Page 1

TS1066

Network Access Controller

Installation Manual

STOP!

Before you begin

Please download the latest version of firmware by

following the instructions at

http://www.interlogix.com.au/downloads

P/N MAINST-TS1066 • REV 3.2 • ISS 16AUG19

Page 2

Copyright

© 2019 UTC Fire & Security Australia Pty Ltd. All rights reserved.

Trademarks and

patents

The Challenger name and logo are trademarks of

UTC Fire & Security Australia Pty Ltd.

Other trade names used in this document may be trademarks or

registered trademarks of the manufacturers or vendors of the

respective products.

Manufacturer

Made in China by United Technologies Safety Systems

No. 80, Changjiang East Road, QETDZ, Qinhuangdao, Hebei,

P. R. China 066004

Imported by UTC Fire & Security Australia Pty Ltd t/a Interlogix

10 Ferntree Place

Notting Hill, Victoria, 3168, Australia

ACMA compliance

Notice! This is a Class B product. In a domestic

environment this product may cause radio interference

in which case the user may be required to take

adequate measures.

WEEE compliance

For proper recycling, dispose all the batteries and the

packaging as required by local ordinances or

regulations

Contact information

For contact information, see www.interlogix.com.au.

2

Page 3

Contents

Important information ................................................................... 5

Limitation of liability ......................................................................... 5

Agency compliance ......................................................................... 5

Contact information ......................................................................... 5

Product overview .......................................................................... 6

Specifications .................................................................................. 7

Product contents ............................................................................. 7

Warning .......................................................................................... 8

Related documentation ................................................................... 8

Before you begin ........................................................................... 9

Safety Warnings.............................................................................. 9

Enclosure Access Restrictions ........................................................ 9

Installing the Network Access Controller ................................. 10

Installation guidelines .................................................................... 10

Installation procedure .................................................................... 10

Mounting Network Access Controller in the enclosure ....... 10

DIP switch settings ........................................................................ 11

Connections .................................................................................. 12

Power Input ........................................................................ 16

Batteries ............................................................................. 17

Battery fitment and replacement ........................................ 18

Battery charging current ..................................................... 19

Auxiliary power terminals ................................................... 19

Siren ................................................................................... 20

RS-485 Networks ............................................................... 21

ChallengerPlus LAN ........................................................... 21

RS-485 buses .................................................................... 21

RS-485 cabling ................................................................... 21

Terminating the RS-485 ..................................................... 25

Lock power ......................................................................... 25

Door lock relay wiring ......................................................... 26

Inputs ................................................................................. 26

Connecting expansion modules .................................................... 28

Relay expansion ................................................................. 28

LED indicators............................................................................... 29

Powering up the Network Access Controller ........................... 31

Defaulting the Network Access Controller ..................................... 31

Defaulting the USB Comms Path .................................................. 32

On-Board Memory Retention ........................................................ 32

3

Page 4

Appendix B: Output fusing and user current limits ................. 34

Appendix C: Operating temperature ......................................... 35

Appendix D: Cabling requirements ........................................... 36

System earthing ................................................................. 36

Ethernet cabling ................................................................. 36

Power supply to RS-485 devices (refer to Figure 5 External

Power Supply Connection to RAS on page 24) .................. 36

4

Page 5

Important information

Limitation of liability

To the maximum extent permitted by applicable law, in no event will Interlogix be

liable for any lost profits or business opportunities, loss of use, business

interruption, loss of data, or any other indirect, special, incidental, or

consequential damages under any theory of liability, whether based in contract,

tort, negligence, product liability, or otherwise. Because some jurisdictions do not

allow the exclusion or limitation of liability for consequential or incidental

damages the preceding limitation may not apply to you. In any event the total

liability of Interlogix shall not exceed the purchase price of the product. The

foregoing limitation will apply to the maximum extent permitted by applicable law,

regardless of whether Interlogix has been advised of the possibility of such

damages and regardless of whether any remedy fails of its essential purpose.

Installation in accordance with these manual, applicable codes and the

instructions of the authority having jurisdiction is mandatory.

The customer is responsible for testing and determining the suitability of this

product for specific applications. The customer is responsible for testing the

product at least once every three months.

While every precaution has been taken during the preparation of this manual to

ensure the accuracy of its contents, Interlogix assumes no responsibility for

errors or omissions.

Agency compliance

This product conforms to the standards set by Standards Australia on behalf of

the Australian Communications and Media Authority (ACMA).

Ensure that enclosure covers are fitted to maintain ACMA compliance.

Notice! This is a Class B product. In a domestic environment this product may

cause radio interference in which case the user may be required to take

adequate measures.

Contact information

For contact information, see www.interlogix.com.au.

5

Page 6

Product overview

This manual applies to the TS1066 Network Access Controller.

Up to 12 Network Access Controllers can be connected to a ChallengerPlus

panel’s RS-485 system LAN. ChallengerPlus panels have two RS-485 system

LANs and can have a total of 24 Network Access Controllers.

The Network Access Controller can operate independently of a ChallengerPlus

panel, depending on its operating mode.

The Network Access Controller, in addition to its Tecom bus, has two RS-485

buses (local LANs) to connect readers for doors, as well as RASs, DGPs, and

Tecom peripherals.

Network Access Controllers provide enhanced access control functionality to the

ChallengerPlus system. This manual describes:

• How to install the Network Access Controller

• How to connect other equipment to the Network Access Controller

This manual is intended for use only by trained Challenger installation and

configuration technicians.

Refer to the MAPROG-TS1066 R1.2 TS1066 Network Access Controller

Programming Manual for more details on supported system configurations.

6

Page 7

Mechanical

Physical dimensions

(W x D x H)

Weight

product

boxed

mm

g

kg

254 x110 x55

330

12

Electrical

AC input voltage

Nominal

Limits*

Battery requirements

Type

Terminal voltage

Nominal

Maximum

Charging current limit

Compliance

Battery lead fuse

Size

Type

Current

Voltage

Example parts

Vrms

Vrms

V

V

A

A

VAC

19

15 to 24.5

SLA(Sealed Lead Acid)/

VRLA(Valve regulated Lead Acid)

12

15 (severely overcharged)

>1.5

AS/NZS 2201.1:2007, Appendix C

3AG/3AB (6x32 mm)

Time lag (slow blow)

8

250

Bel Fuse 3SB 8-R

Littelfuse 0313008.HXP

Schurter 8020.5020

Environmental

Room temperature

Storage

Operating**

Relative humidity

Location

Pollution Class

Altitude

°C

°C

%

m

-20 to +80

0 to +50

0 to 93 non-condensing

Indoor. Dry area.

2 or lower

≤ 2000

Enclosure

details

Compatible enclosure

ENC-LGE

Specifications

* Includes all tolerances and Mains supply variations.

**Refer to Appendix C: Operating temperature.

Product contents

Inspect the package and contents for visible damage. If any components are

damaged or missing, do not use the unit; contact the supplier immediately. If you

need to return the unit, you must ship it in the original box.

Table 1 lists the items that are shipped with a TS1066 Network Access

Controller.

7

Page 8

Table 1: TS1066 shipping list

Quantity

Item

1

TS1066B board

1

TS1066 Network Access Controller Installation Manual

7

M3 x 10 pan head screws

6

Standoff board mounts

12

3-way plug-on screw terminal connectors

14

2-way plug-on screw terminal connectors

2

Battery leads (combined negative and fused positive)

1

1K 1/4 watt resistor

16

10K 1/4 watt resistors

5

Link jumpers

Warning

Take appropriate precautions if working on an active or

recently de-powered device.

The circuit board and the heatsink on the Network

Access Controller board may be hot.

Do not touch.

Related documentation

The ChallengerPlus Installation and Quick Programming Manual and

ChallengerPlus Programming Manual provide detailed information about

configuring and programming a ChallengerPlus system.

The ENC-LGE Large Enclosure Installation Manual provides instructions for

installing the ENC-LGE Large Enclosure.

The TS1066 Network Access Controller Programming Manual provides detailed

information about configuring and programming the Network Access Controller.

The Challenger system is modular. Refer to the documentation that is shipped

with each module that you intend to use.

8

Page 9

Before you begin

When installing a Network Access Controller, or any other parts of the system,

you need to be aware of requirements for cabling and earthing, and plan

accordingly. Refer to “Appendix D: Cabling requirements” on page 36.

Notice! A qualified service person, complying with all applicable codes, should

perform all required hardware installation.

The customer is responsible for testing and determining the suitability of this

product for specific applications. The customer is responsible for testing the

product at least once every three months.

Disclaimer: This manual contains recommendations based on Australia and

New Zealand codes. It is not an authoritative reference regarding codes and has

not been reviewed by the responsible authorities. The codes may change and

may not be reflected in this document.

Safety Warnings

Field wiring errors or damage may present hazardous voltages inside the

enclosure. Treat all wires and boards in the enclosure as hazardous until

checked and validated as safe.

Interlogix recommends the use of personal protection equipment, such

as gloves, glasses, voltage detectors and meters for all installation and

maintenance operations.

Enclosure Access Restrictions

To comply with Australian standard AS/NZS 60950-1, access to the interior of the

enclosure:

Must be restricted to suitably trained and qualified installation and

maintenance technicians.

Must require the use of a tool.

These restrictions can be met by implementing one or more of the following

options:

Fit a lock to the enclosure. Ensure that the unit is locked when

unsupervised.

Tighten the door screws ¼ turn beyond finger tight (i.e. > 2Nm) using a

tool.

Secure the door with M6 standard or tamper proof screws (not

supplied), firmly tightened.

9

Page 10

Installing the Network Access Controller

Installation guidelines

Installers must adhere to any country dependent requirements and local

applicable standards.

• Installation must be performed in accordance with AS/NZS 2201.

• The installation environment must comply with environmental

specifications.

• The Network Access Controller, as well as all other boards with earth

terminals must be earthed according to the recommendations in the

section “System earthing" in Appendix D: Cabling requirements on page

36.

• The batteries used with this unit must comply with the requirements

provided in the section “Batteries” on page 17.

• Avoid loops of wire inside the enclosure, and route cables so that they do

not lie on top or underneath the printed circuit board. The use of cable ties

is recommended and improves neatness of the wiring within the box. All

wires entering the enclosure should be secured near point of entry, as

required by applicable codes.

Installation procedure

The Network Access Controller must be installed in an approved, compatible

enclosure, as detailed in the Specifications table on page 7. Ensure the

enclosure has been mounted on the wall and the transformer is installed in the

enclosure before mounting the Network Access Controller. Refer to the enclosure

installation manual for the details.

Mounting Network Access Controller in the enclosure

The installation procedure is as follows:

1. Install six standoff board mounts for the TS1066B board in the enclosure.

Refer to the enclosure installation for standoff mount location and fitment.

2. Remove the TS1066 board from its antistatic bag.

3. Use six M3 x 10 pan head screws to fix the board to the enclosure’s

standoffs. Refer to Figure 2 on page 13 for the mounting hole locations.

4. Combine terminal blocks as appropriate (e.g. 2 x 3-way, 2-way + 3-way, 2

x 2-way) and attach to the headers (e.g. 6-way, 5-way, 4-way) around the

periphery of the board.

5. If the Network Access Controller is to be connected to a ChallengerPlus

then its address must be configured. Refer to “DIP switch settings” on

page 11.

10

Page 11

LAN

Address

Polled as

S1-1

S1-2

S1-3

S1-4

LAN 1

1

DGP 1

I O O

O

LAN 1

2

DGP 2

O I O

O

LAN 1

3

DGP 3

I I O

O

LAN 1

4

DGP 4

O O I O LAN 1

5

DGP 5

I O I O LAN 1

6

DGP 6

O I I O LAN 1

7

DGP 7

I I I O LAN 1

8

DGP 8

O O O

I

LAN 1

9

DGP 9

I O O

I

LAN 1

10

DGP 10

O I O

I

LAN 1

11

DGP 11

I I O

I

LAN 1

12

DGP 12

O O I I LAN 2

1

DGP 17

I O O

O

LAN 2

2

DGP 18

O I O

O

LAN 2

3

DGP 19

I I O

O

LAN 2

4

DGP 20

O O I

O

LAN 2

5

DGP 21

I O I O LAN 2

6

DGP 22

O I I O LAN 2

7

DGP 23

I I I O LAN 2

8

DGP 24

O O O

I

LAN 2

9

DGP 25

I O O

I

LAN 2

10

DGP 26

O I O

I

LAN 2

11

DGP 27

I I O

I

LAN 2

12

DGP 28

O O I

I

Legend: I = ON, O = OFF

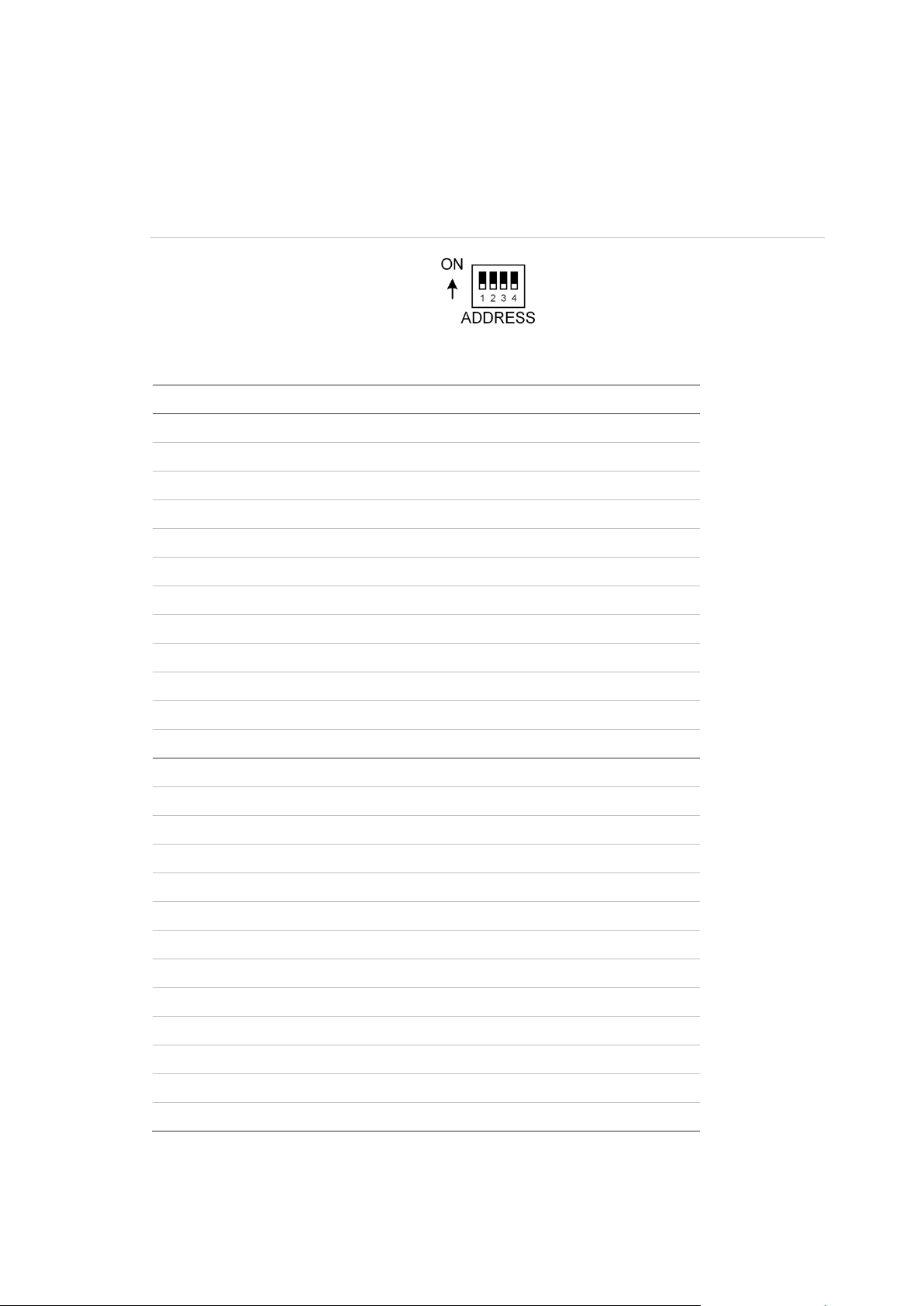

DIP switch settings

If a Network Access Controller is connected to a ChallengerPlus panel’s system

LAN, then it must be addressed as a DGP in the range 1 to 12. Use the foursegment Address DIP switch (Figure 2 on page 13, item 36) to set the address.

Figure 1: Address DIP switch

Table 2: DIP switch settings

11

Page 12

Connections

Figure 2 on page 13 identifies the locations and details of the connectors and

other items. See “Appendix D: Cabling requirements” on page 36 for

recommendations for the application and wiring of Challenger equipment.

12

Page 13

Figure 2: TS1066B board details

13

Page 14

Figure 2 legend

Item

Description

1.

Mounting Hole. Ensure all standoffs are used.

2.

AC power input terminals. Details provided in Specifications.See Power Input on page 16.

3.

Earth terminal. Connect the power earth wire from the enclosure’s mains transformer to

the earth terminal. See System earthing in Appendix D: Cabling requirements.

Data cable shields can also be connected.

4.

Battery 1 terminals. See Batteries on page 17.

5.

Battery 1 terminals. See Batteries on page 17.

6.

Auxiliary power output. See Auxiliary power terminals on page 19.

7.

Siren Output. See Siren on page 20.

8.

ChallengerPlus LAN interface

See: RS-485 Networks on page 21.

Appendix D: Cabling requirements on page 36

9.

Tamper switch input.

Connect the TAMP T and TAMP C terminals to the panel tamper switch in the enclosure.

Short circuit for sealed, open circuit for unsealed. Must be sealed if not used.

Can only be used with normally closed contacts such as the panel tamper switches.

See enclosure manual for tamper switch details.

10.

Relay and lock power connections for four doors.

Refer to Door lock relay wiring on page 26

11.

Earth terminal.

Connection point for cable shields or for earthing other boards connected to the TS1066B

in the enclosure. Preferred length should be approximately 60mm.

Refer to System earthing in Appendix D: Cabling requirements

12.

Input terminals. See Inputs on page 26.

13.

Relay expansion connector.

10 pin plugin cable socket for relay expansion modules.

See Relay expansion on page 28.

14.

PWR Link

Power link for relay expansion cards.

Refer to Relay expansion on page 28.

15.

Micro-B USB port (USB cable not supplied).

16.

Ethernet port (Ethernet cable not supplied).

17.

Heartbeat LED. See LED indicators on page 29.

18.

Bus 1 quick connect header

See RS-485 buses on page 21

Note: This connector is not a STU port.

19.

BUS 2 connector

See RS-485 buses on page 21

20.

BUS 1 connector

See RS-485 buses on page 21

21.

Bus 1 quick connect header

See RS-485 buses on page 21

Note: This connector is not a STU port.

14

Page 15

Item

Description

22.

Lock power 2 quick connect header

See Lock power on page 25

23.

BUS1 Rx LED. See LED indicators on page 29.

24.

BUS 1 Tx LED. See LED indicators on page 29.

25.

Bus 1 TERM link. See Terminating the RS-485 on page 25.

26.

BUS 2 Rx LED. See LED indicators on page 29.

27.

BUS 2 Tx LED. See LED indicators on page 29.

28.

Bus 2 TERM link. See Terminating the RS-485 on page 25.

29.

ChallengerPlus LAN Rx LED. See LED indicators on page 29.

30.

ChallengerPlus LAN Tx LED. See LED indicators on page 29.

31.

ChallengerPlus LAN TERM link. See Terminating the RS-485 on page 25.

32.

Lock power 1 quick connect header.

See Lock power on page 25.

33.

Ethernet 10/100 Mbps LED. See LED indicators on page 29.

34.

Ethernet Link Active LED. See LED indicators on page 29.

35.

Test links (not fitted during normal operations). Refer to Defaulting the Network Access

Controller on page 31.

36.

System Ready LEDs. See LED indicators on page 29.

37.

Address selection DIP switch (If connecting to a ChallengerPlus panel). Refer to DIP

switch settings on page 11.

38.

Relay coil active LED. See LED indicators on page 29

15

Page 16

Figure 3 below details the wiring for terminal blocks in Figure 2, items 1 through 8.

Figure 3: Connection details for terminal blocks

Power Input

AC power input for the NAC is provided via the two unpolarised AC terminals.

Power is typically provisioned from the transformer fitted to the enclosure in

which the NAC is installed.

The NAC AC voltage requirements are specified in Specifications.

The enclosure installation manual provides further details for the transformer,

along with fuse location and specifications.

Notice! Transformers supplied by Interlogix have internal thermal fuses. Shorting

the AC leads together may blow the thermal fuse before the replaceable fuse can

react, rendering the unit inoperative.

Notice! In case of a worn, pinched or otherwise damaged transformer lead, the

transformer must be replaced in order to avoid hazard.

The transformer leads supply high currents to the board. Poor connections lead

to excessive voltage drop and can affect system performance.

At the board connection, the installer must ensure that:

a) Terminal wiring is performed with the transformer power input disconnected

16

Page 17

b) The bare wire ends are neatly dressed and fully inserted into the terminal

housing. Less than 2mm of exposed wire should be visible after termination.

c) The complete bundle of wire strands is inserted into the screw terminal. No

broken strands should be visible.

d) There are no free strands outside of the metal block in the terminal housing.

e) The retaining screw is correctly torqued.

Batteries

The Network Access Controller requires battery backup to maintain functionality

when primary power is lost. Two independent battery channels are provided for

this purpose.

Key battery requirements are listed in the Electrical section of Specifications on

page 5. The table does not specify battery dimensions, capacity and temperature

ratings as they are installation dependent. The installer is responsible for

ensuring that:

a) The specified battery or batteries, in conjunction with the configured

system load and TS1066 charger settings, provide the required system

backup and recharge times.

b) The battery operating temperature range is compatible with the specific

TS1066 installation environment; a minimum range of 0°C to +40°C is

recommended.

c) The batteries fit into the system enclosure and are oriented so that there is

no possibility of their uncovered terminals being bridged by metal when

the leads are not attached.

d) The system enclosure is properly sited and mounted to handle the

configured system weight and allow for safe installation and removal of the

batteries in compliance with the warnings in this manual and all local

codes and OHS requirements.

e) For scheduling on-going battery system checks as required by the

applicable standards and codes to ensure user safety, battery integrity

and system performance; a 3 monthly interval is suggested.

A fuse is required in the positive lead of each battery, as fitted in the

supplied battery leads; a spare is not provided. The fuse is specified in the

Electrical section of Specifications on page 7.

The battery leads are provided with receptacles to suit the 4.75mm FastOn tabs commonly used on 12V SLA batteries with 7Ahr and 12Ahr

capacities. Higher capacity batteries will have different terminal types,

necessitating the use of adaptors or modifications to the leads. When

modifying the leads:

a) Disconnect leads from the NAC.

b) Take care not to damage the fuse holder.

17

Page 18

c) Add sleeving or covers to any exposed metal on the modified battery

connection arrangement.

Notice! Batteries can supply very high currents. This can happen when terminals

are bridged by metalwork, wires, tools, jewelry, etc. The bridging metal can get

very hot, melt, or vaporize, leading to damage and serious injuries.

Take all necessary precautions to ensure safety, including covering bare

terminals, when transporting or replacing batteries.

Notice! Batteries can be large, heavy and have slippery cases. These factors

contribute to mishandling incidents such as slipping and dropping. Impact

damage can rupture the battery case, releasing hazardous chemicals. Slips and

drops can allow terminals to contact metal, or cause injuries to the installer or

others nearby. Take all necessary precautions to ensure safety, including not

working overhead or blind in cramped areas, covering bare terminals, and using

appropriate means to safely handle the awkward and heavy units.

Notice!

Worn, pinched or otherwise damaged battery leads must be replaced in order to

avoid hazard.

Battery fitment and replacement

The battery leads supply high currents to the board during fault conditions.

Poor connections lead to excessive voltage drop and can affect system

performance.

At the board connection, the installer must ensure that:

a) Terminal wiring is performed with the battery disconnected.

b) The bare wire ends are neatly dressed and fully inserted into the terminal

housing. Less than 2mm of exposed wire should be visible after

termination.

c) The complete bundle of wire strands is inserted into the screw terminal.

No broken strands should be visible.

d) There are no free strands outside of the metal block in the terminal

housing.

e) The retaining screw is correctly torqued.

f) On completion, the polarity is verified at the board (red to positive, black to

negative) prior to battery connection.

At the battery connection, the installer must ensure that :

a) The positive lead (red) is the first wire connected and the last wire

disconnected.

18

Page 19

b) The battery terminal polarity and open terminal voltage is validated prior to

a connection being made.

c) The battery tab and receptacle mate firmly and completely. It should not

be possible to remove the terminal with gentle force.

d) If a custom battery terminal is in use, the checks in the prior section

regarding wire dress, strand damage and connection firmness are

appropriately applied.

New batteries must be clearly marked with the date of installation in order

to facilitate future maintenance activities.

When batteries are replaced, the board should be queried using the

control software to validate the newly installed units.

When making voltage measurements at the battery terminals to establish

battery state, healthy batteries that have not been discharged in the

preceding 48hrs should measure >13.5V

The installer is responsible for identifying and specifying batteries within

an operating temperature range that measures up with the specific

TS1066 installation environment; a minimum range of 0°C to +40°C is

recommended.

A fuse is required in the positive lead of each battery. Each fuse must be a

3AG/3AB (6x32 mm) 8A, 250 VAC, slow blow (time lag) fuse, compliant with UL

248.14. Suitable parts include Littelfuse 0313008.HXP, Bel Fuse 3SB 8-R, and

Schurter 8020.5020.

The installer (or user) is responsible for scheduling on-going battery

system checks as required by the applicable standards and codes to

ensure user safety, battery integrity and system performance; a 3 monthly

interval is suggested.

The battery leads are designed to suit 4.75mm Fast-On tabs. SLA batteries with

7Ahr and 12Ahr capacities are available with these tabs as standard from many

suppliers.

Higher capacity batteries will have different terminal types, necessitating the use

of adaptors or modifications to the leads. In these situations, sleeving or covers

should be added to cover exposed metal on the battery tabs or connections.

Battery charging current

Nominal charging current is 600mA.

Auxiliary power terminals

Connect the AUX POWER +12 and AUX POWER − output terminals to devices

that require 12V DC power, such as detectors. Three sets of auxiliary power

19

Page 20

output terminals are provided: if you need more than three connections, you can

use a TS0844 Power Distribution Board or TS1044 Power Distribution Board to

increase the number of terminals.

Note: Network Access Controller system design should consider the fuse

partitioning and load limitations specified in Appendix B: Output fusing and user

current limits on page 34.

Siren

Connect the OUT S+ and OUT S– terminals to an 8 Ω siren speaker or two 8Ω

siren speakers in parallel. Alternatively, connect a device requiring 12VDC

power.

The OUT S+ terminal is always powered. The OUT S- terminal is switched

according to the Siren SW settings.

A 1K 1/4 watt resistor (supplied) should be connected across the OUT S+ and

OUT S– terminals:

a) At the load side when driving digital inputs or other light loads.

b) At the terminals when no device is connected.

Note: Network Access Controller system design should consider the fuse

partitioning and load limitations specified in Appendix B: Output fusing and user

current limits on page 34.

Warning: The siren type must be configured correctly in CTPlus. Specifying a

siren type of DC Volts when there is an 8 Ω siren connected to the Network

Access Controller may damage the siren.

20

Page 21

RS-485 Networks

The TS1066 provides three RS485 networks;

• The ChallengerPlus Lan (Figure 2, item 8)

• RS485 BUS1 (Figure 2, item 19)

• RS485 BUS2 (Figure 2, item 20)

All network interfaces have similar wiring requirements which are detailed

below in section RS485 cabling.

ChallengerPlus LAN

The PANEL (TECOM BUS) connector is used to connect the Network Access

Controller to a ChallengerPlus LAN, if required by its operating mode.

There is no power terminal on this interface: the Network Access Controller is

a slave device on the ChallengerPlus LAN, so it is not expected to power the

host, and its operating current is too high to be supplied by the host.

RS-485 buses

The Network Access Controller can have up to 16 RAS devices such as

keypads, card readers, arming stations, or Smart Door Controllers on each

BUS (local LAN). The Network Access Controller can also have up to 15 DGP

devices on BUS 1 and up to 16 DGP devices on BUS 2.

Each BUS supports protocols other than Tecom, namely OSDP v2 (Open

Supervised Device Protocol), SALLIS by SALTO, and Aperio. The protocol to

be used on each BUS can be independently configured.

All network interfaces have similar wiring requirements which are detailed

below section RS485 cabling.

Note: Devices connected to the RS-485 buses and powered by the Network

Access Controller must comply with Appendix B: Output fusing and user

current limits on page 34

Devices can be connected to the Network Access Controller via the 4-pin RS485 terminals for BUS 1 (Figure 2 on page 13, item 19) or BUS 2 (Figure 2 on

page 13, item 18).

Alternatively, devices can be connected to BUS 1 via the 4-pin plug-in RS485 sockets (Figure 2 on page 13, items 17 and 20). The sockets are for easy

connection to the expander boards that support the connection such as the

TS1061 Dual Wiegand Interface.

RS-485 cabling

Interlogix recommends that the RS485 network wiring comply with the

following:

* Use 2 pair twisted shielded data cable such as Belden 8723.

* Keep the total length of wire on each RS-485 network below1.5 km.

* Networks must not span buildings or separate earth zones without the use

of LAN isolation devices such as TS0893.

21

Page 22

Using the screw terminal interfaces:

The wire colours below assume the use of the recommended cable and follow

the ChallengerPlus LAN conventions.

For communications, the following connections are required:

The - terminal is the interface 0V reference. Connect it to the black

wire.

The D+ terminal is data positive. Connect it to the white wire.

The D- terminal is data negative. Connect it to the green wire.

The data cable shield should be connected or insulated according to

the system earthing plan. Earthing points are identified figure 2 as

items 2 and 10.

On the RS485 BUS1 and BUS2 interfaces, the +12 terminal is able to

provide +12 V to RASs or other remote devices. Connect the +12

terminal to the red wire when using this feature.

Note: Devices connected to the RS-485 buses and powered by the

Network Access Controller must comply with Appendix B: Output

fusing and user current limits on page 34

When multiple devices are to be connected to the same network, the

use of TS0844 or TS1044 Power Distribution Boards is recommended

to increase the number of terminals and simplify the wiring effort.

To prevent failures, false alarms and hazards, all wires inside the

enclosure should be insulated up to the point of contact. Typically less

than 2mm of bare conductor should be exposed outside of the screw

terminal blocks and all conductor strands bound by the crew.

Damaged insulation, poor workmanship and other observed faults

must be corrected as soon as possible.

Using the plug-in BUS 1 sockets:

To easily connect a Tecom peripheral to BUS 1, connect a 4-way RS-485

cable (supplied with the Tecom peripheral) to one of the 4-pin plug-in RS-485

cable sockets (Figure 2 on page 13, items 17 and 20).

Refer to Figure 4 on page 23 for example connections of 4-way RS-485

cables from a Network Access Controller to a Tecom peripheral (items B and

D).

22

Page 23

Figure 4: Example TS1066 to TS1061 cable connections for RS-485 and lock power

23

Page 24

Figure 5 External Power Supply Connection to RAS

24

Page 25

Figure 6: Connecting a Smart Card Reader to the one of the buses

Terminating the RS-485

All RS-485 devices (including the panel) use a 470 Ω RS-485 termination resistor

where required. RS-485 termination resistors are used to set the impedance of

the RS-485 to around 220 Ω in order to minimise noise. The termination resistor

may be external or on-board (devices with an on-board resistor use a link to set

the RS-485 termination to ON).

A RS-485 should have only two devices with the RS-485 termination set to ON

(or the RS-485 termination resistor fitted):

• In a straight RS-485 configuration, the TERM links are ON at the

ChallengerPlus panel and the most distant device.

• In a star RS-485 configuration, the TERM links are ON at the two devices

that are the furthest apart (and OFF at the ChallengerPlus panel).

In a completely connected (but powered down) system, you can check for correct

LAN termination by measuring the resistance across the D+ and D− terminals:

• 0 Ω indicates a short circuit in the cabling

• 160 Ω or less indicates that too many devices are terminated

• 220 Ω is good

• 470 Ω or more indicates that not enough devices are terminated

Lock power

There are two cable sockets providing extra lock power (Figure 2 on page 13,

items 21 and 31), if required. The sockets are for easy connection to Tecom

peripheral that support the connection, such as the TS1061 Dual Wiegand

Interface.

Connect a 2-way lock power cable (supplied with the Tecom peripheral) to one of

the 2-pin plug-in lock power sockets.

Refer to Figure 4 on page 23 for example connections of 2-way lock power

cables from a Network Access Controller to a Tecom peripheral (items A and C).

Note: Devices connected to the RS-485 buses and powered by the Network

Access Controller must comply with Appendix B: Output fusing and user current

limits on page 34

25

Page 26

Door lock relay wiring

Figure 7 below details the wiring for the relay terminal blocks.

Figure 7:

Note: A suppression diode such as 1N4004 must be used in door lock circuits.

The diode must be co-located with the lock.

When using on board 12V power for locks, refer to Appendix B: Output fusing

and user current limits on page 34.

When powering locks from an external power supply or using the relays for other

purposes, the relay contact rating must be observed.

Maximum switching capacity (resistive/load):3A, 30VDC.

Minimum switching capacity: 100mA, 5VDC

Inputs

Inputs can be configured as an alarm input if the Network Access Controller is

connected to a ChallengerPlus system via the LAN.

A Challenger system can receive alarm signals from:

• The Challenger panel’s on-board inputs

• Inputs connected to Data Gathering Panels (DGPs)

Each pair of input terminals may be connected to a device such as a detector or

reed switch.

26

Page 27

The Network Access Controller can monitor its input circuits for four states

(sealed, unsealed, open circuit, and short circuit). This is accomplished by using

two end-of-line (EOL) resistors in each input circuit, as shown in Figure 8 below.

Note: A Network Access Controller can have various EOL resistor values for

input tamper monitoring (the default is 10 kΩ resistors).

Install EOL resistors in input circuits at the end of the circuit.

If an alarm device is connected, place the EOL resistors at the device’s

connections.

If an input is not used, you do not need to connect an EOL resistor.

Tip: Use sleeves on the resistor leads to prevent accidental shorting.

Figure 8: Four-state monitored input circuits

When four-state monitoring is used, the panel uses the circuit’s resistance to

determine the state of the input. In this example, 10 kΩ EOL resistors have been

used:

• 10 kΩ indicates sealed

• 5 kΩ or 20 kΩ indicates unsealed

• Open circuit indicates input tamper

• Short circuit indicates input tamper

To use four-state monitoring, input tamper monitoring must be set to Yes (Install

menu option 7, System Options) for the ChallengerPlus panel, and tamper

monitoring must be enabled for the Network Access Controller. See the TS1066

Network Access Controller Programming Manual for information on enabling

tamper monitoring.

Alternatively, the ChallengerPlus system can be configured to monitor inputs for

two states (sealed and unsealed). This is accomplished by using one resistor in

each circuit, as shown in Figure 9 on page 28.

27

Page 28

Figure 9: Two-state monitored input circuits

The panel uses the circuit’s resistance to determine the state of the input. In this

example, 10 kΩ EOL resistors have been used:

• 10 kΩ indicates sealed

• Open circuit or short circuit indicates unsealed

To use two-state monitoring, tamper monitoring must be disabled for the Network

Access Controller. See the TS1066 Network Access Controller Programming

Manual for information on disabling tamper monitoring.

Note: Two-state monitoring is not compatible with input types 33 or 40. See the

MAPROG-TS1066 R1.2 TS1066 Network Access Controller Programming

Manual for details.

Connecting expansion modules

Relay expansion

The Network Access Controller has four onboard relays that are assigned the

first four relay numbers.

If relay expansion cards are used, additional relays are numbered according to

their physical address, starting at 5. The Network Access Controller allows for

relay mapping to be programmed such that a physical relay number (e.g. 5) can

be mapped to a relay number in the ChallengerPlus system (e.g. 21).

One TS0840 Four-Way Relay Card may be connected to the Relay Card

(Figure 2 on page 13, item 12) to add four relays. Alternatively, TS0841

Eight-Way Clocked Relay Expansion Boards or TS0842 16-Way Clocked Open

Collector Expansion Boards may be connected to the Relay Card individually or

daisy-chained to add eight relays per card (for TS0841) or 16 open collector

outputs per card (for TS0842).

28

Page 29

Item

LED

Item

number

Description

Network

Access

Controller

Heart Beat

16

Slow flashing indicates normal operation.

Rapid flashing if firmware update or Network Access Controller default

is in process.

System Ready

35

Not currently used.

System LAN

Rx

30

Flashing indicates polling data being received from the ChallengerPlus

panel on the system LAN.

Tx

29

Flashing indicates the Network Access Controller is replying to polling

from the ChallengerPlus panel on the system LAN.

Off indicates that the Network Access Controller is not correctly

addressed, the ChallengerPlus panel is not programmed to poll the

DGP address, or there is no ChallengerPlus panel connected.

BUS 1

Rx

22

Flashing indicates remote units, such as readers, replying to polling on

BUS 1

Tx

23

Rapid flashing if a remote unit is connected to BUS 1.

Off if no remote unit is connected to BUS 1.

BUS 2

Rx

25

Flashing indicates remote units replying to polling on BUS 2.

Tx

26

Rapid flashing if a remote unit is connected to BUS 2.

Off if no remote unit is connected to BUS 2.

Note: If TS0841 and/or TS0842 boards are used, then a value for Relay

Controllers must be programmed for the Network Access Controller in CTPlus,

where 1 represents each eight relays or open collector outputs. Refer to the

TS1066 Network Access Controller Programming Manual or CTPlus online help

for details.

The PWR link (Figure 2 on page 13, item 13) enables the Network Access

Controller to power a connected relay expansion module. Remove the link if the

relay card is powered from an external 12 V supply. Note: If two relay boards are

used, link should be removed and the relay boards should be powered from

external supply.

Note: Devices connected to the RS-485 buses and powered by the Network

Access Controller must comply with Appendix B: Output fusing and user current

limits on page 34

LED indicators

LEDs on the printed circuit board indicate the state of the Network Access

Controller, the ChallengerPlus system LAN, the local LANs (BUS 1 and BUS 2),

and Ethernet activity.

Table 3 below shows the LEDs for each of the items above. The numbers in the

Item number column indicate the LED location on the Network Access Controller

as shown in Figure 2 on page 13.

Table 3: LED indications

29

Page 30

Item

LED

Item

number

Description

Ethernet

Relay

Link Active

33

Flashing indicates Ethernet activity.

10/100 Mbps

Relay coil active

LED

32

38

On indicates Ethernet speed is 100Mbps.

On when relay coils is energized.

30

Page 31

Powering up the Network Access Controller

In case the Network Access Controller will be connected to a ChallengerPlus

panel

Ensure the ChallengerPlus system LAN is connected to the Panel

terminals (Figure 2 on page 13, item 7)

Ensure the Network Access Controller’s address is set. (Refer to DIP

switch settings on page 11).

Ensure that jumpers on board are set correctly and that TEST LINKS are not

fitted.

After power-up, check the Heart Beat LED (Figure 2 on page 13, item 16). See

LED indicators on page 29.

Note: Devices connected to the RS-485 buses and powered by the Network

Access Controller must comply with Appendix B: Output fusing and user current

limits on page 5.

Refer to the TS1066 Network Access Controller Programming Manual for

information on configuring the Network Access Controller.

Defaulting the Network Access Controller

You may want to perform a “default” to reset the Network Access Controller to its

factory default state and erase all programming.

To default the Network Access Controller:

1. Remove power to the Network Access Controller and wait for all LEDs to

turn off.

2. Fit test link 1 (Figure 2 on page 13, item 34) and repower the system. The

Heart Beat LED (Figure 2 on page 13, item 16) illuminates for about 20

seconds, flashes quickly for about 20 seconds to indicate reset mode, and

then flashes slowly to indicate normal mode.

Note: The Network Access Controller can only be defaulted in the

20-second interval when the Heart Beat LED is flashing quickly (in reset

mode). The Network Access Controller returns to normal mode

automatically to help protect against accidental reset.

3. Remove test link 1 when the Heart Beat LED is flashing quickly to default

the Network Access Controller.

31

Page 32

Defaulting the USB Comms Path

You may want to perform a “default” for USB.

To default the USB:

1. Access the NAC panel PCB.

2. Fit test link 1 (Figure 2 on page 13, item 34) momentarily, and then

remove the link.

On-Board Memory Retention

In the absence of any power source, the on-board capacitor storage will maintain

the real-time clock and system configuration/logs for 5 days under typical

circumstances.

Programming the Network Access Controller

Refer to the TS1066 Network Access Controller Programming Manual for

detailed information about programming the Network Access Controller.

32

Page 33

Appendix A: Standalone current draw

The current draw of the TS1066 running from battery power only is provided

below for bare configuration:

• Battery charging is off

• Siren is not active

• The tamper input is sealed (wire link, 0 Ω)

• All eight inputs are sealed (10 kΩ EOL resistors)

• The four on-board relays are not active

• There is no relay card attached

• USB is not connected

• The RS-485 system LAN is terminated and is connected to a terminated

ChallengerPlus panel Comms port.

• The local LANs (BUS 1 and BUS 2) are not terminated and not active (no

connection)

• Ethernet is not active.

Consumption = 226mA (whilst battery voltage is 12.0V)

• Active Ethernet adds 25mA.

• Each active relay coil adds 55mA.

Note: Relay coil current forms part of the allowable user current draw. Refer to

Appendix B: Output fusing and user current limits on page 34.

33

Page 34

Appendix B: Output fusing and user current

Device

Item number

Maximum current draw

Auxiliary power

5

0.81 A

Siren output

6

1.25 A

Four onboard relays

9

1.7 A each (when using lock

power 12v and 0v)

Active relay coil

9

55 mA

Relay card

12

0.5 A

BUS 1

17, 19, and 20

1.0 A total

BUS 2

18

0.5 A

Lock power 1

31

1.9 A

Lock power 2

21

1.25 A

limits

The current draw on the Network Access Controller for all user devices must not

exceed 3 A. This value excludes battery charging and standalone board current.

The Network Access Controller will shut down if this is exceeded.

In some environments, further restrictions on user current apply as detailed in

Appendix C.

On-board fuses provide over-current protection for devices as described in

Table 4 below. The numbers in the Item number column refer to items in Figure 2

on page 13.

Table 4: Maximum current draw per output

Consider the maximum current draw from the devices above when calculating

the total user current draw.

34

Page 35

Total User

current %

Appendix C: Operating temperature

The operating ambient (room) temperature for the Network Access Controller is 0

to 50°C.

If the Network Access Controller is to operate for prolonged periods in an

environment with an ambient temperature above 40°C, de-rate the user current

drawn from the Network Access Controller according to the chart in Figure 10

below.

Figure 10: Power derating chart

35

Page 36

Appendix D: Cabling requirements

This section contains recommendations for installers and electricians for the

application and wiring of Challenger equipment with respect to:

• System earthing

• Ethernet cabling

System earthing

The following requirements are essential to the reliable operation of the

Challenger system.

• The earth connection is provided in the enclosure transformer output lead. Do

not extend this wire to any device outside of the enclosure.

• Install LAN isolation devices between multiple buildings and maintain

independent earthing systems. For example, use TS0893, TS0894, or

TS0896 Isolation Interface modules to provide electrical isolation and/or to

extend distance.

Ethernet cabling

To comply with Class B radiated emissions the Ethernet cable should be cable

tied to the enclosure rear for a minimum length of 40cm.This can be a straight

run or a number of loops.

Power supply to RS-485 devices (refer to Figure 5 External Power Supply

Connection to RAS on page 24)

Devices on the Network Access Controller’s buses may be supplied from the

Network Access Controller’s 12V DC LAN output. Use an external 12V power

supply (such as TS0073 2 A Power Supply) when:

• The device is more than 100 m (data cable length) from the panel

• Electrical isolation is required

• More power is needed than can be provided by the LAN

When powering a LAN device from an external 12 V power supply:

• Connect the external power supply ‘+’ terminal to the device ‘+’ terminal.

Do not connect the power supply ‘+’ to the LAN ‘+’.

• Connect the external power supply ‘−’ terminal to the device ‘−’ terminal.

• Connect the LAN cable black wire ‘−’ to the device ‘−’ terminal.

36

Loading...

Loading...