Tecomat TC600, TC601, TC603, TC604, TC602 Series Manual

...

Technical equipment of TC600 PLC

Contents

1. Abbreviations and Terms ...................................................................................................... 3

2. Description............................................................................................................................. 5

2.1 The Specification................................................................................................................. 5

2.2 Compatibility ........................................................................................................................ 5

2.3 Communication.................................................................................................................... 5

2.4 Di str ibuted Control ............................................................................................................... 5

2.5 The Building......................................................................................................................... 6

2.6 Design..................................................................................................................................7

3. Parameters Overview ............................................................................................................. 8

3.1 Basic P r oper ties................................................................................................................... 8

3.2 Oper ational Conditions......................................................................................................... 9

3.3 Basic Parameters.................................................................................................................9

4. Central Unit............................................................................................................................10

4.1 Basic P ar ts and Parameters................................................................................................10

4.2 User Accessible Memories..................................................................................................10

4.3 Analog Outputs...................................................................................................................12

4.4 Serial Com municat ion Channels .........................................................................................13

4.4.1 Serial Communication Channel 1 (CH1).......................................................................13

4.4.2 Serial Communication Channel 2 (CH2).......................................................................16

4.4.3 Serial Communication Channel 3 (CH3).......................................................................16

4.5 Setting of CPU Parameters.................................................................................................17

4.5.1 Setting of Parameters of Ser ial Com municat ion Channels CH1, CH2, CH3..................17

4.5.2 Management of the user program source mem or y .......................................................20

5. Input and Output Unit...........................................................................................................21

5.1 Basic Functions...................................................................................................................21

5.1.1 Binary Inputs................................................................................................................21

5.1.2 Binary Transistor Outputs.............................................................................................22

5.1.3 Binary Relay Outputs...................................................................................................23

5.1.4 Analog Inputs of TC605, TC606, TC625, TC626 Modules ............................................24

5.1.5 Analog Inputs of the TC634 Module .............................................................................25

5.2 Special Functions................................................................................................................29

5.2.1 Interrupt Inputs.............................................................................................................29

5.2.2 Counter of Type 3 ........................................................................................................29

5.2.3 Admeasurement of Position by the I nc r emental E nc oder..............................................30

5.2.4 Measurement of the Signals Period and Phase Shift....................................................31

6. Packaging..............................................................................................................................32

7. Transport...............................................................................................................................32

8. Storage ..................................................................................................................................32

9. Installation.............................................................................................................................32

9.1 Principl es of Proper Installati on...........................................................................................32

9.2 Ensuri ng of the Requi r ed Operational Temperature.............................................................33

9.3 The M ounting......................................................................................................................34

9.4 Arr angement of Connecting of Terminal Boar ds..................................................................36

9.5 Connect ion of t he P LC Inputs and Outputs..........................................................................45

9.5.1 Connection of the Protec tive Connector .......................................................................45

9.5.2 PLC Power Supply .......................................................................................................45

9.5.3 Connection of Binary Inputs .........................................................................................46

9.5.4 Connection of Binary Transistor Outputs......................................................................47

9.5.5 Connection of Binary Relay Output s.............................................................................48

9.5.6 Connection of Analog Inputs of TC605, TC606, TC625, T C626....................................49

9.5.7 Connection of TC634 Analog Inputs.............................................................................49

9.5.8 Connection of Analog Outputs ......................................................................................51

9.5.9 Connection of the CH1 Inter face ..................................................................................52

9.5.10 Connection of the CH2 Inter face ..................................................................................54

9.5.11 Connection of the CH3 Inter face ..................................................................................56

9.5.12 Connection of Interrupt Inputs ......................................................................................56

9.5.13 Connection of the Type 3 Count er................................................................................56

9.5.14 Incremental Encoder Connection..................................................................................57

1 TXV 138 08.02

Tecomat TC600

9.5.15 Connection of Inputs f or M easurement of the Period and Phase Shi ft ..........................57

10. Attendance ............................................................................................................................58

10.1 Instructions for Saf e A ttendance..........................................................................................58

10.2 Putting into Operation.........................................................................................................58

10.3 PLC Initialization.................................................................................................................58

10.4 Operational Modes..............................................................................................................59

10.4.1 Change of Operational Modes......................................................................................59

10.4.2 Activities Perf or med at Changing of the PLC Mode on the Standard Basis ...................59

10.4.3 Optionally Performed A c tivities at Change of the P LC M ode........................................60

10.4.4 Restarts of the User Program.......................................................................................60

10.5 P r ogr amming and Debugging of the PLC Program..............................................................61

10.5.1 Configur ation Constants in t he User Pr ogr am...............................................................62

10.5.2 Software Configuration.................................................................................................63

10.5.3 Serv icing of Binary Inputs ............................................................................................65

10.5.4 Serv i cing of Binary Outputs..........................................................................................66

10.5.5 Serv icing of Analog Inputs............................................................................................66

10.5.6 Serv i cing of Analog Outputs.........................................................................................70

10.5.7 Serv icing of Serial Channels........................................................................................70

10.5.8 Serv icing of Interrupt Inputs .........................................................................................71

10.5.9 Serv icing of the Type 3 Count er...................................................................................76

10.5.10 Incremental Encoder Servic ing.................................................................................79

10.5.11 Measurement of the Signal P er iod and Phase Shift ..................................................81

10.5.12 Physical Addresses of Inputs and Outputs ................................................................84

10.6 Testing of Input and Output S ignals ....................................................................................84

10.7 Instruction Set.....................................................................................................................85

11. Diagnostics and Removal of Faults.....................................................................................86

11.1 Conditions for Proper Function of the Diagnostics...............................................................86

11.2 Indication of Errors..............................................................................................................86

11.3 Serious Errors.....................................................................................................................86

11.3.1 User Program Errors....................................................................................................87

11.3.2 Errors in the Peripheral System....................................................................................89

11.4 Other Errors........................................................................................................................90

11.4.1 Errors of Serial Communication....................................................................................91

11.4.2 System Errors..............................................................................................................91

11.4.3 User Program Errors....................................................................................................92

11.4.4 Errors in the Peripheral System....................................................................................92

11.5 S olution of Communication Problems with the Superi or S y stem..........................................92

12. Removal of F aults .................................................................................................................95

13. Maintenance..........................................................................................................................95

13.1 Demounting of the PLC Par ts..............................................................................................95

13.2 Chec k ing of PE Connec tors Interconnect ion........................................................................95

13.3 Chec k ing of t he P ower Supply.............................................................................................95

13.4 Chec k ing of Voltage of B inary Inputs...................................................................................95

13.5 Chec k ing of Voltage of B inary Transistor Outputs ...............................................................96

13.6 B attery Exchange................................................................................................................96

13.7 Fuse Exchange...................................................................................................................96

13.8 Cleaning..............................................................................................................................96

14. The G uarantee.......................................................................................................................96

TXV 138 08.02 2

Technical equipment of TC600 PLC

Introduction

The manual

provides information necessary for proper application, operation and

lers

maint enance of basic m odules of programm able logic cont rollers Tecomat

TC601 to TC607, ex tension modules TC621 to TC626 and half extension

modules TC631 to TC634. It describes possibilities of the building, differences in technical equipment of individual types, technical parameters of

electronic circuits, control and diagnostics and it determines requirements

for tr ansportati on, storage and i nstall at ion of the system . Out of data necessary for programming, the m anual contains only description of the way of

declaration of individual types in an integrated development environment

and servicing of inputs and outputs. The very description of the development environment for programming of Tecomat programmable logic controll ers is a part of the dev elopment env ironm ent. The princi ple of the programmable logic controller function, programming principles and the

instructi on file of Tecomat programmabl e logic control lers are described in

detail i n the

and

Instruction set of the Tecomat PLC, TXV 001 05.02

tion of m odes of serial communication channels is giv en in the handbook

Serial c omm unicat ion of Tecom at program m able logi c contr oller s, TXV 001

06.02.

Wi th regard to high inheritance of properties of indivi dual types of this

series, maj ority of data i s given together f or the whole series. Parameters

are given indivi dually i n the case that param eters of a series type differ.

Technical equipment of TC600 programm able logic control-

Handbook of the Tecomat PLC programmer, TXV 001 09.02

. Detail ed descrip-

1. Abbreviations and Terms

PLC Programmable Logic Controller

CPU PLC Central Processor Unit

CH1, CH2, CH3 PLC Serial Channels

RTC circuit Real Tim e Clock, c ircuit for generation of real time

Tecomat registered trademark of PLC Teco a. s.

Tecomat TC600 marki ng of PLC of the TC600 series

(TC601-TC607, TC621-TC626, TC631- TC634)

Tecoreg registered trademark of Teco a. s. regulators

Programmable Logic Controller ( P LC)

freely distributable programmable system designed for

logic cont rol of work machines, technologi cal processes,

etc.

Basic Module (BM)

smallest fully functional set of the PLC

Extension Module (EM, EM/2)

module designed f or extension of functi onal possibilities

of the PLC basi c module by additional inputs and outputs

RAM Memory Random Access Memory, memory type f or reading and

writing

EEPROM MemoryElectrically Erasable and Programmable Read Only

Memory, memory type for r eading

User Program Memory

part of the PLC RAM memory assigned f or storage of the

user program, dat a and tables

User Program Sourc e M emory

power independent PLC memory desi gned for storage of

the source (backup) user program, data and tables

User Process

part of the user algorithm assembled by the user from

instructions of the problem ori ented language of the PLC.

Ever y user process is inclosed i n instruct ions P and E of

a comm on number (0 to 64)

3 TXV 138 08.02

Tecomat TC600

User Program set of all user proc esses designed for c ontrol of the given

applicat ion

Multi pr ogr amming

set of rul es according to whic h indi v idual user processes

are activated

Program Cycle set of user processes which are activ ated cyclicall y ac-

cording to rules of m ultiprogr amming

Cycle Turn phase of the system pr ogr am between the last process of

the past cycle and the f irst process of the new cycle. In

the cycle turn, values of outputs are transmitted from re-

gisters Y, new values of i nputs are scanned int o regi sters

X, time data in ti mers and system regi sters are updated,

and data receiv ed by comm unication channels and new

data for transmission are t r ansferred

Cycle Int er r uption by User

updating of processes P41, P43 and P44. These proces-

ses may be activated in arbitrary position of the user

program cycle.

Initialization Processes

processes activated after turning on or restart of the

system (P62 after warm reboot , P63 aft er c old reboot)

User D Data

constants of the user program stored in memory of the

user program

User T Tables

most of ten constants of t he user progr am concentrated in

integrated sets (T tabl es). T hey are usuall y used for defi-

nition of subsystems (decoders, c ombi nation, sequenti al,

tim e or numeric subsystem s).

Configur ation Constants, K Dat a

set of data in the user program memory designed for

setting of the system configuration and modification of

the system activity. Not available to the user program,

are edited f rom within the dev elopment envi ronment. If

not edited, the system shows standard behaviour .

Scratchpad, Registers X, Y, S, R

part of the RAM memory avai lable to the user as input

images (regi sters X), output i m ages (register s Y), system

(S) and user (R) registers.

Remanent Part of the Scratchpad

part of r egisters R the contents of which i s retai ned dur-

ing warm reboot. The extent may be selected by the

configurational constant of remanent registers R. Other

registers R and registers X and Y are not remanent and

are reset in ev ery reboot or turni ng on. The user has t he

possibility to store actual output values in remanent reg-

isters R.

Warm Reboot way of activation of the system and user program in

which the contents of the scratchpad remanent part are

retained. The rest of t he scratchpad is reset.

Cold Reboot way of activation of the system and user program in

which all regi sters of the scratchpad are reset. Cold re-

boot is performed in the case that an attempt at warm

reboot has been non-successful (the system has detec-

ted damage of the stored data).

TXV 138 08.02 4

Technical equipment of TC600 PLC

2. Description

2.1 The Specification

PLC's of the TC600 series are freely programmable logic systems designed for control of work machines and technol ogical pr ocesses in vari ous

and div erse areas of producti on. They com plement the int egrated series of

modular and compact Tecomat PLC's with a small modular system

equipped with the driv e for m ounting on a U strip.

2.2 Compatibility

Although PLC's of the TC600 series are designed f or the smal lest appli cations, use properties of lar ge Tecomat P LC's remain ret ained. Signi fi cant

property is uniformness of technical and program means for creation and

debugging of the user program and uniformness of the highly ef ficient instruction set and system services with other Tecomat PLC's allowing for

evaluation of experience gained in applications of other Tecomat systems.

2.3 Communication

Two serial com muni cation c hannels f itt ed in a standar d m anner with optional int erf ac es and possibility of addition of a thi rd c om m unic ati on channel

allow for simultaneous local connection of intelligent peripheries equipped

with a serial com muni cation channel (readers of the bar code, printer s, frequency conv erters etc.), connec tion of the oper ation board and connection

to a comput er with the dev el opment env ironm ent or i nterconnect ion of indi vidual PLC's in the EPSNET industrial network. Up to 32 Tecomat PLC's,

Tecoreg regulators or other devices can participate in the network which

meet requirem ents of the EPSNET network (data terminal s, laboratory apparatuses etc.).

2.4 Distributed Control

Using the communication possibilities, it is possible to create extensive

systems with distri buted control by gradual connecting of autonom ous systems to the net work and by compl eti on of t he program shell without the necessity to interv ene in t he PLC's technical equipment . Another possibility is

additional interconnection of PLC's and collection of data for the central

monit or ing purposes.

5 TXV 138 08.02

Tecomat TC600

2.5 The Building

The smallest f ully func tional PLC unit of the TC600 seri es is formed by

the basic module (BM). It is produced in six designs which dif fer in the num ber and type of inputs and outputs.

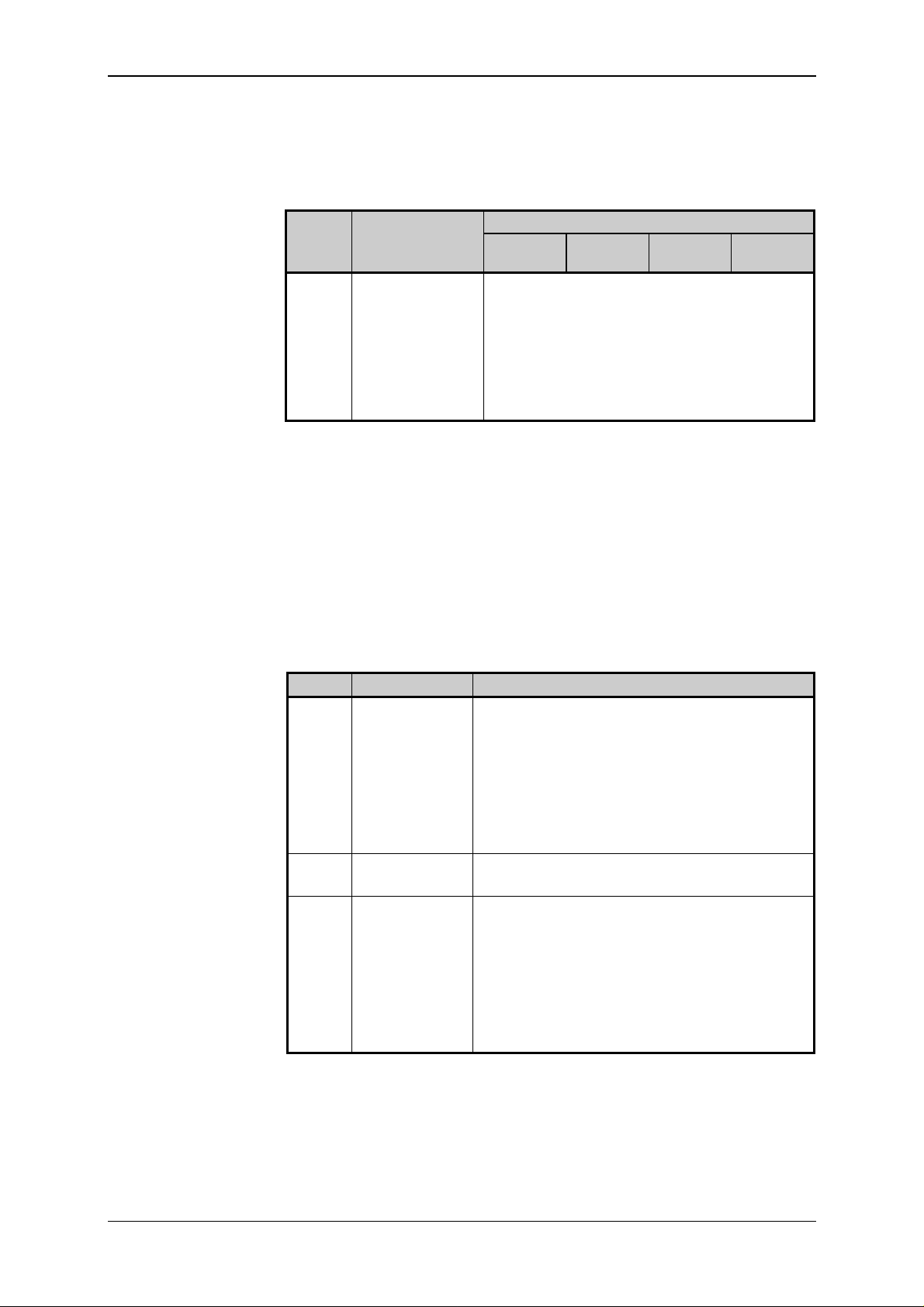

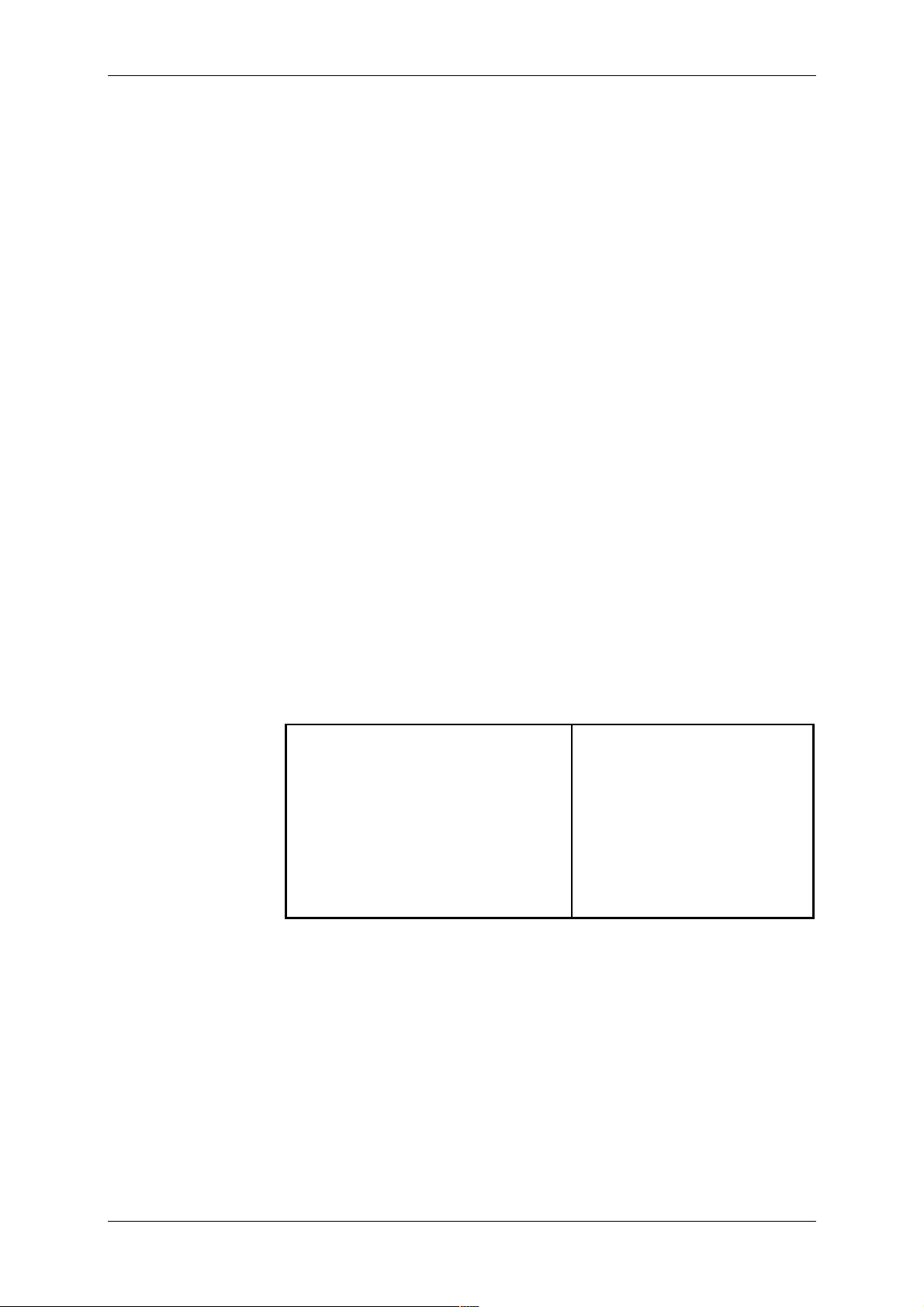

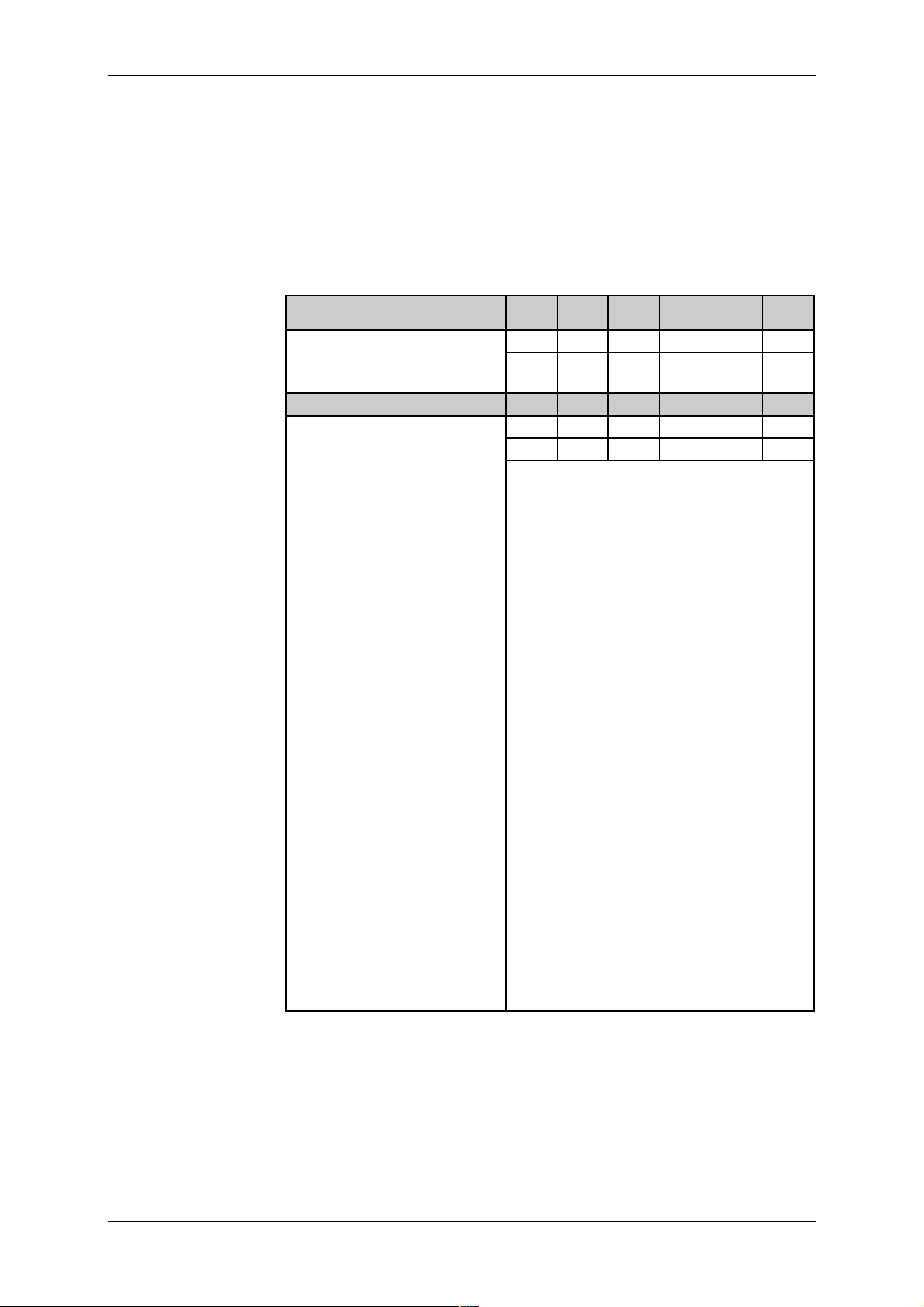

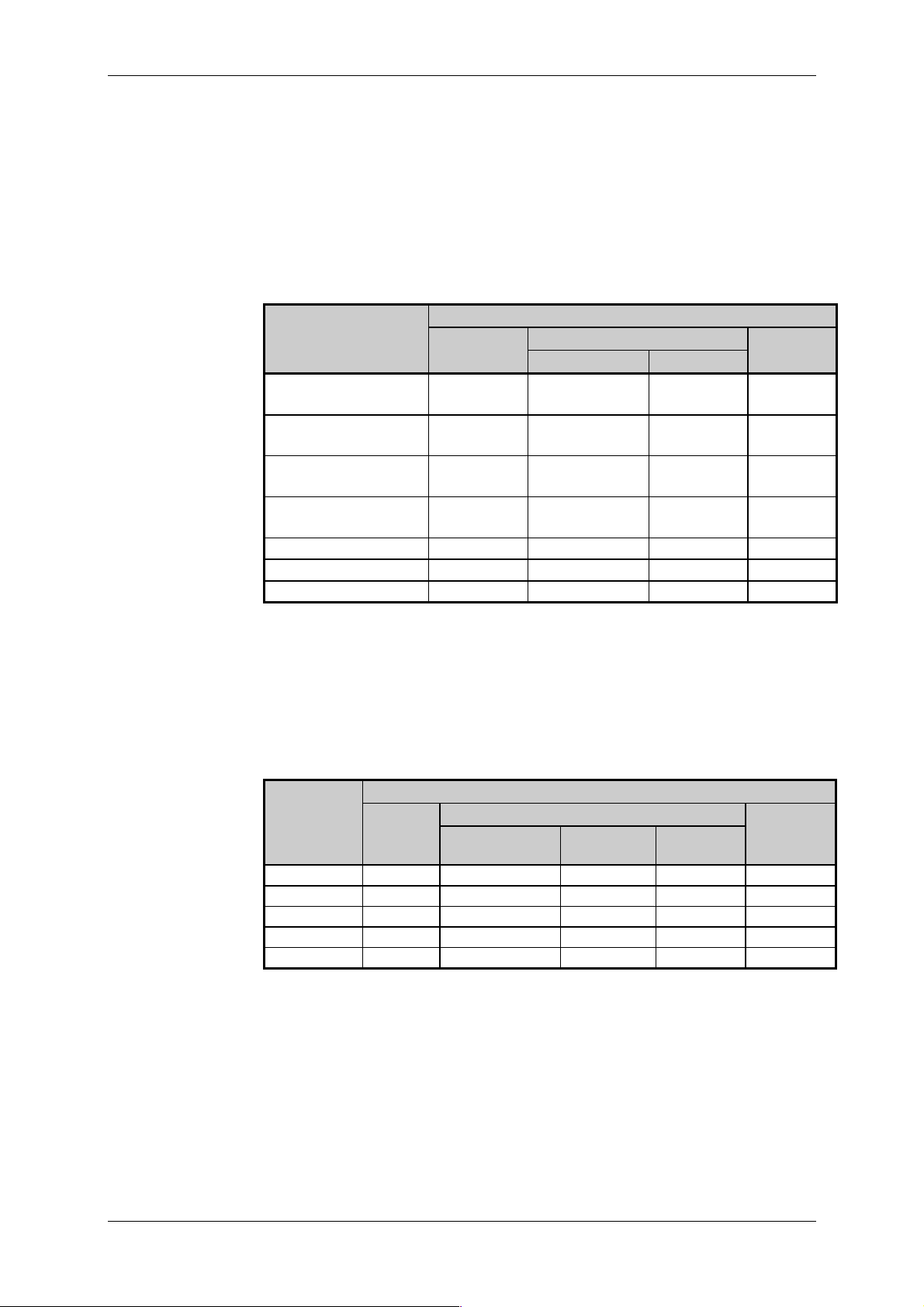

Order numbers f or

BM PLC of the T C600

series

Type Order Number

1)

Binary

inputs

Analog

inputs

Note

Transist.

outputs

Relay

outputs

TC601 TXN 061 51 12 - 8 TC602 TXN 061 52 20 - 16 TC603 TXN 061 53._ _ 12 - 4 4

TC604 TXN 061 54._ _ 16 - - 10

TC605 TXN 061 55._ _ 12 4 - 8

TC606 TXN 061 56._ _ 16 4 4 10

TC607 TXN 061 57._ _ 20 - 20 -

1)

In types TC603 t o TC607, the after-num ber ( two digits af ter the dot)

determine the special B M function:

.00 common function of binary input s (after-number need not be given)

.01 4 interruption binar y inputs

.03 measuring by increm ental position scanner

.05 counter of type 3 (uni directi onal 16 bit counter with pre-selection)

.06 period and phase shift measurement

Optional part of al l BM t ypes are int erf ac es of t wo serial c om m unic ati ons

channels (CH1, CH2) f itted i n the standard design, addi tional data m emory

(DataBox) , and a third serial com munication c hannel (CH3) or analog outputs.

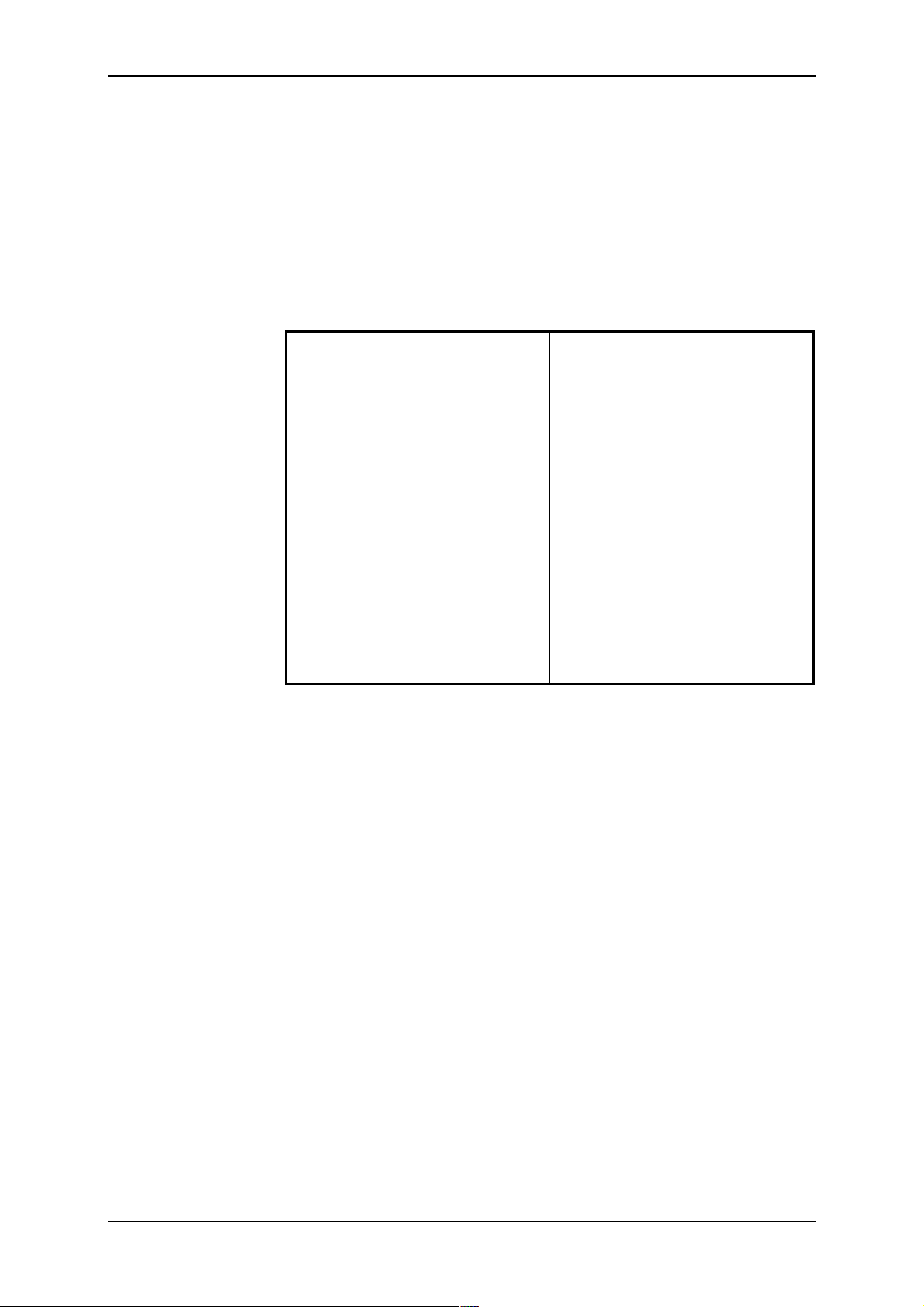

Order numbers of

optional BM

piggybacks

Type Order number Note

MR-02 5XK 068 91 Interface RS-232 without galv anic separation

from internal control ci rcui t s

MR-04 5XK 068 93 Interface RS-485 without galv anic separation

from internal control ci rcui t s

MR-09 TXK 085 03 Interface RS-485 with galv anic separation from

internal control circuits

MR-17 TXK 085 11 Interface RS-422 without galvanic separation

from internal control ci rcui t s

IM-70 TXK 080 10.00 DataB ox, additional dat a memory 128 k B

IM-70 TXK 080 10.02 DataB ox, additional dat a memory 512 k B

MR-14 TXK 085 08.02 CH3 with interfac e RS - 485 without galvanic

separation f r om inter nal control c ircuit s

MR-15 TXK 085 09.02 CH3 with RS-232 without galvanic separat ion

from internal control ci rcui t s

OT-13 TXK 082 60 4 analog outputs without galvanic separation

from internal control ci rcui t s

OT-14 TXK 082 61 8 analog outputs without galvanic separation

from internal control ci rcui t s

1)

DataBox is added in the production plant exclusively

2)

Only 1 pi ggy bac k M R- xx or 1 piggyback OT - xx may be fitted

2)

2)

2)

1)

1)

2)

Number of binary and analog inputs and binar y output s of the BM can be

extended by connecting one extension module (EM), two half extension modules (EM/2) or by combination of EM, EM/2.

TXV 138 08.02 6

Technical equipment of TC600 PLC

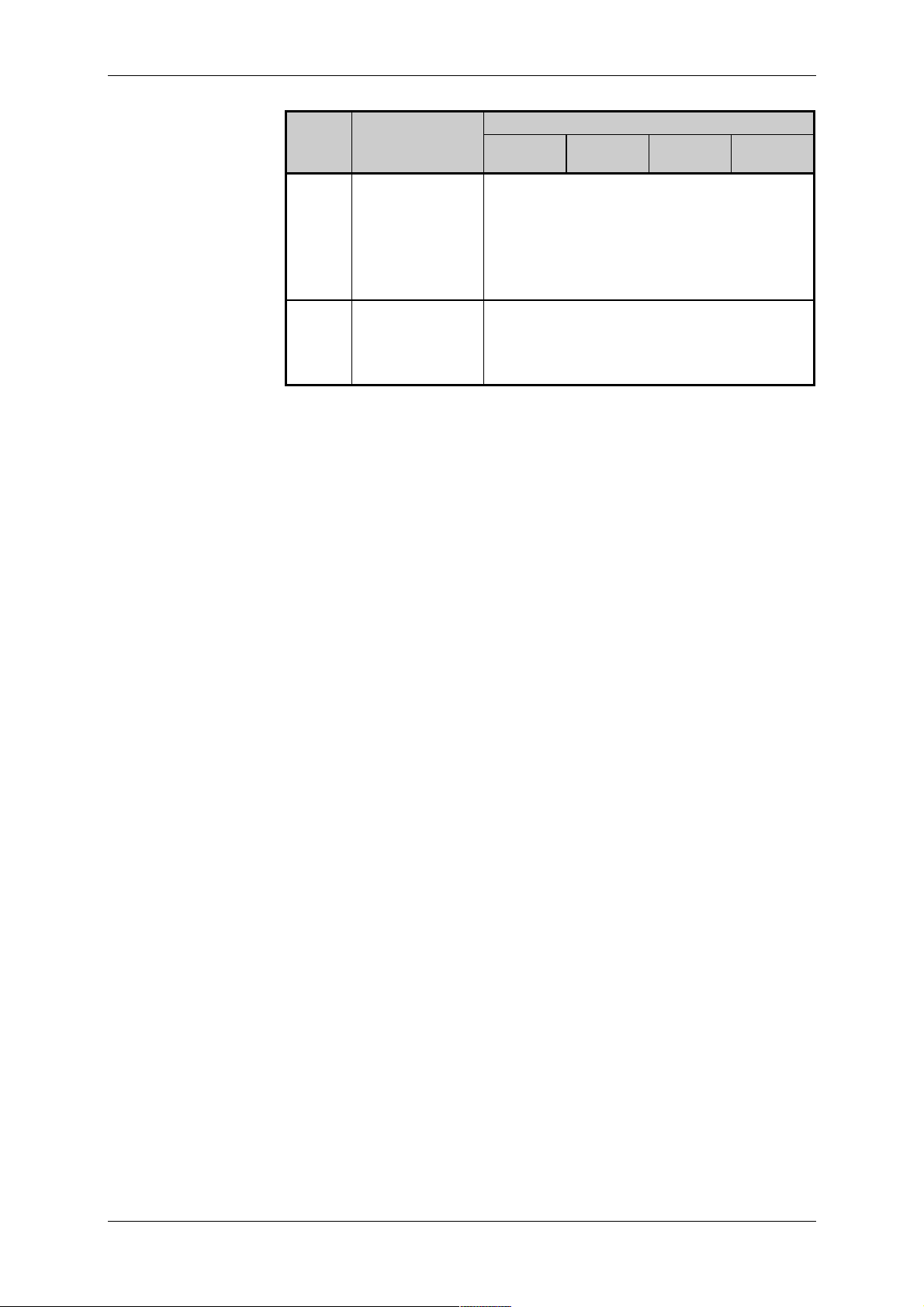

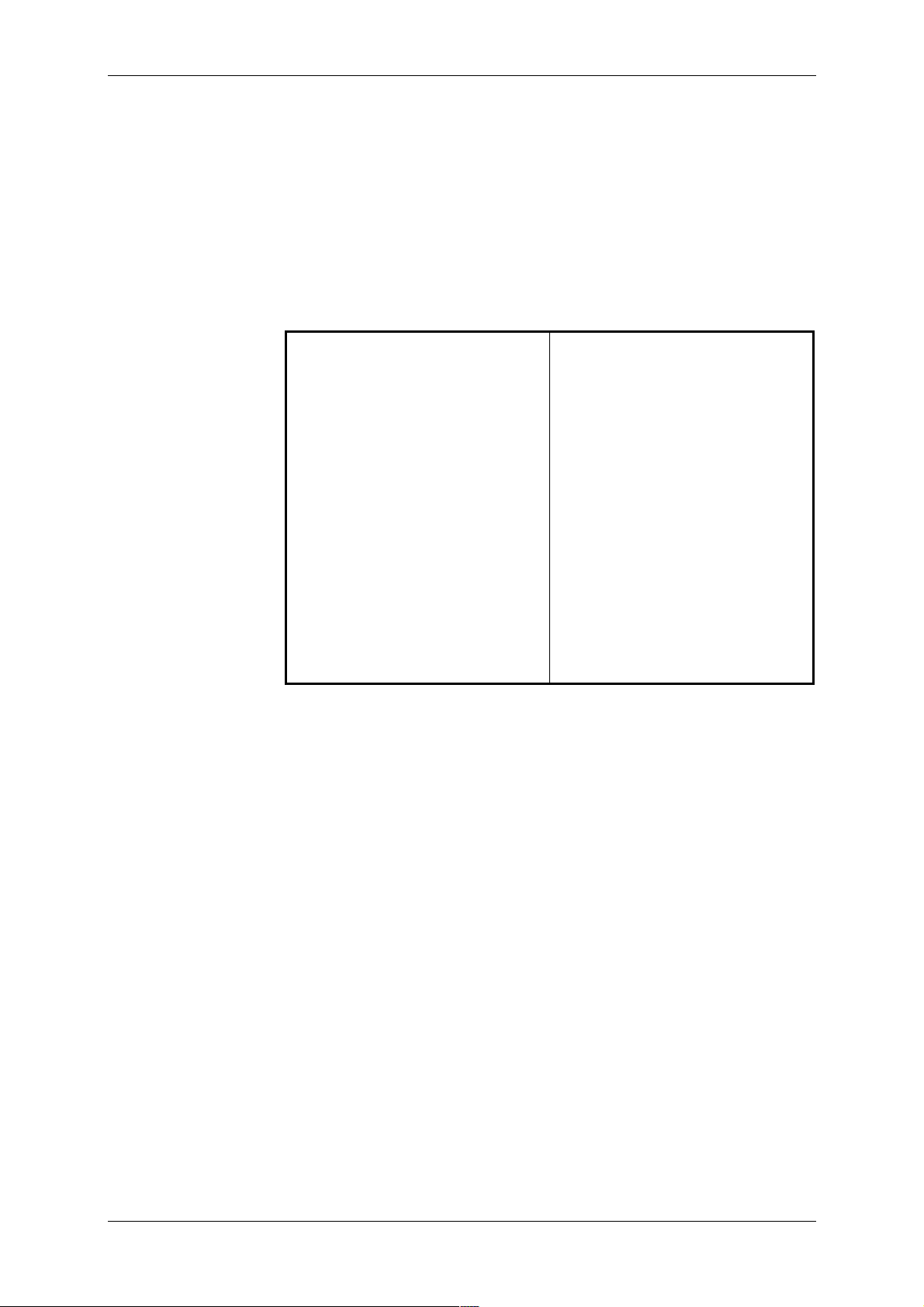

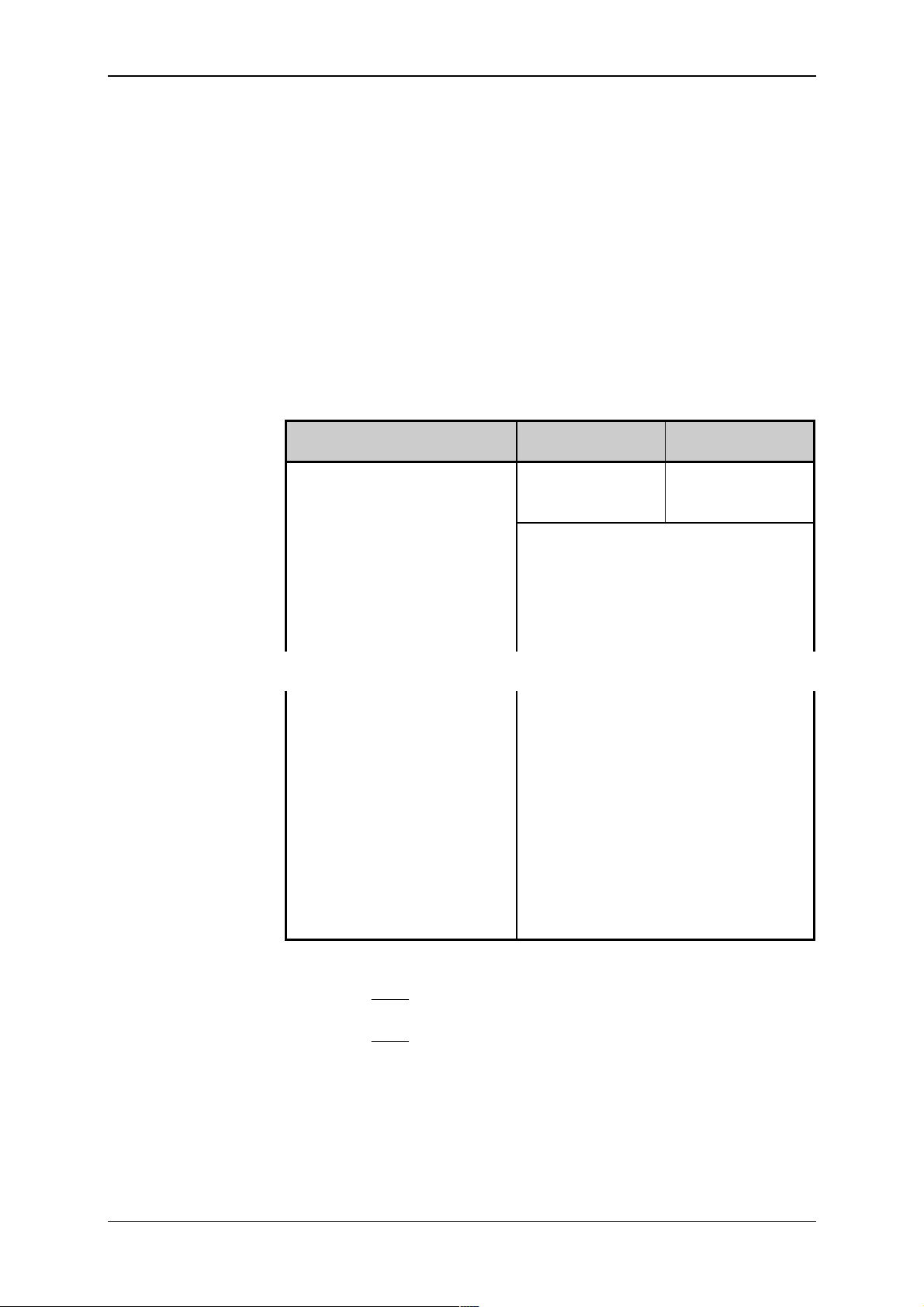

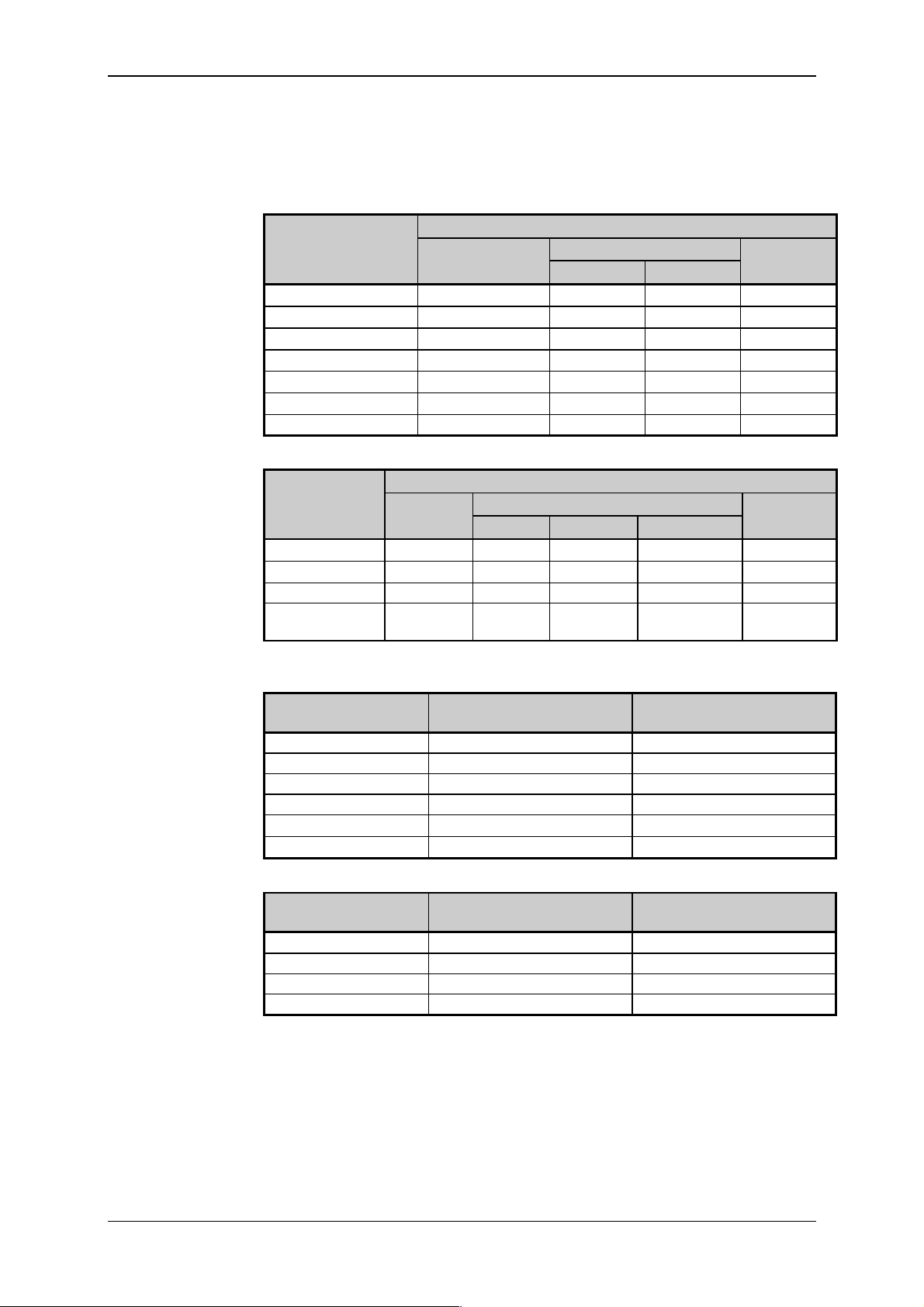

Order numbers of E M

and EM/2, PLC of the

TC600 series

Type Order number Note

Binary

inputs

Analog

inputs

Transist.

outputs

Relay

outputs

TC621 TXN 061 71 12 - 8 TC622 TXN 061 72 20 - 16 TC623 TXN 061 73 12 - 4 4

TC624 TXN 061 74 16 - - 10

TC625 TXN 061 75 12 4 - 8

TC626 TXN 061 76 16 4 4 10

TC631 TXN 061 81 8 - 8 TC632 TXN 061 82 8 - - 8

TC633 TXN 061 83 16 - - TC634 TXN 061 84 - 8 - -

2.6 Design

Modules of PLC's of the TC600 series are designed as devices to be

E N 50022

(idt EN 50022:1977). Metal jacket of the modules and m echanical arrangement guarant ees hi gher r esi stanc e against interferences.

BM electroni c circ uits are real ized on t wo printed wiri ng boards; the central uni t and input and output unit.

EM's are fitted with t he input and output unit only.

7 TXV 138 08.02

Tecomat TC600

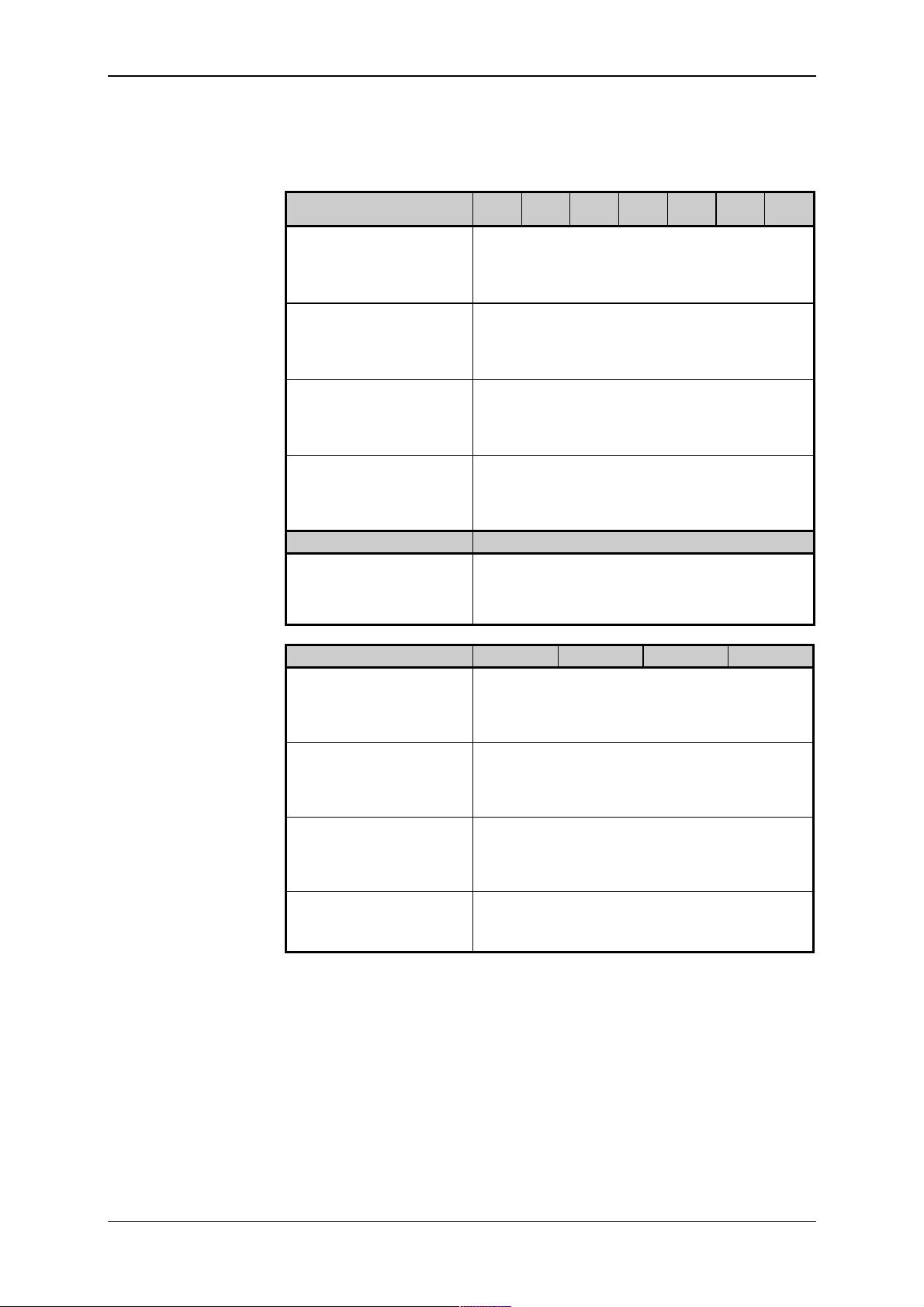

Number of inputs and

outputs of PLC TC600

series

3. Parameters Overview

3.1 Basic Properties

TC601

TC621

Binary inputs

Total number of inputs 12 20 12 16 12 16 20

Arrangement

(no. of groups x no. o f inputs)

Binary transistor out put s

Total number of out puts 8 16 4 - - 4 20

Arrangement

(no. of groups x no. o f outputs)

Binary relay outputs

Total number of out puts - - 4 10 8 10 Arrangement

(no. of groups x no. o f outputs)

Analog inputs

Total number of inputs - - - - 4 4 Arrangement

(no. of groups x no. o f inputs)

Analog outputs

Total number of out puts

Arrangement

(no. of group x no. of outputs)

TC602

TC622

1x8,

1x4

2x8,

1x4

TC603

TC623

1x8,

1x4

TC604

TC624

TC605

TC625

2x8 1x8,

1x4

TC606

TC626

TC607

2x8 2x8,

1x8 2x8 1x4 1x4 2x8,

1x4 2x4,

2x1

2x4 2x4,

2x1

1x4 1x4

TC601 to TC606

4 or 8 - optional

1x4 or 1x8

1x4

1x4

TC631 TC632 TC633 TC634

Binary inputs

Total number of inputs 8 8 16 Arrangement

(no. of groups x no. o f inputs)

2x4 2x4 4x4

Binary transistor out put s

Total number of out puts 8 - - Arrangement

(no. of groups x no. o f outputs)

1x8

Binary relay outputs

Total number of out puts - 8 - Arrangement

(no. of groups x no. o f outputs)

2x4

Analog inputs

Total number of inputs - - - 8

TXV 138 08.02 8

Technical equipment of TC600 PLC

3.2 Operational Conditions

Class of environment effect 33 2000-3

(mod IEC 364- 3:1993)

Range of operational temperatures

Aver age temperatur e dur ing 24

hours

Allowed transportation temperature

Relative ai r humidi ty 50 % to 95 % without condensation

Degree of pol lution

(idt EN 61131-2:1992, IEC 1131-2: 1992)

Ov er vol tage category of installation

33 0420

(eqv IEC 664:1980, IE C 664A :1981)

Immunity against disturbances

(idt EN 61131-2:1992, IEC 1131-2: 1992)

Emitted disturbance levels for gr oup 1, class A

Vibrations Fc 10 Hz to 150 Hz, 0.15 mm, 10 cycles

!

IEC 68-2-6:1995+Corr.1995)

Operating posi tion vertical

Type of oper ation permanent

0 °C to +55 °C

max. +50 °C

-25 °C to +70 ° C

(tab. 16)

(mod CISP R 11:1997)

(idt EN 60068-2- 6:1995,

3.3 Basic Parameters

BM EM EM/2

Type of appliance to be built-in

Class of el. object

(mod IEC 536- 1:1976, IEC 536-2: 1992)

Coverage IP-10B

Supply voltage

(SELV)

Power input max. 20 VA

Mass about 0.8 kg about 0.4 kg about 0.2 kg

Size (h x w x d)

1)

Power input of B M extended by one EM and one E M /2

2)

See fi gs. 9.1, 9.2, 9. 3

2)

24 V~ ±20 %,

50-60 Hz ±5 %

or 24 V- ±20 %

or 13 W

1)

141x182x69 141x157x44 141x89x44

9 TXV 138 08.02

Tecomat TC600

4. Central Unit

4.1 Basic Parts and Parameters

Central unit ensures the majority of PLC control functions. Due to its

properties, i t i s ranked am ong T ecom at CP U D series. It contai ns especi al ly

the supply voltage converter, microcontroller, memories RAM and

EEPROM, RTC circuit , lithium battery to supply v oltage to the RAM mem ory and RTC cir cui t i n the c ase that t he PLC power supply i s t urned of f , t wo

serial communication channels and optional additional data memory and

analog output circuit s or a t hird serial c ommunication channel.

CPU Basic

parameters

Central uni t series D

Real time circ uit (RTC) fitted i n standar d desi gn

User program source m emory fitted in standard design

Memory type EEPROM (FLASH)

Memory size 32 kB

User program and data memory fitted in standard design

Memory type RAM

Memory size 32 kB

Additi onal data memory, Dat aB ox optional

Memory type RAM

Memory siz e 128 kB or 512 kB

Backup of the RAM memory and RTC min. 20 000 h

Cycle peri od per 1k of logic instruct ions 13 ms

Total number of user registers 8 192

Number of remanent r egisters optional 0 to 512

Total number of timer s and count er s 4 096

Range of timers 65 536 x 10 ms to 10 s,

possibility of cascading

Range of counter s 65 536, possibility of cascading

Instructi on set extended

Instructi on length 1 to 6 bytes

Number of serial communi c ation chan-

nels

Transmission speed of CH1, CH2, CH3 0.3 t o 230.4 kBd

Number of analog outputs optionally 0, 4 or 8

2 + 1, optional

1)

1)

Maxim um tr ansmission speed is lim ited by the max im um al lowed transmission speed of the set communication channel m ode.

4.2 User Accessible Memories

User program

memory

User program source

memory

TXV 138 08.02 10

Memory of the user program is f orm ed by a part of the RAM m em ory of

CPU assigned for the user progr am, data and tabl es. When PLC is turned

off, the m emory is supplied by the built-in lithi um battery .

Source memory of the user program is formed by a part of the EEPROM

memory of CPU assigned for saving of a copy of the user program. The

memory power-independent, that is, contents of the memory remain retained even after the power supply of the PLC is turned off or when the

battery i s di scharged. Use of the source memory is contr olled by the user by

setting a parameter in t he P LC S E T mode (see Article 4.5) .

When the source mem or y is allowed, after exiting the SET mode, turning

on of the PLC power supply or restart, c ontents of the user program source

memor y is mov ed to the user program mem ory with which CP U works. The

functi on is used especially for backup of the user program. The m emory is

programmed from within t he devel opment environment direc tly in the PLC.

Technical equipment of TC600 PLC

Memory of CPU

parameters

Scratchpad memory

The DataBox

Support of w or k ing

with the Dat aB ox

Backup of the RAM

memory and RTC

circuit power s upply

Detection of state of

the backup batter y

Memory of CPU param eters is power-independent m emor y designed for

storage of param eters that can be set in the PLC SE T mode. Contents of

the mem ory rem ain ret ained ev en when the PLC power supply i s turned off

or if the battery is discharged.

The scratchpad m emory is a part of the CPU RAM memory accessible to

the user in the f orm of i nput i mages (regi sters X), outputs i mages ( registers

Y), system (S) and user registers (R). Preserving of the scratchpad cont ents

after t urni ng of f of the PLC power supply and restart s i s program - contr oll ed.

The behav iour is described in detail in Chapter 10.

The DataBox is an optional compl ement of the CPU, fi tted by the producer on the basis of an or der. I t ex t ends t he user accessibl e RAM m em ory

by 128kB or the data memory by 512kB. When the P LC is turned off, the

memor y is supplied fr om a bui lt-i n li thium batt ery. It is designed f or working

with greater amounts of data, f or exampl e for arc hiv ing of dat a on the controll ed process for a longer t ime period et c. The data can be writt en to the

memory or read, respectively, either by using the PLC user program or

through the serial line.

For support of the DataBox program attendance, there are thr ee user instructions available. The READDBX instruction is intended for reading of

data from DataBox into R regi sters, the WRI TEDBX instructi on is intended

for writing of data from R registers to the DataBox, and the SIZEDBX instruction serv es for identi fication of the DataBox size. Detailed descripti on

of function of instructions, their definitions, structures of the parameters

zone for i nstructions READDBX and WRI TEDBX and way of c alling of instructions in the user program are given on t he distribution disket te xPRO

which forms a part of the PLC delivery.

For serial communication with the DataBox, either CH1 can be used

which always operates in the PC m ode or c hannels CH2, CH3 set i n the PC

mode. To support serial communication with the DataBox, the

COMPLC.EXE program is av ai labl e which all ows for reading data f rom DataBox i nto a fi le or write dat a from a fil e to DataBox , respectiv ely, and test

size of memory accessible in the form of the DataBox. W orking with the

DataBox i s possible starti ng from the CO MPLC.EXE program version 1. 6.

The program, which is found on the x PRO distr ibuti on diskett e, must be r un

under the MS DOS oper ating system.

When the PLC power is turned of f, the RA M memory and RTC circuit are

supplied from a bui l t-i n l i thi um batt ery. Param et ers of the used batt ery al l ow

for backup wit h the power supply turned of f f or the m ini mum t im e of 20000

hours. In common operating conditions (operating temperature of 20 °C,

unidirectional operation at least) and typical power take-off of the backing

circui ts, the backup time is l imi ted by battery life (5 years at the minimum).

Voltage of the backup battery i s evaluated by the diagnostic system. In

the case the vol tage drops under 2.5 V, bit .0 of the S35 system regi ster is

set to the state log. 1. PLC cont inues with it s activ i ty unti l t he v oltage drops

under the minimum supply voltage of the RTC circuit. Evaluation of the

RTC circuit failure leads to bringing the PLC in the HALT mode and announcing the error message 80 0C 00 00.

11 TXV 138 08.02

Tecomat TC600

4.3 Analog Outputs

Analog outputs are used for control of v olt age-control acti on elem ents of

the control led obj ect . T hey are ar ranged i n a group wit h a com m on ter m inal

of the analog ground. Analog outputs are galvanically connected with the

CPU control circuits. Physically, the analog outputs are realised on small

plug-in units, the so called piggybacks, fitted on the CPU if ordered. Number

of output s depends on the ty pe of the chosen piggy bac k ( see Article 2.5).

Parameters of analog

outputs

OT-13 OT-14

Number of output channel s 4 8

Arrangement of outputs 1x4 1x8

Common gr oup c onduc tor minus

Galvanic separation from inter nal

control circuits

Type of output voltage

Voltage range/ r esol ution (1 LSB 1))

Error of output voltage

Binary output representation 8 bits

Output curr ent max. 10 mA

Setting time of the output

Output l oad r esi stanc e

Resistance against short-circuit min. 5 s

1)

LSB (Least Signifi c ant Bit) - lowest bit of the binar y val ue

1 LSB =

0 to 9.96 V/ 39 mV

no

typ.

1 LSB

max.

4 LSB

max. 30 s

>1 k

TXV 138 08.02 12

To program the PLC,

communication

channel CH1 is used

Interface RS-232 of

CH1 is activated af ter

connection of the

interconnecting cable

TXK 646 51.06

Technical equipment of TC600 PLC

4.4 Serial Communication Channels

Standard design of all PLC's of the TC600 series is equipped with two

comm unication channels. Thi rd communi cation channel is added per order

(see Article 2.5).

4.4.1 Serial Communication Channel 1 (CH1)

CH1 is designed for c onnecti on of t he PLC t o a superior system . The superior system most of ten repr esents a computer of the P C class perfor mi ng

the funct i on of a program m i ng devic e, visual isati on stat ion or contr ol devi ce

of the PLC network. It contains a complete set of the EPSNET network

servi c es. Detailed description of the services is given in the handbook

Communication of T ec om at P r ogr am m able Logic Controllers,

TXV 001 06.02.

CH1 is equipped with fix ed fit ted interface RS-232 without galvanic separation f rom internal circuits. Besides this, in all types of BM, CH1 can be

complem ented with a piggyback with int erface RS- 485 or RS-422. Opt ional

interf ace is impl ici tl y assigned to CH1. Interface RS -232 is assigned to CH1

automati cally by connecting the cable TXK 646 51.06. Together with connecting interface RS-232, the optional interface (if fitted) is disconnected

from CH1. For selection of the inter face ty pe, especiall y functi on of the superior dev ice is decisiv e, type of int erfac e of i ts serial comm unicat ion channel, connect ion distance, transmission speed and level of disturbanc es.

Serial

Interface RS-232 is

used for tw o- point

connection

Parameters of the

RS-232 interface

4.4.1.1 Interface RS-232

Interface RS-232 ensures conversion of output signals of TTL level to

level defined by the specification V.28 (EIA RS-232), and of input signals

according to V .28 to the TTL l evel. I t allows for connec tion of two end devi ces in the duplex mode. I t is suitabl e for c onnection r ealised i n short di stance in an environment with low level of electrom agnetic distur banc es.

For the com municat ion, PLC's of the TC600 series use only bi nding ci rcuits of signal s TxD (Transmit Data), RxD (Receiv e Data), CTS (Cl ear To

Send), and RTS (Request To Send) of the standard RS-232 int er face.

Transmission speed max. 230.4 kBd

Cable length m ax. 15 m

Voltage of outputs TxD, RTS for level 1

Voltage of outputs TxD, RTS for level 0

typ. -8 V against GND (R

typ. +8 V against GND (R

2)

1)

=5 k

l

=5 k

l

Voltage of inputs Rx D, CTS f or lev el 1 min. -3 V against GND

max. -25 V against GND

Voltage of inputs Rx D, CTS f or lev el 0 min. +3 V against GND

max. +25 V against GND

Impedance of inputs RxD, CTS

1)

The maximum transmission speed is limited by the maximum allowed

transmission speed of the set mode of the communic ation channel.

2)

The maximum cable length may only be used provi ded that the maxi-

5 k

mum transmission speed is reduced.

13 TXV 138 08.02

Tecomat TC600

Interface RS-485 is

used for multi-point

connection

4.4.1.2 Interface RS-485

Interf ace RS-485 ensures conversion of output signal s of t he TTL l evel

to lev el def i ned by t he specificat i on V.11 (X.27, EIA RS -485), and i nput signals according t o V.11 to the TTL lev el. Param eters of sym metric bi nding

circui ts of the RS-485 int erface all ow for mul ti-point connection of end devi ces in the half -duplex mode. It is suitable f or connection reali sed in medium di stance i n an environm ent with hi gher l evel of elect rom agnet ic distur bances.

For the communic ation, PLC's of the TC600 series use binding circuit s of

signals TxD (Transmi t Data), RxD (Recei v e Data). Signal RTS (Request To

Send) is used internally for control of the tr ansmitter ac tivation.

Parameters of the

RS-485 interface

Transmission speed max. 230.4 kBd

Cable length max. 1200 m

Sensitivity of differential inputs

±200 mV

1)

2)

RxD+, RxDInput resistance of differential inputs

min. 12 k

RxD+, RxDVoltage of different ial inputs

RxD+, RxD- f or lev el 1

Voltage of different ial inputs

RxD+, RxD- f or lev el 0

Voltage of different ial output s

TxD+, TxD- for level 1

Voltage of different ial output s

TxD+, TxD- for level 0

Difference of the output vol tage

min. 0.2 V

max. 12 V

min. -0.2 V

max. -7 V

min. 1.5 V (R

max. 5 V Io=0)

min. -1.5 V (R

max. -5 V Io=0)

max. ±0.2 V

=75

l

=75

l

value for levels 0 and 1

Output curr ent max. ±250 mA

1)

The maximum transmission speed is limited by the maximum allowed

transmission speed of the set mode of the communic ation channel.

2)

The maximum cable length may only be used provi ded that the maxi-

mum transmission speed is reduced.

TXV 138 08.02 14

Interface RS-422 is

used for tw o- point

connection

Technical equipment of TC600 PLC

4.4.1.3 Interface RS-422

Interface RS-422 of PLC's of the TC600 series ensures conv ersion of

output signals of the TTL level to lev el defined by the specification V.11

(X.27, EIA RS-422), and input signals according to V.11 to the TTL lev el.

Parameter s of symmetr ic binding ci rcuits of t he RS-422 int erface al low for

two-point connection of end dev ices in the duplex mode. It is suitable f or

connection reali sed in m edium distance i n an env ironm ent with hi gher lev el

of elec tromagnetic disturbances.

For the com municat ion, PLC's of the TC600 series use only bi nding ci rcuits of signals TxD ( Transm i t Dat a) and Rx D (Recei ve Data) of the RS-422

interf ace.

Parameters of the

RS-422 interface

Transmission speed max. 230.4 kBd

Cable length max. 1200 m

Sensitivity of t he differenti al input

±200 mV

1)

2)

RxD+, RxDInput resistance of the diff er ential

min. 12 k

input Rx D+, RxDVoltage of the differ ential input

RxD+, RxD- f or lev el 1

Voltage of the differ ential input

RxD+, RxD- f or lev el 0

Voltage of the differ ential out put

TxD+, TxD- for level 1

Voltage of the differ ential out put

TxD+, TxD- for level 0

Difference of the output vol tage

min. 0.2 V

max. 12 V

min. -0.2 V

max. -7 V

max. 5 V Io=0)

2.3 V (R

=100

l

max. -5 V Io=0)

-2.3 V (R

=100

l

max. ±0.2 V

value for levels 0 and 1

Output curr ent max. ±60 mA

1)

The maximum transmission speed is limited by the maximum allowed

transmission speed of the set mode of the communic ation channel.

2)

The maximum cable length may only be used provi ded that the maxi-

mum transmission speed is reduced.

15 TXV 138 08.02

Tecomat TC600

CH2 is designed for

general use

CH3 is designed for

general use

4.4.2 Serial Communication Channel 2 (CH2)

CH2 serves especial ly f or connect ion of int elli gent peri pheries with a serial input or output of data to the PLC, and for mutual interconnection of

PLC's. It can operate in sev er al modes:

Mode PC - c onnec tion of a superior system, usually a PC

Mode PLC - interconnection of PLC's or regulators for mutual tr ansfer of

data

Mode MAS - data collection from subordinate PLC's or regulators in the

EPSNET network

Mode uni - general user channel for universal use

Setting of the required mode is giv en in Arti cle 4.5, detai led descripti on

of the m odes is given in the handbook

Serial Communication of Tecomat

Programmable Logic Contr oller s , TXV 001 06.02.

CH2 interf ace is optional (see Article 2.5). Parameters of the interf ace

are given under item 4.4.1.

4.4.3 Serial Communication Channel 3 (CH3)

CH3 is an optional par t of the P LC. It can be complem ented only in types

without analog out puts. It serv es especially f or c onnection of i ntelli gent peripheries with a serial input or output of data or connecti on of an external

control board, mutual interconnect ion of P LC's or connection of a PLC to a

superior system. It can operate in several modes:

Mode PC - c onnec tion of a superior system, usually a PC

Mode PLC - interconnection of PLC's or regulators for mutual data

transfer

Mode MAS - data collection from subordinate PLC's or regulators in the

EPSNET network

Mode uni - general user channel for universal use

Setting of the required mode is giv en in Arti cle 4.5, detai led descripti on

of the m odes is given in the handbook

Serial Communication of Tecomat

Programmable Logic Contr oller s TXV 001 06.02.

CH3 interfac e is dependent on the type of the c omm unicat ion piggy back

(see Article 2.5). Interface par ameters are given under item 4. 4.1.

TXV 138 08.02 16

Mode SET

Displaying of

parameters

Entrance in the SE T

mode

Termination of the

SET mode

Adjustable

parameters

Technical equipment of TC600 PLC

4.5 Setting of CPU Parameters

CPU parameters are set in the setting mode (mode SET). To set and

display paramet ers, the PLC front boar d is equipped with buttons SET and

MODE and a one-plac e seven-segment LE D display.

In the SET mode, all data are displayed in the rotational way, that is,

number 123 is displayed in such a way that digits 1, 2, 3 are l ighted gradually on the display, then there is a delay, and the whole sequence is repeated. Ev ery character i s displayed for about 0. 5 s and is separated f rom

the foll owing charac ter by a delay which ensures recognit i on of two ident i cal

characters display ed one aft er another (f or ex ampl e, di splaying of the num ber 111).

Switching t o the SET mode can be perf ormed by pressing butt ons SET

and MODE sim ultaneously whil e the PLC power supply is on. Buttons S ET

and MODE are held pr essed unti l the triple dash appears on the display. In

general it holds that by t he SET butt on we change setting of the param eter,

and by the MODE but ton we mov e t hrough i ndiv i dual paramet ers. Pressing

of the but ton is indic ated by lighting of the decim al point on t he display.

The SET mode m ay be term inated any ti me by sim ultaneously pr essing

the buttons SET and MODE. W e again hold the buttons SET and MODE

pressed until the t r iple dash appears on the display. Stat e of param et ers is

saved upon term ination of the mode in the power-independent m emory of

parameters, and the PLC switches to the HA LT m ode or som e of err or m essages may possibly be signalled.

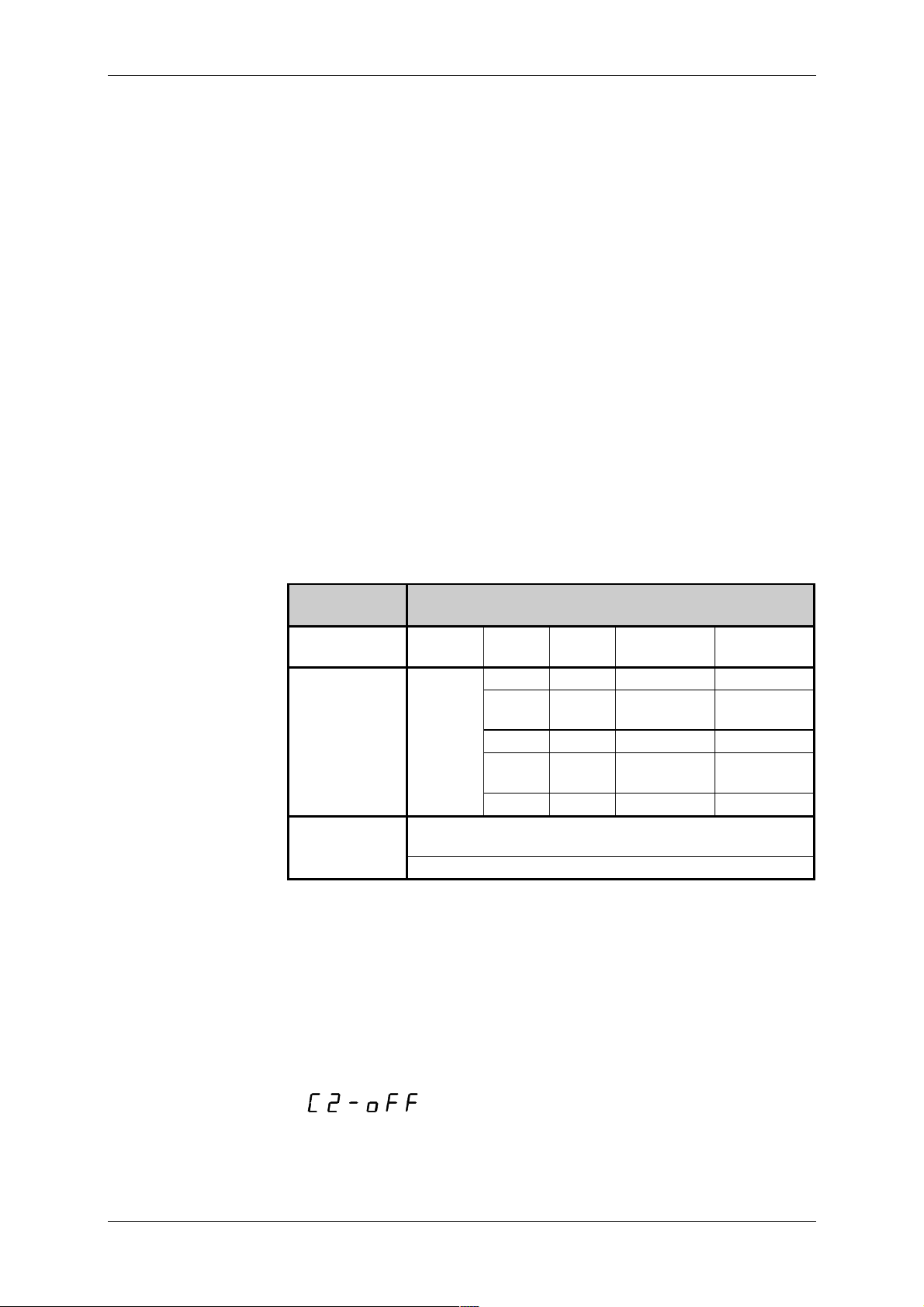

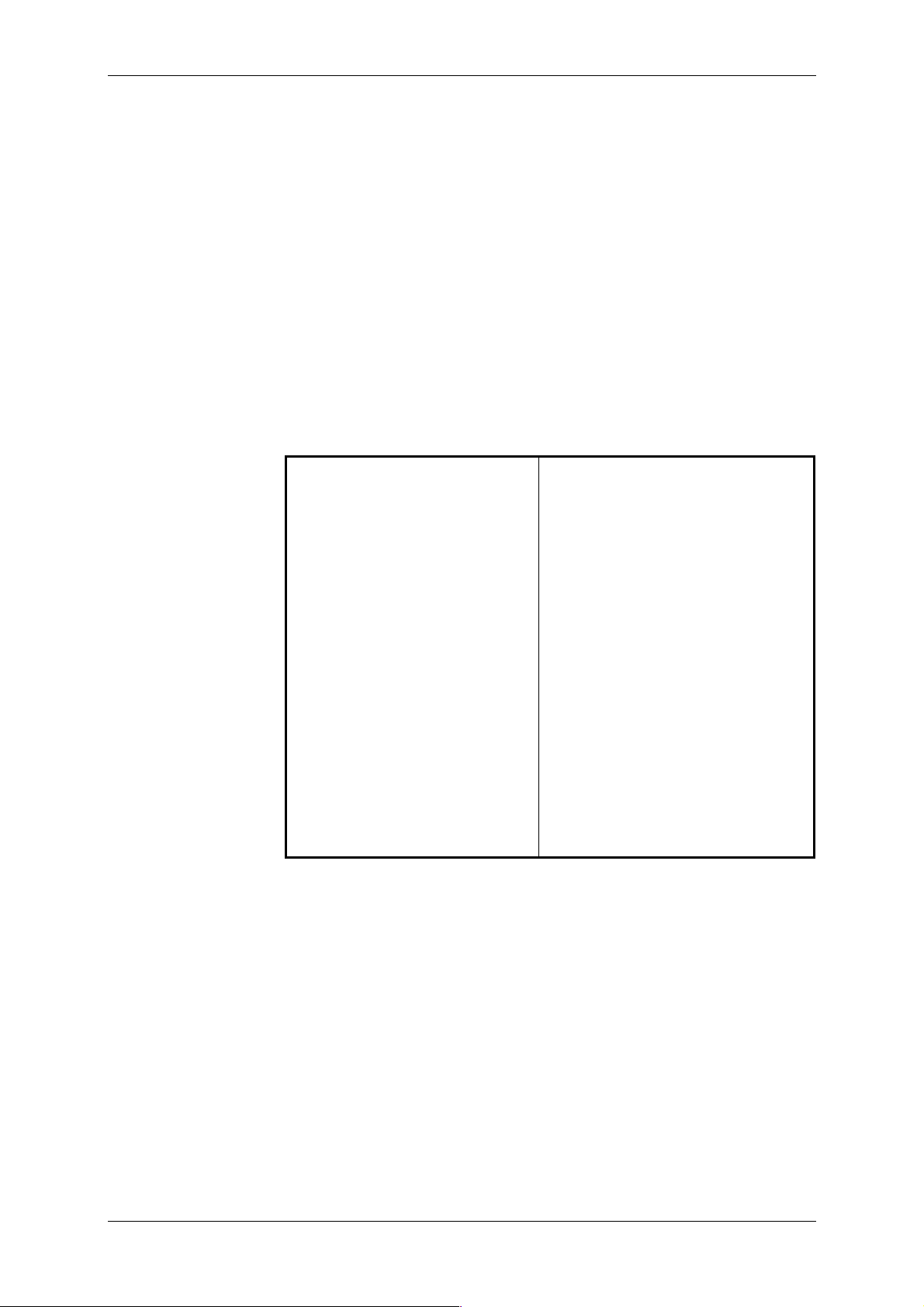

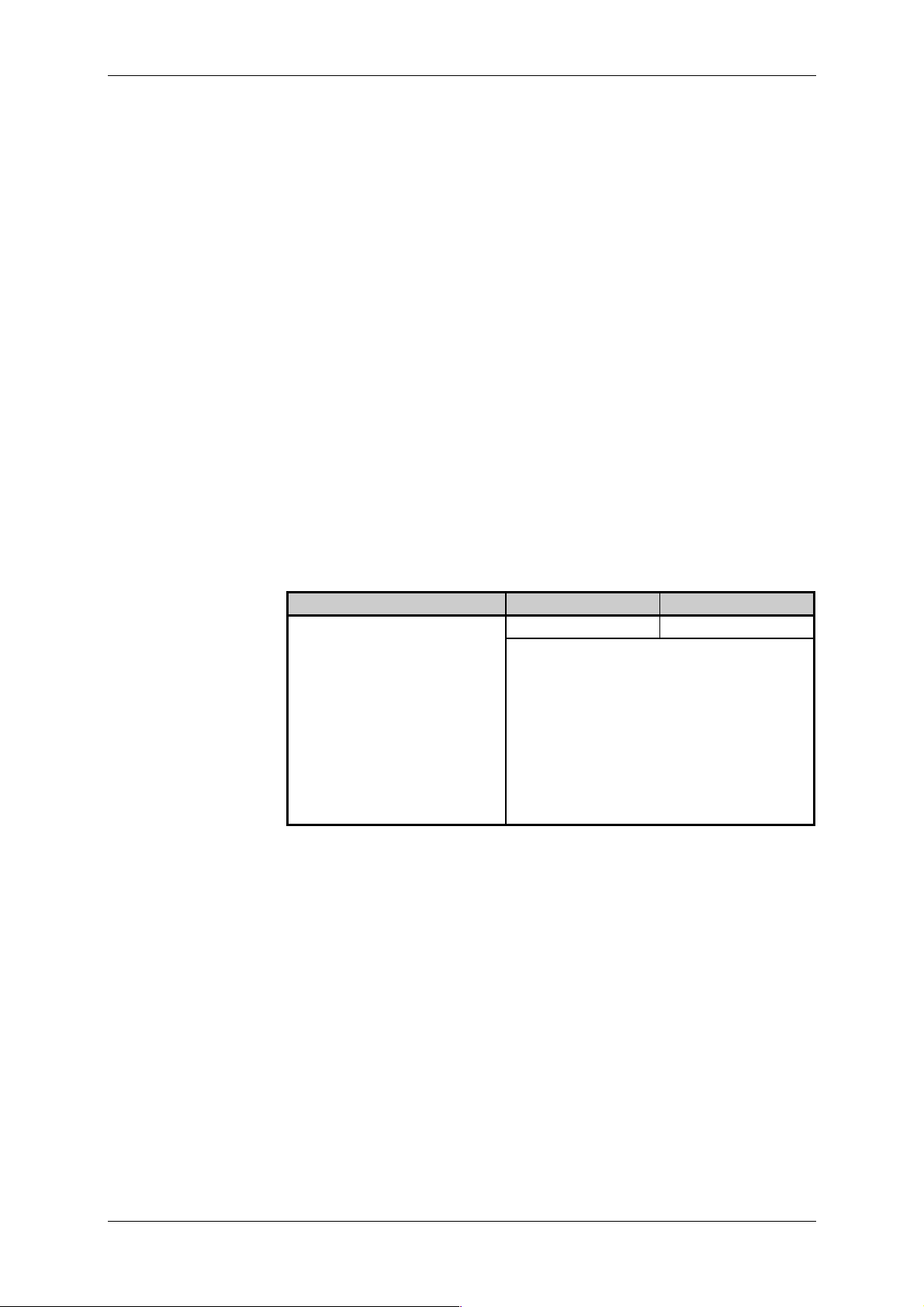

Tab. 4.1 Adjustable CPU parameters

(ordered fr om the left to the right and in the rows)

Setting of t he s er ial

channel mode

Object to

Adjustable parameters

be set

channel CH1 - address speed delay of re-

ply

CTS detec-

tion

off - - - -

channels

CH2 and CH3

Program source

mode PC

reg. PLC

1)

reg. uni

mode

MAS

address speed delay of re-

ply

address speed - -

- speed transport

delay

-- - -

off

CTS detec-

tion

CTS detec-

tion

2)

memory

on

1)

Only BM's fitted with the communication piggyback contain channel

CH3.

2)

CTS detection in the MAS mode cannot be set for CH3.

4.5.1 Setting of Parameters of Serial Communication Channels CH1,

CH2, CH3

Channel CH1 has fixed-set mode PC which c annot be changed. In this

channel, the par ameter serial channel mode is not set.

In setting the parameter serial channel mode for c hannels CH2, CH3, a

message of the foll owing type is shown on the display

with the f ollowing m eaning:

C - setting of t he serial channel mode

2 - number of t he c hannel being set

off- the mode being set

Serial c hannels may operate in the f ollowing m odes:

17 TXV 138 08.02

Tecomat TC600

off - channel is of f (no other c hannel paramet er is set)

PC - connection of a superior system (a PC or an active operation

board)

PLC - interconnect ion wit h other PLC's or regul ators i n t he EPSNET m ul-

tim aster network with fast dat a exchange

MAS - data collection from subordinate PLC's or regulators in the

EPSNET network

uni - general user channel for univ er sal use

By the SET but ton we move t hrough indiv idual modes. B y pressing the

MODE button we save the set mode and move to setting of another parameter

Setting of t he s er ial

channel address

Setting of t he s er ial

channel communication speed

When sett ing the param eter serial ch annel add ress, a message of the

following type is shown on the display

with the f ollowing m eaning:

A - setting of t he serial channel addr ess

2 - number of t he c hannel being set

0 - the set addr ess

Address may take a value from 0 to 99. By shortly pressing the SET

button, we increase i ts val ue by 1, by pressing and holdi ng the SET button

(for about 1s) we incr ease i ts val ue by 10. By pressing the MODE button, we

save the set value and move to setting of another parameter.

Address is set only f or modes PC and PLC. In the uni mode, setting of

the address is a part of the init ialisation table in the user program.

When setting the parameter serial channel communication speed, a

message of the foll owing type is shown on the display

with the f ollowing m eaning:

S - setting of the serial channel c ommunication speed

2 - number of the channel being set

19_2 - set speed in kb/s (the underscore is a substitute for the decimal

point)

The speed may take v alues defined in adv ance according to t able 4.2.

Speed not av ailabl e in the giv en m ode of the gi ven channel, i s not of fered

when browsing by the SET button. By pressing the MO DE button, we save

the set v alue and move to setting of anot her par ameter.

The speed is set only f or modes PC, PLC and MAS. In the uni m ode,

speed setting is a part of the initialisation t able in the user program.

TXV 138 08.02 18

Technical equipment of TC600 PLC

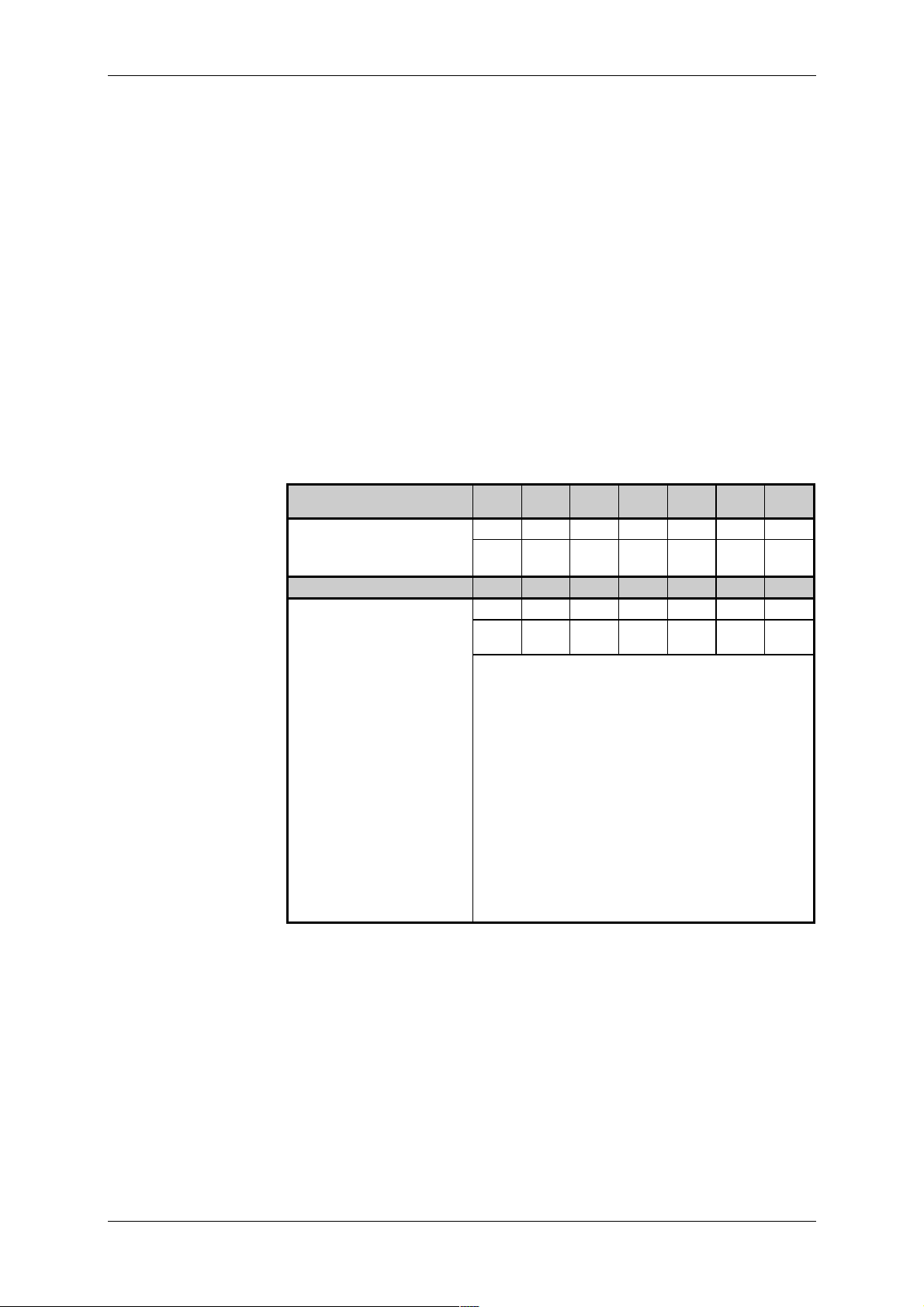

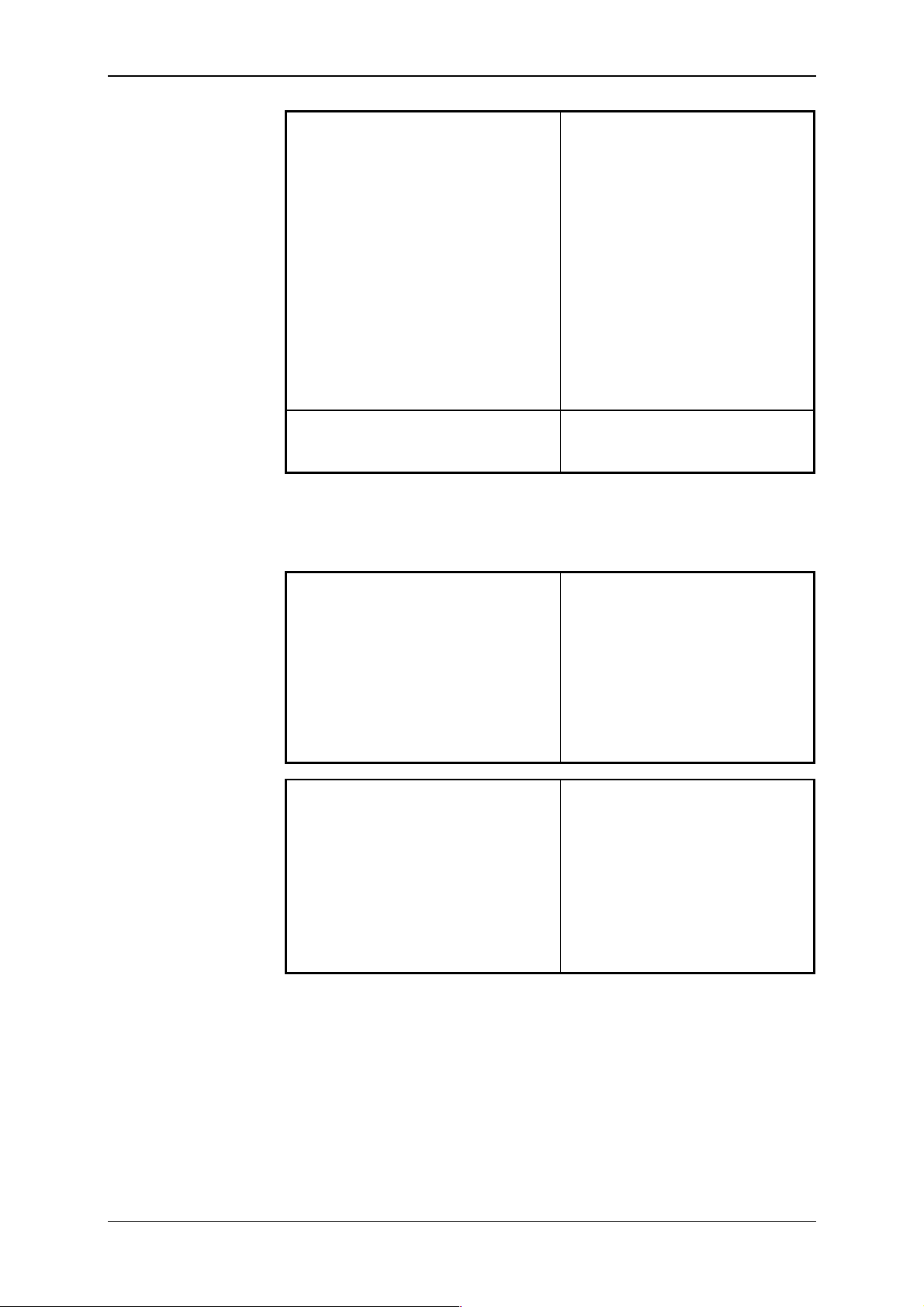

Tab. 4.2 List of available transmission speeds of CH1, CH2 and CH3 in

various modes

Speed Channel mode Speed Channel mode

0.3 kb/s PC,MAS 28.8 kb/s PC,PLC,MAS

0.6 kb/s PC,MAS 38.4 kb/s PC,PLC,MAS

1.2 kb/s PC,MAS 57.6 kb/s PC,PLC,MAS

2.4 kb/s PC,MAS 76.8 kb/s PLC

4.8 kb/s PC,MAS 115. 2 k b/s PLC

9.6 kb/s PC,PLC,MAS 172.8 kb/s PLC

14.4 kb/s PC,PLC, M A S 230.4 kb/s PLC

19.2 kb/s PC,PLC, M A S

Setting of t he r eply

delay and transport

delay

Reply delay

Transport delay

When sett ing the param eter reply delay (in the PC m ode) or transport

delay (in the MAS mode), a message of the f ollowing type i s shown on the

display

with the f ollowing m eaning:

t - setti ng of the reply delay

2 - number of t he c hannel being set

10 - set delay/transport delay in ms

By shortly pressing the SET button, we increase the value of the delay/tr ansport delay by 1, by pr essing and holding the SET button (f or about

1s) we increase its v alue by 10. B y pressing the M ODE button we save the

set value and move to setting of another par ameter.

Optional reply delay serv es for solut ion of si tuations when the superior

system sending the message, cannot switch in time from transmission mode

to receiv ing m ode, and thus it cannot receiv e t he PLC's reply. By ex tending

the reply delay t he superior system gai ns time f or preparati on necessary to

start receivi ng of a reply .

The delay ti m e i s set in m s and m ay take values f rom 0 to 99 m s. Val ue

0 means that the mini mum reply delay shall correspond with the time necessary to transmit 1 byte, thus it depends on the set speed. Val ues 1 to 99

give the delay in milliseconds and are not dependent on the comm unicati on

speed.

The reply delay is set only for mode PC.

Optional transport delay serv es for soluti on of si tuat ions when the PLC i n

the role of the superior system is waiting for reply from a subordinate PLC

for l onger than 0.5 s for t he r eason of delay on the t r ansmission l ine, caused

by modem s etc .

Transport delay is set in multipl es of 100 m s and may take values from 0

to 6 s. Value 0 means that the superior PLC waits for the reply for the

maxi mum of 0.5 s (ti me of cycle of the subordinate PLC may not exceed

this value). Values 1 to 60 give the transport delay of 0.1 to 6 s which is

added to the v alue 0. 5 s. Values 61 to 99 set the m ax im um transport delay

of 6 s.

The transport del ay is set only f or mode MAS.

Setting of t he CTS

signal detection

When setting the param eter CTS signal detection, a message of the

following type is shown on the display

with the f ollowing m eaning:

CTS - setting of the CTS signal detection

2 - num ber of the channel being set

on - det ec tion on

19 TXV 138 08.02

Tecomat TC600

Detection of the CTS si gnal may be either of f or on. By pressing the SET

button we change the setting, by pressing the MODE butt on we save t he set

value and move to setting of another par ameter.

When detect ion of the CTS signal is on, bef ore t ransmission of the repl y

the PLC tests state of the CTS signal af ter setti ng the RT S signal . The repl y

is transmitt ed only if the CT S signal has the sam e v alue as the RTS signal.

This mode i s suitable for com municat ion vi a modems. The set reply delay

holds in this mode too, it is thus ensured that PLC shall not reply before t he

delay elapses even if the CTS signal is already set.

When CT S signal det ecti on is of f, PLC control s the RTS signal but does

not take into considerati on state of the CTS signal.

Detection of the CTS si gnal can be set for the PC mode of all channel s

and for the MAS mode f or channel CH2. For channels CH2 and CH3 in the

uni mode, detec tion of the CTS signal c an be set using the ini tiali sation table in the user progr am.

Default sett ing of

parameters

Parameter s of CH1 are implicitly set by the producer to the following

values: mode - PC, addr ess - 0, speed - 19.2 k b/s, delay - 0, CTS detection

- off

CH2 and CH3 are implici tly off.

4.5.2 Management of the user p rogram source memo ry

When setti ng parameters of the source memory, a message of the fol lowing type i s shown on the display

with the f ollowing m eaning:

EP - setting of the user program source memory

off- m emory off (default val ue)

The source mem ory m ay be eit her of f or on. By pr essing t he S ET but ton

we change the setting, by pressing the MODE but ton we save t he set v alue

and move to setti ng of another parameter.

When t he param et er i s set to the of f v al ue, after t he PLC switches to t he

RUN mode, program stored in the user program memory i s run. When t he

parameter is set to the on value, after the setting mode is ended and in

every subsequent turning on of the PLC power supply, program from the

source memory is first moved to the user program m emory, and this program is then run in the RUN mode. The function serves especially for

backing of power-dependant memory of the user program.

TXV 138 08.02 20

Technical equipment of TC600 PLC

5. Input and Output Unit

5.1 Basic Functions

The majori ty of input and output circui ts of the PLC is real ized on t he input and output unit. Indiv idual types of the series diff er in the type of the

used input and output unit or i n m odificat i on of the uni t f i tt ing wit h ci rcui t s of

binary and analog inputs and binary t r ansi stor and r elay outputs.

5.1.1 Binary Inputs

Binary i nputs serve for c onnection of t wo-state signals of the contr olled

object to t he PLC. To increase f unctional rel iability, every input is galv anically separated by an optical el ement f rom i nternal ci rcuits and is equi pped

with a fi l ter. If the i nput i s exc it ed (cl osed), t hi s is signall ed by l i ghti ng of t he

LED diode. Input s are organized in groups with one c ommon connec tor. A

group of signals may be connected in one or the other polarity .

Inputs DI1 to DI3 of modules TC603 to TC607 can be used for basic

functi on i denti cal wit h other i nput s or f or real i zati on of t he PLC speci al functions.

Parameters of binar y

inputs

TC601

TC621

Total number of inputs 12 20 12 16 12 16 20

Arrangement

(no. of groups x no. o f inputs)

TC631 TC632 TC633 TC634

Total number of inputs 8 8 16 Arrangement

(no. of groups x no. o f inputs)

Group common conductor plus or mi nus

Galvanic separation f r om

other electric circuits

Nominal vol tage 24 V-, 24 V~

Voltage for log. 0 max. 12 V-, 11 V~

Voltage for log. 1 min. 16 V- , 15 V~

Current for log. 1 typ. 10 mA

Delay from log. 0 t o log.1 typ. 4 ms

Delay from log. 1 t o log.0 typ. 4 ms

Pulse overload capacity of

the input

TC602

TC622

1x8,

1x4

2x4 2x4 4x4

TC603

TC623

2x8,

1x4

1x8,

1x4

(max. 14 V-, 13. 5 V~)

(min. 18.5 V-, 17.5 V~)

max. 30 V-, 30 V~

(pulse width 100 s, period 1 s)

TC604

TC624

2x8 1x8,

yes

max. 250 V

TC605

TC625

1x4

TC606

TC626

2x8 2x8

1)

1)

TC607

1x4

1)

Value val i d for inputs DI0 to DI3 of m odul es TC603 to T C607 and TC623

to TC626

21 TXV 138 08.02

Tecomat TC600

5.1.2 Binary Transistor Output s

Binary tr ansistor outputs serv e f or contr ol of two-state act ion and signal ling el ements, which require hi gh count and el. cl osing speed. To i ncrease

functional rel iability, every output is galvanically separated by an opti c al element fr om internal cir cui ts and is protect ed against short ci rcui t, overv ol t age

and rever si ng of polarity.

When connecting an external power supply of outputs, closing of individual outputs i s signalled by lighting of the LED di ode. By lighting, the common LED diode marked as BLK, signals blocking of outputs in the still

(open) state.

Outputs are organi z ed in groups with one common connector.

Parameters of

transistor outputs

TC601

TC621

TC602

TC622

TC603

TC623

TC604

TC624

TC605

TC625

TC606

TC626

TC607

Total number of out puts 8 16 4 - - 4 20

Arrangement

(no. of groups x no. o f outputs)

1x8 2x8 1x4 1x4 2x8

1x4

TC631 TC632 TC633 TC634

Total number of out puts 8 - - Arrangement

(no. of groups x no. o f outputs)

1x8

Group common conductor plus

Galvanic separation f r om

yes

other electric circuits

Operational volt age of out-

9.6 V- to 28.8 V-

puts

Current of outputs max. 1 A

Current of the comm on

conductor

Residual current in el.

max. 6 A max. 4 A 6 A

4 A

max. 300 A

opening

El. closing time

El. opening time

Protection against short

max. 400 s

max. 400 s

yes

circuit

Limi t at ion of the initi al peak

typ. 7.5 A

current

Disconnecting tim e of the

typ. 4 ms

initial peak current

Limitation of short circuit

typ. 4 A

current

Protection against overload yes

Current limitation typ. 4 A

Protection against revers-

yes

1)

ing of polari t y

Servicing of inducti ve load external

1)

The circuit is brought in non-activ e state, loads are closed, current will

flow through the circuit protect iv e diode.

TXV 138 08.02 22

Technical equipment of TC600 PLC

5.1.3 Binary Relay O utputs

Binary rel ay outputs serve for control of two-state action and signalling

element s of the cont roll ed object , suppli ed by alter nating v ol tage or v oltage

higher than the allowed range of closed volt age of transistor outputs. O utputs are realized by the closi ng v oltage-f ree cont act rel ay led out independently or in a group with one com mon connector.

Closing of every output is signalled by lighting of the LED diode. The

comm on LED diode mark ed as BLK, signals by li ghting bl ocking of outputs

in the still (open) state.

Parameters of r elay

outputs

TC601

TC621

TC602

TC622

TC603

TC623

TC604

TC624

TC605

TC625

TC606

TC626

Total number of outputs - - 4 10 8 10

Arrangement

(no. of groups x no. of outputs)

TC631 TC632 TC633 TC634

1x4 2x4,

2x1

2x4 2x4,

2x1

-8-2x4

Galvanic separation from

yes

other elect r ic circ uits

Contact parameters

Closed voltage

max. 250 V

Closed current max. 1 A

Closed alternat ing output m ax. 250 VA

Closed direct- c ur r ent output m ax. 24 W f or vol tage 24 V

max. 43 W for voltage 48 V

max. 57 W for voltage 250 V

Current through t he gr oup

max. 4 A

comm on c onduc tor

Closing and opening t ime typ. 5 ms

Oscillation time typ. 1 ms

6

Mechanical life min. 20 x 10

closings

Serv icing of inductiv e load external

Protection of the c ontact

external

against overload

Dielect r ic resistance of the

1 kV~

open contact

Dielect r ic resistance between

2.2 kV~

relay contac ts and non-live

PLC parts

Dielect r ic resistance between

3.75 kV~

relay contac ts and SELV circuits

Dielect r ic resistance between

contact groups

1)

3.75 kV~

1)

Includi ng c ontacts led out independently

23 TXV 138 08.02

Tecomat TC600

Format of input data

5.1.4 Analog Inputs of TC605, TC606, TC625, TC626 Modules

Analog inputs serve for connection of up to four analog signals of the

controll ed object to the PLC. They are i ntended especial ly f or processing of

analog signals with normalized current or v oltage level. Input circuits are

galvanically connected wit h internal P LC c ontrol ci r c uits.

Inputs are arranged in a gr oup with one common connector of t he analog

ground. Ev ery input can be set indi viduall y by a jumper f or the voltage or

current signal source. T he m easurement range i s set by a pr ogram . T ype of

input and the measurement range c an be selected for every i nput independently of other inputs.

Value of the i nput v ar iabl e i s passed in the FS form at (F ul l S cal e). V alue

0 of the input data corresponds with the lower limit of the measurement

range, the maxi mum v alue of t he input data 4095 cor responds with the upper limi t of the measurem ent range. E x ceedi ng of the c onv er ter r ange is not

signalled. Conversion to technical units is performed on the user program

level. The FS format provides the highest possible resolution.

Parameters of analog

inputs

TC605, TC606,

TC625, TC626

TC601 to TC604

TC621 to TC624

TC605, TC606

TC625, TC626

Number of input channels - 4

Arrangement

1x4

(no. of gr oups x no. of inputs)

Group common conductor minus

Galvanic separation from inter -

no

nal elect r ic circ uits

Input binary r epr esentation 12 bits unsigned

Conversi on time of 4 channels 4 ms

Input type cur r ent or v oltage

Voltage inputs

Measurement range/ r esol ution

(1 LSB)

Input resistance

Recomm ended internal r esi s-

0 V to +10 V/

0 V to +2 V/ 0.49 mV

>10 M

<10 k

2.44 mV

tance of the signal source

Current inputs

Measurement range/ r esol ution

0 mA to +20 mA/

4.9 A

(1 LSB)

Input resistance

100

Input current max. 50 mA

Input voltage max. 5 V

1)

2)

LSB (Least Signifi c ant Bit) - lowest bit of t he binary value

1)

1 LSB =

2)

1 LSB =

TXV 138 08.02 24

Switching of the

current source allows

for connection of two

detector st r ings with

impedance up to 8 k

Technical equipment of TC600 PLC

5.1.5 Analog Inputs of the TC634 Module

Analog input s serve f or connection of up t o eight analog signals of the

controll ed obj ect t o the P LC. T hey are i ntended especial l y f or m easurem ent

of temperatures using passive resistance temperature scanners, and for

processing of analog signal s with normali zed current or v ol tage lev el. Input

circui ts are galvanically connected wit h the PLC internal control c ircuit s.

Inputs are fi xed-confi gured as differenti al ones. Ev ery input can be set

individually using a jumper for direct-current voltage or current signal

source. Measurement r ange and form at of the input variabl e val ue ar e set in

a program. Input type, m easurement range and f ormat of t he v alue of input

data can be selected for every input independently of other inputs.

To supply power to passiv e resistance detector s, an internal power supply prov iding speci fic current 1 mA is av ailable, which is switched in m easurements automatically to one of the two output c lips.

The modul e ensures fil tering off of the disturbance com ponent of input

signals, protect ion of input circ uits, conv er sion of t he analog v ol tage or cur-

rent input level to the binary value, and conv ersion of the value into the

chosen form at.

Parameters of analog

inputs of TC634

Number of input channels 8

Arrangement of input s 8 differential

Method of A /D conv er si on si gma-delt a modulation

Input f iltration digital filter 50 Hz

Calibrat ion automatic at the PLC initialization

and at ev er y c hange of the measure-

ment range

Conversi on time of one channel 60 ms

Reconfiguration time of one channel

Total measurement t ime

Input response time

2)

3)

1)

180 ms

variable according to configuration

60 ms

Binary representation of the input 16 bi ts

Galvanic separation from inter nal

no

electric circuits

Galvanic separation from non-live

yes

PLC parts

Input type

(can be selected by a jumper)

voltage - passive resistance scanners of

1)

Reconfiguration time of one channel is time necessary to change and

current

voltage

temperature

calibrate the measurement range and conversion of one channel. It is

applied at transferring among diff er ent input ty pes.

2)

Total m easurem ent t i m e is the sum of t im es necessary f or conversion or

reconfiguration of all dec lared input c hannels

3)

Response time of t he input i s tim e which the i nput signal needs to reach

100% of it s final v alue. If the signal change i s faster than the response

tim e of the i nput, the signal is reduced by the input fi lter.

25 TXV 138 08.02

Tecomat TC600

Parameters of inputs

for TC634 resistance

temperature sc anner s

Scanner type

(can be selected by a progr am)

Pt100 W

Pt100 W

Ni1000 W

Ni1000 W

= 1.385

100

= 1.391

100

= 1.617

100

= 1.500

100

general 0 to 630

general 0 to 2520

Measurement range see table 5.1a

Resolution see table 5.2a

Format of input data see table 5.1a

Total measurement err or see table 5.3a

Temperat ur e dr ift see table 5.3a

Input resistance

Resistance of t he si gnal source

Input voltage

1)

Current of the power supply for sup-

>10 M

max. 8 k

max. 12 V

1 mA

plying of scanners

Load resistance of the current supply

1)

Greatest v oltage di ff erence measured am ong all i nput cli ps of the m odule may not exceed this value.

2)

The giv en load m ay be connect ed to bot h output cl i ps of t he curr ent sup-

2)

max. 8 k

ply (IoutA, IoutB).

Parameters of TC634

current inputs

Parameters of TC634

voltage inputs

Measurement range

(can be selected by a progr am)

0 mA to +20 mA

+4 mA to +20 mA

Resolution see table 5.2b

Format of input data see table 5.1b

Total measurement err or see table 5.3b

Temperat ur e dr ift see table 5.3b

Input resistance

25.2

Input current max. 50 mA

Input voltage max. 5 V

Measurement range

(can be selected by a progr am)

0 V to +10 V

0 V to +2 V

Resolution see table 5.2b

Format of input data see table 5.1b

Total measurement range see table 5.3b

Temperat ur e dr ift see table 5.3b

Input resistance

Resistance of t he si gnal source

Input voltage

1)

Greatest dif f erenc e of volt age m easured am ong all i nput c li ps of the m o-

1)

>10 M

max. 10 k

max. 12 V

dule may not exceed this value.

Formats of input data

Value of the input v ariabl e is passed in one of three f ormats. Format of

input data is selected in a program.

Format FS

In the FS f orm at (Ful l S cale), v alue 0 of input dat a corresponds with the

lower limit of the measurement range, the maximum value of input data

65535 corresponds with the upper limit of the measurement range. Exceeding of the range of the conv erter is not signalled. Conversion to technical uni ts is perf ormed on t he user program lev el . The F S f orm at provi des

the highest possible resol ution.

Technical units

In the Technical units format, converted value of the input variable is

passed in C, , A or mV. Exceeding of the range is signalled by v alue

TXV 138 08.02 26

Format PID

Format of input

data of resist anc e

temperature

scanners

Technical equipment of TC600 PLC

$7FFF, underflow of the range i s signalled by v alue $-7FFF ($8001). Detailed dat a on signalli ng of ov erf low and underflow of the r ange for indiv idual types of inputs - see notes to table 5.1.

In the PID f or m at, v al ue of t he i nput vari able i s passed, c onv er ted to t he

format compatible with PID instructions of Tecomat programmable logic

controllers. The val ue can be interpreted as percentage expression of the

full measurement range. Ex ceeding of the range is signalled by the v alue

$7FFF. Detailed data on signalling exceeding of the range for i ndiv idual i nput types - see notes to tabl e 5.1.

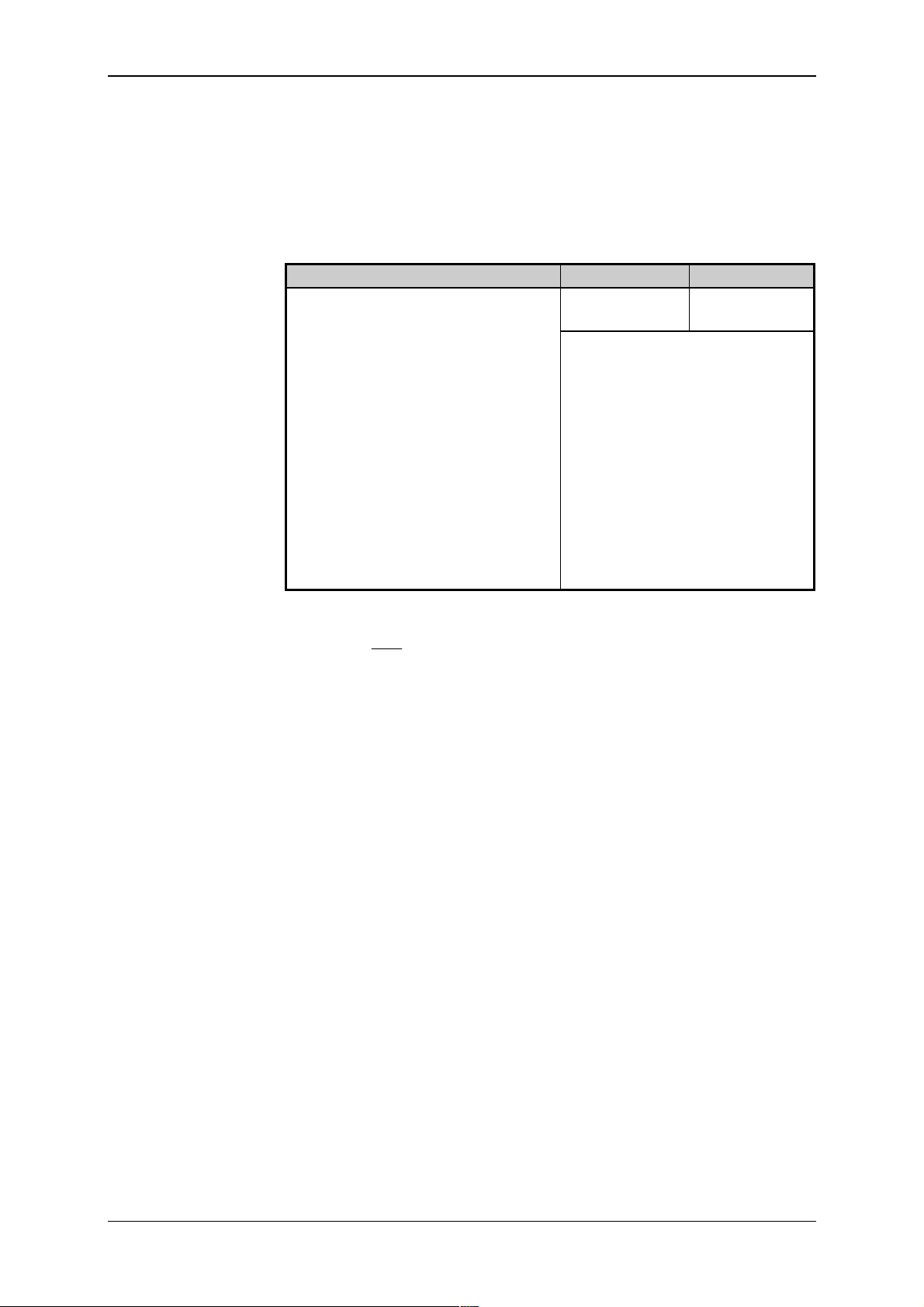

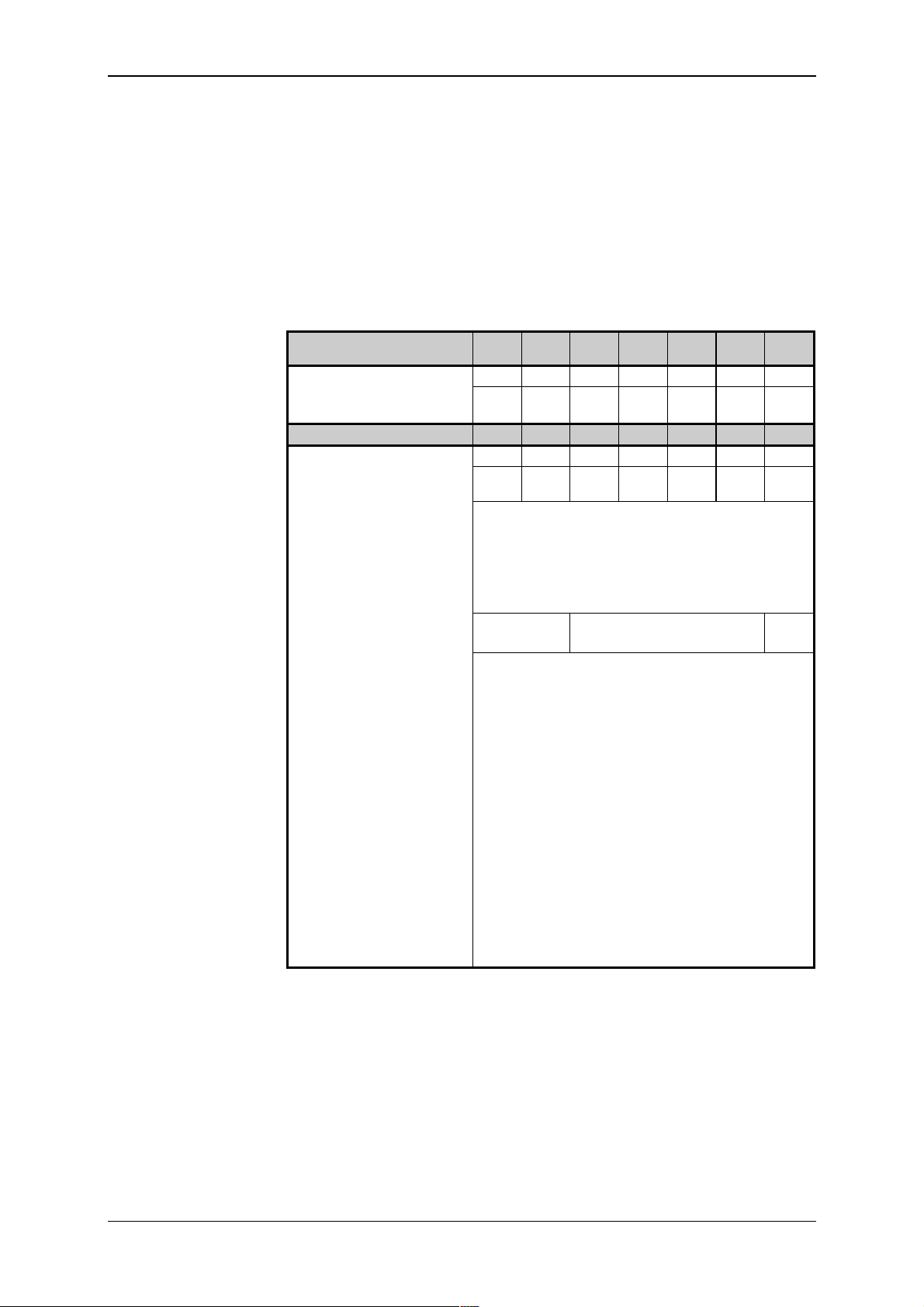

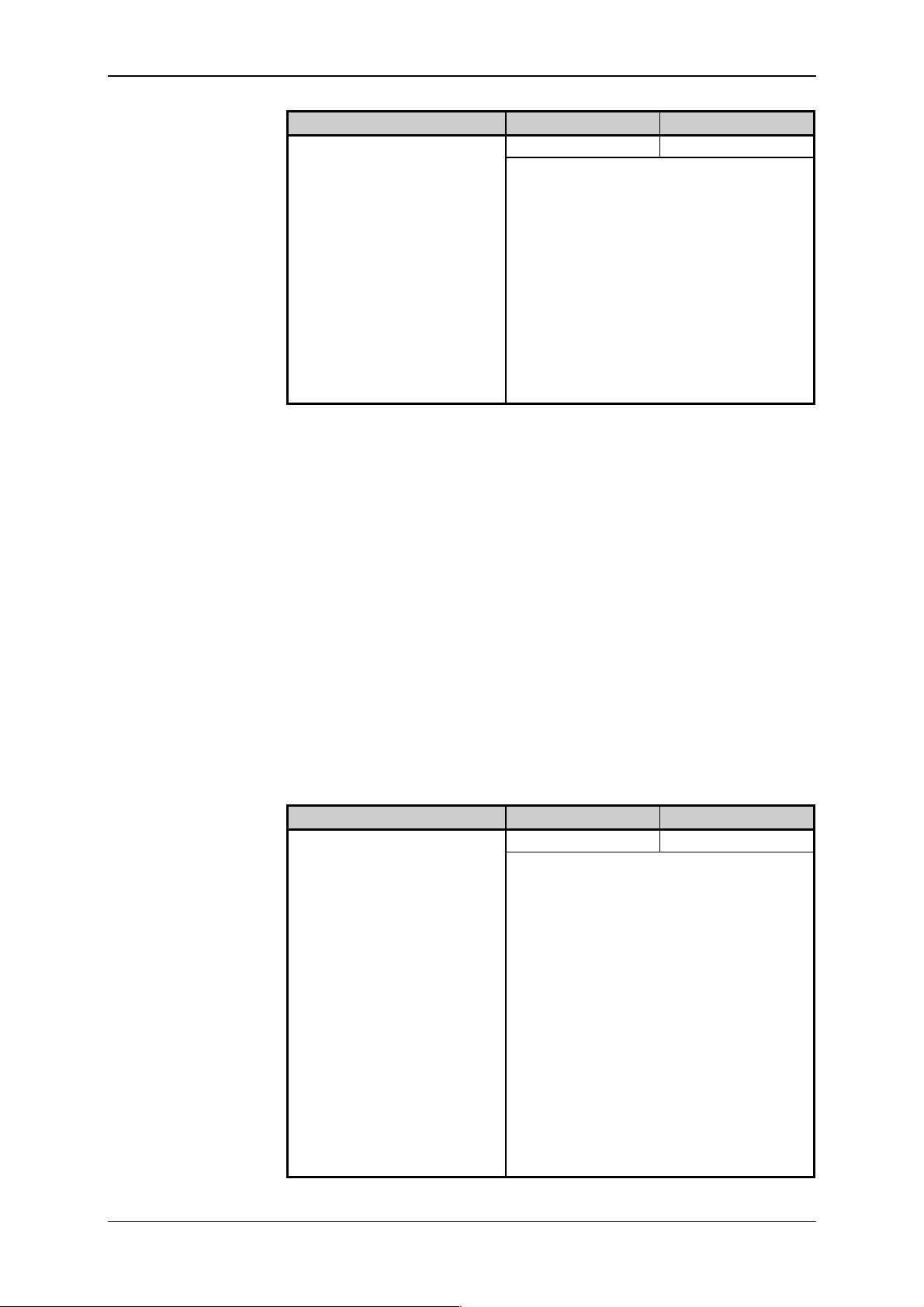

Tab. 5.1a. Format of input data of TC634 r esi stanc e temperatur e scanners

Data format

Scanner type/ FS Technical units PID

measurement rang e

Pt100, W 100 = 1. 385

-200 to +850 C

Pt100, W 100 = 1. 391

-200 to +850 C

Ni1000, W 100 = 1.617

-60 to +200 C

Ni1000, W 100 = 1.500

-60 to +200 C

0 to 630

0 to 2520

tenths of C

1)2)

tenths of

0 to 65535 -2000 to +8500

0 to 65535 -2000 to +8500

0 to 65535 -600 to +2000

0 to 65535 -600 to +2000

0 to 65535 0 to 6300 0 to 10000

0 to 65535 0 to 25200 0 to 10000

3

3

1)

At conv ersion to the f ormat of °C tenths, correction of non-linearity of

"#$%

(idt EN 60751: 1995) .

2)

For the marked format, value $7FFF signals interruption of the scanner,

value $-7FFF ($8001) signals short circuit of the scanner.

3)

For the m arked form at, ex ceeding of the upper lim it of the range is signalled by value $7FFF.

Tab. 5.1b. Format of input data of TC634 c ur r ent and voltage input s

Data format

Measurement

range

0 to +20 mA 0 to 65535 0 to 20000

+4 to +20 mA 0 to 65535 4000 to 20000

0 to +10 V 0 t o 65535 0 to 10000

0 to +2 V 0 to 65535 0 to 20000 4)0 to 10000

1)

For the marked format, exceeding of the range at current higher than

22 mA is signalled.

2)

For the marked format, exceeding of the range at current higher than

FS Technical units PID

A

1)

2)

mV tenths of

mV

3)

0 to 10000

0 to 10000

0 to 10000

22 mA is signalled, and underflow of the range at current lower than

3.5 mA.

3)

For the marked format, exceeding of the range at voltage higher than

10.1 V is signalled.

4)

For the marked format, exceeding of the range at voltage higher than

2.1 V is signalled.

1)

2)

3)

4)

27 TXV 138 08.02

Tecomat TC600

Resolution of input

data

Resolution of input

data of resist anc e

temperature sc anner s

Resolution of input

data of current and

voltage inputs

Resolution means the smallest detectable change of the input variable

expressed in techni cal units. It represents the val ue of the l east signif icant

bit of input data (LSB).

Tab. 5.2a. Resolution of input data of TC634 resistance tem perature scan-

ners

Data format

Scanner type FS Technical units PID

Pt100, W 100 = 1. 385

Pt100, W 100 = 1. 391

Ni1000, W 100 = 1.617

Ni1000, W 100 = 1.500

0 to 630

0 to 2520

tenths of C

0.016021 C/ LSB 0.1 C/ LSB

0.016021 C/ LSB 0.1 C/ LSB

0.0039673 C/ LSB 0.1 C/ LSB

0.0039673 C/ LSB 0.1 C/ LSB

9.6131 m/ LSB 0.1/ LSB

38.452 m/ LSB 0.1/ LSB

tenths of

0.01 %/ LSB

0.01 %/ LSB

Tab. 5.2b Resolut ion of input data of TC634 current and vol tage inputs

Data format

Measurement

range

0 to +20 mA

+4 to +20 mA

0 to +10 V 0. 15259 mV 1 mV /LSB 0. 01 % /LSB

0 to +2 V 0. 030518

FS Technical units PID

A

0.30518 A1 A /LSB

0.24414 A1 A /LSB

mV

mV tenths of mV

0.1 mV /LSB 0.01 % / LSB

0.01 % /LSB

0.01 % /LSB

Accuracy of

measurement of

inputs for resis tance

temperature

scanners

Accuracy of

measurement of

current and voltage

inputs

Tab. 5.3a. Accuracy of measurement of inputs for TC634 resistance tem-

perature scanners

Scanner type Maximu m error

(25 °C)

Pt100, W 100 = 1. 385

Pt100, W 100 = 1. 391

Ni1000, W 100 = 1.617

Ni1000, W 100 = 1.500

0 to 630

0 to 2520

0.5 C

0.5 C

0.4C

0.4C

2

8

Temperature dr i f t

(0 to 50 °C)

0.011 C/ C

0.011 C/ C

0.009 C/ C

0.009 C/ C

40 m/ C

70 m/ C

Tab. 5.3b Accuracy of measurement of TC634 current and volt age inputs

Measurement range

0 to +20 mA

+4 to +20 mA

0 to +10 V

0 to +2 V

Maximum error

(25 °C)

400 A

400 A

200 mV

40 mV

Temperature dr i f t

( 0 to 50 °C)