1

Technical Manual Board

Computer Model MAG-100R

2

Sumário

1. Mechanic Characteristic.................................................................................. 4

1.1. Technical Characteristic .................................................................................. 4

1.2. GPRS, 3G Communication ............................................................................. 4

1.3. Characteristics ................................................................................................ 5

1.4. Data Transmission: ......................................................................................... 5

1.5. Communication XBEE .................................................................................... 6

1.6. Characteristics: ............................................................................................... 7

1.7. Characteristics of the XBee 900-HPS3B for Peru ........................................... 7

1.8. Data Transmission .......................................................................................... 8

1.9. Transmission Power: ...................................................................................... 8

1.10. GPS MODULE MADE BY UBLOX .............................................................. 9

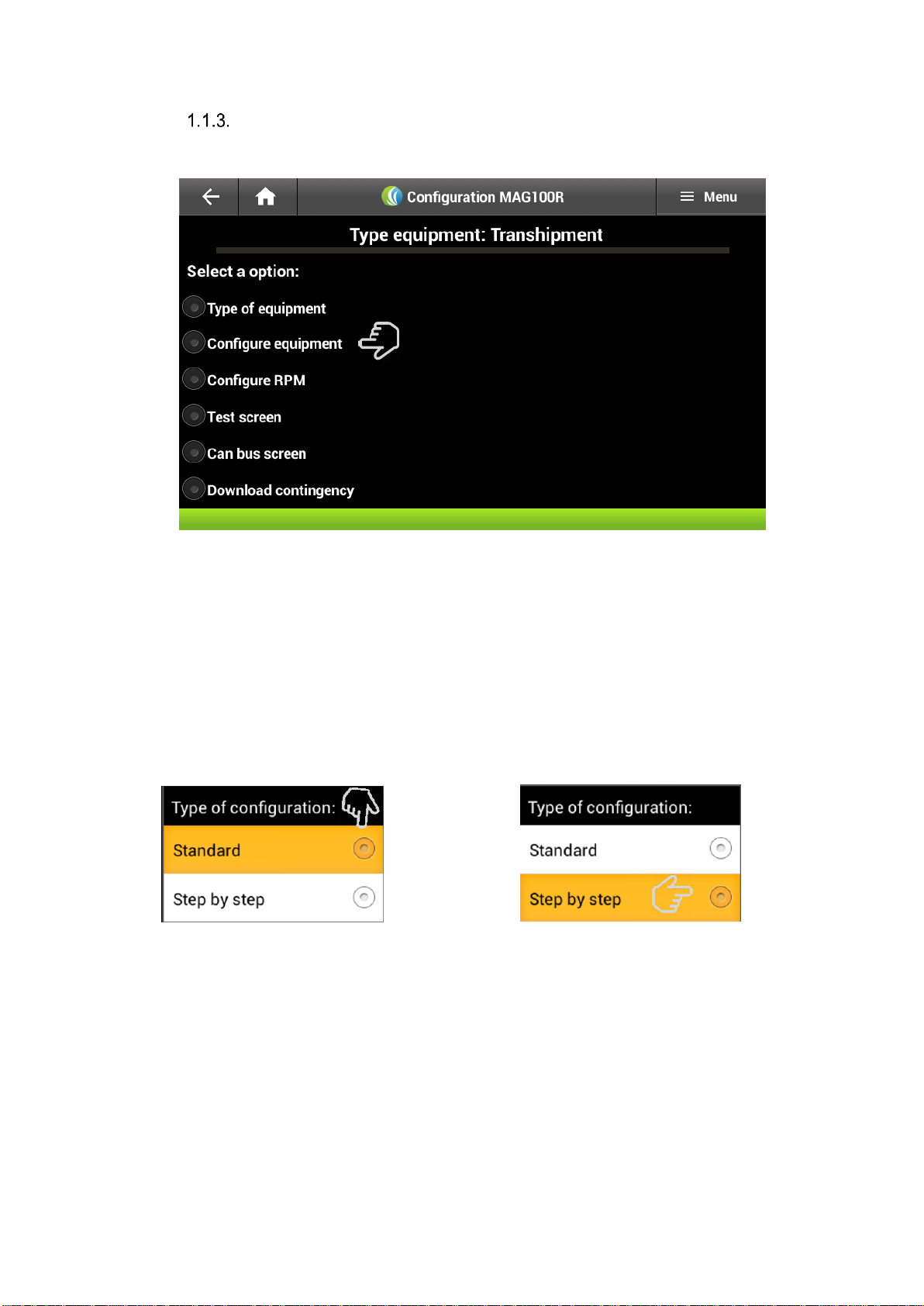

2. MAG-100 Transshipment Configuration. ....................................................... 11

2.1 APK sCBConfigMag100R ............................................................................. 11

Open sCBConfig app. ............................................................................ 11

Configuring type of equipment ............................................................... 12

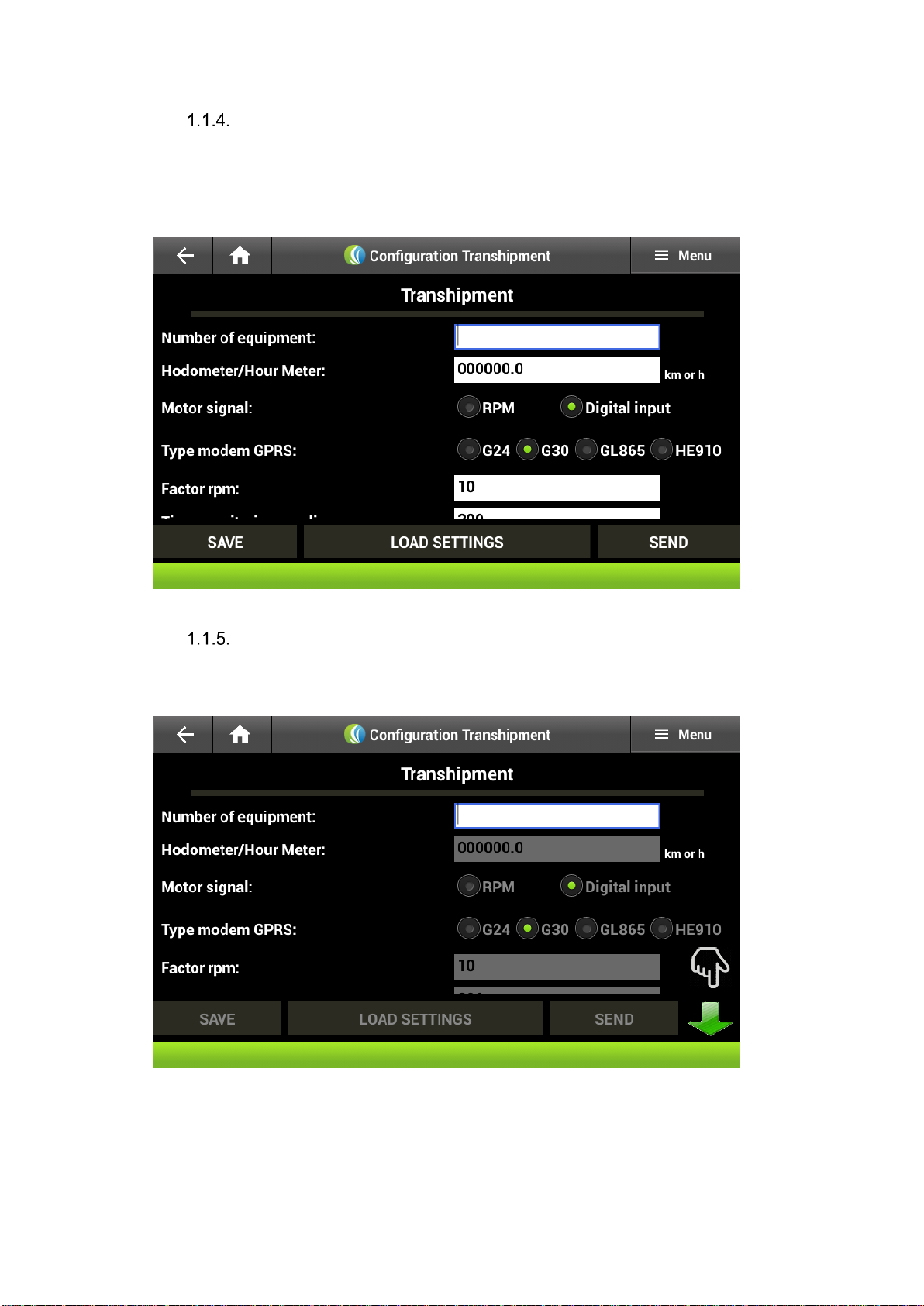

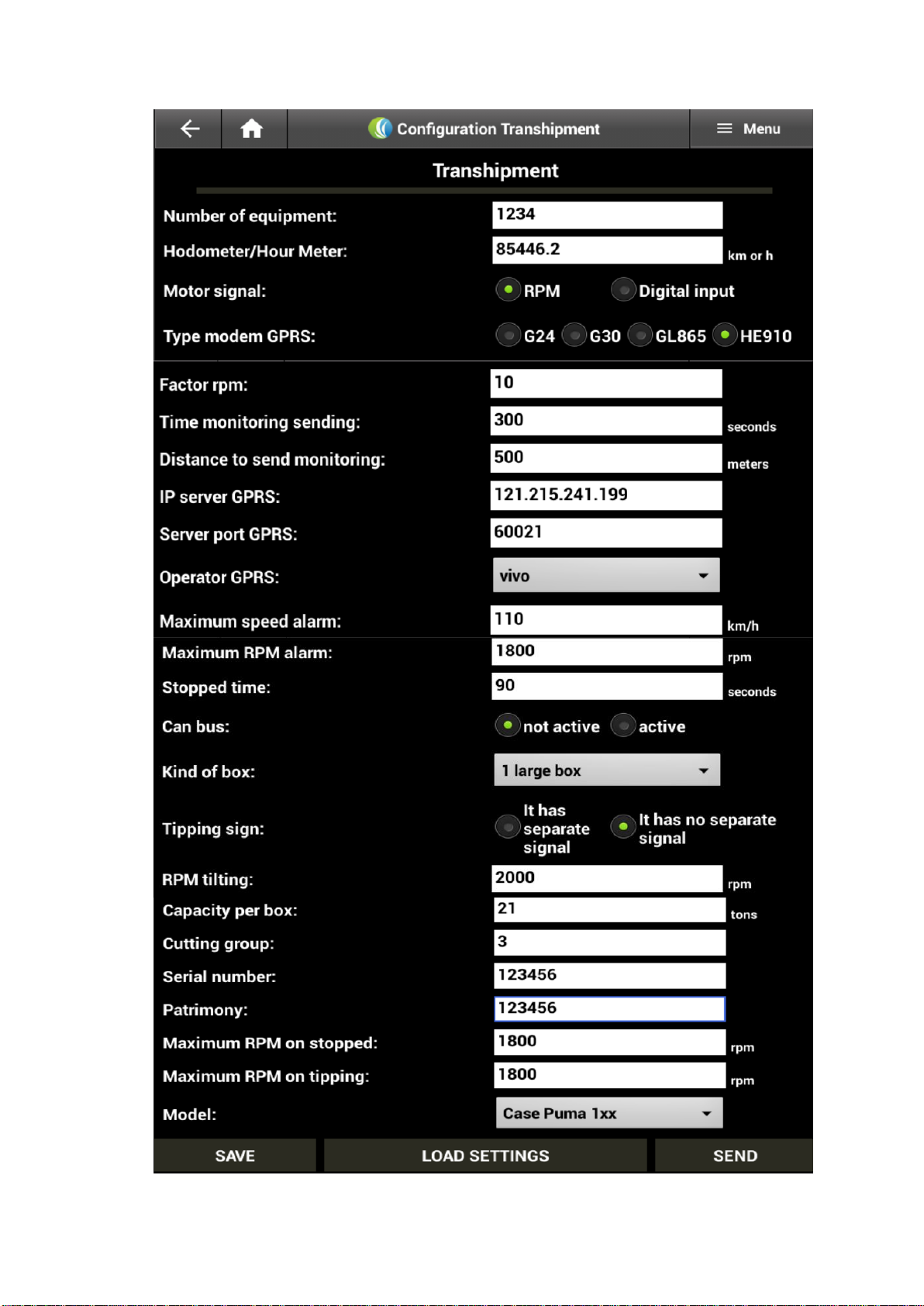

Transshipment Parameters Configuration .............................................. 14

Standard Setting: ................................................................................... 15

Configuration Step-by-Step: ................................................................... 15

RPM Factor Settings .............................................................................. 20

Signal test screen .................................................................................. 21

CAN BUS screen ................................................................................... 23

Download Contingency Option .............................................................. 25

3. APK sCB Transshipment .............................................................................. 26

1.11. sCBTransshipment App ............................................................................. 26

1.12. Importing Registers ................................................................................... 28

1.13. Configuring the Operational Parameters of the Transshipment. ................ 29

1.14. Configuration of the Work shifts................................................................. 30

1.15. Zigbee Communication Test ...................................................................... 31

1.16. Import Records.......................................................................................... 31

1.17. Load Map .................................................................................................. 32

1.18. Request release code ............................................................................... 33

1.19. Enable go-return ....................................................................................... 34

1.20. Save commands in log ................................ .............................................. 34

1.21. CDT Planting ............................................................................................. 35

1.22. Active FLOW ............................................................................................. 35

1.23. CDT active ................................................................................................ 36

3

1.24. Basket type ............................................................................................... 37

1.25. Enter Implements ...................................................................................... 37

1.26. Allow access to Tire Screen ...................................................................... 38

1.27. Maximum number of digits on a trailer. ...................................................... 38

1.28. Max. Trailers GR ....................................................................................... 38

1.29. Exit the application .................................................................................... 39

4. Transshipment Firmware Configuration ........................................................ 40

4.1 Parameters of the Transshipment Firmware Configuration ........................... 40

5. Transshipment records registration ............................................................... 44

4.1 Formatting the records on the transshipment memory card CF. ......................... 44

5.2 File Register to the Transshipment APK ........................................................ 47

5.3 Update of the files registered on the tablet using a flash drive. ..................... 50

6. Commands used on the Transshipment remote update ................................ 52

6.1 Parameters that can be updated remotely on the transshipment .................. 52

4

1. Mechanic Characteristic

1.1. Technical Characteristic

a) Feeding of 12 – 35 volts

b) Four digital input 0-30 volts

c) Two digital output 0-30 volts

d) Three analogue input 0-10 volts,4-20 mA

e) Two pulse input (RPM and pulse)

f) One serial port (RS 232)

g) GRPS,3G Communication

h) Communication Zigbee (mesh net) 7 km/ 35 km (optional)

i) Communication Bluetooth (optional)

j) Optional – Canbus parameters reading (it depends on the vehicle model)

k) Global Positioning System (GPS)

l) Removable storage system (Intern Compact flash, up to 2gb)

m) IP66

The Mag100R has an internal battery (optional), that works as a backup, with a minimum

autonomy of 2 working hours, if it were unplugged from the main battery. It is important

to highlight that; this machine is out of the operator’s range and all the antennas are

external.

Storage Temperature

0 - 50°

Relative Humidity

5 – 85%

1.2. GPRS, 3G Communication

Figure 1 - Module HE910 - D

Module HE910-D Made by TELIT.

Address: Via Stazione di Prosecco, 5/B, I-34010 Sgonico(Trieste), Italy,

Zip Code: 34010

Width (mm) x height (mm) x comprimento (mm)

73 mm x 33 mm x 165 mm

Box material

ABS (plastic)

5

Telephone: +39 040 4192, Fax: +39 040 4192 333

Information Contact and technical assistance.

TS-EMEA@telit.com

TS-AMERICAS@telit.com

TS-APAC@telit.com

TS-SRD@telit.com

Alternative Use: http://www.telit.com/support

Official Page: http//www.telit.com

1.3. Characteristics

• 4 range GSM/GPRS/EDGE: 850/900/1800/1900MHz

• 3 range UTMS/HSPA: 850/900/2100MHz

• WCDMA Multi-band (I, II, IV, V, VI, VIII and XIX)

• HSDPA up to 21.0Mbps (high range; up to 7.2 Mbps for other)

• HSUPA up to 5.76Mbps

• WCDMA 384kbps downlink/uplink

• DTM (double transfer module)

• Reception Diversity, tipo3i Interference Canceling Receptor

• CPC (DRX/DTX) (Continuous package connection)

• Control using AT according with 3GPP TS27.005, 27.007 and other Telit

modules.

• Multiplexed serial port 3GPP TS27.010

• SIM card interface 1.8/3V (Automatic detection 3GPP TS 51.014)

Power Consumption (Conventional Values)

• Quiescent current -by 2G, DRX5, 1.1 mA

• Stand-by current- 3G, DRX7, 1.2 mA

Transmission Power:

• Class 4 (2W) @ 850 / 900 MHz, GSM

• Class 1 (1W) @ 1800 / 1900 MHz, GSM

• Class E2 (0.5W) @ 850/900 MHz, EDGE

• Class E2 (0.4W) @ 1800/1900 MHz, EDGE

• Class 3 (0.25W) @ 850/900/1700/1900/2100 MHz

Sensitivity Reception:

• GSM 850/900MHz - 109 dBm

• GSM 1800/1900MHz - 110 dBm

• WCDMA 850/900/1700/1900MHz - 111 dBm

1.4. Data Transmission:

• HSPA: category 14 in downlink and category 6 in uplink

• DL to 21.0Mbps

• UL to 5.76Mbps

• WCDMA: to 384kbps downlink/uplink

• EDGE: DL to 296kbps, UL to 236.8kbps

• GPRS: DL to 107kbps, UL to 85.6kbps

• GPRS class 10 to Global and variables NAx; class 33 for variables EUx

• EDGE class 10 for Global and variables NAx; class 33 for variables EUx

6

• Not transparent asynchronous CSD up to 9.6kbps

• Code outline from 1 to 4 (GPRS) and codification outline module from 1 to 9

(EDGE)

Antenna Perform

Frequency

880 – 1600 mhz

Efficiency

82%

Impedance

50 ohm

Irradiation

Omnidirectional

Polarization

Lineal

Temperature of the Operation

0 - 85°

FCC ID: RI7 HE910

FCC REGISTER NUMBER (FRN): 0020384608

1.5. Communication XBEE

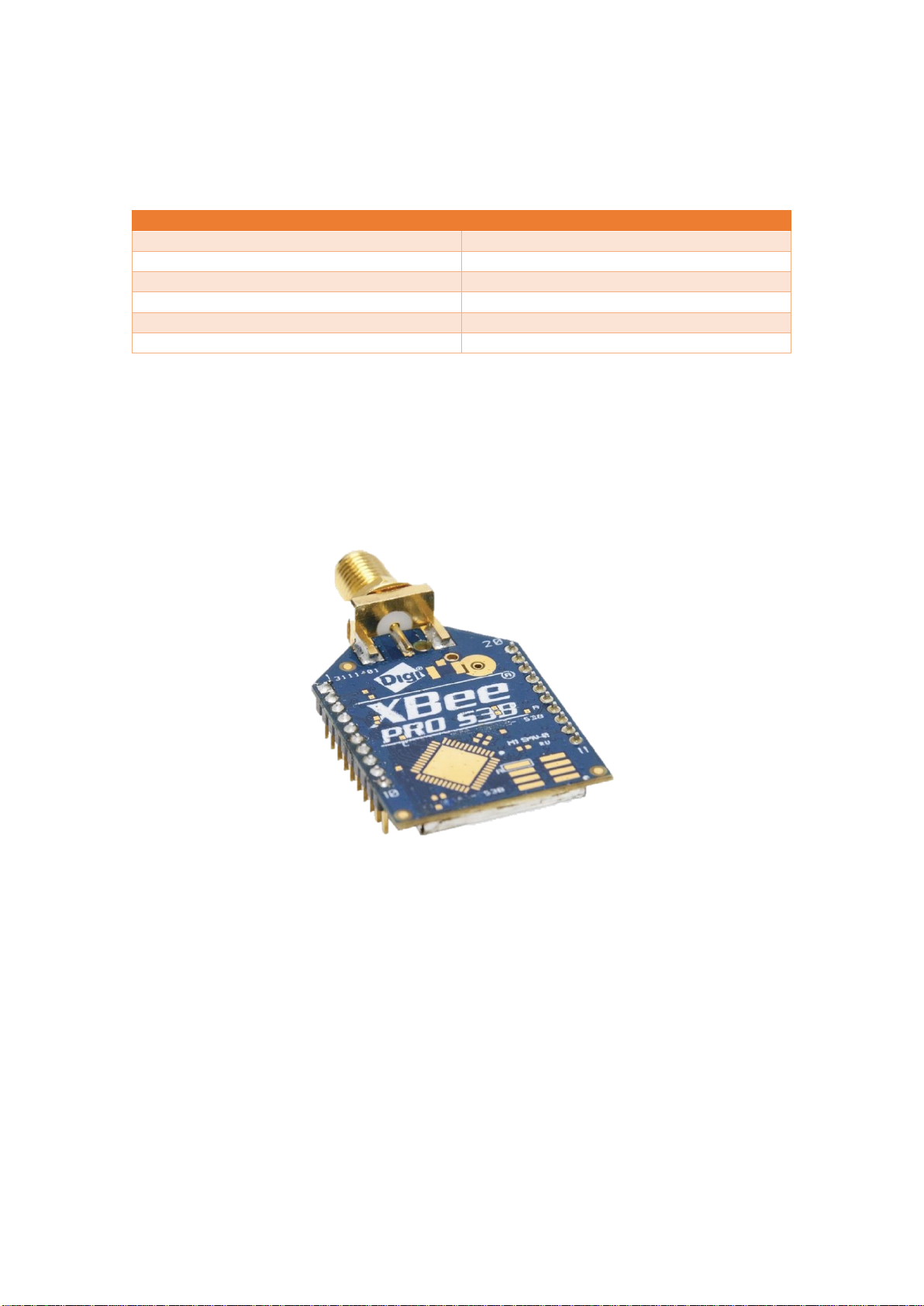

Figure 2 - Module XBEE-PRO S3B

Module XBEE-PRO 900HP S3B Made by Digi International.

Address: 11001 Bren Road East

Minnetonka, MN 55343

Telephone: 1-877-912-3444

Telephone :952-912-3444

Fax: 952-912-4952

Technical Support.

Telephones: (866) 765-9885 toll-free U.S.A and Canada

(801) 765-9885 Worldwide

Online Support: www.digi.com/support

Email: tech.support@digi.com

7

The RF Xbee-pro 900HP is ideal for smaller power consumption, from point to

multipoint on low latency net application. It is used on peer to peer and net from point

to multiple point. The XBee-900 module has a higher selectable transmission power

of 250 mW. This higher Tx power allows a line-of-sight range up to 28 miles with

antenna right. This one is ideal for situations in which the RF penetration and absolute

transmission distance are of extreme importance for the implementation.

As part of the RF XBee line, this module is easy to use, includes drop-in gateways

nets, and uses Digi and Adapters. The RF does not need any out-of-the-box

configuration and any necessary advance configuration can be replaced with simple

commands.

1.6. Characteristics:

Processor: transceiver ADF7023, Cortex-M3 EFM32G230 @ 28 MHz

Includes Programmable: Freescale MC9S08QE32

Frequency range: 902 to 928 MHz, selectable software for the interference resistance.

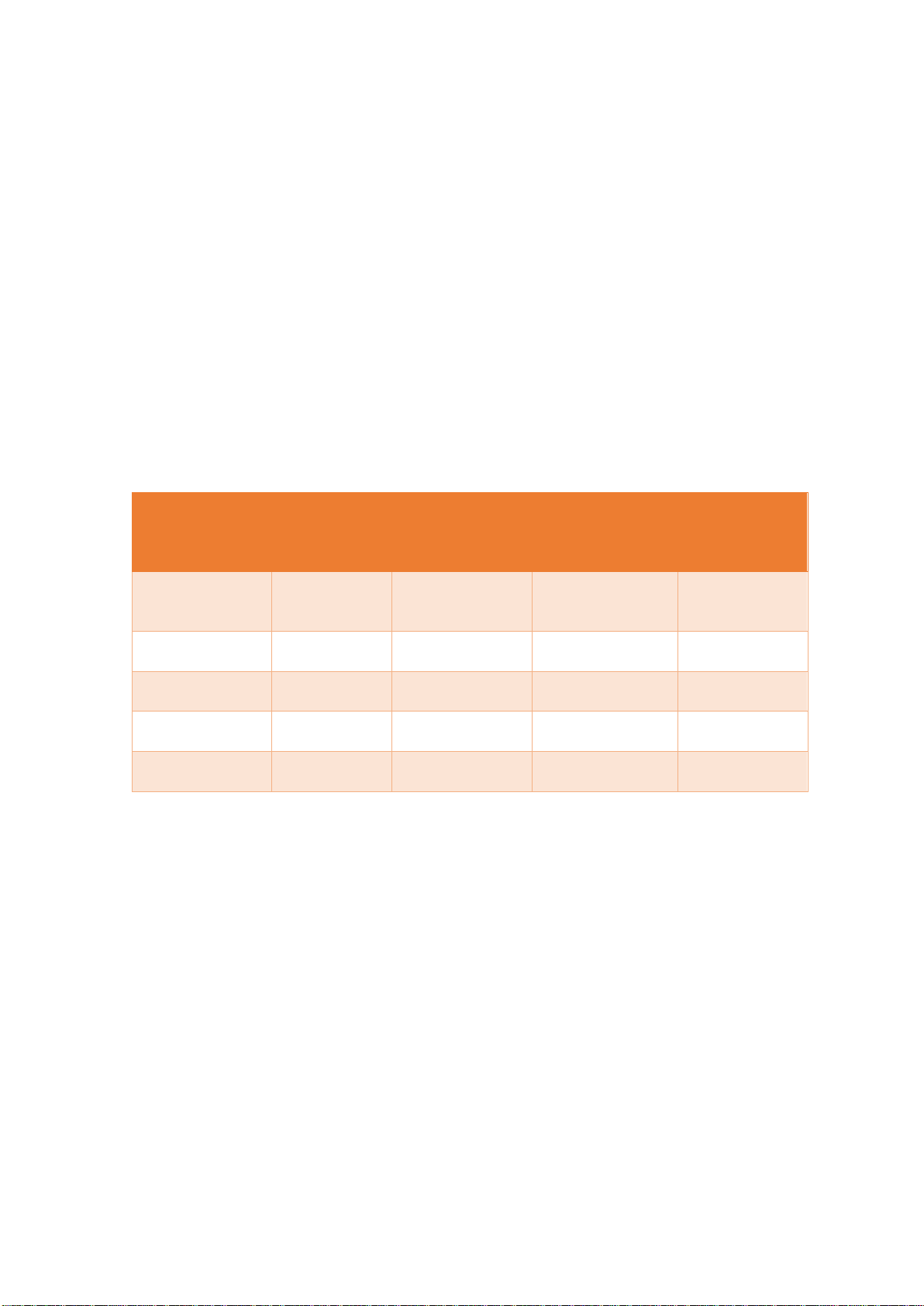

Frequency Intervals, Power and Type of Modulation

Frequency

Interval Tx

(MHz)

Output

Maximum

Power

(W)

Emission

Designation

Technology

Type of

Modulation

920.0 a

928.0

0.23878

290KF7D

LEAP IN

FREQUENCY

FSK

902.0 a

907.5

0.20701

255KF7D

LEAP IN

FREQUENCY

FSK

902.0 a

907.5

0.24266

360KF7D

LEAP IN

FREQUENCY

FSK

915.0 a

928.0

0.20701

255KF7D

LEAP IN

FREQUENCY

FSK

915.0 a

928.0

0.24266

360KF7D

LEAP IN

FREQUENCY

FSK

In the specific case of Peru, the modules were configurated to work on a 915,5 a 927,7

MHz frequency, setting the cm register (Channel Mask) with a value of

FFFFFFFE00000000, that same value is defined during the production of mag-100R and

it is storage on the inter flash of the XBee 900-HP.

The starting process of the Mag-100R is configured following the next steps. If the XBee

900-HP radio module is changed, then the correct configuration is ensured.

1.7. Characteristics of the XBee 900-HPS3B for Peru

• Working Frequency: 915.5 MHz to 927.7 MHz

• Channels: 31

• Main Frequency of the main channel: 915.600 MHz

• Channel division: 400 kHz

8

• Transmission range length: 200 kHz

• Modulation: GFSK

• Channel Leap: Yes (pseudo-random)

• Maximum Power Transmission: 24 dBm (250 mW)

• Baudrate on the air: 200 kbps

• Sensitivity: -101 dBm

1.8. Data Transmission

• Data Speed: RF: 10 Kbps o 200 Kbps

• Interior/Urban range: 10 Kbps: to 2000 feet (610 m); 200 Kbps: to 1000 feet (305

m), outdoor/Line-Of-Sight Range: 10 Kbps: to 9 miles (14 km); 200 Kbps: to 4

miles (6.5 km) (w/2.1 dipole antenna dB)

1.9. Transmission Power:

• to 24 dBm (250 mW) selectable by software

Receptor Sensitivity:

• -101 dBm a 200 Kbps,

• -110 dBm a 10 Kbps

Interface

• Data Interface: UART (3 V), SPI

• GPIO: to 15 E/S Digital, 4 adc input of $ number bits, 2 PWM outputs

• Network Topology: DigiMesh, repeater, point to point, peer to Multipoint, Peer-to-

Peer

• Spread Spectrum: FHSS (Selectable Channel Software)

Program Capacity

• memory: N/A 32 KB

• CPU/Clock Speed: N/A

Feeding Tension

Feeding Tension 2.1 a 3.6 V CC C

Current in transmission 215 mA typical (290 mA max)

Current in reception 29 mA typical a 3.3V (35 mA max)

Current Sleep 2.5 uA typical

Temperature on the Operation -40 ºC to 85 º C (industrial)

Physical Property

Weight: de 5 a 8 g depending on the antenna option

Size: 3.3 cm x 2.5 cm (4.5x2.5 cm with connector)

Antenna Performance

VSWR

<= 2,0 : 1

Maximum Power

20 Watts

Impedance

50 ohm

Irradiation

Omnidirectional

Earnings

6 dBi

9

Homologated by countries:

Country

Approved

United States (FCC Part 15.247)

MCQ-XB900HP

Industry Canada (IC)

1846A-XB900HP

Australia

RCM

Brazil

ANATEL 3727-12-1209

Singapore

License No. DA105737 (XB900HP

only)

Mexico

IFETEL (XB900HP only)

RoHS2

Compliant

FCC ID: MCQ-XBPS3B

FCC REGISTER NUMBER(FRN): 0010283307

1.10. GPS MODULE MADE BY UBLOX

Figure 3 - LEA-6S Module

Model LEA-6S

Contacts

HQ Switzerland: +41 44 722 7444 info@u-blox.com

America +1 703 483 3180 info_us@u-blox.com

APAC – Singapore +65 6734 3811 info_ap@u-blox.com

China +86 10 68 133 545 info_cn@u-blox.com

Taiwan +886 2 2657 1090 info_tw@u-blox.com

• U-blox 6 position engine:

o Navigate up to-162 dBm and-148 dBm coldstart

o Faster Acquisition with AssistNow Autonomous

10

o Configurable energy Management

o Hybrid gps/sbas (waas, egnos, msas)

o Anti-jamming Technology

• Simple Integration with unwired u-blox modules

• A-gps: AssistNow ON-LINE and off-line AssistNow services, OMA SUPL

compliant

• Compatible (hardware and firmware); easy migration to LEA-5 or LEA-4 family

• LCC package for trustable manufacture and effective cost

• Compatible with u-blox GPS for Android

• Based on the GNSS chips qualified according to the aec-q100

• Made on iso/ts 16949 production facility

• Qualified according to ISO 16750

Hot starting and initial auxiliary position for the first time in less than a second.

Tracking capture and sensitivity of 160dBm

Kickstart function, the model can attain an acceleration when the signal level is low at

the beginning.

GPS, Galileo, SBAS (WAAS and EGNOS and MSAS, and GAGAN) hybrid motor

4 Hz update range of the position.

Receptor with 50 channels, frequency L1 code C/A (1575 MHz).

Search sensitivity during navigation -162 dBm

Reacquisition sensitivity -160 dBm

Sensitivity on the cold starting without help -148 dBm.

Maximum Updating interval during navigation 5 Hz

Horizontal Position of without help precision 2,5 m e SBAS 2 m

Configurable interval frequency of leap-time 0,25 Hz a 1 kHz

Speed Precision 0,1 m/s

Orientation Precision 0,5 degrees

Operational Limits: Dynamic ≤ 4 g, Altitude 50,000 m , speed 500 m/s

Source tension 2.7 V – 3.6 V

Consumption of continuous potency 121 mW.

Consumption of potency on Save mode 36 mW.

Support of Antenna active and passive.

Serial Interface: 1 UART, 1 USB V2.0 full speed 12 Mbit/s, 1 DDC (I2 C compliant)

Antenna Performance

Impendence

50 ohm

Central Frequency

1575.42 mhz

Range length

10 mhz

Earnings

27 db

Mitigation for output filter

range (db)

Dielectric fo = 1575.42 mhz

7 typ. Fo +/- 20 mhz

20 typ. Fo +/- 50 mhz

30 typ. Fo +/- 100 mhz

Power Consumption

10 mA (max)

11

2. MAG-100 Transshipment Configuration.

2.1 APK sCBConfigMag100R

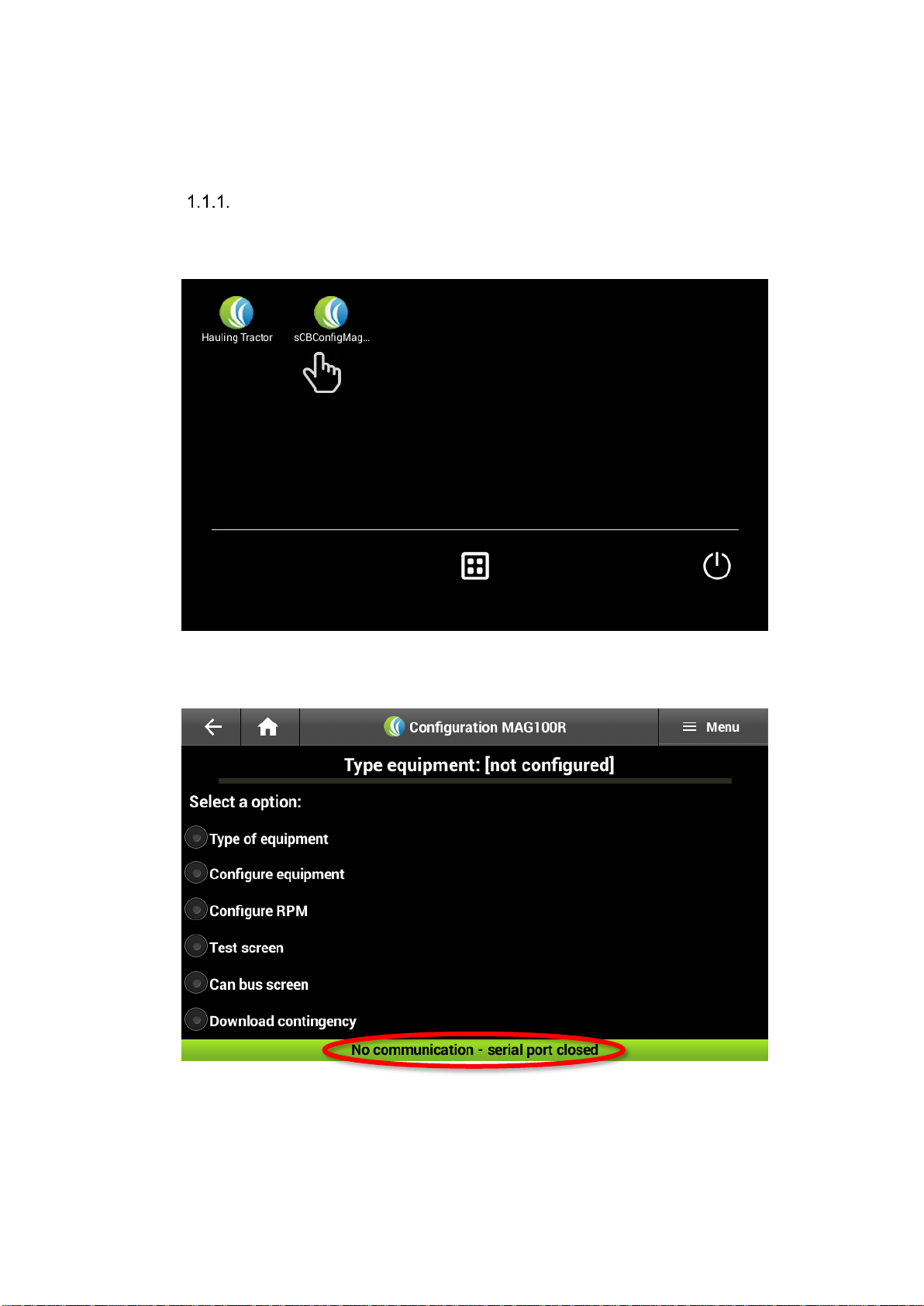

Open sCBConfig app.

The sCBConfig app is used for the initial configurations of the MAG100 in any

machine. On this document, it is explained the configuration process of the

Transshipment.

First, it must be selected the sCBConfigMag app.

Opening of the configuration serial port

Each item on the screen will be explained one by one with all its functionalities. The

configuration main screen by default has no machine configurated and has the serial

port closed:

12

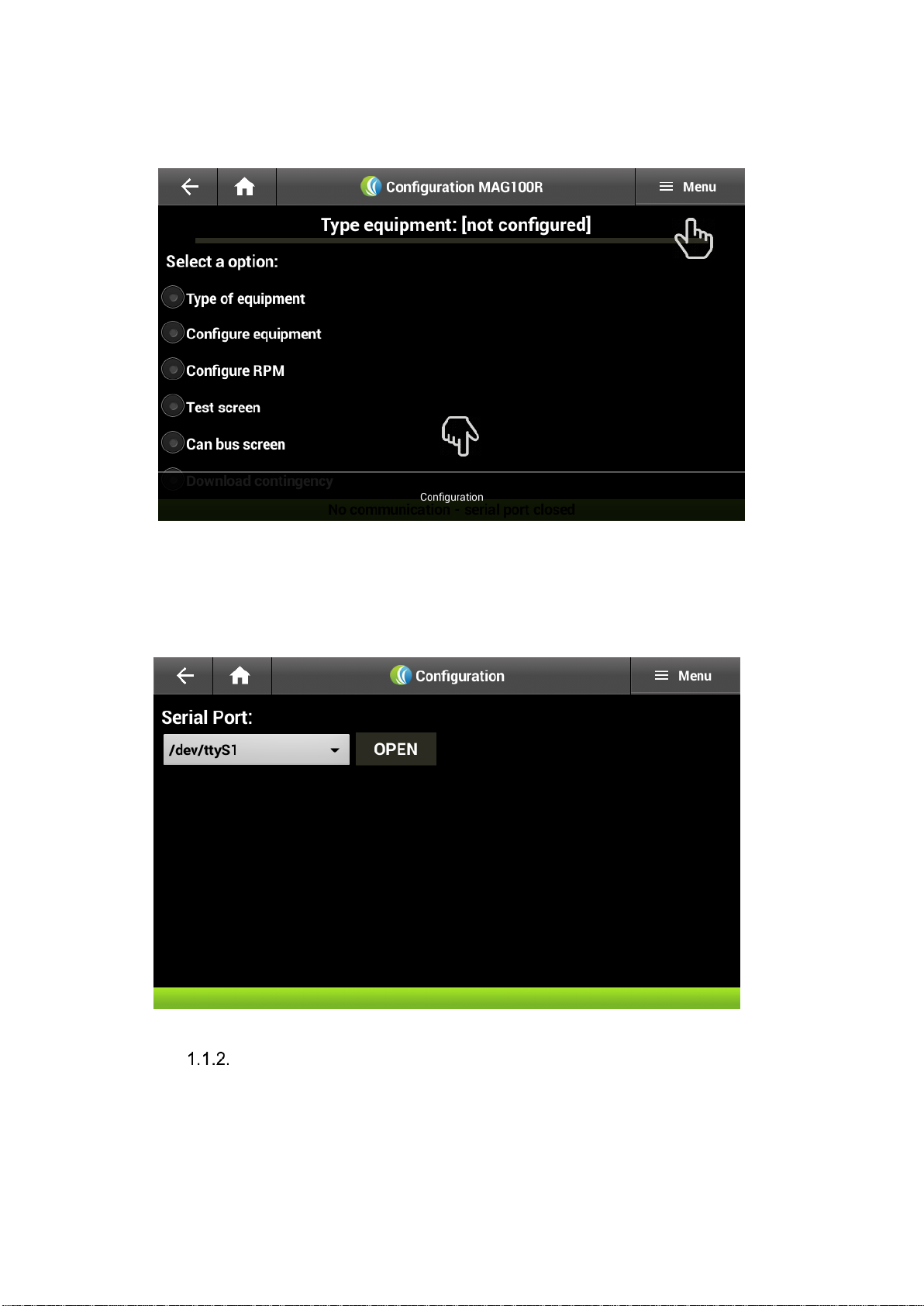

To enable the serial port, it is necessary to click on the “MENU”.

After, that a tab will appear on the lower part of the screen with the option of

“Configuration”.

Once the Configuration option is selected, a portal serial tab will appear on the screen.

Then, it is important to enter the valid address which is (/dev/ttyS1) and select the

option “OPEN”. To return to the main screen click the “BACK” or “HOME bottom

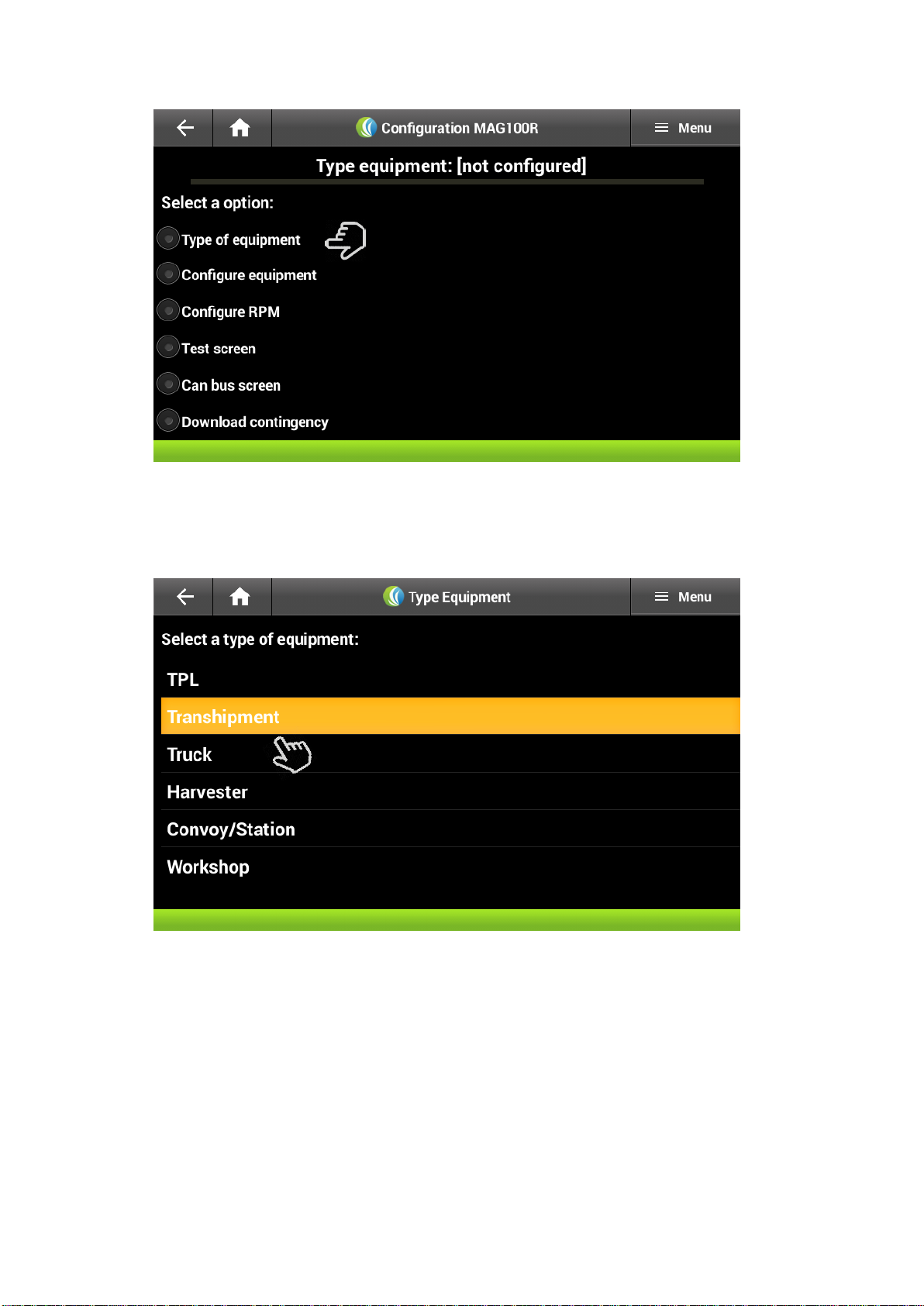

Configuring type of equipment

The first step on the configuration of the computer on board, it is to specify the type

of equipment used on the option “Type of Equipment”.

13

In this case, the equipment will be “Transshipment”

14

Transshipment Parameters Configuration

After that, the app will return immediately to the main screen. Then, the equipment

can be configured

The desired setting can be selected:

Standard: There is complete freedom to change the parameters.

Step-by-Step: It will be changed a field at a time, on the following order.

15

Standard Setting:

This option gives more liberty on the field selection. The desired option can be

selected at any time and the virtual keyboard will appear to enter the data. To move

around on the screen, it is just a matter of sliding the finger.

Configuration Step-by-Step:

In this case, it must be configured field by field following the order on the screen and

changing them using the arrow highlighted on the image:

After that, it is necessary to make some changes which are explained in detail:

16

17

Description of Fields

Fields configuration detail

Machine Number

Machine number registered by the farm.

Odometer/Hour Meter

Odometer and Hour Meter (depends on the machine)

usually on the transshipment panel analyzed by the CAN

BUS network.

Engine Signal

RPM: Engine signal is measured by the alternator or the

CAN BUS network.

Digital Input: The engine signal is measured by the ignition

point or (fixed RPM).

Type of Modem

Specify the type of hardware used (modem GPRS).

RPM Factor

It will be configured afterwards

Monitoring Sending Time

Time measured in seconds for the register of the

monitoring.

Monitoring Sending Distance

Distance in meters for the register of the monitoring

IP server GPRS

IP of the server that will receive the CB info.

Server Port GPRS

The server port will receive the CB info.

GPRS Operator

Operator of the SIM card used on the transmission of the

CB info.

Maximum Speed Alarm

If the Maximum speed is exceeded an alarm is generated

and registered.

RPM maximum alarm

If the maximum RPM speed is exceeded an alarm is

generated and registered.

Stop Time

If the Maximum time is exceeded, it will ask for a code with

the reason of the stop.

Can bus

It enables or disables de Can Bus network.

Type of truck *

No configurated

1 small truck box

2 small truck boxes

3 small truck boxes

1 big truck box

2 big truck boxes

3 big truck boxes

Small together

Big together

2 middle truck boxes

2 extra big truck box

Overturning Signal

There is or not case selection (overturning signal)

Truck bed Capacity

Case capacity in ton.

Harvesting Code

Harvesting team machine code.

Serial number

Serial number fixed on the computer on board by Solinftec

Assets

Identity number of the computer on board fixed by the client

Maximum RPM Stop

Maximum RPM allowed to the machine when there is no

speed

Maximum overturning RPM

Maximum RPM allowed to machine during overturning

Case Type*

Distance between

the GPS antenna

and the center of

the 1st truck crate

Distance between

the GPS antenna

and the center of

the 2

nd

truck crate

Distance between

the GPS antenna

and the center of

the 3

rd

truck crate

18

After clicking on the option Save, the following confirmation message will appear:

Indicating that it is necessary to fill all the fields before saving the settings

If settings were previously saved on the S7 tablet, those can be loaded on the option

“Loading Settings”

1 small crate

3.7 meter

2 small crates

3.7 meter

7 meters

3 small crates

3.7 meter

7meters

12.5 meter

1 large crate

7 meters

2 large crates

5.5 meter

12 meters

3 large crates

5.5 meter

12 meters

22.5 meter

Small Attached

3.7 meter

7 meters

Large Attached

5.5 meter

12 meters

2 medium truck

4.2 meter

10.8 meter

2 extra-large truck

crates

6.3 meter

13.3 meter

19

Then, it is necessary to send such data to the MAG100 computer on board using the

option Send.

After that, the user must return to the main screen using the bottoms return or home

20

RPM Factor Settings

The option RPM Configuration allows to calibrate the RPM measurements by means

of the RPM Factor:

Only equipment without Can Bus net reading need de RPM calibration. Once selected

the field rpm factor, a virtual keyboard will appear to make the necessary value

changes:

21

Once the info is saved, the next screen will appear confirming the previous action.

Signal test screen

The option test screen allows to see the state of the equipment, as well as the value

of all the measurements made by the computer on board and the status of it

peripherals

Adjust de RPM

factor until a

number similar to

the one on the

harvester panel.

Saves the RPM values

RPM measured by the computer on board

RPM value

validation

22

Test Screen Description

Computer on Board

Machine Number:

Number of the machine configured.

Odometer/Hours

meter:

The odometer and hours meter configured on the CAN BUS.

Speed:

Equipment speed.

RPM:

Actual RPM of the equipment measured by the computer on board, by the

CAN BUS net.

Status:

Actual status of the machine:

F: Stopped

C: Harvest

M: Maneuver

D: Moving

CF card:

Actual state of memory card Compact Flash: Error or OK.

ENTRYS

Digital Input:

Digital Input activated by the computer on board (0000 → ED1, ED2, ED3,

ED4).

Pulse Input:

Pulse input values (00 → EP1, EP2).

External Input:

Feed.

Analogue 1:

Value measured by the computer on board on the EA1.

Analogue 2:

Value measured by the computer on board on the EA2.

Analogue 3:

Value measured by the computer on board on the EA3.

GPS

GSP valid:

Actual GPS – Valid or not valid

Latitude:

Equipment Actual Latitude.

Longitude:

Actual Longitude of the equipment.

MODEM GPRS

Status:

It shows the status of the connectivity process of the modem GPRS (0 –

11).

23

Message:

7 (MAG200, RECOK, ALOHA): Modem connected on the monitoring

system.

6 (ERROR) IP and/or wrong Input or communication problem with the

server.

5 (ERROR) Problem with the signal connection with the operator.

1 (ERROR) Problem with the SIM card.

Monitoring time:

Time spent since the last monitoring register.

Monitoring Distance:

Distance travelled since the last monitoring register.

Aloha Time:

Time spent since the last communication with the server.

Alarms:

Alarms actives on the computer on board.

CAN BUS screen

Option “can bus screen” allows to access the screens with all the info of the Can Bus

net, as long as that option is active on the equipment settings.

24

To return to the main screen, you can select the home bottom and the back option.

25

Download Contingency Option

On this option the appointment and monitoring info is downloaded from the CF

memory card into a flash drive on the tablet.

If there is no flash drive the system will display the following warning:

If the flash drive is on the tablet after the info is downloaded the following text will

appear:

Closing of the Setting Serial Port

After the configuration process is finished, it is necessary to close the APK sCBConfig

communication port. This process can be done on the main screen

Menu/Configuration.

26

To exit the app used the back bottom.

3. APK sCB Transshipment

1.11. sCBTransshipment App

The sCBTransshipment app is used on to register and monitor using the MAG 100.

In this part of the document, it will be explained in detail the transshipment

configuration process.

The first step is to open the app:

27

Opening the MAG100 comunication serial port

The first time the app is opened there will appear a warning, of the serial port being

closed, on the main screen. In order to open it, you must click on the “MENU” ,

“Configuration” option.

For security reasons, the configuration process has a password only known by those

authorized to configure the computer on board:

28

After introducing the password select the open bottom and the correct serial port will

appear as a pre-stablished (/dev/ttyS1):

1.12. Importing Registers

Once the serial port is opened, the files registered and saved on the tablet on the file

“data/Trabalho/Cadastros” will be imported automatically

29

If there is any change on the register files saved on the tablet, it will be necessary to

select the option import records without any need of opening the serial port again. If

there is any file missing during this process the following message will appear.

In this case, follow the steps on the option “Updating the register files on the tablet”

1.13. Configuring the Operational Parameters of the Transshipment.

Some of the configurations done on the app sCBConfig can be seen and modified

on this app on the option “General”

30

The General option will show the machine code, the GPRS operator, the monitoring

time among other info that cannot be changed. Other modifiable parameters such as,

minimum and maximum speed and RPM stop time will appear on this option.

Whenever a modifiable field is activated the virtual keyboard will appear. All

modification must be saved using the corresponding option: “Save”

1.14. Configuration of the Work shifts

The transshipment option will allow to alter the configuration of item such as TAG’s

type of crate, lifting signal, crates and cutting capacity as well as configurating the

crates with or without password.

31

1.15. Zigbee Communication Test

The option “Zigbee Communication” allows to test the Zigbee on the computer on

board. Once it is selected, a communication internal test is done. If the test is

successful, the message “Zigbee Communication Ok” will appear. If the message

to appear were “Zigbee Communication Fail” the CB must be sent to maintenance.

1.16. Import Records

This option imports the registers saved on the tablet on the file

“data/Trabalho/Cadastros”. If there is any change on these files saved on the tablet,

it is necessary to select this option to enable the changes. After that, the message

“Records imported successfully” will appear.

32

If there is any record missing on the import process the following message will appear

“Records not found on file /data/Trabalho/Cadastros”: If this were the case, the

steps on section “Update the records registered on the tablet” must be followed.

1.17. Load Map

This option loads on the APK transshipment main screen the harvesting area maps

supplied by the farm and saved on the file “data/Trabalho/Mapas”.

Once this option is selected, on the Menu /Option Map on the main screen of the

Transshipment will appear the harvesting area map of the farm

33

When this option is not selected, then it will return to the main screen of the

Transshipment APK and will show the Solinftec logo:

1.18. Request release code

This option is active on any contingency measure. For example, if a transshipment

doesn’t detect the harvester the computer on board will request the cut order of the

harvest.

34

1.19. Enable go-return

This option is used to the transshipment to send information to the coordinator. If the

firmware or the “Transshipment coordinator” item0 is active, then this option will also

activate the transshipment to act as a coordinator, in case of the CDC:

1.20. Save commands in log

In this case, all the commands given will be saved for further analysis using USB

cable.

35

1.21. CDT Planting

Using this option, the planting features will be activated, if the firmware allows it to

1.22. Active FLOW

A confirmation check box will appear whenever this option is activated.

36

1.23. CDT active

A confirmation check box will appear whenever this option is activated.

37

1.24. Basket type

This option allows to enter the Crate Code if necessary:

1.25. Enter Implements

This option enables to select any implement.

38

1.26. Allow access to Tire Screen

This option is currently on development, therefore, has not been activated on the

transshipment:

1.27. Maximum number of digits on a trailer.

This option shows a range between 10 to 12 digits, depending on the farms

configuration and the maximum number of trailers allowed.

1.28. Max. Trailers GR

This option shows the maximum number of trailers to be storage on the go- return

option.

39

1.29. Exit the application

Through this option the Transshipment APK can be exit and access other apps

installed on android.

Once this option is selected, you can return to the main screen of the transshipment

App and exit the app using the bottom Return.

40

4. Transshipment Firmware Configuration

4.1 Parameters of the Transshipment Firmware Configuration

Every MAG 100 Transshipment firmware will be accompanied by the “Config.txt” file

which has all the current settings of the firmware. In this section will be explained

every parameter and its use on the computer on board.

TRANSSHIPMENT

APP DESCRIPTION

MODOTESTE

Defines the Firmware test mode.

0: Test Mode disable.

1: Test Mode activated (with the ED4

active, a fixed speed of (5Km/h) and RPM

of 640 (Engine on).

FUT

Defines the activation of the FLOW app on

Firmware.

0: FLOW app disables.

1: FLOW app active.

ATIVACCT

Defines the activation of the CDT app on

the Firmware.

0: Applicative CDT disable (identifies the

harvester and changes the status. It

doesn’t send lifting register ZIG22).

1: App CDT active

ATIVACCTPLANTIO

Defines the activation of the CCT

PLANTING app on the Firmware.

0: CCT PLANTING APP disable.

1: CCT PLANTING APP active.

SEMCOORD

Defines the activation of the Transshipment

Coordinator Function.

0: Disables the Transshipment Coordinator

Function.

41

1: Activates Transshipment Coordinator

Function.

CERCAELETRONICA

Defines the activation of the Transshipment

Electronic Fence.

0: Disables Transshipment Electronic

Fence.

1: Activates Transshipment Electronic

Fence.

(file COORD_CERCAS).

ATIVARRFID

Defines the RFID usage activation.

0: Disables the RFID scanner.

1: Activates the RFID scanner.

PRIORIZASOLINFNET

Defines priority of the data traffic into the

system.

0: Prioritizes the GPRS/3G mode for the

data traffic.

1: Prioritizes the SOLINFNET for the data

traffic.

HARDWARE DESCRIPTION

ENTRADAX7

Defines the interface on the MAG100.

0: Interface by Bluetooth.

1: Interface on the S7 screen.

VALIDAEMX7

Defines the validation of the digital data.

0: Uses the CF register on the validation of

the digital data.

1: Uses the S7 register on the validation of

the digital data.

LIMITAPULOS

Configuration of the jumps on the registers

send by the Zigbee.

0: Doesn’t limit the number of jumps on the

Zigbee net.

1: Limits on 2 the number of jumps of the

Zigbee.

TAGBASCULAMENTO

Defines the activation of the Lifting Tag

use.

0: Activates the lifting status of the crates

on the digital input.

1: Activates the lifting status of the crates

on the Lifting Tag.

RPMPELACAN

Defines the activation of the RPM Reading

on the CAN net

0: Activates the RPM reading signal.

1: Activates the RPM reading signal on the

CAN net

HODOMHORIMCAN

Defines the activation of the

Odometer/Hour meter on the CAN net.

0: The Odometer/Hour meter info will be

calculated by the CB.

1: Activates the Odometer/Hour meter

Info Reading by the CAN net.

RTKPORCX3

Defines the activation of the RTK signal

Reading of the crate 3 (pin 7/ED4).

0: Activates the lifting Reading signal of

crate 3on the digital input 4 (pin 7).

42

1: Activates the RTK Reading signal on the

digital entry 4 (pin 7).

BAUDRATEZB

Defines the communication speed with the

ZIGBEE.

9600: Speed Pattern.

15200: Speed Test.

OPERATION DESCRIPTION

VALIDAIMPL

Defines the validation of the digital

implement codes on the register.

0: Doesn’t validate the implement code on

the file registered C_IMPLEMENTO.

1: Validates the implement code in the file

registered C_IMPLEMENTO.

VALIDAEQUP

Defines the validation of the digital

equipment codes on the register.

0: Doesn’t validate the equipment code on

the register C_EQUIP.

1: Validates the equipment code on the

register C_EQUIP.

PRIORIZAPARADA

Activates the function that prioritizes the

call of Harvesters on the FLOW app.

0: Transshipment doesn’t prioritize the

stopped harvesters on the FLOW calls.

1: Transshipments prioritize the stopped

harvesters on the FLOW calls (identifier 17

on the zig call).

GRUPOSFUT

Activates the Group work function on the

FLOW app.

0: Doesn’t send coordinates to the ZIG 29.

1: Sends coordinates to the ZIG 29 to work

on group only to harvesters with MAG100.

DESLOCAC1T

Activates the function maintain Harvester

assigned with ZOG1T register on the

FLOW app

0: Transshipment maintain Harvester

assigned when receives the ZOG1T

register of that harvester with a different

transshipment.

1: Transshipment release the harvester

assigned when it receives the ZIG1T from

that harvester with a transshipment waiting.

COLHEDORA300

Defines the ZIG29 answer time on the

FLOW app.

0: Harvester MAG100.

1: Changes the (zig29) answer time to the

calling of the harvester, it sends ok to the

zig 17.

CARRETA12DIG

Defines the number of digits of the codes

on the crates.

0: Works with 10 digits crates codes.

1: Works with the 12 digits code crate.

PREGQUANTOSQ

Activates the lifted crates request on the

FLOW app.

0: When the FLOW code is entered, it

43

doesn’t ask: “How many crates were

lifted.?".

1: When the FLOW code is entered, it asks:

“How many crates were lifted.?".

NOFUTDESLOCCARR

Defines the usage of the stop time

“Transshipment Line”.

0: Enters on Transshipment Line on any

condition the stop time code with identifiers

is entered. ador "H".

1: It doesn’t enter on Transshipment Line

when the stop time code identifies with and

H if it was previously on moving for loading

stage.

CORRIGEDATAHFUT

Data and time correction using FLOW.

0: Doesn’t correct date or time using

FLOW.

1: Corrects the date and time using FLOW.

DATALIMITEFUT

Defines the validity activation data on the

FLOW app.

0: The FLOW app will be active indefinitely.

170720 (aammdd): The FLOW app will be

active until July 20, 2017.

TPARADABASC

Defines the stop time of the lifting stage to

ask for the stop time code (in seconds).

180: When the transshipment passes the

180 second on lifting stop time, it asks for a

stop time code.

NOBASCMANOBRA

Defines the possibility to enter on lifting

state on the status of loading cane and

maneuver.

0: It sends records of the lifting process

when loading cane and maneuver.

1: It doesn’t send lifting records on the

status of Loading and Maneuver.

BASCLEVANTACX

It Defines a time filter to start the lifting

status.

0: Applies 5 seconds filter to start the lifting

status when the crate is lifted.

1: it starts the lifting status immediately

when the crate is lifted.

LIMITABASC

Defines the lifting limit event for crate.

0: It doesn’t limit the lifting for crate.

1: It limits the lifting for the selected crate.

NOCOLHEDCARREG

Defines the condition that recognizes the

harvester.

0: Recognizes the harvester without

condition

1: It doesn’t recognize the first 5 minutes

loading.

HODOMETRO

Defines the info to be send on the orometer

and hour meter records.

0: It sends the orometer kijos (standard).

1: It sends hour meters kijos.

44

KIJOSCAN

Defines the info system of the CAN net.

0: It doesn’t send Can records even if it is

active.

1: It sends records of the CAN.

DEFINIÇÕES DE ALAMES

TOCIOSO

Defines the idle engine time (in seconds).

300: The engine must maintain the alarm

condition for 300 consecutive second on

stop state to generate the alarm.

REDE ZIGBEE FIRMWARE

REDEZBH

High address of the e Zigbee (H).

REDEZBL

Low address of the Zigbee (L) net – All

together with the high address form the

Zigbee (HHLL).

VERSÃO FIRMWARE

VERSIONE

Development year of the firmware version.

VERSIOND

Sequence of the firmware.

OUTROS CULTIVOS

MAPASANALITICOS

CAMBIOCONDICAO

RELATORIOPOR33

5. Transshipment records registration

4.1 Formatting the records on the transshipment memory card CF.

The CF memory card installed on the MAG100 needs to be formatted, using the app

“CF Formatting” given by Solinftec, using some files to ensure the functioning of the

computer on board. Below, there is a description of the necessary files for the

transshipment:

On the transshipment CF there will be storage the following files:

• C_CHECKLIST;

• C_CHECKLIST_ITEM;

• C_FUNC;

• operacoes_manutencao;

• operacoes_paradas;

• operacoes_produtivas;

• C_EQUIP;

• C_COORDENADAS;

• C_COORD_CERCAS

• fazendas;

• C_FAZENDAS.

Below there is the description of each of the files.

C_CHECKLIST:

In this case, there is a code register of the groups in which every checklist is framed

Example: 01;S

Field

Description

01

Checklist item code

S

Checklist implement indicator

45

Whenever a checklist is not necessary, that file can be registered on one line.

C_CHECKLIST_ITEM:

Checklist Item ordered by group:

Example: 01;001;CHECK FUEL LEVEL

Field

Description

01

Team code

001

Item code

CHECK FUEL LEVEL

Item description

Whenever a checklist is not necessary, that file can be registered on one empty line:

01;001;VAZIO

C_FUNC:

The employee record order from the small to the biggest registration code

Example: 140292;RENATO RUY;O;140292;1

Field

Description

140292

Employee registration

RENATO RUY

Name of the employee

O

Employee Role (O = Operator; M =

Mechanic)

140292

Employee registration

1

Reserved field

operacoes_manutencao:

The maintenance operations record order from the small to the biggest registration

operation code

Example: 999, MANUT HID, 0

Field

Description

999

Operation code

MANUT HID

Operation description

0

Reserved

Whenever the maintenance operation is not necessary, that file can be registered on

one empty line:

0001;VAZIO;0

operacoes_paradas:

The unproductive operations record ordered from the small to the biggest registration

operation code

Example: 104;Treinamento/Orientação;N;N;S

Field

Description

104

Operation Code

Treinamento/Orientação

Operation Description

N

Maximum operation time

(minutes), if the maximum time

isn’t stated, it must remain in N

N

Special code linked to the

operation*

S

Reserved Field

46

Transshipment special codes* and their functionality:

Field

Description

1

Operation Refueling, immediately,

the amount of fuel necessary will be

asked.

2

Shift change, the register of the next

operator will be asked.

4

Transshipment assigned to a

harvester. From the FLOW

0

No special code

N

Stop without special code

S

Maintenance Operation– Enter the

maintenance code

X

Maintenance Operation– Does not

need to enter the maintenance code

L

Indicates the operation to start the

lifting

H

Stop on transshipment line (empty)

– FLOW

C

Waiting for lifting (full) – FLOW

5

Moving on board

6

Increasing the Alarm of Idle engine

A

Cleaning assistance on the

courtyard– available only on ZIG19

calls

D

Enters on Moving for dumping

status

B

Enters on lifting status– for

contingencies if there is no CDC

7

Mandatory, stays on this operation

until a new stop code is entered

operacoes_produtivas:

The productive operations record ordered from the small to the biggest

registration operation code

Example: 1000;COLHENDO CANA;N;N;N

Field

Description

1000

Code operation

COLHendo

Description of the Operation

N;N;N

Reserved Field

C_EQUIP:

This field is used only on the CF card. The equipment records ordered from lowest to

highest operation code.

Example: 1111;COLHEDORA

Field

Description

1111

Code/ equipment number

COLHEDORA

Equipment description

C_COORDENADAS:

This option deals with necessary record of the point that identify a controlled area.

47

Example: PATIO;25.356587;47.547896

Field

Description

PATIO

Coordinates description

25.356587

Latitude

47.547896

Longitude

If it is not needed, that field can be registered with a null line.

C_COORD_CERCAS:

This option deals with necessary record of the coordinates from ambiances that need

to be controlled.

Example: 2152.28788,05026.17930, CERCA_1,1,300, 0

Field

Description

2152.28788

Latitude

05026.17930

Longitude

CERCA_1

Field description

1

Fence code

300

Fence diameter

0

Special code

If it is not needed, that field can be registered with a null line.

It deals with the register of farms, sector, and field. These are registered by the code

of the farm, fallows the zone code and finally the field code.

Example: 0002;FAZENDA TANGARA,0011,0204

Field

Description

0002

Farm Code

FAZENDA TANGARA

Farm Description

0011

Sector Code

0204

Field Code

If it is not needed, that field can be registered with a null line.

C_FAZENDAS

It deals with the register of farms, ordered from the lowest to the highest operation

code.

Example: 0002;FAZENDA TANGARA

Field

Description

0002

Farm Code

FAZENDA TANGARA

Farm Description

5.2 File Register to the Transshipment APK

The Transshipment APK installed on the S7 tablet need some files on the register of

information to avoid typing errors.

The following files must be on the S7 memory.

• C_CHECKLIST_ITEM;

• C_FUNC;

• operacoes_manutencao;

• operacoes_paradas;

48

• operacoes_produtivas;

• C_IMPLEMENTO;

Below there is a more detailed explanation of the previous files.

C_CHECKLIST_ITEM:

It deals with the checklist items organized by the team.

Example: 01;001;VERIFICAR O NIVEL DE ÓLEO

Field

Description

01

Team description

001

Code of the item

VERIFICAR NIVEL DE ÓLEO

Description of the item

If it is not needed, that field can be registered with an empty line as follows:

01;001;VAZIO

C_FUNC:

It deals with the register of the employees organized from the lowest to the highest

registration code.

Example: 140292;RENATO RUY;O;140292;1

Field

Description

140292

Employee register

RENATO RUY

Name of the employee

O

Role of the employee (O =

Operator; M = Mechanic)

140292

Register of the employee

1

Reserved Field

operacoes_manutencao:

it deals with the maintenance operation organized from the lowest to the highest

operation code.

Example: 999, MANUT HID, 0

Field

Description

999

Operation code

MANUT HID

Description of the operation

0

Reserved

If it is not needed, that field can be registered with an empty line as follows:

0001;VAZIO;0

operacoes_paradas:

It deals with the unproductive operation organized from the lowest to the highest

operation code.

Example: 104;Treinamento/Orientação;N;N;S

Field

Description

104

Operation Code

Treinamento/Orientação

Description of the operation

N

Maximum operation time (minutes),

if the maximum time isn’t stated, it

must remain in N

N

Special codes linked to the

operation

S

Reserved fields

49

Transshipment special codes* and their functionality:

Code

Description

1

Operation Refueling, immediately,

the amount of fuel necessary will be

asked.

2

Shift change, the register of the next

operator will be asked.

4

Transshipment assigned to a

harvester. From the FLOW

0

No special code

N

Stop without special code

S

Maintenance Operation– Enter the

maintenance code

X

Maintenance Operation– Does not

need to enter the maintenance code

L

Indicates the operation to start the

lifting

H

Stop on transshipment line (empty)

– FLOW

C

Waiting for lifting (full) – FLOW

5

Moving on board

6

Increasing the Alarm of Idle engine

A

Cleaning assistance on the

courtyard– available only on ZIG19

calls

D

Enters on Moving for dumping

status

B

Enters on lifting status– for

contingencies if there is no CDC

7

Mandatory, stays on this operation

until a new stop code is entered

operacoes_produtivas:

It deals with the register of productive operations organized from lowest to highest

operation code.

Example: 1000;COLHENDO CANA;N;N;N

Field

Description

1000

Operation Code

COLHENDO CANA

Description of the operation

N;N;N

Reserved fields

C_IMPLEMENTO:

It deals with the implement register organized from lowest to highest implement code.

Example: 234;IMPLEMENTO;6

Field

Description

234

Implement code

IMPLEMENTO

Description of the implement

6

Length of the implement

50

5.3 Update of the files registered on the tablet using a flash drive.

This procedure is used to upload the files registered on the S7 using a flash drive

• Firstly, a file with the name “Cadastros” must be created on the flash drive.

All the registers will be updated there.

• Connect the flash drive using the USB-mini on the serial port on the right side

of the S7 tablet.

• Exit the transshipment APK following the steps described on the item ”2.20

Allow to exit the App”.

• Access the S7 menu entering the password to enter the configuration area on

Android.

51

• Opening app “S7Tools”.

Select the option “Import flash drive file”.

52

Select the option “Register” and click on the option “IMPORT”.

• Open the “sCBTransshipment” app again and enter on the

“Menu/Configuration” path option “Import Records” .

6. Commands used on the Transshipment remote update

6.1 Parameters that can be updated remotely on the transshipment

The MAG100 Transshipment firmware are ready to receive remote commands to

update the parameters already registered by the SGPA:

Command

Description

Update Crate

Update crate records

Update Employee

Register a new employee code on the computer on board.

Update Farm, Field

Register FZT on the computer on board

Update Productive

Operation

Register new productive operation code on the computer on

board.

Update

Unproductive

Operation

Register new unproductive operation code on the computer on

board.

Update Productive

Operation

(MAG100)

Register new ´productive operation code on the computer on

board MAG100.

Port Lock

Update the lock used for security matters on the (MAG50R)

Start lock

Update the start lock (MAG50R)

Update

Unproductive

Record

Update the instant stop code of the machine

Text message (64

Characters)

Send text messages to the computer on board up to 64

characters.

Text message

Characters (32)

Send text messages to the computer on boar up to 32 characters.

Machine Code

Change the cut code in which the machine is working.

53

Update Computer

on board

parameters

password

Change the access password to access the computer on board

parameters.

Moving Speed

Change the maximum speed allow.

GPRS transmission

time

Change the monitoring sending time.

Idle engine time

Change the minimum time for the computer on board to show the

idle engine alarm.

Maximum RPM

alarm

Change the maximum RPM for the computer on board to

generate an alarm.

Maximum Speed

Alarm

Change maximum speed for the computer on board to generate

an alarm.

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired operation.

Warning: Changes or modifications to this unit not expressly approved by the

party responsible for compliance could void the user’s authority to operate the

equipment.

NOTE: This equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or

more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

FCC RF Radiation Exposure Statement Caution: To maintain compliance with the

FCC’s RF exposure guidelines, place the product at least 20cm from nearby

persons.

Loading...

Loading...