Page 1

Page 2

BEAMER 17R

ENGLISH VERSION

P. 2

1. Overview

Beamer 17R is a versatile moving head that covers

spot, wash and beam functions. Powered by a 17R

short-arc 350W lamp, achieves 134.000 lux at 30 feet

with its 3.8º beam angle. The unit has a 14 dichroic filter + open and bidirectional rainbow eect color wheel

and sports CTO and CTB filters. Regarding gobos, this

moving head has a 9 dichroic rotating indexable and

interchangeable gobo wheel and a 14 static gobo

wheel, each of them with gobo shaking. Beamer 17R

comes with frost filter, a linear 6-facet & 16-facet rotating prism and a zoom function that allows the user

to choose between 3.8º and 45º to cover beam, spot &

wash applications with only one moving head.

Specifications

Source & Optics

• Light Source: 17R 350W Short-arc Lamp

• Lamp Life: 1,500 hours

• Color temperature: 7800K

• Zoom: 3.8º-45º

• Photometric Data

• B3.8º Beam angle: 134,000 lux @ 10m (30 .)

• Eects and Functions

• Color wheel: 14 filters

• Open & bidirectional rainbow eect

• 2 CTO filters (2500K & 3200K)

• CTB filter

• Rotating gobo wheel: 9 HQ dichroic interchange-

able and indexable rotating gobos + open

• Static gobo wheel: 14 indexable gobos + open & 4

beam reducers

• Gobo diameter: outside 4.9 mm., inside 10.5 mm.

• Gobo shake & morph

• Frost filter

• 6 & 16-facet rotating prism

• Motorized focus

• Dimmer: Full range 0-100%

• Strobe eect

• Control

• DMX Channels: 15/20

• Modes: DMX, Sound-active & Auto-run

• Movement

• Pan: 540°

• Tilt: 265°

• 16-bit resolution

• Auto repositioning

• Electrical

• Input voltage range: 100–240V, 50-60Hz

• Power Supply: Automatic range

• Max. power consumption: 450W

• Physical

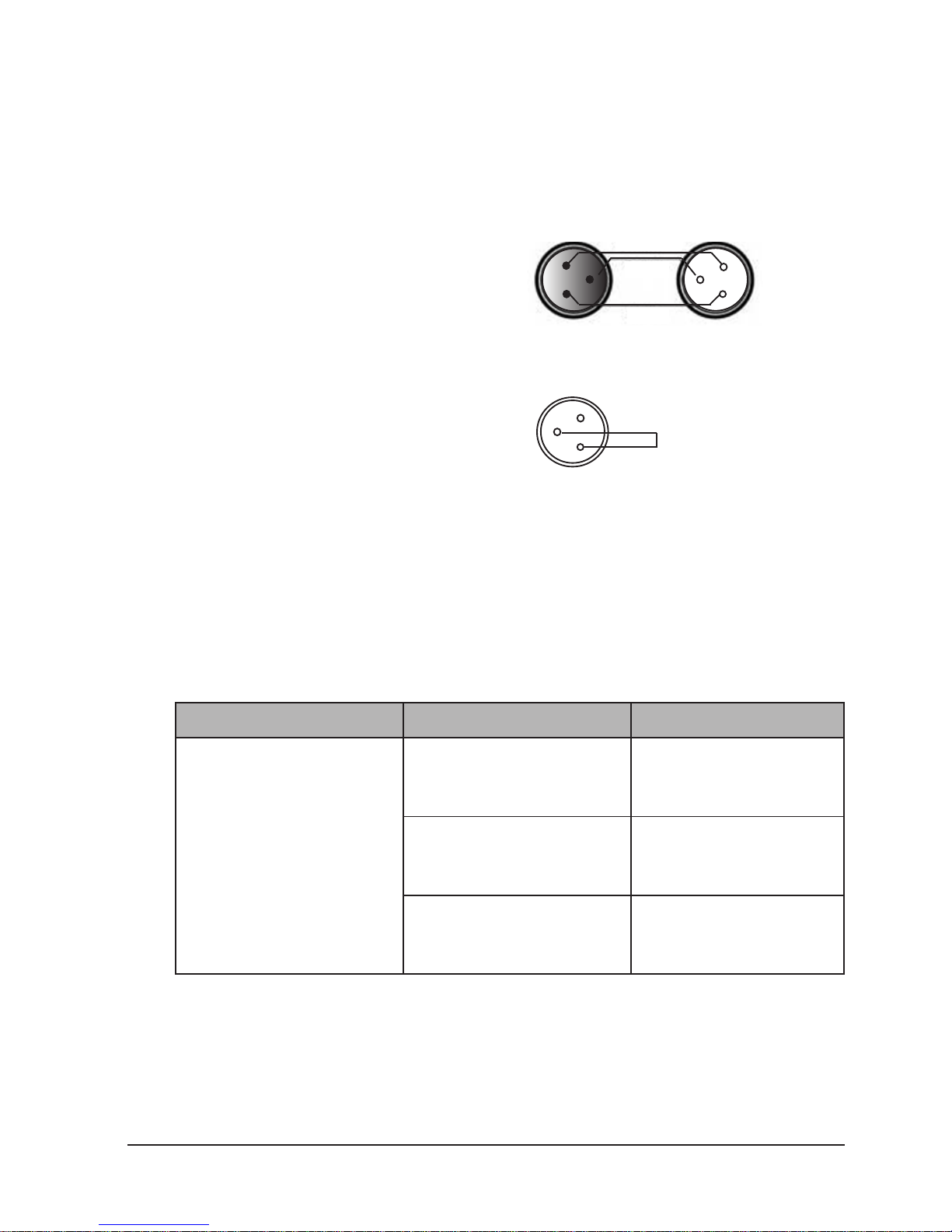

• 2 XLR connectors (XLR-3 input & output)

• Power supply connectors: PowerCON® In

• Backlit LCD display

• Dimensions: 420x382x673 mm. /16.5x15x26.5 in.

• Weight: 23.8 Kg. / 52 Lbs.

Page 3

BEAMER 17R

A. Before Using

What is included

• 1pc fixture(lamp installed)

• 1pc User Manual

• 1pc Power Cable

• 1pc Signal Cable

• 2pc Fast-lock Omega Clamp (1/4 turn)

ENGLISH VERSION

P. 3

2. Open Instructions

Carefully unpack the box and check the contents

to ensure that all parts are present and in good

conditions. If anything damaged during transit,

notify the shipper immediately and keep the packing

material for inspection. Again, please save the carton

and all packing materials. If the fixture must be

returned to manufacturer, it is important that the

fixture be returned in the original manufacturer box

and packing.

Page 4

BEAMER 17R

ENGLISH VERSION

P. 4

3. Safety instructions

Please conserve this manual as operation guidance. If

you sell this product to other user, please make sure

that they also receive this user manual.

1. Always make sure that you are connecting

to the proper voltage and the line voltage not

higher than stated on the decal or rear panel

of the fixture.

2. This lighting is intended to indoor use only.

To prevent risk of fire or shock, do not ex pose fixture to rain or moisture. Make sure

there are no flammable, explosive or corrosive

material in 10 meters around while operating.

3. The unit must be installed in a location with

adequate ventilation, at least 5m away from

adjacent surfaces. Be sure that no ventilation

slots are blocked.

4. Fixture may carry high heat, do not aim at

objective exceeding 2 minutes.

5. Safe wire should be used to install machine.

Bearing of safe wire should be 3 times of the

machine weight.

6. Always disconnect from the power source

before servicing or replacing fuse/lamp and

be sure to replace with same fuse/lamp size

and type. Cut o power before moving, repair ing and cleaning the machine.

7. To avoid electric shock, all fixtures must be

connected to circuits with a suitable ground.

8. Always secure fixture using a safety chain and

carrying handles. Never carry the fixture

by its cord.

9. Do not operate at ambient temperatures

higher than 104F(40C).

10. In case of failure or misfunction occurred, stop

using the unit immediately. Never try to repair the

unit by yourself. Repairs carried out by unskilled

people can lead to damage or malfunction. Please

contact the nearest authorized technical assistance

center. Buy the same spare parts/components

from manufacturer directly.

11. Make sure the power cord is never damaged.

12. Avoid direct eye exposure to the light source

while it is on.

13. Do not power on and power o the fixture in a

short time.

14. When use DMX controller, please make sure

that there is no interference sources (e.g. inter com, high frequency radio waves and radiation.

Caution

There are no user serviceable parts inside

the unit. Do not open the housing or attempt

any repairs yourself. If exceptional problem

happen, please contact related aer-sale department or manufacturer. Any damage that

cased by violating this manual is out of insurance, our company will not take the responsibility.

Page 5

BEAMER 17R

ENGLISH VERSION

P. 5

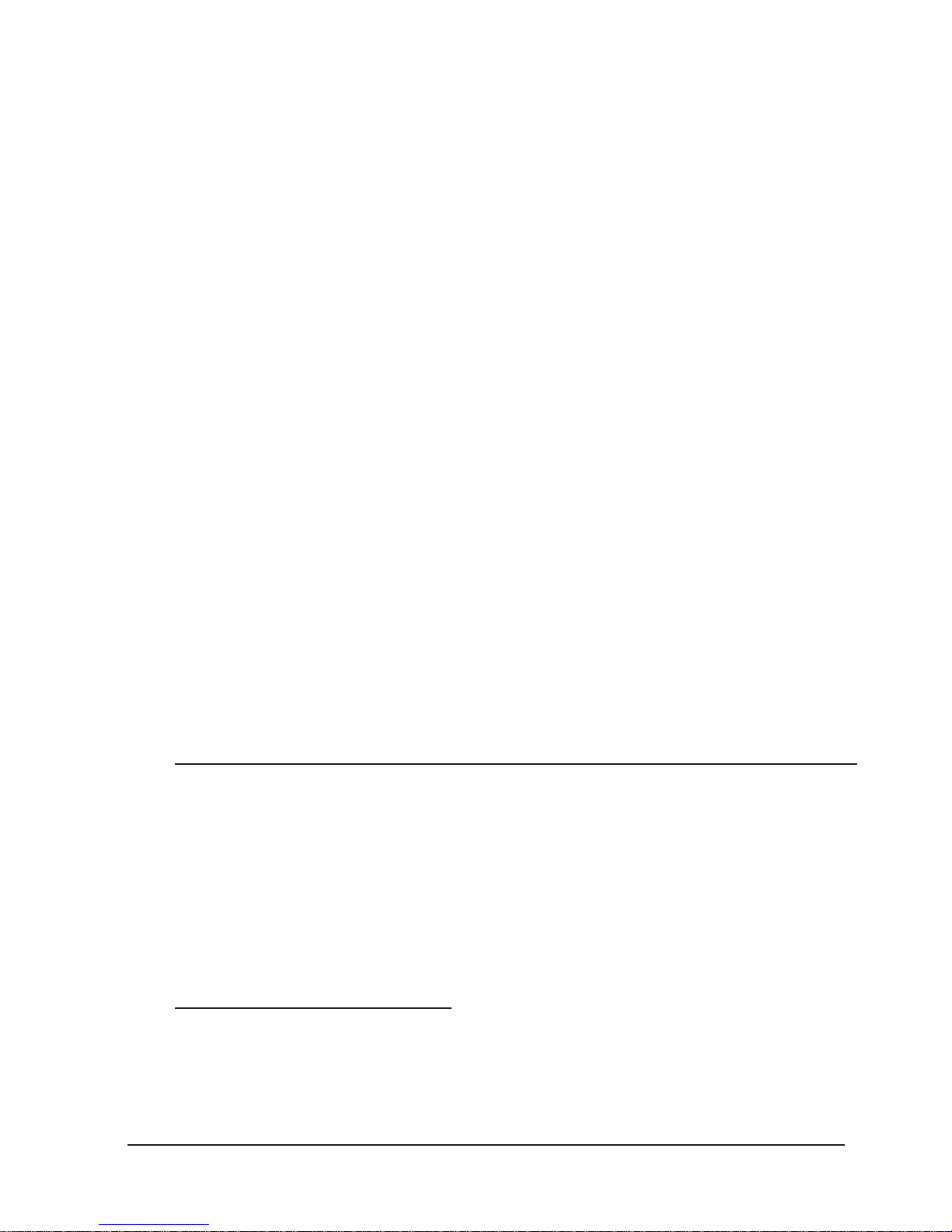

Installation

Installation Requirements

• This machine should be mounted through the

screw holes of truss. Safety wire is a must to fix

fixture well. Make sure truss and safety wire have

strong load capacity to bear 3 times weight than

fixture at least.

• This machine should be installed by qualified

technician.

Controlling Board

MENU

UP

DOWN

ENTER

SIG

MIC

MENU

UP

DOWN

ENTER

SIG

MIC

Page 6

BEAMER 17R

ENGLISH VERSION

P. 6

INPUT OUTPUT

DMX -

DMX +

Common

1

2

3

1

2

3

Machine Connection

• Cables must have a male XLR connector on one

end and a female XLR connector on the other end

• A word on termination: DMX is a resilient commu-

nication protocol, however errors still occasional ly occur. Termination reduces signal errors, and

therefore best practices include use of a ternina tor in all circumstances. If you are experiencing

problems with erratic fixture behavior, especially

over long signal cable runs, a terminator may help

improve performance.

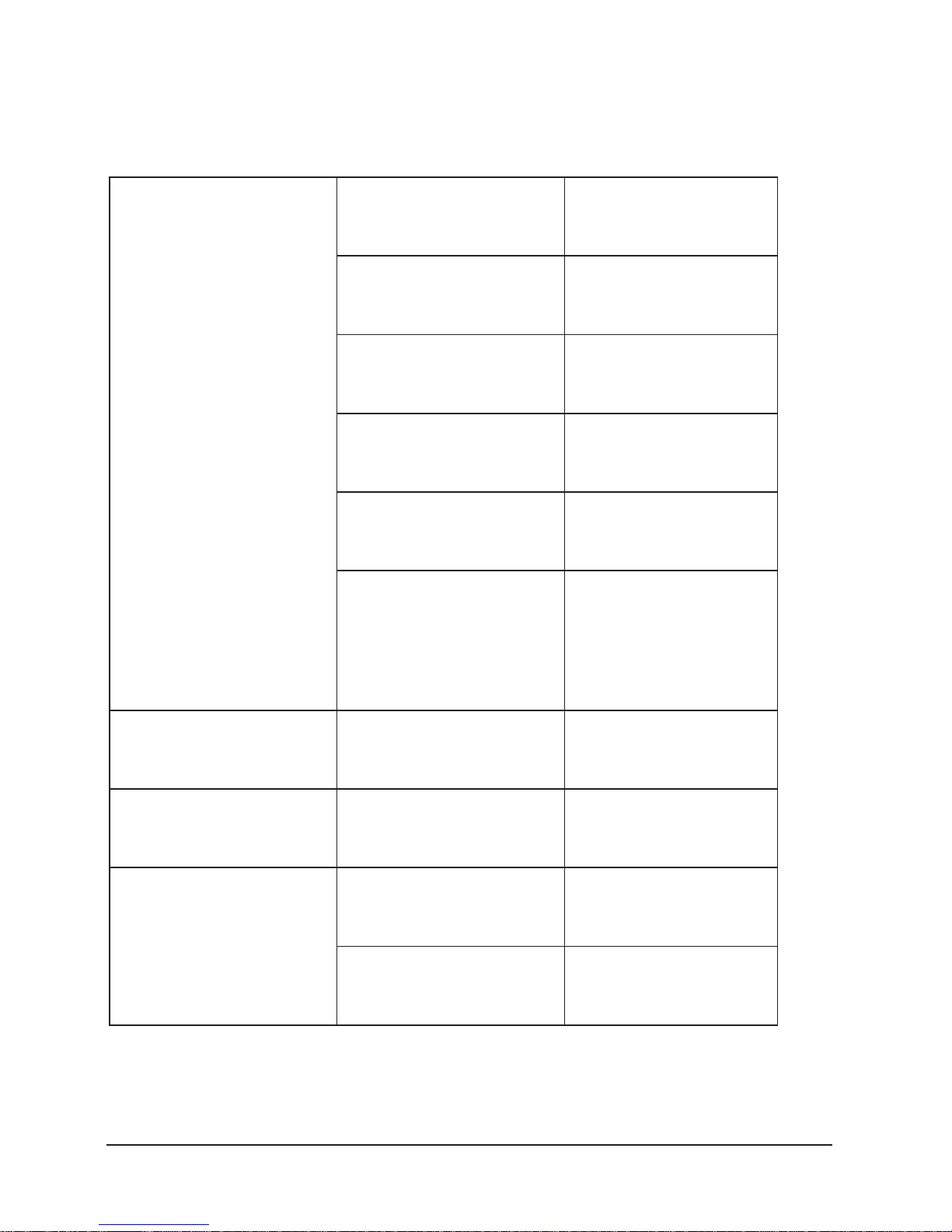

• To build your own DMX Terminator: Obtain a 120-

ohm, 1/4-watt resistor, and wire it between pins

2&3 of the last fixture. They are also readily availa ble from specialty retailers.

1

2

3

120-ohm, 1/4-watt resistor

Complimentary signal cable can transmits signals to 20 unit fixtures at most. Signal amplifier

is a must to connect more fixtures

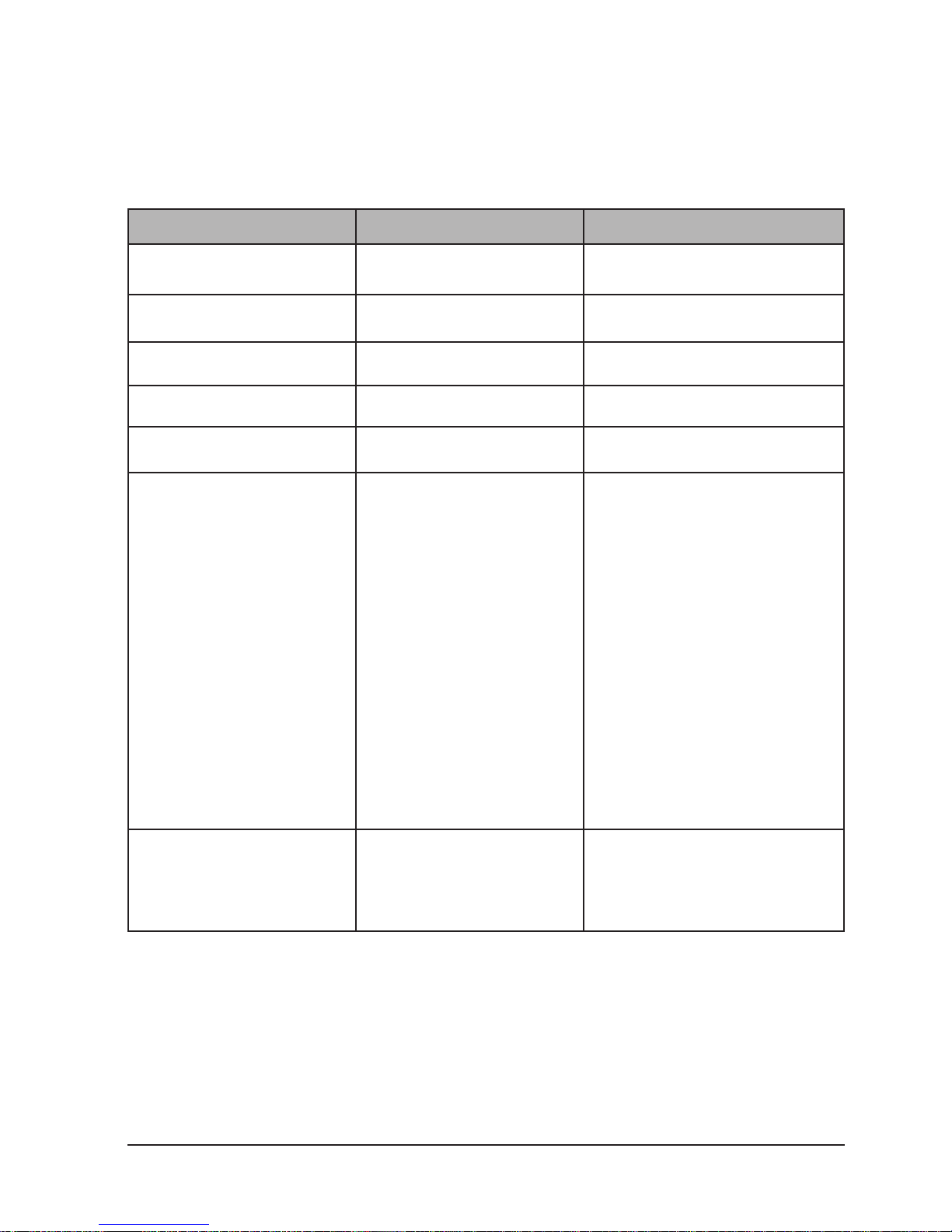

4. Troubleshooting

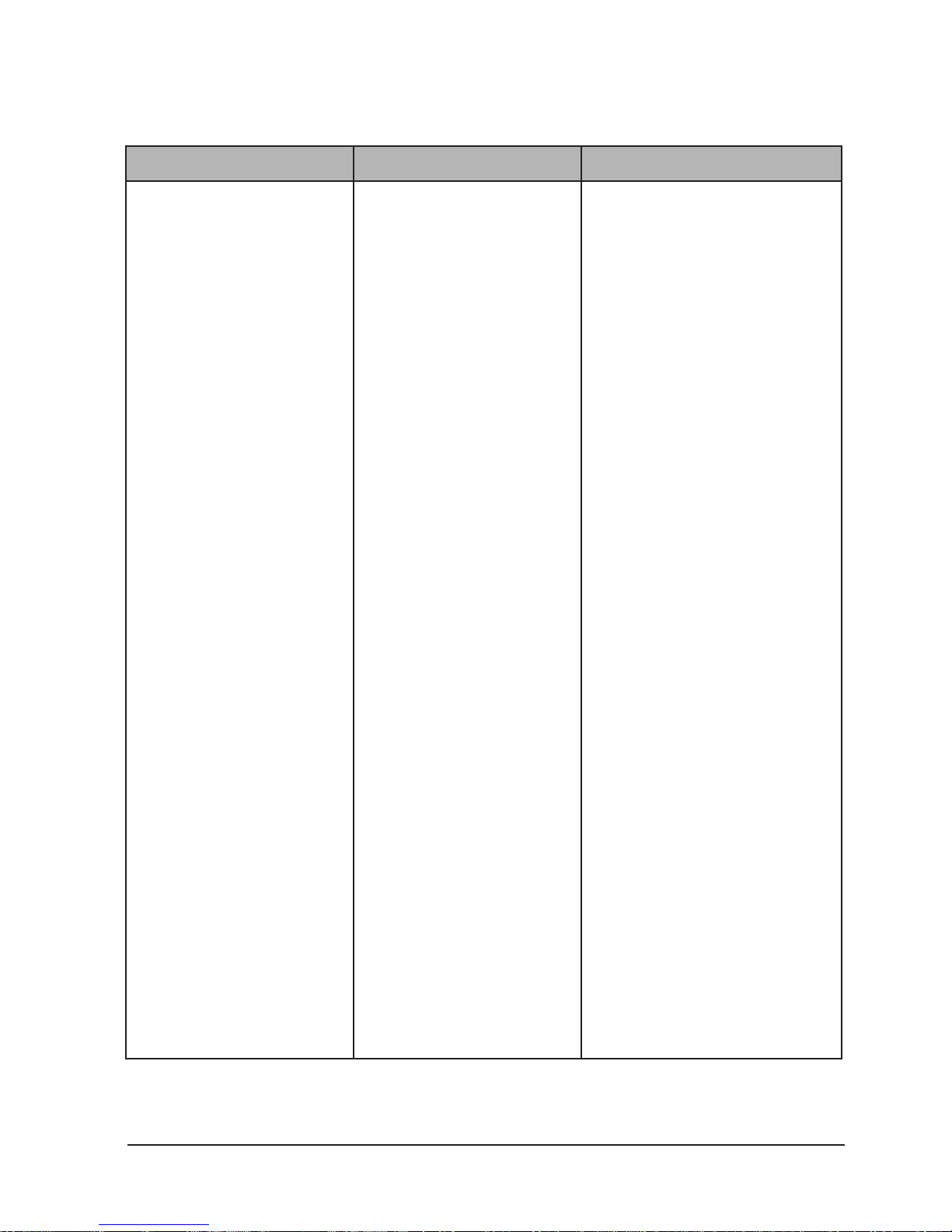

Problem Probable Cause(s) Remedy

No response from fixture

when power is applies

No power to fixture Replace fuse

Primary fuse blown Replace fuse

Secondary fuse blown Connect controller

Page 7

BEAMER 17R

ENGLISH VERSION

P. 7

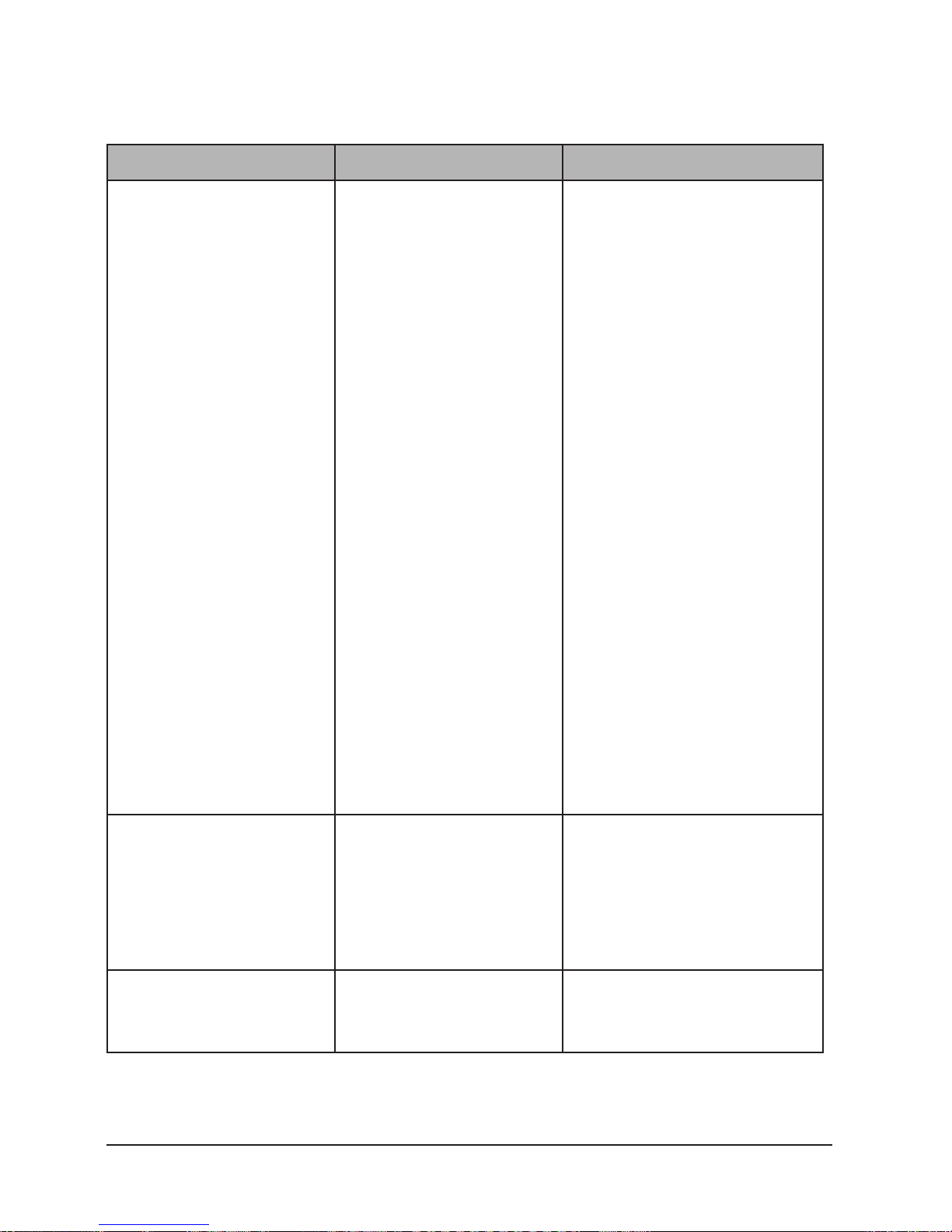

Fixture resets but does not

respond correctly to controller(DMX mode operation)

Controller not connected Connect Controller

Incorrect addressing of the

fixtures

Check address setting on

fixture and controller

Bad data link connection Inspect cables and cor-

rect poor connections

and/or broken cables.

Conflict between tracking

and vector control

Eliminate scene crossfade on controller

Data link not terminated Insert termination plug

in output of last fixture

Defective fixture or 2 devices transmitting on link

Bypass fixtures one at a

time until normal operation is regained:unplug

both connectors and

connect them directly

together

Colors cannot be mixed Random color mixing is on Turn o random color

mixing

Fixure does not reset correctly

Electronic or mechanical

failure

Contact service technician

No light, lamp cuts out

intermittently,or burns out

too quickly

Lamp missing or blown Disconnect fixture and

replace lamp

Fixture or lamp is too hot Allow fixture to cool. If

problem persists,contact

service technician

Page 8

BEAMER 17R

P. 8

ENGLISH VERSION

5.Reference

DMX Protocol 20CH MODE

Channel Function Eect

1 Pan Scan 000~255 0-540°

2 Pan Bit 000~255 2° adjust

3 Tilt Scan 000-255 0°-270°

4 Tilt Bit 000-255 2° adjust

5 Pan/Tilt speed 000-255 from fast to slow

6 Shutter 001~031 Light o

032~063 Light on

064~095 strobe from slow to

fast 096~127 Light on

128~159 free strobe, from slow

to fast

160~191 Light on

192~250 skip strobe, from slow

to fast

251~255 Light on

7 Dimmer 000-255 from dark to bright

Page 9

BEAMER 17R

ENGLISH VERSION

P. 9

8 Color 000~004 Open

005~009 Red

010~014 Yellow

015~019 Dark Blue

020~024 Green

025~029 Magenta

030~034 Blue

035~039 Dark Yellow

040~044 CTB

045~049 Green

050~054 CTO 3200K

055~059 Red

060~064 Orange

065~069 CTO 2500K

070~189 color linear change

190~219 forward flow, from

fast to slow

220~224 Open

225~255 reverse flow, from

slow to fast

Channel Function Eect

Page 10

BEAMER 17R

ENGLISH VERSION

P. 10

9 Fixed Gobo 000~003 open

004~009 Gobo 1

010~015 Gobo 2

016~021 Gobo 3

022~027 Gobo 4

028~033 Gobo 5

034~039 Gobo 6

040~045 Gobo 7

046~051 Gobo 8

052~057 Gobo 9

058~063 Gobo 10

064~069 Gobo 11

070~075 Gobo 12

076~081 Gobo 13

082~087 open

shaking from slow to fast

088~095 Gobo 1 shaking

096~103 Gobo 2 shaking

104~111 Gobo 3 shaking

112~119 Gobo 4 shaking

120~127 Gobo 5 shaking

128~135 Gobo 6 shaking

136~143 Gobo 7 shaking

144~151 Gobo 8 shaking

152~167 Gobo 9 shaking

168~175 Gobo 10 shaking

176~183 Gobo 11 shaking

184~191 Gobo 12 shaking

192~199 Gobo 13 shaking

200~201 No Scroll

202~227 forward flow, fast to

slow

228~229 No Scroll

230~255 reverse flow, slow to

fast

Channel Function Eect

Page 11

BEAMER 17R

ENGLISH VERSION

P. 11

10 Rotating Gobo 000~009 open

010~019 Gobo 1

020~029 Gobo 2

030~039 Gobo 3

040~049 Gobo 4

050~059 Gobo 5

060~069 Gobo 6

070~079 Gobo 7

080~089 Gobo 8

090~099 Gobo 9

shaking from slow to fast

100~110 Gobo 1 shaking

111~121 Gobo 2 shaking

122~132 Gobo 3 shaking

133~143 Gobo 4 shaking

144~154 Gobo 5 shaking

155~165 Gobo 6 shaking

166~176 Gobo 7 shaking

177~187 Gobo 8 shaking

188~199 Gobo 9 shaking

200~201 No Scroll

202~227 forward flow, fast to

slow

228~229 No Scroll

230~255 reverse flow, slow to

fast

11 Gobo Rotating 000~127 0°~400° positioning

128~191 forward flow, fast to

slow

192~255 reverse flow, slow to

fast

12 Prism 1 000-127 prism stop

128-255 prism running

Channel Function Eect

Page 12

BEAMER 17R

P. 12

ENGLISH VERSION

13 Prism 2 000-127 prism stop

128-255 prism running

14 Prism Rotate 0°~400° positioning

128~191 forward flow, fast to

slow

192~255 reverse flow, slow to

fast

15 Frog 000-255 0~100% frog

16 Focus 000-255 0~100% focus

17 Focus Bit 000-255

18 Zoom 000-255 3.8°-45°

19 Zoom Bit 000-255

20 Function 000~029 no function

030~050 stay above 5 second,

lamp stay on low power

049~059 no function

060~080 stay above 5 second,

lamp stay on full power

081~099 no function

100~105 Lamp o

106~119 no function

120~129 color

130~139 gobo

140~149 prism

150~159 Color, gobo, prism

160~199 no function

200~205 Lamp on

204~139 no function

240~255 Reset

Channel Function Eect

Page 13

BEAMER 17R

P. 13

ENGLISH VERSION

DMX Protocol 16CH MODE

Channel Function Eect

1 Pan Scan 000~255 0-540°

2 Tilt Scan 000-255 0°-270°

3 Pan/Tilt speed 000-255 from fast to slow

4 Shutter 001~031 Light o

032~063 Light on

064~095 strobe from slow to fast

096~127 Light on

128~159 free strobe, from slow

to fast

160~191 Light on

192~250 skip strobe, from slow

to fast

251~255 Light on

5 Dimmer 000-255 from dark to bright

6 color 000~004 White color

005~009 Color 1

010~014 Color 2

015~019 Color 3

020~024 Color 4

025~029 Color 5

030~034 Color 6

035~039 Color 7

040~044 Color 8

045~049 Color 9

050~054 Color 10

055~059 Color 11

060~064 Color 12

065~069 Color 13

070~189 color liner change

190~219 forward flow, from fast

to slow

220~224 stop

225~255 Reverse flow, from slow

to fast

Page 14

BEAMER 17R

P. 14

ENGLISH VERSION

7 Fixed Gobo 000~003 open

004~009 Gobo 1

010~015 Gobo 2

016~021 Gobo 3

022~027 Gobo 4

028~033 Gobo 5

034~039 Gobo 6

040~045 Gobo 7

046~051 Gobo 8

052~057 Gobo 9

058~063 Gobo 10

064~069 Gobo 11

070~075 Gobo 12

076~081 Gobo 13

082~087 open

shaking from slow to fast

088~095 Gobo 1 shaking

096~103 Gobo 2 shaking

104~111 Gobo 3 shaking

112~119 Gobo 4 shaking

120~127 Gobo 5 shaking

128~135 Gobo 6 shaking

136~143 Gobo 7 shaking

144~151 Gobo 8 shaking

152~167 Gobo 9 shaking

168~175 Gobo 10 shaking

176~183 Gobo 11 shaking

184~191 Gobo 12 shaking

192~199 Gobo 13 shaking

200~201 open

202~227 forward flow, fast to

slow

228~229 stop

230~255 reverse flow, slow to

fast

Channel Function Eect

Page 15

BEAMER 17R

P. 15

ENGLISH VERSION

8 Rotating Gobo 000~009 open

010~019 Gobo 1

020~029 Gobo 2

030~039 Gobo 3

040~049 Gobo 4

050~059 Gobo 5

060~069 Gobo 6

070~079 Gobo 7

080~089 Gobo 8

090~099 Gobo 9

shaking from slow to fast

100~110 Gobo 1 shaking

111~121 Gobo 2 shaking

122~132 Gobo 3 shaking

133~143 Gobo 4 shaking

144~154 Gobo 5 shaking

155~165 Gobo 6 shaking

166~176 Gobo 7 shaking

177~187 Gobo 8 shaking

188~199 Gobo 9 shaking

200~201 open

202~227 forward flow, fast to

slow

228~229 stop

230~255 reverse flow, slow to

fast

9 Gobo Rotating 000~127 0°~400° positioning

128~191 forward flow, fast to

slow

192~255 reverse flow, slow to

fast

10 Prism 1 000-127 prism stop

128-255 prism running

Channel Function Eect

Page 16

BEAMER 17R

P. 16

ENGLISH VERSION

11 Prism 2 000-127 prism stop

128-255 prism running

12 Prism Rotate 0°~400° positioning

128~191 forward flow, fast to

slow

192~255 reverse flow, slow to

fast

13 Frog 000-255 0~100% frog

14 Focus 000-255 0~100% focus

15 Zoom 000-255 3.8°-45°

16 Function 000~029 no function

030~050 stay above 5 second,

lamp stay on low power

049~059 no function

060~080 stay above 5 second,

lamp stay on full power

081~099 no function

100~105 Lamp o

106~119 no function

120~129 color

130~139 gobo

140~149 prism

150~159 Color, gobo, prism

160~199 no function

200~205 Lamp on

204~139 no function

240~255 Reset

Channel Function Eect

Page 17

BEAMER 17R

Page 18

BEAMER 17R

P. 28

VERSION ESPAÑOL

1. Descripción

Beamer 17R es un versátil cabezal móvil que cubre

las funciones spot, wash y beam. Potenciado por una

lámpara de arco corto 17R de 350W, el equipo alcanza

una luminosidad de 134.000 lux a 10 metros de distancia. La unidad tiene una rueda de color con 14 filtros +

abierto, con efecto de arcoíris bidireccional, dos filtros

CTO y un filtro CTB. En cuanto a los gobos, el equipo

cuenta con una rueda de 9 gobos rotativos dicroicos,

intercambiables e indexables y una rueda de 14 gobos

estáticos, todos con gobo shaking. Beamer 17R cuenta, además, con filtro frost, un prisma rotativo lineal

de 6 facetas, otro prisma rotativo de 16-facetas y una

función zoom que le permite variar su ángulo entre

3,8º y 45º, condensando 3 funciones en un solo cabezal

móvil.

Especificaciones

Fuente y Optica

• Lámpara 17R de arco corto de 350W

• Vida útil promedio: 1.500 horas

• Temperatura de color: 7800K

• Zoom: 3,8º-45º

• Información Fotométrica

• Flujo Luminoso: 134,000 lux @ 10m (30 .)

• Efectos y Funciones

• Rueda de color: 14 filtros + abierto y efecto ar-

coiris bidireccional

• 2 filtros CTO (2500K & 3200K)

• Rueda de gobo rotativa: 9 gobos dicróicos ro-

tativos intercambiables e indexables + abierto

• Rueda de gobo estática: 14 gobos indexables & 4

reductores de haz

• Diámetro del gobo:diámetro externo 14,9 mm. &

diámetro interno 10,5 mm.

• Efecto gobo shake & gobo morph

• Frost: 0-100%

• Prisma rotativo lineal de 6-facetas & prisma rota-

tivo de 16-facetas

• Foco motorizado

• Dimmer: Rango completo 0-100%

• Efecto estrobo

•

• Control

• Canales DMX: 15/20

• Modos de operación: DMX, Maestro/Esclavo &

automático

• Movimiento

• Pan: 540°

• Tilt: 265°

• Resolución: 16-bit

• Reposicionamiento automático

• Eléctrico

• Rango de voltaje de entrada: 100–240V, 50-60Hz

• Consumo de potencia: 450W

• Físico

• 2 conectores XLR (XLR-3 de entrada & salida)

• Alimentación: PowerCON® de entrada

• Display LCD retroiluminado

• Dimensiones: 420x382x673 mm. / 16,5x15x26,5.

Page 19

BEAMER 17R

P. 29

VERSION ESPAÑOL

A. Contenido

Que viene Incluido

• 1 Beamer 17R 3-in-1 (lámpara incluida).

• 1 manual del usuario.

• 1 cable de suministro eléctrico.

• 1 cable de señal.

• 2 soportes Omega.

2. Instrucciones

Gracias por haber elegido el producto Beamer 17R

3-in-1. Abra la caja con cuidado y verifique que todas

las piezas se encuentren presentes y en buen estado.

En caso de que encuentre piezas faltantes o dañadas

por el envío, póngase en contacto de inmediato con su

distribuidor. Si el equipo tuviere que ser devuelto a la

fábrica, utilice la caja y el envoltorio originales.

Page 20

BEAMER 17R

P. 30

VERSION ESPAÑOL

3. Seguridad

Conserve el presente manual para futuras referencias.

En caso de vender la unidad, procure entregar esta

guía al comprador.

1. Utilice el equipo únicamente con la corriente

alterna indicada en las especificaciones téc nicas. Compruebe que el voltaje utilizado no

sea superior ni inferior.

2. Esta equipo se diseño para uso profesional

en espacios interiores. No exponga el equipo

al agua o la humedad con el fin de evitar

descargas eléctricas.

3. Instale el equipo en una zona con ventilación,

a una distancia de, al menos, 5 metros de

otros objetos y 10 metros de superficies

inflamables. Asegúrese de no obstruir las

ranuras de ventilación.

4. La luz produce alta temperatura, no la proyecte

sobre objetos durante más de 2 minutos.

5. Utilice un cable de seguridad para fijar el

equipo al punto de instalación. El cable debe

soportar tres veces el peso del equipo.

6. Siempre desconecte el equipo del suministro

eléctrico antes de realizar cualquier tarea de

mantenimiento o de reemplazar el fusible (utilice

siempre un repuesto del mismo tipo y tamaño).

7. Procure la conexión a tierra del equipo para

prevenir descargas eléctricas.

8. Nunca tire del cable de suministro eléctrico para

trasladar el equipo. Utilice las manijas.

9. No utilice el equipo si la temperatura ambiente

supera los 40 °C (104 °F).

10. En caso de que exista un problema serio de

funcionamiento, deje de utilizar la unidad

inmediatamente. Si el equipo precisa reparación,

pónganse en contacto con el servicio técnico auto rizado. Las reparaciones realizadas por personas

inexpertas pueden causar daños irreparables.

11. Verifique que el cable de suministro eléctrico no

se encuentre cortado o dañado.

12. No mire de forma directa a la fuente de luz

cuando el equipo esté encendido.

13. Evite encender y apagar el equipo de forma

simultánea.

14. Procure que no haya fuentes de interferencia

(radios de alta frecuencia, intercomunicadores,

etc) cuando utilice un controlador DMX.

Precaución

Evite desarmar el equipo. En su interior no

hay piezas que puedan ser reparadas por el

usuario. En caso de que el equipo precise reparación, póngase en contacto con el servicio

técnico autorizado.

La garantía no cubre daños causados por el

uso inapropiado de este producto. El fabricante y el proveedor no aceptarán responsabilidad por el mal uso del equipo.

Page 21

BEAMER 17R

P. 31

VERSION ESPAÑOL

Instalación

Anclaje (rigging)

• Para la instalación en altura siempre utilice or ificios para tornillos del sistema de trussing. Pro cure emplear un cable de seguridad para garan tizar una colocación segura y evitar daños en ob jetos o personas, en caso de que algo falle.

• La instalación debe ser realizada por un profe sional calificado.

Panel de Control

MENU

UP

DOWN

ENTER

SIG

MIC

MENU

UP

DOWN

ENTER

SEÑAL

MIC

Page 22

BEAMER 17R

P. 32

VERSION ESPAÑOL

INPUT OUTPUT

DMX -

DMX +

Common

1

2

3

1

2

3

Conexión

• Los cables deben contar con un conector XLR ma-

cho en un extremo y un conector XLR hembra en el

otro extremo.

• Los finales de línea o terminadores DMX re-

ducen los errores de señal. Para evitar la inter ferencia o el comportamiento anómalo del equi po es recomendable utilizar un final de línea DMX.

En especial cuando el cableado debe recorrer largas

distancias o cuando se encuentra en ambientes

con ruido eléctrico.

• Crear de un terminador DMX: Coloque una resist-

encia de 120 ohm y 1/4 W entre las clavijas 2 y 3

del último equipo. El usuario puede adquirir un

resistor en un establecimiento especializado.

1

2

3

120-ohm, 1/4-watt resistor

El cable de señal complementario transmite señales

a un máximo de 20 equipos. Si precisa conectar más

equipos, utilice un amplificador de señal.

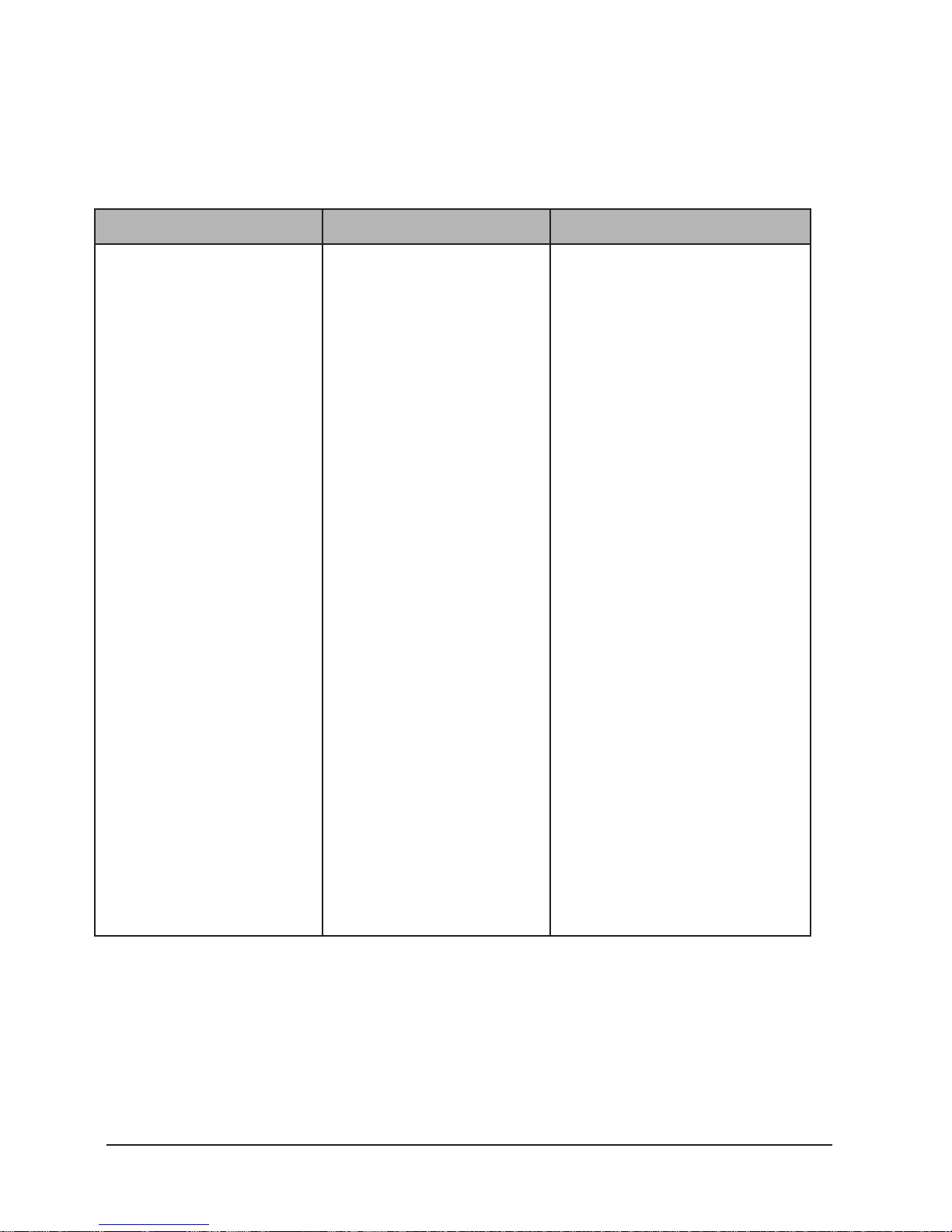

4. Resolución de problemas

Problema Posible Causa Solución

El equipo no enciende. Falta de alimentación Compruebe el estado del

cable de alimentación

Fusible quemado Coloque un fusible nuevo.

Fusible secundario quemado.

Coloque un fusible nuevo.

Page 23

BEAMER 17R

P. 33

VERSION ESPAÑOL

El equipo se reinicia, pero

no responde al controlador (modo DMX)

Controlador desconectado. Conecte el controlador.

Dirección DMX errónea. Compruebe la configura-

ción de la dirección en el

equipo y el controlador.

Conexión de datos errónea. Verifique los cables y

repare las conexiones

defectuosas o los cables

dañados.

Conflicto entre el control

vectorial y las pistas.

Elimine el fade cruzado

entre escenas en el controlador.

Conexión de datos sin terminador.

Coloque un terminador

DMX en la salida del último equipo.

Equipo defectuoso o 2 equipos con transmisión en la

misma conexión.

Omita las unidades una a

una hasta que vuelvan a

funcionar normalmente.

Desconecte ambos conectores y conéctelos juntos

de forma directa.

Falla la mezcla de colores. La mezcla de colores aleato-

ria está activada.

Desactive la función mezcla de colores aleatoria

El equipo no se reinicia

correctamente.

Falla electrónica o mecánica.

Póngase en contacto con

el servicio técnico autorizado.

No hay salida de luz, la

lámpara se apaga o hace

intermitencias,

Lámpara quemada o sin

colocar.

Desconecte el equipo y

coloque un repuesto.

Protección térmica Permita que la unidad se

enfrié. Si el problema persiste, póngase en contacto

con el servicio técnico.

Page 24

BEAMER 17R

P. 34

VERSION ESPAÑOL

5.Funciones

DMX Modo 20 canales

Canal Función Efecto

1 Pan Scan 000~255 0-540°

2 Pan Bit 000~255 2° regulable

3 Tilt Scan 000-255 0°-270°

4 Tilt Bit 000-255 2° regulable

5 Velocidad Pan/Tilt 000-255 velocidad decreciente

6 Shutter 001~031 Lámpara apagada

032~063 Lámpara encendida

064~095 Estrobo velocidad

creciente

096~127 Lámpara encendida

128~159 Estrobo libre velocidad creciente

160~191 Lámpara encendida

192~250 Estrobo interrumpido

velocidad creciente

251~255 Lámpara encendida

7 Dimmer 000-255 Intensidad creciente

Page 25

BEAMER 17R

P. 35

VERSION ESPAÑOL

8 Color 000~004 Abierto

005~009 Rojo

010~014 Amarillo

015~019 Azul oscuro

020~024 Verde

025~029 Magenta

030~034 Azul

035~039 Amarillo oscuro

040~044 CTB

045~049 Verde

050~054 CTO 3200K

055~059 Rojo

060~064 Naranja

065~069 CTO 2500K

070~189 Cambio de color lineal

190~219 Flujo continuo, velocidad decreciente

220~224 Abierto

225~255 Inversión de flujo,

velocidad creciente

Canales Funciones Efectos

Page 26

BEAMER 17R

P. 36

VERSION ESPAÑOL

9 Gobo Estático 000~003 Abierto

004~009 Gobo 1

010~015 Gobo 2

016~021 Gobo 3

022~027 Gobo 4

028~033 Gobo 5

034~039 Gobo 6

040~045 Gobo 7

046~051 Gobo 8

052~057 Gobo 9

058~063 Gobo 10

064~069 Gobo 11

070~075 Gobo 12

076~081 Gobo 13

082~087 Abierto

Vibración, velocidad creciente

088~095 Vibración de Gobo 1

096~103 Vibración de Gobo 2

104~111 Vibración de Gobo 3

112~119 Vibración de Gobo 4

120~127 Vibración de Gobo 5

128~135 Vibración de Gobo 6

136~143 Vibración de Gobo 7

144~151 Vibración de Gobo 8

152~167 Vibración de Gobo 9

168~175 Vibración de Gobo 10

176~183 Vibración de Gobo 11

184~191 Vibración de Gobo 12

192~199 Vibración de Gobo 13

200~201 Sin desplazamiento

202~227 Flujo continuo, velocidad decreciente

228~229 Sin desplazamiento

230~255 Inversión de flujo,

velocidad creciente

Canales Funciones Efectos

Page 27

BEAMER 17R

P. 37

VERSION ESPAÑOL

10 Gobo Rotativo 000~009 Abierto

010~019 Gobo 1

020~029 Gobo 2

030~039 Gobo 3

040~049 Gobo 4

050~059 Gobo 5

060~069 Gobo 6

070~079 Gobo 7

080~089 Gobo 8

090~099 Gobo 9

Vibración, velocidad creciente

100~110 Vibración de Gobo 1

111~121 Vibración de Gobo 2

122~132 Vibración de Gobo 3

133~143 Vibración de Gobo 4

144~154 Vibración de Gobo 5

155~165 Vibración de Gobo 6

166~176 Vibración de Gobo 7

177~187 Vibración de Gobo 8

188~199 Vibración de Gobo 9

200~201 Sin desplazamiento

202~227 Flujo continuo, velocidad decreciente

228~229 Sin desplazamiento

230~255 Inversión de flujo,

velocidad creciente.

11 Rotación Gobo 000~127 0°~400° Posicionami-

ento

128~191 Flujo continuo, velocidad decreciente

192~255 Inversión de flujo,

velocidad creciente

12 Prisma 1 000-127 Prisma sin movimien-

to

128-255 Prisma en movimiento

Canales Funciones Efectos

Page 28

BEAMER 17R

P. 38

VERSION ESPAÑOL

13 Prisma 2 000-127 Prisma sin mov.

128-255 Prisma en movimiento

14 Rotación de Prisma 0°~400° Posicionamiento

128~191 Flujo continuo, velocidad decreciente

192~255 Inversión de flujo,

velocidad creciente

15 Frog 000-255 0~100% Frost

16 Focus 000-255 0~100% Foco

17 Focus Bit 000-255

18 Zoom 000-255 3.8°-45°

19 Zoom Bit 000-255

20 Función 000~029 Sin función

030~050 Lámpara encendida

en bajo consumo (permanezca

5 segundos sobre la función)

049~059 Sin función

060~080 Lámpara encendida

en potencia máxima (permanezca 5 segundos sobre la

función)

081~099 Sin función

100~105 Lámpara apagada

106~119 Sin función

120~129 Color

130~139 Gobo

140~149 Prisma

150~159 Color, gobo, prisma

160~199 Sin función

200~205 Lámpara encendida

204~139 Sin función

240~255 Restablecer valores

Canales Funciones Efectos

Page 29

BEAMER 17R

P. 39

VERSION ESPAÑOL

DMX Modo 16 canales

Canales Funciones Efectos

1 Pan Scan 000~255 0-540°

2 Tilt Scan 000-255 0°-270°

3 Pan/Tilt velocidad 000-255 Velocidad decreciente

4 Shutter 001~031 Lámpara apagada

032~063 Lámpara encendida

064~095 Estrobo velocidad creciente

096~127 Lámpara encendida

128~159 Estrobo libre velocidad

creciente

160~191 Lámpara encendida

192~250 Estrobo interrumpido

velocidad creciente

251~255 Lámpara encendida

5 Dimmer 000-255 Intensidad creciente

6 color 000~004 Blanco

005~009 Color 1

010~014 Color 2

015~019 Color 3

020~024 Color 4

025~029 Color 5

030~034 Color 6

035~039 Color 7

040~044 Color 8

045~049 Color 9

050~054 Color 10

055~059 Color 11

060~064 Color 12

065~069 Color 13

070~189 Cambio de color lineal

190~219 Flujo continuo, velocidad decreciente

220~224 Interrupción

225~255 Inversión de flujo, velocidad creciente

Page 30

BEAMER 17R

P. 40

VERSION ESPAÑOL

7 Gobo Estático 000~003 Abierto

004~009 Gobo 1

010~015 Gobo 2

016~021 Gobo 3

022~027 Gobo 4

028~033 Gobo 5

034~039 Gobo 6

040~045 Gobo 7

046~051 Gobo 8

052~057 Gobo 9

058~063 Gobo 10

064~069 Gobo 11

070~075 Gobo 12

076~081 Gobo 13

082~087 Abierto

Vibración, velocidad creciente

088~095 Vibración de Gobo 1

096~103 Vibración de Gobo 2

104~111 Vibración de Gobo 3

112~119 Vibración de Gobo 4

120~127 Vibración de Gobo 5

128~135 Vibración de Gobo 6

136~143 Vibración de Gobo 7

144~151 Vibración de Gobo 8

152~167 Vibración de Gobo 9

168~175 Vibración de Gobo 10

176~183 Vibración de Gobo 11

184~191 Vibración de Gobo 12

192~199 Vibración de Gobo 13

200~201 Abierto

202~227 Flujo continuo, velocidad decreciente

228~229 Interrupción

230~255 Inversión de flujo, velocidad creciente

Canales Funciones Efectos

Page 31

BEAMER 17R

P. 41

VERSION ESPAÑOL

8 Gobo Rotativo 000~009 Abierto

010~019 Gobo 1

020~029 Gobo 2

030~039 Gobo 3

040~049 Gobo 4

050~059 Gobo 5

060~069 Gobo 6

070~079 Gobo 7

080~089 Gobo 8

090~099 Gobo 9

Vibración, velocidad creciente

100~110 Vibración de Gobo 1

111~121 Vibración de Gobo 2

122~132 Vibración de Gobo 3

133~143 Vibración de Gobo 4

144~154 Vibración de Gobo 5

155~165 Vibración de Gobo 6

166~176 Vibración de Gobo 7

177~187 Vibración de Gobo 8

188~199 Vibración de Gobo 9

200~201 Abierto

202~227 Flujo continuo, velocidad decreciente

228~229 Interrupción

230~255 Inversión de flujo, velocidad creciente

9 Rotación de Gobo 000~127 0°~400° Posicionami-

ento

128~191 Flujo continuo, velocidad decreciente

192~255 Inversión de flujo, velocidad creciente.

10 Prisma 1 000-127 Prisma sin movimiento

128-255 Prisma en movimiento

Ccanales Funciones Efecto

Page 32

BEAMER 17R

P. 42

VERSION ESPAÑOL

11 Prism 2 000-127 prism stop

128-255 prism running

12 Prism Rotate 0°~400° positioning

128~191 forward flow, fast to

slow

192~255 reverse flow, slow to

fast

13 Frog 000-255 0~100% frog

14 Focus 000-255 0~100% focus

15 Zoom 000-255 3.8°-45°

16 Function 000~029 no function

030~050 stay above 5 second,

lamp stay on low power

049~059 no function

060~080 stay above 5 second,

lamp stay on full power

081~099 no function

100~105 Lamp o

106~119 no function

120~129 color

130~139 gobo

140~149 prism

150~159 Color, gobo, prism

160~199 no function

200~205 Lamp on

204~139 no function

240~255 Reset

Channel Function Eect

Page 33

BEAMER 17R

Page 34

FOR MORE INFO ON THIS PRODUCT PLEASE CHECK WWW.TEC-SHOW.COM /

PARA MAS INFORMACION SOBRE ESTE PRODUCTO VISITE WWW.TEC-SHOW.COM

Loading...

Loading...