Page 1

VERTICAL HOLLOW SHAFT WPI

HIGH THRUST with "P" BASE - LOW VOLTAGE

AMRCNH, (MAX-VHP™) NEMA PREMIUM [VHP]*

AMRCFP, (MAX-VH™) HIGH EFFICIENCY [VH_FP]*

APPLICATIONS:

z Deep Well Turbine Pumps z Irrigation z Fire Pumps*

z Fluid Handling Systems z Water/ Waste Water

FEATURES:

z Output Range: 7.5 - 800 HP

z Speed: 1800 RPM

z Enclosure: Weather Protected Type I (WPI)

z Voltage: 230/460V (Usable on 208V); 150HP and Larger is 460V Only

z Three Phase, 60 Hz, 1.15 Service Factor (Continuous on Sine Wave Power)

z Inverter Duty (PWM) per NEMA® MG-1 Part 31 at 1.0 Service Factor

z New Dual Column (60/50 Hz) Design Nameplate as Standard; 50 Hz Data 190/380V at 1.0 S.F.

z Standard Features: Coupling w/ Gib Key, Ball Type NRR, Drip/Splash Cover, Space Heaters (120V)

z 5000 Frames and Above also include Mounting Provisions for bearing RTD's and Insulated Bearing Housing

z Optional Capability for 175% High Thrust Requirement for 444 - 449TP Frames

z Motor Design Suitable to handle 2 stacked bearings; Motors will ship with 1 bearing and 1 spacer as Standard

z Class F Insulation with Phenolic Alkyd Resin Varnish

z Class B Temperature Rise

z NEMA Design B Torques

z Oversized Main Conduit Box Rotatable in 90 Degree Increments - Fully Gasketed with NPT Threaded Entrance

z Cast Iron Conduit Box for F#449TP and Below; Steel Plate Conduit Box for F#5000

z Designed for 40˚C Ambient Temperature

z Designed for 3300 ft. Elevation

z Counterclockwise (CCW) Rotation; Viewed from Top

z Cast Iron Frame & End Brackets

z 1045 Hollow Carbon Steel Shaft

z Aluminum Die Cast Squirrel Cage Rotor Construction for F#449TP and Below

z Squirrel Cage Copper or Copper Alloy Bar Rotor Construction for F#5000

z Paint System: Phenolic Rust Proof Base Plus Polyurethane Top Coat

z Paint Color for AMRC (MAX-VH™): Dark Gray - Munsell 7.5B 3.5/0.5

z Paint Color for AMRCNH (MAX-VHP™): Blue - Munsell 5PB 3/8

z Guide Bearings: 213 - 286TP frames are Grease Pre-packed Double Shielded Bearings (MULTEMP SRL)

324TP - 5009P frames are Re-Greasable (Mobil Polyrex EM)

z Thrust Bearings: 213 - 286TP frames are Re-Greasable Angular Contact (Mobil Polyrex EM);

324 - 449TP frames are Oil Lubricated Angular Contact; F#5000 and Above with Spherical Roller

z Oil Sight Glass for 324TP Frames and Above

z Oil Requirements: 300 S.S.U. @100°F

z Grounding Terminal Inside Main Box

z Stainless Steel Nameplate and Rodent Screens

z 12 Leads (PWS on 230V); Wye/Delta on 230V or 460V for 210TP–400TP

z 6 Leads (PWS on 230V, Wye/Delta on 460V for 444TP-5810P)

z Suitable for Inverter Use per NEMA MG-1 Part 31.4.4.2

10:1 Variable Torque with NRR. 10:1 C.T., 20:1 VT without NRR Using Braking in VFD

z Precautions should be taken to eliminate or reduce shaft currents that may be imposed on the motor by VFD

at stated per NEMA MG-1, part 31 for AMRCNH and Part 30 for AMRC.

(2)

(1)

Effective 07-08-18

Supercedes 03-24-17

EXTRAS/ OPTIONS:

Please refer to pages 147 - 154 which show common modifications that can be performed.

Notes:

* Fire Pump available. See product page for more details.

(1) Consult a Stock Product Application Specialist for suitability in higher ambient environments.

(2) Consult a Stock Product Application Specialist for suitability at higher elevations.

(3) Suitable for Wye/Delta start at 230V or 460V.

Page 2

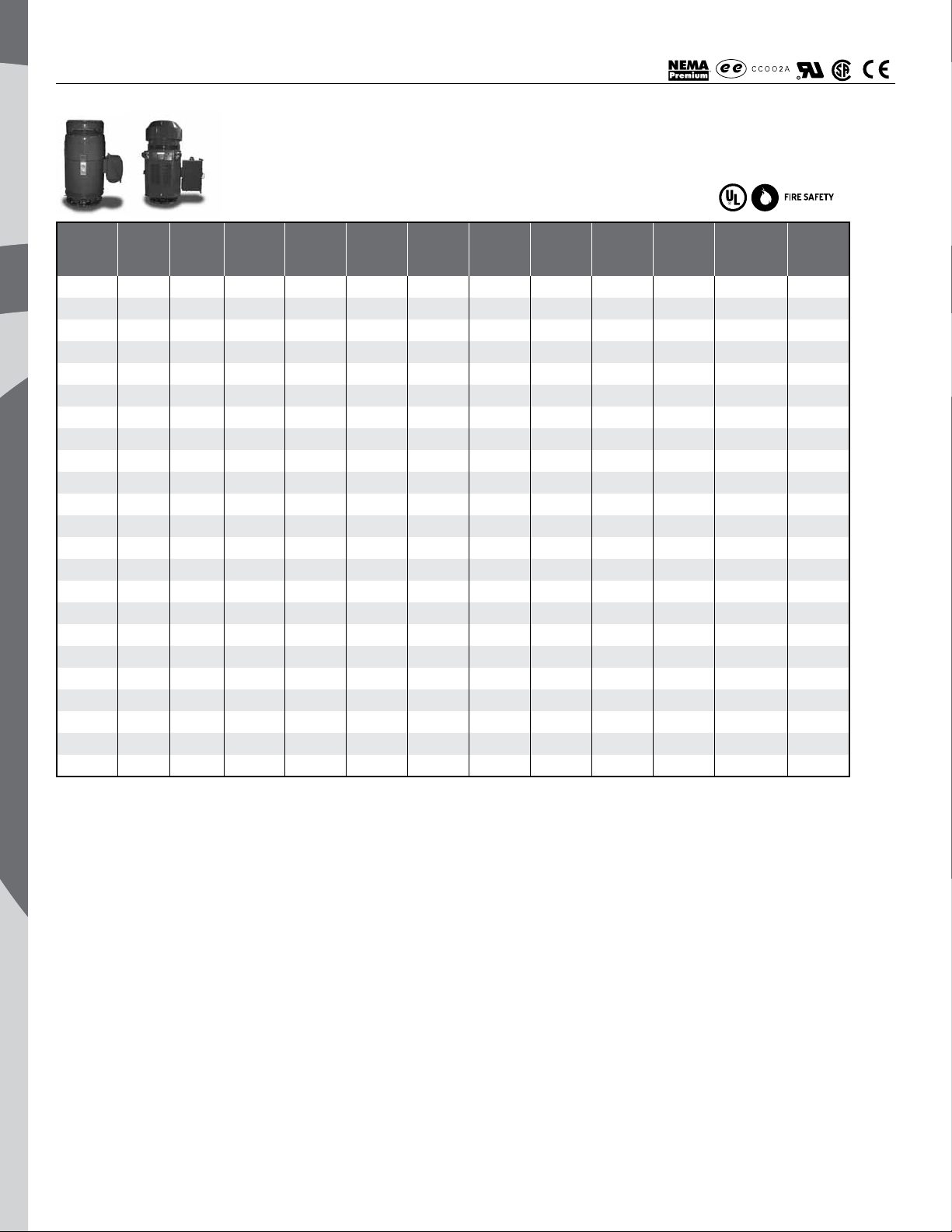

MAX-VHP™ VERTICAL HOLLOW SHAFT WPI

AMRCNH, (MAX-VHP™) NEMA PREMIUM [VHP]*

Effective 07-08-18

Supercedes 03-24-17

CAT. NO. HP RPM FRAME

VHP7/54 7.5 1800 213TP 91.0 81.0 9.6 2,600 10 20.25 1.001 227

VHP0104 10 1800 215TP 91.7 84.0 12.2 2,600 10 20.25 1.001 241

VHP0154 15 1800 254TP 93.0 83.0 18.2 3,350 10 23.38 1.001 349

VHP0204 20 1800 256TP 93.0 83.0 24.3 3,350 10 23.38 1.001 373

VHP0254 25 1800 284TP 93.6 85.0 29.4 3,350 10 24.75 1.001 480

VHP0304 30 1800 286TP 94.1 86.0 34.7 3,350 10 24.75 1.001 525

VHP0404 40 1800 324TP 94.1 86.0 46.3 5,700 16.5 28.22 1.188 716

VHP0504 50 1800 326TP 94.5 85.0 58.5 5,700 16.5 28.22 1.188 777

VHP0604 60 1800 364TP 95.0 85.0 69.5 6,000 16.5 31.16 1.188 892

VHP0754 75 1800 365TP 95.0 86.0 86.0 6,000 16.5 31.16 1.188 989

VHP1004 100 1800 404TP 95.4 85.5 115 7,900 16.5 36.94 1.501 1,278

VHP1254 125 1800 405TP 95.4 84.5 145 7,900 16.5 36.94 1.501 1,398

VHP1504 150 1800 444TP 95.8 86.0 171 10,700 16.5 44.78 1.501 1,815

VHP2004 200 1800 445TP 95.8 86.5 225 10,700 16.5 44.78 1.501 1,815

VHP2504 250 1800 445TP20 95.8 86.5 284 13,400 20 44.78 1.501 2,312

VHP3004 300 1800 447TP 95.8 87.5 337 13,400 20 49.78 1.688 2,841

VHP3504 350 1800 447TP 95.8 88.0 390 13,300 20 49.78 1.688 3,335

VHP4004 400 1800 449TP 95.8 88.5 444 13,200 20 53.91 1.938 3,818

VHP4504 450 1800 5009P 96.2 88.6 494 30,900 24.5 57.06 2.188 3,940

VHP5004 500 1800 5009P 96.2 88.8 548 30,900 24.5 57.06 2.188 4,070

VHP6004 600 1800 5808P 96.2 82.0 647 30,100 30.5 61.30 2.376 5,700

VHP7004 700 1800 5810P 96.2 90.7 751 30,100 30.5 68.78 2.376 6,100

VHP8004 800 1800 5810P 96.2 90.7 859 30,100 30.5 68.78 2.376 6,400

Notes:

* Fire Pump available as made to order. Fire Pump Certificate complies with ANSI/UL 1004-5. Certificate# 20120717 - EX6569.

(1) Delivery for Fire Pump Duty motor (Catalog Number + FP) is standard 5 - 10 working days after receipt of order if standard motor is in stock.

(2) Fire Pump Duty Motor pricing includes: adding UL nameplate, restamping original nameplate to new "VHP_FP" catalog number.

(3) See page125 in order to confirm the TWMC standard coupling size is suitable for customer requirements or to select an alternate coupling size.

Required coupling size must be noted on all vertical hollow shaft motors orders. Coupling will be changed out prior to shipping if a non-TWMC

standard coupling size is needed.

(4) All data subject to change without notice.

FL EFF

%

FL PF

%

FL

AMPS

460V

DOWN

THRUST

lbs.)

BD DIM

in.)

CD DIM

in.)

BX DIM

in.)

APPROX.

SHIPPING

WT. lbs.

Page 3

MAX-VHP™ VERTICAL HOLLOW SHAFT WPI

AMRCNH, (MAX-VHP™) NEMA PREMIUM [VHP_FP]*

Effective 07-08-18

Supercedes 03-24-17

FIRE

PUMP

CAT. NO.

VHP7/54FP 7.5 1800 213TP 91.0 81.0 9.6 2,600 10 20.25 1.001 227

VHP0104FP 10 1800 215TP 91.7 84.0 12.2 2,600 10 20.25 1.001 241

VHP0154FP 15 1800 254TP 93.0 83.0 18.2 3,350 10 23.38 1.001 349

VHP0204FP 20 1800 256TP 93.0 83.0 24.3 3,350 10 23.38 1.001 373

VHP0254FP 25 1800 284TP 93.6 85.0 29.4 3,350 10 24.75 1.001 480

VHP0304FP 30 1800 286TP 94.1 86.0 34.7 3,350 10 24.75 1.001 525

VHP0404FP 40 1800 324TP 94.1 86.0 46.3 5,700 16.5 28.22 1.188 716

VHP0504FP 50 1800 326TP 94.5 85.0 58.5 5,700 16.5 28.22 1.188 777

VHP0604FP 60 1800 364TP 95.0 85.0 69.5 6,000 16.5 31.16 1.188 892

VHP0754FP 75 1800 365TP 95.0 86.0 86.0 6,000 16.5 31.16 1.188 989

VHP1004FP 100 1800 404TP 95.4 85.5 115 7,900 16.5 36.94 1.501 1,278

VHP1254FP 125 1800 405TP 95.4 84.5 145 7,900 16.5 36.94 1.501 1,398

VHP1504FP 150 1800 444TP 95.8 86.0 171 10,700 16.5 44.78 1.501 1,815

VHP2004FP 200 1800 445TP 95.8 86.5 225 10,700 16.5 44.78 1.501 1,815

VHP2504FP 250 1800 445TP20 95.8 86.5 284 13,400 20 44.78 1.501 2,312

VHP3004FP 300 1800 447TP 95.8 87.5 337 13,400 20 49.78 1.688 2,841

VHP3504FP 350 1800 447TP 95.8 88.0 390 13,300 20 49.78 1.688 3,335

VHP4004FP 400 1800 449TP 95.8 88.5 444 13,200 20 53.91 1.938 3,818

Notes:

* Fire Pump available as made to order. Fire Pump Certificate complies with ANSI/UL 1004-5. Certificate# 20120717 - EX6569.

(1) Delivery for Fire Pump Duty motor (Catalog Number + FP) is standard 5 - 10 working days after receipt of order if standard motor is in stock.

(2) Fire Pump Duty Motor pricing includes: adding UL nameplate, restamping original nameplate to new "VHP_FP" catalog number.

(3) See page 125 in order to confirm the TWMC standard coupling size is suitable for customer requirements or to select an alternate coupling size.

Required coupling size must be noted on all vertical hollow shaft motors orders. Coupling will be changed out prior to shipping if a non-TWMC

standard coupling size is needed.

(4) All data subject to change without notice.

HP RPM FRAME

FL EFF

%

FL PF

%

FL

AMPS

460V

DOWN

THRUST

lbs.)

BD DIM

in.)

CD DIM

in.)

BX DIM

in.)

APPROX.

SHIPPING

WT. lbs.

Page 4

MAX-VH™ VERTICAL HOLLOW SHAFT WPI

AMRCFP, (MAX-VH™) HIGH EFFICIENCY [VH_FP]*

Effective 07-08-18

Supercedes 03-24-17

FIRE

PUMP

CAT. NO.

VH7/54FP 7.5 1800 213TP 88.5 85.0 9.35 2,600 10 20.25 1.001 227

VH0104FP 10 1800 215TP 89.5 86.5 12.1 2,600 10 20.25 1.001 241

VH0154FP 15 1800 254TP 91.0 88.0 17.5 3,350 10 23.38 1.001 349

VH0204FP 20 1800 256TP 91.0 88.0 23.4 3,350 10 23.38 1.001 373

VH0254FP 25 1800 284TP 91.7 86.0 29.7 3,350 10 24.75 1.001 480

VH0304FP 30 1800 286TP 92.4 86.5 35.1 3,350 10 24.75 1.001 525

VH0404FP 40 1800 324TP 93.0 88.0 45.7 5,700 16.5 28.22 1.188 716

VH0504FP 50 1800 326TP 93.0 88.0 57.0 5,700 16.5 28.22 1.188 777

VH0604FP 60 1800 364TP 93.6 84.5 71.0 6,000 16.5 31.16 1.188 892

VH0754FP 75 1800 365TP 94.1 84.5 88.5 6,000 16.5 31.16 1.188 989

VH1004FP 100 1800 404TP 94.1 86.0 116 7,900 16.5 36.94 1.501 1,278

VH1254FP 125 1800 405TP 94.5 87.5 142 7,900 16.5 36.94 1.501 1,398

VH1504FP 150 1800 444TP 95.0 86.0 172 10,700 16.5 44.78 1.501 1,815

VH2004FP 200 1800 445TP 95.0 86.5 228 10,700 16.5 44.78 1.501 1,815

VH2504FP 250 1800 445TP20 95.4 86.5 284 13,400 20 44.78 1.501 2,312

VH3004FP 300 1800 447TP 95.4 87.5 337 13,400 20 49.78 1.688 2,841

VH3504FP 350 1800 447TP 95.4 88.0 390 13,300 20 49.78 1.688 3,335

VH4004FP 400 1800 449TP 95.4 88.5 444 13,200 20 53.91 1.938 3,818

Notes:

* Fire Pump available as made to order. Fire Pump Certificate complies with ANSI/UL 1004-5. Certificate# 20120717 - EX6569.

(1) Delivery for Fire Pump Duty motor (Catalog Number + FP) is standard 5 - 10 working days after receipt of order if standard motor is in stock.

(2) Fire Pump Duty Motor pricing includes: adding UL nameplate, restamping original nameplate to new "VHP_FP" catalog number.

(3) Per DOE regulations, this High Efficiency motor line inventory will be available through June 2018, or until current inventory has been depleted,

(4) Once product listed on this page has been depleted from current stock, that model will be sold only as Fire Pump.

(5) Please see our new line of Premium Efficient motors on page 101 or contact your Application Specialist for details.

(6) See page 125 in order to confirm the TWMC standard coupling size is suitable for customer requirements or to select an alternate coupling size.

(7) All data subject to change without notice.

HP RPM FRAME

whichever occurs first.

Required coupling size must be noted on all vertical hollow shaft motors orders. Coupling will be changed out prior to shipping if a non-TWMC

standard coupling size is needed.

FL EFF

%

FL PF

%

FL

AMPS

460V

DOWN

THRUST

lbs.)

BD DIM

in.)

CD DIM

in.)

BX DIM

in.)

APPROX.

SHIPPING

WT. lbs.

Loading...

Loading...