Teco THREE PHASE INDUCTION MOTORS MAINTENANCE Manual

INSTALLATION AND

MAINTENANCE INSTRUCTIONS

FOR THREE PHASE

INDUCTION MOTORS

Frames 56 and 143T - 449TZ

RECEIVING

1. Check nameplate data.

2. Check whether any damage has occurred during transportation.

3. After removal of shaft clamp, turn shaft by hand to check that it turns freely.

4. If motoristobe reshipped (alone or installed toanother pieceofequipment) the shaft must again

be clamped to prevent axial movement.

Note: Remove the bearing clamp before turning the shaft on 284T-449TZ frame motors.

WARNING

THE FOLLOWING SAFETY PRECAUTIONS MUST BE OBSERVED:

1. Electric rotatingmachinery and highvoltage can cause serious or fatal injury if improperly

installed, operated or maintained. Responsible personnel should be familiarized with

NEMA MG-1; Safety Standards for Construction and Guide Selection. Installation and Use of

Electric Motors and Generators; National Electric Code and all local safety requirements.

2. Whenservicing, allpowersources tothe motor andtothe accessory devices should be

de-energized and disconnected and all rotating parts should be at standstill.

3. Liftingmeans, when supplied, are intendedfor lifting the motor only. Whentwo lifting

devices are supplied with the motor a dual chain must be used.

4. Suitable protection must be used when working near machinery with high noise levels.

5. Safeguard or protective devices must not be by-passed or rendered inoperative.

6. The frame of this machine must be grounded in accordance with the National Electric Code and

applicable local codes.

7. A suitable enclosureshould be provided to prevent access to the motor by otherthan

authorized personnel. Extra caution should be observed around motors that are

automatically or have automatic re-setting relays as they may restart unexpectedly.

8. Shaft key must be fully captive or removed before motor is started.

9. Provide proper safeguards for personnel against possible failure of motor-mounted brake,

particularly on applications involving overhauling loads.

10.Explosion proof motors are constructed to comply with the label service procedure manual, repair

of these motors must be made by TECO-Westinghouse Motor Company or U/L listed service

center in order to maintain U/L listing.

LOCATION

1. Drip-proof motors are intendedfor use whereatmosphere is relativelyclean, dry,well

ventilated and non-corrosive.

2. Totally enclosed motors may be installed where dirt, moisture, or dust are present and in outdoor

locations.

3. Explosion-proof motors are built for use in hazardous locations as indicated by

Underwriters’ label on the motor.

4. Chemical dutyenclosedmotors are designedfor installation in high corrosion or excessive

moisture locations.

Note: in all cases, no surrounding structure should obstruct normal flow or

ventilating air through or over the motor.

MOUNTING

2/82537

1/26090

5/8

120

180

1. Mount motor securely on a firm, flat base. All ball bearing normal thrust motors up to and

including 256T frame size may be side-wall or ceiling mounted; all others check nearest

TECO-Westinghouse office for mounting recommendations.

2. Align motor accurately, using a flexible coupling if possible. For drive recommendations,

consult with drive or equipment manufacturer, or TECO-Westinghouse.

3. Mounting bolts must be carefullytightened to prevent changes in alignment and possible

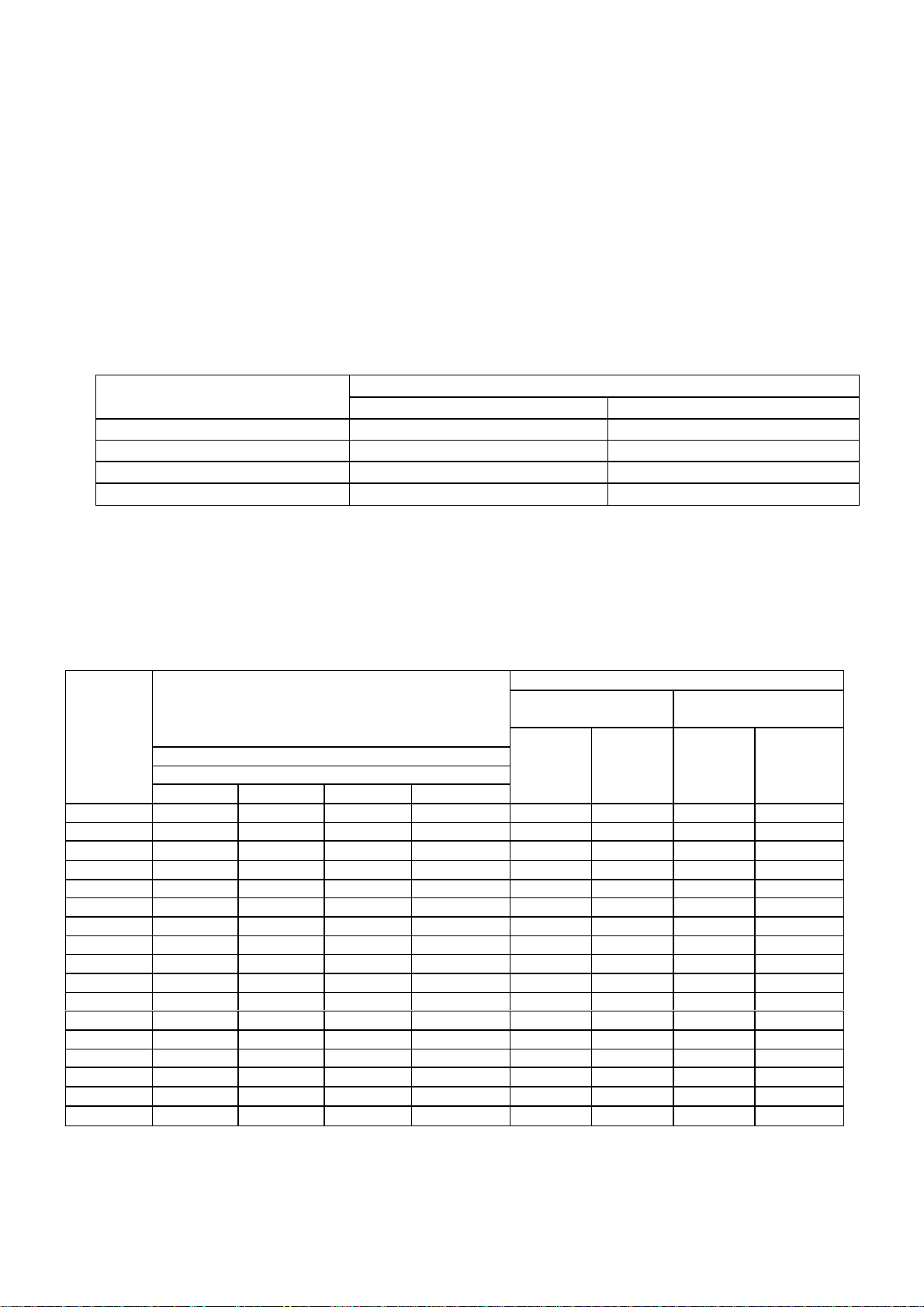

damageto the equipment. The recommended tightening torque’s for medium carbon steel bolts,

identified by three radial lines at 120 degrees on the head, are:

Bolt Size

Recommended Torque (Ft-lb.)

Minimum Maximum

3/4 210 320

4. V-beltsSheavePitchDiametersshould not be lessthanthose shownin Table1 (NEMA

recommended values)

5. Tighten belts only enough to prevent slippage. Belt speed should not exceed 5000 ft. per

min.

TABLE 1. V-Belt Sheave Pitch Diameters (MG1-14.42)

V-Belt Sheave

Conventional

A, B, C, D AND E

Minimum

Horsepower at

Frame

Number 3600 1800 1200 900

143T 1.5 1 .75 .5 2.2 4.25 2.2 2.25

145T 2-3 1.5-2 1 .75 2.4 4.25 2.4 2.25

182T 3 3 1.5 1 2.4 5.25 2.4 2.75

182T 5 ... ... ... 2.6 5.25 2.4 2.75

184T ... ... 2 1.5 2.4 5.25 2.4 2.75

184T 5 ... ... ... 2.6 5.25 2.4 2.75

184T 7.5 5 ... ... 3.0 5.25 3.0 2.75

213T 7.5-10 7.5 3 2 3.0 6.5 3.0 3.375

215T 10 ... 5 3 3.0 6.5 3.0 3.375

215T 15 10 ... ... 3.8 6.5 3.8 3.375

254T 15 ... 7.5 5 3.8 7.75 3.8 4

254T 20 15 ... ... 4.4 7.75 4.4 4

256T 20-25 ... 10 7.5 4.4 7.75 4.4 4

256T ... 20 ... ... 4.6 7.75 4.4 4

284T ... ... 15 10 4.6 9 4.4 4.625

284T ... 25 ... ... 5.0 9 4.4 4.625

286T ... 30 20 15 5.4 9 5.2 4.625

Synchronous Speed, RPM

Pitch

Diameter

Inches

*Maximum

Width

Inches

Minimum

Outside

Diameter

Inches

Narrow

3V, 5V, AND 8V

**Maximum

Width

Inches

Loading...

Loading...