Page 1

BEAMER

Beam Moving Head – Powered

by 2R 132W Lamp

USER MANUAL / MANUAL DE USUARIO

PLEASE READ THE INSTRUCTIONS CAREFULLY BEFORE USE

POR FAVOR LEA LAS INSTRUCCIÓNES ANTES DE USAR

Page 2

Overview

Beamer is a compact design moving head powered by a 2R

132W Lamp with a beam angle of 2.5º. Boost your creativi-

static gobos + open and its 8-facet rotating prism. Stay in control of your show with Beamer’s motorized focus even in the

most challenging environments.

Source & Optics

Light Source: 2R 132W discharge lamp

Color temperature: 8,000K

Lamp life: 10,000 hours

Beam angle: 2.5°

Photometric data

-

Static gobo wheel: 8 indexable gobos + 7 dierent size

beam gobos

Gobo Diameter: 7 mm.

Gobo shaking

8-facet rotating prism

Frost: Linear frost

Electrical focus

Dimmer: Full range 0-100%

Control

DMX channels: 11/14

Operational modes: DMX, Master/Slave, Manual, Auto-run &

Built-in programs

Arm32 SCM system with 48mb/s processing speed

Movement

Pan: 630°

Tilt: 235°

16-bit resolution

Auto repositioning

BEAMER

ENGLISH VERSION

p. 2

Physical

DMX connectors: 2 XLR connectors (XLR-3 In and Out)

Power supply connectors: PowerCON® In

Backlit LCD display

Dimensions: 430x247x338 mm. / 17x9.7x13.3 in.

Weight: 12 Kg. / 26.5 Lbs.

Page 3

BEAMER

ENGLISH VERSION

p. 3

• All maintenance must be carried out by a qualied

electrician.

• A minimum distance of 0.5m must be maintained between

the equipment and a combustible surface.

• The product must always be operated in a well ventilated area.

• DO NOT stare directly into the light source.

• Always disconnect the power before carrying out any

maintenance.

• The earth must always be connected to the ground.

• Ensure that all parts of the equipment are kept clean and

free of dust.

IMPORTANT

Every person involved with the installation, operation

and maintenance of this device has to be qualied.

• Follow the instructions of this manual.

• Consider this manual to be part of the total product.

• Keep this manual for the entire service life of the product.

• Pass this manual on to every further owner or user of

the product

• Download the latest version of the user manual from

the Internet.

OPERATING DETERMINATIONS

• This product is only allowed to be operated with an al-

ternating voltage of 100-240 V, 50/60 Hz.

• This device is designed for professional use, e.g. on stag-

es, in clubs, bars, theatres etc.

• Do not shake the device. Avoid brute force when installing or operating the device.

• When choosing the installation-spot, please make

sure that the device is not exposed to extreme heat,

moisture or dust. There should not be any cables lying around. Please make sure that the unit cannot be

touched or bumped.

• When using smoke machines, make sure that the de-

For your own safety, please read this user manual careful-

ly before you initially start-up.

SAFETY WARNING

vice is never exposed to the direct smoke jet and is installed in a distance of 0.5 meters between smoke machine and device.

• The ambient temperature must always be between -15°

C and +45° C. Keep away from direct insulation (particu-

larly in cars) and heaters.

• Never use the device during thunderstorms. Over volt-

age could destroy the device. Always disconnect the device during thunderstorms.

• The device must only be installed on a non-amma-

ble surface. In order to safeguard suicient ventilation,

leave 50 cm of free space around the device.

• For overhead use (mounting height >100 cm), always

x the xture with an appropriate safety-rope. Fix the

safety-rope at the correct xation points only. The safe-

ty-rope must never be xed at the transport handles!

• Only operate the xture aer having checked that the

housing is rmly closed and all screws are tightly fastened.

• Operate the device only aer having become familiarized

with its functions. Do not permit operation by persons

not qualied for operating the device. Most damages are

the result of unprofessional operation!

• Please consider that unauthorized modications on the

device are forbidden due to safety reasons!

• Never remove the serial barcode from the device as this

would make the guarantee void.

Page 4

Installation

• This machine should be mounted through the screw

holes of truss. Safety wire is a must to x xture well.

Make sure truss and safety wire have strong load capaci-

ty to bear 3 times weight than xture at least.

• This machine should be installed by qualied technician.

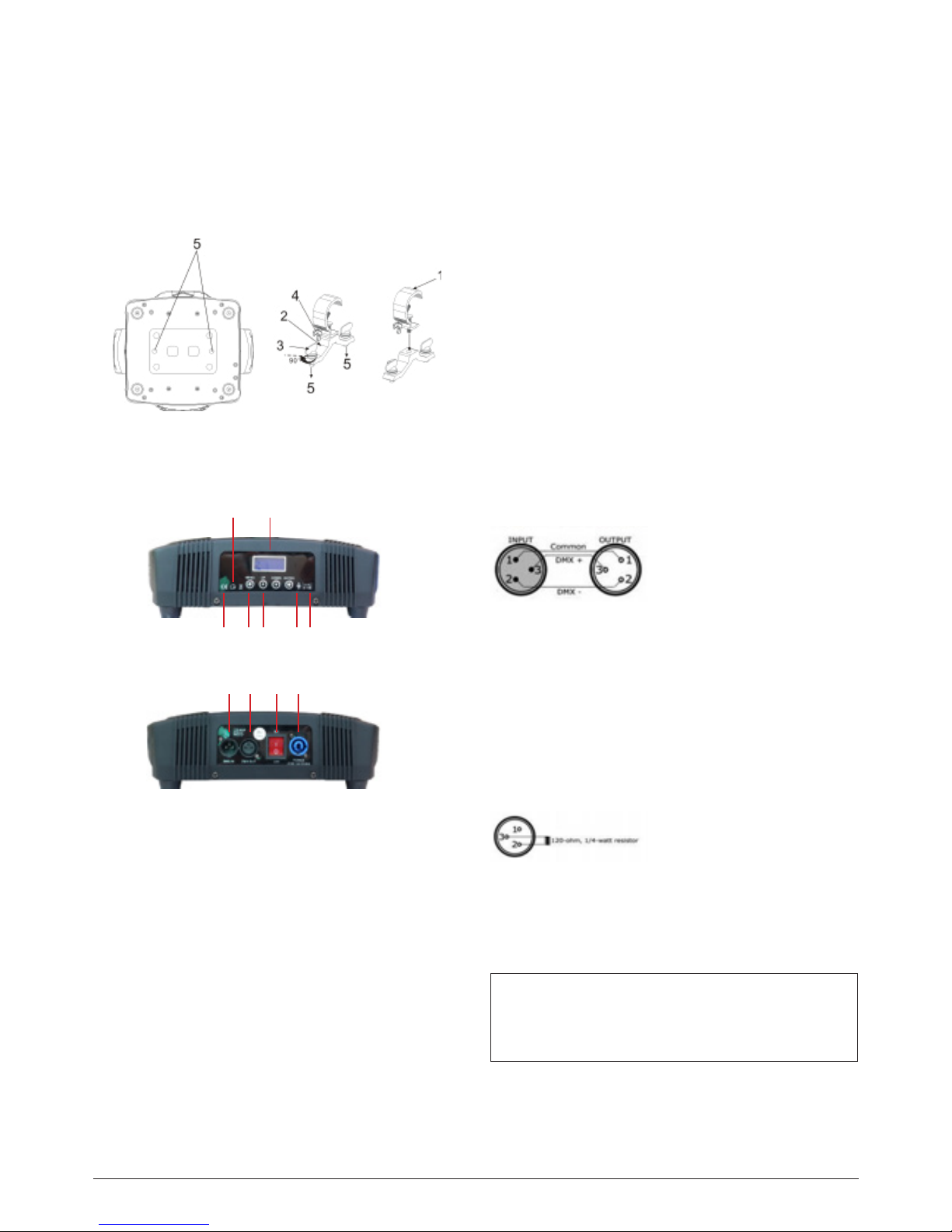

Controlling Board

1. Indoor Used

This unit is for indoor used, cannot bear moist or dusty environment.

2. LCD Display

Shows menu

3. CE Certication

This unit had obtained CE certication.

4. Treatment of Retirement

This unit cannot be dropped to trash can.

5. Control Button

Choose function

6. External Lamp Ignited.

This machine with high voltage sodium lamp unit, needs external igniter.

1 2

3

8 9 10 11

4 5 6 7

7. Operating Environment

Maximum operating environment temperature is 35°C, 5m

minimum distance away from ammable materials.

9. DMX In

Connect 3 pin XLR signal cable with male connector to obtain

signal from other unit or controller

10. DMX Out

Connect 3 pin XLR signal cable with female connector to

transfer signal to next unit

11. Switch

Power on/power o

12. Power Input

Connect power cable to obtain power.

Machine Connection

Cable Connectors

Cables must have a male XLR connector on one end and a

female XLR connector on the other end.

A word on termination: DMX is a resilient communication

protocol, however errors still occasionally occur. Termination reduces signal errors, and therefore best practices

include use of a terninator in all circumstances. If you are

experiencing problems with erratic xture behavior, especially over long signal cable runs, a terminator may help

improve performance.

To build your own DMX Terminator: Obtain a 120-ohm, 1/4-

watt resistor, and wire it between pins 2&3 of the last xture.

They are also readily available from specialty retailers.

Complimentary signal cable can transmit signals to

20 unit xtures at most. Signal amplier is a must to

connect more xtures

BEAMER

ENGLISH VERSION

p. 4

Page 5

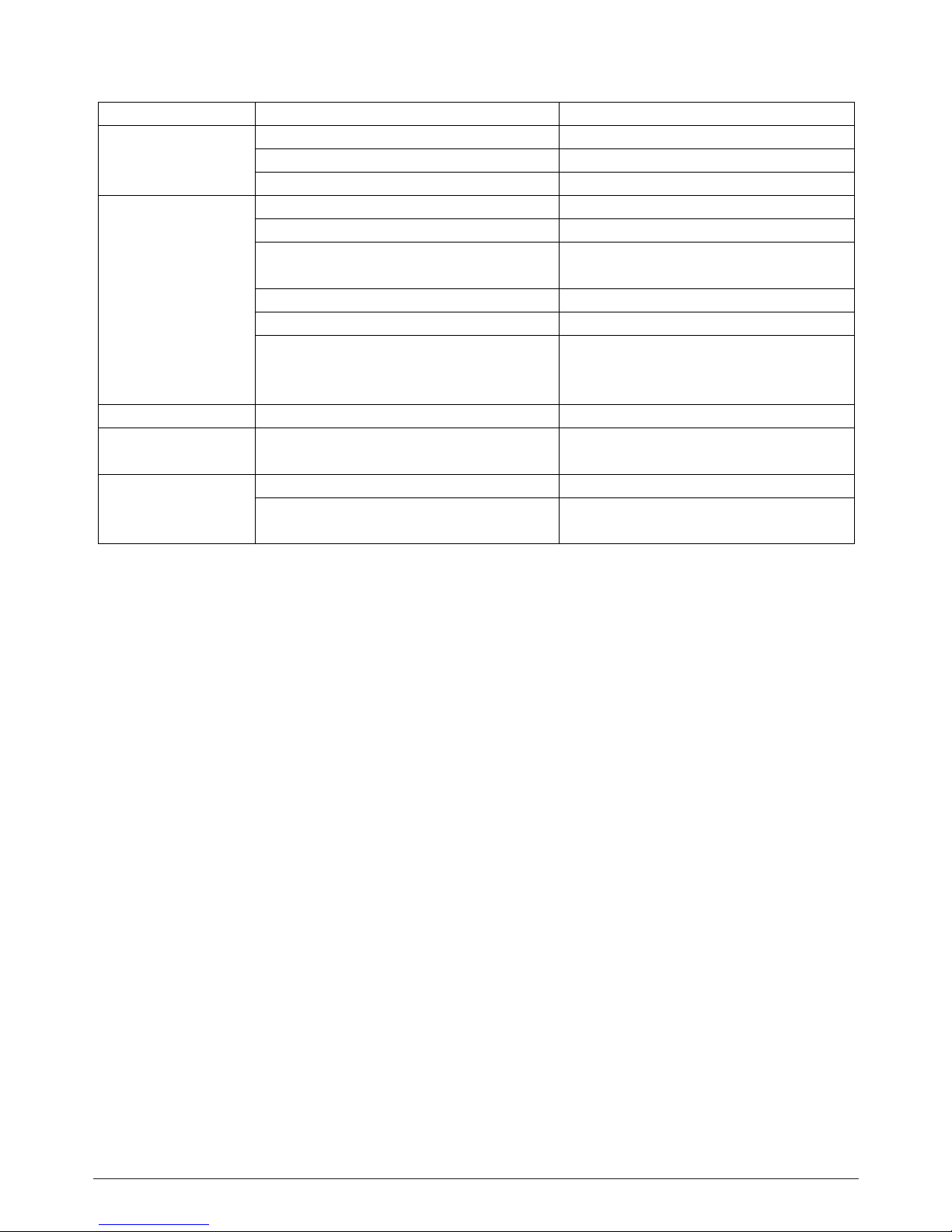

Problem Probable cause(s) Remedy

No response from xture

when power is applies

No power to xture Check power cables

Primary fuse blown Replace fuse

Secondary fuse blown Replace fuse

Fixture resets but does

not respond correctly

to controller(DMX mode

operation)

Controller not connected Connect controller

Incorrect addressing of the xtures Check address setting on xture and controller

Bad data link connection

Inspect cables and correct poor connections

and/or broken cables.

Conict between tracking and vector control Eliminate scene cross-fade on controller

Data link not terminated Insert termination plug in output of last xture

Defective xture or 2 devices transmitting on link

Bypass xtures one at a time until normal oper-

ation is regained: unplug both connectors and

connect them directly together

Colors cannot be mixed Random color mixing is on Turn o random color mixing

Fixture does not reset

correctly

Electronic or mechanical failure Contact service technician

No light, lamp cuts out

intermittently, or burns

out too quickly

Lamp missing or blown Disconnect xture and replace lamp

Fixture or lamp is too hot

Allow xture to cool. If problem persists, contact

service technician

Troubleshooting

Reference

• Control menu

• DMX Channel

• Specication

BEAMER

ENGLISH VERSION

p. 5

Page 6

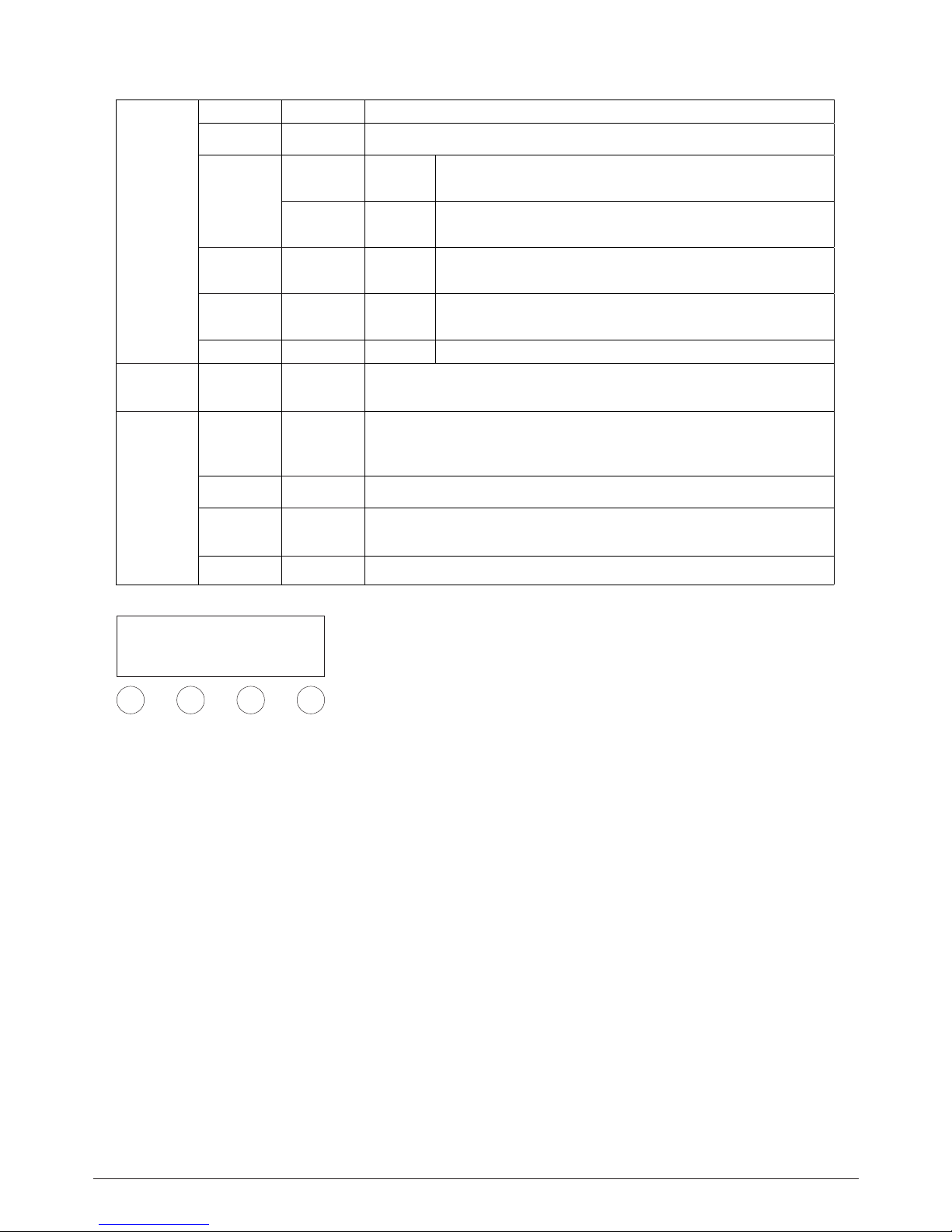

Control Menu

UP DOWN ENTERMENU

MENU

Address ENTER UP/DOWN→ENTER

Control ENTER UP/DOWN to choose 11CH/14CH→ENTER

DMX Reset

ENTER→UP/DOWN→Yes/No(Yes=DMX reset;No=Cannot DMX

reset)→ENTER

ENTER→UP/

DOWN

Pan

ENTER→UP/DOWN→Yes/No(Yes = Pan Anti-clockwise rotate; No=-

clockwise) → ENTER

Option Tilt

ENTER→UP/DOWN→Yes/No(Yes=Anti-clockwise; No=clockwise) →

ENTER

Color

ENTER→UP/DOWN→ Color Step/Color linear ( Color step=color

jumping change; Color linear = color linear change → ENTER

Option ENTER Key lock ENTER→UP/DOWN →Yes/No(Yes =lock, No=unlock)→ENTER

MENU Manual →UP/ DOWN CH11/CH14→ENTER;UP/DOWN to adjust Channel →ENTER

Test

Test Auto/Test Sound(Test Auto= stand alone, Test Sound= music ac-

tive)→ENTER

Lamp Yes/No(Yes = Lamp on, No= Lamp o)→ENTER

Default Yes/No( Yes = reset, NO = Current value address)→ENTER

Reset Yes/No(Yes = reset, No= N/A)→ENTER

Remark: ☐ Always press ENTER to next class menu and save

your settings; return last menu class, press MENU. LCD is dark

automatically if no operation on panel within 30 seconds.

Master and slave model

Set one of the unit as master, choose auto-running function

on the menu. Set other units as slave, press MENU button to

DMX address setting state. Connect master and slave with

signal cable. Then all slave units will run follow the master.

BEAMER

ENGLISH VERSION

p. 6

Page 7

DMX Channel

14 Channel Modes

Channel Function Specication

CH1 X 0-255 0 °-630 °

CH2 Y 0-255 0 ° -235 °

CH3 X16bit 0-255

CH4 Y16bit 0-255

CH5 X,Y speed 0-255 from fast to slow

CH6 Dimmer 0-255 from dark to bright

CH7 Strobe 1-50 lamp on 51-240 strobe from slow to fast; 241-255 lamp on

CH8 Gobo 0-255

CH9 Color 0-255

CH10 Prism 0-127 stay the same; 128-255 8 facet prism

CH11 Prism rotate

0-106 clockwise rotate, from slow to fast; 107-180 anticlockwise

rotate, from slow to fast; 181-255 prism self-rotate and shake,

from slow to fast

CH12 Focus 0-255

CH13 Lamp control

0-99 stay the same; 100-105 lamp o (stop 3 seconds) 106-199

stay the same; 200-205 lamp on (stop 3 seconds) ; 206-255 stay

the same

CH14 Reset 0-254 stay the same 255 (stay 3 seconds reset)

BEAMER

ENGLISH VERSION

p. 7

Page 8

11 Channel Modes

Channel Function Specication

CH1 X 0-255 0°-630°

CH2 Y 0-255 0°-235°

CH3 Dimmer 0-255 from dark to bright

CH4 Strobe

1-50 lamp on ;51-240 strobe from slow to fast; 241-255

lamp on

0-4 white; 5-9 gobo 1; 10-14 gobo 2; 15-19 gobo 3; 20-24

gobo 4; 25-29 gobo 5,30-34 gobo 6;35-39 gobo 7; 40-44

gobo 8; 45-49 gobo 9; 50-54 gobo 10; 55-59 gobo 11; 60-64

gobo 12; 65-69 gobo 13; 70-74 gobo 14, 75-84 gobo 14

shake; 85-94 gobo 13 shake; 95-104 gobo 12 shake; 105-

114 gobo 11 shake; 115-124 gobo 10 shake; 125-134 gobo

9 shake; 135-144 gobo 8 shake; 145-154 gobo 7 shake;

155-164 gobo 6 shake; 165-174 gobo 5 shake; 175-184 gobo

4 shake; 185-194 gobo 3 shake; 195-204 gobo 2 shake; 205-

214 gobo 1 shake; 215-255 gobo ow from slow to fast.

CH5 Gobo

CH6 Color

0-9 white, 10-19 red, 20-29 yellow, 30-39blue, 40-49 green

50-59 orange, 60-69 Magenta, 70-79pink, 80-89light blue,

90-99light yellow, 100-109dark blue,110-119olivine, 120-

129 CTB, 130-139 CTO,140-255 color rainbow eect

CH7 Prism 0-127 N/A 128-255 8-facet prism

CH8 Prism self-rotating

0-106 clockwise rotating from slow to fast,107-255 an-

ti-clockwise from slow to fast

CH9 Focus 0-255

CH10 Lamp on/o

0-99 N/A 100-105 Lamp o (interval 3 seconds) 106-199 N/A

200-205 Lamp on (interval 3 seconds) 206-255 N/A

CH11 Reset 0-254 N/A 255 (interval 3 seconds) Reset

BEAMER

ENGLISH VERSION

p. 8

Page 9

Descripción

Beamer es un cabezal móvil de diseño compacto que tiene

una lámpara 2R de 132W con un ángulo de haz de 2.5º. Explote su creatividad con sus 13 colores + abierto, CTB, CTO,

efecto de arcoiris, 14 gobos estáticos + abierto y su prisma

rotativo de 8 facetas. Gracias a su foco motorizado Beamer le

permite mantener un control de su show aún en los ambientes más difíciles.

Fuente & Óptica

Fuente de luz: Lámpara 2R de 132W

Temperatura de color: 8,000K

Vida de lámpara: 10,000 horas

Ángulo de haz: 2.5°

Información fotométrica

Efectos y Funciones

bidireccional

Rueda de gobo estática: 8 gobos indexables + 7 tamaños diferentes

Efecto gobo shake

Prisma rotativo de 8 caras

Frost: 0-100%

Foco motorizado

Dimmer: Rango completo 0-100%

Control

Canales DMX: 11/14

Modos de operación: DMX, Master/Slave, Manual, Auto-run &

programas integrados

Sistema Arm32 SCM con 487 Mb de velocidad

Movimiento

Pan: 630°

Tilt: 235°

Resolución: 16-bit

Reposicionamiento automático

Físico

Conectores DMX: 2 conectores XLR (XLR-3 de entrada & salida)

Alimentación: PowerCON® de entrada

Pantalla LCD con iluminación de fondo

Dimensiones: 430x247x338 mm. / 17x9.7x13.3 in.

Peso: 12 Kg. / 26.5 Lbs.

Page 10

Por su propia seguridad, por favor lea atentamente el

manual antes de utilizar el equipo.

ADVERTENCIA DE SEGURIDAD

• Este producto debe ser instalado por un profesional

calicado.

• Toda mantención debe ser llevada a cabo por un electr-

icista calicado.

• Una distancia mínima de 0.5m debe ser mantenida entre

el equipo y cualquier supercie combustible.

• El producto debe ser siempre operado en áreas ventiladas.

• NO mire de forma directa hacia la fuente de luz.

• Siempre desconecte el equipo antes de realizar cualqui-

er tipo de mantención.

• El neutro debe estar siempre conectado a tierra.

• Asegúrese que todas las partes del equipo se mantengan

limpias y libres de polvo.

IMPORTANTE

• Toda persona involucrada con las instalación, operación

y mantenimiento del equipamiento debe estar calica-

da para ello.

• Seguir las instrucciones de este manual.

• Considerar este manual parte del producto.

• Mantener este manual durante toda la vida útil del producto.

• Pasar el presente manual a cada uno de los futuros

dueños de la unidad.

• Descargar la última versión disponible del sitio de internet de la empresa.

DETERMINACIONES DE OPERACIÓN

• Este producto solamente puede ser operado en un volta-

je de 100-240 V, 50/60 Hz.

• Este equipamiento está diseñado para uso profesional.

Por ejemplo: escenarios, clubs, bares y teatros.

• No agite el equipo. Evite la fuerza bruta al instalar o hacer funcionar el dispositivo.

• Al elegir el lugar de la instalación, por favor asegúrese de

que el dispositivo no está expuesto a calor extremo, humedad o polvo. No debe haber ningún cable por ahí. Por favor,

asegúrese de que la unidad no puede ser tocada ni golpeada.

• Al usar máquinas de humo, asegúrese de que el dispositivo no está expuesto al chorro de directo de la máquina y de que sea instalado a una distancia mínima de 0,5

metros entre la máquina de humo y el dispositivo.

• La temperatura ambiente debe estar siempre entre -15

° C y + 45 ° C. Mantener alejado del sol directo (especial-

mente en el coche) y calentadores.

• Nunca utilice este dispositivo durante tormentas eléctri-

cas. El Sobre-voltaje podría destruir el dispositivo. Siempre desconecte el aparato durante tormentas eléctricas.

• El equipo sólo se debe instalar sobre una supercie no

inamable. Con el n de salvaguardar la ventilación su-

ciente, deje 50 cm de espacio libre alrededor del aparato.

• Por instalar el equipo encima de la cabeza (altura de

montaje> 100 cm), siempre je el aparato con una cuer-

da de seguridad apropiada. Fijar la cuerda de seguridad

sólo en los puntos de jación correctos. La seguridad de

la cuerda no debe jarse en las asas de transporte.

• Opere el equipo solamente luego de haber comprobado

que el recinto del mismo está bien cerrado y con todos

los tornillos bien apretados.

• Haga funcionar el aparato sólo después de familiarizarse

con sus funciones. No permitir la utilización por parte

de personas no calicadas para operar el dispositivo. La

mayoría de los daños son el resultado de una operación

poco profesional.

• Por favor, considere que las modicaciones no autorizadas

del aparato están prohibidas por razones de seguridad.

• Nunca quite el código de barras de serie del dispositivo

ya que esto haría que la garantía pierda vigencia.

BEAMER

VERSIÓN ESPAÑOL

p. 10

Page 11

1 2

3

8 9 10 11

4 5 6 7

Instalación

• La unidad debe montarse utilizando los oricios para

tornillos del truss. Procure utilizar un cable de seguridad

para jar la unidad en la posición que desee. Asegúrese

de que el truss y el cable de seguridad puedan tolerar,

como mínimo, un peso equivalente a 3 veces el peso de

la unidad.

• Procure que la instalación de la unidad esté a cargo de

un técnico calicado.

1. Advertencia

Mantener una distancia mínima de 5 metros entre el equipo y

materiales inamables. La supercie externa puede alcanzar

una temperatura máxima de 80 °C.

2. Pantalla LCD

Permite visualizar el menú de funciones de la unidad.

3. Encendido externo

La unidad utiliza una lámpara de sodio de alto voltaje, por lo

que debe contar con un sistema de encendido externo.

4. Entorno de operación

La unidad debe operarse en ambientes cuya temperatura sea

Panel de control

menor a 35 °C. Deberá dejar un espacio mínimo de 5 metros

entre el equipo y materiales inamables.

5. Teclas de control

Utilice estas teclas para desplazarse en el menú

6. Certicación CE

Este equipo cuenta con certicación CE.

7. Uso interno

El producto debe utilizarse en espacios interiores únicamente, ya que no puede exponerse a condiciones de humedad o polvo.

8. Desechos

Procure deshacerse del producto de manera adecuada según

las reglamentaciones correspondientes.

9. Entrada DMX

Utilice esta entrada para conectar un cable de señal XLR de 3

pines con conector macho y obtener señales de otro equipo

o controlador.

10. Salida DMX

Utilice esta salida para conectar un cable de señal XLR de 3

pines con conector hembra y transferir señales hacia la siguiente unidad.

11. Interruptor

Utilice este interruptor para encender o apagar la unidad.

12. Entrada de alimentación

Conecte el cable de alimentación para acceder al suministro eléctrico.

13. Fusible

Este elemento permite proteger a la unidad contra cortocircuitos.

BEAMER

VERSIÓN ESPAÑOL

p. 11

Page 12

Conexiones

Cables

Los cables deben tener un conector XLR macho en un extremo y un conector XLR hembra en el otro.

Terminación: DMX es un protocolo de comunicación resiliente,

por lo que pueden presentarse errores de manera esporádica.

La terminación permite reducir errores en la señal. Por eso, es

recomendable utilizar un terminador en todos los casos. Si el

funcionamiento de la unidad no es adecuado, especialmente

cuando se utilizan cables de señal prolongados, el uso de un ter-

minador puede ayudar a mejorar el rendimiento del dispositivo.

Construcción de terminador DMX:

Conecte un resistor de 120 Ω y 1/4 W entre los pines 2 y 3 de

la última unidad. Puede adquirir este resistor en un establecimiento especializado.

Referencias de la imagen

COMMON COMÚN

DMX - DMX DMX + DMX +

INPUT ENTRADA

OUTPUT SALIDA

Referencias de la imagen

120-ohm, 1/4-watt resistor Resistor de 120 Ω y ¼ W

El cable de señal complementario transmite señales a

un máximo de 20 unidades. En caso de necesitar conec-

tar más unidades, utilice un amplicador de señal.

BEAMER

VERSIÓN ESPAÑOL

p. 12

Page 13

Resolución de problemas

Problema Causa probable Solución

La unidad no respon-

de al enchufarla.

Falta de suministro eléctrico. Controle los cables de alimentación.

Fundición de fusible primario. Reemplace el fusible.

Fundición de fusible secundario. Reemplace el fusible.

La unidad se reinicia,

pero no responde

correctamente al

controlador en modo

DMX.

Falta de conexión del controlador. Conecte el controlador.

Direccionamiento incorrecto de las unidades.

Verique la conguración de direcciones en la unidad y

el controlador.

Conexión de datos incorrecta.

Controle los cables y repare las conexiones defectuosas

o los cables dañados.

Conicto entre control vectorial y pistas. Elimine el cross-fade entre escenas en el controlador.

Falta de terminación de la conexión de datos.

Inserte un conector de terminación en la salida de la

última unidad.

Unidad defectuosa o 2 dispositivos con trans-

misión en la misma conexión.

Omita las unidades de a una por vez hasta que vuelvan

a funcionar normalmente. Desenchufe ambos conecto-

res y conéctelos juntos de manera directa.

Falta de mezcla de

colores.

Función de mezcla aleatoria de colores ac-

tivada.

Desactive la función de mezcla aleatoria de colores.

Reinicio incorrecto

de la unidad.

Falla electrónica o mecánica. Contacte a un técnico.

Falta de iluminación

en las lámparas,

cortes intermitentes

o apagado rápido.

Fundición de lámpara o lámpara inexistente. Desconecte la unidad y reemplace la lámpara.

Sobrecalentamiento de la unidad o lámpara.

Permita que la unidad se ventile. Si el problema con-

tinúa, contacte a un técnico.

Menú de control

UP DOWN ENTERMENU

Referencias de la imagen

DOWN DOWN

ENTER ENTER

MENU MENU

UP UP

BEAMER

VERSIÓN ESPAÑOL

p. 13

Page 14

MENU

Address ENTER

Utilice las teclas UP/DOWN para seleccionar el valor deseado y

luego presione ENTER.

Control ENTER

Utilice las teclas UP/DOWN para elegir el modo de canales deseado

(11CH/14CH) y luego presione ENTER.

Option

ENTER→UP/ DOWN

DMX Reset

Presione ENTER. Utilice las teclas UP/ DOWN para

seleccionar la opción deseada: Yes (reiniciar DMX) o No

(no reiniciar DMX). Luego, presione ENTER.

Pan

Presione ENTER. Utilice las teclas UP/ DOWN para

seleccionar la opción deseada: Yes (rotación de Pan

en sentido antihorario) o No (sentido horario). Luego,

presione ENTER.

Tilt

Presione ENTER. Utilice las teclas UP/ DOWN para

seleccionar la opción deseada: Yes (en sentido anti-

horario) o No (sentido horario). Luego, presione ENTER.

Color

Presione ENTER. Utilice las teclas UP/ DOWN para

seleccionar la opción deseada: Color step (cambio por

salto de color) o Color linear (cambio lineal de colores).

Luego, presione ENTER.

Keylock

Presione ENTER. Utilice las teclas UP/ DOWN para se-

leccionar la opción deseada: Yes (bloqueo de teclas) o

No (desbloqueo de teclas). Luego, presione ENTER.

Manual

Seleccione el modo deseado, CH11/CH14, y presione ENTER. Utilice

las teclas UP/DOWN para ajustar los canales. Luego, presione ENTER.

TEST

Seleccione la opción deseada: Test Auto (prueba automática) o

Test Sound (activación por sonido). Luego, presione ENTER.

Lamp

Seleccione la opción deseada: Yes (lámpara encendida) o No (lám-

para apagada). Luego, presione ENTER.

Default

Seleccione la opción deseada: Yes (reiniciar) o No (valor de direc-

ción actual). Luego, presione ENTER.

Reset

Seleccione la opción deseada: Yes (reiniciar) o No (cancelar). Lu-

ego, presione ENTER.

Aclaraciones: *Siempre presione ENTER para acceder al sigui-

ente menú y guardar los cambios realizados. Para volver al

menú anterior, presione la tecla MENU. Si no realiza ninguna

acción durante 30 segundos, la pantalla LCD se apagará en

forma automática.

Modo master/slave

Congure una unidad como master y elija la función de eje-

cución automática en el menú. Congure las otras unidades

como slave y presione la tecla MENU para denir la dirección

DMX. Utilice el cable de señal para conectar las unidades

master y slave. Todas las unidades slave seguirán al equipo

congurado como master.

BEAMER

VERSIÓN ESPAÑOL

p. 14

Page 15

Canales DMX

Modo de 14 canales

Canal Función Valores

CH1 X 0-255 0°-630°

CH2 Y 0-255 0°-235°

CH3 X (16 bits) 0-255

CH4 Y (16 bits) 0-255

CH5 Velocidad de X, Y 0-255 Velocidad decreciente

CH6 Dimmer 0-255 Oscuro-brilloso

CH7 Estrobo

1-50 Lámpara encendida

51-240 Estrobo (velocidad creciente)

241-255 Lámpara encendida

CH8 Gobo 0-255

CH9 Colores 0-255

CH10 Prisma

0-127 Sin cambio

128-255 Prisma de 8 caras

CH11 Rotación del prisma

0-106 Rotación en sentido horario (velocidad creciente)

107-180 Rotación en sentido antihorario (velocidad creciente)

181-255 Rotación automática y vibración del prisma (velocidad

creciente)

CH12 Enfoque 0-255

CH13 Control de la lámpara

0-99 Sin cambio

100-105 Lámpara apagada (luego de 3 segundos)

106-199 Sin cambio

200-205 Lámpara encendida (luego de 3 segundos)

206-255 Sin cambio

CH14 Reinicio

0-254 Sin cambio

255 Reinicio luego de 3 segundos

BEAMER

VERSIÓN ESPAÑOL

p. 15

Page 16

Modo de 11 canales

Función Valores

CH1 X 0-255 0°-630°

CH2 Y 0-255 0°-235°

CH3 Dimmer 0-255 Oscuro-brilloso

CH4 Estrobo

1-50 Lámpara encendida

51-240 Estrobo (velocidad creciente)

241-255 Lámpara encendida

CH5 Gobo

0-4 Blanco

5-9 Gobo 1

10-14 Gobo 2

15-19 Gobo 3

20-24 Gobo 4

25-29 Gobo 5

30-34 Gobo 6

35-39 Gobo 7

40-44 Gobo 8

45-49 Gobo 9

50-54 Gobo 10

55-59 Gobo 11

60-64 Gobo 12

65-69 Gobo 13

70-74 Gobo 14

75-84 Vibración de gobo 14

85-94 Vibración de gobo 13

95-104 Vibración de gobo 12

105-114 Vibración de gobo 11

115-124 Vibración de gobo 10

125-134 Vibración de gobo 9

135-144 Vibración de gobo 8

145-154 Vibración de gobo 7

155-164 Vibración de gobo 6

165-174 Vibración de gobo 5

175-184 Vibración de gobo 4

185-194 Vibración de gobo 3

195-204 Vibración de gobo 2

205-214 Vibración de gobo 1

215-255 Flujo de gobo (velocidad creciente)

BEAMER

VERSIÓN ESPAÑOL

p. 16

Page 17

CH6 Colores

0-9 Blanco

10-19 Rojo

20-29 Amarillo

30-39 Azul

40-49 Verde

50-59 Naranja

60-69 Magenta

70-79 Rosa

80-89 Celeste

90-99 Amarillo claro

100-109 Azul oscuro

110-119 Verde oliva

120-129 CTB

130-139 CTO

140-255 Efecto rainbow

CH7 Prisma

0-127 ND

128-255 Prisma de 8 caras

CH8

Prisma 0-106 Rotación en sentido horario (velocidad creciente)

Rotación

automática

107-255 Rotación en sentido antihorario (velocidad creciente)

CH9 Enfoque 0-255

CH10

Lámpara

On/O

0-99 N/A

100-105 Lámpara apagada (intervalo de 3 segundos)

106-199 ND

200-205 Lámpara encendida (intervalo de 3 segundos)

206-255 ND

CH11 Reinicio

0-254 N/A

255 Reinicio (intervalo de 3 segundos)

Canal Función Valores

BEAMER

VERSIÓN ESPAÑOL

p. 17

Page 18

Versión E spañol

tecshow.amproweb.com

Loading...

Loading...