D

GB

Betriebsanleitung

Operating instructions

Differenzdruckmessgerät mit Magnetkolben und

mit Magnetkolben und Trennmembrane Baureihe P2600

Differential pressure gauge with magnetic piston and

with magnetic piston and separation diaphragm Model P2600

tecsis GmbH

Carl-Legien-Straße 40-44

63073 Offenbach . Germany

Tel.: +49 (0)69/5806 0

Fax:

+49 (0)69/5806 7788

E-Mail: info@tecsis.de

www.tecsis.de

mit Magnetkolben/

with magnetic Piston

mit Magnetkolben,

Trennmembrane

und Reed-Kontakt/

with magnetic Piston,

separation Diaphragm

and Reed-Contact

BD_BE 450 e 06/2011

ADPR1X414002 SN-Nr. 2165384

2

BD_BE 450 e 06/2011

D

GB

Betriebsanleitung Baureihe P2600 Page 3-12

Operating instructions model P2600 Seite 13-22

© 2011 tecsis GmbH

All rights reserved. / Alle Rechte vorbehalten.

tecsis

®

is a registered trademark in various countries.

tecsis

®

ist eine geschützte Marke in verschiedenen Ländern.

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Prior to starting any work, read the operating instructions!

Keep for later use!

3

Betriebsanleitung

BD_BE 450 e 06/2011

D

1. Allgemeines 3

2. Sicherheit 4

3. Technische Daten 7

4. Aufbau und Funktion 7

5. Optionen und Zubehör 8

6. Transport, Verpackung und Lagerung 9

7. Montage, Inbetriebnahme, Betrieb 9

8. Wartung und Reinigung 12

9. Reparatur 12

10. Demontage und Entsorgung 13

Inhalt

Inhalt

Betriebsanleitung

4

BD_BE 450 e 06/2011

D

1. Allgemeines

1. Allgemeines

Das in der Betriebsanleitung beschriebene Differenzdruckmessgerät wird nach

den neuesten Erkenntnissen konstruiert und gefertigt.

Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und

Umweltkriterien. Unsere Managementsysteme sind nach ISO 9001 zertifiziert.

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Differenzdruckmessgerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller

angegebenen Sicherheitshinweise und Handlungsanweisungen.

Die für den Einsatzbereich des Differenzdruckmessgerätes geltenden örtlichen

Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen

einhalten.

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe

des Druckmessgerätes für das Fachpersonal jederzeit zugänglich aufbewahrt

werden.

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig durchgelesen und verstanden haben.

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige

Verwendung, Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend

qualifizierten Fachpersonals sowie eigenmächtiger Veränderung am Differenzdruckmessgerät.

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

Technische Änderungen vorbehalten.

Weitere Informationen:

- Internet-Adresse: www.tecsis.de

- zugehöriges Datenblatt: DD470/DE470

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die zum

Tod oder zu schweren Verletzungen führen kann, wenn sie nicht

gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen für

einen effizienten und störungsfreien Betrieb hervor.

5

Betriebsanleitung

BD_BE 450 e 06/2011

D

2. Sicherheit

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass das

richtige Druckmessgerät hinsichtlich Messbereich, Ausführung und

spezifischen Messbedingungen ausgewählt wurde.

Auswahl- und Einbauempfehlungen für Druckmessgeräte nach

EN 837-2 beachten.

Verträglichkeit der druckbelasteten Werkstoffe mit dem Messstoff

prüfen!

Die Belastungsgrenzen sind einzuhalten, um die Messgenauigkeit

und die Lebensdauer zu gewährleisten.

Bei Nichtbeachten können schwere Körperverletzungen und/oder

Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise befinden sich in den

einzelnen Kapiteln dieser Betriebsanleitung.

2.1 Bestimmungsgemäße Verwendung

Diese Differenzdruckmessgeräte dienen zur Überwachung von Differenzdrücken

bei industriellen Anwendungen.

Das Differenzdruckmessgerät ist ausschließlich für den hier beschriebenen

bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf

nur dementsprechend verwendet werden.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung

sind ausgeschlossen.

2.2 Personalqualifikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualifikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und

Sachschäden führen.

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch Fachpersonal nachfolgend beschriebener Qualifikation durchführen lassen.

Herstellungsdatum

Betriebsanleitung

6

BD_BE 450 e 06/2011

D

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse

der Mess- und Regelungstechnik und seiner Erfahrungen sowie Kenntnis der

landesspezifischen Vorschriften, geltenden Normen und Richtlinien in der Lage,

die beschriebenen Arbeiten auszuführen und mögliche Gefahren selbstständig

zu erkennen.

2.3 Besondere Gefahren

WARNUNG!

Messstoffreste in ausgebauten Druckmessgeräten können zur

Gefährdung von Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

2.5 Beschilderung / Sicherheitskennzeichnungen

Typenschild (bei Option Reed-Kontakt)

Symbolerklärung

Vor Montage und Inbetriebnahme des Druckmessgerätes unbedingt

die Betriebsanleitung lesen!

CE, Communauté Européenne

Geräte mit dieser Kennzeichnung stimmen überein mit den

zutreffenden europäischen Richtlinien.

2. Sicherheit

Model P2600 Cont 6.3

MAX. LASTDATEN / CONTACT RATING

Pmax AC/DC 3 W

Umax AC/DC 30 V

Imax AC/DC 0,2 A

Prod-No: P2600 12/2010

UL-Nr: E103299

CSA-Nr: LR57810

left

right

7

Betriebsanleitung

BD_BE 450 e 06/2011

D

3. Technische Daten

3. Technische Daten / 4. Aufbau und Funktion

Technische Daten Baureihe P2600

Reed-Kontakt

ohne mit

Nenngröße 80

Anzeigegenauigkeit ± 3 % vom Skalenendwert bei

ansteigendem Differenzdruck

± 5 % vom Skalenendwert bei

ansteigendem Differenzdruck

Anzeigebereiche 0 … 400 mbar bis 0 … 10 bar 0 … 160 mbar bis 0 … 2,5 bar

Max. Betriebsdruck

(statischer Druck)

wahlweise 100, 250 oder

400 bar

100 bar

(Anzeigebereiche 0 ... 160 mbar

und 0 ... 250 mbar: 50 bar)

Überlastbarkeit ein-, beid- und wechselseitig bis zum maximalen Betriebsdruck

(Ausnahme bei Geräten mit Reed-Kontakt, Anzeigebereiche

0 ... 160 mbar und 0 ... 250 mbar: Überlastbarkeit bis 50 bar)

Schutzart lP 54 (EN 60529 / lEC 529)

Messkammer mit

Druckanschluss

(messstoffberührt)

CrNi-Stahl 1.4571, 2 x G ¼ Innengewinde, rechts und links

seitlich, gegenüberliegend (EN 837-1 /7.3)

Weitere technische Daten siehe tecsis Datenblatt DD470/DE470 und

Bestellunterlagen.

4. Aufbau und Funktion

Beschreibung

In den

- und - Messstoffkammern herrschen die Drücke p1 und p2,

getrennt durch den druckbeaufschlagten Magnetkolben (bzw. Magnetkolben

und Trennmembrane).

Die Druckdifferenz verursacht eine axiale Bewegung (Messweg) des Kolbens, der

sich gegen die Messbereichsfeder abstützt.

Der sich daraus ergebende Messweg wird von einem auf dem Instrumentenzeiger befindlichen Ringmagneten abgegriffen und zur Anzeige gebracht. Dieser

konstruktive Aufbau verbindet den Vorteil einer vollständigen Trennung von

Messsystem und Anzeige und verhindert jegliche Leckage nach außen.

Der Volumenstrom von der

- zur - Messstoffkammer bei Typ P2600 ist

aufgrund des konstruktiven Aufbaus minimal und in Regelanwendungen nicht

störend.

Bei der Option mit Trennmembrane tritt kein Volumenstrom von der -

zur

- Messstoffkammer auf.

Bewährte Anwendungen/Einsatzgebiete sind Gas- und Luftversorgung und deren

Aufbereitung, in denen keine magnetischen Partikel enthalten sind.

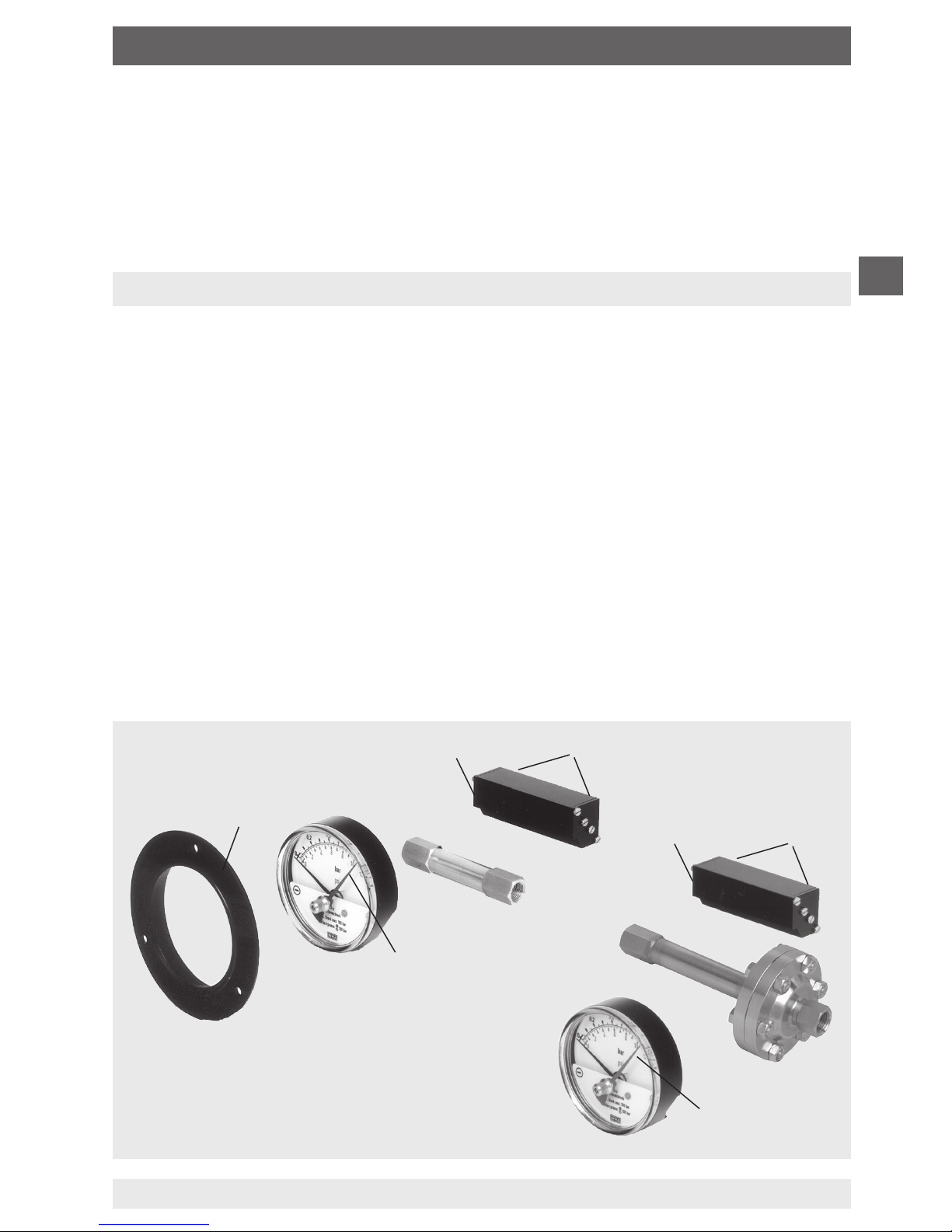

C

D

B

B

A

C

D

Betriebsanleitung

8

BD_BE 450 e 06/2011

D

Befinden sich Schwebekörper im Prozess sollte der Typ P2600 mit Reed-Kontakt

eingesetzt werden.

Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

5. Optionen und Zubehör

5.1 Befestigungsrand

Nach Bedarf vor Ort nachrüstbar.

Ausrichten des Frontringes (A) über eingeprägte Nocken zu am Gehäuseumfang

befindlichen Nuten. Frontring auf Gehäuse bis zum Einschnappen aufschieben.

5.2 Minimum- bzw. Maximum-Schleppzeiger (siehe Darstellungen)

Schleppzeiger (B) dient zur Überwachung und Kontrolle des minimalen bzw.

maximalen aufgetretenen Differenzdruckes.

5.3 Reed-Kontakt Typ 6.3 und 6.3.3 (siehe Darstellungen)

Nach Bedarf vor Ort nachrüst- und einstellbar.

Befestigung erfolgt über zwei im Reedgehäuse (C) integrierte Schrauben (D) am

Anzeigegehäuse mit dem dazugehörigen Innengewinde.

5. Optionen und Zubehör

9

Betriebsanleitung

BD_BE 450 e 06/2011

D

7. Montage, Inbetriebnahme, Betrieb

Mechanischer Anschluss

Die Montage des Differenzdruckmessgerätes erfolgt in Anlehnung an die Einbauempfehlungen für Druckmessgeräte nach EN 837-2 /7.

Montage des Prozessanschlusses nach angebrachten Symbolen

und

hoher Druck, niedriger Druck

Bei Montage mittels Schraubenschlüssel SW 17 an den Anschlussstücken

gegenhalten (Einschrauben ohne gegenhalten kann zur Lockerung des

Messsystems führen).

Maximale zulässige Messstoff-/Umgebungstemperatur darf nicht überschritten werden

Messleitungen vor der Gerätemontage gründlich durch Abklopfen und Ausblasen oder Durchspülen reinigen

Messgeräte sollen erschütterungsfrei montiert und betrieben werden

Messgeräte sollen vor Verschmutzung und starken Temperaturschwankungen

geschützt sein

Um Fremdkörper im Messsystem und somit eine Beschädigung desselben zu

vermeiden, ist das Druckmessgerät oberhalb des Entnahmestutzens anzubringen.

Bei stark schwebekörperhaltigen Messstoffen ist vor der

-

Messstoffkammer ein

Feinfilter vorzusehen.

6. Transport, Verpackung und Lagerung

6.1 Transport

Druckmessgerät auf eventuell vorhandene Transportschäden untersuchen.

Offensichtliche Schäden unverzüglich mitteilen.

6.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen

optimalen Schutz (z. B. wechselnder Einbauort, Reparatursendung).

6.3 Lagerung

Zulässige Bedingungen am Lagerort

Lagertemperatur: -20 ... +70°C (optional: -40 … +70°C)

6. Transport, Verpackung und Lagerung / 7. Inbetriebnahme ...

Betriebsanleitung

10

BD_BE 450 e 06/2011

D

7. Inbetriebnahme, Betrieb

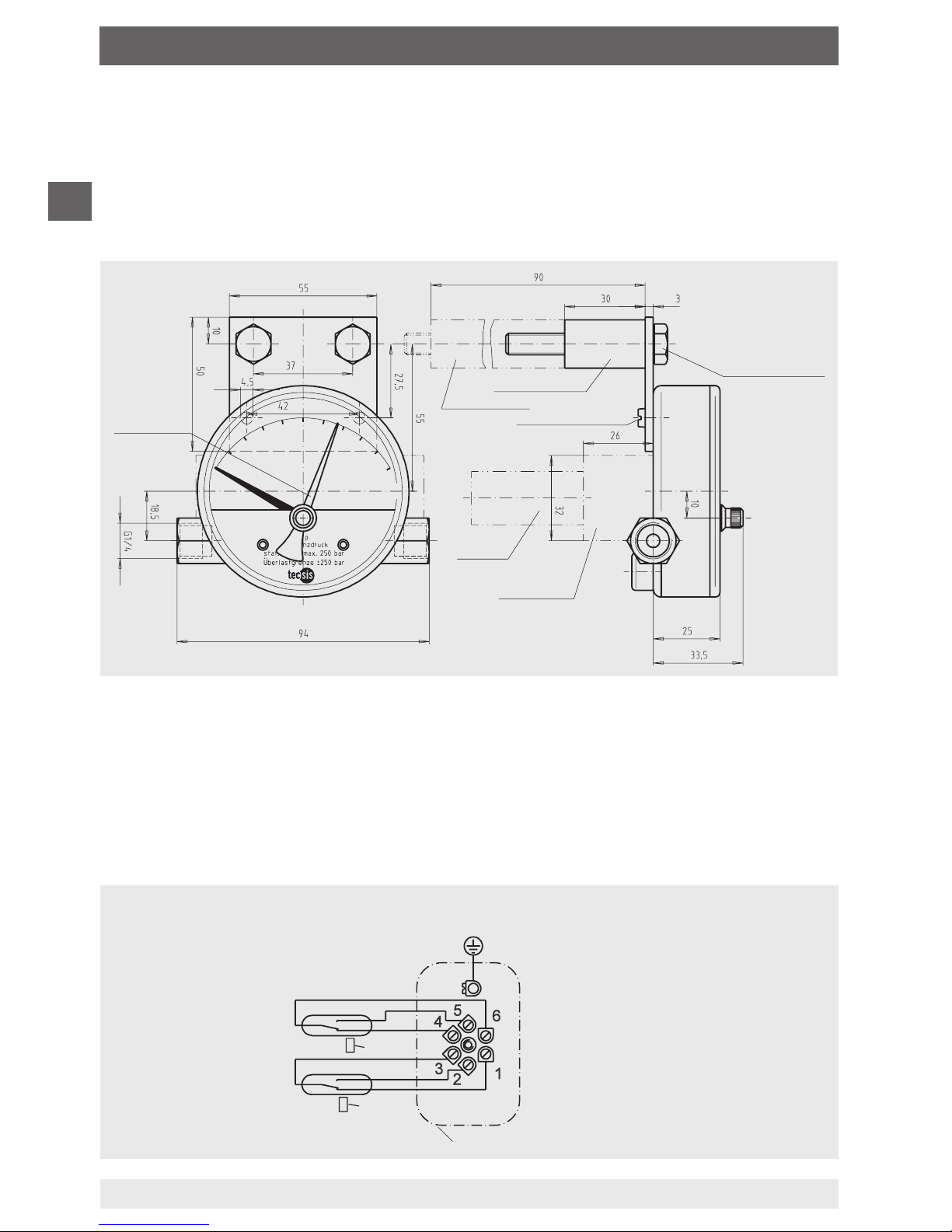

Sechskantschraube

M8 x 50 (M8 x 100)

ohne Reedkontakt

mit Reedkontakt

Schlitzschraube M4 x 10

Reedgehäuse

Schleppzeiger

Stecker

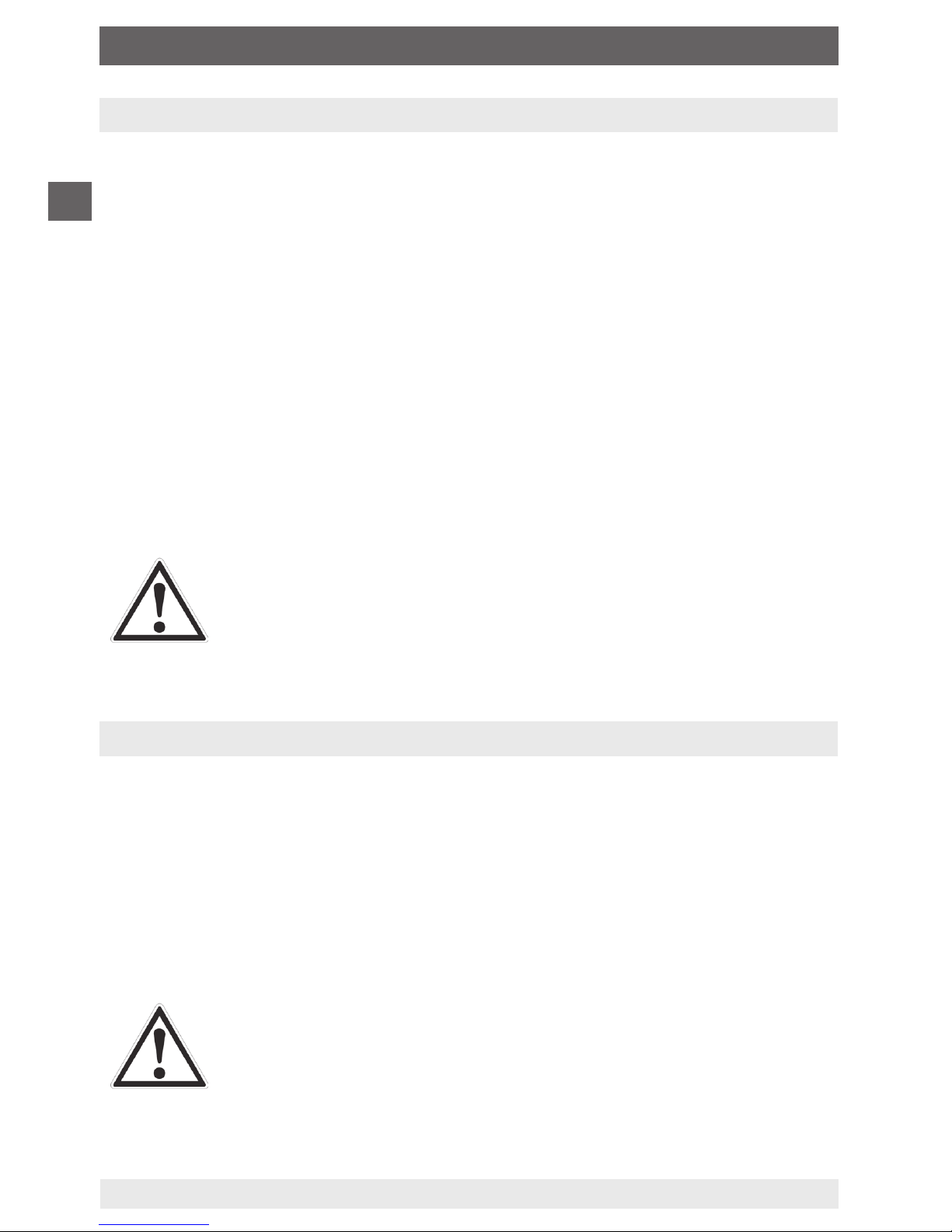

Elektrischer Anschluss

(bei Geräten mit elektrischen Zusatzeinrichtungen)

Der elektrische Anschluss des Druckmessgerätes wird über Kabeldose und

Kabel hergestellt. Die genauen Anschlussbelegungen können dem nachfolgenden

Anschlussschema entnommen werden. Zusätzlich sind Anschlussbelegung und

erforderliche Hilfsenergie auf dem Typenschild des Reedgehäuses vermerkt.

Elektrisches Anschlussschema

Reed-Kontakt Typ 6.3 und 6.3.3

(Wechsler)

In den Geräten sind

keine Überstrom-Schutzeinrichtungen eingebaut.

Falls Schutzeinrichtungen

gefordert werden, sind

diese extern vorzusehen.

Kabeldose

2. Kontakt

1. Kontakt

6. 3

6.3. 3

Ist die Leitung zum Druckmessgerät für eine erschütterungsfreie Anbringung

nicht stabil genug, so ist die Befestigung über entsprechende Befestigungselemente für Wandmontage oder ggf. über eine Kapillare vorzunehmen.

Montage an Wand (siehe Zeichnung)

Anbringung/Befestigung mittels Messgerätehalter

11

Betriebsanleitung

BD_BE 450 e 06/2011

D

7. Inbetriebnahme, Betrieb

Schaltpunkteinstellung

Vorzugsweise erfolgt die Schaltpunkteinstellung vor dem Einbau des

Messgerätes. Der erforderliche Prüfweg wird manuell (z. B. mit Hilfe eines

nicht magnetischen Schraubendrehers) erzeugt.

Manuelle Prüfwegerzeugung

Plusmessstoffkammer

antimagnetisch

Die Schaltpunkteinstellung kann auch im druckbeaufschlagten Zustand nach

Einbau erfolgen. Bei Angabe der Sollwerte werden werkseitig die Schaltpunkte

eingestellt.

Die Verstellung des Schaltpunktes erfolgt durch Drehen der Kontakt-Einstellschrauben an der Reed-Gehäuseaußenseite.

Drehrichtung links:

Schaltpunkt lässt sich in Richtung

Messbereichsanfang verschieben

Drehrichtung rechts:

Schaltpunkt lässt sich in Richtung

Messbereichs

ende verschieben

Nullpunktprüfung

Im Allgemeinen erfolgt die Überprüfung und Einstellung des Nullpunktes im

drucklosen Zustand. Für die Nullpunktkorrektur des Druckmessgerätes ist

die Systembefestigungslasche an der Gehäuserückseite leicht zu lösen. Der

Nullpunkt lässt sich nun durch Verschieben des Messsystems nach rechts

oder links nachjustieren. Anschließend ist das Messsystem wieder mittels

Befestigungslasche (maximales Anzugsmoment der Befestigungsschraube

2,5 Nm) zu fixieren.

Betriebsanleitung

12

BD_BE 450 e 06/2011

D

8. Wartung und Reinigung

8.1 Wartung

Die Geräte sind wartungsfrei.

Bei sachgemäßer Behandlung und Bedienung zeichnen sich die Kolben-Diffe-

renzdruckmessgeräte durch eine hohe Lebensdauer aus.

Die Messgenauigkeit des Druckmessgerätes sollte durch regelmäßige

Prüfungen sichergestellt werden.

Reparaturen sind ausschließlich vom Hersteller oder entsprechend qualifiziertem Fachpersonal durchzuführen.

8.2 Reinigung

Messstoffreste in ausgebauten Druckmessgeräten können zur Gefährdung von

Menschen, Umwelt und Einrichtungen führen. Ausreichende Vorsichtsmaßnahmen sind zu ergreifen.

VORSICHT!

■

Das Druckmessgerät mit einem feuchten Tuch reinigen.

■

Ausgebautes Druckmessgerät vor der Rücksendung spülen

bzw. säubern, um Personen und Umwelt vor Gefährdung

durch anhaftende Messstoffreste zu schützen.

9. Reparatur

Gefährliche Arbeitsstoffe

Wir bitten bei Anlieferung von Reparaturgeräten und Retouren, die mit gefährlichen Arbeitsstoffen im Messstoffraum und/oder an den Oberflächen in Berührung gekommen sind, vorher um Reinigung und möglichst genaue Stoffangabe

des gefährlichen Mediums. Bei Reinigung durch tecsis ist die genaue Angabe

des Messstoffes bzw. dessen Zusammensetzung und Verarbeitungshinweise incl.

Angabe der Schutzmaßnahmen zum sicheren Umgang für unser Annahme- und

Wartungspersonal zwingend erforderlich.

ACHTUNG!

Bei von tecsis nicht zu entsorgenden Arbeitsstoffen erfolgt eine

Rücksendung an den Kunden.

Kennzeichnung und Verpackung gemäß Gefahrstoff-Verordnung.

8. Wartung und Reinigung / 9. Reparatur

13

Betriebsanleitung

BD_BE 450 e 06/2011

D

9. Demontage und Entsorgung

10. Demontage und Entsorgung

WARNUNG!

Messstoffreste in ausgebauten Druckmessgeräten können

zur Gefährdung von Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

10.1 Demontage

Druckmessgerät nur im drucklosen Zustand demontieren!

10.2 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den landesspezifischen Abfallbehandlungs- und Entsorgungsvorschriften umweltgerecht

entsorgen.

Entsorgung durch tecsis gemäß Auftrag. Bei Sendung der zu entsorgenden

Geräte Passus „Gefährliche Arbeitsstoffe“ beachten (siehe Punkt 9).

Entsorgungsempfehlung bei kundenseitiger Entsorgung:

- bei Gefahrenstoffen im/am Gerät zuerst Gefahrstoff unberührte Teile abbauen

- Gefahrenstoff unberührte Teile Schrott, je nach Material

- Gefahrenstoff berührte Teile Sondermüll

- Anbauteile Kunststoff Schrott, Kunststoff

- Anbauteile metallisch Schrott je nach Material

- Elektronikbauteile Sondermüll, geeignete Entsorgung

Informationen zu den verwendeten Werkstoffen und Komponenten können

dem Gerät zugehörigen Typenblatt entnommen werden (falls nicht vorhanden

anfordern). Bei ausgeführten Sonderheiten abweichend vom Inhalt des genannten Typenblattes sind diese der tecsis-Auftragsbestätigung bei Bestellung zu

entnehmen.

Technische Änderungen vorbehalten.

14

BD_BE 450 e 06/2011

Operating instructions

GB

1. General information 15

2. Safety 16

3. Specifications 18

4. Design and function 18

5. Options and accessories 19

6. Transport, packaging and storage 20

7. Installation, commissioning, operation 20

8. Maintenance and cleaning 23

9. Repairs 23

10. Dismounting and disposal 24

Content

Contents

Operating instructions

15

BD_BE 450 e 06/2011

GB

1. General information

1. General information

The differential pressure gauge described in the operating instructions has been

designed and manufactured using state-of-the-art technology.

All components are subject to stringent quality and environmental criteria during

production. Our management system is certified to ISO 9001.

These operating instructions contain important information on handling the

differential pressure gauge. Working safely requires that all safety instructions

and work instructions are observed.

Observe the relevant local accident prevention regulations and general safety

regulations for the differential pressure gauge's range of use.

The operating instructions are part of the product and must be kept in the

immediate vicinity of the pressure gauge and readily accessible to skilled

personnel at any time.

Skilled personnel must have carefully read and understood the operating

instructions prior to beginning any work.

The manufacturer's liability is void in the case of any damage caused by using

the product contrary to its intended use, non-compliance with these operating

instructions, assignment of insufficiently qualified skilled personnel or

unauthorised modifications to the differential pressure gauge.

The general terms and conditions contained in the sales documentation shall

apply.

Subject to technical modifications.

Further information:

- Internet address: www.tecsis.de

- Relevant data sheet: DD470/DE470

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in

serious injury or death, if not avoided.

Information

… points out useful tips, recommendations and information for

efficient and trouble-free operation.

16

BD_BE 450 e 06/2011

Operating instructions

GB

2. Safety

2. Safety

WARNING!

Before installation, commissioning and operation, ensure that

the appropriate pressure gauge has been selected in terms of

measuring range, design and specific measuring conditions.

Observe the selection and installation recommendations for

pressure gauges in accordance with EN 837-2.

Check the compatibility with the medium of the materials

subjected to pressure!

In order to guarantee the measuring accuracy and long-term

stability specified, the corresponding load limits must be

observed.

Non-observance can result in serious injury and/or damage to

the equipment.

Further important safety instructions can be found in the individual chapters of these operating instructions.

2.1 Intended use

These differential pressure gauges are used for monitoring differential pressures

in industrial applications.

The differential pressure gauge has been designed and built solely for the

intended use described here and may only be used accordingly.

The manufacturer shall not be liable for claims of any type based on operation

contrary to the intended use.

2.2 Personnel qualification

WARNING!

Risk of injury should qualification be insufficient!

Improper handling can result in considerable injury and damage

to equipment.

The activities described in these operating instructions may

only be carried out by skilled personnel who have the qualifications described below.

Operating instructions

17

BD_BE 450 e 06/2011

GB

Date of manufacture

2. Safety

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical

training, knowledge of measurement and control technology and on their

experience and knowledge of country-specific regulations, current standards

and directives, are capable of carrying out the work described and independently

recognising potential hazards.

2.3 Special hazards

WARNING!

Residual media in dismounted pressure gauges can result in a

risk to people, the environment and the system. Take sufficient

precautionary measures.

2.5 Labelling / safety marks

Product label (with option reed contact)

Explanation of symbols

Before mounting and commissioning the pressure gauge, ensure

you read the operating instructions!

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant European directives.

Model P2600 Cont 6.3

MAX. LASTDATEN / CONTACT RATING

Pmax AC/DC 3 W

Umax AC/DC 30 V

Imax AC/DC 0.2 A

Prod-No: P2600 12/2010

UL-Nr: E103299

CSA-Nr: LR57810

left

right

18

BD_BE 450 e 06/2011

Operating instructions

GB

3. Specifications

3. Specifications / 4. Design and function

Specifications Model P2600

Nominal size 80

Reed contact without with

Accuracy class ± 3 % of full scale value with

increasing differential pressure

± 5 % of full scale value with

increasing differential pressure

Scale ranges 0 … 400 mbar to 0 … 10 bar 0 … 160 mbar to 0 … 2.5 bar

Max. working

pressure

(static pressure)

optionally 100, 250 or 400 bar 100 bar

(scale ranges 0 ... 160 mbar and

0 ... 250 mbar: 50 bar)

Overpressure safety either side to maximum working pressure

(exception for pressure gauges with Reed contact,

scale ranges 0 ... 160 mbar and 0 ... 250 mbar:

Overpressure safety up to 50 bar)

Ingress protection lP 54 (EN 60529 / lEC 529)

Measuring chamber

with pressure

connection (wetted)

Stainless steel 1.4571, 2 x G ¼ female, on the right and left side,

in-line (EN 837-1 /7.3)

For further specifications see tecsis data sheet DD470/DE470 and the order

documentation.

4. Design and function

Description

Pressures p

1

and p2 are given in the and measuring chambers, separated

by the magnetic piston under pressure (or magnetic piston and separating

diaphragm.

The difference in pressure causes an axial movement (deflection) of the piston

supported by the compression spring.

The deflection resulting from this is taken up by a ring magnet found on the

instrument pointer and appropriately displayed. This design combines the

advantages of complete separation of the measuring system and the indication

while eliminating any leakage to the exterior.

For model P2600 the volume flow from the

measuring chamber to the

measuring chamber is minimised by the constructive design and will not interfere with standard processes. For model with option the separation diaphragm

prevents any flow volume from the

to the measuring chamber.

These instruments are mainly intended for gas/air supply and preparation applications where no magnetic particles are involved.

Operating instructions

19

BD_BE 450 e 06/2011

GB

C

D

B

B

A

C

D

In processes with floating particles model P2600 with Reed contact should be

used.

Scope of delivery

Cross-check the scope of delivery with the delivery note.

5. Options and accessories

5.1 Mounting flange

May be retrofitted on site as required.

Alignment of the front bezel (A) by means of the stamped cams to the grooves

found on the case circumference. Push front bezel on the case until it snaps into

position.

5.2 Minimum or maximum drag pointer (see illustrations)

The drag pointer (B) serves to monitor and control the miniumum or maximum

occurring differential pressure.

5.3 Reed contact model 6.3 and 6.3.3 (see illustrations)

May be retrofitted and adjusted on site as required.

Fastening is by means of two screws (D) integrated in the reed case (C) on the

display case with the pertinent female thread.

5. Options and accessories

20

BD_BE 450 e 06/2011

Operating instructions

GB

7. Installation, commissioning, operation

Mechanical connection

The installation of the differential pressure gauge is made following the installation

recommendations for pressure gauges in accordance with EN 837-2 /7.

Mounting of the process connection according to affixed symbols

and

high pressure, low pressure

Hold against the connection pieces in the case of installation by means of

17 mm screw spanner (installation without holding against the connection

pieces may cause thet measuring system to get loose).

The maximum permissible medium/ambient temperature must not be exceeded.

Prior to the installation of the pressure gauge, clean the measuring lines

thoroughly by tapping and blowing or rinsing.

Mount and operate the measuring instruments free from vibration.

Protect measuring instruments from contamination and high temperature

changes.

To avoid foreign matter in the measuring system and the resulting damage to the

system, the pressure gauge must be mounted above the connector.

A fine filter is to be provided in the

- measuring media chamber in the case of

measuring media containing a high level of floating particles.

6. Transport, packaging and storage

6.1 Transport

Check pressure gauge for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

6.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g.

change in installation site, sending for repair).

6.3 Storage

Permissible conditions at the place of storage:

Storage temperature: -20 ... +70 °C (optional: -40 … +70 °C)

6. Transport, packaging and storage / 7. Installation

Operating instructions

21

BD_BE 450 e 06/2011

GB

7. Installation, commissioning, operation

Hexagon bolt

M8 x 50 (M8 x 100)

without reed contact

with reed contact

Slotted screw M4 x 10

Reed case

Drag pointer

Plug

Electrical connection

(for instruments with electrical accessories)

Electrical connection of the pressure gauge is by means of terminal box and

cable. Precise wiring schemes can be seen in the following connection diagram.

In addition both the pin assignment and the required power supply are stated on

the product label of the reed case.

Electrical connection diagram

Reed contact model 6.3 and 6.3.3

(change-over contact)

The instruments do not

provide for incorporated

overcurrent protectors. If

overcurrent protectors are

requested, these have to

be provided for externally.

Terminal box

2nd contact

1nd contact

6. 3

6.3. 3

If the line to the gauge is not rigid enough for a vibration-free installation, the

gauge should be mounted by means of appropriate fastening elements for wall

mounting, or, if necessary, with a capillary.

Wall mounting (see drawing)

Installation / fastening by means of mounting brackets

22

BD_BE 450 e 06/2011

Operating instructions

GB

7. Commissioning, operation

Switch point adjustment

Preference should be given to setting the switch point before installing the

measuring instrument. The necessary test path is generated manually (e.g. by

means of an antimagnetic screwdriver).

Manual test path generation

Plus media chamber

antimagnetic

The switch point can also be set in a pressurised condition after installation. The

switch points are set at the factory when the set points are given.

The switch point is adjusted by turning the contact adjustment screws on the

outside of the reed case.

Anticlockwise rotation:

Switch point can be moved in the direction of the

start of the measuring range

Clockwise rotation:

Switch point can be moved in the direction of the

end of the measuring range

Zero point check

In general, the zero point should only be checked and adjusted at zero pressure.

The system fastening lug on the back of the case can be easily slackened off for

zero point correction of the pressure gauge. Now the zero point can be readjusted

by moving the measuring system to the right or left. After this has been done the

measuring system is to be secured again by means of the fastening lug (max.

tightening torque of the mounting screw 2.5 Nm).

Operating instructions

23

BD_BE 450 e 06/2011

GB

8. Maintenance and cleaning

8.1 Maintenance

The instruments are maintenance-free.

The differential pressure gauges with piston offer long service life provided they

are handled and operated properly.

Checks should be carried out on a regular basis to ensure the measuring

accuracy of the pressure gauge.

Repairs must only be carried out by the manufacturer or appropriately qualified

skilled personnel.

8.2 Cleaning

Remains of measuring media in dismantled pressure gauges can be a hazard to

people, the environment and facilities. Adequate measures are to be taken as a

precaution.

CAUTION!

■

Clean the pressure gauge with a moist cloth.

■

Wash or clean the dismounted pressure gauge before returning

it, in order to protect persons and the environment from exposure to residual media.

9. Repairs

Hazardous working materials

We would ask for instruments returned or sent in for repair, which have

hazardous materials in the media areas and/or have surface contact with

hazardous materials, to be cleaned beforehand and an as accurate as possible

description of the hazardous medium. It is absolutely essential to provide exact

details of the media or its composition and processing instructions including

safety measures to be taken to safeguard the ambient for our acceptance

and maintenance personnel.

IMPORTANT!

Working materials not to be disposed off by tecsis are returned

to the customer.

Marking and packaging in accordance with hazardous materials

ordinance.

8. Maintenance and cleaning / 9. Repairs

24

BD_BE 450 e 06/2011

Operating instructions

GB

10. Dismounting and disposal

WARNING!

Residual media in dismounted pressure gauges can result in a

risk to persons, the environment and equipment. Take sufficient

precautionary measures.

9.1 Dismounting

Only disconnect the pressure gauge once the system has been depressurised!

9.2 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an

environmentally compatible way and in accordance with the country-specific

waste disposal regulations.

Disposal by tecsis in accordance with order. Please note the paragraph on

“Hazardous Working Materials” when sending instruments for disposal

(see point 9).

Disposal recommendations in the case of disposal by customers:

- First dismantle parts not coming into contact with the hazardous material

in the case or hazardous materials in and on the instrument

- Parts not in contact with hazardous material scrap according to material

- Parts coming into contact with hazardous material special waste

- Mounted parts, plastic scrap, plastic

- Mounted parts, metal scrap according to material

- Electronic components special waste, suitable disposal

Information on the materials and components used can be seen from the type

sheet for the instrument (if not available please ask for copy). In the case of

special features deviating from the contents of the mentioned type sheet these

are to be taken from the tecsis confirmation of order when order is placed.

Technical alteration rights observed.

10. Dismounting and disposal

25

BD_BE 450 e 06/2011

26

BD_BE 450 e 06/2011

27

BD_BE 450 e 06/2011

BD_BE 450 e 06/2011

tecsis GmbH

Carl-Legien-Straße 40-44

63073 Offenbach . Germany

Tel.: +49 (0)69/5806 0

Fax:

+49 (0)69/5806 7788

E-Mail: info@tecsis.de

www.tecsis.de

Loading...

Loading...