TECO-Westinghouse EQ7-20P5-C, EQ7-2007-C, EQ7-2005-C, EQ7-2010-C, EQ7-2015-C Instruction Manual

...

Preface

IMPORTANT

For Advanced Installation, Wiring and Programming of the

EQ7 drive refer to the EQ7 Instruction Manual and User

Manual.

Failure to heed the information indicated by this symbol may lead to

dangerous conditions, possibly resulting in death or serious bodily

injuries.

Failure to heed the information indicated by this symbol may lead to

dangerous conditions, possibly resulting in minor or light bodily injuries

and/or substantial property damage.

The EQ7 product is designed to drive a three-phase induction motor. Read through this Quick Setting

Guide document to become familiar with proper handling and correct use. Improper handling might

result in incorrect operation, shorter life cycle, or failure of this product as well as the motor.

Have this Quick Setting Guide delivered to the end user of this product. Keep this Quick Setting

Guide in a safe place accessible by only people in connection with the VFD until this product is no

longer being used.

Read this Quick Setting Guide in conjunction with EQ7 Instruction Manual and User Manual.

All EQ7 documentation is subject to change without notice. Be sure to obtain the latest editions for

use or visit our website at www.tecowestinghouse.com.

Available Documentation:

1. EQ7 Quick Setting Guide

2. EQ7 Instruction Manual

3. EQ7 User Manual

Safety Precautions

Read this Quick Setting Guide in conjunction with EQ7 Instruction Manual thoroughly before

proceeding with installation, connections (wiring), operation, or maintenance and inspection. Ensure

you have sound knowledge of the device and familiarize yourself with all safety information and

precautions before proceeding to operate the inverter. Read EQ7 User Manual for detailed

description on parameters.

Safety precautions are classified into the following two categories in this manual.

Failure to ignore the information contained under the CAUTION title can also result in serious

consequences. These safety precautions are of utmost importance and must be observed at all

times.

1

IMPORTANT

For Advanced Installation, Wiring and Programming of the

EQ7 drive refer to the EQ7 Instruction Manual and User

Manual.

Table of Contents

1. Drive Models Constant Torque (CT) / Variable Torque (VT) HP Ratings .............. 3

2. Mounting and Wiring ................................................................................................. 4

2.1 Mounting Notes ..................................................................................................... 4

2.2 Wiring .................................................................................................................... 5

3. Input Power and Motor Connection ................................................................ ......... 6

4. LED Monitor, LCD Monitor and Keys ....................................................................... 8

5. Check Motor Rotation and Direction ..................................................................... 11

6. User Wiring Diagram ............................................................................................... 12

7. Speed Reference Command Configuration .......................................................... 14

7.1 Reference from the Keypad ................................................................................ 15

7.2 Reference from an Analog Signal (0-10V / 0-20mA / 4-20mA) / Speed Pot ........ 16

7.3 Reference from Serial Communication – RS485 ................................................. 17

8. Operation Method Configuration (Run / Stop) ...................................................... 19

8.1 Run / Stop from the Keypad ................................................................................ 19

8.2 Run / Stop from External Switch / Contact or Pushbutton ................................... 20

8.3 Run / Stop from Serial Communication – RS485 ................................................ 22

9. Motor and Application Specific Settings ............................................................... 24

9.1 Set Motor Nameplate Data .................................................................................. 24

Appendix: EQ7 Parameter Overview (Fundamental Functions).............................. 25

2

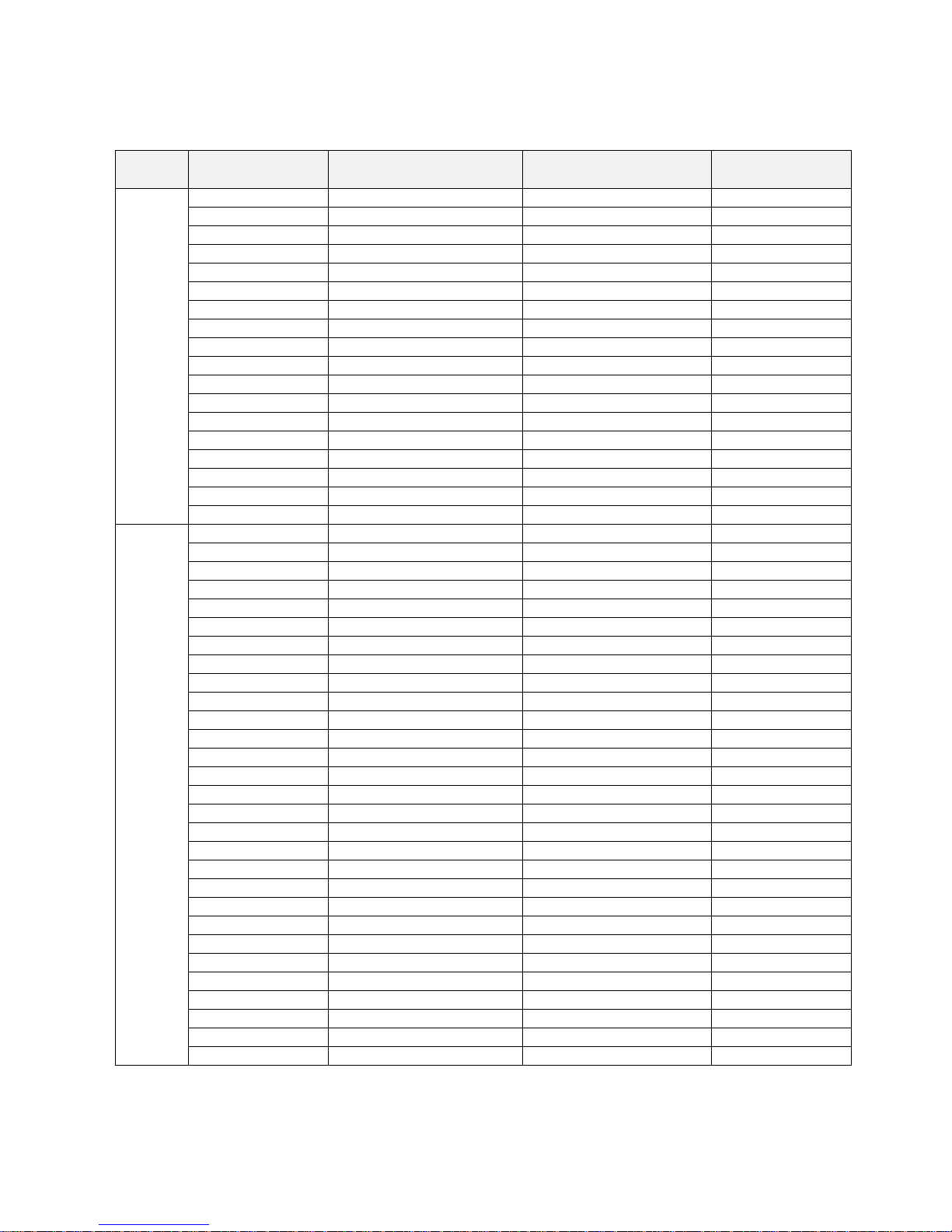

1. Drive Models Constant Torque (CT) / Variable Torque (VT) HP Ratings

Voltage

EQ7 DRIVE

Variable Torque HP

Constant Torque HP

Frame

Enclosure

230V

EQ7-20P5-C

0.5

0.5

Plastic

EQ7-2001-C

1 1 Plastic

EQ7-2002-C

2 2 Plastic

EQ7-2003-C

3 3 Plastic

EQ7-2005-C

5 5 Plastic

EQ7-2007-C

7.5

7.5

Plastic

EQ7-2010-C

10

7.5

Plastic

EQ7-2015-C

15

10

Plastic

EQ7-2020-C

20

15

Plastic

EQ7-2025-C

25

20

Plastic

EQ7-2030-C

30

25

Plastic

EQ7-2040-C

40

30

Plastic

EQ7-2050-C

50

40

Sheet Metal

EQ7-2060-C

60

50

Sheet Metal

EQ7-2075-C

75

60

Sheet Metal

EQ7-2100-C

100

75

Sheet Metal

EQ7-2125-C

125

100

Sheet Metal

EQ7-2150-C

150

125

Sheet Metal

460V

EQ7-40P5-C

0.5

0.5

Plastic

EQ7-4001-C

1 1 Plastic

EQ7-4002-C

2 2 Plastic

EQ7-4003-C

3 3 Plastic

EQ7-4005-C

5 5 Plastic

EQ7-4007-C

7.5

7.5

Plastic

EQ7-4010-C

10

7.5

Plastic

EQ7-4015-C

15

10

Plastic

EQ7-4020-C

20

15

Plastic

EQ7-4025-C

25

20

Plastic

EQ7-4030-C

30

25

Plastic

EQ7-4040-C

40

30

Plastic

EQ7-4050-C

50

40

Sheet Metal

EQ7-4060-C

60

50

Sheet Metal

EQ7-4075-C

75

60

Sheet Metal

EQ7-4100-C

100

75

Sheet Metal

EQ7-4125-C

125

100

Sheet Metal

EQ7-4150-C

150

125/150*

Sheet Metal

EQ7-4200-C

200

200*

Sheet Metal

EQ7-4250-C

250

250*

Sheet Metal

EQ7-4300-C

300

300*

Sheet Metal

EQ7-4350-C

350

350*

Sheet Metal

EQ7-4450-C

400/450

350

Sheet Metal

EQ7-4500-C

500

400/450*

Sheet Metal

EQ7-4600-C

600

500*

Sheet Metal

EQ7-4700-C

700

600*

Sheet Metal

EQ7-4800-C

800

700*

Sheet Metal

EQ7-4900-C

900

800

Sheet Metal

EQ7-41000-C

1000

900

Sheet Metal

This table shows the Variable Torque and Constant Torque ratings for all EQ7 drive models.

* The HP ratings marked with (*) are suitable for constant torque V/F Control. Refer to EQ7

Instruction Manual chapter 11 for constant torque vector control HP ratings.

3

2. Mounting and Wiring

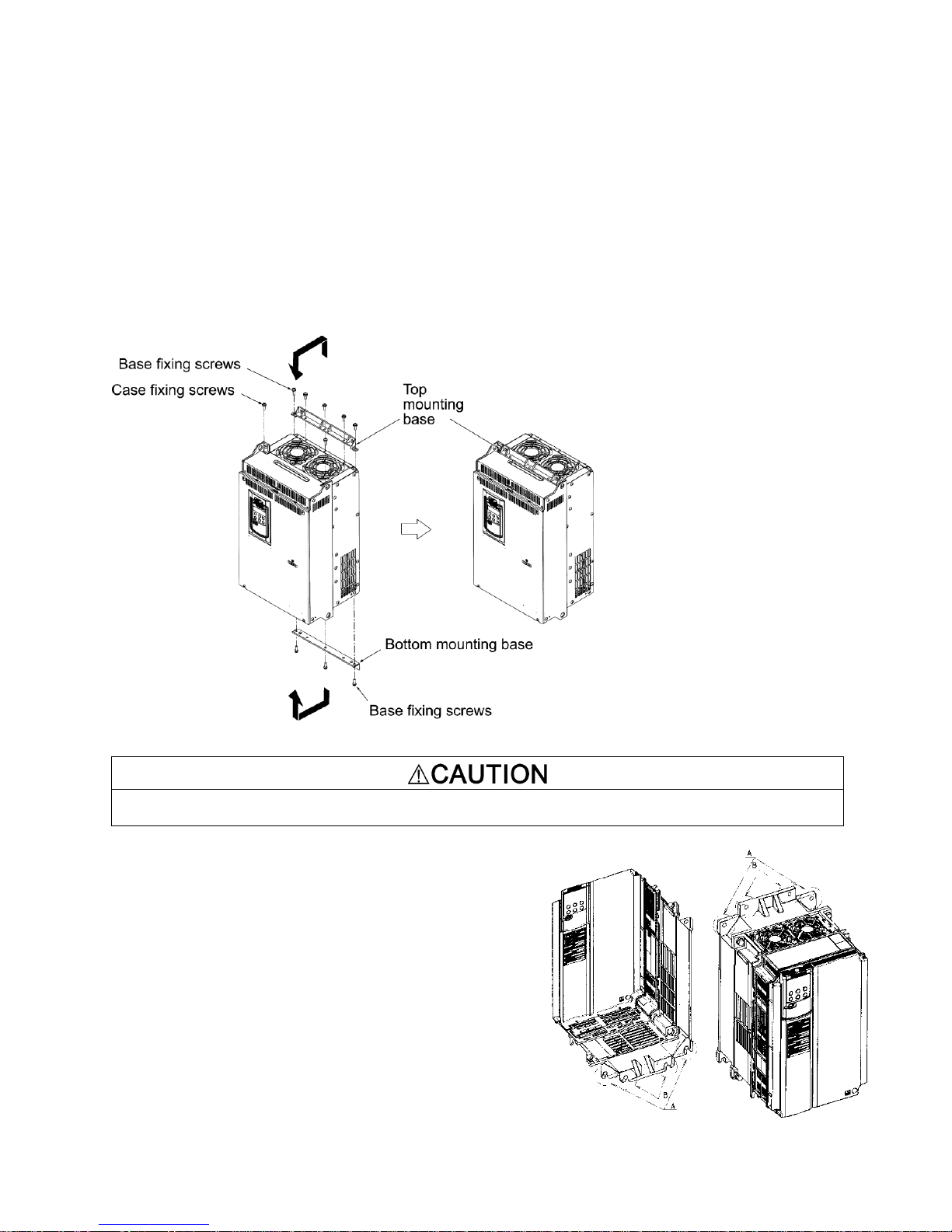

When changing the positions of the top and bottom mounting bases, use only the specified screws.

Otherwise, a fire or accident could occur.

2.1 Mounting Notes

Mounting the EQ7 in a control cabinet

1) Remove all base fixing screws and case fixing screws from the top of the inverter.

2) Move the top mounting base to the center of the inverter and secure it to the case fixing screw

holes with the base fixing screws. (After changing the position of the top mounting base, some

screws may be left unused.)

3) Remove all base fixing screws from the bottom of the inverter, move the bottom mounting base to

the center of the inverter, and secure it with the base fixing screws, just as in step 2). (Inverters of

450 HP or below have no case fixing screws on the bottom.)

Figure 2.1: Changing the Positions of the Top and Bottom Mounting Bases

(4) Mounting notes

Refer to the EQ7 Instruction Manual Chapter 2 for detailed

mounting Information.

The EQ7-2007-C / EQ7-4007-C through EQ7-2040-C / EQ74040-C should be mounted with four screws or bolts using

screw holes A or B shown below. Note that, at each of the top

and bottom of the inverter, the two screws or bolts should be

located in a bilaterally symmetrical position.

4

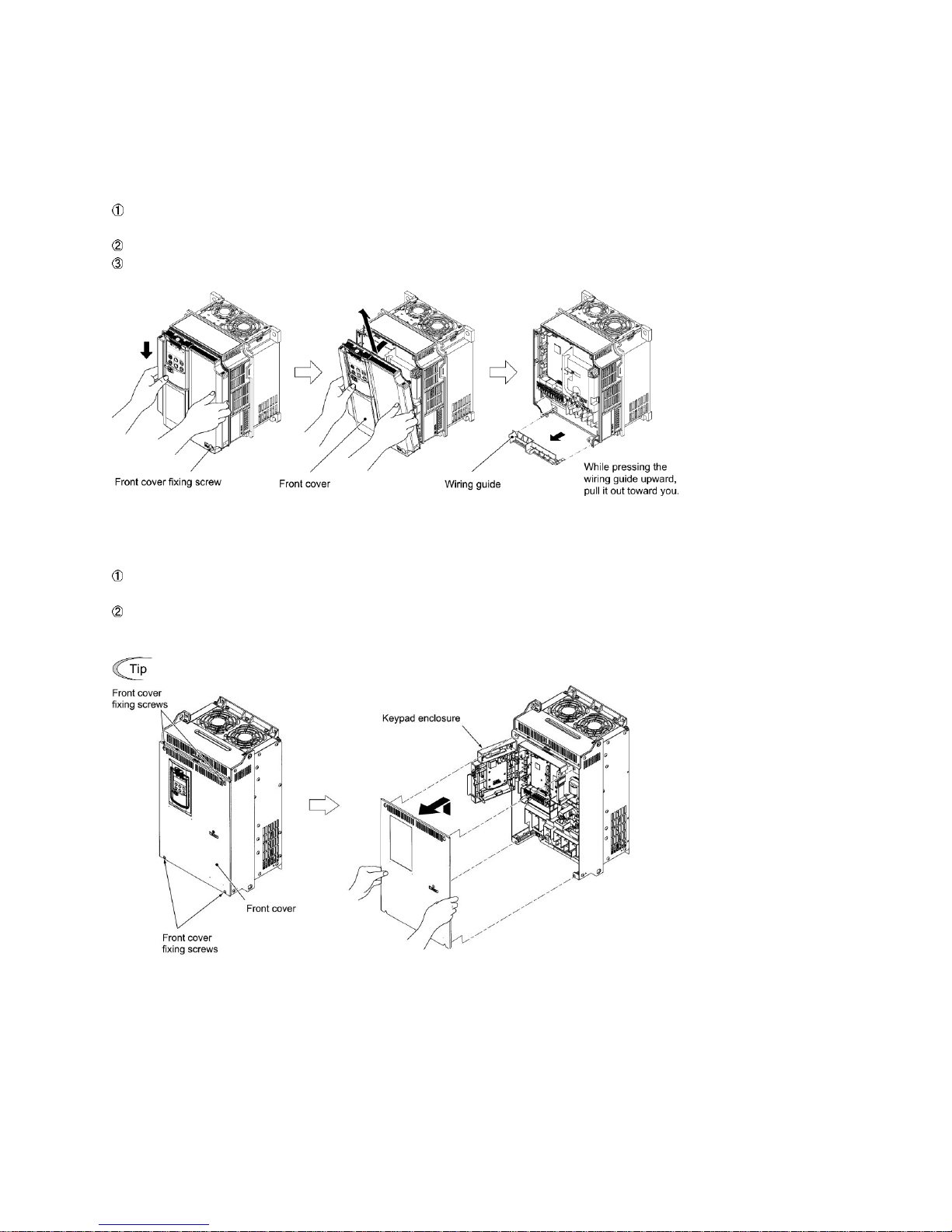

2.2 Wiring

To expose the control printed circuit board (control PCB), open the keypad enclosure.

Follow the procedure below. (In the following description, the inverter has already been installed.)

Removing and mounting the front cover and the wiring guide

(1) For inverters of 40 HP or below

First loosen the front cover fixing screw, slide the cover downward holding both sides, tilt it

forward, and then pull it upward, as shown below.

While pressing the wiring guide upward, pull it out and forward.

After carrying out wiring (see Section 2.3 of the EQ7 Instruction Manual), put the wiring guide

and the front cover back into place in the reverse order of removal.

Figure 2.2: Removing the Front Cover and the Wiring Guide (e.g EQ7-4020-C)

(2) For inverters of 50 to 1000 HP

Loosen the four front cover fixing screws, hold the cover with both hands, slide it upward

slightly, and pull it forward, as shown below.

After carrying out wiring (see Section 2.3 of the EQ7 Instruction Manual), align the screw

holes provided in the front cover with the screws on the inverter case, and then put the front cover

back into place in the reverse order of removal.

Tightening torque: 15.9 lb-in (1.8 Nm) (M4)

31.0 lb-in (3.5 Nm) (M5)

Figure 2.3: Removing the Front Cover (e.g. EQ7-4050-C)

5

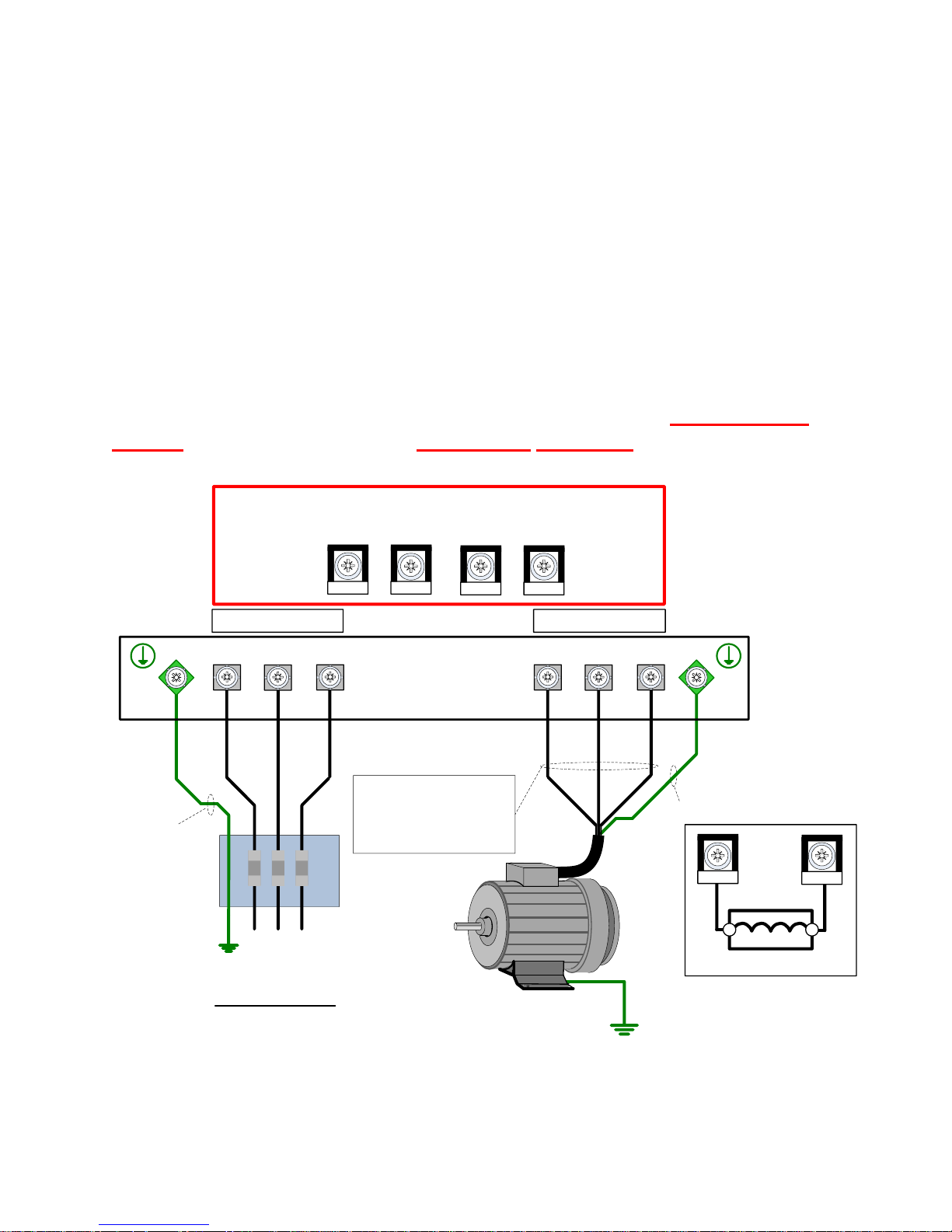

3. Input Power and Motor Connection

MOTOR

U V W

3Ø Induction

motor

Use L1, L2, L3 for

3Ø Input Power

Connect

frame to

ground

Input

Protection

(Fuse or Magnetic

Contactor)

To change direction of

motor rotation swap any

two of the three motor

leads.

L1

L2

L3

(R/L1)

(S/L2)

(T/L3)

(U/T1)

(V/T2)

(W/T3)

Ground

Use L1 & L3 for

1Ø Input Power

Ground

2

INPUT POWER

L1/R L2/S L3/T

P1

P(+)

N(-)

DB

WARNING DO NOT CONNECT ANY OF THE

FOLLOWING TERMINALS TO EARTH GROUND

Fig. 3.1

GND GND

*1 *1

*

DCR

P(+)

P1

EQ7

Checking prior to applying power

Fig.3.1 below shows the electrical connections for the input power and motor terminals for various

EQ7 DRIVE models. Verify the input power and motor terminals of the model you are installing. WITH

POWER OFF, make the appropriate connections.

Make sure to follow good wiring practices and all applicable codes. Ensure

that the equipment is grounded properly as shown.

DANGER, LETHAL VOLTAGES ARE PRESENT- Before applying power to the

EQ7 drive, ensure that the terminal cover is fastened and all wiring

connections are secure. After the power has been turned OFF, wait at least ten

minutes until the charge indicator extinguishes completely before touching

any wiring, circuit boards or components.

6

*1. Refer to page 12 & 13 for connecting a DC reactor from the terminals P1 and P(+).

*2. Make sure the drive is properly sized for single phase input (consult factory).

(Refer to Table 2.6 Recommended Wire Sizes in the EQ7 Instruction Manual).

Never connect power supply wires to the EQ7 drive output terminals U, V, and W. Doing so and turning

the power ON damages the inverter.

Be sure to connect the grounding wires of the EQ7 drive and the motor to the ground electrodes.

Otherwise, an electric shock could occur.

Check the following before powering on the EQ7 drive.

1) Check that the wiring is correct. In particular check the wiring to the EQ7 drive input terminals

L1/R, L2/S and L3/T and output terminals U, V, and W. Also check that the grounding wires are

connected to the grounding terminals ( G) correctly. See Figure 3.1.

2) Check the control circuit terminals and main circuit terminals for short circuits or ground faults.

3) Check for loose terminals, connectors and screws.

4) Check that the motor is separated from mechanical equipment.

5) Make sure that all switches of devices connected to the inverter are turned OFF. Powering on

the inverter with any of those switches being ON may cause an unexpected motor operation.

6) Check that safety measures are taken against runaway of the equipment. Also ensure that all

safety guards are in place to prevent human injury.

7

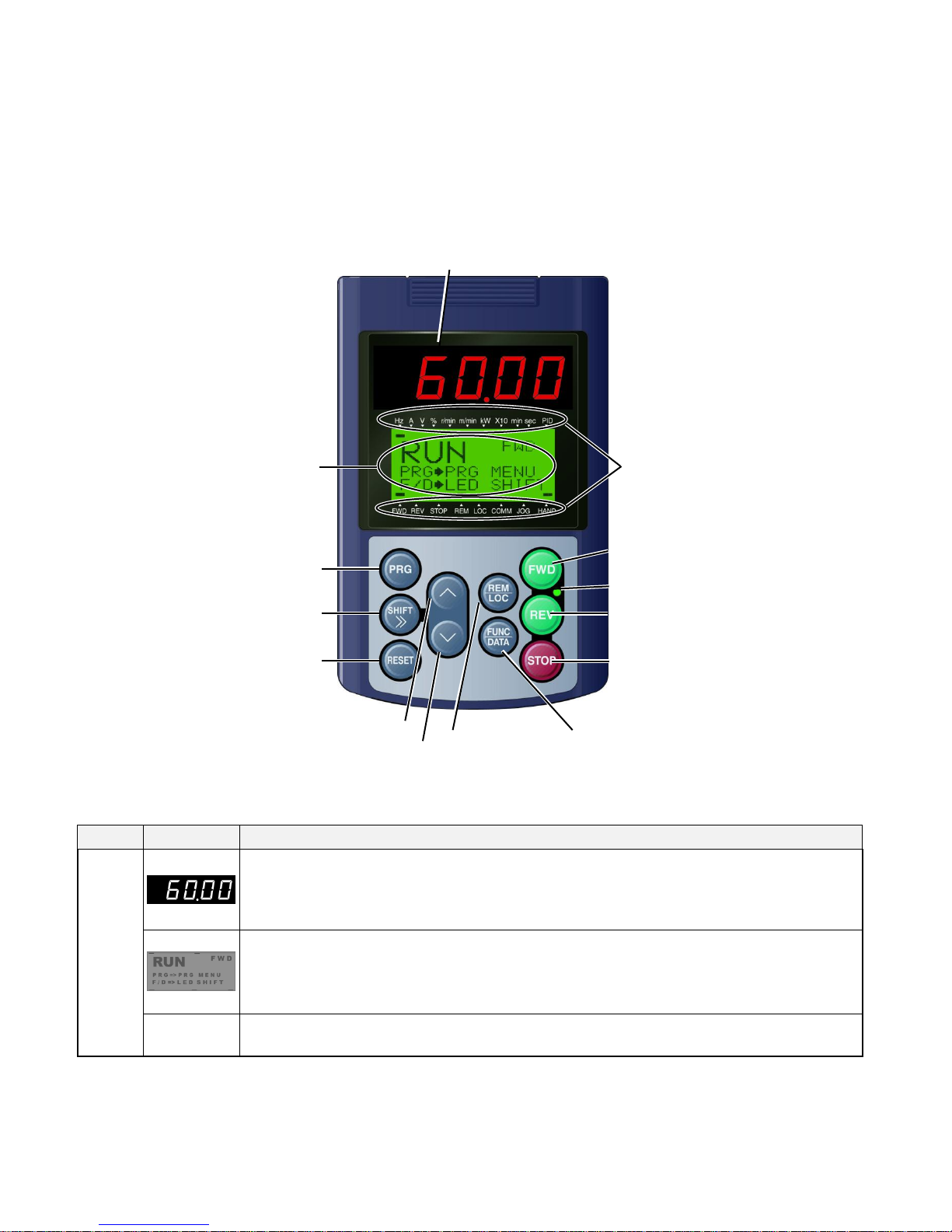

4. LED Monitor, LCD Monitor and Keys

Item

Monitor

Functions

Monitors

Five-digit, 7-segment LED monitor which displays the following according to the operation modes:

In Run mode: Running status information (e.g., output frequency, current, and voltage).

In Programming mode: Same as above.

In Alarm mode: Alarm code, which identifies the alarm when the protective function is activated.

LCD monitor which displays the following according to the operation modes:

In Run mode: Running status information.

In Programming mode: Menus, function codes and their settings.

In Alarm mode: Alarm code, which identifies the alarm when the protective function is activated.

Indication

Units

In Run mode, these show the unit for the number displayed on the 7-segment LED monitor and

the running status information on the LCD monitor. For details, see the next page.

7-segment LED Monitor

Program

Indication units

STOP key

RUN key (forward)

RUN key (reverse)

Reset key

Shift key

LED light

LCD monitor

DOWN key

UP key

Function/Data key

Remote/Local key

The keypad allows you to start and stop the motor, view various data including maintenance

information and alarm information, configure function codes, monitor I/O signal status, copy data, and

calculate the load factor.

Table 4.1: Overview of Keypad Functions

8

Loading...

Loading...