1

STRUCTURE 2

LIQUIDS 2

LABELING 2

MOUNTING INSTRUCTIONS 2

MOUNTING OF MEASURING PROBE 3

ELECTRIC INSTALLATION 3

AUTOM. CHANGEOVER OF TANKS 4

INITIAL SETUP 5

SETUP MENU, COMPL. 7

ERROR CODES 10

FUNCTION CHECK 11

TECHNICAL DATA 11

ACCESSORIES 11

CONNECTION PLAN 12

Page:

IN GENERAL

The tank content display device LX-2 or LX-2-R is to be used for monitoring of tank levels in

pressureless liquid tanks. Aditional functions to liter displaying are e.g. temperature measuring,

data transmission or linking to facility management systems.

The LX-2-R type additionally provides two output relays, e.g. for controlling an alert unit, for

switching magnetic valve or dry protection of pump.

The displayed liter values are not to be used for billing purpose.

For the intended use and to abide the rules for warranty do strictly follow the Mounting and

Instructions, which have to be handed out to the owner.

P. 1 LX-2 / LX-2-R Mounting and Instructions

Version: 07-2009

STRUCTURE

The LX-2 (-R) has an eight characters LCD display and a measuring input for a level probe.

The LX-2-R type additionally provides 2 programable relays, with opening and closing contacts.

The measuring probe can be mounted with a screw joint of R1 “ or R1½ “.

A reduction for 2“ is not included in scope of delivery.

LIQUIDS

Liquid Liquid

Heating oil

Diesel oil

Bio Diesel oil

Plant oil

Petroleum

Carbamide dissolution

DIN EN 51603-1

DIN EN 590

DIN EN 14214

* after consulting

Flash point > 55°C

e.g. AdBlue

LABELING

Confirming to EN 50081-1 , EN 50082-1 and EN 61010-1 / A2

MOUNTING INSTRUCTIONS

Only qualifyed persons are allowed to install the measuring probe and to connect the display

device. Follow the regulation for each liquid, especially for the risk of water pollution and for

flammable liquids.

Condition for proper operation of measuring device is a professional installation. Follow the

technical rules for planning, construction and operation of the entire facility. Additionally follow the

rules for tank mounting and operation.

• Condition for proper operation is a pressureless storage tank. The tank must have proper

ventilation. Oil tanks and gasoline tanks must be equipped with a level limiter.

• The cable entry in the tank has to be made watertight and vapor tight by using PTFE sealing

tape.

• The measuring probe and display device are not safety devices. They do not replace the level

limiter of a tank.

• Installation of the display device in explosive zones is not permitted.

In that case ask for an EEx-probe with Zener barrier. The tank probe must be mounted inside

the tank with a cable protection pipe.

• The display device is connected to 230V AC. Operating is only permitted with closed box lid.

In case of inappropriate installation you lose any warranty.

Motor oil

Hydraulic oil

Glycerin

Glycol

Water

Gasoline with

flash point < 55°C

No used oil !

Only with EEx-probe

and Zener barrier

P. 2 LX-2 / LX-2-R Mounting and Instructions

Version: 07-2009

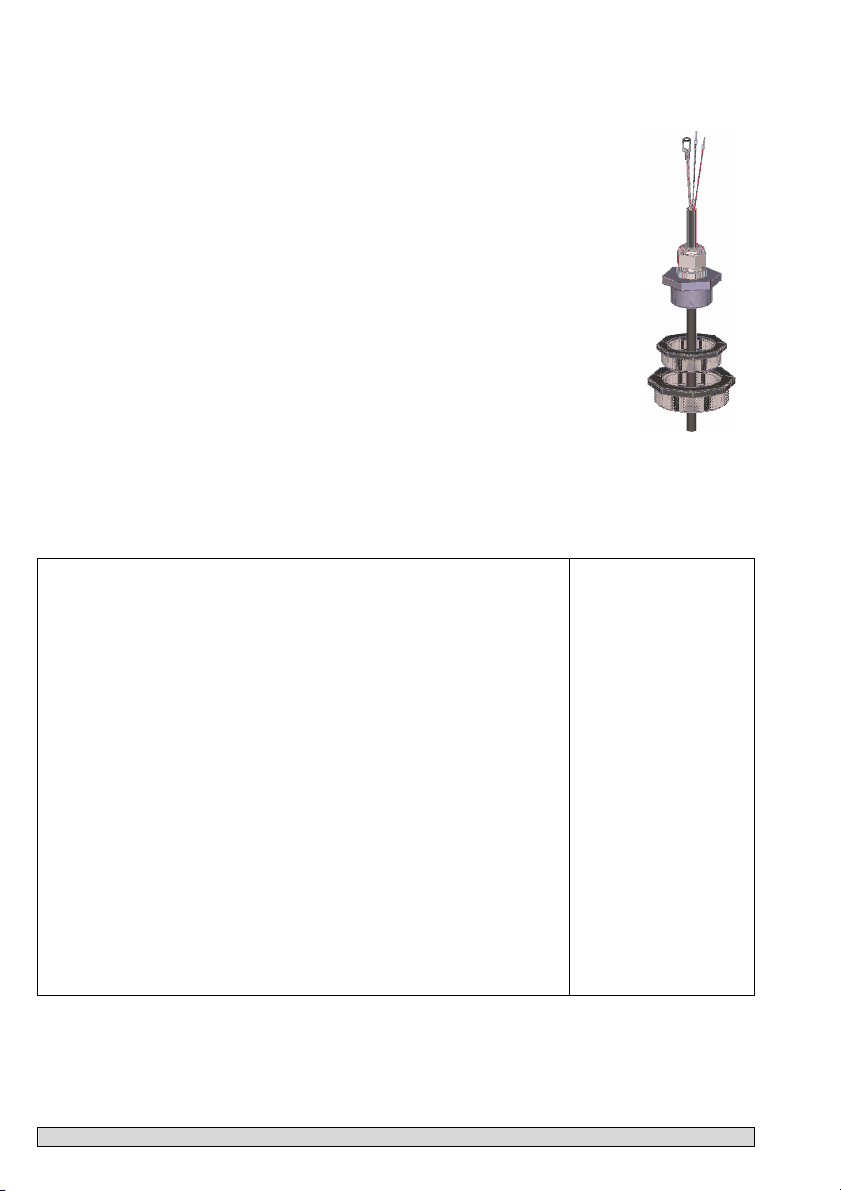

MOUNTING OF MEASURING PROBE

• In case of cellar steal tanks or subgrounded tanks use the included

screwing joint for mounting the measuring probe.

• If an old fuel gauge was used dismount it and use the tank screwing port.

• Subgrounded tanks normally provide an idle screwing port. In that case

dismount the dummy plug.

Mounting:

• In case of a heating oil tank switch off the oil burner and lock the suction

pipe if necessary.

• Clear the tank’s screwing port.

• Put the cable of the probe through the screwing joint. Put the measuring

probe into the tank.

• Mount the screwing joint with PTFE sealing tape.

• Sink the measuring probe down to the ground of the tank. Fix the cable

with the PG screwing. The measuring probe may optionally lay or stand on

the ground of the tank.

• Zero-point calibration is not required in normal case.

• If nessecary unlock the suction pipe, switch on the oil burner and check

the functions.

ELECTRIC INSTALLATION

Interconnection of measuring probe to display device

Probe supply: DC 15 – 24 V

Connection: Connect the 2-wire probe cable in the way:

Red(+) => clamp 1 , Black (-) => clamp 2.

Air capillary: The air capillary must have ventilation to atmosphere.

The end of the probe’s cable and the air capillary must

be protected against humidity.

Extension: The cable of the probe can be extended up to 100 m,

e.g. with NYM or YR or NYY.

Line diameter at least 2 x 0,4 mm².

In case of cable extension in a manhole or outdoors

it is recommended to use a waterproof clamp box with

special air pressure ventilation (accessories).

Shielding: Near by power current cables it is recommended to use

a shielded probe signal line. (Cable shielding has to be

grounded.)

Supply voltage:

Voltage: AC 230 V 50 Hz

Clamps: PE (protective conductor), N (neutral conductor),

L (phase).

Power line is not included in accessories.

P. 3 LX-2 / LX-2-R Mounting and Instructions

Refer to last page.

The capillary in the

probe’s cable must

have ventilation.

The capillary filter

stays attached !

Refer to probe

instructions.

Version: 07-2009

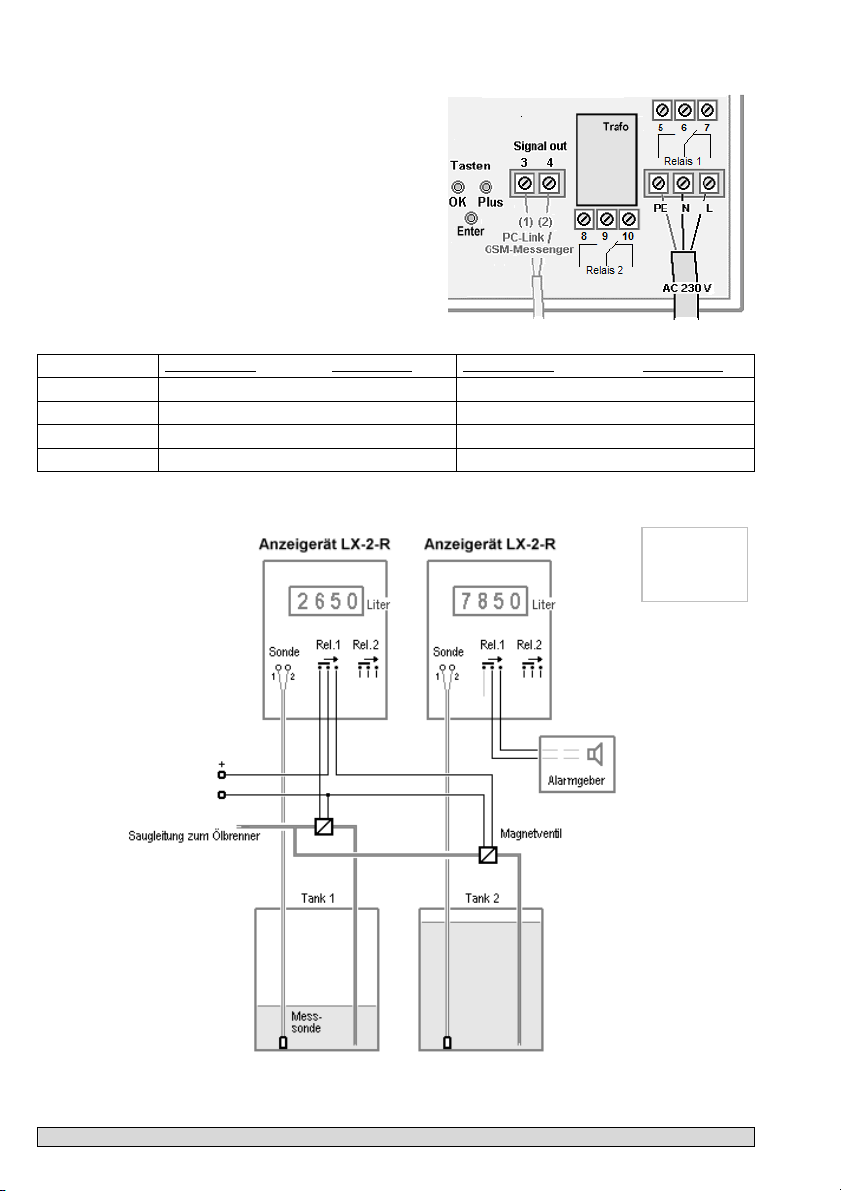

LX-2-R :

Relay connection

The LX-2-R type has two relays for controlling

external electric circuits or for alert signaling.

In case of failure or minimum level (or temperature

limit) the relay outputs 6-7 and 9-10 are linked and

the relay outputs 5-6 and 8-9 are opened; refer to

PCB print.

Normal state / Event state Normal state / Event state

Relay 1 Clamp 5 - 6 opened / Contact links Clamp 6 – 7 linked / Contact opens

Relay 2 Clamp 8 - 9 opened / Contact links Clamp 9 -10 linked / Contact opens

Voltage Max. 250 V AC

Current Max. 3,5 A

AUTOM. CHANGEOVER OF TANKS

Example

LX-2-R

P. 4 LX-2 / LX-2-R Mounting and Instructions

Version: 07-2009

INITIAL SETUP

Determine the tank data and enter them into the mode:

You find the push buttons (blue) on the PCB positioned between the connection clamps.

Press ENTER => Device enters the setup mode (Step „1.Sonde“).

You can step through the input menu items by pressing PLUS or MINUS.

Press ENTER to step into a sub-menu.

Press PLUS or MINUS for selection; press ENTER for confirming.

In step 8 you reach „8.Exit“. Press ENTER for returning to display mode.

For particular parameter setup refer to P.7.

Setup / Programming

Function

1. Probe „Sonde“

2. Liquid „Fluid“

3. Tank shape

„Tank“

4. Tank volume

„Volume“

5. Tank height

(100% value)

„Height“

Select the probe range (refer to probe label) –

default is 250 mbar

Liquid selection (refer to P. 8) e.g. :

- Heating oil (preselection): Heat.oil

- Diesel: Diesel

- select other predefined liquids by + / -

- otherwise enter the specific weight ....kg/l

In case of unknown weight go to step 10.Set h

Tank shape selection (refer to P. 8) e.g. :

- linear (preselection): Linear

- horz. cylinder: Cyl.

- horz. cylinder 50 to 100 m³: Cyl.>50m3

Enter the tank volume (100% of capacity):

Attention: If a bearing chart is available it is

recommended to take the largest value pair out of

the chart.

E.g. in case of a 100 m3 subgrounded tank the

exact value could be of 100 600 liters.

Enter the interior tank height in mm:

E.g. 2.500 mm (Max. value = 9.999 mm)

(Height without manhole)

Attention: If a bearing chart is available it is

recommended to take the largest value pair out of

the chart.

E.g. in case of a 100 m3 subgrounded tank the

exact value chould be 288 cm = 2880 mm.

Description Values

250mbar

Heat.oil

Linear

40.000L

2.500 mm

P. 5 LX-2 / LX-2-R Mounting and Instructions

Version: 07-2009

Step 6 + 7 set up only

in case of relays

6. Relay 1

„Relay1“

7. Relay 2

„Relay2“

8. Exit

„Exit“

Steps 9 – 24

Standard setup ends at step 8 by confirming EXIT.

Then the display shows the current tank content.

After setup close the box lid.

Programming Examples

EXIT or RELAY.

Relay parameters for LX-2-R type

Enter relay switchpoint as %-value 01 – 99

(or as °C-value of -99 - +99 , only in case of

temperature measuring probes)

Deactive => Use + / - , press ENTER

Active => Use + / - , press ENTER

On 10% => Use + / - to set up the

switch-on point.

Off 12% => Use + / - to set up the

switch-off point

On +15°C => ditto for temp. switch-on point

Off+17°C => ditto for temp. switch-off point

deactive sets the relay out of order.

Values of 0% or 0°C for switch-on/-off points

deactivate the relay, too.

Inputs for relay 2 are analog to 6. Relay 1

Press ENTER for returning to display mode

In steps 10 – 25 you will find additional settings

active

On 10%

Off 12%

On +15°C

Off +17°C

16.500L

Example 1 Cellar tank for 6000 L heating oil. Liter displaying. Linear steel tank.

Interior height 165 cm (Current level: 125 cm). Probe 0 - 250 mbar

Step Input

1. Probe: 250 mbar 250mbar

2. Liquid: Heating oil Heat.oil

3. Tank shape: linear Linear

4. Tank volume: 6000 Liter 6000L (select by +/-)

5. Interior tank height: 165 cm 1650mm (select by +/-)

6. Relay1 – no function deactive

7. Relay2 – no function deactive

8. Exit => press ENTER for display mode => 4550L

P. 6 LX-2 / LX-2-R Mounting and Instructions

Version: 07-2009

Tank with interior mantle

In case of tank with interior mantle (e.g. horz. cyl. or cellar steel tank) correct the input values.

Example: Mantle thickness 2 cm => reduce interior height by ca. 4 cm

Example 2 Subgrounded tank for 100,600 L Diesel. Probe 0 - 250 mbar.

Interior height 2.88 m (Current level: 54 cm)

Step Input

1. Probe: 250 mbar 250mbar

2. Liquid: Diesel Diesel

3. Tank shape: horz. cylindric Cyl.>50m³

4. Tank volume: 100,600 liter 100600L (refer to bearing chart)

5. Interior tank height: 288 cm 2880mm (refer to bearing chart)

6. Relay1 – no function deactive

7. Relay2 – no function deactive

8. Exit => press ENTER for display mode => 12800L

Beispiel 3 Font, 7,50 m max. water level from ground (current level 4,20 m).

Probe TDS-6029 (0-1000 mbar). Displaying in m:

Step Input

1. Probe: 1000 mbar 1000mbar

2. Liquid: Water H2O

3. Shape: linear linear

4. Volume: 7,500 liter (or m) 7500L (select by +/-)

5. Height: 7.50 m 7500mm (select by +/-)

6. Relay1 – ON at 0.5% - OFF at 10% active => On: 05% => Off:10%

7. Relay2 – No function deactive

8. Exit => Step forward by pressing PLUS

12. Unit – m Unit: m

13. Rounding auto auto (press ENTER to confirm)

14. Exit => press ENTER for display mode => e.g. 4.20m

Volume 10 m³ => reduce volume by 5%

Volume 20 m³ => reduce volume by 4%

Volume 50 m³ => reduce volume by 3%

Volume 100 m³ => reduce volume by 2.5%

SETUP MENU, COMPL.

Step Function Description

0. Exit

1. Probe

P. 7 LX-2 / LX-2-R Mounting and Instructions

Go back to display mode

100mbar

150mbar

250mbar

500mbar

1000mbar

2000mbar

3000mbar

5000mbar

...mbar

Cal-Mode

Tank height: Heating oil up to 1,2 m / Water up to 1 m

Heating oil up to 1,8 m / Water up to 1,5 m

Default range: Up to 3 m of heating oil / Water up to 2,5 m

Heating oil up to 6 m / Water up to 5 m

Heating oil up to 12 m / water up to 10 m

Heating oil up to 24 m / Water up to 20 m

Heating oil up to 36 m / Water up to 30 m

Heating oil up to 60 m / Water up to 50 m

Enter the specific probe range value.

Is displayed in case of calibration via ‘10.Set H’ or ’11.Set V’.

Version: 07-2009

2. Fluid

Liquid

Heat.oil

H2O

Diesel

BioD

RME,FAME

Rapsoil

Palmoil

Motoroil

AdBlue

Normal-B

Super-B

...kg / liter

Cal-Mode

0,845 - default

0,999

0,830

0,880

0,880 (Raps Methyl Esther, Fatty Acid Methyl Esther)

0,915

0,910

0,865

1,090

0,743

0,750

Enter a density value

Is displayed in case of calibration via ‘10.Set H’ or ’11.Set V’.

If the density of the liquid is unkown the reference height can be entered in step 10 Set h.

Therefore determine the current fill level in mm and substract 10 mm from it. Enter this value and

confirm with YES.

In case the current fill level is less than 75% it is recommended to correct the value to the updated

value after the next filling for getting a good measuring accuracy.

3.Tank

Tank shape

/ type

Linear Default: Linear tank.

Rectangular tank; vertical cylinder; steel cellar

tank.

Cyl.

Cylindric tank ( alternative: Cyl.>50m3).

Horizontal cylindric tank, up to 45 m³ .

Typical tank shape for outdoor tanks and

subgrounded steel tanks.

Ball

Spherical tank.

Ball-shaped subgrounded tank;

common subgrounded plastic tanks (GRP).

Oval

Oval cellar tank.

Typical shape of GRP tanks and single-walled

tank

Konvex

Convex plastic tank.

Slightly bellied tank shape

Konkav

Concave plastic tank battery.

Cave-bellied tank shape.

Plastic Plastic tank with large cavity.

Hollow in the middle of the tank’s body.

(No ring bandages)

3

Cyl. > 50m

Large cylindric outdoor tank

of 50.000 Ltr up to 100.000 Liter of volume

( alternative:

‘Cyl.’ - see obove ).

Table

(for input)

Reference table to be entered;

by up to 15 pairs of values ( cm => Liter ).

P. 8 LX-2 / LX-2-R Mounting and Instructions

Unsymmetrical or

other tank shape.

Version: 07-2009

4.Volume

(capacity)

5.Height

(interior)

6.Relay1

or Exit

On: 10%

Off:12%

On: +15C

Off: +17C

7.Relay2

8. Exit

9.Offset

10.Set h

11.Set V

12. Unit

13.Round

Rounding

14. Show

15-19. Exit Return to displaying mode.

20. LCD

21. Info

xxx xxx L

x xxx mm

LX-2: Step 6 + 7 => EXIT. LX-2-R: Step 6 + 7 => RELAY 1+2

deactive

active

Input for 7.Relay2 refer to 6.Relay1

Return to displaying mode.

ESC/Calibrat Zero-point offset calibration for the measuring probe.

x xxx mm

Cal: No

Cal: Yes

xxx xxx L

Unit: L

Unit: %

Unit: m

Uint: kg

auto

off

or 2, 5,

10… 100

Show %Symbol Y/N

Contr 60 Trimming the contrast of the LCD display.

Displaying

of:

Tank capacity (total 100%).

Presetting is 0 L . The value setup is required in any case.

Interior tank height.

Presetting is 2.000 mm

Selecting by (+).

ENTER for saving and forwarding to On value.

Presetting is 10%, range is 0...99 .

Relay switches On when under-running e.g. 10% level.

Presetting is 12% (Hysteresis).

Relay switches Off again when when level exceeds e.g. 12% again.

Only in case of temperature measuring adaptor is inserted:

Range is –99C ... +99C.

If On=0 and Off=0 the temperature alerting is diabaled.

Presetting is 15 °C.

Relay switches On when under-running e.g. 15°C temperature.

Temperature presetting is 17 °C (Hysteresis).

Relay switches Off again when temp. exceeds e.g. 17°C again.

Input option for a reference height (2-points calibration),

usefull in case of unknown specific weight of the fluid.

Subtract* 10 mm from the beared liquid level, and enter that value.

After confirming with ’Cal: Yes’, then in step 1+2 ‘Cal-Mode’ will be

displayed instead of a value.

If this is done at a low tank filling level it is recommend to repeat this

later on at a higher filling level. Also refer to 11.Set V

Fine trimming of current liter value.

Use +/- buttons and confirm with ’Cal: Yes’

Presetting is L (liter) ( max. value: 999,900L )

( max. value: 100.00% )

( max. value: 999.99 m )

( max. value: 999,900kg )

Rounding of displaying value: Presetting is ‘auto’.

off = highest resolution without rouding; wobbling values.

A certain rounding is recommended => sedation.

Displaying option: A grafical %-symbol corresponding to the current

content appears in 2 s alternation to the liter displaying.

Software version V3.00

Serial no. SN1234

Offset xxxx

Gain xxxx

P. 9 LX-2 / LX-2-R Mounting and Instructions

Version: 07-2009

22.Test I

23.Test R Rel1 ON

24. Init

26. Exit

Rel1 OFF

Rel2 ON

Rel2 OFF

Return to displaying mode

Displaying current measuring value in mA

and displaying the hex. value of the A/D converter.

At LX-2-R type => Testing functions of both relays.

( At LX-2 type => without function )

- Reset ESC = Exit without resetting (Escape).

Reset = Restart of the internal micro program.

Defaults = Re-initializing (clearing) of all parameters

back to the delivery default setting.

ERROR CODES

Message Meaning

Error E 1

Error E 2 Measuring value of the probe is too small !

Error E 3

Error E 4 Setup is possible only if zero-point calibration is done.

Error E 5

Error E 6 The measuring value is too small for reference. Make sure the probe is plunged.

Error E 7 The current measuring value is too small for the corresponding tank height or

Error E 8 The current measuring value (or mA) is too high. Check electrical connection and

Error E 9 The current value is 0 mA. The probe’s connection could be broken. Check the probe

Error E10 Calbration error. Switch off an on the 230V supply voltage and retry.

Error E11 Warning – The liquid level in the tank is too low for an exact calibration.

Error E12

Invalid input value.

- E002 at zero-point calibration: If current is less than 3,5 mA => Probe error.

- E002 at input step 4: Make sure the probe is plunged. Or current fluid level

is under the calibration minimum level.

Measuring value is too high for zero-point calibration.

- The probe must not be plunged ! A probe’s current higher than 4,5 mA indicates

a problem with the probe.

Execute the zero-point calibration again (=> 9. Offset).

Height input is larger than tank height. (Wrong input.)

Settled height is too large (or means the measuring value is too small for setting).

Execute the zero-point calibration again (=> 9. Offset).

If it does not work check the probe current (mA) !

the volume input value. Make sure the probe is plunged.

check the measuring range of the probe.

Switch the 230V supply voltage off and on. Check input steps 3 and 4.

Execute the zero-point calibration again. (=> 9. Offset).

Otherwise the measuring probe has to be checked.

connection (polarity) and extension. Measure the voltage at the probe (red to black).

Otherwise the probe is working not properly.

(Press OK to continue anyway.)

Yet no measurement data is received from the external tanks 2 ... 4.

P. 10 LX-2 / LX-2-R Mounting and Instructions

Version: 07-2009

FUNCTION CHECK

It is recommend to check if the displayed liters are correct after a complete fueling or once year.

Two practical options are: - Lift the probe and check the 0 Liter displaying

- Check the mm value displayed in Step ‘11. Set H’ (without trimming!)

TECHNICAL DATA

Display device

Supply voltage: AC 230 V 50 Hz Protection class:

Power consumtion: max. 2 VA

Measuring input:

Relay output: LX-2-R has 2 relays

Voltage strength (U): max. 250 V AC Analog ouput: Adaptor 0-5 V DC

Current strength (I): max. 3,5 A Analog output:

Dimensions [mm]

Measuring probe

Supply voltage: 24 V DC Protection class: IP 68 (by IEC 529)

Materials:

Mounting orientation: Vertically or horizontally with contact to tank ground.

Temperature range: Liquid temperature 0 °C - +45 °C

4 - 20mA ; U0 = 20V ;

120 x 120 x 49 (IP30)

or

130 x 130 x 60 (IP65)

V4A ; POM;

FPM; HD-PE

Probe length (without cable):

Cable length:

150 / 250 mbar type

Resolution: 10 bit

Accuracy: ± 1 %

Box material:

IP 30 or IP65

(by EN 60529)

Adaptor 4-20 mA

Polystyrol (IP30)

or

Polycarbonat (IP65)

107 mm

5 m / 6 m

ACCESSORIES

Order no.

Component Application

12080

12064 Output adaptor 0 - 5 V

12065 Output adaptor 4-20 mA

12036

12037

P. 11 LX-2 / LX-2-R Mounting and Instructions

Clamp box IP 65, special,

waterproof and ventilated

PC-Link Lite

PC-Link Extended

For extension of the probe’s cable (outdoors)

or in the tank’s manhole.

Plugable module.

Provides an analoge voltage ( linearized ).

Plugable module.

Provides an analog signal of 4-20mA (passive),

2-wire principle ( linearized current signal ).

Add-on set for data transmission to a PC.

Data logging, Charting functions,

automatic emaiI generating.

Version: 07-2009

CONNECTION PLAN

for Tank-Spion Digital LX-2 and LX-2-R (with relays)

Complete set : LX-2 : Art-Nr. 12032

Complete set : LX-2-R : Art-Nr. 12033

Maintenance:

Check if the displayed liters are correct:

Two practical options are:

- Lift the probe above the liquid level. Then check if ~ 0 L is displayed

- Check the mm value displayed in Step ‘11. Set H’ (without trimming!).

In case of deviation it is recommended to recalibrate the measuring probe

via step ‘9. Offset’.

Manufacturer:

TECSON-Digital

Wulfsfelder Weg 2a

D-24242 Felde

Tel. (+49) 4340 / 402530

Fax (+49) 4340 / 402529

Email: info@tecson.de

www.tecson.de

P. 12 LX-2 / LX-2-R Mounting and Instructions

Version: 07-2009

Loading...

Loading...